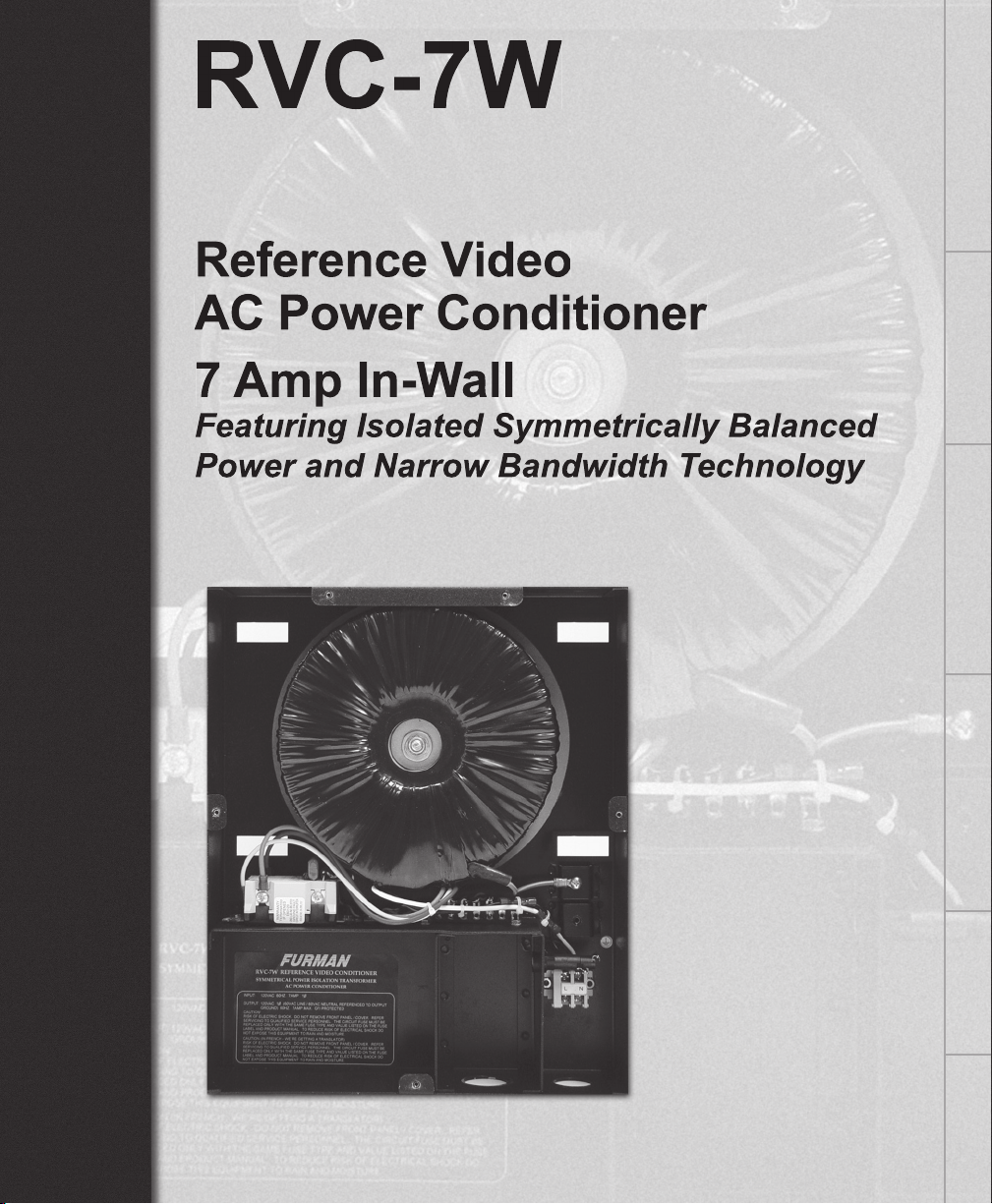

Page 1

AC Power Conditioner

O w n e r ’ s M a n u a l

IN T R O D U C T I ONS FEATURES DESCRIPTION INSTALLATION SAFETY SPECS

Page 2

RVC-7W

- 2 -

The

is a no-compromise,

no-expense-spared design, with painstak-

ing attention paid to every component.

ing them from transient voltage surges.

power regulating and conditioning line of

professionals for more than 28 years.

all video frequencies up to 1 GHz.

suppression protects your valuable equip-

service calls.

exceeds the current demands of the largest

the isolated output eliminates potential AC

accepts any house paint chosen by interior

decorators.

