Page 1

OPERATOR'S MANUAL

NETWORK FISH FINDER

Model

DFF1-UHD

www.furuno.com

Page 2

Page 3

IMPORTANT NOTICES

General

• This manual has been authored with simplified grammar, to meet the needs of international

users.

• The operator of this equipment must read and follow the descriptions in this manual. Wrong

operation or maintenance can cancel the warranty or cause injury.

• Do not copy any part of this manual without written permission from FURUNO.

• If this manual is lost or worn, contact your dealer about replacement.

• The contents of this manual and equipment specifications can change without notice.

• The example screens (or illustrations) shown in this manual can be different from the screens

you see on your display. The screens you see depend on your system configuration and equipment settings.

• Save this manual for future reference.

• Any modification of the equipment (including software) by persons not authorized by FURUNO

will cancel the warranty.

• All brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

How to discard this product

Discard this product according to local regulations for the disposal of industrial waste. For disposal

in the USA, see the homepage of the Electronics Industries Alliance (http://www.eiae.org/) for the

correct method of disposal.

How to discard a used battery

Some FURUNO products have a battery(ies). To see if your product has a battery, see the chapter

on Maintenance. Follow the instructions below if a battery is used. Tape the + and - terminals of

battery before disposal to prevent fire, heat generation caused by short circuit.

In the European Union

The crossed-out trash can symbol indicates that all types of batteries

must not be discarded in standard trash, or at a trash site. Take the

used batteries to a battery collection site according to your national

legislation and the Batteries Directive 2006/66/EU.

In the USA

The Mobius loop symbol (three chasing arrows) indicates that Ni-Cd

and lead-acid rechargeable batteries must be recycled. Take the

used batteries to a battery collection site according to local laws.

In the other countries

Ni-Cd Pb

Cd

There are no international standards for the battery recycle symbol. The number of symbols can

increase when the other countries make their own recycle symbols in the future.

i

Page 4

SAFETY INSTRUCTIONS

The user and installer must read the appropriate safety instructions before attempting to install

or operate the equipment.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Warning, Caution

Safety instructions for the operator

WARNING

Do not open the equipment.

Only qualified personnel should work

inside the equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Turn off the power immediately if the

equipment is emitting smoke or fire.

Fire or electrical shock can result if the

power is left on.

Turn off the power immediately if water

leaks into the equipment or an object is

dropped inside the equipment.

Continued use can cause fire or electrical

shock.

Turn off the power immediately if you

feel the equipment is acting abnormally.

If the equipment is hot to the touch or is

emitting strange noises, turn off the power

immediately and contact your dealer for

advice.

WARNING

Prohibitive Action

Do not operate the equipment with

wet hands.

Electrical shock can result.

Do not place liquid-filled containers

on the top of the equipment.

Electrical shock can result.

Do not install the equipment where

it may be subjected to rain or water

splash.

Fire or electrical shock can result if water

gets inside the equipment.

Use the proper fuse.

Use of a wrong fuse can damage the

equipment and may cause fire.

A warning label is attached to the equipment.

Do not remove this label. If the label is missing

or illegible, contact a FURUNO agent or dealer

about replacement.

Mandatory Action

WARNING

Name: Warning Label (1)

Type: 86-003-1011-3

Code No.: 100-236-233-10

ii

Page 5

CAUTION

Safety instructions for the installer

SAFETY INSTRUCTIONS

WARNING

Do not open the equipment.

Only qualified personnel should work

inside the equipment.

Turn off the power before beginning

the installation.

Fire or electrical shock can result if the

power is left on.

Be sure no water leaks at the mounting

location for the transducer and temperature sensor.

Water leakage can sink the vessel. Also,

confirm that neither the transducer nor

the sensor will loosen by vibration. The

installer is solely responsible for the

installation.

Confirm that the power supply voltage

is within the rating of this equipment.

WARNING

CAUTION

The transducer cable must be handled

carefully, following the guidelines

below.

• Keep fuels and oils away from the

cable.

• Locate the cable away from chemicals.

• Locate the cable away from locations

where it might be damaged.

Do not apply the power with the

transducer exposed to air.

The transducer may be damaged.

A magnetic compass may receive interference if it is placed too close to the

network fish finder. Observe the compass safe distances shown below to

prevent interference to a magnetic

compass.

Standard

compass

Steering

compass

Incorrect voltage will damage the equipment and may cause fire.

1.00 m 0.60 m

iii

Page 6

TABLE OF CONTENTS

FOREWORD ....................................................................................................................v

SYSTEM CONFIGURATION ..........................................................................................vi

1. INSTALLATION ........................................................................................................1

1.1 Equipment Lists............................................................................................................. 1

1.2 Network Fish Finder ...................................................................................................... 2

1.3 Transducer .................................................................................................................... 3

1.4 Optional Speed/Temperature Sensors ST-02MSB, ST-02PSB.................................... 3

1.4.1 Mounting considerations........................................................................................ 3

1.4.2 Mounting procedure............................................................................................... 3

1.5 Optional Temperature Sensors..................................................................................... 4

1.5.1 Transom mount temperature sensor T-02MTB ..................................................... 4

1.5.2 Thru-hull temperature sensor T-02MSB, T-03MSB............................................... 5

2. WIRING .....................................................................................................................6

2.1 Wiring Outline................................................................................................................ 6

2.2 Transducer Cable, Cable for External KP (option)........................................................ 7

2.2.1 How to process the cables..................................................................................... 7

2.2.2 How to connect the transducer cable .................................................................... 9

2.2.3 How to connect the cable for external KP, transducer cable............................... 11

2.3 LAN Cable................................................................................................................... 17

3. INITIAL SETTINGS .................................................................................................19

3.1 DIP Switch Setting ...................................................................................................... 19

3.2 Operation Check ......................................................................................................... 20

4. MAINTENANCE ......................................................................................................21

4.1 Maintenance................................................................................................................ 21

4.2 How to Replace the Fuse............................................................................................ 22

4.3 How to Restore Default Settings ................................................................................. 22

APPENDIX 1 JIS CABLE GUIDE ..............................................................................AP-1

SPECIFICATIONS .....................................................................................................SP-1

PACKING LIST ............................................................................................................A-1

OUTLINE DRAWINGS................................................................................................. D-1

INTERCONNECTION DIAGRAM ................................................................................ S-1

iv

Page 7

FOREWORD

A Word to the Owner of the DFF1-UHD

Congratulations on your choice of the FURUNO DFF1-UHD Network Fish Finder. We are confident you will see why the FURUNO name has become synonymous with quality and reliability.

Since 1948, FURUNO Electric Company has enjoyed an enviable reputation for quality marine

electronics equipment. This dedication to excellence is furthered by our extensive global network

of agents and dealers.

This equipment is designed and constructed to meet the rigorous demands of the marine environment. However, no machine can perform its intended function unless operated and maintained

properly. Please carefully read and follow the recommended procedures for operation and maintenance.

Thank you for considering and purchasing FURUNO.

Features

The DFF1-UHD is a dual frequency echo sounder designed for use with the NavNet TZtouch series. The DFF1-UHD feeds data about underwater conditions via a LAN.

• FURUNO TruEcho CHIRPTM fishfinders provide very high definition images.

• High resolution display greatly reduces the possibility of missing a target.

• Noise-suppressing display for enhanced detection performance.

• Fish size shown for depths up to 200 m and bottom discrimination.

Operating notices

• Echoes are shown in high ultra definition, thus echoes are displayed differently from those presented on the conventional fish finder.

• The interference rejector operates differently from the interference rejector on the conventional fish

finder, thus its effect on echoes is different.

• The transducer cannot be installed inside the vessel.

TM

• The length of the TX pulse changes according to the state of the ACCU-FISH

the appearance of the display changes with the gain setting.

