Fusion PowerPlant PP?CM40, PowerPlant PP?CM65, PowerPlant PP?CM525, PowerPlant PP?CMST1 User Manual

Page 1

POWERPLANT

COMPONENT SPEAKER MODELS

PP−CM40, PP−CM525, PP−CM65, PP−CMST1

Page 2

2

FUSION CULTURE

There’s no point doing something if no one notices. We’ve always believed

the way to make things happen is by getting noticed. From our product, to our

demo cars to our events, FUSION is about making some noise.

And now you’re about to. Step out of the shadows. Announce you’ve

arrived in a world where the old limits are left behind. Where technology is

creatively combined with the latest in product innovation. Where new levels

of entertainment are delivered with outstanding performance and quality. Our

development team evolve distinctively different products; subwoofers, amplifiers,

speakers and peripherals that redefine what can be done in car audio.

Leave the old behind and push the limits of what can be achieved in car audio.

Make some noise.

For more information about FUSION Car Audio visit our website at www.fusioncaraudio.com

or email technical@fusionelectronics.co.nz

POWERPLANT

Explore the limits of car audio and PowerPlant will get you there. Fusion PowerPlant delivers

accurate clear sound reproduction with real power. Push sound further than it’s gone before,

confident that PowerPlant products have been engineered, designed and manufactured to

ensure consistent and reliable performance

To optimise your Fusion experience, we recommend you have your FUSION product installed by

an Authorised FUSION Dealer. Please read the warranty policy, keep your purchase receipt and

original packaging.

If after reading this manual you still have questions regarding this product, please contact

Technical Customer Services via email technical@fusionelectronics.co.nz

Page 3

3

RECORD YOUR PRODUCT DETAILS HERE:

MODEL NUMBER _______________________________ DATE OF PURCHASE______________________

AFFIX RECEIPT HERE

WARNING! Audio Systems can produce sound levels over 1

35dB. Continuous exposure to sound

pressure levels over 100dB may cause permanent hearing loss!

Please watch for emergency vehicles as warning signals may not be heard. USE COMMON SENSE!

TABLE OF CONTENTS

• COMPONENT SPEAKER FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . pg 4

• SPEAKER THEILE/SMALL PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . .pg 4

• SPEAKER DIMENSIONS PP-CM40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 5

•

SPEAKER DIMENSIONS PP-CM525 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 7

• SPEAKER DIMENSIONS PP-CM65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 9

• SPEAKER DIMENSIONS PP-CMSTI . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 11

• INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .p

g 13

• WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 14

• WOOFER AND MIDRANGE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . .pg 15

• TWEETER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 16

• X-OVER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 17

•

WIRING DIAGRAM 2-WAY X-OVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 18

•

WIRING DIAGRAM 3-WAY X-OVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 18

