Page 1

FUJITSU Storage

ETERNUS AF250 S2,

ETERNUS AF250

All-Flash Arrays

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 2

This page is intentionally left blank.

Page 3

Fujitsu would like to thank you for purchasing the FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 (hereinafter referred to as ETERNUS AF

The ETERNUS AF is designed to be connected to Fujitsu servers (Fujitsu SPARC Servers, PRIMEQUEST, or PRIMERGY) or non-Fujitsu servers.

This manual describes how to install the ETERNUS AF and how to start the operation.

This manual is intended for use of the ETERNUS AF in regions other than Japan.

Please carefully review the information outlined in this manual.

About This Manual

Organization

Preface

).

Fourth Edition

December 2017

This manual is composed of the following eleven chapters:

"

Chapter 1 Component Names" (page 17)

•

This chapter provides components names of the ETERNUS AF.

"Chapter 2 Rack Installation" (page 22)

•

This chapter describes the procedure for installing the ETERNUS AF in a rack.

"Chapter 3 Checking the Configuration Environment" (page 34)

•

This chapter describes the environment required for system configuration.

"Chapter 4 Connecting Cables" (page 44)

•

This chapter explains how to connect various cables to the ETERNUS AF.

"Chapter 5 General Settings" (page 55)

•

This chapter describes the basic settings for the ETERNUS AF.

"Chapter 6 Monitoring Settings" (page 85)

•

This chapter describes the settings required to monitor the ETERNUS AF.

"Chapter 7 Power Control Setup" (page 105)

•

This chapter describes the settings required for power control of the ETERNUS AF.

"Chapter 8 SAN Connection Settings" (page 109)

•

This chapter describes the settings required to use the ETERNUS AF with a SAN connection.

"Chapter 9 Advanced Copy Settings" (page 141)

•

This chapter describes the settings required to operate Advanced Copy.

"Chapter 10 System Status Check" (page 152)

•

This chapter describes the status check for the ETERNUS AF after system configuration.

"Chapter 11 Solution Configuration" (page 158)

•

This chapter describes storage solutions using the ETERNUS AF.

3

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 4

Preface

Registered Trademarks and Trademarks

All SPARC trademarks are used under license from SPARC International, Inc. and are trademarks or regis-

•

tered trademarks of that company in the United States and other countries.

UNIX is a registered trademark of The Open Group in the United States and other countries.

•

Microsoft, Windows, Windows Server, and Internet Explorer are either registered trademarks or trademarks

•

of Microsoft Corporation in the United States and/or other countries.

Oracle and Java are registered trademarks of Oracle and/or its affiliates.

•

HP-UX is a trademark of Hewlett-Packard Company in the U.S. and other countries.

•

Mozilla, Firefox, and the Mozilla and Firefox logos are trademarks or registered trademarks of the Mozilla

•

Foundation in the United States and other countries.

Red Hat and Red Hat Enterprise Linux are trademarks of Red Hat, Inc., registered in the U.S. and other

•

countries.

•

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

SUSE is a registered trademark of Novell, Inc. in the United States and other countries.

•

IBM, AIX, and Tivoli are trademarks of International Business Machines Corporation, registered in many ju-

•

risdictions worldwide.

VMware, VMware logos, Virtual SMP, and vMotion are either registered trademarks or trademarks of

•

VMware, Inc. in the U.S. and/or other countries.

Arcserve is a registered trademark or trademark of Arcserve (USA), LLC.

•

NetVault is a registered trademark of Dell Inc. in the United States and other countries.

•

EMC and NetWorker are either registered trademarks or trademarks of EMC Corporation in the United

•

States and/or other countries.

The company names, product names and service names mentioned in this document are registered trade-

•

marks or trademarks of their respective companies.

Microsoft product screen shot(s) reprinted with permission from Microsoft Corporation.

•

Naming Conventions

■

Product Names

Oracle Solaris might be described as Solaris, Solaris Operating System, or Solaris OS.

