Page 1

XG2600 Hardware Guide

Introduction

XG2600

XG2600

xxxx-xxxx-xxxx

HardwareGuide

Page 2

XG2600 Hardware Guide

Preface

You have purchased the XG2600, a compact, 26 port 10 Gigabit Ethernet layer 2 switch that achieves unsurpassed standards

of high throughput and low-latency performance.

This manual explains the procedures required to install your XG2600 and should be read and understood before you start

using your XG2600.

First edition: Jun 2009

This manual contains the technology regulated by "Foreign Exchange and Foreign Trade Control Law."

Therefore when this manual is exported or provided to a nonresident, the appropriate permission based on this law is

required.

Screenshots are used according to the guideline provided by Microsoft Corporation.

Copyright FUJITSU LIMITED 2009

2

Page 3

XG2600 Hardware Guide Contents

Contents

Preface ................................................................................................................................................................2

Organization and Usage of This Manual ............................................................................................................5

About This Manual ....................................................................................................................................................5

Target Readers and Required Knowledge ................................................................................................................. 5

Areas Covered ............................................................................................................................................................5

Trademark Notification in This Manual .................................................................................................................... 6

How the Manuals for This Device Are Organized .................................................................................................... 7

Safety Precautions ...............................................................................................................................................8

About Warning Descriptions ..................................................................................................................................... 8

Notes on Maintenance .............................................................................................................................................. 11

Precautions for Use ..................................................................................................................................................11

Eliminating Static Electricity from Twisted Pair Cables (Grounding) .................................................................... 11

Ensuring Security ..................................................................................................................................................... 11

Cleaning ...................................................................................................................................................................12

Static electricity .......................................................................................................................................................12

Electromagnetic compatibility (CANADA) ............................................................................................................12

Electromagnetic compatibility (EU) ........................................................................................................................12

Safety .......................................................................................................................................................................12

High safety ............................................................................................................................................................... 12

Laser safety ..............................................................................................................................................................13

Notes on Rack Mounting and Connecting a Powerstrip ..........................................................................................13

About Our Green Products .......................................................................................................................................13

Notes on Use .....................................................................................................................................................14

Chapter 1 Getting Started ....................................................................................... 15

1.1 Items in the Package / Names and Functions ........................................................................................16

1.1.1 Parts List .................................................................................................................................................. 16

1.1.2 Installation of Switch: Front Access or Rear Access (User Configured Airflow) ................................... 17

1.1.3 Switch Fan Unit Side ............................................................................................................................... 18

1.1.4 Switch Interface Side ...............................................................................................................................20

1.1.5 Top Surface ..............................................................................................................................................23

1.2 How to attach Cable Holder (Cable Restraints with Tyraps) ................................................................24

1.3 Option ....................................................................................................................................................25

1.3.1 SFP+ Module ...........................................................................................................................................25

Chapter 2 Installation .............................................................................................. 26

2.1 Requirements for Installation Environment ...........................................................................................27

2.1.1 Installation Requirements ........................................................................................................................27

2.1.2 Space Requirements .................................................................................................................................28

2.2 Installation of the switch ........................................................................................................................29

2.2.1 Decide Switch Access Configuration ...................................................................................................... 29

2.2.2 Rear-Access Configuration (Factory Default) ......................................................................................... 33

2.2.3 Change Switch Access Configurations from Rear-Access (Factory Default) to Front-Access and Install .

36

2.3 Connecting the Equipment .....................................................................................................................42

2.3.1 Discharging Twisted Pair Cable .............................................................................................................. 42

2.3.2 Cleaning SFP+ Module / Optical Connector ...........................................................................................43

2.3.3 Connecting Twisted Pair Cable / SFP+ Module ...................................................................................... 45

2.3.4 Plugging in the USB Memory .................................................................................................................. 49

3

Page 4

XG2600 Hardware Guide Contents

2.4 Connecting a Setup PC ..........................................................................................................................50

2.5 Time Setting ...........................................................................................................................................54

2.6 Set up IP address ....................................................................................................................................55

Index............................................................................................................................. 56

4

Page 5

XG2600 Hardware Guide

Organization and Usage of This Manual

This manual explains what you need to know before using this device.

In addition, the README file on CD-ROM contains important information. You will also need to read the file.

About This Manual

This manual contains important information required to use this device safely.

Read this manual thoroughly before using this device. In particular, you must read and fully understand the "Safety

Precautions" described in this manual before using this device. Furthermore, this manual should be kept in an easy-to-

access location for quick reference while using this device.

We take the utmost care so that our products can be used safely without causing any damage to the customer or their

property. Please follow the instructions for using this device set forth in this manual.

Target Readers and Required Knowledge

This manual is intended for persons who perform network management.

To use this manual, basic knowledge of network and the Internet is required.

Areas Covered

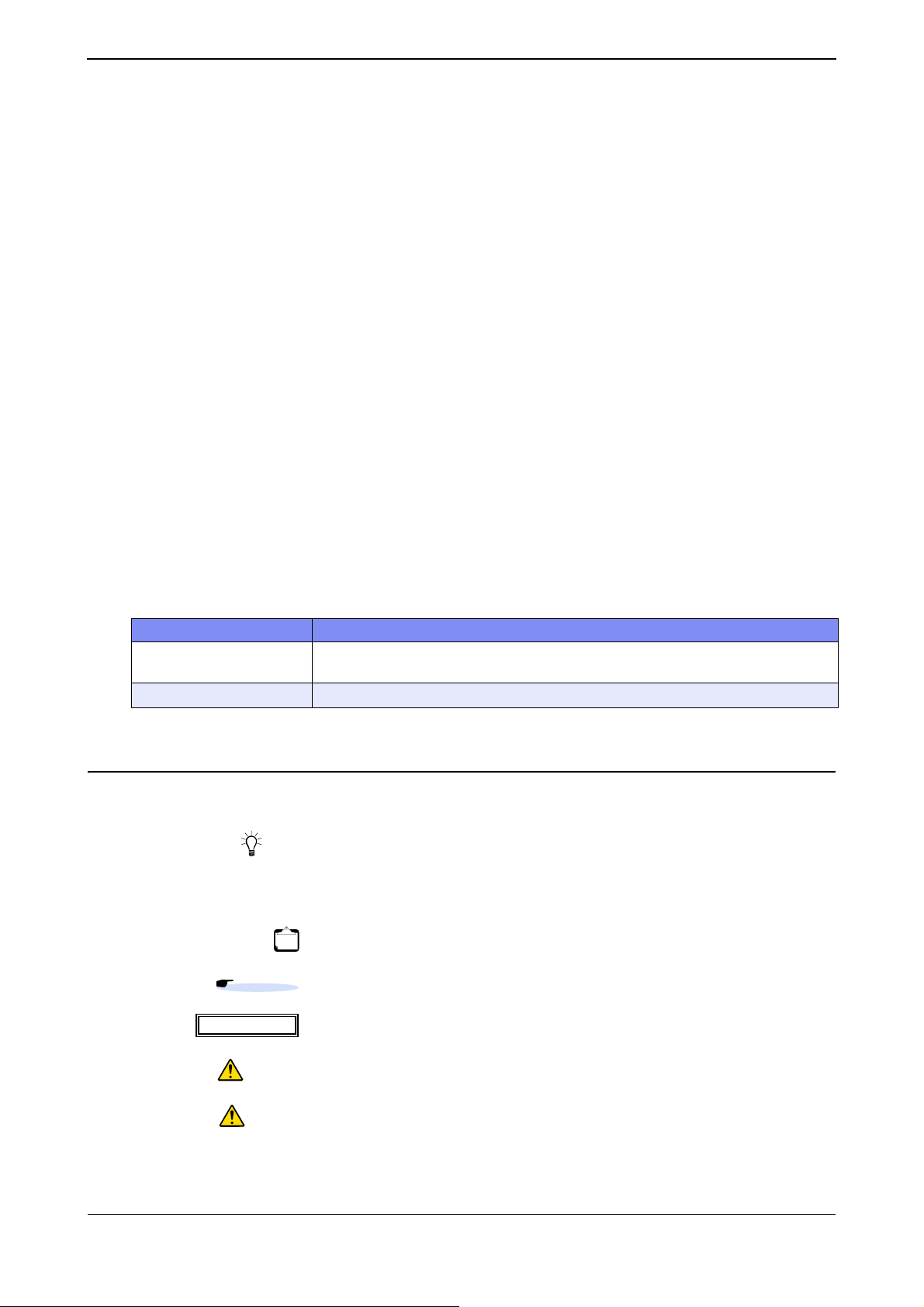

The organization of this manual and the contents of each chapter are shown as follows.

Chapter Titles Contents

Chapter 1

Chapter 2 Installation

Getting Started

About the Symbols

The symbols used in this manual have the following meanings.

Hint

Precautions

Reference

This chapter lists the items that should be in the product package, and describes the names

and functions of the various components.

This chapter describes how to install the switch and connect it to Console PC.

Indicates useful information for using this device.

Indicates precautions that must be taken when using this device.

Indicates additional information to complement operating instructions.

Note

Indicates related matters such as operation procedures, etc.

AvailableModel

Warning

Caution

Indicates the available model name when using functions of this device.

Indicates warning matters related to the Product Liability (P.L.) Law. Please follow them

when using this device.

Indicates cautionary notes related to the Product Liability (P.L.) Law. Please follow them

when using this device.

5

Page 6

XG2600 Hardware Guide

Trademark Notification in This Manual

Microsoft, MS-DOS, Windows, Windows NT, Windows Server and Windows Vista are registered trademarks of the

Microsoft Corporation in the USA and other countries.

Adobe and Reader are trademarks or registered trademarks of Adobe Systems Incorporated in the USA and other

countries.

Netscape is a trademark of Netscape Communications Corporation in the USA.

UNIX is a registered trademark of Open Group in the USA and other countries.

Other company names and product names in this manual are trademarks or registered trademarks of their respective

companies.

