Fujitsu Waterstage WOYG160LJL, Waterstage WOYK150LJL, Waterstage WSYK170DJ9, Waterstage WOYK170LJL, Waterstage WSYG160DJ6 Installation Manual

U0651595_2011_EN_2

10/09/2019

Outdoor unit

WOYG160LJL

WOYK150LJL

WOYK170LJL

Hydraulic unit

WSYG160DJ6

WSYK170DJ9

INSTALLATION

Air to Water Heat Pump Split single service

For professionals. To be kept by the user for future reference

EN

■ Installation and maintenance rules

The appliance must be installed and maintained

by an approved professional in accordance with

current regulations and codes of practice.

• Warning, hydraulic unit should not be installed

in an air current.

■ Handling

The outdoor unit must not be placed in a horizontal

position during transport.

If not kept upright during transport, the appliance

could be damaged through displacement of

the refrigerant and damage to the compressor

suspension.

Any damage caused by transportation in a horizontal

position is not covered by the warranty.

If necessary, the outdoor unit may be tilted only

during manual handling (to go through a door or up

a staircase). This operation must be conducted very

carefully and the appliance must be immediately

restored to the upright position.

■ Containment of refrigeration circuits

All refrigeration circuits are sensitive to contamination

from dust and moisture. If such pollutants penetrate

the refrigeration circuit, they can aect the reliability

of the heat pump.

Make sure that the connections and refrigeration

circuits (hydraulic unit, outdoor unit) are

protected correctly.

In the event of a subsequent failure and following

an inspection, the presence of moisture or

foreign bodies in the compressor oil would

automatically void the warranty.

- Check upon receipt that the ttings and refrigeration

circuit caps mounted on hydraulic unit and outdoor

unit are properly seated and secured (cannot be

loosened with bare hands). If this is not the case,

tighten them using a C spanner.

- Check also that the refrigeration connections are

sealed (plastic caps or tubes crimped at the ends

and brazed). If the caps must be removed during

the installation (tubes to be re-cut for example),

put them back as soon as possible.

■ Hydraulic connections

The connection must comply with industry standard

practice according to current regulations.

Remember: Seal everything when tting in

accordance with industry standard practice for

plumbing work:

- Use suitable seals (bre gasket, O-ring).

- Use Teon or hemp tape.

- Use sealing paste (synthetic depending on the

case).

Use glycol/water mix if the minimum ow

temperature is set below 10°C. If you are using a

glycol/water mix, arrange for an annual check on the

quality of the glycol. Use monopropylene glycol only.

The recommended concentration is 30% minimum.

Never use monoethylene glycol.

• In some installations, the presence of dierent

metals can cause corrosion problems; the

formation of metal particles and sludge can

appear in the hydraulic circuit.

• In this case, it is advisable to use a corrosion

inhibitor in the proportions indicated by the

manufacturer.

• You must also ensure that treated water does

not become corrosive.

■ Electrical connections

2

1

3

• Before any maintenance operation, ensure

that the general power supply is switched o.

• Specications of electricity supply

The electrical installation must be carried out in

accordance with prevailing rules.

Electrical connections will only be made once all

other installation operations (fastening, assembly,

etc.) have been completed.

Warning!

The contract signed with the energy provider must

be sucient not only to cover the heat pump's power

requirements but also the combined sum of all the

appliances likely to be operating at the same time. If

the power is too low, check the power rating stated

in your contract with your energy provider.

Never use a power socket for the power supply.

The heat pump must be supplied directly with power

(without external switch) by special protected leads

from the electric panel via dedicated bipolar circuit

breakers, C curve for the outdoor unit, C curve for

the electrical heating and domestic water backups

(see tables page 35).

The electrical installation must be tted with a 30mA

RCD.

This appliance is designed to operate using a

nominal voltage of 230 V or 400 V, +/- 10%, 50 Hz

(depending on model).

• General remarks on electrical connections

It is essential to maintain neutral-phase polarity

when making electrical connections.

Rigid wires are preferable for xed installations,

particularly in a building.

Tighten the cables using the cable glands to prevent

the feed wires from being accidentally disconnected.

The earth connection and its continuity must be

ensured.

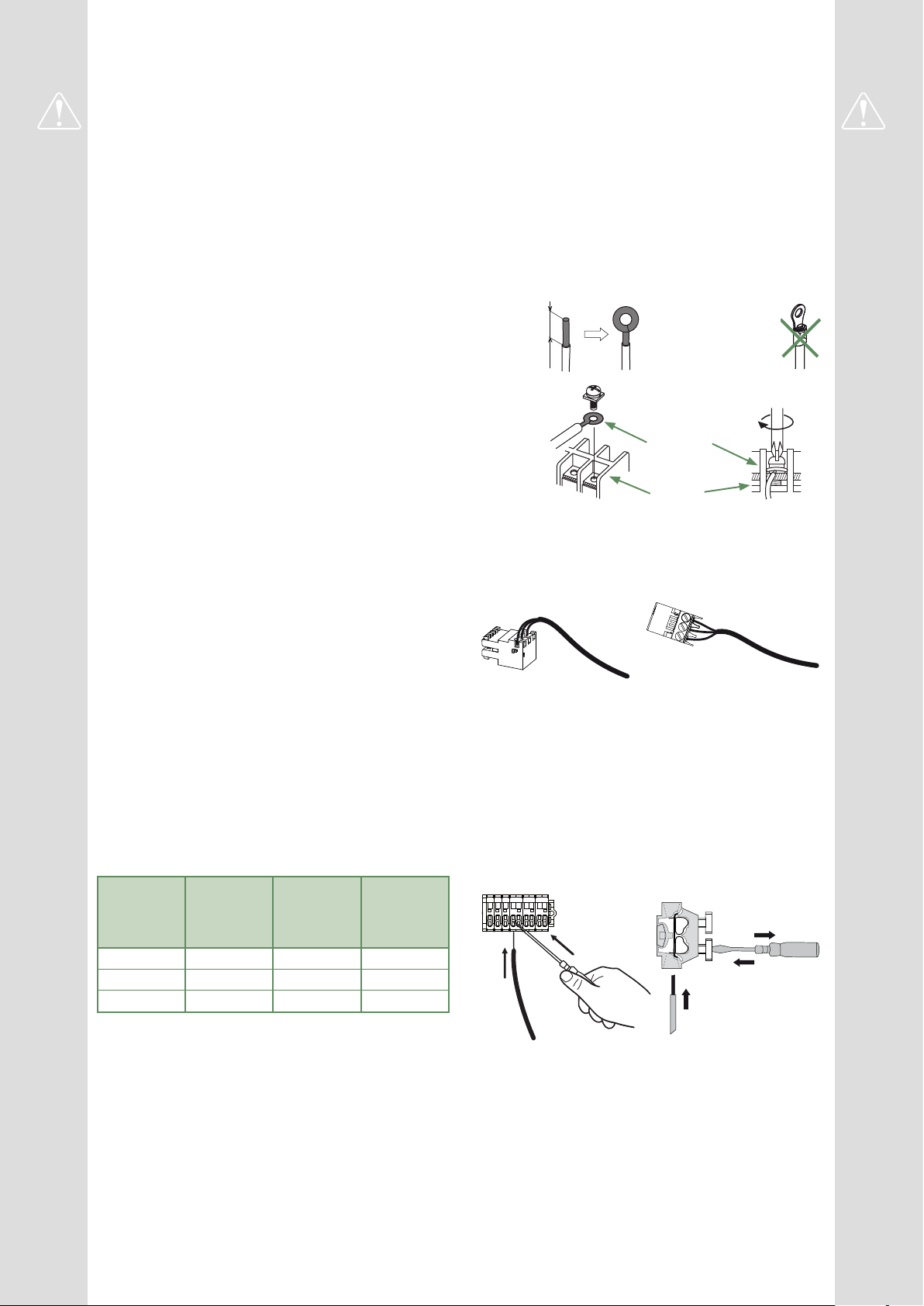

• Cable glands

To ensure the stability of power (Low Voltage) and

sensor (Extra-Low Voltage) cables, it is essential

that the cable glands are tightened according to the

following recommendations:

Size of cable

gland (PE)

(mm)

PG7 1 to 5 1.3 1

PG9 1.5 to 6 3.3 2.6

PG16 5 to 12 4.3 2.6

Diameter of

cable

(mm)

Cable gland

tightening

torque

(check-nut)

(N.m)

Coupling net

tightening

torque

(N.m)

• Connecting to screw terminals

The use of ring, spade or blade terminals or

caps is prohibited.

- Always select wire that complies with current

standards.

- Bare the end of the wire to around 25 mm.

- With round end pliers, form a loop with a diameter

which matches the tightening screws on the

terminal.

- Tighten the terminal screw rmly onto the

loop created. Insucient tightening can cause

overheating, leading to breakdown or even re.

