Page 1

T

TECHNICAL MANUAL

Telephone: 01698 820533

Page 2

2

f.172

All boilers come with a 24 month warranty that covers all

the manufacture of the boilers.

A magnetic filter must be fitted to the system in the horizontal

Page Contents

Page 3

3

f.172

A load check should be taken into consideration when installing

(BS 6700:1997).

tube to BS 2871. Part 1 is recommended.

We recommend that a minimum clearance of 450 mm should be

to the boiler plumbing and the internal electrical connections. A

Page 4

4

f.172

All Fusion Electric Boilers have a 22 mm compression connection

We recommend isolation valves on each side of the magnetic

through the boiler and promote premature boiler shut down

An Auto air vent is integral within the boiler however an addi-

tional auto air vent must be fitted at the cylinder coil if the boiler

Where practical and if at all possible, we recommend that all

We recommend the use of an automatic bypass within this circuit

the heating system (sealed systems). Reference should be made to

to ensure that no debris is trapped in

the flow sensor as this may result in boiler failure. Where existing

the boilers should be set to 1.5 bar. All sealed systems should

to BS 4814, (Specification for Expansion Vessels).

Page 5

5

f.172

to supply a heat pack that contains the relevant control valves,

that you need to connect the systems controls and plumbing

We also recommend the use of thermostatic radiator valves on all

tion.

After the system has been installed the cleansing and inhibiting

thoroughly making sure all drain cocks are fully open and that

the system is completely drained.

Add Fernox Heavy Duty restorer through the header tank or via

to the boiler entering modulation mode, then commission the

the system.

Any further information you may require regarding the protection

the normal way. The cleansing agent must be in the system

temperature. A longer period of time would be more beneficial to

the cleansing process especially if excess flux was used.

that for a protector to work correctly, the system must be properly

test kit.

to prevent overflow ensure the cap is removed prior to starting

the appliance.

We recommend setting to 8l/min.

Page 6

6

f.172

Page 7

7

f.172

troller block as this will damage the boiler’s PCB and Void the

the system be filled with water and set to the proper pressure 1.5

the appropriate settings should be entered into to the system pro-

ALL WIRING MUST BE CARRIED OUT IN ACCORDANCE WITH

ALL ELECTRICAL CONNECTIONS MUST BE MADE BY A QUAL-

A load check should be carried out to ensure that there is a suf-

All boilers must be protected at the meter position with a double

the boiler is not fitted local to the meter position then an isolation

All pipe work must be earthed in accordance with the current IEE

After completion of all electrical works, an electrical safety check

to earth and polarity check, and all relevant test certificates pro-

the mains supply. External controls will require an independent

We recommend the use of the EHC Select 107XL Programmer

to control the room and water temperatures. This will also provide

We recommend the use of TRV’s, however they must not be used

tions

Volt free

To main control board

Volt free control

TAKEN TO THE NA OR RP

Page 8

8

f.172

Page 9

9

f.172

Page 10

10

f.172

Page 11

11

f.172

All the end user is required to do is ensure that the system is filled

temperature the boiler will modulate and will automatically

temperature setting.

the central heating system from being blocked and silted up.

We recommend boiler temperature to be set to 6

ATTENTION: Should the temperature on the front

Working parameters control

inlet temperature displayed

switch – outlet temperature displayed

ing. When this light flashes the flow rate is in

sufficient (less than 5 l per min) Refer to tech

nical specifications

ture has been achieved. (RP is open) When the

green light flashes the NA connection is open.

When RED light is on, the boiler is operating

When GREEN light is on boiler temperature

has been achieved.

When this indicator flashes the return temper

ature sensor is faulty.

When this indicator flashes the flow tempera

ture sensor is faulty.

DHWC temperature sensor is used)

Page 12

12

f.172

Slimline boiler

1 - heat exchanger

2 - flow sensor

3 - manometer

4 - safety valve

5 - circulating pump

6 - safety temperature limiter

7 - return inlet

8 - flow outlet

9 - ZIO board

10 - power board

11 - automatic vent

12 - control board

PF - points of electric mains connection (phases)