•

•

The following abbreviations are used for Microsoft®

Product name Abbreviation

Microsoft® Windows Server® 2008 Datacenter

Microsoft® Windows Server® 2008 R2 Datacenter

Microsoft®

Microsoft® Windows Server® 2008 R2 Enterprise

Microsoft® Windows Server® 2008 Standard

Microsoft® Windows Server® 2008 R2 Standard

Microsoft®

Microsoft® Windows Server® 2008 R2 for Itanium-Based Systems

Microsoft® Windows Server® 2008 HPC Edition

Microsoft® Windows Server® 2008 R2 HPC Edition

Windows Server® 2008 Enterprise

Windows Server® 2008 for Itanium-Based Systems

Windows Server®.

Windows Server 2008

4

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 5

Preface

Product name Abbreviation

Microsoft® Windows Server® 2012 Datacenter

Microsoft® Windows Server® 2012 R2 Datacenter

Microsoft®

Microsoft® Windows Server® 2012 R2 Standard

Microsoft® Windows Server® 2012 Essentials

Microsoft® Windows Server® 2012 R2 Essentials

Microsoft® Windows Server® 2016 Datacenter

Microsoft® Windows Server® 2016 Standard

The following abbreviations are used for Red Hat Linux.

•

Product name Abbreviation

Red Hat Enterprise Linux 5 (for x86)

Red Hat Enterprise Linux 5 (for Intel64)

Red Hat Enterprise Linux 6 (for x86)

Red Hat Enterprise Linux 6 (for Intel64)

Red Hat Enterprise Linux 7 (for Intel 64) Red Hat Enterprise Linux 7

■

Symbols Used in This Manual

Windows Server® 2012 Standard

Windows Server 2012

Windows Server 2016

Red Hat Enterprise Linux 5

Red Hat Enterprise Linux 6

The following symbols are used throughout this manual:

This indicates information for the user to note when using the ETERNUS AF. Please be

sure to read this information.

This indicates supplementary and reference information.

■

Abbreviations Used in This Manual

"

ETERNUS AF250 S2" refers to the FUJITSU Storage ETERNUS AF250 S2 and "ETERNUS AF250" refers to the

•

FUJITSU Storage ETERNUS AF250.

"ETERNUS AF" refers to the ETERNUS AF250 S2 and the ETERNUS AF250.

•

"CA" refers to a host interface module that is used in an ETERNUS AF to connect to a server.

•

"Host Bus Adapter (HBA)" refers to an interface module that is normally used in a server to connect to

•

ETERNUS AF storage systems.

•

Trademark symbols such as ™ and ® are omitted in this document.

5

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 6

Electric Shock

No Disassembly

Unplug

Preface

Warning Signs

Warning signs are shown throughout this manual in order to prevent injury to the user and/or material damage. These signs are composed of a symbol and a message describing the recommended level of caution.

The following explains the symbol, its level of caution, and its meaning as used in this manual.

The following symbols are used to indicate the type of warnings or cautions being described.

This symbol indicates the possibility of serious or fatal injury if the ETERNUS AF is not

used properly.

This symbol indicates the possibility of minor or moderate personal injury, as well as

damage to the ETERNUS AF and/or to other users and their property, if the ETERNUS AF

is not used properly.

This symbol indicates IMPORTANT information for the user to note when using the ETER-

.

NUS AF

The triangle emphasizes the urgency of the WARNING and CAUTION contents. Inside

the triangle and above it are details concerning the symbol (e.g. Electrical Shock).

The barred "Do Not..." circle warns against certain actions. The action which must be

avoided is both illustrated inside the barred circle and written above it (e.g. No Disassembly).

The black "Must Do..." circle indicates actions that must be taken. The required action is both illustrated inside the black disk and written above it (e.g. Unplug).

