Page 1

GP 7000F

M200, M200R, M400A, M400R, M600, M600R

EditionDecember 1999

Page 2

CopyrightandTrademarks

Copyright©FujitsuSiemensComputersGmbH1999.

Allrightsreserved.

Deliverysubjecttoavailability;rightoftechnicalmodificationsreserved.

Allhardwareandsoftwarenamesusedaretrademarksoftheirrespectivemanufacturers.

Page 3

1 Preface

ThismanualcontainstheoperatinginstructionsfortheGranPower7000(GP7000F)system

from Fujitsu Siemens Computers. A chapter about the connection of Siemens specific devices precedes the actual operating instructions.

U42335-J-Z775-1-76 1

Page 4

Page 5

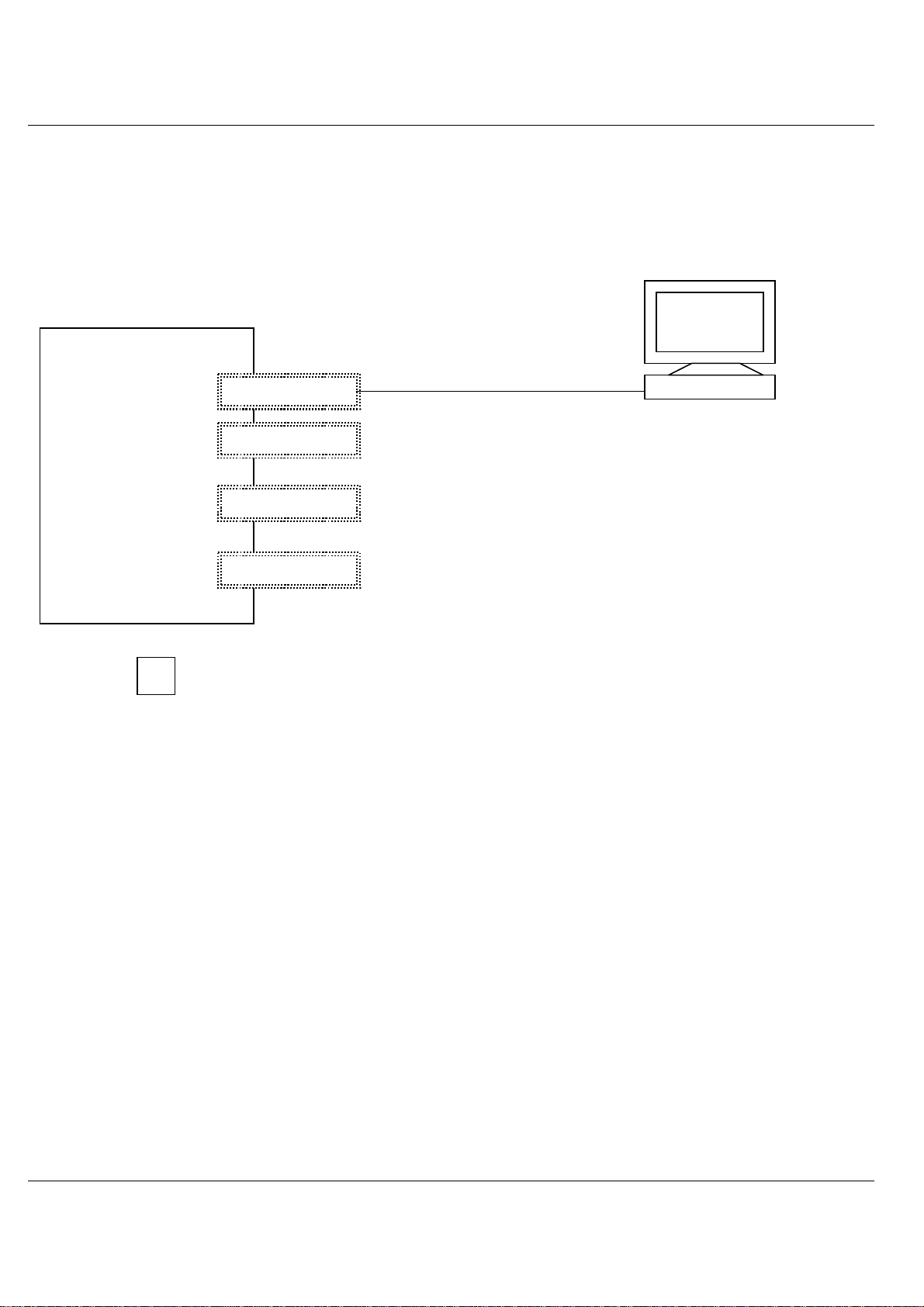

2 Console connections to GP 7000F

This chapter describes connections to the M200, M200R, M400A, M400R, M600 and

M600R models of the Fujitsu Siemens Computers GP 7000F system with a view to

attachingexistingcomponentsofSiemensdevicestoFujitsuequipment.Graphical or serial

consoles can be connected.

The GP 7000F systems do not support SIDATA

!

(installation by customer is not allowed).

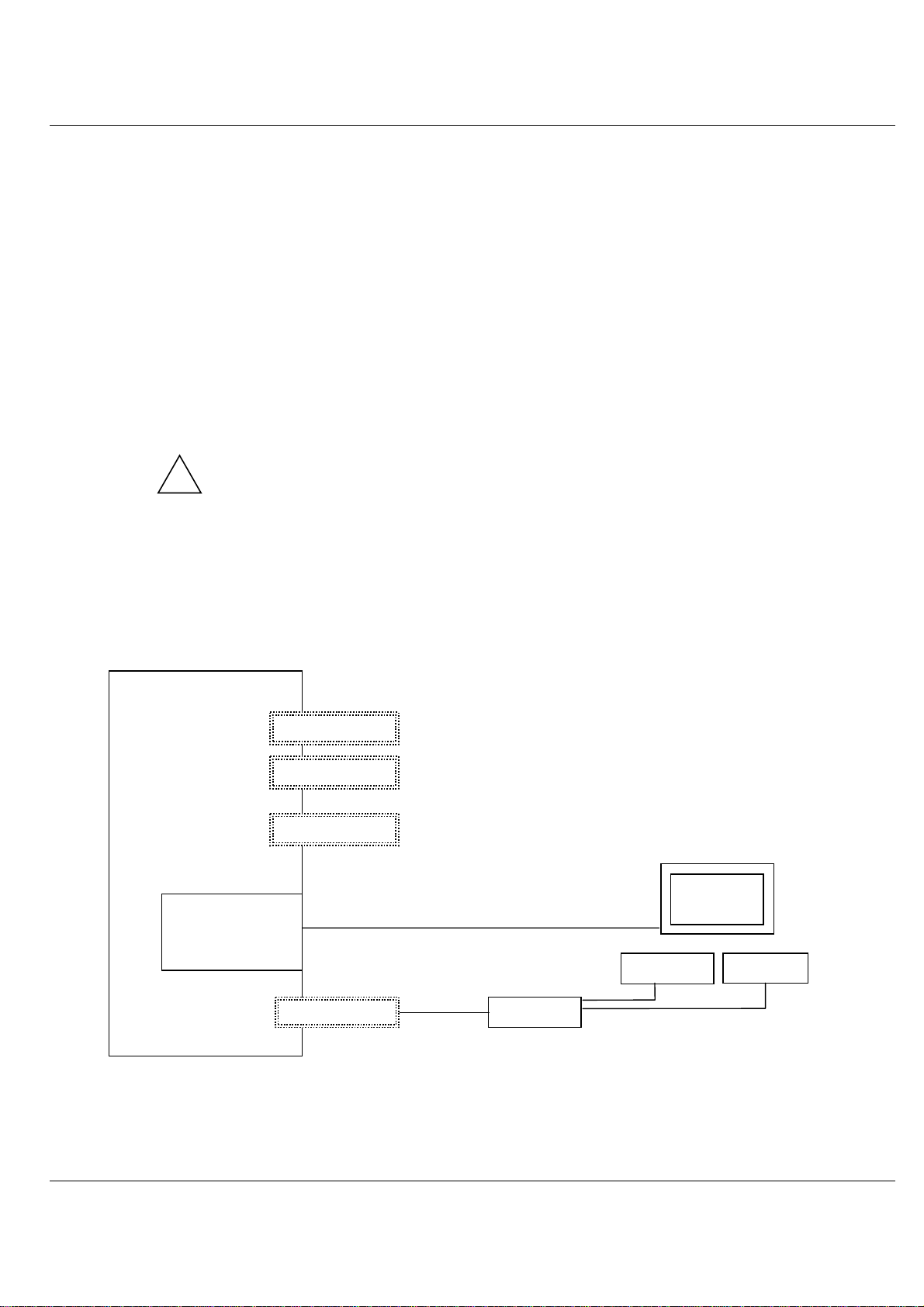

2.1 Graphical console

It is preferable to connect graphical consoles.

GP 7000F

system

PCI graphics

controller

D:GP70F-CC10

(option)

V.24 (A)

V.24 (B)

10/100 Mbit Eth

Keyboard/mouse

Teleservice

preferably

SUNAdapt

Monitor

Keyboard Mouse

(Keyboard with trackball

in the 19" rack)

U42335-J-Z775-1-76 3

Page 6

Graphical console Console connections to GP 7000F

The following technical requirements must be met in order to connect graphical consoles:

– PCI graphics controller D:GP70F-CC10

The GP 7000F models can be made into a workstation or server with a graphical

console by means of a PCI graphics card featuring a frame buffer.

– An RM keyboard and mouse can be connected via the D:GP70F-AN10 interface

converter. All models in the GP 7000F server family have a Sun-compatible

keyboard/mouse interface. The adapter converts the interface signals to allow the

keyboard and 3-button mouse featuringa PC-compatible interfaceto be connected

to the server.

PS /2 M aus

PS/2 mouse

PS /2 Tastatur

PS/2 keyboard

SUN-

Sun keyboard/

Tastatur/M aus-

mouse interface

Schnittstelle

Keyboard/mouse adapter

– Monitor (CRT or LCD)

– Keyboard

–Mouse

The same monitor, keyboard and mouse types have been released as for the Siemens

systems.

4 U42335-J-Z775-1-76

Page 7

Console connections to GP 7000F Serial console

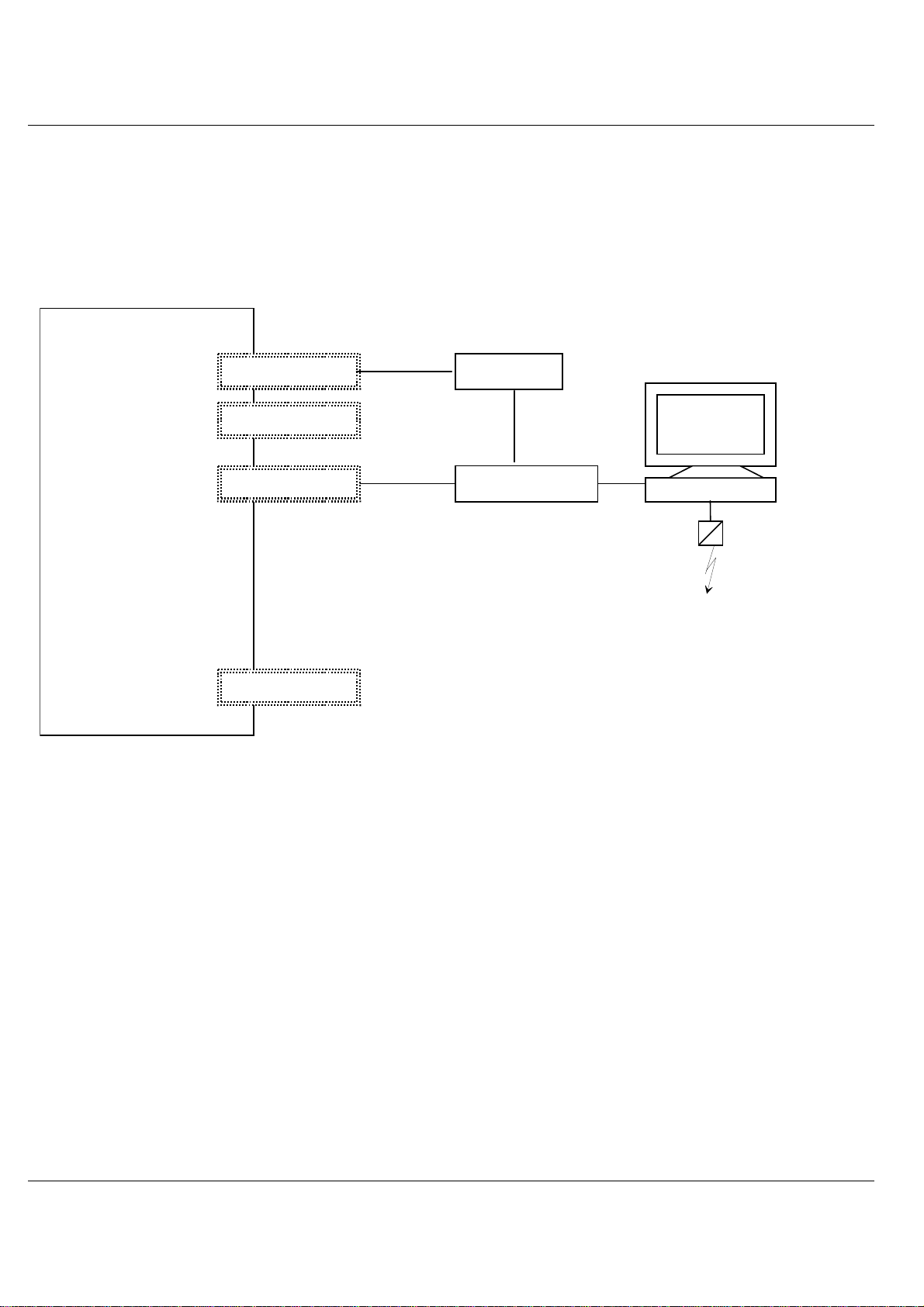

2.2 Serial console

A converter is used here to convert the 25-pin connector of the GP 7000F system to the

usual 9-pin V.24/COM connector. This converter is preinstalled at the factory. A VT100 or

VT200 emulation must be available for a serial console to be used.

V.24/C O M

9-pin

9polig

Dsub

25-pin

25polig

25/9-pin converter

U42335-J-Z775-1-76 5

Page 8

Serial console Console connections to GP 7000F

2.2.1 LAN console

ASolaris PC is connectedasa LAN console via anRCA (Remote CommunicationAdapter)

attached to the V.24 console interface. Up to six servers can be attached to one RCA.

