Fujitsu ETERNUS DX100 S4, ETERNUS DX200 S4, ETERNUS DX60 S3, ETERNUS DX100 S3, ETERNUS DX500 S3 Configuration Manual

...Page 1

P3AM-8012-10ENZ0

FUJITSU Storage

ETERNUS DX, ETERNUS AF

Configuration Guide (Power Synchronized Unit)

ETERNUS DX S4/S3 series Hybrid Storage Systems,

ETERNUS DX60 S2/DX80 S2/DX90 S2 Disk Storage Systems,

ETERNUS AF series, ETERNUS DX200F All-Flash Arrays

Page 2

This page is intentionally left blank.

Page 3

Preface

Fujitsu would like to thank you for purchasing our power synchronized unit for the ETERNUS DX/AF storage

systems.

The power synchronized unit is a device that synchronizes power operations of the ETERNUS DX/AF storage

systems with servers.

This manual introduces the user to the power synchronized unit, and explains the regular checks and

maintenance that are required.

Please carefully review the information outlined in this manual.

This manual is designed for use with the following ETERNUS DX/AF storage systems:

• ETERNUS DX60 S4/DX100 S4/DX200 S4 Hybrid Storage Systems

• ETERNUS DX500 S4/DX600 S4 Hybrid Storage Systems

• ETERNUS DX60 S3/DX100 S3/DX200 S3 Hybrid Storage Systems

• ETERNUS DX500 S3/DX600 S3 Hybrid Storage Systems

• ETERNUS DX8100 S3/DX8700 S3/DX8900 S3 Hybrid Storage Systems

• ETERNUS DX60 S2/DX80 S2/DX90 S2 Disk Storage Systems

• ETERNUS AF250 S2 All-Flash Arrays

• ETERNUS AF650 S2 All-Flash Arrays

• ETERNUS AF250 All-Flash Arrays

• ETERNUS AF650 All-Flash Arrays

• ETERNUS DX200F All-Flash Arrays

Applicable Environment

The power synchronized unit was designed and manufactured with user safety for general office

environments in mind. When using the power synchronized unit, follow the handling instructions, placement

and cautionary notes listed in this manual. If used beyond the limits described, the users may be at risk of

personal injury and/or material damage.

Using this Manual

This manual contains important information regarding safe usage.

Please read this manual carefully before using the power synchronized unit. Pay special attention to

"

Safety Precautions" (page 9), and understand the contents thoroughly before using the power synchronized

unit. Keep this manual in a safe place for future reference.

Fujitsu pays careful attention to the safe use of its products to prevent user injury and/or material damage. To

use the power synchronized unit properly, please follow the instructions in this manual.

Tenth Edition

October 2017

3

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 4

Preface

Compliance with Standards

The power synchronized unit is compliant with the following standards.

Type Standard

Product safety UL60950-1, CSA-C22.2 No. 60950-1, EN60950-1, IEC60950-1

Electromagnetic Compatibility FCC CFR47 part 15 Class A, ICES-003 Class A, EN55022 Class A, VCCI Class A

Electromagnetic Immunity EN55024

CE certification

Environmental compliance

The power synchronized unit is designed, developed and manufactured as contemplated for general use,

including without limitation, general office use, personal use, household use, and ordinary industrial use,

but is not designed, developed and manufactured for use in situations with accompanying fatal risks or

dangers that, unless extremely high safety is secured, could lead directly to death, personal injury, severe

physical damage or other loss (hereinafter "High Safety Required Use"), including without limitation,

nuclear reaction control in nuclear facility, aircraft flight control, air traffic control, mass transport control,

medical life support system, and missile launch control in weapon systems. Do not use the power

synchronized unit for High Safety Required Use without securing the sufficient safety level required. If you

wish to use the power synchronized unit for High Safety Required Use, please consult with our sales

representative before such use.

Electromagnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

RoHS-compliant (Restriction of hazardous substances)

WEEE-compliant (Waste electrical and electronic equipment)

The company names, product names and service names mentioned in this document are registered

trademarks or trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

4

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 5

Preface

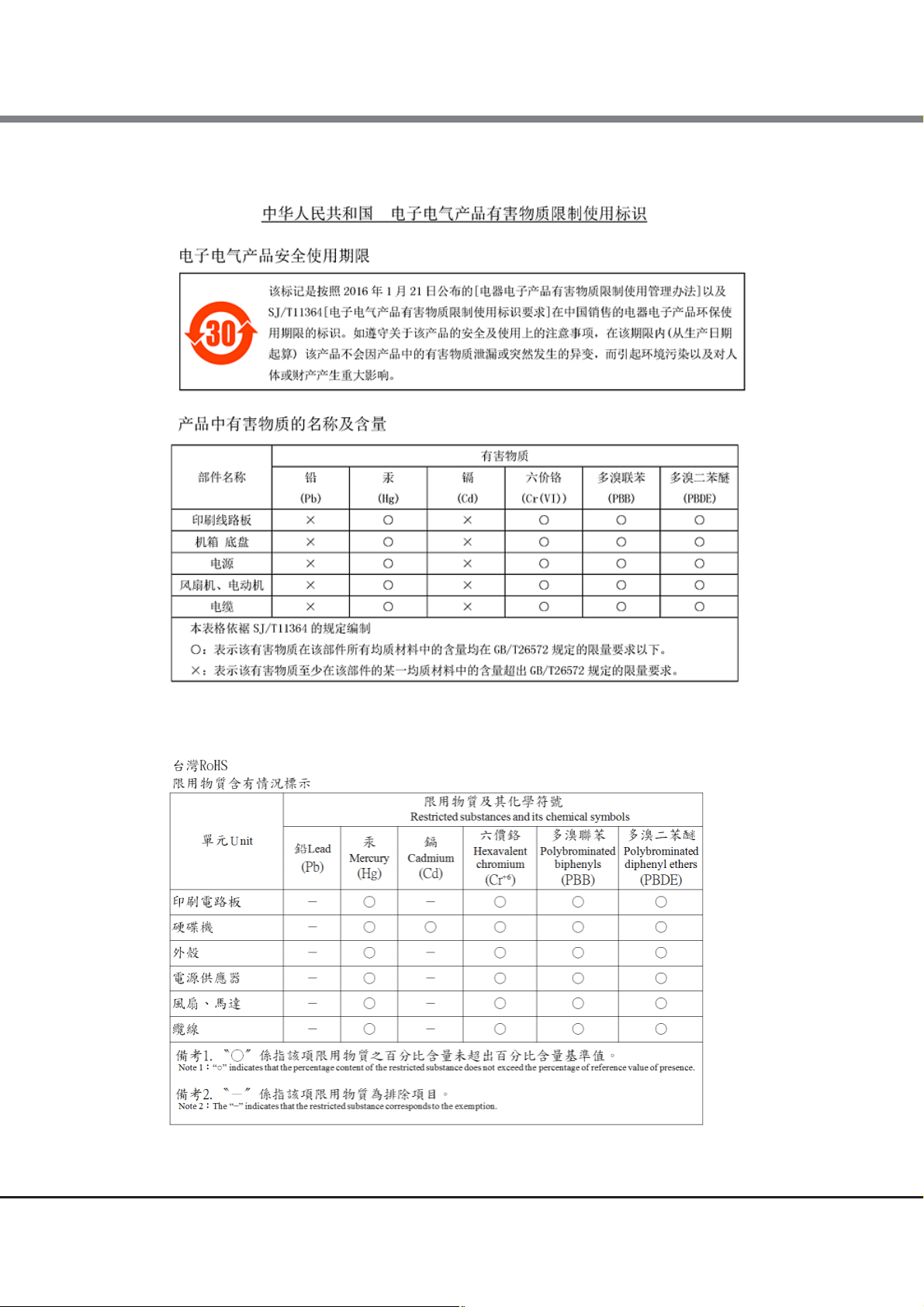

● Traditional Chinese

● Simplified Chinese

5

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 6

Organization

This manual is composed of the following six chapters:

● Chapter 1 Overview

This chapter provides overviews, features, specifications, and system configuration examples of the power

synchronized unit. The names and usage of the various components for the power synchronized unit are

also described.

● Chapter 2 Installation

This chapter describes how to install the power synchronized unit.

● Chapter 3 Powering On and Off

This chapter describes how to turn on and off the power synchronized unit.

About this Manual

● Chapter 4 Connection and Settings

This chapter describes the connection and setup procedures to operate the power synchronized unit.

● Chapter 5 Adding a Connecting Device

This chapter describes how to connect the power synchronized unit when a device is added.

● Chapter 6 Operation and Maintenance

This chapter describes how to change the configuration and appropriate responses for any problems that

may occur.

Read this chapter when operating or performing maintenance on the power synchronized unit, or if an

error occurs.

Refer to the manuals for each peripheral concerning details not included in this manual.

