Page 1

U0651601_2010_EN_1

24/06/2019

OPERATING INSTRUCTIONS

Air to Water Heat Pump

Split single service & Split integrated DHW type

For users. To be kept by the user for future reference.

EN

Page 2

Contents

Safety instructions 3

Overview of installation 4

Precautions and warnings about your installation ..4

Appliance end-of-life .......................5

Overview of the installation ..................5

Carrying out the installation 6

User interface, Room control unit (option) and

Room thermostat (option) ...................6

Display Description ........................8

Appliance start up .........................9

Quick start-up ............................9

Setting the time ..........................10

Structure of the "End user" control menu ......11

Parametering the setting ...................12

Information display .......................17

Details .................................18

Operation of the DHW system* ..............18

Selecting cooling mode* ...................18

Pilot wire* (if kit regulation extension AVS 55) ...18

Telephone modem* (if Regulation extension kit

AVS 55) ................................19

Conguring room control unit* (option) ........19

Maintenance 20

Regular checks ..........................20

Checking the outdoor unit ..................20

Hot water tank* ..........................20

- 2 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 3

Safety instructions

Please comply with the following instructions in order to avoid any risk of injury or

inappropriate use of the appliance.

Commissioning

Do not switch the appliance ON until every lling operation has been performed

Do not attempt to install this appliance yourself. This heat pump must be installed by

qualied personnel holding a certicate of competence.

The installation must always be properly earthed and tted with a safety circuit breaker.

Do not change the power supply.

The appliances are not reproof and should not therefore be installed in an explosive

environment.

How to Use

This appliance can be used by children 8 years and above. Also persons with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, provided

they have been given supervision or instruction concerning use of the appliance in a safe

way and with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

Do not let children insert foreign bodies inside the propeller protection grate or climb onto

the roof of the outdoor unit. The ns of the air heat exchanger are extremely thin and can

cause cuts.

Nothing should obstruct the air circulation through the evaporator and out from the fan.

The outdoor unit must only be installed outside. If a shelter is required,it must have broad

openings on all 4 sides and installation clearances must be observed (see your installation

engineer).

Do not climb on top of the outdoor unit.

The room in which the unit is operating must be correctly ventilated in order to avoid any

shortage of oxygen in the event of a refrigerant gas leak.

If your installation location already meets safety standards, do not carry out any

modications (ventilation, exhaust evacuation, openings, etc.) without the advice of your

installation engineer.

Do not place any heat source under the remote control.

Maintenance

Do not try to repair the appliance yourself.

This appliance does not contain any components which can be repaired by the user.

Removing either of the covers can expose you to dangerous electrical voltages.

In any case, switching o the current is not sucient to protect you from any external

electrical shocks (condensers).

Do not open the outdoor unit or the hydraulic unit while they are in operation.

If you hear unusual noises, smell smoke or other odours coming from the appliance, turn

o the power and contact your installation engineer.

Before starting any cleaning, turn o the power to the appliance.

Do not use aggressive cleaning liquids or solvents to clean the body work.

Do not use a pressure hose to clean the outdoor unit. You may damage the air exchanger

and get water inside the electrical circuits.

Page 4

Overview of installation

Precautions and warnings about

►

your installation

Outdoor unit

▼

The outdoor unit contains the equipment that enables

the capture of energy from the surrounding air.

This unit was installed by your installer in a location

where it is able to operate with best performance.

Nothing should obstruct the air circulation through the

evaporator and out from the fan.

The water contained in the air may condense and ow

out of the outdoor unit. The outdoor unit can generate a

large volume of water called condensate.

In cold weather, this water freezes on contact with the

exchanger and must be regularly removed using the

defrosting cycles. The defrosting cycle is managed

automatically by the control system and can produce

steam emissions which are completely normal.

Hydraulic unit

▼

The hydraulic unit contains the appliance's control

system which manages the room temperature and the

production of domestic hot water.

The hydraulic unit is tted with an electrical backup*

or boiler connection* which intervenes to provide

additional heat during the coldest periods.

Settings

▼

Your installer has carefully adjusted your installation.

Do not change the settings without their consent.

If in doubt, do not hesitate to contact them.

Your heating system is controlled by adjustment in

relation to the outside temperature (temperature

control).

The installation of a room thermostat (option) makes it

possible to improve the operation of the control system

(inuence of the ambient temperature is taken into

account).

In order to ensure operation of the control system,

the room containing the thermostat must not also

contain a thermostatic valve. If this is the case, it must

be opened as far as possible.

A new underoor heating system must initially be

heated slowly to avoid any problems involving cracking.

Check with your installer that this initial heating

procedure has indeed been performed before freely

using your heating system.

An underoor heating system's signicant inertia

prevents sudden room temperature dierences.

However, this inertia implies a reaction time of around

several hours (approx 6 hours).

Any changes to the setting must be made slowly

and leave the installation sucient time to react. Any

exaggerated or abrupt adjustments to the settings

always result in signicant temperature uctuations

during the day.

Similarly if your dwelling has an underoor heating

system, do not reduce it or switch it o if you will be

absent for only short periods. The reheating period is

always quite long (approx 6 hours).

Do not use a room sensor in the area in question.

