Page 1

)

TRT800RT - OLED

Remote Control Unit

P/N 800ATC-H-(Rxx)-(Rxx

Operation and Installation

(Document-No. 03.202.010.71e)

Page 2

Page 3

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

Change History

Revision Date Description of Change

1.00 22.10.2012 First Release

List of Service-Bulletins (SB)

Service Bulletins have to be inserted into this manual and to be enlisted

in the following table.

SB No

Rev.

No.

Issue Date

Insertion

Date

Name

Survey of Variants

Part Number Description

P/N 800ATC-H-(R00)–(R00) First version with OLED-Display

2Document-No: 03.202.010.71e / Revision: 1.00

Page 4

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

Table of Contents

1 GENERAL................................................................................................... 4

1.1 Symbols ........................................................................................... 4

1.2 Abbreviations ................................................................................... 5

1.3 Customer Support ............................................................................ 6

1.4 Features ........................................................................................... 6

2 OPERATION............................................................................................... 7

2.1 Controls............................................................................................ 7

2.2 Switch ON/OFF ................................................................................ 9

2.3 Display - Indications ....................................................................... 10

2.4 Display-Brightness ......................................................................... 11

2.5 Flight-ID (FID) ................................................................................ 11

2.5.1 Display Flight-ID ................................................................. 12

2.5.2 Configure Flight-ID .............................................................12

2.6 Transponder Mode selection.......................................................... 13

2.7 Squawk-Setting .............................................................................. 13

2.8 VFR – Squawk ............................................................................... 14

2.9 ID – Special Position Identification (SPI): “Squawk Ident” ............. 14

3 INSTALLATION ........................................................................................15

3.1 Notes.............................................................................................. 15

3.2 Scope of Delivery ........................................................................... 15

3.3 Unpacking and Inspecting of the Equipment ................................. 15

3.4 Mounting ........................................................................................ 16

3.5 Equipment Connections ................................................................. 17

3.5.1 Electrical Connections........................................................ 17

3.6 Wiring ............................................................................................. 17

3.6.1 Conductor Cross Section.................................................... 17

3.6.2 Pin Assignment................................................................... 17

3.7 Post-Installation Check ..................................................................18

3.8 Drawings ........................................................................................ 19

3.8.1 Dimensions......................................................................... 19

3.8.2 Mounting Advices ............................................................... 19

4 APPENDIX................................................................................................ 20

4.1 Technical Data ............................................................................... 20

4.2 Environmental Conditions .............................................................. 21

3 Document-No: 03.202.010.71e / Revision: 1.00

Page 5

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

1 GENERAL

This manual contains information about the physical, mechanical and

electrical characteristics and about installation and operation of the

transponder remote control TRT800RT.

1.1 Symbols

Advices whose non-observance can cause radiation

damage to the human body or ignition of combustible

materials

Advices whose non-observance can cause damage to the

device or other parts of the equipment.

