Page 1

MARINE RADAR

MODEL

MODEL 1622

Page 2

C

9-52, Ashihara-cho,

Nishinomiya, Japan

Telephone: 0798-65-2111

Telefax: 0798-65-4200

All rights reserved.

Printed in Japan

Your Loc al Agent/Dealer

FIRST EDITION: FEB. 2000

B: SEP. 12, 2000

(KAOK)

PUB. No. SME-34520-B

MODEL 1622

Page 3

CONTENTS

Chapter 1. General

1.1 Display Unit.................................................................. 1

1.2 Scanner Unit.................................................................. 2

Chapter 2. Block Description

2.1 General.......................................................................... 3

2.2 Display Unit.................................................................. 4

2.3 Scanner Unit.................................................................. 5

2.4 Functions of Each Circuit board ................................... 6

Chapter 3. Adjustment

3.1 Display Unit.................................................................. 13

3.2 Scanner Unit.................................................................. 14

Chapter 4. Maintenance

4.1 Maintenance Parts......................................................... 15

4.2 Replacement of Major Parts.......................................... 16

4.3 How to change system program.................................... 21

Chapter 5. Troubleshooting

5.1 Maintenance Menu........................................................ 22

5.2 Error Messages.............................................................. 23

5.3 Troubleshooting Matrix table........................................ 23

5.4 Test points on Each Board ............................................ 25

Exploded View

Schematic Diagram

Electrical Parts List

................................................................. D-1

....................................................... S-1

....................................................... E-1

Page 4

Chapter 1. General

1.1 Display Unit

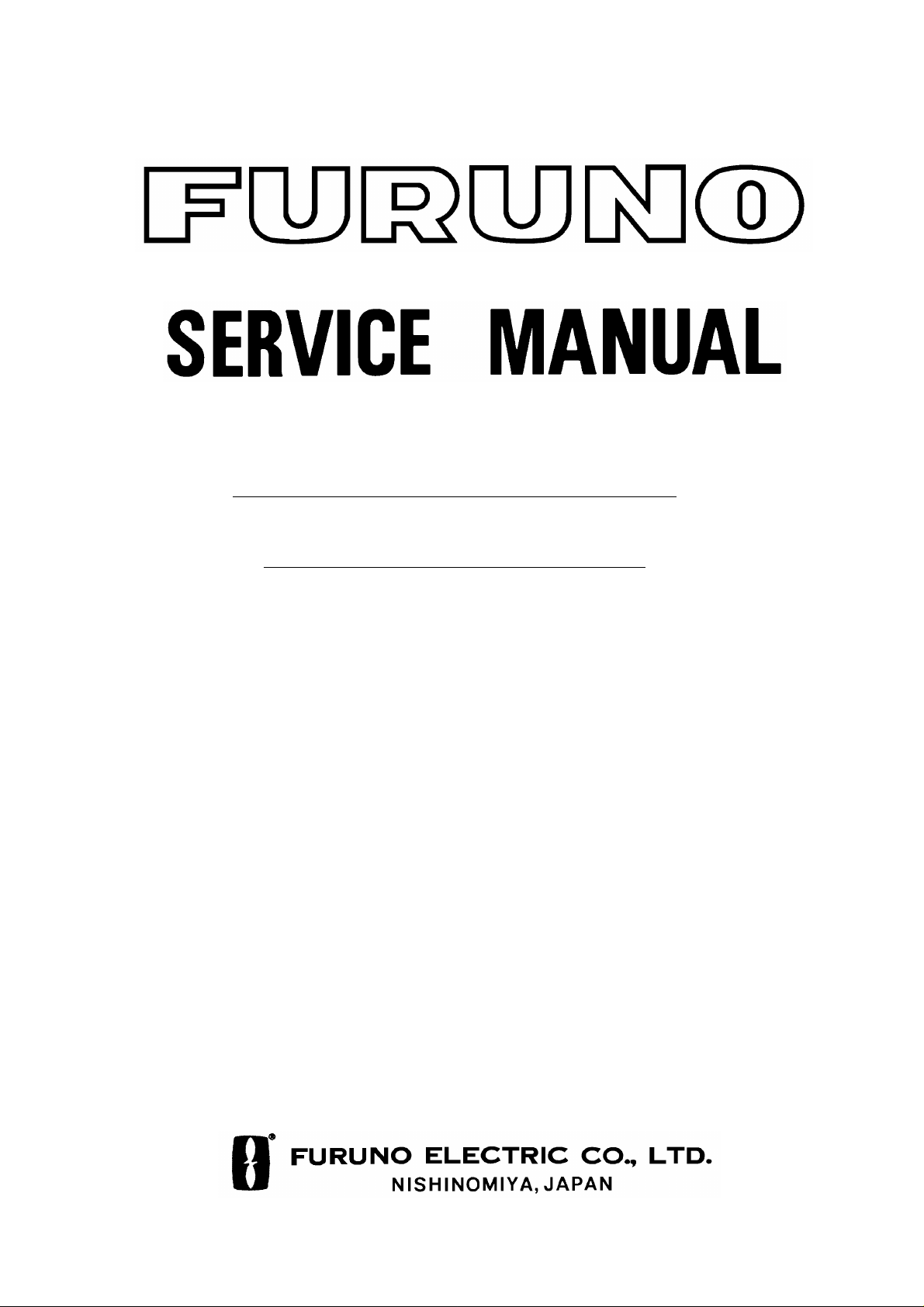

All parts are sandwiched together and fastened by four screws and three connector fixing nuts

from the rear side.

Resin cover

Shield cover

DU Board

LCD Display

PNL pcb

Panel cover

Figure 1-1. Construction of Display Unit

Protection against EMI

Many radars use conductive paint inside their covers to protect against EMI (Electro Magnetic

Interference). This model, however, is not painted, but has a shield cover over the DU board for

protection against EMI.

Waterproofs

The display unit conforms to the IEC standard IPX5; namely, waterproof against water jets. Even

the small hole to the right of the arrow keys, which is where the aural alarm is released, is

waterproof. A “breathing sheet” between the panel cover and the buzzer all ows ai r to pass and

prevents water from being drawn into the enclosure during atmospheric pressure changes.

1

Page 5

1.2 Scanner Unit

1.2 Scanner Unit

The scanner unit mainly consists of INT Board (03P9271), IF AMP Board (03P9269), MIC (RU-

9458), radiator, antenna motor, reed switch which generates HD signal, magnetron, and MD

Board

(03P9270).

Power to Scanner Unit

The ship’s mains is directly supplied to the scanner unit, where various voltages are made.

Therefore, if the antenna cab le length o f 12VDC set is 20m or more, scanner rotation may

be abnormal due to voltage drop. If the antenna cable is more than 20m, modify the unit

to 24VDC set.

