Fusion POWERPLANT PP–SW10E, POWERPLANT PP–SW15E, POWERPLANT PP–SW12E, POWERPLANT PP–SW10H, POWERPLANT PP–SW12H User Manual

...Page 1

POWERPLANT

SUBWOOFER MODELS

PP–SW10E, PP–SW12E, PP–SW15E,

PP–SW10H, PP– SW12H, PP–SW15H

Page 2

22

2

FUSION CULTURE

There’s no point doing something if no one notices. We’ve always believed

the way to make things happen is by getting noticed. From our product, to our

demo cars, to our events, FUSION is about making some noise.

Now you are ready. Step out of the shadows and announce you’ve arrived in

a world where the old limits are left behind. Where technology is creatively

combined with the latest in product innovation. Where new levels of

entertainment are delivered with outstanding performance and quality. Our

development team create distinctively different products; subwoofers, amplifiers,

speakers and peripherals that redefine what can be done in car audio.

Leave the old behind and push the limits of what can be achieved in car audio.

Make some noise.

For more information about FUSION Car Audio visit our website at www.fusionelectronics.com

or email technical@fusionelectronics.co.nz

POWERPLANT

Explore the limits of car audio and PowerPlant will get you there. FUSION PowerPlant delivers

accurate clear sound reproduction with real power. Push sound further than it’s gone before,

confident that PowerPlant products have been engineered, designed and manufactured to

ensure consistent and reliable performance

To optimise your FUSION experience, we recommend you have your FUSION product installed

by an Authorised FUSION Dealer. Please read the warranty policy, keep your purchase receipt

and original packaging.

If after reading this manual you still have questions regarding this product, please contact

Technical Customer Services via email technical@fusionelectronics.co.nz

Page 3

333

RECORD YOUR PRODUCT DETAILS HERE:

MODEL NUMBER _______________________________ DATE OF PURCHASE______________________

AFFIX RECEIPT HERE

WARNING! Audio Systems can produce sound levels over 135dB. Continuous exposure to sound

pressure levels over 100dB may cause permanent hearing loss!

Please watch for emergency vehicles as warning signals may not be heard. USE COMMON SENSE!

TABLE OF CONTENTS

• SUBWOOFER FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 4

• SUBWOOFER THEILE/SMALL PARAMETERS . . . . . . . . . . . . . . . . . . . . . .pg 5

• SUBWOOFER DIMENSIONS PP-SW10E . . . . . . . . . . . . . . . . . . . . . . . . . . pg 7

• SUBWOOFER DIMENSIONS PP-SW12E . . . . . . . . . . . . . . . . . . . . . . . . . . pg 8

• SUBWOOFER DIMENSIONS PP-SW15E . . . . . . . . . . . . . . . . . . . . . . . . . . pg 9

• SUBWOOFER DIMENSIONS PP-SW10H . . . . . . . . . . . . . . . . . . . . . . . . . .pg 10

• SUBWOOFER DIMENSIONS PP-SW12H . . . . . . . . . . . . . . . . . . . . . . . . . .pg 11

• SUBWOOFER DIMENSIONS PP-SW15H . . . . . . . . . . . . . . . . . . . . . . . . . .pg 12

• ENCLOSURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 13

• ENCLOSURE TEST CURVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 15

• TECH TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 21

• TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 26

Page 4

44

4

SUBWOOFER FEATURES

FUSION subwoofers are low frequency drivers capable of delivering extremely high bass

levels from small enclosures. In order to achieve the maximum performance from your new

FUSION Subwoofer, please use one of the recommended sized enclosures that best suits your

application. Sealed and vented enclosure sizes can be found in this manual.

BASKET

PowerPlant Subwoofers feature a uniquely high pressure cast aluminium basket. Development

of the PowerPlant basket allows rigidity and style for any custom install. Finished in a protective

metal black paint and detailed with FUSION green enhancements, the basket displays

impressive strength and style.

CONE ASSEMBLY

Development of the high performance pressed paper cone, creates a dynamic low bass

response and high power performance. The cone is dimple pressed with PowerPlant super

graphic, catering for style, strength and sound performance.

SPIDER

In order to keep the cone assembly balanced and linear, FUSION has used green poly cotton flat

spiders to reduce the mechanical distortion for better sound quality.

VOICE COIL

PowerPlant Subwoofers use dual 4 ohm configuration. This allows a multitude of wiring

combinations for your amplifier system (please see wiring configurations in this manual).

PowerPlant Subwoofers utilise high temperature, multi wound black aluminium voice coils.

