Page 1

29/01/2010

Waterstage 3 phase

Air/Water Heat Pump

Split System, Single Service 3 phase

112, 140 and 160

Document 1394-1 ~ 29/01/2010

Maintenance

Document

Intended for

professional use

Fujitsu General (Euro) GmbH

Werftstrasse 20

40549 Düsseldorf - Germany

Subject to change without notice

Non contractual document

EN

FR NL DE IT

Page 2

Page 3

29/01/2010

Contents

1 Technical Characteristics ..............................................................................................6

1.1 Specifications .................................6

1.2 Performance Data ..........................6

1.2.1 Rated Performance..........................6

1.2.2 Maximum Stated Performance ........6

1.2.3 Performance Curves for Waterstage

112................................................................7

1.2.4 Performance Curves for Waterstage

140................................................................7

1.2.5 Performance Curves for Waterstage

160................................................................8

1.3 Hydraulic Characteristics ...............8

1.4 Refrigeration Diagram.................... 9

2 Installation Rules..........................................................................................................10

2.1 Heat Pump ...................................10

2.1.1 Outdoor Units.................................10

2.1.2 Hydraulic Unit.................................11

2.2 Control Terminal...........................12

2.2.1 Room Unit ......................................12

2.2.2 User Interface ................................ 12

2.3 Electrical Connections .................14

2.3.1 Installation Precautions .................14

2.3.2 Electrical Connection Overview..... 14

2.3.3 Hydraulic Unit Connection Diagram16

3 Getting Started..............................................................................................................17

3.1 Checks .........................................17

3.1.1 Outdoor Unit...................................17

3.1.2 Hydraulic Unit.................................17

3.1.3 Hydraulic System ...........................17

3.1.4 Electrical System ...........................17

3.1.5 Refrigeration System .....................17

3.2 Settings ........................................18

3.3 Operating Modes..........................18

3.3.1 Manual Adjustment........................ 18

3.3.2 Auto Adapt Adjustment.................. 20

3.4 Control of Electric Backups.......... 20

3.5 Domestic Hot Water..................... 20

3.5.1 Principle of Operation.................... 21

3.6 Test Mode ....................................21

3.6.1 Sensor and Input Test Mode .........21

3.6.2 Output Test Mode.......................... 22

4 Faults .............................................................................................................................23

4.1 Fault List.......................................23

4.1.1 Hydraulic Unit Fault........................23

4.1.2 Outdoor Unit Fault..........................25

4.2 Outdoor Unit Clearing...................26

4.2.1 Failures with Error Code ................26

4.2.2 Failures With No Error Code..........48

4.3 Sensor Values..............................52

4.3.1 Outdoor Unit Temperature

Sensors.......................................................52

4.3.2 Hydraulic Unit Temperature

Sensors.......................................................52

4.4 Service parts information..............53

4.4.1 Service parts information 1 :

Compressor ................................................ 53

4.4.2 Service parts information 2 : Inverter

compressor................................................. 54

4.4.3 Service parts information 3 : Outdoor

unit electronic expansion valve (EEV,

EEV(INJ))....................................................55

4.4.4 Service parts information 4 : Outdoor

unit solenoid valve (SV).............................. 56

4.5 Operating Limits........................... 57

5 Failures..........................................................................................................................58

5.1 Hydraulic, Electric and Refrigeration

Systems ...................................................58

5.1.1 Hydraulic System ...........................58

5.1.2 Electrical System ...........................59

5.1.3 Refrigeration System ..................... 60

5.2 Compressor Operating Checks.... 62

5.3 Refrigeration Circuit Leak Test ....62

5.4 Troubleshooting ........................... 62

Page 4

Heat Pump, Split System, Single Service, 3 phase

4 Maintenance Document 1394-1

6 Control Settings............................................................................................................63

6.1 General ........................................ 63

6.2 Function Table ............................. 63

6.3 Adjustment Function Details ........ 69

6.3.1 Date and Time Functions.............. 69

6.3.2 User Interface Functions............... 71

6.3.3 Time Program Functions (heating circuit

1 & 2, DHW, cooling).................................. 73

6.3.4 Heating Circuit 1 & 2 Functions .... 74

6.3.5 Cooling Circuit 1 Functions ........... 82

6.3.6 DHW Functions ............................. 89

6.3.7 Swimming Pool Functions............. 92

6.3.8 Heat Pump Functions ....................92

6.3.9 DHW Tank Functions ....................93

6.3.10 Configuration Functions................. 95

6.3.11 Error Functions ..............................97

6.3.12 Maintenance / Special Operating Mode

Functions .................................................. 101

6.3.13 Input / Output Testing Functions .103

6.3.14 Status Functions.......................... 104

6.3.15 Generator Diagnosis Functions...109

6.3.16 Consumer Diagnosis Functions...110

7 Annual Maintenance Services ...................................................................................113

7.1 Hydraulic Circuit......................... 113

7.2 Outdoor unit ............................... 113

7.3 Electrical .................................... 113

7.4 Operating checks....................... 113

8 Connection Diagrams.................................................................................................114

8.1 Connection Diagram of Hydraulic

Unit..........................................................114

8.2 Connection Diagram of Outdoor

Unit.........................................................115

9 Disassembly Process of Outdoor Unit......................................................................116

9.1 Appearance................................ 116

9.2 Service panel removal ...............116

9.3 Insulation sheet removal ............116

9.4 Main PCB removal .....................117

9.5 INVERTER, PFC, FILTER, and

CAPACITOR PCB removal.................... 117

9.5.1 INVERTER PCB removal............ 118

9.5.2 PFC PCB removal....................... 118

9.5.3 FILTER PCB removal.................. 118

9.5.4 CAPACITOR PCB removal......... 119

9.6 FAN MOTOR removal................ 120

9.7 TOP PANEL removal .................120

9.8 PIPE COVER FRONT removal.. 120

9.9 RIGHT PANEL removal ............. 121

9.10 REACTOR removal....................121

9.11 THERMISTOR removal ............. 121

9.11.1 HEAT EXCHANGER (OUT)

THERMISTOR .......................................... 121

9.11.2 EXPANSION VALVE THERMISTOR

121

9.12 SOLENOID COIL removal......... 122

9.12.1 4WAY VALVE .............................. 122

9.12.2 INJECTION..................................122

9.13 EEV COIL removal .................... 122

9.13.1 MAIN............................................122

9.13.2 INJECTION..................................122

9.14 PRESSURE SENSOR removal. 122

9.15 COMPRESSOR removal........... 123

9.16 Precautions for exchange of

refrigerant-cycle-parts ........................... 125

10 Spare Parts..................................................................................................................126

11 Accessories.................................................................................................................127

11.1 DHW kit...................................... 127

11.2 Swimming pool kit...................... 127

11.3 2nd circuit kit.............................. 127

11.4 Room Sensor............................. 127

11.4.1 Room thermostat......................... 127

11.4.2 Remote control............................ 129

11.5 Boiler connection kit................... 130

11.6 Cooling kit.................................. 130

11.7 High flow rate circulation pump

kit............................................................130

11.8 Heat exchanger for swimming

pool.........................................................130

11.9 DHW tank .................................. 130

11.10 Balancing vessel........................ 130

11.11 External connect kit ................... 130

Page 5

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 5

12 Related Documents .................................................................................................... 131

