Page 1

Primergy

PRIMERGY S60

Storage Subsystem

Xenia Fierley

Fujitsu Siemens Computers GmbH cognitas PS

81730 München

e-mail: email:manuals@fujitsu-siemens.com

Tel.: (089) 61001-157

Fax: 0 700 / 372 00000

U41221-J-Z156-1-74

Sprachen: En

Edition September 2001

Page 2

Comments… Suggestions… Corrections…

The User Documentation Department would like to know

your opinion on this manual. Your feedback helps us to

optimize our documentation to suit your individual needs.

Fax forms for sending us your comments are included at the

back of the manual.

There you will also find the addresses of the relevant User

Documentation Department

Copyright and Trademarks

Copyright © 2001 Fujitsu Siemens Computers GmbH.

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

This manual was produced by

cognitas. Gesellschaft für Technik-Dokumentation mbH

www.cognitas.de

This manual is printed on

paper treated with

chlorine-free bleach.

Page 3

German

English

Page 4

Page 5

Contents

1Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Notation Conventions . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Structure of the Manual . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Notes on Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Electrostatic Sensitive Device Label . . . . . . . . . . . . . . . . 9

2.3 CE certificate . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 RFI Suppression . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 FCC notices (Federal Communications Commission) . . . . . . 10

2.6 Notes on the Rack Model . . . . . . . . . . . . . . . . . . . . 11

2.7 Notes on Transportation . . . . . . . . . . . . . . . . . . . . . 11

2.8 Environmental Protection . . . . . . . . . . . . . . . . . . . . 12

3 Operating and Indicator Elements . . . . . . . . . . . . . . 15

3.1 The Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 Meaning of the S60 Operating Status LEDs . . . . . . . . . . . 16

3.1.2 The Control LEDs for the Hard Disk Drives . . . . . . . . . . . 18

3.2 The Rear Side . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 FFx-RAID Controller Module LEDs . . . . . . . . . . . . . . . 20

3.2.2 Power Supply Unit LEDs . . . . . . . . . . . . . . . . . . . . . 21

3.2.3 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Fan LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Floorstand Model . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Open the Housing . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.1 Removing and Mounting the door . . . . . . . . . . . . . . . . 25

4.1.2 Removing/Mounting the left Side Cover . . . . . . . . . . . . . 26

5Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Power Supply Units . . . . . . . . . . . . . . . . . . . . . . . 29

5.1.1 Replacing the Power Supply Unit . . . . . . . . . . . . . . . . 30

6 Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Installing/Removing the Fan Module . . . . . . . . . . . . . . . 34

U41221-J-Z156-1-74

Page 6

Contents

7 FC Hard Disk Drives . . . . . . . . . . . . . . . . . . . . . . . 37

7.1 Handling Hard Disk Drives/HDD Modules . . . . . . . . . . . . 37

7.2 Installing/Removing HDD/Dummy Module . . . . . . . . . . . . 38

7.3 Hot Swap for FC HDD Modules . . . . . . . . . . . . . . . . . . 42

7.4 Identification Marks and Loop Addresses . . . . . . . . . . . . . 43

8 Plug-in Board Modules . . . . . . . . . . . . . . . . . . . . . 45

8.1 The FFx-RAID Controller Module . . . . . . . . . . . . . . . . . 45

8.1.1 Indicators and Connectors . . . . . . . . . . . . . . . . . . . . 46

8.1.2 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.3 Installing/removing the FFx-RAID controller module . . . . . . . 52

8.1.4 Adding a Second FFx-RAID Controller Module . . . . . . . . . . 54

8.1.5 The FFx-BBU (Battery Backup Unit) Module . . . . . . . . . . . 55

9 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.1 Fibre Channel (FC) Connection . . . . . . . . . . . . . . . . . . 58

9.2 Mains Connection . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.3 Mains Connection with Phase Redundancy . . . . . . . . . . . 59

9.4 Power connection via UPS . . . . . . . . . . . . . . . . . . . . 60

10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.1 Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2 Unpacking the Storage Subsystem . . . . . . . . . . . . . . . . 62

10.3 Setting Up the Floorstand Model . . . . . . . . . . . . . . . . . 62

10.4 Mounting the Rack Model . . . . . . . . . . . . . . . . . . . . 63

10.4.1 Preparing the Slide Rails . . . . . . . . . . . . . . . . . . . . . 64

10.4.2 Mounting Slide Rails . . . . . . . . . . . . . . . . . . . . . . . 65

10.4.3 Mounting the Subsystem . . . . . . . . . . . . . . . . . . . . . 65

10.4.4 Routing the Cables . . . . . . . . . . . . . . . . . . . . . . . . 66

10.5 Connecting and Disconnecting Cables . . . . . . . . . . . . . . 68

10.6 Switching the Storage Subsystem ON/OFF . . . . . . . . . . . 69

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.1 Problem Solutions and Tips . . . . . . . . . . . . . . . . . . . . 71

11.1.1 Power Supply Status Indicator (Front) . . . . . . . . . . . . . . 71

11.1.1.1 Power supply status indicator remains dark . . . . . . . . . . . 71

11.1.1.2 Power supply status indicator lights yellow . . . . . . . . . . . . 72

11.1.1.3 Power supply status indicator lights orange . . . . . . . . . . . 72

11.1.2 Cooling Status . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.1.2.1 Cooling status LED lights yellow . . . . . . . . . . . . . . . . . 73

11.1.2.2 Cooling status LED lights orange . . . . . . . . . . . . . . . . . 73

U41221-J-Z156-1-74

Page 7

Contents

11.1.3 Server Management Status . . . . . . . . . . . . . . . . . . . 74

11.1.3.1 Server Management Status LED lights permanently . . . . . . 74

11.1.4 Storage Subsystem Switches OFF . . . . . . . . . . . . . . . 75

11.1.5 System will not boot after Installation of New HDD Modules . . 75

11.1.6 HDD READY Indicator does not light up . . . . . . . . . . . . . 75

11.1.7 Hard Disk Drives“ dead” on System Start . . . . . . . . . . . . 76

11.1.8 Controller reports Added Hard Disk Drive as defective . . . . . 76

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

U41221-J-Z156-1-74

Page 8

Page 9

1 Introduction

The functionality, mechanics and design of the PRIMERGY S60 storage

subsystem are optimally adapted to the PRIMERGY Nxxx server computenodes. It can be used as rack or as floorstand model. In the 19-inch rack, the

S60 subsystem occupies three height units.

The PRIMERGY S60 storage subsystem use the fiber-channel technology and

can accommodate up to fourteen 1-inch hard disk drives.

The use of fiber-channel technology ensures high transmission speeds over

long distances, using a very uncomplicated infrastructure.

Components such as fans, power supply units, hard disk drives and FFx-RAID

controller modules (dual controller configuration only) can be replaced with the

system running. Redundancy is provided for central components, offering a

high degree of data security and reliability.

Server Management/ServerView

For the first step the server management for the PRIMERGY S60 storage

subsystem will be ensured by SES (SCSI Enclosure Service).

A optional Remote Service Board (RSB) with more functions can be installed.

In this case remote diagnosis is available to the customer or service provider for

analysis, remote system configuration and a remote restart - even if the

operating system or the hardware fails.

The RSB-module is board which includes a completely independent system. It

has a separate operating system with web server and SNMP agents, and can

be driven by an external power supply.

The board is installed in the storage subsystem and connected to the HDD

backplane.

Further informations is provided in the documentation for the Remote Service

Board (see “Related publications” on page 81).

ServerView and the related agents are set up within the group of servers and

storage subsystems being monitored. The received information are evaluated

by ServerView and processed for display or forwarding to the administrator

(manager).

U41221-J-Z156-1-74 1

Page 10

Target Group Introduction

I When installing PRIMERGY S60 storage subsystems in connection with

ServerView please install the ServerStart CD version 4.06 or higher on

each of the connected servers.

See ServerView documentation for notes concerning installing and update (see

also “Related publications” on page 81).

1.1 Target Group

The operating instructions are intended for the person responsible for installing

the hardware and correctly operating the system. The operating manual contain

all the descriptions which are of importance for commissioning your

PRIMERGY S60 storage subsystem in so far as they do not form part of the

publication of your server system.

To understand the different expansion options it is necessary to have a

knowledge of hardware and data transmission, as well as basic knowledge of

the operating system used.

1.2 Notation Conventions

Italics identifies commands and entries in flow text

Bold highlights text

“Quotation marks” indicates references to other chapters or manuals

Ê identifies an operation that you have to perform.

I indicates additional information, notes and tips

V CAUTION! indicates warnings, which, if ignored, will endanger

your health, the operability of your server or the

security of your data

2 U41221-J-Z156-1-74

Page 11

Introduction Structure of the Manual

1.3 Structure of the Manual

The PRIMERGY S60 storage subsystem manual describes how to install and

configure the subsystem and perform expansions or upgrades.

You will find further information (see also entries in the chapter “Related publications” on page 81):

● in the “Safety, Warranty and Ergonomics” manual

● in the documentation on the PRIMERGY server

This manual consists of the following chapters:

● Important notes

This chapter contains instructions on the safe operation of your storage

subsystem as well as information about environmental protection.

● Operating and indicator elements

This chapter gives a detailed description of the operating panel and the

connecting elements on the rear panel of the storage subsystem.

● Floorstand model

This part of the manual describes how opening and closing the floorstand

model housing.

● Power supply

This part of the manual describes the power supply units and their power

supply. Fitting and removing power supply units is also described in detail.

● Fan module

This part of the manual describes the fitting and removal of the fan module.

● FC drives

This chapter describes in detail how the hot swappable drives must be dealt

with.

● Plug-in board modules

This chapter describes the FFx-RAID controller and its mounting and

removal.

● Connections

This chapter describes the FC and the mains connection.

The possibilities of supplying the storage subsystem with mains voltage are

also described.

U41221-J-Z156-1-74 3

Page 12

Technical Data Introduction

● Configurations

This part of the manual gives configuration examples.

● Installation

The activities needed to install and commission the storage subsystem are

described.

● Troubleshooting

This chapter contains advice on solving problems that occur on commissioning or during the operation of the storage subsystem.

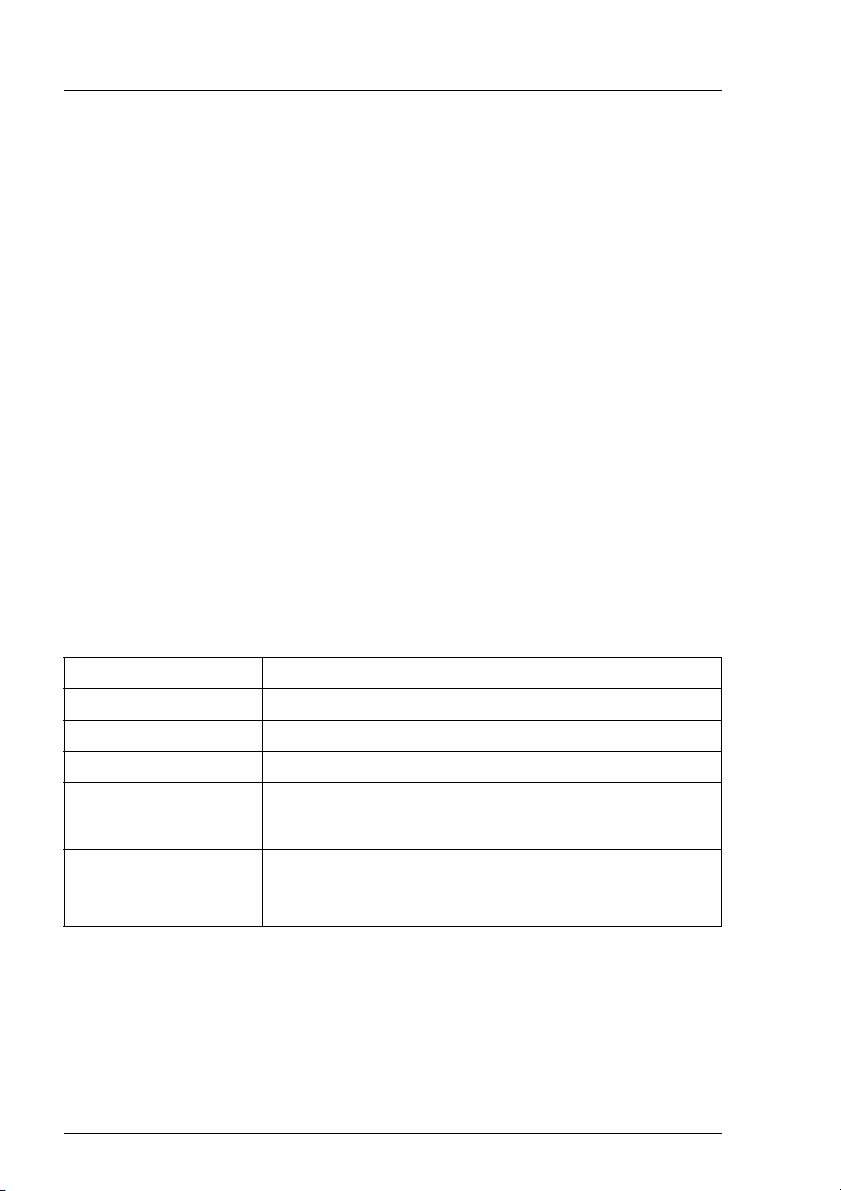

1.4 Technical Data

Electrical Characteristics

Rated voltage 100 V - 240 V

Tolerance of the rated voltage +6 % / -10 %

Rated frequency 50 Hz / 60 Hz

Rated current max. 1.3 A at 240 V

max. 3.1 A at 100 V

Power consumption

Active power (= heat transfer) max. 305 W

Apparent power max. 310 VA

Power factor (PF) 0.95-0.99

Dimensions and

Floorstand model Rack model

Weight

Height 481mm 133 mm

Width 200 mm without legs

483 mm

280 mm with legs

Depth 692 mm 646 mm

Weight max. 32 kg max. 30 kg

4 U41221-J-Z156-1-74

Page 13

Introduction Technical Data

Environmental Conditions (according to DIN EN 60721-3-x)

Climate/operation (class 3K2):

Temperature 15 °C to 35°C

Relative humidity 5% to 85%

altitude (NN) max. 3048 m (10000 ft.)

