Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

PCM

SINGLE STICK

PULSE CODE MODULATION SYSTEM

D60421

Page 2

Thank you for purchasing a Futaba digital

proportional radio control set.

Please read this manual carefully before using

your set.

When reading this manual, refer to the foldout at the end of this manual.

CONTENTS

FEATURES

CONTENTS AND RATINGS

TRANSMITTER ....................................

RECEIVER

AIRCRAFT ADJUSTMENTS

TRANSMITTER CONTROLS

SPLINED HORN AND FREQUENCY CHANNEL NO. FLAG COLOR. . . . 32

S130 EXPLODED

.......................................

...............................

AND

SERVOS

VIEWS

.............................

............................

...........................

.................................

1~2

3

21

24~29

30~31

2

~20

~23

33

Page 3

•FEATURES

1

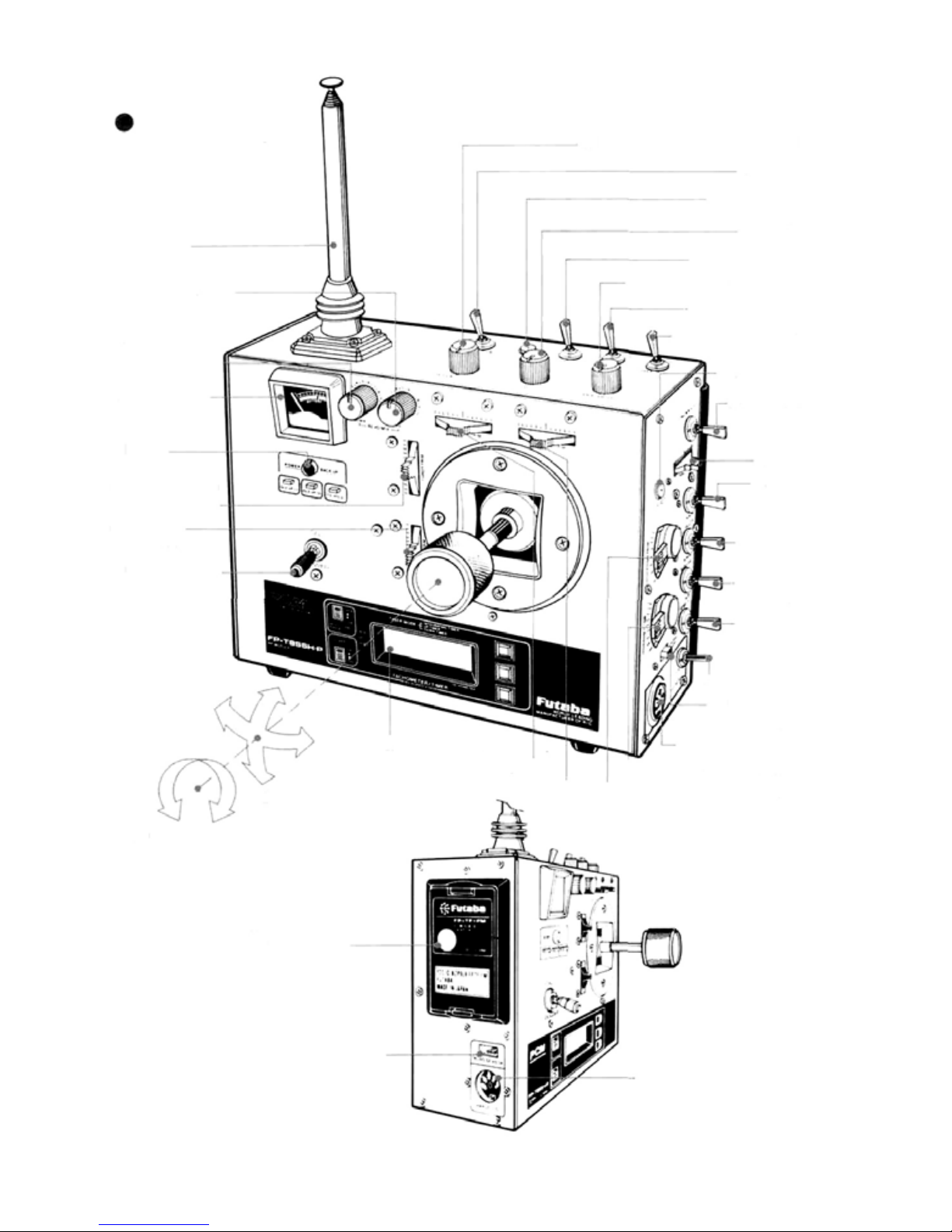

The FP-8SSHP is a digital proportional R/C set with PCM (Pulse Code Modulation) for helicopters.

The system is extremely noise and dead-point resistant digital proportional R/C sets with a microprocessor in the transmitter and receiver.

The FP-8SSHP was specially developed fo r FA I RC aerobatics F3C use.

Please read this manual before using y ou r set.

•Two

idle

up

TRANSMITTER FP-T8SSHP

• Newly designed rotatable open gimbal stick

provide maximum operation feel. Stick position and spring tension can be adjusted.

•RF module system. The frequency band can

be changed with one touch.

•DSC (Direct Servo Controller). The servos ca n

be operated without turning on the trans-

mitter.

Wire operation is also possible by using the

special

cord supplied

•Servo reversing switch on all channels. The

direction of operation of each servo can be

reversed

•Dual

ratio) on the aileron, elevator, and rudder

channels. Aileron and elevator dual rate can

be switched simultaneously, or independently.

•Easy-to-adjust two-knob revolution mixing.

Pitch control -> rudder and throttle -> pitch

control mixing.

•Revolution mixing compensation. The revolution mixing (pitch control -> rudder mixing)

up side can be set in the direction at which

the mixing amount to the rudder becomes

smaller. This increases high-speed s tra ightforward flight and also minimizes the power loss.

•Acceleration mixing.

•Throttle hold function for auto-rotation.

•Throttle

time at throttle hold can be freely set with a

built-in delay circuit.

•Four

for hovering and maneuvering.

•New single-chip microprocessor allows onetouch fail safe setting and introduction of an

automatic transmission system which eliminates the need for fail safe setting at the beginning of each flight and improves safety.

•Hovering throttle permits independent adjustment of the hovering point throttle position.

•Hovering pitch lever permits independent

adjustment of the hovering point pitch without regard to the throttle.

with

rates

or non

hold

(4)

pitch-curve trimmers

the

flip

delay.

with

of a switch.

linear

VTR

The

pitch

the

set.

(FSC-1)

(variable

servo

operating

for

best

trace

pitch

functions

dynamic aerobatics.

•Hovering memory reproduces the best mixing

point at any throttle position & even during

performance of flight.

•Throttle ATL (Adjustable Throttle Limiter)

allows simple and reliable throttle linkage

hook-up.

•Rudder button with timer is convenient in

540* stall turns.

•Tachometer/timer with built-in tachometer,

up timer, down timer, integrating timer, and

battery alarm.

•New

ATV

(Adjustable Travel Volume)

channels allows independent pushbutton adjustment of servo left, right, up, and down

throw.

•Second ATV. Besides new pushbutton ATV

on aileron and elevator, conventional tri mmer

ATV is also installed.

•Monitor lamp glows when two idle up systems

or throttle hold is set and flashes when they

are working.

•

Fail

safe

switch

switches that turn the throttle hold, idle up,

and other functions on and off. If the internal

switch is set to off beforehand, when that

function is not used, it will not operate even

if the switch on the transmitter is set to on.

•Built-in

•Two

•Highest

•Optional CCPM (Cyclic Corrective Pitch Mix-

• Trainer system offers

power

error

internal Nicd battery approaches the fully

discharged state, an LED blinks to indicate

that the memory circuit (memory, ATV, FS,

etc.) is not working.

servo

test functions. A

check neutral characteristic, trackability and

to

cycle servo to test servo operation.

quality

cated design. The transmitter fits easily in

your hand.

ing).

flight for beginners.

aluminum

used

for

(safety

switch). Internal

back-up

circuit.

case

an easy training of

static

slow

with

and

on all

When

sweep

sophisti-

the

to

Page 4

•DSC circuit. Each servo can be controlled

from the transmitter without turning on the

•The

receiver

is a

miniature

PCM

receiver

which the highest reliability has been pursued.

in

transmitter by connecting the transmitter

directly to the C terminal.

It is the first R/C receiver in the world to use

the newest computer technology.

•Miniature

chip microprocessor. Resistance against adja-

cent band and noise interference has been

increased by one full order of magnitude.

•Microprocessor-controlled servo hold function

eliminates erroneous operation when the

"dead

•Microprocessor provides fail-safe

fail-safe functions for greater safety.

•Error

receiver operating state.

•DC-DC converter in the power supply im-

proves the low-voltage operation characteristic.

•High

circuit.

•Ultra narrow-band ceramic filter and PCM

system a r e practically invulnerable to adjacent

band interference.

•Gold-plated connector pins eliminate poor

2

contact. Polarized housing increases reliability

against shock and vibration.

PCM

receiver

point"

area

is

entered.

lamp

display

allows

sensitivity design

with

checking

with

hi-speed

and battery

RF

amplifier

single-

of

the

•New indirect-drive potentiometer improve

vibration and shock resistance and improves

neutral precision tremendously.

•Futaba low-power custom 1C provides high

starting torque, narrow dead band, and excellent trackability.

•Fiberglass-reinforced PBT (polybutylene terephthalate) injection molded servo case is

mechanically strong and invulnerable to glow

fuel.

•Strong polyacetal resin ultra-precision servo

gear features smooth operation, positive neutral, and very little backlash.

•Fiberglass-reinforced epoxy resin PC board

with thru-the-hole plating improves servo amp

vibration and shock resistance.

