Furukawa Unic URW370C4U Series, URW500C4 series, URW547C4U series Operation & Maintenance Manual

SERIES

SERIES

MINI-CRAWLER CRANE

HEAD OFFICE : Nihonbashi nishikawa Bldg, 5-3, Nihonbashi

1-chome, Chuo-ku, Tokyo 103-0027, Japan

MODEL

OPERATION

&

MAINTENANCE

MANUAL

OMURW37C4U50C4U547C4U201510A

PRINTED IN JAPAN

INTRODUCTION

Request to those who operate the crane

The operator’s manual describes correct operation methods, simple inspection, and service for the UNIC crane.

Be sure to read this manual carefully to carry out correct and safe operation of the crane.

Operate the crane after you have understood the contents of this manual.

Although we take all possible measures to ensure quality of the crane, you are requested

to contact our business offices, UNIC sales agents, or authorized service stations whenever you have anything you do not understand.

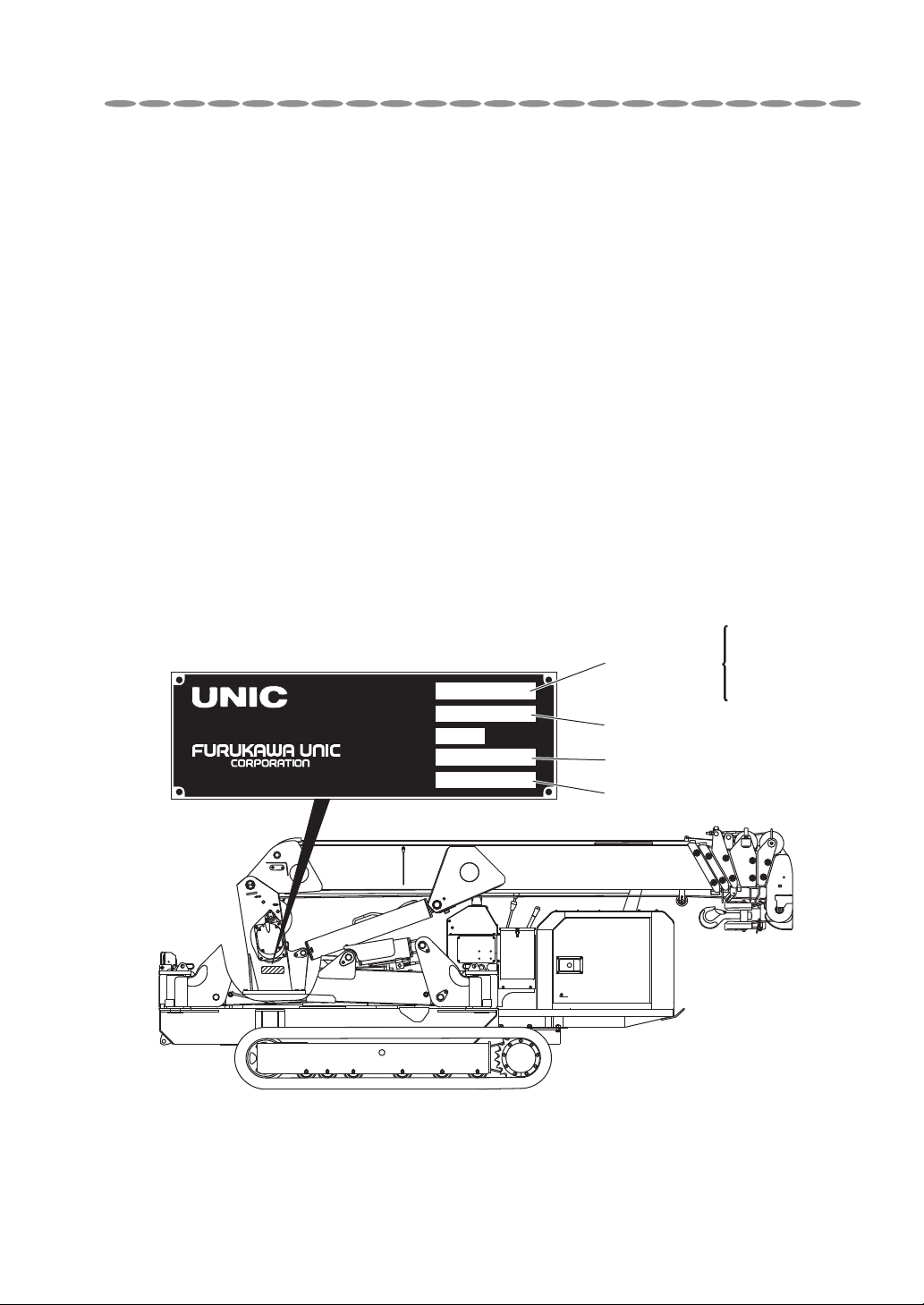

◆ For making inquiries

◆ When making inquiries, ordering spare parts, and requesting repairs, be sure to inform us

of the crane model, specification, serial number, and date of manufacture which are indicated on the name plate.

◆ Name plate of the machine is located at the side of column.

TOKYO JAPAN

MADE IN JAPAN

MODEL

SPEC.

CAPACITY

SERIAL NO.

CODE NO.

LBS

Crane model

Specification

Serial number

Code number

URW375C4U

URW376C4U

URW505C4U

URW506C4U

URW547C4U

0-1

TABLE OF CONTENTS

SETUP OF THIS MANUAL

URW370C4 series ………………………… 0- 4

URW500C4 series ………………………… 0- 5

URW547C4 ……………………………… 0- 6

1. FOR SAFETY OPERATION

Request to customers ……………………… 1- 1

2. SAFETY PRECAUTIONS ON

CARRIER OPERATION

Before operation …………………………… 2- 1

During operation …………………………… 2- 2

When loading and unloading ……………… 2- 4

After operation …………………………… 2- 4

3. SAFETY PRECAUTIONS ON

CRANE OPERATION

Before operation …………………………… 3- 1

During operation …………………………… 3- 2

After operation …………………………… 3- 4

4. DESCRIPTION OF CARRIER

EQUIPMENT

……………………… 4-1

5. DESCRIPTION OF CRANE

EQUIPMENT

……………………… 5-1

6. NAME PLATES

Description of name plates ………………… 6- 1

Stickers in detail …………………………… 6- 2

7. DEFINITION OF TERMS

Outrigger extension ………………………… 7- 1

How boom-sections are extended ………… 7- 6

Net rated load ……………………………… 7-10

Rated load ………………………………… 7-10

Lifting capacity …………………………… 7-10

Working radius …………………………… 7-10

Boom length ……………………………… 7-10

Boom angle ………………………………… 7-10

Lift above ground ………………………… 7-10

8. HOW TO REFER TO WORKING

RANGE CHART AND RATED LOAD

CHART

Working range chart ……………………… 8- 1

Rated load chart …………………………… 8- 2

9. DESCRIPTION OF EACH

CONTROL DEVICE

Overwinding alarm ………………………… 9- 1

Automatic stop for overwinding …………… 9- 2

Boom angle chart ………………………… 9- 4

Warning horn ……………………………… 9- 8

Retaining mechanism for slinging wire rope

Automatic stop for leaving minimum wire rope

(With wire rope retaining roller) …………… 9- 8

…9-8

10. HOW TO OPERATE CARRIER

Designation of each control lever

and its location …… 10- 1

Preparation before operation ……………… 10- 3

Precautions before operation

(air-bleeding procedures) … 10- 6

How to operate …………………………… 10- 7

How to Crawl ……………………………… 10-10

How to fasten carrier when in transportation

… 10-15

11. HOW TO OPERATE CRANE

Designation of each control lever

and its location … 11- 1

Preparation before operation ……………… 11- 3

Inspection before starting crane operation … 11- 4

Procedures to set up outriggers …………… 11- 6

How to operate boom for derricking

(raising and lowering) … 11-15

How to hoist and lower the hook …………… 11-16

How to telescope boom …………………… 11-18

How to slew boom ………………………… 11-20

How to store crane ………………………… 11-22

Procedures for storing hook ………………… 11-23

How to store outriggers …………………… 11-25

0-2

TABLE OF CONTENTS

12. U-WAVE, Radio remote control

device, (Option)

Request to those who operate the crane …… 12- 1

Safety precautions ………………………… 12- 2

Designation of each equipment …………… 12- 5

Inspection before crane operation ………… 12- 8

How to switch crane operation mode ……… 12-10

How to operate the crane through

radio control operation … 12-12

How to replace batteries of transmitter …… 12-35

Daily checks, trouble inspection …………… 12-38

13. MAINTENANCE AND

INSPECTION OF CARRIER

Inspection before operation ………………… 13- 2

Inspection and Maintenance which is to be carried

out every 250 hours or 3 months …………… 13-13

Inspection and Maintenance which is to be carried

out every 500 hours or 6 months …………… 13-21

Inspection and Maintenance which is to be carried

out every 1000 hours or 12 months ………… 13-23

Non-regular maintenance ………………… 13-29

Storage …………………………………… 13-34

Fitting safety covers ……………………… 13-35

Maintenance and inspection of engine ……… 13-35

14. MAINTENANCE AND

INSPECTION OF CRANE

Inspection before operation ………………… 14- 2

Cleaning …………………………………… 14- 3

Inspection of bolts mounting

slewing bearings …… 14- 3

Replacement of wire rope (for winding-up) … 14- 4

Replacement of expendable parts ………… 14- 8

15. WATER SUPPLY AND

LUBRICATION TO CARRIER

Precaution when carrying out filling

water and lubrication …… 15- 1

List of recommended lubricant …………… 15- 2

Filling water and lubrication chart ………… 15- 4

16. LUBRICATION TO CRANE

Precaution when carrying out lubrication …… 16- 1

List of recommended lubricant …………… 16- 2

Lubrication chart …………………………… 16- 3

Lubrication ………………………………… 16- 4

17. MAJOR SPECIFICATIONS

URW375C4U(5-section boom) …………… 17- 1

URW376C4U(6-section boom) …………… 17- 7

URW505C4U(5-section boom) …………… 17-14

URW506C4U(6-section boom) …………… 17-20

URW547C4U(7-section boom) …………… 17-26

Major specification

(Radio remote control device) for

URW370C4U, URW500C4U, URW547C4U

………………… 17-34

18. MODE INDICATOR LAMP

(CONTROL BOX)

Mode indicator lamp (Control box) ………… 18- 1

19. MEASURES TO BE TAKEN IN AN

EMERGENCY

……………………19-1

0-3

SETUP OF THIS MANUAL

SETUP OF THIS MANUAL

Crane covered in this manual have some difference in operation in accordance with the

specifications of with or without radio remote controller.

Difference in operation due to crane specifications is separately illustrated in this manual

for each specification.

