Page 1

XG0440DC/XG0440DCR Hardware Guide

Introduction

TA41001-7879

XG0440DC/XG0440DCR

XG0440DC/XG0440DCR

HardwareGuide

Page 2

XG0440DC/XG0440DCR Hardware Guide

Preface

The Fujitsu XG0440 is a 40 port 1 Gigabit plus 4 port 10 Gigabit Ethernet layer 2 switch that achieves unsurpassed levels

of high throughput.

This manual explains the procedures required to install the XG0440. Please read and fully understand the instructions before

deploying the switch.

First edition: May 2012

This manual contains the technology regulated by "Foreign Exchange and Foreign Trade Control Law."

Therefore when this manual is exported or provided to a nonresident, the appropriate permission based on this law is

required.

Screenshots are used according to the guidelines provided by Microsoft Corporation.

Copyright FUJITSU LIMITED 2012

2

Page 3

XG0440DC/XG0440DCR Hardware Guide

LICENSE AGREEMENT

Product Name XG Series Basic Software

Total number of licenses 1

Thank you for purchasing the XG Series switch product ("Hardware") and accompanying software ("Software," together

with Hardware, collectively, referred to as "Product") manufactured by Fujitsu Limited ("Fujitsu"). The use of the Product

is subject to Customer's acceptance of the terms and conditions of the following requirements ("Use Requirements").

Please note that Customer's use, installation or backup of the Product constitutes your acceptance of the following Use

Requirements. Please keep this License Agreement in a secure location as it will not be re-issued.

1. Use and Copyright of the Software

Customer may use the Software solely in connection with the single Hardware that Customer has purchased.

The total number of Hardware that Customer can use in connection with the Software is limited to the number of license

specified above. Customer needs to purchase an additional license from Fujitsu in order to use the Software in connection

with additional unit of the XG Series switch product or other functions. Customer acquires only right to use the Software

by purchasing, this Software is copyrighted by Fujitsu or the third party that developed the software used in the Software.

2. Transfer

Customer may not assign, transfer, lease, relicense or sublicense the Software or any rights in or to the Software to third

parties. Customer further agrees to keep the Software free and clear of any and all claims, liens, security interests and other

encumbrances.

3. Modification

Customer may not modify, disassemble, decompile or reverse engineer the Software.

4. Scope of Warranty

1) If Customer notifies Fujitsu of any discrepancy between the manual, user guides or other related documents

("Documentation") and the Software, Fujitsu shall, at its sole discretion, correct or provide information relating to such

correction free of charge within ninety (90) days of Customer's purchase of the Product ("Warranty Period").

2) During the Warranty Period, if the said discrepancy between the Documentation and the Software cannot be corrected

despite Fujitsu's repeated corrections or provision of information within reasonable limits as set forth in subsection (1)

above, Fujitsu shall be liable for damages incurred to Customer by reason of such discrepancy.

Fujitsu's aggregate liability for such damages shall not exceed the amount equal to the total price of the Product.

Further, Fujitsu shall not be liable for (i) damages to the extent they are caused by conditions not attributable to Fujitsu, or

(ii) any damages caused by special conditions such as indirect, incidental, special, consequential or punitive damages, or

damages for loss of profits, revenue, business, savings, data, use or cost of substitute procurement, incurred by Customer

or any third party, even if Fujitsu has been advised of the possibility of such damages or even if such damages are

foreseeable.

3) In the event a third party files a lawsuit, an appeal, a claim, or similar action ("Claim") against Customer alleging that the

Software infringes any patent, copyright, trademark, trade secret or any other intellectual property right ("Intellectual

Property Rights") of such third party, upon Customer's request and Customer's delegation of its rights to Fujitsu, Fujitsu

shall assume control of the defense and settlement of any such Claim at its sole cost and responsibility.

In such event, Fujitsu will pay for damages and expenses attributable to such Claim.

4) If it is determined in a final judgment or settlement that the Software infringes Intellectual Property Rights of a third party

as described in subsection (3) above, Fujitsu shall take any one of the measures described below at its sole discretion:

a. modify the Software to be non-infringing;

b. obtain permission from third parties so that the Customer can use the Software; or

3

Page 4

XG0440DC/XG0440DCR Hardware Guide

c. if in Fujitsu's sole judgment it is not commercially reasonable to perform either of the above options, subject to the

limitation of liability set forth in subsection (2) above, Fujitsu shall pay for any damages Customer has incurred

due to nonuse of the Software.

5) If the Claim described in subsection (3) above is withdrawn based on the determination that the Software does not infringe

the Intellectual Property Rights of a third party, or that the Intellectual Property Rights of a third party are invalid, the

expenses incurred by the Customer or Fujitsu in dealing with such Claim shall be equally divided between Customer and

Fujitsu.

6) Except as otherwise expressly set forth above, Fujitsu shall not be liable for any damages (including, but not limited to,

loss of profits, suspension of operations, loss of business-related information, or other monetary damages) arising out of

the use or nonuse of the Product, even if Fujitsu has been advised of the possibility of such damages in advance.

7) If the Software contains software developed by a third party vendor, the warranty with respect to such third party software

is limited to those warranties provided by Fujitsu hereunder, and the third party vendor does not provide any further

warranties with respect to such third party software.

5. High Safety Required Use

The Customer acknowledges and agrees that the Software is designed, developed and manufactured as contemplated for

general use, including without limitation, general office use, personal use, household use, and ordinary industrial uses, but

is not designed, developed and manufactured as contemplated for use accompanying fatal risks or dangers that, unless

extremely high safety is secured, could lead directly to death, personal injury, severe physical damage or other loss

(hereinafter "High Safety Required Use"), including without limitation, nuclear reaction control in nuclear facility, aircraft

flight control, air traffic control, mass transport control, medical life support system, and missile launch control in weapon

system.

The Customer shall not use the Software without securing the sufficient safety required for the High Safety Required Use.

In addition, Fujitsu shall not be liable against the Customer and/or any third party for any claim or damages arising in

connection with the High Safety Required Use of the Software.

FUJITSU LIMITED

4

Page 5

XG0440DC/XG0440DCR Hardware Guide Contents

Contents

Preface ................................................................................................................................................................2

LICENSE AGREEMENT ..................................................................................................................................3

Organization and Usage of This Manual ............................................................................................................7

About This Manual ....................................................................................................................................................7

Target Readers and Required Knowledge .................................................................................................................7

Areas Covered ............................................................................................................................................................7

Trademark Notification in This Manual ....................................................................................................................8

How the Manuals for This Device Are Organized .................................................................................................... 8

Safety Precautions ...............................................................................................................................................9

About Warning Descriptions .....................................................................................................................................9

Notes on Maintenance .............................................................................................................................................. 12

Precautions for Use .................................................................................................................................................. 12

Eliminating Static Electricity from Twisted Pair Cables (Grounding) .................................................................... 12

Ensuring Security ..................................................................................................................................................... 12

Cleaning ...................................................................................................................................................................12

Electromagnetic Compatibility (USA) .................................................................................................................... 13

Electromagnetic Compatibility (CANADA) ...........................................................................................................13

Electromagnetic Compatibility (EU) .......................................................................................................................13

Safety .......................................................................................................................................................................13

High safety ...............................................................................................................................................................13

Laser Safety .............................................................................................................................................................14

Notes on Rack Mounting and Connecting a Powerstrip .......................................................................................... 14

Notes on Use .....................................................................................................................................................15

