Page 1

FUJITSU SEMICONDUCTOR

SUPPORT SYSTEM

SS01-71060-1E

DSU-FR EMULATOR

LQFP-64P HEADER TYPE 2

MB2198-304

OPERATION MANUAL

Page 2

PREFACE

Thank you for purchasing the LQFP-64P*1 header type 2 (MB2198-304) for the DSU-FR emulator.

This product is used together with the BGA-660P adapter for the DSU-FR emulator (MB2198-

300)*

user system that uses a MB91460 series Fujitsu FR*

This manual describes how to use the LQFP-64P header type 2 for the DSU-FR emulator. Please read

the manual carefully before using. Please contact your Fujitsu sales or support representative for details on which production and evaluation MCU models can be used with this product.

*1 : The lead pitch of package (FPT-64P-M23) is 0.65mm and the body size is 14mm × 14mm.

*2 : Referred to as the “adapter”

*3 : Referred to as the “emulator”

*4 : Referred to as the “DSU cable”

*5 : FR is an abbreviation of FUJITSU RISC CONTROLLER and is a product of Fujitsu Limited.

■ Handling and usage

The handling and use of this product and notes regarding safety use are included in the hardware

manual of the DSU-FR family emulator.

Follow the instructions in for the use of this product.

2

to connect the DSU-FR emulator (MB2198-01)*3 and DSU-FR cable (MB2198-10)*4 to a

• DSU-FR EMULATOR MB2198-01 HARDWARE MANUAL

• DSU-FR EMULATOR DSU-FR CABLE MB2198-10 OPERATION MANUAL

• DSU-FR EMULATOR BGA-660P ADAPTER MB2198-300 OPERATION MANUAL

4

microcontroller (LQFP-64P)*5.

■ Caution of the products described in this manual

The following precautions apply to the product described in this manual.

CAUTION

Cuts

Damage

Damage

The wrong use of a device will give an injury and may cause malfunction on customers system.

This product has parts with sharp points that are exposed. Do not touch edge of

the product with your bare hands. There is a possibility that it may be injured.

When connect the header board to the user system, correctly position the index

mark (▲) on the NQPACK mounted on the user system with the index mark (▲)

on the header board, otherwise the emulator system and user system might be

damaged.

When mounting a mass production MCU, correctly position pin 1, otherwise the

mass production MCU and user system might be damaged.

i

Page 3

• The contents of this document are subject to change without notice.

Customers are advised to consult with FUJITSU sales representatives before ordering.

• The information, such as descriptions of function and application circuit examples, in this document are presented solely for the purpose of reference to show examples of operations and uses of FUJITSU semiconductor device; FUJITSU

does not warrant proper operation of the device with respect to use based on such information. When you develop

equipment incorporating the device based on such information, you must assume any responsibility arising out of such

use of the information. FUJITSU assumes no liability for any damages whatsoever arising out of the use of the information.

• Any information in this document, including descriptions of function and schematic diagrams, shall not be construed

as license of the use or exercise of any intellectual property right, such as patent right or copyright, or any other right

of FUJITSU or any third party or does FUJITSU warrant non-infringement of any third-party’s intellectual property

right or other right by using such information. FUJITSU assumes no liability for any infringement of the intellectual

property rights or other rights of third parties which would result from the use of information contained herein.

• The products described in this document are designed, developed and manufactured as contemplated for general use,

including without limitation, ordinary industrial use, general office use, personal use, and household use, but are not

designed, developed and manufactured as contemplated (1) for use accompanying fatal risks or dangers that, unless

extremely high safety is secured, could have a serious effect to the public, and could lead directly to death, personal

injury, severe physical damage or other loss (i.e., nuclear reaction control in nuclear facility, aircraft flight control, air

traffic control, mass transport control, medical life support system, missile launch control in weapon system), or (2)

for use requiring extremely high reliability (i.e., submersible repeater and artificial satellite).

Please note that FUJITSU will not be liable against you and/or any third party for any claims or damages arising in

connection with above-mentioned uses of the products.

• Any semiconductor devices have an inherent chance of failure. You must protect against injury, damage or loss from

such failures by incorporating safety design measures into your facility and equipment such as redundancy, fire protection, and prevention of over-current levels and other abnormal operating conditions.