12.1 Quick-Start Procedure................131

12.2 Startup Checklist........................132

12.3 Settings Sheet............................134

12.4 Startup Data Sheet .................... 135

Page 6

Heat Pump, Split System, Single Service, 3 phase

6 Maintenance Document 1394-1

1 Technical Characteristics

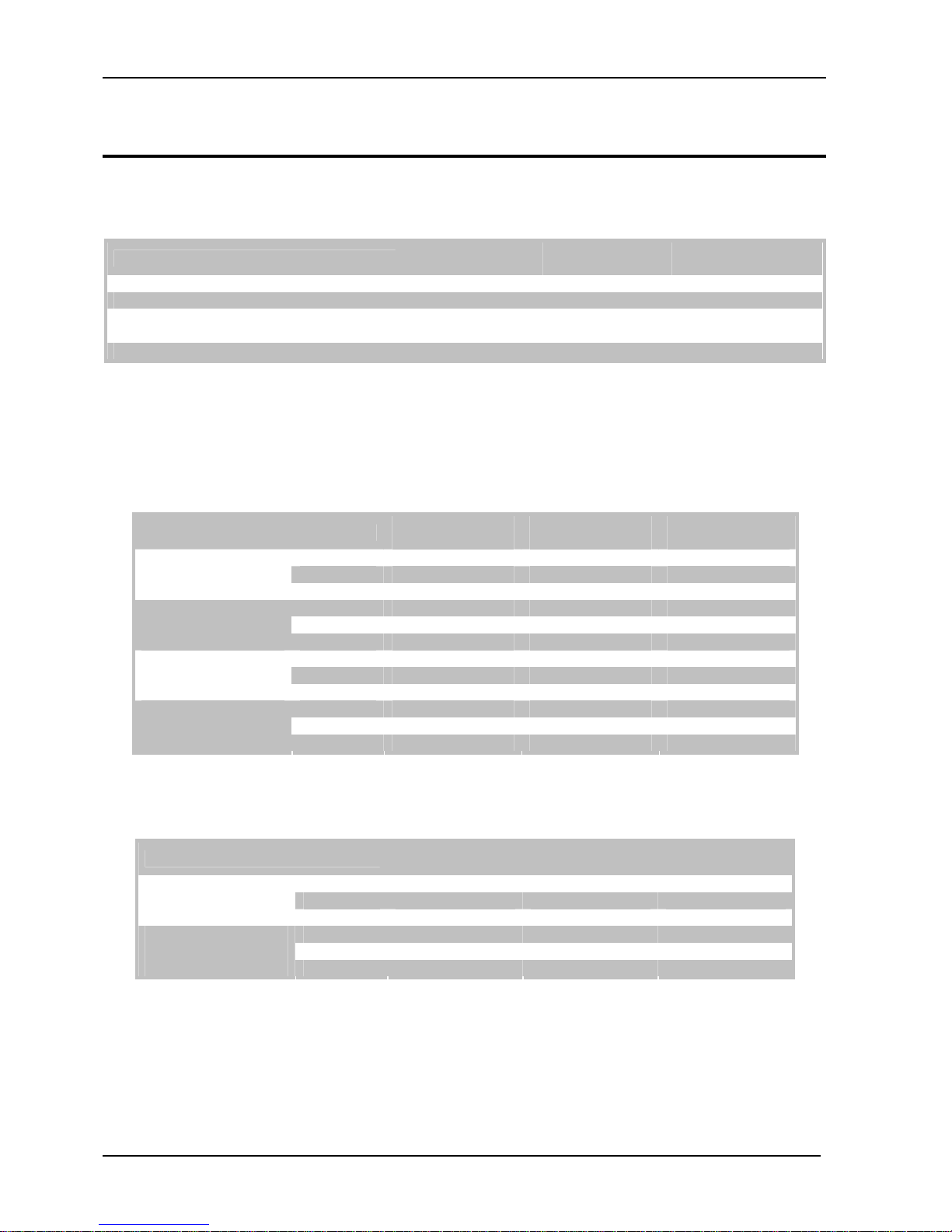

1.1 Specifications

Heating system operating limits

WATERSTAGE

112

WATERSTAGE

140

WATERSTAGE

160

Exterior temp mini/maxi °C -20/+35

Initial max heating water temperature

- Floor heating system °C 45

- Low temperature radiator °C 60

Flow min heating water temperature °C 8

1.2 Performance Data

1.2.1 Rated Performance

HEAT PUMP

WATERSTAGE

112

WATERSTAGE

140

WATERSTAGE

160

P

out

(kW) 11,2 14,00 16,00

Pin (kW) 2,51 3,22 3,72

+ 7°C/ + 35°C

-

HCF COP 4,46 4,35 4,30

P

out

(kW) 11,2 14,00 15,00

Pin (kW) 3,92 5,15 5,55

- 7°C/ + 35°C

-

HCF COP 2,86 2,72 2,70

P

out

(kW) 10,5 13,1 15,1

Pin (kW) 2,9 3,7 4,42

+ 7°C/ + 45°C

-

LT Radiators COP 3,62 3,54 3,42

P

out

(kW) 10,5 13,1 14,5

Pin (kW) 4,16 5,39 6,38

- 7°C/ + 45°C

-

LT Radiators COP 2,52 2,43 2,27

1.2.2 Maximum Stated Performance

HEAT PUMP

WATERSTAGE

112

WATERSTAGE

140

WATERSTAGE

160

P

out

(kW) 20,26 21,91 23,39

Pin (kW) 5,06 5,75 6,5

+ 7°C/ + 35°C

-

HCF COP 4,00 3,81 3,60

P

out

(kW) 17,09 18,67 20,20

Pin (kW) 5,04 5,67 6,43

+ 7°C/ + 45°C

-

LT Radiators COP 3,39 3,29 3,14

Page 7

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 7

1.2.3 Performance Curves for Waterstage 112

1.2.4 Performance Curves for Waterstage 140

Page 8

Heat Pump, Split System, Single Service, 3 phase

8 Maintenance Document 1394-1

1.2.5 Performance Curves for Waterstage 160

1.3 Hydraulic Characteristics

HEAT PUMP

WATERSTAGE

112

WATERSTAGE

140

WATERSTAGE

160

Connection diameter 1’’ – 25.4 mm (male)

Exchanger tank volume (L) 25

Expansion vessel volume (L) 8

Max pressure water circuit (Bar) 3

Max flow rate (l/h) 2400 3000 3400

Min flow rate (l/h) 1200 1500 1700

Min Delta T (°C) 4

Max Delta T (°C) 8

Page 9

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1

9

1.4 Refrigeration Diagram

TH C: Compressor temperature sensor

TH

D

: Discharge temperature sensor

TH HM: Outdoor exchanger middle temperature sensor

TH

HO

: Outdoor exchanger outlet temperature sensor

TH O: Outdoor temperature sensor

TH

PI

: Exchanger temperature sensor

Water

heat

exchanger

Heat

exchanger

Compressor

with

Injection port

Compressor

with

Injection port

4-

Way

valve

Strainer

Strainer

Pressure sensor

Expansion Valve

Outdoor Unit

Hydraulic Unit

Pressure

check valve

Expansion vessel

Air bleeding valve

Circulation pump

Heating

unit

(Floor

heating,

radiator,

etc)

Supply/drain

port

Pressure safety

valve

Pressure

gauge

Hot water

column sensor

Hot water

return sensor

Injection

expansion valve

TH

HO

TH

O

TH

D

TH

PI

TH

C

Expansion valve

inlet thermistor

Strainer

Buffer

tank

Auxiliary heater

Accumulator

Injection circuit

S

olenoid valve

Solenoid valve

Injection

expansion valve

Injection

expansion valve

TH

HM

Page 10

Heat Pump, Split System, Single Service, 3 phase

10 Maintenance Document 1394-1

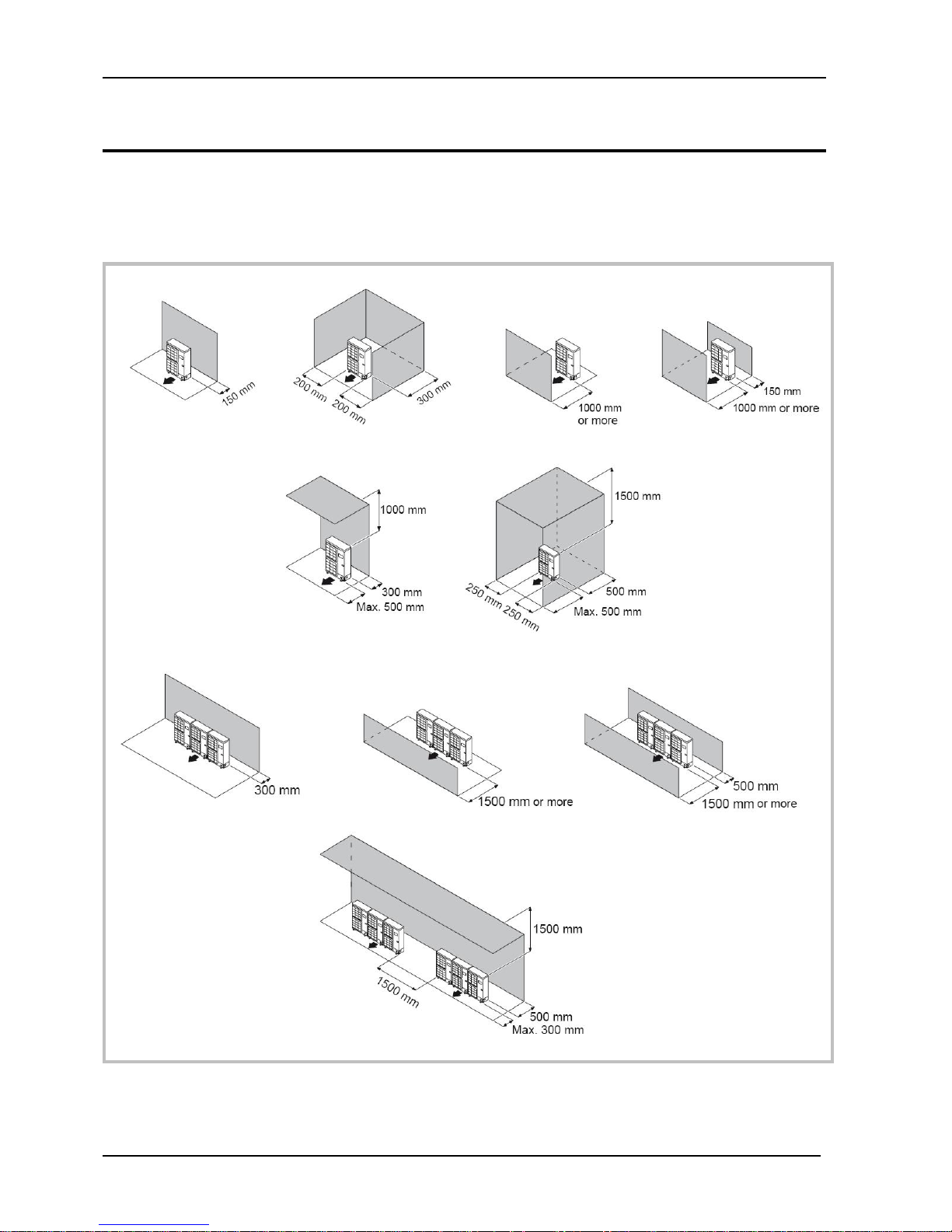

2 Installation Rules

2.1 Heat Pump

2.1.1 Outdoor Units

In snowy areas: raise the outdoor unit by a height equal to the maximum height of snow cover plus 20cm.