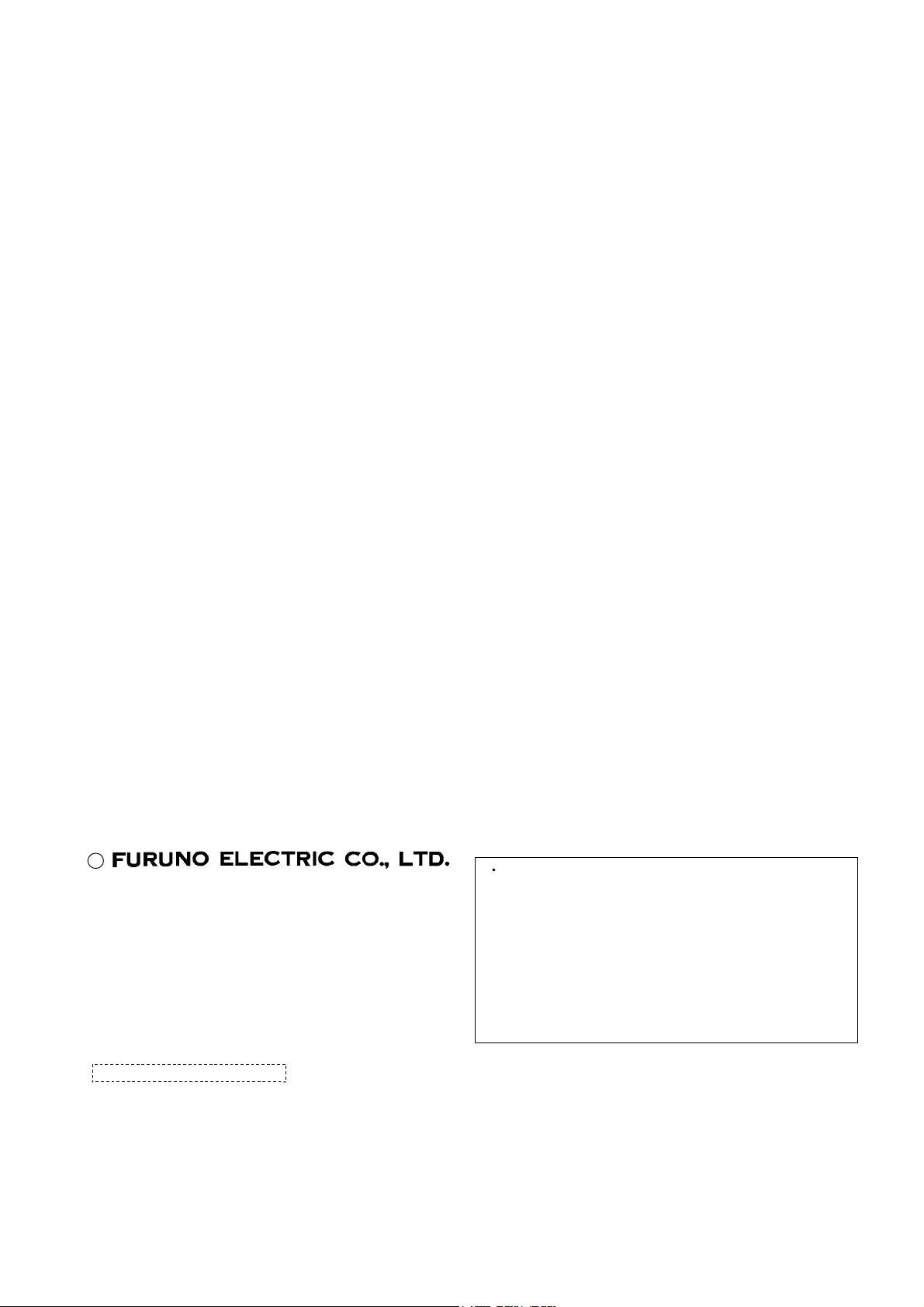

Antenna Cable

Both the scanner unit and the display unit have a CPU. T he y communicat e with each other on

two lines, “COM (HOT)” and “COM (COLD)”. The result: the number of lines in the cable was

reduced.

1 GAIN

2 STC

3 TUNE

4 TUN.IND

5 MOTOR(+)

6 MOTOR(

7BP

8HD

9 P/L-A

10 P/L-B

11 TRIGGER

12 VIDEO

13 GND

14 +12V

15 -12V

16 GND

17 SHIELD

Conventional radars MODEL 1622

-

)