6

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 7

About this Manual

WARNING

CAUTION

Electric Shock

No Disassembly

Unplug

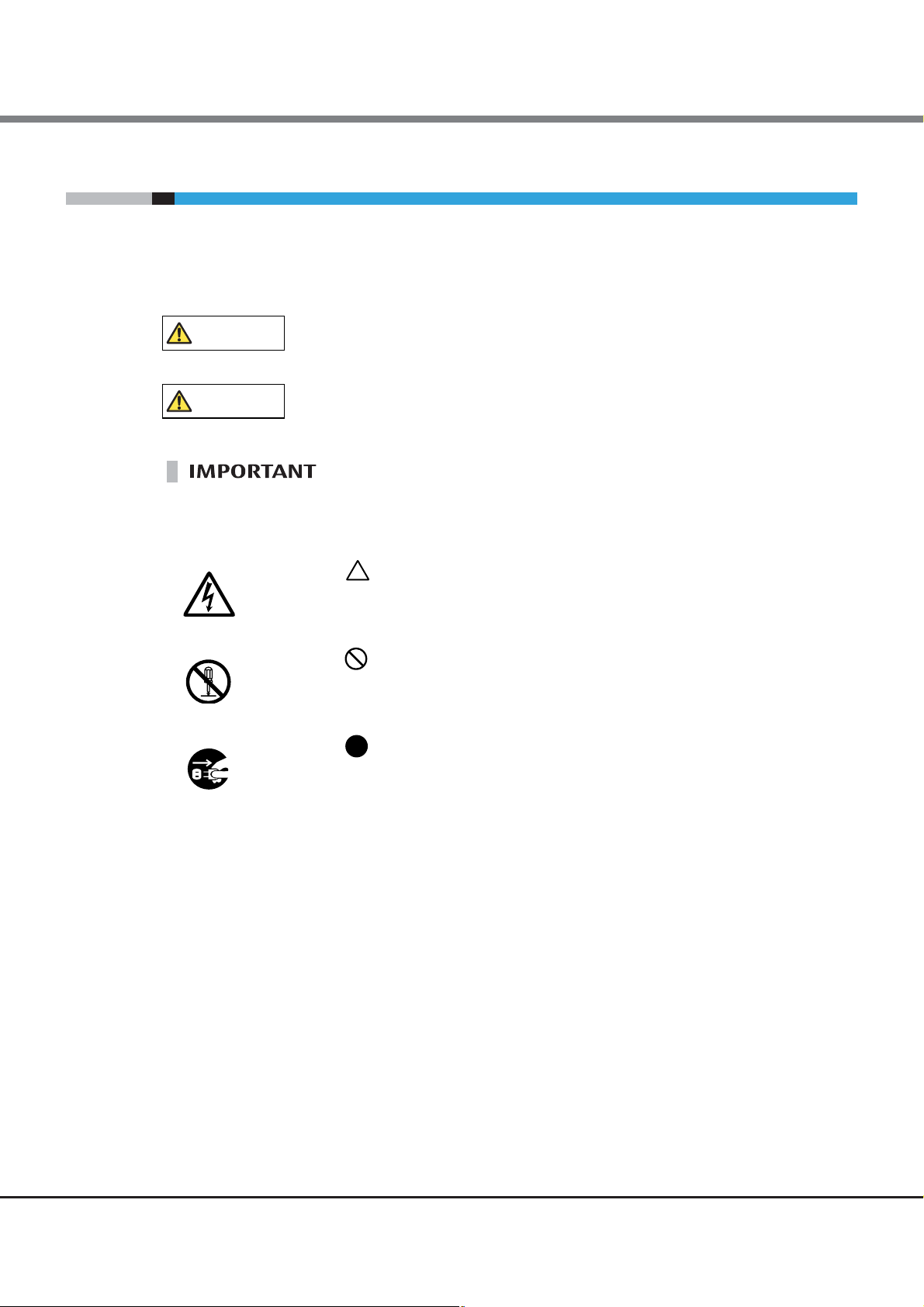

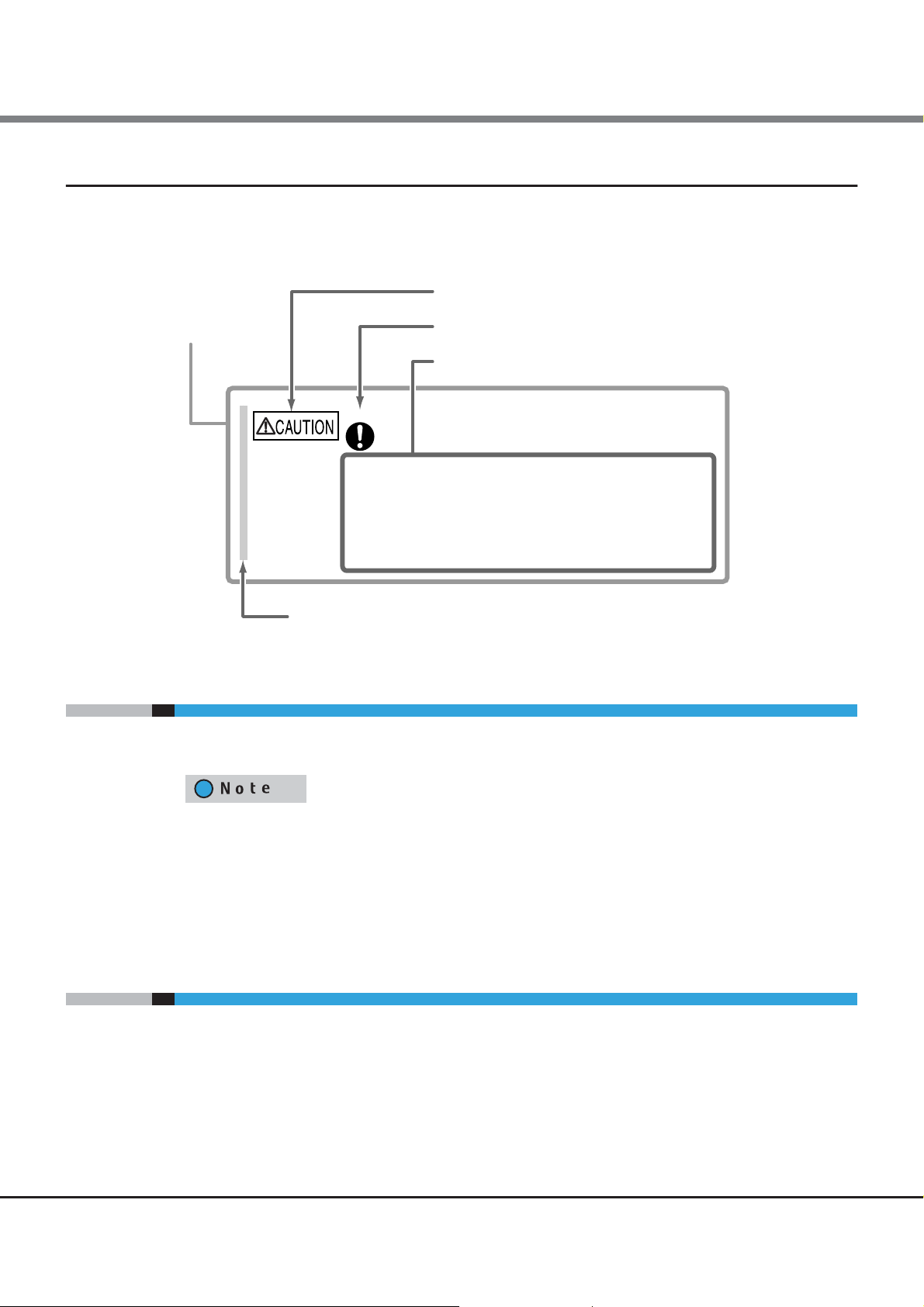

Warning Notations

Warning signs are shown throughout this manual in order to prevent injury to the user and/or material

damage. These signs are composed of a symbol and a message describing the recommended level of caution.

The following section explains the symbols, their levels of caution, and their meanings as used in this manual.

This symbol indicates the possibility of serious or fatal injury if the power

synchronized unit is not used properly.

This symbol indicates the possibility of minor or moderate personal injury, as

well as damage to the power synchronized unit and/or to other users and their

property, if the power synchronized unit is not used properly.

This symbol indicates IMPORTANT information for the user to note when using

the power synchronized unit.

The following symbols are used to indicate the type of warnings or cautions being described.

The triangle emphasizes the urgency of the WARNING and CAUTION

contents. Inside the triangle and above it are details concerning the symbol

(e.g. Electric Shock).

The barred "Do Not..." circle warns against certain actions.

The action which should be avoided is both illustrated inside the barred circle

and written above it (e.g. No Disassembly).

The black "Must Do..." circle indicates actions that must be taken.

The required action is both illustrated inside the black circle and written above

it (e.g. Unplug).

7

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 8

About this Manual

Warning Level Indicator

Warning Type Indicator

Warning Details

•

To avoid damaging the power synchronized unit, pay

attention to the following points when cleaning the power synchronized

unit.

Make sure to disconnect the power when cleaning.Be careful that no liquid seeps into the power synchronized unit

when using cleaners, etc.

-

Do not use alcohol or other solvents thinners to clean the

power synchronized unit.

-

Warning Layout Ribbon

Example Warning

Do

How Warnings are Presented in this Manual

A message is written beside the symbol indicating the caution level. This message is marked with a vertical

ribbon in the left margin, to distinguish this warning from ordinary descriptions.

An example is shown here.

Symbols Used in this Manual

About the Latest Version of this Manual and Contact Details

• The following symbol is used throughout this manual:

Functions and know how which can be useful when setting up or operating the

power synchronized unit.

• "ETERNUS DX/AF" refers to the ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4,

ETERNUS DX60 S3/DX100 S3/DX200 S3, ETERNUS DX500 S3/DX600 S3, and ETERNUS DX8100 S3/DX8700 S3/

DX8900 S3 Hybrid Storage Systems; the ETERNUS DX60 S2/DX80 S2/DX90 S2 Disk Storage Systems; and

the ETERNUS AF250 S2/AF650 S2, ETERNUS AF250/AF650 and ETERNUS DX200F All-Flash Arrays in this

manual.

The information in this manual is subject to change without notice for improvement and functionality

expansion of the power synchronized unit.

The latest version of this manual and important service and support contacts (see "Contact Fujitsu") for Fujitsu

Customer Service in your country of purchase is available at the following website:

http://www.fujitsu.com/global/support/products/computing/storage/disk/manuals/manual.html

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

8

Page 9

Safety Precautions

WARNING

Do Not

Unplug

This section describes safety precautions.

Make sure to follow the instructions described below to ensure the safe use of the power synchronized unit.

■ If you detect an unusual occurrence during operation

• If the power cord and/or power plug is damaged, do not use the power

synchronized unit and contact your sales representative or your maintenance

engineer. Never attempt to repair the power synchronized unit by yourself. Not

doing so may cause electric shock or fire.

• If the power synchronized unit overheats, gives off smoke or an unusual odor,

makes an unusual sound, or shakes abnormally, immediately disconnect the

power plug from the socket. After the problem has subsided, contact your

sales representative or your maintenance engineer. Never attempt to repair

the power synchronized unit by yourself. Not doing so may cause electric

shock or fire.

• If any liquids such as water or foreign objects like metal fragments get into the

power synchronized unit, immediately disconnect the power plug from the

socket. Then, contact your sales representative or your maintenance engineer.

Do not attempt to repair the power synchronized unit by yourself. Doing so

may cause electric shock or fire.

• If the power synchronized unit is dropped or covers are damaged, immediately

disconnect the power plug from the socket. Then, contact your sales

representative or your maintenance engineer. Do not attempt to repair the

power synchronized unit by yourself. Doing so may cause electric shock or fire.

9

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 10

Safety Precautions

WARNING

Do Not

Unplug

CAUTION

Do Not

■ Instructions for installation

• Do not place the power synchronized unit in an area with bad ventilation or

where anything that may cause a fire, or flammable gases are generated.

Doing so may cause a fire and damage the power synchronized unit.

• Do not place the power synchronized unit in locations subject to oil smoke,

steam, humidity and dust, or in places where the power synchronized unit

may come into contact with water. Doing so may lead to electric shock, fire,

and/or damage the power synchronized unit.

