Page 1

PRIMERGY

PRIMERGY TX150 S3

Server System

Service Supplement

Susanne Däschlein

Fujitsu Siemens Computers GmbH München

81730 München

e-mail: email: manuals@fujitsu-siemens.com

Tel.: (089) 61001155

Fax: (++49) 700 / 372 00000

Sprachen: En

Edition February 2005

Page 2

Comments… Suggestions… Corrections…

The User Documentation Department would like to

know your opinion of this manual. Your feedback helps

us optimize our documentation to suit your individual

needs.

Fax forms for sending us your comments are included in

the back of the manual.

There you will also find the addresses of the relevant

User Documentation Department.

Certified documentation

according to DIN EN ISO 9001:2000

To ensure a consistently high quality standard and

user-friendliness, this documentation was created to

meet the regulations of a quality management system

which complies with the requirements of the standard

DIN EN ISO 9001:2000.

cognitas. Gesellschaft für Technik-Dokumentation mbH

© cognitas. Gesellschft für Technik-Dokumentation mbH 2005 Pfad: L:\TX150_S3\TX150S3servsuppl\TX150S3_ss_e\TX150S3_ss_e.vor

www.cognitas.de

Copyright and Trademarks

Copyright © 2005 Fujitsu Siemens Computers Gm bH.

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

This manual is printed on

paper treated with

chlorine-free bleach.

Page 3

Introduction

Procedure

Safety notes

Replacement routines

© cognitas. Gesellschft für Technik-Dokumentation mbH 2005 Pfad: L:\TX150_S3\TX150S3servsuppl\TX150S3_ss_e\TX150S3_ss_e.vor

Appendix

Index

Page 4

© cognitas. Gesellschft für Technik-Dokumentation mbH 2005 Pfad: L:\TX150_S3\TX150S3servsuppl\TX150S3_ss_e\TX150S3_ss_e.vor

Page 5

Contents

1Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview of the documentation . . . . . . . . . . . . . . . . . . 1

1.2 Notational conventions . . . . . . . . . . . . . . . . . . . . . . . 4

2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Replacement routines . . . . . . . . . . . . . . . . . . . . . 13

4.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1 Floorstand model . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1.1 Opening the server . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1.2 Removing the front cover . . . . . . . . . . . . . . . . . . . . 13

4.1.2 Rack model . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.2.1 Opening the server . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.2.2 Removing the rack front cover . . . . . . . . . . . . . . . . . . 14

4.2 Replacing the operating panel module . . . . . . . . . . . . . 15

4.3 Replacing the floppy disk drive . . . . . . . . . . . . . . . . . 16

4.4 Replacing the system fan . . . . . . . . . . . . . . . . . . . . 18

4.5 Replacing the standard PS . . . . . . . . . . . . . . . . . . . 19

4.6 Replacing the Power backplane . . . . . . . . . . . . . . . . . 20

4.7 Replacing the SCSI backplane . . . . . . . . . . . . . . . . . 22

4.8 Replacing the SATA backplane . . . . . . . . . . . . . . . . . 23

4.9 Replacing the IDTEMP combo . . . . . . . . . . . . . . . . . 24

4.10 Replacing the intrusion switches . . . . . . . . . . . . . . . . 26

4.11 Replacing the processor . . . . . . . . . . . . . . . . . . . . . 28

4.12 Replacing the system board . . . . . . . . . . . . . . . . . . . 33

5 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Board layout . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 Operating panel board . . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 SCSI backplane . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1.3 SATA backplane . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.4 Power backplane . . . . . . . . . . . . . . . . . . . . . . . . . 40

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Service Supplement

Page 6

© cognitas. Gese l l sc hft für Technik-Dokumenta tion mbH 2005 Pfad: L:\ T X 150_S3\TX150S 3servsuppl\TX150S3_s s_e\TX150S3_ss_e.ivz

Page 7

1 Introduction

The PRIMERGY TX150 S3 Server is an Intel-based server for medium-sized

networks and large companies. The s erver is suitab le f or use as a fi le server as

well as an application, information, or Internet server. It is available as a floorstand or rack model. The floorstand model can be converted to a rack model

using an optional conversion kit.

1.1 Overview of the documentation

Concept and target groups

This Service Supplement completes the information given in the Operating

Manual, the Options Guide and the Technical Manual of the system board.

The activities described in this manual may only be performed by service

personnel.

Service CD

Service partners of Fujitsu Siemens can order a Service CD. On the CD the

following manuals are available in pdf format:

– The “Security” manual

– The Operating Manual for PRIMERGY TX150 S3

– The Technical Manual for the system board D1979

– The Options Guide for PRIMERGY TX150 S3

– The Service Supplement PRIMERGY TX150 S3

– The “BIOS Setup” manual

Service Supplement 1

Page 8

Overview of the documentation Introduction

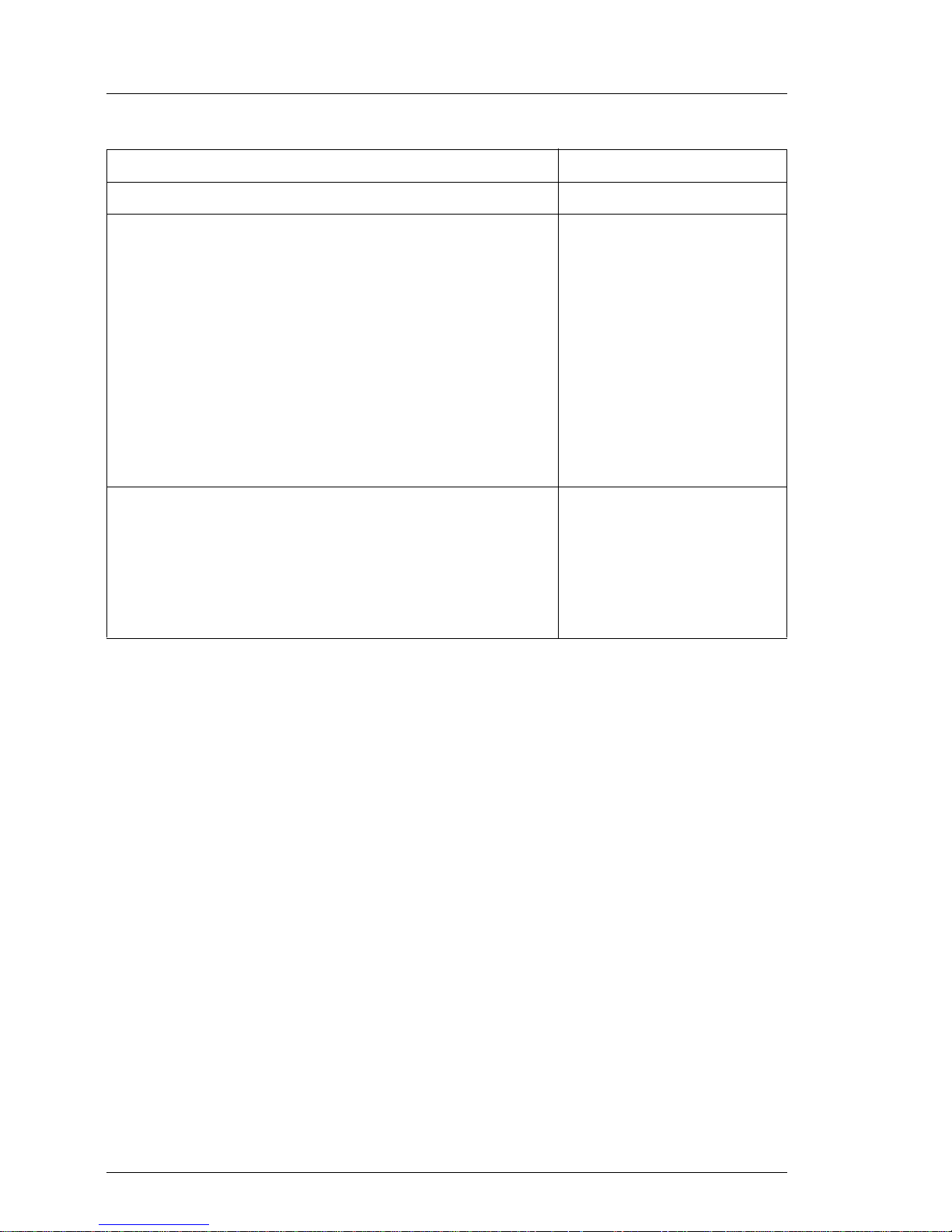

Information/procedure Manual

Detailed safety notes Safety

Features and technical data of the server Operating Manual

Installation and operation, among other things:

– External ports

– Operation

– Configuration of the server

– Installation of the rack mounting kit

Troubleshooting

Installation/removal of all hot-plug components:

– hot-plug power supply units

– hot-plug hard disk drives

Information about the system board:

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k01

– Features of the system board

Technical Manual

– Board layout

– Jumper settings

–LED displays

– Replacing the battery

Table 1: Overview of the documentation TX150 S3

2 Service Supplement

Page 9

Introduction Overview of the documentation

Information/procedure Manual

Extensions and upgrades:

I For some components only the installation

routine is described in the Options Guide.

Removing this components proceed in

reverse order.

– Extending/replacing the main memory

– Installing accessible drives, like CD/DVD-ROM

drive etc.

– Installing the hard disk extension box

– Installing controller in the PCI slots

– Installing RemoteView components

– Installing the external SCSI interface

– Conversion standard PS to hot-plug PS

– Converting from the floorstand model to the

rack model

Cabling

Replacement routines:

– Replacing the operating panel

– Replacing the floppy disk drive

– Replacing the system fan

– Replacing the standard PS

– Replacing the Power backplane

– Replacing the SCSI backplane

– Replacing the SATA backplane

– Replacing the IDTEMP Combo

– Replacing the intrusion switches

– Replacing the processor

– Replacing the system board

Options Guide

Service Supplement

Board layout

BIOS setup BIOS Setup

Table 1: Overview of the documentation TX150 S3

Service Supplement 3

Page 10

Notational conventions Introduction

1.2 Notational conventions

The following notational conventions are used in this manual:

Text in italics indicates commands, menu items or software programs.

„Quotation marks“ indicate names of chapters and terms that are being

emphasized.

Ê describes activities that must be performed in the order

shown.

V CAUTION! pa y particular attention to texts marked with this symbol.

Failure to observe this warning may endanger your life,

destroy the system or lead to the loss of data.

I indicates additional information, notes and tips.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k01

Table 2: Notational conventions

4 Service Supplement

Page 11

2Procedure

V CAUTION!

The actions described in these instructions should only be performed by

service personnel.

Ê First of all please familiarize yourself with the safety instructions in the

section chapter “Safety notes” on page 7 et seqq. .

Ê Ensure that all required man uals (see Service CD) are avail able, printing out

the PDF files if necessary . You will defini tely need the Operating Manual f or

the server, the Options Guide f or the server and the T echnical Man ual for the

system board.

Ê Shut down the server correctly, switch it off, pull out the power plug, and

open the server as described in the chapter “Replacement routines” on

page 13 et seqq. .

Ê Replace the defective component as described in the relevant chapter.

I Procedures which are identical for the floorstand and rack models are

only described for the floorstand model.

Ê Close the server.

Ê Connect the cables.

Ê Connect the server to the power outlet.

Ê Start the operating system.

Ê If necessary, configure the server as required.

1

1

1

1

1

1

This procedures are described in the Operating Manual.

Service Supplement 5

Page 12

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k02

Page 13

3 Safet y notes

I The following safety notes are also provided in the “Safety” manual.

This device complies with the relevant safety regulations for data processing

equipment.

V CAUTION!

The actions described in these instructions should only be performed by

service personnel.

Before operating the device

V CAUTION!

● During installation and before operating the device, observe the

instructions on environmental conditions for your device.

● If the de vice is brought in from a c old environment, condensation ma y

form both inside and on the outside of the machine.

Wait until the device has acclimatized to room temperature and is

absolutely dry before starting it up. Material damage may be caused

to the device if this requirement is not observed.

● Transport the device only in the original packaging or in packaging

that protects it from knocks and jolts.