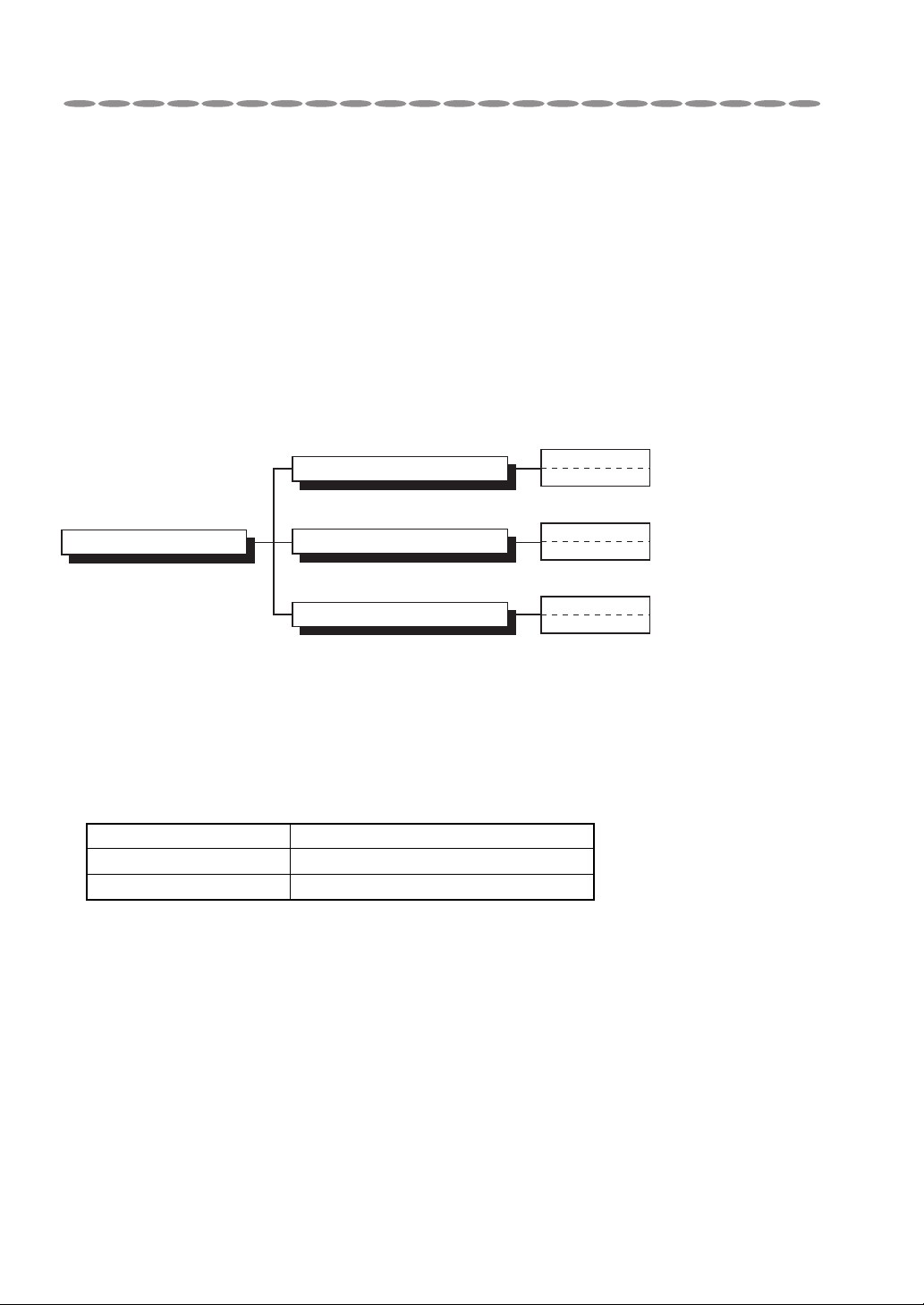

URW370C4 series

1. Designation of specification

Crane covered in this manual are roughly divided into three, the radio remote control

type, the cable remote control type and the manual control type.

URW370C4U

RS

URW370C4U

R

URW370C4U

URW370C4U series

With radio remote controller

With cable remote controller

Manual specification

2. Designation of model

URW370C4 series of crane model is to be designated according to the number of sections of telescoping boom.

(Model) Number of boom section

URW375C4 5

URW376C4 6

0-4

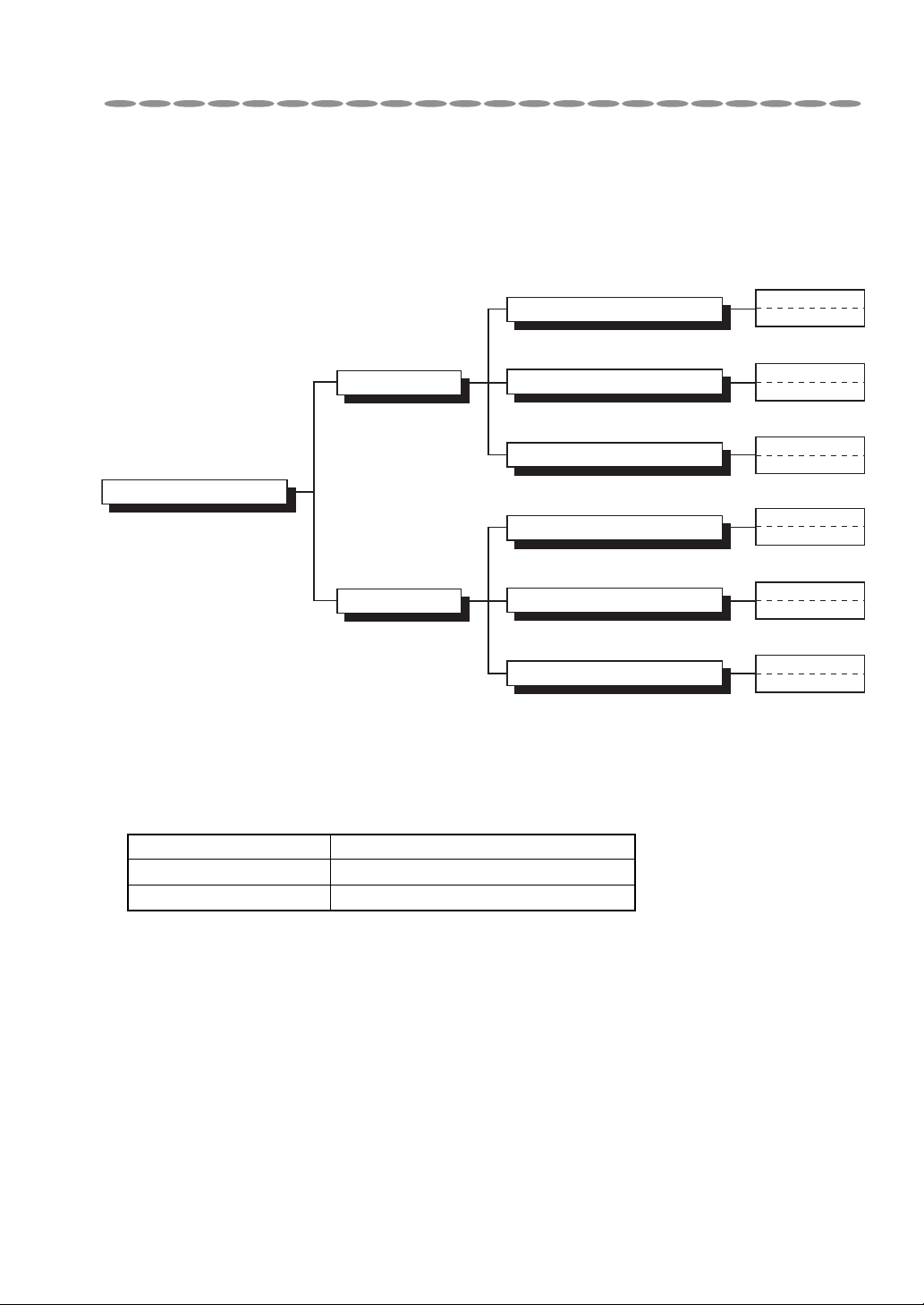

URW500C4 series

1. Designation of specification

Crane covered in this manual are roughly divided into two: short outrigger type and standard outrigger type.

URW506C4U

URW506C4U

URW506C4U

Standard type

With radio remote controller

With cable remote controller

Manual specification

URW500C4U series

URW505C4U

URW505C4U

URW505C4U

Short type

With radio remote controller

With cable remote controller

Manual specification

2. Designation of model

URW500C4 series of crane model is to be designated according to the number of sections of telescoping boom.

RS

R

RS

R

(Model) Number of boom section

URW505C4 5

URW506C4 6

0-5

URW547C4

1. Designation of specification

Crane covered in this manual are roughly divided into three, the radio remote control

type, the cable remote control type and the manual control type.

URW547C4U series

With radio remote controller

With cable remote controller

Manual specification

URW547C4U

RS

URW547C4U

R

URW547C4U

0-6

MEMO

1. FOR SAFETY OPERATION

Observeallthesafetyregulations!

• Read preventive measures

against danger and cautions

stated in this manual for proper understanding.

• Most accidents related to the

crane occur due to operation,

maintenance, and inspection

which have failed in observing

basic safety regulations.

Request to customers

◆ Never failed to observe and

they are of great importance in safety and the crane operation.

…

Failure to observe this may invite an accident resulting in injury or death.

CAUTION

◆ Store this operator's manual where it is easily accessible to read it over and over again.

◆ Failure to observe the right operation and maintenance/inspection illustrated in

this manual may cause trouble in the crane and may invite an accident, and this

will not only shorten its service life but will impair safety in the crane operation.

Please remember, in such cases, that no warranty will be given even if the crane is within

valid warranty period.

◆ In order to prevent injury or death to crane operators and to those who stand close to crane

operating area due to operational mistake, caution plates are stuck on the crane.

You are requested to read them carefully.

◆ Do not alter the crane.

• If you want to make an alteration, contact with UNIC sales agent or an authorized service

shop.

…

Failure to observe this may cause damage to the crane.

CAUTION

described in the manual as

• UNIC does not bear any responsibility for troubles and /or accidents due to unauthorized

alteration.