Page 11

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 11

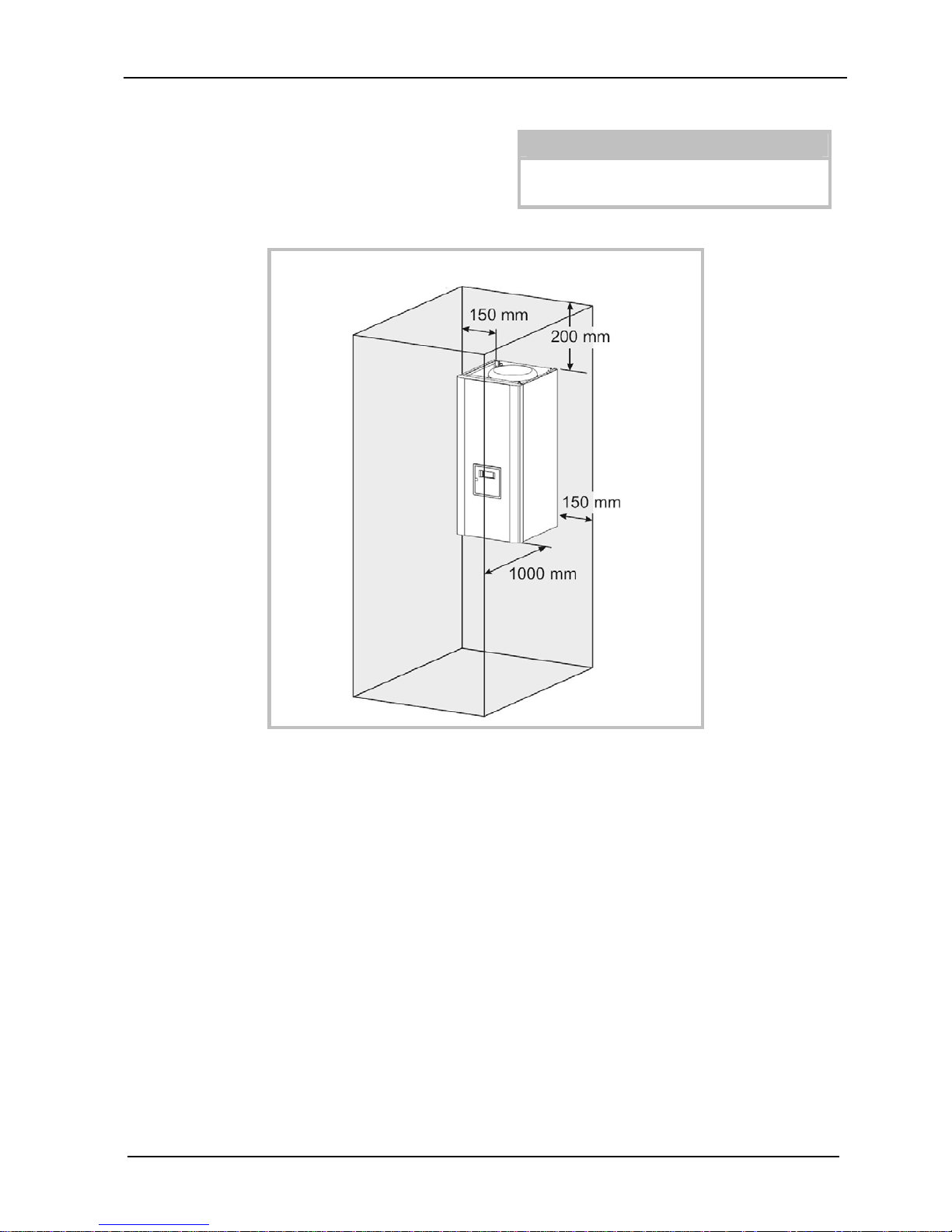

2.1.2 Hydraulic Unit

Minimum clearance dimensions must be provided

around the appliance as shown on the drawing, to

enable the machine to be serviced.

> Warning! <

Maintain a distance of at least 20 cm between

the unit and the ceiling to allow replacement of

heaters.

The Hydraulic Unit should be installed in such a way

that the distance between the module and the

outdoor unit is within the authorized range.

Beware of any flammable gas near the heat pump

during its installation, especially when it requires

brazing. In addition, the devices are not explosionproof and therefore, they must not be installed in an

explosive atmosphere.

Page 12

Heat Pump, Split System, Single Service, 3 phase

12 Maintenance Document 1394-1

2.2 Control Terminal

2.2.1 Room Unit

The room thermostat gives the user access to the

following basic functions:

• Adjustment of the room temperature setting by

simply turning the knob

• Selection of the heating mode

• Switching to comfort temperatures by simply

actuating the occupancy switch.

In addition, the room thermostat shows the user the

following information:

• the current temperature

• the heating mode

• the presence of a fault, when displaying the

symbol

2.2.2 User Interface

DHW function Select heating mode

Display information

Confirm setting

Activate cooling mode, off if

cooling option is not

available

Reset key

Navigation and

adjustment

Exit menu

Outdoor sensor:

2 x 0.5² cable

Service

plug (

BSB)

Select heating

mode

Room temperature setpoint control

knob

Occupancy key / day

ni

g

ht switch

Page 13

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 13

Select heating mode

Auto mode

:

The temperature is controlled automatically:

- Heating mode according to time program

- Automatic summer/winter changeover

Continuous operating modes

or :

The temperature setpoint is maintained:

-

: Heating to the comfort setpoint

-

: Heating to the reduced setpoint

Heating with no time program, no summer/winter

automatic changeover

Protection mode

:

The installation is maintained at the frost protection

temperature, on condition that the heat pump supply

voltage is not interrupted.

Activate cooling mode (off if option

is not available):

Cooling mode

The "Cooling" mode adjusts the room temperature

according to the time program.

Cooling mode properties:

- Manual cooling mode

- Cooling mode according to time program

- Temperature setpoint according to "Comfort

setpoint cooling"

- Protective functions active

- Summer/winter auto changeover active

- Summer compensation

DHW Function

This key stops or allows the production of DHW and

activates the "boost" mode, which allows the nominal

temperature to be reached at any time, regardless of

the time program. Electric auxiliaries are activated if

necessary be to reach the DHW temperature

setpoint. In general they are not activated for daytime

boosting at the reduced temperature setpoint, as long

as the temperature remains below 43°C.

On: DHW is produced according to the time program

Off ---: no DHW is produced, the frost protection

function is active

To start the boost function keep the key pressed for

3 seconds. DHW production comes "on" again when

the nominal setpoint has been reached.

Adjust comfort setpoint temperature

The comfort setpoint is adjusted directly by turning

the knob, the value must be confirmed with the OK

key.

Adjustment of the reduced setpoint will be described

in detail in the "control settings" section.

Display information

The information key displays various items of

information.

Error message symbol.

This symbol appears whenever there is a fault in the

installation. Press the info key for details.

Symbol for maintenance or special operating

mode, press the info key for details.

RESET

Reset symbol.

Keep the key pressed less than 3s for a reset: this

resets all error messages. This function must not be

used in normal operating conditions.

Page 14

Heat Pump, Split System, Single Service, 3 phase

14 Maintenance Document 1394-1

2.3 Electrical Connections

2.3.1 Installation Precautions

All machines in the ATW Split System Inverter range

are designed to operate at 3x400V 50Hz. Power

supplies must be compliant with NFC 15-100. The

power supply contract must be able to cover not only

the power of the unit but also the sum of powers of all

the devices likely to operate at the same time.

Protections will be of the omnipolar, D curve circuit

breaker type, with a contact opening distance of at

least 3 mm. Lines will be made of HO7 RNF cable or

similar. Provide a 300 mA maximum, differential

protection line-end in compliance with the current

standards. Under no circumstances (including during

startup periods) may the voltage across the unit drop

below 198V or rise above 264V. Do not use a power

outlet as the power supply.