Supplementary information

4Document-No: 03.202.010.71e / Revision: 1.00

Page 6

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

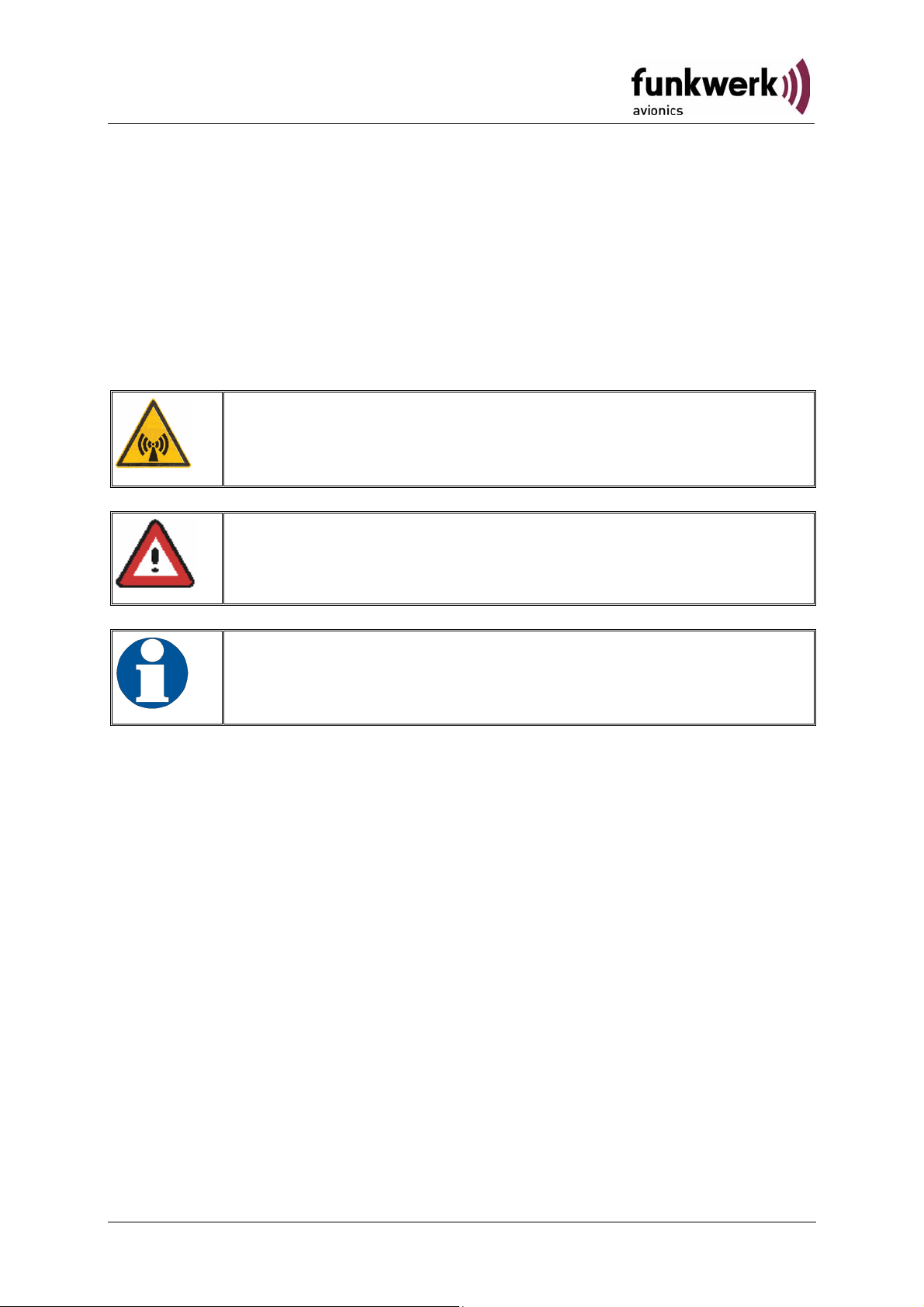

1.2 Abbreviations

Abb. Meaning Explanation

FID Flight ID Flight plan number or if not assigned

registration number of aircraft

SPI Special Position

Identification

Activation on request by controllers

„Squawk Ident“, transmits SPI Pulse

for 18 seconds, which highlights the

respective traffic item on the

controllers radar screen

5 Document-No: 03.202.010.71e / Revision: 1.00

Page 7

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

1.3 Customer Support

In order to facilitate a rapid handling of return shipments, please follow

the instructions of the input guide „Reshipment RMA“ provided at the

Service-Area within the Funkwerk Avionics web portal www.funkwerk-

avionics.com.

Any suggestions for improvement of our manuals are

welcome. Contact: service@funkwerk-avionics.com

.

Informations on software updates are available at Funkwerk

Avionics

1.4 Features

Remote control and indication of all transponder settings/data during

standard operation (e.g. squawk code, operation mode, altitude etc).

