Page 1

MICROSOL II plus

DIFFERENTIAL TEMPERATURE CONTROLLER

FOR SOLAR HEATING WITH TWO

SOLAR BACKING

Ver. 02

UL-Underwriters Laboratories

MCSOL2V02-05T-10793

1.DESCRIPTION

Differential temperature controller for automation of solar heating systems,

MICROSOL II plus

becomes simple the management of the temperature of the water in the thermal reservoirs and

swimmingpools,use thesolarenergybetter..

Itactsinthecommand ofthewatercirculationpumpthrough the differentialoftemperaturebetweenthe

solarcollectors and the thermal reservoir orswimmingpool.It is a dedicated instrument thathasall its

parametersofconfiguration protectedbyaccesscode.

It makes use of two solar backings outputs, that can be electric, gas, diesel or also to program the

filteringoftheswimmingpool. solar backing1istiedwithan schedule thatallowstheconfigurationofup

to four daily events for each day of the week and solar backing 2 can optionally be configured for

functioninginset withtheschedule.

Ithasfunctions that prevent the water freezing and overheating inthetubingsanda clock with internal

batterytoguarantee itssynchronism,evenintheenergylack,permanyyears.Theinstrument hasserial

communicationforconnection withtheSITRAD viaInternet.

®

Productcomplieswith CE(EuropeanUnion)and ULInc.(United StatesandCanada).

2.APPLICATION

•Solarheating pumpedsystems

3.TECHNICAL SPECIFICATIONS

-Powersupply:

-Controltemperature:

115or 230Vac±10%(50/60Hz)

-50to105°

-58to221 ºF

-Resolution:

0.1°Cbetween-10 and100°Cand1°C intherestof therange

1°Fbetween-58 and221°F

-Dimensions:

-Operatingtemperature:

-Operatinghumidity:

-Sensors:

71x28 x71mm

0to50°C /32to122°F

10to90% RH(withoutcondensation)

S1-Sensor ofthecollectors

S2-Sensor oftheReservoir/Pool

S3-Sensorfor controlofsolarbackings

-Controloutputs:

PUMP-Waterpumporsolenoid -5(3)A/ 250Vac1/8HP

AUX1-solar backing1-5(3)A/250Vac1/8HP

AUX2-solar backing2-5(3)A/250Vac1/8HP

CLASSIFICATIONACCORDINGTOIEC60730-2-9STANDARD:

-Temperaturelimitof theinstallationsurface:

-Typeofconstruction:

-Automaticaction:

-Controlof pollution:

-Impulsevoltage:

Built-inelectroniccontroller

Type1

Level2

1,5kV

-Temperatureforthe testofspherepressure:

-Insulation:

ClassII

50°C

75°Cand125°C

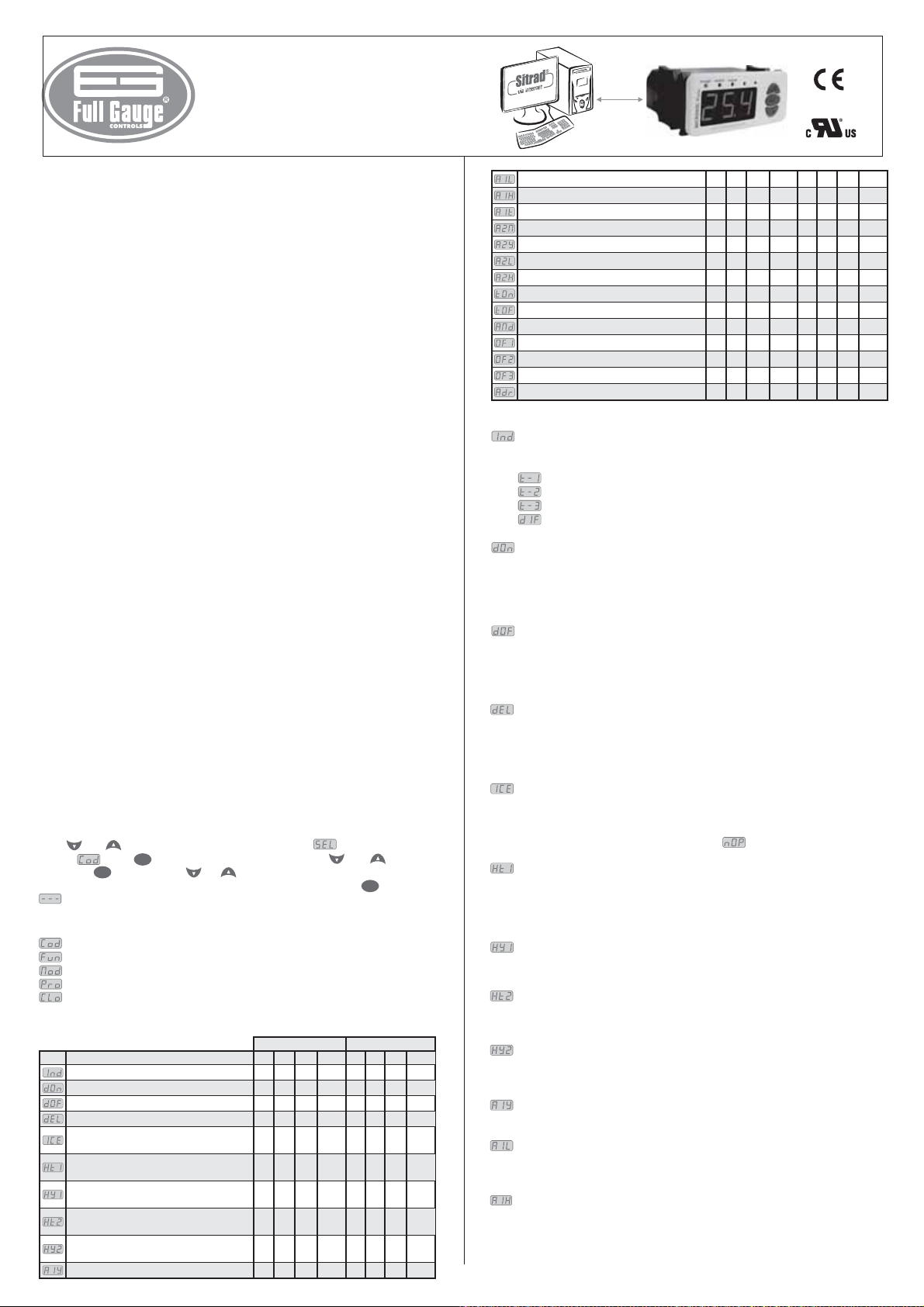

4.CONFIGURATIONS

4.1- Toenter into the functionsmenu

Press and simultaneously for two seconds until it appears , then releasing it. When

appears press (tap) and enter thecode (123) through keys and .Toconfirm,

pressthekey .Throughthekeys and accessthe otherfunctionsandproceedin thesame

manner to adjust them. Toleavethe menu andreturn to normal operations, press (longhit) until

SET

SET

SET

appears.

4.2- Functions

Accesscodeentry

Advancedconfigurationfunctions

Eventsplanneroperating mode

Schedulinginthe eventsplanner

Adjustmentofthe clockandtheday oftheweek

4.2.1- Parameters table

Fun

Indication ofthepreferentialtemperature

Differentialforturningonthewatercirculation pump

Differentialforturningoffthewater circulation pump

Minimum timeforthepumpoff

Temperatureofthe antifreeze for sensor 1

to turnthewatercirculationpumpon

Overheat temperatureforsensor1

to turnthewatercirculationpumpoff

Overheated hysteresisforsensor1

for turningthewatercirculationpumpbackon

Overheat temperatureforsensor2

to turnthewatercirculationpumpoff

Overheated hysteresisforsensor2

for turningthewatercirculationpumpbackon

Hysteresis ofthesolarbacking1operation

Description

CELSIUS

Unit

Max

Min

-

1.0

1.0

0

3.0

0.0

0.1

0.0

0.1

0.1

Standard Standard

-

°C

20.0

°C

20.0

sec.

999

°C

10.0

°C

99.9

°C

20.0

°C

99.9

°C

20.0

°C

20.0

99.9

99.9

FAHRENHEIT

Unid

Max

Min

-

2

36

8.0

2

36

4.0

0

999

0

38

50

3.0

32

212

1

36

1.0

212

32

36

1

1.0

36

1

1.0

-

-

14

°F

7

°F

0

sec.

