Page 1

A

Installation Manual

MARINE RADAR

Model FAR-1513/1513-BB/1523/1523-BB/

FAR-1518/1518-BB/1528/1528-BB

SAFETY INSTRUCTIONS ................................................................................................ i

SYSTEM CONFIGURATION .......................................................................................... iii

EQUIPMENT LIST ........................................................................................................... v

1. INSTALLATION.......................................................................................................1-1

1.1 Before Beginning the Installation... ................................................................................... 1-1

1.2 Antenna Unit Installation Considerations .......................................................................... 1-2

1.3 How to Install the Antenna Unit for FAR-1518, FAR-1528................................................ 1-3

1.4 How to Install the Antenna Unit for FAR-1513, FAR-1523................................................ 1-6

1.5 Processor Unit ................................................................................................................ 1-10

1.6 Display Unit..................................................................................................................... 1-11

1.7 Control Unit ..................................................................................................................... 1-11

1.8 Trackball Control Unit (option) ........................................................................................ 1-12

2. WIRING....................................................................................................................2-1

2.1 Wiring Outline ................................................................................................................... 2-1

2.2 How to Connect the Signal Cable for FAR-1518, FAR-1528 ............................................ 2-2

2.3 How to Connect the Signal Cable for FAR-1513, FAR-1523 ............................................ 2-6

2.4 Processor Unit ................................................................................................................ 2-11

2.5 Trackball Control Unit ..................................................................................................... 2-19

2.6 VDR Connection ............................................................................................................. 2-20

3. ADJUSTMENTS ......................................................................................................3-1

3.1 How to Open the Radar Installation Menu ........................................................................ 3-1

3.2 How to Use the Menu ....................................................................................................... 3-2

3.3 How to Initialize Tuning.....................................................................................................3-2

3.4 How to Align the Heading ................................................................................................. 3-3

3.5 How to Adjust Sweep Timing ............................................................................................ 3-4

3.6 How to Suppress Main Bang ............................................................................................ 3-4

3.7 RADAR INSTALLATION Menu......................................................................................... 3-5

4. INPUT/OUTPUT DATA............................................................................................4-1

4.1 Processor Unit .................................................................................................................. 4-1

4.2 IEC 61162 Sentences ....................................................................................................... 4-2

APPENDIX 1 JIS CABLE GUIDE .............................................................................AP-1

APPENDIX 2 DIGITAL INTERFACE ........................................................................AP-2

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWINGS ................................................................................................ D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1

www.furuno.com

ll brand and product names are trademarks, registered trademarks or service marks of their respective holders.

Page 2

The paper used in this manual

9-52 Ashihara-cho,

A:0000

Z7:JUL.30, 2015

Pub. No.

(

)

Nishinomiya, 662-8580, JAPAN

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

DAMI

FAR-15X3/15X8/BB

Printed in Japan

IME-36380-Z7

Page 3

Radar model Transceiver Magnetron Antenna

100W/m250W/m210W/m

2

XN12A N/A 2.1 m

XN13A N/A 1.9 m

XN12A 0.6 m 4.6 m

XN13A 0.4 m 3.1 m

XN12AF 0.3 m 0.7 m 4.1 m

XN20AF 0.2 m 0.5 m 3.1 m

XN20AF 0.6 m 1.2 m 6.1 m

XN24AF 0.3 m 0.8 m 4.0 m

MAF1565N

M1458F

MAF1615B

MG5436

FAR-1513

FAR-1523

FAR-1518

FAR-1528

RTR-086A

RTR-087A

RTR-100

RTR-101

SAFETY INSTRUCTIONS

The installer of the equipment must read the applicable safety instructions before attempting to install

the equipment.

Indicates a potentially hazardous situation which, if not avoided,

DANGER

WARNING

CAUTION

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury.

Warning, Caution

Prohibitive Action

Mandatory Action

DANGER

Wear a safety belt and hard hat when working on the antenna unit.

Serious injury or death can result if someone falls from the radar antenna

mast.

WARNING

Radio Frequency Radiation Hazard

The radar antenna emits electromagnetic radio frequency (RF) energy which can be harmful,

particularly to your eyes. Never look directly into the antenna aperture from a close distance while the

radar is in operation or expose yourself to the transmitting antenna at a close distance. Distances at

which RF radiation level of 100 W/m

If the antenna unit is installed at a close distance in front of the wheel house, your administration may

require halt of transmission within a certain sector of antenna revolution. See the installation manual

for how to manage blind sectors.