Ideal for tandem seated aircraft:

Use of transponder still possible without activation of remote control

Automatic deactivation of remote control on deactivation of

transponder

6Document-No: 03.202.010.71e / Revision: 1.00

Page 8

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

q

q

q

Operation and Installation

2 OPERATION

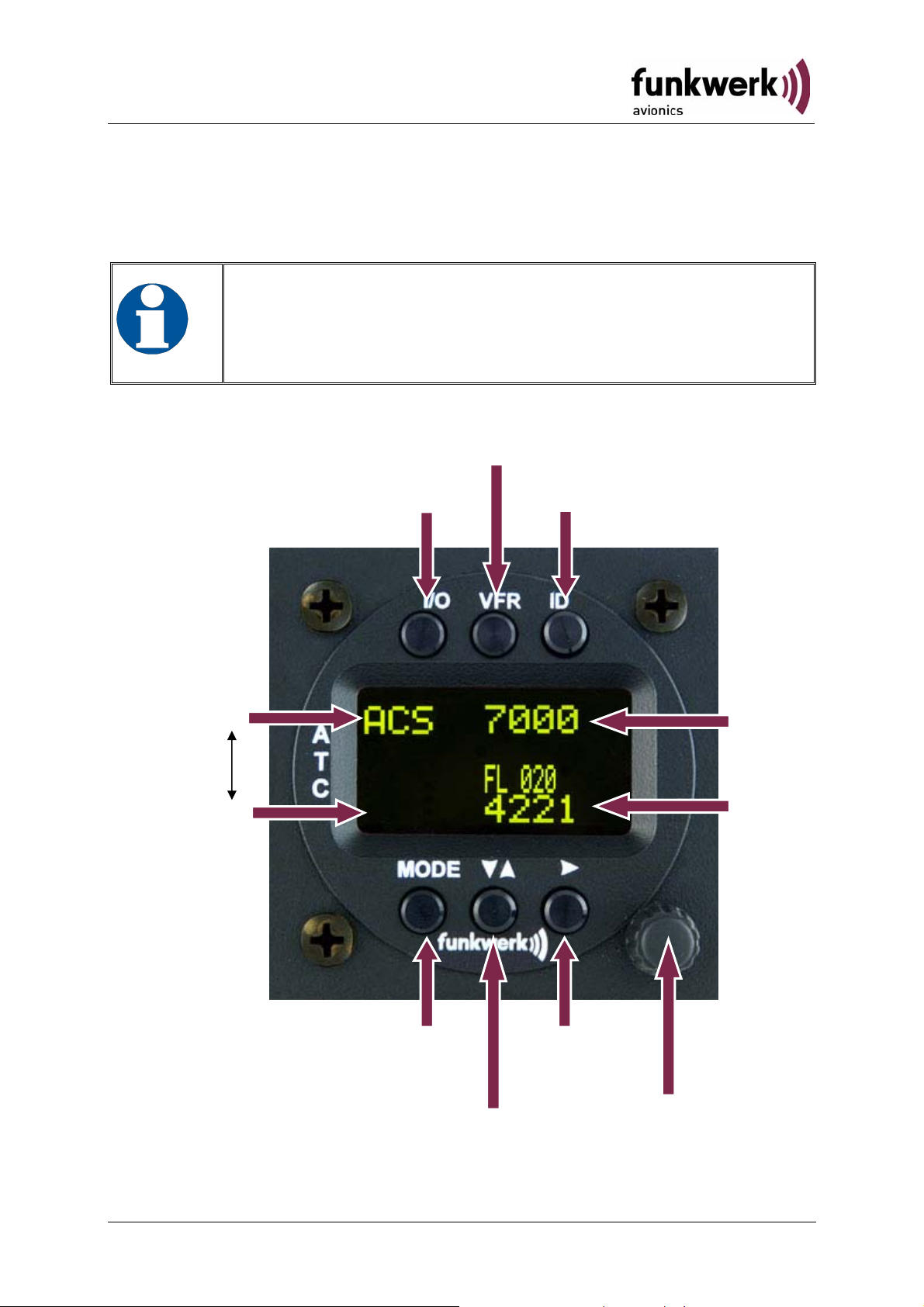

2.1 Controls

If remote unit settings are inconsistent with transponder

settings as a result of short time transmission problem

(e.g. simultaneous user inputs) remote unit settings will be

reverted to current transponder setting.