•Thick-film gold plated connector pins ensure

positive contact and greater reliability against

shock and vibration. The connector housing is

polarized to prevent reverse insertion.

•Six

special

adjustable splined horns

are

avail-

able.

•CONTENTS AND RATINGS

Ratings and specifications are subject to change without prior notice.

Model

Transmitter

Receiver

Servo

Switch

Nicd battery

Accessories

Transmitter

Operating system : Single-stick, 8 channels for Receiving frequency : 50/53MHz BANDSIChosen Control system -+pulse width control

Transmitting frequency : 50/53MHZ BANDSIChosen Intermediate frequency : 455kHz Operating angle : One side 45"or more (in-

Modulation : PCM (FM) Receiving range : 500m on th e ground l38.5xl9.5x34.5mm)

Power requirement : 9.6V 8/500mAH internal 1000m in the air Weight :1.47oz(42gl

Current drain : 250mA (at the best conditions)

Charger FBC-8B12L

Input voltage

Output

FP-T8SSHP———————————— Receiver

helicopter 72/75MHz BANDS) band 1520uS.N

72/75MHz BANDS[band Power requirement . 4.8V Nicd battery (NR-4J- cluding trim)

53MHz • • 72MHz shared with servo) Power requirement : 4.8V (shared with receiver)

Frequency change t o any Current drain : 42mA (at 4.8V reception) Current drain : 5mA (at idle)

of above bands Is possible Dimensions : 2.23 x 1.65 x 0.94 in Output torque : 55.6oz-in (4kg-cm)

by merely changing RF (57 x 4 2 x 24mm) Operating speed : 0.24sec/60°

module. Weight :1.85ozl53g) Dimensions : 1.52 x .7 7 x 1.36 in

Nicd battery (NT.8H) When FP.T8SSHP used

: 120VAC, 50/60H2.4VA

: T x side 9.6V. 45mA

Rx side 4.8V. 45mA

Charger, extension cord, DSC cord ( F S C - 1 ) , CHG adaptor, DSC-CHG cord, frequency

flag, spare horn, mounting screws, tachometer sensor (FTA-3)

Receiver and servo Nicd battery NR-4J_

Voltage

Dimensions

Weight

FP-8SSHP

FP-T8SSHP x 1 with module FP-TF-FM

FP-R118GPx 1

FP-S130x4

SWH-5 (R4-SWJ) x 1

NR-4Jx 1

FP-R118GP______________

4.8V.4/500mAH

:

2.01 x 2.28 x 0.59

151 x5 8 x 15mm)

: 3.350Z (95g)

in

Servo

FP-S130_________________

Page 5

•TRANSMITTER

This section explains the operation of the

transmitter controls when the servo reversing

switches are in the normal position. When the

reversing switches are in the reverse position,

servo operation is the opposite of that described here.

1. AllerOn Controls the ailerons.

2. ElevatOr Controls the elevators.

3. Throttle Controls the throttle.

4. Rudder Controls the rudders.

5.

CH5

Switch

6.

Hovering

•The hovering point pitch can be independently

adjusted without affecting the throttle.

•When the throttle lever 3 is near the

pitch servo can be adjusted over

20% of its total travel with this lever.

•When the throttle lever 3 is at the Low or High

side, this lever has no affect on the pitch servo,

even if it is moved.

pitch

Controls

lever

Right

the

rate

side

gyro

of

transmitter.

approximately

output.

center, the

Low

Servo throw by

throttle trimming

(30% of total

travel)

High

Servo throw by

throttle lever

12. Rudder trim lever

Rudder trimmer.

13. Pitch control HIGH side trim lever

(CH6), Right side of transmitter

Pitch control servo High pitch trimmer. The servo

throw can be adjusted from 0 to 30% of the total

servo travel. Set this lever for optimum pitch during normal flight.

Fig.

5

3

When throttle lever is

at the center, adjustable within

this range with lever (6)

Pitch control servo

total travel

Pitch control servo

7.

CH7

knob

8.

9.

10.

CH8

Aileron

Elevator

Switch

trim

trim

Spare

Spare

lever

Elevator

Aileron

channel.

channel.

trimmer.

trimmer.

lever

11. Throttle trim lever w/ATL

Adjustable travel trim lever. This lever acts as a

trimmer only when t he throttle lever is at the low

side as shown in Fig. 5. It is very convenient because the high side of the throttle position remains

unchanged even when the low side is adjusted.

Fig.

Right-hand side o f transmitter

4

Fig.

6

Page 6

14.

Aileron dual rate switch

Aileron dual rate ON-OFF switch. When set to the

pull position dual rate is turned on, and when

set to the push position, dual rate is turned off.

At dual ON, the deflection can be set as shown in

Fig. 7 with the (1) aileron dual rate trimmer located on the trimmer panel at the back of the transmitter. At dual OFF, the operating linearity

can be switched as shown in Fig. 8 with the (2)

LINEAR-VTR switch also located on the trimmer

panel.

15. Elevator dual rate switch

• Elevator dual

Similar to aileron dual rate, the elevator deflection can be adjusted with the elevator dual rate

trimmer

performed with switch [24] Other functions are

the same as elevator dual rate.

•Aileron dual rate and elevator dual rate can be

switched ON and OFF simultaneously (combination ON-OFF) or separately by setting switch [25]

on the trimmer panel at the back of the transmitter. In the simultaneous ON-OFF mode, aileron

dual rate and elevator dual rate are turned on and

off with the aileron dual rat e switch [14]

rate

ON-OFF switch

[23]

and LINEAR-VTR switching can be

16. Rudder dual rate switch

Rudder dual rate ON-OFF switch. Similar to

aileron dual rate, the rudder deflection can be

adjusted with the rudder dual rat e trimmer [20] and

LINEAR-VTR switching can be performed with

Deflection is adjustable

from 40% to 10 0% of

the total travel within

this range.

switch [21] . Other functions are the same as aileron

dual rate.

17. Revolution mixing up side ratcheted

knob (UP knob)

18. Revolution mixing down side ratchet-

Fig.

7

LINEAR side

4

ed knob

• These knobs vary the pitch control — rudder mixing amount fr om 0 to 70% of the total travel at

the up and down sides. This mixing is performed

when the hovering memory switch [36] on the

back of the transmitter is set to ON, when switch

[36]

knobs [17] a nd

adjusts the high side mixing amount from the

memorized throttle stick hovering position. The

DOWN knob [18] adjusts the low side mixing

amount from the memorized th rottle stick hovering position.

• Switch [22] on the trimmer panel changes the mixing direction and releases the mixing function.

•The mixing amount to the rudder (pitch

-> rudder) is controlled by adjusting the revolution

Fig.

(DOWN knob)

is set to OFF , mixing is not performed even if

mixing compensation

9.

[18]

are turned. The UP knob [17]

with

trimmer [16]

control

in

Fig.

Revolution mixing compensation

Rudder servo

When this compensation is suitably applied, the

high speed linearity in the air is improved and

8

power loss is minimized.

FIG.

9

Page 7

(19) Idle up 1 switch ( 1 switch)

Righ t ON, Left OFF.

( 20) Idle up 1 ratcheted knob (1 knob)

•When the 1 switch [19] is set to ON, the throttle

servo "stop position" (idle up amount) can be

adjusted with this knob.

• If fail safe switch [13] on the trimmer panel at the

back of the transmitter is set to the INH position, the idle up 1 function is inoperative. Light

goes out to indicate that. When switch [13] i s set

to the IDLE1 position, monitor lamp [B] comes

on to indicate that the idle up 1 function is

operative. If the switch [19] is then set to ON,

lamp [B] flashes to indicate that the idle up I

function is operating.

Throttle servo

Throttle servo

Idle up 2 point Adjustable

with trimmer [11] on t he

trimmer panel at the back of

transmitter.

Idle up I point Adjustable with

trimmer9on the trimmer

panel at the back

transmitter.

of the

(21) Idle up 2 switch ( 2 switch)

Right ON, Left OFF.

•Wh en the 2 switch [21] is set to ON, the throttle

servo idle up point can be adjusted with trimmer

[10]

on the trimmer panel at the back of the transmitter. The idle up 2 point can also be adjusted

with trimmer [11].

•When fail safe switch

the back of the transmitter is set to the INH position, the idle up 2 function is inoperative. When

the switch is set to the IDLE2 position, monitor

lamp [C] comes on to indicate that the idle up

2 function is operative. If the 2 switch

then set to ON, lamp [C] goes out to indicate that

the idle up 2 function is operating.

[14]

on the trimmer panel at

Fig.

10

[21]

Fig.

11

•The

pitch

control

control

servo

adjusted with trimmer [6] (when idle up switch

2 is ON). This is convenient in rolls and other

aerobatics.

Pitch

is

servo

low side

When the idle up 2 switch

is ON, the pitch control

servo can be varied 50%

the pitch low side with

trimmer 6 on the trimmer

panel in the back of the

transmitter.

can

also

Pig.

at

12

be

5

Page 8

22 Hovering throttle ratcheted knob

•Trims the throttle servo independently from the

pitch control servo (without regard to mixing).

Since

the throttle

interfering with other mixing, this knob is very

convenient when trimming the throttle while

hovering.

• When the throttle lever

the throttle servo throw can be adjusted about

25% of the total travel with this knob.

•When the throttle lever

sides, the throttle servo does not operate even if

this knob i s turned.

Throttle servo

total travel

servo

Throttle servo

can

be

trimmed

[3]

is at about the center,

[3]

is at the low

Adjustable within this

range with knob 22 .

Fig.

23 Throttle hold switch (TH switch)

Right ON, Left OFF.

