Page 1

evolution

V

er.13

DIGITAL CONTROLLER AND INDICATOR FOR

HEATING OR COOLING WITH NATURAL

DEFROST THROUGH COMPRESSOR SHUTDOWN

MT-512 e 2HP

Control functions

shutdown

Functions

lockdown

Serial

programming

Protection

level

Manual

defrost

IP 65

FRONT

Image I: MT-512E 2HP - 115Vac

1. DESCRIPTION

2. SAFETY RECOMMENDATIONS

3.

4. TECHNICAL SPECIFICATIONS

Periodical defrost may be performed with MT-512e 2HP by stopping the compressor (natural

defrost) and forcing defrost manually. It is provided with a powerful 16A relay for actuating loads of up to

2HP, in addition to a command output combined with a timer for programming refrigeration and

defrosting times. Another feature available is the turning off of the control functions, making the

MT-512e 2HP operate only as a temperature indicator. It is also provided with a configurable

digital filter, which has the purpose of simulating mass increase in the environment sensor, thus

increasing its response time, i.e., it renders the sensor response slower (delay). Through an intelligent

function blocking system, it prevents unauthorized personnel from changing the control parameters.

MT-512e 2HP can also be set for heating.

Product conforming to UL Inc. (United States and Canada) and NSF . (United States)

- Check the controller for correct fastening;

- Make sure that the power supply is off and that it is not turned on during the controller installation;

- Read the present manual before installing and using the controller;

- Use adequate (PPE);

- For application at sites subject to water spills, such as refrigerated counters, install the protecting vinyl

supplied with the controller;

- For protection under more critical conditions, we recommend the Ecase cover, which we make

available as an optional item (sold separately);

- The installation procedures should be performed by a qualified technician.

• Cold storages

•

• Industrial heating / Cooling equipment

• Any other type of equipment requiring precise temperature control

Personal Protective Equipmenet

Reach-In Coolers / Stand Up Coolers

APPLICATIONS

Control temperature (**)

Resolution

5. INDICATIONS AND KEYS

Upper Key

MT-512e 2HP

Lower Key

Set Key

Menu Key (Flatec)

User-friendly

Cooling indication LED

Heating indication LED

Defrost indication LED

Temperature unit indication LED

Control functions OFF indication LED

Functions lockdown indication LED

- 50 to 105°C (-58 to 221°F)

0.1°C (-10 to 100°C) and 1°C at the rest of the range

115 Vac

Image III: MT-512EL 2HP - 12Vac/dc

Power supply

MT-512E 2HP: 115 or 230 Vac * (50/60 Hz)±10%

MT-512EL 2HP: 12 or 24 Vdc or Vac * +10%

Maximum load current (***)

16 A for resistive-type loads and 12 A for inductive-type

loads

Maximum load power (***)

2HP

Operating temperature

0 to 50°C / 32 to 122°F

Operating humidity

10 to 90% RH (without condensation)

(*) Admissible variation in relation to the voltage rating.

(**) This instrument measures and controls temperatures of up to , using the silicone sensor cable SB59

(sold separately).

(***) For higher loads, use contactor.

200°C/392°F

Protection level

Dimensions (mm)

Cutout dimensions (mm)

IP 65 (frontal)

76 x 34 x 77 mm (Width x Height x Depth)

X = 71±0,5 Y = 29±0,5 (see image V)