When hot water is required, the heat pump adapts its

priority to meet the request.

No heating is produced during the preparation of

domestic hot water.

The heat pump produces the domestic hot water

(DHW), which is then additionally heated, if required,

by the electrical backup.

To ensure a DHW setpoint over 45°C, the electrical

backup heating or boiler (boiler connection kit)* must

be left on.

The electrical backup allows the correct operation of the

anti-legionella cycles.

Radiators

▼

Underoor heating system

▼

Fan coils / dynamic radiators with an

▼

integrated control system

Domestic Hot Water (DHW)*

▼

* depending on conguration / option

- 4 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 5

Appliance end-of-life

►

The appliances must be dismantled and recycled by a

specialised service. The appliances must not, under any

circumstances, be thrown out with household waste,

bulky waste or at a tip.

At the end of its service life, please contact your installer

or local representative to proceed with its dismantling

and recycling.

Overview of the installation

►

Your heat pump has been congured by your installation

engineer. It is made up of the following main parts:

- The outdoor unit, as its name suggests, is placed

outside your dwelling, and extracts energy from the

outside air.

- The hydraulic unit is located in your boiler room, cellar,

garage or even in your kitchen, and transfers energy to

the heating and domestic hot water circuits*.

- The outside sensor monitors the outside temperature.

Optional:

- Room sensor(s).

Heat pumps are systems which can be connected to

any type of low temperature distribution system and

the heat captured by the heat pump can be used in

dierent ways:

- Underoor heating system.

- Radiators.

- Domestic Hot Water (DHW)*.

Outside

sensor

Control options

Room thermostat

(wired or radio)

and/or

Remote control

(wired or radio)

