Page 1

MCU-AN-510014-E-10

FM3

32-BIT MICROCONTROLLER

MB9B500 Series

FSS MB9BF506R EV-BOARD

USER MANUAL

APPLICATION NOTE

For more information for the FM3 microcontroller, visit the web site at:

http://www.fujitsu.com/global/services/microelectronics/product/micom/roadmap/industrial/fm3/

FUJITSU SEMICONDUCTOR (SHANGHAI) LIMITED

Page 2

A

TM

RM and Cortex-M3 are the trademarks of ARM Limited in the EU and other countries.

ALL RIGHTS RESERVED

The contents of this document are subject to change without notice.

Customers are advised to consult with sales representatives before ordering.

The information, such as descriptions of function and application circuit examples, in this document are

presented solely for the purpose of reference to show examples of operations and uses of FUJITSU

SEMICONDUCTOR device; FUJITSU SEMICONDUCTOR does not warrant proper operation of the device with

respect to use based on such information. When you develop equipment incorporating the device based on such

information, you must assume any responsibility arising out of such use of the information. FUJITSU

SEMICONDUCTOR assumes no liability for any damages whatsoever arising out of the use of the information.

Any information in this document, including descriptions of function and schematic diagrams, shall not be

construed as license of the use or exercise of any intellectual property right, such as patent right or copyright, or

any other right of FUJITSU SEMICONDUCTOR or any third party or does FUJITSU SEMICONDUCTOR warrant

non-infringement of any third-party's intellectual property right or other right by using such information. FUJITSU

SEMICONDUCTOR assumes no liability for any infringement of the intellectual property rights or other rights of

third parties which would result from the use of information contained herein.

The products described in this document are designed, developed and manufactured as contemplated for

general use, including without limitation, ordinary industrial use, general office use, personal use, and household

use, but are not designed, developed and manufactured as contemplated (1) for use accompanying fatal risks or

dangers that, unless extremely high safety is secured, could have a serious effect to the public, and could lead

directly to death, personal injury, severe physical damage or other loss (i.e., nuclear reaction control in nuclear

facility, aircraft flight control, air traffic control, mass transport control, medical life support system, missile launch

control in weapon system), or (2) for use requiring extremely high reliability (i.e., submersible repeater and

artificial satellite).

Please note that FUJITSU SEMICONDUCTOR will not be liable against you and/or any third party for any claims

or damages arising in connection with above-mentioned uses of the products.

Please note that FUJITSU SEMICONDUCTOR will not be liable against you and/or any third party for any claims

or damages arising in connection with above-mentioned uses of the products.

Any semiconductor devices have an inherent chance of failure. You must protect against injury, damage or loss

from such failures by incorporating safety design measures into your facility and equipment such as redundancy,

fire protection, and prevention of over-current levels and other abnormal operating conditions.

Exportation/release of any products described in this document may require necessary procedures in accordance

with the regulations of the Foreign Exchange and Foreign Trade Control Law of Japan and/or US export control

laws.

The company names and brand names herein are the trademarks or registered trademarks of their respective

owners.

Copyright ©2010 FUJITSU SEMICONDUCTOR (SHANGHAI) LIMITED All rights reserved.

2

Page 3

Revision History

Date Version

2011-04-21 V1.0

3

Page 4

Table of Contents

REVISION HISTORY .................................................................................................3

1 INTRODUCTION.....................................................................................................5

1.1 Product Overview ......................................................................................................... 5

1.2 MB9B506 Series MCU ................................................................................................. 5

1.3 Board Features............................................................................................................. 6

2 HARDWARE SETTING...........................................................................................7

2.1 Main Features .............................................................................................................. 7

2.2 Jumpers Overview........................................................................................................ 8

2.3 Setting for UART On-Board Programming ................................................................... 8

2.4 Setting for USB On-Board Programming ..................................................................... 8

2.5 Setting for Debug Tool ................................................................................................. 9

3 FLASH ON-BOARD PROGRAMMING................................................................. 10

3.1 On-Board Programming via UART............................................................................. 10

3.2 On-Board Programming via USB ............................................................................... 11

4 SAMPLE CODE.................................................................................................... 13

4.1 UART.......................................................................................................................... 14

4.2 Nand Flash................................................................................................................. 16

4.3 RTC............................................................................................................................ 16

4.4 CAN............................................................................................................................ 17

4.5 USB Function ............................................................................................................. 18

4.6 USB Host....................................................................................................................19

4.7 LCD & AD & Key ........................................................................................................ 20