• Observe the following when using the bottom discrimination display (hereafter referred to as BDD):

• Use the BDD under the following conditions:

- Depth: 5-200 m (16.4-656.2 ft)

- Speed: 10 knots or less

• The BDD uses depth measured from the vessel’s draft in its analysis of bottom composition. Be

sure to set the draft at the NavNet equipment.

• The TX interval slows when the BDD is active.

• The BDD is inoperative if the transducer selection setting at the NavNet TZtouch is “Manual.”

feature. Therefore,

Measure for reduction of interference

If you receive interference from the fish finder/echo sounder of another vessel, switch to single frequency operation and change the frequency and/or reduce the transmitting sound pressure level to

remove the interference.

v

Page 8

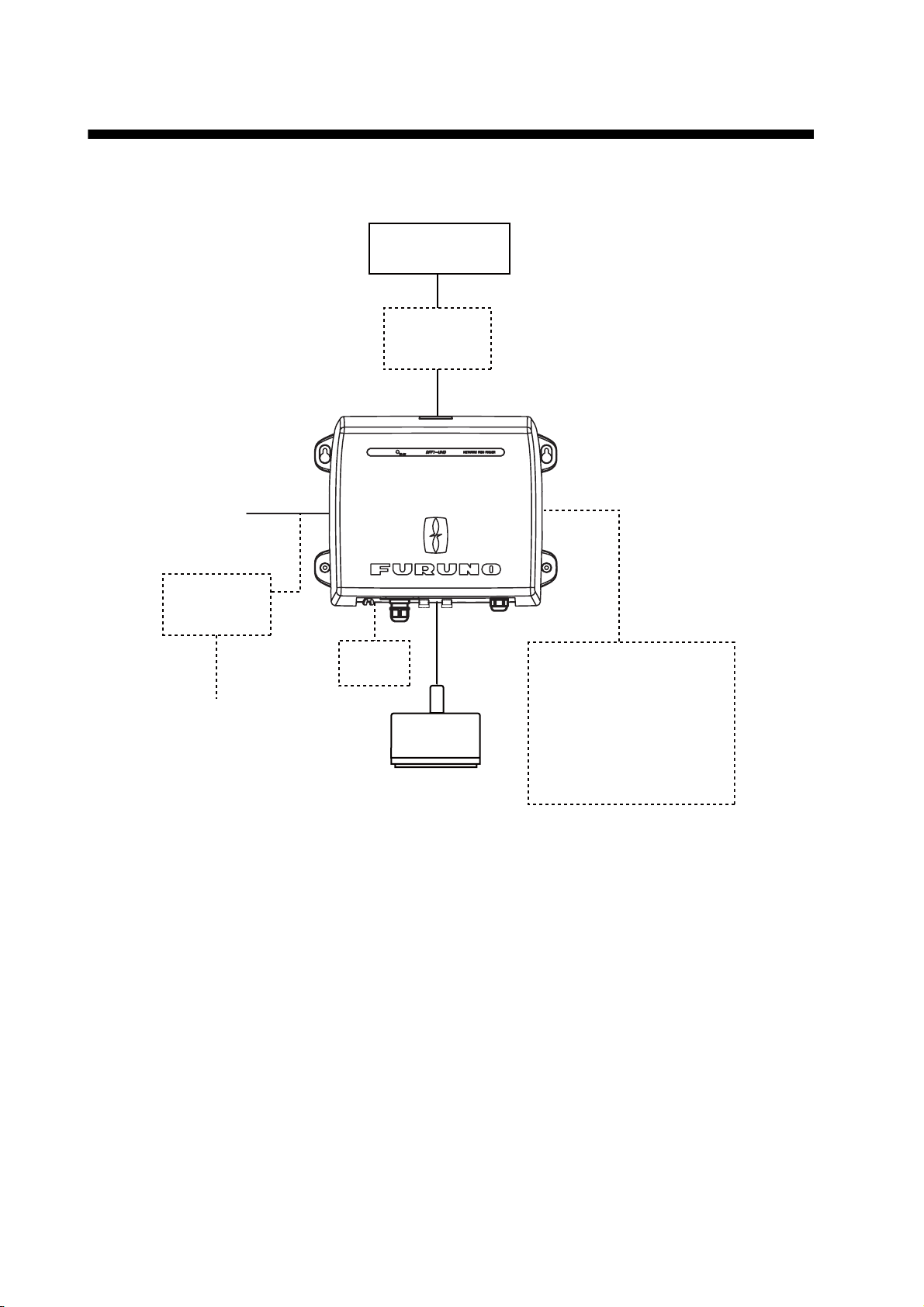

SYSTEM CONFIGURATION

NavNet Equipment

TZT9/14/BB

Ethernet HUB

HUB-101

NETWORK FISH FINDER

DFF1-UHD

12-24 VDC

Rectifier

PR-62

100/110/

220/230 VAC

1ø, 50/60 Hz

External

KP

Transducer

B265LH or

CM265 LH

Speed/Temperature Sensor

ST-02MSB

ST-02PSB

Temperature Sensor

T-02MTB

T-02MSB

T-03MSB

vi

Page 9

1. INSTALLATION

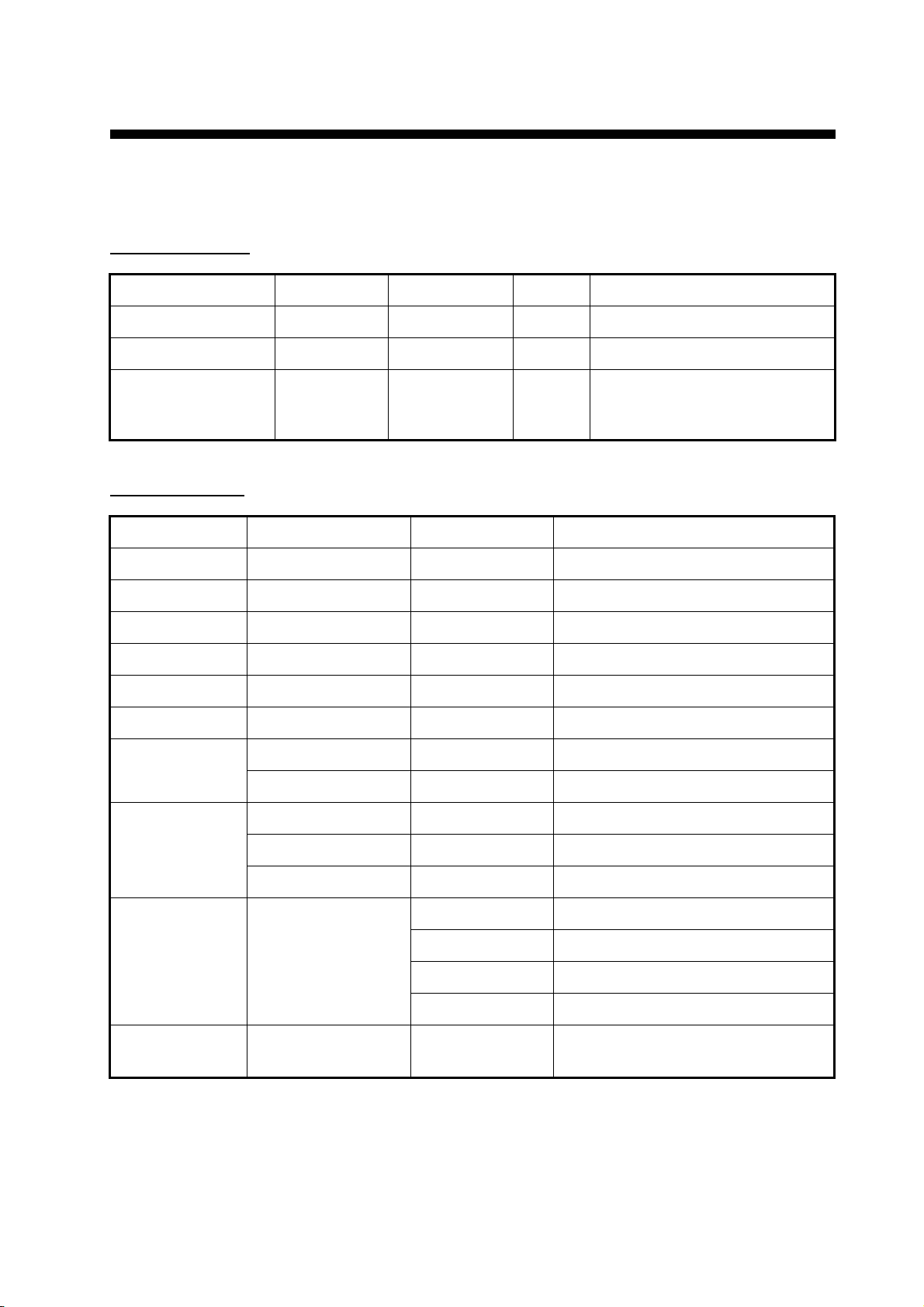

1.1 Equipment Lists

Standard supply

Name Type Code No. Qty Remarks

Network Fish Finder DFF1-UHD — 1

Spare Parts SP02-05601 001-033-740 1 set Fuse (2 pcs.)

Installation Materials CP02-08500 000-011-917 1 set - Power cable assy. (3.5 m)

- LAN cable assy. (5 m)

- Self-tapping screws

Optional supply

Name Type Code No. Remarks

Transducer B265LH 000-022-521 1 kW, bronze housing, thru hull

Transducer CM265LH 000-022-531 1 kW, plastic housing, tank mount

Thru-hull pipe TFB-7000 000-022-532

Tank T-711 000-022-539

Cable Assembly MOD-Z072-020+ 001-167-880-10 2 m, for HUB-101

Cable Assembly MOD-Z072-100+ 001-167-900-10 10 m, for HUB-101

Speed/Temperature Sensor

Temperature

Sensor

Rectifier PR-62 000-013-484 100 VAC

ST-02MSB 001-164-150-10 Thru-hull mount, steel hull

ST-02PSB 001-164-160-10 Thru-hull mount, plastic hull

T-02MTB 000-040-026 Transom mount

T-02MSB 000-040-040 Thru-hull mount

T-03MSB 000-040-027 Thru-hull mount

000-013-485 110 VAC

000-013-486 220 VAC

000-013-487 230 VAC

Connector Kit

for TX Sync

OP02-86 001-205-780

1

Page 10

1. INSTALLATION

1.2 Network Fish Finder

The network fish finder can be installed on a desktop, deck or on a bulkhead. When selecting a

mounting location, keep the following points in mind:

• The temperature and humidity at the mounting site should be moderate and stable.

• The mounting location must satisfy these requirements to get proper performance.

- Operating temperature range: -15 to 55°C (-27 to 99°F)

- Waterproofing standard: IP22

• Locate the unit away from exhaust pipes and vents.

• The mounting location should be well ventilated.

• Mount the unit where shock and vibration are minimal.

• Keep the unit away from electromagnetic field-generating equipment such as motors and generators.

• Leave slack in cables for maintenance and servicing ease.

• A magnetic compass will be affected if the network sounder is placed too close to it. Observe

the compass safe distances noted in the safety instructions to prevent interference to the magnetic compass.

Fasten the network sounder to the mounting location with four self-tapping screws (5×20), referring to the outline drawing at the back of this manual for mounting dimensions.

Note: For mounting on a bulkhead, the connectors must face downward to prevent the possibility

of water leakage into the unit.

2

Page 11

1. INSTALLATION

1.3 Transducer

The performance of the fish finder largely depends upon the transducer position. Select a place

least affected by air bubbles since turbulence blocks the sounding path. The face of the transducer

must be facing the sea bottom in normal cruising trim of the boat. Further, select a place least influenced by engine noise. It is known that air bubbles are fewest at the place where the bow first

falls and the next wave rises, at usual cruising speed.

Do not install the transducer inside the hull. Performance cannot be guaranteed.

1.4 Optional Speed/Temperature Sensors ST-02MSB, ST-02PSB

1.4.1 Mounting considerations

• Select a mid-boat flat position. The sensor does not have to be installed perfectly perpendicular.

However, the sensor must not be located where it may be damaged in dry-docking operations.

• Select a place apart from equipment generating heat.

• Select a place in the forward direction viewing from the drain hole, to allow for circulation of cool-

ing water.

• Select a place free from vibration.

• Do not install near the transducer of an echo sounder, to prevent interference to the echo

sounder.

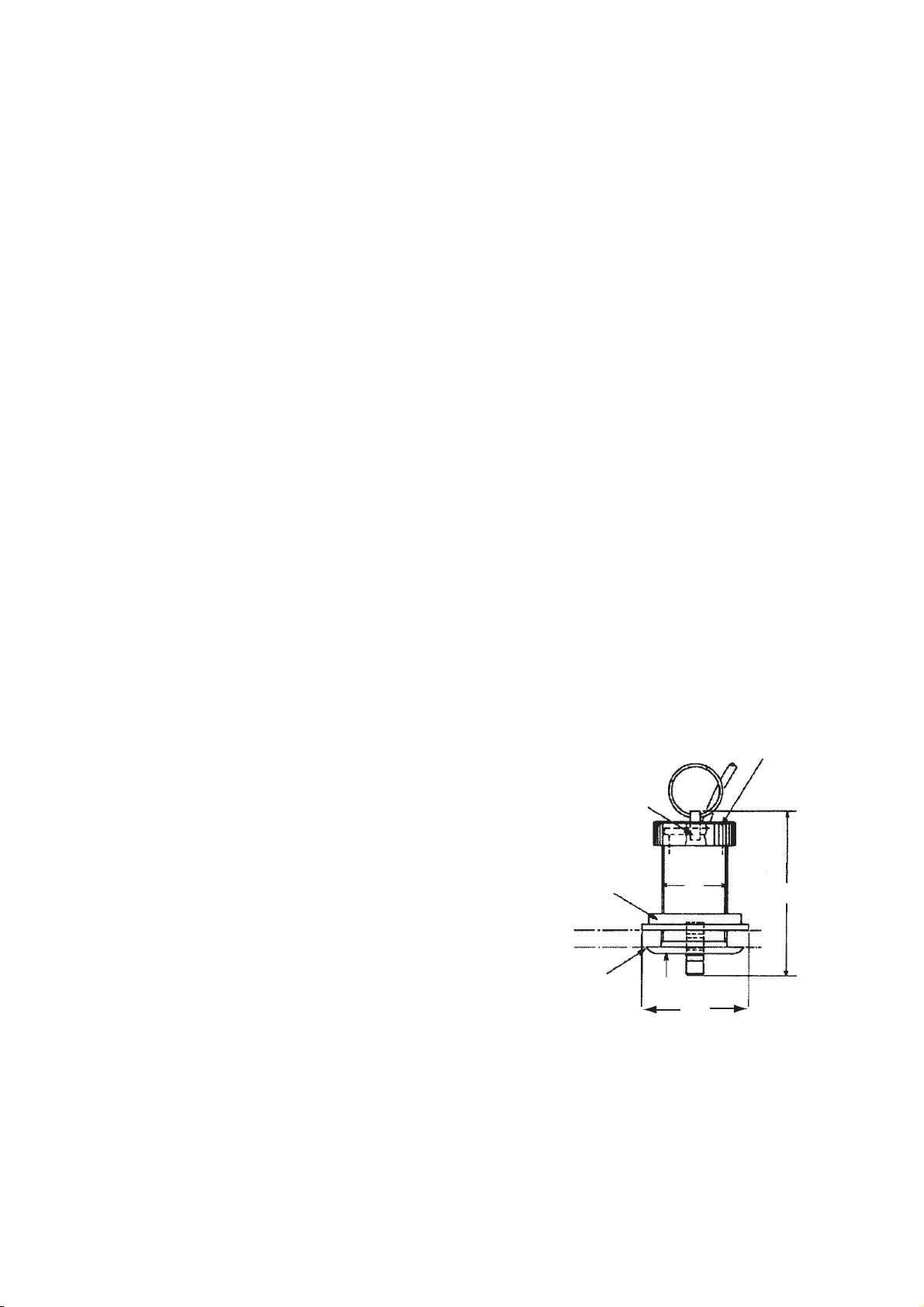

1.4.2 Mounting procedure

1. Dry dock the boat.

2. Make a hole of approx. 51 mm in diameter in

the mounting location.