Options depending

on hydraulic

or

congurations

connection kit

Menu

2

circuit kit

Boiler

Heating circuit

underoor heating

Radiators heating

circuit

Boiler

Hydraulic unit

Outdoor unit

g. 1 - Overview of complete installation conguration

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

* depending on conguration / option

- 5 -

Page 6

Carrying out the installation

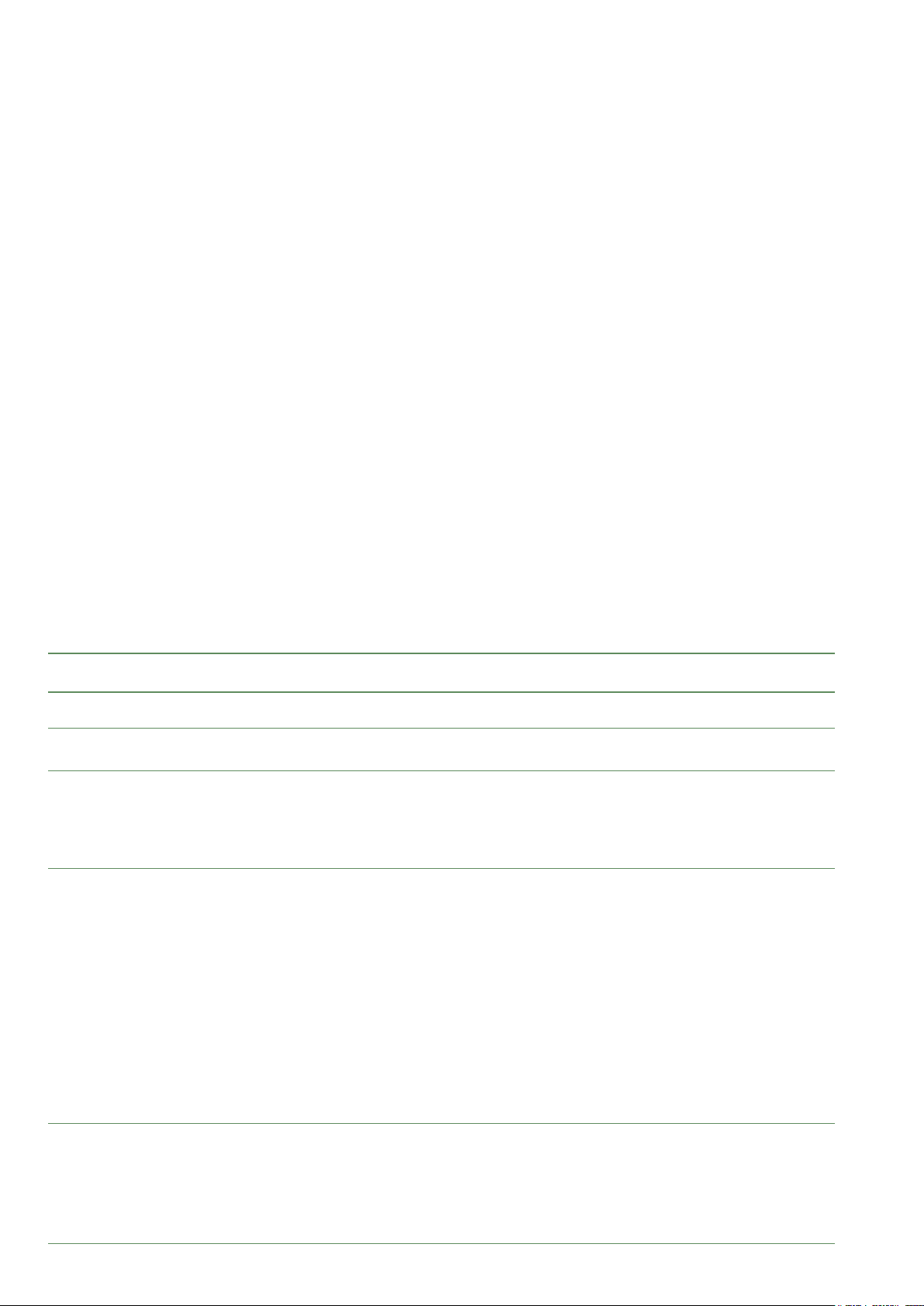

User interface, Room control unit (option) and Room thermostat (option)

►

1

5

2

6

3

7

8

4

9

1

Auto

2

5

Auto

5

3

0 4 8 12 16 20 24

ESC

OK

4

7

11

2

°C

10

11

8

6

- 6 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 7

Ref. Functions - Denitions

Off

Auto

1 Selecting of the DHW operating mode

(Domestic hot water).

- If the installation is tted with a DHW tank.

- On: Production of DHW according to the time program.

- O: Preparing the domestic hot water for stopping with the anti-frost function

On

active.

- Manual start button: Hold down the DHW key for 3 seconds. Switch from

"reduced" to "comfort" until the next time the ECS timer switches over.

2 Digital display. - Operating control. Readout of the current temperature, of the heating mode

and of any faults .

- View the settings.

3 Exit "ESC". - Quit the menu.

4 Navigation and setting. - Selecting the menu.

- Setting parameters.

- Adjusting the ambient temperature setpoint.

5 Selecting the heating mode.

-

Heating operating according to the heating program

(Summer/winter mode switchover is automatic).

- Constant comfort temperature.

- Constant reduced temperature.

- Stand-by mode with anti-frost protection

(Provided that the heat pump's electrical power supply is not interrupted).

6 Information display. - Various data (see page 17).

- Reading error codes.

- Information concerning maintenance, special mode.

7 Conrm "OK". - Input into the selected menu.

- Conrmation of the parameter settings.

- Conrmation of the adjustment to the comfort temp. setting.

8 Selecting cooling mode. - If the installation is tted with the cooling kit:

- Cooling operating according to the heating program

(Summer/winter mode switchover is automatic).

9 RESET button

(Brief press)

- Reinitialising the parameters and cancelling error messages.

Do not use during normal operation.