COM (HOT) 1

COM (COLD) 2

BP/HD 3

TRIGGER 4

VIDEO 5

GND 6

S.M. (HOT) 7

S.M. (COLD) 8

GND 9

SHIELD 10

Figure 1-2 Antenna Cable

2

Page 6

Chapter 2. Block Description

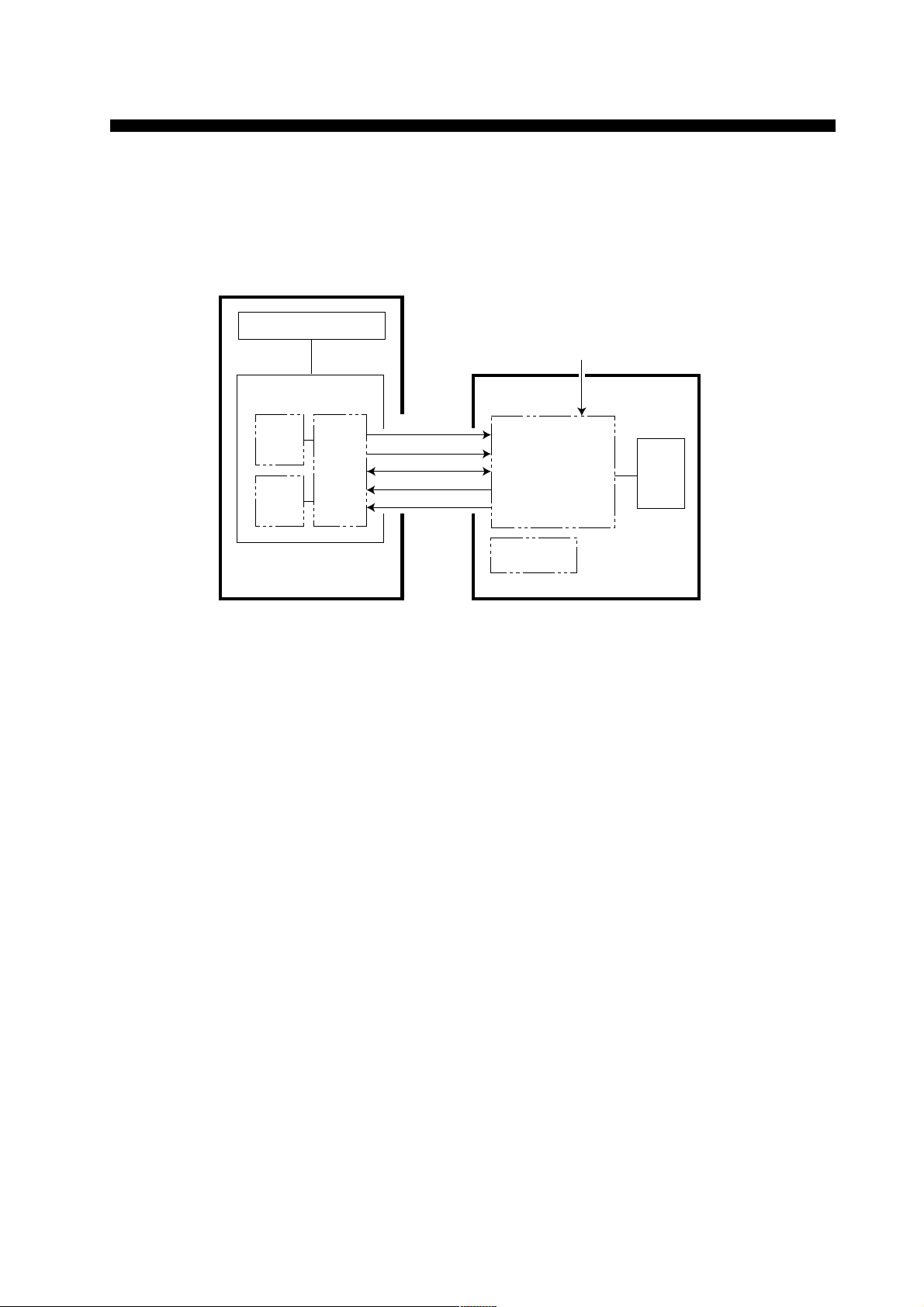

2.1 General

The CPU on the DU board of the display unit communicates with the CPU on the SD board of

the scanner unit in RS-422 format.

Radiator

Ship’s mains

Transceiver

MD

Board

Board

IF

Board

INT

Video signal

BP/HD

Communication (H.C)

Trigger

Ship’s mains (H.C)

Display Unit

DU Board

Signal processor

& power supply

PNL Board

LCD

Scanner Unit

Figure 2-1. Simplified Block Diagram

The trigger pulse from the DU board is modulated at the MD board to oscillate the magnetron.

The echo received by the antenna is amplified by the IF amplifier and is fed to the DU board as a

video signal. The DU board converts the analog signal to digital signal and processes to display

it on the LCD.

Bearing pulse (BP) and heading signal (HD) are generated in the scanner unit and received by

the DU Board in the display unit.

3

Page 7

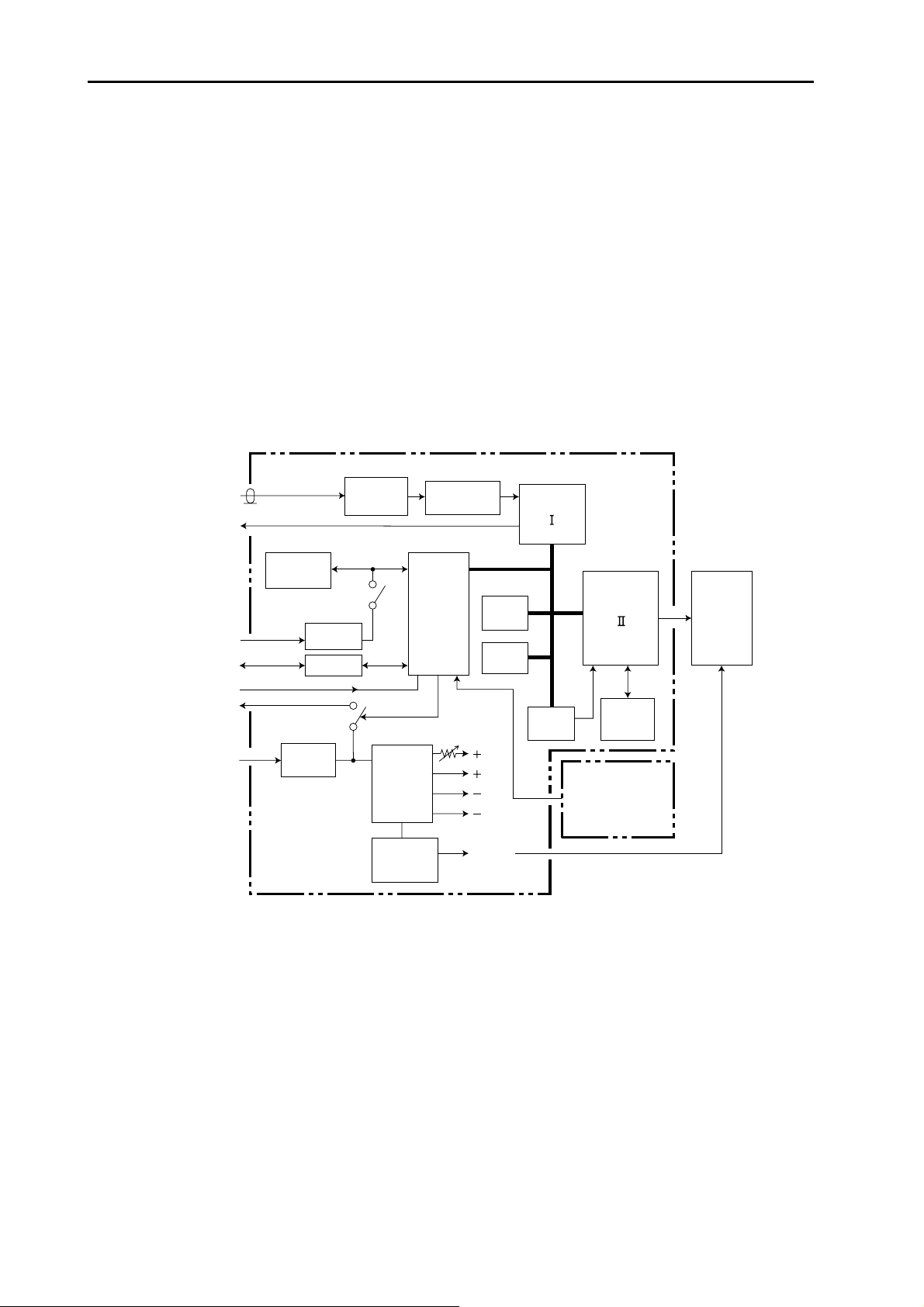

2.2!Display Unit

2.2 Display Unit

The display unit features that;

1) DU Board produces LCD back-light voltage of 210VAC.

2) An artificial echo signal (instead of the video signal) can be selected.

3) The interface comm unicates wit h t he scanner unit in RS - 422 format.

The TX trigger is made at the gate array (!) and is fed to the scanner unit. The received video

signal is A/D converted and is sampled at the gate array (!). The echo on each sweep is stored

on the V-RAM via the gate array ("). Upon receiving the heading pulse, the stored data are

output to the LCD in four shades of gray, according to echo strength.