3. Unfasten locknut and remove the sensor

section.

4. Apply high-grade sealant to the flange of the

sensor.

5. Pass the sensor casing through the hole.

6. Face the notch on the sensor toward boat's

bow and tighten the flange.

Face "notch"

toward bow.

Flange nut

51

Locknut

123

7. Set the sensor section to the sensor casing

and tighten the locknut.

8. Launch the boat and check for water leakage

around the sensor.

Coat with

silicone sealant.

3

Brim

ø77

Page 12

1. INSTALLATION

1.5 Optional Temperature Sensors

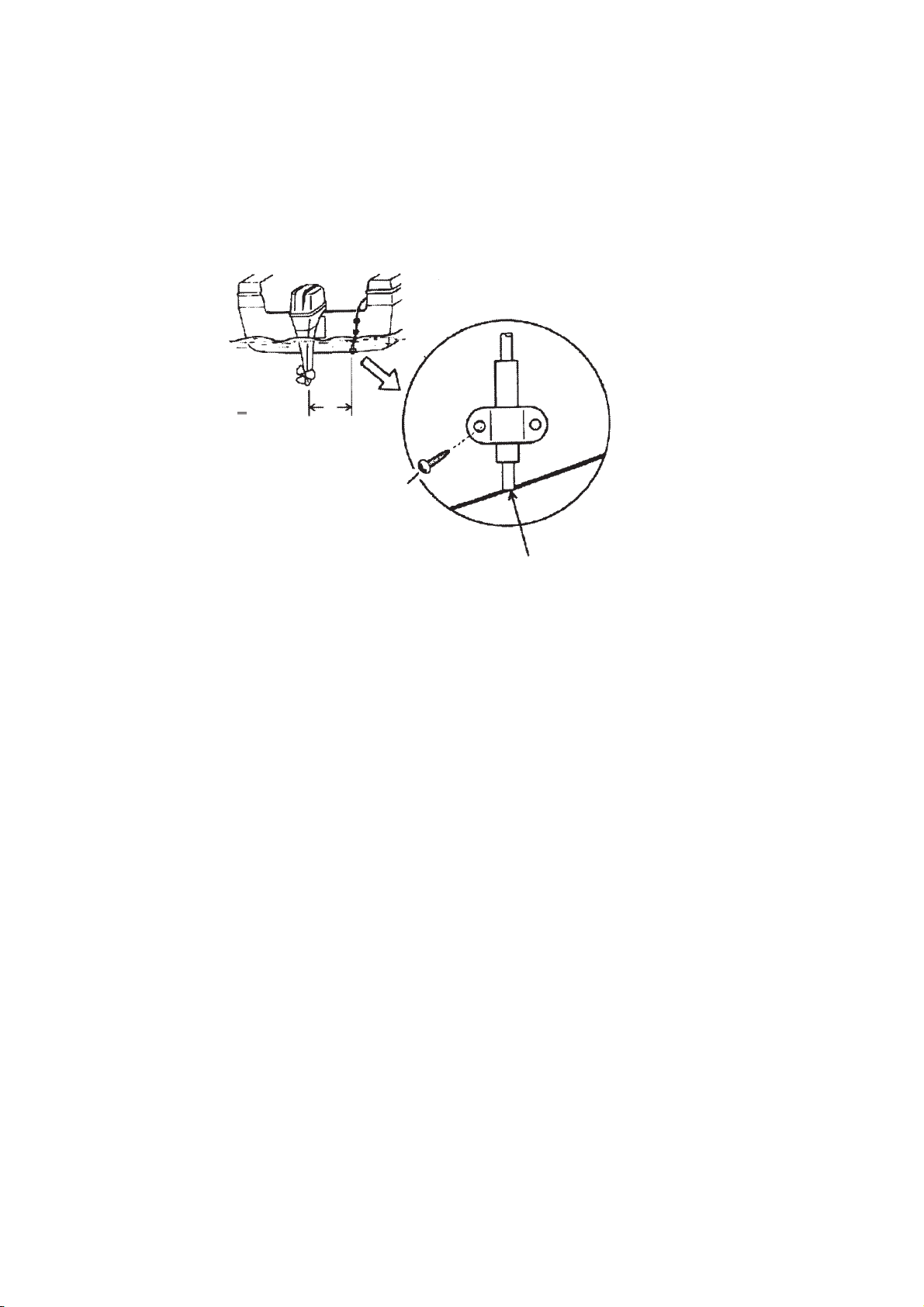

1.5.1 Transom mount temperature sensor T-02MTB

• Fix the cable at a convenient location with cable clamp.

• When the cable is led in through the transom board, make a hole of approx. 17 mm in diameter

to pass the connector. After passing the cable, fill the hole with a sealing compound.

D>50cm

D

5x20

Mount sensor

flush with hull bottom.

4

Page 13

1. INSTALLATION

1.5.2 Thru-hull temperature sensor T-02MSB, T-03MSB

Select a suitable mounting location considering the following points.

• Select a mid-boat flat position. The sensor does not have to be installed perfectly perpendicular.

However, the location should not be such that the transducer may be damaged when the boat

is dry-docked.

• Locate away from equipment which gives off heat.

• Locate away from drain pipes.

• Select a location where vibration is minimal.

T-02MSB T-03MSB

Sensor Holder

Sensor

cable

Sensor

cable

8 m

Locknut

Locknut

Washer

Gasket

Locknut

8 m

21 mm

M20

70 mm

ø42 mm

Mounting procedure

1. Drill a hole of 21 mm in diameter in

the mounting location.

2. Pass the sensor cable through the

hole.

3. Pass gasket, washer and locknut

onto cable in that order.

4. Coat the sensor flange with high

quality sealant and then fasten the

sensor with the locknut.

(Torque: max. 59N·m)

5. Launch the boat to check for water

leakage around the sensor.

Coat with

sealant.

Washer

Gasket

ø25 mm

70 mm

ø50 mm

Holder Guide

Mounting procedure

1. Drill a hole of 25 mm in diameter in the mounting

location.

2. Coat holder guide with high quality sealant, and

pass gasket, washer and locknut onto holder

guide in that order and then tighten the locknut.

3. Set the sensor holder to the holder guide from

inside the boat and then tighten the locknut.

4. Launch the boat to check for water leakage

around the sensor.

M24

Coat with

sealant.

Plate thickness within

25 mm

5

Page 14

2. WIRING

2.1 Wiring Outline

Connect the power cable, transducer cables, sensor cable, network cable and ground wire to their

respective locations on the network sounder. See the next page for how to connect the transducer

cables.