38

°F

212

°F

1

°F

212

°F

1

°F

1

°F

Minimum setpointofthesolarbacking1operation

Maximum setpointofthesolarbacking1operation

Manual activationtimeforsolarbacking1

Solar backing2operationmode

Hysteresis ofthesolarbacking2operation

Minimum setpointofthesolarbacking2operation

Maximum setpointofthesolarbacking2operation

Cyclical timertimeon

Cyclical timertimeoff

Method forlinkingthesolarbackingstothe events schedule

Indication offsetforthetemperatureofthe sensor 1

Indication offsetforthetemperatureofthe sensor 2

Indication offsetforthetemperatureofthe sensor 3

Address oftheinstrumentontheRS-485network

-50.0

-50.0

0.1

-50.0

-50.0

-5.0

-5.0

-5.0

-50.0

221

°C

105.0

°C

105.0

min.

999

0

5

0

°C

20.0

°C

105.0

°C

105.0

min.

999

1

min.

999

1

3

0

°C

5.0

°C

5.0

°C

5.0

247

1

-58

105.0

221

-58

0

999

0

0

1.0

-50.0

105.0

0.0

0.0

0.0

0

1

221

-58

221

-58

1

999

1

1

999

1

0

0

-9

-9

-9

1

247

1

-

-

-

-58

°F

221

°F

0

min.

0

-

5

1

°F

36

-58

°F

221

°F

1

min.

1

min.

0

-

3

0

°F

9

0

°F

9

0

°F

9

1

-

4.2.2 - Parameters description

Indicationofthepreferential temperature

Thisfunctionallowsthe preferentialtemperatureindicationtobe configured.Youmay choosebetween:

temperatureinthesensor 1

temperatureinthesensor 2

temperatureinthesensor 3

differentialtemperature(S1-S2)

Differentialforturningon thewatercirculationpump

Thisfunctionallowstheadjustmentofthedifferentialtemperature(S1-S2)to activate the water circulation

pump. As the solar collectors receive energy, the temperature in sensor S1 increases. When this

temperatureisatavalueestablishedasbeing above the temperature ofsensorS2,thepumpisturnedon

andcirculatesunderthe heatedwater,storingit inthereservoir,for example.

Differentialforturningoff thewatercirculationpump

Thisfunctionallows the adjustment of the differentialtemperature(S1-S2)toturn off the water circulation

pump. With the pump on, the hot water circulates below and cools upwards. After which time, the

temperaturedifferencebetweenS1and S2 tendstodecrease.Whenthisdifferencefalls to anestablished

level,thepumpis turnedoffandthewater circulationstops.

Minimumtimeforthe pumpoff

Thisfunctionallowsthe adjustmentoftheminimumtimeoff thatthepumpshouldhave beforebeingturned

on again. This option avoids the pump from being turned on and off in short periods of time, which thus

increasestheusefullifethereof.Thisfunctionalsodefinesthe delay in the pump's activation onturningon

thecontroller.

Temperatureof the antifreezeforsensor1 to turnthewatercirculationpump on

Thisfunctionallowsadjustmenttothetemperatureforformingice in the collectors. When thetemperature

in the collectors (sensor 1) are very low (Ex.: winter nights), the pump is turned on from time to time, to

prevent the water from freezing in the pipes and damaging them. The hysteresis is set at 2°C/4°F.To

deactivatethisfunctiondecrease thevalueuntilthemessage appearsinthedisplay.

Overheattemperatureforsensor 1toturnthewater circulationpumpoff

This function allows the adjustment of the overheating temperature of the collectors, to turn off the water

circulation pump. When the temperature in the collectors (sensor 1) is above an established value, the

pumpisturnedofftokeeptheoverheatedwaterfromcirculatingthroughthepipesanddamagingthem(if

PVCpipesareused).

Overheatinghysteresisofsensor 1toreconnectthewater circulationpump

Adjustment of the hysteresis of the overheated temperature of sensor 1 to allow the water pump to be

turnedonagain.

Overheattemperaturefor sensor2toturn thewatercirculationpump off

This function allows the adjustment of the overheating temperature of the pool to turn the water

circulationpumpoff, avoidingthermaldiscomfort.