From Scanner

To Scanner

From NAV AID

To Scanner

From Scanner

To Scanner

Ship’s Mains

VIDEO

TRIGGER

EEPROM

U105

NMEA

RS-422

BP-HD

FILTER

L1,L2

DU Board

03P9268

I/F

I/F

U107,C104

U114

U126

U119

FTC

R112

DC-DC

CONV.

U6,Q6,T1

R-C

CONV.

Q52,Q53,T2

A/D CONV.

U101

CPU

U108

ADJ

Back-Light volt.

AC210V

ROM

U115

RAM

U109

5V

12V

6V

22V

GATE

ARRAY

(

)

U111

GDC

U112

GATE

ARRAY

(

)

U108

V-RAM

U113

U116

PANEL Board

PNL9194

LCD

03S9461

Figure 2-2. Block Diagram of Display Unit

4

Page 8

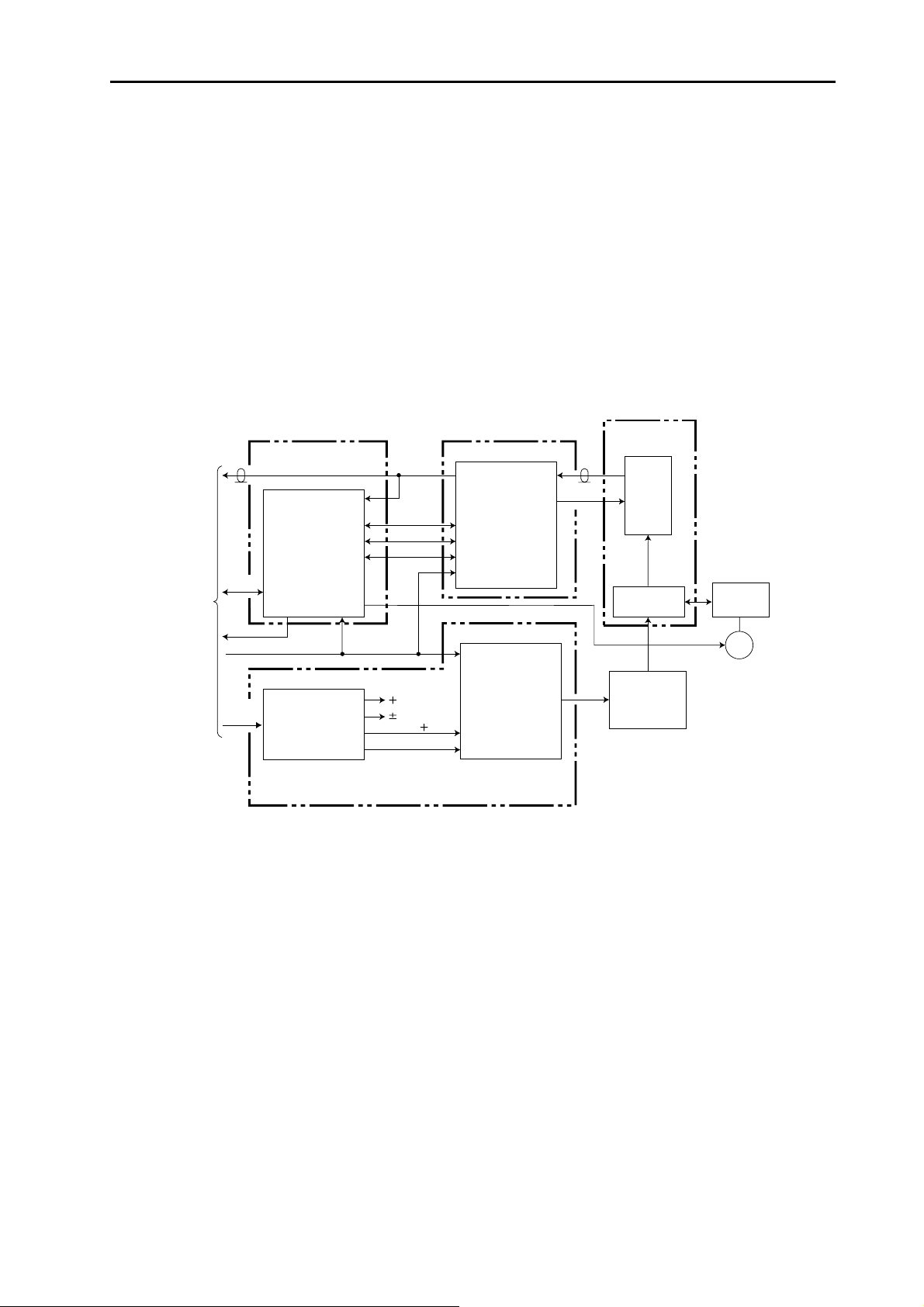

2.3!Scanner Unit

2.3 Scanner Unit

The scanner unit features that ;

1) The powers supply circuit for the scanner unit is provided on the SD board.

2) The SD board in the scanner unit communicates with the display unit.

3) Auto-gain and auto-STC circuits make operation easy.

The TX trigger from the display unit is modulated and oscillates the magnetron. The received

echo is fed to the MIC and is amplified at the IF amp. The output is divided two lines: one is led

to the display unit and the other is applied to the interface for auto-gain and auto-STC functions.

Display

Unit

INT Board 03P9271

INTERFACE

Auto Gain

Auto STC

Auto Tune

Communication

COM

Motor Drive

BP/MD

TRIGGER

SHIP’S

MAINS

POWER

SUPPLY

Figure 2-3. Block Diagram of Scanner Unit

IF Board 03P9269

VIDEO

GAIN

A/C SEA

TUNE

12V

5V

8V

TX-HV

MD Board 03P9270

IF AMP

MODULATOR

TUNE

IF

Magnetron

MIC

RU-9458

(U801)

Circulator

E3588

(V801)

ANT.

03P9267

M

RM-9455

(B801)

5

Page 9

2.4!Functions of Each Cir c uit board

2.4 Functions of Each Circuit board

2.4.1 Display Unit

The display unit consists of DU board (03P9268), PANEL board (PNL9194), and LCD indicator

(03S9461).

PANEL Board

Mounted on this board are the operating keys, panel-illuminating LEDs, and electrical buzzer,

constituting the man-machine interface.

DU Board (03P9268)

The reference oscillator U125 is a quartz oscillator which generates an accurate and stable

reference frequency signal. This reference frequency signal is the source of the transmission

trigger, the clock for video signal processing in the display unit, the time-base signal, the

reference clock for LCD display, the reference clock for CPU, and so on.

According to the distance range selected in the panel operation, CPU computes the ratio of

dividing the reference frequency and sends the data to the gate array U111 (radar signal

processing circuit). Based on the data, U111 creates the transmission trigger from the reference

frequency signal.

This radar intentionally varies the pulse repetition frequency of the transmission trigger to

prevent the interference signals fr o m other radars.