Rigid wires

25 mm

Loop

Lug on

exible wires

prohibited

Screw and special

washer

Terminal

• Connecting to controller boards

- Remove the corresponding connector and make

the connection.

Pre-cabled bundle connector and/or screw connector

• Connecting to spring terminals

- Bare the end of the wire to around 12 mm.

- Push the spring with a screwdriver so that the wire

enters the cage.

- Slide the wire into the opening provided for this

purpose.

- Remove the screwdriver and then check that the

wire stays gripped by the cage by pulling on it.

This appliance must be installed by qualied personnel holding a certicate of competence in the

handling of refrigerants.

Contents

Description of the equipment 6

Packing .................................6

Unpacking and supplies ....................6

Denitions ...............................6

Optional equipment ........................6

Operating Range ..........................6

General characteristics .....................7

Description .............................12

Operating principle .......................14

Installation 16

Installation of refrigeration connections ........16 Installation of the outdoor unit ...............18

Installation of the hydraulic unit ..............20

Refrigeration connections 22

Rules and precautions .....................22

Shaping the refrigeration pipes ..............22

Checks and connection ....................25

Filling the installation with gas ...............26

Hydraulic connections 30

Connecting the hydraulic unit to the heating circuit ..30

Filling and bleeding the installation ...........31

Heating circulation pump speed settings .......32

Electrical connections 34

Cable dimensions and protection rating .......35

Outside sensor ..........................42

Electrical connections on the outdoor unit side ..36

Electrical connections on the hydraulic unit side ..38

Room sensor (optional) ....................42

Commissioning 44

Controller Interface 46

User Interface ...........................46

Display Description .......................47

Installer Menu ...........................48

- 4 -

Navigating the Menus .....................48

Modifying Settings ........................49

Temperature control ......................50

Waterstage / Installation / 2011 - EN

Controller Menu 52

Menu Structure ..........................52

Installed options .........................53

Hydraulic conguration ....................53

Heat Pump Conguration ..................58

System status ...........................60

Auxiliary functions ........................62

Settings ................................64

Easy Start ..............................68

Basic Hydraulic Layout 70

Electrical Cabling Plans 72

Fault Diagnosis 76

Faults in the Hydraulic Unit .................76 Faults in the Outdoor Unit ..................77

Maintenance of the installation 78

Hydraulic checks .........................78

Checking the outdoor unit ..................78

Electrical checks .........................78

Other maintenance 79

Emptying the hydraulic unit .................79 Distribution valve .........................79

Quick-start procedure 80

Start-up check-list ........................80 Commissioning technical datasheet ..........82

Instructions for the end user 83

Waterstage / Installation / 2011 - EN

- 5 -

Description of the equipment

Packing

►

• 1 package : Outdoor unit.

• 1 package : Hydraulic unit and outside temperature

sensor.

Unpacking and supplies

►

While the courier is still present, carefully check the

general appearance of the appliances and check

that the outdoor unit has not been laid in a horizontal

position.

In the event of a dispute, send any relevant reservations

to the carrier in writing within 48 hours and send a copy

of the letter to Customer Services.

Packing contents list

Heat Pump Outdoor unit Hydraulic unit

Model Reference Code

Waterstage SHP 16 WOYG160LJL WSYG160DJ6

Waterstage SHP TRI 15 WOYK150LJL

Waterstage SHP TRI 17 WOYK170LJL

Denitions

►

- Split: The heat pump consists of two elements

(an outdoor unit to be installed outdoors and a hydraulic

unit to be installed inside the dwelling).

- Air/water: The surrounding air is the energy source.

This energy is transmitted to the heating circuit water

by the heat pump.

- Inverter: The fan and compressor speeds are

modulated according to the heating requirements.

This technology enables you to save on energy and

operate on a single-phase power supply, whatever

the heat pump's output, by avoiding pulling signicant

amounts of current at start-up.

- COP (Coecient of Performance): This is the

relationship between the energy transmitted to the

heating circuit and consumed electrical energy.

WSYK170DJ9

Optional equipment

►

• Dual circuit kit (code UTW-KZSXJ)

for connecting 2 heating circuits.

• Regulation extension kit (code UTW-KREXD)

to manage a 2nd heating circuit, swimming pool,

telephone modem etc...

• DHW kit (code UTW-KDWXD)

for connecting a mixed DHW tank

(with built-in electrical backups).

• Boiler connection kit (code UTW-KBSXJ)

for connecting a boiler to the heat pump.

• Room thermostat (code UTW-C55XA),

Wireless room thermostat (code UTW-C58XD)

for correcting the ambient temperature.

• Remote control (code UTW-C74TXF or UTW-C74HXF),

Wireless remote control (code UTW-C78XD)

for correcting the ambient temperature and

programming the heat pump.

• Cooling kit (code UTW-KCLXD).

• High ow rate circulation pump kit (code UTW-PHFXG)

for the installation of 1 underoor heating circuit.

Operating Range

►

This heat pump provides:

- Heating in winter,

- The management of electrical backups, for extra

heating on the coldest days,

or

- Installation with boiler connection* for extra heating on

the coldest days,

- Management of two heating circuits*,

- Production of domestic hot water* (provided that it is

combined with a mixed DHW tank),

- Cooling in summer* (for underoor heating-cooling

system or fan-convectors).

*: These options require the use of additional kits

(see chapter "Required accessory" or "Optional equipment").

- 6 -

Waterstage / Installation / 2011 - EN

General characteristics

►

Model name Waterstage SHP 16 TRI 15 TRI 17

Rated heating performances (outdoor temp. / ow temp.)

Heat output

+7°C/+35°C - Underoor heating system kW 16.00 15.00 17.00

-7°C/+35°C - Underoor heating system kW 14.50 13.20 15.00

+7°C/+55°C - Radiator kW 14.50 13.20 15.00

-7°C/+55°C - Radiator kW 10.90 13.20 14.20

Power consumption

+7°C/+35°C - Underoor heating system kW 3.86 3.46 4.10

-7°C/+35°C - Underoor heating system kW 5.27 4.55 5.32

+7°C/+55°C - Radiator kW 5.58 4.77 5.49

-7°C/+55°C - Radiator kW 5.89 6.77 7.40

Coecient of performance (COP) (+7°C/+35°C) 4.15 4.33 4.15

Electrical specications

Electrical voltage (50 HZ) V 230 400 400

Maximum current for appliance A 28 14 14

Nominal current A 17.2 6.43 7.4

Maximum current of the Heating system electrical backup A 26.1 39 39

Power of the Heating system electrical backup kW

6 kW

(single phase)

9 kW

(3-phase)

9 kW

(3-phase)

Circulation pump actual power consumption W 39.5 39.5 39.5

Maximum power consumed by the outdoor unit W 6300 6770 7400

Hydraulic Circuit

Maximum operating pressure MPa (bar) 0.3 (3) 0.3 (3) 0.3 (3)

Available heating pressure at nominal point +7°C / +55°C (Δt8) MPa (bar) 0.05 (0.5) 0.055 (0.55) 0.045 (0.45)

Minimum allowed hydraulic ow rate l/h 600 600 600

Miscellaneous

Weight of outdoor unit Kg 137 138 138

Noise level at 5 m 1 (Outdoor unit) dB (A) 45 45 45

Sound power level in accordance with EN 12102 2 (Outdoor unit) dB (A) 67 67 67

Weight of hydraulic unit (empty / full of water) Kg 53 / 75 53 / 75 53 / 75

Hydraulic unit water capacity l 30 30 30

Noise level at 1 m 1 (Hydraulic unit) dB (A) 37 37 37

Sound power level in accordance with EN 12102 2 (Hydraulic unit) dB (A) 45 45 45

Heating system operating limits

Outdoor temperature min/max °C -25 / +35 -25 / +35 -25 / +35

Max. heating water ow temperature underoor heating °C 45 45 45

Max. heating water ow temperature low temperature radiator °C 60 60 60

Min. ow water temperature °C 8 8 8

Refrigeration circuit

Gas pipe diameters Inches 5/8 5/8 5/8

Liquid Piping Diameters Inches 3/8 3/8 3/8

Factory ll of refrigerant R410A 3 g 3800 3800 3800

Maximum operating pressure MPa (bar) 4.15 (41.5) 4.15 (41.5) 4.15 (41.5)

Minimum / Maximum length of pipes

Maximum length of pipes

5

Maximum level dierence

(Outdoor unit over hydraulic unit and heating only / Other cases)

4 / 6

m 5 / 15 5 / 15 5 / 15

m 30 30 30

m 25 / 15 25 / 15 25 / 15

1

Sound pressure level at (x) m from the appliance, 1.5m off the ground, open eld

directionality 2.

2

The sound power level is a laboratory measurement of the emitted sound power. It

does not correspond to a measurement of the perceived sound power.

Waterstage / Installation / 2011 - EN

3

Refrigerant R410A as per NF EN 378.1 standard.