•This switch is used during auto-rotation. If this

switch is set to ON when the throttle lever [3] is

in the maximum slow position, the throttle servo

will stop at the position (idling or engine stop)

set at trimmer

back of the transmitter. At this time, the time set

at trimmer

the pitch control servo is set to the optimum

pitch fo r auto-rotation set with trimmer

setting can be made without regard to the posi-

tion

of the

[13]

•When fail safe switch [12] on the trimmer panel

the back of the transmitter is set to the INH position, the throttle hold function is inoperative.

When it is set to the T.HOLD position, monitor

lamp [D] comes on to indicate that the throttle

hold function i s set.

If the TH switch [23] is then set to ON, lamp [D]

goes out to indicate that throttle hold is being

performed.

[8]

on the trimmer panel at the

[7]

(throttle hold delay) is applied and

pitch

control

high

side

trimmer

without

or high

13

[5].

lever

This

at

24 Monitor lamps

Lamp ®

Lamp B Lamp C Lamp D

Lamp

A

When the power switch [30] is set to ON, this lamps

comes on and the pointer of the level meter deflects. At FS data transmission, this lamp goes out

momentarily and data transmission can be monitored. The lamp goes out once every 60 seconds.

When the internal Nicd battery approaches full

discharched, this lamp starts blinking. This ala rm

indicates that the power error backup function is

activitated the memory and circuit (memory, ATV,

FS, etc.) is not functioning.

Lamp

B

When fail safe switch [13] on the trimmer panel at

the back of the transmitter is to the IDLE 1 position (idle up 1 function ON), this lamp lights.

When the idle up 1 switch [19] is set to ON, this

lamp goes out.

Lamp

C

When

fail safe switch

the back of the transmitter is set to the IDL E 2

position (idle up 2 function ON), this lamp comes

on. When the idle up 2 switch [21] is set to ON,

this lamp goes out.

Lamp

D

When fai l safe switch [12] on t he trimmer panel at

the back of the transmitter is set to the T.HOLD

position (throttle hold function ON), this lamp

comes on. Wh en the throttle hold switch [23] is set

to

ON, this lamp goes out.

When the power switch [30] is set to ON, lamp [[A]

will go out momentarily. This indicates automatic

data transmission on and is not a failure.

[14]

on the trimmer panel at

Functions priority

Lamp B (Idle up 1 )

Lamp C (Idle up 2 )

Lamp D (Throttle hold)

The function priority is hold -> idle up 2 -> idle

up 1 . Lamps B, C, and D come on when the

pertinent fai l safe switch (13, 14, 12) is set to the

ON position. When the idle up 1 switch [19] is set

to ON, lamp

switch [19] in the ON position, try setting the idle

up 2 switch [21] to ON. Lamp B comes on and

lamp [C] goes out, indicating that the idle up 2

function has priority. Similarly, if the throttle

hold switch [23] is set to on while the 1 switch

and 2 switch

indicating that the throttle hold function has

priority.

[B]

goes out. Keeping the idle 1

[21]

are ON, lamps B and C go out,

Fig.

14

6

[19]

Page 9

25 Rotative open gimbal stick

7

• Rotative open gimbal stick allows setting of the

operating direction of the stick within a range of

±34 degrees by losening screws 1 to 4 in the

figure 1/2 turn and turning the stick grille.

• Set t he stick in the direction in which operation

is easiest.

• After setting, retighten the screws.

• The new gimbal is open. This one has been used

only for the most expensive radio controls. It

also has the built-in tension adjustment mechanism on open gimbal for the first time. You can

adjust tension of spring for your best stick feel-

ing.

• Remove the rear panel and right side panel and

adjust the spring tension.

Right Side panel mounting screw

Fig.

16

Fig.

15

Turn with a Phillips screwdriver

The spring tension can be adjusted as desired by

removing the transmitter longer back cover and

turning the adjusting screw of each stick. Adjust

the spring tension for the best stick feel.

26 Inverted flight ON/OFF switch

An inverted flight ON/OFF switch is provided. The

pitch

control,

reversed for inverted flight when this switch is

ON, inverted flight is then extremely easy.

to

elevator,

and

rudder

servos

are

set

Page 10

27.

Tachometer/timer

The

tachometer/timer

has the following func-

tions:

1. Tachometer

•Measurement by external sensor.

•Two blade propeller specifications.

• LOW range 100 to 30,000 rpm

•HIGH

range

100

Error +100 rpm

to

60,000

Error +200 rpm

rpm

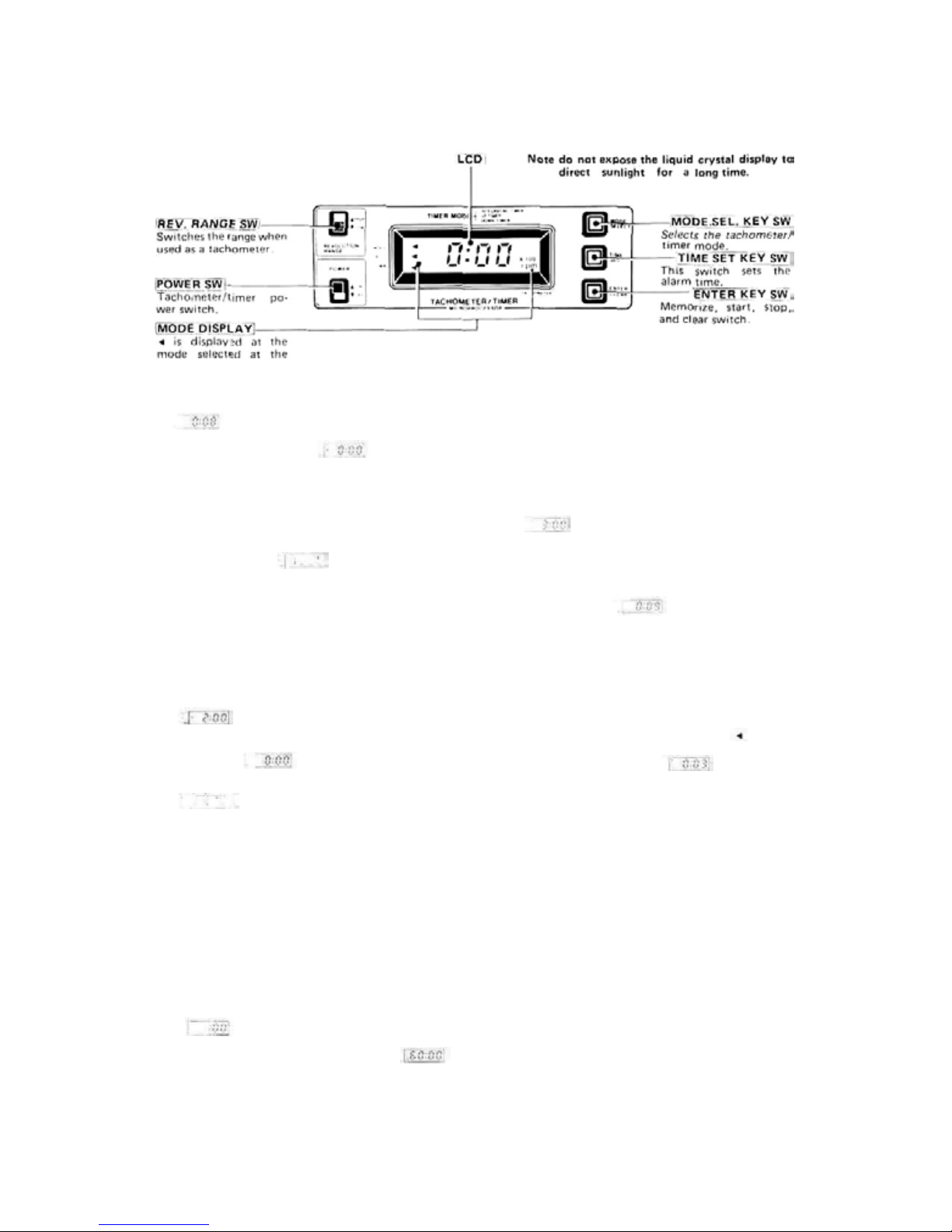

NOMENCLATURE AND FUNCTIONS

2. UP TIMER

• 0 to 60 minutes with seconds displays.

3. DOWN TIMER

•60 to 0 minutes with seconds display

4. INTEGRATING TIMER

• 0 to 60 hours wit h minutes display

5. Battery alarm

•This alarm sounds when the transmitter nicd battery

approaches its limit.

-REV.RANGE SW

Switches the range when used as a

tachometer. LOW - 100 to 30,000 rpm,

HIGH - 100 to 60,000 rpm

LIQUID CRYSTAL DISPLAY

Do not press the keys too quickly.

Press them at a speed of about once

per second.

8

MO D E

SEL

KEY

SW

POWER SW!

Tachometer/timer power switch.

MODE DISPLAY

•< is displayed at the mode selected at

the MODE SEL key switch.

INTEGRATING TIMER

Blinks during counting

and stops blinking when

counting stops.

UP TIMER

DOWN TIMER

TACHOMETER

[Do not expose the display to direct

sunlight

for a long time

Fig.

19

Selects the tachometer/timer mode.

The IN T E G R A TING TIMER mode is selected and

is displayed when the power is turned o n.

The first time this switch is pressed, the UP TIMER

mode is selected and | . is displayed.

The second time it is pressed, the DOWN TIMER

mode

is

selected

The third time it is pressed, the TACHOMETER

is

mode

The fourth time this switch is pressed, the

tachometer/timer returns to the INTEGRATING

TIMER mode and is displayed.

TIME SET KEY SW

This switch sets the alarm time in the UP TIMER

and DOWN TIMER modes. One minute is set each

time this key is pressed. If it is pressed and held for

two seconds or longer, the time is set in 5 minute

steps.

A beeping signal begins 10 seconds before the dot

time. A beep is produced every minute to indicate

the lapse of time.

