OPERATOR'S MANUAL

MULTI BEAM SONAR

Model

DFF-3D

www.furuno.com

9-52 Ashihara-cho,

A:DEC

2016

.

G:JUN.05, 2024

Pub. No.

(

)

Nishinomiya, 662-8580, JAPAN

・FURUNO Authorized Distributor/Dealer

All rights reserved.

REFU

DFF-3D

Printed in Japan

OME-13520-G

0 0 0 1 9 1 4 2 9 1 6

IMPORTANT NOTICES

Cd

Ni-Cd Pb

General

• This manual has been authored with simplified grammar, to meet the needs of international users.

• The operator of this equipment must read and follow the instructions in this manual.

Wrong operation or maintenance can void the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and the equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens you

see on your display. The screens you see depend on your system configuration and equipment

settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO will

void the warranty.

• The following concern acts as our importer in Europe, as defined in DECISION No 768/2008/EC.

- Name: FURUNO EUROPE B.V.

- Address: Siriusstraat 86, 5015 BT, Tilburg, The Netherlands

• The following concern acts as our importer in UK, as defined in SI 2016/1025 as amended SI 2019/

470.

- Name: FURUNO (UK) LTD.

- Address: West Building Penner Road Havant Hampshire PO9 1QY, U.K.

• All brand, product names, trademarks, registered trademarks, and service marks belong to their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal in

the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the chapter

on Maintenance. If a battery is used, tape the + and - terminals of the battery before disposal to prevent fire, heat generation caused by short circuit.

In the European Union

The crossed-out trash can symbol indicates that all types of batteries must

not be discarded in standard trash, or at a trash site. Take the used batteries to a battery collection site according to your national legislation and the

Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that

Ni-Cd and lead-acid rechargeable batteries must be recycled.

Take the used batteries to a battery collection site according to

local laws.

In the other countries

There are no international standards for the battery recycle symbol. The number of symbols can increase when the other countries make their own recycle symbols in the future.

i

SAFETY INSTRUCTIONS

Do not operate the equipment with

wet hands.

Electrical shock can result.

Do not place liquid-filled containers

on the top of the equipment.

Electrical shock can result.

Use the proper fuse.

Use of a wrong fuse can damage the

equipment and may cause fire.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Warning, Caution

Mandatory Action

Prohibitive Action

The installer and user must read the applicable safety instructions before attempting to install

or operate the equipment.

WARNING

WARNING

Do not open the equipment.

Only qualified personnel can work inside

the equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Turn off the power immediately if the

equipment is emitting smoke or fire.

Fire or electrical shock can result if the

power is left on.

Turn off the power immediately if water

leaks into the equipment or an object is

dropped inside the equipment.

Continued use can cause fire or electrical

shock.

Turn off the power immediately if you

feel the equipment is acting abnormally.

If the equipment is hot to the touch or is

emitting strange noises, turn off the power

immediately and contact your dealer for

advice.

WARNING

Safety instructions for the operator

ii

SAFETY INSTRUCTIONS

CAUTIONCAUTION

The transducer cable must be handled

carefully, following the guidelines

below.

• Keep fuels and oils away from the

cable.

• Locate the cable away from chemicals.

• Locate the cable away from locations

where it might be damaged.

Do not disconnect the motion sensor

while the sonar is powered.

The sensor may be damaged.

Do not apply the power with the

transducer exposed to air.

The transducer may be damaged.

A magnetic compass may receive interference if it is placed too close to this

unit. Observe the compass safe

distances shown below to prevent

interference to a magnetic compass.

Standard compass: 1.25 m

Steering compass: 0.80 m

WARNING

WARNING

Do not work inside the equipment

unless qualified to do so.

Electrical shock can occur.

Turn off the power before beginning

the installation.

Fire or electrical shock can result if the

power is on.

Be sure no water leaks at the mounting

location for the transducer.

Water leakage can sink the vessel. Also,

confirm that the transducer will not loosen

by vibration. The installer is solely

responsible for the installation.

Confirm that the power supply voltage

is within the rating of this equipment.

Incorrect voltage will damage the equipment and may cause fire.

Safety instructions for the installer

iii

TABLE OF CONTENTS

FOREWORD ...................................................................................................................vi

SYSTEM CONFIGURATION .........................................................................................vii

1. INSTALLATION .....................................................................................................1-1

1.1 Equipment Lists..........................................................................................................1-1

1.2 How to Install the Sonar ............................................................................................. 1-2

1.3 Transducer ................................................................................................................. 1-3

2. WIRING ..................................................................................................................2-1

2.1 Ground .......................................................................................................................2-1

2.2 Transducer Cable.......................................................................................................2-2

2.3 External KP Cable......................................................................................................2-5

2.4 LAN Cable..................................................................................................................2-9

3. INITIAL SETTINGS ................................................................................................3-1

3.1 DIP Switch Setting .....................................................................................................3-1

3.2 Operation Check ........................................................................................................3-3

3.3 Multi Function Display Initial Settings.........................................................................3-4

4. OPERATION ..........................................................................................................4-1

4.1 Menu Operations........................................................................................................4-1

4.1.1 How to start/stop transmission.......................................................................4-1

4.1.2 How set the background color........................................................................4-1

4.1.3 How to adjust the bottom range shift.............................................................. 4-2

4.1.4 How to change the transmission rate (PRR).................................................. 4-2

4.2 Display Screens Overview .........................................................................................4-3

4.3 Multi-Sounder Display Operations ............................................................................. 4-6

4.3.1 How to switch between TX and STBY ...........................................................4-6

4.3.2 How to switch between single beam and triple beam presentations.............. 4-6

4.3.3 How to set the TX beam angle....................................................................... 4-6

4.3.4 How to set the TX beam width ....................................................................... 4-6

4.3.5 How to change the picture advance speed....................................................4-6

4.3.6 How to show or hide the scale box ................................................................4-7

4.3.7 Availability of points and event marks registration, and go to a point ............4-7

4.4 Side Scan Display Operations ...................................................................................4-8

4.4.1 How to switch between TX and STBY ...........................................................4-8

4.4.2 How to change echo color.............................................................................. 4-8

4.4.3 How to show or hide the scale box ................................................................4-8

4.4.4 Availability of points and event marks registration, and go to a point ............4-9

4.5 Cross Section Display Operations ........................................................................... 4-10

4.5.1 How to switch between TX and STBY .........................................................4-10

4.5.2 How to show or hide the grid........................................................................ 4-10

4.5.3 Zoom display................................................................................................ 4-10

4.5.4 How to smooth echoes (distance)................................................................ 4-10

4.5.5 How to smooth echoes (time) ......................................................................4-11

4.5.6 How to apply correction to the speed of sound ............................................ 4-11

4.5.7 How to show or hide the scale box ..............................................................4-11

4.5.8 Availability of points and event marks registration, and go to a point ..........4-12

4.6 3D Sounder History Display Operations .................................................................. 4-13

4.6.1 How to switch between TX and STBY .........................................................4-13

4.6.2 How to move, zoom in, zoom out the viewpoint position .............................4-13

4.6.3 How to mark school of fish...........................................................................4-13

iv

TABLE OF CONTENTS

4.6.4 How to pause advancement of the display...................................................4-14

4.6.5 How to adjust the echo detection level.........................................................4-14

4.6.6 How to calibrate the seabed echo................................................................4-14

4.6.7 How to use the noise filter............................................................................4-14

4.6.8 How to use terrain shading...........................................................................4-15

4.6.9 How to change the picture advance speed ..................................................4-15

4.6.10 Depth/Color Shading display ........................................................................4-15

4.6.11 How to show or hide the scale box...............................................................4-19

4.6.12 Availability of points and event marks registration, and go to a point...........4-19

4.7 Personal Bethymetric Generator (PBG) ...................................................................4-20

4.7.1 Setting up for PBG .......................................................................................4-21

4.7.2 How to map the seabed ...............................................................................4-21

4.7.3 How to select the depth shading method .....................................................4-22

4.7.4 How to change/remove coloration (depth shading)......................................4-23

4.7.5 How to delete seabed maps.........................................................................4-24

4.7.6 How to share seabed maps between units ..................................................4-25

5. MAINTENANCE,

TROUBLESHOOTING...........................................................................................5-1

5.1 Maintenance...............................................................................................................5-1

5.2 How to Replace the Fuse ...........................................................................................5-2

5.3 How to Restore Default Settings ................................................................................5-2

APPX. 1 MENU TREE ..............................................................................................AP-1

APPX. 2 JIS CABLE GUIDE ....................................................................................AP-3

APPX. 3 INSTALLATION OF TRANSDUCER B54, SS54 ......................................AP-4

APPX. 4 INSTALLATION OF TRANSDUCER TM54 ............................................AP-10

SPECIFICATIONS .....................................................................................................SP-1

PACKING LISTS ......................................................................................................... A-1

OUTLINE DRAWING................................................................................................... D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1

INDEX ......................................................................................................................... IN-1

v

FOREWORD

A Word to the Owner of the DFF-3D

Congratulations on your choice of the FURUNO DFF-3D Multi Beam Sonar. We are confident you

will see why the FURUNO name has become synonymous with quality and reliability.