10 Control knob. - Adjusting the ambient temperature setpoint.

11 Presence key. - Comfort / Reduced switchover.

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 7 -

Page 8

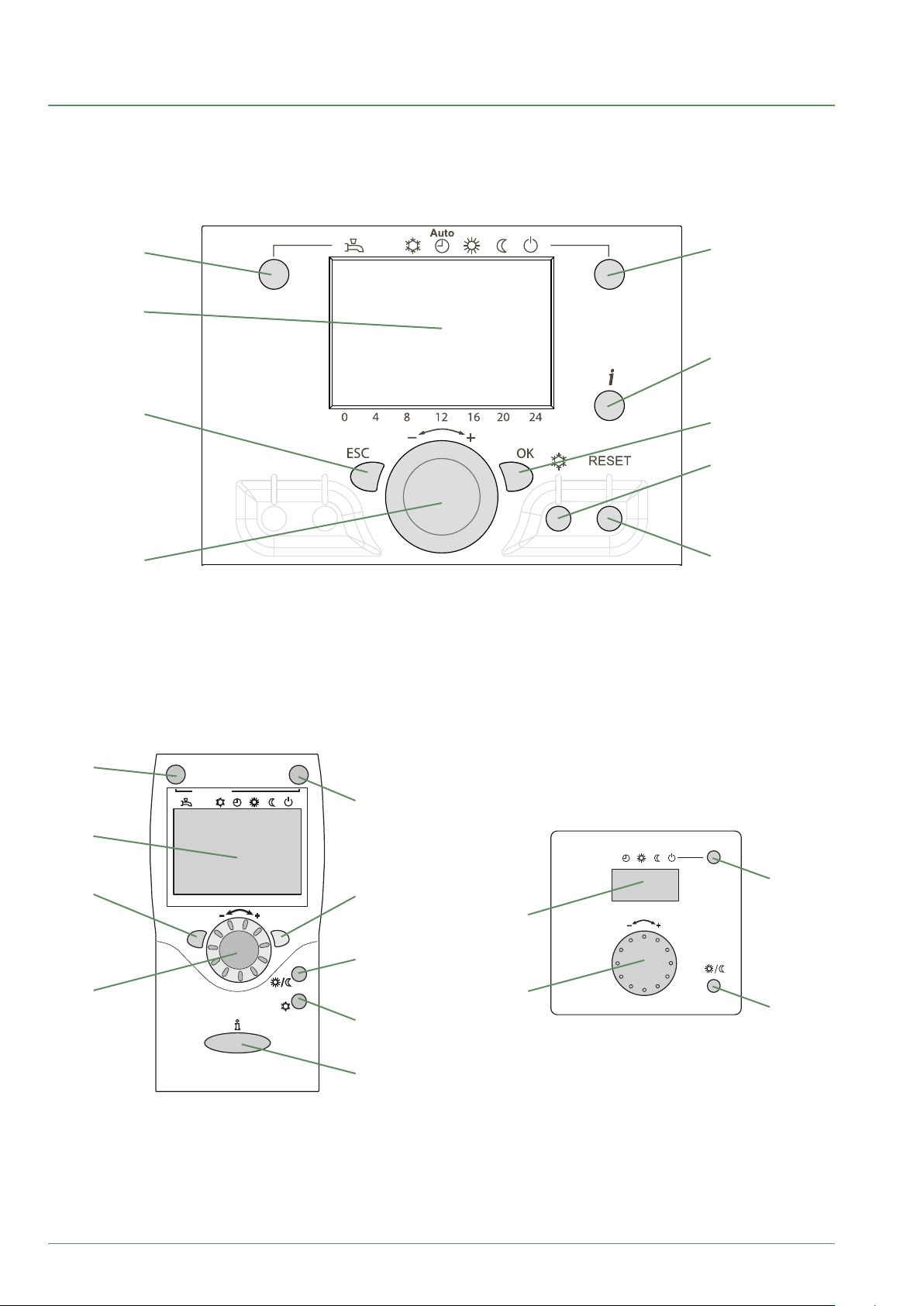

Display Description

►

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Symbols Denitions

- Heating mode active with reference

to the heating circuit*.

- Heating in comfort mode.

- Heating in reduced mode.

INFO

PROG

ECO

- Heating in "standby" mode

(freeze protection).

- Cooling mode active*.

- Holiday mode activated.

- Process in progress.

- Compressor operation.

- Burner operation*.

- Default message.

- Service / Special operation.

- Information level activated.

- Program activated.

- ECO mode activated

(Heating temporarily stopped).

g. 2 - Closing the display

- Hour /

temperature ambiante

temperature ambiante

temperature ambiante

* depending on conguration / option

Parameter number /

Setpoint value.

- Room temperature /

Setpoint value.

- Setpoint information /

Parameter Information.

- 8 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 9

Appliance start up

►

• The installation and 1st start up of the appliance

must be done by a qualied installer. That person will

also give you instructions on starting and running the

appliance.

• Ensure that the installation is fully lled with water

and has been correctly bled and that there is a

sucient pressure of 1.5 to 2 bars on the manometer

(ref. 2, g. 3).

• Close the installation's main circuit breaker.

In winter, so that the compressor can be

preheated, close the installation's main circuit

breaker (outdoor unit's power supply) some

hours before pressing the on/o button.

Quick start-up

►

Once your installer has started your installation for the

rst time:

• Engage the start/stop switch.

During the regulator initialisation phase, the

display shows all the symbols and then "Data,

update" and then "State heat pump".

• Select the "AUTO" heating mode (g. 4).

• Select the DHW mode (g. 4).

• Adjust the date and time if necessary (g. 5)).

Press OK

1. User interface

2. Manometer (installation hydraulic pressure)

3. Start/stop switch

g. 3 - Start-up

_______________

Time and date

Operator section

1

2

Time and date

Hours / minutes

Select menu

hour and date

Press OK

Select one of the

lines :

hour / minutes

or day / month

or years

Press OK

3

Make all the

settings

Time and date

Hours / minutes

Press OK to

conrm each

setting

g. 4 - Selecting the heating mode AUTO

and Select the DHW mode

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Press heating mode key to

return to basic display

g. 5 - Setting the time and the date

- 9 -

Page 10

Setting the time

►

Keys Display example Description

1

AUTO

Room temperature

4812 16 20 24

0

Basic display

If the basic display is not shown,

press ESC to return to it

Press OK to conrm.

2

AUTO

Turn the knob

Select menu hour and date

Time and date

Operator section

4812 16 20 24

0

Press OK to conrm.

3

AUTO

Turn the knob

Time and date

Hours / minutes

4812 16 20 24

0

Select line 1 Hours / minutes

Press OK to conrm.

4

Time and date

Hours / minutes

0

AUTO

4812 16 20 24

The hour display ashes

Turn the knob to set the time

Press OK to conrm.

g. 6 -

- 10 -

5

Time and date

Hours / minutes

0

AUTO

4812 16 20 24

The minutes display ashes

Turn the knob to set the minutes

Press OK to conrm.

6

AUTO

The setting are recorded

Turn the knob to make other settings

Time and date

Hours / minutes

04812162024

or

Press heating mode key to return to

basic display.