Overheatedhysteresisfor sensor2forturning thewatercirculationpump backon

Adjustmentofthehysteresisoftheoverheated temperature of sensor 2 toallowthewaterpumptobe

turnedonagain.

Hysteresisofthe solarbacking1operation

Adjustmentofthe hysteresisfortheactivation temperaturesetpointforsolar backing1.

Minimumsetpointof thesolarbacking1operation

Lower limit, the purpose of which is to avoid the accidental regulation of temperatures far below the

setpointofsolar backing1.

Maximumsetpointof thesolarbacking1 operation

Upper limit, the purpose of which is to avoid the accidental regulation of temperatures far above the

setpointofsolar backing1.

Page 2

Manualactivationtime forsolarbacking1

Timethatsolar backing 1 is activewhenit is activated manually. Once this period oftime is over,solar

backing1returns tofunctionautomatically.

Operationmodefor solarbacking2

Thisfunctionenables configuringthemodeof operationofthesolar backing2output.Themodesare:

“0”-thermostatforrefrigeration

“1”-thermostatforheating

“2”-thermostatforrefrigeration hitchedtotheevent schedule

“3”-thermostatforheating hitchedtotheevent schedule

“4”-cyclictimerwith initialstateon

“5”-cyclictimerwith initialstateonhitched totheeventschedule

Hysteresisofthe solarbacking2operation

Adjustmentofthe hysteresisfortheactivation temperaturesetpointforsolar backing2.

Minimumsetpointof thesolarbacking2 operation

Lower limit, the purpose of which is to avoid the accidental regulation of temperatures far below the

setpointofsolar backing2.

Maximumsetpointof thesolarbacking2 operation

Upper limit, the purpose of which is to avoid the accidental regulation of temperatures far above the

setpointofsolar backing2.

Cyclicaltimertime on

Thisfunctionenables settingthetimeduring whichthecyclictimer willkeepitsoutput on.

Cyclicaltimertime off

Thisfunctionenables settingthetimeduring whichthecyclictimer willkeepitsoutput off.

Methodforlinking thesolarbackingsto theeventsschedule

Thisfunctionenablessettingtowhichofthe 4dailyeventseachsolarbackingoutputwillbe hitched.The

possiblemodesare:

“0”-Aux1hitchedtoevents1,2,3,4 “2”- Aux1hitchedtoevents1,2

Aux2hitched toevents1,2,3,4 Aux2hitched toevents3,4

“1”-Aux1hitchedtoevent 1 “3”- Aux1hitchedtoevents1,2,3

Aux2hitched toevents2,3,4 Aux2hitched toevent 4

Indicationoffsetfor thetemperatureofthe sensor1

Thisfunctionallows theindicationoffsetforthetemperatureofsensor1tobeadjusted(collectors).

Indicationoffsetforthe temperatureofthesensor 2

Thisfunctionallowsthe adjustmentoftheindication offsetforthetemperatureofsensor2(reservoirs/pool).

Sensor3temperaturedisplay offset3

Thisfunctionallowsthe indicationoffsetforthe temperatureofsensor3tobeadjusted(solarbackings).

Addressoftheinstrument onthenetworkRS-485

Addressoftheinstrument inthenetworkfor thecommunicationwiththe software.

Remarks:inasingle network,therecannotbe morethanoneinstrumentwith thesameaddress.

IMPORTANT:

function .Assuch, does not allow invalid adjustments to be madein order to

guaranteeitsperfectfunctioning.

(*)The value adjustedinfunction should beobligatorilygreaterthanwhatis adjusted in