4

Filling with refrigerant R410A is done at the factory.

5

Taking into account a possible additional ll of refrigerant R410A (see "Additional

lling", page 28).

6

The announced thermal and acoustic performances are measured with 7.5m length

refrigerant lines.

- 7 -

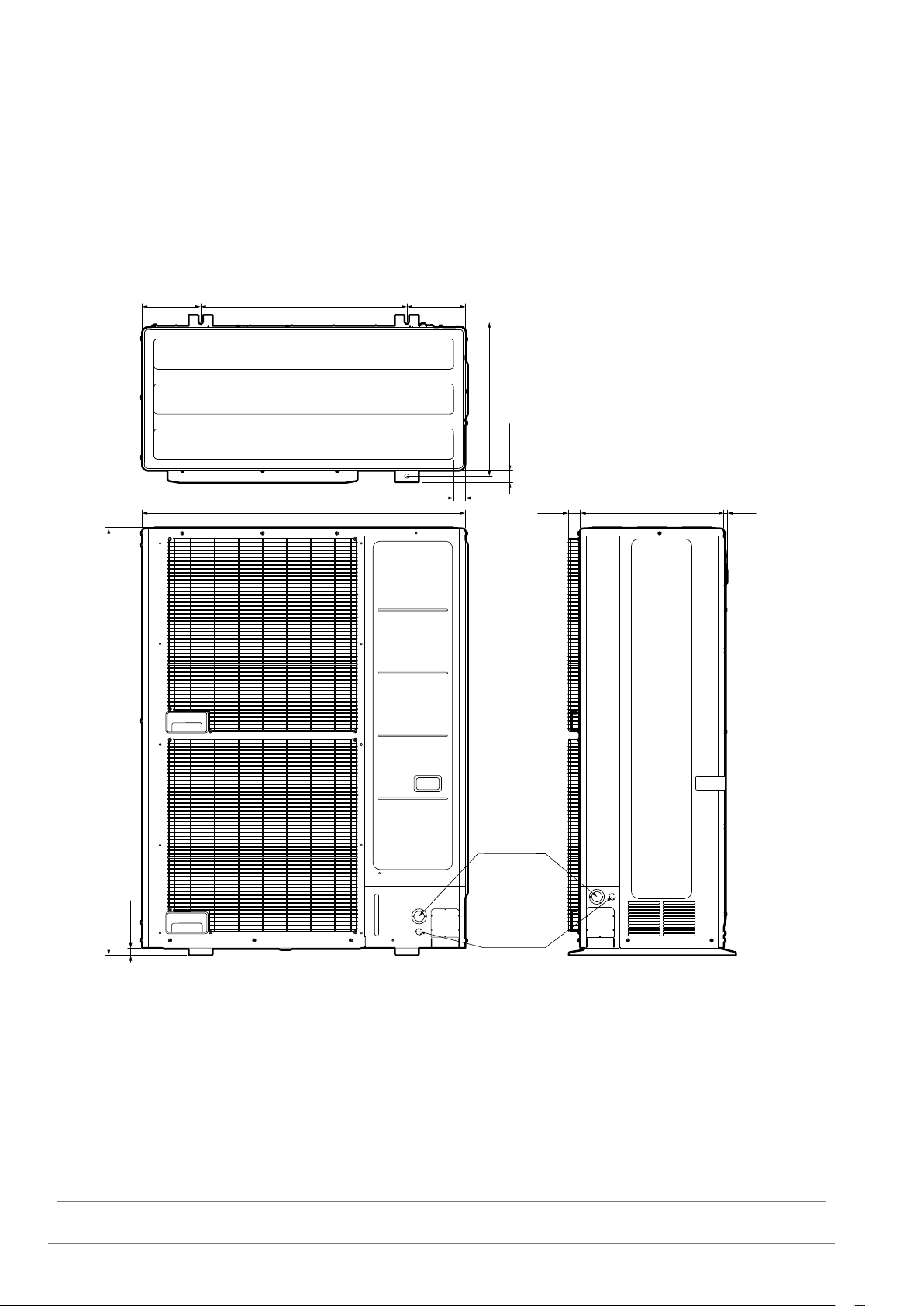

■ Waterstage SHP 16

■ Waterstage SHP TRI 15

Waterstage SHP TRI 17

196 196

688

40

1080

515.5

37.7

39.3

480

12.1

1428

23.6

Ø50

Ø34.5

Ø22.2

g. 1 - Dimensions of outdoor units (in mm)

- 8 -

Waterstage / Installation / 2011 - EN

3**

4

8

7

■ Hydraulic unit

805

847

450

9897

Heating return

ø M 26x34

Space requirements of the hydraulic unit, see page 20.

g. 2 - Dimensions of hydraulic unit (in mm)

1*

Heating ow

ø M 26x34

2*

81

471

493

5 6

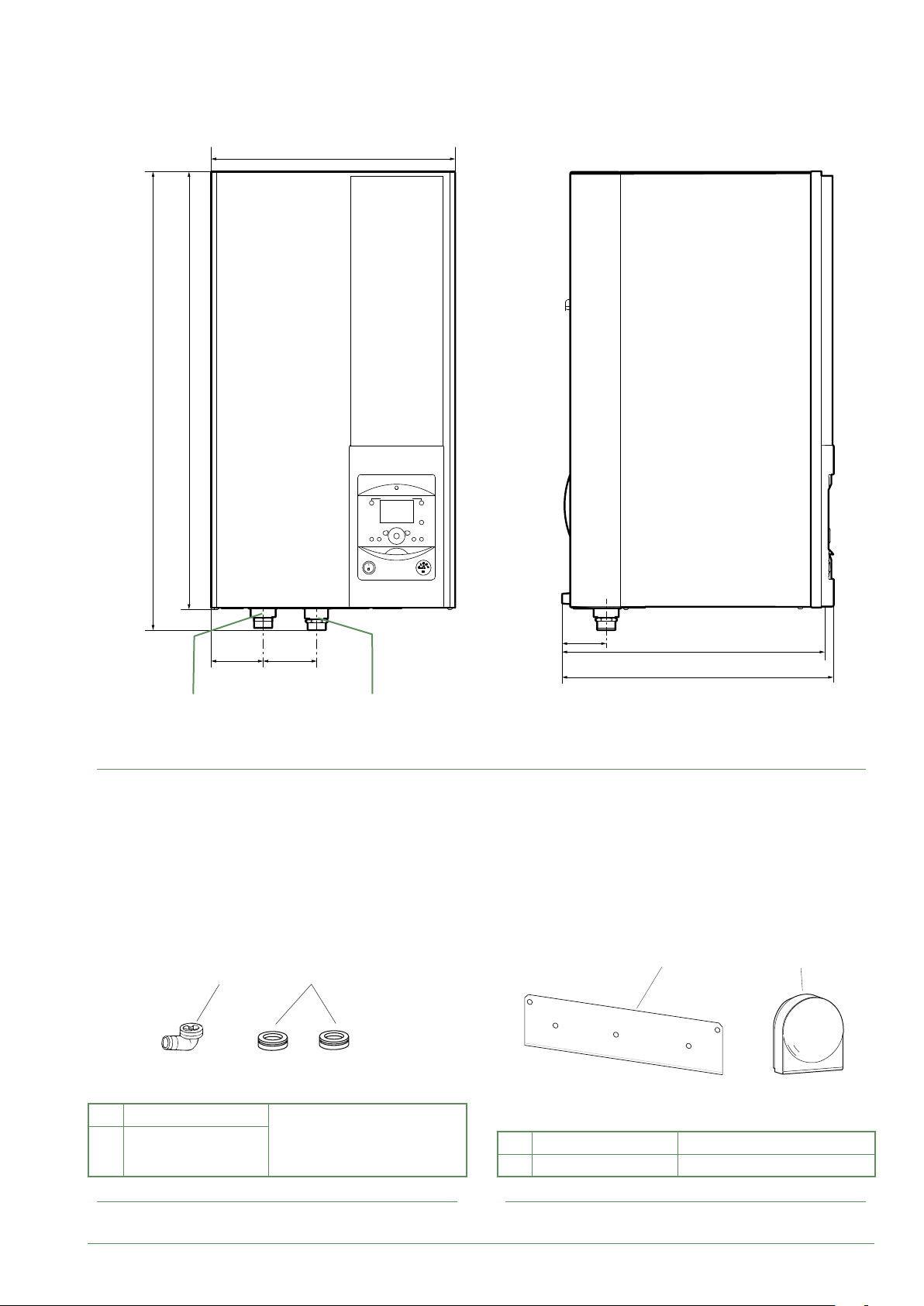

1 Elbow

Plugs (x9)

2

(depending on

model)

g. 3 - Accessories provided with the outdoor unit

Waterstage / Installation / 2011 - EN

for condensate evacuation.