2,

50 W/m2 and 10 W/m2 are given in the table below.

i

Page 4

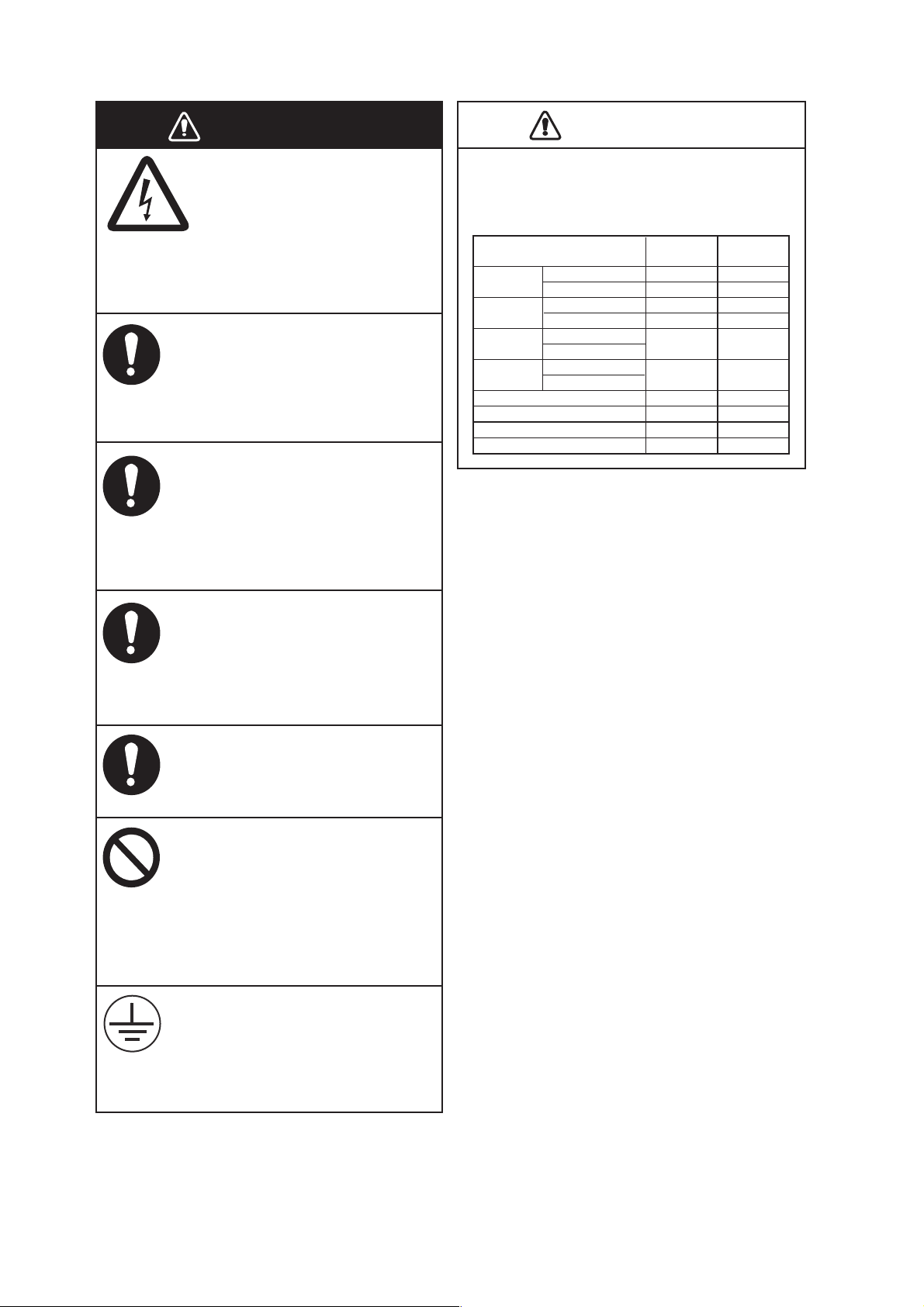

SAFETY INSTRUCTIONS

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service

platform from which to install the

antenna unit.

Serious injury or death can result if

someone falls from the radar antenna

mast.

Turn off the power at the mains

switchboard before beginning the

installation.

Fire, electrical shock or serious injury

can result if the power is left on or is

applied while the equipment is being

installed.

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

Only qualified personnel

are allowed to work inside the

equipment.

CAUTION

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Unit

Antenna Unit

for FAR-1513

Antenna Unit

for FAR-1523

Antenna Unit

for FAR-1518

Antenna Unit

for FAR-1528

Processor Unit (RPU-024) 2.60 m 1.70 m

Control Unit (RCU-028) 0.90 m 0.60 m

Display Unit (MU-150HD(-CV15)) 0.65 m 0.45 m

Trackball Control Unit (RCU-030) 0.50 m 0.30 m

RSB-0070 1.00 m 0.60 m

RSB-0073 1.10 m 0.70 m

RSB-0070 1.85 m 1.25 m

RSB-0073 1.80 m 1.15 m

RSB-120

RSB-121

RSB-120

RSB-121

Standard

compass

1.55 m 1.00 m

2.05 m 1.30 m

Note: For more information, please refer to IMO

SN/Circ.271 “Guidelines for the installation of shipborne radar equipment.”

Steering

compass

Be sure that the power supply is

compatible with the voltage rating

of the equipment.

Connection of an incorrect power

supply can cause fire or damage the

equipment.

Use only the specified power

cable.

Fire or damage to the equipment can

result if a different cable is used.

Do not install the processor unit,

marine display or a control unit in

a dusty environment, orone where

the units may get wet from rain or

water splash.

Dust or water in the units can result in

fire, electrical shock, or damage to

the equipment.

Attach protective earth for

processor unit securely to the

ship's body.

The protective earth (grounding) is

required for the AC power supply to

prevent electrical shock.

ii

Page 5

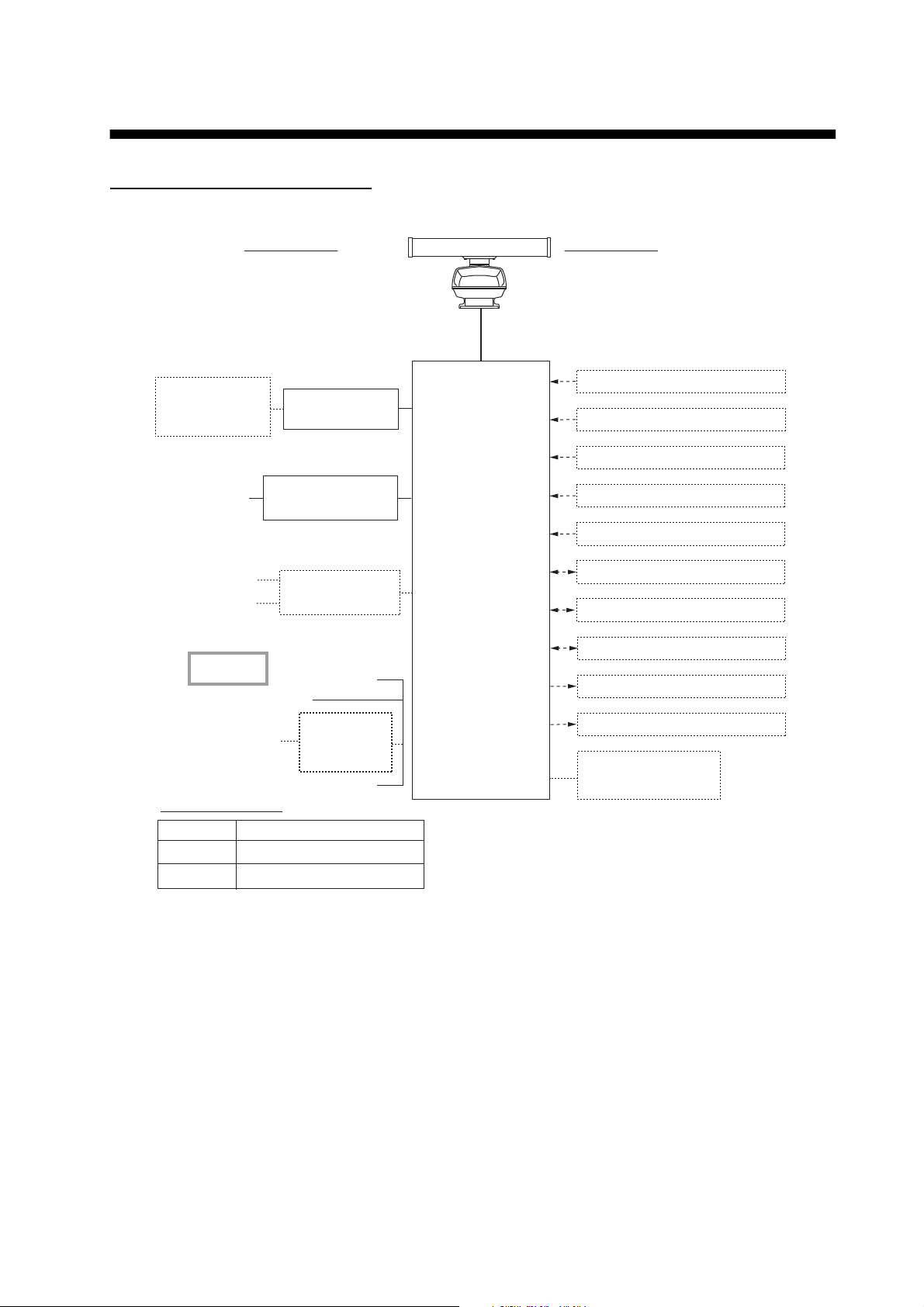

SYSTEM CONFIGURATION

FAR-1513(-BB), FAR-1523(-BB)

ANTENNA UNIT

FAR-1513(-BB)

XN12A-RSB-0070-086A

XN12A-RSB-0073-086A

XN13A-RSB-0070-086A

XN13A-RSB-0073-086A

FAR-1523(-BB)

XN12A-RSB-0070-087A

XN12A-RSB-0073-087A

XN13A-RSB-0070-087A

XN13A-RSB-0073-087A

TRACKBALL

CONTROL UNIT

RCU-030

12-24 VDC

100-230 VAC

1ø, 50/60 Hz

Interswitch

DC Spec.