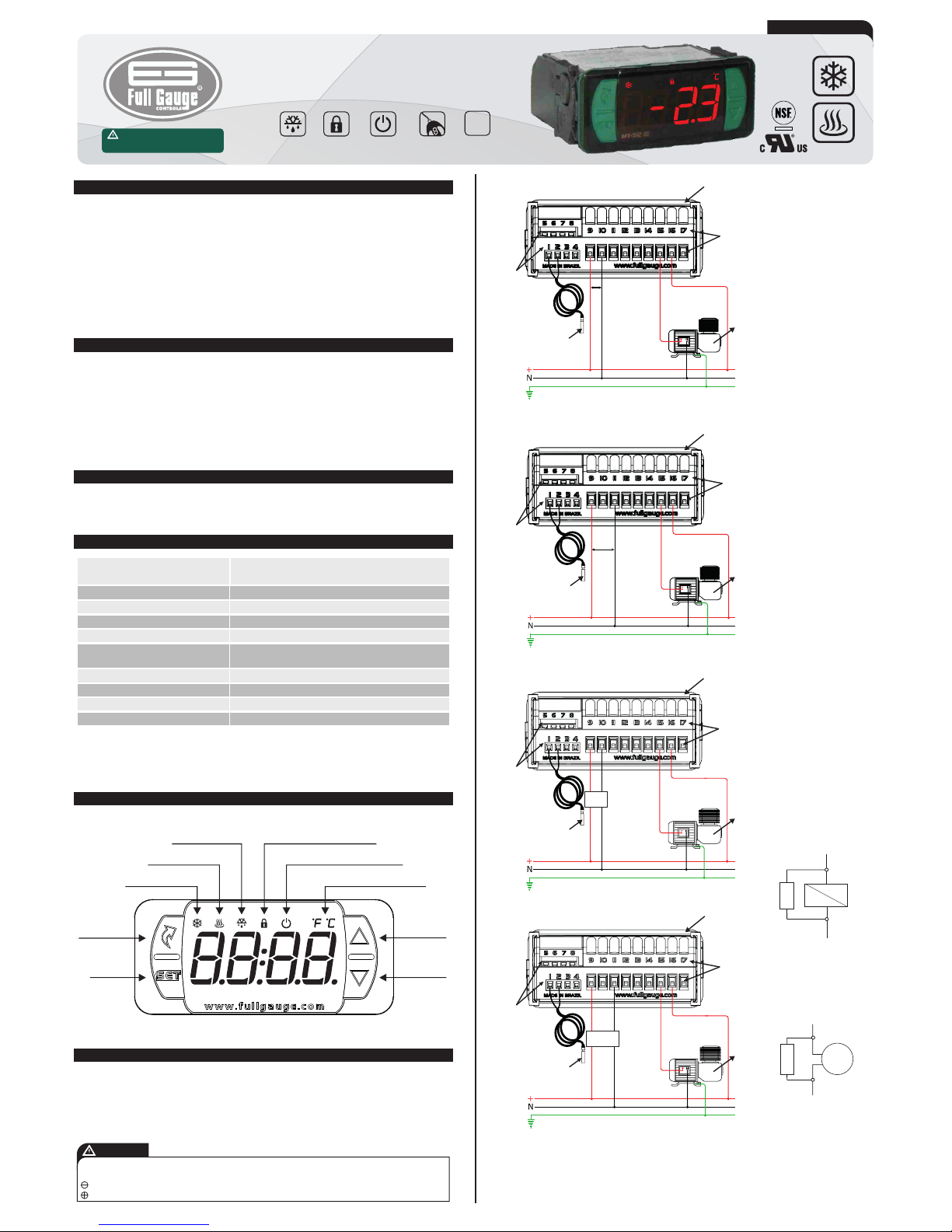

6. WIRING DIAGRAM

6.1. Identifications (see Images I to IV)

- Image I: MT-512E 2HP, supplied at 115 Vac.

- Image II: MT-512E 2HP, supplied at 230 Vac.

- Image III: MT-512EL 2HP, supplied at 12 Vac/dc.

- Image IV: MT-512EL 2HP, supplied at 24 Vac/dc.

Image II: MT-512E 2HP - 230 Vac

230 Vac

POWER

12Vac/dc

Image IV: MT-512EL 2HP - 24Vac/dc

POWER

24Vac/dc

6.2. Temperature sensor connection

- Connect the sensor wires to terminals ‘1 and 2’: the polarity is not relevant.

- Length of the sensor cables can be increased by user himself to up to 200 meters, using a PP 2x24

AWG cable.

- For immersion in water, use a thermowell (Image VI - item 12), available in the Full Gauge Controls

product line (sold separately).

S u r ge P r ot ec t i v e

Device (SPD)

(sold separately)

W ir i ng d ia g ra m f or

in sta lat ion o f S PD in

magnectic contactor

A1 and A2 are the terminals of

the contactor coil.

SPD

A1

A2

W ir i ng d ia g ra m f or

instalation of SPD in line

with loads

For direct drive take in to

consideration the specified

maximum current.