5 Bracket for attaching hydraulic unit.

6 Outside sensor to monitor the outdoor temp.

g. 4 - Accessories provided with the hydraulic unit

- 9 -

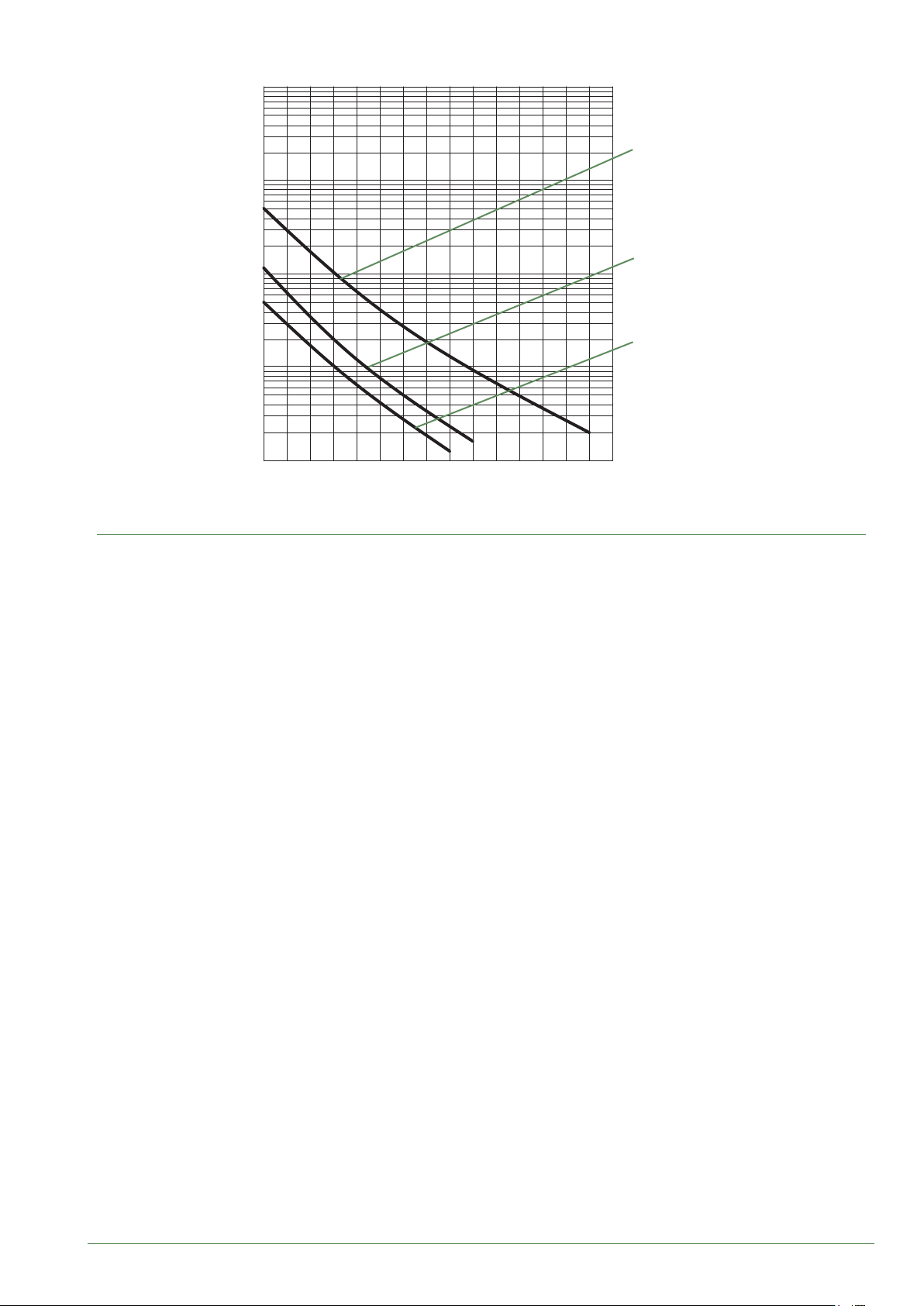

0102030405060708090 100

Variable pressure Constant pressure

mCE

8

7

6

5

4

3

2

1

0

0 0,5 1 1,5 2

1

55

3

1 mbar=10 mmCE=100 Pa

88

77

1

mCE

8

7

6

5

4

3

2

1

3

3

/h

1,5 20,50

m

m/h

0

0 0,5 1 1,5 2

g. 5 - Available hydraulic pressures and ow rates

Outside sensor QAC34

32500

30000

27500

43907

10000

2490

1000

338

-50

-25025 50 75

°C

25000

22500

20000

17500

15000

12500

10000

7500

5000

2500

0

88

77

3

1

HP return sensor

HP ow sensor

1 mbar=10 mmCE=100 Pa

55

1

3

3

/h

1,5 20,50

m

m/h

°C

g. 6 - Ohmic sensor values (Hydraulic unit)

- 10 -

Waterstage / Installation / 2011 - EN

10000

1000

Ohmic value (kΩ)

- Compressor

- Discharge

- Condensation

- Expansion valve

100

10

1

-20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

g. 7 - Ohmic sensor values (Outdoor unit)

- Outdoor unit

- Evaporator inlet

Temperature °C

Waterstage / Installation / 2011 - EN

- 11 -

Description

►

■ Waterstage SHP 16

■ Waterstage SHP TRI 15

Waterstage SHP TRI 17

12

8

13

4

1

3

2

5

9

14

1

2

6

7

11

10

Key:

1. High performance and low noise impeller.

2. Electrical motor with variable "Inverter" operation.

3. "Inverter" control unit.

4. Check lights and buttons.

5. Connection terminal blocks

(power supply and interconnection).

6. Refrigerant storage bottle.

7. 4-way valve.

8. Anti-corrosion treated bodywork.

9. Main circuit electronic expansion valve.

10. Noise and thermally insulated "Inverter" compressor with liquid injection port.

11. Refrigeration connection valves (ared connectors) with protective caps.

12. Holding tank with condensate drain hole.

13. High-performance exchange surface evaporator; anti-corrosion treated hydrophilic aluminium ns and

grooved copper tubes.

14. Solenoid valve for liquid injection.

g. 8 - Outdoor unit components

- 12 -

Waterstage / Installation / 2011 - EN

■ Hydraulic unit

1

13

15

16

8

14

5

2

67

3 4

8

9

10

11

12

5

Key:

1 - Electric box.

2 - User interface.

3 - Start/stop switch.

4 - Pressure gauge.

5 - Heating circulation pump.

6 - Heating ow.

7 - Heating return.

8 - "Gas" refrigeration connection.

9 - "Liquid" refrigeration connection.

10 - Drain valve.

11 - Safety valve.

12 - Flowmeter

13 - Automatic bleeder valve.

14 - Expansion vessel.

15 - HP electrical backup.

16 - Condenser.

g. 9 - Hydraulic unit components

Waterstage / Installation / 2011 - EN

- 13 -

Operating principle

►

The heat pump transmits the energy contained in the

surrounding air into the dwelling to be heated.

The heat pump consists of four main elements, in which

a refrigerant (R410A) circulates.

- In the evaporator (ref. 13, g. 8, page 12):

The calories are taken from the outside air and

transmitted to the refrigerant. Because it has a low

boiling point, it changes from a liquid to a vapour, even

in cold weather (down to -25°C outside temperature).

- In the compressor (ref. 10, g. 8, page 12):

The vaporised refrigerant is pressurised and takes on

even more calories.

- In the condenser (ref. 14, g. 9, page 13):

The energy of the refrigerant is transmitted to the

heating circuit. The refrigerant returns to its liquid state.

- In the expansion valve (ref. 9, g. 8, page 12):

The liqueed refrigerant is returned to a low pressure

and regains its initial temperature and pressure.

The heat pump is equipped with a controller which

controls the room temperature based on the outdoor

temperature measurement. The room thermostat

(option) provides a corrective action for the temperature

control.

The hydraulic unit is tted with an electrical backup or

boiler connection which intervenes to provide additional

heat during the coldest periods.

• Control functions

- The heating circuit's ow temperature is controlled by

the temperature control.

- Depending on the heating ow temperature,

the outdoor unit's power is modulated by the "Inverter"

compressor.

- Control of the backup electrical heating.

- The daily timer program is used to set the periods

where the ambient temperature is comfortable or

reduced.

- Summer/winter time mode switchover is automatic.

- Management of the boiler backup*.

- Room sensor*: The room sensor provides a corrective

action for the temperature control.

- Control of a second heating circuit*.

- Domestic hot water*: Heating timer program.

- Managing cooling*.

* Where the heat pump is tted with options and associated kits.

• Protective functions

- Anti-legionella cycle for domestic hot water.

- Frost protection: Frost protection cuts in if the heating

circuit's ow temperature falls below 5°C (provided

that the heat pump's electrical power supply is not

interrupted).