Chapter 1 Getting Started ....................................................................................... 16

1.1 Items in the Package, Descriptions and Functions ................................................................................17

1.1.1 Parts List .................................................................................................................................................. 17

1.1.2 Switch Port Side .......................................................................................................................................18

1.1.3 Switch Power Inlet Side ........................................................................................................................... 22

1.1.4 Top Surface ..............................................................................................................................................24

1.1.5 Bottom Surface ........................................................................................................................................ 25

1.2 Option ....................................................................................................................................................26

1.2.1 SFP+ Modules .......................................................................................................................................... 26

Chapter 2 Installation .............................................................................................. 27

2.1 Requirements for Installation Environment ...........................................................................................28

2.1.1 Installation Requirements ........................................................................................................................ 28

2.1.2 Space Requirements ................................................................................................................................. 29

2.2 Installation of the switch ........................................................................................................................30

2.2.1 Decide Switch Access Configuration ...................................................................................................... 30

2.3 Connecting the Equipment .....................................................................................................................33

2.3.1 Discharging Twisted Pair Cable .............................................................................................................. 33

2.3.2 Cleaning SFP+ Module / Optical Connector ...........................................................................................33

2.3.3 Connecting Twisted Pair Cable / SFP+ Module ...................................................................................... 35

2.3.4 Plugging in the USB Memory .................................................................................................................. 38

2.4 Connecting a Setup PC ..........................................................................................................................39

2.5 Time Setting ...........................................................................................................................................41

2.6 Set up IP address ....................................................................................................................................42

5

Page 6

XG0440DC/XG0440DCR Hardware Guide Contents

2.7 Turn On/Turn Off the Power .................................................................................................................43

2.7.1 Turn on the Power ....................................................................................................................................43

2.7.2 Turn off the Power ................................................................................................................................... 44

Index............................................................................................................................. 45

6

Page 7

XG0440DC/XG0440DCR Hardware Guide

Organization and Usage of This Manual

This manual explains important details that should be understood before deploying the XG0440.

About This Manual

This manual contains important information required to use this device safely.

Read this manual thoroughly before using this device. In particular, please read and fully understand the "Safety

Precautions" described in this manual before using this device. Furthermore, this manual should be kept in an easy-to-

access location for quick reference while using this device.

Fujitsu takes the utmost care to insure that our products can be used safely without causing injury to the customer or

damage to their property

Target Readers and Required Knowledge

This manual is intended for persons who perform network management.

To use this manual, a basic knowledge of networking and Internet practices and protocols are required.

Areas Covered

The organization of this manual and the contents of each chapter are shown as follows.

Chapter Titles Contents

Chapter 1 Getting Started This chapter lists the items that should be in the product package, and describes the names

and functions of the various components.

Chapter 2 Installation This chapter describes how to install the switch and connect it to a Console PC.

About the Symbols

The symbols used in this manual have the following meanings.

Hint

Precautions

Reference

Indicates useful information for using this device.

Indicates precautions that must be taken when using this device.

Indicates additional information to complement operating instructions.

Note

Indicates related matters such as operation procedures, etc.

AvailableModel

Warning

Caution

Indicates the available model name when using functions of this device.

Indicates warning matters related to the Product Liability (P.L.) Law. Please follow them

when using this device.

Indicates cautionary notes related to the Product Liability (P.L.) Law. Please follow them

when using this device.

7

Page 8

XG0440DC/XG0440DCR Hardware Guide

Trademark Notification in This Manual

All company names and product names referenced in this manual are trademarks or registered trademarks of their

respective companies.

How the Manuals for This Device Are Organized

The manuals for this device are organized as follows. Use these manuals as necessary.

Manual Name Description

Safety and Installation Guide This manual describes the safety and installation.

XG0440DC/XG0440DCR Hardware Guide

(This manual)

User's Guide This manual describes a variety of operations and procedures, including the

This manual describes the hardware of the XG0440.

installation, configuration, and maintenance of XG Series switches.

8

Page 9

XG0440DC/XG0440DCR Hardware Guide

Safety Precautions

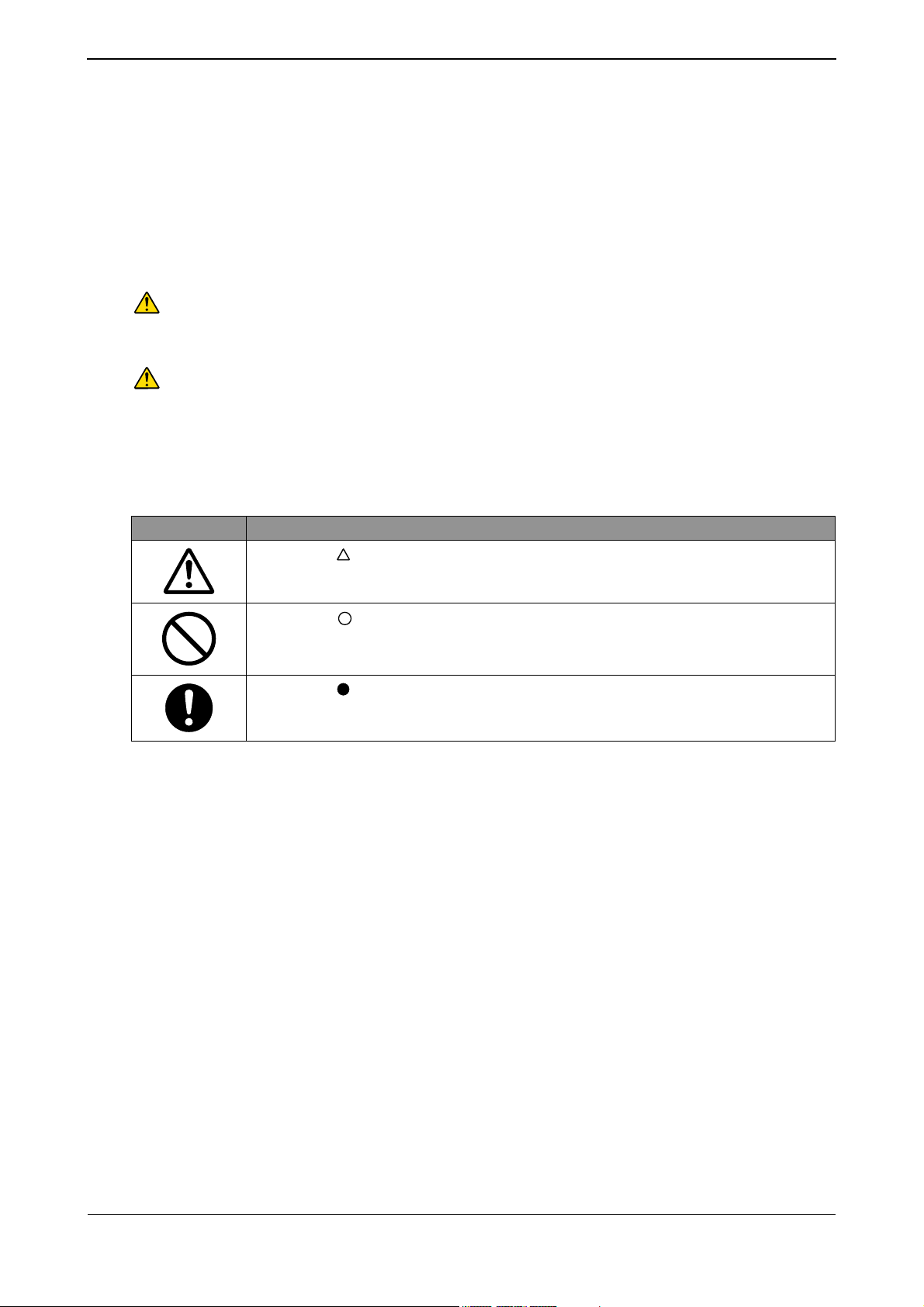

About Warning Descriptions

This manual contains precautions that must be taken in order to use this device safely and prevent personal injury or

property damage. Please fully understand the meanings and contents of the following descriptions and symbols when

reading this manual.