• TECH TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pg 19

• TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .p

g 20

Page 4

4

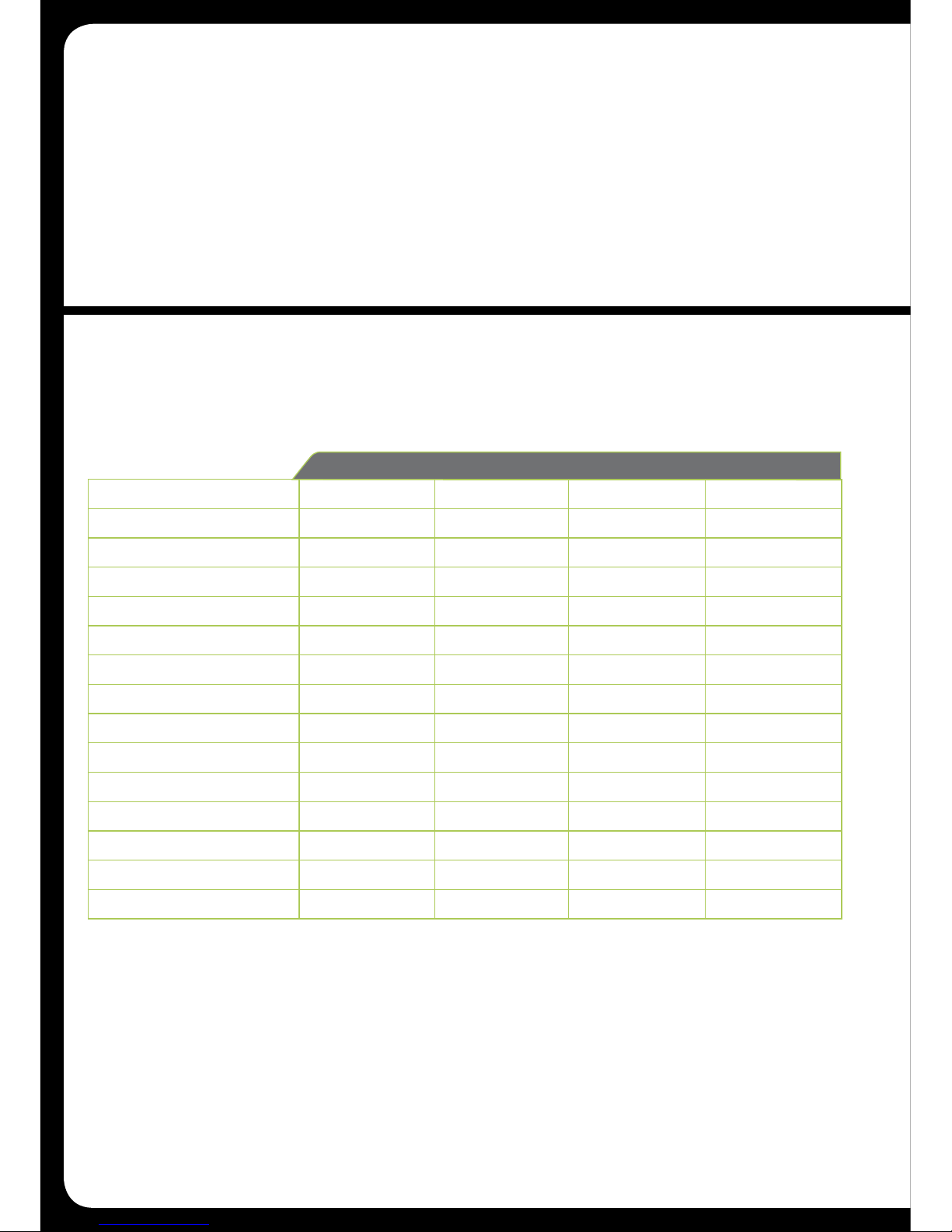

COMPONENT SPEAKER FEATURES

PowerPlant Component Speaker Systems feature an industrial cast basket with a protective

finish, green top and bottom plate and a light-weight polypropylene cone complimented by a

soft dome tweeter. The PowerPlant Component Speaker Systems provide style and great sound

reproduction for the car audio specialist.

Component Parameters PP-CM40 PP-CM525 PP-CM65 PP-CMST1

Max Power Rating (Watts)

1

20 150 180 180

Rms Power Rating (Watts)

40 50 60 60

Compliance (Cms)

50

3.3 722.1 676.3 676.3

Cone Area (Sd)

5.67 8.99 1

3.68 13.68

D.C.coil Resistance (Re)

3

.3 3.3 3.3 3.3

Electrical Q (Qes)

0.89 0.61 0.7

3 0.73

Force Factor (Bl)

3

.57 4.2 4.48 4.48

Free Air Resonance (Fs)

94 67 55 55

Frequency Response

65Hz –

21kHz 57Hz – 21kHz 52Hz – 21kHz 52Hz – 21kHz

Impedance (Nominal)

4 4 4 4

Mechanical Excursion

8 9 1

2 12

Mechanical Q (Qms)

5.4 7.97 7.04 7.04

Sensitivity: (dB) (1w/1m)

88 91 91 91

Total Loudspeaker Q (Qts)

0.77 0.57 0.66 0.66

Magnet Structure

7.

