Page 1

MEMORY CARD INTERFACE UNIT

CU-300

www.furuno.co.jp

Page 2

Page 3

SAFETY INSTRUCTIONS

The user and installer must read the appropriate safety instructions before attempting to install

or operate the equipment.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

Warning, Caution

Safety instructions for the operator

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Prohibitive Action

Mandatory Action

WARNING

Do not open the equipment.

Only qualified personnel should work

inside the equipment.

Immediately turn off the power at the

switchboard if water leaks into the

equipment or something is dropped

into the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Immediately turn off the power at the

switchboard if the equipment is emitting

smoke or fire.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

WARNING

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if a liquid

spills into the equipment.

Do not operate the equipment with

wet hands.

Electrical shock can result.

Turn off the power immediately

if you feel the equipment is behaving

abnormally.

Turn off the power at the switchboard if

the equipment becomes abnormally warm

or is emitting odd noises. Contact a

FURUNO dealer or agent for advice.

Make sure no rain or water splash leaks

into the equipment.

Fire or electrical shock can result if water

leaks in the equipment.

i

Page 4

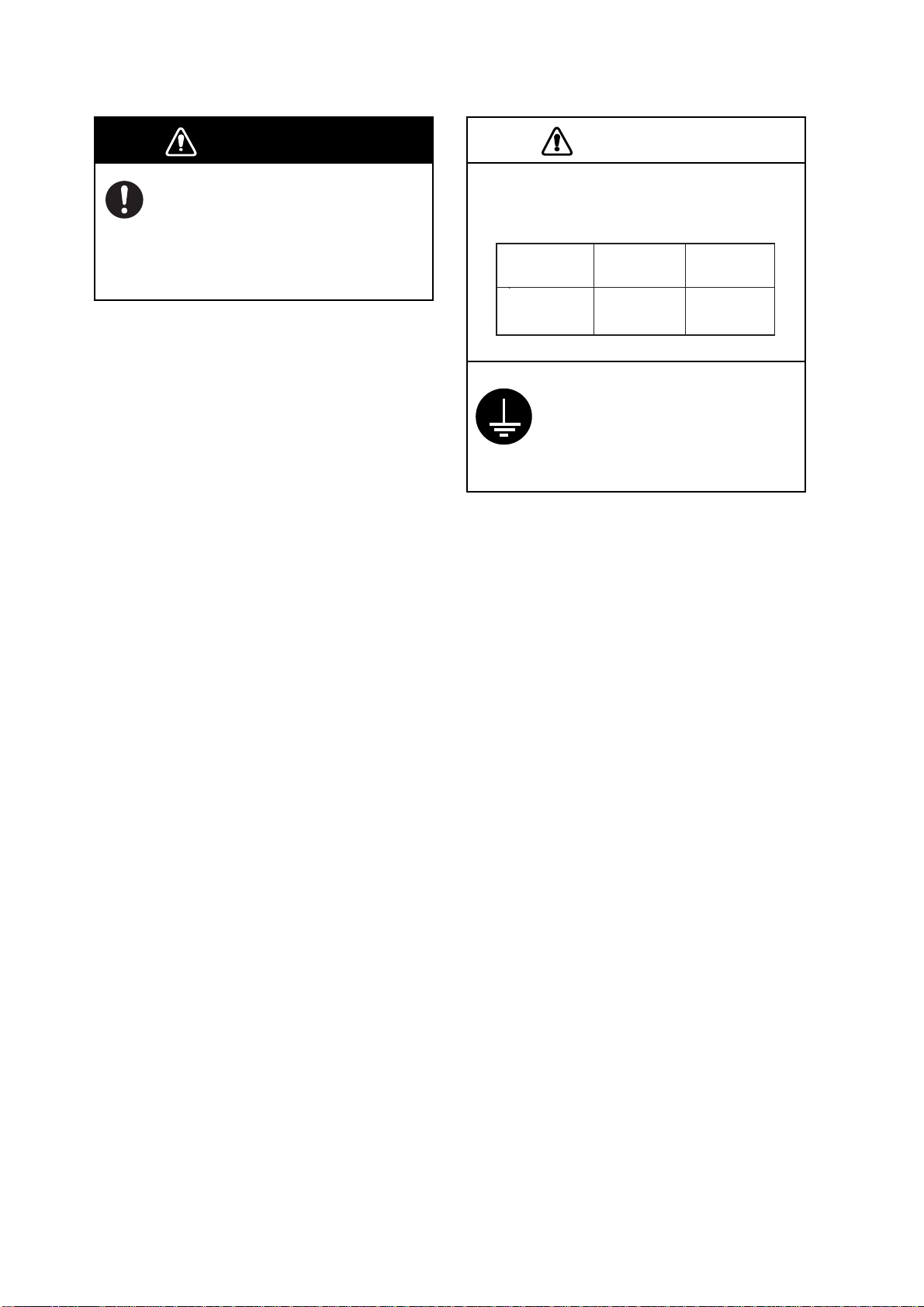

WARNING

CAUTION

Turn off the power at the

switchboard before beginning the

installation.

Fire or electrical shock can result if

the power is left on.

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

Standard

compass

CU-300

Attach grounding securely

to ship's body.

The grounding is required

to prevent electrical shock.