100/110/115

200/220/230

1ø, 50/60 Hz

Equipment category

MU-150HD(-CV15)*

24 VDC

CONTROL UNIT

RCU-028

DISPLAY UNIT

SWITCHING HUB

HUB-100

Rectifier

RU-1746-B

RU-3424

2

PROCESSOR UNIT

RPU-024

Gyrocompass *1, AD-10 format

Gyrocompass *1, IEC61162 format

AIS Transponder

EPFS (GPS)

SDME (Speed log)

AMS, IEC61162 format

ECDIS

AMS (Contact)*

Sub Display 1

Sub Display 2

VDR

Analog RGB Monitor

3

or

Unit Category

Antenna Exposed to the weather

Other units Protected from the weather

*1: The gyrocompass must also have an update rate that is adequate for the ship’s rate of turn.

The update rate must be better than 40 Hz (HSC) or 20 Hz (conventional vessel).

*2:This monitor have been approved by the IMO, MU-150HD(-CV15) for CAT 3. If a different monitor is

to be used on IMO vessels, its effective diameter must meet the applicable Category requirements

(CAT 3: Effective diameter 180 mm or higher). For installation, operation and viewing distance of

other monitors, see their respective manuals. For BB types, a monitor is to be prepared by the user.

*3: Characteristics of contact output for AMS (Alert Management System):

• (Load current) 250 mA

• (Polarity) Normally Open: 2 ports, Normally Close: 2 ports

iii

Page 6

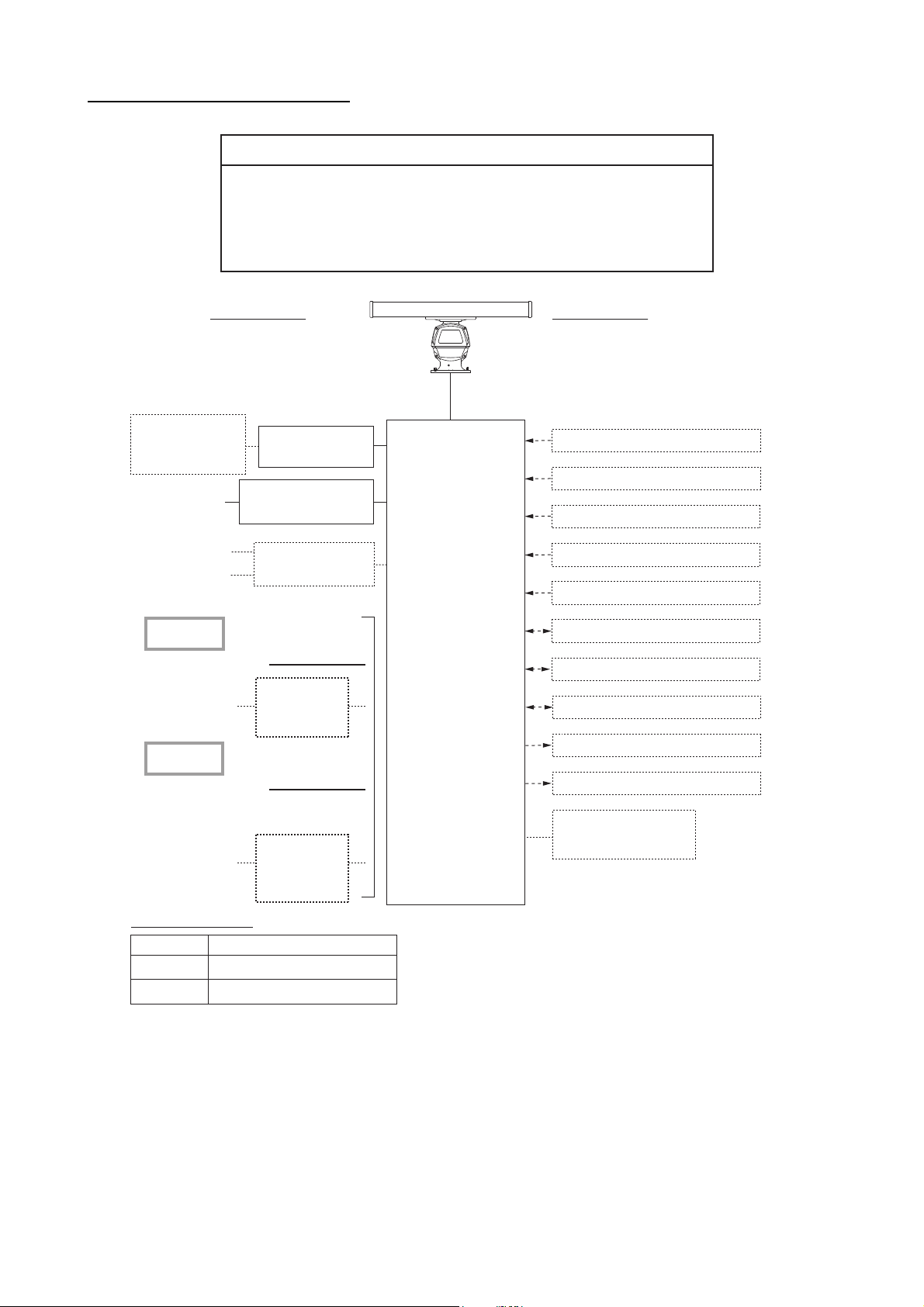

SYSTEM CONFIGURATION

FAR-1518(-BB), FAR-1528(-BB)

NOTICE FOR FAR-1518(-BB)/FAR-1528(-BB)

The radar(s) must be interconnected to the following type approved sensors:

• Gyrocompass meeting requirements of the IMO resolution A.424(XI).

• EPFS meeting the requirements of the IMO resolution MSC.112(73).

• SDME meeting the requirements of the IMO resolution MSC.86(72).

The radar may be interconnected via HUB-100 to other FURUNO processing

units having approved LAN ports.

FAR-1518(-BB)

XN12AF-RSB-120-100

XN12AF-RSB-121-100

XN20AF-RSB-120-100

XN20AF-RSB-121-100

ANTENNA UNIT

FAR-1528(-BB)

XN20AF-RSB-120-101

XN20AF-RSB-121-101

XN24AF-RSB-120-101

XN24AF-RSB-121-101

TRACKBALL

CONTROL UNIT

RCU-030

12-24 VDC

100-230 VAC

1ø, 50/60 Hz

Interswitch

DC Spec.