5 DEBUG TOOL AND IDE....................................................................................... 21

5.1 Debug with J-Link in IAR EWARM Workbench .......................................................... 22

5.2 Debug with U-Link ME in Keil uVision4 ...................................................................... 28

6 MATERIALS DOWNLOAD................................................................................... 34

4

Page 5

1 Introduction

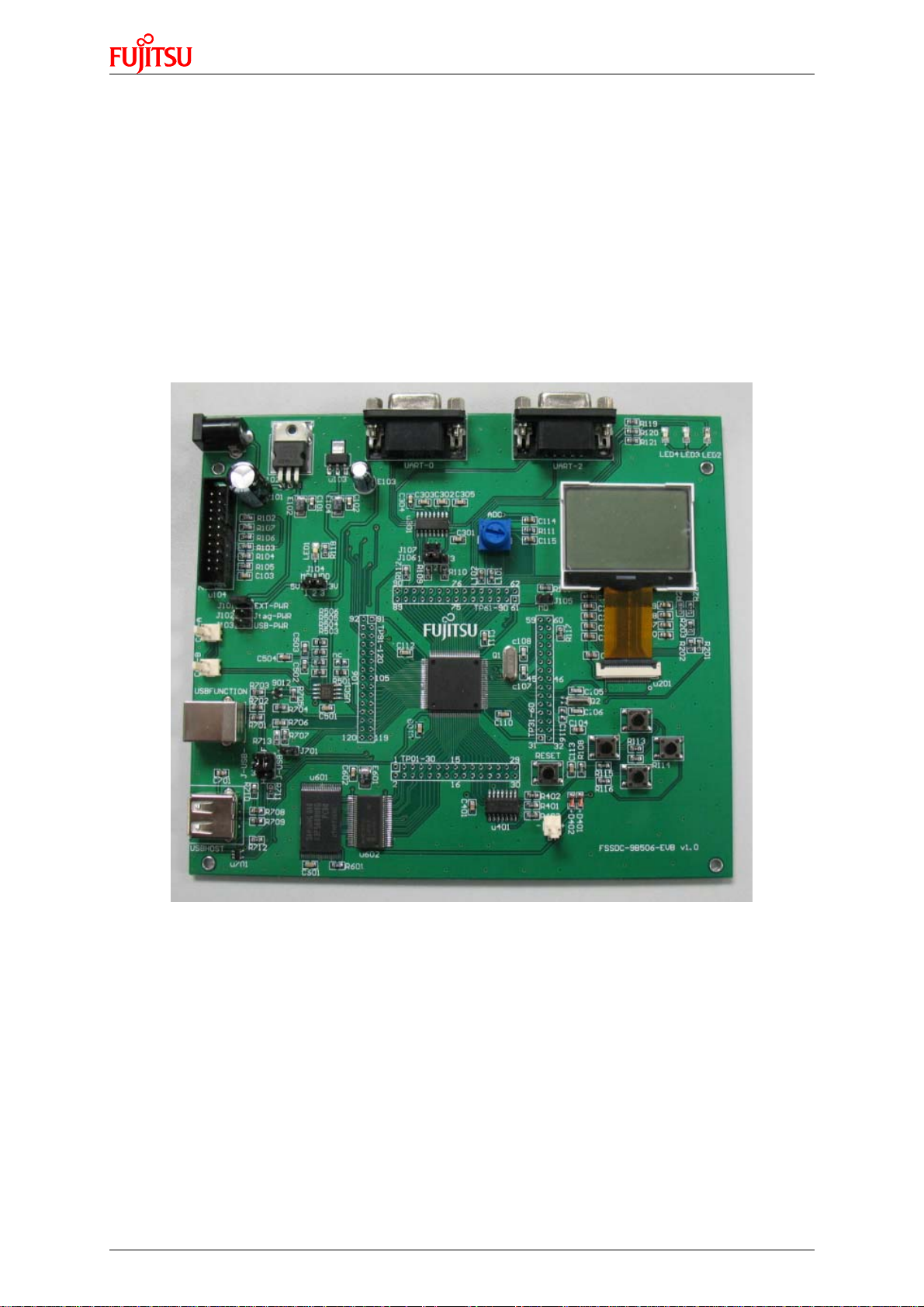

1.1 Product Overview

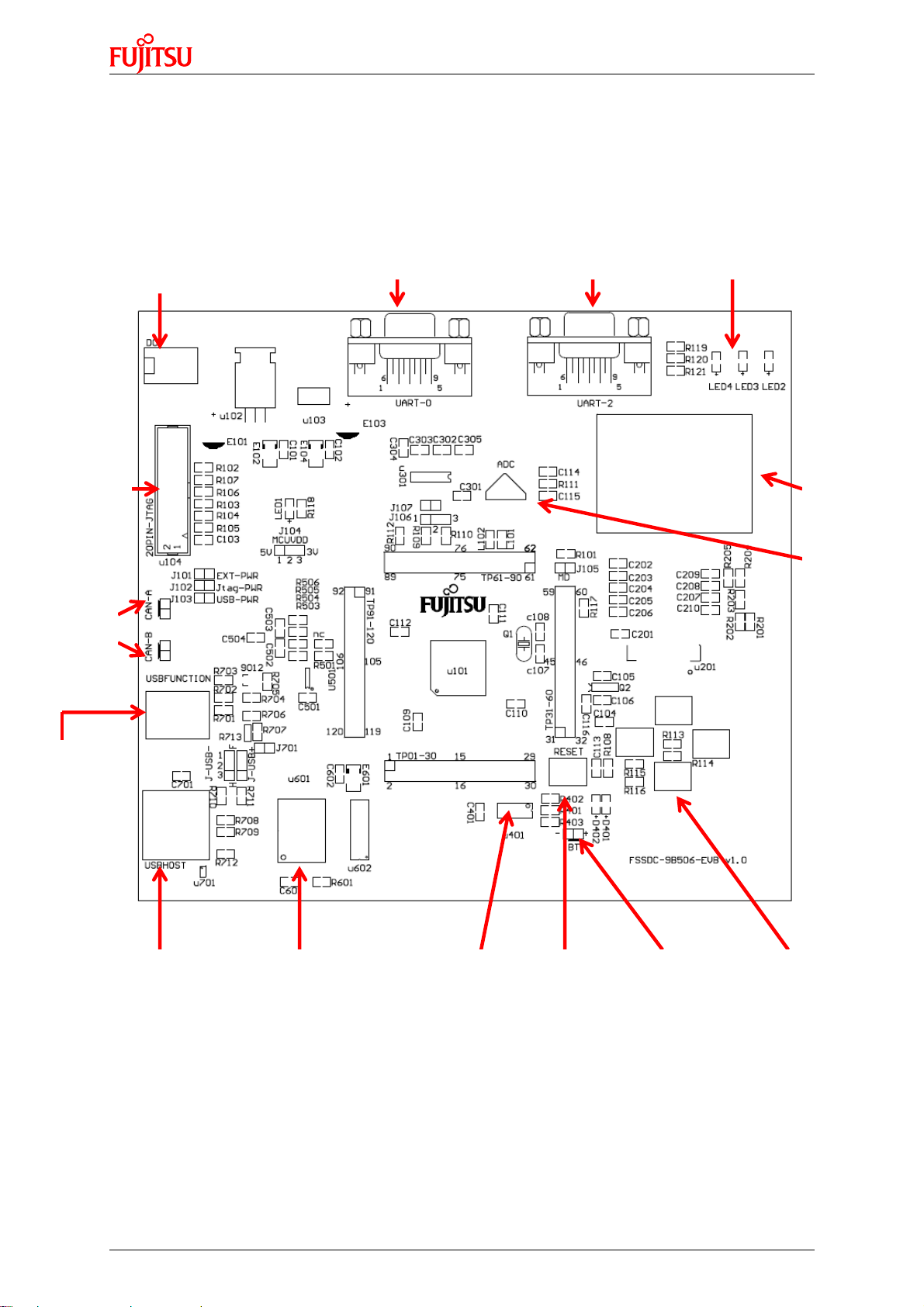

FSS MB9BF506R EV-Board (PN: FSSDC-9B506-EVB) provides an economical and simple

means for study usage for MB9B506 series MCU. The board compatible with both 3.3 and

5V system contains abundant external resources (LCD, buttons, UART, Nand Flash, CAN…)

to demonstrate MCU periphery function.

It also provides standard 20 pin JTAG interface, which is both compatible with IAR and Keil

debug tool. In addition, it allows On-board programming with both USB and UART mode.

Figure 1-1: FSSDC-9B506-EVB Overview

1.2 MB9B506 Series MCU

MB9B506 series MCU is 32-bit general purpose MCU of FM3 family that features the

industry's leading-edge ARM Cortex-M3TM CPU and integrates Fujitsu's highly reliable and

high-speed secure embedded flash technology. This MCU can operate at up to 80MHz CPU

frequency and work at a wide voltage range (2.7V-5.5V), which can be both compatible with

3.3V and 5V system.

It includes a host of robust peripheral features, including motor control timers (MFT), base

timer (can be configured to PWM, PPG, Reload, PWC timer), ADCs, on-chip memory (up to

512K Flash, up to 64K SRAM) and a wide range of communication interfaces (USB, I2C,

SIO, LIN, CAN).