Installation and operation

V CAUTION!

● If the rack model is integrated in an installation that receives power

from an industrial (public) power supply network with the IEC309

connector, the (pub lic) power supply protection must comply with the

requirements for the non-industrial (pub lic) power supply networks for

the type A connector.

● The server automatically sets itself to a voltage in the range of

100 V to 240 V. Make sure that your local voltage i s within this range.

Service Supplement 7

Page 14

Safety notes

● This device has a specially approved power cable and must only be

connected to a grounded insulated socket.

● Ensure that the power socket on the device or the grounded wall

outlet is freely accessible.

● The ON/OFF button does not disconnect the device from the mains

voltage. To disc onnect the line vol tage completely, remove the po wer

plug(s) from the grounded insulated socket(s).

V CAUTION!

● Alwa y s connect the de vice and the attached peripherals to the same

power circuit. Otherwise y ou run the risk of losing data if, for e xample,

the central processing unit is still running but the peripheral device

(e.g. storage subsystem) has failed during a power outage.

● Data cables to peripheral devices must be adequately shielded.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k03

● To the LAN wiring the requirements apply in accordance with the

standards EN 50173 and EN 50174-1/2. As minimum requirement

the use of a protected LAN line of category 5 for 10/100 MBps

Ethernet, and/or of category 5e for Gigabit Ethernet is considered.

The requirements of the specification ISO/IEC 11801 are to be

considered.

● Route the cables in such a way that they do not form a potential

hazard (make sure no-one can trip over them) and that they cannot

be damaged. When connecting up a device, refer to the relevant

notes in this manual.

● Never connect or disconnect data transmission lines during a storm

(lightning hazard).

● In emergencies (e.g. damaged casing, controls or cables, penetration

of liquids or foreign matter), s witch off the device immedi ately , remov e

the power plug and contact your sales outlet or customer service

team.

● Proper operation of the device (in accordance with IEC 60950/

EN 60950) is only ensured if the casing is completely ass embled and

the rear covers for the installation openings have been put in place

(electric shock, cooling, fire protection, interference suppression).

8 Service Supplement

Page 15

● Only install system expansions that satisfy the requirements and

rules governing safety and electromagnetic compatibility and relating

to telecommunications terminal equipment. If you install other expansions, you may damage the system or violate the safety regulations

and regulations governing RFI suppression. Information on which

system expansions are suitable can be obtained from the customer

service centre or your sales outlet.

V CAUTION!

● The components or parts marked with a warning label (e.g. lightning

symbol) may only be opened, remo ved or exchanged by authorized,

qualified personnel. The hot-plug power supply units are exceptions

to this rule.

● The warranty expires if the device is damaged during the installation

or replacement of system expansions.

● You ma y only set those resolutions and refresh rates specified in the

„Technical data“ section of the monitor description. Otherwise, you

may damage your monitor. If you are in any doubt, contact your sales

outlet or customer service centre.

Safety notes

Batteries

V CAUTION!

● Incorrect replacement of batteries may lead to a risk of explosion. The

batteries may only be replaced with identical batteries or with a type

recommended by the manufac turer (see the T echnical Man ual for the

system board).

● Do not throw batteries into the trash can. They must be disposed of

in accordance with local regulations concerning special waste.

● The battery must be disposed of i n accordance with local regulat ions

concerning special waste.

● Replace the lithium battery on the system board in accordance with

the instructions in the Technical Manual for the system board.

Service Supplement 9

Page 16

Safety notes

● All batteries containing pollutants are marked with a symbol (a

crossed-out garbage can). In addition, the marking is provided with

the chemical symbol of the heavy metal decisive f or the classification

as a pollutant:

Cd Cadmium

Hg Mercury

Pb Lead

Notes on handling CDs and CD-/DVD-ROM drives

V CAUTION!

● Use only CDs in proper condition in the CD-/D VD-ROM driv e of your

server to prevent data loss, damage to the device and injuries.

● Theref ore , chec k each CD for damage, crac ks , breakage etc. before

inserting it in the drive.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k03

Please note that any additional labels applied may change the

mechanical properties of a CD and cause imbalance.

Damaged and imbalanced CDs can break at high driv e speeds (data

loss).

Under certain conditions sharp-edged pieces of broken CDs can

penetrate the cov er of the drive (damage to the device) and be thrown

out of the device (danger of injury, particularly on uncovered body

parts such as the face or neck).

I You protect the CD-/DVD-ROM drive and prevent mechanical damage,

as well as premature wearing of the CDs, by observing the following

suggestions:

– Only insert the CDs in the drive when needed and remo v e them after

use.

– Store the CDs in suitable sleeves.

– Protect the CDs from exposure to heat and direct sunlight.

10 Service Supplement

Page 17

Note about the laser

Safety notes

The CD-/D VD-ROM drive

is classified for

laser class 1according to IEC 60825-1.

V CAUTION!

The CD-/DVD-ROM drive contains a laser diode (LED). Sometimes the

LED produces a stronger laser beam than laser class 1. Direct view into

this laser beam is dangerous.

Never remove parts of the CD-/DVD-ROM drive assembly!

Modules with electrostatic-sensitive components:

Systems and components that might be damaged by electrostatic discharge

(ESD) are marked with the following label:

Figure 1: ESD label

When you handle components fitted with ESDs, y ou must observe the f ollowing

points under all circumstances:

● Remov e the power plug from the power sock et bef ore inserting or removing

components containing ESDs.

● You must always discharge yourself of static charges (e.g. by touching a

grounded object) before working.

● The equipment and tools you use must be free of static charges.

● Only touch the components at the positions highlighted in green (touch

points).

● Do not touch any exposed pins or conductors on a component.

● Use a grounding cable designed for this purpose to connect yourself to the

system unit as you install components.

Service Supplement 11

Page 18

Safety notes

● Place all components on a static-safe base.

I You will find a detailed description for handling ESD components in the

relevant European or international standards (DIN EN 61340-5-1,

ANSI/ESD S20.20).

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k03

12 Service Supplement

Page 19

4 Replacement routines

V CAUTION!

Observe the safety instructions in the chapter “Safety notes” on page 7

et seqq. .

4.1 Preparation

4.1.1 Floorstand model

I Y ou wil l find a detailed description of ’Opening the server’ and ’Removing

the front cover’ in the Options Guide TX150 S3.

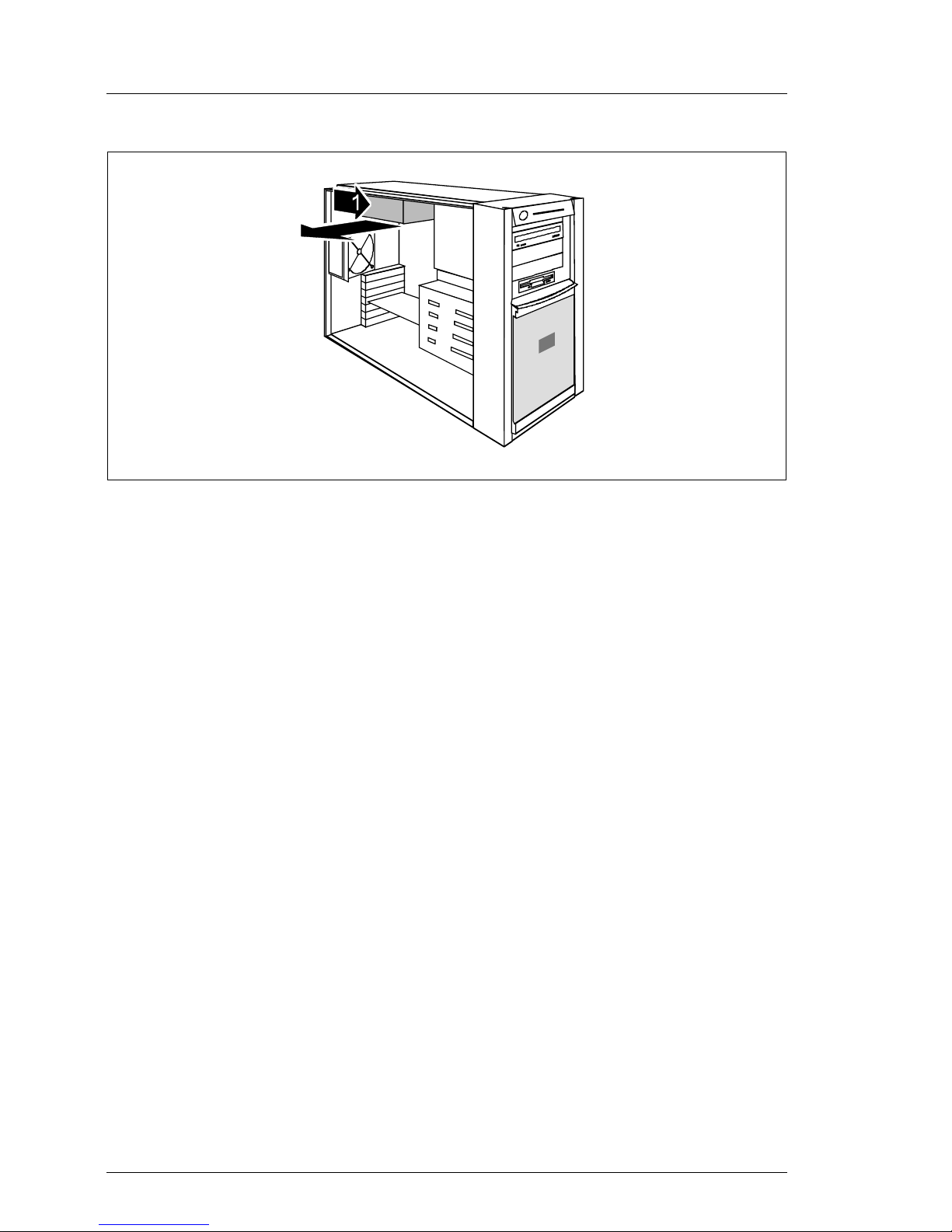

4.1.1.1 Opening the server

Ê Terminate all applications and shut down the server correctly.

Ê If your operating system has not switched off the sever, press the on/off

switch.

Ê Pull all power connectors out of the power outlets.

Ê If required, remove the lock on the side cover.

Ê Unlock the server.

Ê Loosen the two screws at the server’s rear side.

Ê Push back the left-hand side cover approxiate 2 cm.

Ê Remove the left-hand side cover.

4.1.1.2 Removing the front cover

Remove the front cover when making the following replacements:

– Replacing the operating panel

– Replacing the floppy disk drive

– Replacing the intrusion switches

Ê Push the drive cover up as far as possible.

Ê Remove the hard disk cover.

Service Supplement 13

Page 20

Preparation Replacement routines

Ê Disengage the three tabs on the left side one after the other and rotate the

front cover outward about 2 cm.

Ê Press the two hooks on the right side inward and pull out the front cover

frontward.

4.1.2 Rack model

I Y ou wil l find a detailed description of ’Opening the server’ and ’Removing

the rack front cover’ in the Options Guide TX150 S3.

Ê Terminate all applications and shut down the server correctly.

Ê If your operating system has not switched off the server, press the on/off

button.

Ê Pull all power connectors out of the power outlets.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

4.1.2.1 Opening the server

Ê Loosen the f our kn urled screws and pull the s erver as far as possible out of

the rack.

Depending on how accessible the server is in the rack cabinet, it can make

sense to remove it from the cabinet. You will find a detailed description in the

Options Guide or the Operating Manual.

Ê Loosen the two screws at the server’s rear side.

Ê Push back the top cover approxiate 2 cm.

Ê Remove the top cover.

4.1.2.2 Removing the rack front cover

Remove the rack front cover when making the following replacements:

– Replacing the operating panel

– Replacing the floppy disk drive

– Replacing the intrusion switches

Ê Remove two screws on either side.

Ê Remove the rack front cover to the front.

Ê Disengage the three tabs on the top side one after the other and pull out the

plastic front cover frontward about 2 cm.

14 Service Supplement

Page 21

Replacement routines Replacing the operating panel module

Ê Press the two hooks on the bottom side downward and pull out the plastic

front cover frontward.