PN - electrical connections

L - live

PE - permanent earth

N - neutral

M -

boiler fixing positions

RP - control stat connections

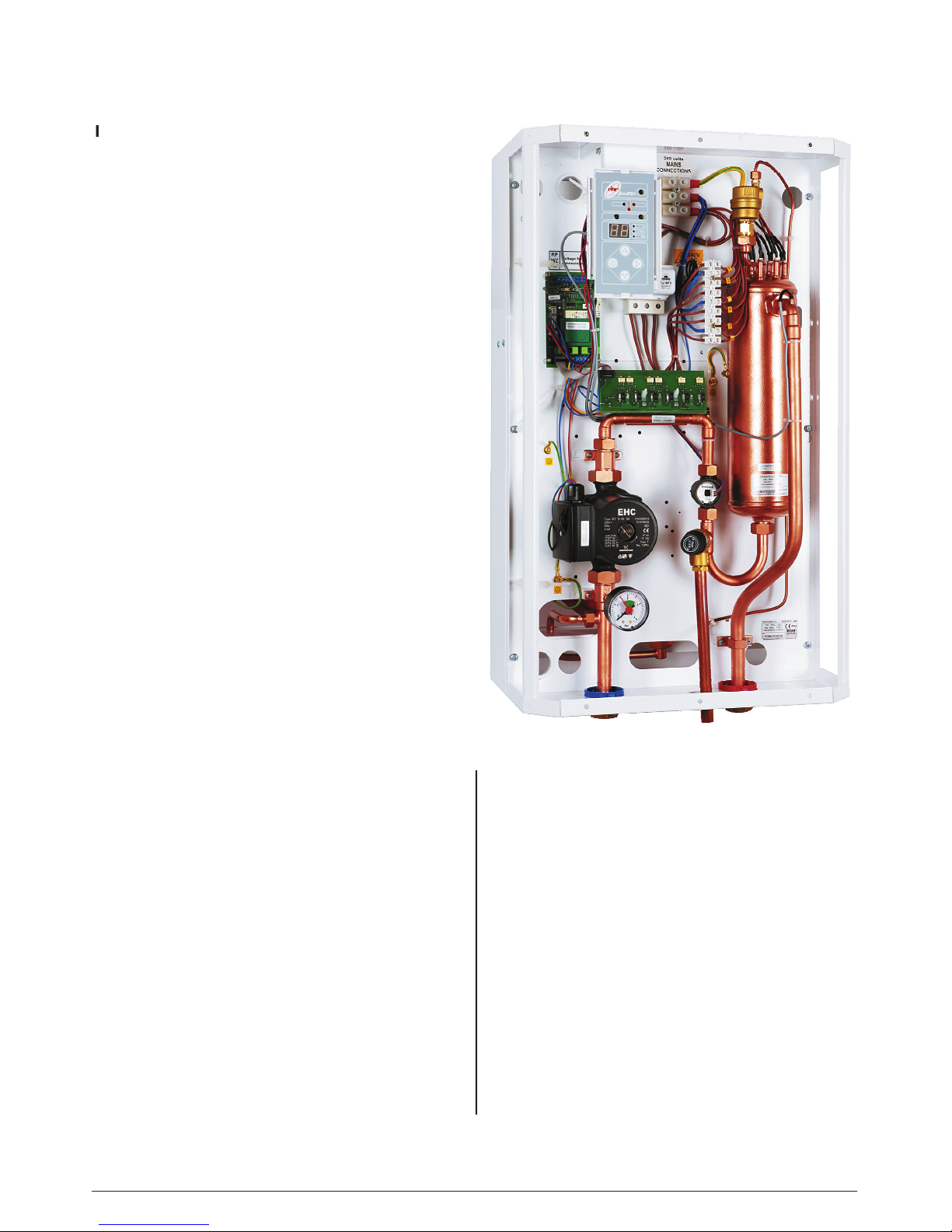

Fusion boiler

1 - heat exchanger

2 - flow sensor

3 - manometer

4 - safety valve

5 - circulating pump

6 - safety temperature limiter

7 - return inlet

8 - flow outlet

9 - ZIO board

10 - power board

11 - automatic vent

12 - control board

13 - expansion vessel connection

14 - expansion vessel

PF - points of electric mains connection (phases)

PN - electrical connections

L - live

PE - permanent earth

N - neutral

M -

boiler fixing positions

RP - control stat connections

Page 13

13

f.172

that the boiler is switched on.

Page 14

14

f.172

Width 420mm

Fax:

6kW

9k

water pressure

bar

lt.

V

415V 3ph N 50Hz

240V; 25,0

Amp

Amp

Amp

Amp

415V; 33,4 Amp

Btu

40,956

Btu

49,147

Btu

40

Yes

45

Amp

Amp

Amp

40 Amp

Loading...

Loading...