24 VDC

100/110/115

200/220/230

1ø, 50/60 Hz

AC Spec.

100/110/115

200/220/230

1ø, 50/60 Hz

440 VAC

1ø, 50/60 Hz

CONTROL UNIT

RCU-028

DISPLAY UNIT

MU-150HD(-CV15)*

SWITCHING HUB

HUB-100

Rectifier

RU-1746-B

RU-3424

Stepdown

Transformer

Unit

RU-1803

2

PROCESSOR UNIT

RPU-024

Gyrocompass *1, AD-10 format

Gyrocompass *1, IEC61162 format

AIS Transponder

EPFS (GPS)

SDME (Speed log)

AMS, IEC61162 format

ECDIS

AMS (Contact)*

Sub Display 1

Sub Display 2

VDR

Analog RBG Monitor

3

or

Equipment category

Unit Category

Antenna Exposed to the weather

Other units Protected from the weather

*1: The gyrocompass must also have an update rate that is adequate for the ship’s rate of turn.

The update rate must be better than 40 Hz (HSC) or 20 Hz (conventional vessel).

*2:This monitor have been approved by the IMO, MU-150HD(-CV15) for CAT 3. If a different monitor is

to be used on IMO vessels, its effective diameter must meet the applicable Category requirements

(CAT 3: Effective diameter 180 mm or higher). For installation, operation and viewing distance of

other monitors, see their respective manuals. For BB types, a monitor is to be prepared by the user.

*3: Characteristics of contact output for AMS (Alert Management System):

• (Load current) 250 mA

• (Polarity) Normally Open: 2 ports, Normally Close: 2 ports

iv

Page 7

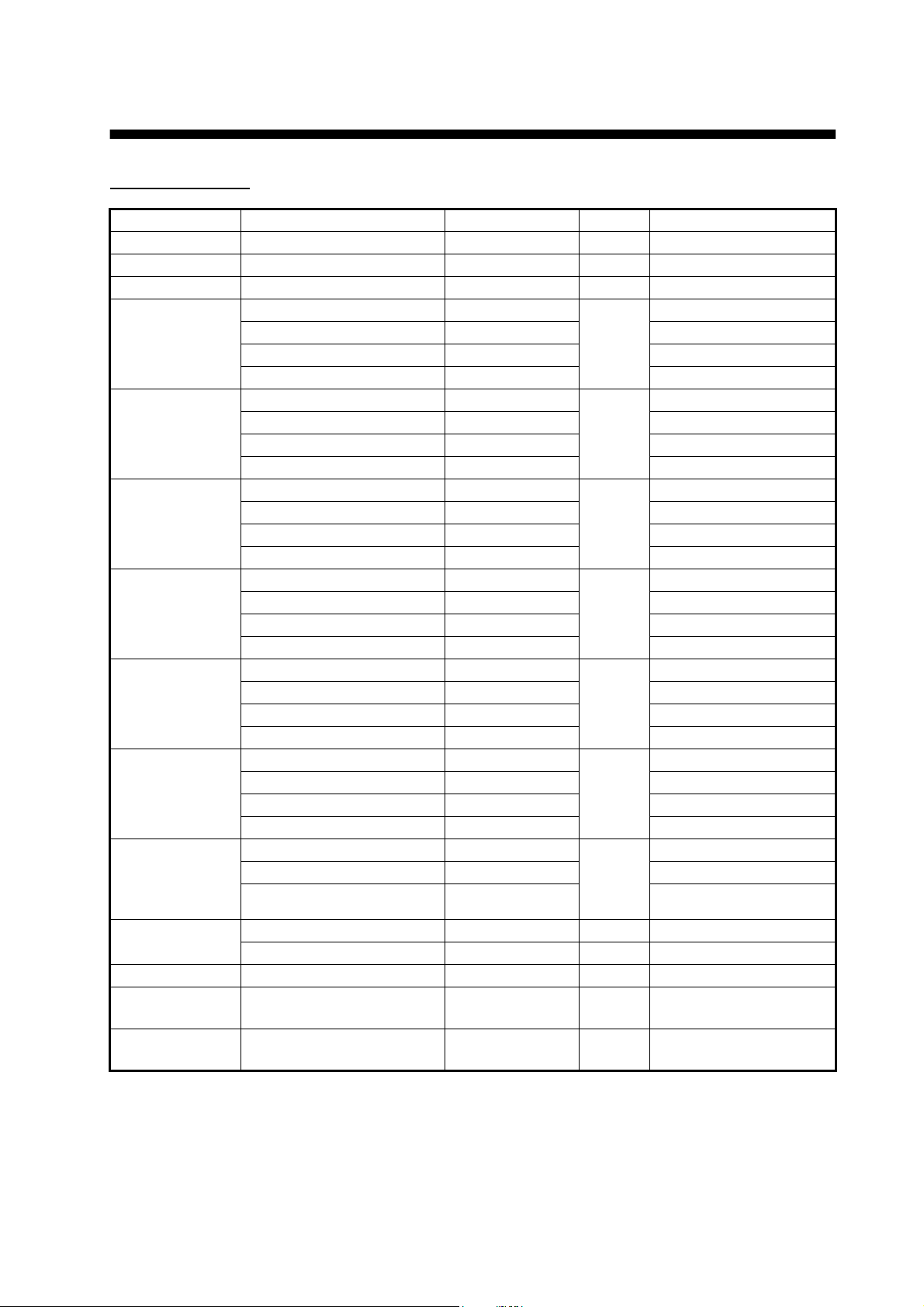

EQUIPMENT LIST

Standard supply

Name Type Code No. Qty Remarks

Processor Unit RPU-024 - 1

Control Unit RCU-028 - 1

Display Unit MU-150HD-CV15 - 1

Antenna Unit

(FAR-1513)

Antenna Unit

(FAR-1523)

Antenna Unit

FAR-1518)

Antenna Unit

(FAR-1528)

Installation

Materials

(FAR-1513)

Installation

Materials

(FAR-1523)

Installation

Materials

(FAR-1518,

FAR-1528)