EXTENDED POLE PIECE

Recognising that an increased linear magnetic field for the subwoofer encourages a better low

frequency response, FUSION has extended the internal pole piece to achieve this. The extended

pole piece also decreases distortion.

MOTOR STRUCTURE

The motor structure is constructed from the highest strontium magnetic material and capped

with an attractive FUSION back plate. This has enabled increased power handling and larger

excursion. With the additional venting holes we assure consistently strong bass.

Page 5

555

SUBWOOFER THEILE/SMALL PARAMETERS

Subwoofer Parameters PP-SW10E PP-SW12E PP-SW15E

MAX Power Rating (Watts) 750 900 1200

RMS Power Rating (Watts) 250 300 400

Coil Height (Hvc) (mm) 25 25 25

Compliance (Cms) (uM/N) 281.69 248.25 148.67

Cone Area (Sd) 31.41 49.09 80.42

D.C.Coil Resistance (Re) 1.81 1.82 1.79

Electrical Q (Qes) 0.46 0.39 0.56

Force Factor (BL)

9 10.38 10.9

Free Air Resonance (Fs)

31.02 27.64 28.94

Frequency Response (Hz)

25Hz − 500Hz 22Hz − 500Hz 23Hz − 500Hz

Gap Height (Hag) (mm)

8 8 8

Impedance (Nominal)

2 2 2

Inductance (Le) (mH)

0.26 0.27 0.3

Linear Excursion (X-Max Total)

26 28 28

Mechanical Excursion

8.5 8.5 8.5

Mechanical Q (Qms)

4.5 4.65 5.87

Moving Mass (Mms)

93.45 133.6 203.39

Sensitivity (dB)

86.5 88.5 89.5

Total Loudspeaker Q (Qts)

0.373 0.36 0.508

VAS (Litres)

39.48 84.94 136.55

VAS (CuFt)

1.39 3 4.82

Magnet Structure (Oz)

152 176 196

Total Loudspeaker Displacement (Litres)

5 7 11

Page 6

66

6

SUBWOOFER THEILE/SMALL PARAMETERS cont...

Subwoofer Parameters PP-SW10H PP-SW12H PP-SW15H

MAX Power Rating (Watts) 900 1200 1500

RMS Power Rating (Watts) 300 400 500

Coil Height (Hvc) (mm) 28 28 28

Compliance (Cms) (uM/N) 291.8 171 147.72

Cone Area (Sd) 31.41 49.09 80.42

D.C.Coil Resistance (Re) 1.75 1.85 1.75

Electrical Q (Qes) 0.41 0.411 0.457

Force Factor (BL)

8.88 11.61 12.08

Free Air Resonance (Fs)

29.62 31.02 28.28

Frequency Response (Hz)

25Hz − 500Hz 25Hz − 500Hz 23Hz − 500Hz

Gap Height (Hag) (mm)

10 10 10

Impedance (Nominal)

2 2 2

Inductance (Le) (mH)

0.29 0.34 0.33

Linear Excursion (X-Max Total)

28 30 30

Mechanical Excursion

9 9 9

Mechanical Q (Qms)

4.86 5.25 4.796

Moving Mass (Mms)

93.95 153.92 214.38

Sensitivity (dB)

86 88 90

Total Loudspeaker Q (Qts)

0.377 0.381 0.417

VAS (Litres)

40.9 58.52 135.67

VAS (CuFt)

1.445 2.07 4.79

Magnet Structure (Oz)

192 235 241

Total Loudspeaker Displacement (Litres)