MICROSOL II plus

SITRAD

®

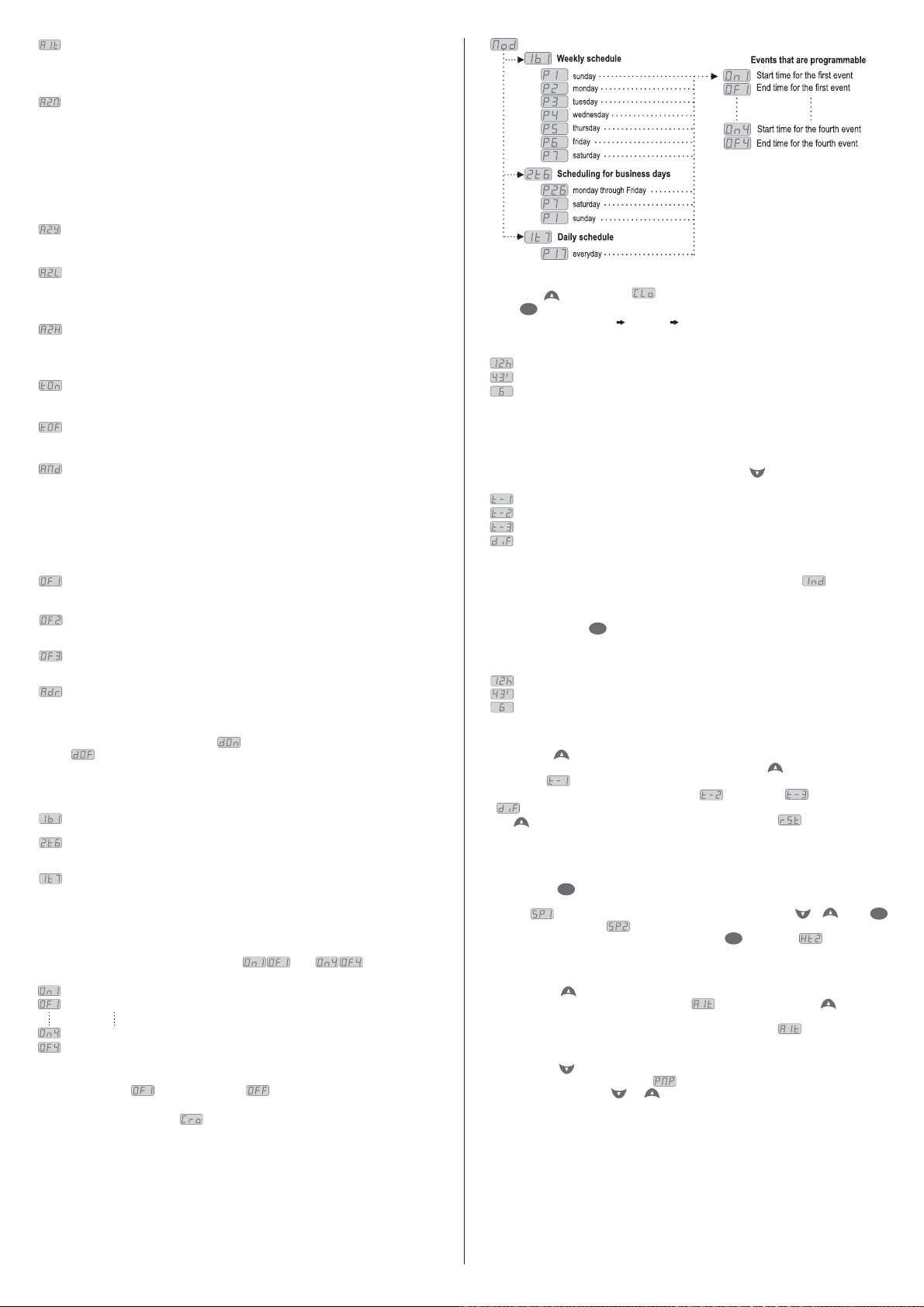

4.2.3 - Eventsscheduleoperating mode

Inthisoption,you canchoosehowthe eventsplannerwilloperate.

Weeklyprogramming

week.

Programming for business days

businessdays(MondaythroughFriday),andallowstheprogrammingofdifferent events for Saturday

andSunday .

Dailyprogramming

week.

-Inthismode,theinstrument can configure upto4eventsforeverydayof the

- In this mode, the instrument keeps the events the same for

-Inthismode,the instrument keeps theeventsthesameforallof the daysofthe

4.2.4- Programmingof the events schedule

Inthisoption,you canenterthevalues forthetimeperiodsfor eachevent.Theentryofthedatadepends

ontheoperatingmode configured.Youcan configure uptofoureventsfor each day.Foreachevent, the

startandend timeareconfiguredthrough theoptions upto , where:

Starttimefor thefirstevent

Endtimefor thefirstevent

Starttimefor the4ºevent

Endtimefor the4ºevent

Ifyoudonotneed to usethefourevents,youcan configure ittobedeactivated,andallyou havetodois

increase the off time ( for example) until the indication appears. It is also possible to

configureaneventtooverlap that itbeginsinonedayandit finishes intheother,andforthatyoushould

increasetheofftimeuntiltheoption appearsandadjustaneventforthenextdaytostartat00h

and00min.According to the operating mode configured, the following schedulingpossibilities may be

presented.