Climate/transport (class 2K2):

Temperature -25°C to 60°C

Relative humidity 15% to 98%

altitude (NN) max. 15240 m (50000 ft.)

Mechanical environmental conditions

Operation Class 3M2

Transport Class 2M1

Standards Complied With

Product safety and ergonomics IEC 60950 (DIN EN 60950), UL 1950,

CSA 950, ZH1/618

Electromagnetic compatibility

Emitted interference EN 55022, class B; FCC part 15, class A

Noise immunity EN 50082-1

CE label Low voltage guideline

LVD 73/23/EEC

EMC guideline 89/339/EWG

Approval certification GS, CSA NRTL/C, CB certificate

Noise Development (ISO 9296) Operation Idle

Sound level (L

Workstation-related

sound pressure level (L

) max. 7.0 B max. 6.2 B

WAd

max. 56 dB(A) max. 46 dB(A)

)

pAm

Maintenance Areas and Ventilation Distances

Floorstand model Rear 400 mm, left 1200 mm *

Rack model Specified by the 19“ rack

* The area on the left need not always be kept open. However, it must be

possible to clear it without too much effort.

U41221-J-Z156-1-74 5

Page 14

Page 15

2 Important Notes

2.1 Notes on Safety

In this section you will find information that you must note when using the

storage subsystem.

This device complies with the relevant safety standards for IT equipment,

including electronic office machines, intended for use in the office environment.

I You will also find the following safety instructions in the manual entitled

“Safety, Warranty and Ergonomics“ which also includes other notes on

guarantee and ergonomics. Also pay attention to the notes in the manual

of the connected PRIMERGY system.

If you have any questions relating to setting up and operating your system in the

environment where you intend to use it, please consult our service organization.

V CAUTION!

● The actions described in these instructions should only be performed

by technicians, service personnel or technical specialists. Equipment

repairs should only be performed by qualified staff. Any failure to

observe the guidelines in this manual could expose the user to risks

(electric shock, fire hazards) and could also damage the equipment.

Note that any unauthorized opening of the device will result in the

invalidation of the warranty and exclusion from all liability.

● Transport the device in its original packaging or in other suitable

packaging which will protect it against shock or impact.

● Read the notes on environmental conditions in section “Technical

Data” on page 4 before setting up and operating the device.

● If the device is brought in from a cold environment, condensation may

form both inside and on the outside of the machine.

Wait until the device has acclimatized to room temperature and is

absolutely dry before starting it up. Material damage may be caused

to the device if this requirement is not observed.

U41221-J-Z156-1-74 7

Page 16

Notes on Safety Important Notes

V CAUTION!

● Check that the rated voltage specified on the device's ID plate is the

same as the local line voltage.

● The device must only be connected to a properly grounded wall outlet

(the device is fitted with a tested and approved power cable).

● Make sure that the protective grounded outlet of the building’s wiring

system is freely accessible.

● Switching off the device does not cut off the supply of power. To do

this you must remove the power plugs.

● Before opening the unit, switch off the device and then pull out the

power plugs.

● Route the cables in such a way that they do not form a potential

hazard (make sure no-one can trip over them) and that they cannot

be damaged. When connecting up a device, refer to the relevant

notes in this manual.

● Never connect or disconnect data transmission lines during a storm

(lightning hazard).

● Systems which comprise a number of cabinets must use a separate

fused socket for each cabinet.

● The system unit and the directly connected external storage

subsystems should be connected to the same power supply

distributor. Otherwise you run the risk of losing data if, for example,

the central processing unit is still running but the storage subsystem

has failed during a power failure.

● Make sure that no objects (such as bracelets or paper clips) fall into

or liquids spill into the device (risk of electric shock or short circuit).

● In emergencies (e.g. damage to housings, power cords or controls or

ingress of liquids or foreign bodies), immediately power down the

device, pull out the power plugs and notify your service department.

● Note that proper operation of the system (in accordance with IEC

60950/DIN EN 60950) is guaranteed only if slot covers are installed

on all vacant slots and/or dummies on all vacant bays and the

housing cover is fitted (cooling, fire protection, RFI suppression).

8 U41221-J-Z156-1-74

Page 17

Important Notes Electrostatic Sensitive Device Label

2.2 Electrostatic Sensitive Device Label

Electrostatic-sensitive components may be identified by the following sticker:

Figure 1: Electrostatic Sensitive Device (ESD) sticker

You must follow the instructions below when handling modules containing

electrostatic-sensitive components

Ê Discharge static electricity from your body (for example by touching a

grounded metal object) before handling modules containing electrostaticsensitive components.

Ê The equipment and tools you use must be free of static charge.

Ê Remove the power plug before installing or removing modules containing

electrostatic-sensitive components.

Ê Only hold modules containing electrostatic-sensitive components by their

edges.

Ê Do not touch any of the pins or track conductors on a module containing

electrostatic-sensitive components.

Ê Use a grounding strap designed for the purpose, to connect you to the

system unit as you install the modules.

Ê Place all components on a static-safe base.

I An exhaustive description of the handling of modules containing electro-

static-sensitive components can be found in “Guidelines on handling

electrostatic sensitive devices and modules (ESD)” or “ITS Circular

4/95”.

U41221-J-Z156-1-74 9

Page 18

CE certificate Important Notes

2.3 CE certificate

The shipped version of this device complies with the requirements

of the EEC directives 89/336/EEC “Electromagnetic compatibility”

and 73/23/EEC “Low voltage directive”. The device therefore

qualifies for the CE certificate (CE=Communauté Européenne).

2.4 RFI Suppression

All other equipment which is connected to this product must also have radio

noise suppression in accordance with EC Guideline 89/336/EWG.

Products which meet this requirement are accompanied by a certificate to that

effect issued by the manufacturer and/or bear the CE mark. Products which do

not meet this requirement may be operated only with the special permission of

the BZT (Bundesamt für Zulassungen in der Telekommunikation).

2.5 FCC notices (Federal Communications Commission)

Class A digital device

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

10 U41221-J-Z156-1-74

Page 19

Important Notes Notes on the Rack Model

2.6 Notes on the Rack Model

● For safety reasons, at least two people are required to install the rack model

because of its weight and size.

● When connecting and disconnecting cables, observe the notes in the

documentation for your PRIMERGY system and the comments in the

“Important notes” chapter in the technical manual supplied with the rack.

● Ensure that the anti-tilt bracket is correctly mounted when you set up the

rack.

● For safety reasons, no more than one unit may be withdrawn from the rack

at any one time during installation and maintenance work.

● If more than one unit is withdrawn from the rack at any one time, there is a

danger that the rack will tilt forward.

● The connection of the rack to the mains voltage must be installed by an

authorized specialist (electrician).

2.7 Notes on Transportation

I Transport the storage subsystem in its original packaging or in other

suitable packaging which will protect it against shock or impact.

Do not unpack it until all transport maneuvers are completed.

If you need to lift or transport the storage subsystem, ask someone to

help you.

U41221-J-Z156-1-74 11

Page 20

Environmental Protection Important Notes

2.8 Environmental Protection

Environmentally friendly product design and development

This product has been designed in accordance with the Fujitsu Siemens

Computers standard for “environmentally friendly product design and development”.

This means that the designers have taken into account important criteria such

as durability, selection of materials and coding, emissions, packaging, the ease

with which the product can be dismantled and the extent to which it can be

recycled.

This saves resources and thus reduces the harm done to the environment.

Notes on saving energy

Devices that do not have to be on permanently should not be switched on until

they need to be used and should be switched off during long breaks and on

completion of work

Notes on packaging

We recommend that you do not throw away the original packaging in case you

need it later for transportation. If possible, devices should be transported in their

original packaging.

Notes on dealing with consumables

Please dispose of batteries in accordance with local regulations.

Notes on labeling plastic housing parts

Please avoid attaching your own labels to plastic housing parts wherever

possible, since this makes it difficult to recycle them.

12 U41221-J-Z156-1-74

Page 21

Important Notes Environmental Protection

Take-back, recycling and disposal

For details on take-back and reuse of devices and consumables within Europe,

contact your Fujitsu Siemens Computers branch office/subsidiary or our

recycling center in Paderborn:

Fujitsu Siemens Computers

Recycling Center

D-33106 Paderborn

Tel. ++49 5251 8180-10

Fax ++49 5251 8180-15

Further information on environmental protection

The Fujitsu Siemens Computers representative for environmental protection

will be happy to answer any further questions you may have concerning

environmental protection.

Fujitsu Siemens Computers

Referat Umweltschutz

Werner-von-Siemens-Straße 6

D-86159 Augsburg

Tel. ++49 821 804-2386

Fax ++49 821 804-2706

U41221-J-Z156-1-74 13

Page 22

Page 23

3 Operating and Indicator Elements

This section describes the position and meaning of the operating and indicator

elements on the PRIMERGY S60 storage subsystem.

3.1 The Front

You can see the following indicator elements on the front of the PRIMERGY

S60 storage subsystem

● The three operating status LEDs which indicate the power supply status, the

cooling status and the server management status.

● Control LEDs for the hard disk drives (two LEDs on each of the HDD

modules).

I There is a HDD Ready and a HDD Status LED for each of the 14

possible hard disk drives.