Installation

Materials

Cable Assy. DVI-D/D S-LINK 5M 001-132-960-10 1

Spare Parts SP03-18001 001-419-820 1 Fuses (2), for DC power

Spare Parts SP03-18002 001-419-830 1 Fuses (2), for AC power

XN12A-RSB-0070-086A XN12A-RSB-0073-086A - 48 rpm, 1200 mm

XN13A-RSB-0070-086A - 24 rpm, 1800 mm

XN13A-RSB-0073-086A - 48 rpm, 1800 mm

XN12A-RSB-0070-087A XN12A-RSB-0073-087A - 48 rpm, 1200 mm

XN13A-RSB-0070-087A - 24 rpm, 1800 mm

XN13A-RSB-0073-087A - 48 rpm, 1800 mm

XN12AF-RSB-120-100 XN12AF-RSB-121-100 - 48 rpm, 1200 mm

XN20AF-RSB-120-100 - 26 rpm, 2000 mm

XN20AF-RSB-121-100 - 48 rpm, 2000 mm

XN20AF-RSB-120-101 XN20AF-RSB-121-101 - 48 rpm, 2000 mm

XN24AF-RSB-120-101 - 26 rpm, 2400 mm

XN24AF-RSB-121-101 - 48 rpm, 2400 mm

CP03-36700 001-421-520

CP03-36710 001-421-530 15 m signal cable

CP03-30720 001-421-540 20 m signal cable

CP03-36730 001-421-550 30 m signal cable

CP03-36800 001-423-400

CP03-36810 001-423-410 15 m signal cable

CP03-36820 001-423-420 20 m signal cable

CP03-36830 001-423-430 30 m signal cable

CP03-36900 001-423-440

CP03-36910 001-423-450 20 m signal cable

CP03-36920 001-423-460 30 m signal cable

CP03-36501 001-419-860 1

CP03-36601 001-419-600 1

Select

one

Select

one

Select

one

Select

one

Select

one

Select

one

Select

one

24 rpm, 1200 mm

24 rpm, 1200 mm

26 rpm, 1200 mm

26 rpm, 2000 mm

10 m signal cable

10 m signal cable

15 m signal cable

processor unit

processor unit

v

Page 8

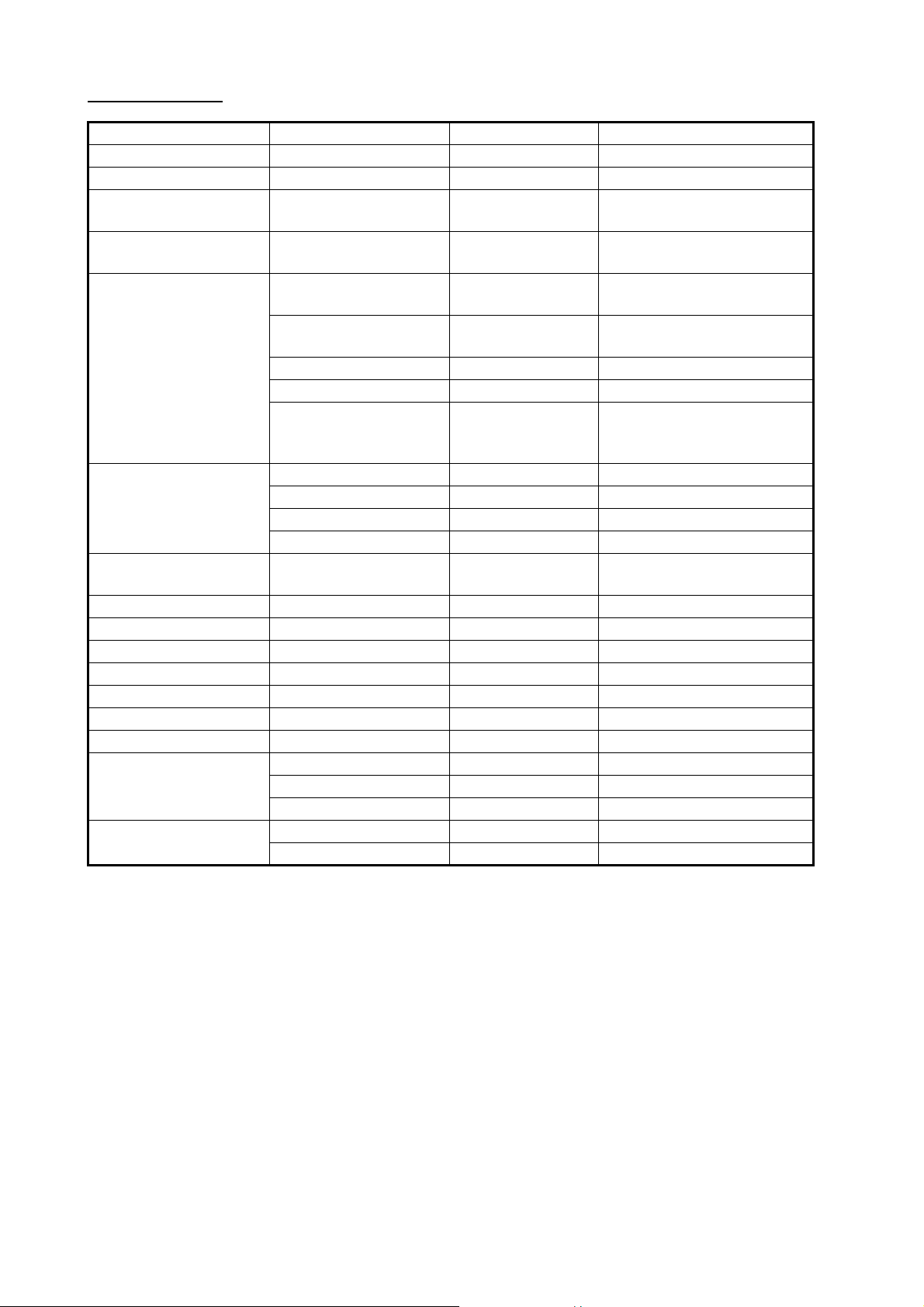

EQUIPMENT LIST

Optional supply

Name Type Code No. Remarks

Trackball Control Unit RCU-030 Performance Monitor PM-32A 001-419-490

Processor Unit IPX2

Kit

Stepdown Transformer

Unit

Rectifier RU-3423 - For display unit,

Cable Assy. RW-4864 1M 001-103-620-10 Radar signal cable, 1 m

Cable Assy. DVI-D/D S-LINK 10M 001-133-980-10 For Display Unit,

Switching Hub HUB-100 Installation Materials CP03-28900 000-082-658 10 m

Installation Materials CP03-28910 000-082-659 20 m

Installation Materials CP03-28920 000-082-660 30 m

Flush Mount Kit OP26-4 001-080-850

Hood Assy. OP26-3 001-080-840

Bracket Assy. OP26-2 000-016-268

LAN Cable MOD-Z072-020+ 001-167-880-10

Cable Assy. 3COX-2P-6C 5M 001-077-230-10

OP03-238 001-419-560

RU-1803 - 440 V100 V

current capacity max. 7A

PR-240 - For display unit,

current capacity max. 8A

RU-1746B-2 - Current capacity max. 13A

RU-3424 - Current capacity max. 20A

PR-850A - 100/110/120/220/240

VAC24 VDC. Current

capacity max. 30A

RW-4864 5M 001-103-630-10 Radar signal cable, 5 m

RW-4864 10M 001-103-640-10 Radar signal cable, 10 m

RW-4864 15M 001-103-650-10 Radar signal cable, 15 m

DVI cable, 10 m

MOD-Z072-050+ 001-167-890-10

MOD-Z072-100+ 001-167-900-10

3COX-2P-6C 10M 001-077-220-10

vi

Page 9

1. INSTALLATION

1.1 Before Beginning the Installation...

Please read the instructions below before beginning the installation.