> Warning ! <

Cable cross-sections and protection ratings

are given for information only. The installation

technician should always check that these

components are in line with the maximum

current ratings and the standards applied on

the installation premises

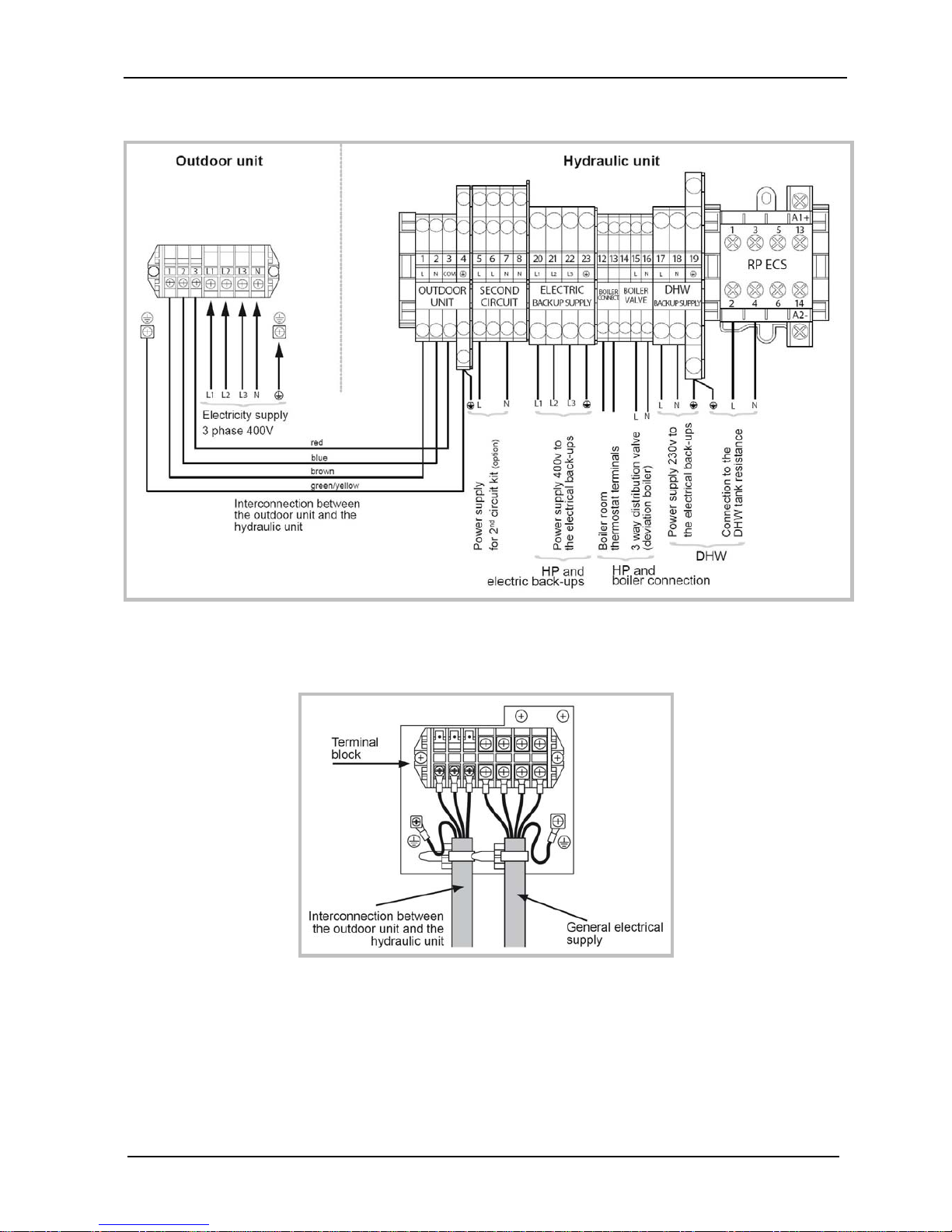

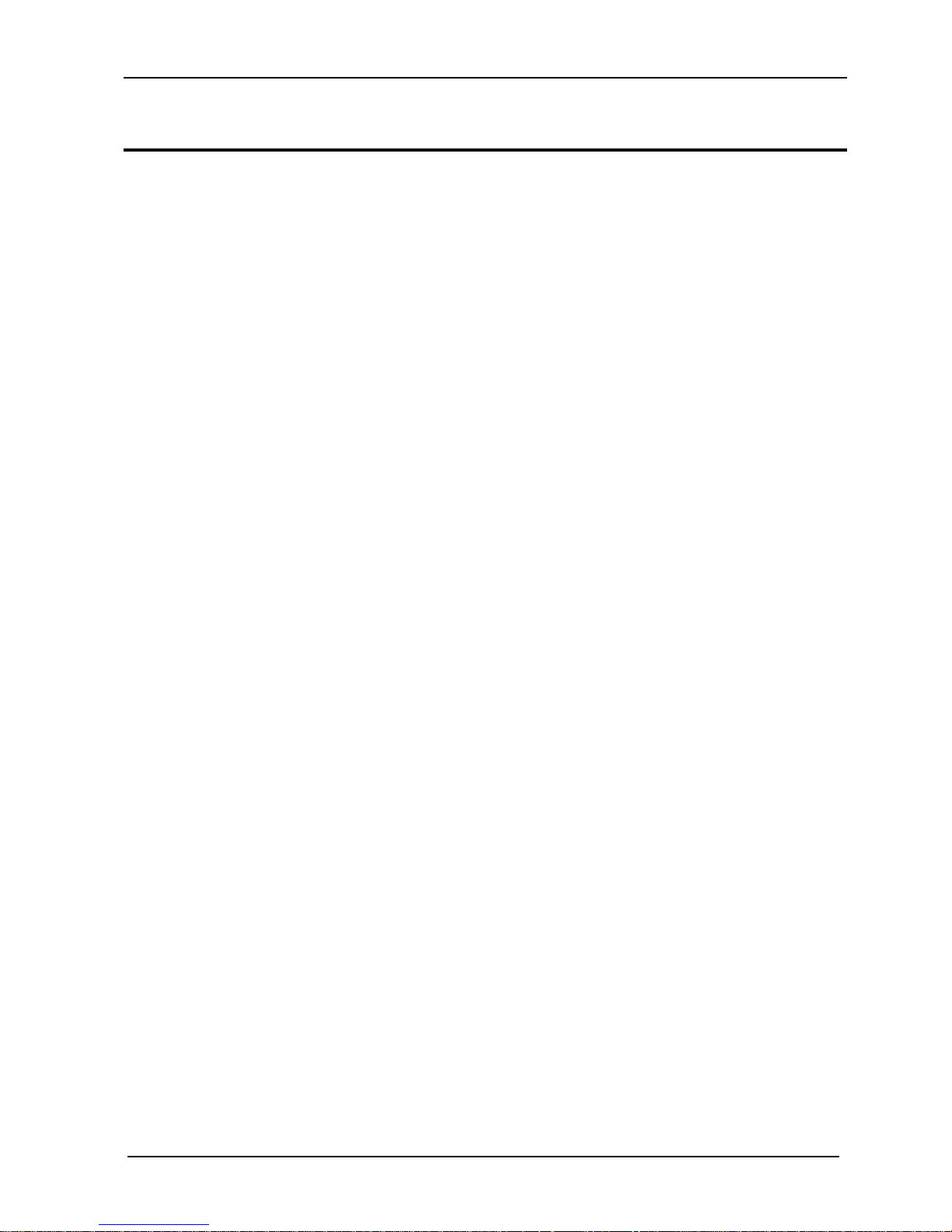

2.3.2 Electrical Connection Overview

Block diagram of electrical connections for a simple installation: one zone, no boiler backup or DH W

Two connections to the electrical panel:

• Heat pump general power supply on the outdoor

unit

• Electric auxiliary power supply on the Hydraulic

Unit

Interconnection between the Hydraulic Unit and the

outdoor unit.

Connection of the outdoor sensor and the room

thermostat.

Page 15

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 15

Hydraulic Unit Connection

Outdoor Unit Connection

The wiring of all Waterstage outdoor units is as follows:

Page 16

Heat Pump, Split System, Single Service, 3 phase

16 Maintenance Document 1394-1

2.3.3 Hydraulic Unit Connection Diagram

* If the control device does not provide a potential-free contact, the contact must be relayed to create equivalent

wiring. In all cases, please refer to the instruction manuals for the external components (load limiting device,

power meters) to create the wiring.

** If several fault inputs are required, they are to be wired in series (they must be of the normally-open type).

Page 17

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 17

3 Getting Started

3.1 Checks

3.1.1 Outdoor Unit

• Unit is secured to a stable surface

• Unit is raised in regions of regular snowfall

• Distances to potential obstacles or hazards are

maintained

• A condensate drain line is connected

3.1.2 Hydraulic Unit

• Unit is secured to a stable surface

• There is enough space for maintenance around the

unit

• There is free access to the unit

• There are no leaks

3.1.3 Hydraulic System

• Check the conformity of connections

• The use of flexible connections is recommended

• The system must be flushed

• Check the expansion vessel pre-charging (1 bar)

• Check the system's pressure and purge

• Check that the pump(s) is/are not locked

3.1.4 Electrical System

• Check the conformity of connections (per NFC

15100)

• Check that the lines are protected (two C curve

circuit breakers for "heat pump" and "auxiliaries",

lines must be separate)

• Differential protection is required (up to 300 mA).

• Check that connections are properly tightened

(flexible wire tips)

• Check the main power supply voltage and make

sure the polarity is correct

• Find out what type of contract has been subscribed

with the power company (load shedding)

3.1.5 Refrigeration System

• Make sure connections are compliant (diameters,

minimum and maximum lengths)

• Flare fittings must be properly made

• Use only HFC-specific tools and materials (POE oil,

etc.)

• For welding, use silver welding (40% min.) under

nitrogen flux

• Comply with the refrigerant handling legislation

• Conduct a nitrogen pressure leak test (~ 25 bar)

• Pump-down is required (preferably using a

vacuometer)

• Open both valves on the outdoor unit (first the liquid

valve then the gas valve)

• Supplement if necessary (according to the tables in

the instructions)

• Check fittings for tightness

• Check that pipes are correctly insulated and

fastened

Page 18

Heat Pump, Split System, Single Service, 3 phase

18 Maintenance Document 1394-1

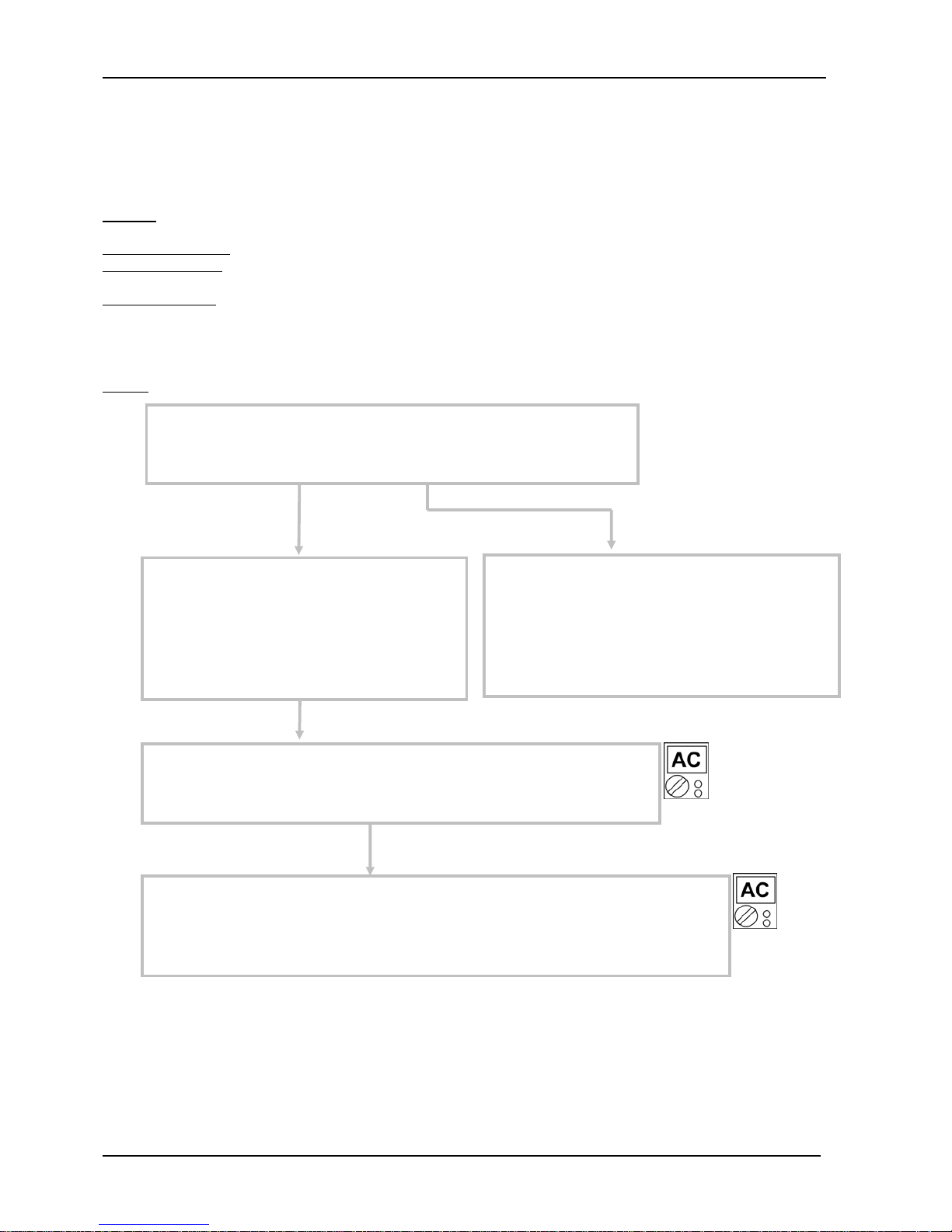

3.2 Settings

Depending on their associated functions, the control

settings are not accessed at the same level. There

are 4 levels of access:

U: end-user level

I: commissioning level (installer start-up)

S: engineer level (specialist)

C: OEM level (manufacturer)

To get to the level of access desired:

• Press OK: you are now on the main menu

• Press the info key for 3s (pressing continuously)

• To select the desired level, turn the control knob

• Press OK to confirm: this takes you back to the

main menu, with the rights associated to that

level. If you exit the main menu by returning to

the main page, the access level goes back to U

(end-user level)

To adjust the various settings:

• From the main menu, after obtaining the desired

level

• turn the control knob to scroll the menu

• When the desired menu appears, press OK to

confirm

• Turn the control knob to adjust the setting

• Press OK to confirm the setting

If not setting has been made for 8 minutes, the

screen automatically returns to the basic display.