Warning

Caution

The following symbols are used to indicate the type of warning or caution.

Symbols Definitions

Indicates that improper use can cause severe damage to person, resulting in serious injury or

death.

Indicates that improper use can cause light or moderate injury.

In addition, this symbol indicates a chance of damage to this device and other connected

equipment.

The symbol in form indicates a warning or cautionary note. Specific information is shown inside or

next to the symbol.

The symbol in form indicates a prohibited (Do Not) action. Specific information is shown inside or

next to the symbol.

The symbol in form indicates actions or instructions that must be followed. Specific information is

shown inside or next to the symbol.

9

Page 10

XG0440DC/XG0440DCR Hardware Guide

Warning

Always follow the instructions for safe use of this device. Indicates that improper use can cause

severe damage to person, resulting in serious injury or death.

Warnings

Do not insert or drop any foreign objects into the

device through the vent.

Also, prevent liquid such as water from entering

it.

In case a foreign object or liquid enters the

device, you must first unplug the power plug

from the socket and contact our engineer or an

engineer certified by Fujitsu.

Continuing to use the device in this condition

may result in electric shock, fire accident or

failure.

Do not score, cut, or rework the power cable.

Do not put any objects on the power cable. The

power cable should not be pulled, bent forcibly,

twisted or heated. These actions may damage the

cable.

Do not use the power cable while it is bundled

together. Otherwise electric shock or fire may

occur.

The same applies to other cables.

If there is lightning near the location, do not

touch this device, the power cable or other cables.

Failure to follow this may result in electric shock.

Do not connect or disconnect the power plug with

wet hands.

Failure to follow this may result in electric shock.

The cover must only be opened by qualified

service personnel.

Also, the power cable must be unplugged during

maintenance.

Failure to follow this may result in electric shock.

Also, keep removed screws out of reach of

children so that they cannot put the screws into

their mouths accidentally.

In the event they put the screws into their mouths,

consult a doctor immediately.

You cannot use this device at a voltage other than

the indicated supply voltage.

Do not overload the electric outlet.

Failure to follow these warnings may result in

electric shock or fire.

If you notice abnormal conditions such as

overheating, smoke emission, or odor, stop using

this device immediately, and pull the power cable

plug from the socket. Make sure that abnormal

conditions such as smoke no longer exist and

contact our engineer or an engineer certified by

Fujitsu.

Continuing to use the device in this condition

may result in electric shock or fire.

Disconnect 2 power supply cords before service

to avoid electric shock.(Except for active

maintenance)

For interface connectors, do not insert a

connector other than the appropriate connector

for a specific line.

Failure to follow this may result in electric shock

or failure.

The plastic sheets used for packaging must be

kept out of reach of children so that they cannot

put the sheets in their mouths or put their heads

into them.

Failure to follow this may result in suffocation.

When cleaning, do not use cleaning sprays (that

includes inflammable material) because it may

cause device breakdown or fire.

Do not use this device when the power cable or

plug is damaged or the socket is loose.

Continuing to use the device in this condition

may result electric shock or fire.

Do not disassemble, dismantle, modify or

reproduce this device.

Failure to follow this may result in electric shock,

fire or failure.

10

Page 11

XG0440DC/XG0440DCR Hardware Guide

Caution

Indicates that improper use can cause light or moderate injury.

In addition, this symbol indicates a chance of damage to this device and other connected equipment.

Cautions

Do not touch this device for more than one

minute while it is turned on.

Failure to follow this may cause low-temperature

burns.

Do not stand this device vertically or stack it.

Failure to follow this may cause the device to fall

over causing injury, damage, or failure.

Do not install this device on shaky stands, unlevel

surfaces, or other unstable places.

In addition, do not use this device in a location where

impact or vibration occurs.

Failure to follow this may result in the device falling

over, causing injury, damage, or failure.

Do not use the device in a corrosive gas

environments or other places where it may be

exposed to chemical substances.

Failure to follow this may cause damage or

failure.

Ensure enough space for access to, and cabling

of, the device

For multiple devices ensure adequate service

areas, front and back, for both devices.

Failure to follow this may cause cable failures.

Do not use any extension card other than the ones

supported by this device.

Failure to follow this may cause system failure.

Do not install this device near heaters or at places

subject to direct sunlight, humidity, and dust.

Electric shock or fire may occur.

Unplug the power cable by pulling the plug with

your hand.

Electric shock or fire may occur due to a damaged

plug.

If dust or dirt accumulate on the metal contacts of

the power plug or device receptacle, wipe it clean

with a dry cloth.

Continuing to use the device in this condition

may result in fire.

Do not use this device near a radio or a TV set.

The device may generate noise in a radio or TV

set.

Avoid looking at the light source (e.g. laser light)

directly.

Failure to follow this may injure your eyes.

Do not put objects on this device or use it as a

work area.

Failure to follow this may cause damage to the

device, or result in injury to person or failure.

Install this device indoors.

Installing outdoors may result in failure.

Do not use this device in places where the

temperature is extremely high/low or fluctuates

greatly.

Failure to follow this may cause system failure.

Follow the operating temperature limit for this

device.

Do not use this device near a microwave oven or

other equipment that emits strong magnetic

fields.

Failure to follow this may cause system failure.

Make sure to unplug the power cable when

transporting this device.

Failure to follow this may cause system fault.

Make sure to connect cables correctly.

Improper cabling hinders reliable communications

and may cause failure of the device.

Do not obstruct the device's air vents to avoid

higher operating temperatures

Failure to follow this may result in fire.

Insert the plug into the socket completely.

Not completely inserting the plug may result in

electric shock, smoke emitting or fire.

When using this device, do not cover it, or wrap it

with anything.

Otherwise overheating may result in fire.

When lifting the device up, do not hold handles of

power supply units or fan units in order to avoid

the handles taken off.

11

Page 12

XG0440DC/XG0440DCR Hardware Guide

Notes on Maintenance

• Customers should not repair this device. In the event of failure, consult with a Fujitsu service engineer or an engineer

certified by Fujitsu for maintenance.

• Do not dismantle or modify this device for any reason. This device contains high voltage and high temperature parts

that can be dagerous.

Precautions for Use

• As a guideline, the expected life of the device is approximately five years, assuming use at an ambient temperature of

°C.

25

• Use of this hardware guide, the device, its firmware, and the management software are the responsibility of the user

and is undertaken at their own risk.

• Fujitsu and its partners accept no responsibility for any errors or data loss arising from use of the product. Before using

the product, it should be understood that the device is not guaranteed against failure for any more than the original

purchase price.

• Fujitsu and its partners do not approve of any use of the firmware provided with the device, or of any authorized

firmware upgrades, for any purpose other than installation in the intended device. Modification and disassembly are

not permitted under any circumstances. Use of the device or upgrading the device firmware implies acceptance of the

End User License Agreement stipulated within the User's Guide.