• Do not place any objects containing water such as vases and cups on or near

the power synchronized unit. Doing so may cause water to get into the power

synchronized unit and lead to electric shock, fire, and/or damage the power

synchronized unit.

• Do not place the power synchronized unit on an unstable floor. Doing so may

cause the power synchronized unit to fall, resulting in injury or damage to the

power synchronized unit.

• Do not connect power cords or any other cables to the power synchronized unit

during thunderstorms. Doing so may lead to electric shock and/or fire.

• When the power synchronized unit is installed or moved, disconnect the power

plug from the socket. Remove all the connected cables. Watch your step during

the operation. Not doing so may damage the power cords and cause electric

shock or fire. Failure to do so may also cause the power synchronized unit to

fall and injure others.

• Do not use the power synchronized unit in an area affected by corrosive gas or

in a salty environment. Doing so may cause device failure.

• Do not knock or place heavy objects on the power synchronized unit or

optional products. Doing so may cause injury or damage the power

synchronized unit.

10

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 11

Safety Precautions

CAUTION

Do Not

Do

WARNING

No Disassembly

Do Not

• Do not place the power synchronized unit in areas with strong magnetic fields,

such as in the vicinity of TVs or speakers. Doing so may damage the power

synchronized unit and cause the power synchronized unit to malfunction.

• Do not place power cords and other cables in locations where they may

become trip hazards. Doing so may cause injury or damage the power

synchronized unit .

• Do not place the power synchronized unit on a slanted or unstable surface or

in areas that tend to shake. Doing so may cause it to tip over and injure

others. Also, do not place the power synchronized unit in high traffic areas

such as in a hallway. Passersby can shake the unit, damage it or cause malfunction.

• Place the power synchronized unit in an environment in which the

temperature and humidity satisfy the environmental conditions described in

"1.3

Specifications" (page 23).

- For 24-hour operation, ensure that the schedule for air conditioning is able

to maintain the required temperature. Failure to do so may result in

damage to the device.

- During the winter, control the heating system to limit ambient

temperature rises to less than 15C per hour to prevent condensation.

Failure to do so could lead to electric shock and damage the power

synchronized unit.

■ Handling the power synchronized unit

• Do not attempt to repair, disassemble, or remodel the power synchronized

unit by yourself. Doing so may cause electric shock or fire.

• Do not use a voltage other than that indicated. Doing so may cause electric

shock or fire.

11

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 12

Safety Precautions

WARNING

Do Not

Do

• Do not handle the power plug with wet hands. Doing so may cause electric

shock.

• Do not wind power cords too tightly at the root of the power cord. Doing so

stresses the cords and may expose or snap the inner wires, which can lead to

electric shock or fire.

• Do not damage or modify the power cord or the power plug. Heating, forced

bending, twisting, pulling, or placing heavy objects on the power cord or the

power plug will damage it, causing electric shock or fire.

• Do not plug all the power cords into a single outlet. Doing so may cause

electric shock or fire.

• Do not use a power cord that does not satisfy the specifications of the power

synchronized unit and the AC sensor unit. Doing so may cause electric shock,

fire, or device failure.

• Do not use any products other than the optional products for the power

synchronized unit. Doing so may cause electric shock, fire, or device failure.

• Do not insert or drop foreign objects such as metals or flammable objects into

openings in the power synchronized unit such as air vents. Doing so may

cause electric shock, fire, or device failure.

• Do not obstruct the openings in the power synchronized unit such as air vents.

Doing so may cause overheating that leads to fire and device failure.

• Do not use any flammable type cleaning sprays. Doing so may cause fire or

device failure.

• Use only power sockets that have a ground. Failure to do so may cause electric

shock, fire, or malfunction.

• Disconnect the power plug from the socket during thunderstorms. Failure to

do so may lead to electric shock, fire, or device failure.

• Ensure the power plug is fully inserted into the socket. Failure to do so may

cause electric shock or fire.

12

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 13

Safety Precautions

WARNING

Do

Do Not Wet

Unplug

CAUTION

Do Not

Do

• Install optional products for the power synchronized unit by following the

instructions described in this manual. If an optional product is installed in any

other way, device failure or electric shock may occur.

• Do not pour or spill water on the power synchronized unit. Doing so may cause

electric shock, fire, or device failure.

• When unplugging the power plug, do not pull on the cable, hold the plug.

Pulling the cable may expose or snap the inner wires, which can lead to

electric shock or fire.

• Use a dry cloth to remove all dust from plugs and sockets. Not doing so may

cause electric shock or fire.

• When the power synchronized unit is not used for a long period of time,

unplug all power plugs. Failure to do so may lead to fire.

• When the power synchronized unit is pulled out from the rack, make sure not

to hit your head if you are operating devices under the power synchronized

unit. Not doing so may cause injury.

• Do not put your finger into the inlet/outlet. Doing so may cause injury or

device failure.

• Do not remove the cover from the power synchronized unit inlet/outlet unless

necessary. Doing so may cause device failure.

• Do not use devices such as mobile phones that emit radiation in the vicinity of

the power synchronized unit. Doing so may cause malfunction.

• Before applying insecticides for pest control, turn off the power synchronized

unit and cover it with a plastic sheet. Not doing so may damage the power

synchronized unit.

13

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 14

Safety Precautions

CAUTION

Do

CAUTION

Do

■ Instructions for rack installation

• Note the following points when cleaning the power synchronized unit. Failure

to do so may cause device failure.

- Make sure the power synchronized unit is turned off.

- Do not allow liquids such as cleaner to get into the power synchronized

unit.

- Never use organic solvents such as alcohol or thinner to clean the power

synchronized unit.

• Especially for an enclosed rack with doors, or when multiple devices are to be

mounted and running, it is important to realize that the temperature inside

the cabinet will be considerably higher than that of the room. Make sure the

rack internal ambient temperatures do not exceed the environmental

conditions for temperature described in "1.3

to do so may damage the power synchronized unit.

• When installing the power synchronized unit with other devices into the same

rack, the airflow of the device installed on and under the power synchronized

unit may interfere with each other and reduce the effect of device cooling.

Make sure to leave plenty of room between the devices if required. Failure to

do so may damage the power synchronized unit and lead to malfunction.

• When installing the power synchronized unit in a rack, be careful not to pinch

your fingers in the rack. Doing so may cause injury.

• Install the blank panels provided with the rack where no other devices are

installed. Failure to do so may cause the power synchronized unit to overheat,

resulting in damage to the device.

• When moving the rack after installing the power synchronized unit, make sure

to contact your sales representative or your maintenance engineer. Do not

move the rack by yourself. Doing so may cause injury and/or damage the

power synchronized unit.

Specifications" (page 23). Failure

14

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 15

Safety Precautions

CAUTION

Do Not

Do

90

Do not bend

more than 90 degrees

Do not fold

■ Handling cables

• Do not damage or modify the cables such as heating, forced bending,

twisting, pulling, or placing heavy objects on them. Doing so may damage the

cables and cause the power synchronized unit to malfunction.

• Do not forcibly bend or fold the cable. Doing so may damage the cable and

cause the power synchronized unit to malfunction.

• Firmly insert cable connectors into inlets, outlets, or sockets. Failure to do so

may cause the power synchronized unit to malfunction.

• When inserting or removing the cable, only hold the connector. Do not hold

the cable. Doing so may damage the cable and cause the power synchronized

unit to malfunction.

• Remove any dirt, dust, oil, grease, etc on cable connectors. Failure to do so

may cause the power synchronized unit to malfunction.

15

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 16

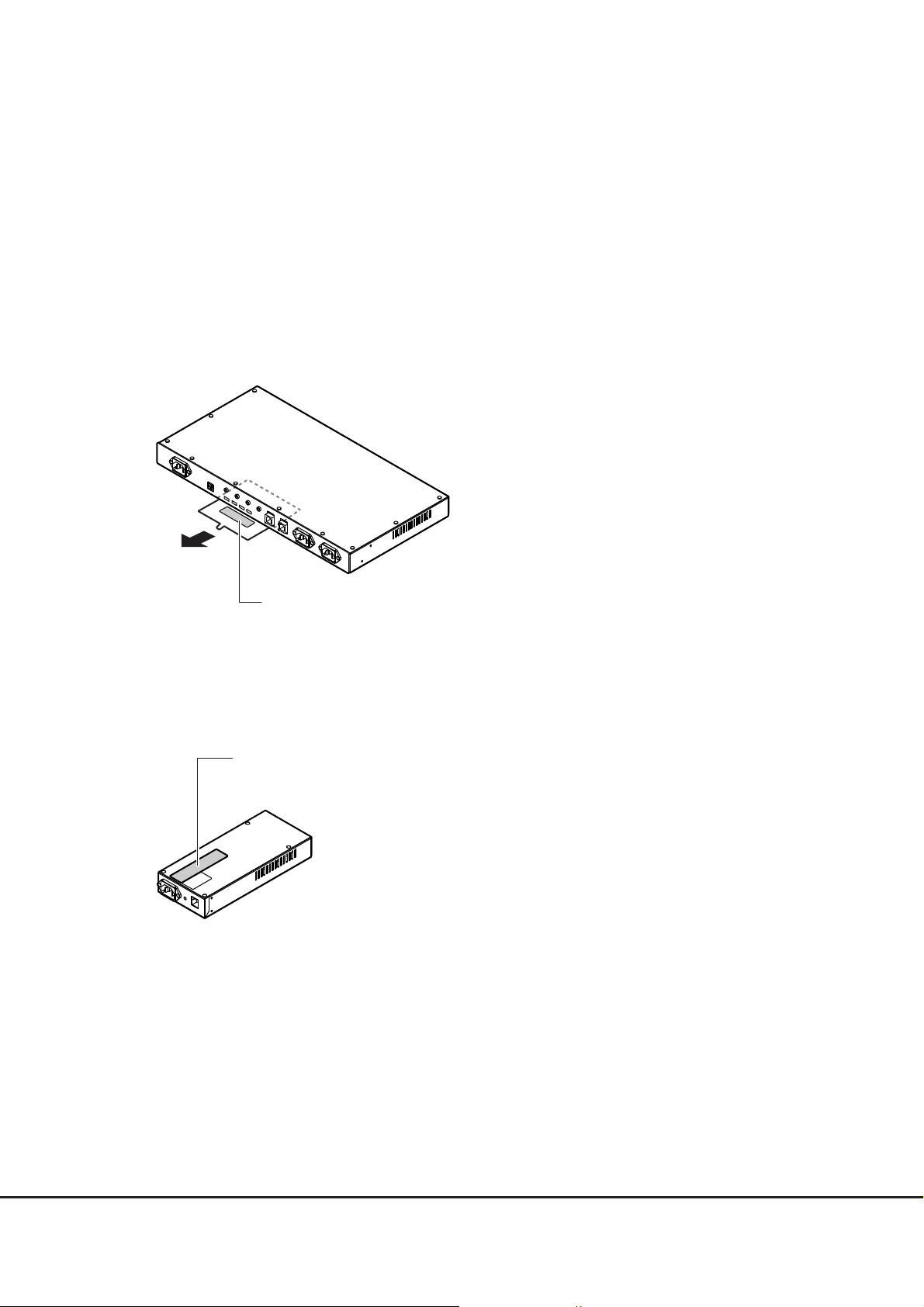

Labels

Manufacturer’s label

Indicates the model, serial number, etc.