3.3 Operating Modes

Heat pumps are controlled according to the heating

curve principle, i.e., the setpoint temperature of the

heating circuit water is adjusted as a function of the

outdoor temperature.

In heating mode, the choice of the heating curve best

suited to the machine's operating conditions can be

made automatically by the machine (auto-adapt) or

adjusted manually by the installation technician

(Settings 720, 721 and 726).

3.3.1 Manual Adjustment

During installation the heating curve must be defined

according to the emitters and the home's insulation.

Page 19

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 19

20

30

40

50

60

70

-20,0-15,0-10,0-5,00,05,010,015,020,0

Outdoor Temperature (°C)

Heating Flow Temperature (°C)

0,25

0,5

0,75

1

1,25

1,5

1,75

2

Heating Curves

Graph 1: Heating Curves

The heating curves shown above refer to a 20°C

room temperature setpoint.

The heating curve slope (setting 720) determines the

impact of outdoor temperature variations on heating

flow temperature variations. The steeper the slope,

the higher will be the increase in the heating circuit

water flow temperature which occurs when the

outdoor temperature increases slightly.

The heating curve offset (setting 721) changes the

flow temperature of all curves, without the slope

being modified.

The corrective actions in case of discomfort are listed

in the following table:

Feeling of discomfort Corrective action

By mild weather By cold weather Heating curve slope Offset

Too cold Too warm Decrease Increase

Too cold OK Decrease Increase

Too cold Too cold OK Increase

OK Too warm Decrease OK

OK OK OK OK

OK Too cold Increase OK

Too warm Too warm OK Decrease

Too warm OK Increase Decrease

Too warm Too cold Increase Decrease

Page 20

Heat Pump, Split System, Single Service, 3 phase

20 Maintenance Document 1394-1

3.3.2 Auto Adapt Adjustment

When this function has been activated (setting 726)

the heating curve is automatically adjusted, and

therefore, there is no need to change the slope or

offset of the heating curve.

In order for the auto adapt feature to be operational:

• a room sensor must be connected

• the room influence parameter must be set

between 1 and 99 (setting 750) (depending on

the system, the room sensor may influence the

heating curve adjustment to a greater or lesser

extent)

• the room in which the room sensor is installed

must not contain any thermostatic valves. If it

does, these valves must be fully opened.

This function may cause some feeling of discomfort.

This is because in order for the function to be valid,

the system needs time to stabilize, which can take

more or less time depending on the weather

conditions. In general it takes at least a week, without

the room temperature setpoint being changed, for the

auto-adaptive control to be operational.

3.4 Control of Electric Backups

H 3

EX 4 EX 5 EX 6

Outdoor

Unit Fault

Load-shedding (EJP) Off-peak/peak

hours

External fault

(369)

(370)

0 V 230 V 230 V 0 V 230 V 0 V 230 V

EJP lock signal (l 2920)

"released"

"locked"

HEAT PUMP

OFF

ON ON OFF ON ON ON OFF

DHW auxiliary

ON (1)

ON OFF OFF ON OFF ON OFF

1st stage elec. auxiliary

ON (2)

ON OFF OFF ON ON ON OFF

2nd stage elec. auxiliary

ON (2)

ON OFF OFF ON ON ON OFF

Boiler backup

ON (2)

ON ON ON ON ON ON OFF

(1) subject to authorization by EX5

(2) provided the outdoor temperature is less than the setting on "2884 or 3700" (+2° from the beginning)

3.5 Domestic Hot Water

The heat pump may be connected to a combined

heating device (heat exhanger + electric auxiliaries)

for domestic hot water.

DHW handling requires a DHW kit. This kit includes a

3-way selection valve and a temperature sensor.

Warning: the maximum DHW temperature reached

with the heat pump does not exceed 60°C. Therefore,

the tank must be equipped with an electric auxiliary,

especially for legionella protection cycles.

Page 21

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 21

3.5.1 Principle of Operation

DHW production starts when the temperature inside

the tank is 7°C less than the setpoint temperature.

The setpoint can be either a "reduced" or a "nominal"

setpoint, depending on time program 4. During the

programmed time periods it is the nominal setpoint

which is active, and outside of these periods it is the

reduced setpoint which is active. Thus, to avoid

accidental DHW charge boosting outside of the

nominal time periods, we recommend having a

reduced setpoint as low as possible in order to avoid

the starting of DHW production outside the

programmed time period.

• T

reduced

: the temperature outside the time period.

This DHW temperature can be reached with the

heat pump alone. This requires that the

temperature does not exceed 35°C.

• T

nominal

: the temperature within time period 4,

which is approached first with the heat pump then

with the electric auxiliaries or the boiler backup (if

necessary).

Both of these temperatures are

adjustable (settings 1610 and 1612).

If the installation's power supply contract includes a

Peak/Off-Peak rate subscription, the heaters will be

controlled by the power rates and T

nominal

will be

reached only during Off-Peak Hours. This requires

that input E5 is wired as shown on Figure 1: Typical

Wiring of External

Devices.

If no special power supply contract has been

subscribed to, or if the DHW input is not wired, T

nominal

will be reached according to time program 4 / DHW.

The T

nominal

temperature can thus be reached at any

time, including during the day.

During the day, DHW has priority over heating,

however, DHW production is controlled by cycles

which regulate the times allocated to heating and to

DHW production in case of simultaneous demands.

A DHW boost function is available on the user

interface front panel. This DHW boost enables the

DHW to be heated up to T

nominal

at any time during the

day. The boost function is automatically cancelled

after a given time (which can be configured). The

boost function can be used only if DHW programming

has been performed. If the DHW is in nominal mode

(nominal T) the boost function is obviously

inoperative.

Legionella protection cycles can be programmed.

3.6 Test Mode

3.6.1 Sensor and Input Test Mode

LINE SENSOR INPUT WATERSTAGE

7730 B9 Outdoor temperature

7820 BX1 DHW temperature

7823 BX4 Heat pump flow temperature

7824 BX5 Heat pump return temperature

7830 BX21 (1) Circuit 1 flow T if 2 circuits (or sw pool)

7831 BX22 (1)

7832 BX21 (2)

7833 BX22 (2)

7841 H1 defrost information

7846 H2 swimming pool operation (if optional)

7855 H3 outdoor unit fault (370)

7914 EX4 Auxiliary load-shedding (EJP)

7915 EX5 Peak/Off-peak rates

7916 EX6 External fault (369)

Page 22

Heat Pump, Split System, Single Service, 3 phase

22 Maintenance Document 1394-1

3.6.2 Output Test Mode

LINE OUTPUT WATERSTAGE

7700 QX23 (1) Circuit 1 heating pump or swimming pool selection valve

QX21 (1) Open mixing valve 1

QX22 (1) Close mixing valve 1

QX1

QX2 DHW heating circuiting pump (if connected)

QX3 Circuit 2 heating pump

QX4 DHW selection valve

QX5 Boiler selection valve (or heater 1)

QX6 Boiler (or heater 2)

QX23 (2)

QX21 (2)

QX22 (2)

QX7 DHW electrical auxiliary

7710 UX Output test UX %

7711 UX Voltage signal UX

7721 DO 1 Heating (or cooling) mode

7722 DO 2 Outdoor unit operation

Page 23

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 23

4 Faults

4.1 Fault List

4.1.1 Hydraulic Unit Fault

Faults which occur on the Hydraulic Unit are shown

by the symbol

. Press the info key for details on the

cause of the fault. The following information is

displayed:

• Description of the error

• Location of the error (sensor or contact)

• Reset. Depending on its type, the fault can be

manually or automatically deleted:

Manual delete: the text displayed when pressing

the info key shows "reset ?". Press OK once, the

yes flashes; press again to confirm deletion of the

fault.

Faults whose deletion is automatic are

automatically reset.

• Heat pump op: shows whether or not the heat pump

operates despite the fault.

Reset

No.: Designation of error

Location

(connection)

Manual Auto

HP op

10: Outdoor sensor B9 No No Yes

33: Heat pump flow temp sensor error B21 No No Yes

44: Heat pump return temp sensor error B71 No No per diagram

50: DHW temp sensor B3 No No Yes

60: Room sensor 1 No No Yes

65: Room sensor 2 No No Yes

105: Maintenance message No No Yes

121: HC1 flow temp not reached No No Yes

122: HC2 flow temp not reached No No Yes

127: Legionella protection temp not reached No No Yes

369: External fault (safety component)

No

370: Outdoor unit fault* Yes Yes No

* A fault in the outdoor unit is indicated by LED located on the Hydraulic Unit interface board.

LED display

LED 2 (green) LED 1(red)

Fault description

1 Flash 1 Flash Communication error between Hydraulic Unit and Outdoor unit.

4 Flashes 1 Flash Heat pump capacity signal error (Open or short).

4 Flashes 2 Flashes Hydraulic Unit heat-exchange thermistor Error.

6 Flashes 3 Flashes Inverter error.

6 Flashes 4 Flashes Active filter error.

PFC error.

7 Flashes 1 Flash Discharge thermistor error.

7 Flashes 2 Flashes Compressor thermistor error.

7 Flashes 3 Flashes Heat-exchange thermistor (outlet) error.

Heat-exchange thermistor (intermediate) error.

7 Flashes 4 Flashes Outdoor thermistor error.

7 Flashes 7 Flashes Heat sink thermistor (inverter) error.

Heat sink thermistor (P.F.C.) error.

7 Flashes 8 Flashes Expansion valve thermistor error.

8 Flashes 4 Flashes Current sensor error.

8 Flashes 6 Flashes Pressure sensor error.

Pressure switch error.

9 Flashes 4 Flashes Current trip.

9 Flashes 5 Flashes Detection of compressor position error.

Compressor start up error.

9 Flashes 7 Flashes Outdoor unit fan motor error.

10 Flashes 1 Flash Discharge temperature protection.

10 Flashes 3 Flashes Compressor temperature protection.

10 Flashes 5 Flashes Low pressure abnormal.

Continuous flashing (1 sec ON / 1 sec OFF) Pump down operation.

Page 24

Heat Pump, Split System, Single Service, 3 phase

24 Maintenance Document 1394-1

Faults external to the heat pump

Any safety device (e.g. thermostat pressure switch)

wired to input Ex6 (E20) allows external problems to

be reported and the heat pump to be immediately

stopped. For example, a safety thermostat on the

heating floor can be wired to input Ex6 (E20) to avoid

excessively high temperatures in the floor.

Figure 1: Typical Wiring of External Devices

If the control unit does not provide a potential-free

contact, the contact will have to be relayed to obtain

an equivalent wiring.