ENTER KEY SW——————————————————————

This switch is used for memorization, starting,

stopping, and clearing in the UP TIMER and

DOWN TIMER modes. In the INTEGRATING

TIMER mode, this switch acts as the reset switch.

selected

and

and

r

—

is

is

displayed.

displayed.

Page 11

OPERATING INSTRUCTIONS

1. Tachometer

Set the tachometer/times POWER switch

appears on the display. Next, press the

MODE

SE L key

three times. The display changes to and

the tachometer mode is selected. Hold th e sensor

about 20 to 30 cm from the rotating propeller

(two blade). The propeller speed is displayed on

the

LCD.

12,300

rpm.

rpm, set t he REVOLUTION RANGE switch at the

upper left-hand corner to LOW and for propeller

speeds above 30,000 rpm, set the REVOLUTION

RANGE switch to HIGH.

The speed of a three blade propeller is displayed

value divided b y 3x2.

The speed of a four blade propeller is 1/2 the displayed value.

switch

indicates

For propeller

that

the

at

the

propeller

speeds

upper-right

is

rotating

up

to

to ON.

corner

30,000

at

Connect the accessory tachometer

sensor to the sensor connector 28

as shown above.

Fig.

20

Make all speed measurements outdoors under natural

lighting. Accurate speed measurements cannot be made

To measure the speed of the main rotor of a

model helicopter, measure the speed o f th e tail

rotor as shown in Fig. 22 and calculate the exact

speed from the equation.

indoors under artificial lighting becau se of the affect

of the 50 or 60 Hz power.

9

Main rotor speed =

Tail

Main rotor and tail rotor gear ratio

rotor

speed

Fig.

22

Page 12

Fig.

MODE SEL K EY SW.

23

2 UP TIMER

Set the tachometer/timer POWER switch to ON.

key switch at the upper right-hand corner one time.

The display changes to , and the UP

TIMER mode is selected. When the ENTER key

switch at the bottom right-hand corner is pressed, a

beep is head and the timer starts and th e second

digit of the display changes every second. A beep is

produced every minute to indicate the passage of

time. To stop counting, press the ENTER key

switch again. The usage tim e i s displayed on t he display. For example, S means that 12 minutes

05 seconds had elapsed. The UP TIMER mode can

be used as a second stop watch. To clear the dis-

10

play, press the ENTER key switch again.

is displayed. Next, press the MODE.SEL

ALARM SETTING

The alarm can be set with the TIME SET key. Clear

the display, by pressing the ENTER key, then press

the TIME SET key twice.

two minutes was set. Next, press the ENTER key

once to memorize this two minutes The display

changes to and is memorized. Start the

timer by pressing the ENTER key. The display

changes every second. When the display reaches

a second, to indicate that two minutes have

elapsed. Thereafter the timer continues to count

up to 60 minutes. If the TIME SET key is pressed

and held for two seconds or longer when memorizing the alarm time, the time is set in five minute

steps and the set alarm times are memorized until

the power is turned off or reset. If the timer is

started without setting the time after the display

has been cleared, the previously set alarm time

remains effective. An arbitrary alarm time up to

59 minutes can be set.

appears on the display indicating that

5 1 fhe timer keeps ten times, every once

second from 10 seconds before the end of the

count-down, the same as the UP TIMER.

TIME AND ALARM SETTING

Set the time and alarm with the TIME SET key,

the same as the UP TIMER. To set the alarm to

at the display, clear the display by

pressing the ENTER key, then press the TIME

SET key three times. Next, memorize this time

by pressing the ENTER key again. The display

begins to count down in seconds. When the display begins to count down in seconds. When the

display reaches the timer begins to

keep every second to indicate that three minutes

have elapsed. If the TIME SET key is pressed

and held for two or more seconds, the time is set

in five minute steps, the same as th e UP COUNTER, and the alarm can be set to any desired

time up to 33 minutes.

4) INTEGRATING TIMER

Set the tachometer/timer POWER switch and the

transmitter power switch to ON. The blinks,

counting begins, and the elapsed time is displayed

in minutes. For example, indicates that

three minutes have elapsed. If the transmitter

power swi tch is set to OF F, counting stops. When

the transmitter power switch is turned back on,

counting continues. The integrating timer function can be started and stopped as long as the

tachometer/timer POWER switch is on even if

another mode is selected with the MODE.SEL

key. This can be used to monitor the transmitter

operating time If the ENTER key is pressed in

the INTEGRATING TIMER mode, the old integrating time is cleared and a new count begins.

This can be used to forecast the remaining

battery capacity and other applications.

Nicd

(3 DOWN TIMER

Set the tachometer/timer POWER switch to ON

and press the MODE S EL key twice.

appears on the display to indicate that

the DOWN TIMER mode was selected. Next,

press the ENTER key. The timer keeps.

appears on the display, and the display begins to

count down every second. The timer keeps every

28 Tachometer sensor connector

The tachometer sensor connectstothis

described in the preceding item.

When this connector and charging

not in use, cover them with the rubber-backed cover

supplied.

connector as

connector [29] are

Page 13

29 Charging and DSC (Direct Servo

1

Controller) connector

This connector is used as both the internal Nicad

battery charging connector and the DSC con-

nector.

Always charge the battery before use.

•Connect the DIN connector of the FBC-8B(2) charger

to the transmitter charging connector and the 3P con-

nector to the receiver/servo NR-4J battery, and plug

the charger int o a 120 V AC outlet as shown in Fig. 24.

The battery can a lso be charged through t he DSC-CHG

cord by installing the CHG adaptor t o the charger as

shown in Fig. 24. The NR-4J receiver/servo Nicad bat-

tery can be charged while inside the aircraft.

•Normally charge the battery for about 15 hours.

When the battery

has

not

been

used

for some

time,

discharge it 2 to 3 times before charging.

(Leaving the battery discharged for a long time will

lower the battery capacity and shorten the battery

life.)

•The

transmitter

and

receiver

Nicad

batteries

can

be

charged simultaneously or independently.

•A fully charged transmitter battery can be used for

about 10 flights of 10 minutes each. The receiver and

servo NR-4J Nicad battery can be used for about 4

flights when used as a common power supply with the

rate gyro and for about 6 flights when a separate rate

gyro power supply is used.

Notes:

(1) First, connect to TX Nicd and red lamp goes on

(2) Then, connect to RX Nicd after connecting,

L,E,D, changes color from red to greenish red

(orange) which indicates that both TX and RX

Nicds are being charged.

In

case

of

(3)

separate charging,

be: RX Nicd - Green T X Nicd - Red

L.E.D,

color

will

•The

direct

servo

control

nals from the transmitter directly to terminal C of

the receiver through a wire and controls the servos

without turning on the transmitter. It is extremely

convenient when ftying on the same band during

competitions, etc.

•Make the connections shown in Fig. 24. Connecting ihe special DSC-CHG cord w ith tab to receiver

terminals C and installing it to the side of t he aircraft

fuselage for convenience.

•Whe n the DIN connectorofthe DSC cord is connected to th e DSC connector 29, th e power to the

encoder inside the transmitter is turned on. Se; the

transmitter power switch to OFF.

•When not using the DSC. disconnect the DIN connector.

•To operate the servos, turn on the receiver and

servo switches.

system connects the

sig-

1

Page 14

30 Power switch

Transmitter lock-type power switch. To turn the switch

on and off, pull the knob forward and set it to the desired position.

31 Antenna

Strong 1m 10cm telescoping antenna. Extend the antenna to its f ull height when using the transmitter. The

antenna will lock in place with a click when pulled up

to

its full height.

32 Level meter

•This meter indicates the transmitter battery voltage

and output power (power mete r).

•When the antenna [31] is fully extended and the power

switch [30] is set to ON, the pointer should deflect

the whi te zone.

•If the transmitter RF module [35] is removed, the

level meter

switch [30] is set to ON.

• If the meter pointer deflects to the red zone, indicating that the Nicd battery voltage is low. the range of

the radiowaves will become shorter and the tachometer/timer

meter pointer deflects to the boundary between the

white and red zones, recharge the battery.

pointer

will

not

deflect

even

[27]

battery alarm [5] will operate. If the

if

the

power

33 Rudder button

•While this button is being pressed, the rudder moves

to the deflection angle preset at trimmer [17] on the

trimmer panel at the back of the transmitter. After

the time set a t trimmer [18] elapses, the rudder servo

returns to the neutral position. This is convenient

when making 540" turns.

•The

rudder

servo

left and

right

throw

can

be

set

trimmer [17] . When fail safe switch [19] is set to the INH

position, the rudder button [33] becomes inoperative.

When the fail safe switch is set to the RUD.REV

position, the rudder button becomes operative.

with

34 Hovering memory switch

•This switch turns the memory function which memorizes the rudder mixing hovering point on and off.

When it is set to OFF, the revolution mixing knobs

[17] and [18] become inoperative.

•When this switch is set to ON when hovering,

position of the throttle lever [3] is memorized.

•The revolution mixing up knob

mixing down knob [18] can be independently adjusted

and set from the throttle lever 3 .

•Mixing can be adjusted within this range with the High

revolution mixing up knob

17

Throttle lever hovering posi

tion (Position at which the

hovering memory switch 36

was

set

to

ON.)

[17]

and revolution

Mixing can be adjusted with-

in this range with the revolu-

tion mixing down knob 18

[

Fig.

the

25

35 Transmitter RF module

Change this module t o switch frequency among

different bands.

to

Transmitter

crystal

Fig.

26

36 FS set button

This pushbutton switch is used when setting the fail

safe servo position.

FS.SET

Fjg, 27 signals to the receiver.

