Page 1

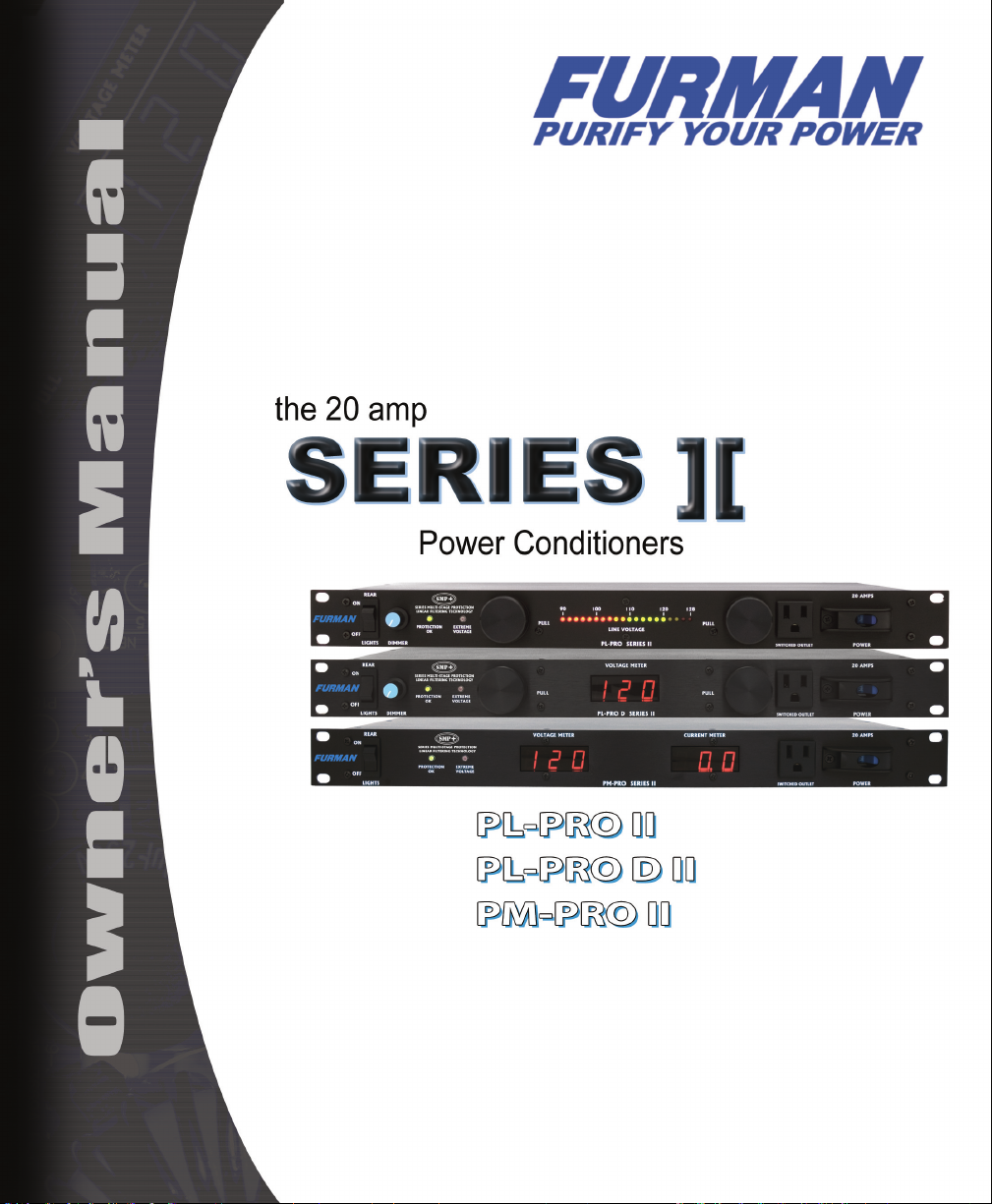

SERIES II 20 AMP POWER CONDITIONERS

Page 2

SERIES II 20 AMP POWER CONDITIONERS

1

Furman Series II Features

• SMP+ with extreme voltage shutdown

• LiFT (Linear Filtering Technology) with zero ground contamination

• Eight rear panel outlets and one front panel outlet

• BNC connector on the rear panel allows you to attach any standard

(12VAC 0.5 amp) gooseneck lamp to illuminate the rear of your rack

• 20 amp rating, with circuit breaker

• Three year limited warranty

PL-PRO Series II Additional Features

• Two retractable, long-life, low-heat LED light xtures with dimmer

control for rack illumination

• Front panel meter to display incoming line voltage ranging from 90 to

128 volts

PL-PRO D Series II Additional Features

• Two retractable, long-life, low-heat LED light xtures with dimmer

control for rack illumination

• Laboratory precision Digital Voltmeter displays incoming line voltage

(+/- 1.5 VAC)