5.3 7.3 11.3

Page 7

777

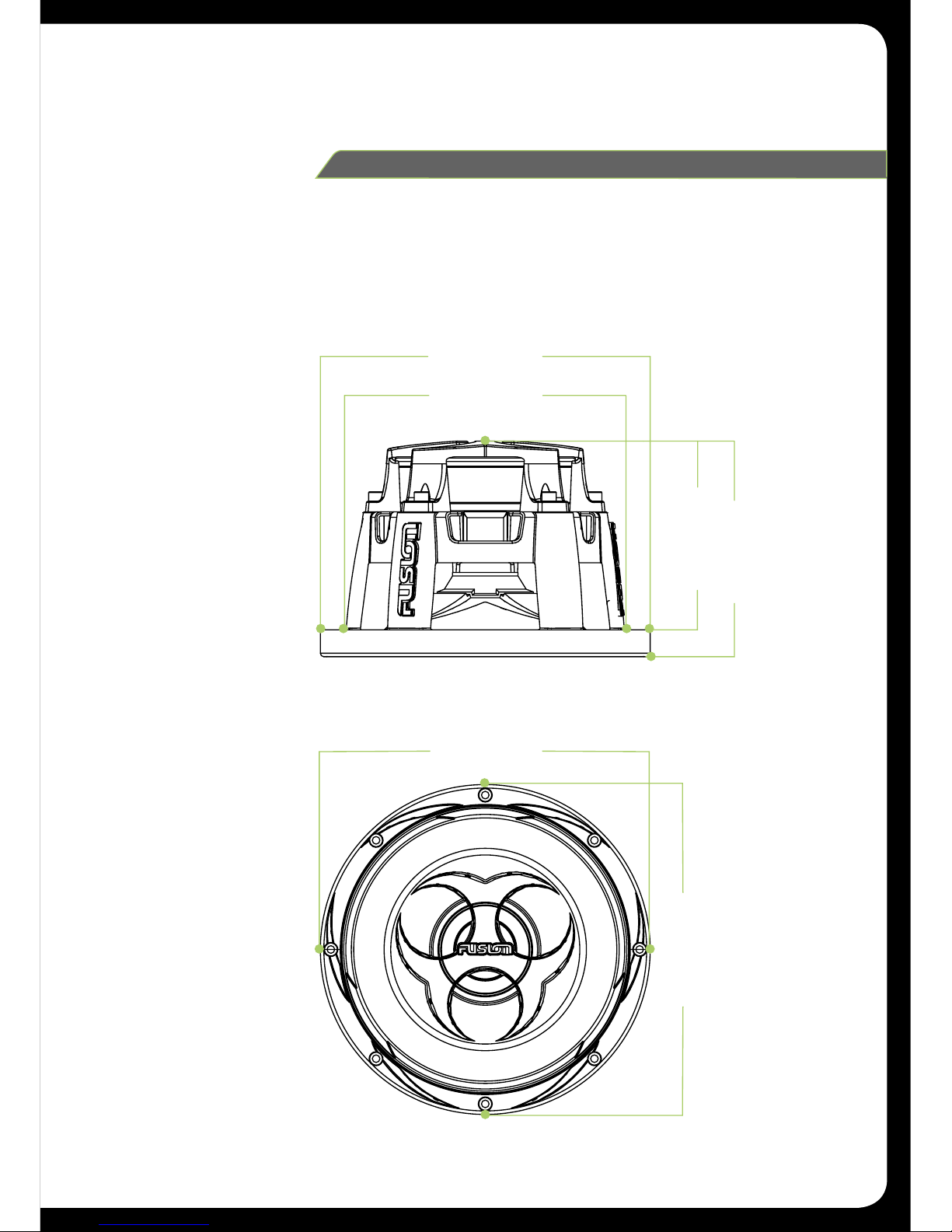

SUBWOOFER

PP-SW10E

DIMENSIONS

282mm (11– 1/8")

282mm (11– 1/8")

282mm (11–1/8")

184mm (7–1/4")

161mm (6

– 3/8")

240mm (9 – 7/16")