GP 7000F

system

V.24 (A)

V.24 (B)

10/100 Mbit Eth

Keyboard/mouse

RCA

LAN

console

Ethernet hub

Teleservice

6 U42335-J-Z775-1-76

Page 9

Console connections to GP 7000F Serial console

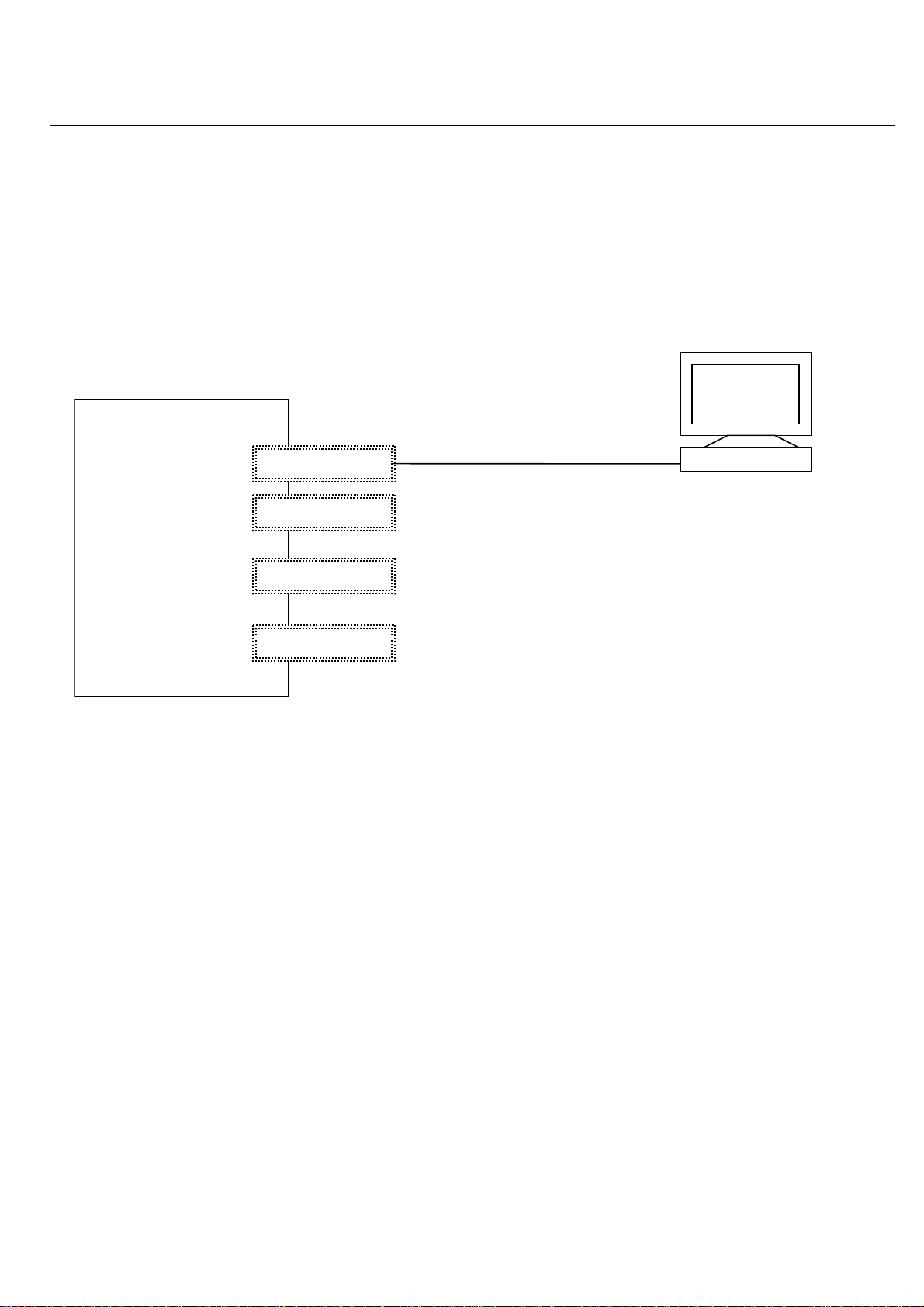

2.2.2 Standard PC with terminal emulation

a) Windows 98 or NT (with NetTerm, for instance, but not with HyperTerminal)

b) LINUX (with Minicom or Seyon)

c) Solaris (cu)

PC

(NT, Windows)

GP 7000F

system

V.24 (A)

V.24 (B)

10/100 Mbit Eth

Keyboard/mouse

Teleservice

preferably

U42335-J-Z775-1-76 7

Page 10

Teleservice Console connections to GP 7000F

2.2.3 TC20 or T100

Use of these terminals is intended as a migration solution only.

αααα

console

GP 7000F

system

V.24 (A)

V.24 (B)

10/100 Mbit Eth

Keyboard/mouse

Whenoperatingwith the LAN console,TC20or T100 it is not possibletoaccess the

i

Open Boot PROM using the BREAK signal.

2.3 Teleservice

The teleservice modem has to be connected via V.24 to the system board. The modemhas

to be ordered separately owing to national variants.

If a LAN console is used, connection of the modem is to the LAN console PC. Thus one

teleservice port serves all connected servers.

Teleservice

preferably

8 U42335-J-Z775-1-76

Page 11

P321-E102-02EN

USER'S MANUAL

Page 12

Page 13

FOR SAFE OPERATION

Handling of This Manual

This manual contains important information regarding the use and handling of this product. Read this manual

thoroughly. Pay special attention to the section "Important Warnings". Use the product according to the

instructions and information available in this manual.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering from damages

to their property. Use the product according to this manual.

IMPORTANT READING

IMPORTANT NOTE TO USERS

READ CAREFULLY ALL THROUGHOUT THIS MANUAL BEFORE USING THE PRODUCT. INCORRECT

USE OF THE PRODUCT MAY CAUSE UNEXPECTED DAMAGE TO THE USERS OR BYSTANDERS.

While all efforts have been made to ensure the accuracy of all information in this manual, FUJITSU assumes no

liability to any party for any damage caused by errors or omissions or by statement of any kind in this manual, its

updates or supplements, whether such errors are omissions or statements resulting from negligence, accidents, or

any other cause. FUJITSU further assumes no liability for incidental or consequential damages arising from the

use of this manual. FUJITSU disclaims all warranties regarding the information contained herein, whether

expressed, implied, or statutory.

DO NOT MAKE MECHANICAL OR ELECTRICAL MODIFICATIONS TO THE EQUIPMENT. FUJITSU

LIMITED IS NOT RESPONSIBLE FOR REGULATORY COMPLIANCE OR SAFETY OF A MODIFIED

FUJITSU PRODUCT.

DO NOT REPAIR OR INSTALLTHE EQUIPMENT BY USERS. IT SHOULD BE PERFORMED BY A

TRAINED SERVICE ENGINNER.

i

Page 14

THIS PRODUCT IS NOT DESIGNED FOR USE IN ON-LINE CONTROL EQUIPMENT IN HAZARDOUS

ENVIRONMENTS SUCH AS OPERATION OF NUCLEAR FACILITIES, AIRCRAFT NAVIGATION OR

CONTROL, OR DIRECT LIFE SUPPORT MACHINES. HENCE, IF THESE PRODUCTS ARE USED IN

SUCH HAZARDOUS ENVIRONMENTS, FUJITSU LIMITED AND SUN MICROSYSTEMS, INC. DOES

NOT WARRANT THEM AT ALL.

FUJITSU reserves all the right to make changes to any products herein to improve reliability, function, or design,

without further notice and without obligation.

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

DOC Class A Notice

This class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numerique de la class A respecte toutes les exigences du Reglement sur le material

brouiller du Canada.

Warning This is a Class A product of Electromagnetic Interference (EMI) standard. In a domestic

VCCI/FCC label

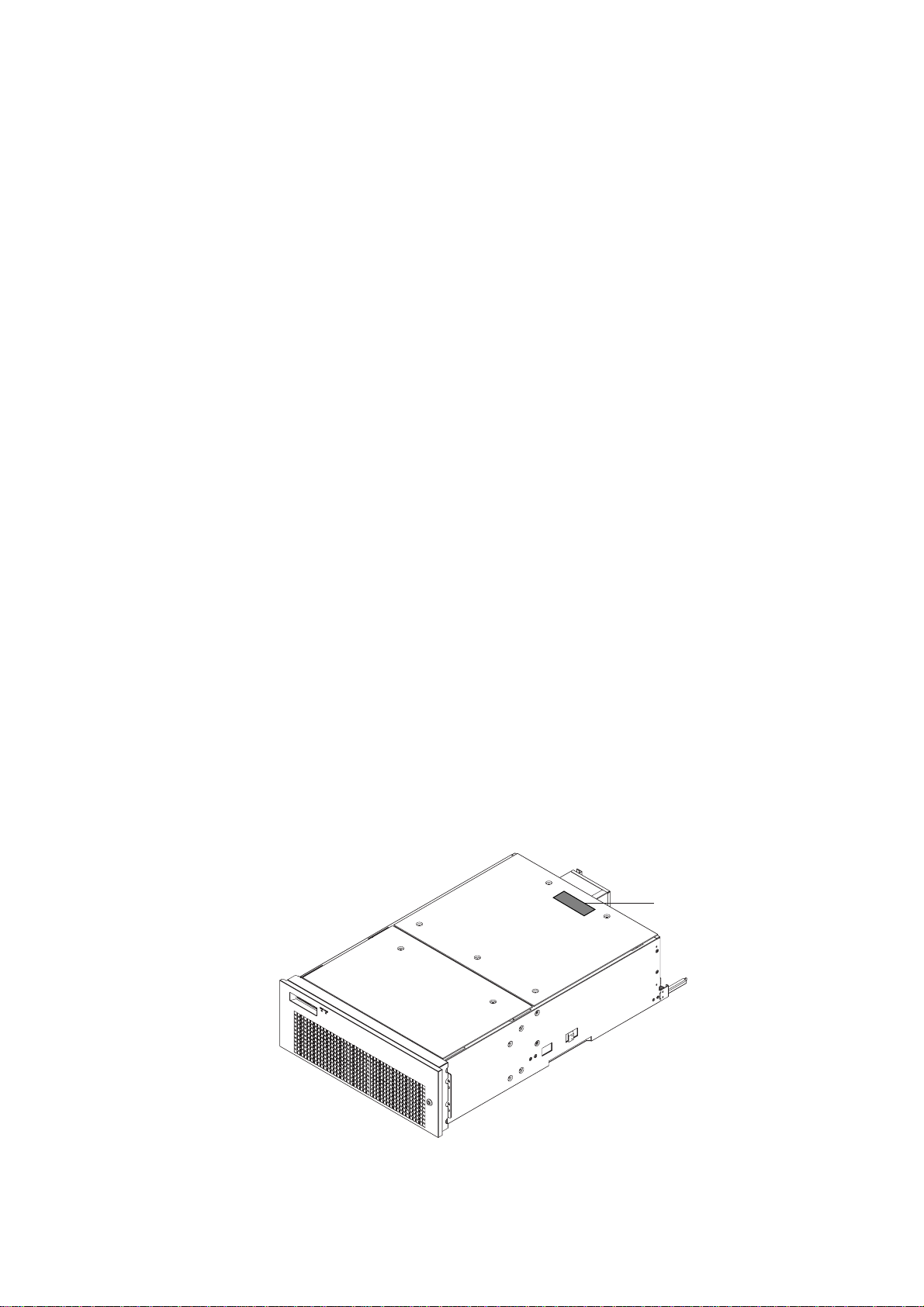

The VCCI/FCC labels for models 200R, 400R, and the Expansion file unit (GP7B7FLxx) are affixed in the

following locations:

environment this product may cause radio interference in which case the user may be required to

take adequate measures.

VCCI / FCC label

ii

Page 15

VCCI / FCC label

VCCI / FCC label

Laser Radiation Statement (EU)

Class 1 Laser Product

TRADEMARK ACKNOWLEDGMENTS

All rights reserved. This product and related documentation are protected by copyright and distributed under

licenses restricting its use, copying, distribution, and recompilation. No part of this product or related

documentation may be reproduced in any form by any means without prior written authorization of Fujitsu

Limited and its licensors, if any.

RESTRICTED RIGHTS LEGEND: Use, duplication, or disclosure by the United States Government is subject to

the restrictions set forth in DFARS 252.227-7013 (c) (1) (ii) and FAR 52.227-19.

The product described in this book may be protected by one or more U.S. patents, foreign patents, or pending

applications.

iii

Page 16

TRADEMARKS

Fujitsu and the Fujitsu logo are trademarks of Fujitsu Limited.

SPARC64 is a registered trademark or trademark of SPARC International, Inc. in the United States

and other countries used under license by Fujitsu Ltd. Products bearing SPARC64 trademarks

comply with SPARC V9 architecture developed by SPARC International, Inc. Products bearing the

SPARC trademarks are based on an architecture originally developed by Sun Microsystems, Inc. "

Sun, the Sun logo, Sun Microsystems, Sun Microsystems Computer Corporation, the Sun

Microsystems Computer Corporation logo, SunSoft, the SunSoft logo, Solaris, Solaris PEX, SunOS,

SunLink, OpenWindows, Direct Xlib, SunSHIELD, NeWS, NeWSprint, SunInstall, DeskSet, ONC,

ONC+, OpenBoot, Online DiskSuite, NFS, JumpStart, AnswerBook, the AnswerBook logo,

SunDiag, ToolTalk, Sun PC, and Wabi are trademarks or registered trademarks of Sun

Microsystems, Inc., in the U.S. and certain other countries.

UNIX is a registered trademark in the United States and other countries, licensed exclusively

through X/Open Company Ltd.

All other product names mentioned herein are the trademarks of their respective owners.

THIS PUBLICATION IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR

MERCHANTABILITY, FITNESS FOR A PARTICULAR POURPOSE, OR NONINFRINGEMENT.

THIS PUBLICATION COULD INCLUDE TECHNICAL INACCURACIES OR TYPOGRAPHICAL ERRORS.

CHANGES ARE PERIODICALLY ADDED TO THE INFORMATION HEREIN; THESE CHANGES WILL BE

INCORPORATED IN NEW EDITIONS OF THE PUBLICATION. FUJITSU LIMITED MAY MAKE

IMPROVEMENTS AND/OR CHANGES IN THE PRODUCT(S) AND/OR THE PROGRAM(S) DESCRIBED

IN THIS PUBLICATION AT ANY TIME.

Documents produced by FUJITSU may contain technology controlled under the

Foreign Exchange and Foreign Trade Control Law of Japan. The document

which contains such technology should not be exported from Japan or

transferred to anyone other than residents of Japan without first obtaining

license from the Ministry of International Trade and Industry of Japan in

accordance with the above law.

Second Edition: November 1999

This manual may be best printed on A4 size. If it is printed on 8.5" ( 11" size, adjust your printer setting in advance.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without the express

written permission of Fujitsu Limited.

All Rights Reserved, Copyright (c) FUJITSU LIMITED 1999

iv

Page 17

This manual explains the function, configuration, and operation of GP7000F. This manual is intended for the

experienced users who have a basic knowledge of computer systems.

The structure of this manual is as follows:

Introduction to Chapters

CHAPTER 1 Product Outline

Chapter 1 describes the distinctive features of GP7000F.

CHAPTER 2 M200 Main Cabinet

Chapter 2 explains the device configuration and operation of M200 Main Cabinet.