3 10.9 1

2.6 12.6

SPEAKER THEILE/SMALL PARAMETERS

X-Over

2 Way Passive Butterworth X-Over Network

12dB/Octave

Adjustable 3 point Tweeter level

High Pass: 3.0 kHz

Low Pass: 4.5 kHz

Page 5

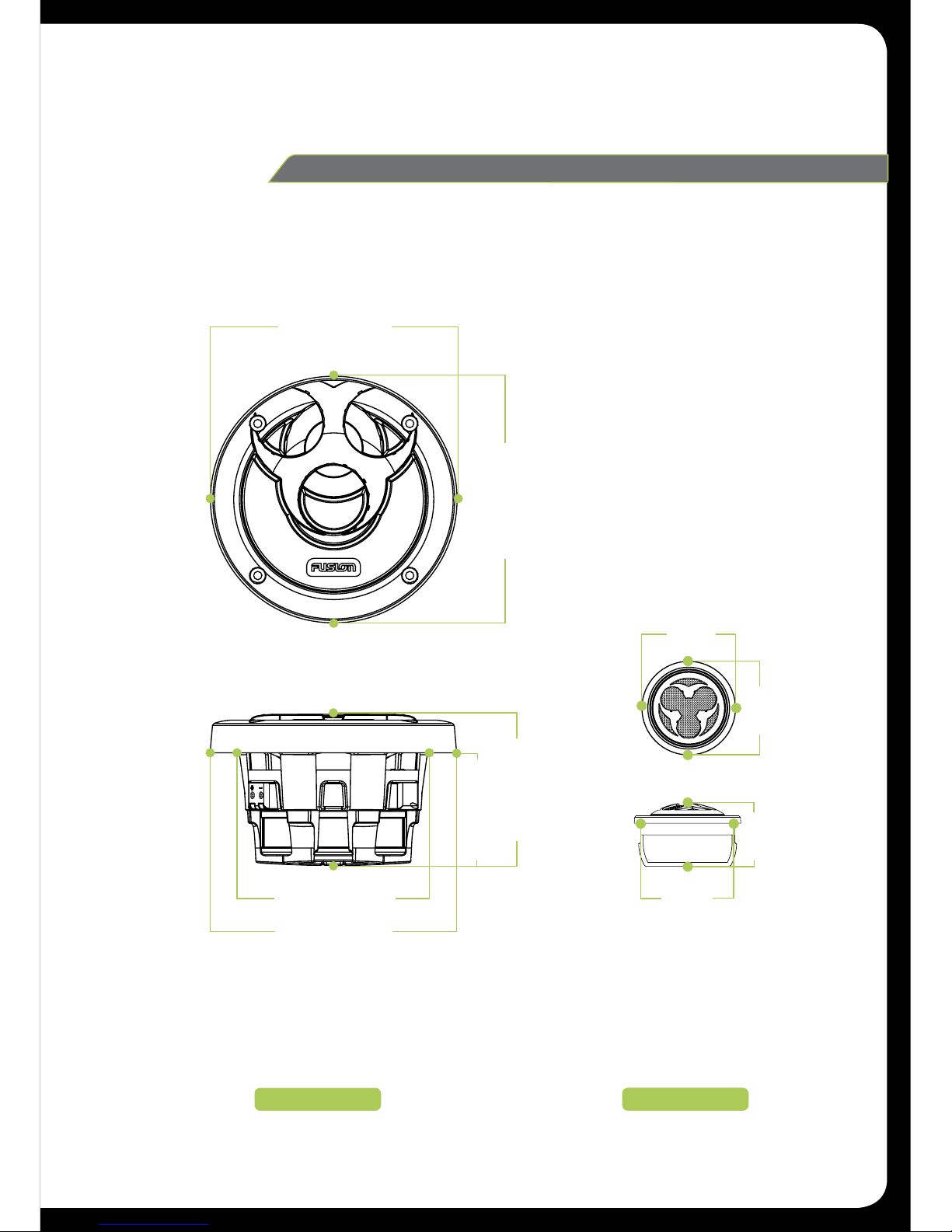

5

TWEETER

WOOFER

SPEAKER

PP-CM40

DIMENSIONS

128mm (5 -1/16")

128mm (5 -1/16")

79mm (3-1/8")

59mm (2-5/16")

128mm (5 -1/16")

100mm (3 -15/16")

51mm

(2")

51mm

(2")

51mm

(2")

32mm

(1-1/4")