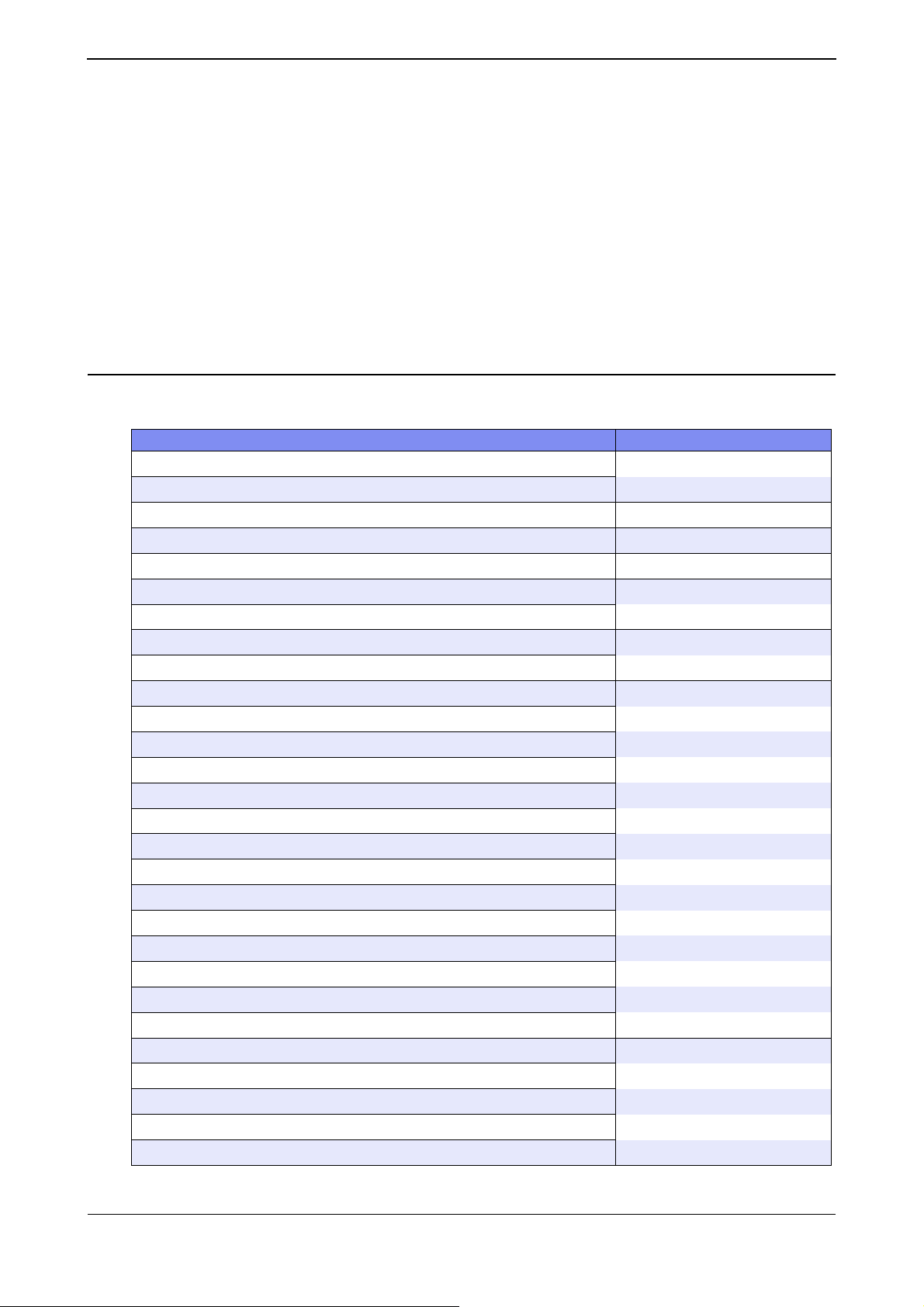

Abbreviated Product Names

The product names used in this manual are abbreviated as follows.

Product name Description in this manual

Microsoft® Windows® XP Professional operating system Windows® XP

Microsoft® Windows® XP Home Edition operating system

Microsoft® Windows® Millennium Edition operating system Windows® Me

Microsoft® Windows® 98 operating system Windows® 98

Microsoft® Windows® 95 operating system Windows® 95

Microsoft® Windows® 2000 Server Network operating system Windows® 2000

Microsoft

Microsoft® Windows NT® Server network operating system Version 4.0 Windows NT® 4.0

Microsoft® Windows NT® Workstation operating system Version 4.0

Microsoft® Windows Server® 2003, Standard Edition Windows Server® 2003

Microsoft® Windows Server® 2003 R2, Standard Edition

Microsoft® Windows Server® 2003, Enterprise Edition

Microsoft® Windows Server® 2003 R2, Enterprise Edition

Microsoft® Windows Server® 2003, Datacenter Edition

Microsoft® Windows Server® 2003 R2, Datacenter Edition

Microsoft® Windows Server® 2003, Web Edition

Microsoft® Windows Server® 2003, Standard x64 Edition

Microsoft® Windows Server® 2003 R2, Standard x64 Edition

Microsoft® Windows Server® 2003, Enterprise x64 Edition

Microsoft® Windows Server® 2003 R2, Enterprise x64 Edition

Microsoft® Windows Server® 2003, Enterprise Edition for Itanium-based systems

Microsoft® Windows Server® 2003, Datacenter x64 Edition

Microsoft® Windows Server® 2003 R2, Datacenter x64 Edition

Microsoft® Windows Vista® Ultimate operating system

Microsoft® Windows Vista® Business operating system

Microsoft® Windows Vista® Home Premium operating system

Microsoft® Windows Vista® Home Basic operating system

Microsoft® Windows Vista® Enterprise operating system

®

Windows® 2000 Professional operating system

Windows Vista

®

6

Page 7

XG2600 Hardware Guide

How the Manuals for This Device Are Organized

The manuals for this device are organized as follows. Use these manuals as necessary.

Manual Name Description

XG2600 Hardware Guide (This manual) This manual describes the hardware of the XG2600.

User’s Guide This manual describes a variety of operations and procedures, including the

installation and maintenance of the XG Series.

7

Page 8

XG2600 Hardware Guide

Safety Precautions

About Warning Descriptions

This manual contains precautions that must be taken in order to use this device safely and prevent personal injury or

property damage. Please fully understand the meanings and contents of the following descriptions and symbols when

reading this manual.

Warning

Caution

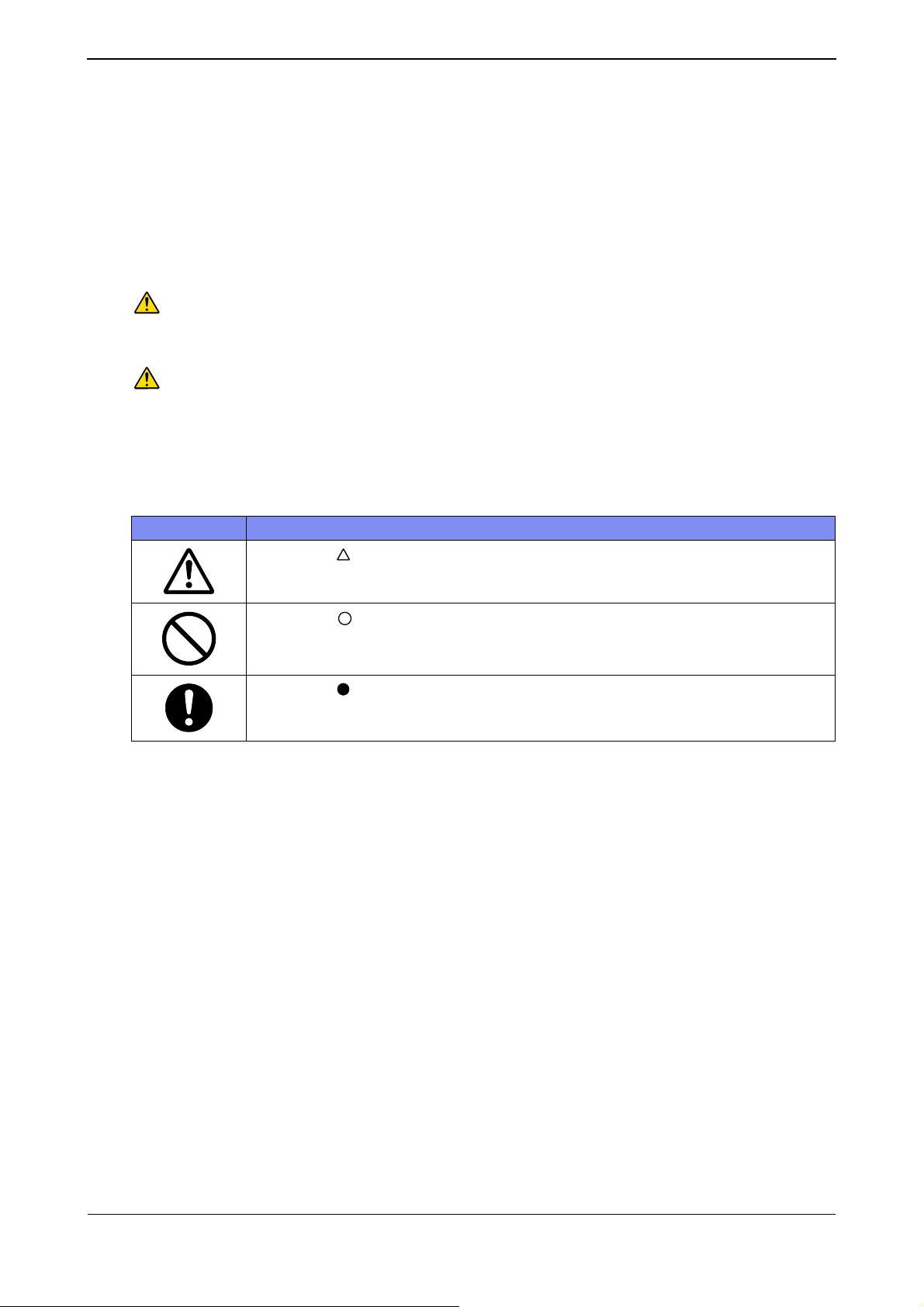

The following symbols are used to indicate the type of warning or caution.

Symbols Definitions

Indicates that improper use can cause severe damage to person, resulting in serious injury or

death.

Indicates that improper use can cause light or moderate injury.

In addition, this symbol indicates a chance of damage to this device and other connected

equipment.

The symbol in form indicates a warning or cautionary note. Specific information is shown inside or

next to the symbol.

The symbol in form indicates a prohibited (Do Not) action. Specific information is shown inside or

next to the symbol.

The symbol in form indicates actions or instructions that must be followed. Specific information is

shown inside or next to the symbol.