In any case, you should refer to the manuals for the

external devices (e.g. load shedders, electricity

meters) to perform the wiring.

…

Phase

Neutral

Heat pump connecting

blocks

… X5 X6 X7 X8

to inputs Ex4,

Ex5 or EX6

External

device

contact

(e.g. load-

shedder,

electricity

meter

)

Heat pump

H

y

draulic Unit

Page 25

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 25

4.1.2 Outdoor Unit Fault

When the system is switched back on after a power

outage, the Hydraulic Unit may display fault 370 for a

few tens of seconds. This is not a serious problem. It

simply means that the outdoor unit is running its

tests. Once the tests have been completed, the fault

should disappear.

If it doesn't, if a fault has occurred on the outdoor unit

as indicated by the Hydraulic Unit, you must remove

the front (right-hand) facing from the outdoor unit.

Faults are coded by LED flashes. Error messages are

listed in the table below:

On the outdoor unit

When an error occurs:

- The diode “ERROR” (2) blinks

Press once on the switch “ENTER” (SW4)

- The “ERROR” (2) diode blinks several times depending on the error’s type

Location of switches and diodes on outdoor unit

LED display on the outdoor unit

LED display

Hydraulic Unit

Diagnosis Clear

Green Red

Outdoor unit

Off Serial reverse transfer error. 1

1 flash 1 flash

1 flash Serial forward transfer error. 2

4 flashes 1 flash 22 flashes Heat pump capacity signal error 4

4 flashes 2 flashes 22 flashes Hydraulic Unit Heat ex. Sensor error 5

6 flashes 3 flashes 18 flashes Inverter error. 20

6 flashes 4 flashes 19 flashes P.F.C. error. 27

7 flashes 1 flash 2 flashes Discharge thermistor error. 7

7 flashes 2 flashes 8 flashes Compressor thermistor error. 11

5 flashes Heat-exchange thermistor (intermediate) error. 12

7 flashes 3 flashes

4 flashes Heat-exchange thermistor (outlet) error. 8

7 flashes 4 flashes 7 flashes Outdoor temperature thermistor error. 9

9 flashes Heat sink thermistor (inverter) error. 10

7 flashes 7 flashes

10 flashes Heat sink thermistor (P.F.C.) error. 13

7 flashes 8 flashes 6 flashes Expansion valve thermistor error. 14

8 flashes 6 flashes 3 flashes Pressure sensor error. 24

9 flashes 4 flashes 13 flashes Current trip (permanent stoppage). 15

14 flashes Detection of compressor position error (permanent stoppage). 33

9 flashes 5 flashes

15 flashes Compressor start up error (permanent stoppage). 17

16 flashes Outdoor unit fan 1 motor error.

9 flashes 7 flashes

17 flashes Outdoor unit fan 2 motor error.

18

10 flashes 1 flash 11 flashes Discharge temperature protection (permanent stoppage). 22

10 flashes 3 flashes 12 flashes Compressor temperature protection (permanent stoppage). 25

10 flashes 5 flashes 20 flashes Low pressure abnormal. 26

Page 26

Heat Pump, Split System, Single Service, 3 phase

26 Maintenance Document 1394-1

4.2 Outdoor Unit Clearing

This section describes the techniques which can be used to identify the failure.

4.2.1 Failures with Error Code

Clear 1: Serial reverse transfer error

Hydraulic Unit LED:

Green 1 flash / Red 1 flash

Outdoor Unit LED: Off

Probable causes:

• Misconnection.

• External cause.

• Main PCB failure.

Check:

1-1. Stop the system and start it again (disconnection time 1min):

Is the error still displayed?

YES NO

3. Check the power supply voltage:

- Check that an AC 198 – 264 V voltage exists between terminals 1 and 2,

L1 and N, L2 and N, L3 and N on the outdoor unit terminal block.

OK

4. Check the serial signal:

- Check the voltage between terminals 2 and 3 of the outdoor terminal block. The

voltage must fluctuate between AC 70 V and AC 130 V.

- If it doesn't, replace Main PCB.

OK

1-2. Check for external causes:

- Check the system's overall isolation.

- Check for any equipment generating

electromagnetic waves which interfere with the

communication between the hydraulic unit and the

outdoor unit.

2. Check the connections:

- Check the connection between the hydraulic

unit and the outdoor unit.

- Check the connections between the outdoor

unit main board and the active filter board.

Page 27

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 27

Clear 2: Serial forward transfer error

Hydraulic Unit LED:

Green 1 flash / Red 1 flash

Outdoor Unit LED: 1 flash

Probable causes:

• Misconnection.

• External cause.

• Interface PCB failure.

Check:

1-1. Stop the system and start it again (disconnection time 1min):

Is the error still displayed?

YES NO

3. Check the power supply voltage:

- Check that an AC 198 – 264 V voltage exists between terminals 1 and 2,

L1 and N, L2 and N, L3 and N on the outdoor unit terminal block.

OK

4. Check the serial signal:

- Check the voltage between terminals 2 and 3 of the outdoor terminal block. The

voltage must fluctuate between AC 70 V and AC 130 V.

- If it doesn't, replace Interface PCB.

OK

1-2. Check for external causes:

- Check the system's overall isolation.

- Check for any equipment generating

electromagnetic waves which interfere with the

communication between the hydraulic unit and the

outdoor unit.

2. Check the connections:

- Check the connection between the hydraulic

unit and the outdoor unit.

- Check the connections between the outdoor

unit main board and the active filter board.

Page 28

Heat Pump, Split System, Single Service, 3 phase

28 Maintenance Document 1394-1

Clear 4: Heat pump capacity signal error

Hydraulic Unit LED:

Green 4 flashes / Red 1 flash

Outdoor Unit LED: 22 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Interface PCB failure.

Check:

1. Check connection interface PCB and Heat pump regulator PCB:

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Check resistance value:

3 pin of CN22 – M < 10Ω

OK

3. Replace interface PCB:

If check point 1 and 2 do not improve the symptom, replace Interface PCB.

OK

Page 29

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 29

Clear 5: Hydraulic Unit Heat exchanger thermistor error

Hydraulic Unit LED:

Green 4 flashes / Red 2 flashes

Outdoor Unit LED: 22 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Interface PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been removed

- See if the connection is correct

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C)

0 5 10 15 20 25 30 35 40 45 50

Resistance (kΩ)

176 134 103 80,3 62,9 49,7 39,6 31,7 25,6 20,8 17,1

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of hydraulic unit and check terminal voltage at thermistor

(DC5.0V)

- If there is no voltage, replace Interface PCB.

OK

Page 30

Heat Pump, Split System, Single Service, 3 phase

30 Maintenance Document 1394-1

Clear 7: Discharge thermistor error

Hydraulic Unit LED:

Green 7 flashes / Red 1 flash

Outdoor Unit LED: 2 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value:

- Check the resistance value

Temperature (°C) 0 5 10 15 20 30 40 50

Resistance (kΩ) 168 130 101 79 63 40 26,3 17,8

Temperature (°C) 60 70 80 90 100 120

Resistance (kΩ) 12,3 8,7 6,3 4,6 3,4 2

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

Page 31

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 31

Clear 8: Heat-exchange thermistor (outlet) error :

Hydraulic Unit LED:

Green 7 flashes / Red 3 flashes

Outdoor Unit LED: 4 flashes

Probable causes:

• Misconnection.

• Sensor fault.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistancer value

Temperature (°C) -10 -5 0 10 15 20 25 30

Resistance (kΩ) 27,5 20,9 16,1 12,4 9,73 7,67 6,1 3,95

- If the thermistor is faulty, replace it.

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor

(DC5.0V)

- If there is no voltage, replace Main PCB.

OK

OK

Page 32

Heat Pump, Split System, Single Service, 3 phase

32 Maintenance Document 1394-1

Clear 9: Outdoor temperature thermistor error

Hydraulic Unit LED:

Green 7 flashes / Red 4 flashes

Outdoor Unit LED: 7 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection :

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C) -20 -10 -5 0 5 10 15 20 30 40 50 60 70

Resistance (kΩ) 115 62,3 46,6 35,2 26,9 20,7 16,1 12,6 7,97 5,18 3,45 2,36 1,65

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

Page 33

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 33

Clear 10: Heat Sink Thermistor (inverter) error

Hydraulic Unit LED:

Green 7 flashes / Red 7 flashes

Outdoor Unit LED: 9 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Inverter PCB failure.

Check:

1. Check the sensor connection :

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C) 0 5 10 15 20 30 40 50

Resistance (kΩ) 15,8 12,2 9,5 7,5 5,9 3,78 2,50 1,69

Temperature (°C) 60 70 80 90 100 120

Resistance (kΩ) 1,17 0,83 0,6 0,44 0,33 0,19

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Inverter PCB.

OK

Page 34

Heat Pump, Split System, Single Service, 3 phase

34 Maintenance Document 1394-1

Clear 11: Compressor thermistor error

Hydraulic Unit LED:

Green 7 flashes / Red 2 flashes

Outdoor Unit LED: 8 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been removed

- See if the connection is correct

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C) 0 5 10 15 20 30 40 50

Resistance (kΩ) 168 130 101 79 63 40 26,3 17,8

Temperature (°C) 60 70 80 90 100 120

Resistance (kΩ) 12,3 8,7 6,3 4,6 3,4 2

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

Page 35

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 35

Clear 12: Heat-exchange thermistor (intermediate) error

Hydraulic Unit LED:

Green 7 flashes / Red 3 flashes

Outdoor Unit LED: 5 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been disconnected.

- See if the connection is correct.

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value

Temperature (°C) -10 -5 0 10 15 20 25 30

Resistance (kΩ) 27,5 20,9 16,1 12,4 9,73 7,67 6,10 3,95

- If the thermistor is faulty, replace it.

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

OK

Page 36

Heat Pump, Split System, Single Service, 3 phase

36 Maintenance Document 1394-1

Clear 13: Heat sink thermistor (P.F.C.) error

Hydraulic Unit LED:

Green 7 flashes / Red 7 flashes

Outdoor Unit LED: 10 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been removed

- See if the connection is correct

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C) 0 5 10 15 20 30 40 50

Resistance (kΩ) 15,8 12,2 9,5 7,5 5,9 3,78 2,50 1,69

Temperature (°C) 60 70 80 90 100

110

120

Resistance (kΩ)

1,17 0,83 0,60 0,44 0,33 0,25 0,19

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

Page 37

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 37

Clear 14:

Expansion valve thermistor error

Hydraulic Unit LED:

Green 7 flashes / Red 8 flashes

Outdoor Unit LED:

6 flashes

Probable causes:

• Misconnection.