• If any products described in this document represent goods or technologies subject to certain restrictions on export under the Foreign Exchange and Foreign Trade Law of Japan, the prior authorization by Japanese government will be

required for export of those products from Japan.

Copyright ©2007 FUJITSU LIMITED All rights reserved

ii

Page 4

1. Checking the Delivered Product

Before using the MB2198-304, confirm that the following components are included in the box:

• LQFP-64P header board*

1

: 1

• Screws for securing the header board (M2 × 10mm, 0.4mm pitch) : 4

• Washer s : 4

• NQPACK064SB*

• HQPACK064SB140*

2

3

: 1

: 1

• Operation manual (Japanese version) : 1

• Operation manual (English version, this manual) : 1

*1 : The YQPACK064SB is mounted on the header board (Tokyo Eletech Corporation, referred to

as the “YQPACK”).

*2 : The IC socket (manufactured by Tokyo Eletech Corporation, referred to as “NQPACK”). This

socket is supplied with a special screwdriver and 2 guide pins. Additionally, the relatively high

reliability NQPACK064SB-SL (Tokyo Eletech Corporation, sold separately) can be used by

preparing screw holes on the user system board for mounting the socket. For more information,

contact Tokyo Eletech Corporation.

*3 : The IC socket cover (manufactured by Tokyo Eletech Corporation, and referred to as “HQ-

PACK”). This cover includes 4 screws for securing HQPACK (M2 × 6mm, 0.4mm pitch).

This product is used as an emulator system by combining with an optional emulator, DSU cable and

adapter.

Consult a sales or support representative from Fujitsu Limited for details on the adapter and emulator

for this product.

2. Handling Precautions

■ Handling precautions

The header board is precision-manufactured to improve dimensional accuracy and to ensure reliable

contact. The header is therefore sensitive to mechanical shock. To ensure correct use of the header

in the proper environment, observe the following points regarding its insertion and removal:

• To avoid placing stress on the NQPACK mounted on the user system during connecting the

header board.

■ Precautions when operating on the sub clock

When using this product, the evaluation MCU cannot be supplied with a sub clock from the user system.

When the evaluation MCU is operating using the sub clock, use the sub clock on the adapter.

Refer to the operation manual for the adapter for more details.