4.2 Replacing the operating panel module

Ê Open the server and remove the front cover / rack front cover as described

in the section “Preparation” on page 13.

1

1

1

Figure 2: Removing the operating panel module

Ê Press the two metal tongues of the EasyClick rails inw ard (1) until the locking

mechanism is released.

Ê Pull the operating panel module forw ard out of its mounting location (2) until

you can remove the ribbon cable and the USB cable from the operating

panel board. Remove the two cables.

Ê Pull the operating panel module out of its bay as far as it is possible to get

access to the cable tie.

Ê Thread the two cables through the cable tie.

Ê Take the operating panel module out of its bay.

Ê Push the new operating panel module into its bay as far as it is possible to

have access to the cable tie.

Ê Thread the two cables through the cable tie.

Ê Push the operating panel module into its bay as far as it is possible to plug

the cables.

Service Supplement 15

Page 22

Replacing the floppy disk drive Replacement routines

Ê Connect the ribbon cable and the USB cable to the operating panel board

(see the board layout on page 37).

Ê Push the operating panel module into the housing until it engages.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

4.3 Replacing the floppy disk drive

Ê Open the server and remove the front cover / rack front cover as described

in the section “Preparation” on page 13.

Ê Remove the power cable and the floppy cable at the rear side of the floppy

disk drive.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

2

1

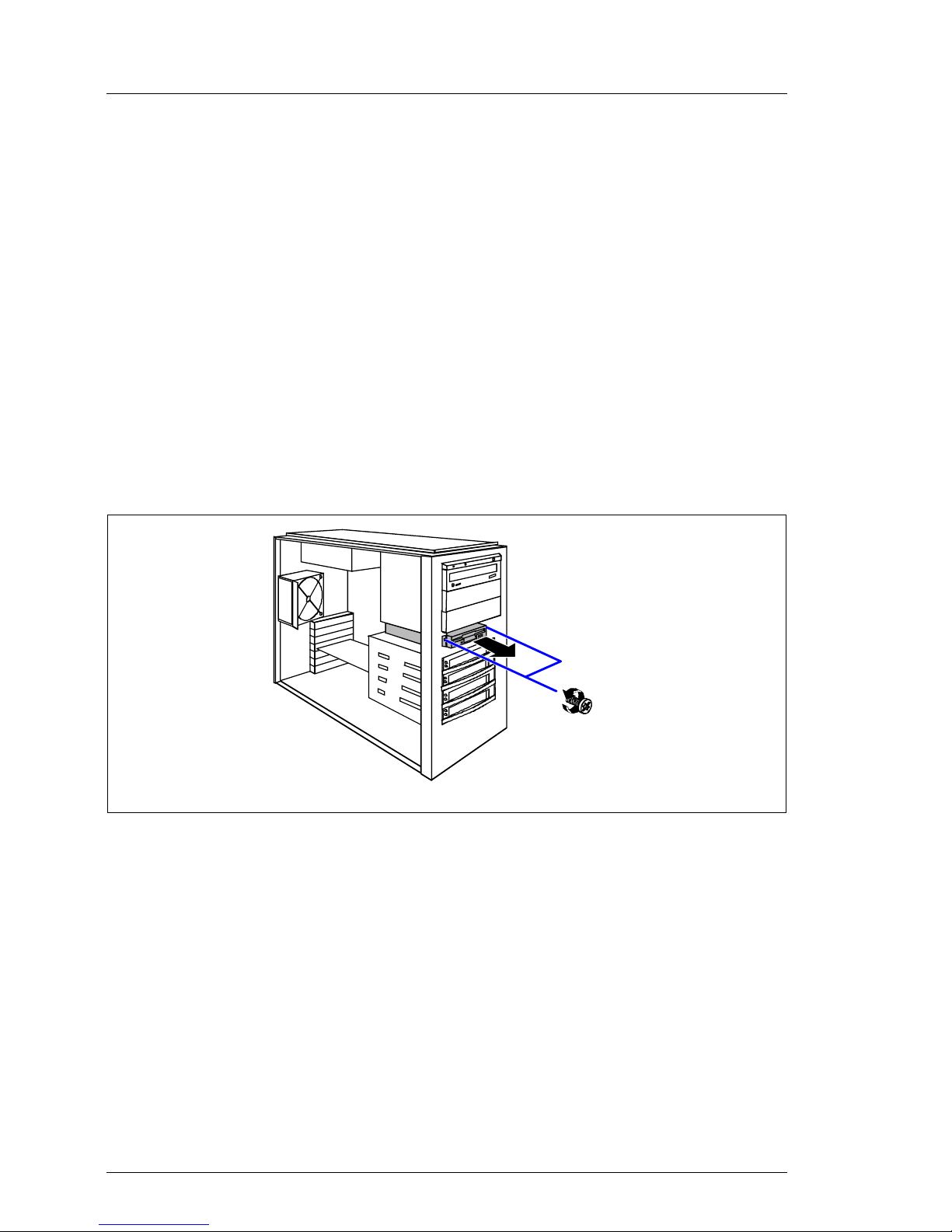

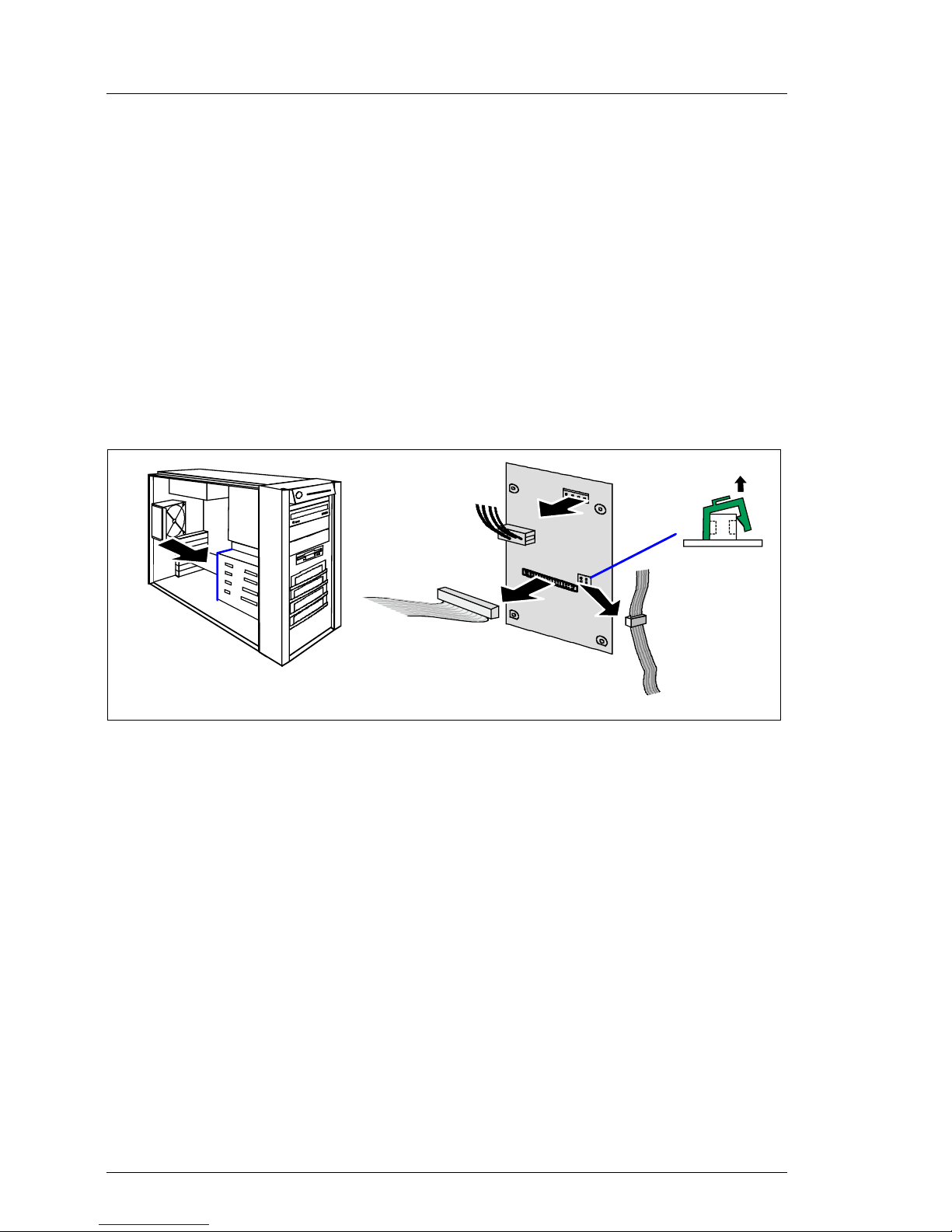

Figure 3: Removing the floppy disk drive with

Ê Remov e the two scre ws (1) that attach the drive holder to the housing front

side.

Ê Pull the drive holder out of the server (2).

16 Service Supplement

Page 23

Replacement routines Replacing the floppy disk drive

1

2

1

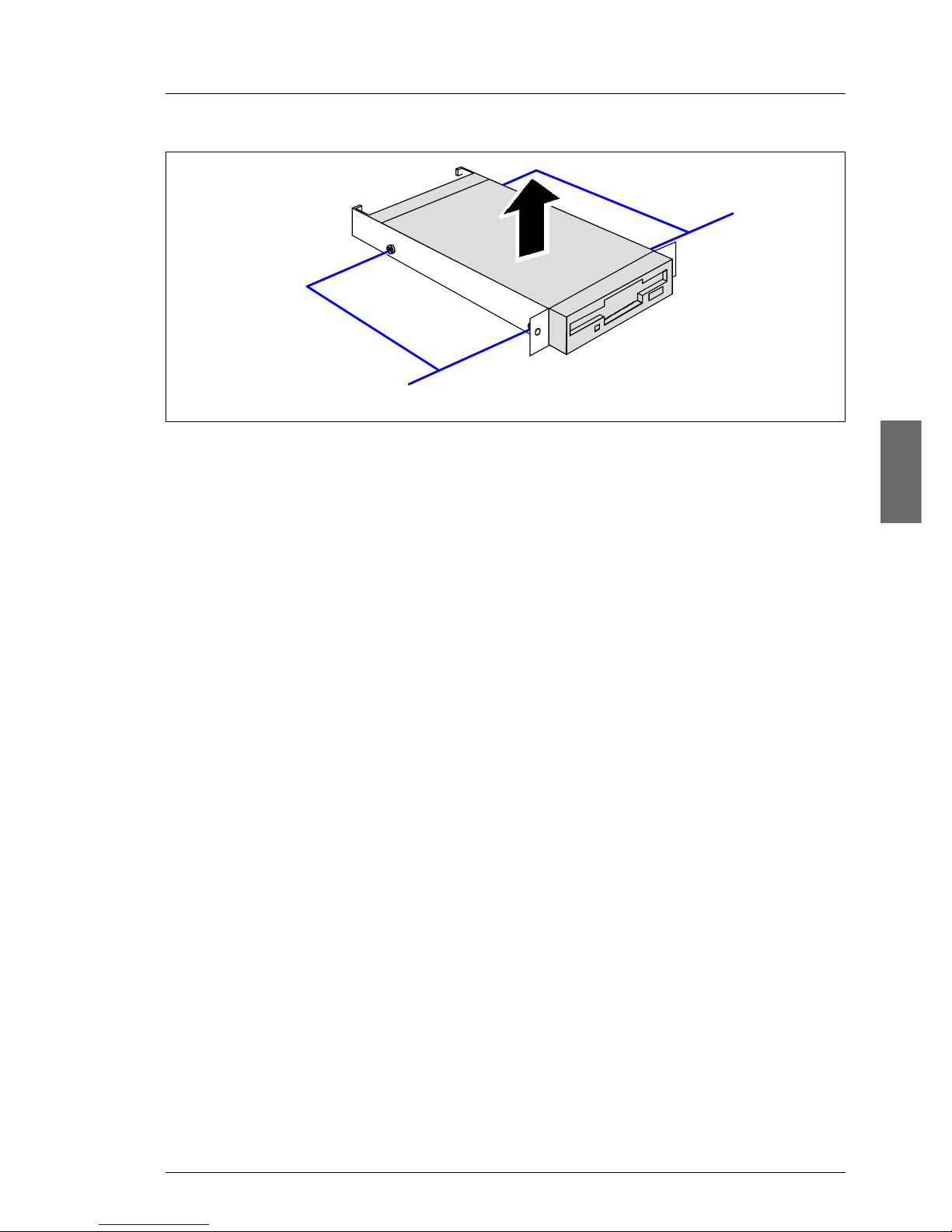

Figure 4: Removing the floppy disk drive from the holder

Ê Remov e two screws (1) on each side and tak e the floppy disk drive out of the

drive holder.