Page 8

88

8

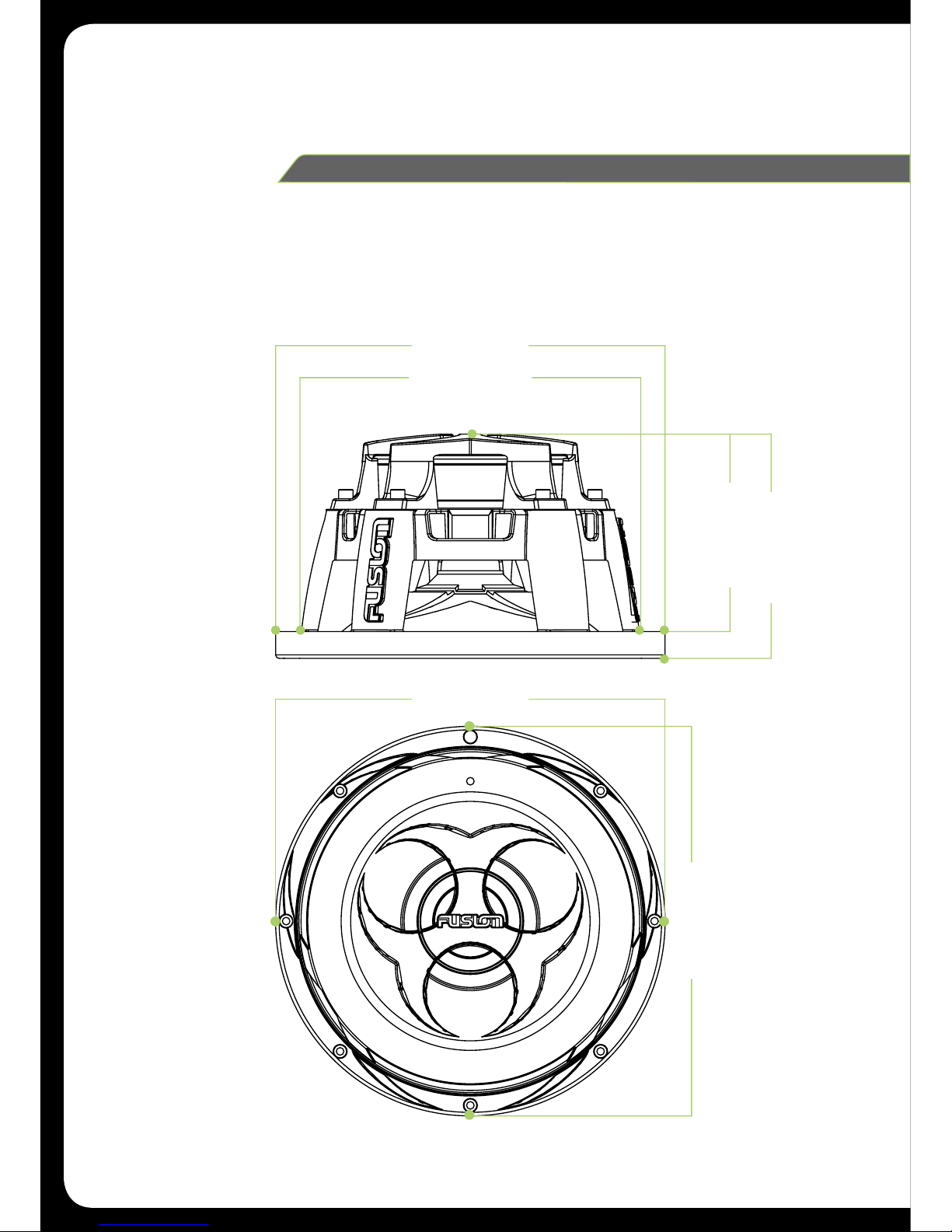

SUBW00FER

PP-SW12E

DIMENSIONS

333mm (13–1/8")

333mm (13 –1/8")

291mm (11– 7/16")

191mm (7–9/16")

168mm (6–5/8")

333mm (13 –1/8")