1

Page 5

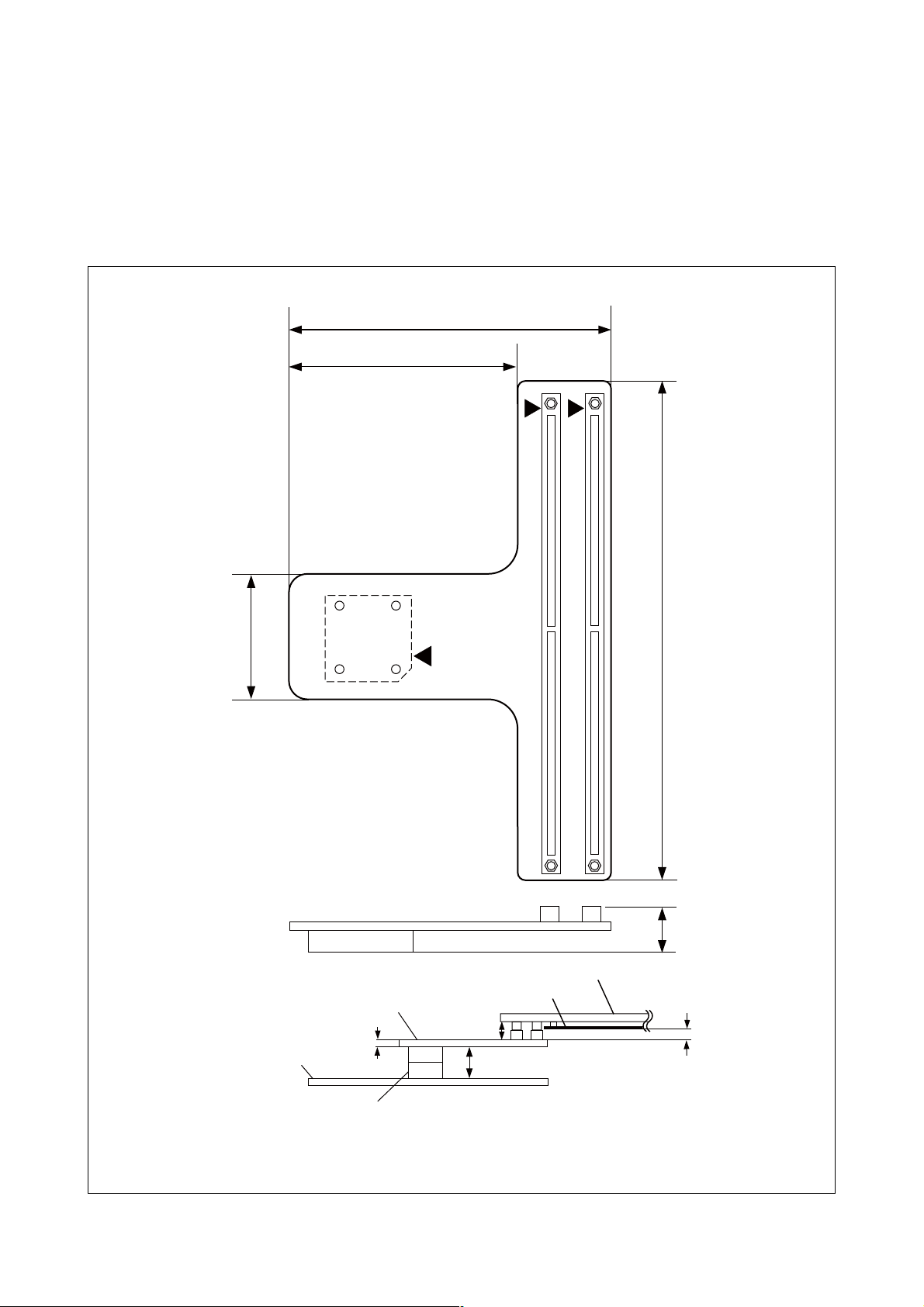

3. Notes on Designing

■ Notes on designing the printed circuit board for the user system

If the header board is connected to a user system, the heights of parts mounted around the

header board are restricted.

When designing the printed circuit board of the user system, consider the heights of components

within the range of the header board, as shown in Figure 1, so that the components mounted on the

user system do not interfere with the header board.

88.0mm

52.0mm

42.0mm

User

system

Header

1.6mm

Approx.

17.0mm*

Insulating plate

Approx.

13.0mm*

Adapter

150.0mm

23.0mm

10.0mm

NQPACK064SB

* : The height differs slightly depending on how the sockets are engaged.

Figure 1 Header board dimensions

2

Page 6

■ MCU footprint design notes

Figure 2 shows the recommended dimensions of the NQPACK footprint mounted on the printed circuit board of the user system.

The printed circuit board of the user system must be designed with due consideration given to this

footprint as well as to the mass production MCU.

For more information, contact the Tokyo Eletech Corporation.

0.65mm

1.8mm

0.65mm × 15 = 9.75mm

0.4mm

φ2.2mm*

12.0mm

2

3-φ1.0mm*

5.0mm

1

0.65mm × 15 = 9.75mm

No.1 pin

1.8mm

5.0mm

12.0mm

1.8mm

1.8mm

*1 : Position of the guide pin hole (φ1.0) when mounting the NQPACK.

These holes do not need to be fabricated if the guide pins are not used.

*2 : Position of the hole (φ2.2) for the screw for affixing the IC socket when the NQPACK064SB-SL

(Tokyo Eletech Corporation, sold separately) is mounted instead of the NQPACK064SB-SL.

This hole does not need to be fabricated if the NQPACK064SB-SL is not used.

Figure 2 Recommended dimensions of the footprint for mounting the NQPACK

3

Page 7

4. Procedure for Connecting to the User System

Before using the MB2198-304, mount the supplied NQPACK on the user system.

Connect the header board directly to the adapter. Refer to the operation manual of the adapter for

details on how to connect the adapter.

■ Connecting

1. To connect the header board to the user system, align pin 1 indicated by the index mark (▲) on

the NQPACK mounted on the user system with the index mark (▲) on the header board and then

insert it (See Figure 3) .

The YQPACK pins are thin and easy to bend. Check that the YQPACK pins are not bent before

inserting it into the NQPACK.