Steering

compass

0.45 m0.70 m

ii

Page 5

TABLE OF CONTENTS

SYSTEM CONFIGURATIONS....................................................................iv

EQUIPMENT LISTS....................................................................................vi

1. MOUNTING............................................................................................1

1.1 Flush Mounting................................... ................................. .................. ................... ....1

1.2 Desktop Mounting......... .... ................................. .................. .................. ................... ....2

1.3 Overhead Mounting................. .... ................................. .................. .................. ............3

2. WIRING..................................................................................................5

2.1 Connection between One Processor Unit and One Memory Card Interface Unit ........5

2.2 Con nection bet w een One Me m ory C ard Interfa c e U nit and Multi ple Process or U nits

(Max. Three Units)........................................................................................................6

2.3 Con nection bet w een Two Memory Car d I nt erf ace Units and Two Proc essor Units.....7

3. OPERATION..........................................................................................9

3.1 Basic Operation.................................. ................................. .................. ................... ....9

3.2 Priority of Card Drives ................................................................................................ 10

SPECIFICATION....................................................................................SP-1

PACKING LISTS......................................................................................A-1

OUTLINE DRAWINGS............................................................................. D-1

iii

Page 6

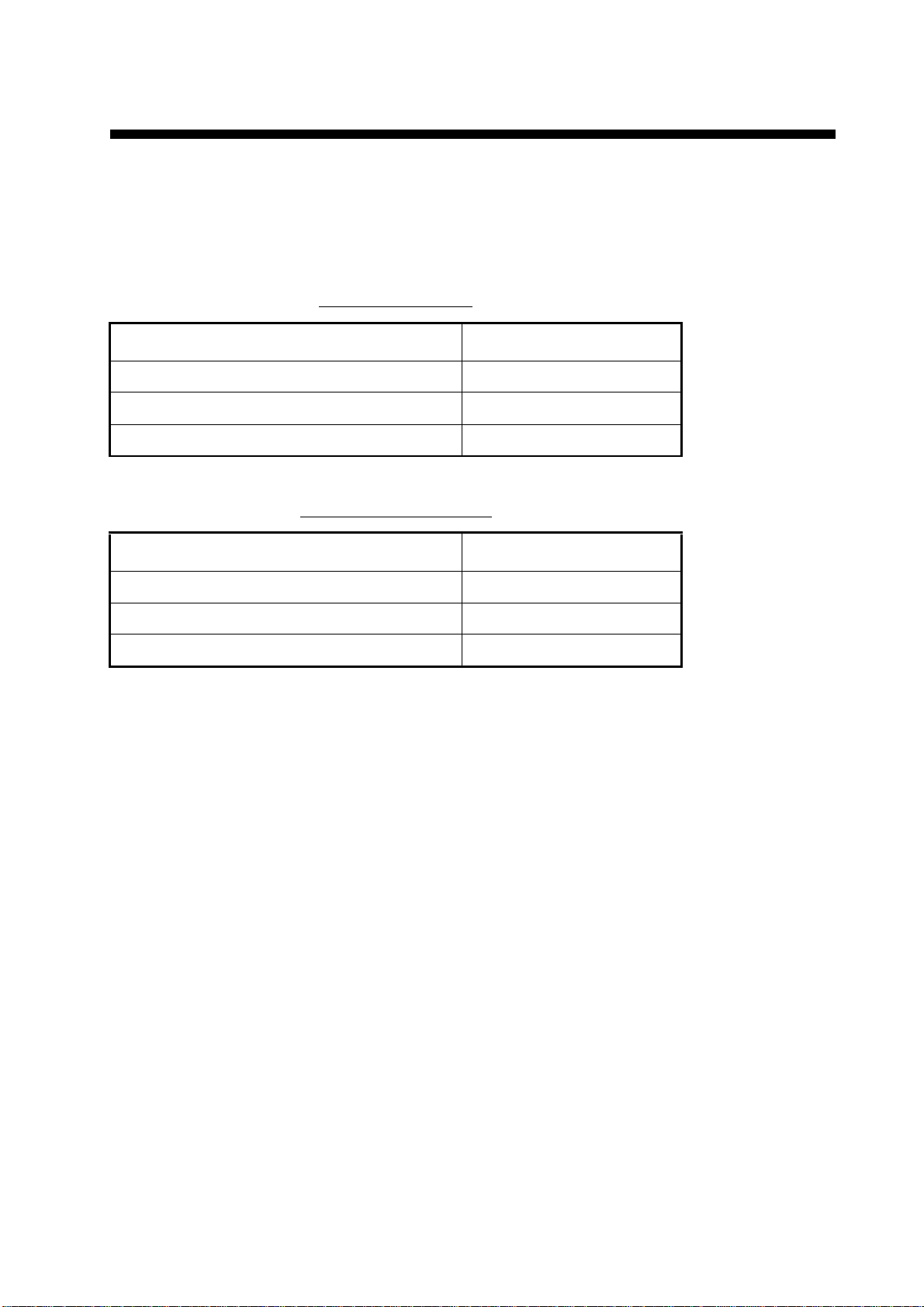

SYSTEM CONFIGURATIONS

The Memory Card Interface Unit CU-300 connects to a processor unit of MODEL18x4C-BB/

19x4C-BB or GD-1920C-BB (NavNet VX2-BB) to provide a card drive(s) in a remote location(s).