The specially constructed toroidal trans-

former is the fi nest available, yielding

extremely low magnetic fi eld leakage, and

of load or AC source contamination.

tacles are individually ground fault (GFCI)

I N TRODU C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 3

RVC-7W

- 3 -

The RVC-7W’s isolated symmetrically bal-

anced power ensures no ground contamina-

tion from your incoming line will affect your

fi ltered AC power, as it is totally isolated. This

total isolation of both ground and incoming

AC power means your critical video reproduc-

tion will not suffer AC hum bars, RF, or EMI

These distortions occur when AC power is

shared throughout a building or home. They

VAC Neutral - reference to output Ground at

and magnetic fi elds from penetrating or radiat-

video components. Additionally, the RVC-7W’s

virtually maintenance free TVSS circuitry, as-

sure electrical safety, and protectionof your

valued video component.

and packing materials for any obvious dam-

age. If internal damage is likely, contact the

damage is evident, contact the carrier. Save

all shipping and packing materials. You may

factory for service. The box should contain

the RVC-7W unit, Left and Right (L - type)

out and return your warranty registration card.

source (wiring) to which a RVC-7W is con-

Wiring to the RVC-7W’s AC input terminal

should have proper safety listing and meet

the electrical codes for your area. If in doubt,

to the walls wooden studs with the supplied

#10 screws. When properly placed, the main

will easily support the RVC-7W’s weight. The

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 4

RVC-7W

- 4 -

that the

back

surface of the unit’s

panel is

fl ush with the outside surface of the wall, and

the panel covers the wall cut-out. Because of

the Reference Series’ low-fl ux density trans-

former design, placement or proximity to a

tened to wall studs on either side of the RVC-

of the chosen mounting location be precisely

2. We have supplied a cut-out template

aid sheet-rock installers for new construction.

wall mount bracket, pay attention to the verti-

front panel will accept any household paint to

further aid in your installation, make sure that

the RVC-7W’s signal wire and AC output cable

are supplied with each RVC-7W, and are also

supplied as a separate accessory (HRKIT-

4. Now it’s time to mark the position of the pilot

struction it’s easier, however you MUST know

the exact depth of the wall material, (1/2” or 5/8”

adjustment from back to front. Both have hole

screw pilot holes will be relatively simple. Once

you’ve determined where the vertical center of

your RVC-7W and or fl at screen will be, mark

the studs with a level to show your center line

the short side facing out). This can be done

with retrofi t installation as well, after the rect-

angular cutout has been made (a fl ash light or

stand mounted light may be necessary to see

6. Mark a horizontal line 1/4” below the center

the vertical pilot hole positions for the RVC-

vertical marks that will determine depth. For

depth or material thickness of the sheet rock,

sheet rock is most common, and it’s usually

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 5

RVC-7W

- 5 -

two scenarios for you. For new construction,

the depth marks for the #10 screw pilot hole

are: (See fi g. 2)

- for 1/2” wall thick-

outside front edge of the stud, or inside surface

of the wall that will be facing you.

or inside surface of the wall that will be facing

you.

surface.

- 1-15/16” deep from the outside

wall surface. Since the stud will be set back

from the wall cutout, it may be benefi cial to

subtract the wall thickness and space the end

of your measuring device fl ush with the inside

of the wall (assuming the devices edge starts

standard 1/2” and 5/8” wall thickness.

the installation center line is NOT drilled, it’s

only a reference marking.

We recommend a drill bit no larger in diameter

than 1/16” as most studs are a soft wood, and

these brackets must support 40lbs. In the rare

event that the studs are made of a metal mate-

CENTER

CENTER

LINE (R)

LOWER BRACKET

LINE - 1/4" BELOW

CENTER (R)

UPPER BRACKET

LINE - 5-1/4" ABOVE

CENTER (R)

WALL STUDS

FIG.1

CENTER

WALL STUDS

RIGHT SIDE

DEPTH LINE

1-5/16" FO

R

5/8" SHEET

ROCK

.

1-15/16" TOTAL

FROM OUTSIDE

EDGE OF WALL

TO DEPTH LINE.

FIG. 2

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 6

RVC-7W

- 6 -

ate to working with metal.

stalled. The “hooks” should be facing upwards

to support the rectangular cutouts in the rear of

the RVC-7W’s chassis.

signal and AC wiring will mount through the

sure there’s suffi cient signal wire or cabling

to pass through the bottom of the RVC-7W,

through the front panel cutout, and ultimately

typically requires less than 1ft. of wire beyond

the bottom of the chassis. However, a service

there will be plenty of space below the RVC-

ton. Use a Phillips screwdriver to remove the

and to the right should not be loosened! It is a

grounding strap screw, and is not used to attach

the front panel to the chassis. (See fi g. 3)

front panel ground strap from the chassis.

wiring through the unit yet. The purpose for

at this time is to check the alignment of the

sticking out, or is recessed too far, an adjust-

so inaccurate as to make the RVC-7W hang at

a noticeable angle clockwise or counter-clock-

wise.