2. Insert each of the screws for securing the header board through a washer and into each of the four

holes in the header board. Partially tighten one of the screws with the special screwdriver supplied

with the NQPACK and then partially tighten the screw in the diagonally opposite corner. Partially

tighten the two remaining screws. Finally repeat the process making the screws equally tight.

(See Figure 4) .

Take care not to overtighten the screws as this may cause a faulty connection.

Adapter I/F connector 2

Adapter I/F connector 1

NQPACK

Index mark (▲)

YQPACK

(It mounts at the back)

Header board

Index mark (▲)

Figure 3 Index position

4

Page 8

■ Disconnection

Screws for securing

the header board

Header board

Washer

YQPACK

User system

NQPACK

Figure 4 Header board connection

To disconnect the header board from the user system, remove all four screws, and then pull the

header board straight out of the NQPACK.

5

Page 9

5. Mounting Mass Production MCUs

Use the supplied HQPACK to mount a mass production MCU on the user system.

■ Mounting

1. To mount a mass production MCU on the user system, align the index mark (▲) on the NQPACK

mounted on the user system with the index mark (●) on the mass production MCU.

2. Confirm that the mass production MCU is correctly mounted on the NQPACK, and then align the

index mark (the only corner with an angle cut-out) of the HQPACK with the index mark of the

NQPACK, and insert it (See “Figure 5”).

The HQPACK pins are thin and easy to bend. Check that the HQPACK pins are not bent before

inserting it into the NQPACK.

3. Insert each of the screws for securing the HQPACK into each of the four screw holes on the HQ-

PACK and tighten the diagonally opposite screws in turn.

To tighten the screws, use the special screwdriver supplied with the NQPACK to finally tighten

the four screws in sequence. Tightening the screws too tight might result in a defective contact.

Screws for securing

the HQPACK

■ Disconnection

HQPACK

Mass production MCU

User system

NQPACK

Figure 5 Mounting a mass production MCU

To remove the HQPACK, remove all of the four screws, and pull the HQPACK vertically out from

the NQPACK.

6

Page 10

6. Connector Pin Assignment

The signals from the evaluation MCU mounted on the adapter board are connected to the YQPACK

(the same assignments as mass production MCU) via adapter I/F connectors 1 and 2 on the header

board.

For details on the mass production MCU pins, refer to the data sheet or hardware manual of each

MCU.

■ Pin assignment

Tables 1 to 4 show the correspondence between the pin numbers for adapter I/F connectors 1 and 2,

the evaluation MCU on the adapter board, and the mass production MCU.

The following explanations apply to these tables. Row A corresponds to the side of the connector

that displays the polarity. Row B corresponds to the opposite side.

*1 : No connection. These are not connected on either evaluation MCUs or mass production MCUs.

*2 : Pin 18 on mass production MCUs is connected to pins AA38, Y37, Y36, and Y35 on evaluation

MCUs.

- : Unconnected (open) pin

: VCC

The evaluation MCU power supply pins (VCC) are as follows:

VCC=Y38, W38, W36, W35, G5, L5, AR7, AM35, H35, D8, R5, W5, AC5, AG5, AP11,

AP19, AP23, AP31, AH34, AD34, T34, H34, E32, E28, E20, E12, G4, AL4, AR31,

D32, AL5, AP7, AP15, AP27, AR7, AM34, Y34, M34, E24, E16, E8, AP33, AP29,

AP25, AP21,AP13, AA5, D15, D25, R35, AE35, AR24, P4, AP17, AP9, AN5, AJ5,

AE5, U5, N5, J5,AR14, AD4, AK34, AF34, AB34, V34, P34, K34, F34, E30, E26, E22,

E18, E14, E10, E6

The mass production MCU power supply (VCC) pin numbers are 16 and 48.

: VSS

The evaluation MCU ground pins (VSS) are as follows:

VSS = E11, E15, E19, E23, E27, E31, G34, L34, R34, W34, AA34, AE34, M5, C3, B37, T5,

Y5, AD5, AJ34, AH5, AT36, AT3, AU37, AU2, AK5, AP8, AP12, AP16, AP20, AP24,

AP28, AP30, AL34, A1, B1, AU1, AV1, AV2, AV37, AV38, AU38, B38, A38, A37,

A2, C36, D4, AR4, AR35, D35, E5, K5, P5, V5, AB5, AF5, AM5, AP5, AP6, AP10,

AP14, AP18, AP22, AP26, AP32, AP34, AN34, AG34, AC34, U34, N34, J34, E34,

E33, E29, E25, E21, E17, E13, E7

The mass production MCU ground (VSS) pin numbers are 17, 33, and 49.