• Do the installation following the instructions contained in this manual.

• Be sure to do the installation setup (tuning, timing, heading alignment, etc.) in chapter 3 after installing the equipment.

• The cable names mentioned throughout this manual are JIS (Japan Industrial Standard) cables. If not available locally, see Appendix 1 for the equivalent cables.

• The control unit cannot be mounted in a console - it is designed to be mounted on

a desktop.

• See the table below for retrofit possibility. For use of the existing antenna cable of

FR-8125 or FR-8255, attachment of a connector (NH and VH) to the cable is necessary. However, replacement of the cable is recommended.

Retrofit possibility

FAR-1518/1528

FAR-1513/1523

FR-8002 series Yes No No

FR-1500 MK3 series Yes Yes No

• The antenna cable for the FAR-1513/FAR-1523 has connectors at both its ends. If

the cable is to be passed through a bulkhead, do not remove the connectors (to

make it easier to pass the cable through the bulkhead). Make an opening in the

bulkhead large enough to pass the connectors.

(no Performance

Monitor)

FAR-1518/1528

(w/Performance

Monitor)

• Use only the specified power cable and fuse.

• Connect the DC power specification processor unit to the ship’s mains via a breaker.

• Ground the AC power specification processor unit.

• If the processor unit is to be installed near where water or rain splash may occur,

install the optional waterproofing kit, which provides waterproofing standard IPX2.

Do not install the unit in an area where water or rain splash exceeds the conditions

of IPX2.

• Do not connect the radar to the ship’s onboard LAN.

• Connect the drain wires of external equipment to the specified locations in the processor unit to prevent noise.

• Do not disassemble the equipment, to prevent electrical shock.

• Do not apply paint, anti-corrosive sealant or contact spray to coating or plastic parts

of the equipment. Those items contain organic solvents that can damage coating

and plastic parts, especially plastic connectors.

• In case of trouble consult with a FURUNO dealer.

• This series of radars are supplied with or without (BB type) a monitor. The configuration is identical otherwise.

1-1

Page 10

1. INSTALLATION

a, b, c: less than 5° respectively

a+b+c+: less than 20°

1.2 Antenna Unit Installation Considerations

• The antenna unit is generally installed either on top of the wheelhouse or on the radar mast, on a suitable platform. Locate the antenna unit in an elevated position to

permit maximum target visibility.

• A line of sight from the antenna unit to the bow of the ship must hit the surface of

the sea in not more than 500 m or twice the ship’s length, depending whichever value is smaller, for all load and trim conditions.

less than 500 m or twice the ship's length

• Install the antenna unit so that any blind sectors caused by objects (mast, etc.) are

kept to a minimum. A blind sector must not exist in arc of the horizon from right

ahead to 22.5° aft of the beam to either side (see the figure below). Also, individual

blind sectors of more than 5° or the total arc of both blind sectors of more than 20°,

must not occur in the remaining arc (Figure 2). Note that any two blind sectors separated by 3° or less are regarded as one sector.

Figure 1 Figure 2

270°

22.5°

90°

22.5°

a, b, c: less than 5° respectively

a+b+c+: less than 20°

less than 3°

• Do not install the antenna where extreme winds may strike the port and starboard

sides of the antenna.

• Install the antenna unit away from interfering high-power energy sources and TX radio antennas.

• Keep the following distance and angle between another radar antenna.

More than 20°

More than 1 m

1-2

• Keep the lower edge of the antenna unit above the safety rail by at least 500 mm.

Page 11

1. INSTALLATION

• No funnel, mast or derrick shall be within the vertical beamwidth of the antenna unit

in the bow direction, especially zero degree ±5° to prevent blind sectors and false

echoes on the radar picture.

• It is rarely possible to place the antenna unit where a completely clear view in all

directions is available. Therefore, determine the angular width and relative bearing

of any shadow sectors for their influence on the radar at the first opportunity after

fitting.

• Locate the antenna of an EPFS clear of the radar antenna to prevent interference

to the EPFS. A separation of more than two meters is recommended.

• A magnetic compass will be affected if the antenna unit is placed too close to the

compass. Observe the compass safe distances on page ii to prevent interference

to a magnetic compass.

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

• Ground the antenna unit with the supplied ground wire.

• Deposits and fumes from a funnel or other exhaust vent can affect the aerial performance and hot gases may distort the radiator portion. Do not install the antenna unit

where the temperature is more than 55°.

• Leave sufficient space around the unit for maintenance and servicing. See the antenna unit outline drawing for recommended maintenance space.

Note: For the IMO radar, please refer to IMO SN/Circ.271 "Guidelines for the installation of shipborne radar equipment".

1.3 How to Install the Antenna Unit for FAR-1518,

FAR-1528

1.3.1 How to fasten the radiator to the radiator bracket

The antenna unit consists of the antenna radiator and the antenna unit chassis, and

they are packed separately. Fasten the antenna radiator to the antenna unit chassis

as shown below.

1. For the XN20AF, XN24AF, Attach two guide pins to the underside of the antenna

radiator.

2. Remove the waveguide cap from the radiator bracket. The cap may be discarded.

3. Coat the waveguide flange with anticorrosive sealant as shown below.

Hole for

guide pin

5 mm

O-ring10 mm

Anticorrosive sealant

Waveguide cap

Hole for

guide pin

1-3

Page 12

1. INSTALLATION

4. Coat fixing holes for the antenna radiator with anticorrosive sealant.

5. Grease the O-ring and set it to the O-ring groove of the radiator flange.

6. Set the antenna radiator to the radiator bracket.

7. Coat hex bolts M840 with anticorrosive sealant and use them to loosely fasten

the antenna radiator to the antenna unit chassis.

8. For the XN20AF, XN24AF, remove two guide pins (inserted at step 1), and then

tighten fixing bolts.

Antenna radiator

CAUTION

Be sure to remove the guide pins.

Injury may result if the guide pins loosen and

fall.

Guide pin

(XN20AF,

XN24AF)

Waveguide

Radiator bracket

Hex bolt

XN12AF: M8×35

XN20AF, XN24AF: M8×40

O-ring

1-4

Page 13

1.3.2 How to mount the antenna unit

Approx.

30 deg.

Hoist

rings

The antenna unit may be assembled before hoisting it to the mounting platform. However, do not lift the antenna unit by the radiator. Always lift the unit by its housing.

When using a crane or hoist, use the hoist rings which should be fastened to the bolt

fixing covers of the antenna housing.

How to Hoist the Antenna Unit

•

To hoist antenna unit aboard vessel, attach ropes to lifting fixtures and hoist

unit with crane.

• To remove load from radiator when hoisting, the length of the rope between

the radiator base and the hook must be at least 130 cm.

• To keep the rope away from the radiator, turn the radiator and chassis

approx. 30 degrees as shown below.

• BE SURE TO REMOVE THE HOIST RINGS AFTER HOISTING.

Approx.

30 deg.

130 cm

1. INSTALLATION

Hook

Lifting fixture

Lifting fixture

(Top view)

NO!