5

Page 6

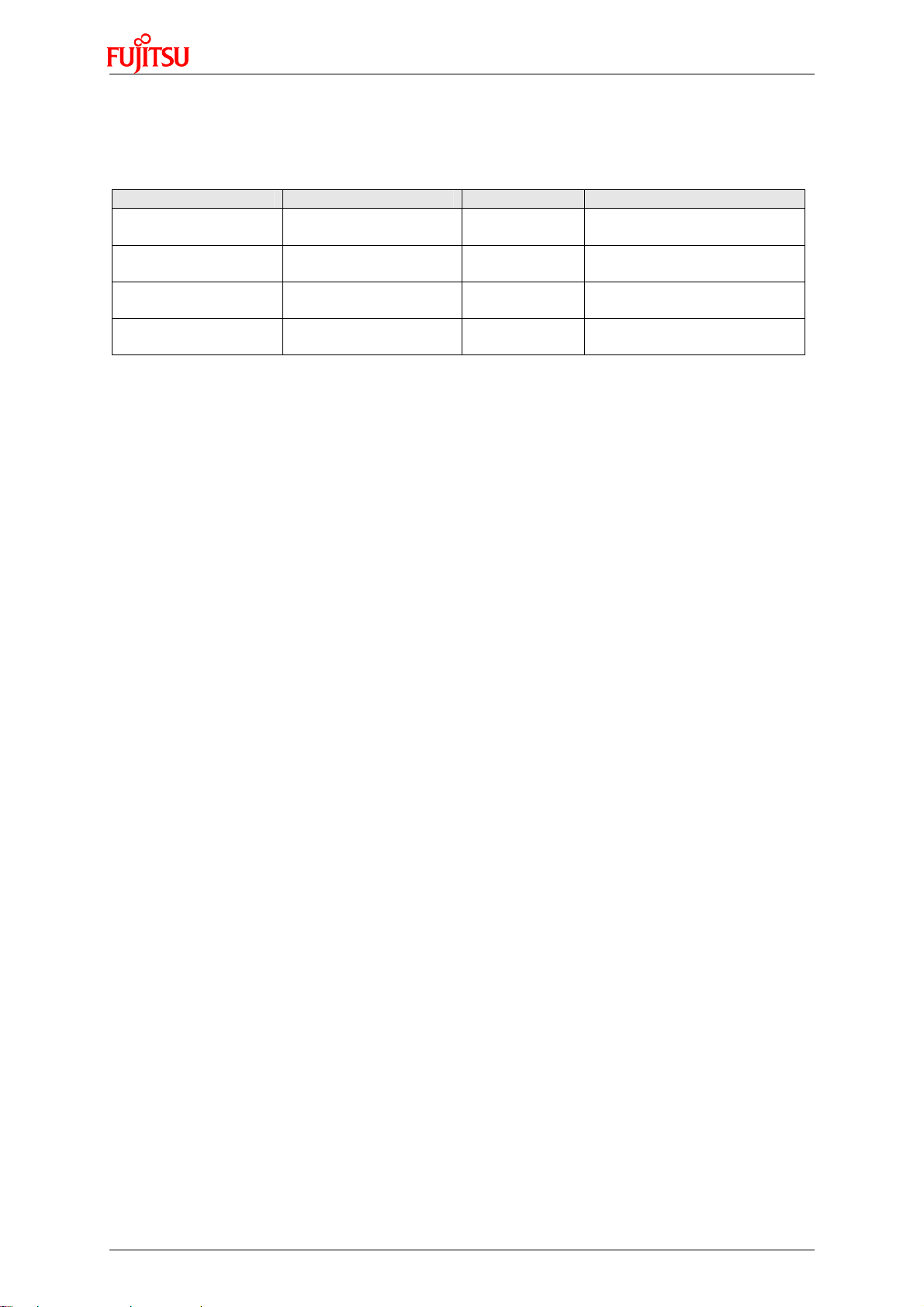

The size of on-chip memory can be configured according to different part number and the

package is available in LQFP and BGA, shown in following table.

Product Flash SRAM Package

MB9BF500N/R 256kB 32kB

MB9BF504N/R 256kB 32kB

MB9BF505N/R 384kB 48kB

MB9BF506N/R 512kB 64kB

Table 1-1: Product List

N: LQFP-100

R: LQFP-120

N: LQFP-100/BGA-112

R: LQFP-120

N: LQFP-100/BGA-112

R: LQFP-120

N: LQFP-100/BGA-112

R: LQFP-120

1.3 Board Features

FSS MB9BF506R EV-Board includes following features:

Microcontroller MB9BF506R

2x UART-Transceiver (Female DB9 connector)

2x High-speed CAN-Transceiver (2 pin header)

1x USB-Host (Type-A connector)

1x USB-Device (Type-B connector)

32M x 8bit Nand Flash (K9F5608U0D)

2

High Stability I

C-Bus Interface RTC Module (RX-8025T)

Standard JTAG Interface on a 20 pin-header

128 x 64 matrix LCD

3x ‘User’ LED

4x ‘User’-button

1x ‘Reset’-button

1x potentiometer regulating input voltage to AD channel

All 120 pins routed to test pads

On-board 5V and 3V voltage regulators, ‘Power’-LED

Power supply via USB-Device, JTAG or external with 15V power connector

6

Page 7

2 Hardware Setting

)

2.1 Main Features

External Power

JTAG

Connector

CAN

TX0_2, RX0_2

DB9 Connector

15V

UART channel 0

DB9 Connector

UART channel 2

LED

LED2-LED4 (P1B-P19

LCD

Potentiome

ter

AD channel 7

USB Device

USB Host

Nand Flash

attached on external bus

CS7 area

RTC

attached on I

2

C channel 7

Key

“Reset”

RTC Battery

”2 pin header”

Key

“Left” (P40), “Right” (P43),

“Up” (P41), “Down” (P42)

7

Page 8

2.2 Jumpers Overview

Jumper Name Function Setting

J101-J103

J104

J-USBJ-USB+

J105 Mode setting

J106 Oscillator Selection

J107 P22 connection

J701 Voltage division

*1

*2

Power selection

Voltage selection

USB Host/Function

selection

Short J101: select external power

Short J102: select JTAG power

Short J103: select USB power

Short 1,2: 5V

Short 2,3: 3.3V

Short 1,2: USB Function

Short 2,3: USB Host

Short: Programming mode

Open: Normal mode

Short 1,2: when 4M oscillator is used

Short 2,3: when 48M oscillator is used

Short: connect P22 (UART_TX0) with MAX3232

Open: disconnect P22 (UART_TX0) with MAX3232

Short: when 5V power is used

Open: when 3.3V power is used

Table 2-1: Jumper List

Attention:

1) Never short J101-103 at the same time! When Keil U-Link ME is used, JTAG power

can not be used.

2) When Keil U-link is used, only 3.3V can be selected, never select 5V power!

2.3 Setting for UART On-Board Programming

Part Number Function Setting

UART-0

DB9 connector Connect with PC via RS232 cable

J106 Oscillator Selection Open

J105 Mode setting short

J107

P22 connection short

Table 2-2: Setting for UART On-Board Programming

2.4 Setting for USB On-Board Programming

Part Number Function Setting

USBFUNCTION USB function connector Connect with PC via USB cable

J-USBJ-USB+

Function/Host selection Short 1,2

J105 Mode setting Short

J106 Oscillator Selection Short 1,2

J107 P22 connection Open

J701 Voltage division

Table 2-3: Setting for USB On-Board Programming

Short: when 5V power is used

Open: when 3.3V power is used

8

Page 9

2.5 Setting for Debug Tool

Use IAR J-Link

Part Number Function Setting

20PIN-JTAG JTAG connctor Connect with J-Link

J101-J103

J104

Power selection

Voltage selection

J105 Mode setting Open

Use Keil U-Link ME

Part Number Function Setting

20PIN-JTAG JTAG connctor Connect with U-Link ME

J101-J103

J104

J105 Mode setting Open

Power selection

Voltage selection Short 2,3

Short J101: select external power

Short J102: select JTAG power

Short J103: select USB power

Short 1,2: 5V

Short 2,3: 3.3V

Table 2-4: Setting for J-Link

Short J101: select external power

Short J103: select USB power

Table 2-5: Setting for U-Link

9

Page 10

3 Flash On-Board Programming

There are two ways to program the on-chip Flash of MB9BF506 series MCU: UART OnBoard Programming and USB On-Board Programming.