The IF video signal from scanner unit inputs to the vi deo circuit on the DU board.

The video circuit includes FTC circuit that rejects the reflecting signals from the rain and snow.

CPU switches on or off the FTC function according to the panel operation.

The IF video signal is converted by a A/D converter to the three-level digital signal, which inputs

to the gate array U111 (radar signal processing circuit). In U111, the input digital IF video signal

is sampled with the sampling clock corresponding to the range setting. Further in U111, when

the interference rejector is turned on in the menu, each receiving video signal is correlated with

the corresponding transmission to reject the interference signals from other radars. The video

signal output from U111 is written in the VRAM U116 for the display.

The antenna bearing signal and heading signal are input to CPU from scanner unit. The heading

correction data, obtained at heading alignment (instllation menu) is stored in EEPROM U105,

and CPU computes the correct direction of the antenna, using the correction data. The data to

correct the difference between the transmitting and receiving timing is obtained at TX time delay

adjustment (installation menu) and is also stored in EEPROM U105. The correction is carried

out in U118.

6

Page 10

2.4!Functions of Each Cir c uit board

While the target scanning system of the radar uses the method of R#$ coordinates, LCD

display of this radar employs the method of X-Y coordinates, which is similar to so called TVsweep method.

The sweep time of the LCD display is independent of that of the radar scanning system, so

VRAM U116 is provided as the interface between them.

In order to write the radar echo signal received after every transmission trigger on VRAM U116,

CPU converts the antenna bearing signal $ into the values of SIN$ and COS$ and send

them to U118. U118 further converts them to X-Y coordinates of RSIN$ and

RCOS$. These values are used as the address to write the radar video signal on VRAM U116.

VRAM U116 also holds the past video signal for display f or a trail time specified by the panel

operation.

According to the settings of the operating panel, CPU writes on VRAM U113 the display data

such as the fixed range rings, EBL, VRM, cursor, guar d alarm range, and scale of azi mu th angle.

Further, CPU also writes on VRAM U113 the character and numbers to be displayed on the

screen. For writing these data, GDC U112 is used.

The data writing/reading onto/from the VRAM is carried out by U118 in time- sharing method.

The display data are read out from VRAM and sent to LCD display using GDC U112.

The signals for controlling scanner unit (including the transceiver) are converted to RS-422 serial

signals in U119 and sent through a balanced RS-422 cable so that the signals may not be affected

by external noise. The control signals include those for switching the transmission on/off,

adjusting the transmitting pulse width and IF amplifier gain, and adjusting STC.

The information from the navigational aid is received through U114 and U126 to be displayed on

the radar screen.

The unit requires power supply source ranging 10.2 to 31.2 V DC. This voltage meets the

voltage requirement for ships: 10% lower and 30% higher than 12V/24V ship’s mains. This DC

power is supplied through noise filters, L1, and L2, to the pulse-width-controlled DC-DC

converter mainly consisting of U6, Q6, and T1, which generates the stable voltages of +5 V, +12

V, -6V, and -22 V that are needed in display unit. The voltage +5 V is mainly used for the digital

circuits, +12 V and -6 V are used for the video and other analog circuits, and –22 V is for the

LCD display. The DC-AC inverter consisting of Q52, Q53, and T2 generates AC 210 V which is

used for the backlighting of the LCD display.

If the power supply is reverse-connected to the radar, the reverse-polarity protector activates so

that the circuit breaker is tripped or fuse is blown off to prevent the damage to the unit.

The power supply circuit contains low- and high-input voltage protectors.

7

Page 11

2.4!Functions of Each Cir c uit board

2.4.2 Scanner Unit

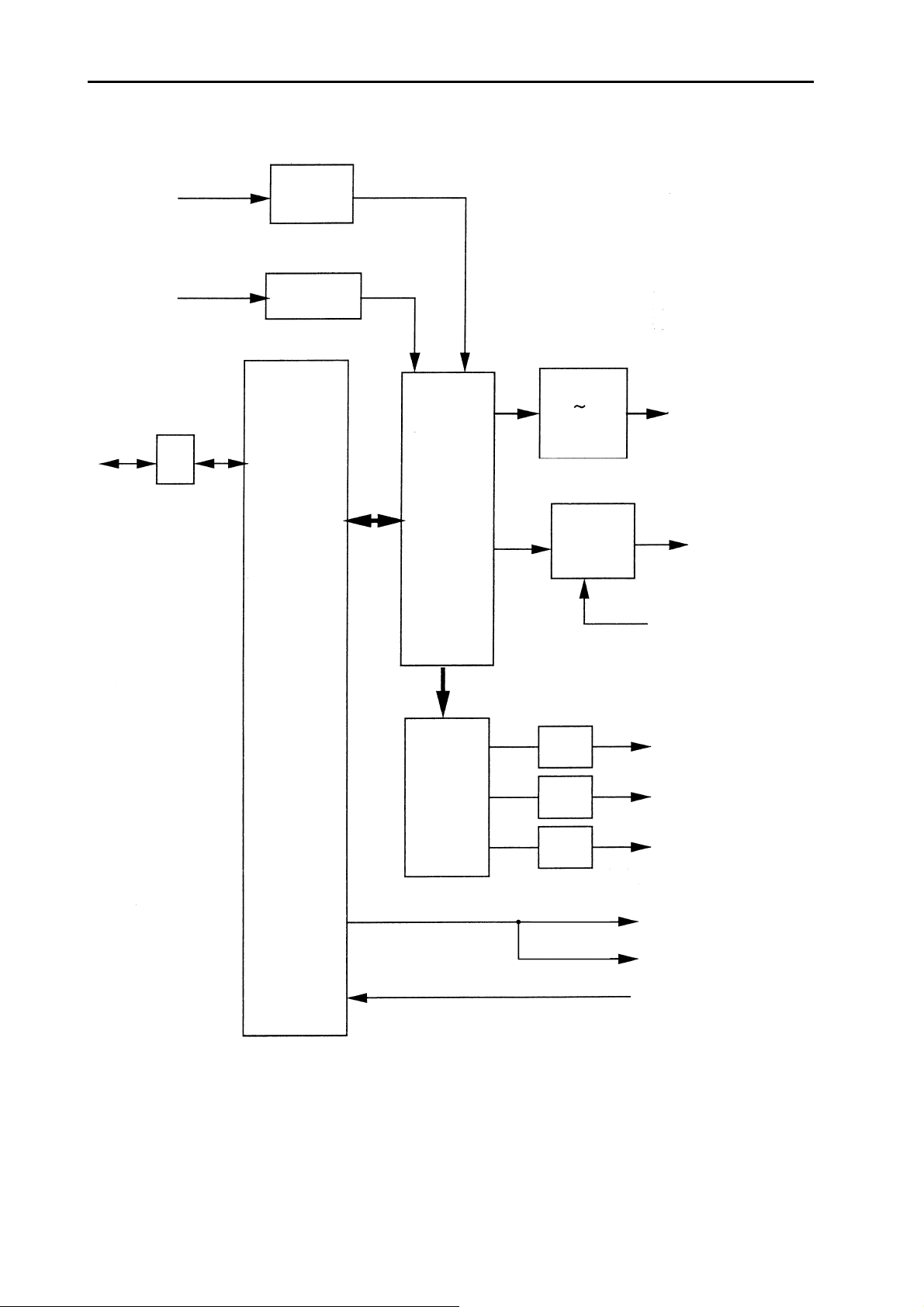

INT Board (03P9271)

INT board contains: one-chip CPU U3, that includes the RAM, ROM, and analog ports; U5

including I/O ports the stepping motor drive circuits; and U7 including the A/D converter which

outputs tuning, gain, and STC control signals.