U41221-J-Z156-1-74 15

Page 24

The Front Operating and Indicator Elements

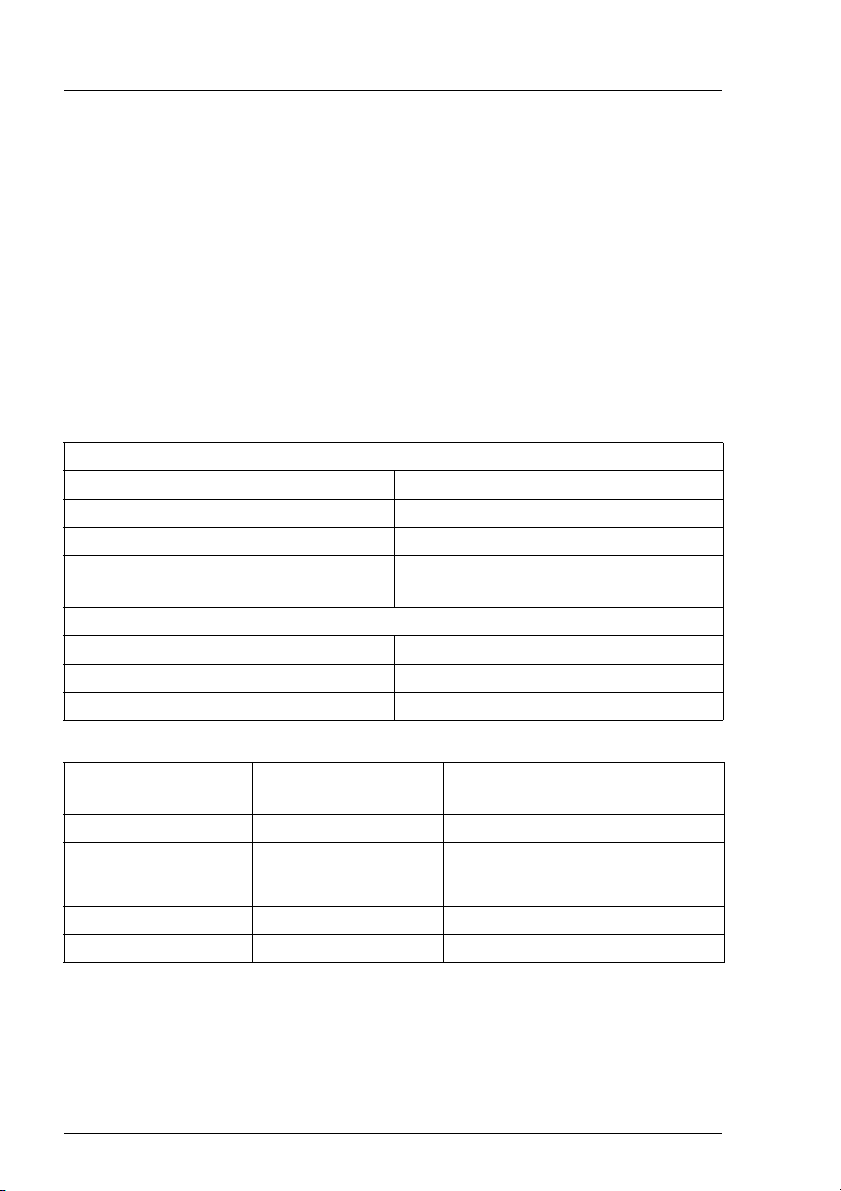

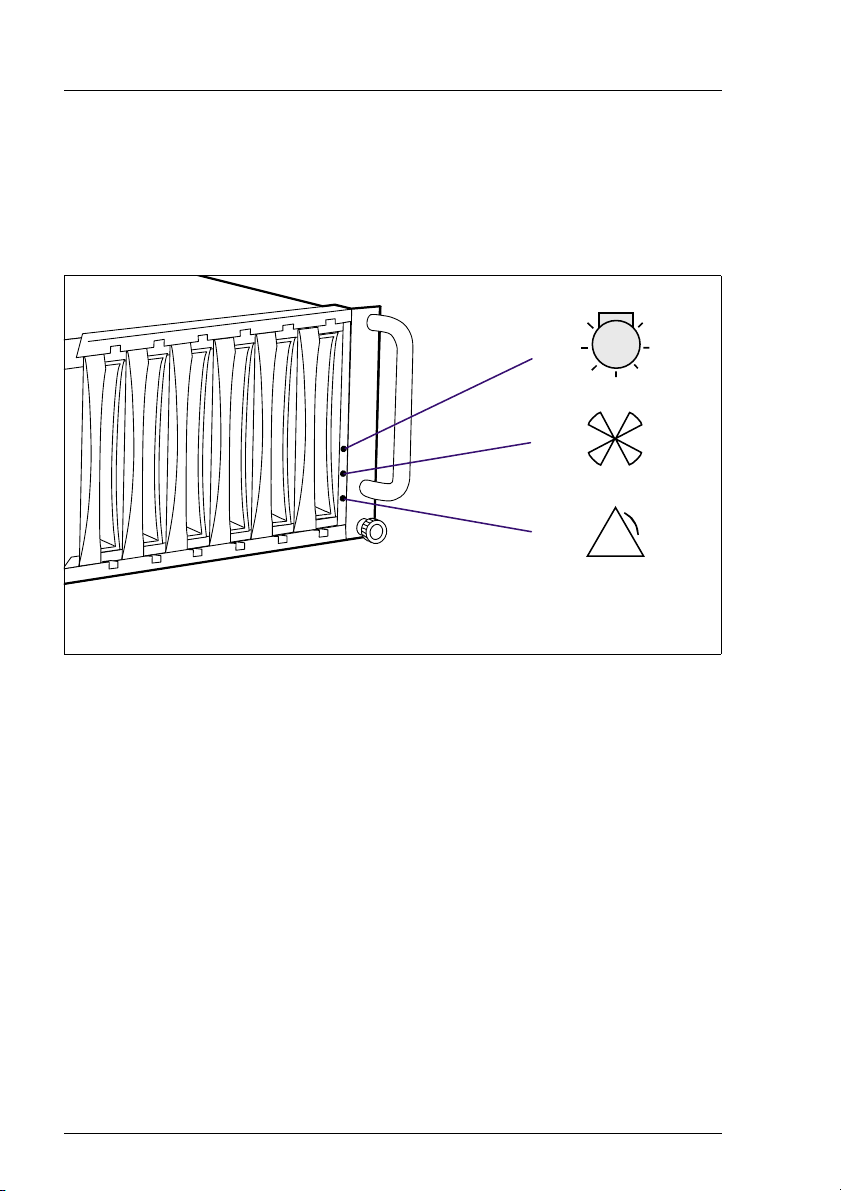

3.1.1 Meaning of the S60 Operating Status LEDs

The state of the status LEDs located on the HDD backplane is transmitted by

optical waveguides so that the power supply status, the cooling status and the

server management status are indicated on the front of the storage subsystem.

1

2

3

Figure 2: Operating Status LEDs and Icons on the Front of the Rack Model

(1) Power supply status

(2) Cooling status

(3) Server management status

!

V CAUTION!

In order to guarantee the server management for the PRIMERGY S60

storage subsystem over SES (SCSI Enclosure Service), at least one of

the two first HDD modules (see also section “Identification Marks and

Loop Addresses” on page 43) must be installed.

I Fault clearing instructions can be found in the chapter “Troubleshooting”

on page 71 of this manual.

16 U41221-J-Z156-1-74

Page 25

Operating and Indicator Elements The Front

Optical Waveguide Color Meaning

Power supply status none No mains voltage present.

green POWER OK

Equipment switched ON, all installed

power supply units OK.

yellow POWER WARNING

One power supply unit has failed.

orange STANDBY

Equipment switched OFF, mains voltage

present.

Cooling status

V CAUTION!

The PRIMERGY S60

storage subsystem

(without Remote Service

Board) switches OFF at

an interior temperature of

55°C (see section

“Cooling status LED lights

orange” on page 73).

Server management

status (global SES

indicator)

green Cooling OK

All installed fans and the interior temperature are OK.

yellow Fan warning

One fan has failed.

The temperature is OK.

orange Cooling fault

All the fans have failed or the interior

temperature exceeds the permissible

values.

none No status indication

orange Identification indication

(can be activated manually from

ServerView).

For troubleshooting see section “Server

Management Status LED lights permanently” on page 74.

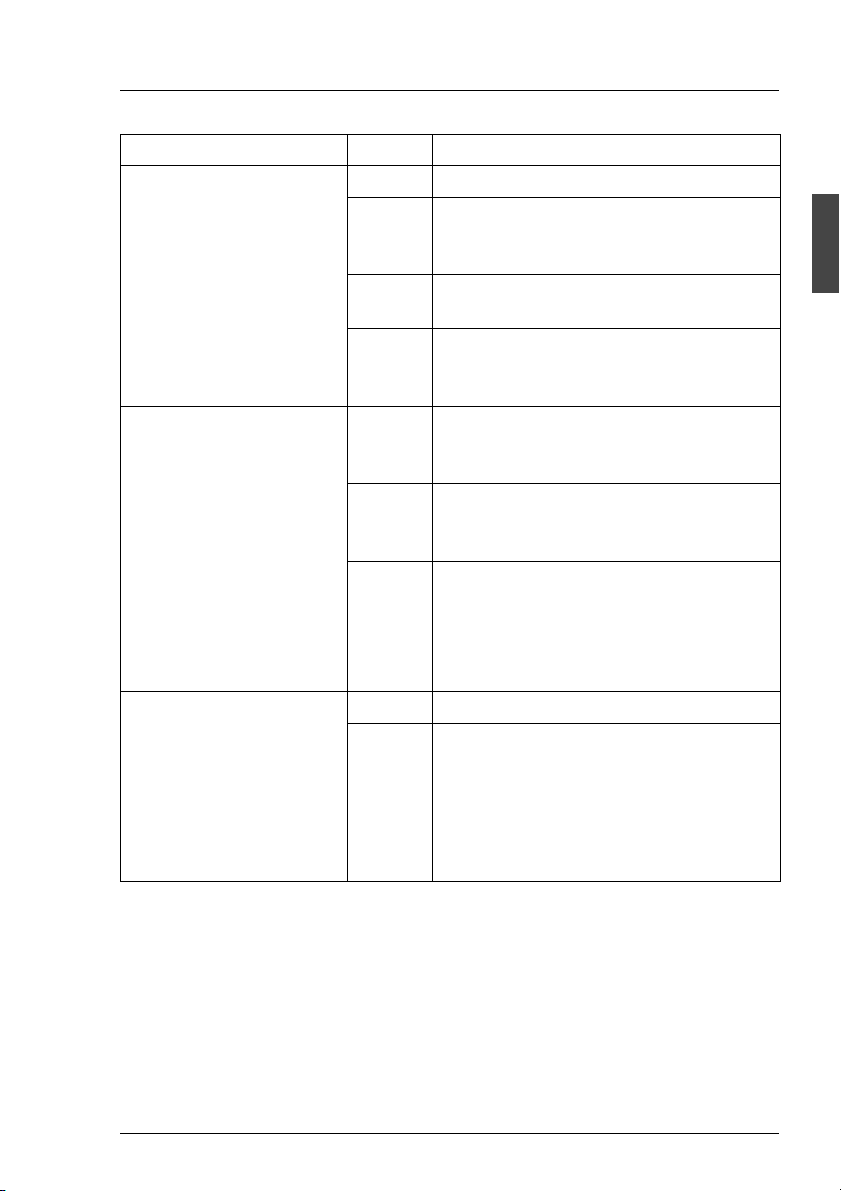

Table 1: Meaning of the Operating Status LEDs Indication

U41221-J-Z156-1-74 17

Page 26

The Front Operating and Indicator Elements

3.1.2 The Control LEDs for the Hard Disk Drives

H D D R E A D Y

H D D S T A T U S

Figure 3: Symbols of the Control LEDs of the Hard Disk Drives

(HDD READY) Operating indication of the hard disk drive.

This LED is driven by the hard disk drive itself.

(HDD STATUS) Status indication of the hard disk drive.

This dual-color (yellow/orange) LED is set by the hard disk

drive itself (yellow indicator) or by the SES controller (orange

indicator).

18 U41221-J-Z156-1-74

Page 27

Operating and Indicator Elements The Front

LED Indication Meaning

HDD

READY

OFF The associated drive is not (correctly)

inserted or it is spun down and it is not

being accessed.

OFF

green intermittent

The associated drive is spun down. The

drive is being accessed.

flashes

ON

green permanently on

The associated drive is spun up and ready.

The drive is not being accessed or hot

spare drive.

ON

green intermittent

The associated drive is spun up and ready.

The drive is being accessed.

flashes

green,

flashes steadily

The associated drive is spinning up or

down (“prepare to remove” command: ca.

10 sec. flashes quickly 3 times per sec.,

followed from slowly flashes in 3 sec.

interval; see also section “Hot Swap for FC

HDD Modules” on page 42).

HDD

STATUS

OFF There is no hard disk fault.

yellow,

HDD error occurred.

permanently on

orange,

Drive identification.

flashes quickly

orange,

flashes quickly

– Drive rebuild: all drives belonging to the

pack blink synchronously.

– Error message from controller:

Critical LUN (Logical Unit Number)

– A drives was set on “Make Offline” and

the remaining HDD modules flash

quickly.

orange,

permanently on

Table 2: Meaning of the HDD Control LEDs Indication

“Make Offline” state for the selected HDD

modules.

U41221-J-Z156-1-74 19

Page 28

The Rear Side Operating and Indicator Elements

3.2 The Rear Side

On the rear side of the PRIMERGY S60 storage subsystem there are the status

LEDs for the FFx-RAID controller module(s) and for the power supply units.

Also the power switch is placed on this side.

