Full Boar FBPWC-208 Instruction Manual

KNOW YOUR PRODUCT

INSTRUCTION MANUAL

WARNING: Read all safety warnings and instructions before use. Failure

to follow the warnings and instructions may result in electric shock, fire and/or

serious injury. Save these instructions for future reference.

0418

• 208CC BRIGGS & STRATTON

ENGINE CR950 (13R2)

• 50MM MAX. CUTTING DIAMETER

6.5HP PETROL

WOOD CHIPPER

2

SPECIFICATIONS - MODEL NO. FBPWC-208

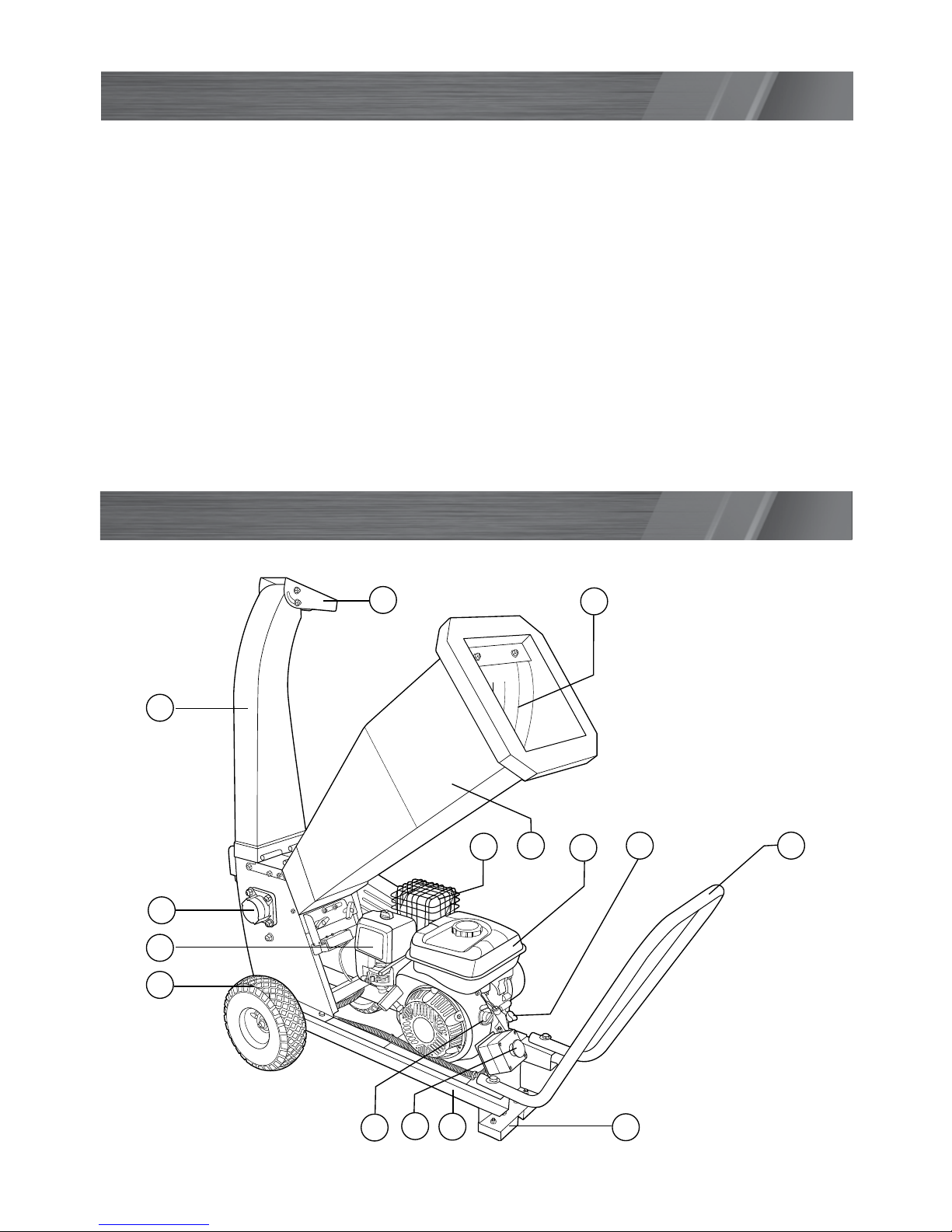

KNOW YOUR PRODUCT

1

6

12

3

2

5

7

9

4

Engine specications:

Make: Briggs & Stratton CR950 (13R2)

Power: 6.5HP

Type: OHV 4 Stroke, air cooled

Fuel type: 91 Oct unleaded petrol

Oil type: 4 Stroke SAE30, 10W30

Fuel tank capacity: 3.0 litres

Oil capacity: 600ml

Displacement: 208cc

Speed: 3,600rpm (max.)