Power to the CU-300 is supplied from the processor unit. Maximum four units can be connected

via a HUB. Note that th e CU- 300 can b e conne cte d only to th e NavNe t V X2 uni ts which have the

followin g s of t w are version N o.

C-MAP specification

Type Version No.

MODEL 18x4C-BB/19x4C-BB, GD-1920C-BB 1950026-02.01 and after

MODEL 18x4C/19x4C, GD-1920C 1950024-02.01 and after

MODEL 17x4C, GD-1720C 1950028-02.01 and after

NAVIONICS spe c ifi ca t ion

Type Version No.

MODEL 18x4C-BB/19x4C-BB, GD-1920C-BB 1950025-01.09 and after

MODEL 18x4C/19x4C, GD-1920C 1950023-01.09 and after

MODEL 17x4C, GD-1720C 1950027-01.09 and after

iv

Page 7

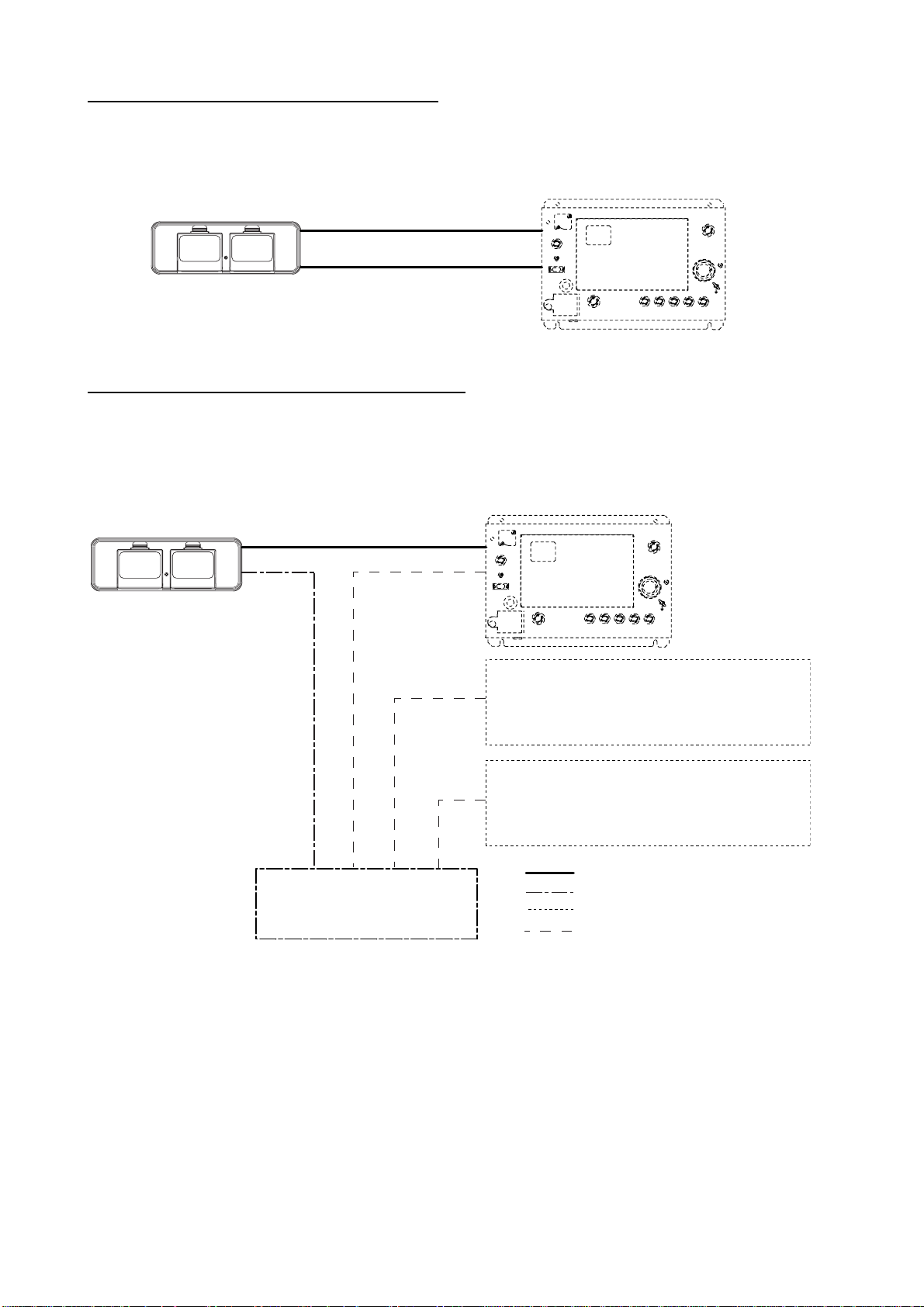

Connection to single NavNet VX2-BB unit

Power cable

CU-300

MJ-A3SPF0026-050C or 100C

Ethernet cable

MJ-A6SPF0017-050C or 100C

Connection to multiple NavNet VX2-BB units

CU-300

Power cable

MJ-A3SPF0026-050C or 100C

Model 18x4C-BB/19x4C-BB

GD-1920C-BB

Model 18x4C-BB/19x4C-BB

GD-1920C-BB

LAN cable (CAT5,

STP, straight)