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 11

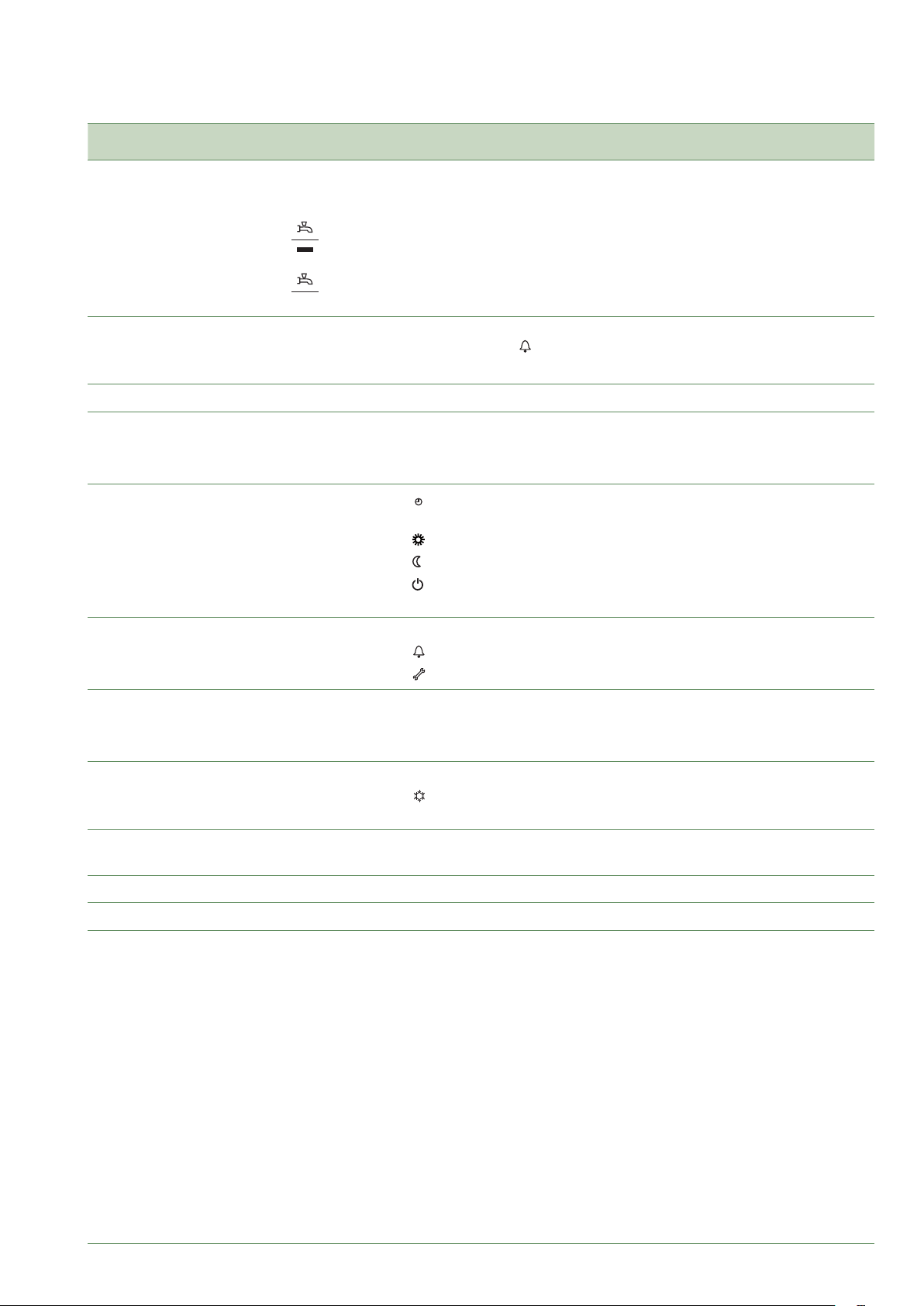

Structure of the "End user" control menu

►

Basic

display

Brief

press

End user

Time of day and date

Operator section Language

Time prog heating circuit 1

Time prog heating circuit 2

Time program 4/DHW

Commissioning Engineer OEM

Hours / minutes

Day / Month

Year

Pre-selection

1st phase on

1st phase off

2nd phase on

2nd phase off

3rd phase on

3rd phase off

Copy

Default values

20

500

501

502

503

504

505

506

515

516

1

2

3

Hours

1 ...24h

Minutes

English, German...

Mon-Sun

Mon-Fri

Sat-Sun

Monday

Tuesday

…

Sunday

0...60 min

Holidays heating circuit 1

Holidays heating circuit 2

Heating circuit 1

Heating circuit 2

Domestic hot water

Fault Reset HP

Service/special operation

Diagnostics heat generation

Diagnostics consumers Outdside temp.

Pre-selection

1st phase on

1st phase off

Operation level

Comfort setpoint Reduced temp...

Reduced setpoint

Frost protect. setpoint

Nominal setpoint

Emergency operation

Return temp HP

Flow temp HP

Compressor modulation

Reset outside temp min

Reset outside temp max

...

Swimming pool temp.

641

642

643

648

710

712

714

1610

6711

7141

8410

8412

8413

8700

8701

8702

...

8900

Period 1

Period 2

...

Period 8

28 °C

Temp. frost protect... comfort

4°C...

No, Yes

Off, On

reduced temp.

Reduced temp...

Off, On

65 °C

g. 7 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 11 -

Page 12

Parametering the setting

►

General

▼

Only the parameters accessible to levels:

End user

... are described in this document.

The parameters accessible at level:

Commissioning

Engineer

… are described in the document reserved for these

professional specialists. Do not make any modications

to these parameters without advice from these

professional specialists. Incorrect use of any kind

may result in serious malfunctioning.