Page 6

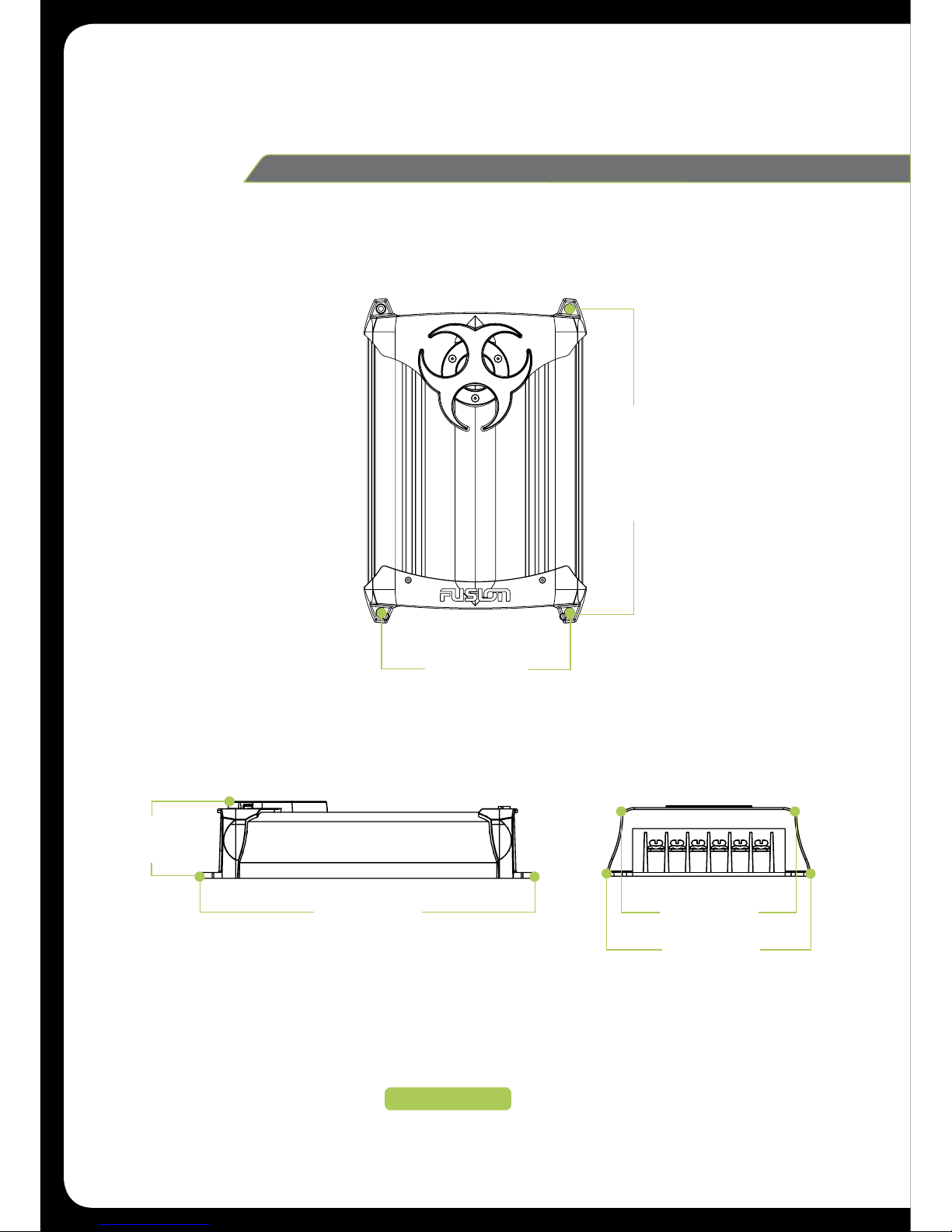

6

X-OVER

X-OVER

PP-CM40

DIMENSIONS

92mm (3-5/8")

IN+ IN- W+ W- T+ T-

92mm (3-5/8")

107mm (4-1/4")

175mm (6-7/8")

162mm (6-3/8")

40mm

(1- 9/16")

Page 7

7

SPEAKER

PP-CM525

DIMENSIONS

TWEETER

WOOFER

152mm (6")

152mm (6")

84mm (3-5/16")

63mm (2-1/2")

152mm (6")

122mm (4-13/16")

51mm

(2")

51mm

(2")

51mm

(2")

32mm

(1-1/4")

Page 8

8

X-OVER

PP-CM525

DIMENSIONS

X-OVER

92mm (3-5/8")

IN+ IN- W+ W- T+ T-

92mm (3-5/8")

107mm (4-1/4")

175mm (6-7/8")

162mm (6-3/8")

40mm

(1- 9/16")