This label is attached to the plate in the label holder

on the bottom of the power synchronized unit.

It can be checked by pulling out the plate

when the power synchronized unit is installed in a rack.

Manufacturer’s label

Indicates the model, serial number, etc.

Warning labels and manufacturer's labels are found in various places of the power synchronized unit, as

shown in the example below.

Never remove these labels from the equipment or allow them to become dirty.

■ Power synchronized unit

■ AC sensor unit

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

16

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 17

Table of Contents

Chapter 1 Overview 21

1.1 External View .................................................................................................................... 21

1.2 Features ............................................................................................................................ 22

1.3 Specifications .................................................................................................................... 23

1.4 Components ...................................................................................................................... 24

1.4.1 Power Synchronized Unit ...............................................................................................................................24

1.4.2 AC Sensor Unit (Optional) .............................................................................................................................. 26

1.5 System Configuration ........................................................................................................27

1.6 Power Management for Power Synchronization ................................................................ 29

Chapter 2 Installation 33

2.1 Package Contents Check ................................................................................................... 33

2.2 Preparation ....................................................................................................................... 34

2.2.1 Installation Area ............................................................................................................................................ 34

2.2.2 Checking Power Sockets and Server UPS Unit Outlets .................................................................................... 34

2.2.3 Preparing Power Cords ...................................................................................................................................34

2.3 Installing in a Rack ........................................................................................................... 35

2.3.1 Installing a Power Synchronized Unit ............................................................................................................ 36

2.3.2 Installing an AC Sensor Unit ........................................................................................................................... 39

Chapter 3 Powering On and Off 43

Chapter 4 Connection and Settings 44

4.1 Setting the ETERNUS DX/AF ............................................................................................... 45

4.2 Turning on the Power Synchronized Unit .......................................................................... 50

4.3 Connecting Cascade Cables ............................................................................................... 53

4.4 Connecting to the Server UPS Unit ....................................................................................56

4.4.1 Connecting the Server UPS Unit to the Power Synchronized Unit ................................................................... 57

4.4.2 Connecting the AC Sensor Unit ...................................................................................................................... 58

4.5 Connecting to the ETERNUS DX/AF .................................................................................... 61

17

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 18

Table of Contents

4.6 Checking after Connection ................................................................................................64

Chapter 5 Adding a Connecting Device 65

5.1 Connection Procedure When Adding a Server ................................................................... 65

5.2 Connection Procedure When Adding an ETERNUS DX/AF ................................................... 67

Chapter 6 Operation and Maintenance 71

6.1 Checking the Power Synchronized Unit Status .................................................................. 71

6.2 Device Replacement After Operation Startup .................................................................... 71

6.2.1 Replacing a Server .........................................................................................................................................71

6.2.2 Replacing a Power Synchronized Unit ............................................................................................................ 72

6.2.3 Replacing an AC Sensor Unit .......................................................................................................................... 72

6.3 Troubleshooting ................................................................................................................ 73

6.3.1 Check List ...................................................................................................................................................... 73

6.3.2 Trouble Record ............................................................................................................................................... 76

18

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 19

List of Figures

Figure 1.1 External view of a power synchronized unit ................................................................................................ 21

Figure 1.2 External view of an AC sensor unit .............................................................................................................. 21

Figure 1.3 Components (power synchronized unit)...................................................................................................... 24

Figure 1.4 Components (AC sensor unit) ...................................................................................................................... 26

Figure 1.5 System configuration example (power synchronization with two server UPS units) .................................... 27

Figure 1.6 System configuration example (power synchronization with three or more server UPS units) .................... 28

Figure 1.7 Power on using a power synchronized unit ................................................................................................. 29

Figure 1.8 Operation timing chart when using a power synchronized unit (powering on) ........................................... 30

Figure 1.9 Power off using a power synchronized unit ................................................................................................. 31

Figure 1.10 Operation timing chart when using a power synchronized unit (powering off) ........................................... 32

Figure 4.1 ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4,

ETERNUS DX60 S3/DX100 S3/DX200 S3, ETERNUS DX500 S3/DX600 S3,

ETERNUS DX8100 S3, ETERNUS AF250 S2/AF650 S2, ETERNUS AF250/AF650, and

ETERNUS DX200F setup (Setup Power Management screen)....................................................................... 45

Figure 4.2 ETERNUS DX8700 S3/DX8900 S3 setup (Setup Power Management screen)................................................ 47

Figure 4.3 ETERNUS DX80 S2/DX90 S2 setup (Setup Power Management screen)........................................................ 48

Figure 4.4 ETERNUS DX60 S2 setup (Setup Power Management screen)...................................................................... 49

Figure 4.5 Cascade cable connection............................................................................................................................ 53

Figure 4.6 Connection for the server UPS units and the AC sensor units....................................................................... 56

Figure 6.1 Trouble record ............................................................................................................................................. 76

19

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 20

List of Tables

Table 1.1 Specifications .............................................................................................................................................. 23

Table 1.2 Status and meanings of each LED (for power synchronized units) .............................................................. 25

Table 1.3 Status and meanings of each LED (for AC sensor units)............................................................................... 26

Table 2.1 List of package contents (power synchronized unit).................................................................................... 33

Table 2.2 List of package contents (AC sensor unit).................................................................................................... 33

20

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 21

Chapter 1

Overview

This chapter provides external views, features, specifications, and system configuration examples of the

power synchronized unit and the AC sensor unit (optional). The names and usages of the various components

of the power synchronized unit and the AC sensor unit are also described.

1.1 External View

Figure 1.1 and Figure 1.2 show the external views of the power synchronized unit and the AC sensor unit.

■ Power synchronized unit

Figure 1.1 External view of a power synchronized unit

■ AC sensor unit

Figure 1.2 External view of an AC sensor unit

21

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 22

Chapter 1 Overview

1.2 Features

1.2 Features

This section explains the features of the power synchronized unit and the AC sensor unit.

• Powering the ETERNUS DX/AF on and off can be synchronized with a server by connecting to the

Uninterruptible Power Supply (UPS) unit to which the server is connected.

As well as the UPS unit to which the server is connected (referred to as "server UPS unit" in the remainder of

this manual), the power synchronized unit can be connected to a unit that can control the output of an AC

outlet.

• The sizes of the power synchronized unit and the AC sensor unit are 1U. These units can be installed in a

19-inch rack for the server or the ETERNUS DX/AF.

• Two server UPS units can be connected to manage power synchronization in a standard configuration. By

adding an AC sensor unit, up to 16 server UPS units can be connected.

• By serially connecting each AC sensor unit, the distance between a server UPS unit and a power

synchronized unit can be extended by up to 100m.

• By cascading power synchronized units, the power of up to eight ETERNUS DX/AF storage systems can be

controlled.

• A redundant configuration is available by using two power synchronized units.

• Power synchronization starts when the power synchronized unit is connected to the server UPS unit and

the ETERNUS DX/AF by cables. Connection procedures can be performed while the server UPS unit and the

ETERNUS DX/AF are operating.

• The status of the power synchronized unit and the status of the AC power output from the server UPS unit

are displayed on the LED. If an error occurs, tracking the error and error recovery can be performed based

on the LED information.

22

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 23

Chapter 1 Overview

1.3 Specifications

1.3 Specifications

Table 1.1 shows the specifications of the power synchronized unit and the AC sensor unit.