TZT9/TZT14/

TZTBB

To HUB-101

Ground wire

(IV-2 sq)

MOD-Z072-050+, 5 m

(option: 2/10 m)

MJ-A3SPF0013-035C

(3.5 m)

GROUND

Black

BATTERY

12 - 24 VDC

12-24 VDC

2.8-1.4 A

TEMP

Temperature or

Speed/Temperature

Sensor*

White

Shield (green)

DFF1-UHD

EXT-KP TRANSDUCER

External

KP

Transducer

* For no connection,

cover connector

with supplied cap.

Ground

Connect a ground wire (IV-2 sq, local supply) between the

ground terminal and ship’s ground to prevent interference to

the sounder picture. Make the length of the wire as short as

possible. For FRP vessels, install a ground plate that measures about 20 cm by 30 cm on the outside of the hull bottom

and connect the ground wire there.

6

CAUTION

Ground the equipment

to prevent mutual

interference.

Page 15

2. WIRING

2.2 Transducer Cable, Cable for External KP (option)

If the external KP is not to be connected, do only the applicable procedures in sections 2.2.1 and

2.2.2.

The KP from an echo sounder or sonar can be connected to this network fish finder to synchronize

transmission (to prevent interference). Use the optional Connector Kit for TX Sync (Type, OP0286, Code No. 001-205-780) and cable MPYC-4 (or MPYC-2) for the connection. (The MPYC-4 is

a Japan Industrial Standard (JIS) cable. If not available locally, see the Appendix 2 for the equivalent cable.)

Connector kit for TX sync

Name Type Code No. Qty

Upset UI Screw-B M4×20 000-163-756-10 2

Super Gland MGB20M-12B 000-177-248-10 1

PH Connector Assembly 02-1097 (4P) 001-206-000 1

Cable Clamping Plate 02-167-1528 100-379-090-10 1

Rainproofing Panel KP 02-167-1529 100-379-100-10 1

EMI Core GRFC-10 000-177-010-10 1

Crimp-on Lug NCW-1.25 000-157-213-10 4

2.2.1 How to process the cables

Note: The label on the transducer cable can be removed if it interferes with treatment of the cable.

How to process the transducer cable

CM265LH

Sheath

B265LH

Approx. 100

Braided shield

6

Extract cores from here and cut inclusion.

Taping

20

Extract braided shield and wrap it around sheath.

(This part lies in cable clamp.)

Approx. 100

㪍

Put unused wires (3)

in vinyl tubing (local

supply) for insulation.

Wind shield around cable.

(This part lies in cable clamp.)

20

Extract cores from here and

cut inner materials.

Vinyl tape (one turn)

7

Page 16

2. WIRING

A

How to process the cable for the external KP

1. Process the PH connector (02-1097, optional supply) as shown below.

a) Make the length of the wires of the PH connector 100 mm.

b) Remove the sheath from the cores 10 mm.

c) Fold back the cores in half.

d) Attach crimp-on lug NCW-1.25 to each core.

(a)

Approx. 100 mm

(c) (d)

Fold back core.

(b)

Approx. 10 mm

2. Remove the armor 170 mm and cut off the vinyl sheath 90 mm.

MPYC-4

rmor

Vinyl sheath

Approx. 210 mm

Approx. 90 mm

3. Remove 5 mm of the vinyl sheath from the cores then connect each crimp-on lug (attached at

step 2) as shown below.

Approx. 5 mm

4. Wrap the armor with vinyl tape.

Armor

Tape here.

This part is fixed

with the lock nut

inside the unit.

Vinyl sheath

This part is fixed

with the cable

clamp.

Crimp-on lug

NCW-1.25

8

Page 17

2. WIRING

2.2.2 How to connect the transducer cable

This procedure shows you how to connect the transducer cable. To connect both the transducer

cable and the cable for external KP, go to section 2.2.3.

1. Open the cover: Grasp the cover at two sides, spread the cover slightly and lift.

2. Loosen five screws to remove the shield cover.

3. Detach the two WAGO connectors (TB3, TB4) inside the equipment.

TB3

TB4

WAGO connector

Clamp fixing plate

WAGO connector

opener

4. Unfasten the sealing nut from the super gland for the transducer cable.

Sealing nut

9

Page 18

2. WIRING

5. Loosen the two screws fixing the clamp fixing plate to detach the plate.

Clamp fixing plate

6. Pass the sealing nut (unfastened at step 4) onto the transducer cable and pass the cable

through the super gland and into the unit.

7. Use the WAGO connector opener, attached inside the equipment, to connect the transducer

cable to the WAGO connectors, following the instructions in the figure below and the interconnection diagram.

Push

WAGO connector opener

1. Twist conductors.

2. Insert opener as directed and press it down.

Twist.

Core

3. Insert core to hole.

4. Release opener.

5. Pull the core to make sure it is correctly inserted.

8. Attach the WAGO connectors.

9. Refasten the clamp fixing plate, referring to the table below for how to orient the plate.

Transducer type Clamp fixing plate orientation

CM265LH Projection on plate upward

B265LH Projection on plate downward

10

Page 19

2. WIRING

10. Tighten the sealing nut according to the information in the table below.

Transducer Clearance Torque

CM265LH 4 mm 1.8 - 2.0N/m

B265LH 2 mm

Clearance

11. Reattach the shield cover and close the outer cover.

2.2.3 How to connect the transducer cable, cable for external KP

1. Remove the cover, shield cover and WAGO connectors, referring to steps 1-3 in section 2.2.2.

2. Unfasten the lock nut of the inside the unit to detach the super gland.

Clamp fixing plate

Clamp

Lock nut

Super gland

3. Unfasten two screws to remove the clamp fixing plate.

4. Unfasten two screws securing the clamp. Save the screws for later use.

5. Unfasten the four screws securing the rainproofing panel. You may discard the panel. Save

the screws for later use.

11

Page 20

2. WIRING

6. Unfasten the nut material inside the unit.

Clamp fixing

plate

Clamp

Nut material

Rainproofing

panel

7. Using the two screws removed at step 5, fasten the upper two holes of the supplied rainproofing panel.

Fasten upper two holes

Rainproofing panel (supplied)

12

Page 21

2. WIRING

8. TIghten the lock nut inside the unit to fasten the super glands (two pcs., see step 12). The

torque for the lock nut shall be 1.8 - 2.0 N/m.

Super gland (two pcs.)

9. Set the nut material (removed at step 6) inside the unit, align its two protrusions with the lower

holes on the rainproofing panel. Use the remaining two screws removed at step 5 to fasten

the lower two holes on the rainproofing panel.

Fasten lower two holes

10. Use two screws to fasten the clamp removed at step 4.

13

Page 22

2. WIRING

11. For the transducer cable and the cable for the external KP, pass each cable through its

super gland, the supplied rainproofing panel and each hole in the unit. Then slip a lock nut

onto each cable. (For the super gland of the cable for the external KP, unfasten the lock nut

from the super gland then pass the cable through the super gland. See page 8 for how to treat

the cable end.)

Lock nut

Cable for

Ext. KP

(MPYC-4)

Super gland

Sealing nut

Rainproofing panel

After passing the cable for the external KP, do as follows:

- Assemble the super gland.

- Tighten the sealing nut until the clearance is 4 mm. The torque shall be 1.8 - 2.0N/m.

4 mm

14

Page 23

2. WIRING

12. Transducer cable: Lay the transducer cable in the cable clamp then refasten the clamp fixing

plate.

Cable for the external KP: Lay the cable in the cable clamp and fix it with the supplied clamp

fixing plate and two upset screws.

Lock nut for super gland (2 pcs.)

Clamp fixing plate

Large: transducer cable

Small: cable for external KP

13. Connect the cables as follows:

• Transducer cable: See section 2.2.2.