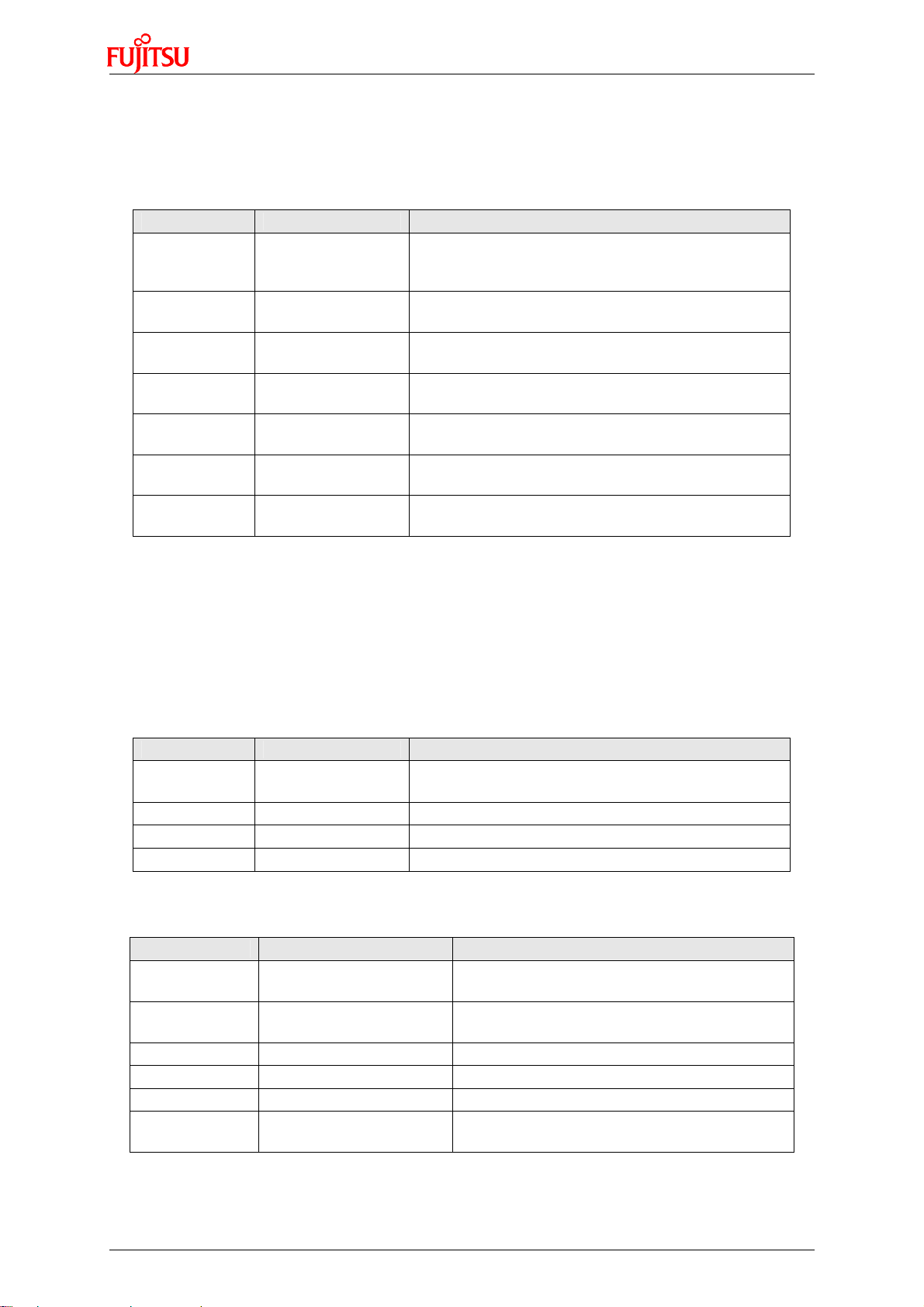

3.1 On-Board Programming via UART

First check the hardware setting as introduced by section 2.3.

Install the UART programmer: PCWFM3_V01L01. (It can be downloaded on the web)

Open it, set the parameter as shown in following figure, and select Hex file.

Figure 3-1: UART Programmer Overview

Click Full Operation.

Figure 3-2: Press Reset Button

Press reset key in the board, and the programming will start.