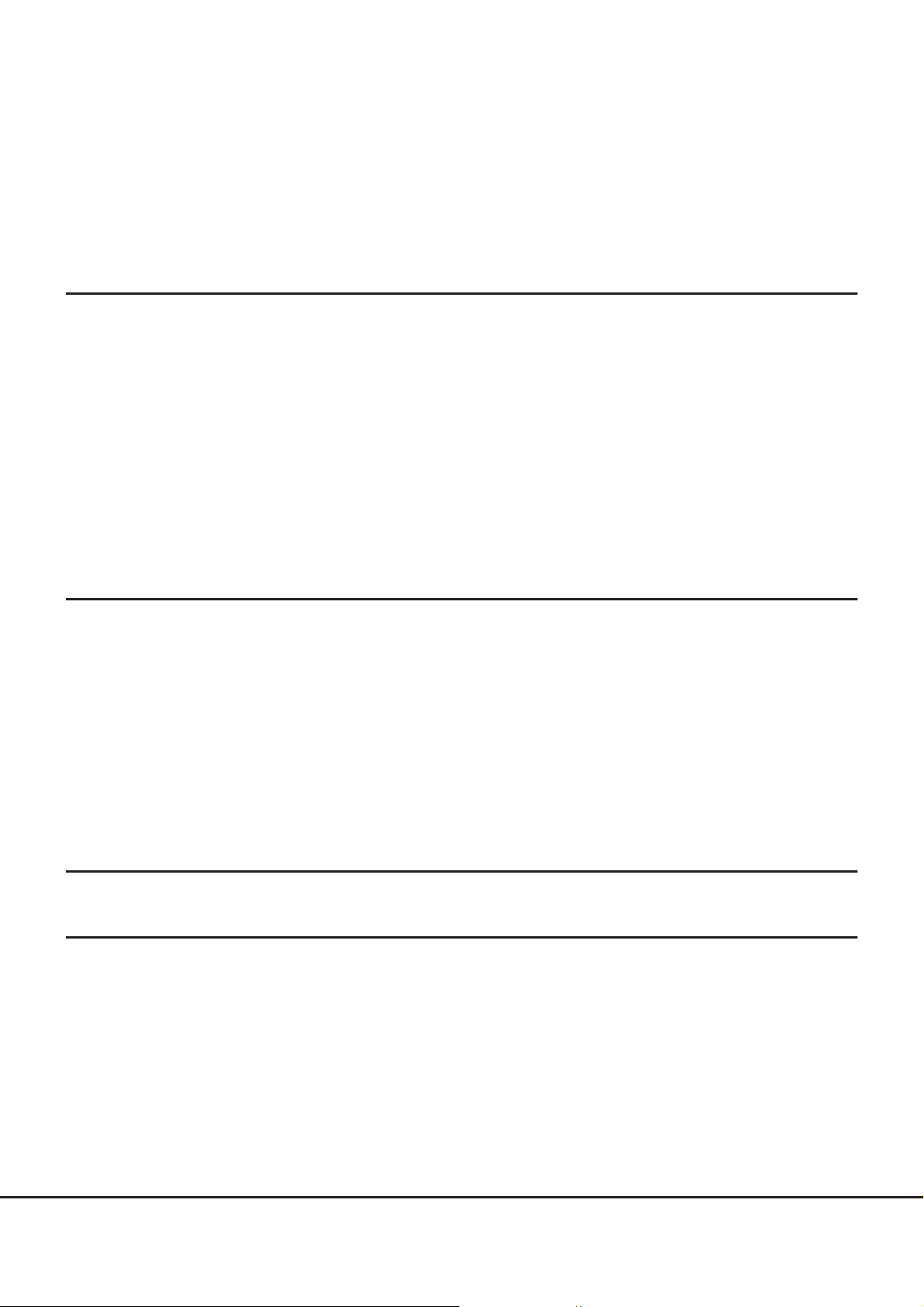

Table 1.1 Specifications

Dimensions (W D H)

Weight

Power

Maximum power requirements

Maximum heat generation

Connection interface

Server UPS unit

Number of

connectable

devices

ETERNUS DX/AF

Cable length

Conditions to detect AC output

Support for a duplicated configuration Yes

Environmental condition

Item Specifications

Power synchronized unit 440 230 40 (mm) [1U]

AC sensor unit 100 150 40 (mm) [1U]

Power synchronized unit 4.0kg

AC sensor unit 1.3kg

Voltage AC100 - 120V, AC200 - 240V

Phase Single

Frequency 50Hz/60Hz

AC100 - 120V 3W

AC200 - 240V 7W

AC100 - 120V 11kJ/h

AC200 - 240V 26kJ/h

For ETERNUS DX/AF storage systems RS232C 4

For AC detection AC sensor 2

Basic 2

Maximum (when AC sensor units

are connected)

Basic 4

Maximum (when a cascade

connection is used)

Between a power synchronized unit

and an AC sensor unit (total)

Between a power synchronized unit

and the ETERNUS DX/AF

Between power synchronized units Max. 10m

Power consumption

Voltage AC100V / AC200V

Phase Single

Temperature

Humidity

0.1A or less AC output for one second or

5 - 40C (during operation)

0 - 50C (during non-operation)

20 - 80%RH (during operation)

8 - 80%RH (during non-operation)

16

8

Max. 100m

Max. 5m

more is detected.

23

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 24

Chapter 1 Overview

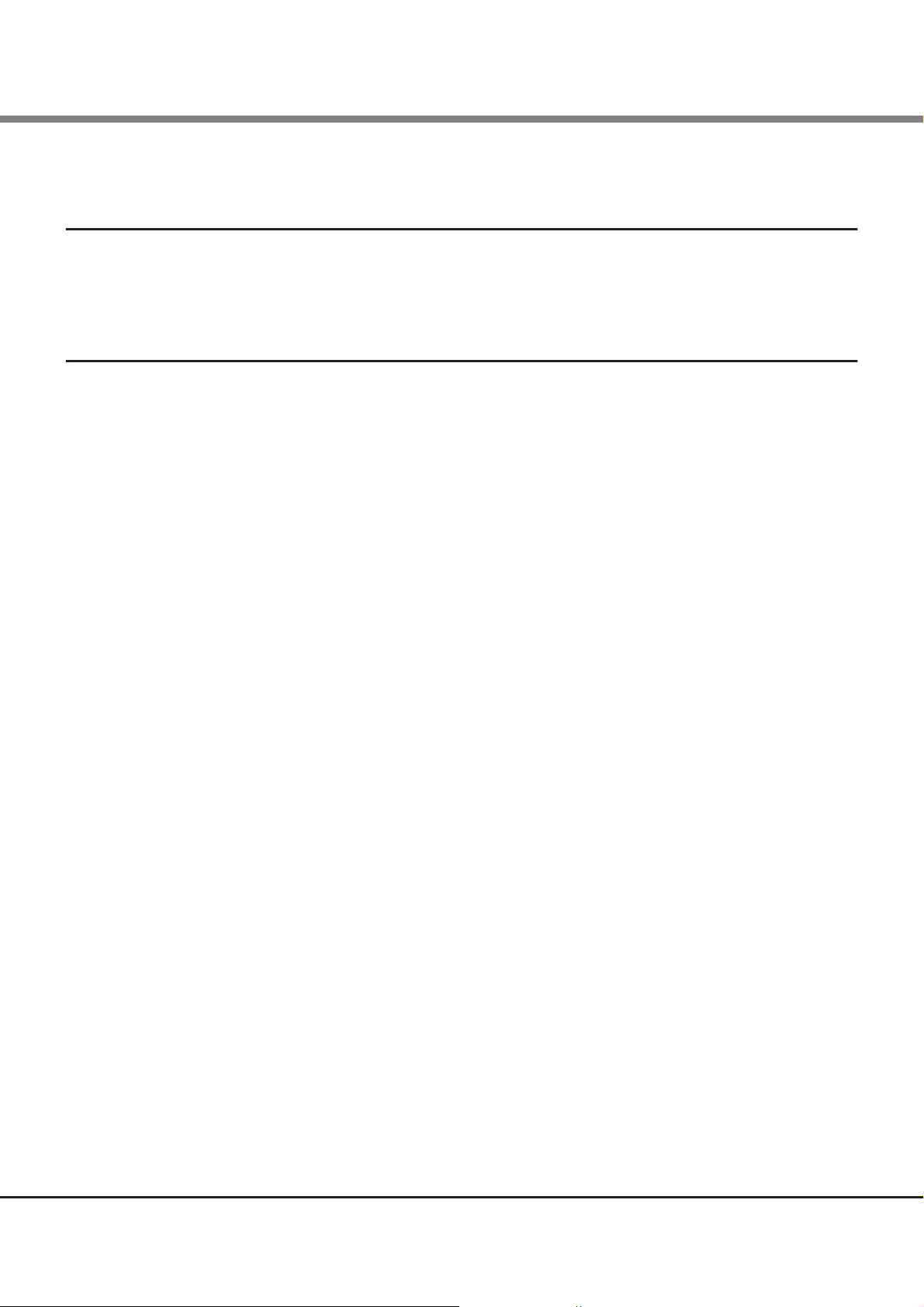

AC IN port

For power cord (for AC power input) connection

RCI port

Not used

PWC ports (#0, #1, #2, #3 from left)

For ETERNUS DX/AF connection with

RS232C cables to a power synchronized unit

AC SENSOR port

- For AC sensor unit connection

with an AC sensor port connection cable

to a power synchronized unit

- For cascading two power synchronized units

with a cascade cable to the AC SENSOR port

on the second power synchronized unit

CASCADE port

For cascading two power synchronized units

with a cascade cable to the CASCADE port

on the first power synchronized unit

SENSOR ports (left: #0, right: #1)

For power cord (for AC sensor) connection

to detect the power status of a server UPS unit

POWER LED

Displays the power status of a power synchronized unit

POWER SENSOR LED

Displays the detection status of AC output from

a server UPS unit

POWER CONTROL LED

Displays the power status of the connected ETERNUS DX/AF

CHECK LED

Displays the starting status of a power synchronized unit

1.4 Components

1.4 Components

This section describes the names and usage of the various components for the power synchronized unit and

the AC sensor unit.

1.4.1 Power Synchronized Unit

Figure 1.3 shows the names and usage of the various components for the power synchronized unit.

Figure 1.3 Components (power synchronized unit)

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

24

Page 25

Chapter 1 Overview

1.4 Components

Table 1.2 shows details about LEDs and the status of a power synchronized unit.

Table 1.2 Status and meanings of each LED (for power synchronized units)

LED name Function

POWER

(green)

POWER

SENSOR

(green)

POWER

CONTROL

(green)

CHECK

(Yellow)

Displays the power

status of the power

synchronized unit.

Displays that the power

synchronized unit has

commanded the

ETERNUS DX/AF to turn

on or off.

Displays the power

status of the ETERNUS

DX/AF.

Displays the starting

status of the power

synchronized unit.

LED

status

(off)

(on)

(blinks)

(off)

(on)

(off)

(on)

(blinks)

(off)

(on)

Power synchronized unit status

The power synchronized unit is off.

After the power synchronized unit is turned on, the

following condition for powering on the ETERNUS DX/AF is

detected.

• AC output from server UPS units using the SENSOR

port, the AC SENSOR port, or the CASCADE port

• Even though the power synchronized unit is turned on,

the following condition for powering on the ETERNUS

DX/AF is not detected.

- AC output from server UPS units using the SENSOR

port, the AC SENSOR port, or the CASCADE port

• The power synchronized unit is starting up.

The following condition is not detected and the power

synchronized unit commands the ETERNUS DX/AF to turn

off.

• AC output from server UPS units using the SENSOR

port, the AC SENSOR port, and the CASCADE port

The following condition is detected and the power

synchronized unit commands the ETERNUS DX/AF to turn

on.

• AC output from server UPS units using the SENSOR

port, the AC SENSOR port, or the CASCADE port

All of the ETERNUS DX/AF storage systems are off.

The ETERNUS DX/AF is on.

The ETERNUS DX/AF is still on even after the power

synchronized unit commands the ETERNUS DX/AF to turn

off (such as when shutting down the ETERNUS DX/AF).

The power synchronized unit is operating normally.

The power synchronized unit is starting up.