Spark plug: Champion QC12YC

or equivalent

Wood chipper specications:

Max. cutting capacity Ø: 50mm green material,

30mm dry material

Blades: 2, 178mm long

Working speed: 3,500rpm (under load)

Wheel diameter: 255mm

Tyre pressure: 20 psi

Drive belt: 1525

Noise level: 110 db

Weight: 104kg

11

8

10

13

14

15

3

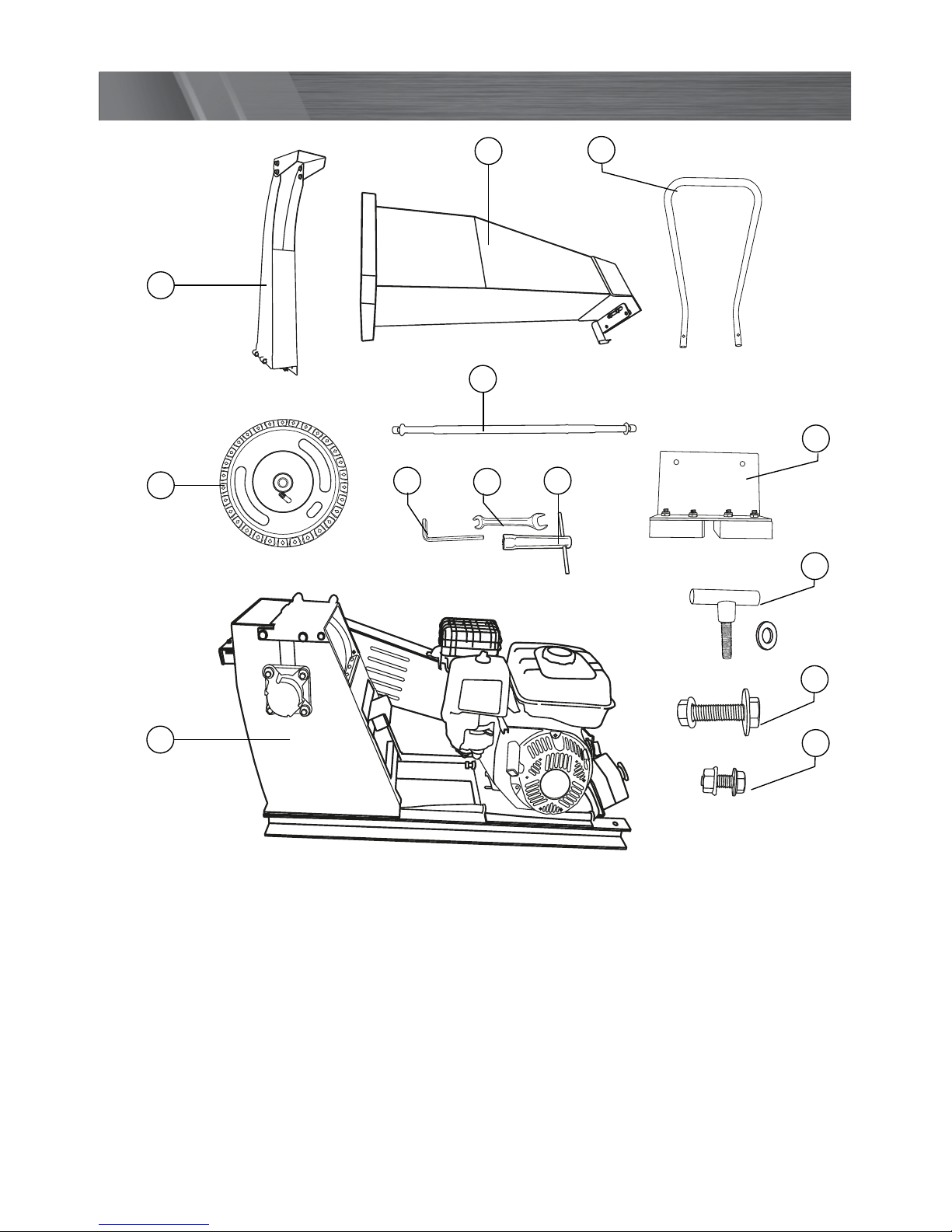

KNOW YOUR PRODUCT (cont.)