4.2.5 - Adjustmentof the currenttimeand day of the week

Pressthekey untilthe message appearsinthe visor.

SET

Hitkey .Thesettingswillappearinthefollowingorder:

HOURS MINUTES DAYOFTHEWEEK

Ex.:12h43min- Friday

Hours

Minutes

Dayofthe week

5.FUNCTIONS WHIT FACILITATEDACCESS

5.1- Visualize othertemperatures

To alternate between viewing the temperature of sensor 1, sensor 2, sensor 3 or the temperature

differencebetweensensor1 and2(differentialtemperature),press until thedesiredtemperatureis

showninthe display:

temperatureinthe sensor1

temperatureinthe sensor2

temperatureinthe sensor3

differentialtemperature(S1-S2)

Thetemperatureselectedwillbeshowninthedisplayfor fifteen seconds, and after that periodoftimehas

ended,thepreferentialindication willbeshownagain(as adjustedintheparameter ).

5.2- Visualize thecurrent time

Quickly pressing thekey , you can visualize the time set in the controller, the current time will be

SET

shown,followedby theminutesandthen thedayofthe week.

Ex.:12h43min- Friday

Hours

Minutes

Dayoftheweek

minimum and5.3 - Visualize maximum temperatures

Pressingthekey ,youcanvisualize the maximumandminimumtemperaturesforeach sensor,aswell

asthe minimum and maximumtemperaturedifferential. On pressing key (shorttouch), the message

will be shown showing the temperature of sensor 1 and soon after its minimum and maximum

temperatures,andthenthetemperaturesofsensor2( ),ofsensor3( )andthedifferential

().

Ifkey remainspressed,the values shall be restarted and the message shallbeshownon the

display.

5.4 - Set the operating tempera tures of the solar backings

(SETPOINTS)

Pressingthekey fortwosecondsmay adjusttheoperatingtemperatureforsolar backing 1andsolar

backing 2, as well as the overheating temperature for sensor 2 (reservoir/pool). A message will be

displayed ,adjusttheoperatingtemperature forsolarbacking1using keys e ,press

toconfirm.Thenthemessage willbedisplayed,adjusttheoperatingtemperatureforsolarbacking

2,pursuanttowhatisdescribedabove.After pressingthekey , the message willbedisplayed

toadjusttheoverheated temperatureforsensor2.

SET

SET

SET

5.5 - Manualactivation of solar backing 1

Pressing the key for ten seconds manually activates the output for solar backing 1. This will be

deactivated after the time adjusted in the function .lapses. By pressing key again for 10

seconds,themanual activationisdisabled,and solarbacking1resumes automaticoperation.

Todeactivatethemanualactivation, allyouhaveto doisconfigurefunction withthevalue“ 000”.

5.6- Manual activation of the watercirculationpump

By pressing key for 10 seconds, one can choose the mode of operation of the water circulation

pump.Afterpressing the key,themessage willbedisplayedandtheuser may thenchoosefromthe

optionslistedbelow,usingkeys and :

Page 3

Circulationpumpalways off

Circulationpumpalways on

Circulation pump operating in automatic mode without sensor 3 temperature validation. In this

modethecirculation pumpwillbeactivated onlybythediferential oftemperature(S1-S2)

Circulation pump operating in automatic mode with sensor 3 temperature validation. In this

mode the circulation pump will be activated by the diferential of temperature (S1-S2) and

whenthetemperature atsensor1is biggerthanatsensor 3.

Confirmtheselectionbypressingkey . The message willbedisplayed,showingtheendof

thefunction.

SET

5.7- Disabling thetemperature sensor 3

To disable the solar backing`s temperature sensor (sensor 3) enter the functions menu and access

function .Afterenteringthe functionpressthe buttonuntilthemessage appearsinthe

display,press the keytoconfirmandexit.