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 7

RVC-7W

- 7 -

S

YMMETRICAL

POWER ISOLA

TION TRANSF

ORMER

A

C POWER CONDITIONER

RVC-7W R

EFERENCE VIDE

O CONDITIONER

INPUT: 120VAC 60HZ. 7AMP 1O

OUTPUT: 120VAC 1O (60VAC LINE / 60VAC NEUTRAL REFERENCED TO OUTPUT

GROUND) 60HZ. 7AMP MAX. GFI PROTECTED

CAUTION!

RISK OF ELECTRIC SHOCK. DO NOT REMOVE FRONT PANEL / COVER. REFER

SERVICING TO QUALIFIED SERVICE PERSONNEL. TO REDUCE RISK OF ELECTRICAL

SHOCK DO NOT EXPOSE THIS EQUIPMENT TO RAIN AND MOISTURE.

AVIS!

CIRCUIT COMMUN ISOLE DE LA MASSE A LA SORTIE. MEME SI LE COURANT

A

LA SORTIE EST MUNI DE PROTECTION GFI, NE JAMAIS TOUCHER LES FILS

EXPOSES

OULES PARTIES EN METAL SANS TESTER POUR LA PRESENSE DE

TENSIONS A.C.

!

ETL LISTED 3041249 CONFORMS TO ANSI/UL #1012

CERTIFIED TO CAN/CSA E335-1/3E-94

L

N

adjusted, remove the chassis and install the

are very common at any hardware or electrical

supply store, and individual installers will have

their preferences as to model and manufac-

ture. All we (and your local inspector) require is

that the cable clamps be standard CSA, C-UL,

The larger hole on the bottom surface is for the

signal wiring and cables. It requires a 1” con-

duit cable clamp. The smaller hole to the right

to neatly dress these wires and cables. There is

dress the signal wiring through the large clamp,

and the A.C. wiring through the small clamp.

this operation, or place it on a stand or table im-

the incoming AC wiring be DISENGAGED dur-

this switch must be at least 3 m.m. (virtually all

switched circuit breakers will meet this criteria).

dressing, and installing these wires!

secured by the clamps, place the chassis on the

the Neutral wire into the A.C. terminal block

a slotted screwdriver. Place the Line wire into

the A.C. terminal block marked “L”, (bottom

opening) and secure with a slotted screwdriver.

The ground wire must be surely fastened to

the green 10-32 slotted screw on the bottom.

A listed ring lug, appropriate for the wire gauge

wire around the screw is acceptable in some

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 8

RVC-7W

- 8 -

your area. Make sure all three wires are se-

tachable A.C. cord to the GFI outlet (this is to

20. Connect the ground strap from the front

of the input ground screw. Make sure this is

secure, as it is for both safety and R.F. shield-

ground connection is compromised, the noise

attenuation will suffer. Now, re-attach the front

21. Go to the electrical panel and switch the

the GFI outlet, and will be visible when you

front panel.

22. If you are using the RVC-7W for a projec-

tor, you’re fi nished! However, if you are mount-

from the wall surface .076” (approximately

will have center sections that press fl ush to

the RVC-7W’s front panel, we have included

of the front panel, when securing the plasma

As the RVC-7W incorporates Isolated Sym-

to guard against catastrophic failure in Refer-

ence components. Under normal conditions,

the addition of Furman’s Isolated Symmetrical

Technology, any form of electrical shock (under

ed a GFCI (ground fault interrupter). This GFCI

will immediately disconnect the output voltage

when it detects an excess of fi ve milliamps cur-

This ensures that even if your lcd, plasma, or

there will be no possibility of electric shock

the RVC-7W.

occasionally possible to false trip the GFCI if

additional fi lters with unacceptable levels of

designs can actually create as much noise as

they attempt to reduce, we recommended they

just press the reset tab in the center of the

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 9

RVC-7W

- 9 -

to your systems components. The GFCI is

anti-chamber located on the RVC-7W’s lower

you do not wish to remove it, the eraser side of

a pencil can easily reset the GFCI. When the

tab is properly reset, the blue AC output indi-

voltage to the unit).