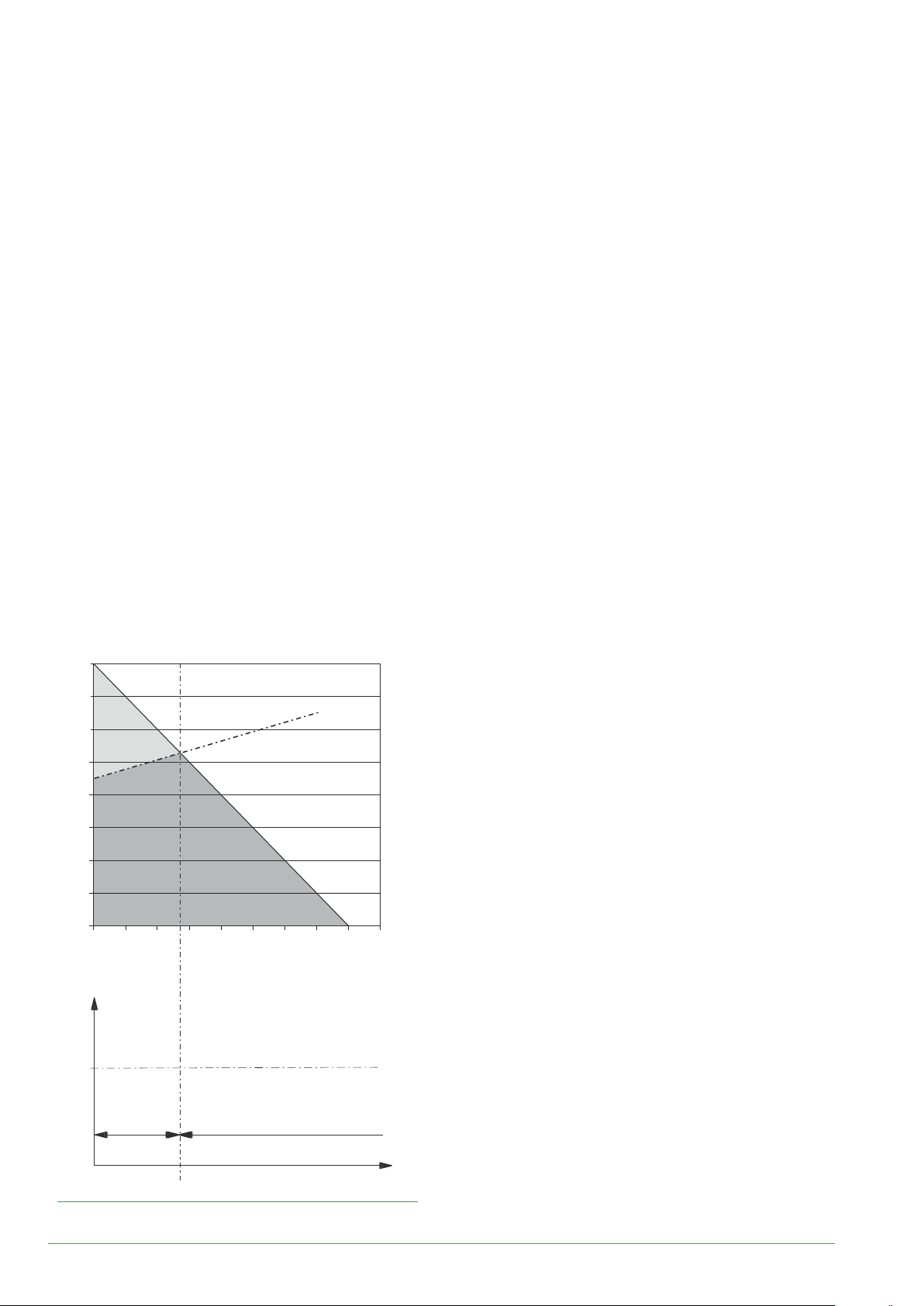

Dwelling heat loss (kW)

8

7

6

Backup

5

4

3

HP power

Heat Pump

2

1

0

-20 -15 -10 -5 0 510152025

HP +

electrical

backup

Outdoor temperature (°C)

Max

authorised HP

start-up temp.

HP only

46

Water return temperature (°C)

Outdoor temperature (°C)

g. 10 - Examples and operating limits

- 14 -

Waterstage / Installation / 2011 - EN

• Domestic hot water (DHW) operating principle

Two domestic hot water (DHW) temperatures can be

set: comfort and reduced.

The default DHW program is set to the comfort

temperature between 00:00 and 05:00 and between

14:30 and 17:00 and to the reduced temperature for the

rest of the day. This optimises electrical consumption

while ensuring comfortable heating and water

temperatures.

The reduced temperature setpoint may be useful to

avoid restarting the DHW too often and for too long

during the day.

The production of domestic hot water (DHW) is started

when the temperature in the tank drops to 7°C below

the temperature setpoint.

The heat pump produces the domestic hot water, which

is then additionally heated, if required, by the tank's

electrical backup or by the boiler. To ensure a DHW

setpoint over 55°C, the electrical backup heating must

be left on.

Depending on the setting, the comfort temperature can

be reached 24h/day or only at night or following the

DHW program.

If the contract signed with the energy provider includes

a day/night tari, the electrical backup is subject to the

supplier’s power tari and the comfort temperature may

only be reached at night.

If no particular contract has been signed, the comfort

temperature can be reached at any time, including

during the day.

The production of DHW takes priority over heating;

nevertheless the production of DHW is managed

by cycles that regulate the amount of time assigned

to heating and production of DHW in the event of

simultaneous demand.

Anti-legionella cycles can be programmed.

• Fan convectors with integrated control system

Do not use a room sensor in the area in question.

Air energy

Ev

Electrical

energy

consumed

Dt

Cp

Cn

1kW

PAC

Heat produced

COP 4

4kW

20 °C

PAC - Heating Pump

Ev - Evaporator

Cp - Compressor

Cn - Condenser

Dt - Expansion Valve

g. 11 - Heat pump operating principle

Waterstage / Installation / 2011 - EN

- 15 -

Installation

Installation of refrigeration

►

connections

Bend the pipes into position and make holes

for them through the oor or walls either with

their protective caps in place or after brazing.

Keep the protective caps in place or ends

brazed until the appliance is commissioned.

The outdoor unit must be connected to the hydraulic unit

only with brand new separately insulated copper

connections (refrigerant quality).

Maintain the same pipe diameters (g. 19).

Observe the maximum and minimum distances

between the hydraulic unit and the outdoor unit

(g. 19, page 24); the guarantee of performance and

the service lifespan of the system depend on this.

The minimum length of the refrigeration

connections for correct operation is 5 m.

The appliance's warranty will be void if it is operated

with refrigeration connections less than 5 m long

(tolerance +/- 10%).

If the refrigeration connections are exposed to

weathering or UV radiation and the insulation is not

resistant, protection must be provided.