6

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 7

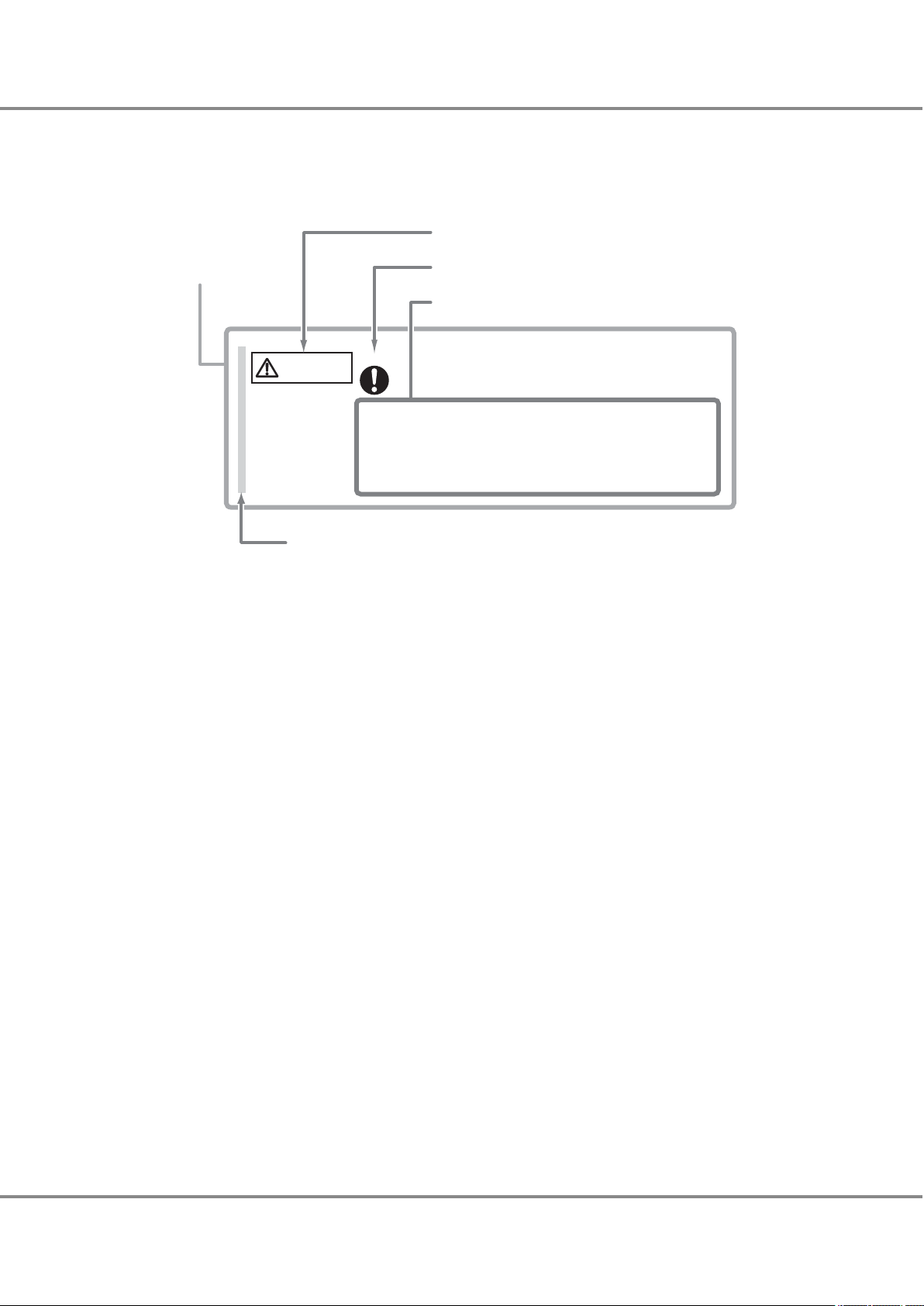

Warning level indicator

Warning type indicator

Warning details

To avoid damaging the ETERNUS storage system, pay attention to the

following points when cleaning the ETERNUS storage system:

- Make sure to disconnect the power when cleaning.