CHAPTER 3 M200R Main Cabinet

Chapter 3 explains the device configuration and operation of M200R Main Cabinet.

CHAPTER 4 M400A Main Cabinet

Chapter 4 explains the device configuration and operation of M400A Main Cabinet.

CHAPTER 5 M400R Main Cabinet

Chapter 5 explains the device configuration and operation of M400R Main Cabinet.

CHAPTER 6 M600 Main Cabinet

Chapter 6 explains the device configuration and operation of M600 Main Cabinet.

CHAPTER 7 M600R Main Cabinet

Chapter 7 explains the device configuration and operation of M600R Main Cabinet.

CHAPTER 8 Expansion Disk Cabinet

Chapter 8 describes the distinctive features of the GP7000F external disk cabinet.

CHAPTER 9 Expansion File Unit Type-2(GP7B7FLxx)

Chapter 9 describes the distinctive features of the GP7000F rack mount expansion disk unit.

CHAPTER 10 Expansion File Unit(GP7B7FU1xx)

Chapter 10 describes the distinctive features of the GP7000F rack mount expansion disk unit.

CHAPTER 11 Input-Output Units

Chapter 11 explains the specifications of Input-Output units.

Preface

v

Page 18

CHAPTER 12 External Interface

Chapter 12 explains the external interface of the main cabinet such as UPS Control Interface,

RS232C Interface, and Centronics Interface.

CHAPTER 13 RCI Setting

Chapter 13 explains the description of RCI commands to be used for managing nodes.

CHAPTER 14 Troubleshooting

Chapter 14 will help the user isolate the cause of system failures, and provides suggested solutions.

Conventions for Warning Messages

A warning message consists of a signal and statements. The signal consists of a symbol and a signal word or just a

signal word.

The following are the signals and their meanings:

CAUTION

This indicates a hazardous situation could result in minor or moderate personal injury if the user

does not perform the procedure correctly. This signal also indicates that damage to the product or

other property,may occur if the user does not perform the procedure correctly.

Attention

IMPORTANT

This indicates information that could help the user use the product more efficiently.

In the text, the signal is centered, followed below by the indented message. A wider line space precedes and

follows the message to show where the message begins and ends. The following is an example:

(Example)

CAUTION

Please forward any comments you may have regarding this manual.

Tomake this manual easier for users to understand, opinions from readers are needed. Please write your opinions

or requests on the "Comment Form" sheet at the back of this manual and forward it to the address provided on the

sheet.

Data destruction: Do not press these buttons before installing the necessary

software package. Otherwise, data may be destroyed. Turn off the system in the

OBP prompt state if the software package is not installed.

vi

Page 19

vii

Page 20

Important Warnings

The following are cautions found in this manual. They have been compiled here with corresponding page

references.

CAUTION

Task Warning

Normal Operation Data destruction: Pressing the RESET switch while the

system is running may destroy data.

System Installation Be sure to install software packages from "Basic Software

Extension" or "Enhanced Support Facility. Otherwise, above

switch functions or proper messages on LCD panel are not

guaranteed.

Terminal break command If used improper commands at the ok prompt, the GP7000F

may be destroyed. If you need to used any other commands

except shown on this manual, you should well understand

the function and usage of the command before using it.

Power Off Be sure to eject backup tape media and any diskettes before

power-off the system, if the media are installed. Other

wise, the data on the media may be destroyed.

Normal Operation Except in an emergency, never turn off the AC switch or

disconnect the power cable wile the GP7000F main cabinet is

turned on. If you do, data in the disk drive may be

destroyed.

A hazardous situation could result in minor or moderate personal injury if the

user does not perform the procedure correctly. Also, damage to the product or

other property may occur.

viii

Page 21

Task Warning

System Installation Install "Basic Software Extension" or "Enhanced Support

Facility"before operating the system. Without this package,

incorrect front panel operations and hardware errors may cause

the system to shutdown or destroy data.

Disk Expansion Unit Be sure to replace the power supply fan when installing the

Installation Disk Expansion Unit. Otherwise, the system will shutdown or

disk units will deteriorate due to a temperature rise in the

M200 main cabinet caused by insufficient cooling.

Disk Expansion Unit If the installing location (slot) is not set or set

Installation incorrectly, the disk drive may not be hot-swappable.

Data may be destroyed as a result of inadvertently replacing

the different disk drive. Be sure to set the installing

location (slot) correctly.

Also, while replacing or initializing NVRAM, set the

installing location again.

Normal Operation Do not set the AC main line switch to OFF, not disconnect

the power cable or RCI cable while the GP7000F main cabinet

is powered on, unless absolutely necessary. Otherwise, the

data may be destroyed in the disk units.

Normal Operation Do not set the AC main line switch to OFF, nor disconnect

the power cable or RCI cable while the GP7000F main cabinet

is powered on, unless absolutely necessary. Otherwise, the

data in the disk units may be destroyed.

Replacing Disk Drives When replacing the disk unit,take the following precautions.

If these precautions are not observed, the disk unit or its

data may be destroyed.

Formatting Disk Drives Carefully proceed formatting a disk drive. Once formatting

a disk drive, data on the disk never restored, if you don't

have backup files.

Handling Floppy Disks Do not eject a floppy disk while the access LED is on, other

wise the floppy disk or the data on the diskette may be

destroyed.

For information on the handling method, see Table 11.2,

"Handling floppy disks."

Ejecting DAT cartridge Data destruction: Do not press the eject switch during an

operation (when the tape LED is blinking). If the eject

switch is held down for about 5 seconds or pressed 3 times

within a 5 minutes period, the forced ejection function may

execute and the data being written may be destroyed.

Handling DAT cartridge When using the data cartridge (DAT), take the following

precautions. If these precautions are not observed, the

DAT unit or its data may be destroyed.

Storing 8-mm cartridge When using or storing the data cartridge, take the following

precautions. If these precautions are not taken, the data

on 8-mm tape may be destroyed.

Ejecting QIC cartridge Data destruction: Do not press the eject switch during an

operation. The forced ejection function may operate and

data being written may be destroyed.

Storing QIC cartridge When using or storing the data cartridge, take the following

precautions. If these precautions are not taken, the QIC

tape unit or its data may be destroyed.

ix

Page 22

Page 23

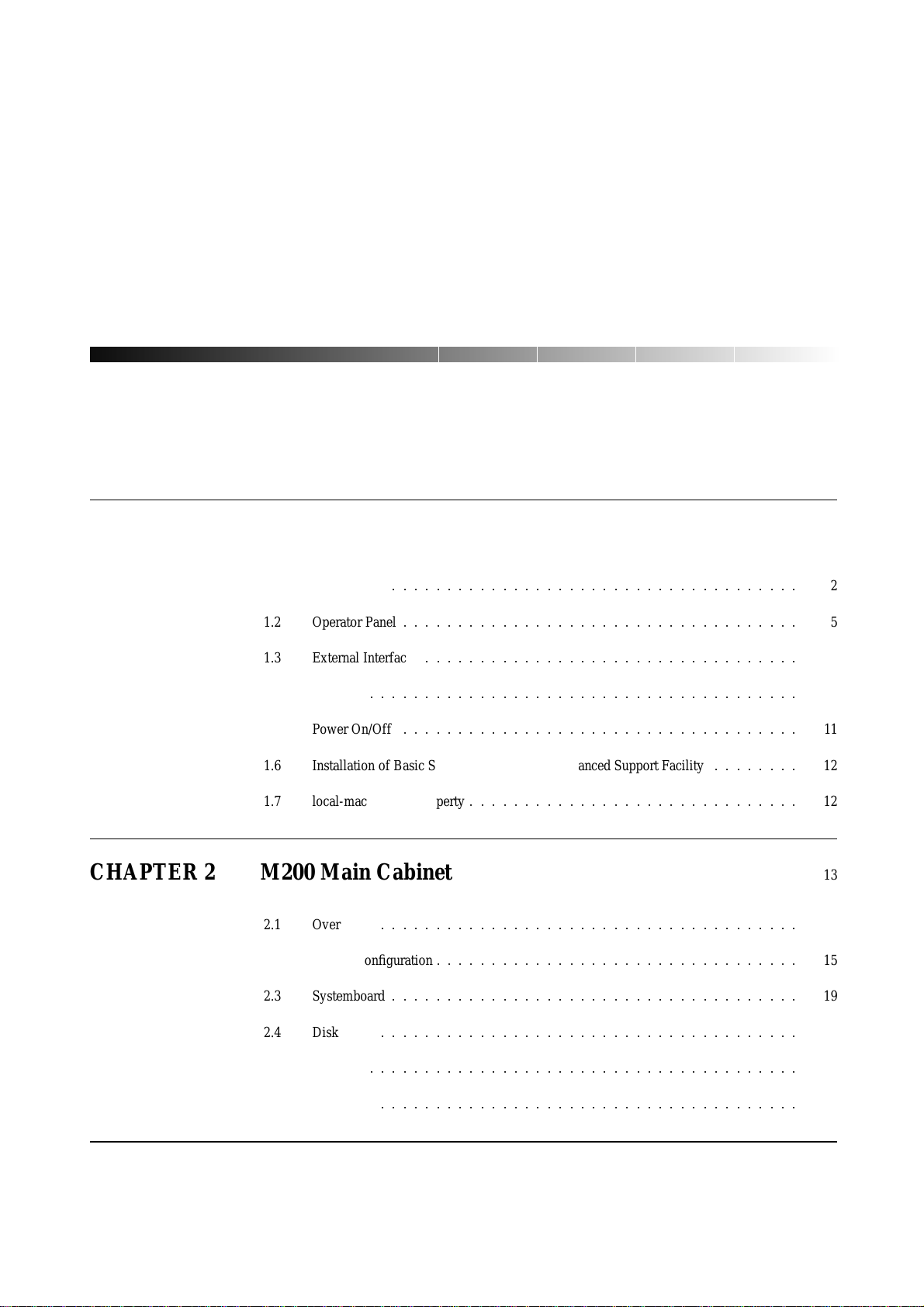

CONTENTS

CHAPTER 1 Product Outline 1

1.1 Key Features

1.2 Operator Panel

1.3 External Interface

1.4 Console

1.5 Power On/Off

1.6 Installation of Basic Software Extension or Enhanced Support Facility

1.7 local-mac-address Property

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::

::::::::

::::::::::::::::::::::::::::::

10

11

12

12

CHAPTER 2 M200 Main Cabinet 13

2.1 Overview

2.2 Device Configuration

2.3 Systemboard

2.4 Disk Units

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

14

15

19

21

2

5

8

2.5 PCI Slots

2.6 Installation

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

23

23

i

Page 24

CHAPTER 3 M200R Main Cabinet 27

3.1 Overview

3.2 Device Configuration

3.3 Systemboard

3.4 Disk Units

3.5 PCI Slots

3.6 Installation

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

28

29

32

34

35

36

CHAPTER 4 M400A Main Cabinet 41

4.1 Overview

4.2 Device Configuration

4.3 Systemboard

4.4 Disk Units

4.5 PCI Slots

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

42

43

46

48

49

4.6 Installation

::::::::::::::::::::::::::::::::::::::

50

CHAPTER 5 M400R Main Cabinet 53

5.1 Overview

5.2 Device Configuration

5.3 Systemboard

5.4 Disk Units

5.5 PCI Slots

5.6 Installation

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

54

55

58

60

61

62

CHAPTER 6 M600 Main Cabinet 67

6.1 Overview

::::::::::::::::::::::::::::::::::::::

68

6.2 Device Configuration

:::::::::::::::::::::::::::::::::

69

ii

Page 25

CONTENTS

6.3 Systemboard

6.4 Disk Units

6.5 PCI Slots

6.6 Installation

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

72

75

75

77

CHAPTER 7 M600R Main Cabinet 81

7.1 Overview

7.2 Device Configuration

7.3 Systemboard

7.4 Disk Units

7.5 PCI Slots

7.6 Installation

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

82

83

86

88

89

91

CHAPTER 8 Expansion Disk Cabinet 95

8.1 Product Outline

8.2 Device Configuration

8.3 Hot System Replacement

8.4 Installation

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

96

97

101

102

CHAPTER 9 Expansion File Unit Type-2 (GP7B7FLxx) 105

9.1 Product Outline

9.2 Device Configuration

9.3 Hot System Replacement

9.4 Installation

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

106

107

109

110

CHAPTER 10 Expansion File Unit (GP7B7FU1xx) 113

10.1 Product Outline

:::::::::::::::::::::::::::::::::::

114

iii

Page 26

10.2 Device Configuration

:::::::::::::::::::::::::::::::::

115

10.3 Hot System Replacement

10.4 Installation

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

117

118

CHAPTER 11 Input-Output Units 121

11.1 Disk Units

11.2 Floppy Disk Units

11.3 CD-ROM Unit

11.4 Tape Unit

11.5 DAT Unit

11.6 8-mm TapeUnit

11.7 QIC Tape Unit

::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::

122

123

126

128

129

135

140

CHAPTER 12 External Interfaces 145

12.1 UPS Control Interface

12.2 RS232C Interface

12.3 Parallel Interface

::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

146

148

151

CHAPTER 13 RCI Setting 153

13.1 Overview

13.2 RCI Commands

13.3 Liquid Crystal Display (LCD) Specifications

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::

154

154

155

CHAPTER 14 Troubleshooting 157

14.1 Overview

14.2 Commands at the ok prompt

::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

158

158

iv

14.3 Initial Diagnosis Sequence

::::::::::::::::::::::::::::::

159

Page 27

CONTENTS

14.4 SCF Error Messages

:::::::::::::::::::::::::::::::::

160

v

Page 28

Page 29

ILLUSTRATIONS

Figure 1.1 Operator Panel (M200, M600)

::::::::::::::::::::::::::::::

Figure 1.2 Operator Panel (M200R, M400A, M400R, M600R)

Figure 2.1 Front View of M200 Main Cabinet

Figure 2.2 Open View of M200 Main Cabinet

Figure 2.3 Rear View of M200 Main Cabinet

Figure 2.4 Systemboard Layout of M200

Figure 2.5 Disk Drive Bays of M200 Main Cabinet

Figure 3.1 Front View of M200R Main Cabinet

Figure 3.2 Open View of M200R Main Cabinet

Figure 3.3 Rear View of M200R Main Cabinet

Figure 3.4 Systemboard Layout of M200R

Figure 4.1 Front View of M400A Main Cabinet

Figure 4.2 Open View of M400A Main Cabinet

Figure 4.3 Rear View of M400A Main Cabinet

Figure 4.4 Systemboard Layout of M400A

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::

:::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

:::::::::::::::::::

5

5

14

16

18

19

21

28

29

31

32

42

43

45

46

Figure 5.1 Front View of M400R Main Cabinet

Figure 5.2 Open View of M400R Main Cabinet

Figure 5.3 Rear View of M400R Main Cabinet

Figure 5.4 Systemboard Layout of M400R

:::::::::::::::::::::::::::::