LOAD

IMPORTANT

SCREWDRIVER SLOT 3/32''(2.4mm) FOR ADJUSTMENTS IN THE SIGNAL TERMINALS;

SCREWDRIVER PHILLIPS #1 FOR ADJUSTMENTS IN THE POWER TERMINALS;

THE USE OF APPROPRIATE TOOLS IS ESSENTIAL TO AVOID DAMAGE IN THE CONNECTION AT INSTRUMENT

TERMINALS:

CONTROLLER

WIRING

TERMINALS

TEMPERATURE

SENSOR

WIRING

TERMINALS

LOAD

CONTROLLER

WIRING

TERMINALS

WIRING

TERMINALS

TEMPERATURE

SENSOR

LOAD

CONTROLLER

WIRING

TERMINALS

WIRING

TERMINALS

TEMPERATURE

SENSOR

LOAD

CONTROLLER

WIRING

TERMINALS

WIRING

TERMINALS

TEMPERATURE

SENSOR

LOAD

SPD

MT512E2HP13-02T-15381

POWER

GRID

}

POWER

GRID

}

POWER

GRID

}

POWER

GRID

}

E251415

COMPONENT

Have this manual in the palm of

your hand by FG Finder application.

Page 2

6.3. Controller power supply

Use the pins according to table below, considering the set version:

6.4. Recommendations of IEC60364 standard

a) Install overload protectors in the controller supply.

b) Install transient suppressors – suppressor filter RC – in the circuit to increase the service life of the

controller relay. See connection instructions of the filter on the previous page.

c) The sensor cables may be together, but not in the same conduit where the power supply of the

controller and/or of the loads passes through.

a) Cut out the panel plate (Image V - item 12) where the controller shall be fastened, with sizes

X = 71±0.5 mm and Y = 29±0.5 mm;

b) Remove side locks (Image VII - item 12): to do that, compress the central elliptical part (with the Full

Gauge Controls logo) and displace the locks backwards;

c) Introduce the controller in the notch made on the panel, inwards;

d) Place the locks again and then displace them until they compress into the panel, fastening the

controller to the housing (see arrow indication in Image VII - item 12);

e) Perform the electric installation as described in item 6;

f) Adjust the parameters as described in item 8.

ATTENTION: for installations requiring liquid tight sealing, the notch sizes for the controller

installation should be no more than 70.5x29mm. The side locks should be fastened so that they

press the sealing rubber avoiding infiltration between the notch and the controller.

Protector vinyl - Image VIII (item 12)

It protects the controller when installed at a site subject to water spills, such as refrigerated counters.

This adhesive vinyl is supplied with the instrument in the package.

IMPORTANT: Make the application only after completing the electrical connections.

a) Retreat the side locks (Image VII - item 12);

b) Remove the protective film from the adhesive vinyl face;

c) Apply the vinyl over the entire upper part, bending the flaps, as indicated by the arrows - Image VIII

(item 12);

d) Reinstall the locks.

NOTE: The vinyl is transparent, allowing visualization of the wiring system of the instrument.

8.1. Quick Access Menu Map

;(Flatec),

8.3.

7. FASTENING PROCEDURE

8. ADJUSTMENT OF THE SETPOINT AND PARAMETERS

By pressing it is possible to navigate through the function menus. For more details, see

chapter See the functions map below:

Pins MT-512E 2HP MT-512EL 2HP

9 and 10

9 and 11

115 Vac

230 Vac

12 Vac/dc

24 Vac/dc

;

FORCED DEFROST

;

FUNCTIONS LOCKDOWN

;

CONTROL FUNCTIONS

SHUTDOWN

ADJUSTING THE DESIRED

TEMPERATURE (SETPOINT)

;

EXIT FUNCTION

;

FUNCTION SELECTION

;

SHOW CURRENT PROCESS

;

ERASE MIN. AND MAX. VALUES

;

MIN. AND MAX. TEMPERATURE

RECORD

;

MT-512e 2HP MT-512e 2HP

MT-512e 2HP MT-512e 2HP

MT-512e 2HP MT-512 e 2HP

MT-512e 2HP MT-512e 2HP

MT-512e 2HP

8.3. Basic operations

8.3.1. Adjustment of the Setpoint (desired temperature)

Press the key/ for 2 seconds until the message [Set,] is displayed. Releasing the key will display

the control temperature currently adjusted.