1

6

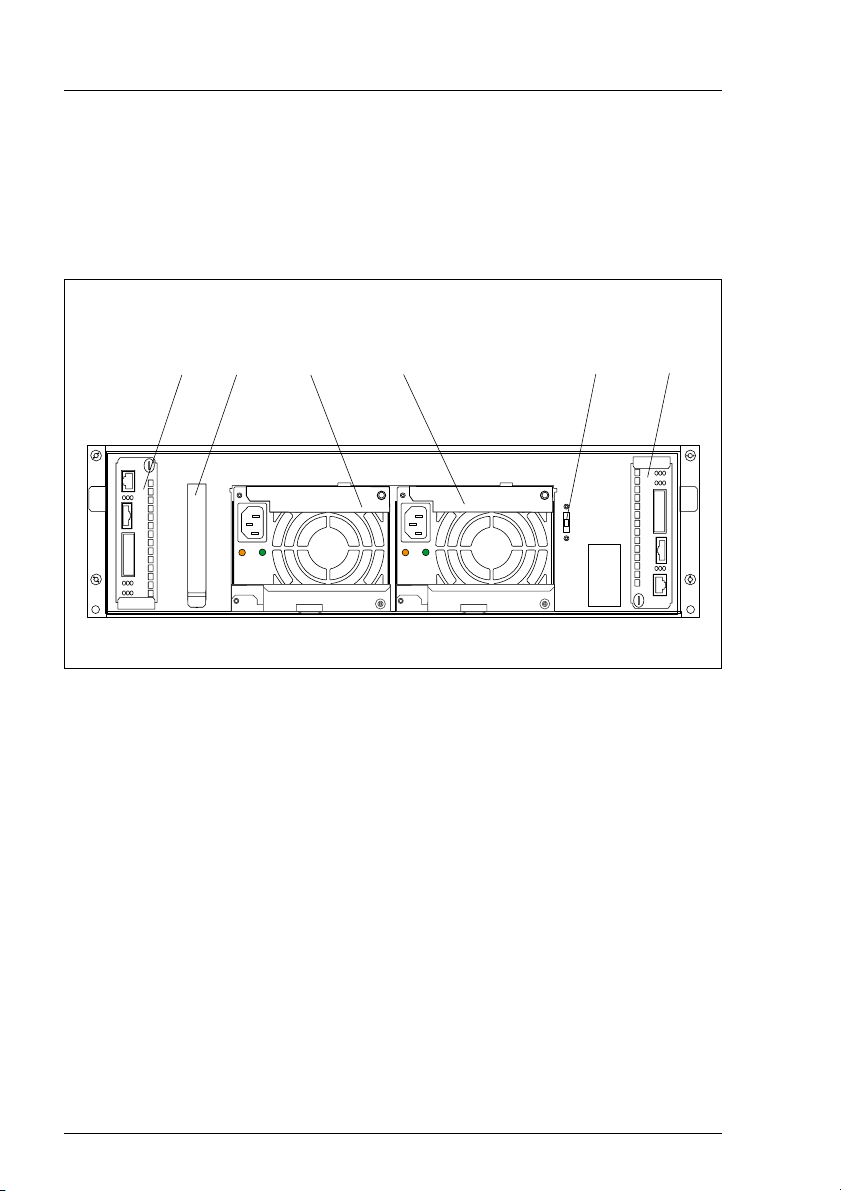

Figure 4: Rear View of the PRIMERGY S60 Storage Subsystem

(1) FFx-RAID controller module 1

(2, 3) Power supply units

(4) Power switch

(5) FFx-RAID controller module 0 (default)

(6) Location for the optional Remote Service Board

2

3 4

3.2.1 FFx-RAID Controller Module LEDs

5

The status LEDs are located on the connection panel of the FFx-RAID controller

module. For description see section “The FFx-RAID Controller Module” on

page 45.

20 U41221-J-Z156-1-74

Page 29

Operating and Indicator Elements The Rear Side

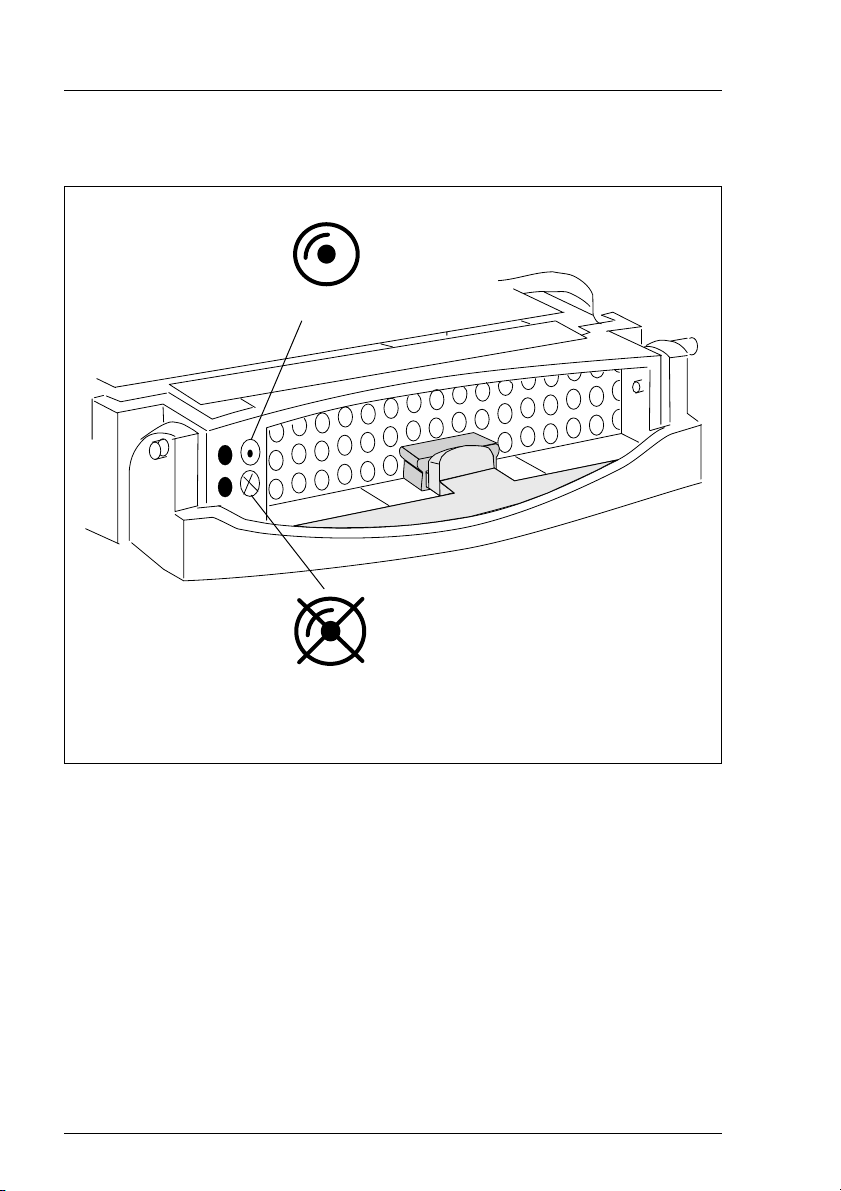

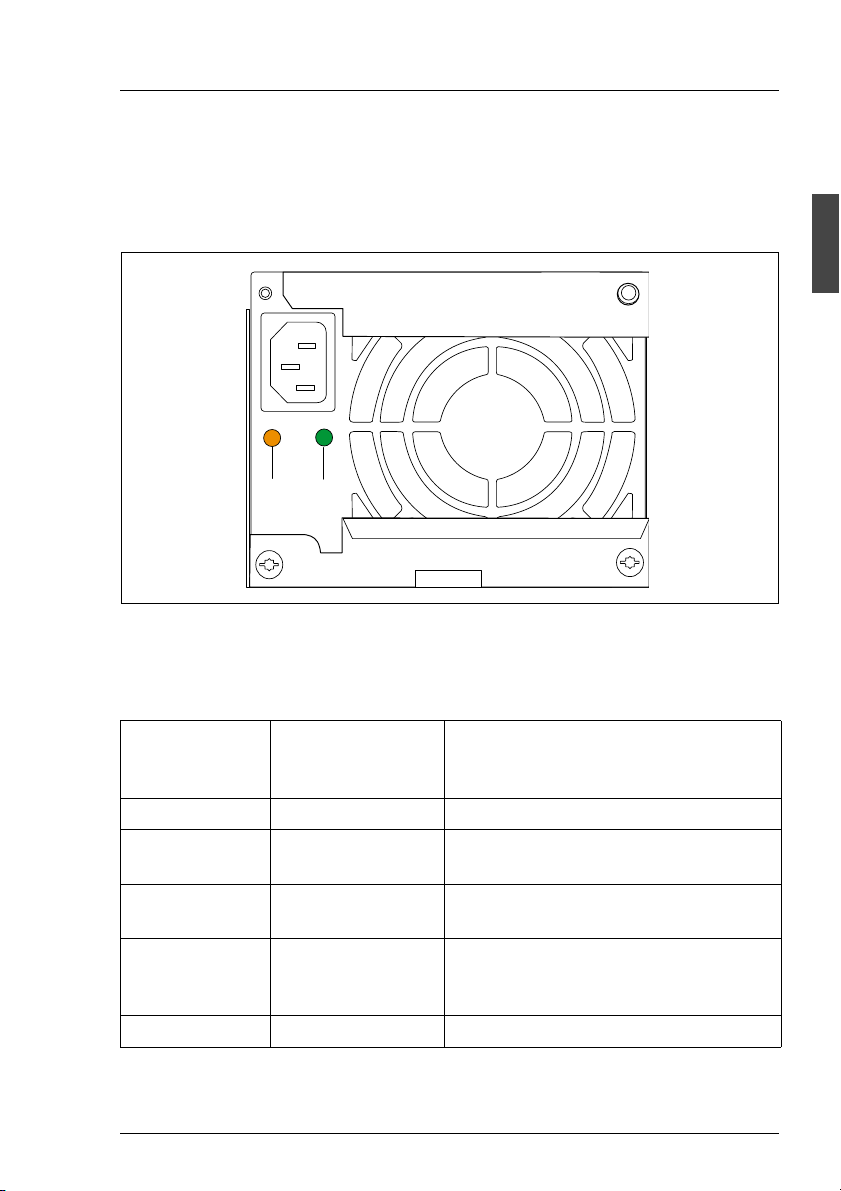

3.2.2 Power Supply Unit LEDs

On the connecting side of the power supply units there are two LEDs that

indicate the status of the power supply units:

2

1

Figure 5: The Power Supply Unit LEDs

(1) Fault indication (amber LED)

(2) Operating indication (green LED)

Fault

indication (1)

(amber LED)

OFF OFF No AC voltage present.

OFF flashing AC voltage present; standby outputs

OFF ON DC outputs ready. Power supply unit

ON OFF No AC voltage present for this power

flashing ON Current limiting.

Table 3: Meaning of the Power Supply Unit LEDs

U41221-J-Z156-1-74 21

Operating

indication (2)

(green LED)

Status of the power supply unit

ready.

operational.

supply unit or power supply unit has

failed.