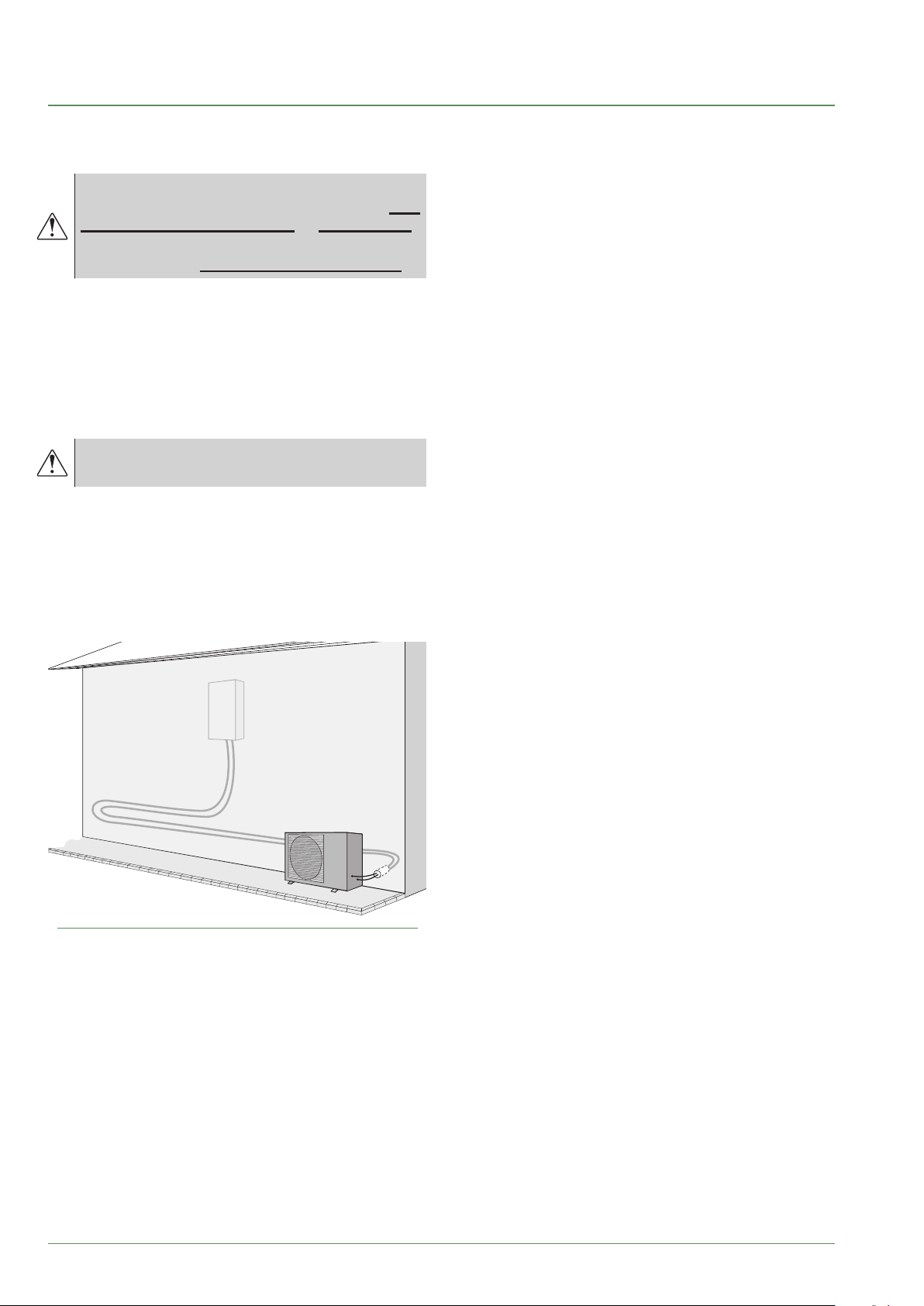

g. 12 - Example of recommendation for layout of

refrigeration connections

- 16 -

Waterstage / Installation / 2011 - EN

D

Installation of the outdoor unit

►

Installation precautions

▼

The outdoor unit must only be installed

outside. If a shelter is required, it must have

broad openings on all 4 sides and installation

clearances must be observed.

• Choose the location of the appliance after discussion

with the client.

• We recommend choosing a site that is sunny but

sheltered from strong cold prevailing winds.

• The unit must be easily accessible for future installation

and maintenance work (page 20).

• Ensure that connections to the hydraulic unit can be

made easily.

• The outdoor unit is able to withstand bad weather but

avoid installing it in a position where it is likely to be

exposed to signicant dirt or owing water (under a

defective gutter for example).

• Water may ow out of the outdoor unit when it is

operating. Do not install the unit on a paved terrace;

choose a well-drained location (e.g. gravel or sand).

If installation is carried out in an area where the

temperature stays below 0°C for long periods, check

that the presence of ice does not present any danger.

A drainage pipe can also be connected to the outdoor

unit (see g. 14).

• Nothing should obstruct the air circulation through the

evaporator and out from the fan (g. 13).

• Keep the outdoor unit away from heat sources and

ammable products.

• Make sure that the unit does not disturb the

surrounding area or inhabitants (noise level, draught,

low temperature of the ejected air freezing the plants

in its path).

A ≥ 80 mm

B ≥ 100 mm

C ≥ 200 mm

D ≥ 300 mm

E ≥ 500 mm

F ≥ 600 mm

G ≥ 1000 mm

H ≥ 1500 mm

J ≥ 2000 mm

K ≥ 3000 mm

A

B

D

BB

E

H

G

B

G

G

B

A

B

B

B

D

B

B

H

B

B

D

E

E

H

B

J

F

G

g. 13 - Minimum installation clearances around the outdoor unit (all models)

- 18 -

B

B

H

B

B

H

E

B

B

E

Waterstage / Installation / 2011 - EN

H

K

F

• The surface on which the appliance is installed must:

- Be permeable (soil, gravel, etc.).

- Support its weight easily.

- Allow a solid fastening base,

- Not transmit any vibration to the dwelling. Anti-vibratory

blocks are available as an option.

• The wall bracket cannot be used where it is likely to

transmit vibrations. Installing the unit on the ground is

preferred.

Positioning Outdoor Unit

▼

The outdoor unit must be raised at least 50 mm above

ground level. In areas prone to snow, this height should

be increased but should not exceed 1.5 m (gure 12).

- Fasten the outdoor unit by means of screws and

rubber tightening or toothed lock washers to prevent

them from coming loose.

H

In areas with heavy snowfall, if the intake and

outlet of the outdoor unit is blocked with snow,

heating may become dicult and a failure is

likely to occur.

Construct a canopy or place the unit on a high stand

(local conguration).

- Place the unit on a solid stand in order to minimise

impacts and vibrations.

- Do not place the unit directly on the ground as this will

cause problems.

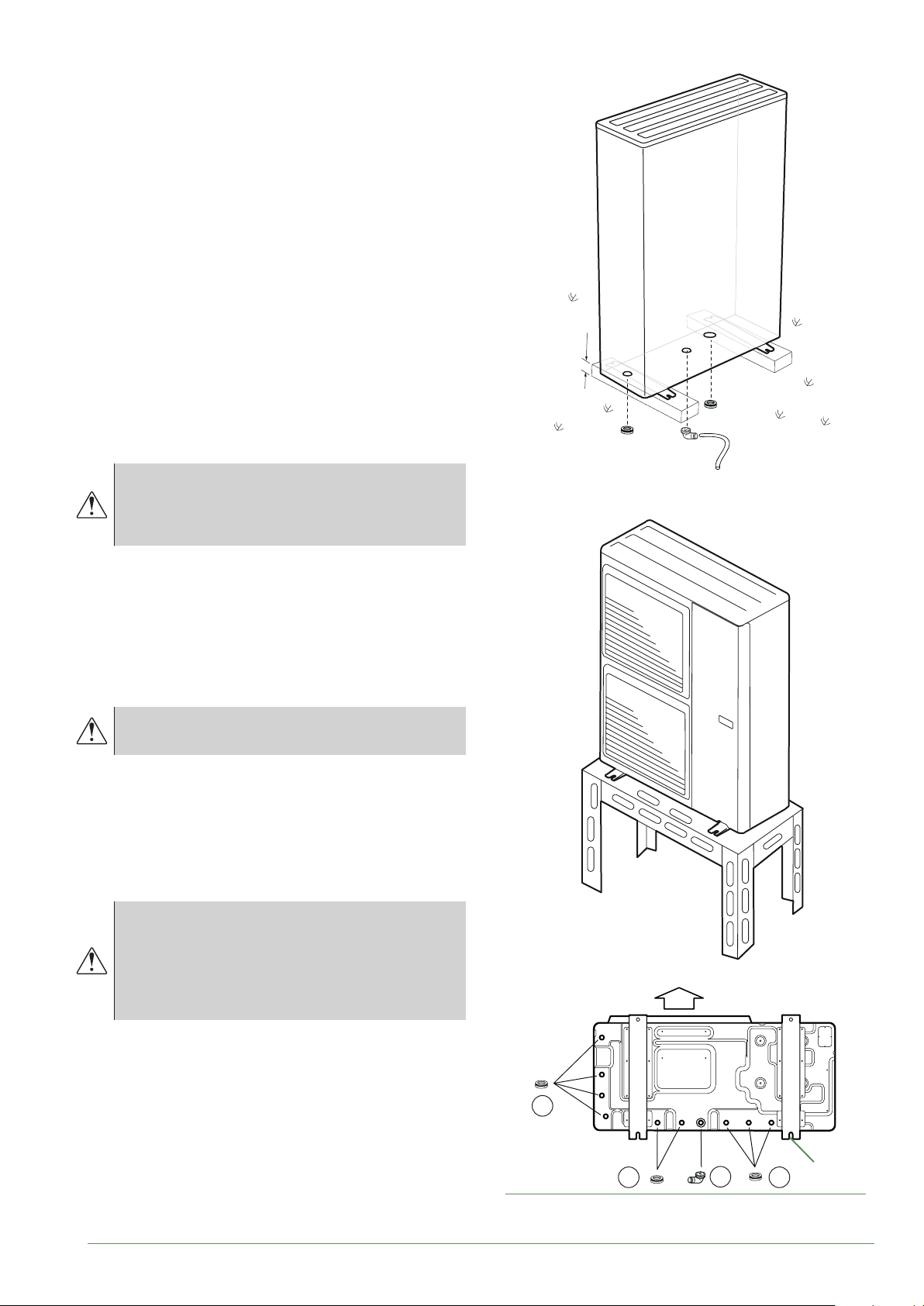

Condensate drain pipe

▼

The outdoor unit can generate a large volume

of water (called condensate).

If the use of a drain pipe is necessary:

- Use the elbow provided (C) and connect a 16 mmdiameter hose for draining the condensate.

- Use the plug(s) provided (B) to block the opening of

the condensate drain pan.