Whenthesensor 3isdisabledthe solarbackings1and 2willbecontrolledbysensor2(reservoir/pool).

If the circulation pump is adjusted for operation with sensor 3 validation and the sensor 3 was

deactivatedthecontroller willautomaticallydisablethe validation.

SET

6.SIGNALING

Sensor1(collectors) disconnectedoroutof range

Sensor2(reservoir /pool)disconnectedorout ofrange

Sensor3(solar backings)disconnectedorout ofrange

Temperatureforsensor1is freezing

Temperatureforsensor1is overheated

Temperatureforsensor2is overheated

Configurationparametersnot programmedoroutof range

Circulationpumpin offmanualmode

Circulationpumpin onmanualmode

7.UNIT SELECTION (°C /°F)

Todefine the unit that the system will use to operate, enter into the functions menu usingthe

access code “231” and confirm it by hitting key . The indication will appear,press or

tochoosebetween: or andconfirmwithkey .Afterselectingtheunitthe

SET

SET

messagewillappear,andtheinstrument will return to the function . Whenevertheunitisaltered,

theparametersshould bereconfigured,sincethey assume”standard”values.

IMPORTANT

Accordingtothe chaptersofnormIEC 60364:

1:

Install onthepower supply.

protectoragainstovervoltage

2:

Sensorcablesandsignalcables of the computer may be joined, but not in thesameelectricconduit

throughwhichthe electricinputandthe activationoftheloads run.

3:

Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

For more information,pleasecontactourTechnical Support by e-mail: or by

support@fullgauge.com

phone +5551 3475.3308.

Schematic for the connection of supresors

to contactors

A1

Suppresor

A1 andA2arethe

contactor coil terminals.

A2

Schematic for the connection of supresors to

direct activation loads

For direct activation themaximum

Load

specified current should betaken

Suppresor

into consideration.

PROTECTIVE VINYL:

This adhesive vinyl (included inside the packing) protects the instruments against

waterdrippings,as incommercialrefrigerators,for example.

Dotheapplication afterfinishingtheelectrical connections.

Remove the protective paper

andapplythevinyl on theentire

superior part of the device,

foldingtheflapsasindicatedby

thearrows.

8.WIRING DIAGRAM

9

230V

7

7

115V

Power

supply

9

8

8

10

10

PUMP

0

COMMON

Pump

Load 1

Above thecurrentspecified

use contactor

12

12

11

11

AUX1

AUX2

Load 2

Teardimensions

to position the instrument

Loads

supply

in the panel

72 mm

1

1

2

2

A

B

RS-485

Serial communication

Totheterminal of

the distributionbox

MICROSOLIIplus

9-8

9-7

3

3

Sensor 1

(collectors)

115V

230V

4

4

Sensor 2

(reservoir/pool)

5

5

6

6

Sensor 3

(solar backings)

Note: The sensor cable length can be increased by the user until 200 meters using PP 2 x 24 AWG

cable.

Integrating Controllers, RS-485 Serial Interface and Computer

®

External

mesh

Serial interface

RS-485

Full Gauge

terminal

grounded

RS-485SerialInterface

Device used to establish the

connectionFullGauge Controls’

instrumentswiththeSitrad

RS-485 Network

MOD 64

A

BB

B

A

AB

A

®

.

A

A

BB

B

A

A

BB

B

A

Instrument

Distribution Box

Usedtoconnectmorethan oneinstrument totheInterface.Thewire'sconnectionsmust

bemadein agreementwiththe followingrules:terminal oftheinstrument connectsto

theterminal of the distributionbox,thatmust be connectedwiththe terminal ofthe

Interface.Repeattheactionforterminals and , being thecableshield.

Theterminal ofdistributionbox mustbeconnected totherespective terminals of

eachinstrument.

A

B

MR

OUT4

L

A

OUT1

OUT2

3

T

OU

s

lu

p

R

0

0

-4

T

C

P

AA

RS-485 Network

A

A

BB

B

A

A

B

A

MP

U

P

s

lu

p

II

L

O

S

O

R

IC

M

X1

U

A

X

U

A

A

BB

2

A

B

A

A

B

A

B

29 mm

Loading...

Loading...