Ê Position the new floppy disk drive in the drive holder and fasten it with two

screws on each side.

Ê Push the drive holder with the floppy disk drive in its bay.

Ê Fasten the drive holder with two screws to the housing.

Ê Reconnect all cables.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

Service Supplement 17

Page 24

Replacing the system fan Replacement routines

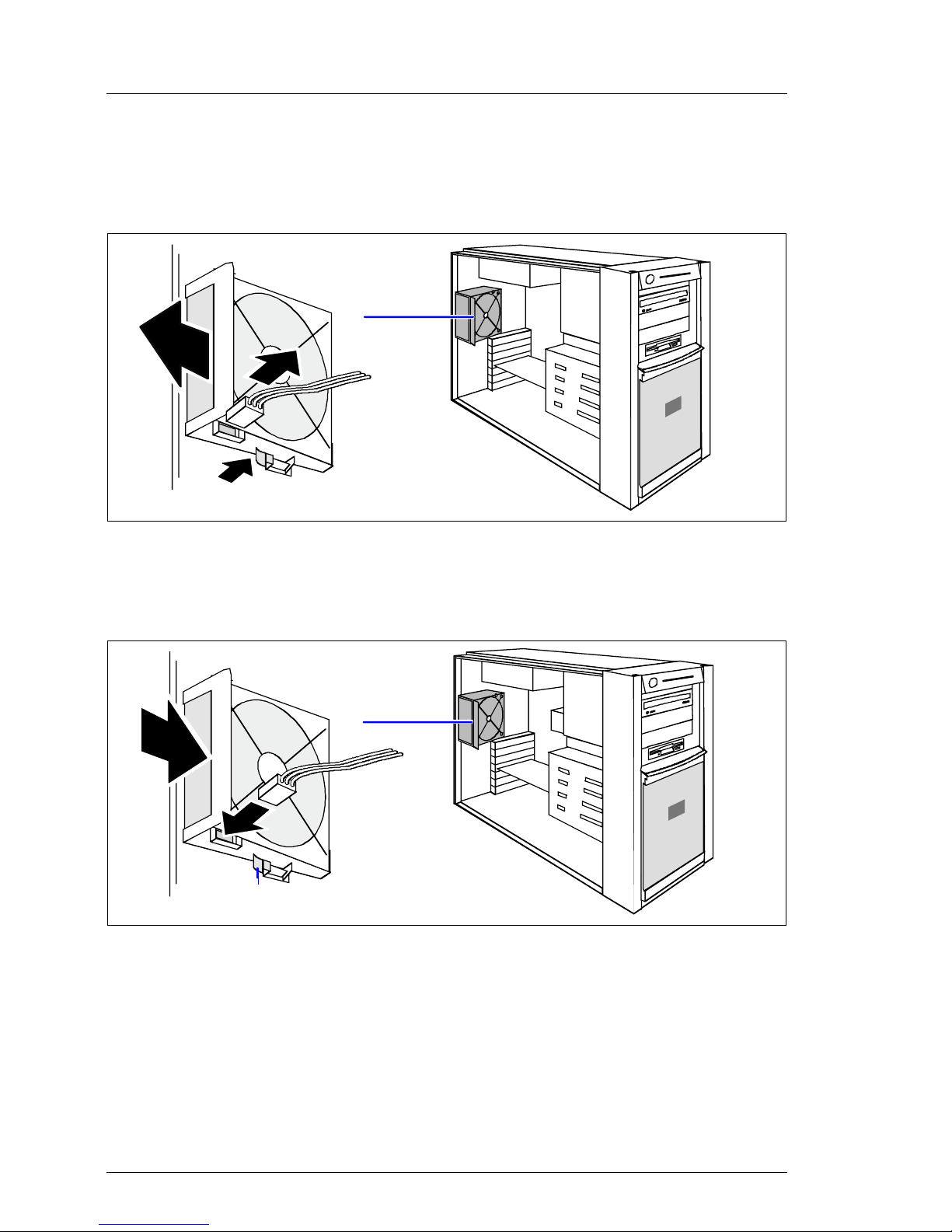

4.4 Replacing the system fan

Ê Open the server as described in the section “Preparation” on page 13.

3

1

2

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Figure 5: Removing the system fan

Ê Pull the cable off the system fan (1).

Ê Press on the clip (2) from behind and remove the system fan (3).

1

2

a

Figure 6: Installing the system fan

Ê Place the new system f an in the bay (1). The proper fan position can best be

judged from the outside at the rear side of the server. When doing so, make

sure the fan clip (a) engages properly.

Ê Connect the cable to the system fan (2).

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

18 Service Supplement

Page 25

Replacement routines Replacing the standard PS

4.5 Replacing the standard PS

Ê Open the server as described in the section “Preparation” on page 13.

I You can replace the power supply without removing the adapter plate.

Ê Disconnect all power cab les fro m the system board and the drives (see the

cabling plans in the Appendix of the Options Guide).

Figure 7: Removing the screws

Ê Remove the four screws of the standard power supply (see the circles).

Service Supplement 19

Page 26

Replacing the Power backplane Replacement routines

2

Figure 8: Taking out the standard PS

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Ê Slide the standard power suppl y somewhat tow ard the inside (1) to detach it

from the adapter plate and take the standard power supply out toward the

side (2).

Ê Push the new power supply into the bay. Take care not to trap the cables.

Ê Fasten the power supply with four screws to the adapter plate.

Ê Connect all power cabl es to the system board and the drives (see the cabling

plans in the Appendix of the Options Guide).

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

4.6 Replacing the Power backplane

The Power backplane is mounted on the PS cage. The power cables are

permanently connected to the Power backplane.

Ê Open the server as described in the section “Preparation” on page 13.

Ê Push the green latch of the hot-plug power supply unit upward and pull the

power supply unit simultaneously out of the PS cage using the handle (see

also the Operating Manual).

20 Service Supplement

Page 27

Replacement routines Replacing the Power backplane

Ê If a second hot-plug power supply unit has been installed, remove this one

in the same way (if there is a dummy cover instead of a second hot-plug

power supply unit, this can remain in place).

I The Power backpl ane in the floorstand model is positioned directly under

the top cover and it makes sense to lay the server on a table with the

uncovered side facing upward. Place the server in such a way that the

feet can project over the edge.

Ê Remove all power cables from the system board and the drives (see the

cabling plans in the Appendix of the Options Guide).

Figure 9: Removing the Power backplane

Ê Remove the knurled screw (see the circle).

Ê Push the P ower backplane downward (see direction of the arrow) until it gets

out of the three bolts of the PS cage. Take out the Power backplane.

Ê Insert the new P ower bac kplane and push the P ower bac kplane upward until

the three bolts of the PS cage engage.

Ê Fasten the Power backplane with the knurled screw in the PS cage.

Ê Plug the power cab les on the system board and the drives (see the cabling

plans in the Appendix of the Options Guide).

Ê Reinstall the hot-plug power supply unit(s).

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

Service Supplement 21

Page 28

Replacing the SCSI backplane Replacement routines

4.7 Replacing the SCSI backplane

The SCSI backplane is mounted on the hard disk cage. It is not necessary to

remove the hard disk cage before replacing the SCSI backplane.

Ê Open the server as described in the section “Preparation” on page 13.

Ê Remov e all the hot-plug hard disk drives (f or a description see the Operating

Manual).

V CAUTION!

Check if all hard disk drives are uniquely identified so that you can

reinsert them into their original bays.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

2

1

1

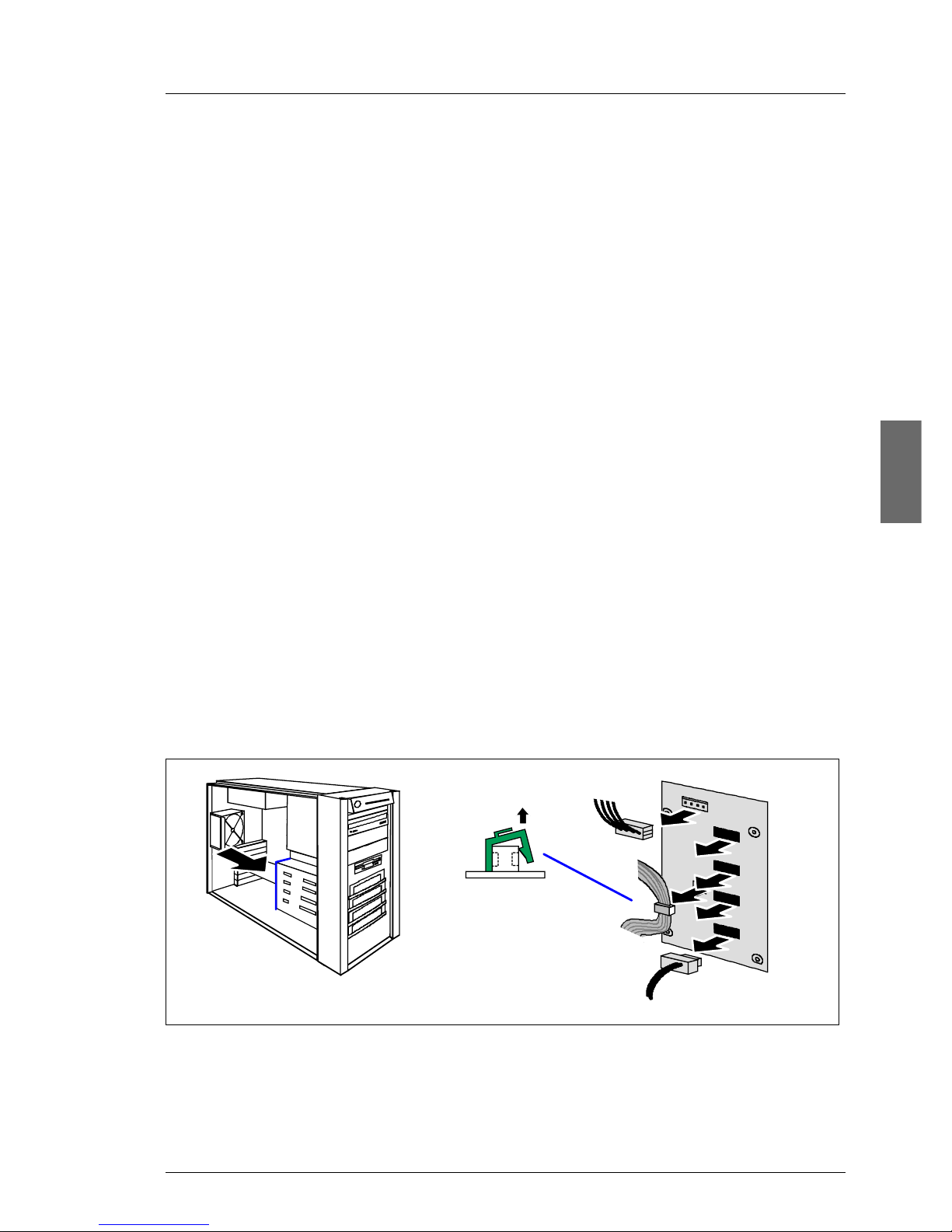

Figure 10: Disconnecting cables

3

4

Ê Take the I2C cable out of the green cable clamp and remov e the cable clamp

(1).

Ê Pull out the connectors of the power cable (2), the SCSI cable (3) and the

2

I

C cable (4) from the SCSI backplane.