The output from U7 is used to control the STC and gain of the IF amplifier and the frequency of

microwave local oscillator for MIC.

The operating conditions of the radar that have been set on the operating panel of the display unit

are sent to the CPU U3 on the INT board through the RS422 communication line. The CPU U3

controls the stepping motor drive circuit U5 which drives the stepping motor to rotate the

antenna. The antenna azimuth signal is created in the stepping motor drive circuit and mixed

with the heading signal (S801), and sent to the display unit.

In order to change the transmitting radar pulse length according to the selected range, the pulse

width information is sent from the INT board to the modulation circuit on the MD board.

There are the automatic mode and manual mode to adjust the gain of the IF amplifier. In the

automatic mode, CPU U3 monitors the video signal from the IF amplifier, and the monitored

signal inputs to the A/D converter U7 through the I/O port U5, and the A/D converter output

controls the IF amplifier gain. In the manual mode, the signal set by manual setting inputs to the

A/D converter, and the A/D converter output controls the gain of the IF amplifier.

This radar employs an automatic tuning system in which the main bang signal from the IF

amplifier is amplified and inputs to CPU U3 as the signal indicating the tuning level.

The CPU U3 controls the output of the A/D converter U7 so that the tuning indication level may

become maximum.

The adjustment of STC is also carried out in the same way as the gain adjustment.

IF Amplifier Board (03P9269)

The IF amplifier, the intermediate frequency of 60 MHz and band width of 7 MHz, consists of

Q1, U1, U2, and a buffer Q4. This board includes the gain and STC control circuits consisting of

Q2 and Q3. Another circuit, consisting of Q5 to Q10, detects the main bangs to indicate the

tuning level.

8

Page 12

2.4!Functions of Each Cir c uit board

RU-9458 Module

This module includes the circulator and MIC circuit that converts the microwave frequency to

the intermediate frequency.

The circulator switches between the transmitting and receiving microwave circuits so that the

transmitting radio energy may be efficiently transmitted to the antenna without leaking to the

receiver side and the receiving radar signal fr o m the antenna may be sent with efficiency t o the

receiver without leaking to the transmitter side.

The receiver side is provided with the waveguide to coaxial converter, diode limiter, and

balanced mixer. The diode limiter, set after the converter, protects the balanced mixer from the

excessive input power, and the mixer converts the input microwave signal to the 60-MHz IF

signal.

A voltage-controlled FET oscillator outputs the signal to the mixer.

MD Board (03P9270)

The power supply circuit and modulation circuit of the scanner unit (transceiver) are mounted on

the MD board.

There are provided two DC-DC converter power supply circuits: one supplies –6 V, +5 V, and

+12 V to the circuits except the magnetron and the other supplies power to the magnetron heater

and TXHV. The two DC-DC converters generate stable voltage outputs with Q803 and Q832

driven by the pulsewidth controllers U801 and U805.

The magnetron current, -6 V, +5 V, +12 V, +8 V (magnetron heater voltage), and TX HV can be

checked at the check points TP804 on the board.

In the magnetron modulation circuit, the transmitting pulse waveform is determined by the oneshot multivibrator U851 which is triggered by the transmitting trigger pulse. The pulsewidth of

the multivibrator is set by the time constant which is determined by the pulsewidth control signal

from INT board. The output of the multivibrator inputs to the FET switching transistor Q857

through transistor buffer Q853 and variable resistor VR851. The VR851 presets the voltage for

driving Q857 to determine the magnetron output power.

9

Page 13

2.4!Functions of Each Cir c uit board

VIDEO

RS422

TRIG

U1

U4

Amplifier

Q1

Buffer

U5

I/O PORT

BP

Q6

Q3

Buffer

Q11 Q12

Q13

Mixer

Antenna

motor drive signal

BP/HD

HD Marker

U3

CPU

U7

D/A

Buffer

Q14

Q15

Q16

PL B

PL A

TUNE IND

Figure 2-4. Block Diagram of INT Board (03P9271)

GAIN

Control

STC

Control

Tune

Control

10

Page 14

TX HV

8V

2.4!Functions of Each Cir c uit board

MAG.CUR.

TUNE GATE

6V

CR831

12V

CR832

5V

U804

Regulator

VR801

T802

CR837

CR838

Q832

CR836

U805

Inverter driver

L851

TP804

MAG.CUR. HV.CHECK5V 8V

12V

CR855

T851

Medulation

Q857

transformer

Q855

VR851

Q853

Q856

Buffer

Buffer

Q801

6V

Q801

Pulse width

Q803

Ship’s mains

controller

Q801 Q802

Q805 CR804

Error detector

Q851,Q852

PL-A

Figure 2-5. Block Diagram of MD Board (03P9270)

11

Pulse width

decoder

PL-B

U851

Pulse width controller

TRIG

Page 15

2.4!Functions of Each Cir c uit board

STC Control

GAIN Control

Trigger

VIDEO

Output

TUNE GATE input

TUNE IND output

Q2 Q3

GAIN

STC

Controllers

Q4

Buffer

U2 3rd

IF AMP

Video detector

60MHz IF

LC filter

U1

2nd

IF AMP

Q5 to Q10

Tune level

detector

60MHz IF

LC filter

Figure 2-6. Block Diagram of IF AMP Board (03P9269)

Q1

Q1

1st

1st

IF AMP

IF AMP

60MHz

IF-IN

12

Page 16

Chapter 3. Adjustment

(

)

DANGER

Both display and scanner units use high voltage electricity, which

endanger human life. Precautions must always be exercised when

reaching inside the unit. (1 kVAC for LCD backlighting and 300

VDC for TX)

3.1 Display Unit

Voltage check

Remove the resin cover, and measure each voltage. It is not necessary to open the shield cover

on the DU board.

Table 3-1

Item Setting Test point Ratings Adjuster

"

"

&

&

5 V

12 V

22 V

6 V

TX

#

8NM

ST-BY

ST-BY

ST-BY

$

#"$%

TP4

J1#7

J1#10

J1#9

#"$%

#"$%

#"$%

#&$

TP5

#&$

J1#5

#&$ &

J1#5

#&$ &

J1#5

4.95'5.05 Vdc

11.2'12.4 Vdc

'&

22.9

6.0

'&

20.7 Vdc

5.0 Vdc

VR2

J1

TP4

"

5V

VR2

Figure 3-1. Test points on DU Board

13

Page 17

3.2 Scanner Unit

Voltage check

Open the radome, and measure each voltage with the modulator cover removed.