7

Page 11

Table 1 Adapter I/F Connector 1 (Row A)

Connector

Pin No.

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

Connector

Pin No.

Mass Production

MCU Pin No.

Evaluation MCU

A1 VCC A51 GND

A2 VCC A52 GND

A3 - J36 A53 - C30

A4 - H37 A54 - A32

A5 - K36 A55 - C31

A6 - J35 A56 - D30

A7 - J83 A57 - B31

A8 - K35 A58 - D31

A9 - J37 A59 - B32

A10 - K38 A60 - A33

A11 GND A61 GND

A12 GND A62 GND

A13 - E38 A63 61 D28

A14 - F37 A64 62 A30

A15 - F38 A65 59 D29

A16 - G35 A66 60 C28

A17 - G38 A67 - B29

A18 - H36 A68 - C29

A19 - G37 A69 - B30

A20 - H38 A70 - A31

A21 GND A71 GND

A22 GND A72 GND

A23 - C38 A73 32 C26

A24 - D37 A74 31 A28

A25 - D38 A75 42 C27

A26 - E35 A76 41 D26

A27 - F36 A77 - B27

A28 - F35 A78 - D27

A29 - E37 A79 - A29

A30 - G36 A80 - B28

A31 GND A81 - AC38

A32 GND A82 - AB36

A33 - C34 A83 - AC36

A34 - A36 A84 - AC35

A35 - C35

A85 GND

A36 - B35 A86 - AF38

A37 - D36 A87 - AD36

A38 - B36 A88 - AE36

A39 - E36 A89 - AG38

A40 - C37 A90 - A41 GND A91 - AD3

A42 GND A92 - AC3

A43 - C32 A93 - A44 - A34

A45 - C33

A94 VCC

A95 GND

A46 - B33 A96 40 AD1

A47 - D33

A97 GND

A48 - B34 A98 - AD2

A49 - D34

A50 - A35 A100

A99 GND

NC*

1

Pin No.

8

Page 12

Table 2 Adapter I/F Connector 1 (Row B)

Connector

Pin No.

B1 - B2 - -

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

Connector

Pin No.

Mass Production

MCU Pin No.

B51 GND

B52 GND

Evaluation MCU

Pin No.

B3 - B23 B53 57 B13

B4 - A26 B54 58 A14

B5 - B24 B55 - C15

B6 - C24 B56 56 B14

B7 - B25 B57 54 B15

B8 - C25 B58 55 C16

B9 - B26 B59 - B16

B10 - A27 B60 53 A15

B11 GND B61 GND

B12 GND B62 GND

B1351C22B6322B11

B1452A24B6421A12

B1547C23B6524C13

B1650B21B6623B12

B17 45 D23 B67 13 C9

B1846B22B6812 B8

B19 43 A25 B69 - A13

B20 44 D24 B70 - D14

B21 GND B71 GND

B22 GND B72 GND

B23 - D20 B73 - B9

B24 - B20 B74 - A10

B25 - D21 B75 - C11

B26 - A21 B76 - B10

B27 - C21 B77 - D11

B28 - A22 B78 - C12

B29 - D22 B79 - D12

B30 - A23 B80 - A11

B31 GND B81 - AD38

B32 GND B82 - AA37

B33 - D18 B83 - AB37

B34 - A18 B84 - AD35

B35 - D19 B85 - AE38

B36 - B19 B86 - AC37

B37 - C19 B87 - AD37

B38 - A19 B88 - AE37

B39 - C20

B89 GND

B40 - A20 B90 - B41 GND B91 - L4

B42 GND B92 - L3

B43 26 D16 B93 - B44 25 A16

B94 VCC

B45 - C17 B95 18 *2

B46 27 D17 B96 - B47 29 C18 B97 - B48 28 B17 B98 - B49 - A17 B99 - -

B50 30 B18 B100

NC

*1

9

Page 13

Table 3 Adapter I/F Connector 2 (Row A)

Connector

Pin No.