Ê Remove the four screws (two at each side) that fasten the SCSI backplane

holder to the hard disk cage.

Ê Take the SCSI backplane together with the holder out of the server. Be

careful with the isolation foil positioned on the rear side of the SCSI

backplane.

Ê Remove the isolation foil and lift the SCSI backplane from the holder.

Ê Insert the new SCSI backplane in the holder.

Ê Position the isolation foil.

22 Service Supplement

Page 29

Replacement routines Replacing the SATA backplane

Ê Fasten the SCSI backplane holder using the four screws on the hard disk

cage.

2

Ê Attach the connectors of the SCSI cable , the po wer cab le and the I

to the SCSI backplane (see the figure 10 on page 22).

2

Ê Attach the green cable clamp to the connect or of the I

cable in the cable clamp.

Ê Reinstall all hot-plug hard disk drives.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

C cable and place the

C cable

4.8 Replacing the SATA backplane

The SATA backplane is mounted on the hard disk cage. It is not necessary to

remove the hard disk cage before replacing the SATA backplane.

Ê Open the server as described in the section “Preparation” on page 13.

Ê Remov e all the hot-plug hard disk drives (for a desc ription see the Operating

Manual).

V CAUTION!

Check if all hard disk drives are uniquely identified so that you can

reinsert them into their original bays.

2

1

1

4 x

4

3

Figure 11: Disconnecting cables

Ê Take the I2C cable out of the green cable clamp and remov e the cable clamp

(1).

Service Supplement 23

Page 30

Replacing the IDTEMP combo Replacement routines

Ê Pull out the connectors of the power cab le (2), the f our SATA cables (3) and

2

the I

C cable (4) from the SATA backplane.

Ê Remove the four screws (two at each side) that fasten the SATA backplane

holder to the hard disk cage.

Ê Take the SATA backplane together with the holder out of the server. Be

careful with the isolation foil positioned on the rear side of the SATA

backplane.

Ê Remove the isolation foil and lift the SATA backplane from the holder.

Ê Insert the new SATA backplane in the holder.

Ê Position the isolation foil.

Ê Fasten the SATA backplane holder using the four screws on the hard disk

cage.

Ê Attach the connectors of the four SATA cables, the power cable and the I

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

cable to the SATA backplane (see the figure 11 on page 23).

Ê Attach the green cable clamp to the connector of the I

2

C cable and place the

2

C

cable in the cable clamp.

Ê Reinstall all hot-plug hard disk drives.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

4.9 Replacing the IDTEMP combo

This board includes two important system components:

– EEPROM for the chassis ID and ident number of the server

– temperature sensor for monitoring the environment temperature

The current temperature values and EEPROM data are transmitted to the

system board via the connected I2C bus.

The IDTEMP combo must be correctly installed in order:

– to monitor the temperature correctly,

– to enable the server management to display the correct system picture,

– to install the server using ServerStart.

24 Service Supplement

Page 31

Replacement routines Replacing the IDTEMP combo

V CAUTION!

The IDTEMP combo may not be changed because of the information

which is in the EEPROM to identify the system.

If the combo is defective, a spare part must be ordered specially by

specifying the ident number (see the type label).

The IDTEMP combo is situated on a separate holder under the hard disk cage .

Ê Open the server as described in the section “Preparation” on page 13.

Figure 12: Removing the holder

Ê Push the holder in direction of the arrow.

Ê Take out the holder carefully.

Ê Remove the green cable clamp from the connector of the I

Ê Remove the I

2

C cable from the connector on the IDTEMP combo.

Ê Remove the IDTEMP combo from the holder.

Ê Plug the new IDTEMP combo in the holder.

Ê Plug the I

Service Supplement 25

2

C cable on the connector on the IDTEMP combo.

2

C cable.

Page 32

Replacing the intrusion switches Replacement routines

Ê Plug the green cable clamp on the connector of the I2C cable.

Ê Insert the holder in a slight angle. Make sure that the cables are routed as

shown in figure 12 on page 25.

Ê Push the holder in direction of the front side until the holder engage in the

bottom of the chassis.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

4.10 Replacing the intrusion switches

In the floorstand model two intrusion detection switches monitor the removing

of the left side cover and the hard disk cover. In the rack model only one

intrusion switch is active, this one monitors the removing of the top cover.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

One switch is situated at the left (floorstand model) or the top (rack model) side

of the hard disk cage, the other switch at the front cover beneath the hard disk

cage. The two i ntrusion detection s witc hes are serially connected on one ca ble

and have to be replaced in pairs.

Ê Open the server and remove the front cover / rack front cover as described

in the section “Preparation” on page 13.

Ê Remove the IDTEMP combo with its holder as shown in figure 12 on

page 25.

26 Service Supplement

Page 33

Replacement routines Replacing the intrusion switches

Figure 13: Removing screws and intrusion switch 1

Ê Remove the two screws (see the arrows) and take out the intrusion switch.

1

2

1

1

Figure 14: Removing the screws and intrusion switch 2

Ê Remove the two screws (1) and take out the intrusion switches inward (2).

Ê Pull the first removed intrusion switch out of the cable clamp.

Service Supplement 27

Page 34

Replacing the processor Replacement routines

Ê Remov e the intrusion switch cable from the connector on the system board

(see also the Technical Manual of the system board).

V CAUTION!

Note the cable routing.

Ê Plug the new intrusion switch cable to the connector on the system board.

Ê Route the intrusion switch cable.

Ê Position the intrusion switch with the three wires on the front cover and

fasten it with two screws.

Ê Insert the intrusion switch with the two wires in its holder and fasten the

switch with two screws.

Ê Reinsert the IDTEMP combo with its holder as shown in figure 12 on

page 25.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

4.11 Replacing the processor

V CAUTION!

Processors are modules which can react extremely s ensitively to electrostatic discharges and which must therefore alw ays be handl ed with care.

After a processor has been remov ed from its protectiv e sleev e or from its

socket, place it with its smooth side down on a non-conducting, antistatic

surface. Never push a processor over a surface.

Ê Open the server as described in the section “Preparation” on page 13.

28 Service Supplement

Page 35

Replacement routines Replacing the processor

1

4

Figure 15: Removing the heat sink

3

2

Ê Loosen the four screws in a crossover pattern.

Ê Loosen the heat sink by turning it back and forth and then lift it out.

Ê Remove the residual thermal paste from the underside of the heat sink.

Ê Clean the underside of the heat sink using a lint-free cloth.

Service Supplement 29

Page 36

Replacing the processor Replacement routines

2

1

Figure 16: Removing an old processor

Ê Press down the lever (1) and unhook it.

Ê Fold up the frame.

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Ê Lift the installed processor carefully out of the socket (2).

1

Figure 17: Inserting a new processor

a

Ê Remove the protective cap from the bottom side of the new processor.

Ê Position the new processor over the socket and then carefully press it into

the socket (1).

V CAUTION!

The processor can only be installed in one particular direction. Note

the marking on one of the corners. To av oid damaging the pins or the

processor, do not fo rce it into the socket.

30 Service Supplement

Page 37

Replacement routines Replacing the processor

1

Figure 18: Fixing the processor

Ê Fold down the frame (1).

2

3

V CAUTION!

The processor holder must fall do wn by itself . Do not close with f orce,

because soldering pads may be damaged.

Ê Press the lever slowly downward (2) until it is hooked in again (3).

Ê Apply a small amount of thermal paste to the upper side of the new

processor.

Ê Ensure a thin and even distribution of the thermal paste.

Service Supplement 31

Page 38

Replacing the processor Replacement routines

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Figure 19: Position of the holes to fasten the heat sink

Ê Position the heat sink carefully on the processor.

V CAUTION!

The heat sink must be positioned in the way that a wide side of the

heat sink is in direction of the system fan to enable the air flow through

the ribs.

Ê Position the screws in the holes carefully, making sure they are upright.

32 Service Supplement

Page 39

Replacement routines Replacing the processor

1

4

Figure 20: Mounting the heat sink

3

2

Ê Tighten the four screws crosswise. Follow the following steps:

1. T urn screw no .1 two/three turns, then will be no tension on the processor

when tightening the next screws.

2. Tighten screws no. 2, 3 and 4 in this order.

3. Tighten screw no.1 finally.

Tighten all screws as far as they will go with a torque of 0.6 NM.

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

Service Supplement 33

Page 40

Replacing the system board Replacement routines

4.12 Replacing the system board

Ê Open the server as described in the section “Preparation” on page 13.

Ê Lay the server on a table with the uncovered side facing upward. Place the

server in such a way that the feet can project over the edge.

Ê Remove all external cables.

Ê Remove all controllers from their slots (for a description see the Operating

Manual and the Options Guide). Tak e note of the slots of the controllers and

the cabling.

Ê Remove the system fan (see the section “Replacing the system fan” on

page 18).

Ê Remove the processor (see the section “Replacing the processor” on

page 28).

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Ê Remove the memory modules (for a description see the Options Guide).

Ê Remove all cables which may be connected to the system board.

34 Service Supplement

Page 41

Replacement routines Replacing the system board

1

4

8

2

5

9

3

6

7

1110

Figure 21: Removing the screws

Ê Remove the eleven screws from the system board.

Ê Lift the system board slightly using the socket of PCI slot 5, thereby you lift

the system board out of the centre rings of the spacer bolts.

Ê Carefully lift the system board (using both hands) out of the chassis in a

slight angle. Thereby you pull the connectors out of the connector panel.

V CAUTION!

Always take the system board with both hands!

Never lift the system board one-sided or at the heat sink, because

the solder connections between the socket and the system board

come under tension and increase the risk of damage and

malfunction!

Don’t damage the EMI springs to comply with applicable EMC regulations and satisfy cooling requirements and fire protection measures.

Ê Place the removed and the new system board on an antistatic surface.

Service Supplement 35

Page 42

Ê Remove the protective plastic cover from the processor socket of the new

system board and fit it onto the socket of the defective system board which

will be sent back to spares.

I Returned system boards without this cover probably have to be

scrapped.

Ê Check the settings on the new system board (for a description see the

Technical Manual of the system board).

Ê Insert the system board by holding it at a slight angle. Slide the connectors

into the connector panel.

Ê Lower the system board carefully into the chassis.

Ê Adjust the system board. If necessary adjust the position of the system

board with a gentle twisting motion.

I When the system board is in the right position, the centre rings engage

© cognitas. Gese l l sc hft für Technik-Dokumentati on mbH 2005 Pfad: L:\ T X150_S3\TX15 0S 3servsuppl \ T X 1 50S3_ss_e\T X150S3_ss_e.k04

Ê Fasten the system board with the eleven screws.

with the holes indicated. The centre rings are placed under the screw

positions 1 and 5.

Ê Reconnect the cables to their original connectors (see also the c abling plans

in the Options Guide).

Ê Install the memory modules (for a description see the Options Guide).

Ê Install the processor (see the section “Replacing the processor” on

page 28).

Ê Install the system fan (see the section “Replacing the system fan” on

page 18).

Ê Install all controllers in their former slots (f or a description see the Operating

Manual and Options Guide).

Ê Close the server and connect all power plugs (for a detailed description see

the Options Guide).

Ê Connect all external cables.

V CAUTION!

After installing the new system board, it is necessary to update the BIOS

to ensure proper operation (for a description see the BIOS Manual).

Page 43

5 Appendix

5.1 Board layout

I The board layout of the system board is described in the Technical

Manual of the system board D1979.

5.1.1 Operating panel board

Part number: A3C40050401

1 Connector operating panel cable

2 Connector USB cable

I The operating panel board is included in the spare part „operating panel

module“ (C26361-K644-Z331).