PM-PRO Series II Additional Features

• Laboratory precision Digital Voltmeter displays incoming line voltage

(+/- 1.5 VAC)

• True RMS Current Meter displays power draw (+/- 0.5 amp)

Page 3

SERIES II 20 AMP POWER CONDITIONERS

2

I N T R O D U C T I O N

Thank you for purchasing a Furman Series II

Power Conditioner, and Congratulations on

your choice. The Series II power conditioners

feature Furman’s revolutionary Series MultiStage Protection Plus (SMP+) circuit, as well

as our exclusive Linear Filtering Technology

(LiFT). Together, these technologies comprise

what is, without question, the world’s most

advanced and comprehensive transient

voltage surge suppressor / conditioner.

SMP+ (Series Multi-Stage Protection

Plus)

Furman’s SMP+ surge suppression virtually

eliminates service calls. Traditional surge

suppression circuits “sacrice” themselves

when exposed to multiple transient voltage

spikes, requiring the dismantling of your

system, and repair of your surge suppressor.

Not so with SMP+. With Furman’s SMP+,

damaging transient voltages are safely

absorbed, clamped, and dissipated.

Unique to Furman’s SMP+ is its unparalleled

clamping voltage. While other designs offer

clamping voltages that are well above 330

Vpk, Furman’s SMP+ clamps at 188 Vpk,

(133 VAC RMS). This unprecedented level

of protection is only available with Furman’s

SMP+ technology. Additionally, Furman’s

trusted over-voltage circuitry protects against

all too frequent accidental connections to 208

or 240 VAC, by shutting off the incoming power

until the over voltage condition is corrected.

[For E versions: Furman’s SMP+ clamps at 376

VpK, (266 VAC RMS.)]

LiFT (Linear Filtering Technology)

Unfortunately, traditional AC lter - conditioners

have been designed for unrealistic laboratory

conditions. Prior technologies, whether

multiple pole lter or conventional series

mode, could actually harm audio and video

performance more than they help, due to the

resonant peaking of their antiquated, non-linear

designs. Under certain conditions, these

designs can actually add more than 10 dB of

noise to the incoming AC line! Worse still, lost

digital data, the need to re-boot digital pre-sets,

or destroyed digital converters are frequently

caused by excessive voltage spikes and AC

noise contaminating the equipment ground.

Furman’s SMP+ with LiFT takes another

approach, ensuring optimal performance

through linear ltering and no leakage to

ground.

S A F E T Y I N F O R M AT I O N

To obtain best results from your Furman Series

II Power Conditioner, please read this manual

Page 4

SERIES II 20 AMP POWER CONDITIONERS

3

carefully before using.

WA R N I N G

To reduce the risk of electrical shock, do not

expose this equipment to rain or moisture.

Dangerous high voltages are present inside the

enclosure. Do not remove the covers. Refer

servicing to qualied personnel only. The

lightning ash with an arrowhead symbol, is

intended to alert the user to the presence of

un-insulated dangerous voltage within the

product’s enclosure that may be of sufcient

magnitude to constitute a risk of electric shock.

I M P O R TA N T S A F E T Y

I N S T R U C T I O N S

(Please read prior to installation)

1. Please read and observe all safety and

operating instructions before installing your

Series II unit. Retain these instructions for

future reference.

2. Your Series II unit should not be used near

water – for example, near a bathtub, washbowl,

kitchen sink, laundry tub, in a wet basement,

near a swimming pool, etc.

3. Do not place your Series II unit near heat

sources such as radiators, heat registers,

stoves, or other appliances that produce heat.

4. The PL-PRO II, PL-PRO D II, and PM-PRO

II should only be connected to a 120 VAC,

60Hz, 20 amp grounded electrical outlet. Do

not defeat the ground or change polarization of

the power plug. (E versions 220 – 240 VAC 50 Hz., J

versions 100 – 120 VAC 50 Hz.)