8

Page 9

XG2600 Hardware Guide

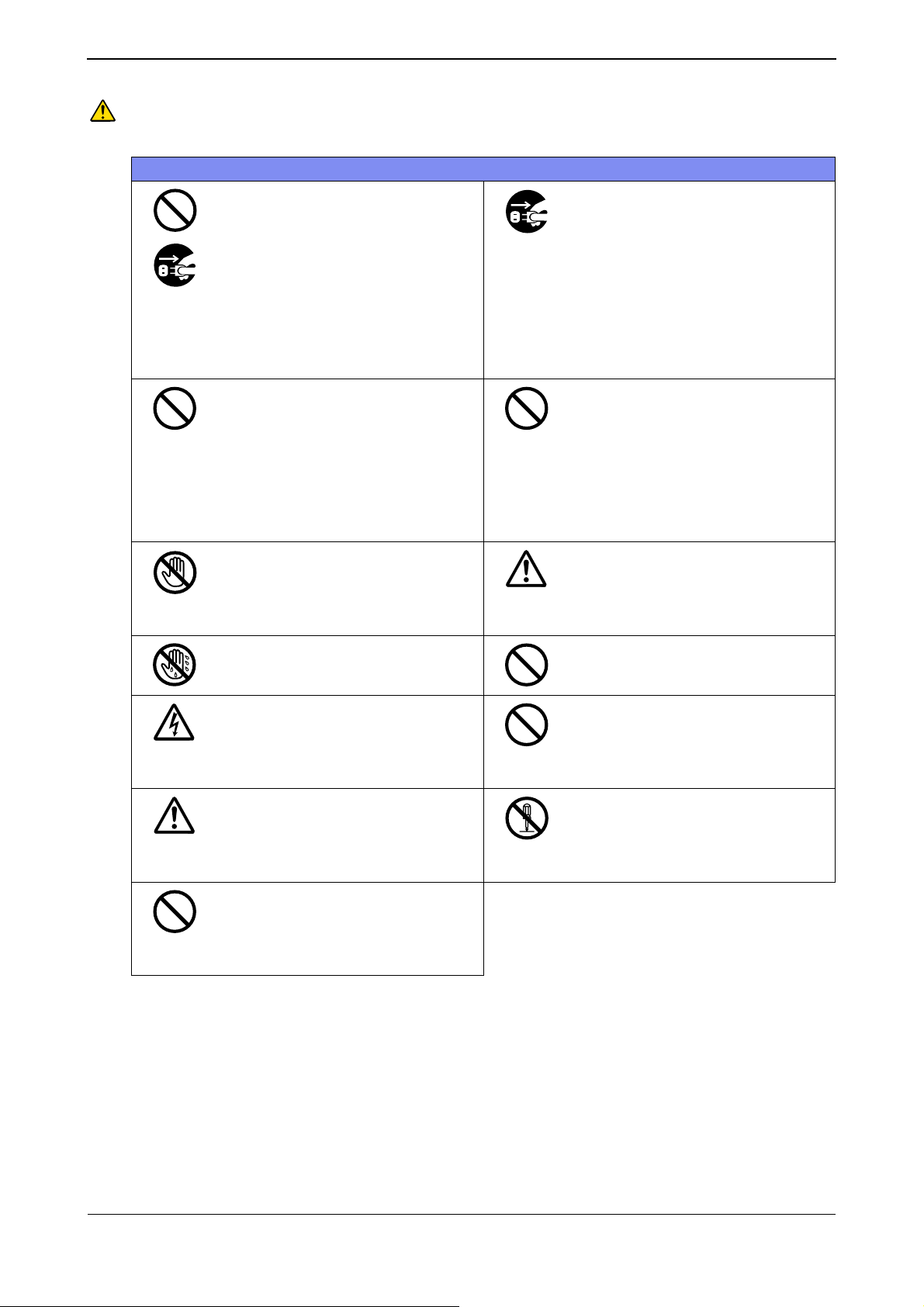

Warning

Always follow the instructions for safe use of this device. Indicates that improper use can cause

severe damage to person, resulting in serious injury or death.

Warnings

Do not insert or drop any foreign objects into the

device through the vent.

Also, prevent liquid such as water from entering

it.

In case a foreign object or liquid enters the

device, you must first unplug the power plug

from the socket and contact our engineer or an

engineer certified by Fujitsu.

Continuing to use the device in this condition

may result in electric shock, fire accident or

failure.

Do not score, cut, or rework the power cable.

Do not put any objects on the power cable. The

power cable should not be pulled, bent forcibly,

twisted or heated. These actions may damage the

cable.

Do not use the power cable while it is bundled

together. Otherwise electric shock or fire may

occur.

The same applies to other cables.

If there is lightning near the location, do not

touch this device, the power cable or other cables.

Failure to follow this may result in electric shock.

Do not connect or disconnect the power plug with

wet hands.

Failure to follow this may result in electric shock.

The cover must only be opened by qualified

service personnel.

Also, the power cable must be unplugged during

maintenance.

Failure to follow this may result in electric shock.

Also, keep removed screws out of reach of

children so that they cannot put the screws into

their mouths accidentally.

In the event they put the screws into their mouths,

consult a doctor immediately.

You cannot use this device at a voltage other than

the indicated supply voltage.

Do not overload the electric outlet.

Failure to follow these warnings may result in

electric shock or fire.

If you notice abnormal conditions such as

overheating, smoke emission, or odor, stop using

this device immediately, and pull unplug the

power cable from the socket. Make sure that

abnormal conditions such as smoke no longer

exist and contact our engineer or an engineer

certified by Fujitsu.

Continuing to use the device in this condition

may result in electric shock or fire.

For the interface connector, do not insert a

connector other than the appropriate connector

for a specific line.

Failure to follow this may result in electric shock

or failure.

The plastic sheets used for packaging must be

kept out of reach of children so that they cannot

put the sheets in their mouths or put their heads

into them.

Failure to follow this may result in suffocation.

When cleaning, do not use cleaning sprays (that

includes inflammable material) because it will

cause the device breakdown or fire.

Do not use this device when the power cable or

plug is damaged or the socket is loose.

Continuing to use the device in this condition

may result electric shock or fire.

Do not disassemble, dismantle, modify or

reproduce this device.

Failure to follow this may result in electric shock,

fire or failure.

9

Page 10

XG2600 Hardware Guide

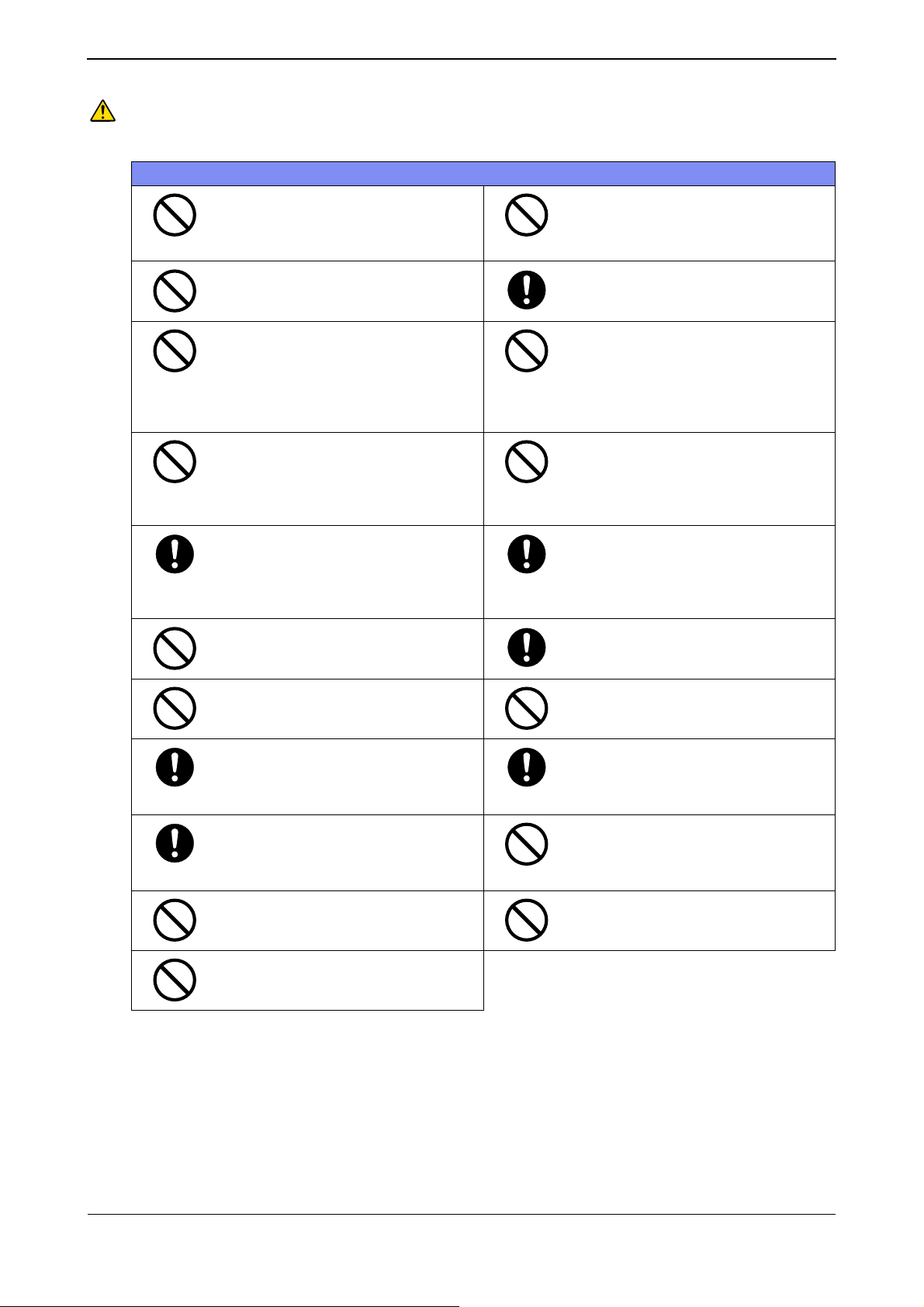

Caution

Indicates that improper use can cause light or moderate injury.

In addition, this symbol indicates a chance of damage to this device and other connected equipment.

Cautions

Do not touch this device for more than one

minute while it is turned on.

Failure to follow this may cause low-temperature

burns.

Do not stand this device vertically or stack it.

Failure to follow this may cause the device to fall

over causing injury, damage, or failure.

Do not install this device on shaky stands, unlvel

surfaces, or other unstable places.

In addition, do not use this device in a location where

impact or vibration occurs.

Failure to follow this may result in the device falling

over, causing injury, damage, or failure.

You must not use this device in corrosive gas

environment and other places where it is exposed

to spray of chemicals or chemical substance.

Failure to follow this may cause damage or

failure.

Ensure enough space for the vent of this device

and cables.

If you use two of the same type of device in

parallel, you need to have service areas for each.

Failure to follow this may cause cable failures.

Do not use any extension module other than the

ones supported by this device.

Failure to follow this may cause system failure.

Do not install this device near heaters or at places

subject to direct sunlight, humidity, and dust.

Electric shock or fire may occur.

Unplug the power cable by pulling the plug with

your hand.

Electric shock or fire may occur due to a damaged

plug.

If dust is accumulates on the metal part of the

plug and its peripheral, wipe it out with dry cloth.

Continuing to use the device in this condition

may result in fire.

Do not use this device near a radio or a TV set.

The device can generate noise that is picked up

on the radio or the TV set.