A1 VCC A51 GND

A2 VCC A52 GND

A3 11 B7 A53 3 J1

A4 10 A8 A54 2 L2

A5 - C14 A55 5 C2

A6 - D13 A56 4 D3

A7 15 C10 A57 7 B3

A8 14 D9 A58 6 C4

A9 20 A9 A59 9 B4

A1019D10A60 8 C5

A11 GND A61 GND

A12 GND A62 GND

A13 - E2 A63 - L1

A14 - F2 A64 - N2

A15 - D1 A65 - N4

A16 - F4 A66 - N3

A17 - C1 A67 - M4

A18 - E4 A68 - M3

A19 - D2 A69 - K1

A20 - E3 A70 - M2

A21 GND A71 GND

A22 GND A72 GND

A23 - H4 A73 - N1

A24 - J4 A74 - P1

A25 - F1 A75 - R3

A26 - H2 A76 - T2

A27 - E1 A77 - P3

A28 - G2 A78 - R2

A29 - F3 A79 - M1

A30 - G3 A80 - P2

A31 GND A81 - AF37

A32 GND A82 - AF36

A33 - K3 A83 - AG36

A34 - K4 A84 - AG37

A35 - H1

A36 - K2 A86 - AK38

A37 - G1 A87 - AH36

A38 - J2 A88 - AJ36

A39 - H3 A89 - AL38

A40 - J3 A90 39 AE1

A41 GND A91 37 AE2

A42 GND A92 - A43 - D5

A44 - A3

A45 - D6

A46 - A4

A47 - C7

A48 - C6 A98 - AB38

A49 - A5

A50 - B5

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

Connector

Pin No.

A85 GND

A93 63 A6

A94 64 C8

A95 64 E9

A96 VCC

A97 GND

A99 GND

A100 GND

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

10

Page 14

Table 4 Adapter I/F Connector 2 (Row B)

Connector

Pin No.

B1 - - B51 - L37

B2 - - B52 - M38

B3 - - B53 - M37

B4 - -

B5 - R1 B55 - N35

B6 - U4 B56 - N36

B7 - V2 B57 - P35

B8 - U3 B58 - P36

B9 - U2 B59 - P38

B10 - T3 B60 - N38

B11 - R4

B12 - T4 B62 - N37

B13 GND B63 - R36

B14 GND B64 - P37

B15 - W2 B65 - R37

B16 - W3 B66 - T36

B17 - V1 B67 - T37

B18 - W4 B68 - R38

B19 - U1 B69 - T35

B20 - V4 B70 - T38

B21 - T1 B71 - U35

B22 - V3

B23 GND B73 - U37

B24 GND B74 - U36

B25 - AA1 B75 - V37

B26 - AB1 B76 - V36

B27 - Y2 B77 - V38

B28 - AA4 B78 - U38

B29 - Y1

B30 - Y4 B80 - V35

B31 - W1 B81 - AH38

B32 - Y3 B82 - AF35

B33 GND B83 - AG35

B34 GND B84 - AH37

B35 - AC1 B85 - AJ38

B36 - AC2 B86 - AH35

B37 - AB4 B87 - AJ35

B38 - AC4 B88 - AJ37

B39 - AB2

B40 - AB3 B90 38 AF2

B41 - AA2 B91 - B42 - AA3 B92 - B43 GND B93 1 D7

B44 GND B94 1 B6

B45 - L36

B46 - K37

B47 - L35

B48 - M36 B98 34 AA36

B49 - M35

B50 - L38 B100 35 AB35

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

Connector

Pin No.

B54 GND

B61 GND

B72 GND

B79 GND

B89 GND

B95 63 A7

B96 VCC

B97 GND

B99 GND

Mass Production

MCU Pin No.

Evaluation MCU

Pin No.

11

Page 15

SS01-71060-1E

FUJITSU SEMICONDUCTOR • SUPPORT SYSTEM

DSU-FR EMULATOR

LQFP-64P HEADER TYPE 2

MB2198-304

OPERATION MANUAL

February 2007 the first edition

Published FUJITSU LIMITED Electronic Devices

Edited Business Promotion Dept.

Page 16

Loading...

Loading...