Eliminating Static Electricity from Twisted Pair Cables (Grounding)

Under certain conditions, twisted pair cables can become charged with static electricity. Connecting a statically charged

twisted pair cable to the XG0440 can cause the device or its LAN port to operate falsely or to become damaged.

Use a static removal tool to discharge twisted pair cables to ground prior to connecting them to the XG0440.

Note that a discharged twisted pair cable that has been left unconnected for a long time may become statically charged

again.

Reference

"2.3.1 Discharging Twisted Pair Cable", p. 33.

Ensuring Security

If no password is set, any users on the network can configure this device. This does not ensure any level of security against

unauthorized use. It is strongly recommended that a password be set.

Reference

User's Guide "5.14 Password Information", p. 262.

Cleaning

If cleaning the device while in service, use a damp soft cloth. Only use water or a mild detergent to dampen the cloth.

Avoid moisture entering vents or crevices in the chassis of the device.

12

Page 13

XG0440DC/XG0440DCR Hardware Guide

Electromagnetic Compatibility (USA)

FCC Part-15 Class A

Warning

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC

Note

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FCC WARNING:

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

Electromagnetic Compatibility (CANADA)

Industry Canada Interference-Causing Equipment Standard ICES-003 Class A.

This Class A digital appartatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

Electromagnetic Compatibility (EU)

EN55022:2006+A1:2007

EN61000-3-2:2006+A2:2009

EN61000-3-3:2008

EN55024:1998+A1:2001+A2:2003

Warning

This product meets the Class A requirements of EN55022. In a domestic environment this

product may cause raido interference in which case the user may be required to take

adequate measures.

Safety

CAN/CSA C22.2 No. 60950-1, UL60950-1 and EN60950-1, Second Edition

High safety

High Safety Required Applications

The XG0440 is designed, developed and manufactured for general use, including, without limitation, general office use,

personal use, household use, and ordinary industrial use, but is not designed, developed and manufactured for use in

situations wherein failure of the XG0440 may result in death, personal injury, severe physical damage or other loss (herein

after referred to as "High Safety Required"), including, without limitation, nuclear reaction control systems in a nuclear

facility, aircraft flight control systems, air traffic control systems, mass transport control systems, medical life support

systems, and missile launch control weapons systems.

Do not use the XG0440 for High Safety Required applications without otherwise ensuring the safety level required. Fujitsu

and its related companies assume no liability whatsoever for damages arising from use of the XG0440 by the user in High

Safety Required applications, and for any claims or compensation for damages by the user or a third party.

13

Page 14

XG0440DC/XG0440DCR Hardware Guide

Laser Safety

The XG0440 may be installed with optical transceiver modules (SFP+ modules), which emit invisible laser light.

In the USA, these optical modules are certified as Class 1 laser products that conform to the requirements of the

Department of Health and Human Services (DHHS) regulation 21 CFR, Subchapter J. This certification is indicated by a

label attached to each optical module.

Outside the USA, these SFP+ modules are certified as Class 1 laser products that conform to the requirements of

EN60825-1 (2007).

Even when cables are not connected, invisible laser light may still be emitted from the optical module's port openings. To

avoid possible injury, do not look directly into the optical module's port openings.

Optical transceiver modules intended for use in the XG0440 must be selected from the Optical Transceiver Approved

Vendor List (obtainable from the vendor's service department).

Notes on Rack Mounting and Connecting a Powerstrip

Warning

• Monitor and control the internal and external temperature and humidity of the rack, so that it does not exceed the range

• The air intake and exhaust of the device is conducted at the port side and Fan Unit side. Do not block the intake side or

• Make sure to check the maximum loading capacity of the rack to be used for mounting.

• Check the power supply capability of the installation location.

• When connecting the power cable of the device to a powerstrip within a rack, a large amount of current leakage may

If mounting this device in a rack, assure device operational temperature specification compliance,

mechanical stability of the rack, and proper electrical grounding of the device. This device must only

be mounted in a rack by a qualified engineer with the required training and knowledge. Failure to do

so may result in property damage, electric shock, or fire.

of guaranteed operation temperature and humidity.

exhaust side in order not to prevent airflow when installing.

occur through the ground line of the powerstrip. Assure a good ground connection exists before connecting power to

the device. Assure power sourcing and leakage current carrying capabilities for the power strip are not exceeded. The

maximum current leakage for the device is 3.5 mA.

14

Page 15

XG0440DC/XG0440DCR Hardware Guide

Notes on Use

Before using this device, please read the following.

• It is strongly recommended that customers store and maintain configuration information for the device after

configuration is complete.

The configuration information can be used by a Fujitsu or Fujitsu's certified support engineer to restore configurations

if a failure occurs.

Unless the configuration information is available, it may cause difficulties and delays for the support engineer in

restoring the device to service, Please backup and maintain the configuration information so it is always up to date.

• This device contains a protection circuit against lightning and electrostatic discharge. Therefore, some of the functions

may not work when lightning or static electricity enters the device.

In such case, the device can be restored to its normal condition by power cycling the device. If the functions are still

not available after power-on, or if the power itself cannot be turned on, the device may have been destroyed due to

lightning or electrostatic discharge beyond the threshold of the protection circuit. In this case, contact Fujitsu or

Fujitsu's certified support engineer for further instruction.

• Do not turn the power off or reset the system during a firmware update, or the device cannot be enabled.

• A User's Guide for this product is provided on the included CD-ROM in PDF format. A PDF viewer is required to

access this manual.

15

Page 16

Chapter 1

Getting Started

This chapter lists the items that should be in the product package, and describes the names and functions of the various

components.

1.1 Items in the Package, Descriptions and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1.1.1 Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.1.2 Switch Port Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.1.3 Switch Power Inlet Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.1.4 Top Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.1.5 Bottom Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.2 Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.2.1 SFP+ Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page 17

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

1.1 Items in the Package, Descriptions and Functions

Before proceeding, check all the items described below.

1.1.1 Parts List

Please check that all of the following parts are included in the package.

XG0440

(TheXG0440DCisusedasanexample.)

CONSOLECableAdapter

M6MachineScrews

(Qty6)

SafetyandInstallationGuid

PowerCables(Qty2)

SFP+DummyCaps

(Qty4)

RackMountingRails(1set)

XG0440DC/XG0440DCRHardwareGuide

(withLicenceAgreement)

M6CountersunkScrews

(Qty4)

CD-ROM

• XG0440 The XG0440 switch.

• Power Cables (Qty 2) Cables to connect the XG0440 to an AC power source.

• CONSOLE Cable Adapter (RJ45 to Serial Adapter)

Straight cable with RJ-45 to D-SUB9 Converter Adapter.

• SFP+ Dummy Caps (Qty 4) Dummy caps to prevent dust when the SFP+ slots are open and unplugged.

The dummy caps come with the switch, installed on the slots at the time of purchase.

• M6 Countersunk Screws (Qty 4)

Screws for fastening the rack rails to the front side of the rack.

• M6 Machine Screws (Qty 6) 4 screws for fastening the rack rails to the rear side of the rack, and 2 screws for

fastening the rack rails to the front side of the rack.

• Rack Mounting Rails (1 set) Rails for mounting the switch in a rack.

• CD-ROM It contains the Firmware and User Guide (in a PDF format) necessary for operating and

configuring the switch. A PDF viewer is required to access this manual.