Page 30

The Rear Side Operating and Indicator Elements

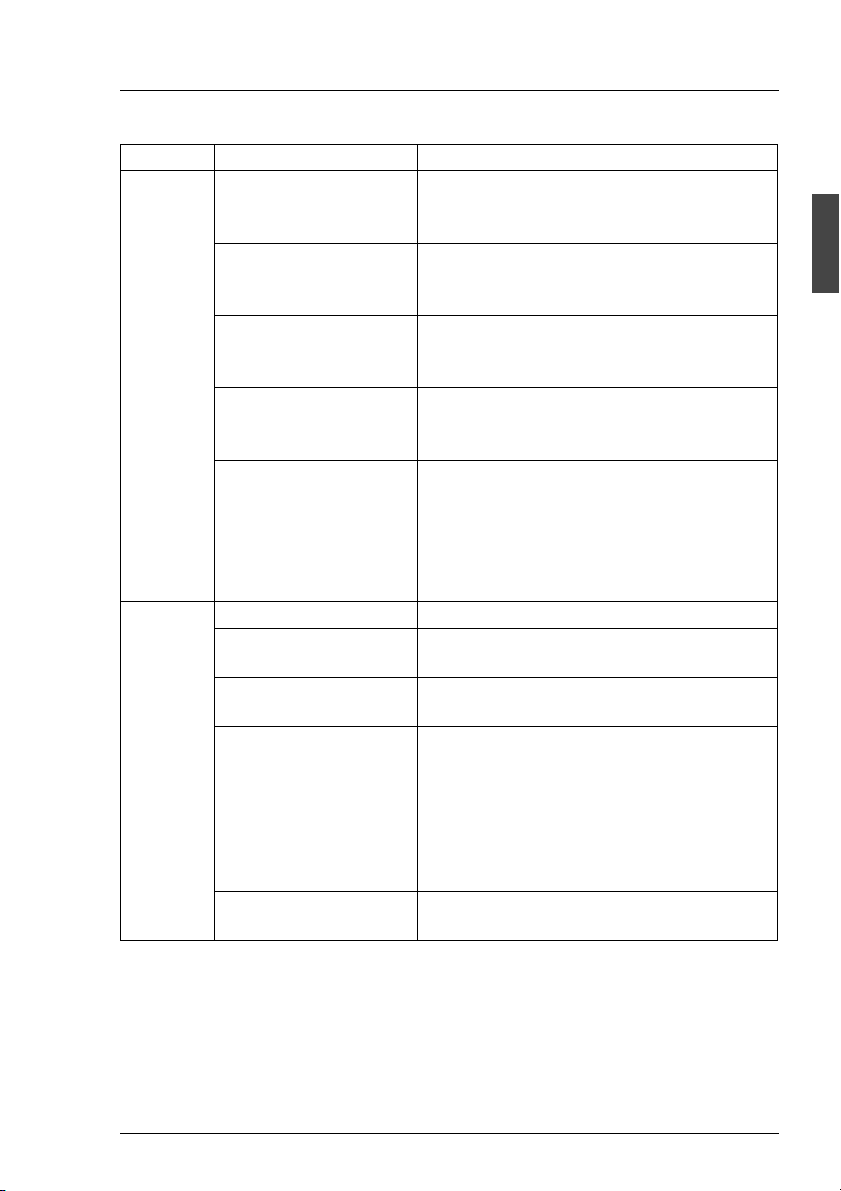

3.2.3 Power Switch

The power switch is located also on the rear of the PRIMERGY S60 storage

subsystem. It is a slide switch with three possible settings.

I

R

O

Figure 6: Power Switch on the Rear of the PRIMERGY S60 Storage Subsystem

Position Function Description

(I) local ON The storage subsystem is switched ON permanently

and is connected directly to the mains (default

setting).

(R) The operating mode (on/off) is controlled via the Remote Service

Board. In this default setting, the storage subsystem is switched

on and off simultaneously with the server. If two servers are

connected, it remains active as long as one of the servers is

switched on.

(O) OFF The storage subsystem is switched OFF permanently.

Table 4: Possible Settings of the Power Switch

22 U41221-J-Z156-1-74

Page 31

Operating and Indicator Elements Fan LED

3.3 Fan LED

If you have been notified, via corresponding warning or error messages on the

server or via the cooling status LED on the front of the storage subsystem, that

there is a cooling problem, the fan status can be read on the fan LED.

1

Figure 7: Installed Fan Module, View with Fan LED

(1) Fan LED

Color Meaning Required Measures

green Both fans are in operation. No action required.

yellow One fan has failed. The fan module must be replaced.

orange Both fans have failed. The fan module must be replaced.

Table 5: Meaning of the Fan LEDs

I Replacement of the fan module is described in the chapter “Fan Module”

on page 33.

U41221-J-Z156-1-74 23

Page 32

Page 33

4 Floorstand Model

4.1 Open the Housing

4.1.1 Removing and Mounting the door

!

1

Figure 8: Removing the Door

2

Ê Unlock the door with the key (1) and open it.

Ê Remove the door by lifting it up (2).

Mounting is performed in the reverse order.

U41221-J-Z156-1-74 25

Page 34

Open the Housing Floorstand Model

4.1.2 Removing/Mounting the left Side Cover

I To replacing the fan module (see section “Installing/Removing the Fan

Module” on page 34) in the floorstand model the left side cover must be

removed.

3

2

1

Figure 9: Removing the Side Cover

Ê Open the door.

Ê Loosen the lower left knurled screw (1) and slide the left side cover in the

direction of the arrow for approx. 3cm (2).

Ê Remove the side cover from the six guides by sliding it in the direction of the

arrow marked (3).

26 U41221-J-Z156-1-74

Page 35

Floorstand Model Open the Housing

Mounting is performed in the reverse order.

V CAUTION!

For mounting the left side cover pay attention to the connection strip (1)

for the door switch (see figure 10). It can be damaged.

1

Figure 10: Floorstand model: door switch with connection strip

U41221-J-Z156-1-74 27

Page 36

Page 37

5Power Supply

5.1 Power Supply Units

The PRIMERGY S60 storage subsystem contains two power supply units which

guarantee the power supply to all installed components.

Using two power supply units, power supply redundancy is achieved. If a power

supply unit fails, the subsystem will continue to operate without restrictions.

I To guarantee a power supply unit redundancy, a failed power supply unit

must be replaced urgently.

The power supply units are supplied with mains voltage via the supplied

connecting cables.

The power supply units can be connected directly to two different phases of the

in-house circuit in order to achieve phase redundancy (see section “Mains

Connection with Phase Redundancy” on page 59).

U41221-J-Z156-1-74 29

Page 38

Power Supply Units Power Supply

5.1.1 Replacing the Power Supply Unit

V CAUTION!

It is imperative that you read the chapter “Important Notes” on page 7 in

this manual before you carry out work on your storage subsystem.

If faults occur with the power supply, it could be necessary to replace a power

supply unit. Information about the relevant error messages can be found in the

sections “Meaning of the S60 Operating Status LEDs” on page 16, “Power

Supply Unit LEDs” on page 21 and in the chapter “Troubleshooting” on page 71.

Figure 11: Power Supply Unit Removed

V CAUTION!

When a power supply unit is replaced in a non-redundant power supply

system (only one power supply unit present) the server must be

switched OFF and/or the FC channels deactivated.

Ê If only one power supply unit is present, shut down the server and switch it

OFF.

Ê Remove the cable of the defective power supply unit.

Ê Raise the lower catch on the power supply unit and carefully remove it from

its slot by pulling on the upper catch. To remove the power supply unit the

lower catch must be in the up position.

30 U41221-J-Z156-1-74

Page 39

Power Supply Power Supply Units

Installing occurs in reverse of order:

1

Figure 12: Power Supply Unit Removed with Coding Pin

Ê Push the new power supply unit into the empty slot.

I Please note the coding of the power supply unit. Only one power

supply unit, to which the coding pin (1) is attached in such a way that

it does not adversely affect the installation, may be used in the

PRIMERGY S60 storage subsystem. The coding may not be

removed under any circumstances.

V CAUTION!

Please ensure that the power supply unit engages correctly in the

mounting frame and is locked in position. This is the only way to avoid

the power supply unit being shaken out of its mountings and

damaged during transport.

Ê Connect the cable to the power supply unit (see the section “Mains

Connection” on page 58).

Ê Connect the power cable to the mains (see section “Mains Connection” on

page 58).

U41221-J-Z156-1-74 31

Page 40

Page 41

6 Fan Module

The redundant fan module ensures cooling of the PRIMERGY S60 storage

subsystem. It is equipped with two fans. If one fails, the other working fan sufficiently guarantees cooling and prevents the components of the storage

subsystem from overheating.

A temperature sensor on the rear panel of the power supply unit and a

revolution monitor fitted for each fan are used to permanently check the cooling.

Error messages can be read on the cooling status LED on the front of the

storage subsystem (see section “Meaning of the S60 Operating Status LEDs”

on page 16) and on the fan LED (see section “Fan LED” on page 23).

As soon as fan failure is detected, the fan module with the defective fan should

immediately be replaced with an intact module so that the redundancy characteristics (availability) are retained.

I Only the complete fan module may be replaced.

I The fan module can be replaced during operation.

V CAUTION!

The fan module should be replaced within 30 seconds to prevent

possible overheating.

U41221-J-Z156-1-74 33

Page 42

Installing/Removing the Fan Module Fan Module

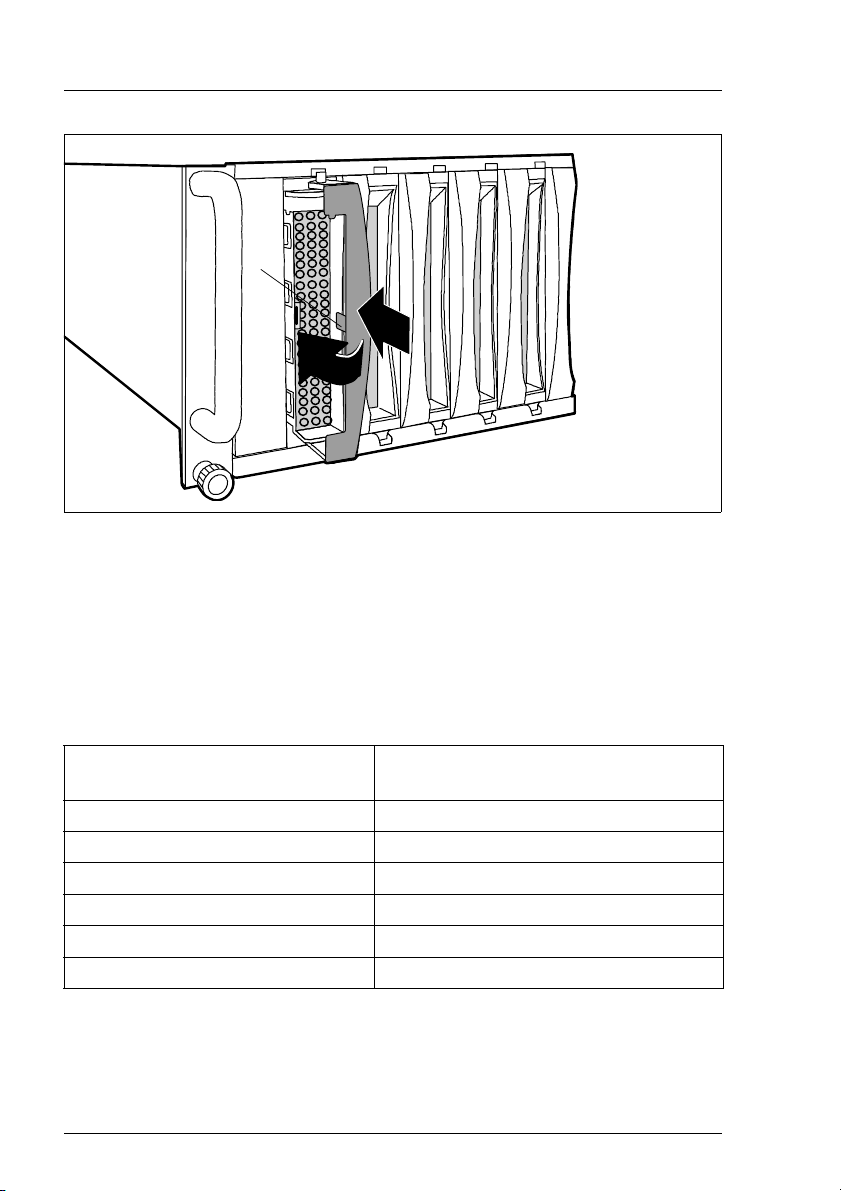

6.1 Installing/Removing the Fan Module

I Please note the status of the fan LED before removing and after installing

the fan module (3) (see section “Fan LED” on page 23).

Floorstand model

Ê Remove the left side cover (see section “Removing/Mounting the left Side

Cover” on page 26).

Rack model

Ê Loosen the two knurled screws on the front of the rack model and pull out

the storage subsystem from the rack.

2

1

1

4

3

Figure 13: Releasing and Removing the Fan Module

Ê Release the fan module by putting two fingers into the recessed grips and

push the locking mechanisms found here inwards (1).

V CAUTION!

Note the warning label “Rotating Parts“ (4) on the fan module. There

is an increased risk of injury from rotating parts.

Ê Remove the fan module from the storage subsystem in the direction of the

arrow (2).

34 U41221-J-Z156-1-74

Page 43

Fan Module Installing/Removing the Fan Module

Proceed as follows when installing the fan module:

2

1

1

Figure 14: Installing the Fan Module

Ê Put two fingers into the recessed grips (1). When installing, it is not

necessary to push the locking mechanism inwards.

Ê Lift the fan module over the slot and insert it carefully (2).

Ê Gently push the fan module down until you can feel and hear it engaging.