Since 1948, FURUNO Electric Company has enjoyed an enviable reputation for quality marine

electronics equipment. This dedication to excellence is furthered by our extensive global network

of agents and dealers.

This equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless installed, operated and

maintained properly. Please carefully read and follow the recommended procedures for installation, operation and maintenance.

Thank you for considering and purchasing FURUNO.

Features

The DFF-3D Multi Beam Sonar provides high definition images of underwater conditions and the

seabed. Connected to the NavNet TZtouch/NavNet TZtouch2 Multi Function Display, the DFF-3D

distributes images of the undersea throughout the NavNet network, via LAN.

The main features of the DFF-3D are as follows.

• TX beam detects undersea conditions 120° in port and starboard directions.

• The motion sensor, provided standard, stabilizes the display to give clear and stable images

even under rough sea conditions.

CE/UKCA declaration

With regards to CE/UKCA declarations, please refer to our website (www.furuno.com) for further

information about RoHS conformity declarations.

Disclosure of Information about China RoHS

With regards to China RoHS information for our products, please refer to our website

(www.furuno.com).

vi

SYSTEM CONFIGURATION

MULTI BEAM SONAR

DFF-3D

NavNet TZtouch

TZT9/TZT14/TZTBB

NavNet TZtouch2

TZTL12F/TZTL15F/TZT2BB

NavNet TZtouch3

TZT12F/TZT16F/TZT19F

12-24 VDC

Rectifier

PR-62

100/110/220/230 VAC

1ø, 50/60 Hz

External

KP

Transducer

B54, SS54, or TM54

: Optional or local supply

: Standard supply

vii

SYSTEM CONFIGURATION

This page is intentionally left blank.

viii

1. INSTALLATION

1.1 Equipment Lists

Standard supply

Name Type Code No. Qty Remarks

Multi Beam

Sonar

Transducer B54 - 1 Select one.

Spare Parts SP02-05601 001-033-740 1 set Fuses

Installation

Materials

DFF-3D - 1

SS54 -

TM54 -

CP02-09400 000-029-992 1 set • Power cable assy. (3.5 m)

B54: Thru-hull mount (bronze)

SS54: Thru-hull mount (stainless steel)

TM54: Transom mount

• LAN cable assy. (5 m)

• Self-tapping screws

• Conductive tape

Optional supply

Name Type Code No. Remarks

Connector Kit for TX Sync OP02-86 001-205-780

Cable Assembly MOD-Z072-020+ 001-167-880-10 2 m, for HUB-101

Cable Assembly MOD-Z072-100+ 001-167-900-10 10 m, for HUB-101

Rectifier PR-62 000-013-484 100 VAC

000-013-485 110 VAC

000-013-486 220 VAC

000-013-487 230 VAC

AC/DC Power Supply Unit PR-241 -

Ferrite Core OP86-11 001-594-450 For use with PR-241,

1-1

1. INSTALLATION

1.2 How to Install the Sonar

This sonar can be installed on a deck or on a bulkhead. When selecting a mounting

location, keep the following points in mind:

• Install the unit indoors.

• The operating temperature range of this unit is -15°C to 55°C (5°F to 131°F). Be

sure the mounting location satisfies this requirement.

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away from electromagnetic field-generating equipment such as motors and generators.

• Observe the minimum recommended maintenance space shown in the outline

drawing at the back of this manual. Also, leave slack in cables for maintenance and

servicing ease.

• A magnetic compass may receive interference if it is placed too close to this unit.

Observe the compass safe distances noted in the safety instructions to prevent interference to the magnetic compass.

• For mounting on a bulkhead, the connectors must face downward.

Fasten the unit to the mounting location with four self-tapping screws (5×20, supplied),

referring to the outline drawing at the back of this manual for mounting dimensions.

1-2

1.3 Transducer

Thru-hull mount

The installation position of the transducer directly affects the performance of the transducer. For best performance, keep the following points in mind when selecting the

mounting location.

• Select a location where the influence of water flow and air bubbles is minimal.

• Select a place least influenced by engine noise.

• Do not install the transducer inboard.

• For FRP vessel, do not cover the transducer with fiberglass, to prevent damage to

the transducer if the temperature rises.

• Bottom slope angle less than 24°

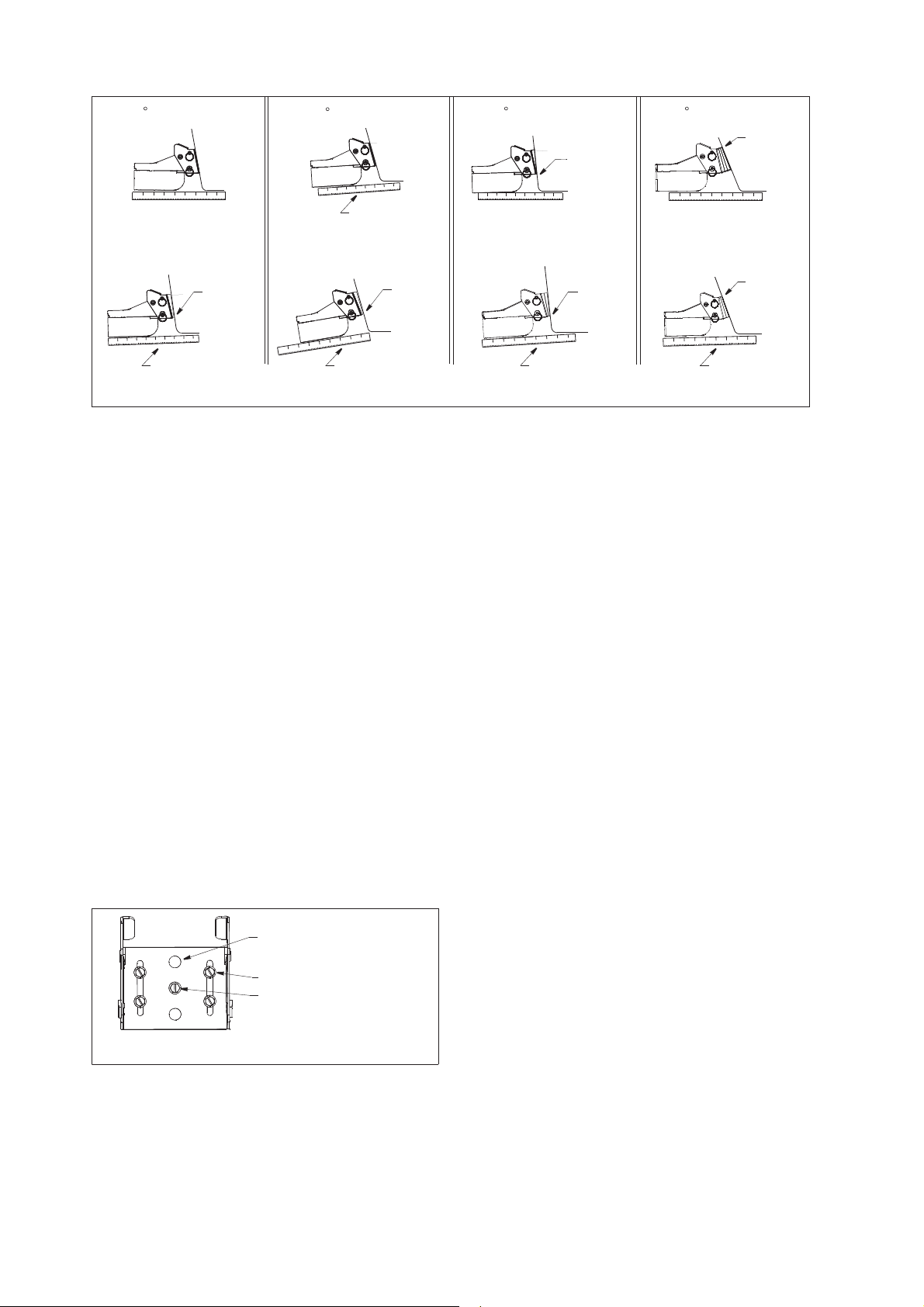

The illustration below is the transducer with fairing, and was created by the Airmar

Technology Corporation. The BOW mark (arrow) on the fairing and the triangular recess should be facing the bow.