Service Supplement 37

21

Page 44

Board layout Appendix

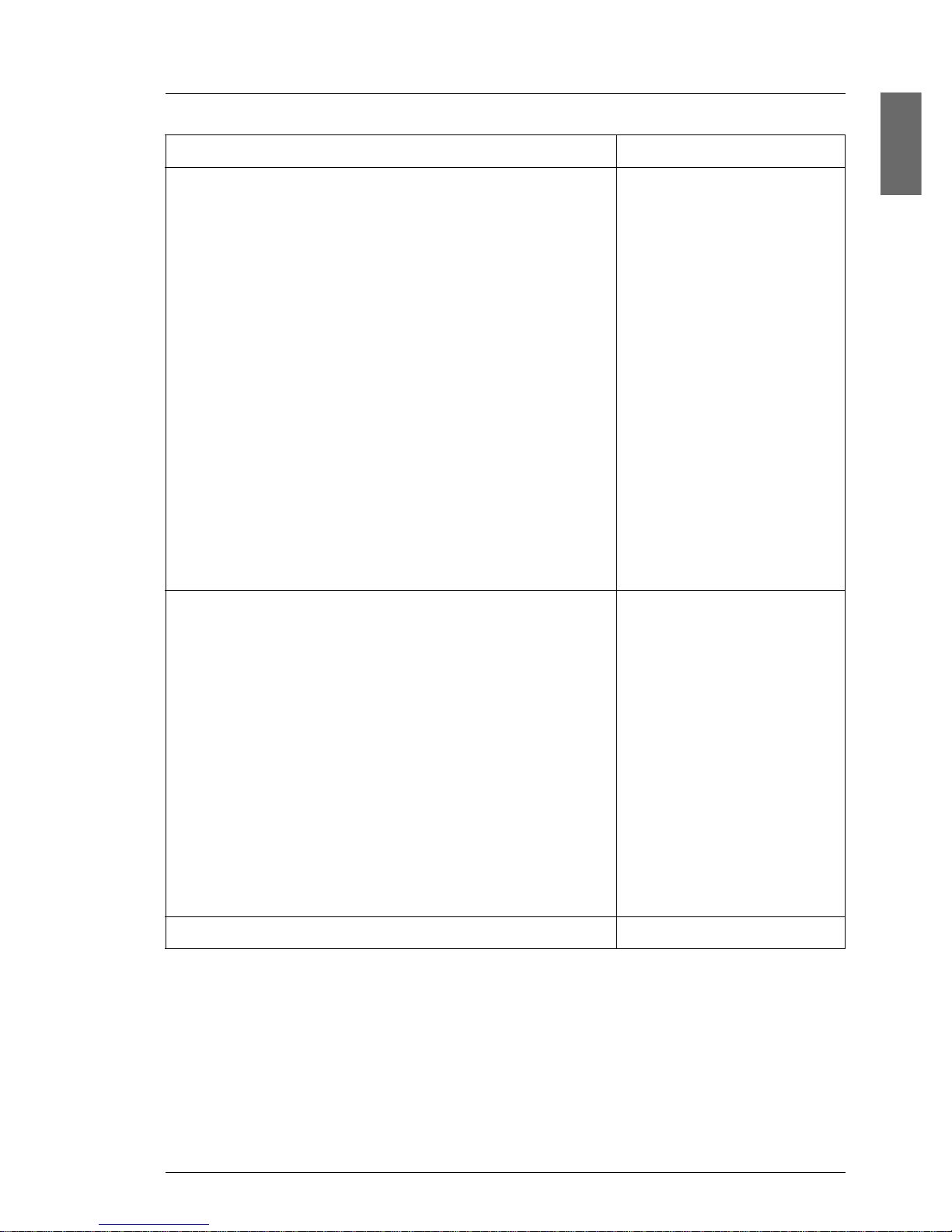

5.1.2 SCSI backplane

Part number: A3C40020516

You will find the SCSI backplane with 4 slots for hard disk modules on the hard

disk cage. The termination is done by the SCSI backplane

2

SCSI ID3

© cognitas. Gesel l sc hft für Technik-Dokumenta tion mbH 2005 Pfad: L:\T X150_S3\TX150S3servsu ppl\TX150S3_ss_e\TX150S3_ss_e.anh

4

SCSI ID 2

5

1

1 X 5 SC SI input connector 4 LEDs

2 X6 Power connector 5 SCA connect ors (ID0 to ID3)

3 X 7 SM B connector (i²C bus)

3

SCSI ID 1

SCSI ID 0

The LEDs are made visible at the front side of the mounting frames via light

conductors, which are situated at the mounting fr ames of the drives. You will find

the description of the LEDs in the Operating Manual TX150 S3.

38 Service Supplement

Page 45

Appendix Board layout

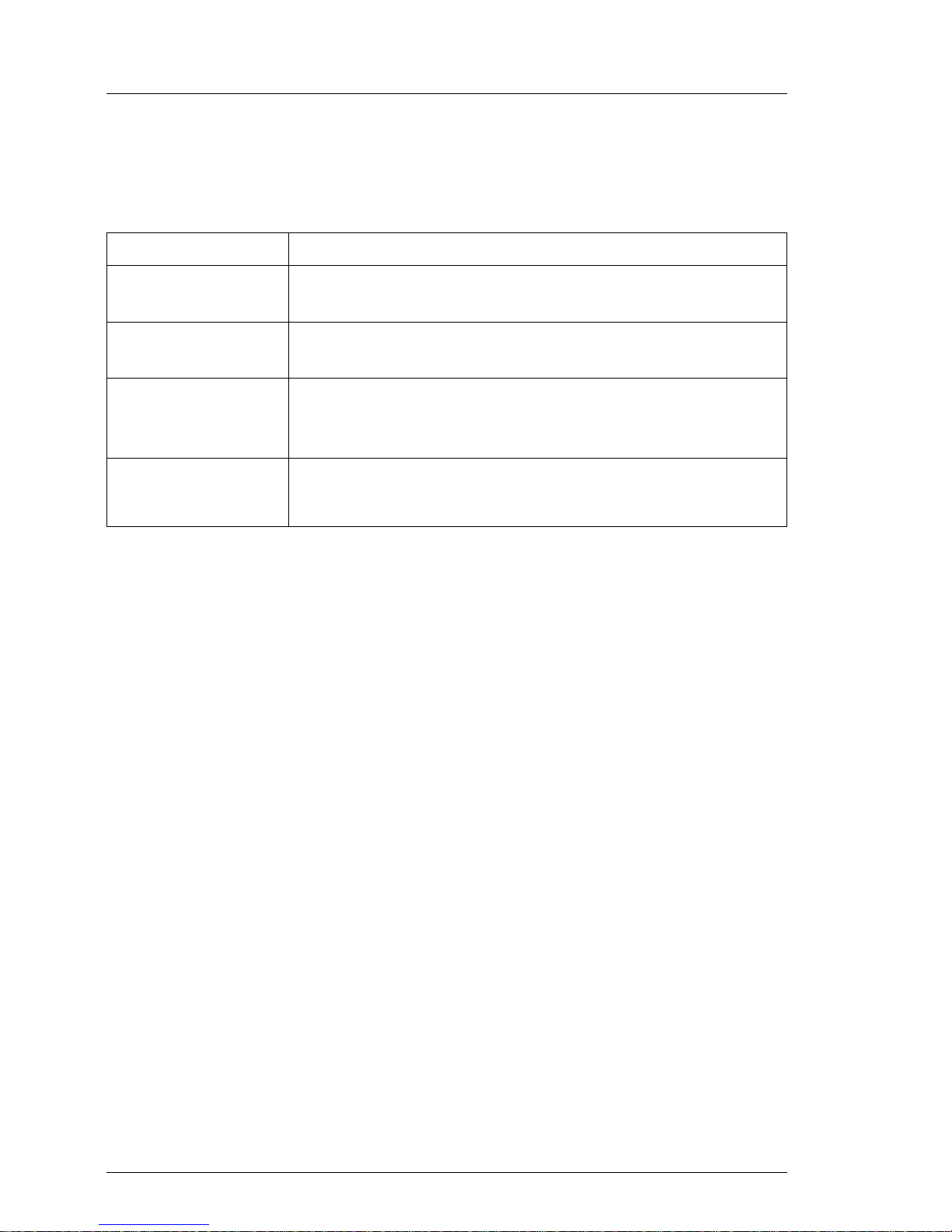

5.1.3 SATA backplane

Part number: A3C40040589

You will find the SATA backplane with 4 slots for SAT A hard disk modules located

on the hard disk cage.

4

3

5

6

8

2

1

7

1I2C bus connector (X11) 5 not used (Program con nec t or)

2 SMB connector (I

3 Jumper FW Run (X13)

jumper is not set

4 Connector power supply ( X 9) 8 SATA connectors for hard disk drives

The LEDs are made visible on the front side of the mounting frames via light

conductors, which are situated at the mounting frames of the drives. Th e signal

of the LEDs is the same as for SCSI hard disk drives. The controlling of the

LEDs does only work if a driver has been loaded.

Service Supplement 39

2

C bus, X10) 6 LEDs

7 Connectors to SATA controller (HDD0

- HDD3)

Page 46

Board layout Appendix

5.1.4 Power backplane

Part number: A3C40052762

© cognitas. Gesel l sc hft für Technik-Dokumenta tion mbH 2005 Pfad: L:\T X150_S3\TX150S3servsu ppl\TX150S3_ss_e\TX150S3_ss_e.anh

2

1

1 Connector power supply m odule 1

2 Connector power supply m odule 2

40 Service Supplement

Page 47

Index

E

ESD (devices sensitiv e to electrostatic

discharge) 11

F

floppy disk drive 16

I

IDTEMP combo 24

intrusion detection switches 26

L

light-emitting diode (LED) 11

lithium battery 9

M

meaning of the symbols 4

N

notational conventions 4

note about the laser 11

O

operating panel board 37

operating panel module 15

P

Power backplane 20, 40

processor 28

S

SATA backplane 23, 39

SCSI backplane 22, 38

standard PS 19

system board 33

T

target group 1

Service Supplement 41

Page 48

© cognitas. Gese l l sc hft für Technik-Dokumenta tion mbH 2005 Pfad: L:\ T X 150_S3\TX150S 3servsuppl\TX150S3_s s_e\TX150S3_ss_e.six

Page 49

Fujitsu Siemens Computers GmbH

User Documentation

81730 München

Germany

Fax: (++49) 700 / 372 00000

email: manuals@fujitsu-siemens.com

http://manuals.fujitsu-siemens.com

Submitted by

Comments on PRIMERGY TX150 S3

Server System

Comments

Suggestions

Corrections

✁

Page 50

© cognitas. Gese l l sc hf t für Technik-Dokumentation mbH 2005 Pfad: L:\ T X1 50_S3\TX150S 3servsuppl\TX150S3_ss_e\TX150S3_s s_e.nac

Page 51

Fujitsu Siemens Computers GmbH

User Documentation

81730 München

Germany

Fax: (++49) 700 / 372 00000

email: manuals@fujitsu-siemens.com

http://manuals.fujitsu-siemens.com

Submitted by

Comments on PRIMERGY TX150 S3

Server System

Comments

Suggestions

Corrections

✁

Page 52

© cognitas. Gese l l sc hf t für Technik-Dokumentation mbH 2005 Pfad: L:\ T X1 50_S3\TX150S 3servsuppl\TX150S3_ss_e\TX150S3_s s_e.nac

Page 53

PRIMERGY

PRIMERGY TX150 S3

Server System

Options Guide

Susanne Däschlein

Fujitsu Siemens Computers GmbH München

81730 München

e-mail: email: manuals@fujitsu-siemens.com

Tel.: (089) 61001155

Fax: (++49) 700 / 372 00000

U41604-Z156-1-76

Sprachen: En

Edition January 2005

Page 54

This manual is printed on

paper treated with

chlorine-free bleach.

Comments… Suggestions… Corrections…

The User Documentation Department would like to

know your opinion of this manual. Your feedback helps

us optimize our documentation to suit your individual

needs.

Fax forms for sending us your comments are included in

the back of the manual.

There you will also find the addresses of the relevant

User Documentation Department.

Certified documentation

according to DIN EN ISO 9001:2000

To ensure a consistently high quality standard and

user-friendliness, this documentation was created to

meet the regulations of a quality management system

which complies with the requirements of the standard

DIN EN ISO 9001:2000.

cognitas. Gesellschaft für Technik-Dokumentation mbH

www.cognitas.de

Copyright and Trademarks

Copyright © 2005 Fujitsu Siemens Computers GmbH.