Use the keys < or > to modify the value and press / for recording.

The desired temperature can also be changed by the facilitated menu (see map in item 8.1) or by the

function [,F02]: see item 8.4.2.

8.3.2. Manual Defrost

Manual defrost is activated by the facilitated menu. Press the key ;(short touch) until the message

[defr] (led @flashing) is displayed. Then press the key/(short touch) to select. The message

[defr][On,,] (led @on) will be displayed.

In order to disable the manual defrost, press the key ; (short touch) until the message[defr](led

@flashing) is displayed. Press the key / (short touch) to select. The message[defr][Off,] (led

@off) will be displayed.

The manual defrost process also can be activated/deactivated by pressing the key < for 4 seconds.

MT-512e 2HP

8.3.3. Function blocking

The activation of function blocking feature allows safety against undue alterations of the Setpoint and of

the other parameters. In this condition, when trying to alter the values, the message [LOC,] will be

displayed. However, the parameters can still be seen.

In order to perform the function blocking the parameter [,F20] (Time for function blocking) must be

set with the value above 14 (if below 15, [No,,] will be displayed, which means function blocking is

prevented).

With the key ; (short touch), select , then press / (short touch), and keep pressing the key >

until the message [LOC,] is displayed.

Releasing the key will display the message [On,,].

MT-512e 2HP

8.3.4. Turning the Control Functions Off

Turning the control functions off will make the controller start operating just as a temperature indicator

and the output relay remains off.

How the operation of turning the control functions off is made shall depend on the parameter [,F21]

setting (Turning the control functions off).

With the key ; (short touch), select and then press / (short touch) to confirm.

Soon the message [Ctrl][Off,] will be displayed and the temperature display will be alternated

with the message [Off,].

For turning the control functions on again, apply the same procedure used for turning off, selecting with

the key ; (short touch), . When pressing the key / the message [Ctrl][On,,] will be

displayed.

NOTE: When turning the control functions on again, the will continue to

respect the functions [,F09](Minimum output-off time) and [,F12] (initial status when

powering the instrument on).

Also is possible turn on/ turn off the control functions by pressing the key ; for 5 seconds.

MT-512e 2HP

MT-512e 2HP

8.3.5. Viewing the Processes

For viewing the status and the time elapsed, press > (short touch).

The controller will display the current process, which may be with the following messages:

[----]Control off

[DEL,]Initial delay

[REFR]Refrigeration

[HOT,]Heating

[DEFR]Defrost

Pressing the key < or also by the facilitated menu (see map in item 8.1) the message [rEg,] will be

displayed, and then the minimum and maximum temperatures will be recorded.

To delete the current minimum and maximum values, press the key ; (short touch) until the message

[CrEg] is displayed. Press the key/ to confirm.

8.3.7. Selection of Temperature Measurement Unit

For defining the unit with which the instrument will operate enter the function[,F01] with access code

231 and press the key / . Then, select the unit by pressing the keys > or <: the units [,=C,] or

[,=F,] will be displayed. Press the key / to confirm the selection. The indication corresponding to

the unit ({or}) will be displayed.

NOTE: Every time the unit is changed, the parameters should be reset, since they assume the

‘standard’ values of the parameter’s table.

8.3.6. Minimum and Maximum Temperature Recording

8.2. Quick access keys map

When the controller is on temperature display mode, the following keys serve as a shortcut for the

following functions:

Hold down for 2 seconds: setpoint adjustment.

Quick touch: current process display.

Quick touch: maximum and minimum temperatures display (record).

Pressed simultaneously: access to functions selection.

/

<

<

<

<

8.4. Advanced operations

- NOTE 1: The graph below illustrates the meaning of temperature-related parameters.

- NOTE 2: The access to all parameters is protected by the access code: see item 8.4.3 (F01).

Refrig.

Heat.

105°C (221°F)

*200°C (392°F)

-50°C (-58°F)

F02F04 F05

F06

*Only if a silicone sensor

cable is used (SB59)

To unblock, turn the controller off, and then turn it on again with the key > pressed. Keep the key

pressed until the message[LOC,]is displayed. After releasing it, the message[OFF,]will be

displayed.