Page 9

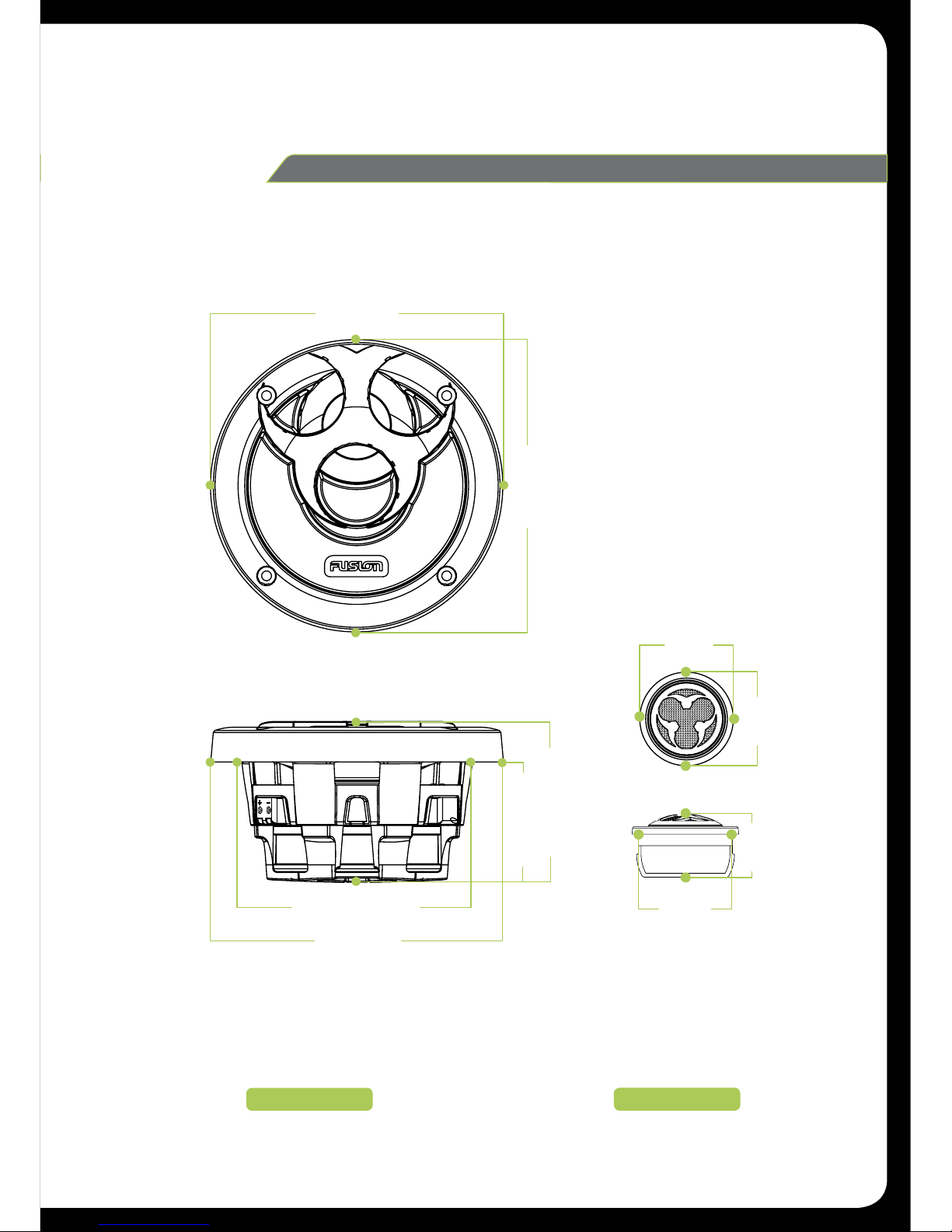

9

SPEAKER

PP-CM65

DIMENSIONS

TWEETER

WOOFER

176mm (6-15/16")

176mm (6-15/16")

89mm (3-1/2")

67mm (2-5/8")

146mm (5-3/4")

176mm (6-15/16")

51mm

(2")

51mm

(2")

51mm

(2")

32mm

(1-1/4")