17

Items in the Package, Descriptions and Functions

Page 18

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

• Safety and Installation Guide This manual describes the safety and installation of the XG0440.

• XG0440DC/XG0440DCR Hardware Guide (with Licence Agreement)

This manual describes the hardware of the XG0440.

• A RS232 Crossover (Null Modem) Cable is not included in the product package

Note

• USB memory is not included in the product package

1.1.2 Switch Port Side

The XG0440DC is used as an example.

The front and back direction of the rack mounting brackets attached to the side of the switch is reversed for the XG0440DC

and XG0440DCR.

ProductPartNumber,

SerialNumberLabel

DumpSwitch

MACaddress

Label

10/100/1000BASE-TPorts

SFP+Slots

USBPort

ResetSwitch

CONSOLEPort

RackMounting

Brackets

• Rack Mounting Brackets

A metal fitting which attaches to the back side of the rack to fix the switch onto the rack.

RackMounting

Brackets

• MAC address Label This indicates the MAC addresses assigned to the switch.

• Product Part Number, Serial Number Label

The label is provided for easy access to product information for inventory purposes at

the port side of the switch.

• 10/100/1000BASE-T Ports 10/100/1000BASE-T Ports. These ports for connecting to Ethernet (10/100/1000BASE-

T) Network Equipment.

Please use Category 5 LAN cable (if 1000BASE-T, use Category 5E or above) for

cabling.

• SFP+ Slots Receptacles for SFP+ optical transceivers and Direct Attach copper (TWINAX) cable

assemblies.

Port numbers are assigned from the upper left to the lower right port receptacles.

Reference

See User's Guide "1.1 Hardware Specifications", p. 23, for technical details and qualified devices.

18

Items in the Package, Descriptions and Functions

Page 19

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

• Dump Switch Press the dump switch to copy the following switch files to an installed USB memory.

Information File Name

Configuration Definition 1 /um0/config1

Configuration Definition 2 /um0/config2

Firmware /um0/firmware

Error Log /um0/elog

The switch default configuration disables the dump switch. To activate the dump switch

use the dumpswitch command.

• Reset Switch Press to reboot. Press for 10 seconds during power up to access the backup firmware

operating mode.

Reference

See User's Guide "6.4 Actions When Firmware Update Failes (Backup Firm Function)", p. 593, for detailed

instructions.

• USB Port Insert a USB memory device to load/save configuration files or update firmware.

• CONSOLE Port (Console Connection)

The CONSOLE Port is used to connect the switch with a host computer for direct

configuration and management of the switch. Use the attached Console Cable Adapter

(RJ45 to Serial Adapter) and a RS232C crossover (Null Modem) cable (D-SUB9) to

connect to this port.

Caution

The CONSOLE Port is only used for connecting the switch with a RS-232C interface. Ethernet

or ISDN connections will cause errors or damage to the switch.

Reference

User's Guide "1.1.5 Console Port Specifications", p. 29.

19

Items in the Package, Descriptions and Functions

Page 20

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

LED Details

READY

LINK/ACT

SPEED

FDX

CHECK

PSU1

PSU2

FLASH

ERROR

FAN

Port42SFP+

LINK/ACT

Port41SFP+

LINK/ACT

Port41

Port41SFP+

Port42SFP+

Port42

• LINK/ACT/SPEED LED Lights to indicate the status of the link, signal transmission, transmission speed.

• FDX LED Lights to indicate the status of transmission mode for the management port.

• READY LED Indicates the operational state of the switch.

• CHECK LED Lights orange when the switch detected an abnormal operating condition. This may

indicate that the switch has failed. Consult with your Fujitsu or Fujitsu's certified

support engineer immediately to correct this condition.

• PSU1 LED Lights to indicate the status of the PSU1.

• PSU2 LED Lights to indicate the status of the PSU2.

• FLASH LED Lights to indicate read/write operations on external USB or internal memory.

Precautions

Do not shut down or reboot when the FLASH LED is blinking green. It may corrupt the switch or external memory

device configuration files.

• ERROR LED There a problem with the attached USB memory or SFP+ devices. An error occurred

when mounting or accessing these devices.

• FAN LED Lights to indicate the status of the Fans.

• SFP+ LINK/ACT LED Lights to indicate the establishment of the link and status of the signal transmission.

• SFP+ LED Lights to indicate the status of optical detection of the SFP+ slot.

20

Items in the Package, Descriptions and Functions

Page 21

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

LED Functions/Behaviors

LED Name State Status

LINK/ACT/

SPEED

FDX Green The Management Port is operating in full-duplex mode.

READY Green Switch has started up correctly.

CHECK Orange An abnormal condition was detected which may require switch replacement.

PSU1 Green PSU1 is operating normally.

PSU2 Green PSU2 is operating normally.

FLASH Green USB memory is installed.

ERROR Orange A fault condition exists in USB memory or one of the SFP+ devices.

FAN Green Both Fan Units are operating normally.

SFP+ LINK/ACT Green The SFP+ device has linked up.

SFP+ Green The SFP+ device has detected an external signal.

Green A 1000 Mbps link is established.

Green Blinking A 1000 Mbps link is trafficking data.

Orange A 100 Mbps or 10 Mbps link is established.

Orange Blinking A 100 Mbps or 10 Mbps link is trafficking data.

Off A link is not established.

Off The Management Port is operating in half-duplex mode.

Green Blinking The switch is in the diagnostic or backup firmware operating mode. (*)

Off The switch has faulted or AC power is not applied to the switch.

Orange Blinking A fault condition exists in the switch firmware or flash memory.

Off The switch is operating normally.

Green Blinking PSU1 is not installed or is installed incorrectly.

Off A problem has occurred with PSU1, or the power is not on.

Green Blinking PSU2 is not installed or is installed incorrectly.

Off A problem has occurred with PSU2, or the power is not on.

Green Blinking Read/write operations to USB memory or internal flash memory are occurring.

Off USB memory is not installed and/or internal flash memory is not being accessed.

Off The SFP+ devices and USB memory, if installed are operating normally.

Green Blinking A Fan assembly is not installed or is installed incorrectly.

Off Both Fan assemblies are operating normally or AC power is not applied to the

switch.

Green Blinking The SFP+ device is trafficking data.

Off The SFP+ device is link down.

Off The SFP+ device has not detected an external signal.

* When in the system diagnositic mode the READY LED blinks Green every 0.5 second.

When in the backup firmware operating mode the READY LED blinks Green every 1 second.

Reference

See "2.2.1 Decide Switch Access Configuration", p. 30, for detailed LED functions/behaviors under normal operation.

21

Items in the Package, Descriptions and Functions

Page 22

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

1.1.3 Switch Power Inlet Side

The XG0440DC is used as an example.

The front and back direction of the rack mounting brackets attached to the side of the switch is reversed for the XG0440DC

and XG0440DCR.

PSUSlots

PSU1PowerSupplyUnit

PowerInlet

FanUnit

PSUSlots

PSU2PowerSupplyUnit

PowerInlet

• Power Inlet Plug the attached Power Cable in the package.

• PSU Slots Power Supply Units are interchangeable between slots. The Power Supply Units are hot-

swappable.

• Power Supply Unit This switch is installed with two PSUs.

• Fan Unit This switch is provided with one Fan Unit.

LED Details

POWER

STATUS

READY

CHECK

• POWER LED Lights to indicate the status of the PSU.

• STATUS LED Lights to show the status of the Fan Unit.

• READY LED Indicates the operational state of the switch.