Hold down for 5 seconds: turn on/turn off the control functions.

;

Page 3

8.4.1. Adjustment of the parameters

Access the function [,F01] by pressing simultaneously the keys<and>or by the facilitated menu.

When [,F01] is displayed, press the key / (short touch).

Use the keys < or > to enter with the access code [,123] and, when ready, press /.

Use the keys < or > to access the desired function.

After selecting the function, press the key / (short touch), to view the value set for that function. Use

the keys < or > to alter the value and press/ to memorize the value set and return to the function

menu.

To exit the menu and return to the normal operation (temperature indication), press / (long touch) until

[----] is displayed.

NOTE 1: If function blocking is active, pressing the keys<or>, the controller will display the

message [LOC,] and parameters will not be allowed to be altered.

NOTE 2: 15 seconds after supplying the access code and/or after setting a parameter, with no touches

in the buttons, the controller returns to the operation mode and the access code will have to be entered

again in function F01.

8.4.2. Parameters table

8.4.3. Parameters description

F01 - Access codes:

The is provided with two different access codes:

[,123]Allows changing the advanced parameters.

[,231]Allows selecting the temperature unit: Celsius or Fahrenheit.

F02 - Desired temperature (Setpoint):

This is the reference value for temperature control, i.e., the desired temperature to maintain in the

controlled environment, or the temperature at which the load supply output is turned off.

F03 - Indication shifting (Offset):

It allows the offsetting of any temperature deviations in view of the sensor replacement or alteration in

the cable length.

F04 - Minimum setpoint allowed to the user:

Avoid selection, by mistake, of extremely low setpoint temperatures.

F05 - Maximum setpoint allowed to the user:

Avoid selection, by mistake, of extremely high setpoint temperatures.

F06 - Control differential (hysteresis):

This is the difference in temperature (hysteresis) between turning the refrigeration (or heating) ON and

OFF.

Examples:

- Refrigeration: One wants to control the temperature at 4.0 °C with a differential of 1.0 °C: the output

will be turned off at 4.0 °C and turned on again at 5.0 °C (4.0 + 1.0).

- Heating: One wants to control the temperature at 30.0 °C with a differential of 5.0 °C: the output will be

turned off at 30.0 °C and turned on again at 25.0 °C (30.0 – 5.0).

NOTE: Using very low hysteresis values will cause a high frequency at the on and off action of the relay,

reducing its service life.

F07 - Operation mode:

Allows selecting the controller operation mode:

[,,,0] Refrigeration

[,,,1] Heating

F08 - Minimum output-on time:

This is the minimum time in which the load will remain on, i.e., the interval between the last start and the

next stop.

F09 - Minimum output-off time:

This is the minimum time in which the load will remain off, i.e., the interval between the last stop and the

next start. In the case of refrigeration, one relieves the discharge pressure, increasing the compressor

service life.

F10 - Refrigeration time (defrost interval):

Corresponds to the time in which the controller will operate in refrigeration. After this period, the

controller starts the defrost process.

F11 - Defrost time:

This is the defrost duration time. Within this period, the relay will remain off. After this period, the

controller will return to the refrigerated state.

MT-512e 2HP

F12 - Initial state when powering the instrument on:

When selecting the option[,,,0] (Refrigeration), the controller starts the refrigeration.

When selecting the option[,,,1] (Defrost), the system will perform defrost when the controller is

powered on. Duration of defrost will be according to parameter F11.

F13 - Locked temperature indication during defrost:

Select the acronym [No,,] for not locking the indication and [yes,] to lock it.

With the indication locked, this will only be released at the next refrigeration cycle after the temperature

reaches again this ‘locked’ value or after 15 minutes in refrigeration (as a safety measure).

F14 - Instrument powering-on delay:

When the instrument is turned on, this may remain for a while with the control disabled, delaying the

process start. Within this period, it works only as a temperature indicator. This delay may occur with the

compressor or with defrost (when defrost is set at the start).

The goal is to avoid power demand peaks upon return thereof after fault, when several pieces of

equipment are connected in the same electric grid. The delays should be adjusted at different values for

each piece of equipment.

NOTE: After the end of delay, the ‘minimum output-off time’ count is started (if it has been set in

parameter F09).