Activate/

deactivate VFR

active

Operation

Mode

standby

ON / OFF

„Squawk Ident“

Active

uawk

S

Standby

uawk

S

Select Operation

Change

Active Ù Standby

S

7 Document-No: 03.202.010.71e / Revision: 1.00

Cursor

adjustment

uawk

Rotary Knob

for adjusting values

at the cursor

position

Page 9

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

►►Switch ON press button for approx. 0,5 s

I/O ON/OFF

Switch OFF press button for approx. 3 s

►

activate/deactivate VFR Squawk

(press shortly)

VFR VFR

store active Squawk as VFR/VFRW-Squawk

►

(press button 3 s, →2.8)

►►change between active and standby-Squawk

works as cursor back button (opposite function

▲▼ CHANGE

of the cursor button) during entering values and

also for navigating backwards through the

configuration menu (→Fehler! Verweisquelle

konnte nicht gefunden werden.)

►

„Squawk Ident“, sends Ident marking (SPI) for

18 s (→ 2.9)

ID IDENT

►

Enter Flight-ID (FID) setup (in standby mode,

press button for approx. 5s)

► Select transponder operational mode (→ 2.6)

MODE MODE

► Set position of Cursor

► CURSOR

► Adjust/Enter values at current cursor position,

Rotary

select options; set standby Squawk (→ 2.7)

Knob

8Document-No: 03.202.010.71e / Revision: 1.00

Page 10

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

S

000

Operation and Installation

2.2 Switch ON/OFF

Switch ON: press I/O for 0.5 s

Switch OFF: press

2.2.1 Display information after power up

After turning-on the display appears as follows (example):

I/O for 3 s

Device Name

TRT800RT.

V1.1

2000

FL 030

TBY 7

Software Version

Connection to transponder

is successfully established

Transponder

not

detected

9 Document-No: 03.202.010.71e / Revision: 1.00

Transponder is not found /

data transmission failed

Page 11

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

A

Operation and Installation

2.3 Display - Indications

Operational Mode:

ctive

ACS

SPI indicator

Operational Mode

Standby

Value Meaning Remarks

7000 active Squawk

2000 Standby Squawk Could be changed with active

PLL/TRX/

IDT FL 030

STBY

Lock out

indication

DC | BAT/DIM

Error

indications

Reply

indication

7000

2000

Passive

Squawk

Squawk by pressing

Active Squawk

Backlight setup

Low battery ind.

Flight level

F

GND switch

status

▲▼

FL 010

FLerr

ACS Operational Mode

IDT transmits Ident-Marking (SPI) ID („Squawk Ident“) has been

| Transponder is locked by a

F

G

Flight Level

Invalid altitude measuring

(STBY, A-S, ACS, AC, A)

Transponder replies

on Mode-S, Mode-A or ModeC interrogations

ground station and will be

directly addressed

in-flight

on-ground

Flight Level (in 100 ft steps)

Modes see section 2.6

pressed – active for 18 s

No indication on ADSB and

squitter transmission

Lock Information (indicated

below the diamond)

Ground-Switch-Info

(if available)

10Document-No: 03.202.010.71e / Revision: 1.00

Page 12

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

Error indicators

PLL PLL Error Internal Error

TRX Transmit Failure Check antenna and wiring

DC Low internal voltage Internal error

FPG FPGA-Failure Internal error

BAT Battery Power too low maybe battery/generator fault

Note: Short time indication symbols (e.g. lock-out indication or reply

indication) are displayed/cleared in different time interval or delayed in

comparison with TRT800H screen.