1. INSTALLATION

®

Unit of measurement

Top: millimeter

Bottom: inch

BOW

BOW

BOW

Triangular recess

BOW mark

1-3

1. INSTALLATION

Unit of measurement

Top: millimeter

Bottom: inch

1-4

1. INSTALLATION

Unit of measurement

Top: millimeter

Bottom: inch

Transom mount

For a vessel with an inboard engine, the transducer cannot be installed aft of the propeller screw because of the turbulence created by the propeller ahead of the transducer. Determine the mounting location considering the guidelines shown below and the

instructions on page AP-8.

• Select a location as far as possible from the propeller screw.

• Select a location where the propeller screw is not within 120° of the beam range of

the transducer.

Be sure to select the location considering these guidelines, to prevent echo noise on

the display.

The illustration below was created by the Airmar

®

Technology Corporation.

1-5

1. INSTALLATION

This page is intentionally left blank.

1-6

2. WIRING

Ground wire

(IV-2 sq)

MOD-Z072-050+, 5 m

(option: 2/10 m)

TZT9/TZT14/TZTBB

TZTL12F/TZTL15F/TZT2BB

TZT12F/TZT16F/TZT19F

GROUND

MJ-A3SPF0013-035C

(3.5 m)

External

KP

Transducer

B54, SS54, or TM54

Power supply

(12-24 VDC)

1.4-0.7A

Connect the power cable and transducer cable as shown below. See the next page

for how to fabricate the transducer cable.

2.1 Ground

Connect a ground wire (IV-2 sq, local supply) between the ground terminal and ship’s

ground to prevent interference to the sounder picture. Make the length of the wire as

short as possible. For FRP vessels, install a ground plate (approx. 20 cm by 30 cm)

on the outside of the hull bottom and connect the ground wire there.

2-1

2. WIRING

x9

Shield

2.2 Transducer Cable

Separate the transducer cable as far as possible from power cables to prevent interference to the sonar. Keep the transducer cable away from televisions and monitors

to prevent noise in the cable.

Fabricate the cable as shown in the procedure below, then connect it inside the unit

with a WAGO connector.

1. Fabricate the cable as shown below.

Note: Keep the recommended lengths to prevent noise in the cable.

Sheath

110

80

Sheath

The cable has one or three shield cores. Wrap the shield(s)

around the sheath.

Wrap shield with conductive tape.

Unit: mm

6

x9

Shield

Wrap with vinyl tape (width: 30 mm).

2. Remove the outer cover.

3. Unfasten four screws to remove the inner chassis cover.

2-2

4. Detach three WAGO connectors, TB1, TB2, TB3.

WAGO connector

opener

WAGO connector

TB1TB2TB3

Super gland

Sealing nut

Unfasten these screws to

remove the clamping plate.

5. Unfasten the sealing nut from the super gland for the transducer cable.

2. WIRING

6. Unfasten two screws to remove the clamping plate for the transducer cable.

7. Pass the transducer cable through the sealing nut (unfastened at step 5), then

pass the cable through the super gland and into the unit.

2-3

2. WIRING

How to connect cable to WAGO connector

Push down

Opener

WAGO

connector

Wire

Twist

<Procedure>

1. Twist core.

2. Insert opener in hole and

push down.

3. Insert core into hole.

4. Release opener.

5. Tug on wire to confirm tight

connection.

2 mm

8. Referring to the interconnection diagram (at the back of this manual) and the illustration below, connect the transducer cable to WAGO connectors. (The WAGO

connector opener is provided inside the unit. See the figure at step 4 for the location.)

9. Reattach the WAGO connectors.

10. Set the cable where the clamping plate was removed (at step 6). As shown in the

figure below, lay the cable such that its conductive tape lies beneath the clamping

plate. Hold the clamping plate in place with your fingers then fasten the plate.

Conductive

tape

Clamping plate

11. Fasten the sealing nut into the super gland. The gap between the sealing nut end

and the super gland should be 2 mm. The fastening torque is 1.8 - 2.0 N•m.

12. Reattach the inner and outer covers.

2-4

2. WIRING

(b)

Approx. 10 mm

(a)

Approx. 100 mm

(c)

Fold back core.

A

2.3 External KP Cable

The Connector Kit for TX Sync (see the table below) and the cable MPYC(SLA)-4 are

required to connect external KP.

Contents of Connector kit for TX sync

Name Type Code No. Qty Remarks

Upset UI Screw-B M4×20 000-163-756-10 2

Super Gland MGB20M-12B 000-177-248-10 1

PH Connector Assembly 02-1097 (4P) 001-206-000 1

Cable Clamping Plate 02-167-1528 100-379-090-10 1

Rainproof Panel 02-167-1529 100-379-100-10 1 No use. May be

discarded.

EMI Core GRFC-10 000-177-010-10 1

Crimp-on Lug NCW-1.25 000-157-213-10 4

Note: FURUNO recommends use of the JIS cable MPYC(SLA)-4 (or equivalent, see

Appendix 1). However, if the wiring environment is such that the cable may contact

seawater, use a cable whose armor is covered with a vinyl sheath to prevent corrosion.

1. Fabricate the cable for the external KP as shown below.

a) Make the length of the wires of the PH connector assembly (supplied) 100 mm.

b) Remove the sheath from the cores 10 mm.

c) Fold back the cores in half. Attach crimp-on lug NCW-1.25 (supplied) to each

core.

d) Remove the armor 300 mm and cut off the vinyl sheath 130 mm

MPYC(SLA)-4

rmor

Vinyl sheath

300 mm

80 mm

Shield

130 mm

2-5

2. WIRING

Approx. 5 mm

This part is fixed with

the sealing nut.

Lay this part in

the cable clamp.

Armor

Vinyl sheath

NCW-1.25

Wrap with

vinyl tape.

Wrap with

vinyl tape.

Crimp-on lug

FV1.25-4(LF) RED

Protective sheet

e) Remove 5 mm of the vinyl sheath from the cores then connect a crimp-on lug

to each core as shown below.

f) Attach supplied crimp-on lug (FV1.25-4(LF) RED)) to the shield.

g) Referring to the illustration below, wrap the armor with vinyl tape at the loca-

tions shown. Pass the cable through its cable gland. Fix the cable with the cable clamp and sealing nut.

2. Remove the outer cover.

3. Loosen four screws to remove the inner chassis cover.

4. Detach the protective sheet from the location for the external KP cable.

2-6

2. WIRING

Lock nut

Super gland

Cable for external KP

(MPYC(SLA)-4)

Sealing nut

4 mm

Secure cable with cable clamping plate.

5. Unfasten the sealing nut and lock nut from the supplied super gland. As shown

below, pass the cable through the sealing nut, super gland, hole in the unit and

the lock nut.

6. Fasten the lock nut to fix the super gland to the unit.

7. Fasten the sealing nut into the super gland. The gap between the sealing nut end

and the super gland should be 4 mm. The fastening torque is 1.8 - 2.0 N m.

8. Position the cable so its vinyl sheath lies in the cable clamp. Use the supplied cable clamping plate to secure the cable.

2-7

2. WIRING

J9

Clamp

Lay vinyl sheath in the cable clamp and

secure the cable with the cable clamp.

Make sure cable does

not contact TB3.

Shield

EMI coreEMI core

10 mm10 mm

Super glandSuper gland

9. Connect the KP cable. Pass the PH connector through the clamp shown below,

then connect it to J9 on th DIGI board. Make sure the cable does not contact the

WAGO connector (TB3). Also, secure the shield of the external KP cable to the

plate where the transducer cable is fixed.

Note 1: As shown in the figure below, pass the cable through the cable saddle.

Make sure the crimp connectors are not clamped by the cable saddle.

Note 2: Confirm that the direction of the clamping plate is as shown below.

Cable saddle

Crimp connectors

Clamping

plate

10. Attach the supplied EMI core (GRFC-10) to the cable for the external KP, approx.

10 mm from the super gland.