F15 - Additional time to the end of the first cycle:

It is used to increase the working time only of the first refrigeration cycle, increasing the efficiency.

F16 - Compressor situation with damaged sensor:

If the temperature sensor is undergoing short circuit, turned off or is off the measuring range, the

compressor assumes the state set in this parameter:

[,,,0] Compressor off.

[,,,1] Compressor on.

[,,,2] Cycling according to times defined in F17 and F18.

NOTE: If it is in heating mode, and with some error, the output will be turned off.

F17 - Compressor-on time in the event of error:

It defines the minimum time during which the compressor will remain on, if the sensor is off or outside the

measuring range.

F18 - Compressor-off time in the event of error:

It defines the minimum time during which the compressor will remain off, if the sensor is off or outside the

measuring range.

F19 - Digital filter intensity:

This filter has the purpose of simulating thermal mass increase in the sensor, thus increasing its

response time (thermal inertia). The greater the value set in this function, the greater the sensor

response delay will be.

F20 - Function blocking time:

This functionality being active, the setpoint and the other parameters will be protected against undue

alterations, with only the setpoint and the parameters being visualized. In order to block the functions,

please refer to item 8.3.3. Function blocking.

F21 - Turning the control functions off:

Authorizes switching off the control functions (see item 8.3.4).

[no,,]Disables the control functions shutdown.

[,,,1]Enables activation/deactivation of the control functions only if the functions are unlocked.

[,,,2]Enables activation/deactivation of the control functions even if the functions are locked.

[,,,3]Enables activation/deactivation of the control functions only if the functions are unlocked.*

[,,,4]Enables activation/deactivation of the control functions even if the functions are locked.*

* When F21 is configured as 3 or 4 and the control functions shutdown is activated, the controller will turn

off the display, keeping only the indication light on.

If any key is touched the display turns on by 5 seconds, turning off again until a new key is touched.

9. DISPLAY SIGNALINGS

10. GLOSSARY OF ACRONYMS

- °C: Temperature in Celsius degrees.

- °F: Temperature in Fahrenheit degrees.

- Defr: Defrost.

- LOC: Blocked.

- No: No.

- OFF: Turned off/disabled.

- ON: Turned on, enabled.

- Refr: Refrigeration.

- SET (as in "Setting") (setting or configuration).

- Vac: Electrical voltage (volts) of alternating current.

- Vdc: Electrical voltage (volts) of direct current.

- Yes: Yes.

Error in sensor: Sensor disconnected or damaged.

Control functions off.

Manual activation of the defrost process.

Manual activation of the cooling process.

Temper proof function.

Unlocking of functions.

Reconfigure the values of the functions.

[Er1,]

[OFF,]

[Defr][On,,]

[defr][Off,]

[LOC,][On,,]

[LOC,][OFF,]

[pppp]

Access codes

Desired temperature (Setpoint)*

Indication shifting (Offset)

Minimum setpoint allowed to the user

Maximum setpoint allowed to the user

Control differential (hysteresis)

Operation mode

Minimum output-on time

Minimum output-off time

Refrigeration time (defrost interval)

Defrost time

Initial state when powering the instrument on

Locked temperature indication during defrost

Instrument powering-on delay

Additional time to the end of the first cycle

Compressor situation with damaged sensor

Compressor-on time in the event of error

Compressor-off time in the event of error

Digital filter intensity

Function blocking time

Turning the control functions off

[,F01]

[,F02]

[,F03]

[,F04]

[,F05]

[,F06]

[,F07]

[,F08]

[,F09]

[,F10]

[,F11]

[,F12]

[,F13]

[,F14]

[,F15]

[,F16]

[,f17]

[,f18]

[,F19]

[,F20]

[,F21]

DescriptionFun

Min

Max

Unit

-

200

5.0

200

200

20.0

1-heat.

999

999

999

999

1-defr.

yes.

240

240

2

999

999

9

60

4

-

°C

°C

°C

°C

ºC

-

sec

sec

min

min

-

-

min

min

-

min

min

-

sec

-

CELSIUS

-

-58

-9

-58

-58

1

no

no

1

no

no

no

no

0

1

1

no

no

no

0-cool.

0-cool.