U41221-J-Z156-1-74 35

Page 44

Page 45

7 FC Hard Disk Drives

Up to fourteen one inch hard disk drives can be installed into the

PRIMERGY S60 storage subsystem. The FC hard disk drives can be controlled

via up to two FC ports. The two FC ports are in each case over two outward lead

Nodes in one loop. This means that each port is in one FC Loop (all ports A

from the FC hard disk drives are in the same loop as the channel 0 from (both)

FFx-RAID controller(s) and all ports B from the FC hard disk drives are in the

same loop as the channel 1 from (both) FFx-RAID controller(s)).

The FC hard disk drives are built on a carrier which allows defective drives to

be replaced (hot swap) or new drives to be added during operation. The hard

disk drive and the carrier constitute the hard disk drive module (HDD module).

The hot-swap function can only be performed together with a corresponding

RAID configuration. Further information about the RAID configuration or RAID

level can be found in the RAID controller documentation.

A hard disk drive may only be replaced if it is inactive (see description of the

LEDs in the table “Meaning of the HDD Control LEDs Indication” on page 19) or

if it has been marked as defective in the management tool.

The hot swap procedure increases the availability of the system operation and

guarantees a high degree of data integrity and protection against failure.

7.1 Handling Hard Disk Drives/HDD Modules

Hard disk drives incorporated in the HDD modules are highly sensitive electromagnetic devices and must be handled with great care. It is extremely likely that

an incorrect handling will lead to a partially and/or total failure of the hard disk

drives.

These failures will result in data errors and to loss of data or to total destruction

of the hard disk drive.

Please observe following rules, which will help to avoid the occurrence of this

type of problems:

● Store and transport HDD modules only within the limits stipulated in the

specification.

● When transporting HDD modules (even over short distances), always use

the original packaging (ESD labeling).

U41221-J-Z156-1-74 37

Page 46

Installing/Removing HDD/Dummy Module FC Hard Disk Drives

● Never expose a HDD module to a temperature shock. Avoid the formation

of condensation inside and on the outside of the hard disk drives.

The hard disk drives may be expose only to defined temperature and

climatic conditions.

● Always put the HDD module down carefully, with its largest surface facing

downwards, to avoid the danger of tipping over.

7.2 Installing/Removing HDD/Dummy Module

V CAUTION!

Under no circumstances should you remove a HDD module while the

system is in operation if you are not sure that the hard disk drive is

operated by a RAID controller and belongs to a disk array which is

operating in RAID level 1 or 5.

V CAUTION!

The HDD modules must all be marked clearly (see also section “Identification Marks and Loop Addresses” on page 43) so that they can be put

back into the original slots after an upgrade. If this is not taken into

account, existing data can be destroyed.

The hard disk drives which can be ordered for the PRIMERGY S60 storage

subsystem are delivered as HDD modules which include the hard disk drive preinstalled in a carrier. Only a service technician may remove a hard disk drive

from the carrier.

Free slots are provided with a dummy module (an empty carrier) which must be

removed before installing an additional HDD module.

Removing the dummy module

Ê Press the upper and lower tabs on the dummy module together (see

figure 15 on page 39) until the locking mechanism disengages, and remove

the dummy module from the slot.

Installation of the dummy module occurs in reverse order.

38 U41221-J-Z156-1-74

Page 47

FC Hard Disk Drives Installing/Removing HDD/Dummy Module

Figure 15: Dummy Module and corresponding HDD Module

V CAUTION!

Keep the dummy module for future use. If the HDD module is removed

again and not replaced with a new module, then the dummy module must

be reinstalled due to cooling, the applicable EMC (electromagnetic

compatibility) regulations and fire protection.

Installing the HDD module

Ê Solve the locking mechanism by pressing the locking button (1) .

Ê Push the handle of the HDD module fully in the direction of the arrow.

U41221-J-Z156-1-74 39

Page 48

Installing/Removing HDD/Dummy Module FC Hard Disk Drives

3

1

2

Figure 16: Installing the HDD Module

Ê Push the HDD module into the empty slot (1) until it stops .

Ê Push the module handle completely in the direction of the arrow (2) until the

locking mechanism (3) engages.

V CAUTION!

The HDD module must be acclimatized in its operating environment for

an acclimatization time.

Temperature difference (°C)

(operating environment/outside)

53

10 5

15 7

20 8

25 9

30 10

Table 6: Acclimatization Time for the HDD Module

40 U41221-J-Z156-1-74

Minimum acclimatization time

(hours)

Page 49

FC Hard Disk Drives Installing/Removing HDD/Dummy Module

Removing occurs in reverse order:

1

Figure 17: Removing the HDD Module

Ê Pull out the HDD module. Observe the notes in the section “Handling Hard

Disk Drives/HDD Modules” on page 37.

U41221-J-Z156-1-74 41

Page 50

Hot Swap for FC HDD Modules FC Hard Disk Drives

7.3 Hot Swap for FC HDD Modules

V CAUTION!

The hot-swap function can only be performed together with a corresponding RAID configuration.

Only pull out a HDD module if the drive is not being accessed. Observe

the control LEDs for the corresponding HDD module (see section “The

Control LEDs for the Hard Disk Drives” on page 18).

If you want to replace an FC HDD module during operation, proceed as follows:

Ê If you want to pull out a HDD module which is not defective, it must be set to

“Offline“ via software (RAID controller configuration software), and/or it must

be prepared for removal by the “prepare to remove” command.

Ê Pull out the HDD module (defective/not defective) by a few centimeters.

Ê Wait for at least 60 seconds.

I This period is necessary for the RAID controller to recognize that a

HDD module has been pulled out and for the hard disk drive to come

to a stop.

Ê Pull out the HDD module right.

Ê Insert the new HDD module.

When you have removed the HDD module and are not replaced with a new

module, then insert a dummy module into the empty slot. Ensure that the

dummy module engages in the slot correctly.

42 U41221-J-Z156-1-74

Page 51

FC Hard Disk Drives Identification Marks and Loop Addresses

7.4 Identification Marks and Loop Addresses

The identification of the hard disk drives with marks as HDD1 through HDD14

must be performed from the bottom up (floorstand model) or from left to right

(rack model).

The loop addresses of the FC hard disk drives are hardware-predefined as

follows:

HDD 1234567891011121314

ID (Dec.) 012 3 45678910111213

ID (hex) 00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D

Table 7: Address IDs

U41221-J-Z156-1-74 43

Page 52

Page 53

8 Plug-in Board Modules

8.1 The FFx-RAID Controller Module

The module will be inserted in an individual slot on the rear of the storage

subsystem. The two modules in figure 4 on page 20 are marked (1) for the FFx-

RAID controller module 1 and (5) for the FFx-RAID controller module 0.

V CAUTION!

In a simplex configuration the storage subsystem can be accessed only

via the FFx-RAID controller module 0 (see figure 4 on page 20).

In a dual-active configuration both FFx-RAID controller modules must have the

same size of cache memory and the same firmware version.

The module incorporates the FFx-RAID controller itself (1), the device adapter

(DA) (2) and the host adapter (HA) (3).

1 2 3 4

1 2 3 4

O N

O N

2

Figure 18: The FFx-RAID controller module

1

3

The FFx-RAID controller is a high-performance FC host to FC disk array

controller. The device adapter makes the connection between the FFx-RAID

controller and the FC hard disk drives, the host adapter the connection to the

server.

U41221-J-Z156-1-74 45

Page 54

The FFx-RAID Controller Module Plug-in Board Modules

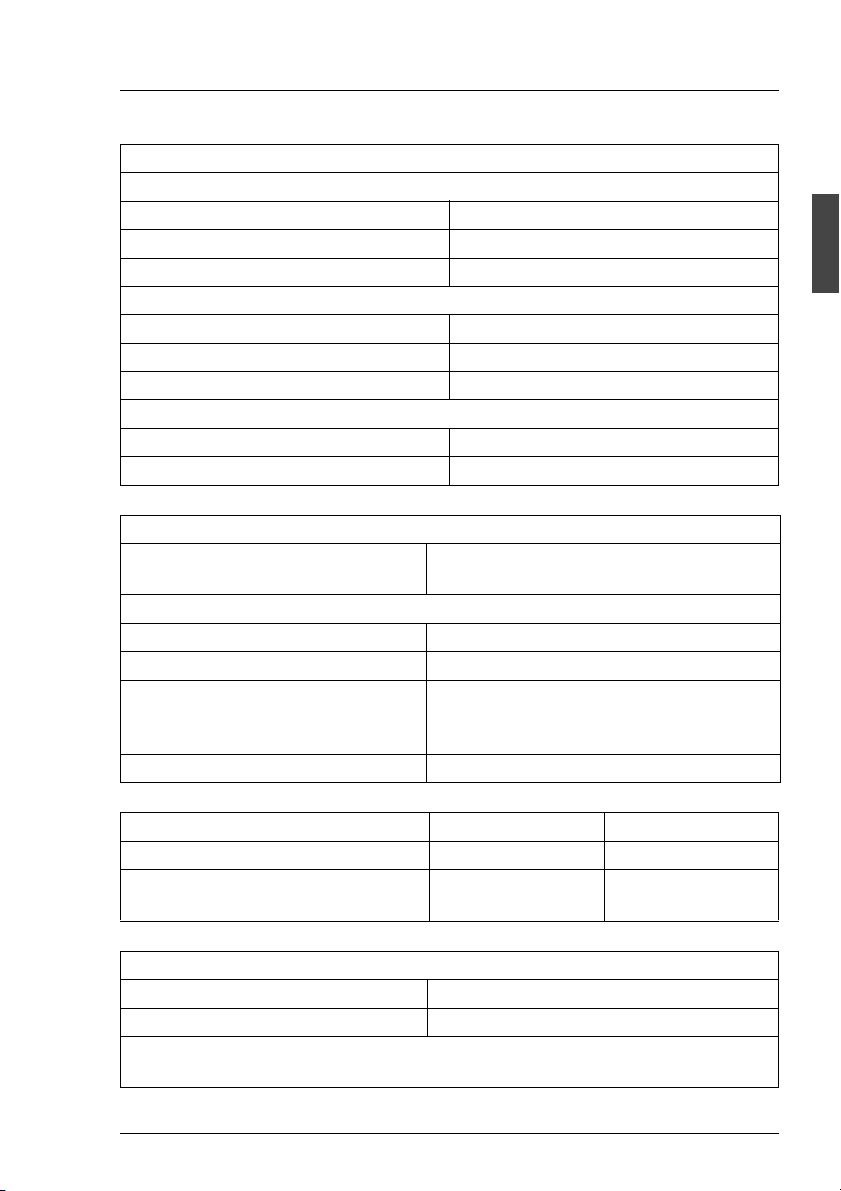

8.1.1 Indicators and Connectors

The integrated FC-HUB provides the standard host-interface (two nodes) for

the storage subsystem. One node will be connected via a fixed HSSDC

connector (11) (see figure 19 on page 47) available only for cooper cable up to

10 m.

The other node will be connected via a GBIC (Gigabit Interface Converter) (12).

The FC-transmission medium (CU/HSSDC, MMF or SMF) depends on the type

of GBIC being used.

I Perfect functioning will be ensured only by the use of the GBIC types

released by Fujitsu Siemens Computers GmbH.

LEDs indicate the operating status of the module, of the corresponding nodes

and/or loop and the channel activity (see tables under „Description of the LED

indicators“ on the following pages).

To configure the FFx-RAID controller, use the VT100 Terminal-EmulationInterface (see “Related publications” on page 81) or SAM (SAN Array Manager)

software. The VT100 Terminal-Emulation-Interface can be connected via the

VT100-DEBUG connector (10).