11. Reattach the inner and outer covers.

2-8

2.4 LAN Cable

How to detach clamping claw

Hold the clamping

claw/seal assy. as shown

left, with the teeth of

the clamping claw toward

you.

Push in the sealing insert

with your thumbs.

Sealing nut

Seal assy.Seal assy.

Clamping

claw

Sealing

insert

Super

gland

Sealing nut

LAN cable

Sealing insert

(Push cable into slit.)

Clamping claw

Do as follows to connect the supplied LAN cable (MOD-Z072-050+) or the optional

LAN cable (MOD-Z072-020+, MOD-Z072-100+).

1. Unfasten the sealing nut from the LAN connector then remove the sealing insert

and clamping claw.

2. Detach the sealing insert from the clamping claw as shown below.

2. WIRING

3. Pass the sealing nut, clamping claw and sealing insert onto the LAN cable in the

order shown in the figure below. Connect the cable to the LAN connector. (Note

the orientation of the sealing insert when passing it onto the cable. Push the cable

into the slit in the sealing insert.)

4. Set the sealing insert and clamping claw into the sealing nut then tighten the nut.

2-9

2. WIRING

Screw (2 pcs.)

Gland

5. Fasten the sealing nut to fasten the LAN cable. The clearance between the sealing nut and the super gland shall be 3 mm. The fastening torque for the sealing

nut is 1.8 - 2.0 Nm.

3 mm

How to disconnect the LAN cable

Loosen the two screws on the gland to access the cable’s connector. A lock washer

is fitted to the gland, so the screws cannot be unfastened completely.

2-10

3. INITIAL SETTINGS

S2S3

WARNING

Do not open the equipment unless totally

familiar with electrical circuits.

Only qualified personnel are permitted to

work inside the equipment.

3.1 DIP Switch Setting

The DIP switches S2 and S3 should be left in the default position (OFF).

DIP switch S2

12345678

OFF

DIP switch S3

1234

OFF

3-1

3. INITIAL SETTINGS

DIP switch S2 setting options (reference only)

Switch

No.

1 Automatic IP address assignment OFF: Fixed (static) IP address. Set the IP address

2 IP address no. Effective when #1 segment is OFF. (See the table

3 Restore default settings (other than

LAN)

4 Restore ALL default settings See section 5.3.

5 - 6 Keep these switches in the OFF position.

7 No use.

8 No use.

#2 Host name IP address

OFF ES092021 172.031.092.021

ON ES092022 172.031.092.022

Function Setting

with switch #2.

ON: IP address assigned automatically.

below for IP address. Currently, this function has no

use.)

See section 5.3.

After setting up the DFF-3D transducer, initial settings must also be done on your

NavNet device (NavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3). See respective Installation Manual for the procedure.

3-2

3.2 Operation Check

After connecting the NavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3, power the

unit on/off from the ship’s switchboard. The LED on the cover of the DFF-3D lights or

flashes according to equipment state, as described in the table below.

LED state Meaning

Lit continuously Standby state. (If no signal is received via LAN for more

Blinking every two seconds Normal operation

㻸㻱㻰

3. INITIAL SETTINGS

LED state and meaning

than 10 minutes, the equipment automatically goes into

standby to lessen power consumption.)

3-3

3. INITIAL SETTINGS

3.3 Multi Function Display Initial Settings

How to open the menu

NavNet TZtouch:

1. Push the Home button (or tap the home icon) to display the menu icon bar.

2. Select [Menu], [Multibeam Sonar].

3. Enter initial settings referring to the table below.

NavNet TZtouch2/NavNet TZtouch3:

1. Tap the Home icon to go to the home screen.

2. Select [Settings], [Multibeam Sonar].

3. Enter initial settings referring to the tables that follow.

Multibeam Sonar menu

Menu item Description Options (setting range)

[Transducer Draft] Set the distance between the transducer

and the draft line to show the distance

from the sea surface.

[Salt Water] Select [ON] to use this equipment in salt

water.

[Transducer Setup] See "Transducer Setup menu" on page 3-6.

[Transmission Power Au-

to]

[Transmission Power] Set the TX power level manually. Inter-

[External KP] Select [ON] to synchronize with external

[Bottom Level] The default bottom level setting (0) de-

[Auto Gain Offset (Multi

Sounder)],

[Auto Gain Offset (Side

Scan)],

[Auto Gain Offset (Cross

Section)]

Turn on to automatically adjust trans-

mission power to display the seabed

echo properly.

ference may appear on your display

when a sonar of the same frequency as

yours is being operated on a vessel

nearby. When this occurs, lower the

transmission power and request the

nearby vessel to lower its sonar’s TX

power to reduce the interference. The

setting range is 0 to 10 and 10 is maxi-

mum power.

sounder’s keying pulse.

termines that two strong echoes re-

ceived in sequence are seabed echoes.

If the depth indication is not stable in the

default setting, adjust the bottom level

here. If you can not discriminate the fish

near the seabed from the seabed echo,

increase the bottom level.

In the auto mode, lower or raise the gain

as necessary.

[0.0m] to [99.9m]

[OFF], [ON]

[OFF], [ON]

[0] to [10]

[ON], [OFF]

[-40] to [40]

[-5] to [5]

3-4

3. INITIAL SETTINGS

Menu item Description Options (setting range)

[STC (Side Scan)],

[STC (Multi Sounder)]

[TX Pulse] The pulse length is automatically set ac-

[DFF-3D Monitoring] Display pitch and roll (measured by internal sensor) and B voltage.

[Set Hardware to Factory

Default]

[Restore Default Settings] Restore all menu settings to default. [OK], [Cancel]

STC reduces surface layer noise, to discriminate surface fish from surface layer

noise. [0] is OFF and [10] reduces noise

approx. 5 m from the transducer. Too

high a setting may erase wanted fish

echoes.

cording to range. Use a short pulse for

better resolution and a long pulse when

detection range is important. To improve

resolution on the side scan display, etc.,

use [Short 1] or [Short 2].

• [Short 1] improves the detection resolution, but the detection range is

shorter than with [Std] (pulse length is

1/4 of [Std]).

• [Short 2] raises the detection resolution, however detection range is

shorter (pulse length is about 1/2 of

([Std]) than [Std].

• [Std] is the standard pulse length, and

is suitable for general use.

• [Long] increases the detection range

but lowers the resolution (about 1/2

compared to the [Std] pulse length)

Reset the external fish finder to its factory default settings.

[0] to [10]

[Short1], [Short2],

[Standard], [Long]

[OK], [Cancel]

3-5

3. INITIAL SETTINGS

Transducer Setup menu

For the oscillation center see "Motion Sensor menu" on page 3-7.

Port dir.: "+"

Top view

GCTD

Stern dir.: “+”

Up dir.: "+"

GC

TD

GC: Gravity Center, TD: Transducer

Starboard view

If the center of gravity is not known, see the drawing below.

W/2

GC

GC

Top view

L

Starboard view

H/2

Engine

W

L/3

H

Engine

GC: Gravity Center

Note: The location of the center of gravity may be different than as shown in the figures above, depending on hull shape, engine position and the installation status of

other equipment. However, the method of estimating the center of gravity location remains the same; approximately one-third of the ship length from stern (L/3), one half

of ship width (W/2) and one half of ship height from keel to roof (H/2).

Menu item Description

[Transducer Mis-

Set to [ON] if the transducer is installed facing the stern. [ON], [OFF]

mount Correction]

[Transducer Position

Bow/Stern]

Set the distance from the transducer to the ship’s center

of gravity in the bow/stern direction. For stern location,

set a positive value.

[Transducer Position

Up/Down]

Set the distance from the transducer to the ship’s center

of gravity in the up/down (vertical) direction. For upward

location, set a positive value.

[Transducer Position

Port/Starboard]

Set the distance from the transducer to the ship’s center

of gravity in the port/starboard direction. For port location,

set a positive value.

Options

(setting range)

-100.0 to 100.0

(m)

-100.0 to 100.0

(m)

-100.0 to 100.0

(m)

3-6

3. INITIAL SETTINGS

GC

GC

W

W/2

Top view

Starboard view

Engine

H

H/2

L/3

L

GC: Gravity Center

GC: Gravity Center, TD: Transducer

Engine

Motion Sensor menu

Select [Transducer Setup] on the [Multibeam Sonar] menu to show the [Motion Sensor] menu (below the [Transducer Setup] menu).