Page 9

999

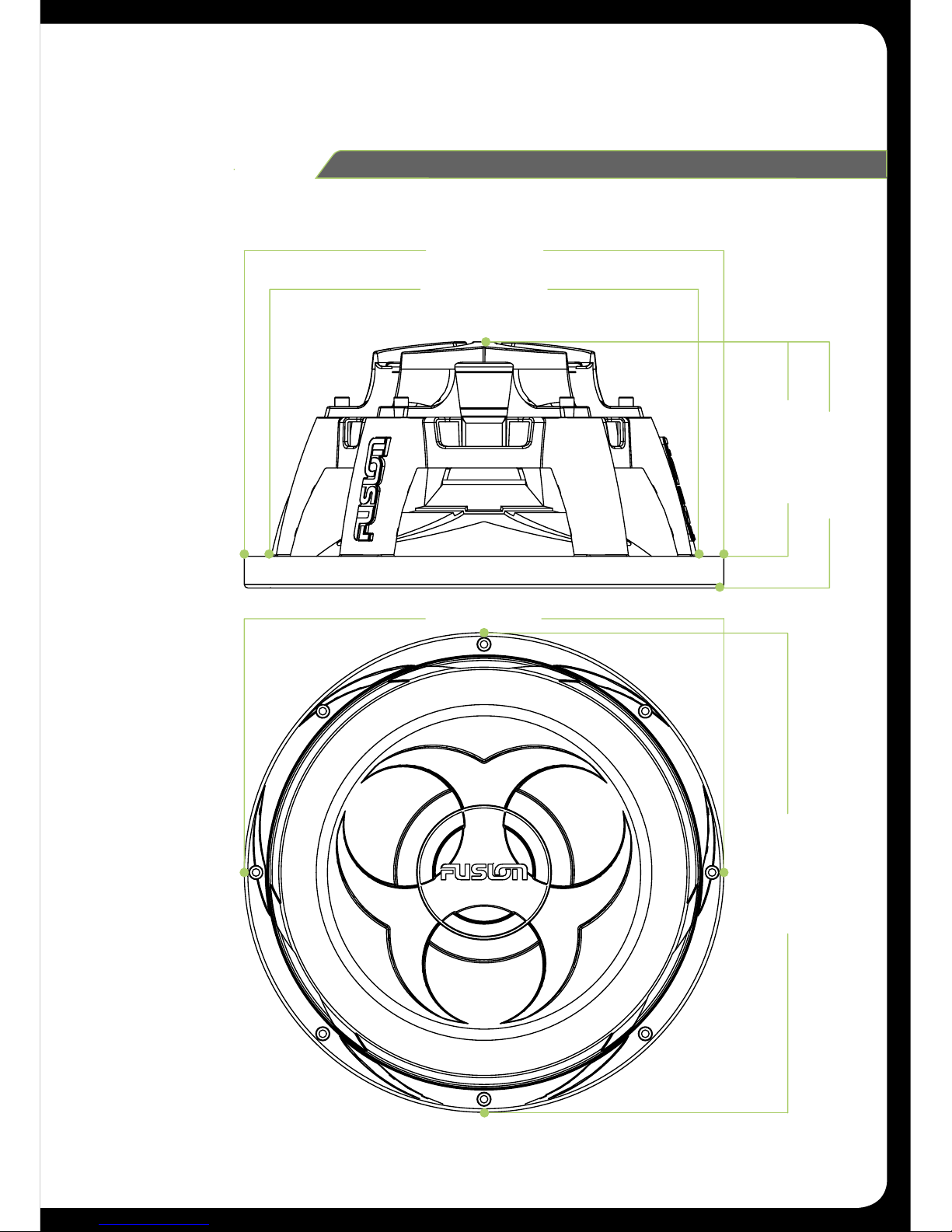

366mm (14 – 7/16")

210mm (8 –1/4")

183mm (7–1/4")

410mm (16–1/8")

410mm (16 –1/8")

410mm (16 –1/8")

SUBWOOFER

PP-SW15E

DIMENSIONS

Page 10

1010

10

282mm (11–1/8")

282mm (11–1/8")

282mm (11–1/8")

198mm (7– 1

3/6")

175mm (6

–7/8")

240mm (9 –7/16")

SUBW00FER

PP-SW10H

DIMENSIONS

Page 11

111111

333mm (13 –1/8")

333mm (13–1/8")

291mm (11–7/16")

205mm (8 –1/8")

182mm (7–3/16")

333mm (13 –1/8")

SUBWOOFER

PP-SW12H

DIMENSIONS

Page 12

1212

12

366mm (14–7/16")

224mm (8 –13/16")

197mm (7– 3/4")

410mm (16 –1/8")

410mm (16 –1/8")

410mm (16 –1/8")

SUBW00FER

PP-SW15H

DIMENSIONS

Page 13

131313

ENCLOSURES

All enclosures include port and subwoofer displacement. All ports are circle aero ports unless

otherwise stated.

Ported Enclosures: A ported enclosure is generally larger than a sealed enclosure

Sealed Enclosures: A sealed enclosure will be the smallest enclosure you can build. It will have a

tight low frequency response, but not as low as a ported enclosure.

OPTIMUM ENCLOSURES

Ported PP-SW10E PP-SW12E PP-SW15E

Volume (litres) 35.41 67.11 87.44

Volume (cu.ft.) 1.25 2.37 3.08

Port diameter (mm / in) 76.2mm / 3" 101mm / 4" 101mm / 4"

Port length (mm / in) 222.4mm / 8-3/4" 246.9mm / 9-3/4" 163.9mm / 6.7/6"

Tuned frequency (Hz) 36 35 34

Sealed

Volume (litres) 25.8 58.9 72.2

Volume (cu.ft.) 0.912 2.08 2.55

Tuned frequency (Hz) 49 44 45

Ported PP-SW10H PP-SW12H PP-SW15H

Volume (litres) 29.9 59.8 93.63

Volume (cu.ft.) 1.05 2.12 3.31

Port diameter (mm / in) 76.2mm / 3" 101mm / 4" 101mm / 4"

Port length (mm / in) 263.4mm / 10-3/8" 274.2mm / 10-13/16" 155.5mm / 6-1/8"

Tuned frequency (Hz) 37 34 33

Sealed

Volume (litres) 25.7 50.6 71.14

Volume (cu.ft.) 0.907 1.6 2.512

Tuned frequency (Hz) 48 46 48

Page 14

1414

14

ENCLOSURE CONSTRUCTION

All enclosures should be constructed from 18mm (3/4”) Medium Density Fibre board.