Figure 3-3: Start Programming

10

Page 11

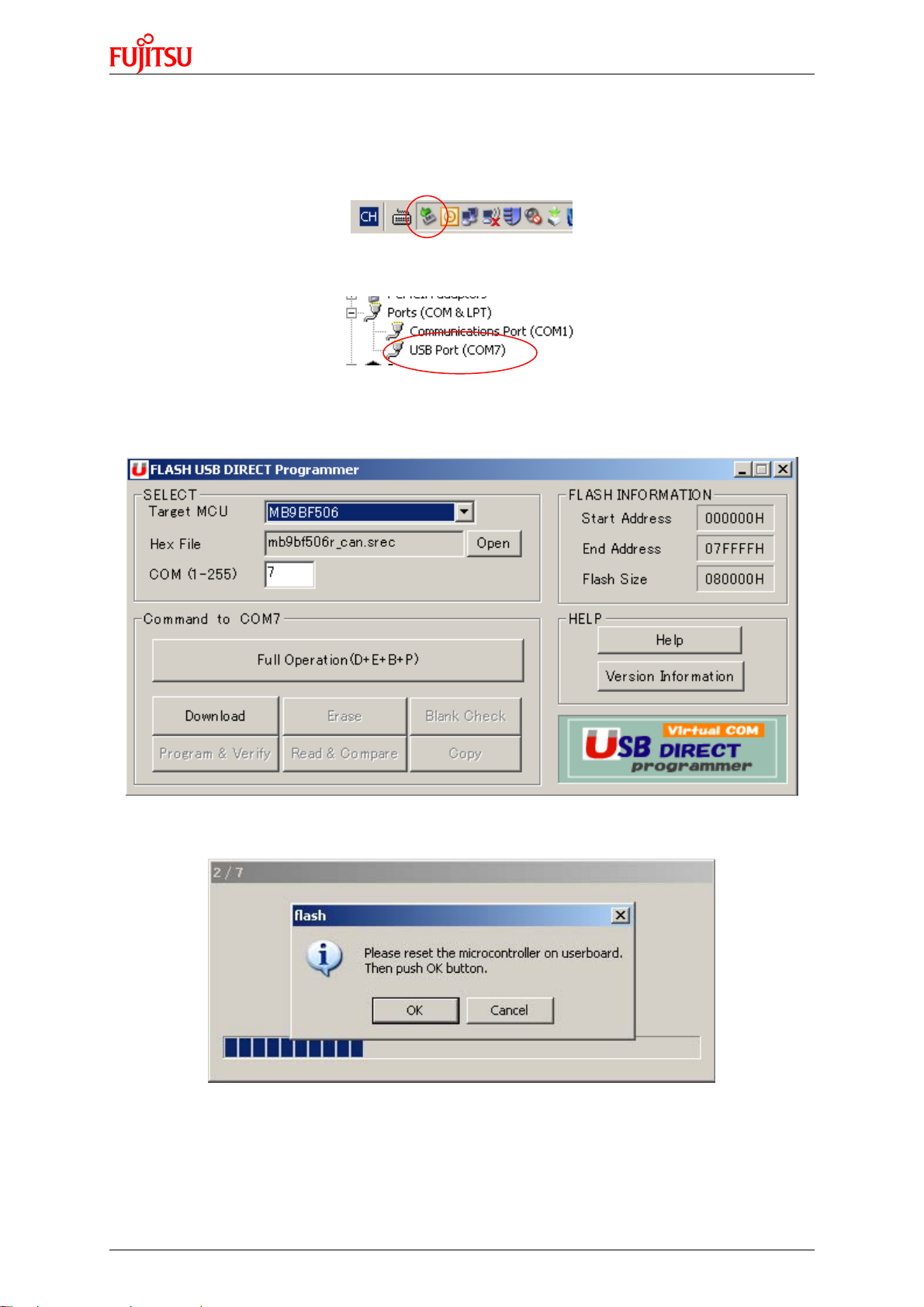

3.2 On-Board Programming via USB

First check the hardware setting as introduced by section 2.4.

After connect with PC via USB cable, the EVB can be identified as a USB device.

Figure 3-4: USB Device Sign

Check the COM port for this USB port in the device manager.

Figure 3-5: COM Port in Device Manager

Install the USB programmer: USBDW_V01L03. (It can be downloaded on the web)

Open it, set the parameter as shown in following figure, and select Hex file.

Click Full Operation.

Figure 3-6: USB Programmer Overview

Figure 3-7: Press Reset Button

11

Page 12

Press reset key on the board. Programming will start.

Figure 3-8: Start Programming

12

Page 13

4 Sample Code

The sample codes for FSSDC-9B596-EV board are listed as following table.

Project Name Description

ext_bus_nandflash Use external bus to access Nand Flash

uart Use UART to communicate with PC

can

rtc Use IIC to access RTC module

usb_function_mose

usb_host_catch_mouse

lcd_ad_key Display ad value and key status on LCD

Notes:

1) It provides both IAR and Keil project for these sample code, IAR project is

developed in EWARM Embedded Workbench V6102, and Keil project is developed

in Keil uVision 4.20.

2) If user use other version to open these projects, compiling error may occur, in this

case, please check following setting.

IAR IDE

¾ MCU type

¾ Pre-included file

¾ ICF file

¾ Flash loader

Keil IDE

¾ MCU type

¾ Pre-included file

¾ ROM & RAM memory address

Implement CAN communication between 2

CAN nodes

Implement the USB mouse to demonstrate

USB function

Identify a USB mouse and print the mouse

position on debug window

13

Page 14

4.1 UART

Hardware Setting

Connect UART-2 with PC via RS232 cable

Flowchart

Figure 4-1: UART Sample Code Flowchart

Usage

1) Open a COM assistant software, make following setting, and open COM port

Figure 4-2: COM Assistant Setting

2) Open UART sample code and run it, user can watch a string on the COM assistant

window. Then send character to EV-board, the character can be received.