- Be careful that no liquid seeps into the ETERNUS storage system

when using cleaners, etc.

- Do not use alcohol or other solvents to clean the ETERNUS storage system.

Warning layout ribbon

Example warning

CAUTION

Do

Preface

How Warnings are Presented in This Manual

A message is written beside the symbol indicating the caution level. This message is marked with a vertical

ribbon in the left margin, to distinguish this warning from ordinary descriptions.

A display example is shown here.

7

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 8

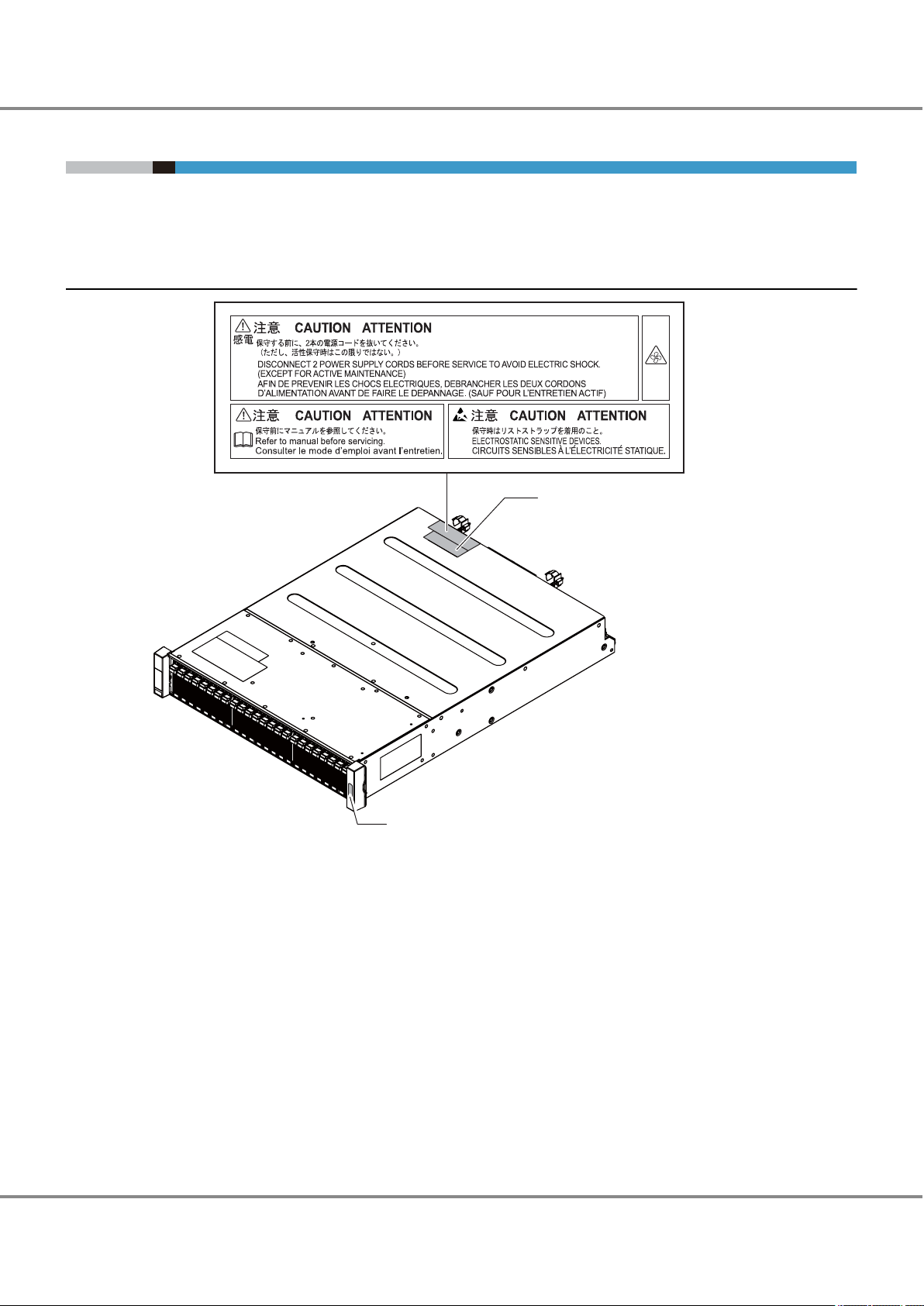

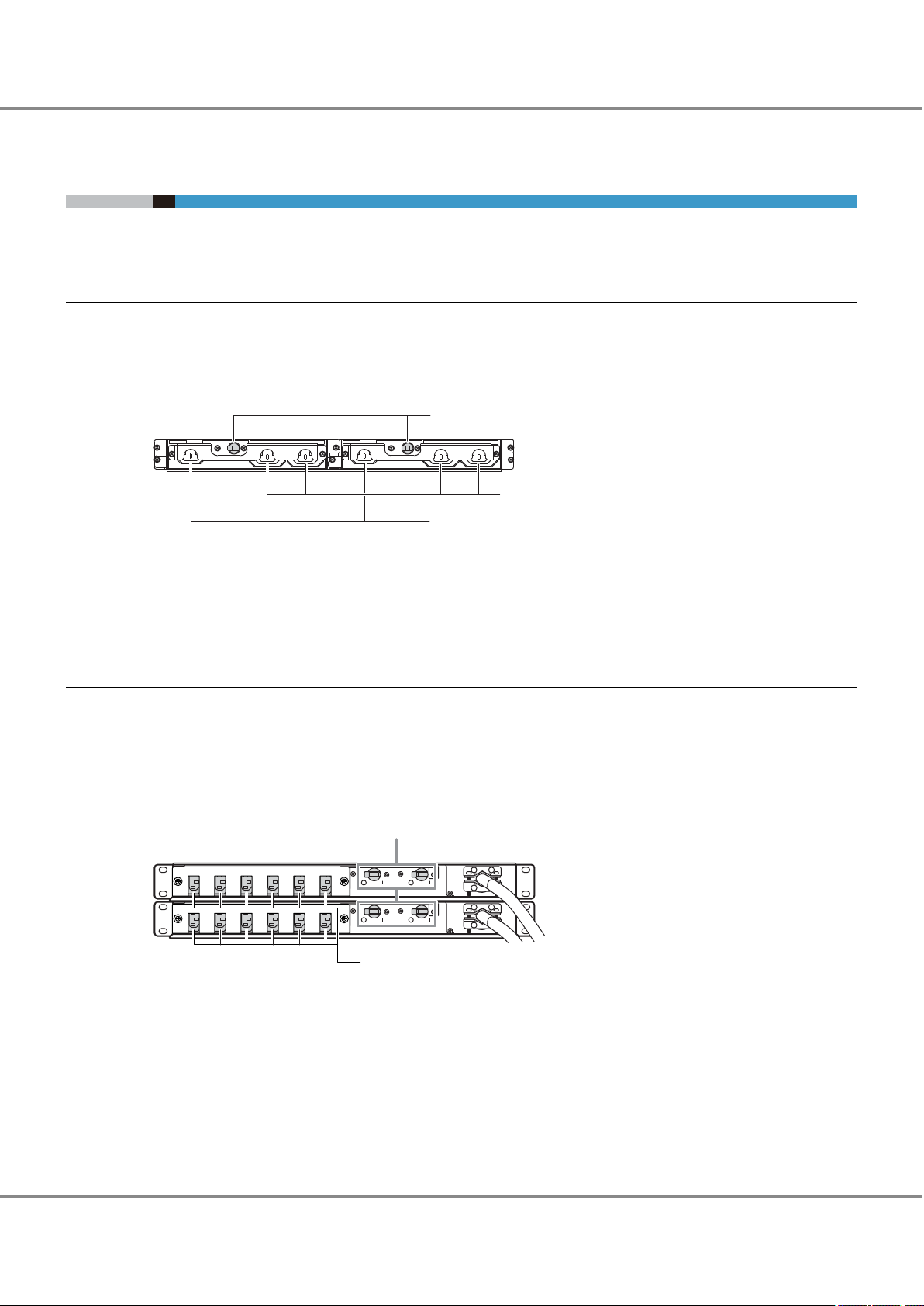

Manufacturer’s label

The model name and

the serial number are

listed.

Device ID label

The model name and the serial number

are listed.