1-1

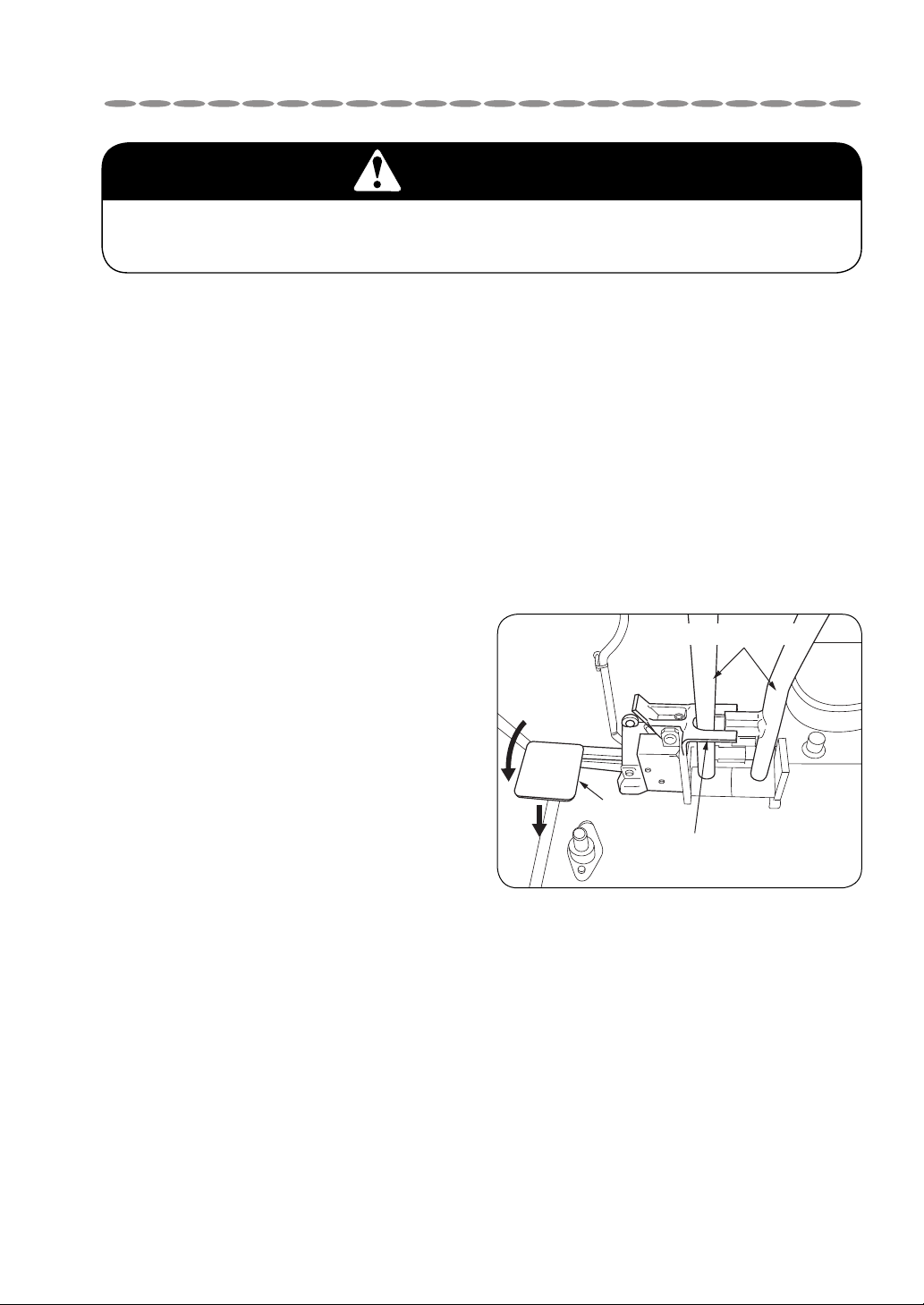

2. SAFETY PRECAUTIONS ON CARRIER OPERATION

Pedal

Crawling

Interlock for crane-crawl

operation

Crawling lever

WARNING

Observe the cautions for securing safety.

Failure to observe the cautions may cause trouble or serious accident.

Before operation

Dress neatly and wear protectors such as

1

helmet, safety shoes, and gloves without

fail.

Do not wear baggy clothes and accessories

which can be caught by control levers and fittings, and oil-stained working clothes which

may catch fire.

Be sure to make inspection before oper-

2

ation and periodical voluntary inspection.

If found something wrong, repair it immediately.

The crane is prohibited to crawl on a

3

public road by the road traffic law.

Check that no safety covers have been

4

left removed.

It is very dangerous to start the engine,

to operate the crane with the safety cover

removed as the driving mechanism is

exposed.

When starting the engine in a small lim-

6

ited area or indoors, open the windows

and doors for well ventilation.

Poor ventilation may invite an exhaust gas

poisoning.

Shift the interlock for crane-crawl lever

7

to “Crawl” when crawling the crane.

Crane will not work by controlling crane

operation levers with the interlock for cranecrawl lever shifted to “Crawl”.

Be sure to stop the engine before refuel-

ing or supplying and changing lubricant.

5

A fire source such as smoking cigarette in

mouth is strictly prohibited.

Failure to observe this may cause a fire.

2-1

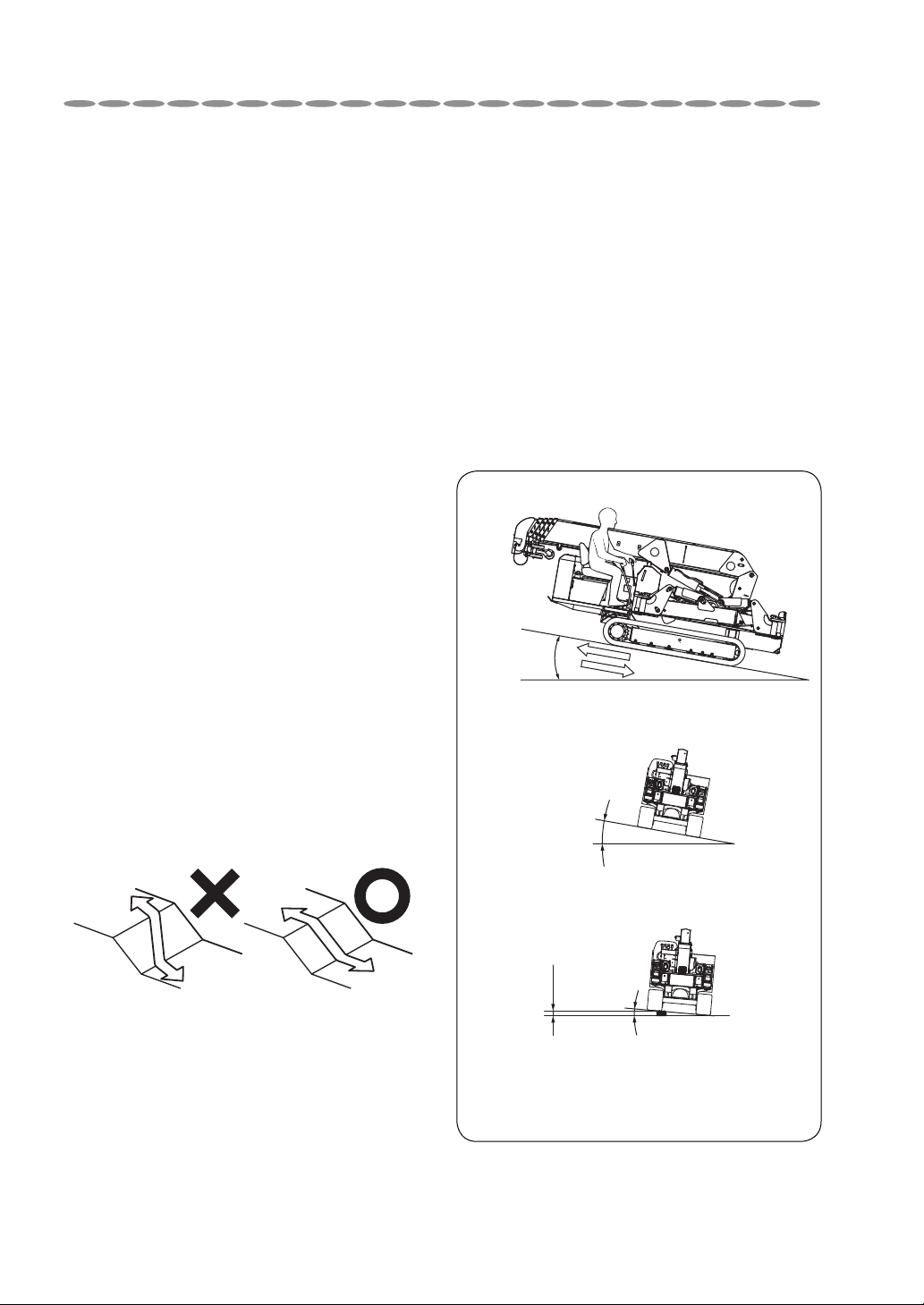

SAFETY PRECAUTIONS ON CARRIER OPERATION

Less than

20°

Less

than

23°

Less than 10°

on the unstable road

Less than

10°

Less than

0.6ft

(170 mm)

Move forwards and backwards

(straight)

When driving over a gap of the step, there is a risk of tipping

over caused by vibration or a shock. Therefore, make sure

the gradient of carrier is less than 10°, or the gap of the step

is less than 0.6ft (170 mm). The driving speed should be

“Very Low Speed” and sudden turning is strictly prohibited.

Left/Right gradients

Drive over a gap of the

step with either left or

right side of the carrier

・

During operation

The machine employs particularly small

1

truck to facilitate working in a restricted space.

Since high performance crane is mounted on

the small truck, it has been built with a higher

center of gravity.

Take special care not to overturn the crane

when crawling on a unleveled ground.

When crawling the crane, be sure to put

2

outriggers in a condition of being stored

and store the hook.

Do not run the crane with a cargo hoist-

3

ed or without the crane being stored.

Special care must be taken to run the

4

crane slowly when making a quick turn

and crawling on a rough road.

10

11

at a higher position than the crane body.

12

as there is a risk of roll-over.

Do not make an abrupt stop and

start, and change a course on a slope.

When crawling up and down a

slope, operate the crane by standing

Do not operate the carrier on the

more steep slope than shows below,

When running over a bump, be sure

5

to slow down the crane and direct it

straight to the bump to avoid unnecessary

shock to the crane body.

When driven over an irregular road sur-

6

face or going up and down the slopes,

the carrier must get over the slope straight and

try not to give any shocks to it.

Be sure to use a foot-board to run over a

7

ramp of more than 0.5ft(15cm).

Crawl the crane with low (1st) speed

8

gear on a slope.

Be sure to use a pallet against the rub-

9

ber crawler when parking the crane on

a slope.

2-2

SAFETY PRECAUTIONS ON CARRIER OPERATION

Hook holder

Do not run the crane over bumpy

13

rough solid rock, small broken stones, edges

of steel plate, steel bars for reinforcement,

scrap metals, and waste materials and on a

road such as in riverside where covered with

many stones which may remarkably shorten

service life of rubber crawler.

14

It may invite critical situation due to abrupt

swing or shift of center of gravity.

15

being spread.

It may cause a fire by heat of exhaust pipe or

exhaust gas.

16

body as a means of pulling a vehicle.