Figure 6.1 Front View of M600 Main Cabinet

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

::::::::::::::::::::::::::::

54

55

57

58

68

vii

Page 30

Figure 6.2 Open View of M600 Main Cabinet

::::::::::::::::::::::::::::

69

Figure 6.3 Rear View of M600 Main Cabinet

Figure 6.4 Systemboard Layout of M600

Figure 6.5 PCI IO Board Layout of M600

Figure 7.1 Front View of M600R Main Cabinet

Figure 7.2 Open View of M600R Main Cabinet

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::

Figure 7.3 Front View of M600R Main Cabinet (remove Front cover)

Figure 7.4 Rear View of M600R Main Cabinet

Figure 7.5 Systemboard Layout of M600R

Figure 7.6 PCIBPR Board Layout of M600R

Figure 7.7 PCIRSR Board Layout of M600R

Figure 8.1 Front View of Expansion Disk Cabinet

Figure 8.2 Drive Bays of Expansion Disk Cabinet

Figure 8.3 Rear View of Expansion Disk Cabinet

Figure 9.1 Front View of Expansion File Unit Type-2

Figure 9.2 Drive Bays of Expansion File Unit Type-2

Figure 9.3 Drive Bays of Expansion File Unit Type-2

:::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::

::::::::::::::::::::::::::

::::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::

71

72

75

82

83

84

85

86

89

89

97

98

100

106

107

108

Figure 9.4 Rear View of Expansion File Unit Type-2

Figure 10.1 Front View of Expansion File Unit

Figure 10.2 Drive Bays of Expansion File Unit

Figure 10.3 Rear View of Expansion File Unit

Figure 11.1 Floppy Disk Unit Front Panel

Figure 11.2 Inserting Floppy Disks

::::::::::::::::::::::::::::::::::

Figure 11.3 CD-ROM Unit Front Panel

Figure 11.4 Mark on CD-ROM Disk

Figure 11.5 DAT Unit Front Panel

Figure 11.6 DDS Logos

:::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

Figure 11.7 DDS Media Recognition System Logo

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::

Figure 11.8 Inserting a Data Cartridge in The DAT Unit

Figure 11.9 DAT Data Cartridge Write-protection Tab

Figure 11.10 8-mm Tape Unit Front Panel

Figure 11.11 8-mm Tape Data Cartridge

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::

Figure 11.12 Cleaning Cartridge of The 8-mm Tape Unit

::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::

108

114

115

116

123

124

126

127

130

132

132

132

133

136

137

139

viii

Figure 11.13 Cleaning Cartridge of The 8-mm Tape Unit

Figure 11.14 QIC Tape Drive Front Panel

Figure 11.15 QIC Data Cartridge

::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::

139

140

142

Page 31

ILLUSTRATIONS

Figure 12.1 Signal Configuration

:::::::::::::::::::::::::::::::::::

Figure 12.2 Configuration of Signal Line when Connecting DCE Device(Example)

Figure 12.3 Configuration of Signal Line when Connecting DTE Line(Example)

Figure 14.1 Power-on Sequence

:::::::::::::::::::::::::::::::::::

::::::::::

:::::::::::

147

150

150

159

ix

Page 32

TABLES

Table1.1 Data Protection for Components and Interfaces

Table1.2 POWER LED

Table1.3 CHECK LED

Table1.4 MODE Switch Settings

Table1.5 Connectors and Switches

::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::

Table1.6 Connectors and Switches for Maintenance

Table2.1 Fans

Table2.2 PCI Slot Specifications

:::::::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

::::::::::::::::::::::

::::::::::::::::::::::::

Table2.3 Installation Specifications of M200 Main Cabinet (1)

Table2.4 Installation Specifications of M200 Main Cabinet (2)

Table3.1 Fans

Table3.2 Power Supply Units

Table3.3 PCI Slot Specifications

Table3.4 Mounting Combination for Expansion Rack

Table3.5 Installation Specifications of M200R (1)

Table3.6 Installation Specifications of M200R (2)

:::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::

:::::::::::::::::::::::::

:::::::::::::::::::::::::

:::::::::::::::::::

:::::::::::::::::::

3

6

6

7

9

9

17

23

24

25

30

30

35

37

38

39

Table4.1 Fans

Table4.2 Power Supply Units

Table4.3 PCI Slot Specifications

Table4.4 Installation Specifications of M400A Main Cabinet (1)

Table4.5 Installation Specifications of M400A Main Cabinet (2)

:::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

::::::::::::::::::

::::::::::::::::::

44

44

49

51

52

x

Page 33

TABLES

Table5.1 Fans

Table5.2 Power Supply Units

Table5.3 PCI Slot Specifications

Table5.4 Mounting Combination for Expansion Rack

Table5.5 Installation Specifications of M400R

Table5.6 Installation Specifications of M400R (2)

Table6.1 Fans

Table6.2 Power Supply Units

Table6.3 CPU Module Configurations

Table6.4 PCI Slot Specifications

:::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

Table6.5 Installation Specifications of M600 Main Cabinet (1)

Table6.6 Installation Specifications of M600 Main Cabinet (2)

Table7.1 Fans

Table7.2 Power Supply Units

Table7.3 CPU Module Configurations

Table7.4 PCI Slot Specifications

:::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

:::::::::::::::::::

:::::::::::::::::::

56

56

61

63

64

65

70

71

73

76

78

79

84

85

87

90

Table7.5 Mounting Combination for Expansion Rack

Table7.6 Installation Specifications of M600R

Table7.7 Installation Specifications of M600R (2)

Table8.1 CHECK LED Status

Table8.2 LEDs

::::::::::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::

:::::::::::::::::::::::::::

:::::::::::::::::::::::::

Table8.3 Expansion Disk Cabinet Installation Specifications (1)

Table8.4 Installation Specifications of Expansion Disk Cabinet (2)

Table9.1 CHECK LED Status

Table9.2 LEDs

::::::::::::::::::::::::::::::::::::::::::

Table9.3 Mounting Combination for Expansion Rack

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::

Table9.4 Installation Specifications of Expansion File Unit Type-2

Table10.1 CHECK LED Status

Table10.2 LEDs

::::::::::::::::::::::::::::::::::::::::::

Table10.3 Mounting Combination for Expansion Rack

Table10.4 Installation Specifications of Expansion File Unit

:::::::::::::::::::::::::::::::::::

:::::::::::::::::::::::

:::::::::::::::::::::

::::::::::::::::::

:::::::::::::::::

:::::::::::::::::

92

93

94

99

101

103

104

108

109

111

112

116

117

119

120

Table11.1 Disk Units LEDs

Table11.2 Handling Floppy Disks

:::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::

Table11.3 LED Displays on The DAT Unit

Table11.4 DAT Cartridge Capacity

:::::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

122

125

131

131

xi

Page 34

Table11.5 8-mm Tape Cartridge Capacity

::::::::::::::::::::::::::::::

136

Table11.6 QIC Tape Cartridge Capacity

Table12.1 Definitions of UPS Signal Lines

Table12.2 Input Circuits

Table12.3 Output Circuits

::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::

Table12.4 Electrical Rating Specifications

Table12.5 Definitions of Signal Lines

Table12.6 IEEE1284-A Connector Terminal Distribution

:::::::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::

::::::::::::::::::::::

Table12.7 IEEE1284-A Connector Terminal Distribution (Continued)

Table14.1 The ’show-post-results’ Command

Table14.2 OBP Error Messages

:::::::::::::::::::::::::::::::::::

Table14.3 Power Unit Configuration Error Messages

Table14.4 Power/Fan/Environmental Error Messages

Table14.5 Processor Monitoring Error Messages

Table14.6 Lithium Battery Error Messages

Table14.7 Other Error Messages

::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::

::::::::::::::::::::::::::

:::::::::::::::::::::::::::::

::::::::::::::::

141

146

147

147

148

149

151

152

158

160

161

162

163

163

164

xii

Page 35

CHAPTER 1 Product Outline

1.1 Key Features .................................................................................... 2

1.2 Operator Panel ................................................................................. 5

1.3 External Interface .............................................................................. 8

1.4 Console .................................................................................... 10

1.5 Power On/Off ................................................................................. 11

1.6 Installation of Basic Software Extension or Enhanced Support Facility ........................... 12

1.7 local-mac-address Property .................................................................. 12

1

CONTENTS

1

Page 36

CHAPTER 1 Product Outline

1.1 Key Features

The GP7000F is SMP (Symmetric Multi-Processor) servers with 64-bit SPARC64 GP processors. Each model in

the group has high-performance 64-bit processors, high-speed I/O interfaces and enhanced reliability, availability,

and serviceability (RAS) features. The crossbar configuration is used as the system architecture of the GP7000F,

and the performance of the multi-processor configuration has been improved almost linear scalability.

The GP7000F, which has excellent scalability and reliability, is an ideal server for not only group or department

servers but also for mission-critical enterprise servers.

IMPORTANT

The availability of these products depends on the Sales and Support Companies. Please contact these

companies.

High-performance SPARC64 GP Processor

The SPARC64 GP is a high performance processor which has an out-of-order execution engine.

The SPARC64 GP supports large size external cache of 2MB/4MB/8MB per processor as well

as 64KB(instruction)+64KB(Data) on-chip cache.

Error Correcting Code (ECC) is used for both on-chip and external cache.

High-performance Multi-Processor Platform

Symmetric Multiprocessing (SMP) architecture

The memory system has a high bandwidth, up to 8-way interleaving, and which enables fast

access.

A packet-based bus protocol, to enable a throughput of 1.3 to 1.6 GB/s per processor, is

implemented.

A crossbar configuration, which is based on a packet bus, enables high-level parallel operations

of processors and memory modules, I/O and memory modules, and data transfer among

processors. And, the system delivers scalable performance by installing additional processors

and I/Os.

– The crossbar switch enables parallel operations of several processors and I/Os.

– The performance of the single bus is improved by expanding the bus width and high

frequency operation.

– The efficiency of bus usage is drastically improved by bus control in the packet exchange

system.

High-performance EDO DRAM (Extended Data Out DRAM) is used on the platform for the

memory expansion.(M200, M600)

High-performance SDRAM (Synchronous DRAM) is used on the platform for the memory

expansion.(M200R, M400A, M400R, M600R)

2

Page 37

High-speed I/O interface

One built-in 40 MB/s UltraSCSI Single-Ended interface for internal devices.

One built-in 100BASE-TX interface (10/100 Mbps, auto-sensing).

The GP7000F has some 64-bits PCI (Peripheral Component Interconnect) buses.

Additional interfaces, such as 100BASE-TX, FDDI, ATM, can be provided by installing PCI

cards. Both short and long size PCI cards can be installed. (*1)

*1) The maximum length of the cards that can be installed in PCI slots #8to#12 of the

M600R Main cabinet is 19.4cm.

High-performance, Large-capacity File Devices

Up to 22, 7200rpm or 10000rpm, UltraSCSI disk drives can be built in. Note that the number of

drives that can be installed depends on each model.

The disk drives can be hot-swappable

One CD-ROM drive unit is provided as standard.

One tape drive can be built in as optional.

1.1 Key Features

Reliability, Availability, and Serviceability (RAS) features

Error Correction Code (ECC) is implemented for on-chip cache, external cache, memory

module and data paths. The data for the I/O data path(PCI) is protected by parity.