When this button is pressed when the

function select switch

mer panel [38] at the back of the transmitter is set to the FS ALL or FS

SELECT position and the transmitter

sticks are set to the desired servo positions, the transmitter memorizes those

servo positions and simultaneously

Since this data is automatically transmitted every 60 seconds thereafter,

pressing the button at every flight is

unnecessary. After the servo position

data has been se t, set sw itch [35] to the

OFF position to prevent erroneous

setting.

During fail safe data transmission, lamp

[A] of monitor lamps

mentarily and transmission of the data

is then confirmed.

[35]

[24]

goes out mo-

on the trim-

Page 15

37 Back cover

To operate the trimmers and switches on the trimmer

panel [38] , remove this cover as shown in Fig. 28.

Remove the back cover by pulling stoppers in

the direction of arrows.

Fig.

28

38 Trimmer panel

Switch and adjust the trimmers and switches on this

panel with the small flat blade screwdriver supplied.

A Ailerons

1. Ailerons dual rate trimmer

This trimmer sets the aileron deflection

angle when the aileron dual rate switch

[14] is set to the ON position.

The deflection angle is adjustable from

40% to 100% of the total travel. When

the dual rate switch is set to ON, the

servo throw can be set to an arbitrary

angle smaller than that when the dual

rate switch is OFF (normal) as shown

in Fig. 30. Use the throw matched to the helicopter and maneuvers

be performed.

2. LINEAR-VTR switch

This switch switches the travel linearity

of the aileron servo when the aileron

dual rate switch

tion.

•When this switch is set t o the LINEAR position, servo tracking is directly

proportional to the deflection of the

transmitter stick as shown by curve

of

Fig.

30.

•When this

(Variable Trace Ratio) position,

maximum servo throw is the same

LINEAR shown in Fig. 32. However,

Fig.

31

Fig. 32 shows the servo tracking operation when

dual r at e sw itc h is O F F and when switch is set

to

the VTR position.

to

servo tracking is the same as the dual

rate switch ON up to about 80% of the

total travel. Servo tracking then increases abruptly up to the same throw

as

dual rat e OFF. T h i s tracking method

resembles

easy to use.

Servo tracking can be set

within this range wi t h the

dual rate trimmer.

[14]

is in the O FF posi-

switch is set to the VT R

exponential operation and is

B

the

as

13

Dual rate switch OFF

(Switch 2 in LINEAR position)

When the dual rate switch

is ON, the servo throw can

be adjusted (within this

range) with the dual rate

trimmer,

FIG 30

When the dual rat e switch is

set to ON, operation is the

same as dual rate ON at

LINEAR.

Fig.

32

Page 16

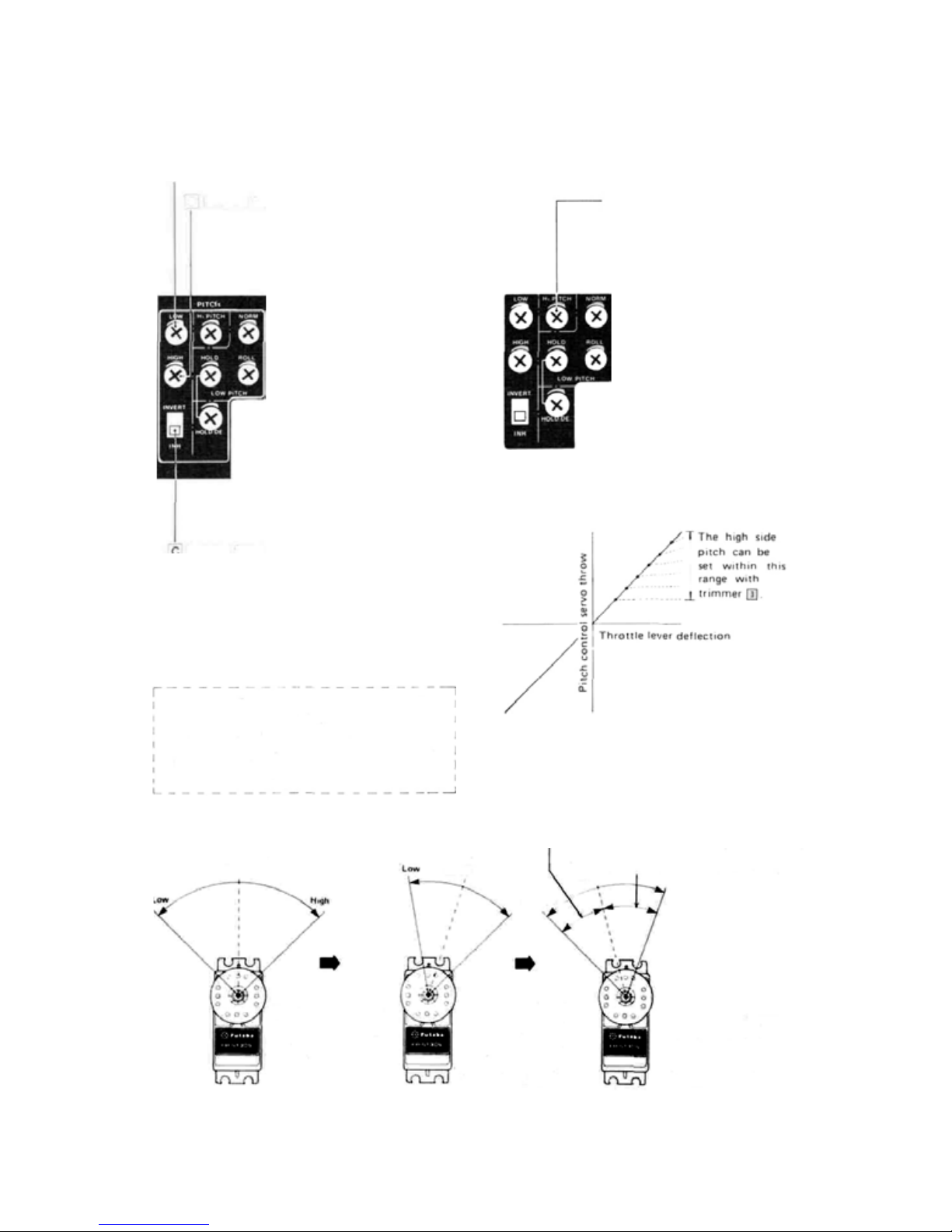

B Pitch

A Inverted flight low-side trimmer

B Inverted flight high-side trimmer

• The inverted flight function

can be turned on and off

with the [c] inverted flight

FS

switch on the trimmer

panel at t he back of t he s et .

INVERT: Inverted flight

INH

• When the [C] switch is in the

INVERT (function ON) position, normal flight - inverted flight switching can

be performed with the [26]

Inverted flight ON-OFF

swi tch at the side top corner of th e transmitter.

* When the [26] s witch is

pushed back, normal flight

is selected. At this time,

the pitch can be adjusted

with trimmers [3 , 4 , 5,

6 , and 7] as usual. When

C Inverted flight

FS switch

Fig.

33

14

the [26] switch is pulled

forward, inverted flight is

selected. At this time, the

pitch control servo, elevator servo, and rudder servo

are reversed and the pitch

control servo low-side and

high-side throws can be ad-

justed

function ON

: Inverted flight

function OFF

with trimmer A and

B.

3 High side pitch trimmer.

Adjusts the high side pitch

from about 60% of the full

throw of the pitch control

servo as shown in Fig. 35.

Whe n the [C] inverted flight FS switch and [26]

Inverted flight ON-OFF switch are switched,

the A inverted flight low-side trimmer and

inverted flight high-side trimmer operate the

pitch control servo (servo connected to channel

6 of the receiver) as shown in the figure.

Fig.

34

Throttle lever

neutral

When switch [C] is set

to the INH position,

the pitch cont rol servo

operates normally.

B

Throttle lever

neutral

When the [C] switch

is in the INVERT position and the [26]

switc h is pushed back

(INVERT OFF)

[NORMAL FLIGHT]

Can be adjusted and set over this range with

trimmer B

Can be adjusted and set over

lever

this

range

with

Low

When

is in the INVERT position and the [26]

switch is pulled forward (INVERT ON)

(INVERTED FLIGHT]

High High

Throttle

neutral

trimmer A

the [C]

Fig.

35

switch

Page 17

Fig.