Setting parameters

▼

With the screen on basic display.

- Press OK.

Once in "End user" level.

- Scroll the menu list.

- Choose the desired menu.

- Scroll the function lines.

- Choose the desired line.

- Adjust the parameter.

- Check the setting by pressing OK.

- To return the menu, press ESC.

If no setting is made for 8 minutes, the screen returns

automatically to the basic display.

OK

Brief

press

End user

OK OK OK

Time and date Hours / minutes 1 Hours 1...24 h

User interface Day / Month 2 Minutes 0...60 min

CC1 time program Year 3

...

List of "End user" settings

▼

Line Function

Time of day and date

1 Hours / Minutes 00:00... 23:59 1

Setting range

or display

Setting

increment

Basic

setting

2 Day / Month 01.01... 31.12 1

3 Year 1900... 2099 1

Operator Section

20 Language English, Français, Italiano,

Nederlands...

- 12 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

English

Page 13

Line Function

Time program heating / cooling, circuit 1

Setting range

or display

Setting

increment

Basic

setting

500 Pre-selection (Day / Week) Mon-Sun, Mon-Fri, Sat-Sun,

Monday, Tuesday, …

501 1st phase On (start) 00:00... --:-- 10 min 6:00

502 1st phase O (end) 00:00... --:-- 10 min 22:00

503 2nd phase On (start) 00:00... --:-- 10 min --:--

504 2nd phase O (end) 00:00... --:-- 10 min --:--

505 3rd phase On (start) 00:00... --:-- 10 min --:--

506 3rd phase O (end) 00:00... --:-- 10 min --:--

516 Default values, Circuit 1 No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your customised settings are therefore lost.

Time program heating / cooling, circuit 2

Only with the 2nd circuit kit option.

520 Pre-selection (Day / Week) Mon-Sun, Mon-Fri, Sat-Sun,

Monday, Tuesday, …

521 1st phase On (start) 00:00... --:-- 10 min 6:00

522 1st phase O (end) 00:00... --:-- 10 min 22:00

523 2nd phase On (start) 00:00... --:-- 10 min --:--

524 2nd phase O (end) 00:00... --:-- 10 min --:--

Mon-Sun

Mon-Sun

525 3rd phase On (start) 00:00... --:-- 10 min --:--

526 3rd phase O (end) 00:00... --:-- 10 min --:--

536 Default values, Circuit 2 No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your customised settings are therefore lost.

Time program 4 / DHW

If the installation is tted with the DHW kit.

560 Pre-selection (Day / Week) Mon-Sun, Mon-Fri, Sat-Sun,

Monday, Tuesday, …

561 1st phase On (start) 00:00... --:-- 10 min 00:00

562 1st phase O (end) 00:00... --:-- 10 min 05:00

563 2nd phase On (start) 00:00... --:-- 10 min 14:30

564 2nd phase O (end) 00:00... --:-- 10 min 17:00

565 3rd phase On (start) 00:00... --:-- 10 min --:--

566 3rd phase O (end) 00:00... --:-- 10 min --:--

576 Default values No, Yes No

Yes + OK: The default values memorised in the regulator replace and cancel the customised heating programs.

Your customised settings are therefore lost.

Holidays, heating circuit 1 (For the Holiday program is active, the heating mode should be on AUTO).

Mon-Sun

641 Preselection Period 1 to 8 Period 1

642 Period Start (Day / Month) 01.01... 31.12 1

643 Period End (Day / Month) 01.01... 31.12 1

648 Operating level Frost protection, Reduced Frost

protection

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 13 -

Page 14

Line Function

Holidays, heating circuit 2 (For the Holiday program is active, the heating mode should be on AUTO).

If the installation consists of 2 heating circuits (Only with the 2nd circuit kit option).

651 Preselection Period 1 to 8 Period 1

652 Period Start (Day / Month) 01.01... 31.12 1

653 Period End (Day / Month) 01.01... 31.12 1

Setting range

or display

Setting

increment

Basic

setting

658 Operating level Frost protection, Reduced Frost

Heating adjustment, circuit 1

710 Comfort setpoint Reduced setpoint…

Comfort setpoint maximum

712 Reduced setpoint Frost protection setpoint…

Comfort setpoint

714 Frost protection setpoint 4 °C… Reduced setpoint 0,5 °C 8 °C

Cooling circuit 1

If the installation is tted with the cooling kit (Only with the cooling kit option).

901 Operating mode Protection, Automatic, Reduced,

Comfort

902 Comfort cooling setpoint 17... 40 °C 0,5 °C 24 °C

903 Reduced setpoint 5... 40°C 26 °C

Heating adjustment, Circuit 2

Only with the 2nd circuit kit option (If the installation consists of 2 heating circuits).

1010 Comfort setpoint Reduced setpoint…

Comfort setpoint maximum

1012 Reduced setpoint Frost protection setpoint…

Comfort setpoint

0,5 °C 20 °C

0,5 °C 19 °C

0,5 °C 20 °C

0,5 °C 19 °C

protection

Protection

1014 Frost protection setpoint 4 °C… Reduced setpoint 0,5 °C 8 °C

Cooling circuit 2

If the installation is tted with the cooling kit (Only with the cooling kit option).