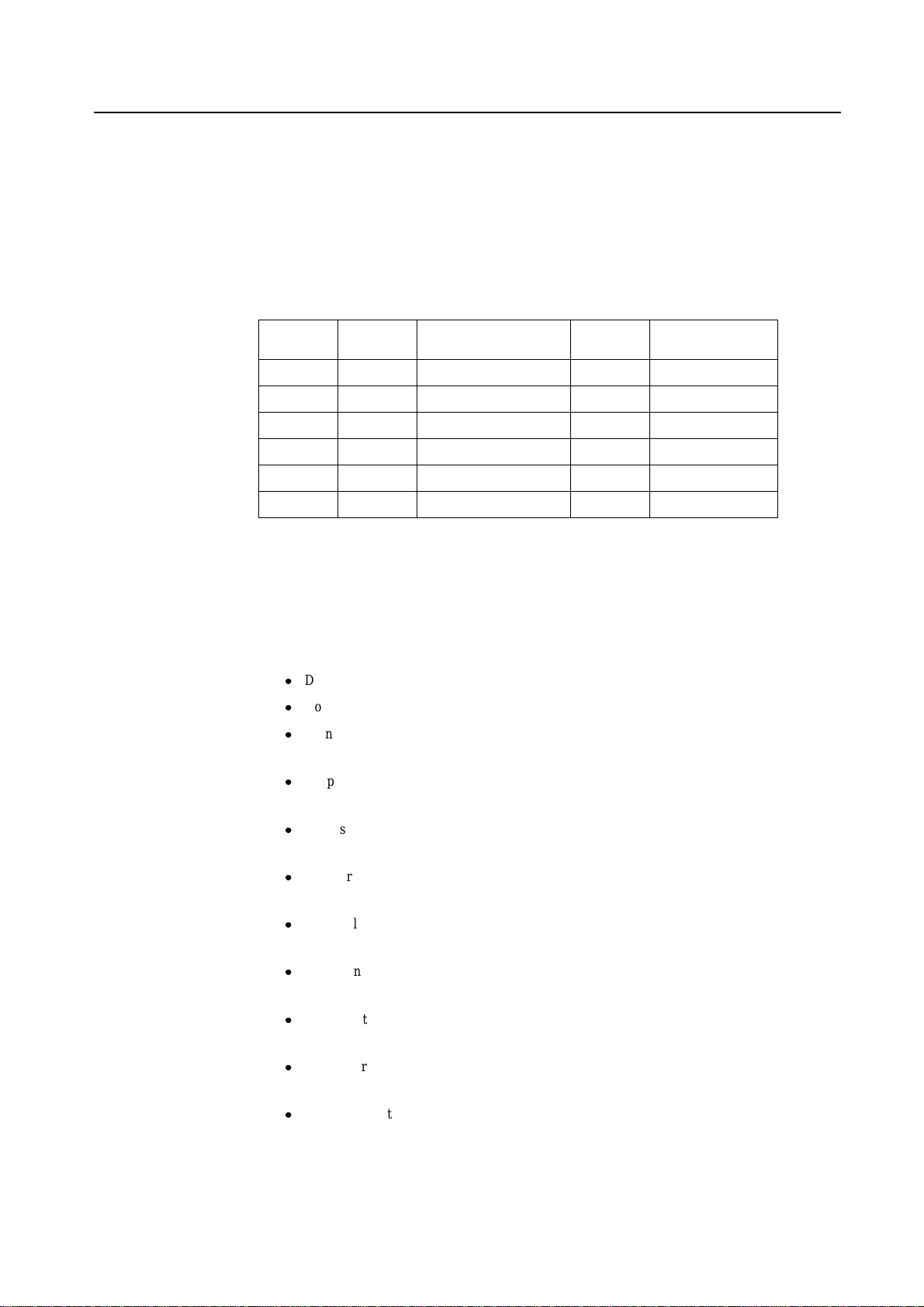

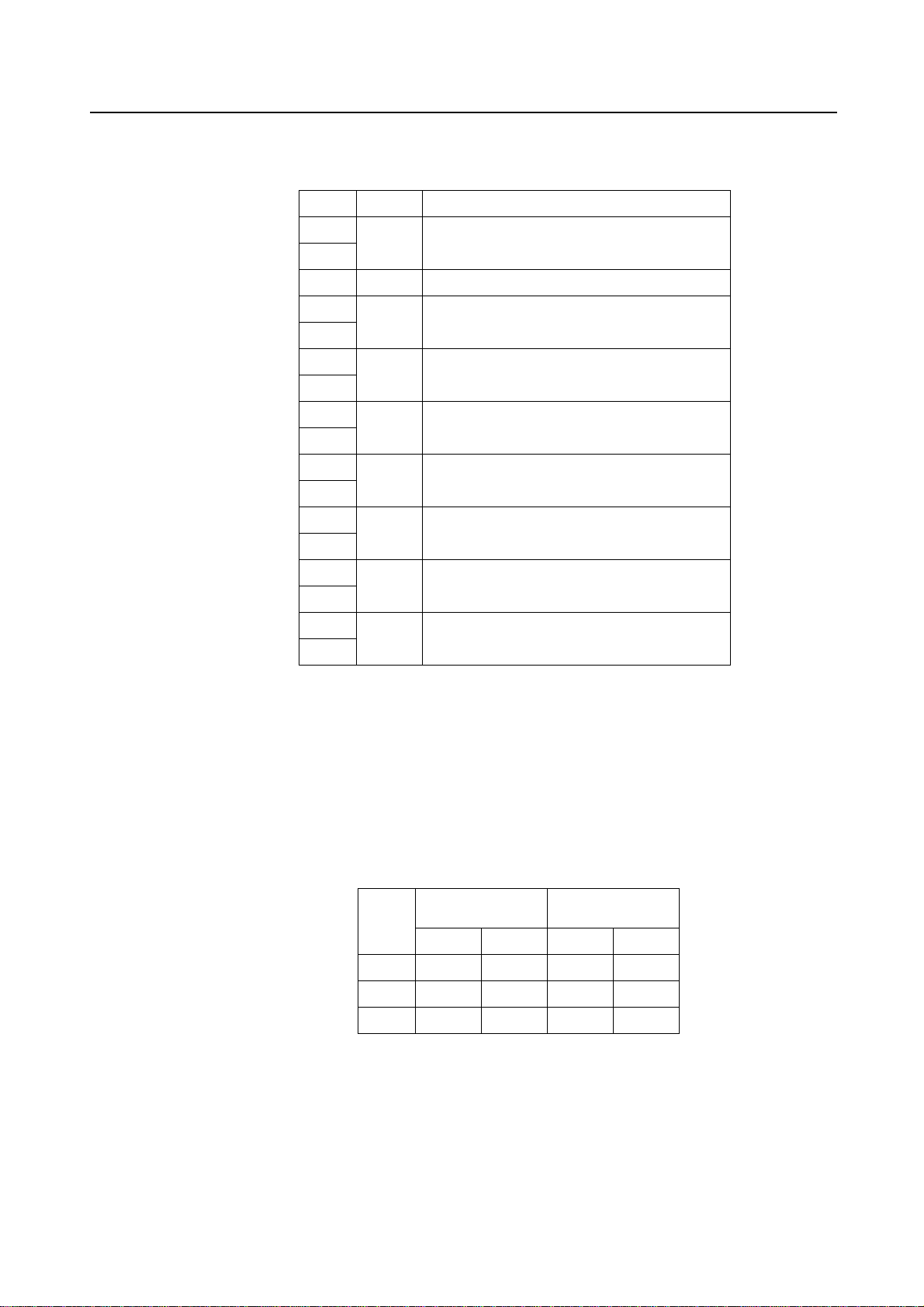

Table 1.1 Data Protection for Components and Interfaces

Components and interfaces

Processor (on-chip & external cache)

Memory

Data path

Address path

I/O bus (PCI)

Processor operation

Built-in basic SCSI, LAN, parallel

Data protection method

By ECC (corrects 1 bit and detects 2 bit)

By ECC (corrects 1 bit and detects 2 bit)

By ECC (corrects 1 bit and detects 2 bit)

By parity

By parity

Operation monitoring by an independent

processor

By parity, IP check sum

Note: The RS232C interface and a floppy disk on a standard configuration are not

protected by parity.

Power-on diagnostics are executed on the system components, such as processors, memory

modules and so on, during initial power-on or reset of the system.

Automatic System Reconfiguration (ASR) isolates faulty hardware components immediately

after detecting it. The ASR function isolates not only faulty components detected during initial

power-on but also those detected while the system is running. However, the ASR function

cannot restart the system if errors are detected in the resources required for booting up the

system, or in the basic components of the system.

3

Page 38

CHAPTER 1 Product Outline

A SCF (System Control Facility), which has an integrated service processor, monitors the

operation of SPARC64 GP processors, and reports erroneous events such as environmental

monitoring explained below. With a GUI-based intelligent monitoring and reporting tool,

which is provided in "Basic Software Extension" or "Enhanced Support Facility",

administration and management of GP7000F is easy and less time consuming.

The SCF monitors environmental temperature, powering and cooling conditions. This function

prevents the system from environmental condition that can cause error or damages to the

system.

– Monitoring Environmental Temperature ; The guaranteed operating temperature of the

system ranges from 5 to 35 degrees Celsius (41 to 95 degrees Fahrenheit). A warning

message is displayed at about 35 degrees Celsius (95 degrees Fahrenheit). If the

temperature reaches about 40 degrees Celsius (104 degrees Fahrenheit), the system is shut

down automatically.

– Monitoring Powers ; The power supplies are always monitored, and a message is displayed

on the LCD panel, if power supply failure is detected. When the system doesn’t have a

redundant power supply, the system will be powered off immediately. Besides it, the

integrated service processor monitors and controls DC-DC converter which provides

power to the processor modules.

– Monitoring Fans ; Several fans are installed inside the GP7000F main cabinet. If one of the

fans breaks down, a warning message which indicates the defective fan is displayed on the

LCD panel. And, if the fans cannot provide enough cooling, the system is shut down

automatically.

RCI (Remote Cabinet Interface) makes power cycle control of expansion I/O unit, such as

Expansion Disk Unit and Expansion File Unit, which has the RCI interface.

Status of LEDs and messages on LCD panel of GP7000F main cabinet as well as console

messages make trouble shooting easy and less time consuming.

All internal disk drives are hot-swappable, and these drives can be mirrored for higher data

availability. In addition, redundant power supplies and fans are supported for higher availability.

The front cover/panel has a lock key to prevent unauthorized access to the internal I/O devices

as well as front panel switches.

4

Page 39

1.2 Operator Panel

The operator panel has a set of status LEDs, switches, and a LCD panel. The switches as well as built-in I/O

device are covered with a panel cover that can be locked with a key. It prevents incorrect operations and ensures

security for the internal I/O device as well as the switches.

1.2 Operator Panel

RESET switch

REQUEST

RESET

AUTO

MANUAL SECURE

MODE switch

REQUEST switch LCD panel

CHECK

POWER

POWER LED( green )

CHECK LED( amber )

Figure 1.1 Operator Panel (M200, M600)

CHECK LED (amber)

LCD panel

POWER switch

POWER

POWER LED (green)

POWER switch

POWERCHECK

POWER

SECURE

RESET swich

REQUEST switch

REQUEST

MANUAL

MODE switch

RESET

AUTO

Figure 1.2 Operator Panel (M200R, M400A, M400R, M600R)

5

Page 40

CHAPTER 1 Product Outline

LED (CHECK LED/POWER LED)

The POWER LED indicates whether the system is turned on while the CHECK LED indicates

system operation by lighting up or blinking.

Table 1.2 POWER LED

Status

ON

OFF

Descriptions

The power is on

The power is off

The user and system administrator can recognize the system operation status from the CHECK LED

and messages that appear on the LCD panel.

Table 1.3 CHECK LED

Status Descriptions

ON The system is turned on, but the processors are not operating.

Blinking System down.

(quickly)

Blinking There are faulty components in the system. (The system is still

(slowly) operating)

OFF The system is not turned on or it is operating normally

If the system administrator shuts down the system (when the AC main line switch is on) while there

are degraded-mode components remaining in the system, the CHECK LED will continue to blink

slowly to remind the system administrator there are faulty components to be diagnosed. Possible

causes of a CHECK LED alarm are: errors in temperature monitoring, related components (such as

the power supplies and fans) or degraded-mode components (such as processors and memory

modules, etc.).

When the system is turned on, the CHECK LED lights up briefly. However, this is not an error

unless the CHECK LED remains light up for more than three seconds, or begins to blink.

LCD The LCD panel can display 2 rows of 16 digits. The messages displayed on it are status or results of

the power-on diagnostics, and environmental events such as over temperature, etc. Therefore, when

an error occurs, the user or system administrator can recognize the state of the hardware system

easily by checking the messages displayed on the LCD panel as well as console messages.

Error messages remain on the LCD panel until the error is corrected. There is only one LCD panel,

therefore, it displays messages in turn when there are several errors. Note that error events are

corrected even though their message displayed on the panel is overwritten by messages of other

events. However, since the initial diagnostics is allowed to report only one event, the next message

of another event will be displayed on the panel after repaired a reported event.

Messages are erased from the panel when:

an error event is corrected.

the power of the main cabinet is cycled

the AC main line switch is turned off, or

the RESET switch is pressed (partial messages are erased).

When an error or an abnormal state occurs, record the messages displayed on the LCD panel and

status of the CHECK LED. Then, contact the system administrator or service engineers. See 14

"Troubleshooting" for more information regarding the messages displayed on the LCD panel.

6

Page 41

Switches There are 4 switches on the operator panel, as below.

POWER switch

The user can turn on and off the system by pressing this switch. The POWER switch

operation is managed by the setting of the MODE switch as well as software setting

with "scftool". By pressing the POWER switch while the system is running, the

system will be powered off after graceful shutdown. Refer to the user’s guide of

"Basic Software Extension" or "Enhanced Support Facility" for the information of the

"scftool".

RESET switch

The user can reset the system forcibly with the RESET switch. Enabling the RESET

switch is managed by the state of the MODE switch setting. If the user cannot restart

the system with the RESET switch, check the LCD panel if there are any messages,

then press this switch again.

Data destruction: Pressing the RESET switch while

CAUTION

the system is running may destroy data.

1.2 Operator Panel

REQUEST switch

The REQUEST switch is used by trained service engineers only for maintenance

purpose. Do not use the REQUEST switch by users.

MODE switch

The MODE switch is used to set boot-up mode of the system as well as

enabling/disabling the POWER, RESET and REQUEST switches. The MODE

switch has 3 states as shown in the Table 1.4 . In the table below, YES means that a

switch is enabled when the MODE switch is set to the position/state, while NO means

a switch is disabled.

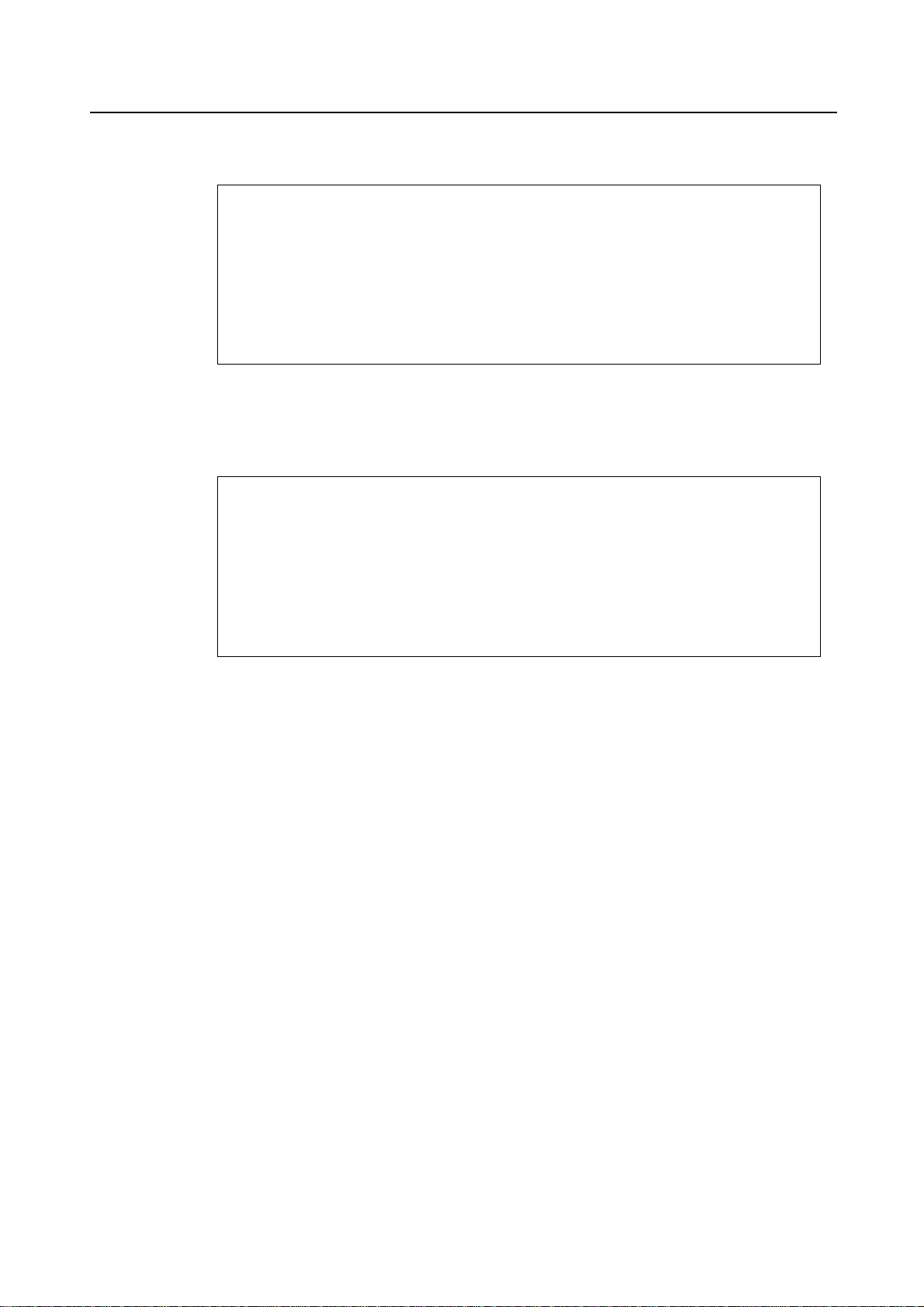

Table 1.4 MODE Switch Settings

POWER RESET REQUEST Remarks

switch switch switch

MANUAL

YES YES

YES

AUTO

NO NO

YES

SECURE

NO NO

NO

The system stops at ok prompt after the

power-on diagnostics.