5. Route the power cord and other cables so

that they are not likely to be walked on, tripped

over, or stressed. Pay particular attention

to the condition of the cords and cables at

the plugs, and the point where they exit your

Series II unit. To prevent risk of re or injury,

damaged cords and cables should be replaced

immediately.

6. Clean your Series II unit with a damp cloth

only. Do not use solvents or abrasive cleaners.

Never pour liquid on or into the unit.

7. Your Series II unit should be serviced by

qualied service personnel when:

• The power supply cord or the plug has been

frayed, kinked, or cut.

• Objects have fallen or liquid has spilled into

the unit.

• The unit has been exposed to rain or other

moisture.

• The unit does not appear to operate normally.

• The “Protection OK” indicator is not lit.

• The unit has been dropped, or the enclosure

has been damaged.

• The retractable LED lights have failed. (not

applicable to the PM-PRO II)

8. Your Series II unit requires that a safety

ground be present for proper operation. Any

attempt to operate the unit without a safety

ground is considered improper operation and

could invalidate the warranty.

Page 5

SERIES II 20 AMP POWER CONDITIONERS

4

9. Do not attempt to service your Series II unit

beyond what is described in this manual. All

other servicing should be referred to qualied

service personnel.

ADDITIONAL F E A T U R E S

PL-PRO SERIES II

The PL-PRO II features LED rack lights which

produce virtually no heat and provide an

extremely long life span. A dimmer control

for the rack lights allows the user to adjust the

level of illumination or simply switch the lights

off. A rear mounted BNC jack accepts any

standard (12VAC 0.5 amp) gooseneck lamp for

rear rack illumination.

Additionally, the PL-PRO II offers a 20 segment

LED bar-graph meter that displays incoming

voltage between 90 and 128 volts in 2-volt

steps. The normal range voltages are indicated

in green, with moderately and extremely high

or low voltages in yellow and red respectively.

The voltmeter’s accuracy is ±2 volts. It can

easily be re-calibrated, if necessary.

versions 180 – 256 VAC in 4 volt steps)

The PL-PRO II has a master magnetic circuit

breaker switch for the front and rear outlets that

is protected from accidental disconnection by

a hinged cover. The PL-PRO II also features a

10 foot, 12 gauge heavy-duty power cable.

PL-PRO D SERIES II

(E-

The PL-PRO D II features LED rack lights

which produce virtually no heat and provide

an extremely long life span. A dimmer control

for the rack lights allows the user to adjust

the level of illumination. A rear mounted BNC

jack accepts any standard (12VAC 0.5 amp)

gooseneck lamp for rear rack illumination.

Additionally, the PL-PRO D II offers a

laboratory precision digital meter that displays

incoming voltage in 1-volt steps. The

voltmeter’s accuracy is ±1.5 volt.

The PL-PRO D II has a master magnetic circuit

breaker switch for the front and rear outlets

that is protected from accidental disconnection

by a hinged cover. The PL-PRO D II also

features a 10 foot, 12 gauge heavy-duty power

cable.

PM-PRO SERIES II

The PM-PRO II features two laboratory

precision digital meters that display both

incoming voltage in 1-volt steps, and a true

R.M.S. current meter that measures the AC

power draw within 0.5 amp. A rear mounted

BNC jack accepts any standard (12VAC 0.5

amp) gooseneck lamp for rear rack illumination.

The PM-PRO II has a master magnetic circuit

breaker switch for the front and rear outlets

that is protected from accidental disconnection

by a hinged cover. The PM-PRO II also

features a 10 foot, 12 gauge heavy-duty power

cable.

Page 6

SERIES II 20 AMP POWER CONDITIONERS

5

O P E R AT I O N

Retractable Rack Lights, Rear Panel Lamp

and Dimmer Control:

The PL-PRO II and PL-PRO D II utilize a

dimmer control for the two retractable front

panel light tubes. The dimmer knob controls

the brightness of both light xtures. Turn

it clockwise to increase brightness; turn it

counterclockwise to decrease brightness.

When the lights are not in use, we recommend

turning the dimmer fully counterclockwise to

maximize the life of the LED’s, however, this

is not absolutely necessary. Whether the light

tubes are retracted or ush with the front panel,

there will be no appreciable heat regardless of

dimmer setting due to the efciency of our full

light spectrum LED’s.