Enclosures should be glued and screwed, because MDF is porous. FUSION recommends

sealing the internal sides with a polyurethane sealer prior to installation. To accurately cut the

subwoofer hole use the unique FUSION ruler guide included inside the FUSION Subwoofer

packaging

ENCLOSURE PLACEMENT

An important factor is to place the subwoofer enclosure as far back in the vehicle as possible,

so that the natural bass gain of the vehicle is utilised. If your vehicle is a hatch back, always

experiment with which direction the subwoofer is facing. Facing the subwoofer towards the rear

of the car, should enhance the low down bass that PowerPlant Subwoofers are designed to

produce.

ENCLOSURE TUNING

When tuning the system it is always a good idea to try running the subwoofer out of phase

(which means switching the speaker wires around) with your other speakers. Do this and listen

to the system to see if the perception of bass is more from the subwoofer location or the front

speaker location. Which ever way gives the better perception that the bass is coming from the

front speakers, would quite safely guarantee the subwoofer is wired correctly.

CALCULATING ENCLOSURE ‘BOX’ VOLUME

Cuft:

To calculate Cuft multiply the height (A), width (B), depth (C) in inches, then divide that number

by 1728.

Example: 10" high x 18" wide x 12" deep = 2160 inches³

Divide 2160/1728 = 1.25 ft³

Litres:

To calculate Litres, multiply the height (A), width (B), depth (C) in centimetres, then divide that

number by 1000.