Hoist

rings

1. Construct a suitable mounting platform referring to the outline drawing at the end

of this manual.

2. Drill four mounting holes of 15 mm diameter and one cable entry hole of about 50

mm diameter in the mounting platform.

3. Lay the rubber mat (supplied) on the mounting platform.

4. Place the antenna unit on the rubber mat, orienting the unit so the bow mark on

its base faces the ship’s bow.

Ground

terminal

Anti-corrosion

rubber

Bow mark

1-5

Page 14

1. INSTALLATION

5. Fasten the antenna unit to the mounting platform with M1260 hex. bolts, nuts, flat

washers and seal washers.

6. Use hex. bolt (M625), nut (M6) and flat washers (M6) to establish the ground system on the mounting platform as shown below. The location of the grounding point

should be within 340 mm of the ground terminal on the antenna unit. Connect the

ground wire (RW-4747, 340 mm, supplied) between the grounding point and the

ground terminal on the antenna unit. Coat the entire ground system with silicone

sealant (supplied).

Coat with

marine

sealant.

Coat with marine

sealant.

Seal washer

Flat washer

Spring washer

Nut

(Torque: 49 N•m)

Fixing bolt Antenna base

Fasten ground wire

then coat with marine

sealant.

Ground wire

Antenna chassis

Coat with marine sealant.

Ground wire

Coat with

marine

sealant.

Hex bolt

Flat washer

Flat washer

OR

Flat washer

Spring washer

Hex nut

Grounding

Ground wire

Hex nut

Spring washer

Flat

washer

Hex

bolt

Welding

7. Confirm that the hoist rings are removed.

1.4 How to Install the Antenna Unit for FAR-1513,

FAR-1523

1.4.1 Installation guidelines

1-6

Below are common mounting locations. See the guidelines in section 1.1 for siting

considerations.

(a) Bridge (b) Common mast (c) Radar mast

Page 15

1.4.2 How to fasten the radiator to the radiator bracket

Make five holes in the platform - four holes to fasten the antenna unit and one hole for

the signal cable, referring to the outline drawing at the back of this manual for the dimensions.

See the packing list at the back of this manual for the installation materials.

1. Remove the radiator cap from the radiator bracket.

2. Apply marine sealant to the surface of the antenna radiator and the radiator bracket. See the figure below for the location.

RADIATOR BRACKET

(top view)

10mm

Coat hatched area with

marine sealant.

1. INSTALLATION

3. Apply the marine sealant to the threads in the four holes on the antenna radiator.

4. Apply the grease to the O-ring and set the O-ring to the radiator bracket.

5. Set the antenna radiator on the radiator bracket.

6. Fasten the antenna radiator to the radiator bracket with the radiator bolts, flat

washers and spring washers. Apply the marine sealant to the radiator bolts (4

pieces).

Antenna

radiator

Apply marine sealant

to threaded holes.

O-ring

Radiator bracket

Flat washer

Spring washer

Hex head bolt

(M8×30)

Apply marine sealant

to bolts.

1-7

Page 16

1. INSTALLATION

1.4.3 How to mount the antenna unit

The antenna unit can be mounted using the holes on the outside or inside of the chassis. Choose the mounting method and follow the applicable procedure below.

Mounting using the outside holes on the chassis

1. Put the rubber mat (supplied) on the mounting location.

2. Referring to paragraph 1.3.2, hoist the antenna unit to the mounting location.

3. Place the antenna unit on the anti-corrosion rubber, orienting the unit so the bow

mark on its base faces the ship’s bow.

Bow mark

4. Set four hex head bolts (M1260, supplied) and seal washers (supplied) from the

top of the antenna housing, as shown below.

Ground

terminal

Anti-corrosion

rubber

Hex bolt

Seal washer

Flat washer

Spring washer

Nut

5. Set the flat washers (M12, supplied), spring washers (supplied) and nuts (supplied) to the hex head bolts. Tighten by turning the nuts. Do not tighten by turning

the hex head bolts, to prevent damage to the seal washers.

6. Apply anticorrosive sealant to the flat washers, spring washers, nuts and visible

parts of bolts.

Bolt

Nut

Marine sealant

Seal washer

Antenna chassis

Anti-corrosion

rubber

Seal washer

Marine sealant

7. Prepare the ground point on the mounting platform. Use an M625 bolt, nut and

flat washer (supplied). The ground point must be within 300 mm from the ground

terminal on the antenna unit.

1-8

Page 17

1. INSTALLATION

8. Fasten the ground wire (RW-4747, 340 mm, supplied) between the ground terminal and the ground point.

9. Apply marine sealant to the ground terminal and ground point as shown below.

Coat with marine sealant.

Ground wire

Coat with

marine

sealant.

Hex bolt

Flat washer

Flat washer

OR

Flat washer

Spring washer

Hex nut

Ground wire

Hex nut

Spring washer

Flat

washer

Welding

Mounting using the inside holes

This method requires removal of the RF unit in the antenna unit to access inside fixing

holes. Use hex head bolts, flat washers, spring washers and nuts (local supply) to

mount the antenna unit, confirming length of bolts.

1. Unfasten four antenna bolts on the cover to open the antenna unit.

2. Unfasten four screws on the RTB cover to remove it.

3. Unplug connector J827 and J834 on the RTB board.

4. Separate upper chassis from lower chassis by removing two hex head bolts

(M825).

5. Remove RF unit by unfastening four hex head bolts.

Hex

bolt

Hex. bolt(M10×20)

Hex. bolt(M8×25)

Remove from cable clamp

J827, J834

6. Lay the corrosion-proof rubber mat (supplied) on the mounting platform.

1-9

Page 18

1. INSTALLATION

7. Fasten the lower chassis to the mounting platform with hex head bolts, spring

washers, flat washers and nuts (local supply), and then coat flat washers, nuts

and exposed parts of bolts with marine sealant. Cut a slit in the rubber bushing

and insert bolt into the bushing. Do not use seal washers.

8. Reassemble the RF unit, cover and chassis.

9. Set four knob caps (supplied) into outside fixing holes.

1.5 Processor Unit

1.5.1 Mounting considerations

The processor unit can be mounted on a desktop or bulkhead. When selecting a

mounting location, keep in mind the following points.

• Locate the unit out of direct sunlight and away from heat sources because of heat

that can build up inside the cabinet.

• Locate the equipment away from places subject to water splash and rain.

• Select a mounting location considering the length of the cables connected.

• Leave sufficient space on the sides and rear of the unit to facilitate maintenance.

(See the outline drawing at the back of this manual.)

• A magnetic compass will be affected if placed too close to the processor unit. Ob-

serve the compass safe distances shown on page ii to prevent interference to a

magnetic compass.

1.5.2 How to mount the processor unit

Desktop installation

Fasten the unit with four bolts (M5, supplied) or self-tapping screws (520, local supply).

Note: If the installation must meet the waterproofing standard IPX2, use the processor

unit IPX2 kit. See paragraph 2.4.4 for details.