All Series II units feature a rear rack BNC

socket which will accept any 12 VAC (0.5A)

gooseneck lamp assembly, (such as the

Multi -Segm ent L ED Voltme ter R eadi n gs

Mains Vltg. Voltage Status Voltmeter Reading Outlets

Furman GN-LED or GN-I). Simply slide the

BNC plug over the socket and rotate clockwise

until the connector snaps into the locked

position. The rear rack lamp can be powered

on or off with the rear light power switch

located on the far left of the front panel.

The Series II’s front panel LED lamps must

be replaced by qualied Furman service

personnel.

Multi-Segment LED voltmeter:

(PL-PRO II only)

This three-color, 20-LED bargraph is an

accurate, self checking AC voltmeter that

continually measures normal voltages. The

meter reads from 90 to 128 volts in 2 volt

increments (PL-PRO E II: 180 to 256 volts, in

4 volt increments). The normal range voltages

are indicated in green, with moderate and

extremely high or low voltages in yellow and

red respectively. The voltmeter provides three

special ashing patterns to indicate abnormal

conditions.

80-90 Low Marginal The LED beneath the 90V mark flashes ON

90-104 Low Meter Reads in Low Red ON

106-108 Medium Low Meter Reads in Low Yellow ON

110-120 Normal Meter Reads in Green ON

122-124 Medium High Meter Reads in High Yellow ON

126-128 High Meter Reads in High Red ON

130-140 High Marginal All Meter LEDs Flash ON

Above 140 Extreme (Shutdown) Meter off—Extreme Voltage LED illuminates OFF

Page 7

SERIES II 20 AMP POWER CONDITIONERS

6

current meter continually measures the total

(1) If only the single leftmost (beneath the

90V mark – 180V for E version) LED

ashes, the input voltage is marginally

low.

(2) If all of the LED’s on the voltmeter

ash, the input voltage is marginally

high. Power to the PL-PRO’s outlets

will remain unless the incoming

voltage rises above the Extreme

Voltage Shutdown cutoff voltage

(135 - 140 volts / 260 – 265 volts E

version / 120 – 125 volts J version).

(3) If none of the LED’s on the voltmeter

are lit, and the Extreme Voltages LED

indicator is illuminated, then the PL Plus II has shut down power to its

outlets because the input voltage is in

a range considered extreme (in excess

of 135 volts - 260 volts E version /

120 volts J version).

Digital Voltmeter:

(PL-PRO D II and PM-PRO II only)

Furman’s laboratory precision AC digital

voltmeter continually measures incoming

voltages, within a typical tolerance of +/-

1.5VAC. It should be noted that the voltage

reading is incoming. No adjustment should be

necessary on these units.

Digital Current Meter: (PM-PRO II only)

Furman’s laboratory precision AC digital

circuit AC load, within a typical tolerance of +/-

0.5 amp. Because these meters feature true

R.M.S. technology, the current readings are

accurate regardless of load conditions (capacitive,

inductive or resistive).

NOTE: The PL-PRO II, PL-PRO D II, and PMPRO D II, do not compensate for high or low

line voltage. If you frequently move your rack to

different locations, derive power from generators,

use long extension cords, travel internationally,

or are in an area prone to brownouts, you may

benet from the use of one of Furman’s AC Line

Voltage Regulators.

On/Off Circuit Breaker:

This 20 amp capacity magnetic circuit breaker

switch is specically designed to stand up to

the enormous high inrush current demands of

many Power Ampliers. Additionally, the switch

is shielded from accidental power disconnection

with a hinged cover. (E-versions feature 16 amp

capacity)

Extreme Voltage Shutdown Indicator:

This LED is normally off. It monitors a hazard

common in the entertainment industry: wiring

faults – for example, accidental connection

to 220VAC where 120VAC is expected, or an

open neutral from a 208 or 240VAC feed. The

Series II SMP+ circuit senses voltages that

are so high that operation would be impossible

and shuts the power down before damage can

occur. Upon initially applying power to these

Page 8

SERIES II 20 AMP POWER CONDITIONERS

7

units, the Extreme Voltage indicator LED will

light if the input voltage is above the extreme

voltage cutoff, and power will not be applied

to the unit’s outlets. If the unit has been

operating with an acceptable input voltage and

subsequently that voltage exceeds 135V, it will

shut off power to the outlet and the Extreme

Voltage LED will light. (E version: over voltage

shut down is 260 VAC. Guards against open

neutral and accidental connection to 300+

VAC)

Protection OK Indicator:

Although the Furman SMP circuit assures

virtually protection from transient voltage

spikes and surges, nature has a way of

occasionally creating electrical forces that are

beyond the capabilities of any TVSS device to

absorb without some degree of damage. In

the rare instance that this occurs, the green

“Protection OK” LED indicator located on your

front panel will dim. If this happens some level

of protection from voltage surges will remain,

but the Furman’s clamping voltage rating will

be compromised. The unit must be returned

to Furman Sound, or an authorized Furman

Service center for repair.