• CHECK LED Lights orange when the switch detected an abnormal operating condition. This may

indicate that the switch has failed. Consult with your Fujitsu or Fujitsu's certified

support engineer immediately to correct this condition.

22

Items in the Package, Descriptions and Functions

Page 23

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

LED Functions/Behaviors

LED Name State Status

POWER Green PSU is in normal operation.

Off A problem has occurred with the PSU.

STATUS Green The Fan Unit is operating normally.

Green Blinking A problem has occurred with the Fan Unit.

Off Fan Units are configured incorrectly or the power is not on.

READY Green Switch has started up correctly. The switch is operating correctly if the CHECK LED is

not lit.

Green Blinking Switch is being diagnosed or operating under backup firmware. (*)

Off A problem has occurred if AC power is connected to the switch.

CHECK Orange An abnormal operating condition occurred. This may indicate that the switch has

failed. Consult with your Fujitsu or Fujitsu certified support engineer immediately to

correct this condition.

Orange Blinking Firmware in the internal flash memory of the switch is destroyed.

Off No abnormal operating conditions are detected.

* When in the system diagnositic mode the READY LED blinks Green every 0.5 second.

When in the backup firmware operating mode the READY LED blinks Green every 1 second.s

Reference

See "2.2.1 Decide Switch Access Configuration", p. 30, for detailed LED functions/behaviors under normal

operation.

23

Items in the Package, Descriptions and Functions

Page 24

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

1.1.4 Top Surface

The XG0440DC is used as an example.

The front and back direction of the rack mounting brackets attached to the side of the switch is reversed for the XG0440DC

and XG0440DCR.

RatingLabel

WarningSticker

Productlabel

PartNo.,SerialNo.

withbarcodelabel

• Rating Label This indicates the AC voltage rating of the switch.

• Warning Sticker This indicates the warning for safety use.

• Product label This indicates the CE mark and WEEE mark of the switch.

• Part No.,Serial No. with barcode label

This indicates Part No. and Serial No. with barcode of the XG series switch device.

24

Items in the Package, Descriptions and Functions

Page 25

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

1.1.5 Bottom Surface

The XG0440DC is used as an example.

The front and back direction of the rack mounting brackets attached to the side of the switch is reversed for the XG0440DC

and XG0440DCR.

ProductManufacturingLabel

• Product Manufacturing Label

This indicates the model name, serial number, manufacturing date, and Class 1 Laser

Product, etc.

25

Items in the Package, Descriptions and Functions

Page 26

XG0440DC/XG0440DCR Hardware Guide Chapter 1 Getting Started

1.2 Option

1.2.1 SFP+ Modules

SFP+ modules (10GBASE-SR/10GBASE-LR) are available for use.

Reference

"2.3.3 Connecting Twisted Pair Cable / SFP+ Module", p. 35.

User's Guide " SFP+ Module", p. 26.

26

Option

Page 27

Chapter 2

Installation

This chapter describes how to install the switch and connect it to a Console PC.

2.1 Requirements for Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1.1 Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.1.2 Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Installation of the switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2.1 Decide Switch Access Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3 Connecting the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.1 Discharging Twisted Pair Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.2 Cleaning SFP+ Module / Optical Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.3.3 Connecting Twisted Pair Cable / SFP+ Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.3.4 Plugging in the USB Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.4 Connecting a Setup PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.5 Time Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.6 Set up IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.7 Turn On/Turn Off the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7.1 Turn on the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.7.2 Turn off the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 28

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.1 Requirements for Installation Environment

Before installing the switch, please check the following:

• Make sure that the switch and all the other options shown in this document are available for installation.

• All the cables comply with the specifications of the interface connectors.

Warning

Do not connect cables to interface connectors other than those compatible with the connector's

specifications.

Reference

Install the product under the following environmental conditions.

"1.1.1 Parts List", p. 17.

2.1.1 Installation Requirements

Caution

Install the product under the following conditions. Using the product outside the required

environment may cause failure of the product.

Temperature and Humidity Requirements

Temperature (degrees C) Humidity (%RH)

Operation 0 to 40 15 to 85

Non-operation 0 to 50 8 to 90

Power Requirements

Item Requirements

Vol tage AC90V-264V

Frequency 50Hz / 60Hz +2%, -4%

Ground

Electricity AC input more than 102W

Inrush Current

Separate ground wire from air conditioners and building, and D-class grounding

with ground resistance of 100

Maximum 100A

Ensure installation environment that avoids lowering voltage to power supply

equipment at the time of power-on due to the inrush current, although there's no

impact from the inrush current in normal use.

Ω or less.

28

Requirements for Installation Environment

Page 29

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Installation Requirements

The product is specifically designed for rack-mounting.

Check-list

Check the following items.

Check Item Check Result

Nothing is put on the switch.

Vents are not obstructed.

The switch is not located on a table or stacked atop another switch.

The switch is not located under direct sunshine, near heating appliance, under high humidity

or in a dusty area..

The switch is not located on unstable places where vibrating, or tilting.

"About Warning Descriptions" has been thoroughly read p. 9.

Reference

Reference

2.1.2 Space Requirements

When installing the switch and providing maintenance, ensure the space below is maintained.

Ensuring the Space for Installation (Maintenance) of the Switch

The internal cooling fans require unobstructed airflow at both the Port and Fan Unit sides of the switch. Ensure adequate

clearance for maintenance as indicated in the diagram and that airflow is unobstructed.

800mm

Backspacefor

themaintenance

rack

150mm

ormore

300mmormore

Spaceforthe

maintenance/

installation

XG0440

300mmormore

Spaceforthe

maintenance/

installation

19"rack

Depth

90mm

ormore

800mm

Frontspacefor

themaintenance

19"rackWidth

29

Requirements for Installation Environment

Page 30

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.2 Installation of the switch

This section describes how to install the switch.

2.2.1 Decide Switch Access Configuration

The switch is specifically designed for rack-mounting.

The XG0440DC is used as an example.

The front and back direction of the rack mounting brackets attached to the side of the switch is reversed for the XG0440DC

and XG0440DCR.

The XG0440DC is mounted in a rack so that the port side of the switch is located at the front.

The XG0440DCR is mounted in a rack so that the power inlet side of the switch is located at the front.

Decide positions for rack mounting brackets

1. Decide positions of rack mounting brackets.

The switch can be installed flush to or offset from the front of the rack. To offset mount the switch move the position of the

rack mounting forward fro the face of the switch.

[STANDARD]

[OFFSET]

RackMountingBrackets

30

Installation of the switch

Page 31

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Install the switch in a 19” rack

The switch can be installed and operated in the EIA standard 19" rack.

Prepare the following rack mounting components attached.

• Rack Mounting Rails (1 set): Rails for mounting the switch in a rack.

• M6 Countersunk Screws (Qty 4)

• M6 Machine Screws (Qty 6)

Reference

"1.1.1 Parts List", p. 17.

Precautions

• Please locate the switch near the electrical outlet to which the power cable will be connected and allow sufficient

space for the power cable to be pulled out easily.

• Check that the ambient air temperature inside and outside of the rack is within the specified operating temperature

range of the switch.

• Check that airflow in and out of the switch is unobstructed.

• Ensure physical stability of the whole rack when the switch is installed.

• Check that the capacity of the power source to the switch is sufficient for safe operation.

• Ensure a good electrical ground connection exists before connecting power to the switch. Assure power sourcing

and leakage current carrying capabilities of the power source are not exceeded.