HUB

Model 18x4C-BB/19x4C-BB, GD-1920C-BB,

Model 18x4C/19x4C, GD-1920C

Model 17x4C or GD-1720C

Model 18x4C-BB/19x4C-BB, GD-1920C-BB,

Model 18x4C/19x4C, GD-1920C

Model 17x4C or GD-1720C

: Standard supply

: Local supply

: NavNet VX2

: Option for NavNet VX2

v

Page 8

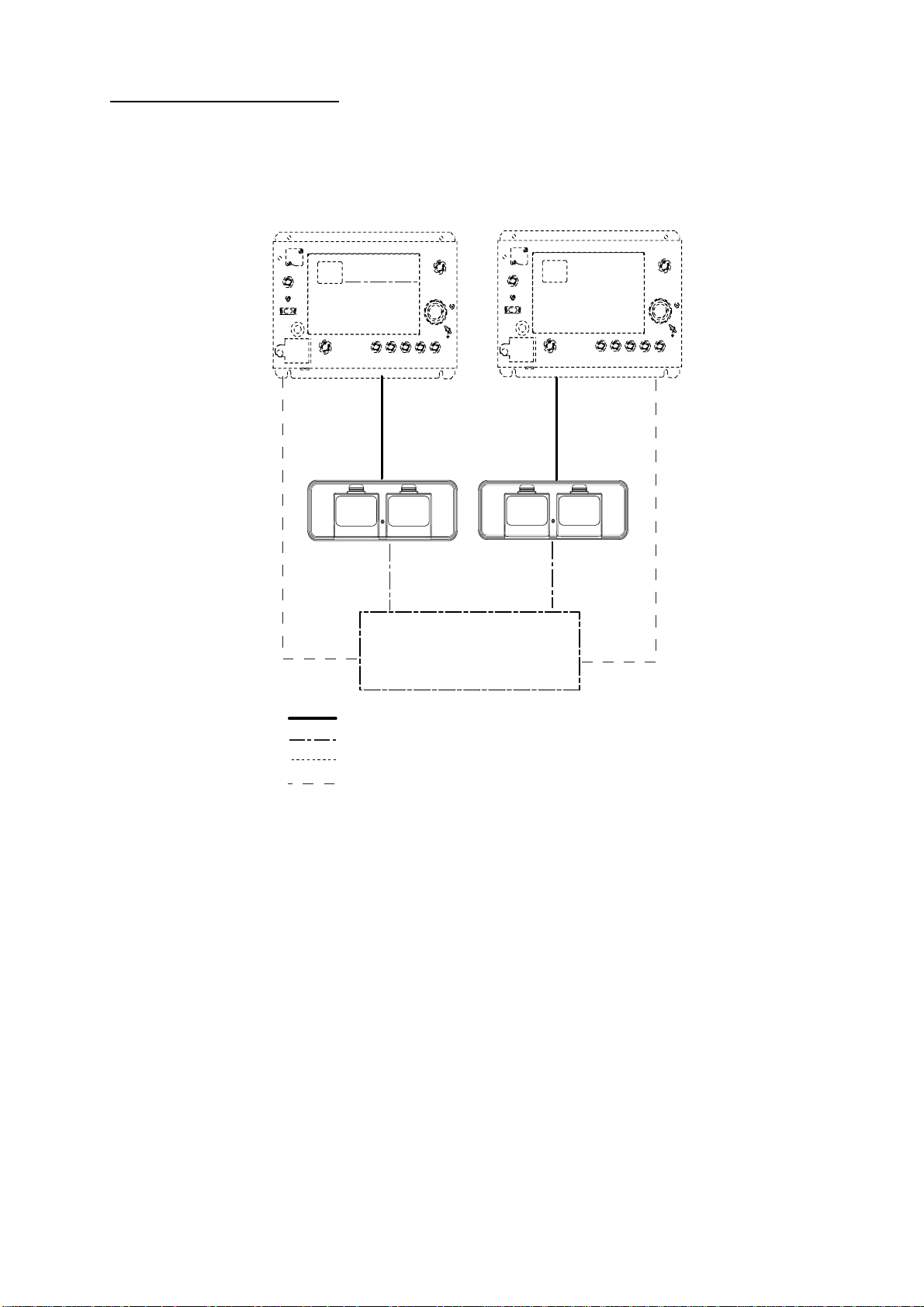

Connection for two CU-300

Model 18x4C-BB/19x4C-BB

GD-1920C-BB

Power cable

MJ-A3SPF0026-050C

CU-300

or 100C

LAN cable (CAT5,

STP, straight)

Model 18x4C-BB/19x4C-BB

GD-1920C-BB

CU-300

HUB

: Standard supply

: Local supply

: NavNet VX2

: Option for NavNet VX2

vi

Page 9

EQUIPMENT LISTS

Standard supply

Name Type Code No. Qty Remarks

Memory Card Interface

Unit

Installation Materials

(Select one.)