25

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 26

Chapter 1 Overview

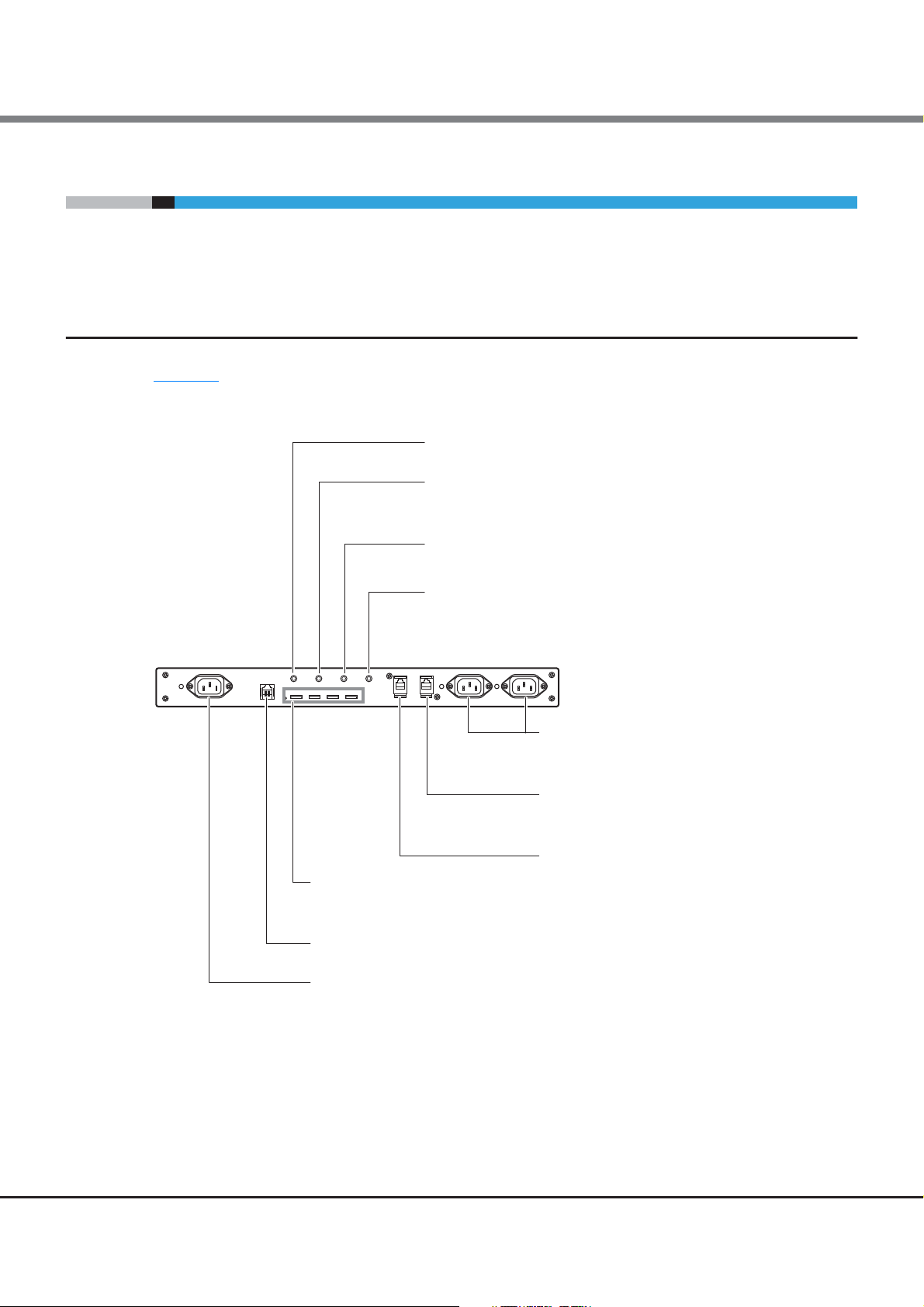

AC In port

For server UPS unit connection with

a power cord (for AC sensor) to an AC sensor unit

AC sensor output port

For power synchronized unit connection

with an AC sensor port connection cable

to an AC sensor unit

LED

Lights up green when AC output from

a server UPS unit is detected

1.4 Components

1.4.2 AC Sensor Unit (Optional)

Figure 1.4 shows the names and usage of the various components for the AC sensor unit.

Figure 1.4 Components (AC sensor unit)

Table 1.3

shows details about LEDs and the status of an AC sensor unit.

Table 1.3 Status and meanings of each LED (for AC sensor units)

LED name Function

Displays the AC output

LED

(green)

status of the

connected server UPS

unit.

LED

status

(off)

(on)

AC output from server UPS units using the AC In port is not

detected.

AC output from server UPS units using the AC In port is

detected.

AC sensor unit status

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

26

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 27

Chapter 1 Overview

Server#0

UPS unit for

Server#0

UPS unit for

Server#1

Server#1

SENSOR#0 SENSOR#1

PWC#0

ETERNUS DX/AF

PWC

Power synchronized unit#0

#0 #1 #2 #3

Power cord (for AC sensor)

Power cord (for AC power input)

RS232C cable

Provided cables are indicated by solid lines.

Optional cables that can be added are indicated by dotted lines.

1.5 System Configuration

1.5 System Configuration

System configuration examples when the power synchronized unit is used are shown below.

The server UPS unit must have a function in the management software (PowerChute plus, etc.) that controls

the AC power output according to when the server powers on and off.

■ Power synchronization with two server UPS units

The following configuration is an example of power synchronization with two server UPS units.

One power synchronized unit can connect up to two server UPS units and four ETERNUS DX/AF storage

systems.

Figure 1.5 System configuration example (power synchronization with two server UPS units)

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

27

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 28

Server#0

Server#1 Server#3 -

Server#2

CASCADE

AC SENSOR

Power synchronized unit#1 (*2)

#0 #1 #2 #3

SENSOR#0 SENSOR#1

AC SENSOR

AC sensor unit#0

AC sensor unit#1

PWC

~

~

Power synchronized unit#0

#0 #1 #2 #3

UPS unit for

Server#1

UPS unit for

Server#0

UPS unit for

Server#3 -

UPS unit for

Server#2

*1: Do not attach a termination resistor to

the branch connector on the AC sensor unit.

*2: For a cascade connection, do not connect

the server UPS unit to power synchronized

unit#1.

(*1)

ETERNUS DX/AF

#0

PWC

ETERNUS DX/AF

#1

PWC

ETERNUS DX/AF

#2

PWC

ETERNUS DX/AF

#3

PWC

ETERNUS DX/AF

#4

PWC

ETERNUS DX/AF

#5

PWC

ETERNUS DX/AF

#6

PWC

ETERNUS DX/AF

#7

PWC

PWC

Cascade cable

AC sensor port connection cable

RS232C cable

Provided cables are indicated by solid lines.

Optional cables that can be added are indicated by dotted lines.

Power cord (for AC sensor)

Power cord (for AC power input)

Chapter 1 Overview

1.5 System Configuration

■ Power synchronization with three or more server UPS units

The following configuration is an example of power synchronization with three or more server UPS units.

Up to 16 server UPS units can be connected by using optional AC sensor units. By cascading two power

synchronized units, up to eight ETERNUS DX/AF storage systems can be connected.

Figure 1.6 System configuration example (power synchronization with three or more server UPS units)

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

28

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 29

Chapter 1 Overview

ETERNUS DX/AF

PWC

Power synchronized unit

PWC

UPS unit for

Server#0

Server#0

UPS unit for

Server#1

4

5

3, 6

3, 6

2

2

UPS management

software

Server#1

UPS management

software

ETERNUS DX/AF

UPS unit

UPS settingUPS setting

RS232C cable

An instruction is

issued to turn on the

ETERNUS DX/AF

when AC output is

detected.

1

1.6 Power Management for Power Synchronization

1.6 Power Management for Power Synchronization

This section explains power management with a power synchronized unit.

The power synchronized unit detects the AC power output of the target devices for power synchronization and

commands the ETERNUS DX/AF to synchronize the power with the target devices.

When the power synchronized unit detects the AC power output of any server UPS unit, the power

synchronized unit commands the ETERNUS DX/AF to turn on.

When the power synchronized unit does not detect AC power output in any of the server UPS units, the power

synchronized unit commands the ETERNUS DX/AF to turn off.

The server UPS unit must have a function in the management software that controls the AC power output

according to when the server powers on and off. The server UPS unit must have one unused outlet to connect

to the power synchronized unit.

Connect the power cords of the ETERNUS DX/AF and the power synchronized unit to a UPS (UPS for the

ETERNUS DX/AF) that uses a power line that is not the same as the server UPS unit. This enables power to be

supplied or stopped according to the scheduled operations and the power failure settings of the server.

■ Powering on sequence for turning on power or power recovery

Figure 1.7 Power on using a power synchronized unit

1 Power on of an ETERNUS DX/AF UPS unit

2 Issuance of command to turn on the server (power on of the server UPS units)

3 Server startup (OS startup is suspended)

The server OS startup is suspended until the ETERNUS DX/AF startup is complete. For the set suspend

time of the server, refer to "Figure 1.8

(powering on)" (page 30).

Operation timing chart when using a power synchronized unit

29

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 30

Chapter 1 Overview

1.6 Power Management for Power Synchronization

4 Issuance of command to turn on the ETERNUS DX/AF from the power synchronized unit

5 ETERNUS DX/AF startup

6 Server OS startup

The following figure shows the timing chart of power on operations for scheduled operations and power

recovery. For details about setting items and values, refer to the manual of the expansion card that is

installed in the UPS unit and the manual of the UPS management software that is used.

Figure 1.8 Operation timing chart when using a power synchronized unit (powering on)

2 Issuance of command to turn on the server

S1 (>E1)

Server

Server UPS unit

ETERNUS DX/AF

ETERNUS DX/AF

UPS unit

S1: Waiting time interval starting from when the command is issued to turn on the server to the beginning of the OS startup process.

Set a longer time than the time that is required to complete ETERNUS DX/AF startup (E1).

E1: Time that is required to complete ETERNUS DX/AF startup from the start of powering on of the ETERNUS DX/AF.

For details, refer to the manual that is provided with the connected ETERNUS DX/AF.

Shutdown state

2 Power on of the server UPS unit (Power supply starts)

OFF

4 Issuance of command to turn on the ETERNUS DX/AF from the power synchronized unit

1 Power on of an ETERNUS DX/AF UPS unit (Power supply starts)

OFF

3 OS startup suspension

E1

5 Startup Operating

6 OS startup

ON

ON

Operating

30

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 31

Chapter 1 Overview

ETERNUS DX/AF

PWC

Power synchronized unit

PWC

UPS unit for

Server#0

Server#0

UPS unit for

Server#1

3

4

1 1

2 2

5

UPS management

software

Server#1

UPS management

software

ETERNUS DX/AF

UPS unit

UPS settingUPS setting

RS232C cable

An instruction is issued

to turn off the

ETERNUS DX/AF

when no AC output is

detected.