The system boots up automatically after

the initial diagnostics.

The system boots up automatically after

the initial diagnostics, and keyboard

STOP+A command and terminal break

command are ignored while Solaris is

running.

Notes: At the maintenance of main cabinet, be sure to set the MODE switch to

the MANUAL state even if the AC line switch is OFF.

The POWER, RESET and REQUEST switches must be pressed longer

than 0.3 seconds for valid operation.

7

Page 42

CHAPTER 1 Product Outline

CAUTION

IMPORTANT

Under the MANUAL and AUTO state, keyboard STOP+A command and terminal break command will

abort booting-up the system or halt the system while operating system is running. Toprevent system

down by unexpected break or STOP+A command, set MODE switch SECURE state.

1.3 External Interface

Various interfaces are available for peripherals and network connections.

Be sure to install software packages in the "Basic Software Extension" or

"Enhanced Support Facility". Otherwise, above switch functions or proper

messages on LCD panel are not guaranteed.

PCI Interface

The GP7000F provides the PCI bus as the I/O interface. The PCI interface has the following

characteristics:

Connector

The following connectors are installed on the back of the GP7000F main cabinet:

PCI Local Bus Specification, Rev 2.1 compliant.

64-bit bus widths, 33 MHz (5.0V) and 33/66 MHz (3.3V).

Short and long size card can be installed into any of the PCI slots. (*1)

Data paths are protected by parity.

*1) The maximum length of the cards that can be installed in PCI slots #8to#12 of the

M600R Main cabinet is 19.4cm.

8

Page 43

1.3 External Interface

Table 1.5 Connectors and Switches

Connector/ Marking Type Remarks

Switch

RS232C

KB

Parallel

10 Mb/100Mb

Ethernet

UPS

RCI

PC

SERIAL A/B

KB

PARALLEL

LAN

UPS

RCI

PC

Dsub/25 pin*

8-pin DIN

Dsub/25 pin*

RJ45

Dsub/9 pin

RJ11

8-pin DIN

The same connector as Parallel

Connect a mouse via a keyboard

AT compatible

10 Mb/100 Mb automatic recognition

Connector to a UPS (Uninterruptable Power

Supply) which has the UPA interface.

Install a terminating resistor

For controlling power on for the main

cabinet

* This type will not operate if connected improperly. However, it does not affect the

system performance.

The RS232C, Parallel and Ethernet interfaces use industry-standard connectors. Therefore, the user

can connect them to various peripheral devices. For the specifications of the RS232C, parallel

interface and UPS control interface, see 12 , "External Interfaces".

Table1.6 shows other connectors and switches than the above:

Table 1.6 Connectors and Switches for Maintenance

Connector/ Marking Type Remarks

Switch

SCF/switch No notation Push pin Unavailable

SCF/RS232C No notation Dsub/9 pin Unavailable

IMPORTANT

The connector and switches in Table 1.6 are used only for the maintenance purpose by

trained service engineers. If used for any other reason the server will malfunction.

9

Page 44

CHAPTER 1 Product Outline

1.4 Console

Serial Terminal

Terminal break command

If your GP7000F has no local graphic console, a serial terminal, such as Personal Computer, should

be attached to the GP7000F in order to install the system and to run diagnostic programs. To attach

a serial terminal :

Connect a terminal data cable to serial port A on your server.

Set a terminal to receive 8bit per character, 1 stop bit and no parity at 9600 baud.

Refer to the document accompanying your terminal for more information about the terminal itself.

You can disable to enter the OpenBoot mode from break command and keyboard STOP+A

command, by the following proceedings.

set no-break value to fw-option variable at the ok prompt, with the procedures as below.

Then, running the system on SECURE mode, which you can set on the operator panel.

1 To display current setting, type print-fw-options command as below. Below shows

default setting, and no default value means that the break command and STOP+A command are

enabled.

ok print-fw-options

fw-options =

2 To disable break command and keyboard STOP+A command, type as below.

ok set-fw-options no-break

fw-options = no-break

3 To make sure the settings, type print-fw-options command and check the no-break value

is set as below.

ok print-fw-options

fw-options = no-break

To enable the break command and STOP+A command, use the following command at the ok

prompt. Note that the commands are enabled as the default of the GP7000F.

4 To display currrent setting, type print-fw-options command as below. The no-break

value means the break command and keyboard STOP+A command are disabled.

ok print-fw-options

fw-options = no-break

5 To enable break command and keyboard STOP+A command, type as below.

ok clear-fw-options no-break

fw-options =

6 To make sure the setting, type print-fw-options command and check the no value is set

as below.

ok print-fw-options

fw-options =

10

CAUTION

If used improper commands at the ok prompt, the GP7000F

may be destroyed. If you need to used any other commands

except shown on this manual, you should well understand the

function and usage of the command before using it.

Page 45

1.5 Power On/Off

Power On

1.5 Power On/Off

After connected cables necessary to the system as well as console (or local graphic display), take the

following procedures.

1 Turn on any peripherals and external IO devices attached to the main cabinet as well as a

terminal (or local graphic display).

2 Set the AC main line switch to ON.

3 Press the POWER switch on the operator panel, when the mode switch is in MANUAL/AUTO

mode. Note that power on function by pressing keyboard power-on key is not supported.

IMPORTANT

If a serial terminal is attached to the system, be sure to power on the terminal before the

main cabinet is powered on, and never power off the terminal during the system is running.

Otherwise, the system may be halted and it may destroy data.

Power Off

Before power-off the system, notify users that the system will be shut down. And, back-up the files

if necessary.

1 Press the POWER switch on the operator panel, then the system will be powered off after a

graceful shutdown.

2 Turn off any peripherals and external IO devices attached to the main cabinet as well as

terminal(or local graphic display).

Be sure to eject backup tape media and any diskettes before

CAUTION

IMPORTANT

When turning on the main line switch under a state that the MODE switch is AUTO or

SECURE, the GP7000F may be powered up automatically just turn on the main line switch

if APCS(Auto Power Control System) software is installed in your GP7000F system.

To avoid powering up just turning on the main line switch even if the softwares is installed

in your GP7000F system, turn on the main line switch under the state of the MODE switch

is set to MANUAL position.

power-off the system, if the media are installed. Otherwise, the

data on the media may be destroyed.

Except in an emergency, never turn off the AC switch or disconnect

the power cable while the GP7000F main cabinet is turned on. If

you do, data in the disk drives may be destroyed.

11

Page 46

CHAPTER 1 Product Outline

1.6 Installation of Basic Software Extension or Enhanced Support Facility

Toenable support of GP7000F specific functions, software packages in the "Basic Software Extension" or

"Enhanced Support Facility"are needed to install on the system. Please refer to the user’s guide and installation

guide of the "Basic Software Extension" or "Enhanced Support Facility" for more information.

CAUTION

Install "Basic Software Extension" or "Enhanced Support Facility" before

operating the system. Without this package, incorrect operator panel operations

or hardware errors may cause the system to shut down or destroy data.

1.7 local-mac-address Property

The network interface of the Ethernet (100BASE-TX) is assigned a unique MAC (Media Access Control)adress,

which represents the 48-bit ethernet address for the channel. The OpenBoot(R) firmware reports this MAC address

via the local-mac-address property in the device nodes corresponding to the network interfaces.

A system is not obligated to use this assigned MAC address if it has a system-wide MAC address. In such cases,

the system-wide MAC address applies to all network interfaces on the system.

The device driver, or any other adapter utility, can use the network device’s MAC address (local-mac-address)

while configuring it. In future Solaris releases, you will be able to use the channel’s MAC address when booting

over the network.

The mac-address property of the network device specifies the network device specifies the network address

(system-wide or local-mac-address) used for booting the system. Tostart using the MAC address assigned to the

network interface of the Ethernet (100BASE-TX), set the NVRAM configuration variable local-mac-address? to

true.