Allow for the condensate to ow away under the force of

gravity (waste water, rain water, gravel bed).

If installation is carried out in an area where the

temperature stays below 0°C for long periods,

equip the drain pipe with trace heating to

avoid it icing up. Trace heating must heat not

only the drain pipe but also the bottom of the

appliance's condensate collection tank.

* In areas with heavy snowfall,

(H) must be higher than the average snow layer.

Air

Waterstage / Installation / 2011 - EN

B

4 holes

B

g. 14 - Installation of the outdoor unit evacuation of

condensates

C

(ø 12 mm)

B

- 19 -

Installation of the hydraulic unit

►

Installation precautions

▼

• Choose the location of the appliance after discussion

with the client.

• The installation space should comply with current

regulations.

• To facilitate maintenance and allow access to the

various parts, we recommend that you provide

sucient space all the way around the hydraulic unit.

350 mm

mini

300 mm

mini

1000 mm

- If the refrigeration connection is only performed at the

end of the installation, make sure that the refrigeration

circuit caps* remain in place and tight throughout the

installation.

* (Hydraulic unit side and outdoor unit side).

- After each maintenance operation on the refrigeration

circuit and before the nal connection, take care to

put the caps back in position to avoid any pollution

of the refrigeration circuit (sealing with adhesive is

prohibited).

Positioning the hydraulic unit

▼

- Fix the bracket S securely (4 screws and plugs) to a

strong, at wall (not a light partition) ensuring that it is

correctly levelled.

350 mm

min.

mini

538 mm

min.

mini

• In accordance with EN 378-1 -2017 standard

(Refrigerating systems and heat pumps - Safety and

environmental requirements), the system's hydraulic

unit and all refrigeration connections passing through

inhabited areas must comply with the minimum room

volume requirements shown hereafter.

The minimum volume of a room (in m3) is calculated

using the formula: "uid ll load" (in kg) / 0.39.

Alternatively, you must ensure that

- The location has natural ventilation through another

room where the combined volume of the two rooms

is greater than "liquid ll load" (in kg) / 0.39 kg/m³.

The opening between the two rooms must have a door

clearance of at least 1 cm.

- Or that the location is mechanically ventilated.

Be careful not to bring ammable gas

near the heat pump during installation,

in particular when brazing is required.

The appliances are not reproof and should

not therefore be installed in an explosive

environment.

- To avoid condensation inside the condenser, remove

the refrigeration circuit caps only when making the

refrigeration connections.

300 mm

mini

min.

118 mm

188 mm

418 mm

min.

mini

(S)

g. 15 - Mounting bracket

- Hook the appliance onto its bracket S.

Weight of the appliance (full of water) = 58Kg

- 20 -

Waterstage / Installation / 2011 - EN

10

9

19

C

7

7

C

C

C

6

5

B

B

(S)

4

3

2

1

A

A

TX20

8

19

TX20

g. 16 - Removing the casing

Waterstage / Installation / 2011 - EN

D

12

11

D

TX20

D

11

- 21 -

Refrigeration connections

This appliance uses refrigerant R410A.

Comply with the legislation on handling of refrigerants.

Rules and precautions

►

Connections must be made on the same day

the installation is lled with gas (see para.

"Filling the installation with gas", page 26).

• Minimum tools required

- Set of pressure gauges (Manifold) with hoses

exclusively designed for HFCs (Hydrouorocarbons).

- Vacuum gauge with isolation valves.

- Vacuum pump specically for HFCs (using a standard

vacuum pump is allowed if, and only if, it is tted with

a non-return valve on the suction side).

- Flaring tool, Pipe-cutter, Deburring tool, Spanners.

- Certied refrigerant leak detector (sensitivity 5g/year).

Using tools that have been in contact with

HCFCs (R22 for example) or CFCs is prohibited.

The manufacturer declines any liability with

regard to the warranty if the above instructions

are not observed.

• Flared connections

Lubricating with mineral oil (for R12, R22)

is prohibited.

- Lubricate only with polyolester oil (POE). If POE is not

available, t without lubrication

Coat the ared surface

with POE refrigeration oil.

Do not use mineral oil.

described above, condensation will form on the

surface of the insulation material. Lastly, use insulating

sleeves whose thermal conductivity will be less than

or equal to 0.045 W/mK if the temperature is equal to

20°C. The insulation must be impermeable in order to

withstand the passage of vapour during the defrosting

cycles (glass wool is prohibited).

Shaping the refrigeration pipes

►

Bending

▼

The refrigeration pipes must be shaped only on a

bending machine or with a bending spring in order to

avoid any risk of crushing or breaking them.

Remove the insulation material from the section of

pipe to be bent.

Do not bend copper to an angle greater than 90°.

Never bend pipes more than 3 times in the

same place otherwise traces of fracturing may

appear (hardening of the metal).

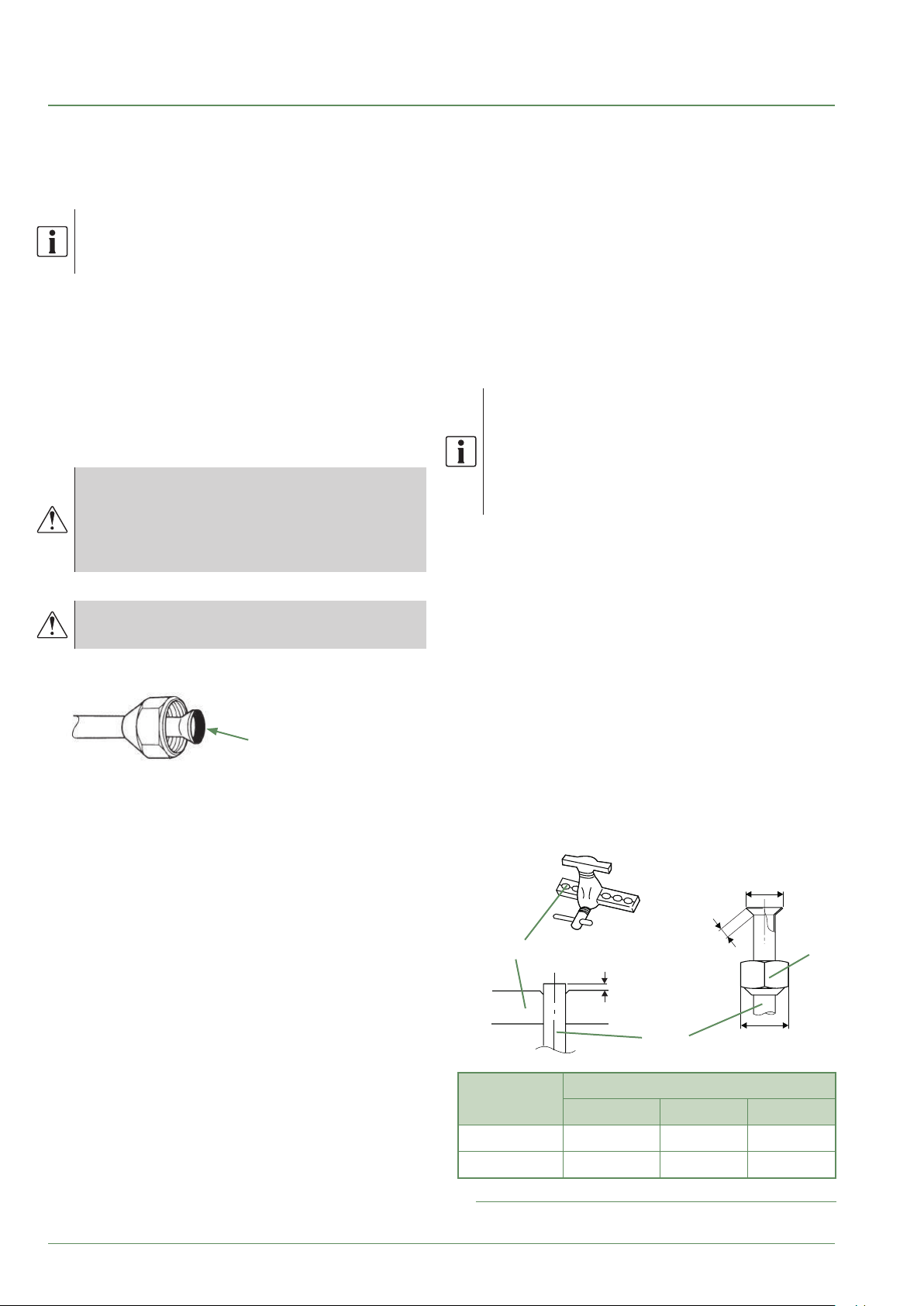

Creating the arings

▼

- Cut the pipe to an appropriate length with a pipe-cutter

without damaging it.

- Carefully deburr it, holding the pipe pointing downward

to avoid introducing lings into the pipe.

- Remove the ared connection nut situated on the

valve to be connected and slide the pipe into the nut.