This may break the holder.

area, lying rocks with sharp edges,

Do not take an article or an animal

in the crane.

Do not park the crane over a place

where withered grass or straw are

Do not use the hook holder mounted in the rear side of the crane

To avoid rubber crawler damage.

17

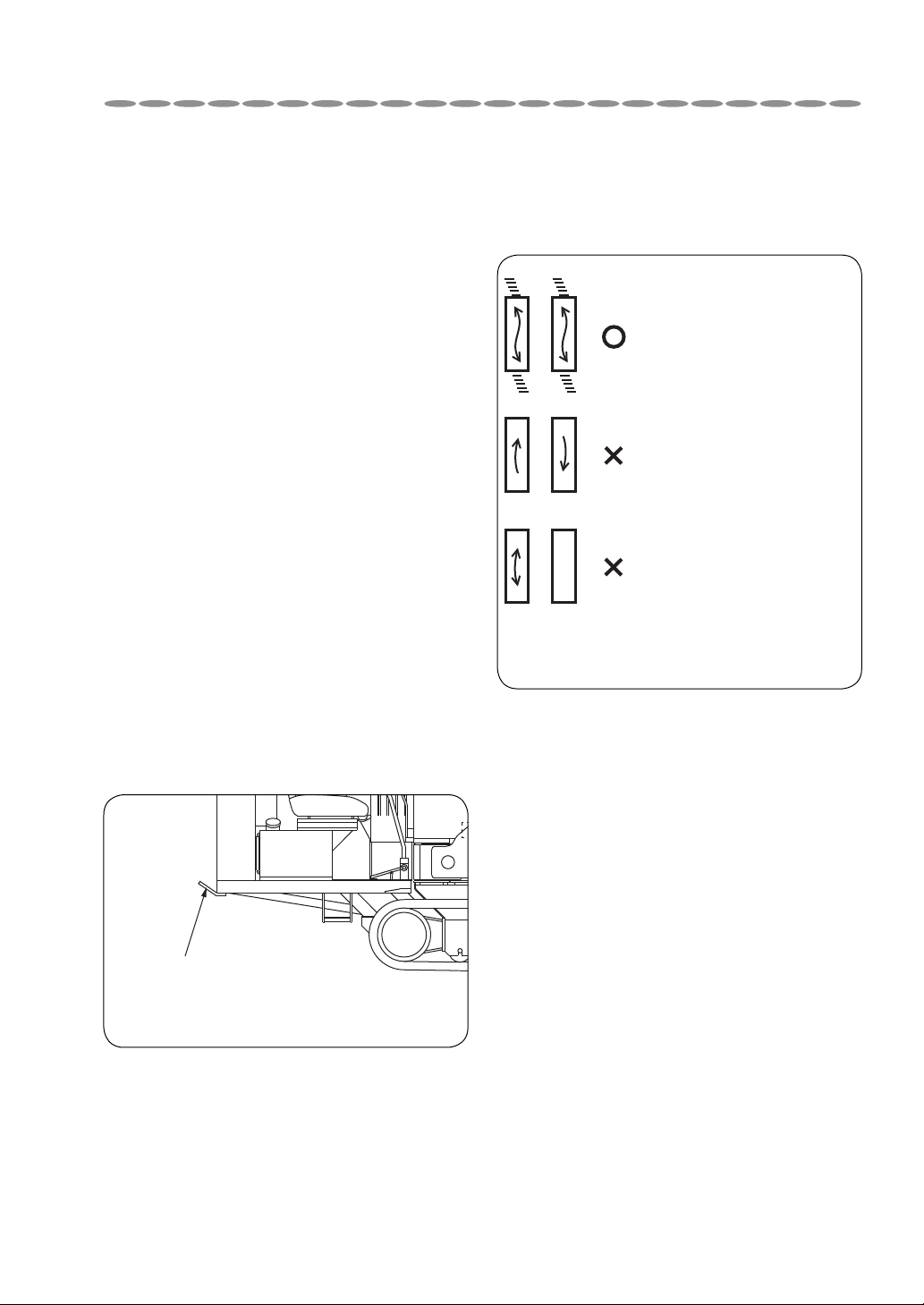

Be sure to drive both sides

()

()

()

For the white (or gray) crawler, observe the

driving strictly in terms of its characteristics.

of crawler in the same

direction for making a turn.

Do not drive both sides of

crawler in the opposite

direction each other.

Do not drive only one

side of the crawler.

2-3

SAFETY PRECAUTIONS ON CARRIER OPERATION

When loading and

unloading

When loading and unloading the crane,

1

use a non-slip foot-board with a enough

capacity of strength, width, and length and

run the crane straight up and down at a very

low speed.

Changing direction of the crane on the footboard may cause the crane to fall off.

Stop the engine, apply parking brake,

2

and put drags to wheels to secure the

mounting vehicle when loading and unloading the crane.

Failure to observe this may cause the crane

to fall off because the vehicle shift while it is

being loaded and unloaded.

Work by following the instructions illustrated

in the sticker, “Loading and unloading procedures”. (Refer to page 6-6.)

After operation

Return the crawling lever and run the

1

engine at a low speed.

Shift the crawling lever to “Crane” posi-

2

tion.

Stop the engine and remove dirt and dust

3

stuck on the crane body.

Since dust stuck on the battery, electric wiring, and engine related components such as

muffler may cause a fire in particular, be sure

to remove it.

Cover the crane or store it in a storage

4

house to prevent it from being accessed

by unrelated persons such as children.

Cover the crane after heated sections have

been cooled off.

Putting a cover on while the crane body is

still hot may cause a fire.

Remove the starter switch key to store.

5

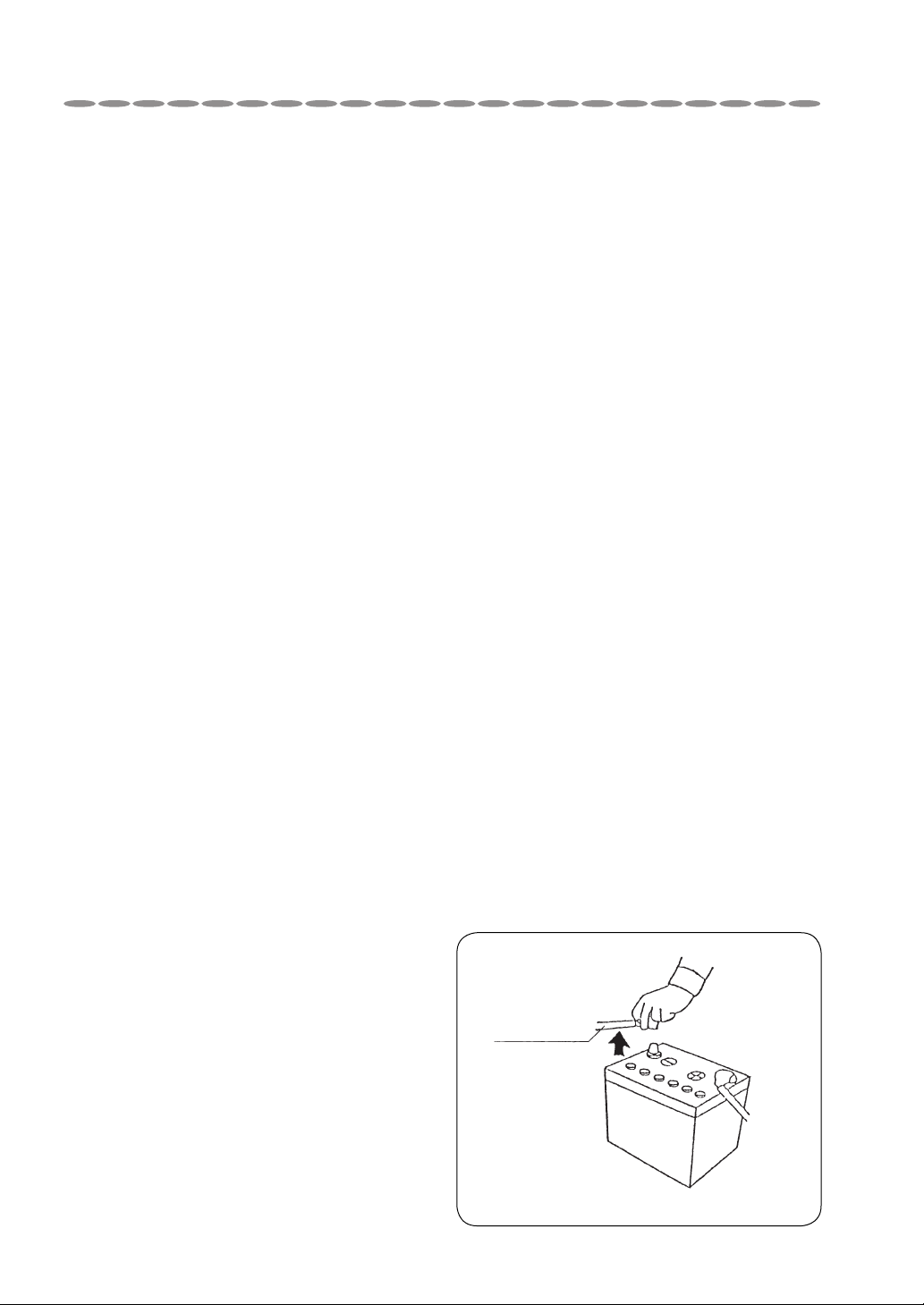

Disconnect a battery cable before the

6

crane is to be stored for a long period of

time.

Failure to disconnect it may cause a fire as

cables short-circuited by gnawing animals

such as rat.