CU-300 - 1

CP03-27400 000-081-570 1 set For 5 m, MJ-A6SPF00 17-050C,

MJ-A3SPF0026-050C, and

CP03-27401

CP03-27410 000-081-571 1 set For 10 m, MJ-A6SPF0017-

100C, MJ-A3SP F00 26- 10 0C,

and CP03-27401

CP03-27440 000-083-403 1 set For 5 m, MJ-A3SPF0026-050C

and CP03-27401

CP03-27450 000-010-245 1 set For 10 m, MJ-A3SPF0026-100C

and CP03-27401

Option a l supply

Name Type Code No. Qty Remarks

Hanger FP03-10201 008-539-530 1 set For desktop mounting

Console Mounting

Kit

FP03-10203 001-011-710 1 set For bulkhead mounitng

Cable Assy MJ-A3SPF0026-050C 000-157-944-10 1 5 m, power cable

MJ-A3SPF0 026 -100C 000-157 -945- 10 1 10 m, power cable

MJ-A6SPF0017-050C 000-159-705-11 1 5 m, Ethernet cable

MJ-A6SPF0017-100C 000-159-706-11 1 10 m, Ethernet cable

vii

Page 10

1. MOUNTING

d

rod

The memory card interface unit can be flush mounted in a console, or mountd on a desktop or the

overhead.

Choose a m ounting location for th e unit consid ering the follow ing points:

• Leave s uffic ient space aro und the unit t o fa c ilita t e c hec k ing and ma int enance. See outline

drawing at the bac k o f this m anual for re c om m ended ma int enance spac e.

• Locate th e unit well aw ay fr om ex haust gas es and other act iv e gases.

• The location should be well ventilated.

• Choose a location where shock and vibration are minimal.

• Only the front panel is waterproofed.

Note: For flush mount or bulkhead mount, the DIP switch setting should be completed before

mountin g. See page 8.

1.1 Flush Mounting

1. Prepare a cutout in the mo unt ing location as below.

150.5+0.5

143+1

24+0.5

54+1

R2.25

2. Screw four threaded rod (M4×50, supplied) into holes on the front panel (reverse side).

Screw threaded rods into

these holes.

4.5

Rear view

3. Insert the unit into the cutout made at step 1.

4. Fix the unit with four spring, flat washers, and hex. nuts.

1

Threade

Page 11

Spring washer, flat washer and hex. nut

20

42

171

60

98

1.2 Desktop Mounting

This meth od requires th e optional h anger FP03 -10201.

Name: H anger (Typ e: F P03-10201, Code no. : 008-539-530)

Contents of kit FP03-10201

Name Type Code No. Qty

198

145

#100

Hanger 19-023-3081 100-316-250 1

Self-tapping screw

Pan head screw

φ5×20, SUS304

M4

×10, C2700W

000-162-608-10 4

000-163-167-10 4

1. Fasten four pan head screws (M4×10) to fix the hanger to the unit.

2. Fix the hanger with unit to the mounting location with four self-tapping screws (φ5×20).

2

Page 12

198

#20

163+0.5

171

179

#20

6 Fixing hole

100+0.5

41.5

2.2

62

42

198

#100

1.3 Overhead Mounting

This met hod requires th e optional kit F P03-10203.

Name: C onsole mounting kit (Ty pe: FP03 -10203, Code no.: 001-011-710)

Contents of kit FP03-10203

Name Type Code No. Qty

Mounting plate 19-023-3091 100-316-260 1

Pan head screw

Hex. nut M4 SUS304 000-863-106 4

Flat washer M4 SUS304 000-864-126 4

Spring washer M4 SUS304 000-864-256 4

M4

×10 C2700W

000-163-167-10 4

3

Page 13

1. Prepare four fix ing holes in the bulkhead whose dimensions are as shown below.

5

120+0.5

120+0.5

2. Fast en four pan he ad screws (M 4) to fix the mounting pl at e t o the unit.

3. Insert four studs at th e top o f th e mounti ng pla te in fi xi n g h oles made at ste p 1, and then pass

spring washers, flat washers and hex. nuts onto in that order from inside the bulkhead.

4. Tighten hex nuts to fix the unit.

#20

120+0.5

171

77

120+0.5

31.5

2.2

#20

Max. 8

102

42

14

63

198

Dimensions for overhead mounting

Nut (M4)

#100

4

Page 14

2. WIRING

There are three types of connec t ions:

• Connec t ion between one proc es s or unit and memory car d int erface un it .

• Connec t ion between one memory card int erf ace unit and multiple processor unit s

• Connection between two memory card interface un its and two pr ocessor units.

Note that the total number of card slots is maximum four in a series.

2.1 Connection between One Processor Unit and

One Memory Card Interface Unit

Ethernet cable

MJ-A6SPF0017-050C or 100C

POWER

GND

F.G.

321

NTSC/PAL

RGB OUT

OPTION

OUTPUT

12 VDC

CARD SLOT

0.3 A MAX

REMOTE FMD DISPLAY

DJ-1

INPUT

2

1

12-24 VDC

3

GND

NETWORK

Power cable

MJ-A3SPF0026-050C or 100C

DATA 3

CONT DATA 1

DATA 2

Ground wire

IV-1.25sq

(Local supply)

Ground

5

Page 15

2.2 Connection betwe en O ne Mem o ry Car d I nter fac e

Unit and Multiple Processor Units (Max. Three

Units)

Prepare th e f ollowing cables and connectors :

• Commercial LAN cable (CAT5, STC, straight)

• Cable assy, MJ-A6SPF0014-010C/050C/100C/200C/300C (option for NavNet VX2)

• Converter connector, MJA6SERMD/TM11AP8-005 (option for NavNet VX2)

Power cable

POWER

GND

F.G.