12

OK setenv local-mac-address? true

Page 47

CHAPTER 2 M200 Main Cabinet

2.1 Overview .................................................................................... 14

2.2 Device Configuration ........................................................................ 15

2.3 Systemboard ................................................................................. 19

2.4 Disk Units .................................................................................... 21

2.5 PCI Slots .................................................................................... 23

2.6 Installation .................................................................................... 23

2

CONTENTS

13

Page 48

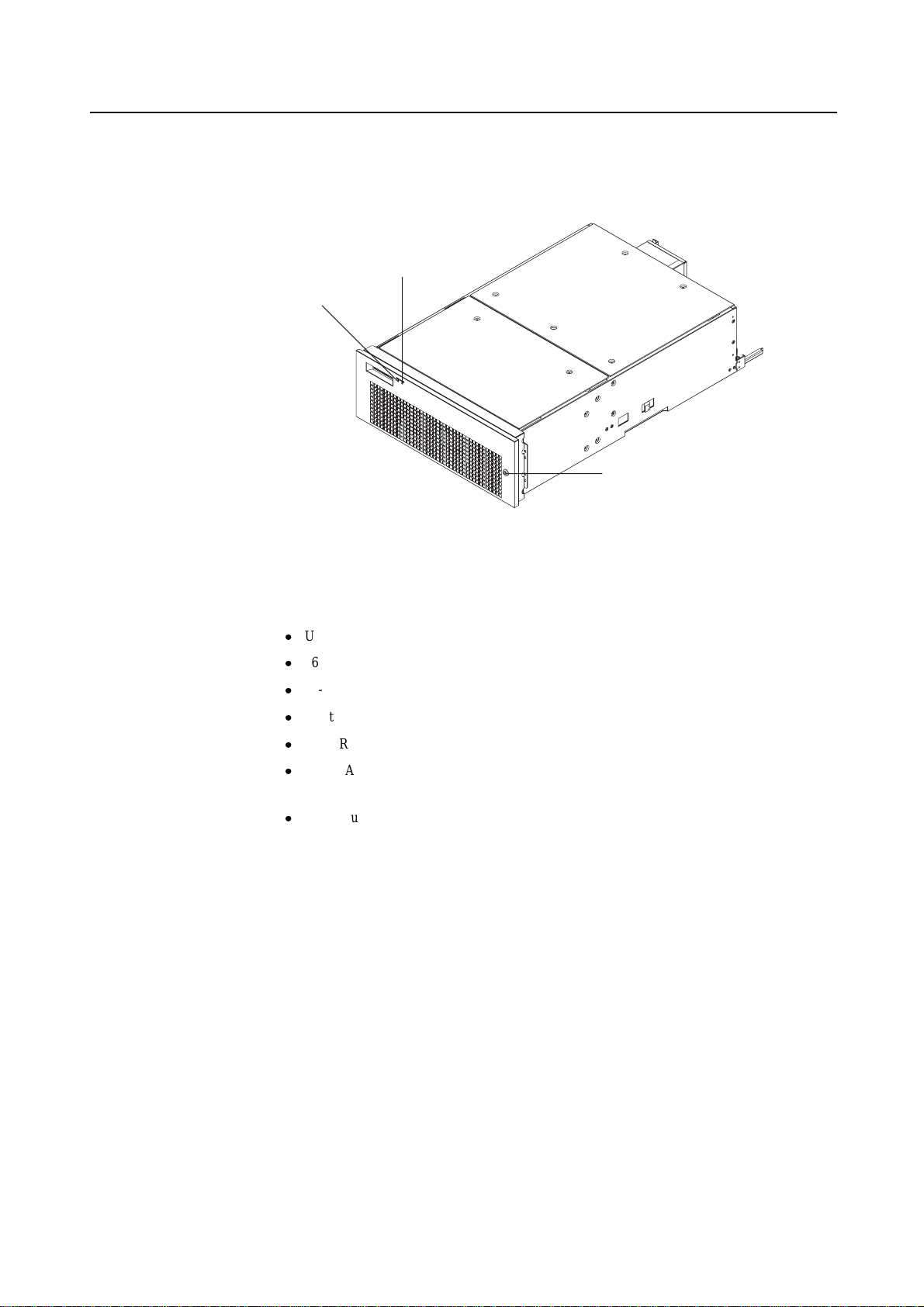

CHAPTER 2 M200 Main Cabinet

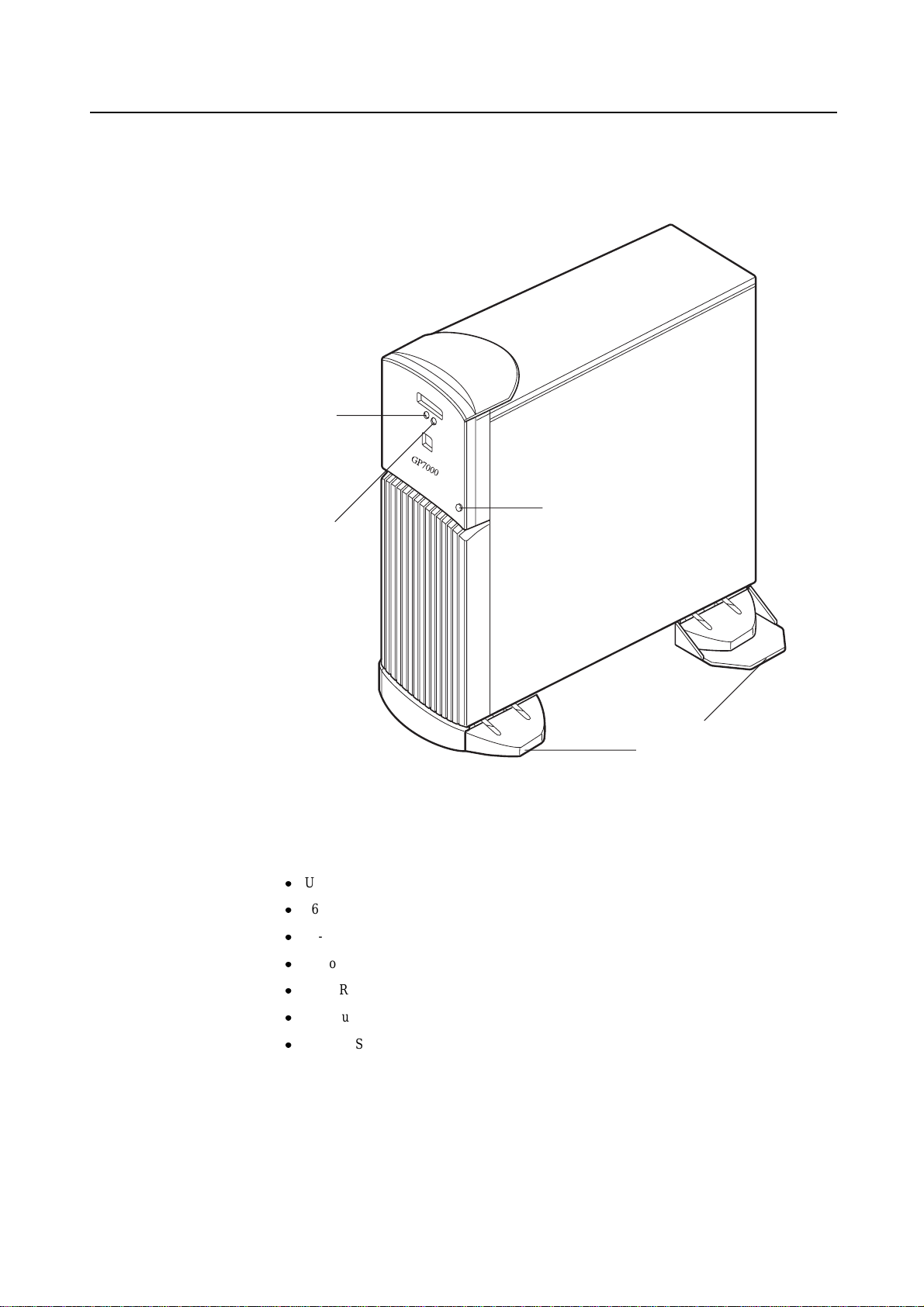

2.1 Overview

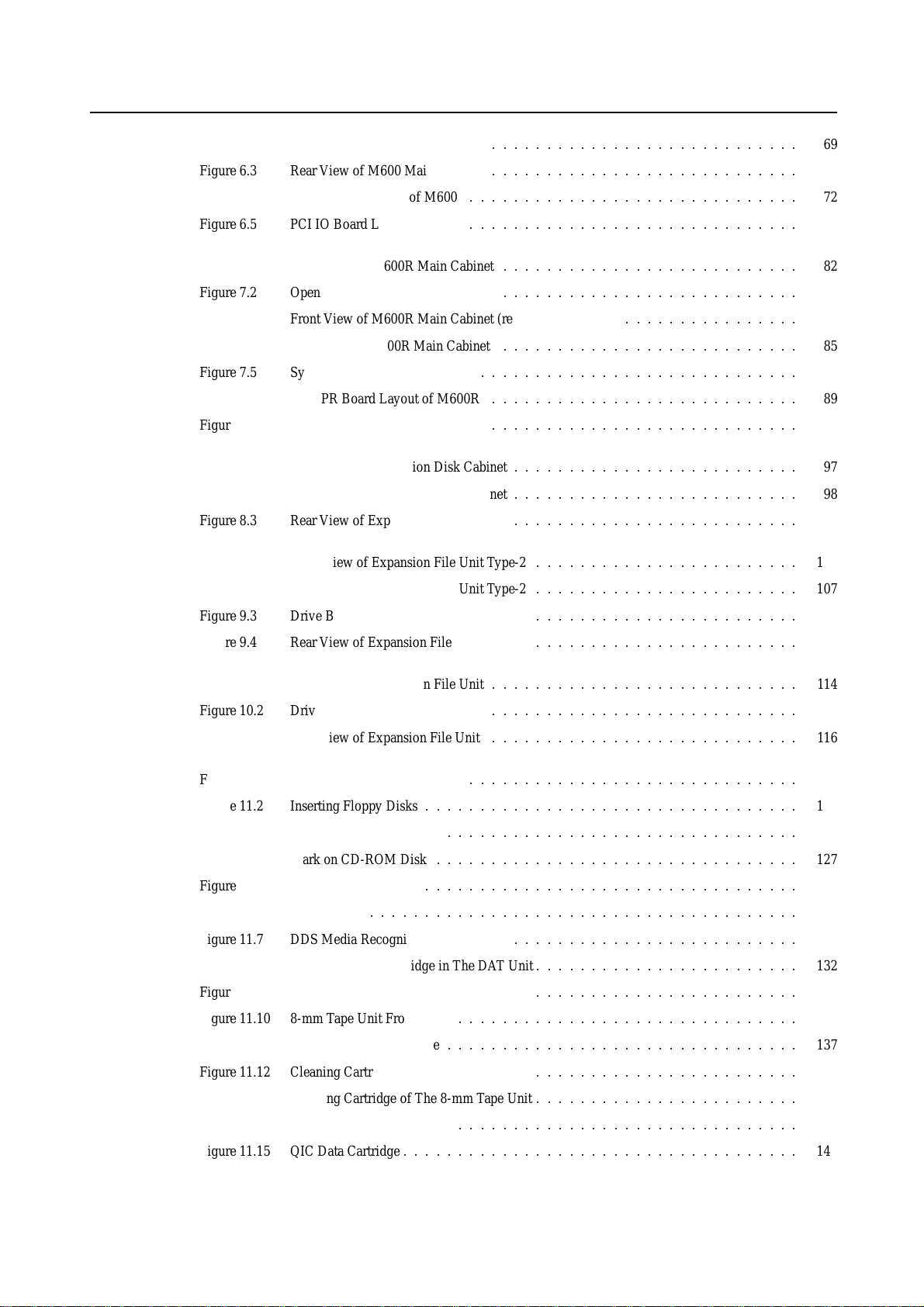

Appearance

CHECK LED

( amber )

POWER LED

( green )

Key Features

Lock

Stabilizing Feet

Figure 2.1 Front View of M200 Main Cabinet

Up to 2 processors

16 DIMM slots. Up to 4 gigabytes of memory.

64-bits width, 4 PCI buses provide 6 PCI slots ( 2*33/66MHz + 4*33MHz).

14

Up to 8 UltraSCSI disk drive bays, which support hot-swap features.

1 CD-ROM unit and 1 floppy disk unit as the basic configuration.

1 tape unit can be installed.

1 100BASE-TX (auto-sensing 10/100Mbps), 2 Serial, 1 parallel, and 1 Keyboard/Mouse port

Page 49

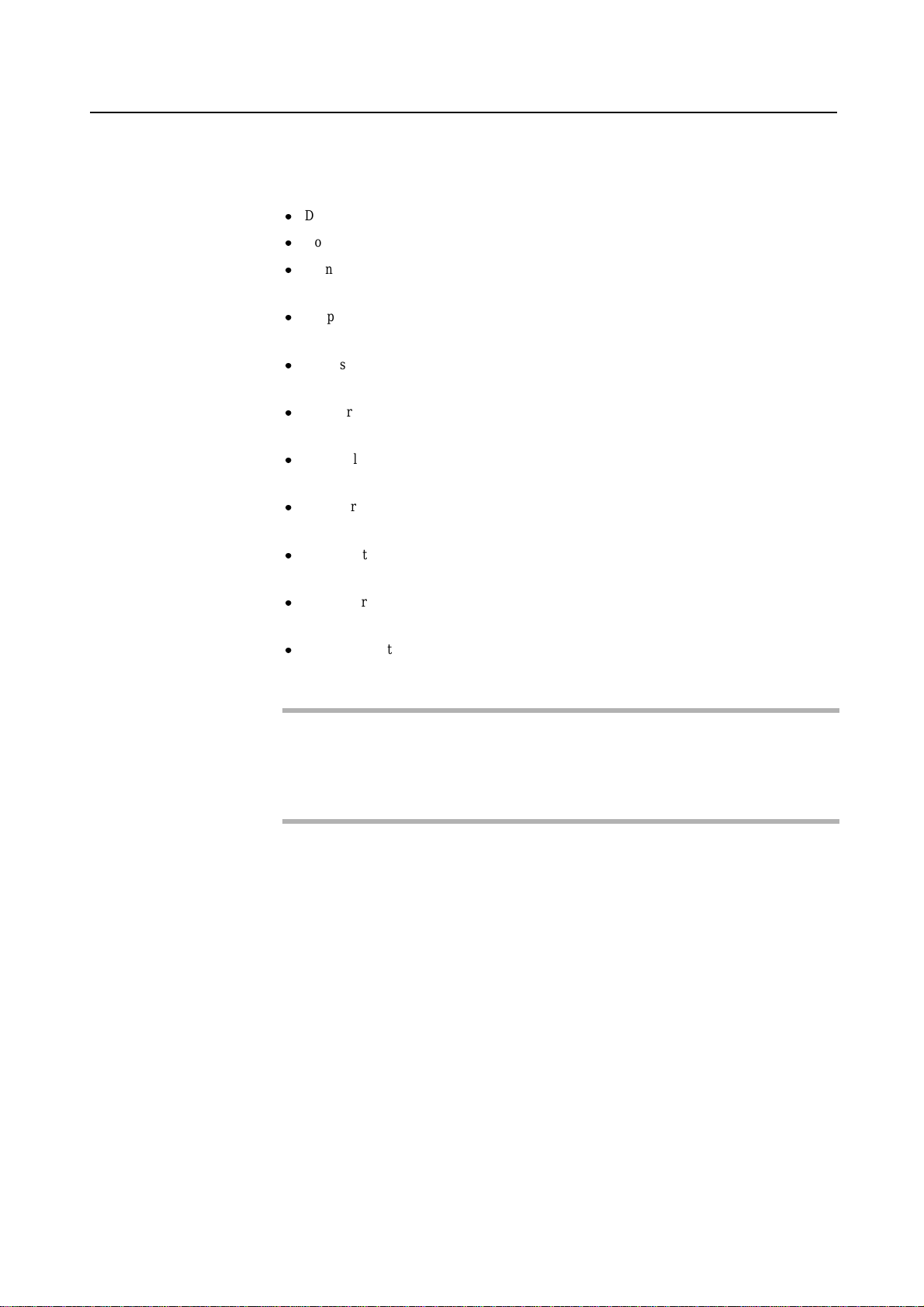

2.2 Device Configuration

The M200 main cabinet consists of the following components:

Desk-side type cabinet

Basic power supply and optional expansion power supply unit

Cooling fans

Systemboard

Processor modules

DIMM (Dual Inline Memory Module)

Operator panel

PCI card (option)

SCSI-BP boards (1 basic board, 1 option board)

Disk drive units

CD-ROM unit

Tape unit (optional QIC tape, 8-mm tape, or DAT)

2.2 Device Configuration

Floppy disk unit

The processor modules, DIMMs, PCI cards, tape drive unit, expansion power supply, disk expansion feature

(SCSI-BP board), and disk drive units of the above components are available as options.

15

Page 50

CHAPTER 2 M200 Main Cabinet

Front view of the M200 main cabinet

Operation Panel

Panel Cover

DAT unit,8-mm Tape Unit,

QIC Tape Unit( option )

CD-ROM Unit

Floppy Disk Unit

Front Cover

Panel cover

Stabilizing Feet

Figure 2.2 Open View of M200 Main Cabinet

The panel cover can be opened from its right side after unlocking it. Then, you can access switches

on the operator panel, CD-ROM drive unit, Floppy drive unit, tape drive unit, and so on.

16

Page 51

Fans Table2.1 lists the fans installed in the M200 main cabinet.

Table 2.1 Fans

2.2 Device Configuration

*1 The 80-mm square fan is replaced by the 120-mm square fan when the expansion

Power supplies

The M200 main cabinet has a basic power supply unit as well as DDC(DC-DC Converter)s

dedicated to each processor module. When the Disk Expansion Unit is installed, The expansion

power supply is required (when 5 to 8 disks are installed in the M200 main cabinet).

If the expansion power supply is not installed when the Disk Expansion Unit is installed, an

indication that a mounting rule has been violated is reported on the LCD panel and power-on is

inhibited. This checking function prevents faulty configurations. The checking function is executed

when a disk cage is expanded regardless of whether a disk unit is installed.

The alarm detection feature is not implemented for the expansion power supply of the M200 main

cabinet. If a failure occurs in the expansion power supply, the power cannot be supplied to the Disk

Expansion Unit. In this case, the POWER LED on the disk expansion cage turns off. If an error

occurs in the disk unit installed in the Disk Expansion Unit (because the power is not supplied), the

expansion power supply may be at failed. Check the POWER LED on the expansion disk cage.

Name Shape

Fan #0 120-mm (4.7 inch) square fan

Fan #1 120-mm (4.7 inch) square fan

Fan #2 92-mm (3.6 inch) square fan

Fan #3 80-mm (3.1 inch) or 120-mm

(4.7 inch) square fan (*1)

Fan #4 92-mm (3.6 inch) square fan

power supply is installed.

Location

Behind the Systemboard

Under the disk unit

Above the processor module

Behind the power supply

Side the PCI slot

Stabilizing feet

The stabilizing feet prevent the M200 main cabinet from falling over when it is pushed from its side

or if there is an earthquake. When installing the M200 main cabinet, be sure to install the stabilizing

feet.