46 U41221-J-Z156-1-74

Page 55

Plug-in Board Modules The FFx-RAID Controller Module

Following indicators and connectors are located on the connection panel of the

module (figure 19):

No. Element Label on the connection panel

1 LED green 1 DAC DEVICE ACTIVITY

2 LED yellow/green 2 VT100/DEBUG STATUS

3 LED yellow/green 3 HSSDC NODE STATUS

4 LED green 4 DAC HOST ACTIVITY

5 LED yellow/green 5 DAC NODE STATUS

6 LED yellow/green 6 GBIC NODE STATUS

7 LED yellow 7 CACHE

8 LED green 8 DAC STATUS

9 LED red 9 DAC POWER ALARM

10 VT100-DEBUG connector VT100/DEBUG

11 HSSDC connector HSSDC NODE

12 GBIC connector GBIC NODE

1 D A C D E V I C E A C T I V I T Y

2 V T 1 0 0 / D E B U G S T A T U S

D A C

V T 1 0 0 / D E B U G H S S D C N O D E G B I C N O D E

3 H S S D C N O D E S T A T U S

1

2

3

1 0

4 D A C H O S T A C T I V I T Y

5 D A C N O D E S T A T U S

6 G B I C N O D E S T A T U S

1 1 1 2

7 C A C H E

8 D A C S T A T U S

9 D A C P O W E R A L A R M

4

5

6

7

8

9

Figure 19: FFx-RAID Controller Module / Connectors and Indicators

U41221-J-Z156-1-74 47

Page 56

The FFx-RAID Controller Module Plug-in Board Modules

Description of the LED indicators

LED

7

CACHE

(yellow)

OFF ON OFF Normal operation, module ready and partner

8

DAC

STATUS

(green)

9

DAC

POWER

ALARM

(red)

Description

OK

I This signal is activated only if two

FFx-RAID controller modules are

used; only the non-defective module

can indicate that the other one has

failed.

OFF flashing

0.5 sec.

OFF flashing

1 sec.

OFF Normal operation, FFx-RAID controller

module not ready and partner OK.

OFF Normal operation, FFx-RAID controller

module ready and partner failed

I This signal is activated only if two

FFx-RAID controller modules are

used; only the non-defective module

can indicate that the other one has

failed.

OFF OFF ON Alarm:

FFx-RAID controller not powered (5 VDC;

3.3 VDC)

OFF OFF flashing

0.5 sec.

OFF OFF flashing

1 sec.

ON OFF OFF Cache dirty:

flashing

0.5 sec.

flashing

0.5 sec.

Table 8: FFx-RAID Controller Module: Status Indicators

OFF OFF Conservative Cache activated (DIP switch

flashing

0.5 sec.

flashing

0.5 sec.

Alarm:

FFx-RAID controller 5 VDC failed

Alarm:

FFx-RAID controller 3,3 VDC failed

Data in cache and on the hard disk drives

are not identical (cache active)

K1 see “DIP Switches” on page 51)

Diagnosis Mode activated (DIP switch J1

see “DIP Switches” on page 51)

48 U41221-J-Z156-1-74

Page 57

Plug-in Board Modules The FFx-RAID Controller Module

LED

1

DAC DEVI CE

ACTIVITY

(green)

4

DAC HOST

ACTIVITY

(green)

Description

-- OFF No FC channel activity on the host side

-- ON FC channel activity on the host side

OFF -- No FC channel activity on the device side

ON -- FC channel activity on the device side

Table 9: FFx-RAID Controller Module: FC channel Activity Indicators

LED

DAC (5); GBIC (6);

HSSDC (3)

NODE STATUS

Description

(yellow/green)

green yellow

OFF OFF Module not inserted or not powered

ON OFF Full Operation: node in the loop active

OFF ON Node not in the loop (generally). Possible causes

on GBICs:

GBIC HW-Error status signals active:

RX_LOS, i. e. the received signal is not valid, or

TX_FAULT, i. e. sender works not correctly

OFF flashing

Node disabled from Service Processor (RSB)

0.5 sec.

ON ON

flashing between green

and yellow

Module OK; missing or corrupted data

approx. 0.5 sec.

Table 10: FFx-RAID Controller Module: Node Status Indicators

U41221-J-Z156-1-74 49

Page 58

The FFx-RAID Controller Module Plug-in Board Modules

LED

VT100/DEBUG STATUS

(3b yellow/green)

green yellow

flashing between green

and yellow

approx. 0.3 sec.

OFF ON RS232 switch* on position “1” (ext) and “debug

OFF flashing

2 sec.

ON OFF RS232 switch* on position “2” (RSB) and “debug

flashing

0.5 sec.

* The switches will be described in the section “Switches”.

Table 11: RS232 and FFx Status Indicators-

OFF RS232 switch* on position “2” (RSB) and “debug

Description

Voltage OK, FFx-RAID controller ready

mode” not activated

RS232 switch* on position “1” (ext) and “debug

mode” activated

mode” not activated

mode” activated

8.1.2 Switches

The RS232 Switch

This switch (figure 20 on page 51) enables the RS232-FFx receiver to be

switched between an external (default) and an internal (service processor on

the Remote Service Board) means of control.

Pos. Description

1 ext. RS232 (default)

The external controlling means will be attached via the VT100/DEBUG

connector (see figure 19 on page 47).

2RSB

Internal controlling means via the service processor on the optional

Remote Service Board.

I When the PRIMERGY S60 storage subsystem operates without

the optional Remote Service Board the switch must be set on

position “1”.

Table 12: RS232 switch settings

50 U41221-J-Z156-1-74

Page 59

Plug-in Board Modules The FFx-RAID Controller Module

K 1 - K 4

O N

D I P s w i t c h

4

3

1 2

1 2 3 4

ON

J 1 - J 4

4

3

1 2

O N

1 2 3 4

ON

R S 2 3 2 s w i t c h

2

1

Figure 20: FFx-RAID Controller Module: Switches on the Host Adapter

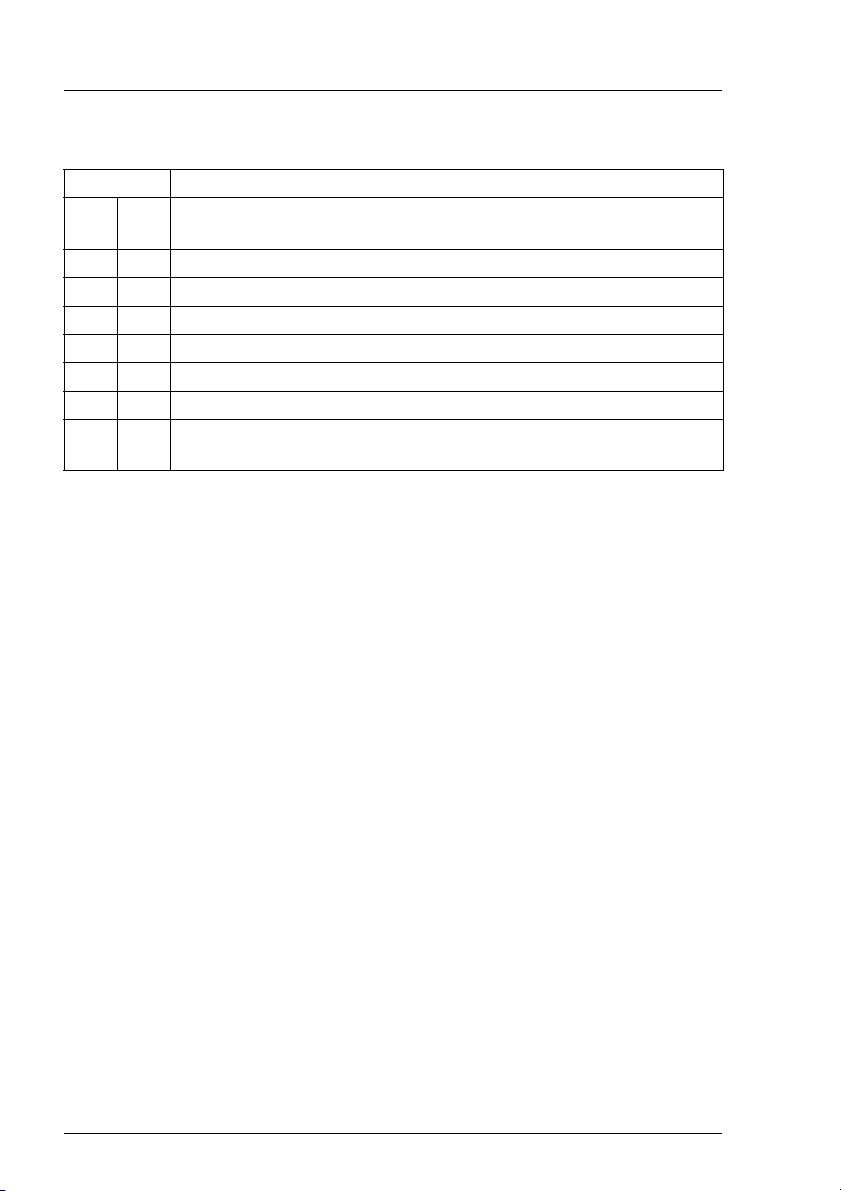

DIP Switches

DIP switches J1-J4 and K1-K4 (functionality switches) for the setting test and

analyzing possibilities in arrangement with the service are available on the host

adapter.

For normal operation the DIP switches J1-J4, K1, K2 and K4 must be set to

OFF, the DIP switch K3 to ON.

U41221-J-Z156-1-74 51

Page 60

The FFx-RAID Controller Module Plug-in Board Modules

The individual DIP switch positions ON have the following function:

DIP switch Function

J1 ON Manufactory Diagnosis Mode activated: status indicator LEDs

(red, green, yellow) for the FFx-RAID controller flash 0.5 sec.

J2 ON Debug Mode

J3 ON Disable HSSDC NODE

J4 ON Disable GBIC NODE

K1 ON Conservative Cache active

K2 ON Enable delayed FFx-RAID controller power ON (delay ca. 17 sec.)

K3 ON Enable/Reset FFx-RAID controller from I2C bus active

K4 ON Multi Frame Mode: node ON/OFF after 4 consecutive erroneous

or error-free frames

Table 13: DIP Switches: Functions

8.1.3 Installing/removing the FFx-RAID controller module

V CAUTION!

Observe the notes on safety and the information on electrostatic

sensitive device labeling in chapter “Important Notes” on page 7.

The FFx-RAID controller module can be installed and removed while the

subsystem is running provided that the configuration involved is a dual-active

configuration (two modules with dual-active configuration have been installed)

and the MultiPath software is active. If one FFx-RAID controller module is

removed, the second module automatically takes over its function (hot swap).

V CAUTION!

As condition for a hot swap action the replaced FFx-RAID controller

modules (FFx-RAID controller) must have the same firmware version

and the same cache memory size.

52 U41221-J-Z156-1-74

Page 61

Plug-in Board Modules The FFx-RAID Controller Module

I Refer also to the MultiPath software requirements for the FFx-RAID

controller settings, e. g.: both controller must be configured identically.

In a single-mode configuration (with only one module installed), the storage

subsystem must be turned OFF before removing the module.

Ê Remove all connection cables from the FFx-RAID controller module

connectors.

Figure 21: Loosening the Knurled Screw

Ê Loosen the knurled screw on the FFx-RAID controller module.

U41221-J-Z156-1-74 53

Page 62

The FFx-RAID Controller Module Plug-in Board Modules

Figure 22: Removing the Module

Ê Carefully pull out the FFx-RAID controller module from the slot. Grasp the

module on the knurled screw and on the bracket so that it does not tilt.

Installing occurs in reverse order:

Ê Make sure that the FFx-RAID controller module engages correctly in the

plug connection on the HDD backplane.

8.1.4 Adding a Second FFx-RAID Controller Module

I The addition of a second FFx-RAID controller module may be carried-out

when upgrading the simplex configuration to a dual-active configuration.

The action cannot be accomplished during normal operation.

In a dual-active configuration, the two FFx-RAID controller modules must

accept each other as partners. This requires both modules to have the same

FW status and the same cache configuration.

Ê Check (with SAM software) whether the FW status of the existing FFx-RAID

controller module matches that of the new FFx-RAID controller module.

Ê If the FW statuses do no match, use the SAM software to load the firmware

with the status of the new FFx-RAID controller module onto the existing

FFx-RAID controller module.

54 U41221-J-Z156-1-74

Page 63

Plug-in Board Modules The FFx-RAID Controller Module

Ê Install the second FFx-RAID controller module in the free slot as module 1

(see figure 4 on page 20).

Ê Switch the storage subsystem OFF and ON again.

Ê Configure both FFx-RAID controller modules identically.

Ê Reboot the host system.

8.1.5 The FFx-BBU (Battery Backup Unit) Module

The purpose of the FFx-BBU module is to provide AC glitch ride-through

wherein power loss is momentary for maintaining cache data content.

A short power loss cycle may result in loss of FFx-RAID controller availability

while the controllers re-boot. The FFx-BBU module guaranties that in this time

no cache memory data will be lost.

Depending on the cache memory size and the battery condition the

FFx-BBU module is capable to maintaining cache memory content for many

hours.

V CAUTION!