Avoid looking at the light source (e.g. laser light)

directly.

Failure to follow this may injure your eyes.

Do not put objects on this device or use it as a

work area.

Failure to follow this may cause damage to the

device , or result in injury to person or failure.

Install this device indoors.

Installing outdoors may result in failure.

Do not use this device in places where the

temperature is extremely high/low or fluctuates

greatly.

Failure to follow this may cause system failure.

Follow the operating temperature limit for this

device.

Do not use this device near a microwave oven

and other equipments that emit strong magnetic

field.

Failure to follow this may cause system failure.

Make sure to unplug the power cable when

transporting this device.

Failure to follow this may cause system fault.

Make sure to connect cables correctly.

Improper cable connections hinder normal

communication and causes failure of this device.

Do not obstruct the vent since the internal

temperature can become very high.

Failure to follow this may result in fire.

Insert the plug into the socket completely.

Not completely inserting the plug may result in

electric shock, smoke emitting or fire.

When using this device, do not cover it, or wrap it

with anything.

Otherwise overheating may result in fire .

When lifting the device up, do not hold handles of

power supply units or fan units in order to avoid

the handles taken off.

10

Page 11

XG2600 Hardware Guide

Notes on Maintenance

• Customers should not repair this device. In the event of failure, consult our engineer or an engineer certified by Fujitsu

for maintenance.

• Do not dismantle or modify this device for any reason. This device contains high voltage and high temperature parts

that can be dagerous.

Precautions for Use

• As a guideline, you can use this device in stable state for five years, if it is operated within the guaranteed operation

temperature range.

• Please use the main component, the manual, and the firmware provided as a part of this product at your own risk.

• Fujitsu assumes no liability for damages or data loss that may occur as a result of using this device for any reason.

Warranty for this device only covers failures within the range of purchased price. Please be forewarned.

• You are prohibited from using the firmware provided with this product and the Fujitsu-provided update firmware as

non-integrated part of this product and from modifying or dismantling them.

•

★同梱が決定したら翻訳お願いします★

コンソールポートには、同梱のコンソールケーブル以外は接続しないでください。コネクタ形状(

ピンモジュラーコネクタ)が同じ ISDN や LAN などの異なったインタフェースケーブルを誤接続すると故障

の原因となります。

RJ-45、8

Eliminating Static Electricity from Twisted Pair Cables (Grounding)

A twisted pair cable can build up static electricity depending on the environment. If you connect the twisted pair cable with

a built up static electricity to any equipment, a malfunction or damage may occur in the equipment or its connection port.

You must use a static electricity elimination tool (See Note below) to discharge static electricity built up on the twisted pair

cable by grounding immediately before connecting to any equipment.

Also note that the discharge effect is lost if you leave it unconnected for a long period after discharging static electricity.

Note: About the Static Electricity Elimination Tool

For the following static electricity elimination tool, contact our engineer or an engineer certified by Fujitsu.

Maker : トシシステム株式会社 ★確認のうえ教えてください★

Product Name : LAN Cable ESD Removal Tool

Part Number : TS2002-001

Reference

"2.3.1 Discharging Twisted Pair Cable" (pg.42)

Ensuring Security

If no password is set, any users on the network can configure this device. In that situation, you cannot ensure security

against unauthorized use. Therefore we strongly recommend that you set a password.

Reference

User’s Guide "5.15 Password Information" (pg.251)

11

Page 12

XG2600 Hardware Guide

Cleaning

When cleaning the device, please wipe with a cloth firmly wrung out of water (or watered-down neutral detergent). Please

be careful so that water does not get into the device or gap when wiping.

Static electricity

Under certain conditions, twisted pair cables can become charged with static electricity. Connecting a statically charged

twisted pair cable to the XG2600 can cause the device or its LAN port to operate falsely or to become damaged.

Use a static removal tool to discharge twisted pair cables to ground prior to connecting them to the XG2600.

Note that a discharged twisted pair cable that has been left unconnected for a long time may become statically charged

again.

Electromagnetic compatibility (CANADA)

Industry Canada Interference-Causing Equipment Standard ICES-003 Class A.

This Class A digital appartatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

Electromagnetic compatibility (EU)

EN55022(2006) Class A

EN61000-3-2(2000)

EN61000-3-3(1995)+A1(2001)

EN55024(1998) + A1(2001) + A2(2003)

Warning

This is a product which meets Class A of EN55022. In a domestic environment this product

may cause raido interference in which case the user may be required to take adequate

measures.

Safety

CAN/CSA C22.2 No. 60950-1, UL60950-1 and EN60950-1

High safety

High Safety Required Applications

The XG2600 is designed, developed and manufactured for general use, including, without limitation, general office use,

personal use, household use, and ordinary industrial use, but is not designed, developed and manufactured for use in

situations wherein failure of the XG2600 may result in death, personal injury, severe physical damage or other loss (herein

after referred to as "High Safety Required"), including, without limitation, nuclear reaction control systems in a nuclear

facility, aircraft flight control systems, air traffic control systems, mass transport control systems, medical life support

systems, and missile launch control weapons systems.

Do not use the XG2600 for High Safety Required applications without otherwise ensuring the safety level required. Fujitsu

and its related companies assume no liability whatsoever for damages arising from use of the XG2600 by the user in High

Safety Required applications, and for any claims or compensation for damages by the user or a third party.

12

Page 13

XG2600 Hardware Guide

Laser safety

The XG2600 may be installed with optical transceiver modules (SFP+ modules), which emit invisible laser light.

In the USA, these optical modules are certified as Class 1 laser products that conform to the requirements of the

Department of Health and Human Services (DHHS) regulation 21 CFR, Subchapter J. This certification is indicated by a

label attached to each optical module.

Outside the USA, these SFP+ modules are certified as Class 1 laser products that conform to the requirements of IEC825-

1 (1993) and Amendment11 (1996) of EN60825-1 (1994).

Even when cables are not connected, invisible laser light may still be emitted from the optical module’s port openings. To

avoid possible injury, do not look directly into the optical module’s port openings.

Optical transceiver modules intended for use in the XG2600 must be selected from the Optical Transceiver Approved

Vendor List (obtainable from the vendor’s service department).

Notes on Rack Mounting and Connecting a Powerstrip

Warning

• Monitor and control the internal and external temperature and humidity of your rack, so that it does not exceed the

• The air intake and exhaust of the device is conducted at the interface side and FAN unit side. Do not block the intake

• Make sure to check the maximum loading capacity of the rack to be used for mounting.

• Check the power supply capability of the installation location.

• If you connect the power cable of this device to a powerstrip, a large amount of current leakage can occur through the

If you mount this device on a rack, pay close attention to operation temperature management,

physical stability establishment and current leakage. This device must only be mounted on the rack

by a qualified engineer with the required knowledge. Failure to follow this may result in electric shock

or fire.

range of guaranteed operation temperature and humidity.

side or exhaust side in order not to prevent airflow when installing.

ground line of the strip. Make sure to establish a ground connection before connecting to the power. If the power cable

is not directly connected to the distribution board, you must use a powerstip with industrial use plugs (The maximum

current leakage for this device is 3.5mA).

About Our Green Products

"Green Products" that have passed our strict environment assessment standard are earth-friendly and

environmentconscious products.

• Main Features

- Small size/resource saving

- Power saving function

- High rate of recycling

This symbol is attached to the Green Products that passed the Green Product Assessment Standard of Fujitsu.

For Fujitsu's environment protection efforts, refer to the following Fujitsu Web site.

URL : http://www.fujitsu.com/global/about/environment/ "Environment Protection Efforts"

13

Page 14

XG2600 Hardware Guide

Notes on Use

Note the following points when using this device.

• Manage and store the configuration for this device yourself after configuration is completed.

If you ask Fujitsu to perform restore works in case of failure, our engineer needs to use the configuration managed and

stored by you.

If you do not provide the configuration for us, it can take time to restore the device.

Please make a backup for the configuration as required to manage and keep the latest information.

• This device contains a protection circuit against lightning and static electricity. Therefore some of the functions cannot

work when lightning power or static electricity enters the device.

In this case, you can restore the device to its normal state by turning on the power again. If the functions are still not

enabled after turning the power again, or if the power cannot be turned on, the device may have been destroyed due to

factors where the protection circuit cannot provide full protection. In this case, contact our engineer or an engineer

certified by Fujitsu.

• Do not turn off or reset the power during firmware update. If power is turned off or reset during an update, you will not

be able to start the device.

• The manual for this product is provided on the accompanied CD-ROM in PDF format. You will need Adobe Reader, a

PDF reading software, to refer to the manual.

14

Page 15

Chapter 1

Getting Started

This chapter lists the items that should be in the product package, and describes the names and functions of the various

components.

1.1 Items in the Package / Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.1 Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.2 Installation of Switch: Front Access or Rear Access (User Configured Airflow) . . . . . . . . 17

1.1.3 Switch Fan Unit Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1.4 Switch Interface Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.1.5 Top Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.2 How to attach Cable Holder (Cable Restraints with Tyraps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3 Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.3.1 SFP+ Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page 16

XG2600 Hardware Guide Chapter 1 Getting Started

1.1 Items in the Package / Names and Functions

Before proceeding, check all the items described below.