Table 3-2

Item Setting Check point Rating Adjuster

"

12 V

"

8 V

heater volt.

TX-HV

(divided)

Magnetron

current

ST-BY

ST-BY

TX(Note)

(3NM)

TX(Note)

(3NM)

TP804#3

TP804#4

TP804#6

TP804#4

TP804#7

TP804#4

TP804#5

TP804#4

#"$%

#&$

#"$%

#&$

#"$%

#&$

#"$%

#&$

11.9'12.1 Vdc

7.8'8.2 Vdc

8.5'9.35 V

2.8'3.6 V

3.2!Scanner Unit

VR801

VR851

Note) To transmit with scanner rotation suspended, turn on the power while pressing and

holding down the%&'key. After one minute, the radar is in transmission mode.

VR851

VR801

TP804

Figure 3-2. Test points on MD Board

14

Page 18

Chapter 4. Maintenance

This unit is designed for board level maintenance, not component replacement.

4.1 Maintenace Parts

Table 4-1 Maintenance Parts

Parts Type Code No. Remarks

DU Board 03P9268 008-499-680

PNL Board PNL9194 008-481-680

MD Board 03P9270 008-499-650

IF Board 03P9269 008-499-640

INT Board 03P9271 008-499-660

LCD Unit DG52Y-5MC 000-142-310

MIC S-RX50/RU-9458 000-142-269

Magnetron E3588 000-142-270

Antenna Motor RM-9455 000-142-252

Fuse FGBO-A, 5A, 125 V 000-549-064

Program ROM PROM0359158101 008-499-730 U115, DU Board

Radome cover RSB- 0060 008-440-720

Radome packing 03-118-3203 100-185-430

15

Page 19

4.2!Replacement of Major Part s

4.2 Replacement of Major Parts

Removing display unit cover and shield plate

1. Loosen and remove the nuts from three jacks at the display unit cover.

2. Remove four screws fixing the display unit cover.

3. Remove the display unit cover, the shield cover will be exposed.

4. Of the two shield tapes attached to the shield cover, remove the shorter one.

5. Remove four screws fixing the shield case.

6. Lift up the shield case to expose the board.

Shield tape

Figure 4-1. Display Unit, rear view

Figure 4-2. Display Unit, cover removed

Reassembling

7. Fix the shield case to the board with four screws.

8. Attach the shield tape (shorter one) supplied to the same position as before.

!!!!""""

Shield case

Space

P.C. Bo ar d

Chassis

Figure 4-3. How to run shield tape

9. If the longer shield tape came off during work, exchange it with new one.

Parts Name Type Code No.

Shield tape DK-102-35/ L=45

Shield tape DK-102-19/ L=110

#$%&'()*+,&

P.C. Bo ar d

Chassis

10. Make sure that each of three jacks on the board is fitted with a gasket.

11. Put the display unit cover back in position.

12. Set and tighten three nuts and four screws to fix the jacks and the display unit cover.

16

Page 20

Panel(E) 03-135-1021

4.2!Replacement of Major Part s

Cover

LCD Assy.

Round side

O-ring (large)

LCD

DG 052Y-5MC

A

(P)DU

03P9268

View from A

LCD

Never run wires beyond this line.

Figure 4-4.

O-ring (small)

J3

VH connector wires from LCD

Shield plate

03-146-1002

P2, 4P VH connector

Figure 4-5.

17

J2

PCB fixing plate, 03-118-1001

P3, Flat cable

Page 21

Panel packing

03-118-1006

4.2!Replacement of Major Part s

(P)PNL

PNL9194

PW sheet

86-009-1022

Rubber key(E) 03-135-1022

Figure 4-6.

18

Page 22

STS Belt and Motor

1. Unscrew four M3(8 screws (() fixing the bearing retainer.

2. Remove the radiator assembly.

3. Replace the belt (or motor) with new one.

No tension adjustment of the belt is necessary.

4. Assemble the unit by reversing above steps.

M3

6 SCM3

Driving Pulley

03-146-3304

4.2!Replacement of Major Part s

Radiator Assy.

Fix at the

same time.

M3

B801 Motor

RM-9455

STS Bert

40S2M266UG

8 2pcs.

Connector

M3 8 4pcs.

Driver Pulley

tw

o

d

o

w

e

ls

dowels

B

Bearing

Retainer

Use this hole to loosen

the screw fixing the

bearing retainer.

Driver pulley, top view

STS Belt

Driving pulley

View from B

Driver pulley

Figure 4-7.

19

Page 23

4.2!Replacement of Major Part s

Magnetron

Handle the magnetron, taking the followings into account.

1. Use a non-magnetic screw driver to dismount and mount the magnetron.

2. Keep the magnetron 25mm away from the metals.

3. Never pull the magnetron lead wires.

MIC

See figure below.

M4 20

Remove shorting plug.

Dowels

Dowels

IF

03P9269

J810

Figure 4-8.

J808

U801

S-RX50

M4

10 4pcs.

V801 Magnetron

E3588

20

Page 24

4.3!How to change system progr am

4.3 How to change system program

PROM, U115 on the DU Board stores system program. Change the ROM to update the program.

Raw ROM Type : M27C1001-10F1

Program No.: 035915800X

Replacing pr ogr am ROM

1. See page 18 to gain access to the DU board.

2. Remove the lock band of the program ROM (U115)

3. Detach the program ROM from the socket by using a dedicated tool or a screwdriver.

4. Insert the update ROM (0359158104) to the socket.

U115(PROM)

5. Secure the ROM by using the lock band previously removed.

Figure 4-9. DU Board (03P9268)

How to read program number

1. Turn the radar on.

2. Wait until the initial screen appears, then press and hold UP and DOWN keys together.

3. In about 10 seconds, the maintenance menu as shown below will appear.

4. Press MENU key to close the menu.

21

Page 25

Chapter 5. Troubleshooting

The unit does not provides self-test functi on. Th is chapter mainly describes how t o check each

block.

5.1 Maintenance Menu

To open the maintenance menu;

1. Turn the radar on.

2. Wait until the initial screen appears, then press and hold UP and DOWN keys together.

3. In about 10 seconds, the maintenance menu as shown below will appear.

4. Press MENU key to close the menu.

Figure 5-1. Maintenance Menu

1) Reading program Number:

The program number appears at the upper left corner.

2) When connecting M1621MK2 scanner unit

The scanner unit of M1621 and M1621MK2 can be connected to the display unit of M1622.