Bulkhead installation

Mark locations for four self-tapping screws if screws will be

used. Insert four M5 bolts (or self-tapping screws), leaving

approx. 5 mm of the bolts (screws) exposed. Hang the processor unit on the four bolts (screws) inserted at step 2.

Tighten all bolts (screws).

Blind seal

1-10

Note: If the installation must meet the waterproofing stan-

dard IPX2, set the blind seal supplied with the processor unit

installation materials (CP03-36501) to the unit as shown in

the right figure.

Page 19

1.6 Display Unit

Viewing point

Viewing point

See the operator's manual for MU-150HD (OMC-44560) for the installation procedure.

Keep in mind the following points when selecting a location.

• Locate the display unit where no framing is installed immediately forward of the display unit.

• Locate the display unit where it is easy to view the display in all ambient lighting conditions.

Bridge window

Viewing point

1. INSTALLATION

Viewing point

Bridge

window

1.7 Control Unit

The control unit is designed to be fixed to a desktop. Install the control unit within five

meters from the processor unit since the length of the cable connecting them is five

meters.

1. Drill four mounting holes of 5 mm diameter referring to the outline drawing at the

back of this manual.

2. Fix the control unit with four self-tapping screws (4, local supply) from the top of

the control unit. Make the screws are long enough.

3. Attach four cosmetic caps to the fixing holes on the control unit.

Fixing hole

Note: A plastic bag is attached to the end of the USB cable at the factory to fulfill the

requirements for waterproofing standard IPX2. If the waterproofing standard is required, do not remove the plastic bag.

1-11

Page 20

1. INSTALLATION

1.8 Trackball Control Unit (option)

How to mount the unit tilted

Use the desk fixing plate to mount the unit tilted. Fasten the desk fixing plate to the

bottom of the control unit. Fasten the control unit with self-tapping screws (local supply).

Desk fixing plate

How to mount the unit flush with mounting surface

Drill four mounting holes of 5 mm in diameter referring to the outline drawing at the

back of this manual. Fasten the control unit with four M4 screws (local supply) from

the underside of the desktop.

1-12

Page 21

2. WIRING

2.1 Wiring Outline

12-24 VDC

Radar

ECDIS

FAR-1513/1523

XN12A

XN13A

DISPLAY UNIT

MU-150HD(-CV15)

Analog RBG

Monitor

SWITCHING HUB

HUB-100

DC Spec.

24 VDC

100/110/115

200/220/230

1ø, 50/60 Hz

AC Spec.

100/110/115

200/220/230

1ø, 50/60 Hz

440 VAC

1ø, 50/60 Hz

ANTENNA UNIT

DVI-D/D

S-LINK

(5/10 m)

3COX-2P-6C

(5/10 m)

FR-FTPC-CY

10/20/30 m)

MOD-Z072

(2/5/10 m)

100-230 VAC

1ø, 50/60 Hz

DPYC-6

Rectifier

RU-1746-B

RU-3424

DPYC-2.5

Stepdown

Transformer

Unit

RU-1803

OR

FAR-1513

RW-00024

FAR-1523

RW-00025

(15/20/30 m)

PROCESSOR UNIT

RPU-024

FAR-1518/1528

RW-0030

(15/20/30 m)

TTYCSLA-1Q

ANTENNA UNIT

FAR-1518

XN12AF

XN20AF

FAR-1528

XN20AF

XN24AF

TTYCSLA-4

TTYCSLA-4

TTYCSLA-1

TTYCSLA-1

TTYCSLA-4

TTYCSLA-4

TTYCSLA-7

RW-4864

(1/5/10 m)

RW-4864

(1/5/10 m)

CONTROL UNIT

RCU-028

AD-100

Heading sensor

AIS transponder

GPs navigator

Doppler log

AMS (serial)

ECDIS

AMS (contact)

Master

Sub display 1

Sub display 2

TRACKBALL

CONTROL UNIT

RCU-030

2-1

Page 22

2. WIRING

2.2 How to Connect the Signal Cable for FAR-1518,

FAR-1528

In order to minimize the chance of picking up electrical interference, avoid where possible routing the signal cable near other onboard electrical equipment. Also, avoid running the cable in parallel with power cables.

NOTICE

The magnetron in the transceiver module will demagnetize if it contacts ferrous material. When

dismounting the transceiver module, lay it on its

side or on top of non-ferrous material as shown

below.

Transceiver module

(magnetron inside)

Non-ferrous block

Height more

than 5 cm

1. Open the antenna cover.

2. Disconnect plugs P821, P822, P801 and P802.

J822

(on pcb 03P9487)

J801 and J802

(on pcb 03P9506)

J821

Ground terminal

2-2

3. Unfasten the transceiver module (two bolts). Remove the transceiver module.

4. Unfasten four fixing bolts on the cable gland at the base of the antenna unit. Re-

move clamping ring, rubber gasket and washers.

5. Pass the signal cable through the cable entry hole in the antenna unit mounting

platform. Trim the cable to 500 mm length from the cable gland.

Page 23

2. WIRING

500

20

10

Expose the cables then twist shield.

430

6. Slide two washers, rubber gasket, washer and clamping ring onto the cable in that

order.

Flat washer

Gasket Clamping ring

Flat washer

7. Fabricate the signal cable as shown below.

1) Remove the vinyl sheaths 500 mm.

2) Unravel the outer shield to expose the cores in the outer layer. Then, expose

the cores in the inner layer. Label all inner cores to aid in identification.

3) Trim each core (except coaxial wire) considering its location on the terminal

board.

4) Trim the inner and outer shields leaving 510 mm each. Twist shields together

and attach crimp-on lug FV5.5-4 (blue, 4).

5) Remove insulation of each core approx. 8 mm.

6) Fabricate the coaxial cable.

Vinyl sheath

10

Armor

20

Vinyl sheath (inner)

Expose the cables then twist shield.

Trim armor.

500

430

Fold back shield.

Shield

Coaxial

cable

8

Core

Inner/Outer shield

Attach the crimp-on lug to the core.

Attach the TNC

connector (local

supply) here.

2-3

Page 24

2. WIRING

Core

entrance

8. Pass the shield between the clamping ring and the washer as shown below. Fasten the clamping ring with the screws.

Bolt

Clamping ring

Washer

4-M4×16

9. Connect the signal cable to the terminal board TB801, TB802 and TB803 on the

RF board (03P9488), referring to the interconnection diagram.

TB801

(WAGO connector)

Rubber gasket

Armor

Shield

Terminal opener

RF board (03P9488A)

TB803

(High-Voltage line)

How to insert the core

1. Push lever.

Core

entrance

2. Insert core.

3. Release lever.

TB802

(WAGO connector)

Cable clamp

How to connect wires to WAGO connector

Press downward.

<Procedure>

1. Twist the cores.

2. Press the terminal opener downward.

3. Insert the wire to hole.

4. Remove the terminal opener.

5. Pull the wire to confirm that it is secure.

Wire

Twist

Terminal

opener

WAGO

connector

Cable clamp

Motor

2-4

Loading...

Loading...