• Sensor failure.

• Main PCB failure.

Check:

1. Check the sensor connection:

- See if the connector has been removed

- See if the connection is correct

- Check for any damage on the sensor cable.

After solving the misconnection problem, switch the heat pump back on.

2. Remove the sensor and check its resistance value :

- Check the resistance value.

Temperature (°C) 0 5 10 15 20 30 40 50

Resistance (kΩ) 168 130 101 79 63 40 26,3 17,8

Temperature (°C) 60 70 80 90 100 120

Resistance (kΩ) 12,3 8,7 6,3 4,6 3,4 2

- If the thermistor is faulty, replace it.

OK

3. Check the electronic board voltage:

- Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

- If there is no voltage, replace Main PCB.

OK

Page 38

Heat Pump, Split System, Single Service, 3 phase

38 Maintenance Document 1394-1

Clear 15: Current trip (permanent stoppage)

Hydraulic Unit LED:

Green 9 flashes / Red 4 flashes

Outdoor Unit LED: 13 flashes

Probable causes:

• Connection failure.

• Outdoor Heat Exchanger clogged.

• Outdoor Fan operation failure.

• Compressor failure.

• Inverter PCB failure.

Check:

1. Check connections condition in control unit:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

OK

3. Check Outdoor Fan:

- Check Outdoor Fan Motor. (Refer to Clear 18)

If the Fan Motor is failure

,

replace it.

OK

4. Check Compressor:

Refer to “Service parts information 2 : Inverter compressor

If it is abnormal, replace compressor.

OK

2. Check Outdoor Heat Exchanger:

- Is there any obstructing the air flow route?

- Is there any clogging of outdoor unit Heat Exchanger?

If clogged, clear the clog.

5. Replace Inverter PCB:

If Check Point 1 ~ 4 do not improve the symptom, replace Inverter PCB.

OK

Page 39

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 39

Clear 17: Compressor startup error (permanent stoppage)

Hydraulic Unit LED:

Green 9 flashes / Red 5 flashes

Outdoor Unit LED: 15 flashes

Probable causes:

• Misconnection of the various electrical components.

• Inverter PCB failure.

• Compressor failure.

Check:

2. Check Compressor:

Refer to “Service parts information 2 : Inverter compressor

If it is abnormal, replace compressor.

3. Replace the electronic board :

- If steps 1 and 2 do not solve the problem, replace Inverter PCB.

OK

1. Check connections condition in control unit:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

OK

Page 40

Heat Pump, Split System, Single Service, 3 phase

40 Maintenance Document 1394-1

Clear 18: Fan motor error (permanent stoppage)

Hydraulic Unit LED:

Green 9 flashes / Red 7 flashes

Outdoor Unit LED: 16 flashes (fan 1), 17 flashes (fan 2)

Probable causes:

• Fan motor failure.

• Motor protection.

• Main PCB failure.

Check:

1. Check fan rotation:

- Switch off the heat pump and rotate the fan manually.

- If the fan or bearings are faulty, replace them.

2. Check the ambient temperature around the motor:

- Check excessively high temperature around the fan.

Wait until the temperature comes down again and switch the

fan back on.

3. Check the main board output voltage:

- On the outdoor unit, check the output voltage (DC) of the following connectors:

Terminals Voltage

1 (red)/ 3 (black) 250 400V

4 (white)/3 (black) 15 ±2V

If the voltage is incorrect, replace Main PCB.

OK

OK

Page 41

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 41

Clear 20: Inverter error

Hydraulic Unit LED:

Green 6 flashes / Red 3 flashes

Outdoor Unit LED: 18 flashes

Probable causes:

• Connection failure.

• Main PCB failure.

• Inverter PCB failure.

Check:

1. Check connections in control unit:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset

the power.

2. Replace Main PCB and Inverter PCB:

If Check Point 1 do not improve the symptom, replace Main

PCB and Inverter PCB.

OK

Page 42

Heat Pump, Split System, Single Service, 3 phase

42 Maintenance Document 1394-1

Clear 22: Discharge temperature protection (permanent stoppage)

Hydraulic Unit LED:

Green 10 flashes / Red 1 flashes

Outdoor Unit LED: 11 flashes

Probable causes:

• Valve is close.

• EEV failure.

• Gas leak, less.

• Discharge Thermistor failure.

• Outdoor Fan operation failure.

• Outdoor Heat Exchanger clogged.

Check:

1. Check if gas valve is open:

If it is not open, open it and check the

operation.

2. Check EEV and Strainer:

Are EEV and Strainer open?

If EEV or Strainer is defective, replace it.

OK

Cooling mode

1. Check if liquid valve is open:

If it is not open, open it and check the

operation.

2. Check EEV and Strainer:

Are EEV and Strainer open?

If EEV or Strainer is defective, replace it.

OK

Heating mode

3. Check if gas leak or less gas:

Measure gas pressure, if there is a leak, correct it.

If recharging refrigerant, make sure to perform vacuuming and recharge the specified amount.

OK OK

4. Check Discharge Pipe Thermistor:

- Is it on the holder?

- Is there a cable pinched?

Check characteristics of thermistor (Refer to Clear 7), If defective, replace the thermistor

OK

5. Check Outdoor Heat Exchanger:

- Is there any obstructing the air flow route?

- Is there any clogging of outdoor unit Heat Exchanger?

If clogged, clear the clog.

OK

6. Check Outdoor Fan:

Check Outdoor Fan Motor. (Refer to Clear 18)

OK

Page 43

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 43

Clear 24: Pressure sensor error

Hydraulic Unit LED:

Green 8 flashes / Red 6 flashes

Outdoor Unit LED: 3 flashes

Probable causes:

• Connector connection failure.

• Pressure Sensor failure.

• Main PCB failure.

Check:

2. Check output voltage of Main PCB :

Check voltage of Main PCB (Measure at Main PCB side connector)

1 pin(Red) - 3 pin(Black) DC5V +/- 5%

If the voltage is not correct, replace Main PCB.

OK

3. Check output voltage of Pressure Sensor

Check voltage of Main PCB (Measure at Main PCB side connector)

2 pin(White) - 3 pIn(Black) Voltage is refer to the following graph.

If the voltage is not correct, replace Presure Sensor.

OK

1. Check connection of the Pressure Sensor:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

Page 44

Heat Pump, Split System, Single Service, 3 phase

44 Maintenance Document 1394-1

Clear 25: Compressor temperature protection (permanent stoppage)

Hydraulic Unit LED:

Green 10 flashes / Red 3 flashes

Outdoor Unit LED: 12 flashes

Probable causes:

• Valve is close.

• EEV failure.

• Gas leak, less.

• Compressor Thermistor failure.

• Outdoor Fan operation failure.

• Outdoor Heat Exchanger clogged.

Check:

1. Check if gas valve is open:

If it is not open, open it and check the

operation.

2. Check EEV and Strainer:

Are EEV and Strainer open?

If EEV or Strainer is defective, replace it.

OK

Cooling mode

1. Check if liquid valve is open:

If it is not open, open it and check the

operation.

2. Check EEV and Strainer:

Are EEV and Strainer open?

If EEV or Strainer is defective, replace it.

OK

Heating mode

3. Check if gas leak or less gas:

Measure gas pressure, if there is a leak, correct it.

If recharging refrigerant, make sure to perform vacuuming and recharge the specified amount.

OK OK

4. Check compressor temperature Thermistor:

- Is it on the holder?

- Is there a cable pinched?

Check characteristics of thermistor (Refer to Clear 11), If defective, replace the thermistor

OK

5. Check Outdoor Heat Exchanger:

- Is there any obstructing the air flow route?

- Is there any clogging of outdoor unit Heat Exchanger?

If clogged, clear the clog.

OK

6. Check Outdoor Fan:

Check Outdoor Fan Motor. (Refer to Clear 18)

OK

7. Replace Main PCB:

If Check Point 1 ~ 6 do not improve the

symptom, replace Main PCB.

OK

Page 45

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 45

Clear 26: Low pressure abnormal

Hydraulic Unit LED:

Green 10 flashes / Red 5 flashes

Outdoor Unit LED: 20 flashes

Probable causes:

• Connector connection failure.

• Pressure Sensor failure.

• Main PCB failure.

• Gas leak, less.

Check:

2. Check output voltage of Main PCB :

Check voltage of Main PCB (Measure at Main PCB side connector)

1 pin(Red) - 3 pin(Black) DC5V +/- 5%

If the voltage is not correct, replace Main PCB.

OK

3. Check if gas leak or less gas

Measure Gas pressure, if there is a leak, correct it.

If recharging refrigerant, make sure to perform vacuuming and

recharge the specified amount.

OK

1. Check connection of the Pressure Sensor:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

OK

4. Replace Pressure Sensor

If Check Point 1 ~ 3 do not improve the symptom, replace Pressure

Sensor.

Page 46

Heat Pump, Split System, Single Service, 3 phase

46 Maintenance Document 1394-1

Clear 27: P.F.C. error

Hydraulic Unit LED:

Green 6 flashes / Red 4 flashes

Outdoor Unit LED: 19 flashes

Probable causes:

• Connector connection failure.

• Main PCB failure.

• PFC PCB failure.

Check:

2. Check output voltage of Main PCB :

Check voltage of Main PCB (Measure at Main PCB side connector)

1 pin(brown) - 2 pin(Red) DC5V +/- 5%

If the voltage is not correct, replace Main PCB.

OK

3. Replace PFC PCB

If Check Point 1, 2 do not improve the symptom, replace PFC PCB.

OK

1. Check connections of between Main PCB and PFC PCB:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

Page 47

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 47

Clear 33: Detection of compressor position error (permanent stoppage)

Hydraulic Unit LED:

Green 9 flashes / Red 5 flashes

Outdoor Unit LED: 14 flashes

Probable causes:

• Misconnection.

• Inverter PCB failure.

Check:

1. Check connections condition in control unit:

- Check if the terminal connection is loose.

- Check if connector is removed.

- Check if connector is erroneous connection.

- Check if cable is open.

Upon correcting the removed connector or mis-wiring, reset the power.

OK

2. Replace the electronic board :

- If steps 1 do not solve the problem, replace Inverter PCB.