NOTE: If the mains power is above the high

cutoff voltage and has caused the unit to

remove power from its outlets, it cannot restore

power without the operator manually turning

the unit off, then on again. Avoid turning the

unit back on, without rst checking the source

of the problem, and perhaps changing the AC

source.

T R O U B L E S H O O T I N G G U I D E

1.) Symptom: No power to the AC outlets.

Possible Cause: Circuit breaker switch has

tripped to the off position, due to excessive

load.

Action Needed: Remove one piece of

equipment from the Series II unit, open the

hinged switch / breaker cover, and reset the

switch to the on position.

2.) Symptom: No power to the AC outlets,

“Protection OK” indicator is not lit.

Possible Cause: Either the AC outlet to which

your Series II device is connected has no AC

voltage present, or the unit has been subjected

to a sustained voltage in excess of 400 Volts.

Action Needed: Plug the Series II unit into an

AC receptacle where AC voltage is present. If

the problem persists, the protection circuit may

be damaged, and require factory service.

3.) Symptom: Extreme Voltage indicator lit.

Possible Cause: Input voltage is above 135-

140 volts (270 – 280 volts E version), causing

power to the unit’s outlets to be shut down.

Additionally, if the voltage is below 85 - 90 volts

at turn on, the unit will not allow AC voltage to

reach the outlets.

Action Needed: Correct the line voltage, then;

turn the unit on. Consider installing a Furman

voltage regulator.

Page 9

SERIES II 20 AMP POWER CONDITIONERS

8

DEFINITIONS

SPIKE: This is a pulse of energy on the

power line. Spikes can have voltages as

high as 6000 volts. Though they are usually

of very short duration, the energy they

contain can be considerable, enough to

damage sensitive solid-state components

in audio and computer equipment. Spikes

can also foul switch contacts and degrade

wiring insulation. They are an unavoidable

component of electric power. They are caused

unpredictably by electric motors switching

on or off (on the premises or outside), utility

company maintenance operations, lightning

strikes and other factors. Spikes (also called

surges or transients) are absorbed by special

components in the series II Series Multi-Stage

Protection circuitry to provide safe voltage

levels to protect your equipment.

RFI/EMI INTERFERENCE: Noise from RFI

(Radio Frequency Interference) or EMI (Electro

Magnetic Interference) involves lower voltages

and less energy than is found in spikes, but it

is continuous rather than transient in nature.

It is not likely to cause damage, but it can

certainly be annoying, producing static in audio

circuits, “snow” on video screens, or garbled

data in computers. Noise can be introduced

into AC lines by nearby radio transmitters,

certain kinds of lighting, electric motors, and

other sources. Because noise occurs at higher

frequencies than the 50 or 60 Hz AC line, it can

be effectively reduced through use of low-pass

ltering.

THREE YEAR LIMITED

WARRANTY

Furman Sound, LLC., having its principal place

of business at 1997 South McDowell Blvd.,

Petaluma, CA 94954 (“Manufacturer”) warrants

its 20 amp Series II Power Conditioners (the

“Product”) as follows:

Manufacturer warrants to the original

Purchaser of the Product that the Product sold

hereunder will be free from defects in material

and workmanship for a period of three years

from the date of purchase. The Purchaser

of the product is allowed fteen days from

the date of purchase to complete warranty

registration by mail or on-line at the Furman

website. If the Product does not conform to this

Limited Warranty during the warranty period

(as herein above specied), Purchaser shall

notify Manufacturer in writing of the claimed

defects. If the defects are of such type and

nature as to be covered by this warranty,

Manufacturer shall authorize Purchaser to

return the Product to the Furman factory or to

an authorized Furman repair location. Warranty

claims should be accompanied by a copy of

the original purchase invoice showing the

purchase date; this is not necessary if the

Warranty Registration was completed either via

the mailed in warranty card or on-line website

Page 10

SERIES II 20 AMP POWER CONDITIONERS

9

registration. Shipping charges to the Furman

factory or to an authorized repair location must

be prepaid by the Purchaser of the product.