Port dir.: "+"

SC

GCTD

Stern dir.: "+"

SC

Up dir.: "+"

GC

TD

GC: Gravity Center, TD: Transducer,

Top view

Starboard view

SC: Satellite Compass

If the center of gravity is not known, see the drawing below.

Note: The location of the center of gravity may be different than as shown in the figures above, depending on hull shape, engine position and the installation status of

other equipment. However, the method of estimating the center of gravity location remains the same; approximately one-third of the ship length from stern (L/3), one half

of ship width (W/2) and one half of ship height from keel to roof (H/2).

Menu item Description

[Motion Sensor

Source]

[Motion Sensor

Pos. Bow/Stern]

Select the sensor connected to your NavNet TZtouch/TZtouch2/TZtouch3 unit.

Set the distance from the transducer to the motion sensor

in the bow-stern direction. For the stern side, set a positive

value.

Note: This menu appears if the motion sensor source is

selected to [SC].

Options

(setting range)

[SC], [Internal],

[OFF]

-100 to 100.0 (m)

3-7

3. INITIAL SETTINGS

Heading sensor time lag: 20 msec

DFF-3D

SC-30

-----------------Ethernet

CAN bus

------------

Motion sensor time lag: 20 msec

Position sensor time lag: 20 msec

Multi Function

Display

Menu item Description

[Motion Sensor

Pos. Up/Down]

[Motion Sensor

Pos. Port/Starboard]

[GPS Sensor

Pos. Bow/Stern]

[GPS Sensor

Pos. Up/Down]

[GPS Sensor

Pos. Port/Starboard]

[Roll Sensor Offset]

[Pitch Sensor

Offset]

[Motion Sensor

Time Lag (in ms)]

Set the distance from the transducer to the motion sensor

in the up/down (vertical) direction. Use a "+" value for upward direction.

Note: This menu appears if the motion sensor source is

selected to [SC].

Set the distance from the transducer to the motion sensor

in the port-starboard direction. For port location, set a positive value.

Note: This menu appears if the motion sensor source is

selected to [SC].

Set the distance from the transducer to the GPS sensor in

the bow-stern direction. For stern location, set a positive

value.

Set the distance from the transducer to the GPS sensor in

the up/down (vertical) direction. Use a "+" value for upward

direction.

Set the distance from the transducer to the GPS sensor in

the port-starboard direction. For port location, set a positive value.

Set the roll offset to use with the motion sensor. -45.0 to 45.0

Set the pitch offset to use with the motion sensor. -45.0 to 45.0

Set the time lag to use with the external motion sensor.

Note: This menu appears if the motion sensor source is

selected to [SC].

Options

(setting range)

-100 to 100.0 (m)

-100 to 100.0 (m)

-100 to 100.0 (m)

-100 to 100.0 (m)

-100 to 100.0 (m)

0 to 400

[Heading Sensor

Time Lag (in ms)]

[Position Sensor

Time Lag (in ms)]

Note: All length-related settings items, such as GPS sensor position, are internally

processed in metric units (m), regardless of the user-selected measurement unit.

Sync (time lag) setting

• If the equipment is connected as shown below, no adjustment to the time lag settings is necessary.

Set the time lag for the data received from the position sensor.

Set the time lag for the data received from the position sensor.

0 to 3500

0 to 3500

3-8

3. INITIAL SETTINGS

Heading sensor time lag: 65 msec

DFF-3D

PG-700 (Motion data and heading data)

-----------------Ethernet CAN bus

------------------

Motion sensor time lag: 65 msec

Position sensor time lag: 65 msec

-----------

㻂

㻂

GP-330B (Position data)

Multi Function

Display

• If the equipment is connected as shown in the figure below, change the time lag settings as indicated.

• If the connection is different from those mentioned here, calculate the time lag for

each sensor and enter them accordingly, using the following formula.

Time lag = Transmission delay + Propagation delay

Transmission delay: Delay required for calculation and output by the motion sensor, heading sensor, and position sensor.

SC-30: Use 5 msec for the calculation.

PG-700: Use 50 msec for the calculation.

GP-330B: Use 50 msec for the calculation.

Propagation delay: Time required for the data to reach the DFF-3D, via repeater

and data route. For the multi function display connected by CAN bus, use 15 msec

for the calculation. If NMEA data is fed to the DFF-3D via the NMEA Data Converter

(IF-NMEA2K2), set the calculation figure according to the baud rate between the

sensor and the IF-NMEA2K2 as shown below.

38400 bps: Use 40 msec for the calculation.

4800 bps: Use 145 msec for the calculation.

For example, the sensor feeding data to the multi function display via the IFNMEA2K2 has a transmission delay of 30 msec and a baud rate of 38400 bps.

Then, the time lag would be as shown in the calculation below.

Time lag 70 msec = Transmission delay 30 msec + Propagation delay 40 msec

3-9

3. INITIAL SETTINGS

This page is intentionally left blank.

3-10

4. OPERATION

This chapter describes the display and operations for the Multi Beam Sonar. For basic

operations with the NavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3 multi function display, such as touch operations and power on/off, see the Operator’s Manual

for your NavNet TZtouch unit.

The DFF-3D has four display screens (modes), multi sounder, side scan, cross section, and 3D sounder history.

4.1 Menu Operations

This section covers the top layer of the [Multi-beam Sonar] menu. For details regarding menu operations with each of the displays, see the respective section.

Display Section no.

Multi-Sounder section 4.3

Side Scan section 4.4

Cross Section section 4.5

3D Sounder section 4.6

Note: This section is authored with the understanding that the user has already accessed the [Multi Beam Sonar] menu from their NavNet TZtouch unit. For the procedure for each TZtouch model, see the table below.

TZtouch model(s) Menu access procedure

TZT9, TZT14 Press the Menu key, then select [Multi Beam Sonar]

TZTBB Tap the [Menu] icon, then select [Multi Beam Sonar]

TZTL12F, TZTL15F,

TZT2BB; TZT12F, TZT16F,

TZT19F

Tap [Home] → [Settings], then select [Multi Beam Sonar]

4.1.1 How to start/stop transmission

You can start/stop transmissions from the Multi Beam Sonar by using the menu.

In the [Multi Beam Sonar] menu, tap the [Multi Beam Sonar Transmit] item to toggle

between [OFF] and [ON].

4.1.2 How set the background color

You can set the background color for Day mode and Night mode to suit your preferences.

1. From the [Multi Beam Sonar] menu, select [Day Background Color] or [Night

Background Color] as required.

2. Select the desired color.

3. Close the menu.

4-1

4. OPERATION

5050

Seabed

3030

Seabed

7070

Seabed

4.1.3 How to adjust the bottom range shift

The bottom range shift feature changes the location at which the seabed appears on

the screen. This is particularly useful when the seabed is “off-screen”.

Note: This feature requires [Auto Range] to be active. See your respective Operator’s

Manual for details.

Slide the slide bar at [Bottom Range Shift Area] (in the [Multi Beam Sonar] menu) to

adjust the value as required. The following figure shows some examples of how the

settings affect the on-screen display.

A lower value places the seabed at a higher location on-screen. A higher value places

the seabed at a lower location on-screen.

4.1.4 How to change the transmission rate (PRR)

You can adjust the rate at which the sonar beam is transmitted (PRR, Pulse Repetition

Rate) using one of the three available settings. Each setting has distinct characteristics allowing for a broad range of applications.

Setting Characteristics

[Manual] Affected by the selected range. A shorter range has a

faster transmission rate; a longer range has a slower rate.

[Auto] Affected by vessel speed. Slow speeds have a slower

transmission rate; high speeds have a faster rate.

Note: Speeds of 20 kn or higher are fixed at a transmission rate of 20.

[Maximum] Affected by detected depth. Shallows have a faster trans-

mission rate; deeper waters have a slower rate.

Note: Where the selected range exceeds the detected

depth, the transmission rate may exceed 20.

1. From the [Multi Beam Sonar] menu, select [Transmit Rate Mode].

2. Select [Manual], [Auto] or [Maximum] as required.

3. If you selected [Manual], adjust the rate at [Transmit Rate Manual Value], using

the slide-bar or the software keyboard. For [Auto] or [Maximum], go to step 4.

4. Close the menu.

Note: Adjustments made to the transmission rate also affect how the on-screen display appears for the Multi-Sounder and 3D Sounder History features. The following

figures show examples of the same object and how the echo display is affected.