2.4 Display-Brightness

In active mode (not standby) press ► for 2 s

Display indicates “DIM” Æ Adjust brightness (DIM) with rotary knob

Return to normal operation: press

► or wait 5 s.

2.5 Flight-ID (FID)

The FID is an identifier required by Mode-S Operation. During future

application of flight plans a FID could be assigned on a per flight basis. If

no FID is assigned (today’s normal case) the registration marking of the

aircraft should be used as FID. The FID should not

blanks.

contain dashes or

11 Document-No: 03.202.010.71e / Revision: 1.00

Page 13

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

_ _

_

Operation and Installation

2.5.1 Display Flight-ID

Press

Press and hold ID while a counter is shown beside the active squawk.

During a few seconds Flight Identification is displayed

MODE (repeatedly) until „STBY“ appears

FID 02

A B C D E F G H

2.5.2 Configure Flight-ID

Press

Press and hold ID while a counter is shown beside the active squawk.

Release

CHANGE FID

MODE (repeatedly) until „STBY“ appears

ID when “CHANGE FID” is displayed

_ _ _ _ _

A B C D E F G H

exit

Enter Flight-Id with cursor button ► and rotary knob

Enter FID left-aligned, without any blanks or dashes (!)

12345621DEFAV for the marking D-EFAV. The last

remaining digits shall be filled with blanks

Press

12Document-No: 03.202.010.71e / Revision: 1.00

MODE to save and return to STBY

After FID is changed: Check that new FID is accepted and

correctly set

, e.g.

Page 14

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

2.6 Transponder Mode selection

Press MODE (repeatedly) to select from following Modes:

• STBY Æ „Standby“

Transponder does not respond to any interrogation. Squitter and

ADS-B output is not active.

• ACS Æ„Mode A+C+S“

Standard condition; transponder responds to mode A, C and S

interrogations.

• A-S Æ „Mode A+S, no C“

Altitude is not transmitted (neither on C nor on S requests). All

other Mode-S data as well as Mode-A replies are transmitted.

If no 24-bit address (AA) was defined or entered as “000000“ the

transponder works as Mode A-C transponder, in that case the

following Modes are possible apart from Standby:

• AC- Æ „Mode A+C“

Transponder replies only on Mode A and Mode-C interrogations.

• A-- Æ „Mode A“

Transponder replies only on Mode A interrogations.

In STBY (Standby) mode, all transponder transmissions

are disabled completely! Therefore, the transponder is not

visible in this mode to air traffic control or the anti-collision

systems onboard other aircrafts.

Never use the STBY mode in flight

unless you are requested

to do so by air traffic control. Always remember to put the

transponder in active mode prior to take off!

2.7 Squawk-Setting

The active Squawk is displayed in the upper line, while the standby

Squawk is presented at the lower line.

Setting the Standby Squawk:

• Press

► to set the cursor („^“), turn rotary knob to set numbers

of the standby Squawk.

• Press

▼▲ to activate the Standby Squawk (this moves the

current active Squawk into Standby)

13 Document-No: 03.202.010.71e / Revision: 1.00

Page 15

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

2.8 VFR – Squawk

The transponder features a user-defined squawk code for VFR-flight

(factory setting: 7000):

• Activate VFR-Squawk:

Press

moved into Standby but not visible because the indication of the

Standby Squawk is overlapped by „VFR“

• Display Standby Squawk:

Press

Squawk remains active!)

Example:

FL 030

STBY

• Now the Standby Squawk can be adjusted by using the

knob and activated with

VFR („VFR“ is indicated), now the active Squawk is

VFR or ▼▲ or use the rotary knob (the VFR-

4700

5600

FL 030

STBY

VFR VFR

▼▲.