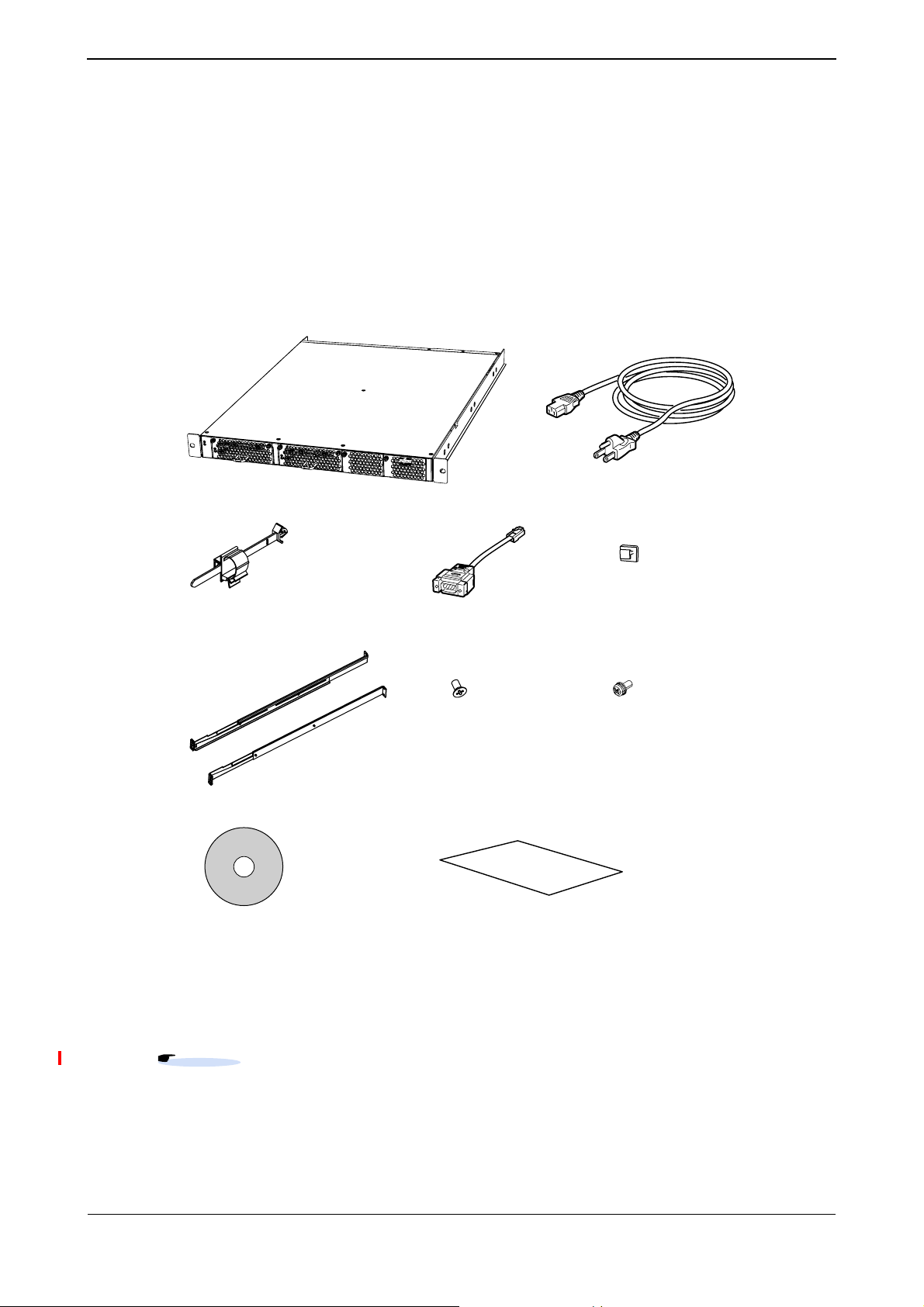

1.1.1 Parts List

Please check all of the following parts are included in the package.

XG2600

CableHolder(Qty1)

RackMountingRails(1set)

XG2600

ConsoleCable

M6CountersunkScrews

(Qty4)

PowerCables(Qty2)

SFP+DummyCaps

(Qty26)

M6MachineScrews

(Qty6)

CD-ROM EULA

• XG2600 The XG2600 switch.

• Power Cables (Qty 2) Cables to connect the XG2600 to an AC power source.

• Cable Holder (Cable Restraints with Tyraps)

Holder to fix the power cable to the switch.

Reference

"1.2 How to attach Cable Holder (Cable Restraints with Tyraps)" (pg.24)

• Console Cable (RJ45 to Serial Adapter)

Straight cable with RJ-45 to D-SUB9 Converter Adapter.

16

Items in the Package / Names and Functions

Page 17

XG2600 Hardware Guide Chapter 1 Getting Started

• SFP+ Dummy Caps (Qty 26)

Dummy caps to prevent dust when the SFP+ slots are open and unplugged.

The dummy caps come with the switch, installed on the slots at the time of purchase.

• Rack Mounting Rails (1 set)

Rails for mounting the switch in a rack.

• M6 Countersunk Screws (Qty 4)

Screws for fastening the rack rails to the front side of the rack.

• M6 Machine Screws (Qty 6) 4 screws for fastening the rack rails to the rear side of the rack, and 2 screws for

fastening the switch (rack mounting brackets attached to the side of the switch) to the

front side of the rack).

• CD-ROM It contains the Firmware and User Guid e (in a PDF format) necessary for operating and

conguring the switch. Adobe Reader is required for viewing.

• EULA End User License Agreement for the Product

Note

• USB memory is not included in the product package

1.1.2 Installation of Switch: Front Access or Rear Access (User

Congured Airow)

There are two options available to install the switch in a dierent direction in a rack that helps suppress heat interference,

depending on user’s requirements

Reference

• Rear-Access Conguration (Factory Default)

The interface side (SFP+ slots) is fa cing backward in a rack, which serves better for connecting the switch to

equipment whose interface side is also located in the backside of the rack such as servers.

• Front-Access Conguration (User Congured)

The interface side (SFP+ slots) is facing forward in a rack, which serves better for connecting the switch to equipment

whose interface side is facing forward such as other switches, routers, etc.

Choose either of the above to install the switch in the rack, depending on user’s requirements.

See "2.2.1 Decide Switch Access Conguration" (pg.29) for the detailed instructions for installation.

17

Items in the Package / Names and Functions

Page 18

XG2600 Hardware Guide Chapter 1 Getting Started

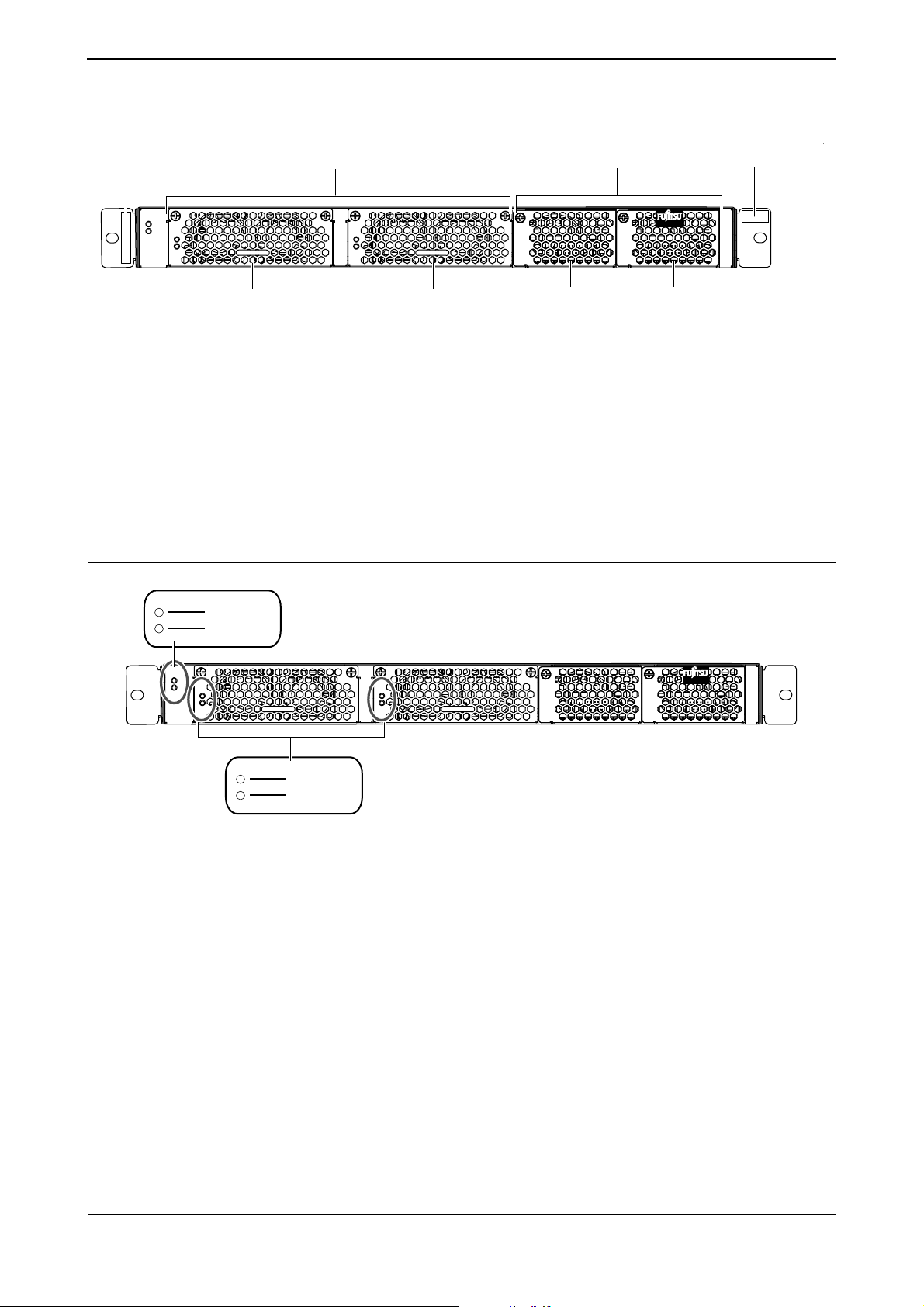

1.1.3 Switch Fan Unit Side

MACFirmwareLabel

FanUnit

FAN2 FAN1

PSUSlotsfor

Front‑AccessConfiguration

PSU2 PSU1

ProductManufacturing

XG2600

• MAC Firmware Label This indicates the MAC addresses and firmware revision assigned to the switch.

• Fan Unit This switch is installed with two Fan Units.

• PSU Slots for Front-Access Configuration

Power Supply Units are plugged in the slots when the switch is used in a Front-Access

configuration.

• Product Manufacturing Label This indicates the model name, serial number, manufacturing date, and Class 1 Laser

Product, etc.

LED Details

Label

READY

CHECK

XG2600

STATUS

OUTFLOW

• READY LED Lights when the XG2600 is in an operable state.

• CHECK LED Lights in orange when there is a problem. In that case, consult with responsible

engineers immediately.

• STATUS LED Lights to show the status of the Fan Unit.

• OUTFLOW LED Lights to show the direction of fan (airflow).

18

Items in the Package / Names and Functions

Page 19

XG2600 Hardware Guide Chapter 1 Getting Started

LED Functions/Behaviors

LED Name Light Status

READY Green Switch has started up correctly.

Green Blinking Switch is being diagnosed or operating under backup firmware. (*)

Off A problem has occurred.

CHECK Orange A problem has occurred which requires replacement.

Orange Blinking Firmware in the internal flash memory of the switch is destroyed.

Off Switch is in normal operation.

STATUS Green Fan Unit is in normal operation.

Green Blinking A problem has occurred with the Fan Unit.

Off Fan Units are configured incorrectly or the power is not on.

OUTFLOW Green This indicates the FAN unit side is the exhaust side.

Off This indicates the FAN unit side is the intake side.

*) During the system diagnosis, READY LED is blinking in Green in every 0.5 second.

When the switch is operating under backup firmware, READY LED is blinking in Green in every 1 second.

Reference

See "2.2.1 Decide Switch Access Configuration" (pg.29) for detailed LED functions/behaviors under normal

operation.