14

Page 15

Figure 4-3: Send UART Data From PC Side

15

Page 16

4.2 Nand Flash

Hardware Setting

None

Flowchart

Start

Initial external bus

(Use CS7 area,

8 bit data width)

Read Flash ID

Figure 4-4: Nand Flash Sample Code Flowchart

Erase page 11 of

block 0

Write data into

page 11 of block 0

Read data from

page 11 of block 0

Erase page 20 of

block 100

Write data into page

20 of block 100

Read data from page

20 of block 100

Usage

1) Open Nand Flash sample project, and start debug.

2) Use “step over” to debug, and watch local variable “flash_id”, “buf”.

4.3 RTC

Hardware Setting

End

It is an option that user can user external battery to supply power for RTC module

(RX8025-T) so that the date and time can be stored after system power shut down.

Flowchart

Start

Initial MFS channel 5

(set IIC mode)

Enable FOE signal

(FOUT output 32.768khz

wave after it is enabled)

Write 0 to second register Read to second register

Write 30 to minute register

Write 8 to hour register

Figure 4-5: RTC Sample Code Flowchart

Read to minute register

Read to hour register

16

Page 17

Usage

1) Open Nand Flash sample project, and start debug.

2) Use “step over” to debug, and watch local variable “sec”, “min”, “hour”.

4.4 CAN

Hardware Setting

Connect 2 EV-board with CAN interface, as following figure.

EV board 1

CAN 1

(Node A)

CAN 2

CAN 1

EV board 2

(Node B)

CAN 2

Figure 4-6: CAN Hardware Connection

Block Diagram

¾ Node A: use buffer 10 (ID = 0x12345678) to transfer and buffer 8 (ID = 0x08765432)

to receive

¾ Node B: use buffer 7 (ID = 0x12345678) to receive and buffer 10 (ID = 0x08765432)

to transfer.

Node A Node B

Buffer 10

(ID=0x12345678)

Buffer 7

(ID=0x12345678)

Buffer 8

(ID=0x08765432)

Buffer 10

(ID=0x08765432)

Figure 4-7: CAN Demo Block Diagram

Usage

1) Define “CAN_TX_RX” in the code, and compile, then program the code into Node A

2) Don’t define “CAN_TX_RX” in the code, and compile, then program the code into

Node B.

3) Connect Node A with Node B

When in real usage, user can program one node, and use the other node to debug.

17

Page 18

4.5 USB Function

Hardware Setting

¾ Check if 1,2 of J-USB- and J-USB+ short

¾ Check J701 (Short: 5V, Open: 3.3V)

¾ Connect with PC via USB cable

Flowchart

The following flowchart illuminates the procedure to implement a USB mouse, it is not a

certain flow of a function, but provides a clue to study and understand the sample code.

Start

Check ButtonInit(),

HIDInit()

Check

EXTI8_15_IRQHandler()

Device has been

connected with

Host

Button, USB core,

HID initialization

Check Ext INT7

occurred?

Initial Endpoint 0

Bus reset

Configure

Endpoint 0-5

Get Device, HID

description

Enable Endpoint 5

interrupt transfer

Use interrupt transfer to

communicate with host

USB_2_IRQHandler()

HidMouseSendReport()

USB_1_IRQHandler()

Figure 4-8: USB Function Sample Code Flowchart

Usage

1) Make the hardware setting.

2) Watch the mouse moving when pressing “Up”, “Down”, “Left”, “Right” buttons.

Check

Check

Check

18

Page 19

4.6 USB Host

Hardware Setting

¾ Check if 2,3 of J-USB- and J-USB+ short

¾ Connect with a USB mouse

Flowchart

The following flowchart illuminates the procedure to implement USB host function, which

can catch the position of a USB mouse, it is not a certain flow of a function, but provides

a clue to study and understand the sample code.

Start

SystemInit ( )

main ( )

minihost_init( )

Initialize system

clock

Initialize timer

Init USB host

Figure 4-9: USB Host Sample Code Flowchart

Enumeration

Mouse data

process

Display mouse

data

USB_Handler ( )

USBF_Handler ( )

get_mouse_data ( )

Main()

Usage

1) Make the hardware setting

2) Enable definition “Debug” in the code

3) Run the code.

4) Move the USB mouse, and watch the mouse position in the terminal IO window as

following figure. (Debug viewer window in Keil IDE)

Figure 4-10: USB Mouse Position Display

19

Page 20

4.7 LCD & AD & Key

Hardware Setting

None

Flowchart

(clock, key, lcd,

led, dual timer, ad)

Start

Initialization

Usage

Press key?

N

AD convert

Pre_AD_value-

Cur_AD_calue>threshold value

N

Count Time = 1s

N

Count time++

Y

Figure 4-11: LCD, key, AD Sample Code Flowchart

Set LCD update

flag

Y

Y

Count time = 0

N

LCD update flag = 1 ?

Clear LCD update

Set LCD update

flag

Y

flag

Display key

pressed in LCD

Display new AD

value on LCD

Clear window and

display logo in LCD

1) Run the code

2) Press key, and the key pressed can display on the LCD

3) Regulate the potentiometer to change the input voltage of channel 7, and this

voltage can be detected and displayed on LCD.

20

Page 21

5 Debug Tool and IDE

FSS MB9BF506R EV-Board supports both Keil U-Link-ME and IAR J-Link for debug shown

as following.