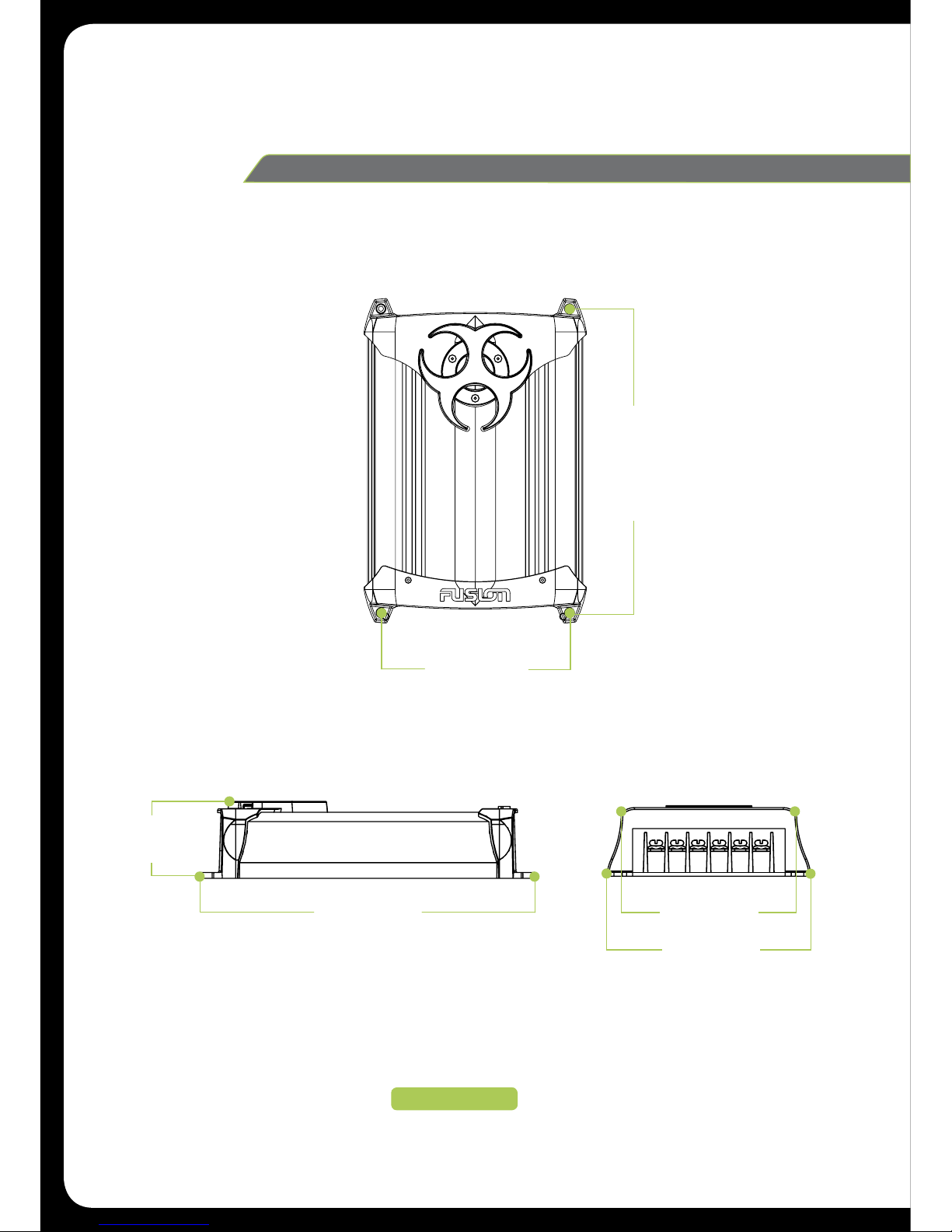

Page 10

10

X-0VER

PP-CM65

DIMENSIONS

X-OVER

92mm (3-5/8")

IN+ IN- W+ W- T+ T-

92mm (3-5/8")

107mm (4-1/4")

175mm (6-7/8")

162mm (6-3/8")

40mm

(1- 9/16")

Page 11

11

SPEAKER

PP-CMST1

DIMENSIONS

TWEETER

WOOFER

176mm (6-15/16")

176mm (6-15/16")

89mm (3-1/2")

67mm (2-5/8")

146mm (5-3/4")

176mm (6-15/16")

51mm

(2")

51mm

(2")

51mm

(2")

32mm

(1-1/4")

Page 12

12

SPEAKER & X-OVER

PP-CMST1

DIMENSIONS

WOOFER

X-OVER

128mm (5 -1/16")

128mm (5 -1/16")

79mm (3-1/8")

59mm (2-5/16")

128mm (5 -1/16")

100mm (3 -15/16")

51mm

(2")

51mm

(2")

51mm

(2")

32mm

(1-1/4")

92mm (3–5/8")

107mm (4–1/4")

92mm (3-5/8")

175mm (6-7/8")

162mm (6-3/8")

40mm

(1-9/16")

IN+ IN- W+ W- M+ M- T+ T-

Page 13

13

INSTALLATION

Before any wiring and installation is performed, FUSION recommends you first plan the complete

installation. Look at wiring routing, speaker location and fitment. Please re-check the installation

at completion.