321

NTSC/PAL

RGB OUT

OPTION

OUTPUT

12 VDC

0.3 A MAX

MJ-A3SPF0026-050C or 100C

REMOTE FMD DISPLAY

DJ-1

Ground wire

IV-1.25sq

(Local supply)

Ground

INPUT

2

1

12-24 VDC

3

CARD SLOT

GND

NavNet VX2-BB

Processor unit

NavNet VX2 or

NavNet VX2-BB

Processor unit

NavNet VX2 or

NavNet VX2-BB

Processor unit

NETWORK

DATA 3

CONT DATA 1

DATA 2

Cable assy

MJ-A6SPF0014-010C/

050C/100C/200C/300C

(Option for NavNet VX2)

LAN cable

(CAT5, STP, straight,

local supply)

HUB

Converter connector

MJA6SRMD/TM11AP8-005

(Option for NavNet VX2)

6

Page 16

2.3 Connection between Two Memory Card

Interface Units and Two Processor Units

Prepare th e f ollowing cables and connectors :

• Commercial LAN cable (CAT5, STP, straight)

• Cable as s y, MJ-A6SPF 0014-010C/050C / 100C/200C / 300C (option for NavNet VX2)

• Conve rt er c onnector, MJA6S ER M D / T M11AP8-005 (opti on for NavNet VX2)

Power cable

POWER

F.G.

321

0.3 A MAX

GND

OUTPUT

12 VDC

NTSC/PAL

RGB OUT

OPTION

INPUT

2

1

12-24 VDC

3

CARD SLOT

GND

NavNet VX2-BB

Processor unit

NETWORK

CONT DATA 1

MJ-A3SPF0026-050C or 100C

REMOTE FMD DISPLAY

DJ-1

DATA 3

DATA 2

Converter connector

MJA6SRMD/TM11AP8-005

(Option for NavNet VX2)

Ground wire

IV-1.25sq

(Local supply)

Ground

LAN cable

(CAT5, STP, straight,

local supply)

NavNet VX2-BB

Processor unit

POWER

F.G.

3

0.3 A MAX

2

GND

OUTPUT

12 VDC

NTSC/PAL

RGB OUT

OPTION

INPUT

2

1

12-24 VDC

3

CARD SLOT

GND

Cable assy

MJ-A6SPF0014-010C/

050C/100C/200C/300C

(Option for NavNet VX2)

REMOTE FMD DISPLAY

DJ-1

DATA 3

NETWORK

CONT DATA 1

DATA 2

Power cable

MJ-A3SPF0026-050C or 100C

HUB

Converter connector

MJA6SRMD/TM11AP8-005

(Option for NavNet VX2)

Ground wire

IV-1.25sq

(Local supply)

LAN cable

(CAT5, local supply)

Ground

7

Page 17

Setting of the IP address for the second memory card interface unit

When connecting two memory card interf ace uni ts, ch ange th e DIP swit ch se tting on the second

unit as below to change its IP address. Note that the second unit is exclusively for reading chart

card.

1. Unfas ten two pan head screws (M3x 8) , a wing bol t a nd a washer for MJ co nnector at the rear

of the unit.

2. Unfasten four screws and the connector at the location shown below to remove the front

panel.

3. Unfasten four pan head screws at the inner front chassis to remove it.

4. Pull out the inner chassis to it.

5. Set the #4 segment of DIP switch S1 as below.

4 3 2 1

OFF

ON

S1

6. Re-assemble the unit.

PCB 19P1050

8

Page 18

3. OPERATION

3.1 Basic Operation

Card box

Card drive

Power lamp

(green)

Card drive

Insert the appropriate chart SD card (or memory card) for your area as below. For details of SD

cards, see the operator’s manual for NavNet VX-2.

(Strage for two cards)

1. Open the card drive.

2. Insert the card (label side up) prior to turning on the power at NavNet VX2-BB.

3. Clo s e t he lid.

To remove the card, f ollow the instr uctions sh own on the display of NavNet VX2 an d then co nfirm

that the power lamp on the front panel lights. Do not read/write the data.

Power lamp

Lights (g reen): The pow er is on.

Blinks: The unit is reading/writing data.

Card box

You can s to re t w o SD cards h ere.

Note 1: When the connection between NavNet VX2-BB and memory card interface unit is wrong,

the NavNet VX2-BB searches for chart data in the SD card for 50 seconds, and then returns to

the norm al operation . Th e display look s fr oz en, howev er normal operation wil l be restarted af te r

the search is completed.

Note 2:

To prevent loss of card data if the power sudd enly goes of f, it is recomm ended that

you periodically back up data to an SD card.

9

Page 19

3.2 Priority of Card Drives

The pr io rit y of c ard dr iv es is aut om ati ca ll y s et af ter tur ni ng t he po wer on. T his pr io rit y or d er v ar ie s

depen ding on the numb er of card dri v es connect ed.