Page 48

Heat Pump, Split System, Single Service, 3 phase

48 Maintenance Document 1394-1

4.2.2 Failures With No Error Code

Clear 35: No voltage on Hydraulic Unit

Probable causes:

• Power supply fault.

• External causes.

• Faulty electrical components.

Check:

1. Check the installation :

- Is the circuit breaker cut off?

- Check the wiring.

2. Check for external causes on the Hydraulic Unit and outdoor unit (noise or voltage drop):

- Check for any other electrical device on the same electric circuit which might cause a drop in

voltage.

- Check for any current leaks.

- Check for any equipment generating electromagnetic waves which interfere with the

communication between the Hydraulic Unit and the outdoor unit.

3. Check the electrical components:

If all of these checks are unsuccessful, replace Interface PCB.

OK

OK

OK

- Check that a voltage between AC 198 and AC 264 V exists between terminals 1 and 2 on the

Hydraulic Unit terminal block.

NO

- Check Interface PCB for :

o either the fuse (F1).

o or the varistor (VA1). Fault: overvoltage - external causes - power supply to be

checked).

- Replace the faulty component (if the varistor is blown, the PCB must be replaced).

YES

Page 49

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 49

Clear 36: No voltage on outdoor unit

Probable causes:

• Power supply fault.

• External cause.

• Faulty electrical components.

Check:

3. Check the electrical components:

2. Check for external causes on the Hydraulic Unit and outdoor unit (noise or voltage drop) :

- Check for any other electrical device on the same electric circuit which might cause a drop in

voltage.

- Check for any current leaks.

- Check for any equipment generating electromagnetic waves which interfere with the

communication between the Hydraulic Unit and the outdoor unit.

OK

OK

1. Check the installation

- Is the circuit breaker cut off?

- Check the wiring.

NO

If all of these checks are unsuccessful, replace Filter PCB, Main PCB,

Inverter PCB and PFC PCB.

OK

- Check that a voltage between AC 198 and AC 264 V exists between terminals 1 and 2 on the

Hydraulic Unit terminal block.

- Check Main PCB (power supply) for :

o either the fuse (F1, F3).

o or the varistor (VA1-VA5). Fault: overvoltage - external causes - power supply to be

checked).

- Replace the faulty component (if the varistor is blown, the PCB must be replaced).

YES

Page 50

Heat Pump, Split System, Single Service, 3 phase

50 Maintenance Document 1394-1

Clear 38: No heat

Probable causes:

• Hydraulic Unit error.

• Outdoor unit error.

• Influence from the outdoor environment.

• Misconnections of connectors and cables.

• Refrigeration system fault (not enough gas, clogging, dirty filters).

Check:

2. Check the Hydraulic Unit :

- Is the pump operating?

- See if the exchanger is not clogged?

3. Check the outdoor unit:

- Is the fan rotating at high speed?

- Are there any objects blocking the air flow?

- Is the outdoor exchanger clogged?

- Are the valves open?

4. Check the configuration of the room:

- Is the heat pump power suited to the need?

5. Inspect the Hydraulic Unit and outdoor unit installation:

- Check the refrigeration connections (length, diameter)

6. Inspect the refrigeration circuit:

- See if the dehydrator is clogged (there should be no temperature variation

between the dehydrator input and output in normal operating conditions).

- Check the electronic expansion valve

- Check the compressor

1. The unit provides heating or cooling

No

Is the cooling kit

connected ?

Yes

Check the wiring of the cooling kit

control wire

Page 51

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 51

Clear 39: Abnormal noise

Probable causes:

• Abnormal installation (outdoor)

• Fan failure

• Compressor failure.

Checks:

1. The noise comes from the outdoor unit:

- Is the unit stable?

- Is the protection screen properly mounted?

- Is the propeller broken or distorted?

- Has the propeller screw been lost?

- Is any object blocking the propeller rotation?

OK

- Check for any vibration noise caused by a

bolt.

- Check for any sound of contact with a pipe.

OK

- Is the compressor locked?

OK

Page 52

Heat Pump, Split System, Single Service, 3 phase

52 Maintenance Document 1394-1

4.3 Sensor Values

4.3.1 Outdoor Unit Temperature Sensors

Outdoor Heat Exchanger (outlet), Outdoor Heat Exchanger (middle)

Temperature (°C) -10 -5 0 10 15 20 25 30

Resistance value (kΩ)

27,5

20,9 16,1 12,4 9,73 7,67 6,1 3,95

Outdoor Discharge Pipe / Compressor / Expansion valve inlet

Temperature (°C) 0 5 10 15 20 30 40 50 60

Resistance value (kΩ)

168

130 101 79 63 40 26,3 17,8 12,3

Temperature (°C) 70 80 90 100 120

Resistance value (kΩ)

8,7

6,3 4,6 3,4 2

Outdoor Temperature

Temperature (°C) -20 -10 -5 0 5 10 15 20 30

Resistance value (kΩ)

115

62,3 46,6 35,2 26,9 20,7 16,1 12,6 7,97

Temperature (°C) 40 50 60 70

Resistance value (kΩ)

5,18

3,45 2,36 1,65

Heat sink (INV), Heat sink (PFC)

Temperature (°C) 0 5 10 15 20 30 40 50 60

Resistance value (kΩ)

15,8

12,2 9,5 7,5 5,9 3,78 2,50 1,69 1,17

Temperature (°C) 70 80 90 100 110 120

Resistance value (kΩ)

0,83

0,60 0,44 0,33

0,25

0,19

4.3.2 Hydraulic Unit Temperature Sensors

Heat Exchanger (Condensing sensor)

Temperature (°C) 0 5 10 15 20 25 30 35 40 45 50

Resistance value (kΩ)

176

134 103 80,3 62,9 49,7 39,6 31,7 25,6

20,8 17,1

Outdoor sensor

Temperature (°C) -20 -15 -10 -5 0 5 10 15 20

Resistance value (kΩ)

7,60

5,85

4,60

3,60 2,85 2,30 1,85 1,50 1,20

Temperature (°C) 25 30 35 40 45

Resistance value (kΩ)

1

0,83 0,70 0,58 0,48

Heat pump flow and return sensor – DHW and heating zone 2 sensor – Swimming pool return sensor

Temperature (°C) -15 -10 -5 0 5 10 15 20 25

Resistance value (kΩ)

72,5

55 42 32,5 25 20 15,7 12,5 10

Temperature (°C) 30 35 40 45 50 55 60 65 70

Resistance value (kΩ)

8

6,5 5 4 3,5 3 2,5 2 1,7

Page 53

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 53

4.4 Service parts information

4.4.1 Service parts information 1 : Compressor

Does not start up

Diagnosis method of compressor (if outdoor unit LED displays error, refer to Failures and clears)

Abnormal noise Stops soon after starting up

Is there open or loose

connection cable?

Check connection of

compressor, and winding

resistance (Refer to the next

page).

If there is no failure, the

defected of compressor is

considered (locked

compressor due to clogged

dirt or less oil).

Replace compressor

Is there open or loose

connection cable?

Is gas pipe valve open ?

(Low pressure is too low)

Check if refrigerant is leakin.

Recharge refrigerant.

Check if stainer is clogged

(Parts information 3)

Check inverter PCB, connection of compressor, and

winding resistance (refer to the next page).

If there is no failure, the defected of compressor is

considered (Compression part broken or valve

defective).

Replace compressor

Check if vibration noise by

loose bolt or contact noise of

piping is happening.

Defective compressor can

be considered (due to inside

dirt clogging or broken

component).

Replace compressor

Page 54

Heat Pump, Split System, Single Service, 3 phase

54 Maintenance Document 1394-1

4.4.2 Service parts information 2 : Inverter compressor

Check point 1 : Check connection

Check terminal connection of compressor

(Loose or incorrect wiring)

Check connection of inverter PCB

(Loose or incorrect wiring)

Check point 2 : check winding resistance

Check winding resistance on each terminal

If the resistance value is 0Ω or infinite, replace compressor.

Check point 3 : replace inverter PCB

If check point 1 and 2 do not improve the symptom, replace Inverter PCB.

Page 55

Heat Pump, Split System, Single Service, 3 phase

Maintenance Document 1394-1 55

4.4.3 Service parts information 3 : Outdoor unit electronic expansion

valve (EEV, EEV(INJ))

Check point 1 : Check connection

Check connection of connector

(Loose connector or open cable)

Check point 2 : Check coil of EEV

Remove connector, check each winding resistance of

coil.

Read wire Resistance value

White-Red

Yellow-Red

Orange-Red

Blue-Red

46Ω +/- 4Ω

at 20°C

If resistance value is abnormal, replace EEV.

Check point 3 : Check voltage from main PCB

Remove connector and check voltage (DC12V)

If it does not appear, replace Main PCB.

Check point 4 : Check noise at start up

Turn on power and check operation noise.

If an abnormal noise does not show, replace Main

PCB.

Check point 5 : Check opening and closing operation of valve

When valve is closed, it has a temp. (Add period)

difference between inlet and outlet.

If it is open, it has no temp. (Add period) difference

between inlet and outlet.

There is no refrigerant flow coming to EEV(INJ) while the liquid injection is inactive. Check whether the liquid

injection is active before executing check point 5 for EEV(INJ).

Check point 6 : Check stainer

Stainer normally does not have temperature difference between inlet and outlet as shown in 1, but if there is a

difference as shown in 2, there is a possibility of inside clogged. In this case, replace stainer.

Page 56

Heat Pump, Split System, Single Service, 3 phase

56 Maintenance Document 1394-1

4.4.4 Service parts information 4 : Outdoor unit solenoid valve (SV)

Check point 1 : Check connections

Check connection of connector

(Loose connector or open cable)

Check point 2 : Check solenoid coil

Remove connector and check if coil is open

(normal resistance value of each coil : 1495+/7%)

If resistance value is abnormal, replace

solenoid coil.

Check point 3 : Check voltage from main

PCB

Remove connector and check the voltage

(AC230V).

If the voltage does not appear, replace Main

PCB.

Check point 4 : check opening and closing operation valve

Depending on the injection activity, check if valve is operating normally.

(When valve opens, ther is no temperature difference between inlet and outlet)

• If the valve closes by removing the connector of the

valve which does not close, it is considered to be

Main PCB failure. Replace Main PCB.

• If it does not closeby removing connector, there is a

possibility of (1) clogging by dirt, or (2) deformation

by the heat at the time of solenoid valve installation.

In this case, replace solenoid valve.

SV