A front stage and stereo image can be achieved by proper speaker placement. Speakers need to

be positioned on an axis with the listener. Ideally speakers should be situated in locations where

the sound produced is directed to the occupants of the vehicle.

In some circumstances modification to the speaker location may be required. FUSION

recommends a location with sufficient air volume for the speaker to work within its frequency

range. If the air volume is too small there could be lost low frequency notes. FUSION speakers

are designed for optimal sound reproduction across the full audible spectrum – the human ear is

most sensitive to amplitude, pitch, clarity and linearity in the

375Hz to 3 Khz bandwidth.

INSTALLATION WARNING

1: Ensure the vehicle 12 volt lead is removed from the battery before any equipment is

connected.

2:

Investigate the vehicles gas tanks, brake lines and electrical wiring locations before you begin

installation.

3:

Attach the product securely to the vehicle to prevent damage in the event of an accident.

4:

Ensure all wiring is protected to avoid damage or pinching of the cables.

Page 14

14

WIRING

Before any connection is made to the amplifier or source unit, make sure that you turn the audio

system off. Failure to do so could result in either the stock system or new FUSION product

being damaged. FUSION will not warranty damaged speakers due to incorrect installation.

When wiring the FUSION speakers, ensure that the wires are away from sharp objects and that

rubber grommets and insulated bungs are used when wiring through door jams and any other

steel panels. FUSION recommends using the supplied speaker wire for installation. Do not use

wire thinner than the specific wire supplied.

Ensure that when connecting the wires to the speakers and audio system, the terminals and

connections are protected from the vehicles chassis and shorting to each other. If the wires short

together or touch the vehicle chassis, the audio system could be damaged.

When wiring the source and FUSION speakers, ensure you keep the polarity correct. To

successfully do this, wire the positive speaker output from the source unit or amplifier to the

positive of the speaker in the desired location. Do the same with the negative. If you follow this

step then the audio system will be in phase. The result of an out of phase system is lack of bass,

as the left and right, front and rear speakers are opposing audio signals and cancellation occurs.

Page 15

15

1: Check clearance around the mounting area before

installation ensuring that the area is free from

obstruction and there is adequate depth for the

woofer.

2: Using the supplied mounting template, mark the

correct diameter on the mounting surface.

3: Use a suitable cutting tool to remove the marked

surface and drill four holes for the screws to pass

through.

4: Ensure correct polarity before connecting the

speaker terminals to the source unit or amplifier

using the speaker cable provided.

5: Insert speaker and grill into the speaker mounting

hole and affix the speaker with the screws and

mounting hardware provided.

Note: If a stock location is used, the grill frame will

not be required.

WOOFER & MIDRANGE INSTALLATION

Note: Ensure the audio system is off during installation of FUSION product. Once the installation

is complete FUSION recommends that you turn the volume of the source unit up slowly to prevent

damaging the speakers. Please recheck the complete installation prior to turning the audio system

on.

Page 16

16

TWEETER INSTALLATION

TWEETER (surface/angle mount)

FUSION offers three choices of mounting styles

to accommodate the varying requirements for

on and off axis mounting positions. The most

important goal for tweeter placement is the

need to keep an un-obstructed path on axis to

approximately 4" below the rear vision mirror.

The reason for this is to enhance the perception

of centre image. When mounting, make sure

there is no wiring behind the mounting surface,

use the tweeter mount that enables the best

sound focus and use this as the template for

drilling the mounting holes. If using the double

sided adhesive pad, clean all surfaces down

with isopropyl alcohol or some other residue free

cleaner and stick the tweeter down. Ensure it

does not obstruct either car door from closing.

Run the wiring back to the x-over.

TWEETER (flush mount)

First check that the tweeter can be flush mounted

into the surface you have chosen, especially

with regards to depth. Mark out a 51mm hole

and cut this out. Having a hole saw will greatly

improve the tidiness and the integrity of the hole.

Assemble the rear mount with the spring clamp

and press through from the rear of the mounting

surface, then bayonet the front plate and the

rear mount together as shown in the flush mount

illustration. Run the wiring back to the x-over.

SELECTABLE TWEETER GAIN SWITCH

The FUSION x-over comes with a selectable

gain switch. This allows the tweeter volume to be

adjusted +/-

3 dB (half or double volume).

Page 17

17

X-OVER INSTALLATION

X-OVER INSTALLATION

1:

FUSION x-overs are manufactured specifically for use with the FUSION full range component

system. Use of any other crossover may result in damage to one or more of the components.