• Cable for external KP: See the illustration below. Pass the cable through the edge saddle

and connect the cable to J12 on the PWRTX board. Be sure the cable does not contact TB4.

J12

Be sure cable does

Edge saddle

not contact TB4.

Lay vinyl sheath in

cable clamp and

fasten clamp fixing

plate (supplied).

(See step 11.)

Note: For cable MPYC-2, tape the vinyl sheath of the cable (approx. 6 to 7 turns) where it lies

in the cable clamp and fasten the cable clamp. The PH connector has two unused harnesses.

Cut them at their base or wrap them with vinyl tape.

15

Cut off two unused

harnesses at base.

Taping.

Page 24

2. WIRING

14. Attach the supplied EMI core (GRFC-10) to the cable for the external KP approx. 100 mm from

the super gland.

10 mm

15. Attach the shield cover and close the outer cover.

Super gland

(for ext. KP)

EMI core

16

Page 25

2. WIRING

2.3 LAN Cable

Do as follows to connect the supplied LAN cable (MOD-Z072-050+) or the optional LAN cable

(MOD-Z072-020+, MOD-Z072-100+).

1. Unfasten the sealing nut from the LAN connector then remove the sealing insert and clamping

claw.

2. Detach the sealing insert from the clamping claw as shown below.

Seal assy.

Super

gland

Sealing insert

Insert seal

Clamping claw

Sealing nut

How to detach clamping claw

Push in the sealing insert

with your thumbs.

Hold the clamping

claw/seal assy. as shown

left, with the teeth of

the clamping claw toward

you.

17

Page 26

2. WIRING

3. Pass the sealing nut, clamping claw and sealing insert onto the LAN cable in the order shown

in the figure below. Connect the cable to the LAN connector. (Note the orientation of the sealing insert when passing it onto the cable. Push the cable into the slit in the sealing insert.)

LAN cable

Sealing insert

(Push cable into slit.)

Clamping claw

Sealing nut

4. Set the sealing insert and clamping claw into the sealing nut then tighten the nut.

5. Tighten the sealing nut to fasten the LAN cable. The clearance between the lock nut and the

sealing nut shall be 3 mm. The torque for the sealing nut shall be 1.8 - 2.0 N/m.

Clearance

How to disconnect the LAN cable

Loosen the two screws on the gland to access the cable’s connector. A lock washer is fitted to the

gland and the screws cannot be unfastened completely.

Screw (2 pcs.)

Gland

18

Page 27

3. INITIAL SETTINGS

WARNING

Do not open the equipment unless totally

familiar with electrical circuits.

Only qualified personnel should work inside

the equipment.

3.1 DIP Switch Setting

The DIP switch S2 sets up the system according to the equipment connected. In the default setting

all switches (1-8) are OFF. The DIP switch S3 should not be adjusted; leave all switches in the

OFF position.

DIP Switches

(factory settings)

S3

4-1

ON

OFF

S2

1-8

ON

OFF

DIP switch S2 description

Switch

No.

1 IP mode OFF: FIxed (static) IP address. Set the IP address

2 IP address no. OFF: Set the #1 switch to OFF to set IP address. See

3 Restore default settings (other than

LAN and transducer)

4 Restore ALL default settings See section 4.3.

5 - 6 Keep these switches in the OFF position.

7 No use

8 No use

Function Setting

with switch #2, referring to the table below.

ON: Use IP address assigned by DHCP.

the table on the next page for IP address assignment.

See section 4.3.

19

Page 28

3. INITIAL SETTINGS

#2 Host name IP address

OFF ES092002 172.031.092.002

ON ES092003 172.031.092.003

After setting up the transducer at the DFF1-UHD, set the transducer type at the NavNet device.

See respective Installation Manual for the procedure.

Note: DIP Switch S2 is for factory use. Do not change the settings.

3.2 Operation Check

For NavNet TZtouch, the DFF1-UHD is powered on/off from ship’s switchboard. For NavNet 3D,

it is powered on/off from the display unit. The LED on the cover of the DFF1-UHD lights or blinks

according to equipment state, as described in the table below.

LED state and meaning

LED state Meaning

Lighting continuously • Standby state. (If no signal is received via LAN for more than 10

minutes, the equipment automatically goes into standby to lessen

power consumption.)

• Power on (20 seconds during initialization)

• IP address not set

Blinking every two seconds Normal operation

Blinking every 0.4 seconds Transducer settings at NavNet device not properly set.

LED

20

Page 29

4. MAINTENANCE

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Do not apply paint, anti-corrosive sealant or

contact spray to coating or plastic parts of

the equipment.

Those items contain organic solvents that can

damage coating and plastic parts, especially

plastic connectors.

NOTICE

4.1 Maintenance

Regular maintenance is essential for good performance. Check the items listed in the table below

at the suggested interval to help keep your equipment in good shape for years to come.

Item Check point, action Check interval

Transducer cable Check that cable is tightly fastened and is not

damaged. Refasten if necessary. Replace if

damaged.

Power cable, sensor

cable

Check that these cables are tightly fastened and

not damaged. Refasten if necessary. Replace if

damaged.

Once a month

Once a month

Ground Check for corrosion. Clean if necessary. Once a month

Power supply voltage Check voltage. If out of rating correct problem. Once a month

Cleaning the network

fish finder’s cabinet

Transducer Marine life on the transducer face will result in a

Dust or dirt on the cabinet may be removed with a

dry cloth. Do not use chemical-based cleaners to

clean the cabinet; they can remove markings and

damage the cabinet.

gradual decrease in sensitivity. Check the transducer face for cleanliness each time the boat is

removed from the water. Carefully remove any

marine life with a piece of wood or fine-grade

sandpaper.

Once a month

When vessel is removed from the water

21

Page 30

4. MAINTENANCE

4.2 How to Replace the Fuse

The 5A fuse (Type: FGBO-A 125V 5A PBF, Code No. 000-155-853-10) in the snap-in fuse holder

on the power cable protects the equipment from equipment fault and reverse polarity of the power

supply. If the equipment cannot be powered, the fuse may have blown. Find out the cause for the

blown fuse before replacing it. If the fuse blows again after replacement, contact a FURUNO agent

or dealer for instructions.

WARNING

Use the proper fuse.

Use of a wrong fuse can damage the equipment and cause fire.

4.3 How to Restore Default Settings

This procedure restores all default sounder settings on the NavNet series device. You can restore

all default settings or restore those other than transducer and LAN. This procedure should only be

performed by a suitably qualified FURUNO technician.

1. Disconnect the power and LAN cables from the DFF1-UHD.

2. Turn on the #3 or #4 switch of DIP Switch S3 as applicable.

#3: Restore default settings other than LAN and transducer.

#4: Restore all default settings. Use this when changing transducers.

3. Connect the power cable to the DFF1-UHD, and turn on the power at the ship’s switchboard.

4. The LED blinks (every 0.4 seconds) when default settings are completely restored.

5. Set up the transducer at the NavNet equipment.

22

Page 31

APPENDIX 1 JIS CABLE GUIDE

Cables listed in the manual are usually shown as Japanese Industrial Standard (JIS). Use the following guide to locate an

equivalent cable locally.

JIS cable names may have up to 6 alphabetical characters, followed by a dash and a numerical value (example: DPYC-2.5).

For core types D and T, the numerical designation indicates the cross-sectional Area (mm

2

) of the core wire(s) in the cable.

For core types M and TT, the numerical designation indicates the number of core wires in the cable.