19

Items in the Package / Names and Functions

Page 20

XG2600 Hardware Guide Chapter 1 Getting Started

1.1.4 Switch Interface Side

SerialPort

ResetSwitch

Port25

USBPort

ManagementPort

PSU1

PowerSupplyUnit

PowerInlet

PSUSlotsfor

Rear-AccessInstallation

PSU2

PowerSupplyUnit

SFP+Slots

Port1

Port2 Port26

• PSU Slots for Rear-Access Installation

PSUs are plugged in the slots when the switch is used in Rear-Access configuration.

• Power Inlet Plug the attached Power Cable in the package.

• Power Supply Unit This switch is installed with two PSUs.

• SFP+ Slots Plug SFP+ modules for connecting Ethernet based networking equipment (10GBASE-

SR/10GBASE-LR).

Port number is assigned from the upper side of the leftmost port to the right. For

example, Port 1 is the upper side of the leftmost port, and Port 26 is the lower side of the

right most port.

• Reset Switch Push to reboot.

• USB Port Connect USB memory for backup-copying and restoring configuration files and

firmware.

• Serial Port (Console Connection)

The Serial Port is used to connect the switch with the console (PC) for setting and

command line interface via the attached Console Cable (RJ45 to Serial Adapter) and

RS232C crossover cable (D-SUB9) .

Caution

Serial Port is only used for connecting the switch with RS-232C interface of the console. Do not

connect other interfaces such as LAN/ISDN which cause an error.

Reference

User’s Guide "1.1.5 Console Port Specifications" (pg.28)

• Management Port This is used to connect Ethernet based (10/100BASE-TX) networking equipment. Use

Category-5 LAN cables.

20

Items in the Package / Names and Functions

Page 21

XG2600 Hardware Guide Chapter 1 Getting Started

LED Details

FLASH

ERROR

FDX

POWER

Port2SFP+

LINK/ACT

Port1SFP+

LINK/ACT

Port1

Port2

Port1SFP+

Port2SFP+

READY

CHECK

PSU1

PSU2

FAN

LINK/

ACT

• POWER LED Lights to indicate the status of PSU.

• SFP+ LINK/ACT LED Lights to indicate the establishment of the link and status of the signal transmission.

• SFP+ LED Lights to indicate the status of optical detection of the SFP+ slot.

• READY LED Lights when the XG2600 is in an operable state.

• CHECK LED Lights in orange when there is a problem. In this case, consult with responsible

engineers.

• PSU1 LED Lights to indicate the status of the PSU1.

• PSU2 LED Lights to indicate the status of the PSU2.

• FAN LED Lights to indicate the status of the Fan.

• FLASH LED Lights to indicate the status of read/write of the external USB memory or internal.

Precautions

Do not shut down or reboot when FLASH LED is blinking in green. That may cause to destroy configuration files.

• ERROR LED There’s a problem with USB memory or SFP+ modules, or mount/access error.

• LINK/ACT LED Lights to indicate the status of the link, signal transmission, transmission speed.

• FDX LED Lights to indicate the status of transmission mode for the management port.

21

Items in the Package / Names and Functions

Page 22

XG2600 Hardware Guide Chapter 1 Getting Started

LED Functions/Behaviors

LED Name Light Status

POWER Green PSU is in normal operation.

Orange A problem has occurred with the PSU.

SFP+ LINK/ACT Green SFP+ link is established.

Green Blinking SFP+ is in communication.

Off SFP+ link is not established.

SFP+ Green This indicates light detection of the SFP+ slot.

Off This indicates light undetected of the SFP+ slot.

READY Green Switch has started up correctly.

Green Blinking Switch is being diagnosed or operating under backup firmware. (*)

Off A problem occurs.

CHECK Orange A problem occurs which requires switch replacement.

Orange Blinking Firmware in the Flash memory of the switch is out of order.

Off Switch is operating normally.

PSU1 Green PSU1 is in normal operation.

Green Blinking PSU1 is not installed or PSU1 is installed incorrectly, causing configuration error.

Off A problem has occurred with PSU1, or the power is not on.

PSU2 Green PSU2 is in normal operation.

Green Blinking PSU2 is not installed or PSU2 is installed incorrectly, causing configuration error.

Off A problem has occurred with PSU2, or the power is not on.

FAN Green 2 Fan Units are in normal operation.

Green Blinking Fan is not installed or Fan is installed incorrectly, causing configuration error.

Off 2 Fan Units are in normal operation.

FLASH Green USB memory is installed.

Green Blinking External USB memory or internal flash memory are under read/write.

Off USB memory is not installed, or internal flash memory are not under read/write

status.

ERROR Orange There’s a problem with USB memory or SFP+ modules, or mount/access error.

Off USB memory and SFP+ modules are in normal operation.

LINK/ACT Green A link is established for the management port.

Green Blinking Management port is in communication.

Off A link is not established for the management port.

FDX Green Transmission mode for the management port is duplex.

Off Transmission mode for the management port is half-duplex.

*) During the system diagnosis, READY LED is blinking in Green in every 0.5 second.

When the switch is operating under backup firmware, READY LED is blinking in Green in every 1 second.

Reference

See "2.2.1 Decide Switch Access Configuration" (pg.29) for detailed LED functions/behaviors under normal operation.

22

Items in the Package / Names and Functions

Page 23

XG2600 Hardware Guide Chapter 1 Getting Started

1.1.5 Top Surface

RatingLabel

• Warning Sticker This indicates the warning for safety use.

• Rating Label This indicates the rated voltage of the switch.

23

WarningSticker

Items in the Package / Names and Functions

Page 24

XG2600 Hardware Guide Chapter 1 Getting Started

1.2 How to attach Cable Holder (Cable Restraints with Tyraps)

The Cable Holder prevents the power cable from being accidently pulled out of the switch.

Below describes how to attach Cable Holder to the power code.

Warning

In case of installing the switch in a lockable rack and fixing the power cable with the attached

Cable Holder, use service outlet in the rack.

In case of using outlet outside of the rack, be sure to fix the power cable separately inside the

rack.

If the power cable is tensioned from outside, unexpected pressure is given to Cable Holder,

causing disconnected cable and loose connection, which then cause electric shock and fire.

1. Attach Cable Holder to the switch first.

Movingpart

CableHolder

2. Fasten the moving part of Cable Holder to the joint of the power cable.

24

How to attach Cable Holder (Cable Restraints with Tyraps)

Page 25

XG2600 Hardware Guide Chapter 1 Getting Started

1.3 Option

1.3.1 SFP+ Module

SFP+ modules (10GBASE-SR/10GBASE-LR) are available for use.

Reference

"2.3.3 Connecting Twisted Pair Cable / SFP+ Module" (pg.45)

User’s Guide " SFP+ Module" (pg.23)

25

Option

Page 26

Chapter 2 Install

ation

This chapter describes how to install the switch and connect it to Console PC.

2.1 Requirements for Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1.1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1.2 Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.2 Installation of the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.1 Decide Switch Access Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2.2 Rear-Access Configuration (Factory Default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2.3 Change Switch Access Configurations from Rear-Access (Factory Default) to Front-

Access and Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 Connecting the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.3.1 Discharging Twisted Pair Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.3.2 Cleaning SFP+ Module / Optical Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.3.3 Connecting Twisted Pair Cable / SFP+ Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.3.4 Plugging in the USB Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.4 Connecting a Setup PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.5 Time Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.6 Set up IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Page 27

XG2600 Hardware Guide Chapter 2 Installation

2.1 Requirements for Installation Environment

Before installing the switch, please check the following:

• Make sure that the switch and all the other options shown in this document are available for installation.

• All the cables comply with the specifications of the interface connectors.

Warning

Do not connect cables to interface connectors other than those adaptable to the connector’s

specifications.

Reference

Install the product under the following environmental conditions.

"1.1.1 Parts List" (pg.16)

2.1.1 Installation Requirements

Caution

Install the product under the following conditions. Using the product outside the required

environment may cause failure of the product.

Temperature and Humidity Requirements

Temperature (degrees C) Humidity (%RH)

Operation 0 to 50 15 to 85

Non-operation 0 to 50 8 to 90

Power Requirements

Item Requirements

Vol tage AC90V-264V

Frequency

Ground

Electricity AC input more than 111VA

Inrush Current

50Hz / 60Hz +2%, -4%

Separate ground wire from air conditioners and building, and D-class grounding

with ground resistance of 100

Maximum 30A

Ensure installation environment that avoids lowering voltage to power supply

equipment at the time of power-on due to the inrush current, although there’s no

impact from the inrush current in normal use.

Ω or less.

27

Requirements for Installation Environment

Page 28

XG2600 Hardware Guide Chapter 2 Installation

Installation Requirements

The product is specifically designed for rack-mounting.

Check-list

Check the following items.

Check Item Check Result

Nothing is put on the switch.

Vents are not obstructed.

The switch is not located on the table or not stuck on another switch.

The switch is not located under direct sunshine, near heating appliance, under high humidity

or in a dusty area..

The switch is not located on unstable places where vibrating, or tilting.

"For Safe Use of the Product" has been thoroughly read (pg.8)

Reference

Reference

2.1.2 Space Requirements

When installing the switch and providing maintenance, ensure the space below is maintained.

Ensuring the Space for Installation (Maintenance) of the Switch

Internal cooling fans of the switch allow the air intake and exhaust performed at both at the Interface Side and Fan Unit Side.

Ensure the indicated space below and do not put anything which avoids airflow.

800mm

Backspacefor

themaintenance

rack

150mm

ormore

300mmormore

Spaceforthe

maintenance/

installation

XG2600

300mmormore

Spaceforthe

maintenance/

installation

19"rack

Depth

90mm

ormore

800mm

Frontspacefor

themaintenance

19"rackWidth

28

Requirements for Installation Environment

Page 29

XG2600 Hardware Guide Chapter 2 Installation

2.2 Installation of the switch

This section describes how to install the switch.

2.2.1 Decide Switch Access Configuration

The switch is specifically designed for rack-mounting.

The switch can be installed in two different switch access configurations (airflow directions) in a rack.

• Rear-Access Configuration (Factory Default)

• Front-Access Configuration (User Configured)

The following describes how to install each airflow configuration.

Caution

Do not hold the handle of PSU and Fan Unit when picking up the switch. The handle may come

off and cause injury.

Rear-Access Configuration (Factory Default)

The interface side (SFP+ slots) is facing backward in the rack.

Exhaust

RackRear

PSU1PSU2

Intake

(Caution) (Caution)

FAN1FAN2

RackFront

XG2600

29

Installation of the switch

Page 30

XG2600 Hardware Guide Chapter 2 Installation

Caution

• Do not install PSUs to face the front side of the rack. They do not work properly.