2:

The x-over is designed for installation under the vehicle dash, under the rear parcel shelf or in

the trunk of the vehicle. They should not be located where they are subject to moisture, such

as a leaky door. If possible locate the x-overs closer to the speakers than the amplifier.

3:

Remove the x-over bottom plate to gain access to the connecting screws (do not attempt to

pry the bottom plate off).

4:

Use the x-over to mark the mounting holes. Make sure there is sufficient clearance on the

other side of the mounting surface and that the mounting surface is perfectly flat to avoid

damage to the x-over.

5:

Drill four 1/8" pilot holes for the screws and wire the x-overs.

6:

Cut the pre-run speaker cable to the correct length. Connect the cable to the x-over, ensure

the correct polarity.

7:

Refit the x-over bottom plate and screw into position.

8:

Adjust the tweeter level at the opposite end of the wire connection block, –3, 0, +3dB.

INSTALLATION TIPS

1:

To avoid confusion, mark the opposite ends of each cable in the same manner, but mark the

second cable differently from the first. (A good idea is to mark the + and – ends of the left

tweeter cable with one piece of electrical tape and both the + and – ends of the left woofer

have two pieces of electrical tape).

2:

For doors, route the cabling through the factory cable harnesses or existing holes, where

possible. If drilling holes, file the burred edges and install rubber grommets to protect the

wires against abrasion. For the rear of the vehicle, route cables along the door sills, lifting and

replacing the carpet as required. You may have to remove the rear seat (depending on your

vehicle configuration) to route cables to the rear.

Page 18

18

+

+

2-WAY X-OVER

PP-CM40, PP-CM525, PP-CM65

WIRING DIAGRAM

3-WAY X-OVER

PP-CMST1

WIRING DIAGRAM

Page 19

19

TECH TIPS

In order to achieve accurate stereo imaging in your vehicle some basic principles should be

applied. Designing a system around the principles of front stage and rear fill will enable the

listener to perceive a stereo image in the front of them. The rear fill is the result of sound

reflecting off the rear windshield and other surfaces which then travels to the listener.

A front stage image can be achieved by proper speaker placement. Speakers need to be

positioned on an axis with the listener, which means speakers in doors may not always be the

best location since you are relying on how well their off axis dispersion is.

It must be understood that one speaker alone cannot reproduce the humans ear’s audible

bandwidth of

20Hz-20kHz. There is a critical bandwidth which is a three octave range centred

around 1kHz. This bandwidth starts at 375Hz. This is where the human ear is most sensitive to

amplitude, pitch, clarity and linearity.

Basic tools required: In any installation these basic tools may be required. For custom type

installations, additional tools maybe necessary.

• Electric drill

• Flat blade screwdrivers

• Crimping tool

• Electrical tape

• Phillips screwdriver

• Wire strippers

• Utility knife, sabre saw, jigsaw, nibbler

• Silicon sealant

Page 20

20

TROUBLE SHOOTING

Before you contact your FUSION dealer or service centre, FUSION requires that you do some

simple trouble shooting to help to diagnose the problem.

If the FUSION speaker has been installed by a professional installation company, then

we recommend that you return to the company so the technician can assess the problem

and advise.

No sound:

Check all connections from the source unit and amplifier to the speaker, tweeter and x-over

terminals.

System lacks in bass:

1:

Check the connections from the source unit/amplifier to the x-over and speakers. Ensure

the positive wire from the source is connected to the positive of the x-over and speaker.

2:

Ensure the speakers are mounted firmly to the mounting surface.

System lacks in high frequencies:

1:

Check polarity.

2:

Check tweeter connections on the x-over.

3:

Check the bass/treble control settings on the source unit.

Distorted sound:

1:

Check all wiring.

2:

Check that it is not the surrounding panels of the vehicle rattling. Check connections from

the source to the x-over and speaker.

Page 21

21

NOTES

Page 22

22

NOTES

Page 23

23

YOU CAN HELP PROTECT THE ENVIRONMENT!

Please remember to respect the local regulations:

Hand in the non-working electrical equipment

to an appropriate waste disposal center

PUBLISHED BY FUSION ELECTRONICS LIMITED:

© Copyright

2006 by FUSION Electronics Limited.

All rights reserved. Specifications and design are

subject to change without notice.

NOTES

Page 24

Specifications and design are subject to change without notice.

Loading...

Loading...