4-2

4. OPERATION

A-scope

Frequency

Depth scaleDepth scale

19.5

Below transducerBelow transducer

Seabed

echo

Max. display depthMax. display depth

Depth

Display Screen

Multi Sounder

3D History

Rate = 0

Rate = 10 Rate = 20

4.2 Display Screens Overview

Multi-sounder display

Tap the multi-sounder display icon on the home screen to show the multi-sounder display.

The multi-sounder display operates similar to the conventional fish finder, providing information about the seabed and underwater conditions. The video display scrolls from

the right to left with the passing of time.

The echoes appearing at the right edge of the display are the latest echoes. Echoes

from individual fish, schools of fish and the seabed are shown. With the gain set properly, the distance to the seabed appears on the screen.

The gain, clutter suppressor and TVG are adjusted according to the mode selected,

auto fishing or auto cruising. Manual adjustment of those controls is also possible.

The single beam presentation displays the information detected by the downwardlooking beam. The triple beam presentation displays the information detected by the

port beam, starboard beam, and downward-looking beam.

Single beam display

4-3

4. OPERATION

19.5

Depth

scale

Depth

scale

Seabed

echo

Frequency

Depth

PortPort StarboardStarboardDownwardDownward

Max. display depthMax. display depth

Depth

Port direction echoes Starboard direction echoes

Fish bedFish bed

Fish bedFish bed

Depth scale

FrequencyFrequency

Max. display depthMax. display depth

Underwater

Underwater

Underwater

Underwater

SeabedSeabed

SeabedSeabed

Side scan display

Tap the side scan display icon on the home screen to show the side scan display.

Triple beam display

The side scan display shows the echoes received from the port and starboard directions.

The side scan display starts from the center of the vessel, and traces in the port and

starboard directions. The most recent echoes are at the top of the screen and the oldest are at the bottom of the screen.

The side scan display is different from the other modes employed by this equipment it clearly displays the shape of echoes (fish bed, etc.).

Cross section display

Tap the cross section display icon

on the home screen to show the

cross section display.

4-4

The cross section display, shows

seabed and underwater conditions.

㻻㼣㼚㻿㼔㼕㼜㻻㼣㼚㻿㼔㼕㼜

Seabed

STBDPORT

School of

fish

4. OPERATION

Horizontal range scaleHorizontal range scale

SeabedSeabed

FrequencyFrequency

GridGrid

Depth

Depth

scale

Depth

scale

Max. display depthMax. display depth

Transducer

position

Transducer

position

UnderwaterUnderwater

DownwardDownwardPortPort StarboardStarboard

Horizontal range scaleHorizontal range scale

FrequencyFrequency

Depth

Own shipOwn ship

Depth/Color Shading

color scale

Max. display depthMax. display depth

Depth scaleDepth scale

School of fishSchool of fish

SeabedSeabed

This multi beam sonar uses a 120° beam (downward to port 60°; downward to starboard 60°), providing highly accurate underwater images.

3D sounder history display

Tap the 3D sounder history display icon on the home screen to show the 3D sounder

history display.

The 3D sounder history provides a 3D graphic of the past seabed and underwater

echoes detected by your vessel. The display can be used to detect schools of fish.

4-5

4. OPERATION

4.3 Multi-Sounder Display Operations

This section covers the functions available with the multi-sounder display. For the

menu items shared with the conventional fish finder, see the applicable Operator’s

Manual.

4.3.1 How to switch between TX and STBY

Tap the multi-sounder display to show the pop-up menu. Select [TX] to start transmitting. [ST-BY] appears at the center of the screen when transmission is stopped.

4.3.2 How to switch between single beam and triple beam presentations

1. Tap the multi-sounder display to show the pop-up menu.

2. Select [Mode].

3. Select [Single Beam] or [Triple Beam] as required.

4. Select [Close] to close the pop-up menu.

4.3.3 How to set the TX beam angle

You can set the TX beam angle for the port, starboard and downward beams.

1. Tap the multi-sounder display to show the pop-up menu.

2. Select [Beam Angle].

3. Set the beam angle as required.

4.3.4 How to set the TX beam width

You can set the TX beam width for the port, starboard and downward beams.

1. Tap the multi-sounder display to show the pop-up menu.

2. Select [Beam Width].

3. Set the beam width as required.

4.3.5 How to change the picture advance speed

The Picture Advance setting sets how quickly vertical scan lines move across the display. When viewing a seabed with sharp rises and falls, such as a reef-bed or submerged wreck, a fast advance speed helps to “smooth” out the seabed for easier

viewing. On the other hand, when viewing a smooth seabed with little to no undulations, a slow advance speed helps to identify rises and falls.

4-6

1. From the [Multi Beam Sonar] menu, select [Multi-Sounder].

2. Select [Picture Advance].

3. Select an advance speed to suit your requirements.

The default speed is [1/1] (normal speed), the fastest speed is [4/1] (four times

normal speed) and the slowest speed is [1/16] (sixteen times slower than normal

speed).

Select [Stop] to stop the picture advance for closer examination and screenshots/

photos.

4. OPERATION

4.3.6 How to show or hide the scale box

The scale box, shown at the bottom left corner on the display, shows depth, current

range, and TX frequency. You can show the box as follows.

1. Tap the multi-sounder display to show the pop-up menu.

2. Select [Scale Box] to show the scale box.

4.3.7 Availability of points and event marks registration, and go to a point

For how to register points and event marks, see Operator’s Manual for your NavNet

TZtouch/NavNet TZtouch2/NavNet TZtouch3.

The table below shows function availability according to latitude/longitude, heading

data presence or absence. If there is no latitude/longitude data, none of the functions

below are available.

For NavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3, input PGN data. The PGN

data available is as shown below.

Latitude/longitude data

• 129025 Position, Rapid Update

• 129029 GNNS Position Data

Heading data

• 127237 Heading/Track Control

• 127250 Vessel Heading

• 130577 Direction Data

Latitude/Longitude / Heading data: YES

Item Starboard Downward Port

Point registration Yes Yes Yes

Go to point Yes Yes Yes

Event mark registration Yes Yes Yes

Latitude/Longitude: YES, Heading data: NO

Item Starboard Downward Port

Point registration No Yes No

Go to point No Yes No

Event mark registration Yes Yes Yes

4-7

4. OPERATION

Port

Starboard

Downward

Port

Downward

Starboard

4.4 Side Scan Display Operations

This section covers the functions available with the side scan display. For the menu

items shared with the conventional fish finder, see the applicable Operator’s Manual.

4.4.1 How to switch between TX and STBY

Tap the side scan display to show the pop-up menu. Select [TX] to start transmitting.

[ST-BY] appears at the center of the screen when transmission is stopped.

4.4.2 How to change echo color

1. Select [Menu] from the menu icon bar to show the menu.

2. Select [Multibeam Sonar].

3. Select [Echo Color].

4. Select [White], [Blue] or [Brown] as required.

5. Select [Close] to close the pop-up menu.

4.4.3 How to show or hide the scale box

The scale box, shown at the bottom left corner on the display, shows depth, current

range, and TX frequency. You can show the box as follows.

1. Tap the side scan display to show the pop-up menu.

2. Select [Scale Box] to show the scale box.

4-8

4. OPERATION

4.4.4 Availability of points and event marks registration, and go to a point

For how to register points and event marks, see the manual for your NavNet TZtouch/

NavNet TZtouch2/NavNet TZtouch3.

The table below shows function availability according to latitude/longitude, heading

data presence or absence. If there is no latitude/longitude data, none of the functions

below are available.

For NNavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3, input PGN data. The

PGN data available is as shown below.

Latitude/longitude data

• 129025 Position, Rapid Update

• 129029 GNNS Position Data

Heading data

• 127237 Heading/Track Control

• 127250 Vessel Heading

• 130577 Direction Data

Latitude/Longitude / Heading data: YES

Item Starboard Port

Point registration Yes Yes

Go to point Yes Yes

Event mark registration Yes Yes

Latitude/Longitude: YES, Heading data: NO

Item Starboard Port

Point registration No No

Go to point No No

Event mark registration Yes Yes

4-9

4. OPERATION

Zoomed display

Normal display

4.5 Cross Section Display Operations

This section covers the functions available with the cross section display. For the

menu items shared with the conventional fish finder, see the applicable Operator’s

Manual.

4.5.1 How to switch between TX and STBY

Tap the cross section display to show the pop-up menu. Select [TX] to start transmitting. [ST-BY] appears at the center of the screen when transmission is stopped.