For this combination, the MODEL in the maintenance menu must be set to “1621/M2” which

provides magnetron warm-up time of 90 seconds. The use in wrong setting may shorten the

life of the magnetron or damage the magnetron. The scanner unit of the M1622 is designed

for the warm-up time of 60 seconds.

3) Selecting “Demo display”

Select “Demo” to display the preprogramm ed echo on the screen.

4) Receiving signal (Nav data)

The sentence of nav data receiving from the navaid is shown by reversed video.

22

Page 26

5.2!Error massages

5.2 Error Messages

The following messages appear to call the operator’s attention to missing heading or bearing

pulses. Check the scanner cable for damage or disconnection when these messages appear.

Table 5-1. Error Messages

Message Meaning

HD-SIG-MISS

BP-SIG-MISS

Heading pulse is not applied to the CP U on the DU board.

The heading mark disappears .

Bearing pulse is not applied to the CPU on the DU board.

Radar automatically changes from TX to ST-BY mode.

5.3 Troublesh ooting Matrix tabl e

The troubleshooting matrix table on the next page helps the service technician to quickly identify

defective pcb or block. To use the table, locate the symptom in one of the three columns of the

table. Possibly defective circuits and their likelihood of defectiveness, indicated by a circle, star

or triangle, corresponding to 70 to 80%, approximately 20% and a few percent respectively, are

listed in each column. Numeral inside circle shows degree of possibility; the smaller the number,

the higher the possibility.

Note) Before consulting the table, check the ship’s mains (input voltage at J1351#1(+) and

#2(-) of the display unit: 10.2 to 31.2VDC) and the power fuse.

23

Page 27

5.3! Troubleshooting m atrix table

7) Incorrect target bearing.

9

8

7

8) Poor sensitivity.

9) Keyboard is pressed but no response.

6

5

)

+

)

+

*

*

*

)

+

*

)

)

,

,

4) Marks and legends do not appear.

1) Power can not be supplied.

Symptom

nor echo.

5) Marks and legends appear, but no noise

echo.

6) Marks, legends and noise appear but no

2) Power is supplied but nothing

3) Scanner does not rotate.

appears on LCD.

4

3

2

1

)

,

)

,

+

)

*

)

!!!!!!!!

Check Point

!!

DU PCB 03P9268

PNL PCB 03P9194

$

5A

#

LCD Display, DG52Y-5MC

IF PCB 03P9269

MD PCB 03P9270

INT PCB 03P9271

Magnetron

MIC

Motor and belt

Fuse

24

Page 28

5.4!Test points on Each Board

5.4 Test points on Each Board

1) DU Board)03P9268*

Test point Check Item Ratings Remarks

TP1

TP2/TP1

TP3/TP1 Q6-D

TP4/TP1

TP5 GND GND

TP7/C55 INV

TP11/TP5 XTAL

TP12/TP5 BLCK

TP13/TP5 TRIG

TP14/TP5 BP

TP15/TP5 HD

TP16/TP5 VIDE

&

DC

"

9V 8.7'9.9Vdc

21.7'29.4us

"

5V 4.8'5.2Vdc

11.2'14.5V-68'92kHz

36.85'40.85kHz

8.1725'10.7125kHz

V=9.0'12.0

T=6.0'10.0us

V=4.0'5.2V

T=5.5'6.5ms

V=4.0'5.2V

T=2.5'2.9S

Same wave as

TP602, IF Board (03P9269)

.

U3-#5

Switching Waveform (Primary)

Adjuster: VR2

Same reading at between J1#2(+) and J1-#5(- )

DC-AC Inverter, Primary

BLCK, U118-#87

TX Trigger, U1 11-#60

Bearing, U118-#138

Heading, U118-#137

Video, DJ1-#6

2) MD Board)03P9270*

Test point Check It em Ratings Remarks

TP801/TP802

TP803/TP802

TP804-1/ TP804-4

TP804-2/ TP804-4

TP804-3/ TP804-4

TP804-5/ TP804-4

TP804-6/ TP804-4

TP804-7/ TP804-4

TP805/TP806

TP807

TP808

TP811

TP812

TP813

TP814

+9V

VD1

-6V

+5V

+12V

Magnetron Current

+8V

ST-BY/TX

+12V

GATE2

VD2

TRIG

GND

TX. PW.

GATE1

8.7'9.9Vdc

34'46kHz Save wave as VD2

-6.9'-5.5Vdc

4.75'5.25Vdc

11.9'12.1Vdc Adjuster: VR801

2.8'3.6Vdc Adjuster: V R851, TX, 3nm Range

7.8'8.2Vdc

8.5'9.35Vdc

(8.1'9.1Vdc)

11.9'12.1Vdc

Waveform 2 Gate signal of switc hing FET

Waveform 3

Waveform 1

Waveform 4 Pulse transfor mer drive signal

Waveform 5 Gate signal of switc hing FET

ST-BY

(TX-6nm)

Not SHIP’S MAIN COLD

25

Page 29

5.4!Test points on Each Board

3) IF Board)03P9269*

Test Point Check Item Ratings Remarks

TP601 IND 2.5Vdc

TP602 ECHO Waveform 6

TP603 AGC Same as STC waveform

TP604 IF Not measurable

4) STC Waveform

Condition ; TX, STC voltage (J809 #9) adjusted to 3.4 to 3.6 V manually.

Test Point ; Between R46 and R47.

Ratings ; V1+3.1,3.5V, V2=0. 8,1.0V, V3=0.2,0.4V, T1=40,50us

26

Page 30

5.4!Test points on Each Board

6

6

6

-./001-23"45

78790:)6

.;9/4:-,

-<8=>!"

.

#&??%@A,)B@)B,*%''B,*B7&

C4::)6D)0:4:-,

;+E &FBG H

-./:I1"J-KC5

78790:)6

F9L/MNO

.BP&G),Q77'RS)CT)6

.

#&??%@A,)B@)B,*%''B,*B7&

C4::)6D)0:4:-,

;+E &FBG H

-./:/16UC5

7879CV)6

/

0

F9L/MNO

.BP&G),Q77'RS)CT)6

.

#&??%@A,)B@)B,*%''B,*B7&

V4::)6D)0:4:-,

;+E &FBG H

1

27

Page 31

5.4!Test points on Each Board

6

6

-./0L1-<4.;45

78790:)6

.;904:-,

-<8=>!"

.

#&??%@A,)B@)B,*%''B,*B7&

C4::)6D)04::-,

;+E &FBG H

-./0T1"J-K05

7879/)6

F9T:MNO

.BP&G),Q77'RS)CT)6

.

#&??%@A,)B@)B,*%''B,*B7&

C4::)6D)0:4:-,

;+E &FBG H

:L.WCXW

-.X:C1KYN>5

2

3

K*$B)+77&+G,)+F?&G)H+%@)Z+@A

0)?B)L)6

#&??%@A,)B@)B,*%''B,*B7&

04::)6D)C::@,

;+E &FBG H

4

28

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Loading...

Loading...