The FFx-BBU module is not intended to protect memory contents in the

event of accidental removal while the FFx-RAID controller module is in

operation. A normally operating FFx-RAID controller module should be

shut down prior to removal from the system.

U41221-J-Z156-1-74 55

Page 64

The FFx-RAID Controller Module Plug-in Board Modules

Conditioning the Battery

Prior to beginning normal operation, it is recommended that you condition the

battery for maximum longevity.

I During the conditioning, the FFx-RAID controller will be in write-through

cache mode. This may slow normal operations. Therefore, schedule this

operation accordingly.

To ensure that the battery is fully charged and properly conditioned:

Ê From SAM software, select Administration/Intelligent BBU.

Ê Make sure the % Charge Level is 100. If the battery is currently charging, do

not continue until the Charge Level is 100%.

Ê Select Recondition Battery and Apply.

Refer to the SAM software documentation (see “Related publications” on

page 81) for more information.

56 U41221-J-Z156-1-74

Page 65

9 Connections

If you would like to put the PRIMERGY S30 storage subsystem into operation,

the FC and the mains connections must be attached.

1 2

Figure 23: The Terminals on the Rear Panel

(1) FC connection (module 1)

(2) Mains connection 2

(3) Mains connection 1

(4) FC connection (module 0)-default

3

4

U41221-J-Z156-1-74 57

Page 66

Fibre Channel (FC) Connection Connections

9.1 Fibre Channel (FC) Connection

The required connectors are on the connection panel of the corresponding

FFx-RAID controller module at the rear of the storage subsystem (see figure 19

on page 47).

The possibilities to configure and connect the storage subsystem are described

in an additional manual (“PRIMERGY S60 Technical Configuration Guide”,

see“Related publications” on page 81).

Ê Set up the data connection between the system unit and the storage

subsystem by connecting the plug on the cable from the system unit with the

corresponding FC connector of the storage subsystem.

I Pay attention that the plug is securely attached to the FC connector. Only

in this way a smooth data transfer between the system unit and the

storage subsystem can be ensured.

9.2 Mains Connection

The storage subsystem is supplied with the mains voltage via the delivered

power cables.

2

2

1

1

Figure 24: Connecting the Power Cable

Ê Plug the end of the power cable marked (1) into the socket of the power

supply unit on the rear of the storage subsystem.

58 U41221-J-Z156-1-74

Page 67

Connections Mains Connection with Phase Redundancy

Ê Plug the end of the power cable marked (2) into a properly grounded power

outlet of the in-house mains or into the mains socket strip of the rack.

I Ensure that the power outlet used to connect the storage subsystem is

adequately protected with a 16 A or 15 A (USA) automatic circuit

breaker.

9.3 Mains Connection with Phase Redundancy

In order to provide phase redundancy in the power supply of the subsystem,

each of the power supply units are directly connected either to two different

phases or to two different power circuits of in-house mains.

2

1

Figure 25: Mains Connection with Phase Redundancy

Ê Connect one end of each power cable marked (1) to one of the power supply

units of the storage subsystem.

Floorstand Model

Ê Connect the ends of the power cables marked (2) to two different phases or

to two different circuits of the in-house mains.

Rack Model

Ê Connect the ends of the power cables marked (2) to two different phases of

the mains socket strip of the rack.

U41221-J-Z156-1-74 59

Page 68

Power connection via UPS Connections

9.4 Power connection via UPS

The availability of the storage subsystem can be improved further by using

Uninterrupted Power Supplies (UPS) and/or a Redundant PowerSwitch.

I IWhen the PRIMERGY S60 works in the higher performance Cache

Write Back mode, you should use a APC UPS to secure the cache

contents (256 MB).

In such cases, the storage subsystem is connected to one of the outlets of the

UPS or to the Redundant PowerSwitch. It is generally advisable to connect both

the server and the storage subsystem to a shared UPS.

A further possibility to secure the PRIMERGY S60 storage subsystem against

power failure is given by the following configuration:

– one power supply unit is connected via an UPS

– the second power supply unit is connected directly (without UPS) to the

same phase as the UPS

If a power failure occurs the UPS will secure the first power supply unit, the

second (unsecured) power supply unit will fail. This failure causes the FFx-RAID

Controller to switch into the degraded mode and the current cache content will

be secured (duration approx. 5 minutes).

The power supply unit secured over UPS is able to supply the subsystem alone

with current. Further data accesses on the storage subsystem are executed

however, without cache memory of the controller and are written directly on the

hard disks. Data security is ensured if the duration of the power failure is such

that the UPS switches the subsystem OFF.

If power failure is restored briefly (before the subsystem was switched OFF),

then the failed second power supply unit again becomes active and the

degraded mode of the FFx-RAID Controller is deactivated.

I Phase redundancy can be easily achieved by the additional use of a

Redundant PowerSwitch.

60 U41221-J-Z156-1-74

Page 69

10 Installation

10.1 Installation Steps

V CAUTION!

The storage subsystem should not be subjected to any extreme environmental conditions (see section “Technical Data” on page 4). Protect it

from dust, moisture and heat.

The storage subsystem must be acclimatized in its operating

environment for an acclimatization time.

Temperature difference (°C)

(operating environment/outside)

53

10 5

15 7

20 8

25 9

30 10

Table 14: Acclimatization Time

The following installation steps are described in detail in other sections of this

chapter:

● Unpacking the storage subsystem.

● Setting up the floorstand model or mounting the rack model into the rack.

● Cabling the storage subsystem (see chapter “Connections” on page 57).

● Setting the desired system parameters.

● Connecting the storage subsystem to the mains voltage (see section “Mains

Connection” on page 58 or section “Mains Connection with Phase Redundancy” on page 59).

● Switching ON the storage subsystem.

Minimum acclimatization time

(hours)

U41221-J-Z156-1-74 61

Page 70

Unpacking the Storage Subsystem Installation

10.2 Unpacking the Storage Subsystem

V CAUTION!

Please note the safety instructions in chapter “Important Notes” on

page 7.

If you need to lift or transport the storage subsystem, ask someone to

help you.

You should retain the original packaging of the storage subsystem for possible

further transport.

Ê Unpack all the individual parts.

Ê Check the contents of the package for visible transport damage.

Ê Check whether the delivery matches the information given on the delivery

note.

Ê Check whether the first page of the guarantee booklet has been completed

in full.

If you find transport damage or inconsistencies between the contents of the

package and the delivery note, inform your supplier immediately!

10.3 Setting Up the Floorstand Model

Position the storage subsystem at the intended location.

Note the following:

– The device must be protected against direct sunlight.

– The required minimum distances for operation and maintenance areas must

be adhered to.

– In order to connect the server, the rear of the storage subsystem must be

accessible.

– The mains plug must be accessible easily and safely.

– To ensure sufficient ventilation of the storage subsystem, a minimum

clearance of 200 mm must be provided at the front and rear of the storage

subsystem.

62 U41221-J-Z156-1-74

Page 71

Installation Mounting the Rack Model

10.4 Mounting the Rack Model

V CAUTION!

Please take note of the safety information and the notes on mounting in

the rack in the chapter “Important Notes” on page 7.

At least two people are needed to position the storage subsystem in the

rack.

The rack may tip over if more than one heavy unit (e.g. PRIMERGY

K400) is removed.

For mounting the subsystem in the DataCenter Rack at first a support bracket

must be mounted on the rear left support upright of the DataCenter Rack. This

support bracket is used for the rear fixing of the left slide rail and must be

mounted level with the lower edge of the subsystem. Cage nuts and/or spring

nuts also must be inserted in the support uprights. The cage nuts are used for

fixing the support bracket and the subsystem, the spring nuts for fixing the slide

rails.

Ê Take the installation instruction in the Technical Manual for the corre-

sponding rack model for aid.

Ê Using the mounting aid (stencil) mark the position of the attachment points

of the storage subsystem on the support uprights (three height units).

Refer to the information on the mounting aid.

Ê Mark the mounting points of the subsystem (knurled screws on the front) on

the front support upright. Also mark the fastening points of the slide rails on

the inside grooves of the support uprights facing backwards. The bottom

edge of the fastening flange must be flush with the top housing cover of any

device already mounted.

Ê Place the cage nuts and/or the spring nuts in the groove of the support

uprights and/or of the support bracket at the marked attachment points. If

necessary, adjust the position of the nuts in the groove until they lock into

the correct position.

Ê If required, you can mount one additional cable clip for vertical cable routing.

U41221-J-Z156-1-74 63

Page 72

Mounting the Rack Model Installation

10.4.1 Preparing the Slide Rails

Before the slide rails can be screwed to the support uprights, a holding-down

clamp must be secured to each slide rail. Seen from the front of the rack, the

holding-down clamps are secured to the front area of the slide rails. They

prevent the storage subsystem from tilting down on removing it from the rack.

1

2

1

2

3

4

Figure 26: Securing the Support brackets to the Slide Rails

Ê Position the slide rails (1) on your work surface in the same way as they are

to be mounted in the rack, with the longer angular edge onto which the

storage subsystem will be placed at the bottom and on the inside.

Ê Position the holding-down clamps (2) on the slide rails from the outside so

that the drilled holes for your assembly match up on the slide rails and on

the holding-down clamps.

Ê For each holding-down clamp, insert two of the screws supplied (3) from the

inside through the drilled holes into the slide rails and into the holding-down

clamps and tighten the screws.

64 U41221-J-Z156-1-74

Page 73

Installation Mounting the Rack Model

10.4.2 Mounting Slide Rails

Ê Fasten the slide rails with the holding-down clamps to the cage nuts

provided on the support uprights, for this purpose, using four of the screws

supplied in the rack mounting kit for each rail.

10.4.3 Mounting the Subsystem

Ê Lift the storage subsystem onto the two slide rails at the front of the rack and

move it back on the rails so that you can work comfortably from behind on

the rear of the rack.

3

1

2

Figure 27: Rear Left Stop

Ê Fasten the stop (1) on the left rear edge of the casing box (2). The stop

prevents the storage subsystem from being pulled forwards too far since

there is resistance on the rear edge of the holding-down clamp (3).

Ê Secure the storage subsystem with the two knurled screws to the front

support uprights of the rack.

U41221-J-Z156-1-74 65

Page 74

Mounting the Rack Model Installation

10.4.4 Routing the Cables

The cables of the storage subsystem are routed in the rack in such a way that

the unit can be pulled forwards without the cables having to be loosened.

The articulated cable guides on which the cables are routed are located in the

interior of the DataCenter Rack (on the right if seen from the rear of the rack).

The procedure can be found in the chapter “Cable Management“ in the

DataCenter Rack manual.

1

Figure 28: Leads Routing

Ê Connect the cables to the system unit and to the storage subsystem.

V CAUTION!

The cables must have enough over-length when connecting to the

storage subsystem (see figure 28). This is necessary to prevent them

being pulled out of the connectors when the subsystem is withdrawn

from the rack (the mains connectors could be pulled out unintentionally).

Ê Route the cables as shown in the figure.

Ê Insert the cables through the articulated cable guides.

Ê Secure the cables with the cable ties (1).

66 U41221-J-Z156-1-74

Page 75

Installation Mounting the Rack Model

In other rack models, the leads are secured to articulated cable guides delivered

with the installation kit for the 42-HE rack. The screw and the spring nut which

are used for installation form part of the racks or the installation kit for the rack.

Figure 29: Articulated Cable Guide

Proceed as follows:

Ê Secure the articulated cable guide with the screw to the spring nut placed in

the support uprights according to the description in the rack manual. The

articulated cable guide must be fitted within the height range of the storage

subsystem.

V CAUTION!

The articulated cable guide should be fixed on the support uprights

only. Do not fix it on the storage subsystem.

U41221-J-Z156-1-74 67

Page 76

Connecting and Disconnecting Cables Installation

10.5 Connecting and Disconnecting Cables

V CAUTION!

The power plug must be pulled out!

Read the documentation for the external device before connecting any

cables.

Cables may neither be connected nor disconnected during thunder-

storms.

When disconnecting a cable, always hold it by the plug, never pull on the

wire!

When connecting or disconnecting cables, follow the sequence

described below:

Connecting leads

Ê Switch off all the relevant devices.

Ê Pull the power plugs of all the relevant devices out of their sockets.

Ê Connect all the cables to the server and the storage subsystem. Mark the

cables and make a note of the function of each cable. Always note the safety

instructions in chapter “Important Notes” on page 7.

Ê Connect the power plugs to appropriately properly grounded power outlets.

For rack models make sure that the power cables of the devices are

connected in such a way that a even distribution of power to the three