- Proceed to are it, letting the pipe protrude out of the

aring tool's tube.

- After aring, check the state of the working radius (L).

This must not present any scratches or signs of

fracturing. Also check the dimension (B).

• Brazing the refrigeration circuit (if necessary)

- Silver brazing (40% minimum recommended).

- Brazing only with dry nitrogen internal ux.

• Other remarks

- After each maintenance operation on the refrigeration

circuit and before nal connection, take care to put

the caps back in position to avoid any pollution of the

refrigeration circuit.

- To eliminate any lings getting into the pipes, use dry

nitrogen to avoid introducing any humidity that may

adversely aect the appliance's operation. In general,

take every precaution to avoid humidity penetrating

into the appliance.

- Proceed with thermal insulation of the gas and liquid

pipes to avoid any condensation. Use pipe insulators

resistant to temperatures over 90°C. In addition, if the

humidity level in areas where the refrigerant pipes are

installed is expected to exceed 70%, protect the pipes

with pipe insulators. Use an insulating material thicker

than 15mm if the humidity level reaches 70 ~ 80%,

and an insulating material thicker than 20mm if

the humidity exceeds 80%. If the recommended

thicknesses are not observed under the conditions

- 22 -

B

-0.4

L

C

C

Flaring tool

Pipe

Dimensions in mm

Pipe ø

L B 0/

9.52 (3/8") 2.5 to 2.7 13.2 22

15.88 (5/8") 2.9 to 3.1 19.7 29

g. 17 - Flaring of the ared connections

Waterstage / Installation / 2011 - EN

Nut

are

■ Outdoor unit

Front Side Lower

■ Hydraulic unit

Sortie dessousSortie avant Sortie latérale

g. 18 - Feeding through ared connections

Waterstage / Installation / 2011 - EN

- 23 -

HP model Waterstage SHP

gas liquid

Outside unit connections 5/8" 3/8"

Diameter (D1) 5/8" (D2) 3/8"

Refrigeration

connections

Maximum Height Difference

Hydraulic unit connections 5/8" 3/8"

1 Without additional lling of R410A.

2 Taking into account a possible additional ll of refrigerant R410A (see "Additional lling", page 28 ).

3 Outdoor unit over hydraulic unit and heating only / Other cases.

Minimum length (L) 5

Maximum length 1 (L) 15

Maximum length 2 (L) 30

2/3

(D) 25 / 15

Hydraulic

unit

Outdoor unit

Heat Pump

Hydraulic

Heat

Pump

mini

mini

min.

5m

5m

unit

DL

DL

"Liquid” valve

“Gas” valve

"Liquid" refrigerant

connection

D2 diameter

Flared nut

Flared nut

Flared nut

Flared nut

Outdoor unit

"Gas" refrigerant

connection

D1 diameter

g. 19 - Refrigeration connections (authorised diameters and lengths)

- 24 -

Waterstage / Installation / 2011 - EN

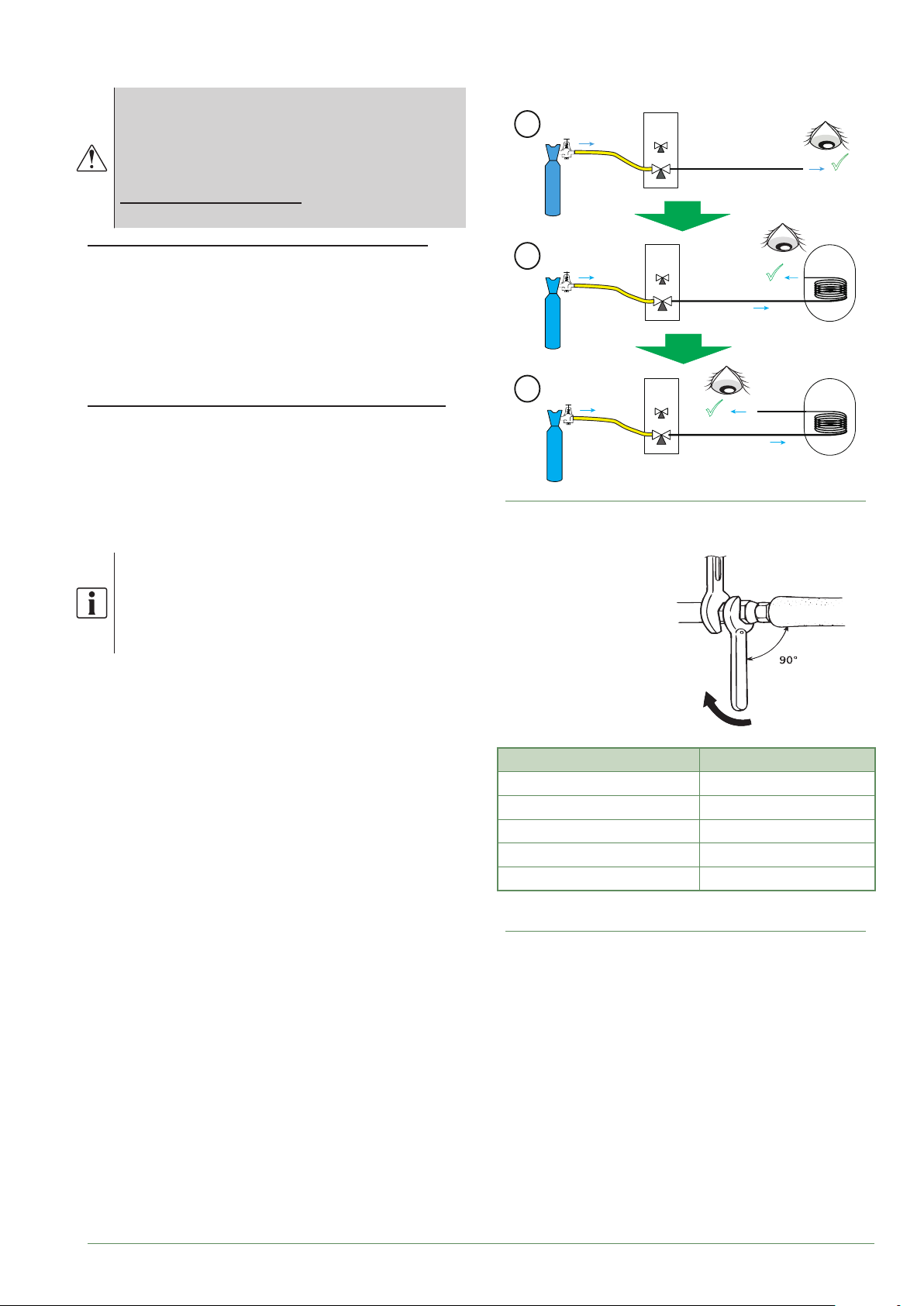

Checks and connection

►

The refrigeration circuit is very sensitive

to dust and humidity: check that the area

around the connection is clean and dry before

removing the plugs protecting the refrigeration

connectors.

Indicated blowing value: 6 bar for minimum

30 seconds for connection of 20 m.

Checking the gas connection (large diameter).

Connect the gas connection to the outdoor unit.

Blow dry nitrogen into the gas connection and inspect

its end:

- If water or impurities emerge, use a brand new

refrigeration connection.

Otherwise, proceed with aring and connect the

refrigeration connection to the outdoor unit immediately.

Checking the liquid connection (small diameter).

Connect the liquid connection to the hydraulic unit.

Blow nitrogen into the gas-condenser-liquid

connection system and inspect its end (outdoor unit side).

- If water or impurities emerge, use a brand new

refrigeration connection.

- Otherwise, proceed with aring and connect the

refrigeration connection to the outdoor unit immediately.

UE

1

Azote

Nitrogen

2

Azote

Nitrogen

3

Azote

Nitrogen

g. 21 - Checking refrigeration connections

OU

UE

OU

UE

OU

Gas

Liaison

connection

gaz

Liaison

Gas

connection

gaz

gaz

Gas

Liaison

Liquid

connection

liquide

MH*

HIU

MH*

HIU

Take particular care to position the tube

opposite its connector so as not to risk

damaging the threads. A properly aligned

connector can be attached easily by hand

without much force being required.

- Remove the plugs from the pipes and the refrigeration

connections.

- Warning! Avoid positioning the gas pipe in front of the

pump.

- Comply with the indicated tightening torques.

Holding spanner

Torque wrench

Designation Tightening torque

Flared nut 9.52 mm (3/8") 32 to 42 Nm

Flared nut 15.88 mm (5/8") 63 to 77 Nm

Plug (A) 3/8" 20 to 25 Nm

Plug (A) 5/8" 30 to 35 Nm

Plug (B) 3/8", 5/8" 10 to 12 Nm

Plug (A) and (B) : see g. 22, page 27.

g. 20 - Tightening torques

Waterstage / Installation / 2011 - EN

- 25 -

Loading...

Loading...