1. Discharge chute cover

2. Hopper inlet

3. Muffler

4. Hopper

5. Fuel tank

6. Oil filler cap

7. Transport Handle

8. Foot mounting bracket

9. Base frame

10. Emergency stop

11. Engine On/Off switch

12. Wheel x 2

13. Air filter

14. Blade shaft cover

15. Discharge chute

16. Axle

17. Hex key

18. Spanners x 2

19. Spark plug tool

20. T-Bolt & washer x 4

21. M10 Handle assembly fasteners x 2

22. M8 Foot mounting bracket fasteners x 2

15

9

8

4

7

12

20

22

19

21

16

17

18

4

SPECIFICATIONS....................................................... Page 02

KNOW YOUR PRODUCT........................................... Page 02

INTRODUCTION........................................................ Page 05

SAFETY INSTRUCTIONS........................................... Page 05

ASSEMBLY.................................................................. Page 09

PRE-OPERATION CHECK.......................................... Page 13

OPERATION............................................................... Page 15

MAINTENANCE......................................................... Page 20

TRANSPORT & STORAGE.......................................... Page 24

TROUBLESHOOTING................................................ Page 25

CONTENTS................................................................ Page 26

DESCRIPTION OF SYMBOLS..................................... Page 27

WARRANTY................................................................ Page 28

TABLE OF CONTENTS

5

INTRODUCTION

WARNING! When using this equipment, basic safety precautions,

including the following, should always be followed to reduce risk of fire, electric

shock, personal injury and material damage.

SAFETY INSTRUCTIONS

Read and understand the manual prior to operating this tool.

Save these instructions and other documents supplied with this tool for future reference.

Congratulations on purchasing a Full Boar petrol wood

chipper.

It has been designed for shredding garden material such

as trees, branches, hedge cuttings, leaves and general

woody garden material. It is best suited for branches up

to 50mm diameter green and 30mm diameter dry.

Engine manual

The engine manufacturer is responsible for all enginerelated issues with regards to performance, power rating,

specifications, warranty and service. Please refer to the

Engine Manufacturer owner/operator manual, packed

separately with your unit, for more information.

GENERAL SAFETY WARNINGS

RISK OF EXPLOSION OR FIRE

What can happen:

¥ Spilled petrol and its vapours can become ignited from cigarette sparks, electrical arcing,

exhaust gases and hot engine components such as the muffler.

¥ Heat will expand fuel in the tank which could result in a fire.

¥ Operating the tool in an explosive environment could result in a fire.

¥ Muffler exhaust heat can damage painted surfaces, melt any materials sensitive to heat

(such as siding plastic, rubber or vinyl) and damage live plants. Keep hot tool away from

other objects.

6

GENERAL SAFETY WARNINGS (cont.)

¥ Improperly stored fuel could lead to accidental ignition. Fuel improperly secured could get

into the hands of children or other unqualified persons.

How to prevent it:

¥ Shut off engine and allow it to cool before adding fuel to the tank.

¥ Use care when filling the tank to avoid spilling fuel. Move tool away from fuelling area

before starting engine.

¥ Keep maximum fuel level 20mm below top of tank to allow for expansion.

¥ Operate and refuel in well ventilated areas free from obstructions. Never re-fuel indoors.

¥ Store fuel in a approved container (AS/NZS 2906-1999) for petrol. Store in a secure

location away from the work area. Make sure the container is clearly marked "fuel".

RISK TO BREATHING

What can happen:

¥ Breathing exhaust fumes can cause serious injury or death.

How to prevent it:

¥ Operate tool in a well ventilated area. Avoid enclosed areas.

¥ Never operate unit in a location occupied by other people or animals.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b)

Do not operate petrol tools in explosive atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a petrol tool.

Distractions can cause you to lose control.

2) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

petrol tool. Do not use a power tool while you are tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as a

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Remove any adjusting key or wrench before turning the tool on. A wrench or a key

that is left attached to a rotating part of the petrol tool may result in personal injury.

d) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the petrol tool in unexpected situations.

e) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

f) If devices are provided for the connection of dust extraction and collection facilities

ensure that these are connected and properly used. Use of these devices can reduce

dust-related hazards.

7

GENERAL SAFETY WARNINGS (cont.)

3) Petrol tool use and care

a) Do not force the petrol tool. Use the correct petrol tool for your application. The

correct petrol tool will do the job better and safer at the rate for which it was designed.

b) Do not use the petrol tool if the switch does not turn it on and off. Any petrol tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Turn tool off completely before making any adjustments, changing accessories, or

storing petrol tools. Such preventive safety measures reduce the risk of starting the

petrol tool accidentally. Hair can be caught in moving parts.

d) Store idle petrol tools out of the reach of children and do not allow persons

unfamiliar with the petrol tool or these instructions to operate the petrol tool. Petrol

tools are dangerous in the hands of untrained users.

e) Maintain petrol tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the petrol tool’s operation. If

damaged, have the petrol tool repaired before use. Many accidents are caused by poorly

maintained petrol tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the petrol tool, accessories and tool bits etc., In accordance with these

instructions and in the manner intended for the particular type of petrol tool, taking

into account the working conditions and the work to be performed. Use of the petrol

tool for operations different from intended could result in a hazardous situation.

h) This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

i) Children should be supervised to ensure that they do not play with the appliance.