Example: 25.4cm high x 45.72cm wide x 30.48cm deep = 3539cm³

Divide 35396/1000 = 35.39 litres

A

B

C

Page 15

151515

5 10 50 100 500 1000 20

K

87

81

93

99

105

111

117

123

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 750 watts

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 1000 20

K

87

81

93

99

105

111

117

123

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 750 watts

PORTED

SUBWOOFER

PP-SW10E

Page 16

1616

16

5 10 50 100 500 1000 20

K

89

83

95

101

107

113

119

125

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 900 watts

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 1000 20

K

90

84

96

102

108

114

120

126

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 900 watts

PORTED

SUBW00FER

PP-SW12E

Page 17

171717

5 10 50 100 500 1000 20

K

91

85

97

103

109

115

121

127

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1200 watts

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 1000 20

K

91

85

97

103

109

115

121

127

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1200 watts

PORTED

SUBWOOFER

PP-SW15E

Page 18

1818

18

5 10 50 100 500 1000 20

K

87

81

93

99

105

111

117

123

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 900 watts

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 20

K

10K5 K1 K

87

81

93

99

105

111

117

123

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 900 watts

PORTED

SUBW00FER

PP-SW10H

Page 19

191919

5 10 50 100 500 1000 20

K

90

84

96

102

108

114

120

126

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1200 watts

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 1000 20

K

90

84

96

102

108

114

120

126

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1200 watts

PORTED

SUBWOOFER

PP-SW12H

Page 20

2020

20

ENCLOSURE TEST CURVES

SEALED

5 10 50 100 500 1000 20

K

93

87

99

105

111

117

123

129

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1500 watts

PORTED

SUBW00FER

PP-SW15H

5 10 50 100 500 1000 20

K

93

87

99

105

111

117

123

129

Hz

dB

Amplitude Response (dB-SPL/Hz at 1 m) with 1500 watts

Page 21

212121

TECH TIPS

OHMS LAW SIMPLIFIED

IR

E

voltage

watt

s

amperage

curren

t

resistance

R

I W

E

I

E

2

W

W

I

2

E

2

R

I2R

W

E

E

R

WR

W

I

W/R EI

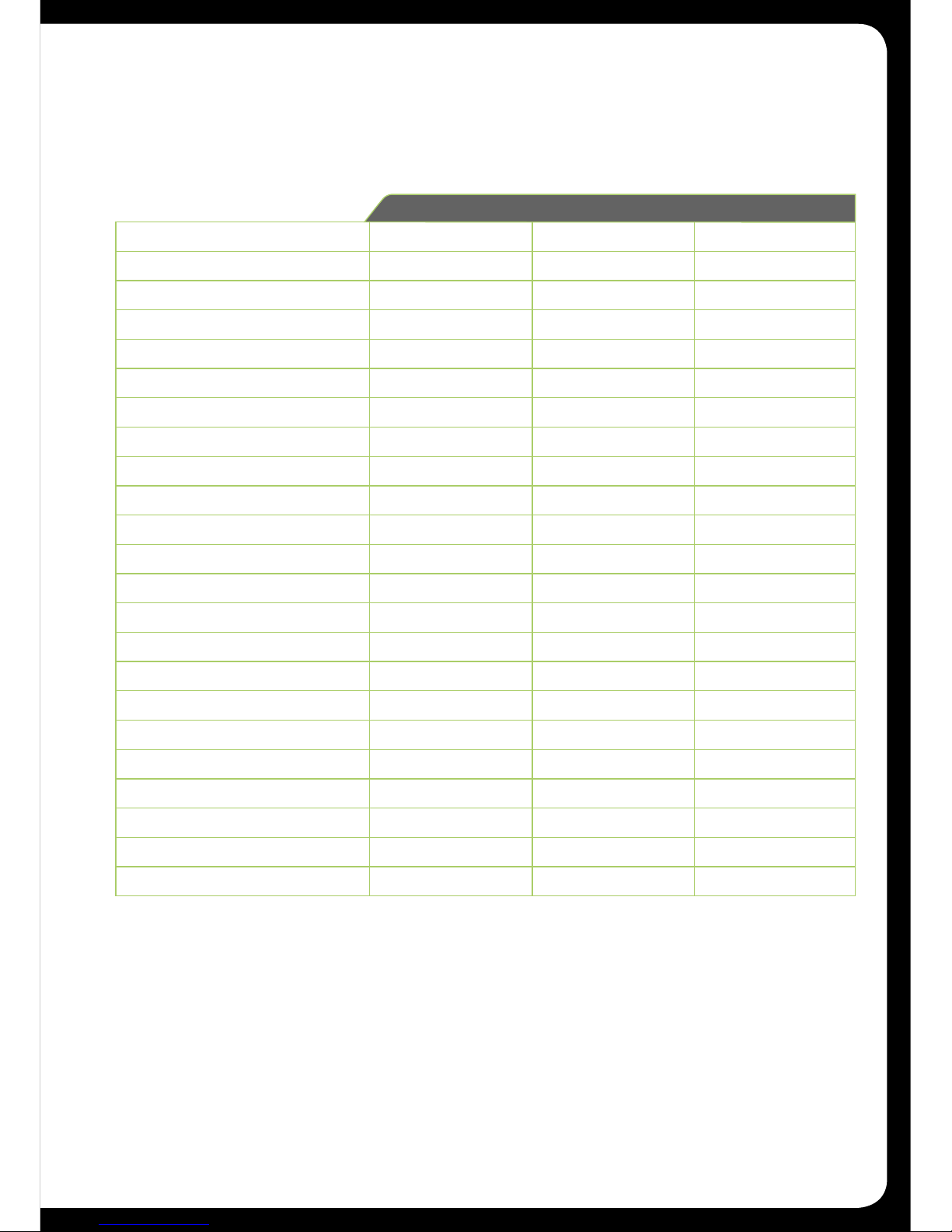

POWER CABLE CALCULATOR

TOTAL AMPERAGE

0-4 FT 4-7 FT 7-10 FT 10 -13 FT 13-16 FT 16-19 FT 19-22 FT 22-28 FT

0 – 20 14 12 12 10 10 8 8 8

20 – 35 12 10 8 8 6 6 6 4

35 – 50 10 8 8 6 4 4 4 4

50 – 65 8 8 6 4 4 4 4 2

65 – 85 6 6 4 4 2 2 2 0

85 – 105 6 6 4 2 2 2 2 0

105 – 125 4 4 4 2 0 0 0 0

125 – 150 2 2 2 0 0 0 0 0

The above chart shows cable gauges to be used, if no less than a 0.5 volt drop is acceptable. If aluminium

wire or tinned wired is used, the gauges should be of an even larger size to compensate. Cable gauge size

calculation takes into account terminal connection resistance.

Page 22

2222

22

SUBWOOFER RULER GUIDE

Use the FUSION ruler guide to create a perfect subwoofer mounting surface.

1: Mark the centre position on the MDF (Medium Density Fibre) board where the subwoofer is

to be mounted.

2: Fix the first hole (centre) to the marked out position on the MDF.

1 2 3 4 6 7 8 9 11 12 13 14 16

(inch)

(mm)

Centre

1"0

cutout

15"

cutout

12"

cutout

10"outside

263mm

12"outside

312mm

15"outside

389mm

�� ���usionc� r�udio�com

50

0 10 20 30 40 60 70 80 90 110 120 130 140 160 170 180 190 210 220 230 240 260 270 280 290 310 320 330 340 360 370 380 390

100 150 200 250 300 350 400

0 15105

Fig. 1

Fig. 2

Page 23

232323

5: Using a jigsaw or router, cut out this measurement.