7000

VFR

FL 030

STBY

7000

4700

rotary

• In order to store the current active Squawk as new VFR-Squawk

(replacing the factory setting 7000):

Press and hold

releasing the button „VFR“ is shown

VFR until an „S“ is indicated (approx. 3 s); after

2.9 ID – Special Position Identification (SPI): “Squawk

Ident”

Press ID to activate transmission of the special position identification

pulse with every reply within 18 seconds; “IDT” appears on the display

By pressing

transmitted with every reply within 18 seconds, which causes an

accented marking on the Controller’s screen. The „Special Position

Identification“ has to be activated after the „Squawk Ident“ request of the

Controller.

14Document-No: 03.202.010.71e / Revision: 1.00

ID a special position identification pulse (SPI) is

Page 16

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

3 INSTALLATION

3.1 Notes

The following suggestions should be considered before installing.

The assigned installation company will supply wiring. For diagrams refer

to 3.6 Wiring.

Remote Header and cables shall be installed according to „FAA AC-

143.13-2A Acceptable Methods, Techniques and Practices – Aircraft

Alterations“ and the appropriate manufacturer’s instructions.

3.2 Scope of Delivery

Item name / number Description

TRT800RT Remote Header

TRT800H-Remote Control Unit

ATR600RTK3 Connector

M4X8ZSW

(3 pieces)

03.202.010.71e Manual „Operation and Installation“

EASA Form 1

screw for panels up to 5 mm thickness

3.3 Unpacking and Inspecting of the Equipment

Carefully unpack the equipment and inspect for transport damages. If a

damage claim has to be filed, save the shipping container and all

packing materials as evidence to your claim.

For storage or reshipment the original packaging should be

used.

15 Document-No: 03.202.010.71e / Revision: 1.00

Page 17

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

3.4 Mounting

• In cooperation with a maintenance shop, location and kind of the

installation are specified. The maintenance shop can supply all

cables. Suitable sets of cables are available from Funkwerk

Avionics GmbH.

• Select a position away from heat sources. Care for adequate

convection cooling.

• Leave sufficient space for the installation of cables and connectors.

• Avoid sharp bends and wiring close to control cables.

• Leave sufficient lead length for inspection or repair of the wiring of

the connector (containing the memory), so that when the mounting

hardware for the rear connectors is removed, the assembly may be

pulled forward several inches.

• Bend the harness at the rear connectors to inhibit water droplets

(formed due to condensation) from collecting in the connector.

• For mounting details/drawing refer to chapter 3.8.2 Mounting

Advices.

16Document-No: 03.202.010.71e / Revision: 1.00

Page 18

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

3.5 Equipment Connections

3.5.1 Electrical Connections

One 9 pin D-SUB miniature connector includes all electrical connections.

When powering the remote control not by the output of the

switched power output of the remote controlled device but

directly by the aircraft’s power supply, the power input line

(+UB) must be equipped with an external fuse (1Amp./slow).

3.6 Wiring

3.6.1 Conductor Cross Section

Power Supply (Power, GND): AWG20 (0,62 mm²)

Signals: AWG22 (0,38 mm²)

The conductors must be approved for aircraft use. RX and TX should be

shielded individually, or at least be pair-twisted and shielded together.

3.6.2 Pin Assignment

Pin Signal Remarks

1 GND (Data) -

2 Data TX Output

3 -

4 Light Input

5 UB+ Power input

6 GND (Data)

7 Data RX Input

8 - -

9 UB+

(1)

UB+: Can be connected to switched power output of

Power input

(1)

transponder.

17 Document-No: 03.202.010.71e / Revision: 1.00

Page 19

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

3.7 Post-Installation Check

A certified maintenance shop must verify proper operation of

remote control header”.

All steering and control functions of the aircraft are to be examined, in

order to exclude disturbances by the wiring.