4) Service

a) Have your petrol tool serviced by a qualied repair personnel using only identical

replacement parts. This will ensure that the safety of the petrol tool is maintained.

WOOD CHIPPER SAFETY WARNINGS

Safe operating practices

Training

Become familiar with the owner’s manual before attempting to operate this equipment.

Preparation

1) Do not allow children to operate this equipment;

2) Do not operate this equipment in the vicinity of bystanders;

3) Do not run engine powered machines in an enclosed area since the exhaust from an engine contains

carbon monoxide, which is colourless, odourless, and tasteless; carbon monoxide can be extremely

dangerous in enclosed areas;

4) Wear ear protection and safety glasses at all times while operating the machine;

5) Avoid wearing clothing that is loose fitting or that has hanging cords or ties;

8

WOOD CHIPPER SAFETY WARNINGS

6) Only operate the machine in open space (e.g. not close to a wall or other fixed object) and on a firm,

level surface;

7) Do not operate the machine on a paved or gravel surface where ejected material could cause injury;

8) Before starting the machine, check that all screws, nuts, bolts, and other fasteners are properly secured

and that guards and screens are in place. Replace damaged or unreadable labels;

9) Use extra care in handling fuels. They are flammable and the vapours are explosive. The following

points should be observed:

− Use only an approved container;

− Never remove the fuel cap or add fuel with the power source running. Allow engine and exhaust

components to cool before refuelling;

− Do not smoke;

− Never refuel the machine indoors;

− Never store the machine or fuel container inside where there is an open flame, such as a water

heater;

− If fuel is spilled, do not attempt to start the power source, but move the machine away from the area

of spillage before starting;

− Always replace and securely tighten the fuel cap after refuelling;

− If the fuel tank is drained, this should be done outdoors.

Operation

1) Before starting the machine, look into the feeding chamber to make certain that it is empty;

2) Keep your face and body away from the feed intake opening;

3) Do not allow hands or any other part of the body or clothing inside the feeding chamber, discharge

chute, or near any moving part;

4) Keep proper balance and footing at all times. Do not overreach. Never stand at a higher level than the

base of the machine when feeding material into it;

5) Always stand clear of the discharge zone when operating this machine;

6) When feeding material into the machine be extremely careful that pieces of metal, rocks, bottles, cans

or other foreign objects are not included;

7) If the cutting mechanism strikes any foreign objects or if the machine should start making any unusual

noise or vibration, shut off the power source and allow the machine to stop. Disconnect the spark plug

wire from the spark plug (electric unit disconnect from supply) and take the following steps:

− Inspect for damage;

− Check for and tighten any loose parts ;

− Have any damaged parts replaced or repaired with parts having equivalent specifications.

8) Do not allow processed material to build up in the discharge zone; this may prevent proper discharge

and can result in kickback of material through the feed intake opening;

9) If the machine becomes clogged at the inlet opening or discharge chute shut-off the power source

and disconnect the spark plug wire or remove the ignition key before clearing debris in the inlet

opening or discharge chute. Keep the power source clear of debris and other accumulations

to prevent damage to the power source or possible fire. Remember that operating the starting

mechanism on engine powered machines will still cause the cutting means to move;

10) Keep all guards and deflectors in place and in good working condition;

11) Do not tamper with the power source governor settings; the governor controls the safe maximum

operating speed and protects the power source and all moving parts from damage caused by overspeed. Seek authorised service if a problem exists;

12) Do not transport this machine while the power source is running;

13) Shut off the power source and disconnect the spark plug lead (electric unit disconnect from supply)

whenever you leave the work area;

14) Do not tilt the machine while the power source is running.