-

392

9

392

392

36

1-heat.

999

999

999

999

1-defr

yes

240

240

2

999

999

9

60

4

-

°F

°F

°F

°F

°F

-

sec

sec

min

min

-

-

min

min

-

min

min

-

sec

-

FAHRENHEIT

Min

Max

Unit

Standard

-

-50

-5.0

-50

-50

0.1

0-cool.

no

no

1

no

0-cool.

no

no

no

0

1

1

no

no

no

-

39

0

-58

167

1

20

20

240

30

no

no

no

0

15

15

no

no

no

0-cool.

0-cool.

-

4

0

-50

75

1.0

0-cool.

20

20

240

30

0-cool.

no

no

no

0

15

15

no

no

no

Standard

Legend: [yes,]= yes

[no,,]= no

*The minimum and maximum values depend on

the values configured in [,F04] and [,F05].

Page 4

Extended frame

It allows the installation of Evolution line controllers with sizes 76 x 34 x 77 mm in various situations,

since it does not require precision in the notch of the instrument fitting panel.

The frame integrates two switches of 10 Amperes that may be used to actuate interior light, air curtain,

fan, and others.

- version 2 or higherEasyProg

It is an accessory that has as its main function to store the parameters of the controllers. At any time, you

can load new parameters of a controller and unload them on a production line (of the same controller),

for example. It has three types of connections to load or unload the parameters:

WARRANTY - FULL GAUGE CONTROLS

Products manufactured by Full Gauge Controls, as of May 2005, have a two (02) year

warranty, as of the date of the consigned sale, as stated on the invoice. They are guaranteed

against manufacturing defects that make them unsuitable or inadequate for their intended

use.

EXCEPTIONS TO WARRANTY

The Warranty does not cover expenses incurred for freight and/or insurance when sending

products with signs of defect or faulty functioning to an authorized provider of technical

support services. The following events are not covered either: natural wear and tear of parts;

external damage caused by falls or inadequate packaging of products.

LOSS OF WARRANTY

Products will automatically lose its warranty in the following cases:

- The instructions for assembly and use found in the technical description and installation

procedures in Standard IEC60364 are not obeyed;

- The product is submitted to conditions beyond the limits specified in its technical

description;

- The product is violated or repaired by any person not a member of the technical team of

Full Gauge Controls;

- Damage has been caused by a fall, blow and/or impact, infiltration of water, overload

and/or atmospheric discharge.

USE OF WARRANTY

To make use of the warranty, customers must send the properly packaged product to Full

Gauge Controls together with the invoice or receipt for the corresponding purchase. As much

information as possible in relation to the issue detected must be sent to facilitate analysis,

testing and execution of the service.

These procedures and any maintenance of the product may only be provided by Full

Gauge Controls Technical Support services in the company's headquarters at Rua Júlio de

Castilhos, 250 - CEP 92120-030 - Canoas - Rio Grande do Sul – Brasil

Rev. 03

ENVIRONMENTAL INFORMATION

Packaging:

The materials used in the packaging of Full Gauge products are 100% recyclable. Try to

perform disposal through specialized recyclers.

Product:

The components used in Full Gauge controllers can be recycled and reused if

disassembled by specialized companies.

Disposal:

Do not incinerate or dispose the controllers that have reached the end of their service as

household garbage. Observe the laws in your area regarding disposal of electronic

waste. If in doubt, please contact Full Gauge Controls.

12. ANNEXES - Reference Images

Image V Image VI

Image VII

Image VIII

Y

X

- Serial RS-485: It connects via RS-485 network to the controller (only

for controllers that have RS-485).

- USB: it can be connected to the computer via the USB port, using

Sitrad's Recipe Editor.

- Serial TTL: The controller can be connected directly to

EasyProg by the TTL Serial connection.

CONTROLLER

EXTENDED FRAME

SWITCHES

EASYPROG

CONTROLLER

LOCKS

PANEL

CONTROLLER

CONTROLLER

VINYL

PANEL

11. OPTIONAL ITEMS - Sold Separately

Ecase protective cover

It is recommended for the Evolution line, keeps water from entering the back part of the instrument. It

also protects the product when the installation site is washed.

ECASE PROTECTIVE COVER

Copyright 2016

Loading...

Loading...