• Before installing the switch in the rack, check if the airflow direction of the fans is correct. If the

air flows incorrectly, it may cause failure to the switch

The diagram below shows in which slots PSUs need to be installed and airflow direction of the fans.

: Installing – : not installing

Power Supply Unit Fan Unit

Switch Interface Side Switch Fan Unit Side FAN1 Slot FAN2 Slot

PSU1 Slot PSU2 Slot PSU1 Slot PSU2 Slot Installation Airflow Installation Airflow

––

Intake

Intake

The LED lights in a correct configuration as follows:

– : Unsupported because the unit is not installed

Power Supply Unit Switch Fan Unit Side

Switch Interface Side

READY CHECK PSU1 PSU2 FAN

Green Off Green Green Green Green Green – – Green Off

Switch Interface

Side

PSU1 PSU2 PSU1 PSU2

POWER

Switch

Fan Unit Side

Slot 1/Slot 2

STATUS OUTFLOW

If the LED indicators are different from the above, it may be due to the incorrect configuration of PSUs and/or Fans, or

there may be failures with PSUs and/or Fans.

30

Installation of the switch

Page 31

XG2600 Hardware Guide Chapter 2 Installation

Front-Access Configuration (User Configured)

The interface side (SFP+ slots) is facing forward in a rack.

PSU1 PSU2

(Caution)

(Caution)

Exhaust

FAN1 FAN2

RackRear

Intake

XG2600

Caution

RackFront

• Do not install PSUs facing the front side of the rack. They do not work properly

• Before installing the switch in the rack, check if the airflow direction of the fans is correct. If the

air flows incorrectly, it may cause failure to the switch.

31

Installation of the switch

Page 32

XG2600 Hardware Guide Chapter 2 Installation

The diagram below shows in which slots PSUs need to be installed and airflow direction of the fans.

: Installing – : not installing

Power Supply Unit Fan Unit

Switch Interface Side Switch Fan Unit Side FAN1 Slot FAN2 Slot

PSU1 Slot PSU2 Slot PSU1 Slot PSU2 Slot Installation Airflow Installation Airflow

––

Exhaust

Exhaust

The LED lights in a correct configuration as follows:

– : Unsupported because the unit is not installed

Power Supply Unit Switch Fan Unit Side

Switch Interface Side

READY CHECK PSU1 PSU2 FAN

Green Off Green Green Green – – Green Green Green Green

Switch Interface

Side

PSU1 PSU2 PSU1 PSU2

POWER

Switch

Fan Unit Side

Slot 1/Slot 2

STATUS OUTFLOW

If the LED indicators are different from the above, it may be due to the incorrect configuration of PSUs and/or Fans, or

there may be failures with PSUs and/or Fans.

If the switch is installed in Front-Access configuration, it is necessary to remove PSUs and install them in different slots

than factory default ones, and change direction of fans.

32

Installation of the switch

Page 33

XG2600 Hardware Guide Chapter 2 Installation

2.2.2 Rear-Access Configuration (Factory Default)

This section describes how to install switch in Rear-Access configuration (Factory Default).

Decide positions for rack mounting brackets

1. Decide positions of rack mounting brackets.

It is possible to install the switch either in a standard front position of the rack or in an offset position of the rack.

In case to locate the switch offset from the front side, change the positions of rack mounting brackets.

[STANDARD]

XG2600

[OFFSET]

Plugintothe

holeofthedevice.

XG2600

RackMountingClamps

33

Installation of the switch

Page 34

XG2600 Hardware Guide Chapter 2 Installation

Install the switch in a 19” rack

The switch can be installed and operated in the EIA standard 19" rack.

Prepare the following rack mounting components attached.

• Rack Mounting Rails (1 set): Rails for mounting the switch in a rack.

• M6 Countersunk Screws (Qty 4)

• M6 Machine Screws (Qty 6)

Reference

"1.1.1 Parts List" (pg.16)

Precautions

• When installing the switch in the rack, separately procure screws according to the specifications of the rack.

• Pay attention to control temperature inside and outside of the rack so that guaranteed operating temperature can be

maintained properly for the switch.

• Reserve certain space for air cooling in accordance with the cooling structure of the switch.

• Ensure physical stability of the whole rack when the switch is installed.

• Check if power supply capacity (Rated Current) is sufficient from the power supply equipment such as power strip,

service outlet from other devices or rack.

• When rack mounted devices with multiple power cables are connected to one single service outlet, or multiple rack

mounted devices with single power cable are connected to one single service outlet, there’s a risk that total ground

leakage current may exceed the power specifications. Pay special attention to the ground leakage current.

Installation procedure is described below.

Be sure to keep sufficient front and rear space for safe installation service.

1. Fix rack mounting rails to the rack posts.

Loosen four M4 screws which are originally fixed to rails, adjust length of the screws, and fix the rails to the rack.

Once the rails are fixed to the rack, fasten again the four M4 screws.

M6

MachineScrews

M4MachineScrews

M6

MachineScrews

M6CountersunkScrews

M6CountersunkScrews

34

Installation of the switch

Page 35

XG2600 Hardware Guide Chapter 2 Installation

2. Slide the switch between rails which are fixed to the rack, and fasten the 2 M6 screws to the front

posts.

XG2600

M6MachineScrews

M6MachineScrews

Precautions

Pre-occupied devices in the upper and/or lower row of the rack may interfere with the power cable of the switch from

being properly installed. In that case, plug the power cable to the switch before install it in the rack.

35

Installation of the switch

Page 36

XG2600 Hardware Guide Chapter 2 Installation

2.2.3 Change Switch Access Configurations from Rear-Access

(Factory Default) to Front-Access and Install

This section describes how to change Rear-Access configuration (Factory Default) to Front-Access.

For Front-Access configuration to Rear-Access, make the procedure reversed.

Note

Remove rack mounting brackets

1. Remove rack mounting brackets attached to the sides of the switch.

XG2600

RackMountingClamps

Change the direction of fans to adjust airflow

Change the direction of fans, depending on which switch access configuration to go with, Rear-Access or Front-Access.

Check the direction of fans before installing the switch in the rack.

Airflow is as shown below.

• Rear-Access Configuration (Factory Default)

Exhaust

AirflowLabel

• Front-Access Configuration

Intake

Intake

AirflowLabel

36

Exhaust

Installation of the switch

Page 37

XG2600 Hardware Guide Chapter 2 Installation

1. Loosen two screws to remove fan unit.

XG2600

Screw

Screw

2. Remove fans

(1) Remove two screws.

(2) Unlock Cable Holder (which prevents cables from being pulled out).

(3) Remove cables

(3)

(2)

3. Change direction of fans.

(1) Turn over the fan.

(1)

37

(1)

Installation of the switch

Page 38

XG2600 Hardware Guide Chapter 2 Installation

(2) Check if the direction shown in Airflow Label matches the airflow direction required.

(3) Unlock Cable Holder to which the cable is connected.

(4) Lock the unused Cable Holders.

(3)

(2)

(4)

4. Fix fans.

(1) Fasten screws.

(2) Connect cables.

(3) Lock Cable Holder for the connected cables to prevent the cable from being accidently pulled out.

(3)

(2)

(1)

5. Insert back the Fan unit in the fan slot and fasten two screws to fix it to the switch.

38

Installation of the switch

Page 39

XG2600 Hardware Guide Chapter 2 Installation

Change PSU’s positions to meet different switch access configurations

There are two types of PSU Slot Bezel.

• PSU Bezel (Vents with Logo)

Put it to empty PSU1 slot.

• PSU Bezel (Vents without Logo)

Put it to empty PSU2 slot right next to PSU1 slot.

XG2600

VentswithLogo VentswithoutLogo

The procedure to change PSU configurations is shown below.

1. Remove screws to take off two PSU slot bezels on the Fan Unit side (PSU1 and PSU2 slots).

SR-X526R1

Screw

XG2600

2. Remove screws and take off PSU units on the Interface Side.

39

Installation of the switch

Page 40

XG2600 Hardware Guide Chapter 2 Installation

3. Put PSU Bezel (Vents with Logo) to PSU1-slot on the Interface Side with screws. Put PSU Bezel

(Vents without Logo) to PSU2-slot right next to PSU1 slot with screws.

XG2600

4. Slide PSUs into PSU1-slot and PSU2-slot and fix them to the switch with screws.

SR-X526R1

40

Installation of the switch

Page 41

XG2600 Hardware Guide Chapter 2 Installation

Attach rack mounting brackets to the switch

1. Attach rack mounting brackets to fit either a standard front position of the rack or a offset position of

the rack.

[STANDARD]

XG2600

[OFFSET]

XG2600

RackMountingClamps

Precautions

PSUs have to always be located in the rear side of the rack. If the position of PSUs is not appropriate, rack mounting

brackets cannot be attached to the switch properly. Check the PSU configuration.

Install the switch in a 19" rack

The switch can be installed and operated in the EIA standard 19" rack.

Reference

" Install the switch in a 19” rack" (pg.34)

Plugintothehole

ofthedevice.

41

Installation of the switch

Page 42

XG2600 Hardware Guide Chapter 2 Installation

2.3 Connecting the Equipment

We recommend discharging static electricity of twisted pair cable before connecting it to the switch.

See below for the procedure of discharging. Also see below for how to install USB memory.

2.3.1 Discharging Twisted Pair Cable

Discharge static electricity of the twisted pair cable through the ground wire cable (ground wire for power supply,

buildings, etc.) using static electricity removal tool, before connecting twisted pair cable to the switch.

There is a product below for the static electricity removal tool.

Maker :

Product Name : LAN Cable ESD Removal Tool

Part Number :TS2002-001

トシシステム株式会社

ANCableESDRemovalTool

Crocodileclip

Precautions

• Unplug both ends of the twisted pair cable from equipments (HUB, router, and workstation) during discharging

operation.

• Do not use ground wire of electronic devices. Use grounded cable for power supply or buildings.

• Do not short circuit with AC power supply when using ground wire for power suppl.

1. Insert one plug of the twisted pair cable to LAN Cable ESD Removal Tool.

The condition of twisted pair cable can be either both ends open or one end open.

2. Connect (contact) crocodile clip of LAN Cable ESD Removal Tool to the ground wire for more than

one minute.

3. Remove LAN Cable ESD Removal Tool from twisted pair cable, and connect twisted pair cable to

the switch.

4. Continue discharging the twisted pair cable one by one following the process from 1 to 3 above.

Precautions

Quickly connect twisted pair cable to the switch after discharge. Discharge effect will be lost if twisted pair cable is left

unconnected to the switch.

42

Connecting the Equipment

Page 43

XG2600 Hardware Guide Chapter 2 Installation

2.3.2 Cleaning SFP+ Module / Optical Connector

When invisible small dust is adhered to SFP+ module /optical connector, optical signal will be shut or space caused by dust will

impede transmission of optical signal.