1.6 Power Management for Power Synchronization

■ Powering off sequence for turning off power or power recovery

Figure 1.9 Power off using a power synchronized unit

(0 Power failure occurred (commercial power is stopped))

1 Shutdown of all the servers

2 Shutdown of all the server UPS units

3 Issuance of command to turn off the ETERNUS DX/AF from the power synchronized unit

4 ETERNUS DX/AF shutdown

5 Shutdown of the ETERNUS DX/AF UPS unit

31

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 32

Chapter 1 Overview

Shutdown state

Operating

ON

OFF

OFF

ON OFF

ETERNUS DX/AF

Server UPS unit

Server

ETERNUS DX/AF

UPS unit

1 Shutdown of the server

(Server shutdown starts)

3 Issuance of command to shut down the ETERNUS DX/AF

from the power synchronized unit

S3 (>S2)

S2

E3 (>S3+E2)

Operating (Power is on)

E2

5 UPS shutdown

(Power supply stops)

S2: Processing time for server shutdown.

E2: Required time to turn off the ETERNUS DX/AF.

For details, refer to the manual that is provided with the connected ETERNUS DX/AF.

S3: Battery operation time until server UPS unit shutdown when a power failure occurs.

E3: Battery operation time until ETERNUS DX/AF UPS unit shutdown when a power failure occurs.

Shutdown process

4 Shutdown process

2 UPS shutdown

(Power supply stops)

(0 Power failure occurred (commercial power is stopped))

Shutdown state

Operating

ON

OFF

OFF

ON OFF

ETERNUS DX/AF

Server UPS unit

Server

ETERNUS DX/AF

UPS unit

1 Shutdown of the server

(Server shutdown starts)

3 Issuance of command to shut down the ETERNUS DX/AF

from the power synchronized unit

S3 (>S2)

S2

E3 (>S3+E2)

Operating (Power is on)

E2

5 UPS shutdown

(Power supply stops)

S2: Processing time for server shutdown.

E2: Required time to turn off the ETERNUS DX/AF.

For details, refer to the manual that is provided with the connected ETERNUS DX/AF.

S3: Battery operation time until server UPS unit shutdown when a power failure occurs.

E3: Battery operation time until ETERNUS DX/AF UPS unit shutdown when a power failure occurs.

Shutdown process

4 Shutdown process

2 UPS shutdown

(Power supply stops)

(0 Power failure occurred (commercial power is stopped))

1.6 Power Management for Power Synchronization

The following figure shows the timing chart of power off operations for scheduled operations or for when a

power failure occurs. For details about setting items and values, refer to the manual of the expansion card

that is installed in the UPS unit and the manual of the UPS management software that is used.

Figure 1.10 Operation timing chart when using a power synchronized unit (powering off)

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

32

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 33

Chapter 2

Installation

This chapter describes the installation procedures for the power synchronized unit and the AC sensor unit.

Make sure to check "

Safety Precautions" (page 9) before installation.

2.1 Package Contents Check

Check the list of package contents in Table 2.1 and Table 2.2 to confirm that there are no missing parts.

If there are missing parts, contact your sales representative.

Table 2.1 List of package contents (power synchronized unit)

Package contents Quantity Note

Power synchronized unit 1 —

RS232C cable 2

Rack mount kit One set —

Safety Precautions 1 —

Read Me First 1 —

Table 2.2 List of package contents (AC sensor unit)

1m

For ETERNUS DX/AF connection

Package contents Quantity Note

AC sensor unit 1 —

AC sensor port connection cable 1

Branch connector 1 —

Rubber foot 4

Rack mount kit One set —

4m

For power synchronized unit connection

This is not used when the AC sensor unit is installed in a

rack.

33

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 34

Chapter 2 Installation

2.2 Preparation

2.2 Preparation

2.2.1 Installation Area

■ Placement area

Refer to the placement area of the rack to install the power synchronized unit and the AC sensor unit.

■ Installation condition

Install the power synchronized unit and the AC sensor unit in an area that meets all the conditions described

in "

Instructions for installation" (page 10) of "Safety Precautions".

2.2.2 Checking Power Sockets and Server UPS Unit Outlets

Check the required number and specifications of power sockets and server UPS unit outlets.

• One power socket is required for each power synchronized unit. Make sure to check the plug type of the

power socket.

Connect the power synchronized unit to the same power socket line as the ETERNUS DX/AF.

• Make sure each server UPS unit has an unused outlet for connecting a power synchronized unit or an AC

sensor unit. In addition, make sure to check the plug type of the outlet.

2.2.3 Preparing Power Cords

Note that power cords (for AC power input) for power synchronized units and power cords (for AC sensor) to

connect server UPS units to power synchronized units or AC sensor units are not supplied with power

synchronized units.

The IEC 60320-C14 port type is used for the AC IN ports and the SENSOR ports of the power synchronized units.

This port type is also used for the AC IN ports of the AC sensor units.

Check the specifications of the power sockets and server UPS unit outlets that are to be used for the power

synchronized units and AC sensor units. Prepare the required number of appropriate power cords.

• Power cord (for AC power input)

- Each power synchronized unit requires one power cord.

- The voltage for the AC IN port is 10A 250V or less.

• Power cord (for AC sensor)

- Each server UPS unit that is to be connected to the power synchronized unit requires one power cord.

- Each AC sensor unit requires one power cord.

Be sure that the power cords have the approval of the appropriate safety agencies of the country where the

equipment will be used.

34

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 35

Chapter 2 Installation

WARNING

Do Not

CAUTION

Do

2.3 Installing in a Rack

• Do not use a power cord that does not satisfy the specifications of the power

synchronized unit and the AC sensor unit. Doing so may cause failure, fire, or

electric shock.

2.3 Installing in a Rack

This section explains how to install a power synchronized unit and an AC sensor unit in a rack.

Make sure to check "

sensor unit in a rack. Also refer to the manual that is provided with the racks.

Safety Precautions" (page 9) before installing the power synchronized unit and the AC

• If the power synchronized unit and the AC sensor unit are installed or

disassembled other than as described in this manual, device failure or electric

shock may occur.

• The power synchronized unit contains delicate components, and should be

handled gently. Do not drop or knock the power synchronized unit against the

rack during installation.

• Install the blank panels provided with the rack where no other devices are

installed.

• Especially for an enclosed rack with doors, or when multiple devices are to be

mounted and running, it is important to realize that the temperature inside

the cabinet will be considerably higher than that of the room. Make sure the

rack internal ambient temperatures do not exceed the environmental

conditions for temperature described in "1.3

to do so may damage the power synchronized unit.

Specifications" (page 23). Failure

• When installing the power synchronized unit with other devices into the same

rack, the airflow of the device installed on and under the power synchronized

unit may interfere with each other and reduce the effect of device cooling.

Make sure to leave plenty of room between the devices if required. Failure to

do so may damage the power synchronized unit and lead to malfunction.

• Do not obstruct the air vents in the power synchronized unit.

35

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 36

Chapter 2 Installation

Procedure

(Rear rack pillars)

Base line of

power synchronized unit

1st position

3rd position

1U (power synchronized unit size)

2.3 Installing in a Rack

2.3.1 Installing a Power Synchronized Unit

This section describes how to install a power synchronized unit in a rack.

■ Checking the package contents of the rack mount kit

Check the following package contents to confirm that there are no missing parts. If there are missing parts,

contact your sales representative.

❏ L-shaped bracket: 2

Same for right and left.

❏ M6 cross recessed head screw

with captive washer: 4

❏ M3 flat head screw: 4

For attaching L-shaped

brackets

❏ Blank panel: 1

■ Procedure for installing a power synchronized unit

1 Open the front and rear doors of the rack.

2 Attach the M6 cage nuts to the rear rack pillar.

❏ M6 cage nut: 4

Used when the holes in the rack

pillars are square

• Attachment positions

Insert four M6 cage nuts in the 1st and 3rd holes above the power synchronized unit base line.

36

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 37

Chapter 2 Installation

Top view

M6 cage nut

Rack pillar (square)

M3 flat head screws

L-shaped bracket

M3 flat head screws

L-shaped bracket

(Rear rack pillars)

M6 cross recessed head screws

with captive washer

M6 cross recessed head

screws with captive washer

2.3 Installing in a Rack

3 Attach the L-shaped brackets to the power synchronized unit.

• Attachment procedure

Clip the M6 cage nut tabs into the desired hole from the inside.

Use four M3 flat head screws to attach the L-shaped brackets to the power synchronized unit on both

sides.

4 Install the power synchronized unit in the rack.

Use four M6 cross recessed head screws with captive washer to fasten the power synchronized unit in

the rack.

37

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 38

Chapter 2 Installation

End of procedure

(Front rack pillars)

(Rear rack pillars)

Blank panel

2.3 Installing in a Rack

5 Attach the blank panel to the rack front.

The blank panel should be attached at the same height as the power synchronized unit.

38

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 39

Chapter 2 Installation

2.3 Installing in a Rack

2.3.2 Installing an AC Sensor Unit

This section describes how to install an AC sensor unit in a rack.

Install the AC sensor unit in the same rack as the server UPS unit. When installing the AC sensor unit, the

length of the power cord (for AC sensor) that connects the AC sensor unit and the server UPS unit must be

taken into consideration.

■ Checking the package contents of the rack mount kit

Check the following package contents to confirm that there are no missing parts. If there are missing parts,

contact your sales representative.

❏ Shelf plate: 1 ❏ L-shaped bracket: 2

❏ M4 cross recessed head screw

with captive washer: 2

❏ M6 cross recessed head screw

with captive washer: 4

❏ M3 cross recessed head screw

with captive washer: 4

❏ Blank panel: 1

Same for right and left.

❏ M6 cage nut: 4

Used when the holes in the

rack pillars are square

39

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 40

Chapter 2 Installation

Procedure

(Rear rack pillars)

Base line of AC sensor unit

1st position

3rd position

1U (AC sensor unit size)

Top view

M6 cage nut

Rack pillar (square)

M3 cross recessed head screws

with captive washer

L-shaped bracket

L-shaped bracket

M3 cross recessed head

screws with captive washer

2.3 Installing in a Rack

■ Procedure for installing an AC sensor unit

1 Open the front and rear doors of the rack.

2 Attach the M6 cage nuts to the rear rack pillar.

• Attachment positions

Insert four M6 cage nuts in the 1st and 3rd holes above the AC sensor unit base line.

• Attachment procedure

Clip the M6 cage nut tabs into the desired hole from the inside.