1. Core Type 2. Insulation Type 3. Sheath Type

Double core power line

D

Triple core power line

T

Multi core

M

Twisted pair communications (1Q=quad cable)

TT

4. Armor Type 5. Sheath Type 6. Shielding Type

Steel

C

Y

-SLA

1 2 3 4 5 6 1 2 3 4

Ethylene Propylene Rubber

P

Anticorrosive vinyl sheath

PVC (Vinyl)

Y

SLA

All cores in one shield,

plastic tape w/aluminum tape

Individually shielded cores,

plastic tape w/aluminum tape

DPYCY

TPYCY

MPYC-4

EX: DPYCYSLA - 1.5 MPYC - 4

Designation type

Core Area (mm

2

)

Designation type

# of cores

TTYCSLA-4

The following reference table lists gives the measurements of JIS cables commonly used with Furuno products:

Core Cable Core Cable

Type Area Diameter Type Area Diameter

2

DPYC-1.5 1.5mm

DPYC-2.5 2.5mm

DPYC-4 4.0mm

DPYC-6 6.0mm

DPYC-10 10.0mm

DPYC-16 16.0mm

DPYCY-1.5 1.5mm

DPYCY-2.5 2.5mm

DPYCY-4 4.0mm

DPYCYSLA-1.5 1.5mm

DPYCYSLA-2.5 2.5mm

MPYC-2 1.0mm

MPYC-4 1.0mm

MPYC-7 1.0mm

MPYCY-12 1.0mm

MPYCY-19 1.0mm

1.56mm 11.7mm

2

2.01mm 12.8mm

2

2.55mm 13.9mm

2

3.12mm 15.2mm

2

4.05mm 17.1mm

2

5.10mm 19.4mm

2

1.56mm 13.7mm

2

2.01mm 14.8mm

2

2.55mm 15.9mm

2

1.56mm 11.9mm

2

2.01mm 13.0mm

2

1.29mm 10.0mm

2

1.29mm 11.2mm

2

1.29mm 13.2mm

2

1.29mm 19.0mm

2

1.29mm 22.0mm

Diameter Diameter

2

TPYCY-1.5 1.5mm

TPYCY-2.5 2.5mm

TPYCY-4 4.0mm

TPYCYSLA-1.5 1.5mm

TTYC-7SLA 0.75mm

TTYCSLA-1 0.75mm

TTYCSLA-1Q 0.75mm

TTYCSLA-4 0.75mm

TTYCY-4SLA 0.75mm

TTYCYSLA-1 0.75mm

TTYCYSLA-4 0.75mm

1.56mm 14.5mm

2

2.01mm 15.5mm

2

2.55mm 16.9mm

2

1.56mm 13.9mm

2

1.11mm 20.8mm

2

1.11mm 9.4mm

2

1.11mm 10.8mm

2

1.11mm 15.7mm

2

1.11mm 19.5mm

2

1.11mm 11.2mm

2

1.11mm 17.9mm

AP-1

Page 32

FURUNO

SPECIFICATIONS OF NETWORK FISH FINDER

DFF1-UHD

1 GENERAL

1.1 TX frequency 50/200 kHz, alternative transmission

1.2 Output power 1 kW nominal

1.3 Amplifier type Straight amplifier (H/L gain switching available)

1.4 Depth range and Pulse repetition rate (PRR) at 200 kHz, TX rate: 20

Range (m) PRR (times/min, max.)

2 2403

5 2403

10 1621

40 476

100 222

400 58

1200 34

2 INTERFACE

2.1 I/O port

Network 1 port

Temp/speed sensor 1 port

External KP 1 port (external KP kit: option)

2.2 Network method Ethernet 10Base-T/100Base-TX

3 POWER SUPPLY

3.1 Network fish finder 12-24 VDC: 2.5-1.3 A

3.2 Rectifier (PR-62, option) 100/110/220/230 VAC, 1 phase, 50/60 Hz

4 ENVIRONMENTAL CONDITIONS

4.1 Ambient temperature -15°C to +55°C

4.2 Relative humidity 93% or less at +40°C

4.3 Degree of protection IP22

4.4 Vibration IEC 60945 Ed.4

5 UNIT COLOR

5.1 Network fish finder N2.5 (fixed)

DFF1-UHD

SP - 1 E2040S01A

121203

Page 33

PACKING LIST

A-1

DFF1-UHD

02GL-X-9851 -0

1/1

N A M E

O U T L I N E

DESCRIPTION/CODE №

ユニット UNIT

ネットワーク魚探

NETWORK FISH FINDER

DFF1-UHD

000-022-520-00

予備品 SPARE PARTS SP02-05601

ヒューズ

GLASS TUBE FUSE

FGB0-A 125V 5A PBF

000-155-853-10

工事材料 INSTALLATION MATERIALS CP02-08500

+トラスタッピンネジ 1シュ

SELF-TAPPING SCREW

5X20 SUS304

000-162-608-10

ケーブル(組品)LAN

LAN CABLE ASSEMBLY

MOD-Z072-050+

000-167-176-10

ケーブル組品MJ

CABLE ASSEMBLY

MJ-A3SPF0013-035C(5A)

000-157-939-10

図書 DOCUMENT

取扱説明書

OPERATOR'S MANUAL

OM*-20400-*

000-177-244-1*

Q'TY

1

2

4

1

1

1

**

コ-ド番号末尾の[**]は、選択品の代表コードを表します。

CODE NUMBER ENDING WITH "**" INDICATES THE CODE NUMBER OF REPRESENTATIVE MATERIAL.

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWO TYPES AND CODES MAY BE LISTED FOR AN ITEM. THE LOWER PRODUCT MAY BE SHIPPED IN PLACE OF THE UPPER

PRODUCT. QUALITY IS THE SAME.

(略図の寸法は、参考値です。 DIMENSIONS IN DRAWING FOR REFERENCE ONLY.)

02GL-X-9851

Page 34

D-1

7/Dec/2012Y.NISHIYAMA

Page 35

DFF1-UHD

S-1

ネットワーク魚探

相互結線図

NETWORK FISH FINDER

INTERCONNECTION DIAGRAM

イーサネットハブ

ETHERNET HUB

*2

HUB-101

または OR

MULTI FUNCTION DISPLAY

MFD8/12/BB

マルチファンクションディスプレイ

TZT9/14/BB

TITLE

名称

NAME

43

02-167-1001-2C2040-C01- C

REF.No.

MOD-Z072-050+,5m

(2/10m *2)

RJ45 RJ45

8 8

*3

TEMP

J5

NETWORK

DFF1-UHD

NETWORK FISH FINDER

ネットワーク魚探

TRIG_IN_P

TRIG_IN_N

TRIG_OUT_P

123

MPYC-4

KP OUT

TRIG_OUT_N

4

KP IN

J12(PH4P)

1B 2 02P6385

(+)

(-)

SHIELD

SHIELD

TEMP

TEMP_0V

J1

2

123

MJ-A3SPF

WHTシロ

5A

BLK

クロ

GRN

ミドリ

J2

MJ-A6SPF

1

2

8mDPYC-1.5

SPEED

345

*1

12V_P

IV-2sq.

02P63601B 3

GND

6

*2

TEMP/SPEED

水温・船速センサー

SENSOR

ST-02MSB/PSB

T-02MTB/MSB

*2

KP KIT

*1

T-03MSB

TEMP_XID_GND

XID

SHIELD

NC

TB4

XD_LO_P

NC

XD_LO_SHIELD

XD_LO_M

XD_HI_M

XD_HI_SHIELD

NC

XD_HI_P

TB3

5

4

3

2

1

8

7

6

5

4

3

2

1

*1

IV-2sq.

WHT

BRN

ORG

DRAIN

BLU/WHT

DRAIN

BLK/WHT

BLK

DRAIN

BLU

シロ

チャ

ダイ

アオ/シロ

クロ/シロ

クロ

アオ

12m

送受波器

B265LH

TRANSDUCER

CM265LH

DRAWN

T.YAMASAKI

9/Jan/2013

CHECKED

kg

H.MAKI

9/Jan/2013

9/Jan/2013Y.NISHIYAMA

APPROVED

SCALE MASS

DWG.No.