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

Page 55

Introduction

Procedure

Safety notes

Preparation

Main memory

Accessible drives

Controller in the PCI slots

RemoteView components

External SCSI interface

Conversion standard PS to hot-plug PS

Continued

Page 56

Page 57

Converting from the floorstand model to the rack model

Completion

Appendix

Abbreviations, Related publications and Index

Page 58

Page 59

U41604-Z156-1-76 Options Guide

Contents

1Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview of the documentation . . . . . . . . . . . . . . . . . . 1

1.2 Extensions and conversions . . . . . . . . . . . . . . . . . . . . 2

1.3 Notational conventions . . . . . . . . . . . . . . . . . . . . . . . 4

2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Floorstand model . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.1 Opening the server . . . . . . . . . . . . . . . . . . . . . . . 13

4.1.2 Removing the front cover . . . . . . . . . . . . . . . . . . . . 14

4.1.3 Removing the hard disk cover . . . . . . . . . . . . . . . . . . 15

4.2 Rack model . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Opening the server . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Removing the rack front cover . . . . . . . . . . . . . . . . . . 19

5Main memory . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Equipping rules . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Extending/replacing the main memory . . . . . . . . . . . . . 22

6 Accessible drives . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Installing an accessible 5.25-inch drive . . . . . . . . . . . . . 25

6.2 Installing the hard disks extension box . . . . . . . . . . . . . 29

7 Controller in the PCI slots . . . . . . . . . . . . . . . . . . . 31

7.1 Installing a controller . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 PCI slot assembling . . . . . . . . . . . . . . . . . . . . . . . 34

8 RemoteView components . . . . . . . . . . . . . . . . . . . 35

8.1 RemoteView Service Board S2 LP . . . . . . . . . . . . . . . 35

9 External SCSI interface . . . . . . . . . . . . . . . . . . . . 39

9.1 Installing the external SCSI interface . . . . . . . . . . . . . . 39

10 Conversion standard PS to hot-plug PS . . . . . . . . . . . 41

11 Converting from the floorstand model to the rack model . . 53

12 Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

12.1 Floorstand model . . . . . . . . . . . . . . . . . . . . . . . . 59

Page 60

Options Guide U41604-Z156-1-76

Contents

12.1.1 Attaching the hard disk cover . . . . . . . . . . . . . . . . . . . 59

12.1.2 Attaching the front cover . . . . . . . . . . . . . . . . . . . . . 60

12.1.3 Closing the server . . . . . . . . . . . . . . . . . . . . . . . . . 61

12.2 Rack model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

12.2.1 Attaching the rack front cover . . . . . . . . . . . . . . . . . . 62

12.2.2 Closing the server . . . . . . . . . . . . . . . . . . . . . . . . . 64

13 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.1 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.1.1 SCSI version . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.1.2 SATA version . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Page 61

U41604-Z156-1-76 Options Guide 1

1 Introduction

The PRIMERGY TX150 S3 Server is an Intel-based server for medium-sized

networks and large companies. The server is suitable for use as a file server as

well as an application, information, or Internet server. It is available as a floorstand or rack model. The floorstand model can be converted to a rack model

using an optional conversion kit.

1.1 Overview of the documentation

I PRIMERGY manuals are available in PDF format on the ServerBooks CD

which is supplied in the ServerView Suite package for every server

system.

These PDF files can also be downloaded free of charge from the

Internet: at http://manuals.fujitsu-siemens.com you will find an overview

page with the online documentation available on the Internet. You can go

to the PRIMERGY Server documentation by clicking on “intel based

Servers”.

Concept and target groups

This Options Guide shows you how you can expand and upgrade the server.

I The Operating Manual for the server describes how you install/remove

the hot-plug components.

The activities described in this manual may only be performed by technicians,

service personnel or technical specialists.

Additional documentation about the server

The PRIMERGY TX150 S3 documentation comprises the following additional

manuals:

– The “Security” manual (printed copy always supplied with the server, and

available as a PDF file on the ServerBooks CD supplied)

– The “Guarantee” manual (printed copy always supplied with the server, and

available as a PDF file on the ServerBooks CD supplied)

– The Operating Manual for the PRIMERGY TX150 S3 (PDF available on the

ServerBooks CD supplied)

Page 62

2 Options Guide U41604-Z156-1-76

Extensions and conversions Introduction

– The Technical Manual for the system board D1979 (PDF available on the

ServerBooks CD supplied)

– The “BIOS Setup” manual (PDF available on the ServerBooks CD supplied)

– The “PRIMERGY ServerView Suite - ServerStart” manual (printed copy

always supplied with the server, and available as PDF file on the ServerBooks

CD supplied)

– The “Global Array Manager Client Software User’s Guide” (PDF available on

the ServerBooks CD supplied)

– The “Integrated Mirroring User’s Guide” (PDF available on the ServerBooks

CD supplied)

I You can order a supplementary ServerBooks CD by sending an e-mail to

the following address, quoting your server data:

Reklamat-PC-LOG@fujitsu-siemens.com

Further sources of information:

– Technical Manual on the relevant rack

– Manual on the monitor

– Manual on ServerView Server Management

– Manual on the RemoteView Remote Test and Diagnostics System

– Documentation on boards and drives

– Documentation on your operating system

– Information files on your operating system

(see also “Related publications” on page 79)

1.2 Extensions and conversions

Extension of the main memory

The four slots for the main memory are suitable for DDR1 333/400 MHz (unbuffered) SDRAM memory modules. The organization in two memory banks, 1 and

2, permits rapid memory access with two-way interleaving.

If the memory modules are populated in pairs, each pair must consist of

identical memory modules (2-way interleaved mode).

Additional SATA hard disk drives

In the SATA version four bays are available for SATA hard disk drives.

Page 63

U41604-Z156-1-76 Options Guide 3

Introduction Extensions and conversions

Additional accessible drives

Three 5.25-inch bays are available for accessible drives. The top side bay is

already occupied by a CD/DVD ROM drive.

Hard disks extension box

In the SCSI version the two lower 5.25-inch bays for accessible drives can be

used to integrate a hard disks extension box.

The hard disks extension box enables up to three additional HDD modules to be

integrated. Each HDD module can accommodate a SCSI hard disk drive with

an SCA (Single Connector Attachment) interface and a height of at most 1 inch.

The connection to the SCSI backplane is made without cables via the SCA

interface. This makes it simple to plug in or pull out the HDD modules. If the

server has a RAID controller and the corresponding RAID configuration,

defective HDD modules can also be replaced while the system is operating.

Additional controllers in the PCI slots

The system board offers six PCI slots: 2 x PCI-X (64 Bit / 66 MHz), 3 x PCI (32

Bit / 33 MHz) and 1 x PCI-Express x1 slot.

The PCI slot 2 is prepared for Zero Channel RAID (ZCR).

RemoteView Service Board S2 LP

The RemoteView Service Board S2 LP (RSB S2 LP) is a PCI board with a

completely independent system, i.e. it has its own operating system with Web

server and SNMP agents and can optionally be equipped with an external

power supply. The RSB S2 LP permits remote diagnosis for system analysis,

remote system configuration and remote restart even in the event of operating

system failure or hardware faults. It has its own LAN connection and its own

COM port. All the functions of the RSB S2 LP are thus available either via a LAN

or modem.

External SCSI interface

If the internal hard disks are connected via a PCI RAID controller, one channel

of the on-board controller can also be made available for connecting a

peripheral cabinet SX10 via an external SCSI interface.

Page 64

4 Options Guide U41604-Z156-1-76

Notational conventions Introduction

Conversion standard power supply to hot-plug power supply

The standard power supply can be replaced by a hot-plug power supply. The

hot-plug power supply consists of two power supply modules.

If one power supply module fails, the other power supply module guarantees the

unrestricted operation and the defective power supply module can be replaced

be replaced while the system is operating (hot-plug).

Conversion of the floorstand model to a rack model

The floorstand model can optionally be converted so that the server can be

integrated into the common rack systems.

1.3 Notational conventions

The following notational conventions are used in this manual:

Text in italics indicates commands, menu items or software programs.

„Quotation marks“ indicate names of chapters and terms that are being

emphasized.

Ê describes activities that must be performed in the order

shown.

V CAUTION! pay particular attention to texts marked with this symbol.

Failure to observe this warning may endanger your life,

destroy the system or lead to the loss of data.

I indicates additional information, notes and tips.

Table 1: Notational conventions

Page 65

U41604-Z156-1-76 Options Guide 5

2Procedure

V CAUTION!

The actions described in these instructions should only be performed by

technicians, service personnel or technical specialists. Equipment

repairs should only be performed by authorized, qualified staff. Any

unauthorized opening and improper repairs could expose the user to

risks (electric shock, energy hazards, fire hazards) and could also

damage the equipment. Please note that any unauthorized opening of

the device will result in the invalidation of the warranty and exclusion from

all liability.

Ê First of all please familiarize yourself with the safety instructions in the

section chapter “Safety notes” on page 7 et seqq. .

Ê Ensure that all required manuals (see “Additional documentation about the

server” on page 1) are available, printing out the PDF files if necessary. You

will definitely need the Operating Manual for the server and the Technical

Manual for the system board.

Ê Shut down the server correctly, switch it off, pull out the power plug(s), and

open the server as described in the chapter “Preparation” on page 13 et

seqq. .

Ê Extend or upgrade your server as described in the relevant chapter.

I The Operating Manual for the server describes how you

install/remove the hot-plug components.

I Procedures which are identical for the floorstand and rack models are

only described for the floorstand model.

Ê Close the server, connect it to the power outlet, and switch it on as described

in the chapter “Completion” on page 59 et seqq. .

Ê Start the operating system and, if necessary, configure it as required (see

the Operating Manual).

Page 66

Page 67

U41604-Z156-1-76 Options Guide 7

3 Safety notes

I The following safety notes are also provided in the “Safety” manual.

This device complies with the relevant safety regulations for data processing

equipment.

If you have any questions about where you can set up the device, contact your

sales outlet or our customer service team.

V CAUTION!

The actions described in these instructions should only be performed by

technicians, service personnel or technical specialists. Equipment

repairs should only be performed by authorized, qualified staff. Any

unauthorized openings and improper repairs could expose the user to

risks (electric shock, energy hazards, fire hazards) and could also

damage the equipment. Please note that any unauthorized openings of

the device will result in the invalidation of the warranty and exclusion from

all liability.

Before operating the device

V CAUTION!

● During installation and before operating the device, observe the

instructions on environmental conditions for your device.

● If the device is brought in from a cold environment, condensation may

form both inside and on the outside of the machine.

Wait until the device has acclimatized to room temperature and is

absolutely dry before starting it up. Material damage may be caused

to the device if this requirement is not observed.

● Transport the device only in the original packaging or in packaging

that protects it from knocks and jolts.

Page 68

8 Options Guide U41604-Z156-1-76

Safety notes

Installation and operation

V CAUTION!

● If the rack model is integrated in an installation that receives power

from an industrial (public) power supply network with the IEC309

connector, the (public) power supply protection must comply with the

requirements for the non-industrial (public) power supply networks for

the type A connector.

● The server automatically sets itself to a voltage in the range of

100 V to 240 V. Make sure that your local voltage is within this range.

● This device has a specially approved power cable and must only be

connected to a grounded insulated socket.

● Ensure that the power socket on the device or the grounded wall

outlet is freely accessible.

● The ON/OFF button does not disconnect the device from the mains

voltage. To disconnect the line voltage completely, remove the power

plug(s) from the grounded insulated socket(s).

V CAUTION!

● Always connect the device and the attached peripherals to the same

power circuit. Otherwise you run the risk of losing data if, for example,

the central processing unit is still running but the peripheral device

(e.g. storage subsystem) has failed during a power outage.

● Data cables to peripheral devices must be adequately shielded.

● To the LAN wiring the requirements apply in accordance with the

standards EN 50173 and EN 50174-1/2. As minimum requirement

the use of a protected LAN line of category 5 for 10/100 MBps

Ethernet, and/or of category 5e for Gigabit Ethernet is considered.