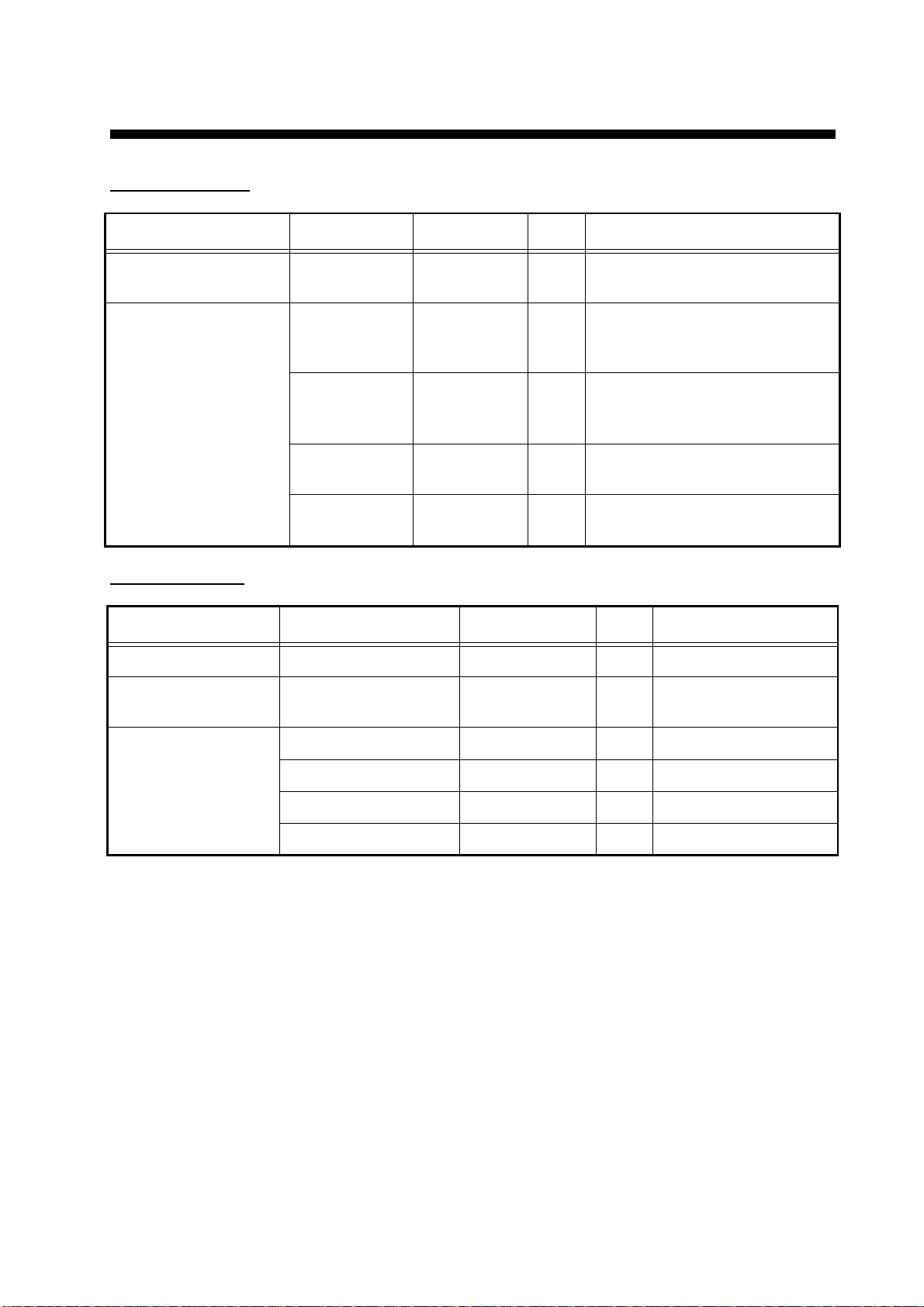

One memory card interface unit

2

CU-300

1

NavNet VX2-BB

Processor unit

3

NavNet VX2 or

NavNet VX2-BB

Processor unit

4

NavNet VX2 or

NavNet VX2-BB

Processor unit

HUB

Unit and available chart card and memory card locations

The num bers in the tab le refer to the correspon ding units in th e f igure abov e.

Unit

Available chart card

locations

Available memory card

location

11 2 3 42

3

4

NavNet VX2

NavNet VX2-BB

NavNet VX2

NavNet VX2-BB

1 2 3 43

1 2 3 42

1 2 3 44

1 2 3 42

10

Page 20

Two memory card interface units

1

2

NavNet VX2-BB

CU-300

Processor unit

HUB

3

4

NavNet VX2-BB

Processor unit

Unit and available chart card and memory card locations

The numbers in the table refer to the corresponding units in the figure

above.

CU-300*

*: For the second CU-300, DIP switch setting is necessary.