123

(+)

(-)

*2

PR-62

整流器

*1

A

RECTIFIER

5

6

100-115/

220/230VAC,

1φ,50/60Hz

NOTE

*1: SHIPYARD SUPPLY.

注記

*1)造船所手配。

*2)オプション。

*3)CM265LHのみ。

B

C

*2: OPTION.

*3: CM265LH ONLY.

MJ-A3SPF0013-035C,3.5m

1

12-24VDC (+)

(-)

GND

Page 36

FURUNO Worldwide Warranty for Pleasure Boats (Except North America)

This warranty is valid for products manufactured by Furuno

Electric Co. (hereafter FURUNO) and installed on a pleasure

boat. Any web based purchases that are imported into other

countries by anyone other than a FURUNO certified dealer may

not comply with local standards. FURUNO strongly recommends

against importing these products from international websites as

the imported product may not work correctly and may interfere

with other electronic devices. The imported product may also be

in breach of the local laws and mandated technical requirements.

Products imported into other countries as described previously

shall not be eligible for local warranty service.

For products purchased outside of your country please contact

the national distributor of Furuno products in the country where

purchased.

This warranty is in addition to the customer´s statutory legal

rights.

1. Terms and Conditions of Warranty

FURUNO guarantees that each new FURUNO product is the

result of quality materials and workmanship. The warranty is

valid for a period of 2 years (24 months) from the date of the

invoice, or the date of commissioning of the product by the

installing certified dealer.

2. FURUNO Standard Warranty

The FURUNO standard warranty covers spare parts and labour

costs associated with a warranty claim, provided that the product

is returned to a FURUNO national distributor by prepaid carrier.

The FURUNO standard warranty includes:

Repair at a FURUNO national distributor

All spare parts for the repair

Cost for economical shipment to customer

3. FURUNO Onboard Warranty

If the product was installed/commissioned and registered by a

certified FURUNO dealer, the customer has the right to the

onboard warranty.

The FURUNO onboard warranty includes

• Free shipping of the necessary parts

• Labour: Normal working hours only

• Travel time: Up to a maximum of two (2) hours

• Travel distance: Up to a maximum of one hundred

and sixty (160) KM by car for the complete journey

4. Warranty Registration

For the Standard Warranty - presentation of product with serial

number (8 digits serial number, 1234-5678) is sufficient.

Otherwise, the invoice with serial number, name and stamp of

the dealer and date of purchase is shown.

For the Onboard Warranty your FURUNO certified dealer will

take care of all registrations.

5. Warranty Claims

For the Standard Warranty - simply send the defective product

together with the invoice to a FURUNO national distributor.

For the Onboard Warranty – contact a FURUNO national

distributor or a certified dealer. Give the product´s serial number

and describe the problem as accurately as possible.

Warranty repairs carried out by companies/persons other than a

FURUNO national distributor or a certified dealer is not covered

by this warranty.

6. Warranty Limitations

When a claim is made, FURUNO has a right to choose whether

to repair the product or replace it.

The FURUNO warranty is only valid if the product was correctly

installed and used. Therefore, it is necessary for the customer to

comply with the instructions in the handbook. Problems which

result from not complying with the instruction manual are not

covered by the warranty.

FURUNO is not liable for any damage caused to the vessel by

using a FURUNO product.

The following are excluded from this warranty:

a. Second-hand product

b. Underwater unit such as transducer and hull unit

c. Routine maintenance, alignment and calibration

services.

d. Replacement of consumable parts such as fuses,

lamps, recording papers, drive belts, cables, protective

covers and batteries.

e. Magnetron and MIC with more than 1000 transmitting

hours or older than 12 months, whichever comes first.

f. Costs associated with the replacement of a transducer

(e.g. Crane, docking or diver etc.).

g. Sea trial, test and evaluation or other demonstrations.

h. Products repaired or altered by anyone other than the

FURUNO national distributor or an authorized dealer.

i. Products on which the serial number is altered,

defaced or removed.

j. Problems resulting from an accident, negligence,

misuse, improper installation, vandalism or water

penetration.

k. Damage resulting from a force majeure or other natural

catastrophe or calamity.

l. Damage from shipping or transit.

m. Software updates, except when deemed necessary

and warrantable by FURUNO.

n. Overtime, extra labour outside of normal hours such as

weekend/holiday, and travel costs above the 160 KM

allowance

o. Operator familiarization and orientation.

FURUNO Electric Company, March 1, 2011

Page 37

FURUNO Warranty for North America

FURUNO U.S.A., Limited Warranty provides a twenty-four (24) months LABOR and twenty-four (24) months PARTS

warranty on products from the date of installation or purchase by the original owner. Products or components that are

represented as being waterproof are guaranteed to be waterproof only for, and within the limits, of the warranty

period stated above. The warranty start date may not exceed eighteen (18) months from the original date of purchase

by dealer from Furuno USA and applies to new equipment installed and operated in accordance with Furuno USA’s

published instructions.

Magnetrons and Microwave devices will be warranted for a period of 12 months from date of original equipment

installation.

Furuno U.S.A., Inc. warrants each new product to be of sound material and workmanship and through its authorized

dealer will exchange any parts proven to be defective in material or workmanship under normal use at no charge for a

period of 24 months from the date of installation or purchase.

Furuno U.S.A., Inc., through an authorized Furuno dealer will provide labor at no cost to replace defective parts,

exclusive of routine maintenance or normal adjustments, for a period of 24 months from installation date provided the

work is done by Furuno U.S.A., Inc. or an AUTHORIZED Furuno dealer during normal shop hours and within a radius

of 50 miles of the shop location.

A suitable proof of purchase showing date of purchase, or installation certification must be available to Furuno U.S.A.,

Inc., or its authorized dealer at the time of request for warranty service.

This warranty is valid for installation of products manufactured by Furuno Electric Co. (hereafter FURUNO). Any

purchases from brick and mortar or web-based resellers that are imported into other countries by anyone other than a

FURUNO certified dealer, agent or subsidiary may not comply with local standards. FURUNO strongly recommends

against importing these products from international websites or other resellers, as the imported product may not work

correctly and may interfere with other electronic devices. The imported product may also be in breach of the local

laws and mandated technical requirements. Products imported into other countries, as described previously, shall not

be eligible for local warranty service.

For products purchased outside of your country please contact the national distributor of Furuno products in the

country where purchased.

WARRANTY REGISTRATION AND INFORMATION

To register your product for warranty, as well as see the complete warranty guidelines and limitations, please visit

www.furunousa.com

provided through its authorized dealer network. If this is not possible or practical, please contact Furuno U.S.A., Inc.

to arrange warranty service.

and click on “Support”. In order to expedite repairs, warranty service on Furuno equipment is

FURUNO U.S.A., INC.

Attention: Service Coordinator

4400 N.W. Pacific Rim Boulevard

Camas, WA 98607-9408

Telephone: (360) 834-9300

FAX: (360) 834-9400

Furuno U.S.A., Inc. is proud to supply you with the highest quality in Marine Electronics. We know you had several

choices when making your selection of equipment, and from everyone at Furuno we thank you. Furuno takes great

pride in customer service.

Page 38

Page 39

Page 40

9-52, Ashihara-cho,

Nishinomiya, 662-8580, JAPAN

(Elemental Chlorine Free)

The paper used in this manual

is

elemental chlorine free.

FURUNO Authorized Distributor/Dealer

All rights reserved.

Printed in Japan

Pub. No. OME-20400-B

(DAMI) DFF1-UHD

A: JAN. 2013

B: JAN. 31, 2013

Loading...

Loading...