Cable (-)

Disconnect

2-4

3. SAFETY PRECAUTIONS ON CRANE OPERATION

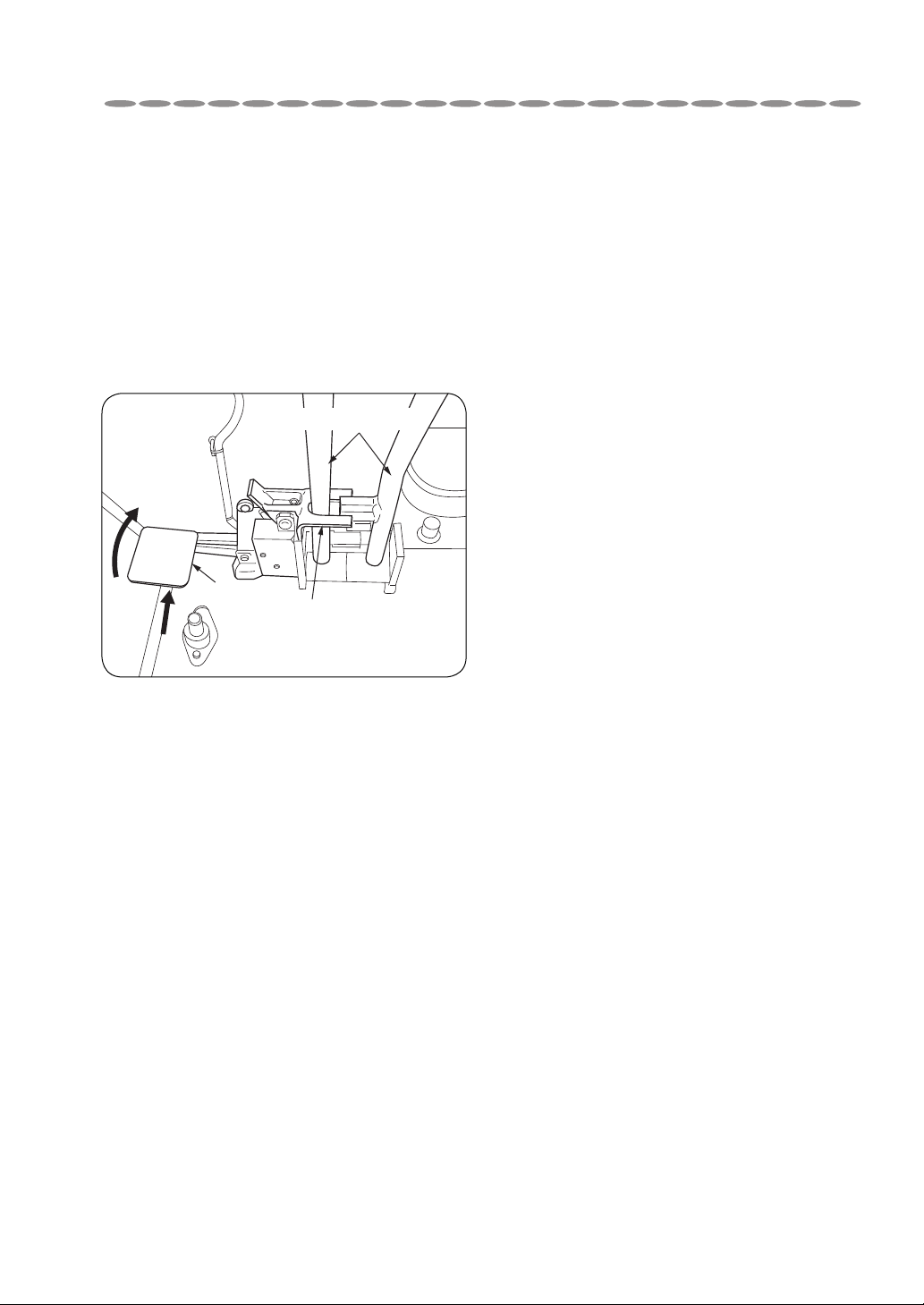

Pedal

Interlock for crane-crawl

operation

Crawling lever

Crane

Before operation

Be sure to make inspection before oper-

1

ation and periodical inspection for sling-

ing implements.

If a defective slinging implement is used, fall

of lifted cargo may result.

Shift the interlock for crane-crawl lever

2

to “Crane”.

Turn ON the overwinding alarm switch.

3

Make sure that each safety device is

4

always functioning properly.

Be sure to turn ON the overwinding alarm

switch before starting crane operation.

• When the crane is to be operated close

to the power transmission or distribution

line, contact in advance with a local power

company to make arrangements concerning safety for starting the crane operation.

• If crane operation close to the power transmission or distribution line is unavoidable,

be sure to secure safety distance from the

power lines.

List of target safety distance

Power transmission line

Voltage Safety distance (target)

500,000 volts 36ft(11.0m) or more

275,000 volts 23ft(7.0m) or more

187,000 volts 20ft(6.0m) or more

154,000 volts 17ft(5.0m) or more

66,000 volts 14ft(4.0m) or more

22,000 volts 10ft(3.0m) or more

Power distribution line

Voltage Safety distance (target)

6,600 volts 7ft(2.0m) or more

Do not operate the crane when wind

6

velocity exceeds 22mph(10m/sec). and/

or while thundering.

Crane operation while strong wind is blowing

can cause fall of a lifted cargo or overturn of

the crane as the boom and/or a lifted cargo

are hit by a gust of wind.

Keep a safety distance away from the

5

high-voltage power line to avoid an

electric shock.

• The crane is not electrically insulated.

• When the crane is operated near the power

transmission line or the power distribution

line, there may be a risk of electric shock

due to electric discharge even if a part of

the crane such as boom will not make a

direct contact with the power lines.

Pay attention that anyone except per-

7

sons concerned will not enter within a

working radius of the crane.

Take good care to carry out safety operation

by keeping a close watch around the working

area.

3-1

SAFETY PRECAUTIONS ON CRANE OPERATION

During operation

Make sure that the ground on which

8

outriggers are to be set up is solid and

firm.

When setting up the outriggers on an

unleveled ground or on a slope, be sure to

place a support (such as plank, steel plate

etc.) under the outrigger foot flanges to keep

the crane level.

In addition, when the crane is to be operated

on a soft ground, take the same measures to

prevent the outrigger foot flanges from sinking into the ground when a cargo is lifted up.

Lift up the crawler by approx. 2in.

9

(50mm)from the ground.

DANGER

BEFORE OPERATING THE CRANE

IT IS MANDATORY TO

SET UP ALL THE

OUTRIGGERS

Pay attention that the hook will not be

1

overwound.

Be sure to turn ON the “overwinding alarm

switch”.

• Remember that the hook is wound up

when boom is extending.

• If the hook hits against the boom top due

to overwinding of the hook, it may cause

damage to wire rope and the sheaves at the

boom top and may cause the fall of lifted

cargo.

Operate each lever slowly and smooth-

2

ly.

An abrupt lever operation with a cargo lifted

gives an excessive shock to the crane which

may cause damage or overturn to the crane.

Slew the crane at low speed.

3

Operation with the crane kept

10

cargo is lifted up.

Such operation can cause the crane to be

overturned.

11

outriggers fully extended.

12

13

leaning makes it unstable when a

In normal crane operation, be sure

to set up the crane level with the

Do not stand under or in front of the

hook when unhooking as it swings.

Do not try adjusting hydraulic

equipment.

Swing of a lifted cargo increases working

radius of the crane which may cause it to be

overloaded.

If the engine speed is too slow when

4

operating the crane, press the accelerator to increase it.

Crane operation with the engine (and pump)

running at low speed may cause a cargo

hoisted up to swing due to pulsation of

the engine.

This is not a malfunction but impairs smooth

control of the crane.

Overloaded operation is strictly prohib-

5

ited.

Crane operation with a load exceeding the

rated load hoisted may cause damage or overturn to the crane.

3-2

SAFETY PRECAUTIONS ON CRANE OPERATION

Pulling a cargo sideways, straight, or

6

obliquely is strictly prohibited.

These operation may cause slewing members, booms, columns, and derrick cylinder to

be damaged.

When a cargo to be lifted is detached

7

from the ground, stop lifting it up tem-

porarily to confirm safety.

• When a cargo to be lifted is detached from

the ground, stop lifting it up temporarily

to make sure that the cargo is kept horizontally, the crane maintains its stability,

and the rope slinging up the cargo is positioned properly.

Then lift it up again after making sure of

the safety.

• For lowering a cargo, stop lowering it

immediately before it touches the ground

then lower it again gradually.

Do not leave from operating position

8

with a cargo hoisted.

Lower a hoisted cargo onto the ground before

leaving from the operation site.

Do not get up on a cargo being hoisted.

9

This may cause a fall from the cargo being

hoisted.

Do not stay under a hoisted cargo.

10

Pay attention that wire ropes will

11

prevent ropes from being wound around the

drum irregularly.

• Operation such as paying out wire ropes

• Wind the first layer of rope firmly and

• Correct kinks of rope immediately with a

12

be lowered further than the work on the

ground.

When paying out wire ropes, be sure that

more than 3 turns of rope must always be left

on the drum.

13

176°F(80°C).

• Oil temperature is apt to rise easily if

• Excessive high temperature of hydraulic

not be paid out unnecessarily to

further with a cargo placed on the ground,

retraction and/or lowering boom loosen

the ropes to cause them irregular winding

which results in remarkable shortening

service life of the ropes.

regularly around the drum.

mallet.

Pay extra attention to underground

crane work in which the hook must

Stop crane operation when temperature of hydraulic oil exceeds

repeated operation of winding up and

down the hook, especially in a high lift, is

required.

oil damages high-pressure hoses and gaskets being employed to cause the oil to

spout out so that a scald may result.

3-3

SAFETY PRECAUTIONS ON CRANE OPERATION

After operation

Make sure that the booms, the outrig-

1

gers, and the hook have been stored

before crawling the crane.

Do not carry out maintenance and

2

inspection while temperature of either

hydraulic oil or gear oil is still high.

Temperature of both hydraulic and gear

oil is high immediately after crane operation so that accumulated high pressure still remains.

Removing filling cap, draining oil, or replacing oil filter while temperature is still high

allows hydraulic and/or gear oil to spout out

and a scald may result.

Since temperature on the engine and the

3

hood in the side is too high immediately

after crane work, touch them after they have

been cooled down.