3 Attach the L-shaped brackets to the AC sensor unit.

Use four M3 cross recessed head screws with captive washer to attach the L-shaped brackets to the AC

sensor unit on both sides.

40

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 41

Chapter 2 Installation

M4 cross recessed head screws with captive washer

Shelf plate

(Rear rack pillars)

M6 cross recessed head screws

with captive washer

M6 cross recessed head screws

with captive washer

2.3 Installing in a Rack

4 Attach the shelf plate to the AC sensor unit.

Use two M4 cross recessed head screws with captive washer to attach the shelf plate to the AC sensor

unit.

Up to two AC sensor units can be attached to the same shelf plate. Attach the first AC sensor unit on

the right side when facing the shelf plate as shown in the figure above.

5 Attach the shelf plate to the rack.

Use four M6 cross recessed head screws with captive washer to fasten the shelf plate in the rack.

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

41

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 42

Chapter 2 Installation

End of procedure

(Front rack pillars)

(Rear rack pillars)

Blank panel

2.3 Installing in a Rack

6 Attach the blank panel to the rack front.

The blank panel should be attached at the same height as the AC sensor unit.

42

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 43

Chapter 3

Powering On and Off

This chapter explains how to turn on and off the power synchronized unit.

■ Powering on

When a power cord (for AC power input) is connected to the AC IN port and the power socket, the power

synchronized unit turns on.

For details about how to connect a power cord (for AC power input), refer to "4.2

Synchronized Unit" (page 50).

■ Powering off

When a power cord (for AC power input) is disconnected from the AC IN port, the power synchronized unit

turns off.

Turning on the Power

For normal operation, there is no need to turn the power off.

If the power synchronized unit must be turned off, such as before any inspections of power supply devices are

performed, check that the power synchronized unit and the devices that connect the power synchronized

unit are all turned off before disconnecting the power cords (for AC power input).

43

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 44

Chapter 4

Procedure

End of procedure

Connection and Settings

This chapter describes the installation and setting procedures for a power synchronized unit and an AC sensor

unit.

If your sales representative or maintenance engineer does not perform the settings of the power synchronized

unit and the AC sensor unit, perform the settings yourself.

Attach labels to each cable that is to be connected and make a note of the connection source and

destination. This helps with cable management and prevents incorrect connections.

For the connection and setting details of a device that is connected to the power synchronized unit, refer to

the manual that is provided with the connected device.

■ Workflow

Perform the following procedure for connection and settings:

1 Set the ETERNUS DX/AF.

For details, refer to "4.1 Setting the ETERNUS DX/AF" (page 45).

2 Turn on the power synchronized unit.

For details, refer to "4.2 Turning on the Power Synchronized Unit" (page 50).

3 When five or more ETERNUS DX/AF storage systems are installed, connect the cascade

cables.

For details, refer to "4.3 Connecting Cascade Cables" (page 53).

4 Connect the power synchronized unit to the server UPS unit.

For details, refer to "4.4.1 Connecting the Server UPS Unit to the Power Synchronized Unit" (page 57).

5 When three or more server UPS units are connected, connect the AC sensor unit.

For details, refer to "4.4.2 Connecting the AC Sensor Unit" (page 58).

6 Connect the power synchronized unit to the ETERNUS DX/AF.

For details, refer to "4.5 Connecting to the ETERNUS DX/AF" (page 61).

44

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 45

Chapter 4 Connection and Settings

4.1 Setting the ETERNUS DX/AF

4.1 Setting the ETERNUS DX/AF

Perform the necessary settings for power synchronization by using the setting and maintenance program of

the ETERNUS DX/AF.

If the power synchronized unit and the ETERNUS DX/AF storage system are connected with a redundant

configuration, the operations during a power down are as follows:

• For the ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4, ETERNUS DX60 S3/DX100

S3/DX200 S3, ETERNUS DX500 S3/DX600 S3, ETERNUS DX8100 S3, ETERNUS AF250 S2/AF650 S2, ETERNUS

AF250/AF650, ETERNUS DX200F, and ETERNUS DX60 S2/DX80 S2/DX90 S2

When the controllers for CM#0 and CM#1 both receive shutdown instructions, the shutdown process

starts.

• For the ETERNUS DX8700 S3/DX8900 S3

When the Service Controllers (SVC) for SVC#0 and SVC#1 both receive shutdown instructions, the

shutdown process starts.

■ ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4, ETERNUS DX60 S3/

DX100 S3/DX200 S3, ETERNUS DX500 S3/DX600 S3, ETERNUS DX8100 S3, ETERNUS AF250

S2/AF650 S2, ETERNUS AF250/AF650, and ETERNUS DX200F

This section explains the setting items on the power synchronization setting screen for the ETERNUS DX60 S4/

DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4, ETERNUS DX60 S3/DX100 S3/DX200 S3, ETERNUS DX500

S3/DX600 S3, ETERNUS DX8100 S3, ETERNUS AF250 S2/AF650 S2, ETERNUS AF250/AF650, and ETERNUS

DX200F.

Figure 4.1 ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500 S4/DX600 S4, ETERNUS DX60 S3/DX100

S3/DX200 S3, ETERNUS DX500 S3/DX600 S3, ETERNUS DX8100 S3, ETERNUS AF250 S2/AF650 S2,

ETERNUS AF250/AF650, and ETERNUS DX200F setup (Setup Power Management screen)

45

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 46

Chapter 4 Connection and Settings

4.1 Setting the ETERNUS DX/AF

• Auto Power

Select "Disable".

• Power Resume

Select "Disable".

• Connection CM

Select the controllers (CM#0 and/or CM#1) of the ETERNUS DX60 S4/DX100 S4/DX200 S4, ETERNUS DX500

S4/DX600 S4, ETERNUS DX60 S3/DX100 S3/DX200 S3, ETERNUS DX500 S3/DX600 S3, ETERNUS AF250 S2/

AF650 S2, ETERNUS AF250/AF650, and ETERNUS DX200F that are connected to the power synchronized

unit with the RS232C cable.

Select "CM#0" when the power synchronized unit is connected to the PWC port on controller 0. Select

"CM#1" when the power synchronized unit is connected to the PWC port on controller 1.

When different power synchronized units are connected to controller 0 and controller 1 in a duplicated

configuration, select both "CM#0" and "CM#1".

• Delay until Shutdown

Do not change the default setting (0 minute).

• Set management unit interface

Select "Power Synchronized Unit".

• Power Failure Signal

"Positive" (positive logic) is automatically set.

• Low Battery Signal

"Negative" (negative logic) is automatically set.

• UPS Shutdown Signal

Do not select the "Enable" checkbox.

"Positive" (positive logic) is set by default.

46

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 47

Chapter 4 Connection and Settings

4.1 Setting the ETERNUS DX/AF

■ ETERNUS DX8700 S3/DX8900 S3

This section explains the setting items on the power synchronization setting screen for the ETERNUS DX8700

S3/DX8900 S3.

Figure 4.2 ETERNUS DX8700 S3/DX8900 S3 setup (Setup Power Management screen)

• Auto Power

Select "Disable".

• Power Resume

Select "Disable".

• Connection SVC

Select the SVCs (SVC#0 and/or SVC#1) of the ETERNUS DX8700 S3/DX8900 S3 that are connected to the

power synchronized unit with the RS232C cable.

Select "SVC#0" when the power synchronized unit is connected to the PWC port on SVC#0. Select "SVC#1"

when the power synchronized unit is connected to the PWC port on SVC#1.

When different power synchronized units are connected to SVC#0 and SVC#1 in a duplicated configuration,

select both "SVC#0" and "SVC#1".

• Delay until Shutdown

Do not change the default setting (0 minute).

• Set management unit interface

Select "Power Synchronized Unit".

• Power Failure Signal

"Positive" (positive logic) is automatically set.

• Low Battery Signal

"Negative" (negative logic) is automatically set.

• UPS Shutdown Signal

Do not select the "Enable" checkbox.

"Positive" (positive logic) is set by default.

47

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 48

Chapter 4 Connection and Settings

4.1 Setting the ETERNUS DX/AF

■ ETERNUS DX80 S2/DX90 S2

This section explains the setting items on the power synchronization setting screen for the ETERNUS DX80 S2/

DX90 S2.

Figure 4.3 ETERNUS DX80 S2/DX90 S2 setup (Setup Power Management screen)

• Enable

Select the controllers (CM#0 and/or CM#1) of the ETERNUS DX80 S2/DX90 S2 that are connected to the

power synchronized unit with the RS232C cable.

Select "CM#0" when the power synchronized unit is connected to the PWC port on controller 0. Select

"CM#1" when the power synchronized unit is connected to the PWC port on controller 1.

When different power synchronized units are connected to controller 0 and controller 1 in a duplicated

configuration, select both "CM#0" and "CM#1".

• Delay until Shutdown (min.)

Do not change the default setting (0 minute).

• Set management unit interface

Select "Power Synchronized Unit".

• Power Failure Signal

"Positive" (positive logic) is automatically set.

• Low Battery Signal

"Negative" (negative logic) is automatically set.

• UPS Shutdown Signal

Do not select the "Enable" checkbox.

"Positive" (positive logic) is set by default.

• Auto Power

Select "Disable".

• Power Resume

Select "Disable".

48

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)

Copyright 2017 FUJITSU LIMITED P3AM-8012-10ENZ0

Page 49

Chapter 4 Connection and Settings

4.1 Setting the ETERNUS DX/AF

■ ETERNUS DX60 S2

This section explains the setting items on the power synchronization setting screen for the ETERNUS DX60 S2.

Figure 4.4 ETERNUS DX60 S2 setup (Setup Power Management screen)

• Enable

Select the controllers (CM#0 and/or CM#1) of the ETERNUS DX60 S2 that are connected to the power

synchronized unit with the RS232C cable. Select "CM#0" when the power synchronized unit is connected to

the PWC port on controller 0. Select "CM#1" when the power synchronized unit is connected to the PWC port

on controller 1.

When different power synchronized units are connected to controller 0 and controller 1 in a duplicated

configuration, select both "CM#0" and "CM#1".

• Delay until Shutdown (min.)

Do not change the default setting (0 minute).

• Set management unit interface

Select "Power Synchronized Unit".

• Power Failure Signal

"Positive" (positive logic) is automatically set.

• Low Battery Signal

"Negative" (negative logic) is automatically set.

• UPS Shutdown Signal

Do not select the "Enable" checkbox.

"Positive" (positive logic) is set by default.

49

FUJITSU Storage ETERNUS DX, ETERNUS AF Configuration Guide (Power Synchronized Unit)