Unit (priority)

Available chart card

locations

11 2 3 42

31 2 3 42

Available memory card

location

11

Page 21

FURUNO

CU-300

SPECIFICATIONS OF MEMORY CARD INTERFACE UNIT

CU-300

1 GENERAL

1.1 Number of card slot 1

1.2 Card storage 2 SD-card

1.3 Ethernet 100BASE-TX/10BASE-T, auto-negotiation

1.4 Cable Connection RJ-45, STP LAN (CAT5)

1.5 Card type (at February 2007)

ADTEC AD-SDH512/1G/2G, AD-SDPS128M/256M/512M/1G

BUFFALO RSDC-S64M/S128M/S256M/S512M/S1G/S2G/G512M/G1G/G2G

HAGIWARASYS-COM HPC-SD256M/SD512M2/SD1GM2/SD2GM2/SD256TP/SD512TP/

SD1GTP/SD128T/SD256T/SD512T/SD1GT/SD2GT

I/O DATA SD-128M/256M/512M/1G/2G, SDP-256M/512M/1G/2G

Kingston SD/1GBFE, SD/2GBFE

LEXER SD256/512/1GB-231

PANASONIC RP-SDR512/01G/02G-J1A, RP-SD128MBL1A, RP-SD256BJ1A,

RP-SDK512/01G/02G-J1A

PQI QSDS-256/512/1G/2G

SANDISK SDSDB-256/512/1024/2048-J60, SDSDH-512/1024/2048-903

2 POWER SUPPLY

12 VDC: 0.14 A, 1.7 W or less

3 ENVIRONMENTAL CONDITIONS

3.1 Ambient temperature -15°C to +55°C

3.2 Relative humidity 93% at 40°C

3.3 Degree of protection IP22 (IP55: flush mount or front panel only)

3.4 Bearing vibration IEC 60945-4

3.5 CE marking IEC 60945-4

4 COATING COLOR

N3.0

SP - 1 E3550S01A

Page 22

PACKING LIST

A-1

CU‑300‑G5/G10[GENERAL用]

19AZ‑X‑9852 ‑1

1/1

NAME

OUTLINE

DESCRIPTION/CODE№

ユニット UNIT

メモリーカードインターフェイス

MEMORYCARDINTERFACEUNIT

CU‑300

000‑010‑244‑00

工事材料 INSTALLATIONMATERIALS CP03‑27440/27450

ケーブル組品MJ

CABLEASSY.

MJ‑A3SPF0026‑050C

MJ‑A3SPF0026‑050

000‑157‑944‑10

000‑149‑445‑00

ケーブル組品MJ

CABLEASSY.

MJ‑A3SPF0026‑100C

MJ‑A3SPF0026‑100

000‑157‑945‑10

000‑149‑446‑00

工事材料

INSTALLATIONMATERIALS

CP03‑27401

008‑539‑520‑00

図書 DOCUMENT

取扱説明書

OPERATOR'SMANUAL

OME‑35501‑*

000‑165‑406‑1*

Q'TY

1

1

(*1)

1

(*1)

1

1

(*1)は、仕様選択品を表します。

(*1)INDICATESPECIFICATIONSELECTIVEITEM.

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりません。

TWOTYPESANDCODESMAYBELISTEDFORANITEM.THELOWERPRODUCTMAYBESHIPPEDINPLACEOFTHEUPPER

PRODUCT.QUALITYISTHESAME.

(略図の寸法は、参考値です。DIMENSIONSINDRAWINGFORREFERENCEONLY.)

19AZ‑X‑9852

Page 23

工事材料表

,

A-2

INSTALLATIONMATERIALS

番号

NO.

1

2

3

4

名 称

NAME

六角ナット 一種

HEX.NUT

ミガキ平座金

FLATWASHER

バネ座金

SPRINGWASHER

寸切ボルト

THREADEDROD

略 図

OUTLINE

CODENO.

TYPE

型名/規格

DESCRIPTIONS

M4SUS304

CODE

NO.

M4SUS304

CODE

NO.

M4SUS304

CODE

NO.

M4X50SUS304

M4X50SUS304

CODE

NO.

008‑539‑520‑00

CP03‑27401

000‑863‑106‑00

000‑864‑126‑00

000‑864‑256‑00

000‑162‑679‑10

000‑147‑539‑00

数量

Q'TY

4

4

4

4

03GO‑X‑9403

用途/備考

REMARKS

‑1

1/1

型式/コード番号が2段の場合、下段より上段に代わる過渡期品であり、どちらかが入っています。 なお、品質は変わりませ

ん。

TWOTYPESANDCODESMAYBELISTEDFORANITEM.THELOWERPRODUCTMAYBESHIPPEDINPLACEOFTHEUPPER

PRODUCT.QUALITYISTHESAME.

(略図の寸法は、参考値です。 DIMENSIONSINDRAWINGFORREFERENCEONLY.)

FURUNO ELECTRIC CO .

LTD.

03GO‑X‑9403

Page 24

Feb.13'07R.Esumi

D-1

Page 25

Feb.13'07R.Esumi

D-2

Page 26

Feb.13'07R.Esumi

D-3

Page 27

Page 28

9-52 Ashihara-cho,

*

00016540610

**00016540610

*

Nishinomiya, 662-8580, JAPAN

Telephone : +81-(0)798-65-2111

Fax :+81-(0)798-65-4200

The paper used in this manual

is elemental chlorine free.

・FURUNO Authorized Distributor/Dealer

All rights reserved.

Pub. No. OME-35501-A

(HIMA ) CU-300

Printed in Japan

A : MAY 2007

*00016540610**00016540610*

* 0 0 0 1 6 5 4 0 6 1 0 *

Loading...

Loading...