3-4

17

19

8

10

6

14 7

9

521 4 3

14

18

17

11

12

16

20

13

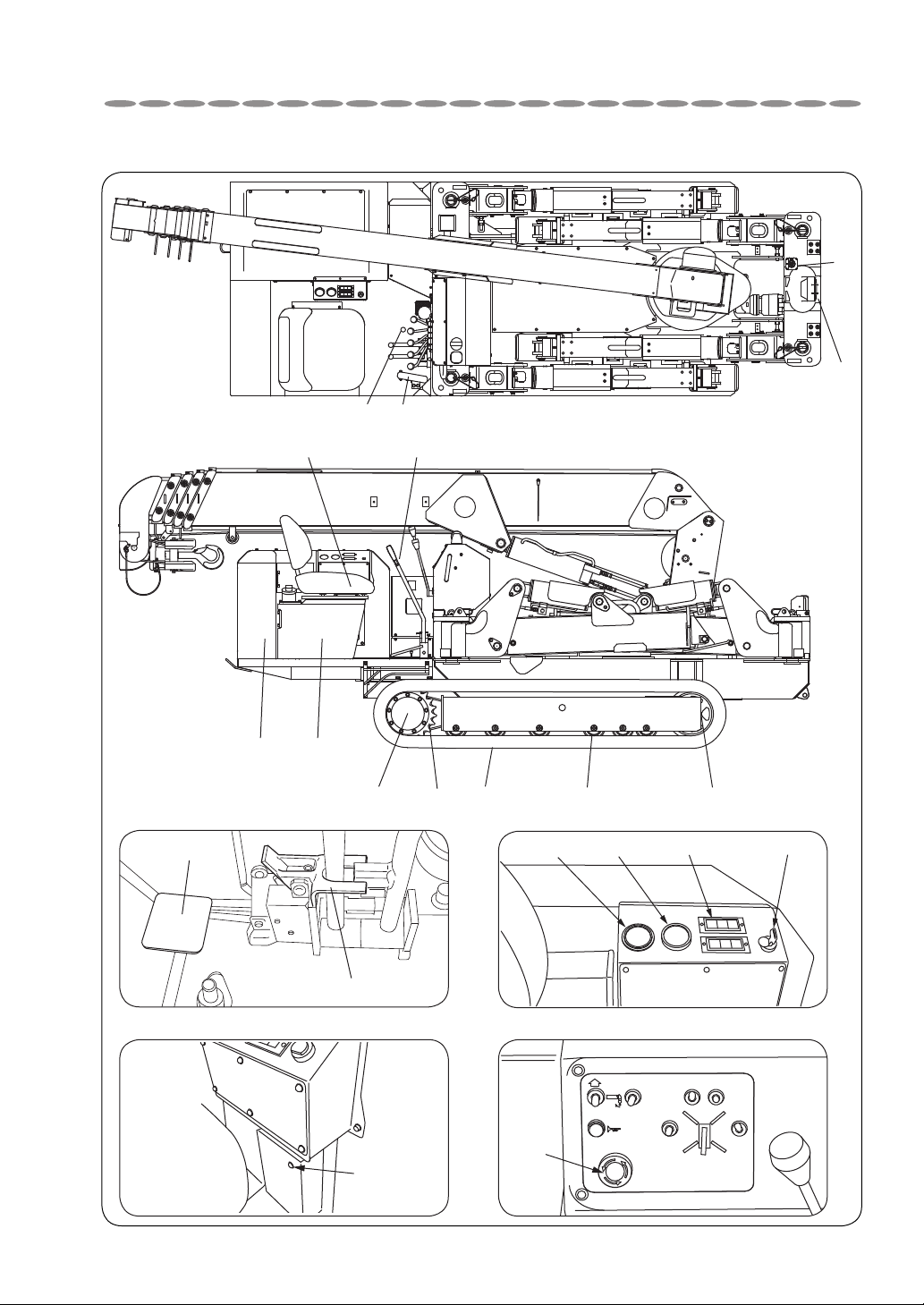

URW505C4U

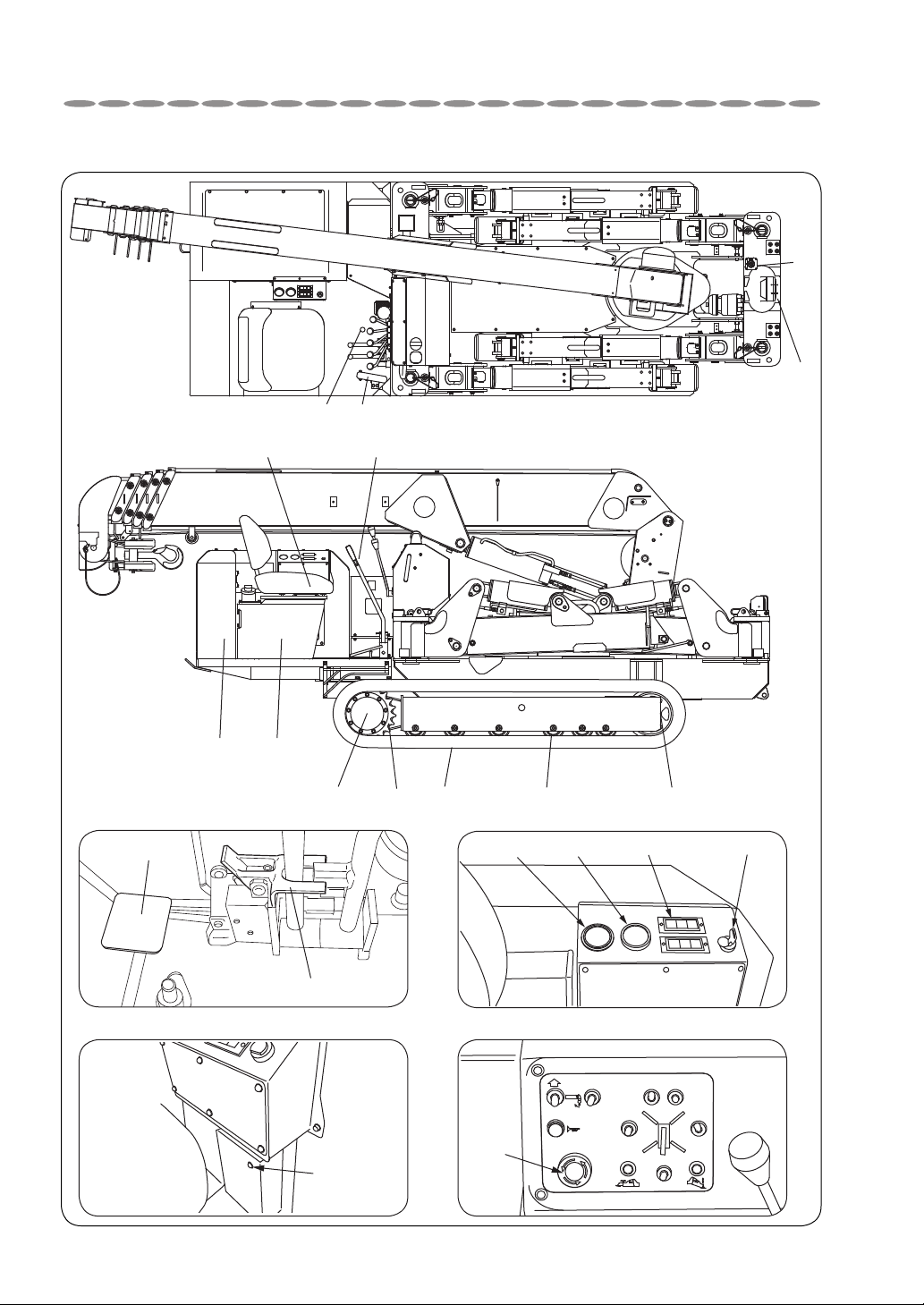

4. DESCRIPTION OF CARRIER EQUIPMENT

4-1

17

19

8

10

6

14 7

9

521 4 3

14

18

17

11

12

16

20

13

DESCRIPTION OF CARRIER EQUIPMENT

URW375C4U / URW376C4U / URW506C4U / URW547C4U

4-2

DESCRIPTION OF CARRIER EQUIPMENT

1. Rubber crawler

Cored bar and steel fabric(cords) are integrally

molded in the rubber which is of the same

quality as automobile tire.

2. Wheel sprocket

It transmits driving power to the rubber crawler to allow the crane to crawl.

3. Idle roller

This is a roller which gives a proper tension to

the rubber crawler.

4. Truck roller

This supports the weight of crane and rolls on

the rubber crawler.

5. Crawling motor

Hydraulic motor with reduction gears which

transmits driving power to the wheel sprocket

is built inside.

6. Crawling lever

This is to change crawling speed and direction.

7. Accelerator pedal

This is to control engine speed.

8. Driver's seat

This is a seat on which operator sits to operate the crane.

9. Fuel tank

This is filled with diesel oil.

10. Hydraulic oil tank

This is filled with hydraulic oil which is commonly supplied both to the carrier and to the

crane.

13. Fuel meter

This indicates a residual quantity of the fuel.

14. Interlock for crane-crawl operation

This allows the crawling levers to lock while

the crane is being operated and allows the

crane not to be operated by the crane control levers when it is crawling. This can be

switched by pressing “18 pedal”.

15. Button for selecting crawling speed

This allows the crane to crawl faster while it

is being depressed.

16. Warning lamp

The lamp lights to indicate that something is

wrong with each section.

17. Emergency stop (engine) button

Depression of the switch allows the engine

to stop and all the crane operation including

traveling stop functioning.

18. Pedal

It is used to release crawling levers.

19. Head light

20. Indicator lamp for High altitude

solenoid

The lamp lights when the solenoid operates at

an altitude of 2622 ~ 5500 ft.(800~1676m)

It allows the engine to decrease quantity of

jet.

11. Starter switch

This is a switch to start and stop the engine.

12. Hour meter

This indicates total engine running time.