1201 Operating mode Protection, Automatic, Reduced,

1202 Comfort cooling setpoint 17... 40 °C 0,5 °C 24 °C

1203 Reduced setpoint 5... 40°C 26 °C

Domestic hot water

If the installation is tted with the DHW kit.

1600 Operating mode O, On, Eco On

1610 Nominal setpoint Reduced setpoint (line 1612)…

The backup electrical system is required to reach this level.

1612 Reduced setting 8 °C...

Swimming pool (Only with swimming pool kit option)

2055 Setpoint solar heating 8... 80 °C 26 °C

2056 Setpoint source heating 8... 35 °C 22 °C

Comfort

65 °C

Nominal setting (line 1610)

1 55 °C

1 40 °C

Protection

- 14 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 15

Line Function

Energy meter

3095 --> 3110 : Not used

3113 Energy brought in Kwh --

Cumulation of total consumed electrical energy.

Electrical energy consumed = Electrical energy absorbed by outdoor unit + electric energy absorbed by the heating

electrical backup and / or DHW electrical backup (if installed).

3121 --> 3123 : Not used

3124 Energy brought in heating 1 (N - 1) Kwh --

3125 Energy brought in DHW 1 Kwh --

3126 Energy brought in cooling 1 Kwh --

3128 --> 3130 : Not used

3131 Energy brought in heating 2 (N - 2) Kwh --

3132 Energy brought in DHW 2 Kwh --

3133 Energy brought in cooling 2 Kwh --

3135 --> 3137 : Not used

3138 Energy brought in heating 3 (N - 3) Kwh --

Setting range

or display

Setting

increment

Basic

setting

3139 Energy brought in DHW 3 Kwh --

3140 Energy brought in cooling 3 Kwh --

3142 --> 3144 : Not used

3145 Energy brought in heating 4 (N - 4) Kwh --

3146 Energy brought in DHW 4 Kwh --

3147 Energy brought in cooling 4 Kwh --

3149 --> 3151 : Not used

3152 Energy brought in heating 5 (N - 5) Kwh --

3153 Energy brought in DHW 5 Kwh --

3154 Energy brought in cooling 5 Kwh --

3156 --> 3158 : Not used

3159 Energy brought in heating 6 (N - 6) Kwh --

3160 Energy brought in DHW 6 Kwh --

3161 Energy brought in cooling 6 Kwh --

3163 --> 3165 : Not used

3166 Energy brought in heating 7 (N - 7) Kwh --

3167 Energy brought in DHW 7 Kwh --

3168 Energy brought in cooling 7 Kwh --

3170 --> 3172 : Not used

3173 Energy brought in heating 8 (N - 8) Kwh --

3174 Energy brought in DHW 8 Kwh --

3175 Energy brought in cooling 8 Kwh --

3177 --> 3179 : Not used

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 15 -

Page 16

Line Function

3180 Energy brought in heating 9 (N - 9) Kwh --

3181 Energy brought in DHW 9 Kwh --

3182 Energy brought in cooling 9 Kwh --

3184 --> 3186 : Not used

3187 Energy brought in heating 10 (N - 10) Kwh --

3188 Energy brought in DHW 10 Kwh --

3189 Energy brought in cooling 10 Kwh --

390 --> 3267 : Not used

Error

6710 Reset Defaut relais No, Yes No

6711 Reset HP No, Yes No

Maintenance / special regime

7141 Emergency operation O, On O

O: Heat pump functions normally (with boosters if necessary).

On: Heat pump uses the electric boost system or the boiler connection.

Use the “On” position only in Assist mode or Test mode: may result in high power bills.

Setting range

or display

Setting

increment

Basic

setting

Generator diagnosis

8410 Return temp HP 0... 140 °C --

Setpoint (ow) HP --

8412 Flow temp HP 0... 140 °C --

Setpoint (ow) HP --

8413 Compressor modulation 0... 100% --

Diagnostics consumers

8700 Outdoor temperature -50... 50 °C --

8701 Outdoor temp min

Reset ? (no, yes)

8702 Outdoor temp max

Reset ? (no, yes)

8740 Room temperature 1 0... 50 °C --

Room setting 1 20 °C

8743 Flow temperature 1 0... 140 °C --

Flow temperature setpoint 1 --

8756 Cooling ow temperature 1 0... 140 °C --

Cooling ow temperature setpoint 1 --

-50... 50 °C 50 °C

-50... 50 °C -50 °C

8830 DHW (domestic hot water) temperature 0... 140 °C --

DHW temperature setpoint 50 °C

- 16 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 17

Information display

►

Various data can be displayed by pressing the info

button .

Depending on the type of unit, conguration and

operating state, some of the info lines listed below may

not appear.

- Possible error messages: The display shows the "Bell"

symbol .

Consult your heating technician.

- Service messages ; Special mode messages:

The display shows the “Key” symbol .

Consult your heating technician.

- Various data (see below).

Designation Line

Floor drying current setpoint . -

Current drying day. -

Terminated drying days. -

State heat pump. 8006

State supplementary source. 8022

State DHW. 8003

State swimming pool. 8011

State heating circuit 1. 8000

State heating circuit 2. 8001

State cooling circuit 1. 8004

Outdoor temperature. 8700

Room temperature 1.