4.5.2 How to show or hide the grid

The grid, which is useful for measuring the distance to a target, can be shown or hidden as follows.

1. Tap the cross section display to show the pop-up menu.

2. Select [Grid] to show the grid.

4.5.3 Zoom display

The seabed echo can be zoomed.

1. Tap the cross section display to show the pop-up menu.

2. Select [Zoom] to zoom the seabed echo. Select [Zoom] again to restore the normal display.

4.5.4 How to smooth echoes (distance)

If echoes are "disconnected" because of an undulating seabed, change the setting to

[Low], [Medium] or [High] as necessary. Smoothing is done in the range direction to

smooth the echo presentation.

4-10

1. Select [Menu] from the menu icon bar to show the menu.

2. Select [Multibeam Sonar].

3. Select [Echo Smoothing (Distance)].

4. Select [Low], [Medium] or [High] as required. The default setting is [Medium]. Select [OFF] to stop smoothing.

5. Select [Close] to close the pop-up menu.

4.5.5 How to smooth echoes (time)

If echoes are difficult to see because they appear "speckled," use the echo smoothing

feature to suppress the speckling by time.

1. Select [Menu] from the menu icon bar to show the menu.

2. Select [Multibeam Sonar].

3. Select [Echo Smoothing (Time)].

4. Select [Low], [Medium] or [High] as required. The default setting is [Medium]. Select [OFF] to stop smoothing.

5. Select [Close] to close the pop-up menu.

4.5.6 How to apply correction to the speed of sound

Even though the sea bottom is flat, the left or right edge, up or down may be distorted.

To compensate for this problem, adjust the speed of sound. The procedure differs

slightly, depending on your equipment and defines the TZT9/14/BB as “TZtouch1”;

TZTL12F/15F/TZT2BB as “TZtouch2”; TZT9F/12F/16F/19F as “TZtouch3”.

4. OPERATION

Manual correction

1. For TZtouch1 users, select [Menu] from the menu icon to show the menu.

For TZtouch2 and 3 users

2. Select [Multibeam Sonar] → [Cross Section].

3. Select [Sound Speed Correction], then enter a correction. The setting range is

-200 to +200.

For reference, if a flat seabed appears to have a “mound”, enter a negative value

for correction. If a flat seabed appears to have a “valley”, enter a positive value.

4. Select [Close] to close the menu.

, select [Settings] on the home screen.

Automatic correction

1. For TZtouch1 users, select [Menu] from the menu icon to show the menu.

For TZtouch2 and 3 users

2. Select [Multibeam Sonar] → [Cross Section].

3. For TZtouch1 users

For TZtouch2 and 3 users

[ON].

Select [OFF] to remove the correction.

4. Select [Close] to close the menu.

, select [Temp.-Based Correction], then select [ON].

, select [Settings] on the home screen.

, select [Temperature Based Correction], then select

4.5.7 How to show or hide the scale box

The scale box, shown at the bottom-left corner on the display, shows depth, current

range, and TX frequency. You can show the box as follows.

1. Tap the cross section display to show the pop-up menu.

2. Select [Scale Box] to show the scale box.

4-11

4. OPERATION

4.5.8 Availability of points and event marks registration, and go to a point

For how to register points and event marks, see the manual for your NavNet TZtouch/

NavNet TZtouch2/NavNet TZtouch3.

The table below shows function availability according to latitude/longitude, heading

data presence or absence. If there is no latitude/longitude data, none of the functions

below are available.

For NavNet TZtouch/NavNet TZtouch2/NavNet TZtouch3, input PGN data. The PGN

data available is as shown below.

Latitude/longitude data

• 129025 Position, Rapid Update

• 129029 GNNS Position Data

Heading data

• 127237 Heading/Track Control

• 127250 Vessel Heading

• 130577 Direction Data

Latitude/Longitude / Heading data: YES

Point registration Yes

Go to point No

Event mark registration Yes

Latitude/Longitude: YES, Heading data: NO

Point registration No

Go to point No

Event mark registration Yes

Item Cross section

Item Starboard

4-12

4. OPERATION

4.6 3D Sounder History Display Operations

This section covers the functions available with the 3D sounder history display. For the

menu items shared with the conventional fish finder, see the applicable Operator’s

Manual.

4.6.1 How to switch between TX and STBY

Tap the 3D sounder history display to show the pop-up menu. Select [TX] to start

transmitting. [ST-BY] appears at the center of the screen when transmission is

stopped.

4.6.2 How to move, zoom in, zoom out the viewpoint position

How to move the viewpoint

The viewpoint can be moved by dragging.

How to zoom in, zoom out

Zoom in Zoom out

How to restore default view

If you get lost in viewpoint or zoom, you can restore the default view as follows.

1. Tap the 3D sounder history display to show the pop-up menu.

2. Select [Default View] to show the depth/frequency box.

4.6.3 How to mark school of fish

A detected school of fish can be marked with a "dot" mark for

easy identification.

1. Tap the 3D sounder history display to show the pop-up

menu.

2. Select [Fish School Icon] to mark the detected school of fish with the dot mark.

4-13

4. OPERATION

4.6.4 How to pause advancement of the display

You can pause advancement of the history display to observe the distribution of sea

floor topography and school of fish.

1. Tap the 3D sounder history display to show the pop-up menu.

2. Select [Pause] to pause the display.

4.6.5 How to adjust the echo detection level

Adjust the echo detection level if schools of fish are detected unstably.

1. Select [Menu] from the menu icon to show the menu.

2. Select [Multibeam Sonar].

3. Select [Fish Detection Level].

4. Select [Low], [Medium] or [High] as required. The default setting is [Medium]. If too

many schools of fish are being detected, select [Low]. If too few schools are detected, select [High].

5. Select [Close] to close the menu.

4.6.6 How to calibrate the seabed echo

If schools of fish or a fish reef are detected and displayed as the seabed echo, adjust

the strength of the seabed echo as shown below to correctly identify the seabed echo.

1. Select [Menu] from the menu icon to show the menu.

2. Select [Multibeam Sonar].

3. Select [Seabed Echo Calibration]. Drag the slider bar to adjust.

The setting range is -15 to +15. A large figure helps distinguish bottom fish from

the seabed echo; however, it is difficult to distinguish a fish bed. Use a small figure

to distinguish a fish bed; however, it is difficult to distinguish bottom fish from the

seabed echo.

4. Select [Close] to close the menu.

4.6.7 How to use the noise filter

If the seabed echo is displayed with undulations, use the noise filter to smooth the seabed echo.

1. Select [Menu] from the menu icon to show the menu.

2. Select [Multibeam Sonar].

4-14

3. Select [Noise Filter].

4. Select [Low], [Medium] or [High] as required. The default setting is [Medium].

5. Select [Close] to close the menu.

4.6.8 How to use terrain shading

Setting: 0 Setting: 50

Setting: 100

The thickness of the shading for the seabed terrain can be adjusted.

1. Select [Menu] from the menu icon to show the menu.

2. Select [Multibeam Sonar].

3. Select [Terrain Shading]. Drag the slider bar to adjust.

The default setting is 50. See the figure below for setting and resulting terrain

shading

4. Select [Close] to close the menu.

4. OPERATION

4.6.9 How to change the picture advance speed

The [Picture Advance] setting sets how quickly vertical scan lines move across the display. When viewing a seabed with sharp rises and falls, such as a reef-bed or submerged wreck, a fast advance speed helps to “smooth” out the seabed for easier

viewing. On the other hand, when viewing a smooth seabed with little to no undulations, a slow advance speed helps to identify rises and falls.

1. From the [Multi Beam Sonar] menu, select [3D Sounder History].

2. Select [Picture Advance].

3. Select an advance speed to suit your requirements.

The default speed is [1/1] (normal speed), the fastest speed is [4/1] (four times

normal speed) and the slowest speed is [1/8] (eight times slower than normal

speed). The following figure shows examples of the same object at [4/1], [1/1] and

[1/4] speeds.

[

1/4

]

] [

1/1

4/1

][

Select [Stop] to stop the picture advance for closer examination and screenshots/

photos.

4.6.10 Depth/Color Shading display

The seabed echo and schools of fish can be shown in shades of colors according to

depth, to help you see the differences in depths more easily.