4-3

MEMO

URW505C4U

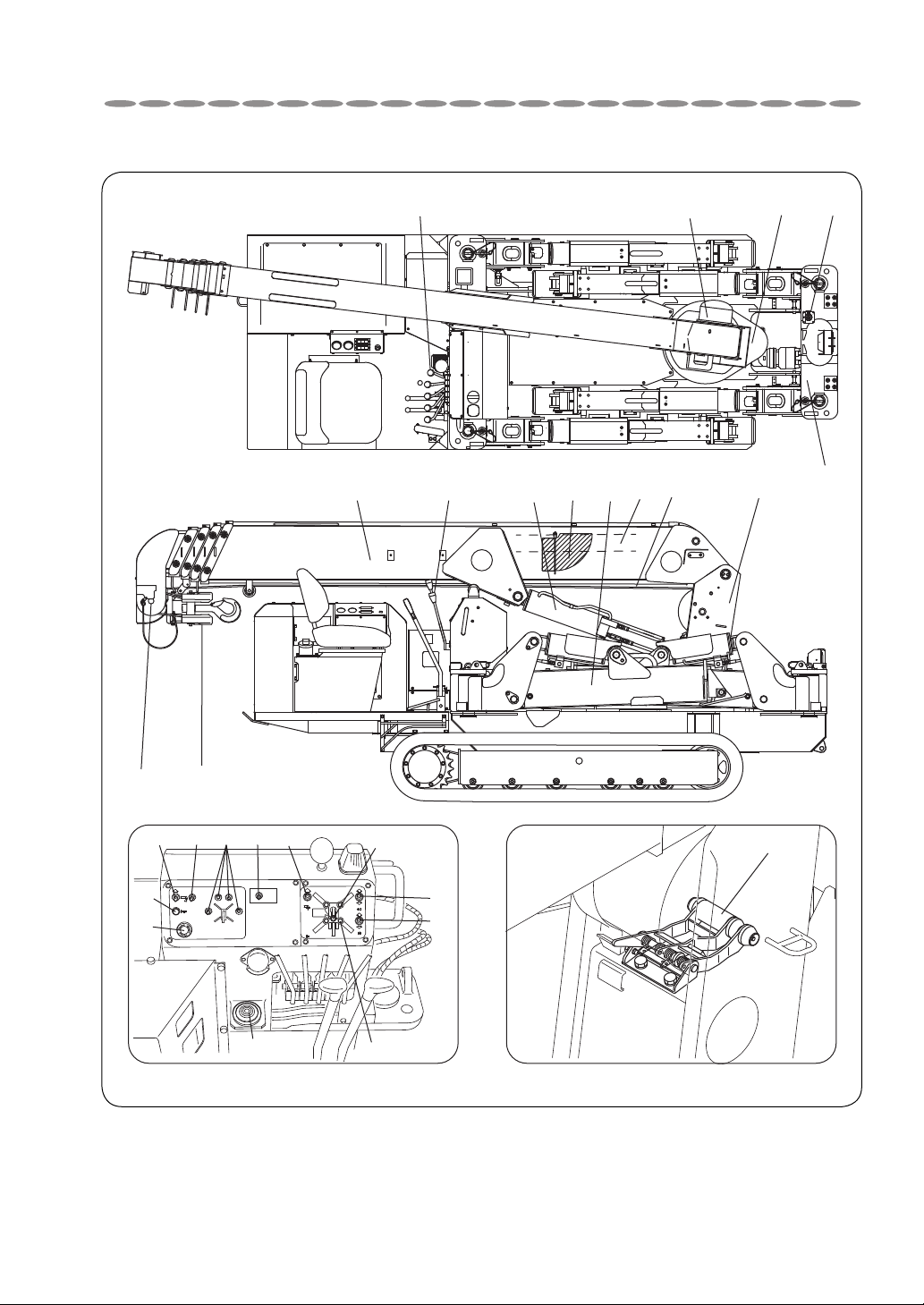

5. DESCRIPTION OF CRANE EQUIPMENT

10

19

45

6

14

8

7

13

2

24

3

12

23

24

22

11

18 21 29

16

25

28

27

15

26

17

5-1

DESCRIPTION OF CRANE EQUIPMENT

URW375C4U / URW376C4U / URW506C4U / URW547C4U

10

19

45

6

14

8

7

13

2

24

3

5-2

12

23

24

20

22

11

181921 29

16

25

20

28

27

15

26

17

DESCRIPTION OF CRANE EQUIPMENT

1. Boom

It extends and retracts by hydraulic cylinder

and the hook is suspended from its top.

2. Column

This is a vertically mounted member on the

crane in which boom, winch, and derrick cylinders are installed.

The column can be turned by slewing device.

3. Frame

This is fixed on the vehicle to support the column and outriggers.

4. Hoist winch

This is a device which rotates the wire drum

by hydraulic motor to hoist up and down a

cargo via wire ropes.

5. Slewing device

This turns the column by hydraulic motor.

6. Derrick cylinder

This raises and lower the boom.

12. Overwinding alarm

When the hook comes close to the boom top,

this makes an alarm to warn that wire ropes

are to be overwound.

13. Wire rope

14. Boom angle chart

This can read the working radius value corresponding to extended length of the boom and

its raised angle.

15. Automatic stop for leaving mini-

mum wire rope (With wire rope

retaining roller)

This is a devise to restrict slackening of

wire rope on the drum which allows to stop

unwinding automatically when remaining

wire ropes on the drum come close to 3 turns.

16. Level

This an instrument for checking horizontal

plane of the crane body.

7. Telescoping cylinder

This extends and retracts sections of boom.

8. Outrigger

This supports the crane to maintain its stability while it is operated.

9. Crane operating levers

Respective levers control raising and lowering boom, hoisting a cargo up and down, telescoping boom, and slewing boom.

10. Outrigger operating levers

This lever controls outriggers.

The outrigger control switch (section 20)

selects each movement of extension and

retraction.

11. Hook

17. Voice switch

This switches ON and OFF the voice message.

18. Operation mode switch

This selects crane operation mode and outrigger operation mode.

19. Outrigger vertical/horizontal selec-

tor switch (URW505C4U exclude)

This switches extension/retraction control of

vertical cylinder for outriggers and of inner

boxes.

20. Outrigger vertical/horizontal lamp

(URW505C4U exclude)

The lamp indicates to which side the outriggervertical/horizontal selector switch has

been thrown.

5-3

DESCRIPTION OF CRANE EQUIPMENT

21. Outrigger control switch

This selects extension/retraction of each outrigger of four (4).

Simultaneous extension and retraction of outriggers can be impossible.

22. Hook storing switch

Turning the switch to the storing position

allows the hook to be stored.

23. Horn switch

Depression of the switch allows the alarm

horn to sound.

24. Emergency stop (engine) switch

Depression of the switch allows the engine

to stop and all the crane operation including

traveling stop functioning.

25. Automatic stop for overwinding

reset switch

When the crane cannot to be operated due

to a fault in function of automatic stop for

overwinding, turning the switch to reset side

releases the automatic stop for overwinding

device.

29. Mode selector switch

This switches between radio remote control

mode and manual operation mode.

26. Head light switch

Turning the switch ON allows the head light

to light.

27. Boom storage monitor lamp

The monitor lamp lights when the boom has

been stored.

Outriggers can be operated only when the

monitor lamp lights.

28.

Outrigger monitor lamp (extension)

When turning outriggers manually from their

stored positions and set pins have fully been

inserted, the lamp indicating extension of outrigger lights.

Outriggers cannot be operated unless all the

four (4) pins have been inserted.

5-4

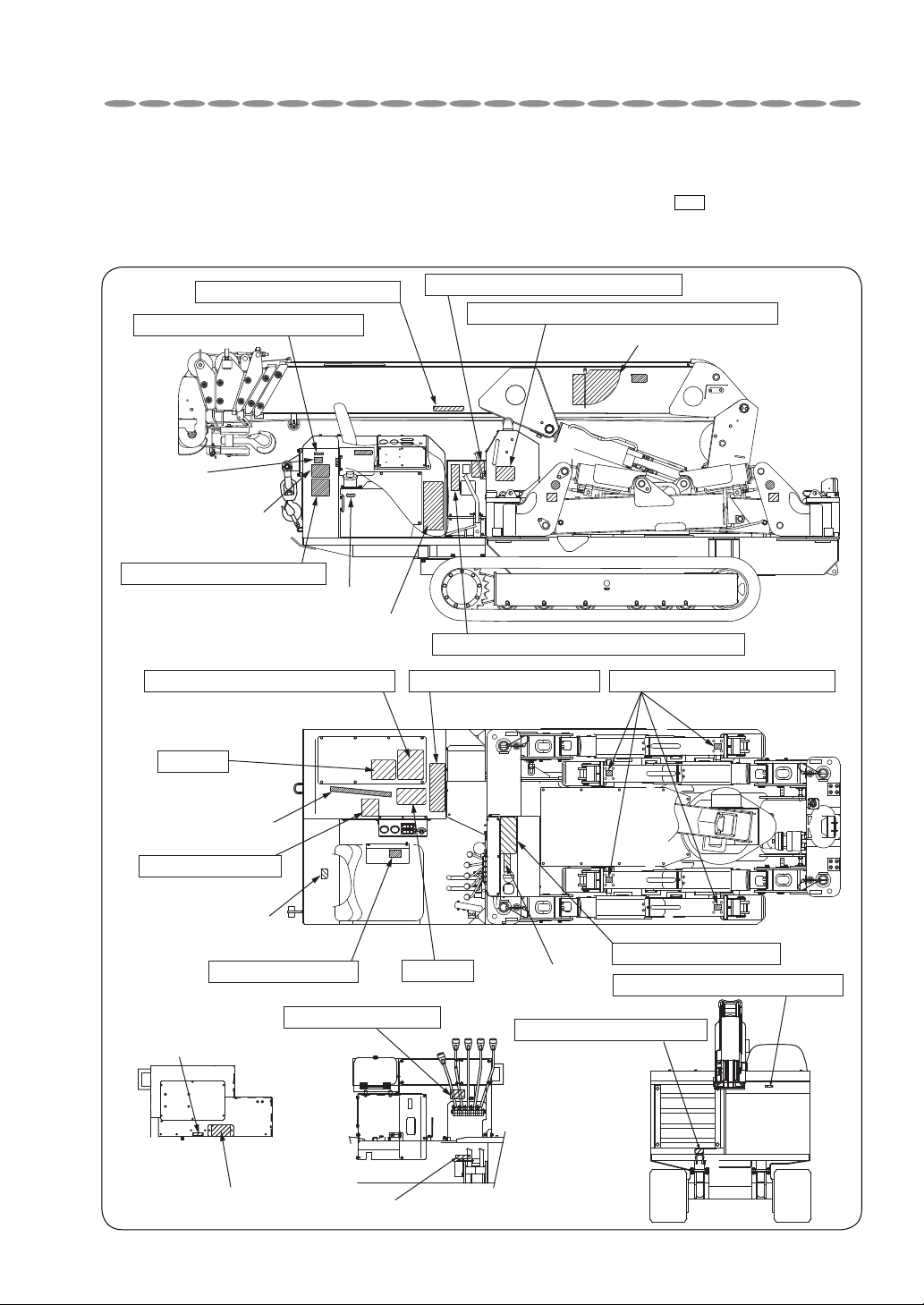

6. NAME PLATES

Caution, Crawling

Selector, Crawling/Crane

Caution, Storing hook

OR selector valve

Outrigger buzzer

Caution, High temperature

Boom raius indicator

Caution, High temperature

Caution, Mode indicator lamp

Loading and unloading procedures

Caution, Slewing boom

Mass of

crane body

Boom storage

Preparing crane operation

and Storing hook

Diesel fuel

Lifting up position

of crane body

Hydraulic oil

Outrigger mode

Chart of rated load

Caution, Radio controlled operation

Caution, Battery

Caution,Oil level check

Caution, Watch-your-foot

ì²

Emergency operationCaution, Outrigger operation

Working range

Caution

Caution

Description of name plates (Stickers)

The machine is provided with stickers indicating caution (framed in box ) and specifications

as shown in the figure below, and in addition to that there are stickers showing control levers,

switches, and instructions for lubrication.