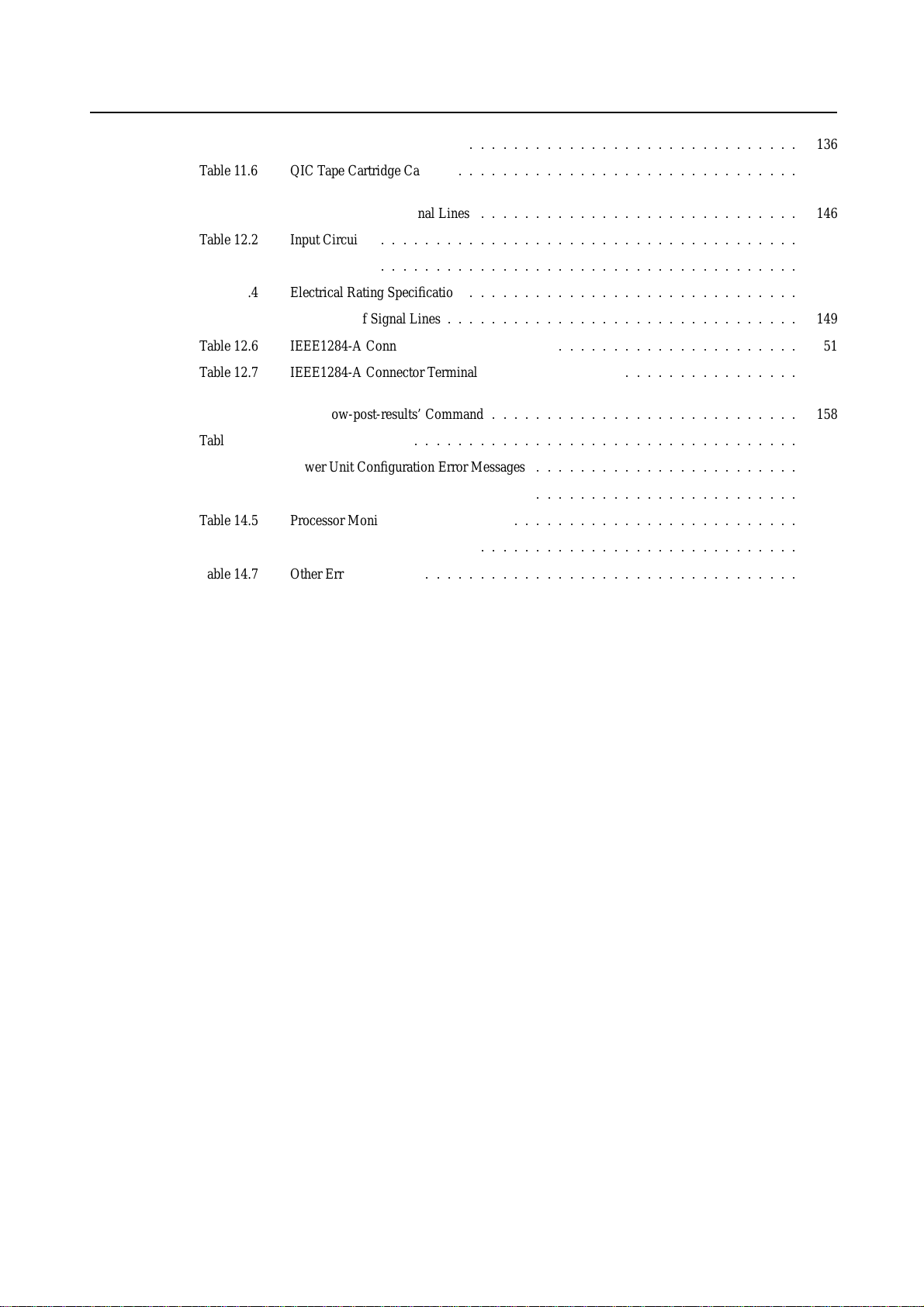

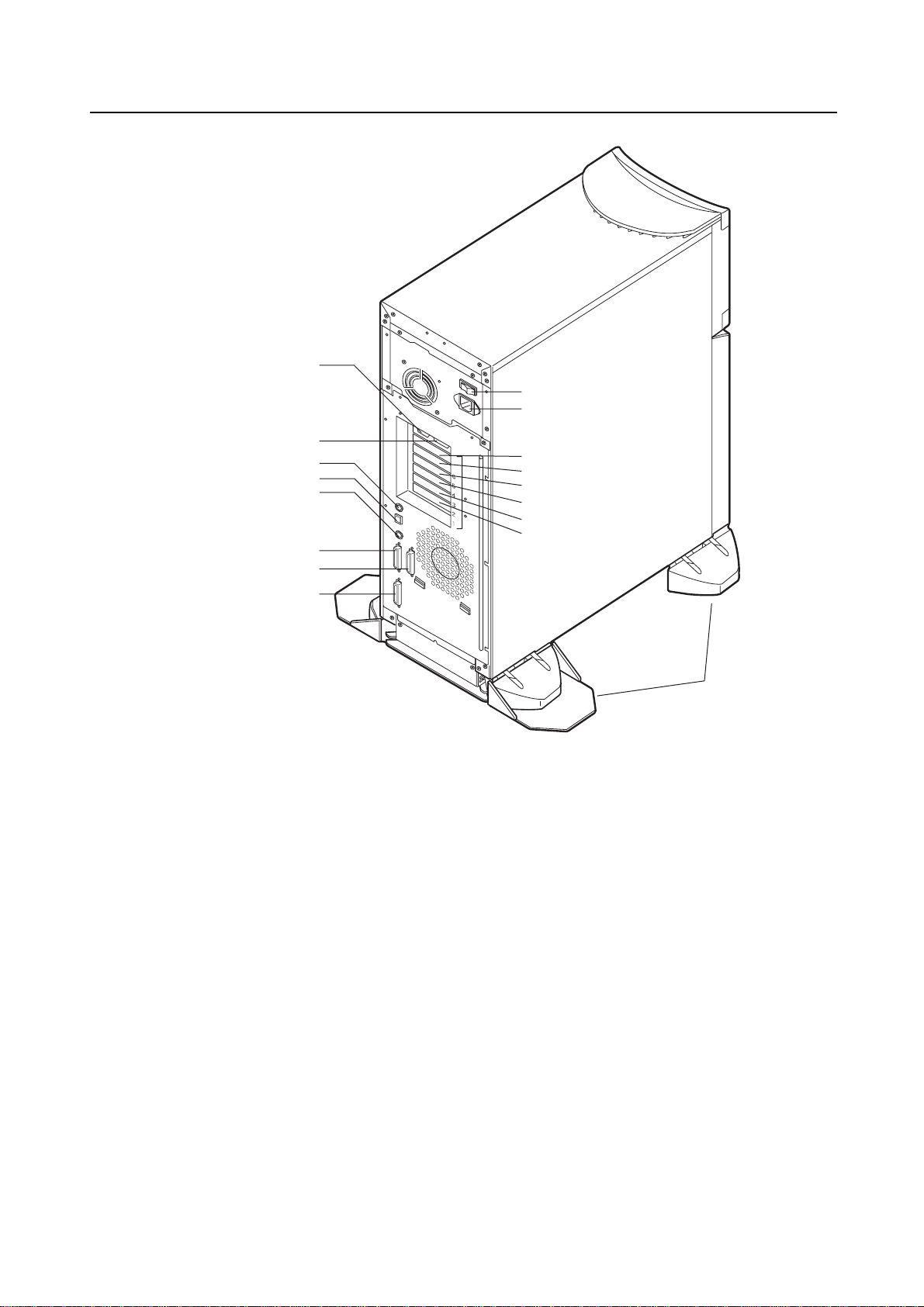

Rear of the M200 main cabinet

AC input, AC main line switch, power supply(FEP) and some connectors are located on the rear

panel of the M200 main cabinet as shown in the Figure 2.3 .

17

Page 52

CHAPTER 2 M200 Main Cabinet

RCI

AC Main Line Switch

AC Power Input

UPS

PC

100BASE-TX

Keyboard

RS232C

( Port A)

RS232C

( Port B )

Parallel

( AT Centrenics )

PCI slot #6

PCI slot #5

PCI slot #4

PCI slot #3

PCI slot #2

PCI slot #1

Stabilizing Feet

Figure 2.3 Rear View of M200 Main Cabinet

18

Page 53

2.3 Systemboard

Systemboard layout

2.3 Systemboard

CPU module slots, memory module slots, and PCI slots are located on the Systemboard as described

in Figure 2.4 .

NVRAM

SCF BOARD ONLY

PCI Slot #6

PCI Slot #5

PCI Slot #4

PCI Slot #3

PCI Slot #2

PC LAN KB

Serials Parallel

#13

#12

#9

#8

#5

#4

#1

#0

Processor Configuration

Up to 2 processors can be installed in the M200 main cabinet. When installing the processor

modules, the following conditions must be satisfied:

The installed processor modules must be the same type (including the cache size).

Install a processor module in slot 0 before installing one in slot 1.

When installing a processor module, install DC-DC converters along with the processor in the

corresponding slot.

PCI Slot #1

DDC #3

DDC #2

DDC #1

DDC #0

MEMORY SLOT

CPU #1

CPU #0

Figure 2.4 Systemboard Layout of M200

#15

#14

#11

#10

#7

#6

#3

#2

IMPORTANT

If any of the above conditions is not satisfied, the operation is not guaranteed.

19

Page 54

CHAPTER 2 M200 Main Cabinet

Memory configuration

The M200 has 16 DIMM slots, allowing for as much as 4 gigabytes of main memory. When

installing the DIMMs, the following conditions must be satisfied:

IMPORTANT

If any of the above conditions is not satisfied when installing the DIMMs, some DIMMs are

degraded in the power-on diagnostics. When adding the memory modules, check that the

DIMMs are installed correctly.

Memory ECC feature

The EDO DRAM is used as the memory element. The single-bit error correction and multiple-bits

error detection features are available for a large capacity memory by using the Error Check Code

(ECC) system. A single-bit error can be isolated down to the memory slot on which it occurred. A

multiple-bit error can be isolated down to the pair of slots on which it occurred.

When installing the first set of DIMM, install a set of 4 modules of the same size in slots 0 to 3.

At subsequent memory expansions, install a set of 4 modules of the same size in slots 4, 5, 6, 7;

and 8, 9, 10, 11; then 12, 13, 14, 15.

Checking the memory diagnostics

Tocheck that the system recognizes installed memory modules correctly, execute the

show-post-results command at the ok prompt. A module that does not satisfy any condition

described in "Memory configuration" or a module judged to be faulty by memory diagnostics is

treated as an invalid module. The screen below lists the command execution results related to

memories and their meanings.

Example for normal operation

=== Memory =========

Type : EDO

SLOT# Size[Valid(MB)/Existing(MB) Total

0-3 32/32 32/32 32/32 32/32 : 128/128 MB

4-7 32/32 32/32 32/32 32/32 : 128/128 MB

8-11 ----- ----- ----- ----- : 0/0 MB

12-15 ----- ----- ----- ----- : 0/0 MB

*=Error SLOT

In this example, a memory module has been placed in degraded mode.

=== Memory =========

Type : EDO

SLOT# Size[Valid(MB)/Existing(MB) Total

0-3 32/32 32/32 32/32 32/32 : 128/128 MB

4-7 0/32 0/0* 0/32 0/32 : 0/96 MB

8-11 ----- ----- ----- ----- : 0/0 MB

12-15 ----- ----- ----- ----- : 0/0 MB

*=Error SLOT

20

Page 55

2.4 Disk Units

Disk drive configuration

2.4 Disk Units

The denominator indicates the size of the memory module for a slot (unit: megabytes); 0* indicates

a faulty slot. The numerator indicates the size of the memory that is actually available for use. The

numerator 0 indicates that no memory is used.

In this example, DIMMs are installed in slots 0 to 7. The size of each module is 32 megabytes

except the one installed in slot 5. The initial system diagnostics detected an error in the module

installed in slot 5 and placed the module in degraded mode, assuming there was no available space.

As a result, the group of modules in slots 4 to 7 is not available for use.

When the Disk Expansion Unit (which includes an expansion disk cage) is added, up to 8 disk units

can be installed in the M200 main cabinet. Basic disk cage (bay #0-#3) is connected to UltraSCSI

bus, and the expansion disk cage (bay #0-#3) is connected to another UltraSCSI bus. Each disk

drive has two status LEDs. For the status of these LEDs, refer to 11 , "Input-Output Units."

ACTIVE LED( Green )

FAULT LED( Amber )

Expansion disk cage

POWER LED

Basic disk cage

Figure 2.5 Disk Drive Bays of M200 Main Cabinet

#0

#0

#1

#1

#2 #3

#2 #3

21

Page 56

CHAPTER 2 M200 Main Cabinet

Disk Expansion Unit

By using the Disk Expansion Unit, up to 8 disk drives can be installed in the M200 main cabinet.

The Disk Expansion Unit consists of the following components:

A Power LED is installed on the SCSI-BP board. If both ACTIVE LED and FAULT LED above a

disk bay do not lights, check to see if the POWER LED on the SCSI-BP board is turned on. If this

POWER LED does not turn on, disk expansion unit or its cable may be faulty.

When installing the Disk Expansion Unit, the installed location (slot) of the PCI card used for

connection must be set. Below shows the setting procedure.

Disk cage (including SCSI-BP)

PCI adapter (UltraSCSI Wide Single-Ended)

Expansion power supply unit (requires changing to 120-mm (4.7 inch) square fan: included)

Cables

Be sure to replace the power supply fan when installing the Disk

CAUTION

Expansion Unit. Otherwise, the system will shutdown or disk units

will deteriorate due to a temperature rise in the M200 main cabinet

caused by insufficient cooling.

1 First, execute show-scsi command at the ok prompt, to get the path name of the UltraSCSI

card and it’s PCI slot. The followings example shows that a Ultra SCSI card is installed in PCI

slot#6.

ok show-scsi

PCI#6 : /pci@1d,4000/scsi@5,1

PCI#6 : /pci@1d,4000/scsi@5

SCSI#0: /pci@1f,4000/scsi@3

ok

2 Then, set led-control-1 to correspond to the PCI slot by using setenv command at the

ok prompt. The followings example shows that a Disk Expansion Unit connection to SCSI

Conector #1 of the UltraSCSI card in PCI slot#6.

ok setenv led-control-1 /pci@1d,4000/scsi@5

If the installing location (slot) is not set or set incorrectly, the disk

CAUTION

drive may not be hot-swappable. Data may be destroyed as a

result of inadvertently replacing the different disk drive. Be sure to

set the installing location (slot) correctly.

Also, while replacing or initializing NVRAM, set the installing

location again.

22

Page 57

2.5 PCI Slots

PCI slots configuration

2.5 PCI Slots

PCI slots are located on the Systemboard as described in Figure 2.4 , and each PCI slots has the

following specifications. There are 4 separate PCI Bus channels: A, B, C, and D. All PCI slots

provide for the full 64-bit data path and can accommodate both 32-bit and 64-bit data path cards.

The specifications for the PCI slots are described in Table 2.2 .

Table 2.2 PCI Slot Specifications

PCI slot # PCI Bus Slot width / card width PCI clock Card input voltage

(bits) (MHz)

6 D

5 D

4 D

3 C

2 B

1 A

64 / 32,64 33 5 V or Universal

64 / 32,64 33 5 V or Universal

64 / 32,64 33 5 V or Universal

64 / 32,64 33 5 V or Universal

64 / 32,64 33 / 66 3.3 V or Universal

64 / 32,64 33 / 66 3.3 V or Universal

2.6 Installation

Notes on installation:

Do not block the ventilation slits.

Do not install the M200 main cabinet where it will be exposed to sunlight or sources of heat.

Do not install the M200 main cabinet in dusty places or places where it will be exposed to

corrosive gas or sea breeze.

Keep the M200 main cabinet isolated from vibration. Install the M200 main cabinet on a level

surface so that it does not tilt.

Make sure that the AC power supply source is grounded properly. Otherwise, the M200 main

cabinet may malfunction.

Do not run a cable under a unit or allow a cable to become taut. Do not disconnect the power

cable when the power is on.

Do not place anything on the M200 main cabinet. Do not use the cabinet of the M200 main

cabinet as a work space.

To prevent condensation in the M200 main cabinet, do not raise the ambient temperature

rapidly, in winter. Use the M200 main cabinet only after it has warmed up sufficiently.

Do not install the M200 main cabinet near a noise generating device such as a photocopier, air

conditioner, or welder.

Take electrostatic prevention measures. Note that some carpets generates static electricity

easily and can cause the M200 main cabinet to malfunction.

When moving the M200 main cabinet, do not pull on the front cover. Otherwise, the main

cabinet may be damaged.

23

Page 58

CHAPTER 2 M200 Main Cabinet

IMPORTANT

If the above conditions are not satisfied, the M200 main cabinet may be damaged. Be sure

to follow these precautions.

Installation specifications

Item Specification

Mass Up to 43kg (approx.94.9 lb)

Power condition Input voltage

Maximum consumption current 5.0 A

Leakage current 3.5 mA or less

Ground resistance 100ohm or less ( class C installation standard)

Temperature condition Operating 5 to 35 degrees Celsius (+41 to +95 F) (*1)

Humidity condition Operating 20 to 80%RH (no condensation)

Vibrations condition Operating 0.2 G

Noise 47 db (A) (*2)

Installation standalone type

Table 2.3 Installation Specifications of M200 Main Cabinet (1)

Single phase

100 to 120 VAC

(+-10%)

Input frequency

Not operating 0 to 50 degrees Celsius (+32 to +122F)