Preface

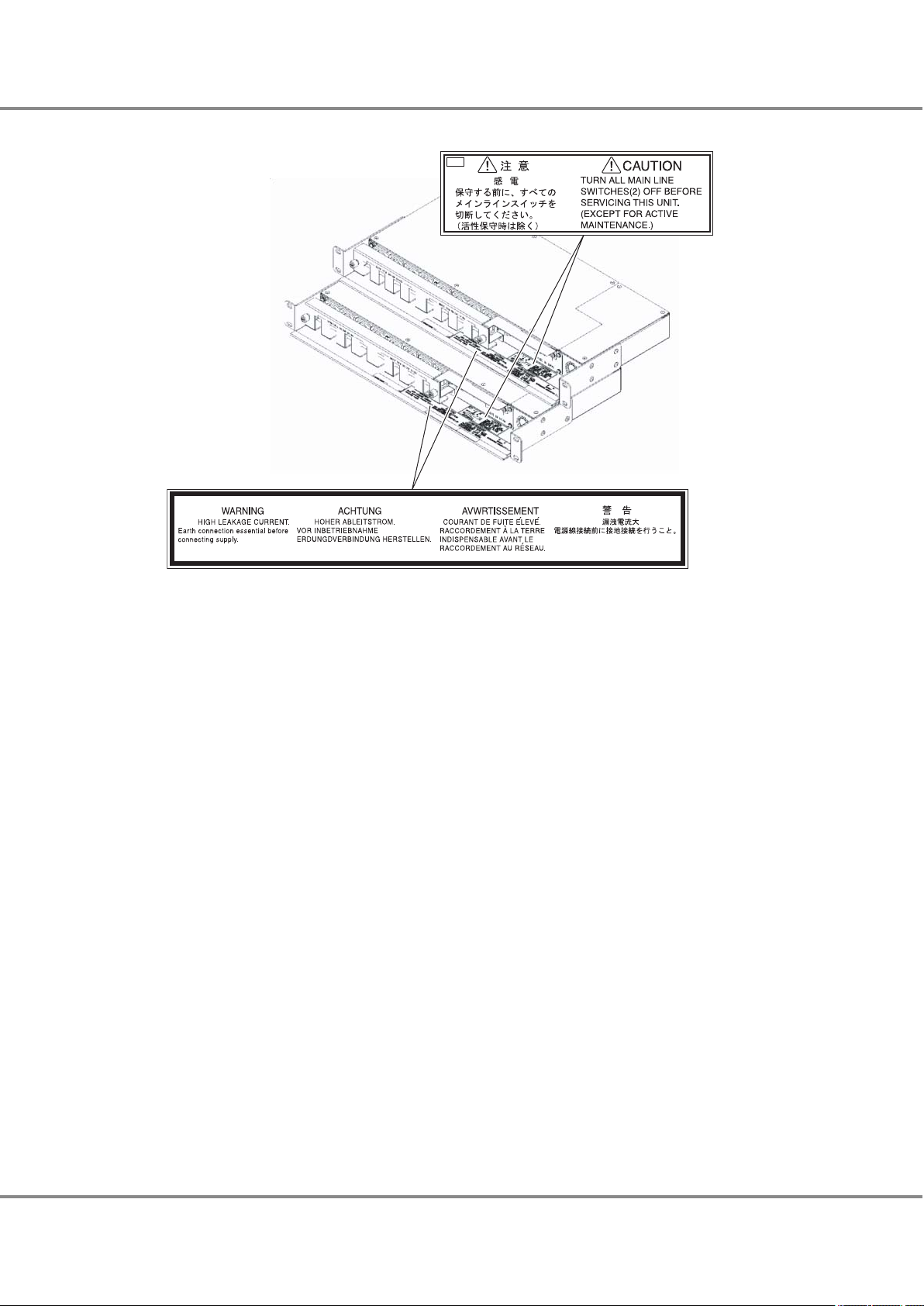

Warning Labels and Manufacturer's Labels

Warning labels, manufacturer's labels, and a device ID label are found in the ETERNUS AF, as shown in the

example below.

Never remove these labels from the equipment or allow them to become dirty.