The maximum current leakage for the switch is 3.5 mA.

Installation procedure is described below.

1. Fasten the rack mounting rails to the rack posts.

Loosen the M4 screws fastened to the rail brackets and adjust the length of the rails for the depth of the rack, Position the

rails within the rack one at a time and fasten to the rack with the M6 screws provided.

Use two M6 screws at each end of the rails. . Once the rails are installed in the rack, tighten the M4 screws.

M6

MachineScrews

M4MachineScrews

M6

MachineScrews

M6CountersunkScrews

M6CountersunkScrews

31

Installation of the switch

Page 32

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2. Slide the switch on to the rails in the rack, Secure the switch to the rack using two M6 screws at the

front of the rack.

The XG0440DC is mounted in a rack so that the port side of the switch is located at the front.

The XG0440DCR is mounted in a rack so that the power inlet side of the switch is located at the front.

M6MachineScrews

M6MachineScrews

Precautions

Devices mounted imediately atop and beneath the switch may block installation of the switch power cable. In that case,

plug the power cable into the switch before installing it in the rack.

32

Installation of the switch

Page 33

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.3 Connecting the Equipment

We recommend discharging static electricity of twisted pair cable before connecting it to the switch.

Also see below for how to install USB memory.

2.3.1 Discharging Twisted Pair Cable

Discharge static electricity of the twisted pair cable through the ground wire cable (ground wire for power supply,

buildings, etc.) using static electricity removal tool, before connecting twisted pair cable to the switch.

Precautions

• Unplug both ends of the twisted pair cable from equipments (HUB, router, and workstation) during discharging

operation.

• Do not use ground wire of electronic devices. Use grounded cable for power supply or buildings.

• Do not short circuit with AC power supply when using ground wire for power suppl.

2.3.2 Cleaning SFP+ Module / Optical Connector

When invisible small dust is adhered to SFP+ module /optical connector, optical signal will be shut or space caused by dust will

impede transmission of optical signal.

Therefore, clean up SFP+ module /optical connector before connection.

Cleaning of SFP+ Module

1. Blow dust away with cleanly dry air or nitrogen.

Check end face, and conduct operation below if dust is left.

2. Lightly dampen a cleaning stick (1.25mm across, for LC/MU) with isopropyl alcohol. After wiping off

dust, slowly and carefully wipe off alcohol with a new and dry cleaning stick.

3. Insert a cleaning stick to the optical connector insertion part of SFP+ module, and slowly wheel it.

SFP+module

cleaningstick

4. Insert and slowly wheel a new cleaning stick, and dry the SFP+ module.

5. Check if the dust is removed with 200-fold magnification fiber scope.

33

Connecting the Equipment

Page 34

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Cleaning of Optical Connector

1. Remove the connector guard cap of optical fiber part, and check the connector end face.

If the end face is not clean, clean it with a reel type fiber cleaner.

2. Push thumb holder of a fiber cleaner and open a cap of the fiber cleaner.

3. When a cap slides and a new cleaning tape comes out, lightly apply the end face to a cleaning tape.

4. Apply the end face of the connector and rotate it (quarter turn four times).

5. Apply the end face to the cleaning tape, and move it to forward direction of a fiber cleaner.

Caution

Do not friction the end face to the cleaning tape. It will cause micro dust or scratch.

6. Take thumb holder off, and close a cap of a fiber cleaner.

7. Check the end face and continue cleaning if necessary.

Removal of Micro Dust

Remove micro dust on the optical fiber part following the method below if necessary.

1. Wipe the optical fiber part with ethanol or cleaning fluid.

2. Softly and slowly wipe the optical fiber part with cleaning fabric.

3. Wipe with a new cleaning stick in the same fashion, and dry the optical connector.

Caution

• Do not use fluid such as bleach because it will damage optical coupling.

• Use ionizer when cleaning in order to avoid the ESD damage to SFP+ module.

• SFP+ module cannot be washed with water. Do not use or clean SFP+ module in a wet space such

as bathroom or kitchen.

• Carefully treat SFP+ module as it sometimes becomes very hot.

Precautions

• Do not use alcohol, spray, and cotton swab for cleaning of optical connector other than special optical connector

cleaner because dust on the end face of the optical connector plug may not be completely wiped off and more dust

may adhere.

• Immediately connect optical connector to the switch after cleaning. Dust will adhere when the optical connector is

left unconnected.

• Keep the connector guard cap fixed before using SFP+ module in order to avoid contamination.

• When SFP+ module is contaminated, check end face and clean only if necessary.

• If a lot of fluid is used, it will possibly be accumulated or leak out because SFP+ module is not hermetically closed.

34

Connecting the Equipment

Page 35

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.3.3 Connecting Twisted Pair Cable / SFP+ Module

Below is how to connect twisted pair cable and SFP+ module.

Use the crossover cable when connecting with routers and terminals. Use the straight cable in case of cascading connection

with other switching HUBs with transmission mode at fixed setting other than auto negotiation.

straightcable

crossovercable opticalcable

Management port of the switch is set auto negotiation enable by default.

(However, SFP+ slots only support 10Gbps full duplex mode fixed setting.)

Ports automatically apply to the maximum speed that plugged equipment supports by the auto negotiation function.

• 100BASE-TX port : Up to maximum 100Mbps full duplex mode

The Management Port is MDI fixed. If a device that has a MDI fixed port is to

be connected to the Management Port, please use a UTP Crossover Cable.

Connecting Twisted Pair Cable

Insert twisted pair cable to 10/100BASE-TX port until it clicks.

Twisted

PairCable

Precautions

• Usable twisted pair cables are unshielded twisted pair cable (UTP) over category 5E and shielded twisted pair cable

(STP).

• Discharge twisted pair cable before connecting as twisted pair cable may be charged static electricity. Refer "2.3.1

Discharging Twisted Pair Cable", p. 33, for discharging method.

35

Connecting the Equipment

Page 36

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Connecting SFP+ Module

Firmly install SFP+ module to SFP+ slot and lock module to the switch.

SFP+module

Precautions

• SFP Module (100BASE-FX, 1000BASE-SX/LX, etc.) cannot be installed.

• Safely keep a guard cap of SFP+ module.

• Make sure to clean the end face of SFP+ module / optical cable before connecting optical connector because the

end face may possibly be contaminated.

• Do not directly touch the contact part of SFP+ module by hands. Use wristbands when touching SFP+ module.

• Connecting part to the optical cable of SFP+ module is the laser opening.

There are two types of SFP+ modules, bale latch type and standard latch type.

Below is how to connect.

• Bale Latch Type

Insert SFP+ module to the SFP+ slot with a lever locked, and lock the module and the switch.

Connect optical cable (connector shape: DLC) after inserting SFP+ module to the SFP+ slot.

When removing SFP+ module, unlock the lever, module and the switch, and remove the module after unplug the

optical fiber.

Lever

• Standard Latch Type

Insert SFP+ module to the SFP+ slot, and lock the module and the switch.

Connect optical cable (connector shape: DLC) after inserting SFP+ module to the SFP+ slot.

When removing SFP+ module, remove the module after pressing a tab to unlock the module and the switch.

Tab

36

Connecting the Equipment

Page 37

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Precautions

Cable length will be as below based on the specification of the optical fiber cable.

Typ e Core/Cladding Diameter Minimum Transimission Band Cable Length (m)

MMF 62.5/125

50/125

Use the appropriate cable according to the installation place.