9

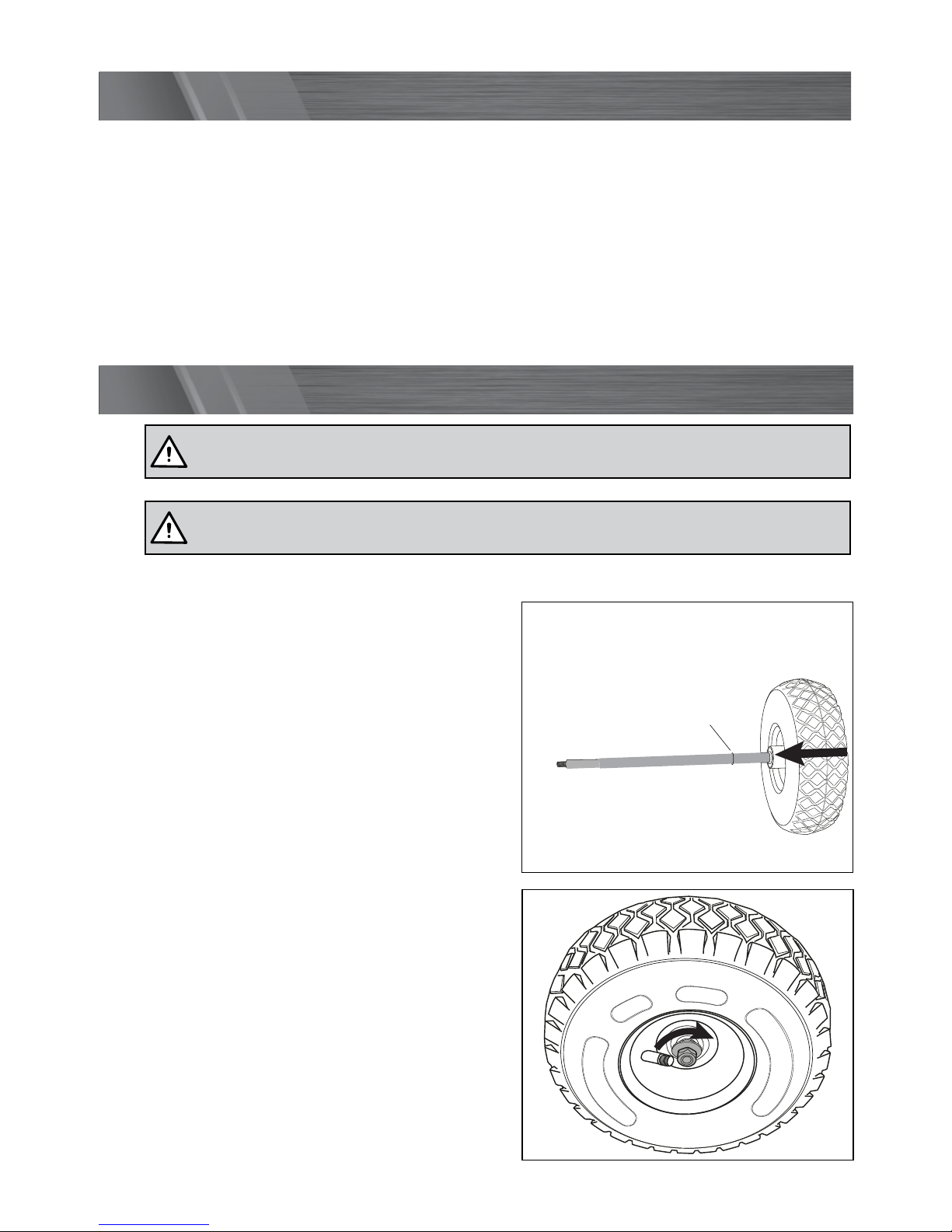

Circlip

WOOD CHIPPER SAFETY WARNINGS (cont).

ASSEMBLY

CAUTION! Some parts are heavy, two-person lift may be required to avoid injury.

Wheels & Axle

Parts required: Wheel x 2 (12) and Axle (16)

1. Slide a wheel (12) with valve stem facing

out onto the axle (16) (fig. 1).

Note: Slide the first wheel on the circlip side

of the axle (16).

2. To secure, place the wheel washer and nut

onto the axle. Tighten the nut (fig. 2)..

Note: Only assemble one wheel (12) at this

stage.

WARNING! Ensure the tool has been shut off and completely stopped before

performing any of the following operations.

Fig. 1

Fig. 2

Maintenance and storage

a) When the machine is stopped for servicing, inspection, or storage, or to change an accessory, shut

off the power source, disconnect the spark plug wire from the spark plug (electric unit disconnect

from supply), make sure that all moving parts have come to a complete stop and, where a key is fitted

remove the key. Allow the machine to cool before making any inspections, adjustments, etc.

b) Store the machine where fuel vapour will not reach an open flame or spark. For extended storage

periods, run the unit dry of fuel. Always allow the machine to cool before storing;

c) When servicing the cutting means be aware that, even though the power source will not start due

to the interlock feature of the guard, the cutting means can still be moved by a manual starting

mechanism.

Loading...

Loading...