Controller Enclosure

8

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 9

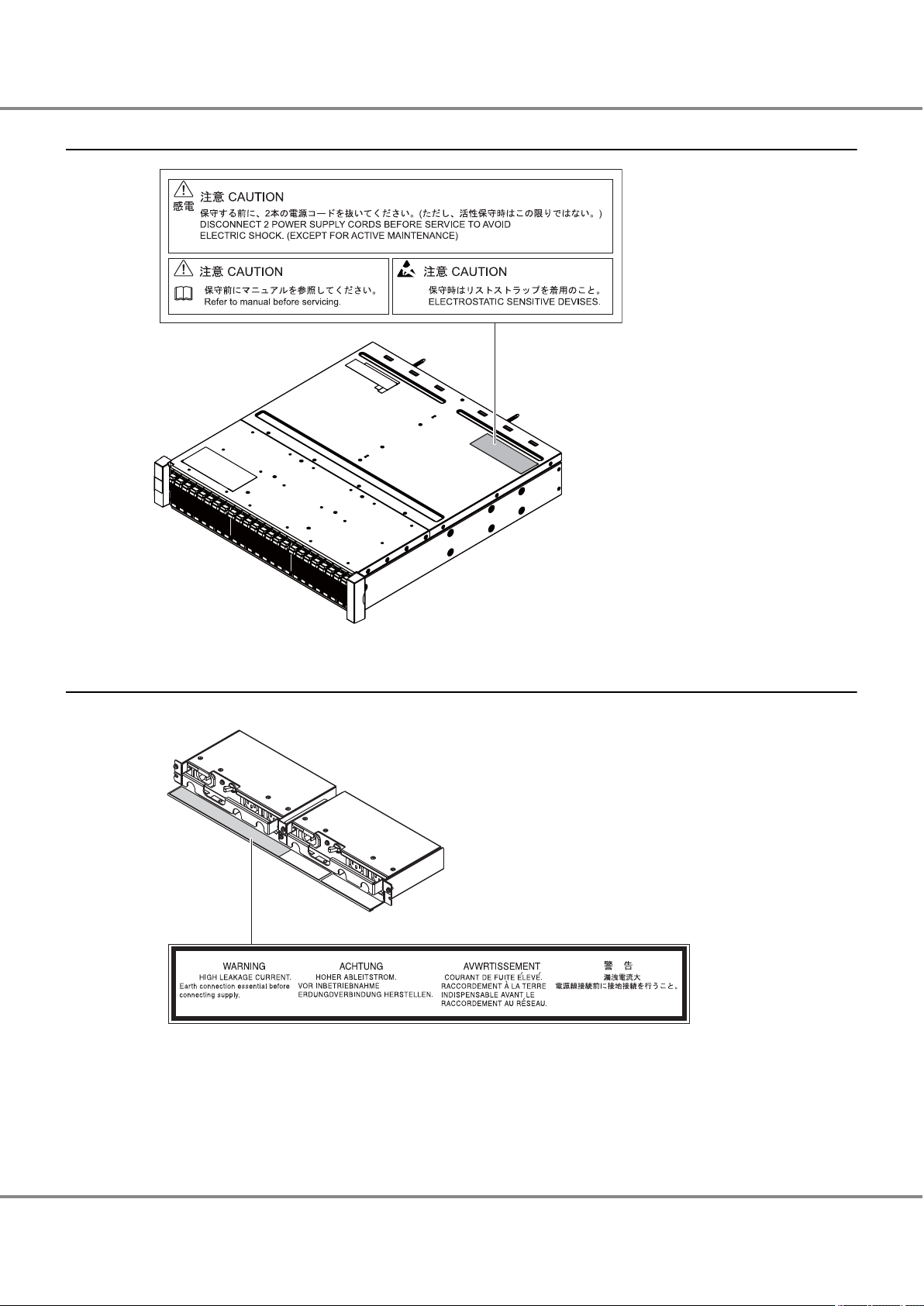

Preface

Drive Enclosures

Power Distribution Units (for Regions other than the EMEIA, Central American, and Caribbean Regions)

Power distribution unit (AC200-240V, 1U)

•

9

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 10

Preface

Power distribution unit (AC200-240V, 2U)

•

10

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 11

Table of Contents

Chapter 1 Component Names 17

1.1 Controller Enclosure ..................................................................................................................... 17

Front...................................................................................................................................................................17

1.1.1

1.1.2 Rear ....................................................................................................................................................................18

1.2 Drive Enclosures ........................................................................................................................... 18

1.2.1 Front...................................................................................................................................................................19

1.2.2 Rear ....................................................................................................................................................................19

1.3 Power Distribution Units (for Regions other than the EMEIA, Central American, and Caribbean Re-

gions) ........................................................................................................................................... 20

1.3.1 Power Distribution Units (1U).............................................................................................................................20

1.3.2 Power Distribution Units (2U).............................................................................................................................20

Chapter 2 Rack Installation 22

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2.1.1 Installing Power Distribution Unit (1U)...............................................................................................................24

2.1.2 Installing Power Distribution Unit (2U)...............................................................................................................26

........................................................................................................................... 23

2.2 Controller Enclosure Installation (for Regions other than the EMEIA, Central American, and Carib-

bean Regions) .............................................................................................................................. 28