Figure 5-1: J-Link Overview

Figure 5-2: U-Link Overview

The U-Link-me should be used with Keil uVision 4 which can be downloaded freely from

following web.

https://www.keil.com/update/sw/RVMDK/4.20

The J-Link should be used with IAR Embedded Workbench which can be downloaded freely

from following web.

http://www.iar.com/website1/1.0.1.0/68/1/

21

Page 22

Tool bar

Project

list

5.1 Debug with J-Link in IAR EWARM Workbench

The sample code can be debugged in IAR EWARM Workbench with J-Link. The following

figure shows basic debug window.

Watch

window

Main

window

Log

window

Figure 5-3: IAR IDE Overview

Run an Existed Project

1) Open a project by clicking “File | Open | Workspace”

Figure 5-4: Open a Project

22

Page 23

2) Select a project (eww file)

3) Click “Project | Rebuild All”

Figure 5-5: Select a Project

Figure 5-6:Rebuild All

23

Page 24

4) Click “Download and Debug”

5) Use following tool bar to debug

Figure 5-7:Click Download and Debug

Figure 5-8: Debug Tool Bar

The sample codes support both Flash and RAM debug in IAR EWARM Workbench, if Flash

debug is used, the code is programmed into MB9BF506 Flash. If RAM debug is used, the

code only runs in RAM area, and after power off, the code will not be stored, but the RAM

debug will be faster than Flash debug.

Setting for Flash Debug

1) Check the configuration file path ($PROJ_DIR$\config\mb9bf506.icf) in Linker table.

Figure 5-9: ICF File for Flash Debug

24

Page 25

2) Don’t select “Use macro files” in “Debugger|Setup” table.

Figure 5-10: Macro File Disabled

3) Set Flash loader file path ($TOOLKIT_DIR$\config\flashloader\Fujitsu\MB9BF506.board)

in “Debug|Download” table.

Figure 5-11: Flash Load File Path

25

Page 26

Setting for RAM Debug

1) Check the configuration file path ($PROJ_DIR$\config\mb9bf506_ram.icf) in Linker

table.

Figure 5-12: ICF File for RAM Debug

2) Select “Use macro files” in “Debugger|Setup” table.

Figure 5-13: Macro File Enabled

26

Page 27

3) Don’t use Flash loader file.

Figure 5-14: Flash Loader File Disabled

If user need to program the hex file into Flash via UART or USB programmer, a hex file

need to be produced first.

How to Make a HEX File

1) Use Flash debug

2) Select “Generate additional output” in “Output Converter” table.

Figure 5-15: Hex File Genration in IAR IDE

3) User can find the generated file in path (../Debug/Exe)

27

Page 28

Tool bar

Project

list

Build

output

5.2 Debug with U-Link ME in Keil uVision4

The sample code can also be debugged in Keil μVersion4 with U-Link. The following figure

shows basic debug window.

Watch

window

Main

window

Figure 5-16: Keil IDE Overview

Run an Existed Project

1) Open a project by clicking “Project | Open Project…”

Figure 5-17: Open a Project

28

Page 29

2) Select a project (uvproj file)

3) Rebuild all

4) Start debug

Figure 5-18: Select a Project

Figure 5-19: Rebuild All Files

Figure 5-20: Start Debug

29

Page 30

5) Use following tool bar to debug

Figure 5-21: Debug Tool Bar

The sample codes support both Flash and RAM debug in Keil uVison 4, if Flash debug is

used, the code is programmed into MB9BF506 Flash. If RAM debug is used, the code only

runs in RAM area, and after power off, the code will not be stored, but the RAM debug will

be faster than Flash debug.

Setting for Flash Debug

1) Set ROM address in Flash area. (0x00000000-0x00080000)

Figure 5-22: ROM Address Setting for Flash Debug

30

Page 31

2) Don’t use initialization file.

Figure 5-23: Don’t use initialization File

3) Check “Update Target before Debugging” checkbox

Figure 5-24: Select Update Target Before Debugging

31

Page 32

Setting for RAM Debug

1) Set ROM address in Code SRAM area. (0x1fff8000-0x1fffffff)

Figure 5-25: Set RAM Address for RAM Debug

2) Set initialization file path. (..\Debug_RAM.ini)

Figure 5-26: Select Initialization File

32

Page 33

3) Don’t Check “Update Target before Debugging” checkbox

Figure 5-27: Select Update Target Before Debugging

If user need to program the hex file into Flash via UART or USB programmer, a hex file

need to be produced first.

How to Make a HEX File

1) Check “Create HEX File” checkbox (This file is Intel Format HEX)

Figure 5-28: HEX File Generation in Keil IDE

2) User can find the generated file in path “..\output\debug\”

33

Page 34

6 Materials Download

The following materials can be downloaded from below web.

http://www.fujitsu.com/cn/

Software

z FUJITSU Flash MCU Programmer

z FUJITSU Flash USB DIRECT Programmer

Document

z FSSDC-9B506-EVB User Manual

z FSSDC-9B506-EVB Schematic

z MB9B506 Series Datasheet

z MB9B506 Series Peripheral Manual

z MB9B506 Series Flash Programming Manual

Sample code

z uart

z iic_rtc

fss/events/contest/2010/index_download.html

z ext_bus_nandflash

z can

z usb_func_mouse

z usb_host_catch_mouse

z lcd_ad_key

IDE Study Material

z IAR IDE study material

z Keil IDE study material

34

Loading...

Loading...