6-1

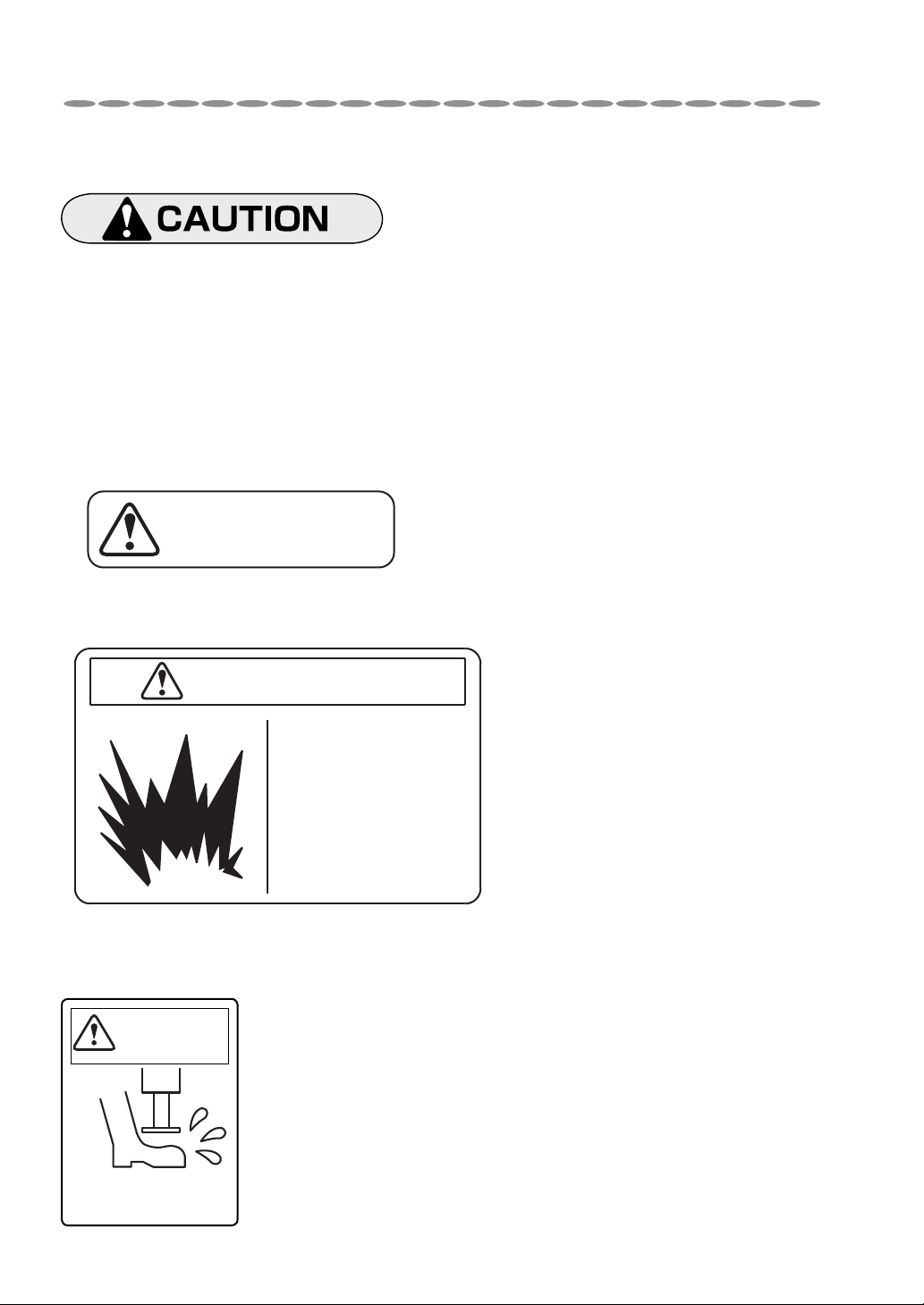

NAME PLATES

094383140

CAUTION, BATTERY

Wrong handling of battery may cause

to catch fire leading to explosion.

Do not make it short-circuiting,

sparking, and bring close to a fire.

In addition, you may be blinded or

burned by battery electrolytic solution.

When your eye, skin, or clothes was

stained with the solution, wash it away

with plenty of water immediately.

In case where the solution entered into

someone’s eye accidentally, see a

doctor to receive treatment after

washing it with water.

Stickers in detail

• Always keep the stickers clean so that they can be read easily.

• If any of the stickers has come off, stick it again or replace it with new

sticker.

• When ordering stickers, specify the part number shown at the bottomright of the sticker concerned.

Sticker [HIGH TEMPERATURE]

CAUTION, HIGH

TEMPERATURE

Sticker [BATTERY]

Sticker [WATCH-YOUR-FOOT]

Mind your

feet

Pay attention to your

feet when extending

outriggers.

6-2

094383110

NAME PLATES

Sticker [CAUTION]

Carry out operation after you have read the instruction manual carefully.

Confirm safety around the crane before starting operation.

Be sure to carry out inspection and maintenance before starting operation.

Be sure to stop power (engine,power source)before inspection and maintenance.

Carry out inspection and maintenance of engine after it has been cooled down.

As the engine heats up, pay attention to prevent fire,always checking the surrounding area.

Set up the crane flat and even by referring to a level.

Load indicator reads the crane capacity when the crane has been set up on the level and solid ground.

By referring to the reading of loadmeter,never try operating the crane overloaded.

When lifting up a cargo exceeding the rated load, the crane may be in danger of overturn.

Operate the crane by keeping to the rated load.

Do not travel with a load lifted and operate the crane without outriggers extended

which are very dangerous.

Operate the crane with the outriggers extended and with the truck raised

by approx. 2in above the ground.

Operation without the truck raised may damage the truck and operation

with truck raised too high is dangerous so that it is strictly prohibited.

Keep an appropriate distance between the boom top and the hook while extending the booms.

Simultaneous operation for extension and retraction of outriggers will not be possible.

Store the hook securely before traveling.

Be sure to turn OFF the key switch after crane operation has been completed.

09TV81061-W546C1UR

Sticker [CAUTION SLEWING BOOM]

CAUTION SLEWING BOOM

B-524360

6-3

NAME PLATES

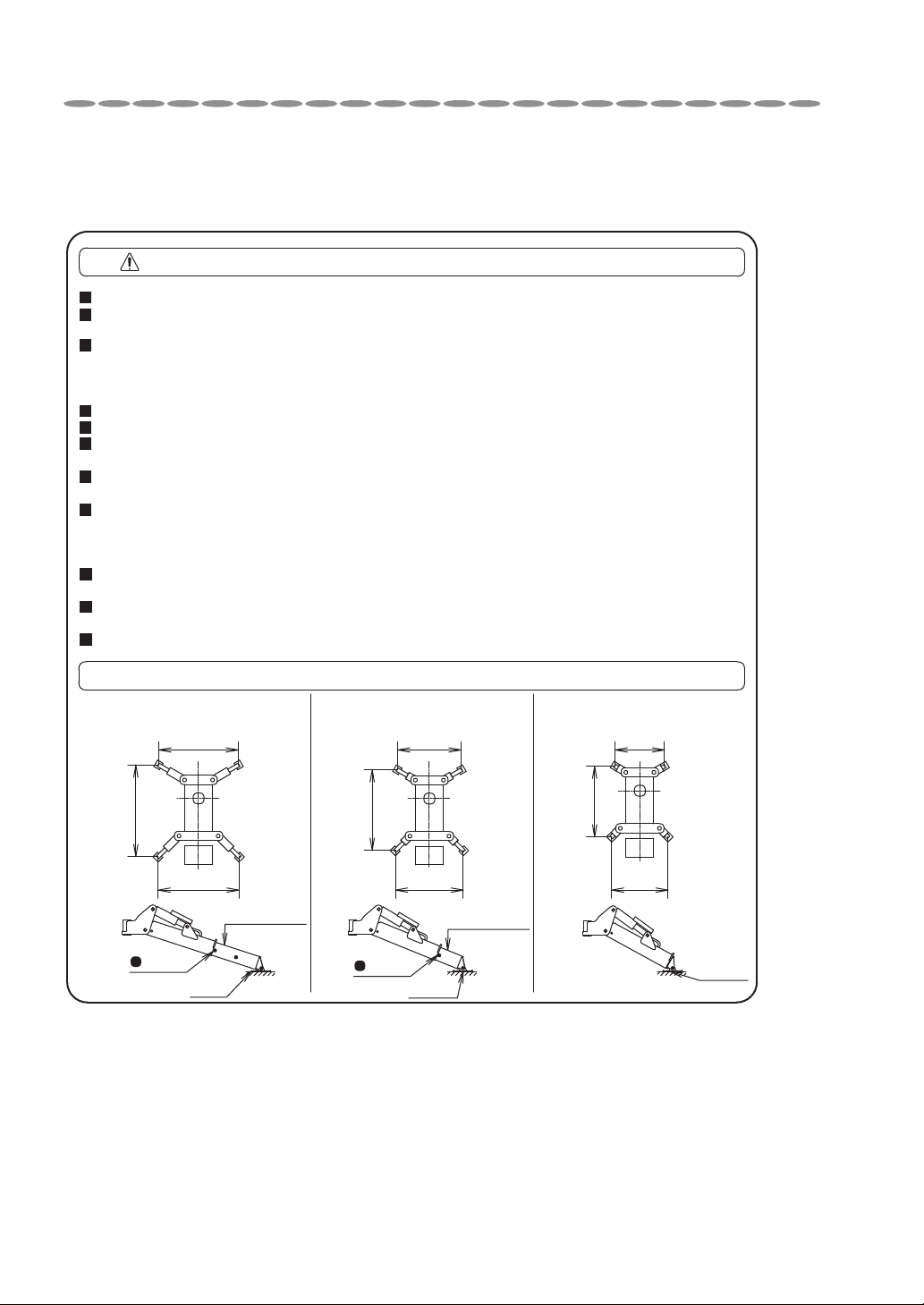

Sticker [POINTS TO NOTICE IN HANDLING OUTRIGGERS]

URW505C4U exclude

CAUTION OUTRIGGER OPERATION

When operating the crane, be sure to use outriggers to keep the crane body to be level.

Set up the outriggers on a flat and solid ground and in principle, operate the crane

with the outriggers fully extended.

When extending outriggers halfway, align the inner box extended either with the

halfway, or the minimum extension according to the “arrangement of outrigger extension”

and operate the crane each under the halfway or the minimum capacity specified in the

rated loads.

Do not extend vertical cylinder and inner box with the outriggers retracted.

Retract vertical cylinders before the stored outriggers are to be rotated.

Outriggers may become hard to be rotated when the floats touch to the supports

mounted lower side.

When setting up outriggers, be sure to touch them to the ground with vertical

cylinders after each inner box has been extended.

When swinging the boom with a cargo lifted up, stability of the crane is different

in the cargo lifted in front and rear and on the right and left.

Operate the crane with the working radius as short as possible and paying attention

that it will not to be overturned.

When storing outriggers, be sure to retract the inner boxes to their extremes after

each vertical cylinder has fully been retracted.

When outriggers are to be extended or stored, be sure to insert the pins so that

outriggers may not be rotated unexpectedly.

Be sure to store the outriggers before travelling.

ARRANGEMENT OF OUTRIGGER EXTENSION

Outriggers extended to maximum

Front

14.6ft

15.0ft

14.3ft

Rear

Inner box

Mark

(2nd)

Float

Outriggers extended halfway

Front

12.5ft

13.6ft

12.5ft

Rear

Inner box

Mark

(1st)

Float

Outriggers extended to minimum

Front

10.3ft

12.1ft

10.5ft

Rear

09VL81040-W376C1UR

Float

6-4

Loading...

Loading...