3: Insert a pencil into the correct subwoofer cut out measurement. 10", 12", or 15".

1 2 3 4 6 7 8 9 11 12 13 14 16

(inch)

(mm)

Centre

1"0

cutout

15"

cutout

12"

cutout

10"outside

263mm

12"outside

312mm

15"outside

389mm

�� ���usionc� r�udio�com

50

0 10 20 30 40 60 70 80 90 110 120 130 140 160 170 180 190 210 220 230 240 260 270 280 290 310 320 330 340 360 370 380 390

100 150 200 250 300 350 400

0 15105

4: Scribe a perfect cut out diameter onto the MDF board.

1 2 3 4 6 7 8 9 11 12 13 14 16

(inch)

(mm)

Centre

1"0

cutout

15"

cutout

12"

cutout

10"outside

263mm

12"outside

312mm

15"outside

389mm

www.fusioncaraudio.com

50

0 10 20 30 40 60 70 80 90 110 120 130 140 160 170 180 190 210 220 230 240 260 270 280 290 310 320 330 340 360 370 380 390

100 150 200 250 300 350 400

0 15105

Fig. 3

Fig. 4

Fig. 5

Page 24

2424

24

Parallel Voice Coil Wiring (2 Ohm operation)

To wire a DVC subwoofer in parallel (to get 2 Ohms), use two short pieces of speaker wire and

link the positive from one coil to the positive of the second coil, and do the same for the negative

as shown in fig 1. Then wire the amplifier to opposite sides of the subwoofer in order to equalise

any connection resistance.

Series Voice Coil Wiring (8 Ohm operation)

To wire a DVC subwoofer in series (to get 8 Ohms), use one short piece of speaker wire and link

the positive from one voice coil to the negative of the second coil as shown in fig 2. Then wire

the amplifier to opposite sides of the subwoofer.

SERIES AND PARALLEL SUBWOOFER WIRING FOR

DUAL VOICE COIL SUBS

+

-

2 Ohm operation

+

-

8 Ohm operation

Fig.1

Fig. 2

Page 25

252525

SERIES WIRING FORMULA FOR 2 SPEAKERS

4 Ohm

+ +

+

–

–

–

8 Ohms

R1 + R2 = LO AD IMPEDANCE

4 Ohm

PARALLEL WIRING FORMULA FOR 2 SPEAKERS

4 Ohm 8 Ohm

2.67 Ohms

R1 x R2

R1 + R2

4 Ohms x 8 Ohms

4 Ohms + 8 Ohms

32

12

= L OA D IMPEDANCE

= = 2.67 Ohms

Page 26

2626

26

TROUBLE SHOOTING

No sound from your subwoofer: Check amplifier and wiring connections.

Distorted sound: Check the connections from amplifier, processor or head unit.

Subwoofer makes unusual noise in sealed enclosure: The enclosure may have leaks causing

a lack of back pressure. Remove the subwoofer and ensure the enclosure is completely sealed.

Use sealer and polyurethane to do this.

Ported enclosure makes an unusual noise: Possibly due to incorrect port used. The correct

term is chuffing, and to rectify this you will need to increase the port area. The diameter will need

to increase and the port length will need recalculating.

Bad smell: If you smell a burning smell, then chances are the subwoofer has been damaged.

This can be due to the enclosure parameters being incorrect, too small an amplifier used and the

subwoofer is receiving unwanted clipped signals or the music choice has enhanced bass notes

played for long periods of time. Check the enclosure volume used and ensure the subwoofer is

receiving clean audio signals from the amplifier.

Vehicle rattles: The best way to solve this problem is to add sound deadening material to the

steel panels of your vehicle. Ensure all screws and plastic panels are affixed firmly.

INSTALLATION WARNING

1: Ensure the vehicle 12 volt lead is removed before any equipment is connected.

2: Investigate the vehicle’s gas tanks, brake lines and electrical wiring locations before you

begin installation.

3: Attach the product securely to the vehicle to prevent damage in the event of an accident.

4: Ensure all wiring is protected to avoid damage or pinching of the cables.

Page 27

272727

NOTES

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

YOU CAN HELP PROTECT THE ENVIRONMENT!

Please remember to respect the local regulations:

Hand in the non-working electrical equipment

to an appropriate waste disposal center.

PUBLISHED BY FUSION ELECTRONICS LIMITED:

© Copyright 2006 by FUSION Electronics Limited.

All rights reserved. Specifications and design are

subject to change without notice.

Page 28

Specifi cations and design are subject to change without notice.

Loading...

Loading...