Color shading display

Color shading can be applied to the seabed echo or schools of fish. For the seabed

display, the seabed color can be multi tone or single tone, and schools of fish can be

4-15

4. OPERATION

Minimum Value

Maximum Value

Auto Seabed Shading

Minimum Value

Maximum Value

Auto Fish Shading

Seabed Color

Fish Monochrome Color

0 m

50 m

0 m

50 m

Classic Hue

Gray Hue

Minimum Value

Maximum Value

Auto Seabed Shading

Minimum Value

Maximum Value

Auto Fish Shading

Fish Color

Seabed Monochrome Color

0 m

50 m

0 m

50 m

Classic Hue

Gray Hue

[Color Mode] selected to [Seabed] [Color Mode] selected to [Fish]

shown in single tone or single color. For the schools of fish display, schools can be

shown in multi tone or single tone and the bottom color is in a single tone.

Note: Objects that are detected outside of the selected color range are shown onscreen in white color.

[Color Mode] selected to [Seabed]

Depth/Color

Shading display

Color Scale

1. Tap the 3D sounder history display to show the pop-up menu.

2. Select [Color Mode].

3. Select [Seabed] or [Fish] as required.

How to set color shading

Open the menu, select Multi Beam to show the menu for setting color shading.

Depth/Color Shading

Depth/Color Shading

display

display

[Color Mode] selected to [Fish]

Depth/Color

Shading display

Color Scale

Depth/Color Shading

Depth/Color Shading

display

display

[Seabed Color] For setting multi tone or single tone. [Classic Hue]

4-16

Menu item Description Setting options

[Color Mode] selected to [Seabed]

[Inverted Classic Hue]

[Red Hue]

[Blue Hue]

[Green Hue]

[Yellow Hue]

4. OPERATION

[Minimum Value]

Shallowest depth value

0.0 m

50.0 m

AUTO

[Maximum Value]

Shallowest depth value

0.0 m

50.0 m

AUTO

Menu item Description Setting options

[Fish Monochrome Color] For setting single tone or single color. [Gray Hue]

[Brown Hue]

[Red]

[Green]

[Blue]

[Cyan]

[Magenta]

[Black Or White]

[Pink]

[Light Green]

[Yellow]

[Auto Seabed Shading] Use automatic or manual seabed shading.

Tap here to turn the automatic

seabed shading scale [ON] or [OFF].

[ON], [OFF]

0.0 m

0.0 m

AUTO

ON

AUTO

OFF

(AUTO is greyed out)

50.0 m

50.0 m

Note: Objects that are detected outside of

the selected color range are shown onscreen in white color.

[Minimum Value] Use the software keyboard to set the shal-

lowest depth to use. [Auto Seabed Shading]

must be OFF to enter depth.

Alternatively, tap the minimum value indication on the color bar scale to show the slider

bar. Drag the slider bar to set.

0 to 1200 (m)

[Maximum Value] Use the software keyboard to set the deepest

0 to 1200 (m)

depth to use. [Auto Seabed Shading] must be

OFF to enter depth.

Alternatively, tap the maximum value indication on the color bar scale to show the slider

bar. Drag the slider bar to set.

4-17

4. OPERATION

[Minimum Value]

Shallowest depth value

0.0 m

50.0 m

AUTO

[Color Mode] selected to [Fish]

Menu item Description Setting options

[Fish Color] For setting multi tone or single tone. [Classic Hue]

[Inverted Classic Hue]

[Red Hue]

[Blue Hue]

[Green Hue]

[Yellow Hue]

[Fish Monochrome Color] For setting single tone or single color. [Gray Hue]

[Brown Hue]

[Auto Fish Shading] Use automatic or manual fish shading.

Tap here to turn the automatic fish

shading scale [ON] or [OFF].

[ON], [OFF]

0.0 m

0.0 m

AUTO

ON

AUTO

OFF

(AUTO is greyed out)

50.0 m

50.0 m

Note: Objects that are detected outside of

the selected color range are shown onscreen in white color.

[Minimum Value] Use the software keyboard to set the shal-

lowest depth to use. [Auto Fish Shading]

must be OFF to enter depth.

Alternatively, tap the minimum value indication on the color bar scale to show the slider

bar. Drag the slider bar to set.

0 to 1200 (m)

[Maximum Value] Use the software keyboard to set the deepest

4-18

depth to use. [Auto Fish Shading] must be

OFF to enter depth.

Alternatively, tap the maximum value indication on the color bar scale to show the slider

bar. Drag the slider bar to set.

0.0 m

AUTO

[Maximum Value]

Shallowest depth value

0 to 1200 (m)

50.0 m

4. OPERATION

4.6.11 How to show or hide the scale box

The scale box, shown at the bottom left corner on the display, shows depth, current

range, and TX frequency. You can show the box as follows.

1. Tap the 3D sounder history display to show the pop-up menu.

2. Select [Scale Box] to show the scale box.

4.6.12 Availability of points and event marks registration, and go to a point

For how to register points and event marks, see the multi function display operator’s

manual.

The table below shows function availability according to latitude/longitude, heading

data presence or absence. If there is no latitude/longitude data, none of the functions

below are available.

For the multi function display, input PGN data. The PGN data available is as shown

below.

Latitude/longitude data

• 129025 Position, Rapid Update

• 129029 GNNS Position Data

Heading data

• 127237 Heading/Track Control

• 127250 Vessel Heading

• 130577 Direction Data

Latitude/Longitude / Heading data: YES

Item Fish Seabed

Point registration Yes Yes No

Go to point Yes Yes No

Event mark registration No No Yes

Latitude/Longitude: YES, Heading data: NO

Item Fish Seabed

Point registration No No No

Go to point No No No

Event mark registration No No Yes

Other than Fish

or Seabed

Other than Fish

or Seabed

4-19

4. OPERATION

Depth and coloration bar. Minimum

detected depth is shown on the left,

maximum on the right.

Coloration mode indicator

Own vessel icon

Map width indicator

PBG map

4.7 Personal Bethymetric Generator (PBG)

Note: This feature is available only for the NavNet TZtouch3 series (TZT9F, TZT12F,

TZT16F and TZT19F). Seabed maps recorded on a networked unit are not shared

across the network. Use the file transfer functions of the TZT3, or record using each

of the desired units.

The PBG feature creates a map of the seabed, colored according to recorded depth

readings. An area of roughly twice the size of the depth is mapped, with the transducer

as the center point. For example, a map of a 20 m deep seabed will be approximately

20 m wide to both port and starboard. Unlike 3D Sounder History, the color-mapped

seabed appears on the plotter display.

Note: Tide data received from tidal stations is applied as an offset to show a depth

which as close as possible to the actual depth.

Requirements

This feature is supported on all software versions of the DFF-3D provided the following

requirements are met:

• Connection to a NavNet TZtouch3 using software version 2.01 or later.

• A micro SD card with sufficient blank space, inserted into the TZtouch3 unit.

Note 1: Chart cards may be used, provided sufficient free space is available.

Note 2: The data space required varies, depending on several factors, such as sea-

bed complexity, own ship speed and length of time spent mapping.

The following cases, both based on a 24 hours period of recording, are intended as

a reference for space required:

A highly complex seabed, at depth of 200 m, traversed at a speed of 10 knots, with

no overlaps in mapping area, uses approximately 13 MB.

A shallow and relatively plain and flat seabed, traversed at a slow speed and with

overlaps in the mapping area uses approximately 2 MB.

4-20

• Heading and positioning PGN data input to the NavNet TZtouch3.*

Heading: 127237 (Heading/Track Control) or 127250 (Vessel Heading) or 130577

(Direction Data).

Positioning: 129025 (Position, Rapid Update) or 129029 (GNSS Position Data).

*: FURUNO’s SC-33 or SCX-20, both boasting high quality positioning and relatively

easy setup/synchronization, are recommended as a positioning/heading data source.

4.7.1 Setting up for PBG

To use the PBG feature, following settings must be completed in advance:

• Transducer initial settings, Motion Sensor initial settings, EPFs device (GPS antenna, etc.) initial settings. The procedure for these items are covered in the “HOW TO

SET UP YOUR EQUIPMENT” chapter of your TZTouch3 Installation Manual.

• DFF-3D initial settings. See "Multi Function Display Initial Settings" on page 3-4.

• Sound speed adjustments. See "How to apply correction to the speed of

sound" on page 4-11.

4.7.2 How to map the seabed

To start mapping, open the plotter screen, swipe the right edge of the screen inwards

to show the slide menu, then tap [PBG Recording]. The menu item changes to a yellow color, indicating that the feature is active. The coloration mode indicator also appears with a white background.