18Document-No: 03.202.010.71e / Revision: 1.00

Page 20

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

g

Operation and Installation

3.8 Drawings

3.8.1 Dimensions

3.8.2 Mounting Advices

Fixing clips (spring)

left / ri

ht

Connector (plug) has to be clamped with both spring locks.

New screws may be turned in more than max. 15mm into

the device – even if no hard limit is noticeable.

19 Document-No: 03.202.010.71e / Revision: 1.00

Page 21

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

4 APPENDIX

4.1 Technical Data

Compliance CS-ETSO-2C112a

EASA.21O.269

Applicable Documents CS-ETSO-2C112a

EUROCAE ED-73B Class 1 Level 2es

EUROCAE ED-26

RTCA DO-160D

RTCA DO-178B Software-Level D

Temperature Ranges

Operation -20 °C to +55 °C; for 30 min +70°C

Storage -55 °C to +85 °C

Altitude Range ≤ 35 000 ft

Shock 6 G Operation

20 G crash safety

Environmental Categories RTCA DO-160D Env.Cat.:

[C1Z]CAA[SM]XXXXXXZBAAA[TT]M[B3F3]

XXA

Power Supply 13,8 VDC (10 VDC .. 16 VDC)

0,06 A @ 13,8 VDC (typ.)

600 mW (max)

Fuse External 1A-slow-blow fuse

Mounting Panel cut-out d=57,5 mm

Weight 0,2 kg (0.43 lbs.)

20Document-No: 03.202.010.71e / Revision: 1.00

Page 22

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

4.2 Environmental Conditions

Characteristic DO–160D Section Cat. Condition

Temperature / Altitude 4.0

Low ground survival

4.5.1 – 55°C

temperature

Low operating temperature 4.5.1 – 20°C

High ground survival

C1

4.5.2 + 85°C

Temperature

High Short-time Operating

4.5.2 + 70°C

Temperature

High Operating Temperature 4.5.3

+ 55°C

No auxiliary cooling

In-Flight Loss of Cooling 4.5.4 Z

required

Altitude 4.6.1 C1 35 000 ft

2°C change rate

Temperature Variation 5.0 C

minimum per minute

Humidity 6.0 A

6 G operational shocks

20 G Crash Safety

Shock 7.0 A

Test Type R in all 6

directions

Vibration 8.0 S Vibration Curve M

Explosion Proofness 9.0 X No test required

Water Proofness 10.0 X No test required

Fluids Susceptibilities 11.0 X No test required

Sand and Dust 12.0 X No test required

Fungus Resistance 13.0 X No test required

Salt Spray 14.0 X No test required

Magnetic Effect 15.0 Z Less than 0,3 m

Power Input (DC) 16.0 B

Voltage Spike Conducted 17.0 A

Audio Frequency Conducted

18.0 A

Susceptibility

21 Document-No: 03.202.010.71e / Revision: 1.00

Page 23

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

Characteristic DO–160D Section Cat. Condition

Induced Signal Susceptibility 19.0 A

Radio Frequency

20.0 TT

Susceptibility

Emission of RF Energy 21.0 M

Lightning Induced Transient

22.0 B3F3

Susceptibility

Lightning Direct Effects 23.0 X No test required

Icing 24.0 X No test required

Electrostatic Discharge (ESD) 25.0 A

22Document-No: 03.202.010.71e / Revision: 1.00

Page 24

TRT800RT / P/N 800ATC-H-(Rxx)-(Rxx)

Operation and Installation

Notes:

23 Document-No: 03.202.010.71e / Revision: 1.00

Page 25

Funkwerk Avionics GmbH

Heinz-Strachowitz-Str. 4

DE-86807 Buchloe

Germany

phone.: +49-8241 80066 0

fax.: +49-8241 80066 99

E-mail:

service@funkwerk-avionics.com

www.funkwerk-avionics.com

Loading...

Loading...