Manufacturer shall, at its own expense, furnish

a replacement Product or, at Manufacturer’s

option, repair the defective Product. Return

shipping charges back to Purchaser will be

paid by Manufacturer.

THE FOREGOING IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED

TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. Manufacturer

does not warrant against damages or defects

arising out of improper or abnormal use of

handling of the Product; against defects or

damages arising from improper installation,

against defects in products or components

not manufactured by Manufacturer, or against

damages resulting from such non-Manufacturer

made products or components. This warranty

shall be cancelable by Manufacturer at its

sole discretion if the product is modied in

any way without written authorization from

Furman Sound. This warranty also does not

apply to Products upon which repairs have

been affected or attempted by persons other

than pursuant to written authorization by

Manufacturer.

THIS WARRANTY IS EXCLUSIVE. The sole

and exclusive obligation of Manufacturer shall

be to repair or replace the defective Product

in the manner and for the period provided

above. Manufacturer shall not have any other

obligation with respect to the Products or

any part thereof, whether based on contract,

tort, strict liability or otherwise. Under no

circumstances, whether based on this Limited

Warranty or otherwise, shall Manufacturer be

liable for incidental, special, or consequential

damages. Manufacturer’s employees or

representatives’ ORAL OR OTHER WRITTEN

STATEMENTS DO NOT CONSTITUTE

WARRANTIES, shall not be relied upon by

Purchaser, and are not a part of the contract

for sale or this limited warranty. This Limited

Warranty states the entire obligation of

Manufacturer with respect to the Product. If

any part of this Limited Warranty is determined

to be void or illegal, the remainder shall remain

in full force and effect.

S E R V I C E

Before returning any equipment for repair,

please be sure that it is adequately packed and

cushioned against damage in shipment, and

that it is insured. We suggest that you save

the original packaging and use it to ship the

product for servicing. Also, please enclose

a note giving your name, address, phone

number and a description of the problem.

NOTE: All equipment being returned for

repair must have a Return Authorization (RA)

Number. To get an RA Number, please call the

Furman Service Department: (707) 763-1010,

ext. 121. Please display your RA Number

prominently on the front of all packages.

Page 11

SERIES II 20 AMP POWER CONDITIONERS

10

SPECIFICATIONS

Current rating:

20 amps (“E” versions 16 amps)

Operating Voltage:

90 to 140 VAC (“E” versions 180 to 280 VAC)

Over Voltage Shutdown:

140 VAC typically (“E” versions 260 VAC typically, “J” versions 125 VAC typically)

Voltmeter Accuracy:

PL-PRO II only: ±2 VAC, calibrated with internal

trimpot adjustments

PL-PRO D II & PM-PRO II: ±1.5 VAC,

PM-PRO II Current meter: ±0.5 amp

Spike Protection Modes:

Line to neutral, zero ground leakage

Spike Clamping Voltage:

188 Vpk @ 3,000 amps, (133 VAC RMS)

(“E” Version: 376 Vpk (266 VAC RMS)

Response time:

1 nanosecond

Maximum surge current:

6,500 amps

Noise attenuation:

10 dB @ 10 kHz

40 dB @ 100 kHz

100 dB @ 10 MHz

Linear attenuation curve from 0.05 - 100 ohms line impedance

Mechanical:

Dimensions: 1.75” H x 19” W x 10.5” D.

Weight: 11 lbs (5 kg).

Construction: Steel chassis, .125” brushed and black anodized aluminum front panel; glass epoxy printed circuit boards

Power Consumption:

PL-PRO II, 12 watts

PL-PRO D II, 12 watts

PM-PRO II, 12 watts

Safety Agency Listings:

CE, NRTL-C

Make sure to pick up one of

Furman’s goosneck lights the perfect accesory for your

Series II unit.

GN-LED

GN-I

Page 12

SERIES II 20 AMP POWER CONDITIONERS

111804-C

Furman Sound, LLC.

1997 South McDowell Blvd.

Petaluma, California 94954-6919 USA

Phone: 707-763-1010 Fax: 707-763-1310

Web: www.furmansound.com

E-mail: info@furmansound.com

Loading...

Loading...