5

37

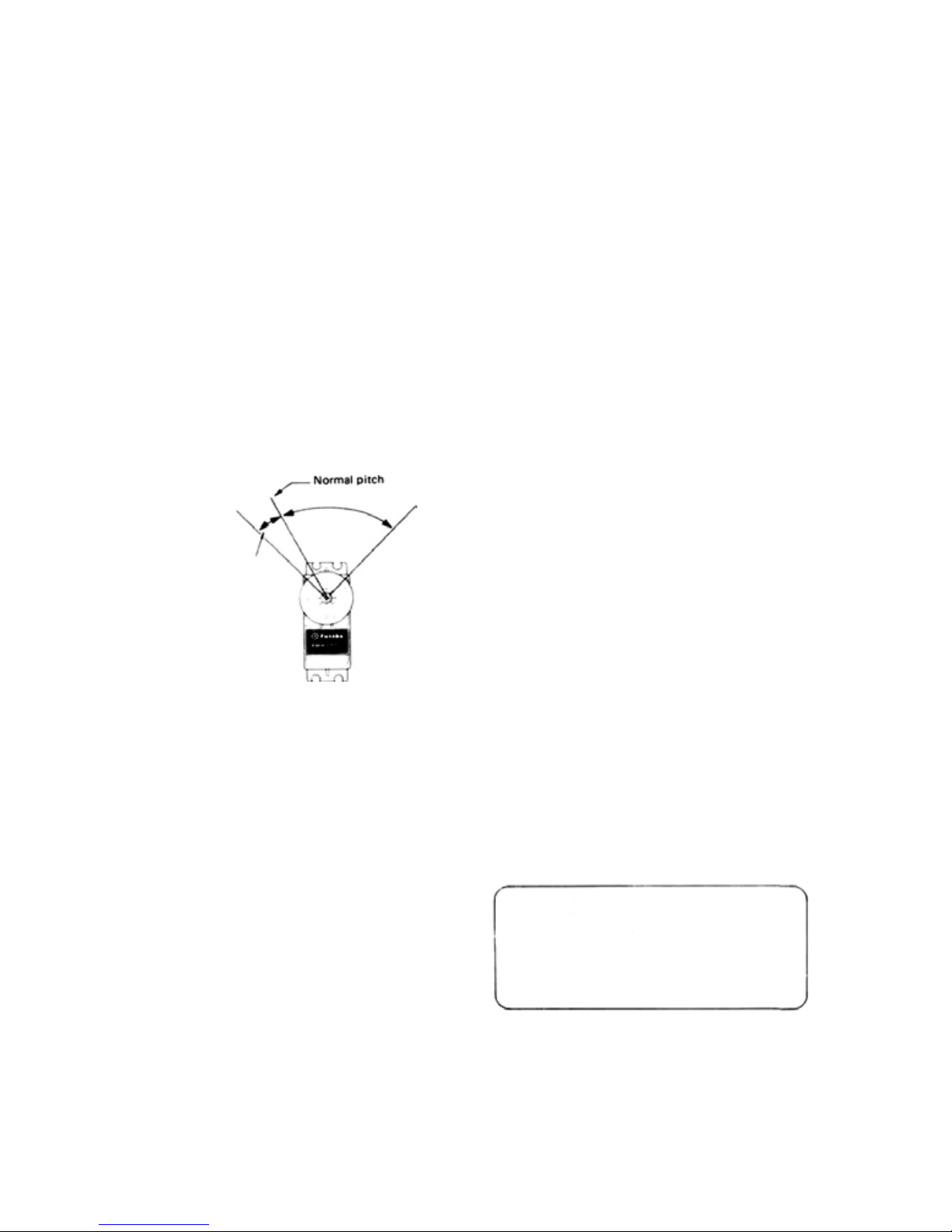

4. Normal pitch trimmer

Adjusted to match normal

flight.

5. This trimmer sets the low

pitch (minus pitch) when the

throttle hold switch

ON. It is adjusted to the

auto-rotation pitch.

6. This trimmer adjusts the low

pitch (minus p itch) when the

idle up [2] switch

It is used during rolls, etc.

7. Hold delay trimmer. This

trimmer adjusts the delay

time the pitch servo operates

when the throttle hold

switch

[23]

operating time of 0 to

2 seconds can be set.

8. This trimmer sets the

9. Idle up 1 point trim-

is set to ON. An

throttle servo stop point

when the throttle hold

switch

[23]

The stop point can be

set as described in the

throttle hold swit ch

section on on page 6.

When the trimmer is

turned clockwise, the

throttle servo moves to

the slow side.

mer. For a description

of this trimmer,

page 5 and Fig.

When the trimmer is

turned counterclockwise, the idle point

moves to th e low side.

[23]

[21]

is ON.

about

is set to ON.

see

10.

[23]

12. Throttle hold switch

fail safe switch

•When this switch is set to

the T.HOLD position,

is

14. Idle up 2 switch [21] fail safe switch

•When this switch is set to the IDLE2 side, the idle

up 2 function operates and the ID LE UP 2 monitor lamp comes on.

•When this switch is set to the INH side, the idle up

2 function does not operate even if the idle up 2

switch

[21]

is set to ON.

the throttle hold function operates and the

TH.HOLD monitor lamp

comes on.

• When this switch is set

the INH side, the throttle

hold function does not

operate even if the throttle hold switch

to

ON.

13 Idle up 1

fail safe switch

• When this switch is set to

the IDLE1 position, the

idle up 1 function operates and the IDL E UP I

monitor lamp comes on.

• When this switch is set

the INH side, the idle up

1 function does not

operate even if the idle

up 1 switch

ON.

switch [19]

[19]

[23]

to

[23]isset

to

is set to

1

D. Rudder

15. Rudder servo acceleration amount trimmer

•When hovering is stable, but the tail yaws a little

during takeoff, reduce the acceleration with this

trimmer until the tail no longer yaws.

10. This trimmer adjusts

Fig.

38

11. Idle up 2 point trim-

the idle up amount of

the throttle servo when

the idle up 2 switch

[21]is set

idle up amount can be

set as described in the

idle up 2 switch

section on page 5 and

in Fig. 11. When the

trimmer is turned counterclockwise, the idle

up amount decreases.

mer. For a description

of this trimmer, see the

page 5 and Fig. 11.

When the trimmer is

turned

wise, the idle up point

moves to t he low side.

to

ON. The

counterclock-

[21]

Fig.

40

•The

acceleration

fers with fixed pitch helicopters. The acceleration

amount can be set to a maximum of amount 50% by

turning this trimmer clockwise and to a minimum of

0% by turning this trimmer

counterclockwise.

16 Revolution mixing com-

pensation trimmer

The revolution mixing

(pitch control —> rudder

mixing) can be set in the

direction in which the mix-

ing amount decreases as

shown in Fig. 41 with this

trimmer.

amount

dif-

Page 18

16

Rudder servo

Settable within

this range by

trimmer [16] .

Fig. 41

17. This trimmer sets the

rudder servo throw and

direction when the rudder

button [33] is set to ON

(pressed). The servo throw

can be adjusted up to the

total travel.

18. Rudder time trimmer

This trimmer

the rudder servo stops at a

fixed deflection when the

rudder button [33] is pressed. A time from 0 to

about 3 seconds can be set.

19.Rudder button fail safe

Fig.

42

22. Revolution

trimmer [15] d irection switching and function OFF

switch

•When the main rotor turns clockwise, set this switch

to the R position. If the main rotor rotates counterclockwise, set this switch to the L position. (The

linkage may als o be reversed.)

•When the switch is set to the

revolution

turned off.

are

[17]

[17]

and [18]

switch

When this switch is set to

the RUD.REV position,

the rudder button operates. When it is set to the

INH side, the rudder but-

ton becomes inoperative.

20. Rudder dual

This trimmer adjusts the

rudder servo throw when

the

rudder dual rat e sw it c h

[16]

is

same functions as the aileron dual rate trimmer [1]

described on page 13.

221 LINEAR <->VTR switch.

This switch has the same

functions as the aileron

LINEAR <-> VTR switch

described on page 13.

and

[18]

and

and acceleration [15] functions

sets

the

time

rate

trimmer

set

to ON. It

acceleration

center position, the

has

mixing

the

E. Elevator

23. Elevator dual rate trimmer

This trimmer adjusts t he elevator servo throw when

the elevator dual rate switch [15] is set to ON. It has

the same functions as the aileron dual rate trimmer

[1] described on page 13.

24. LINEAR <-> VTR

This switch has the same

functions as the aileron

LINEAR <-> VTR switch

described on page 13.

25. Thi s s wit ch is used to select

aileron dual rate and elevator dual rate simultaneous

ON-OFF or separate ONOFF.

• When th i s switch is set to the

lower position, the aileron

dual rate switch [14] and

elevator dual rate switch

can be turned on and off

separately.

•When this switch is set

Fig.

44

F.

2nd

ATV

ATV is the abbreviation of Adjustable Travel Volume.

It is a device which allows independent a djustment of

the servo left and right (up and down) throw without

affecting the neutral position. Because of the engine

torque, precision of the model, and for other reasons,

the radius of left and right turns is always different

even if the left and right steering throws are perfectly

matched. The A T V is most convenient when lef t tu r ns

are good, but right turns are to sharp. In this case, left

and right turns of the same radius can be easily made

by reducing the servo right throw slightly. The aileron

and elevator 2nd ATV is the conventional trimmer

type ATV.

Aileron [26]

right

Aileron [27]

left

When the ATV trimmer is turned clockwise,

the throw increases. When it is turned counter-

clockwise, the throw decreases.

the COMB position, the

aileron and elevator dual

rates can be turned on and

off simultaneously with the

aileron dual rate switch

Set it to the position you

like best.

[28 Elevator

up

[291

Elevator

down

Fig.

45

[14].

[2]

[15]

to

Page 19

G. Cyclic Corrective Pitch Mixing (optional)

7

CCP mixing is performed after the helicopter corrective pitch and cyclic pitch control systems are electrically mixed. Since direct linkage from the servo to the

swash plate is possible by using CCP mixing, the model

can be made lighter by eliminating the intermediate

mechanism. Linkage rattle is also minimized.

30 CCPM switch

1 and 2 turn MIX ON-OFF

and switch the pitch direc-

Fig.

46

•When mounting the servos in the fuselage, mount

the CH1 servo (aileron servo) at the right side facing

the front and the CH6 servo (pitch servo) at the left

side facing the front.

•Set the CH2 (elevator) up and down directions with

the reversing switch. Next, set CH2 elevator to pitch

operation and set the switching and pitch direction

wi th CCPM SW 1 and 2.

•Check if the high, low,

elevator up

operation.

•Set aileron CH1, elevator CH2, pitch CH6, ATV, and

2nd ATV to maximum.

•Set the CCPM switch from OFF to 1 or 2 (ON).

When the CCPM switch is set to ON, th e CH1, CH2,

and CH6 servos throw is automatically set to 50% of

the total travel.

• The C H1 and CH6 deflection width is set so that the

left and right throws of the two servos at each ATV

are the same.

• Adjust the aileron left and right throws using the

2nd AT V when CH1 and CH6 operate with mixing

ON. (CH1 and CH6 can be adjusted simultaneously.)

•Check the aileron direction when CH1 & CH6

operate. Use the reversing switches to correct

aileron direction.