Room setpoint 1.

Flow temperature 1.

Flow temperature setpoint1.

Room temperature 2.

Room setpoint 2.

Flow temperature 2.

Flow temperature setpoint 2.

DHW (domestic hot water) temperature. 8830

Heat pump return temperature.

Setpoint (return) HP.

Heat pump ow temperature.

Setpoint (ow) HP.

Swimming pool temperature.

Swimming pool temperature setpoint.

Minimum remaining stop time for compressor 1. -

Minimum remaining running time for compressor 1. -

8740

8743

8770

8773

8410

8412

8900

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 17 -

Page 18

Details

►

If the electrical power supply has been cut o while

the heat pump is operating (electrical power failure or

unprogrammed pressing of the on/o switch on the

hydraulic unit) the display will show error 370 when

the appliance restarts. Do not be concerned, the

communication between the outdoor and hydraulic unit

will re-establish itself in a few moments.

Operation of the DHW system*

►

The key enables you to switch the DHW (domestic hot

water) mode on and o. The selection is shown by a

bar, which appears under the corresponding symbol.

Manual activation: Hold down the DHW key for 3 seconds

(Switch from "reduced" to "nominal" until the next time

the DHW timer switches over).

To ensure a DHW setting over 45°C, the electrical backup heating or the boiler must be left on.

In order to optimise operation of the DHW, it is possible to:

- Program the timer settings (parameters 560 to 576),

- Adjust the comfort temperature set point (parameter 1610),

- Adjust the reduced temperature set point (parameter 1612).

g. 8 - Select the DHW mode

Brief

press

g. 9 - Information key

Details of any error

Operating values

...

Press the info key to obtain the details on the DHW

(temperature setting operation).

Selecting cooling mode*

►

If the installation is tted with the cooling kit.

The key activates and deactivates cooling mode.

Pilot wire* (if kit regulation

►

extension AVS 55)

It's possible to order up to 15 electric heaters via output

"pilot wire".

The "pilot wire" handles only the hourly operation

of electric heaters (comfort mode / reduced mode

commutation and Frost protection mode).

The comfort temperature setting should be done

directly on the electric heater(s). The "pilot wire" does

not handle the temperature of the electric heaters.

Refer to the manual supplied with the electric heater(s).

Put the electric heaters on "PROG" mode or "AUTO"

mode for piloting by the regulation board.

The dierence between the comfort temperature and

the reduced temperature is from 3.5°C.

Frost protection temperature is set directly on the

electric heaters. Refer to the manual supplied with the

electric heater(s).

In the absence of signal, electric heaters operating in

comfort mode.

g. 10 - Selecting cooling mode

g. 11 - Selecting the frost protection

* depending on conguration / option

- 18 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 19

Telephone modem* (if Regulation

►

extension kit AVS 55)

It is possible to command the switching of the heating

mode to the "freeze" protection mode / reduced

(and vise versa) on the heat pump using a modem

contact.

The telephone command switches the current heat

pump settings to "freeze" protection mode / reduced

(and vise versa). In accordance with the setting, any

temperature requests from the heating circuits and the

DHW are ignored or activated.

The "freeze" protection mode / reduced must not be

selected on the heat pump and/or the remote control.

See with your installer.

Conguring room control unit*

►

(option)

In the event that the room control unit (see page 6),

is used, on start-up, after initialising for around

3 minutes, the language needs setting:

- Press OK.

- Choose menu "Operator section".

- Choose language "Language" English.

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 19 -

Page 20

Maintenance

In order to ensure that your appliance operates correctly

for many years, the maintenance operations described

below are required at the start of each heating season.

They are generally carried out as part of a maintenance

contract.

Regular checks

►

- Check the water pressure in the heating circuit

regularly (refer to the installer's recommended

pressure - between 1 and 2 bar)

- If a lling operation and a pressure increase are

required, check what type of uid was used initially

(when in doubt, contact your installer).

- If frequent rells are required it is absolutely essential

that you check for any leaks.

The frequent addition of water risks scaling the

exchanger and aects its performance and lifespan.

Checking the outdoor unit

►

Remove any dust from the exchanger, if necessary,

while making sure not to damage the blades.

Check that there is nothing blocking the air ow.

• Checking the refrigeration circuit

If the amount of refrigerant in the system exceeds 2kg

(models > 10 kW), the refrigeration circuit must be

checked annually by an approved engineer (they must

have a certicate of competence for the handling of

refrigerants).

Consult your heating technician.

Hot water tank*

►

Maintenance on the tank must be carried out annually

(frequency may vary according to water hardness).

Consult your heating technician.

* depending on conguration / option

- 20 -

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

Page 21

LED O:

The circulation pump is not working, no power supply.

Green LED On:

The circulation pump is operating normally.

Green LED ashing:

Venting mode in operation (10 minutes).

Red/green LED ashing:

Operating error with automatic restart.

Red LED ashing:

Operating error, consult your heating engineer.

g. 12 - Operating signals of the HP circulation pump

Waterstage / OPERATING INSTRUCTIONS / 2010 - EN

- 21 -

Loading...

Loading...