Therefore, clean up SFP+ module /optical connector before connection.

Cleaning of SFP+ Module

1. Blow dust away with cleanly dry air or nitrogen.

Check end face, and conduct operation below if dust is left.

2. Lightly dampen a cleaning stick (1.25mm across, for LC/MU) with isopropyl alcohol. After wiping off

dust, slowly and carefully wipe off alcohol with a new and dry cleaning stick.

3. Insert a cleaning stick to the optical connector insertion part of SFP+ module, and slowly wheel it.

SFP+module

cleaningstick

4. Insert and slowly wheel a new cleaning stick, and dry the SFP+ module.

5. Check if the dust is removed with 200-fold magnification fiber scope.

Cleaning of Optical Connector

1. Remove the connector guard cap of optical fiber part, and check the connector end face.

If the end face is not clean, clean it with a reel type fiber cleaner.

2. Push thumb holder of a fiber cleaner and open a cap of the fiber cleaner.

3. When a cap slides and a new cleaning tape comes out, lightly apply the end face to a cleaning tape.

4. Apply the end face of the connector and rotate it (quarter turn four times).

5. Apply the end face to the cleaning tape, and move it to forward direction of a fiber cleaner.

Caution

Do not friction the end face to the cleaning tape. It will cause micro dust or scratch.

6. Take thumb holder off, and close a cap of a fiber cleaner.

7. Check the end face and continue cleaning if necessary.

43

Connecting the Equipment

Page 44

XG2600 Hardware Guide Chapter 2 Installation

Removal of Micro Dust

Remove micro dust on the optical fiber part following the method below if necessary.

1. Wipe the optical fiber part with ethanol or cleaning fluid.

2. Softly and slowly wipe the optical fiber part with cleaning fabric.

3. Wipe with a new cleaning stick in the same fashion, and dry the optical connector.

Caution

• Do not use fluid such as bleach because it will damage optical coupling.

• Use ionizer when cleaning in order to avoid the ESD damage to SFP+ module.

• SFP+ module cannot be washed with water. Do not use or clean SFP+ module in a wet space such

as bathroom or kitchen.

• Carefully treat SFP+ module as it sometimes becomes very hot.

Precautions

• Do not use alcohol, spray, and cotton swab for cleaning of optical connector other than special optical connector

cleaner because dust on the end face of the optical connector plug may not be completely wiped off and more dust

may adhere.

• Immediately connect optical connector to the switch after cleaning. Dust will adhere when the optical connector is

left unconnected.

• Keep the connector guard cap fixed before using SFP+ module in order to avoid contamination.

• When SFP+ module is contaminated, check end face and clean only if necessary.

• If a lot of fluid is used, it will possibly be accumulated or leak out because SFP+ module is not hermetically closed.

44

Connecting the Equipment

Page 45

XG2600 Hardware Guide Chapter 2 Installation

2.3.3 Connecting Twisted Pair Cable / SFP+ Module

Below is how to connect twisted pair cable and SFP+ module.

Use straight cable when connecting with routers and terminals. Use crossing cable in case of cascading connection with

other switching HUBs with transmission mode at fixed setting other than auto negotiation.

straightcable

opticalcable

crossingcable

Management port of the switch is set auto negotiation enable by default.

(However, SFP+ slots only support 10Gbps full duplex mode fixed setting.)

Ports automatically apply to the maximum speed that plugged equipment supports by the auto negotiation function.

• 100BASE-TX port : Up to maximum 100Mbps full duplex mode

Connecting Twisted Pair Cable

Insert twisted pair cable to 10/100BASE-TX port until it clicks.

Precautions

• Usable twisted pair cables are unshielded twisted pair cable (UTP) over category 5E and shielded twisted pair cable

(STP).

• Discharge twisted pair cable before connecting as twisted pair cable may be charged static electricity. Refer "2.3.1

Discharging Twisted Pair Cable" (pg.42) for discharging method.

Twisted

PairCable

45

Connecting the Equipment

Page 46

XG2600 Hardware Guide Chapter 2 Installation

Connecting SFP+ Module

Firmly install SFP+ module to SFP+ slot and lock module to the switch.

SFP+module

Precautions

• Safely keep a guard cap of SFP+ module.

• Make sure to clean the end face of SFP+ module / optical cable before connecting optical connector because the

end face may possibly be contaminated.

• Do not directly touch the contact part of SFP+ module by hands. Use wristbands when touching SFP+ module.

• Connecting part to the optical cable of SFP+ module is the laser opening.

There are two types of SFP+ modules, veil latch type and standard latch type.

Below is how to connect.

• Veil Latch Type

Insert SFP+ module to the SFP+ slot with a lever locked, and lock the module and the switch.

Connect optical cable (connector shape: DLC) after inserting SFP+ module to the SFP+ slot.

When removing SFP+ module, unlock the lever, module and the switch, and remove the module after unplug the

optical fiber.

Lever

• Standard Latch Type

Insert SFP+ module to the SFP+ slot, and lock the module and the switch.

Connect optical cable (connector shape: DLC) after inserting SFP+ module to the SFP+ slot.

When removing SFP+ module, remove the module after pressing a tab to unlock the module and the switch.

Tab

46

Connecting the Equipment

Page 47

XG2600 Hardware Guide Chapter 2 Installation

Precautions

Cable length will be as below based on the specification of the optical fiber cable.

Typ e Core/Cladding Diameter Minimum Transimission Band Cable Length (m)

MMF 62.5/125

50/125

Use the appropriate cable according to the installation place.

µm160MHz/km 26

200MHz/km 33

µm400MHz/km 66

500MHz/km 82

2000MHz/km 300

Replacing SFP+ Module

Precautions

It is possible to install/replace SFP+ module with the power on.

When replacing SFP+ module, follow the process below.

1. Make the replacing SFP+ slot to the "disable status".

• In case of using telnet or console

Enter replacing SFP+ slot number in <port>

# offline ether <port>

• In case of using www browser

Make the SFP+ slot number to the selective status by "Setting of physical port" of settings menu.

Select "Disuse" of "Use of Physical Port", and click "Regist" icon.

Reference

Refer below for how to display top page of the switch.

★ User’s Guide にもし 8 章に ”Using the Web Interface”を記載するのになったらリンクする

"1.2 本装置のトップページを表示させる " (pg.9)

2. Replace the SFP+ module after removing optical cable, and then install the SFP+ module.

47

Connecting the Equipment

Page 48

XG2600 Hardware Guide Chapter 2 Installation

3. Connect optical cable and release the “disable status” of the SFP+ slot.

• In case of using telnet or console

Enter replacing SFP+ slot number in <port>

# online ether <port>

• In case of using www browser

Make the SFP+ slot number at the selective state by "Setting of physical port" of settings menu.

Select "Use" of "Use of physical port", and click "Regist" icon.

4. In case ERROR LED was blinking before replacement, confirm that ERROR LED is off after

replacement.

Reference

User’s Guide "5.41.1.1 offline" (pg.493), "5.41.1.2 online" (pg.494)

48

Connecting the Equipment

Page 49

XG2600 Hardware Guide Chapter 2 Installation

2.3.4 Plugging in the USB Memory

USB memory can be plugged in from the interface panel of the switch.

Caution

Do NOT unplug out the memory stick during access. It may result in crashing setting data.

Precautions

It is possible to plug/unplug SFP+ module with the power on.

Plug in the USB Memory

Please refer to the following instructions;

1. Firmly insert the USB memory to USB port on the interface panel of the switch.

USBMemory

Replacing the USB Memory (Unplug)

Please refer to the follow instructions;

1. Make the USB port to "disable status" using the console command.

# usbctl disable

2. Check and confirm that USB port is in a "disable status".

Execute command "show usb hcd status", and check and confirm that the status is displayed as "disable".

# show usb hcd status

[USB HCD STATUS]

status : disable

3. Unplug the USB memory from the switch.

The process ends here, when you are only detaching the USB memory from the switch.

Note

4. Plug in the replacing USB memory onto the switch.

5. Release the "disable status" of the USB port using the console command.

# usbctl enable

49

Connecting the Equipment

Page 50

XG2600 Hardware Guide Chapter 2 Installation

2.4 Connecting a Setup PC

This is to connect a set up PC to the console port of the switch using RS232C cable.

Necessary Hardware / Software

Please prepare the hardware & software specified below to connect to the switch.

• Personal Computer

1 unit of personal computer for setting up configuration is required.

• RS232C cable (Cross, D-SUB9 pin)

RS232C cable is required to connect the set up PC to the switch.

Also, please use the console cable which is included in this product for connection.

Reference

• Communication Software

Terminal software is required.

User’s Guide "1.1.5 Console Port Specifications" (pg.28)

Connect RS232C Cable

1. Confirm power of both the PC and the switch are off.

2. Connect the RS232C cable and the console cable which is included in this product, and firmly fix

them with the screw.

3. Plug in the RJ45 plug of the console cable to the console port of the switch.

Precautions

Please use cross cable for RS232C cable.

50

Connecting a Setup PC

Page 51

XG2600 Hardware Guide Chapter 2 Installation

Turn on the Power

Caution

• Please use the power cable included in this product. Also, please do NOT use this power cable

on other products.

• If the power outlet does not match with the power cable plug, please use the change plug

adapter.

As a safety measure to prevent electrical shocks, please make sure to connect the ground wire

of the change plug.

Precautions

• Please set the switch (product) to a place near the electrical outlet which the power cable will be connected and

secure a space for the power cable to be pulled off easily.

• Please connect the power cable in the following order. PSU1

If you connect the cable in the wrong order, the CHECK LED will lit in orange. If the CHECK LED is lit, delete the

error log using the console command after turning on the power of the switch.

# clear logging error

#

→ PSU2

Reference

• When turning off the power. Please follow the above steps in an opposite order.

User’s Guide "5.18.1.5 clear logging error" (pg.349)

1. Connect the power cable to the electrical outlet.

2. Plug in the power cable to the power connecter of PSU1.

Power will turn on.

51

Connecting a Setup PC

Page 52

XG2600 Hardware Guide Chapter 2 Installation

3. POWER LED of PSU1 and PSU1 LED of the switch will light in green.

Next, plug in the power cable to the power connecter of PSU2.

The POWER LED of PSU2 and PSU2 LED of the switch will light in green.

POWER

PSU1

PSU2

Prepare a Setup PC

Log on using the terminal software.

1. Start up the terminal software by using the set up PC.

2. Set the setting conditions to the following;

Setup Items

Star t Bit 1

Data Bit 8

Parity Bit n/a

Stop Bit 1

Synchronous System Asynchronous Communication System (Start-Stop Communication System)

Communication Speed 9600

Flow Control None

Number of digits on screen 80 (If other than 80 digits, set it through terminal command)