•The CH2 deflection

2nd

When mixing is used, the swash plate is moved up

down. Use a coaxial swash plate.

Since the servo throw is about one half of the total

travel, so that the servo horn throw must be adjusted

to

make larger at the servo horn side.

and down directions are correct by pitch

ATV.

tion when the CH2 (elevator) servo is operated as

the pitch servo.

aileron left and right, and

the

can be adjusted with ATV or

and

CH1: Reverse

CH6:Normal

CH2: Reverse

CCPM: (2)

CH1 solid line indicates reverse

CH1 dotted line in-

dicates normal

Fig.

47

CH1: Normal

CH6: Reverse

CH2: Normal

CCPM: (2)

CH6 solid line indicates reverse

CH6 dotted line indicates normal

When CH2 servo is

behind the main

rotor shaft

When the CH2 servo is in front of the main rotor

shaft, CCPM ( 1 ) and the horn rod are indicated by

the dotted lines.

When the CH2 servo

is in front of the

main rotor shaft,

CCPM (1) and the

horn rod are indicated by the dotted

lines.

Swash plate

When

CH2

Fig.

ser-

48

Cl-12 \''vo is mounted

', at the right as

\\ viewed from

'.'' the rear.

1

Page 20

H. Servo reversing switches

These switches reverse the direction of the servos.

They are very convenient when connecting the linkage.

Fig.

Rudder

Throttle

Elevator

Aileron

NORM position

: Forward

REV position

: Reverse

CH8 switch

channel

CH7 lever channel

CH6 pitch control

CH5 switch channel

49

I. ATV/FS button

•These two pushbutton switches are used for servo

deflection angle setting of ATV, FS or HOLD function; servo test start & stop; reset; battery FS memory

set,

etc.

•USING AT V (Aileron ATV

taken as an example)

1 First, set switch [K] [35] to the AT V side.

2 Next, set CHANNEL

1 (aileron) position.

3 Set the transmitter and receiver power switches to

ON, and check the operation of the servos.

4 Set the aileron stick for full right rudder, hold it in

that position, and s et the aileron right throw to the

desired angle by

5 To set aileron left, hold the aile ron stick in the full

left position and set the servo throw with buttons

[33] and [32]

(ATV can be adjusted in 64 steps. ATV can be continuously varied by pressing and holding the button f or more than 1.5 seconds.)

6 For th e other channels,

CHANNEL SELECT switch [J] [34] and operate

ATV.

7 At the end of adjustment, set switch [K] [35] to the

center OF F position and set switch [J] [34] to OFF

position.

8 This ATV function is memorized

switch is set to off , the AT V function

transistor Nicd is fully discharge.

9 When clearing the ATV, set switch [35] to RESET

and switch [34]

and [33] simultaneously. ATCs of a ll channels are

cleared and servos deflect their 100% angle.

pressing

.

to

position 2 and

SELECT switch

buttons [33] and [32]

select

the

channel

even if the power

press

[J] [34]

to the

.

with

the

is lost if the

buttons [32]

18

[32]This

pushbutton

1 Making the ATV servo deflection angle larger.

2 Turning the FS function on.

3 Starting the servo test.

—[33] This pushbutton sw i tc h is used when:

1

Making the ATV servo deflection angle smaller.

2 Turning the HOLD function on.

3 Stopping the servo test.

When button [32] and [33] are pressed at the same time,

reset or battery FS memory setting is possible. At this

time, lamp [ A] of monitor lamps [24] goes out momentarily so that setting can be monitored.

switch

is

used

when:

Fig.

ATV SETTING

Press button [32] and [33] while

holding the aileron stick in the

full position.

Switch switches [J] [34] and [K] [35]

51

HOW TO USE FS (Fail Safe)

(Throttle channel as an example.)

1 First, set switch [K] [35]toFS SELECT.

2 Set the transmitter and receiver power switches

ON, and check the movement of each servo.

3 Next, while switching the channel select switch [34]

from 1 to 8 in order, set the channels to be used

with FS, with button [32] and set the channels to

be used with HOLD, with button [33]. In this example, set 3 (throttle) to FS with button [3 2 ] .

4 Set the throttle lever to the slowest position, and

press

the FS

set

transmitter.

5 The 1 — 4 above set low throttle for the FS

function. After setting FS function, turn switch

[35] and [34]

transmitter power switc h to OFF.

button

to

OFF. Test

[36]on the

fail

safe

back

by

of

turning

the

to

the

Page 21

Each servo moves to the neutral position except

the throttle servo which moves to the slow position

that was just set.

6 Pail safe for all channels can be set with one touch

by setting the sticks and switches of the all channel

to any predetermined position

button [36] one time.

7 The FS function can be set for all channels and any

servo deflection angle in this manner. When using

FS in all channels the function select switch must

be set to the FS A LL position.

8 Since this FS function is memorized by the trans-

mitter which transmits the data every 60 seconds,

even when the receiver power sw itch is set to OFF,

resetting is unnecessary.

9 After those settings, set switch [35]

vent erroneous setting.

10 When button [36] is pressed twice, setting FS in

flight, etc., the servo position of the second is

memorized in FS and transmitted.

11 To clear the preset FS information, set switch [35]

to reset position switch [34] to position 1 and press

buttons [32] and [33] simultaneously. FS of all the

channels is cleared and all the servos move to the

neutral position.

and

pressing the FS

to

OFF-to pre-

FS function/HOLD function

The FS function is turned on with button [32] and

the

HOLD

previously described.

function

FS (Fail safe function)

FS is a function which moves the servo of each channel to a position preset on the transmitter when no

radio waves are received by the receiver from the

transmitter or when continuous strong noise is received for about one second or longer. The set operates

by the hold mode in one second and then, by the FS

mode. When the noise or interference disappears and

normal radio waves are received in approximately one

second, FS is released.

HOLD (Hold function)

HOLD is a function which stops all the servos specified by

HOLD

command immediately before the erroneous signal

was received.

When the noise, interference, etc. disappears and

normal radio waves are received, HOLD is released.

Set the FS function and HOLD function as you like.

•The

operation of the

ting the transmitter and receiver power switches to

ON.

•When switch [35] is switched to TEST-A, the servos

move half-side first and then, come back to neutral

and repeat the other-half from channel 1 to channel

8. (Channel select switch [34] to TEST-ALL position

at this time.) The servos set by the channel select

switch do not operate. (If set to 5, the landing gear

servo does not operate.)

is

turned

(by

button [33] to the

servos

can

on

with

button [33]

be checked by

last

as

correct

set-

•When

switch [35]

operate linearly over their full travel. (Channel select

switch [34] in TEST-ALL position at this time.) Only

the servos set at the channel select switch are oper-

ated.

•

The

servo

is

stopped

test

by

pressing

is

started

is

switch

button [33].

Fig.

to

TEST-B. all

by pressing

52

the

button [32]

servos

BFS MEMORY SETTING

1 BFS (Battery fail safe function) is a function which

moves the throttle servo to a preset position as set

by the FS when there is only a small amount of

power left in the receiver Nicd battery. (If not

set, the throttle servo will be set to medium slow

automatically.)

2 The BFS setting method is the same

usage method previously described.

3 To release the throttle servo from the preset posi-

tion

set

by BFS and

throttle lever in the slow direction. When the

throttle lever reaches a certain point, BPS will be

released and the throttle servo can be controlled

for 36 seconds.

4 Setting this throttle lever point is called BFS

memory setting, and is done a s follows:

•First, set switch [35] to BFS MEMO.SET and set

switch [3 4] to position [3] (throttle channel.).

• Next, while watching the movement of the servo,

set the throttle lever to the desired position (between slow and medium s low recommended) and

press buttons [32] and [33] simultaneously. This

completes BFS memory setting.

•This

memory allows

position, slowtohigh.

•Lamp

[A]

of

the

monitor

BFS

[35]

point where BFS is released, this allows BFS to

be checked.

•When there is little power left in the receiver

Nicd battery, the throttle servo automatically

stops at the position set by BFS, BFS is released

when the throttle lever is moved to the memorized point. Throttle can th en be controlled for 36

seconds by throttle lever

•When

immediately lower the throttle lever to release

BFS. then quickly land.

Function setting can be confirmed by means of lamp

[A] of m onitor lamps

1 When switch

When lamp [A] is on, HOLD and

off,

FS.

2 When switch [35] set to ALL FS, off .

3 When switch [35] se t to ATV and button [32] or [33]

pressed, blink.

regain

control, lower the

setting

the throttle to any

lamps [24]

status

comes

[24].

is at FS SELECT

goes

out

during

when lamp

as the FS

out

at

the

flight,

[A] is

and

19

Page 22

J Channel select switch

•This

switch

selects

FS, when used in conjunction with item [1] ATV/FS

button previously described. It is also the select

switch for servo test and th e switch which selects the

channel to be by switch [35] RESET.

Fig.

53

the channel

[34] Channel select switch

to

be

set

by

ATV

or

K Function select switch

•This

switch

selects

ATV,

FS,

servo

test,

BFS memory setting as described at [I] ATV/FS

button.

• Normally set it to OFF.

1FS ALL

Switch to this position when setting fail safe for all

channels, FS is described in the "HOW TO USE

FS" section.

2 FS

3

SELECT

This position allows setting of fail safe and hold as

described in the "HOW TO USE FS" section.

ATV

This position allows setting ATV as described in

the "HOW TO USE ATV" section.

reset,

and

4 TEST A

Relationship among channel select switch number,

servo and reset.

At

switch [35]

No.

ATV, TEST A.B

1

Aileron

Elevator

2

Throttle

3

4

Rudder

Channel 5 switch

5

Channel 6 pitch

6

7

Channel 7 knob

Channel 8 switch

8

20

RESET &

TEST ALL

OFF

FS

SELECT,

All the servos are

operated at servo

test.