The RVC-7W is capable of suppressing virtu-

ally any instantaneous voltage surge. However,

the protection device may be damaged if the

over-voltage spike is sustained and extreme,

switch will not stay in the “on” position. If this

though typically this will not be necessary.

and operating instructions before the

service and installation professionals.

a switched electrical panel that has been

disengaged.

enter the unit.

standards for use of Balanced A.C. Power,

we recommend that the RVC-7W be limited

to use with video equipment, and screen art

accessories.

The RVC-7W should be serviced by qualifi ed

service personnel when:

treme moisture.

ground be utilized from the source AC power

to the input of the Reference unit. This ground

without the incoming safety ground is consid-

ered improper operation and will invalidate the

warranty.

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 10

RVC-7W

- 10 -

WARRANTY

Furman Sound, Inc. warrants to the original purchaser of

free from defects in material and workmanship for a period

at the Furman website. If the purchaser fails to complete

reduced to one year from the date of purchase.

purchaser shall notify Furman in writing of the claimed

be covered by this warranty, Furman shall authorize the

purchaser to return the product to the Furman factory or

should be accompanied by a copy of the original purchase

invoice showing the purchase date; this is not necessary if

in the completed warranty card or by registering on-line

at the Furman website. Shipping charges to the Furman

factory or to an authorized repair location must be prepaid

by the purchaser of the product. Furman shall, at its own

ment that is damaged by transient voltage (an “Occur-

rence”) while properly connected through the Furman

Equipment Warranty is limited to the amount of the deduct-

ible on the Purchaser’s personal property insurance policy

Equipment Warranty, the Purchaser must forward a copy

aged equipment to Furman and complete the Furman

right to review the damaged Furman product, the damaged

man for inspection shall be borne solely by the Purchaser.

Damaged equipment must remain available for inspec-

All warranties contained herein are null and void if: the Fur-

man Surge Protector in use during the occurrence is not

provided to Furman for inspection upon Furman’s request

at the sole expense of the Purchaser, Furman determines

properly installed, altered in any way or tampered with,

Furman determines that the damage did not result from

Furman determines that the connected equipment was not

ment. All Furman Surge Protectors must be plugged di-

rectly into a properly wired AC power line with a protective

ground and must not be “daisy-chained” together in serial

fashion with other power strips, UPS’s, other surge protec-

such installation voids this warranty. The Furman warranty

ment where Furman has determined, at its sole discretion,

not protect against acts of God (other than lightning) such

as fl ood, earthquake, war, terrorism, vandalism, theft,

normal-use wear and tear, erosion, depletion, obsoles-

product in anyway with a generator, heater, sump pump,

automobile, motorcycle, or golf-cart battery charger. To

be used indoors only and in dry areas. All warranties con-

NOT LIMITED TO THE IMPLIED WARRANTIES OF

PURPOSE. Furman does not warrant against damages

from improper installation, against defects in products or

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 11

RVC-7W

- 11 -

ages resulting from such non-Furman made products or

at its sole discretion if the product is modifi ed in any way

also does not apply to products upon which repairs have

been affected or attempted by persons other than pursuant

fective product in the manner and for the period provided

above. Furman shall not have any other obligation with

respect to this product or any part thereof, whether based

sentatives’ ORAL OR OTHER WRITTEN STATEMENTS

DO NOT CONSTITUTE WARRANTIES, shall not be relied

sale or this limited warranty. This Limited Warranty states

a Warranty Registration Card was mailed in at the time of

purchase or if the product was registered on-line, this is

not necessary). Before returning any equipment for repair,

please be sure it is adequately packed and cushioned

against damage in shipment, and that it is insured.

that it is insured. We suggest that you save the

original packaging and use it to ship the product

for servicing. Also, please enclose a note giving

your name, address, phone number and a de-

scription of the problem.

To get an R/A Number, please call the Furman

or 121, between 8 a.m. and 5 p.m., U.S. Pacifi c

Time. Please display your R/A Number promi-

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Page 12

RVC-7W

- 12 -

Web: www.furmansound.com

draw Outlets: 2 (Isolated Symmetrical Balanced A.C.

outlets) Protection: GFCI circuit protection for all AC

outlets

Transient Voltage

Surge Suppression: Stand-off Voltage 200V Maximum Clamping Voltage

324V 10/1000 – 65,000 Watts @ 20uS. Test = 300,000

Watts Peak Power Handling

Overall (installed): 3.45” (from outside front panel) 3.375” from out side

wall surface

Weight: 42 lbs. (without brackets) Weight in shipping carton

Agency Listing: C-ETL to U.L. standard #1012

I N T R O D U C T I O N F E A T U R E S DESCRIPTION INSTALLATION SAFETY SPECS

Loading...

Loading...