The requirements of the specification ISO/IEC 11801 are to be

considered.

● Route the cables in such a way that they do not form a potential

hazard (make sure no-one can trip over them) and that they cannot

be damaged. When connecting up a device, refer to the relevant

notes in this manual.

● Never connect or disconnect data transmission lines during a storm

(lightning hazard).

Page 69

U41604-Z156-1-76 Options Guide 9

Safety notes

● In emergencies (e.g. damaged casing, controls or cables, penetration

of liquids or foreign matter), switch off the device immediately, remove

the power plug and contact your sales outlet or customer service

team.

● Proper operation of the device (in accordance with IEC 60950/

EN 60950) is only ensured if the casing is completely assembled and

the rear covers for the installation openings have been put in place

(electric shock, cooling, fire protection, interference suppression).

● Only install system expansions that satisfy the requirements and

rules governing safety and electromagnetic compatibility and relating

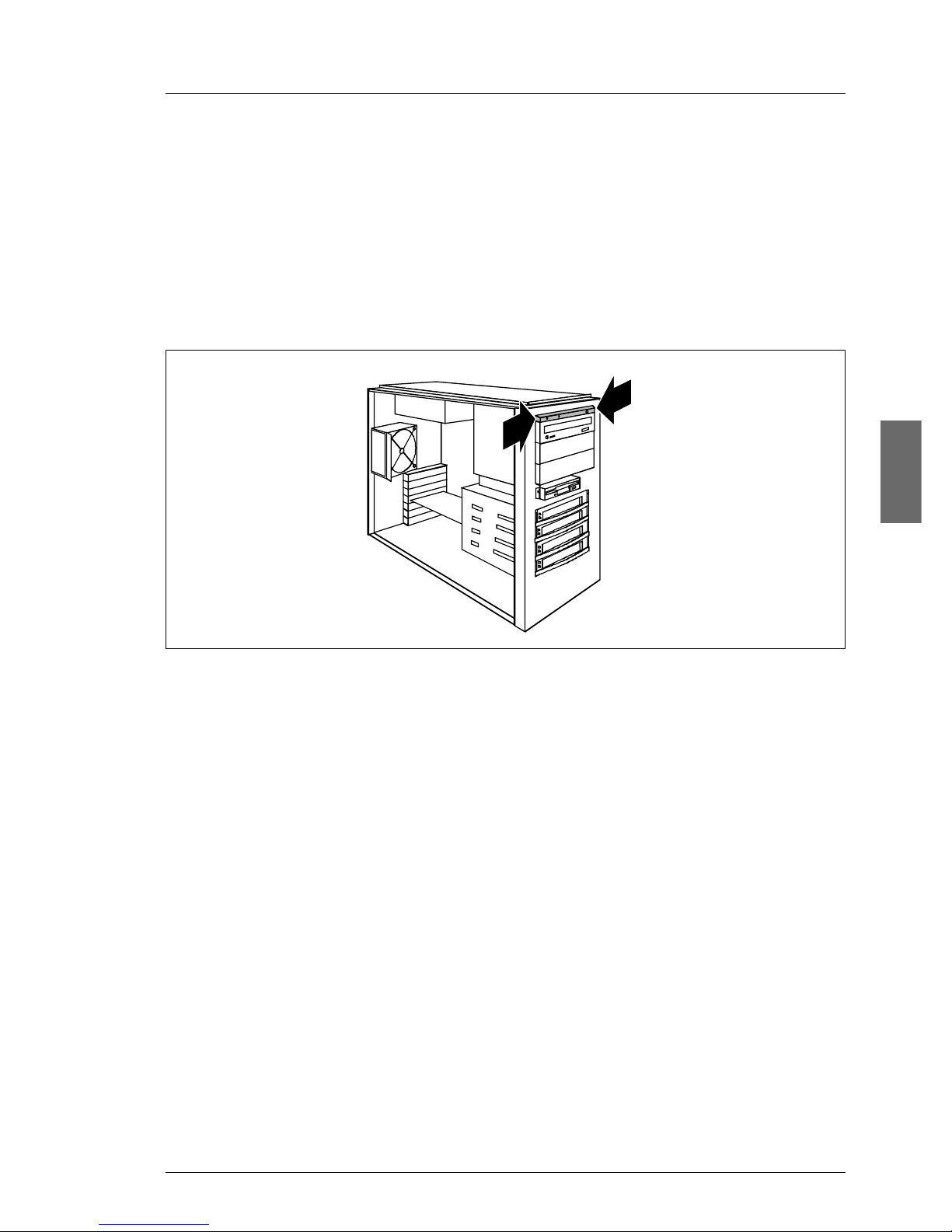

to telecommunications terminal equipment. If you install other expansions, you may damage the system or violate the safety regulations

and regulations governing RFI suppression. Information on which

system expansions are suitable can be obtained from the customer

service centre or your sales outlet.

V CAUTION!

● The components or parts marked with a warning label (e.g. lightning

symbol) may only be opened, removed or exchanged by authorized,

qualified personnel. The hot-plug power supply units are exceptions

to this rule.

● The warranty expires if the device is damaged during the installation

or replacement of system expansions.

● You may only set those resolutions and refresh rates specified in the

„Technical data“ section of the monitor description. Otherwise, you

may damage your monitor. If you are in any doubt, contact your sales

outlet or customer service centre.

Page 70

10 Options Guide U41604-Z156-1-76

Safety notes

Batteries

V CAUTION!

● Incorrect replacement of batteries may lead to a risk of explosion. The

batteries may only be replaced with identical batteries or with a type

recommended by the manufacturer (see the technical manual for the

system board under “Related publications” on page 79).

● Do not throw batteries into the trash can. They must be disposed of

in accordance with local regulations concerning special waste.

● The battery must be disposed of in accordance with local regulations

concerning special waste.

● Replace the lithium battery on the system board in accordance with

the instructions in the technical manual for the system board (see

“Related publications” on page 79).

● All batteries containing pollutants are marked with a symbol (a

crossed-out garbage can). In addition, the marking is provided with

the chemical symbol of the heavy metal decisive for the classification

as a pollutant:

Cd Cadmium

Hg Mercury

Pb Lead

Page 71

U41604-Z156-1-76 Options Guide 11

Safety notes

Notes on handling CDs and CD-/DVD-ROM drives

V CAUTION!

● Use only CDs in proper condition in the CD-/DVD-ROM drive of your

server to prevent data loss, damage to the device and injuries.

● Therefore, check each CD for damage, cracks, breakage etc. before

inserting it in the drive.

Please note that any additional labels applied may change the

mechanical properties of a CD and cause imbalance.

Damaged and imbalanced CDs can break at high drive speeds (data

loss).

Under certain conditions sharp-edged pieces of broken CDs can

penetrate the cover of the drive (damage to the device) and be thrown

out of the device (danger of injury, particularly on uncovered body

parts such as the face or neck).

I You protect the CD-/DVD-ROM drive and prevent mechanical damage,

as well as premature wearing of the CDs, by observing the following

suggestions:

– Only insert the CDs in the drive when needed and remove them after

use.

– Store the CDs in suitable sleeves.

– Protect the CDs from exposure to heat and direct sunlight.

Note about the laser

The CD-/DVD-ROM drive

is classified for

laser class 1according to IEC 60825-1.

V CAUTION!

The CD-/DVD-ROM drive contains a laser diode (LED). Sometimes the

LED produces a stronger laser beam than laser class 1. Direct view into

this laser beam is dangerous.

Never remove parts of the CD-/DVD-ROM drive assembly!

Page 72

12 Options Guide U41604-Z156-1-76

Safety notes

Modules with electrostatic-sensitive components:

Systems and components that might be damaged by electrostatic discharge

(ESD) are marked with the following label:

Figure 1: ESD label

When you handle components fitted with ESDs, you must observe the following

points under all circumstances:

● Remove the power plug from the power socket before inserting or removing

components containing ESDs.

● You must always discharge yourself of static charges (e.g. by touching a

grounded object) before working.

● The equipment and tools you use must be free of static charges.

● Only touch the components at the positions highlighted in green (touch

points).

● Do not touch any exposed pins or conductors on a component.

● Use a grounding cable designed for this purpose to connect yourself to the

system unit as you install components.

● Place all components on a static-safe base.

I You will find a detailed description for handling ESD components in the

relevant European or international standards (DIN EN 61340-5-1,

ANSI/ESD S20.20).

Page 73

U41604-Z156-1-76 Options Guide 13

4 Preparation

V CAUTION!

Observe the safety instructions in the chapter “Safety notes” on page 7

et seqq. .

4.1 Floorstand model

4.1.1 Opening the server

Ê Terminate all applications and shut down the server correctly.

Ê If your operating system has not switched off the sever, press the on/off

switch.

Ê Pull all power connectors out of the power outlets.

Ê If required, remove the lock on the side cover.

Figure 2: Loosening the screws

Ê Unlock the server (1).

Ê Loosen the two screws at the rear side (2).

Ê Push back the left-hand side cover approxiate 2 cm (3).

Ê Remove the left-hand side cover (4).

1

4

2

3

Page 74

14 Options Guide U41604-Z156-1-76

Floorstand model Preparation

4.1.2 Removing the front cover

Remove the front cover when making the following extensions and upgrades:

– Installing further accessible drives

– Upgrading the floorstand model to a rack model

Ê Remove the hard disk cover as shown in figure 5 on page 15.

Figure 3: Removing the front cover

Ê Disengage the three tabs (1) on the left side one after the other and rotate

the front cover outward (2) about 2 cm.

Figure 4: Removing the front cover

Ê Press the two hooks (1) on the right side inward and pull out the front cover

frontward (2).

1

2

2

1

Page 75

U41604-Z156-1-76 Options Guide 15

Preparation Floorstand model

4.1.3 Removing the hard disk cover

Remove the hard disk cover when making the following extensions and

upgrades:

– Installing further SATA hard disk drives

Ê Terminate all applications and shut down the server correctly.

Ê If your operating system has not switched off the sever, press the on/off

switch.

Figure 5: Removing the hard disk cover

Ê Unlock the server (1) and remove the key.

Ê Push the drive cover up as far as possible (2).

Ê Remove the hard disk cover (3 + 4).

1

2

4

3

Page 76

16 Options Guide U41604-Z156-1-76

Rack model Preparation

4.2 Rack model

Ê Terminate all applications and shut down the server correctly.

Ê If your operating system has not switched off the server, press the on/off

button.

Ê Pull all power connectors out of the power outlets.

4.2.1 Opening the server

Figure 6: Loosening the knurled screws

Ê Loosen the four knurled screws (1) and pull the server as far as possible out

of the rack (2).

1

2

Page 77

U41604-Z156-1-76 Options Guide 17

Preparation Rack model

Figure 7: Loosening the locking spring

Ê Press in the locking spring (1) on both sides and carefully pull the server

outward (2).

Figure 8: Removing the server from the rack cabinet

Ê Disconnect all cables on the rear of the server.

Ê Remove the telescopic rails on the left and right side (three screws).

1

2

2

Page 78

18 Options Guide U41604-Z156-1-76

Rack model Preparation

V CAUTION!

At least two people are needed to lift the server out of the rack cabinet.

Ê Lift the server out of the rails and place it on a table, for example.

Figure 9: Loosening the screws

Ê Unlock the top cover by removing the two screws at the rear side (1).

Ê Push back the top cover approxiate 2 cm (2).

Ê Remove the top cover (3).

2

3

1

2

Page 79

U41604-Z156-1-76 Options Guide 19

Preparation Rack model

4.2.2 Removing the rack front cover

Remove the rack front cover when carrying out the following extension:

– Installing further accessible drives

Figure 10: Removing the rack front cover

Ê Remove two screws on either side (1).

Ê Remove the rack front cover to the front (2).

Figure 11: Removing the plastic front cover

Ê Disengage the three tabs (1) on the top side one after the other and pull out

the plastic front cover frontward (2) about 2 cm.

Ê Press the two hooks (3) on the bottom side downward and pull out the plastic

front cover frontward (4).

1

1

2

1

3

2