µm160MHz/km 26

200MHz/km 33

µm400MHz/km 66

500MHz/km 82

2000MHz/km 300

37

Connecting the Equipment

Page 38

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.3.4 Plugging in the USB Memory

USB memory can be plugged in from the port side of the switch.

Caution

Do NOT unplug out the memory stick during access. It may result in crashing setting data.

Precautions

It is possible to plug/unplug SFP+ module with the power on.

Plug in the USB Memory

Please refer to the following instructions;

1. Firmly insert the USB memory to USB port on the Port side of the switch.

USBMemory

Replacing the USB Memory (Unplug)

Please refer to the follow instructions;

1. Make the USB port to "disable status" using the console command.

# usbctl disable

2. Check and confirm that USB port is in a "disable status".

Execute command "show usb hcd status", and check and confirm that the status is displayed as "disable".

# show usb hcd status

[USB HCD STATUS]

status : disable

3. Unplug the USB memory from the switch.

This completes detaching the USB memory from the switch.

Note

4. Plug in the replacing USB memory onto the switch.

5. Release the "disable status" of the USB port using the console command.

# usbctl enable

38

Connecting the Equipment

Page 39

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.4 Connecting a Setup PC

This is to connect a set up PC to the console port of the switch using RS232C cable.

Necessary Hardware / Software

Please prepare the hardware & software specified below to connect to the switch.

• Personal Computer

1 unit of personal computer for setting up configuration is required.

• RS232C crossover (null modem), D-SUB9F to D-SUB9F cable.

A RS232C cable is required to connect the set up PC to the switch.

A RS232C crossover cable is not provided with the switch.

The console cable adapter which is included in this product is used with the RS232 cable to connect the set up PC to

the switch.

Reference

• Communication Software

Terminal emulation software is required.

User's Guide "1.1.5 Console Port Specifications", p. 29.

Connect RS232C Cable

1. Connect the PC and the RS232C cable.

2. Connect the RS232C cable and the console cable adapter which is included in this product, and

firmly fix them with the screw.

3. Plug in the RJ45 plug of the console cable adapter to the console port of the switch.

39

Connecting a Setup PC

Page 40

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

Turn On the Po wer

If the power of the switch is off, turn it on.

Reference

It is not necessary to turn off the power when connecting or removing the console cable adapter.

Note

"2.7 Turn On/Turn Off the Power", p. 43.

Prepare a Setup PC

Log on using the terminal software.

1. Start up the terminal software by using the set up PC.

2. Set the setting conditions to the following;

Setup Items

Star t Bit 1

Data Bit 8

Parity Bit n/a

Stop Bit 1

Synchronous System Asynchronous Communication System (Start-Stop Communication System)

Communication Speed 9600

Flow Control None

Number of digits on screen 80 (If other than 80 digits, set it through terminal command)

Number of rows on screen 24 (If other than 24 rows, set it through terminal command)

Please refer to the terminal software manual for instructions on setting conditions.

3. Press [Return] key or [Enter] key.

Precautions

The following message may appear When pressing the [Return] key or [Enter] key. In such case, the switch is

processing another job, and waiting for such process to finish. Please wait for a moment until it finishes such process.

Waiting for completion of the other operation...

4. Confirm "Login :" on screen.

5. Key in "admin" and press [Return] key or [Enter] key.

6. Confirm "Password:" on screen

7. Key in password, then press the [Return] key or [Enter] key.

Since password is not set at the initial state, simply press [Return] key or [Enter] key without keying in the password.

If the password is already set, key in the password. Then press [Return] key or [Enter] key.

8. Confirm "#" is shown on screen.

If the wrong password is entered, "invalid password." will be displayed, then the "Login :" prompt will be displayed again.

Go to step 5 and repeat the login process if it was unsuccessful.

40

Connecting a Setup PC

Page 41

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.5 Time Setting

It is strongly recommended that the date and time be set before configuring other switch settings. The date and time are not

set at the factory.

Please refer to the following command sequence for setting the date and time manually using a console or telnet session.

z Command

When setting time and date to be "Jan 1, 2011 12:30:00am" type in command

# date 2012/01/01.12:30:00

XG0440DC# configure Switch to Configuration mode.

XG0440DC(config)# time zone -0500 When setting time zone to be "-0500".

XG0440DC(config)# commit Apply the configuration.

XG0440DC(config)# save Save the configuration.

XG0440DC(config)# exit Switch to Operation mode.

XG0440DC# date 2011/01/01.12:30:00 Set time and date to be "Jan 1, 2012 12:30:00am".

Precautions

If the power switch is left turned off for 72 hours or more, information about the date and time is lost.

41

Time Setting

Page 42

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.6 Set up IP address

Please set the IP address at times when it is required.

Eg. When setting the switch through www browser or installing a firmware from the initial state of the purchase.

The following commands show how to set up the IP address (ex. 192.168.1.1)

z Command

XG0440# configure

XG0440DC(config)# lan 0 ip address 192.168.1.1/24 3

XG0440DC(config)# lan 0 vlan 1

XG0440DC(config)# commit

XG0440DC(config)# exit

XG0440DC#

Precautions

The IP address is not set at the initial state of the purchase. Please set the IP address through a console session.

42

Set up IP address

Page 43

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

2.7 Turn On/Turn Off the Power

The following describes the method for turning on and turning off the power of the switch.

Caution

• Please use the power cable included in this product. Also, please do NOT use this power cable

on other products.

• If the power outlet does not match with the power cable plug, please use the change plug

adapter.

As a safety measure to prevent electrical shocks, please make sure to connect the ground wire

of the change plug.

Precautions

• Please set the switch (product) to a place near the electrical outlet which the power cable will be connected and

secure a space for the power cable to be pulled off easily.

• Please connect a power cable to PSU1 first, then PSU2.

If power cables are not connected in this order, the CHECK LED will light orange. If the CHECK LED is lit, delete the

error log using the console command after turning on the power of the switch.

# clear logging error

#

Reference

• When turning off the power. Please follow the above steps in an opposite order.

User's Guide "5.18.1.5 clear logging error", p. 372.

2.7.1 Turn on the Power

1. Connect the power cable to the electrical outlet.

2. Plug in the power cable to the power connecter of PSU1.

Power will turn on.

43

Turn On/Turn Off the Power

Page 44

XG0440DC/XG0440DCR Hardware Guide Chapter 2 Installation

3. Power LED of PSU1 and PSU1 LED of the switch will light in green.

Next, plug in the power cable to the power connecter of PSU2.

The Power LED of PSU2 and PSU2 LED of the switch will light in green.

PSU1

PSU2

POWER

2.7.2 Turn off the Power

When turning off the power. Please follow the above steps in an opposite order.

44

Turn On/Turn Off the Power

Page 45

XG0440DC/XG0440DCR Hardware Guide Index

Index

Number

10/100/1000BASE-T Port ........................................ 18

B

Bottom Surface ......................................................... 25

C

CD-ROM .................................................................. 17

CHECK LED ..................................................... 20, 22

Communication Software ......................................... 39

Connecting the Equipment ....................................... 33

CONSOLE Cable Adapter ....................................... 17

Console port ............................................................. 39

CONSOLE Port (Console Connection) ................... 19

D

Dump Switch ............................................................ 19

E

ERROR LED ............................................................ 20

F

FAN LED ................................................................. 20

Fan Unit .................................................................... 22

FDX LED ................................................................. 20

FLASH LED ............................................................ 20

H