Usually set to this OFF position.

At switch [35]

RESET

FS (fail safe)

ATV

BFS memory

FS,

ATV,

memory are reset

simultaneously.

and BFS

This position allows servo

"SERVO TEST" section.

5 TEST B

This position allows servo test B as described in the

"SERVO TEST" section.

6 BFS MEMO SET

Switch to this position when setting the BFS release

point

as

MEMORY SETTING" section.

7

OFF

Normally

described in the "BATTERY

set to this position.

test A as described in the

FS

35 Function select switch

39 Trainer cord socket

40 Trainer switch

Push on/self-off switch. The transmitter connected

by the trainer cord (M-TC) operates and when it is

OFF, your-own transmitter only operates.

Connect the transmitters with the trainer cord (MTC-FM, purchased separately) as shown in Fig. 55.

When the switch is in the ON (push) position, the

student's transmitter operates and whe n the switch

is in the OFF position, the instructor's transmitter

Operates. The transmitter at which the trainer

switch is operated on-off becomes the inst ruct or's.

Instructor transmitter

(Power switch ON and transmitter operating)

Fig.

54

Page 23

RECEIVER AND SERVOS

1

FS (Fail safe) and HOLD functions

•The HOLD function holds all the servos

sition immediately before a bad set of signal is

received. When normal radio waves arrive, or the

interference disappears, hold is released.

•The

FAIL

SAFE

preset position set at the transmitter, one second

after interference is received. When the interference

disappears, FAI L SAFE is released.

Although already described in the transmitter section,

FS

servo of all the channels to the position preset at the

transmitter when continuous strong noise is received

set operates in the hold mode during the one second

the noise or interference is received.

(fail

by the receiver for about one second or longer. The

function

safe)

moves the

is a function

which

at the

servos

moves

po-

to

the

B.F.S, (battery fail safe) function

The B.F.S, locks the throttle channel only in the position preset by FS when there is very little power left

in the receiver and servo side Nicd battery. (If nothing

is set, the throttle channel becomes medium slow.)

The throttle channel can be released and operated for

36 seconds by moving the throttle stick in the slow

direction. After 36 seconds, th e set reenters the B.F.S.

mode. When the set enters the B.F.S, state, immediately land the aircraft.

•Connect

tery firmly as shown in Fig. 57. Then extend

the transmitter and receiver antennas to their

full length.

•Set the transmitter power switch to ON, then

set the receiver switch to ON. The servos stop

near the neutral position. Operate the transmit-

ter sticks and check that each servo follows the

movement of the stick.

•Connect the pushrod to each servo horn, then

check if the direction of travel of each servo

matches the direction of operation of its transmitter stick. If the direction of servo travel is

opposite the desired direction, switch the servo

reversing switch.

•Operate each servo to its full stroke and check

if the pushrod binds or is l oose. Unreasonable

force

for the horns, but will also cause the battery to

run down quickly. Always make the stroke of

the

receiver,

servo

switch,

and

bat-

applied to the servo horns is not only bad

a

each control mechanism somewhat larger than

the full stroke (including the trim component)

of the servo horn. Adjust the servo horns so

they move smoothly even when the trim lever

and stick are operated simultaneously in the

same direction.

•Be alert for noise.

This set has noise rejection circuits, however,

noiseless parts are recommended.

•When installing the switch harness, cut a rectangular hole somewhat

larger

than the

full

stroke of the switch, and install the switch so it

moves smoothly from ON to OFF. Install the

switch inside the fuselage and attach a piece of

wire to the switch so it can be turned on and

of f fr om the outside. Install the switch where it

will not be exposed to engine oil, dust, etc.

•Even though the receiver antenna may

appear

to be to o long, do not cu t or bundle it.

•Install the servos securely. Tighten the mounting screws until the rubber damper is slightly

If

the

screws

are

too

tight,

crushed.

the cushion-

ing affect of the rubber damper will be lost.

•The

crystal

can

be

changed

from the outside

of the receiver case. Always use the Futaba

transmitter/receiver matched crystal set to

change the band.

•

A spare

servo

horn

is

supplied

with

the

set.

Use this horn as needed.

•Use extension cords as needed.

•Wrap the receiver in sponge rubber. Waterand dust-proof the receiver by placing it in a

plastic bag and wrapping a rubber band around

the mouth of the bag. Do the same with the

receiver/servo battery.

•Use the rubber bands wrapped around the re-

ceiver to hold the servo and switch leads.

•After mounting is complete, recheck each part,

then check the transmitting range by making

the transmitter antenna as short as possible, extending the receiver antenna to its full length,

and operating the transmitter from a distance

of 20m to 30m from the receiver. The move-

ment of each servo should follow the movement of each transmitter stick.

2

Page 24

PCM RECEIVER FP-R118GP

Antenna wire

Receiver, servo switch, an d battery

connections

Antenna

wire

AEC-3

Extension cord

22

Crystal

Fig. 5 6

Error lamp

• System checking can be performed with this lamp.

•When the receiver and servo side N icd is connected and this LED is on, radiowaves are not being

received from the transmitter, check to be sure

the frequency is correct.

the lamp being on.

•When strong noise has been received, or the

radiowaves from the transmitter are intermittently interrupted, this lamp will blink.

This usually is not a problem.

Checkingispossible by

Remove the receiver crystal

pulling it in this direction.

by

PCM receiver

FP R118GP

Power switch

SWH-5 (R4-SWJ)

Charging connector

Receiver crystal

Fig.

58

NR-4J

Pay careful attention to the

connector polarity.

Fig.

59

Page 25

Aileron servo

2

Elevator servo

3

Throttle servo

4

Rudder servo (When

gyro is used, this servo

connects to the receiver

through the rate gyro.)

5.

Landing gear servo, or rate

gyro output switching

connector

6

Pitch control servo

8SSHP

a rate

4 servos

Fig.

57

23

Connected servo (rudder servo

for helicopter) neutral position

trimmer. (This trimmer is

operative even when the

control box power switch is

to OFF.)

Connects to

receiver CH5

(Gyro output

switching)

Gyro output

polarity switch

Control amp

set

Gyro body

Gyro output trimmer

Control box

Five battery pack 6V connector Motor regulated

power supply. (Insert the jumper connectors

when the power supply is shared with the receiver.)

(C) connector Red Jumper connector

Page 26

•General adjustments

Make the basic fuselage linkages and adjustments according to the helicopter manufac-

turer's assembly and adjustment instructions.

1. Check the direction of operation of each servo. If

the servo rotates in the wrong direction, switch the

setting of the pertinent servo reserving switch.

2. Set the idle up [1] switch

[21]

and throttle hold switch [23] to OFF (to the

opposite side).

3. Set the hovering pitch lever [6] and hovering throttl e knob [22] to about the center of the scale.

4. Check the left and r ight (up a nd down) throw of

each servo. If the throw is wrong, correct it with

the ATV trimmer and by changing the hole position of the servo horn, etc.

(5 Set the throttle lever

um slow position and set the hovering memory

switch [34] to ON.

Set the compensation setting amount to 0 by

turning the hovering mix compensation setting

trimmer [16] on the trimmer panel at the back of

the transmitter.

6 Set the revolution mixing up knob [17] to about

division 5 and the revolution mixing down knob

[18] to about division 7.

7. Check the pitch control -> rudder mixing direction.

24

If the direction is wrong, correct it with switch [22]

on the trimmer panel on the back of the transmitter.

8. Recheck the operating and mixing directions of

each servo, and set the hovering memory switch

to

OFF,

[34]

9. Check the

o Pull throttle when throttle lever in high position

o Set the ATL (Adjustable Throttle Limiter) to the

10 Turn the normal pitch trimmer [4] (high side pitch

trimmer [3] at the pitch trimmer [B] on the

trimmer panel at the back of the transmitter and

set the pitch control high side trimmer [13] to th e

maximum (upper) position. Set for maximum

pitch control servo throw when t he throttle lever

is operated over i ts fu ll stroke. Set the maximum

pitch width and set the pitch control high side

trimmer lever [13] to about the center.

engine and throttle linkage.

Zero throttle when throttle lever in maximum

slow position and throttle trim in maximum slow

position.

maximum limit. This is very convenient because

the high side does not change even if the slow

side is adjusted.

[19],

idle up [2] switch

[3]

to about the center medi-

11. Start the engine. After needle adjustment, hover

the helicopter, trim the ailerons and e levators, and

make the ma in rotor pitch larger during the next

hovering with the fuselage linkages. Then trim with

the hovering throttle knob [22] and pitch control

trimmer [6] . Adjust the throttle lever position at

hovering to 50% to 55% of its full stroke.

12. Trim

18 Rate gyro output adjustment (when FP-G152

the rudder by adjusting the linkage

rudder is in the neutral position when hovering.

13 After adjusting all the trim levers, hover and set

the hovering memory switch [34] to ON. The

memorized hovering point remains memorized

even when the transmitter power is turned of f. It

is cleared when the hovering memory switch [34] is

set

to

OFF.

14

If the helicopter slips to the right when hovering,

increase the mixing amount by turning the revolution

mixing down

helicopter slips to the left. turn the knob counterclockwise.

15 If the helicopter slips to the left when climbing

from hovering, turn the revolution mixing up

knob [17] clockwise. If the helicopter slips to the

right, turn the knob counterclockwise.

16 Next adjust the acceleration amount with trimmer

[15] of the rudder trimmers [D] on the trimmer

panel at the back of the transmitter. Although it

depends on the helicopter, it should have some

effect because of the interaction with the rate

gyro output. For fixed pitch helicopters, a pitch

of about 0 is usually suitable.

17 Adjust the normal pitch trimmer [4] of the pitch