2.3 Drive Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean

Regions) ....................................................................................................................................... 31

Chapter 3 Checking the Configuration Environment 34

3.1 System Configuration Example..................................................................................................... 34

3.2 Server Connection Preparation

3.2.1 Driver Preparation ..............................................................................................................................................35

3.2.2 Driver Installation ...............................................................................................................................................36

..................................................................................................... 35

3.2.3 iSCSI Initiator Parameter Settings .......................................................................................................................37

3.3 Preparing the PC Terminal for Setup............................................................................................. 40

3.4 LAN Connection Preparation for Operation Management............................................................. 41

3.4.1 Completing and Attaching the Network Setting Label ........................................................................................41

3.4.2 LAN Related Specifications..................................................................................................................................42

11

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 12

Table of Contents

Chapter 4 Connecting Cables 44

4.1 Host Interface Cable Connection................................................................................................... 44

4.2 Drive Enclosure Connection

.......................................................................................................... 47

4.3 Power Synchronized Unit Connection ........................................................................................... 49

4.4 Power Cord Connection................................................................................................................. 49

4.4.1 When No Power Distribution Units Are Installed.................................................................................................50

4.4.2 When 1U Power Distribution Unit Is Installed (for Regions other than the EMEIA, Central American, and Carib-

bean Regions).......................................................................................................................................................51

4.4.3 When 2U Power Distribution Unit Is Installed (for Regions other than the EMEIA, Central American, and Carib-

bean Regions).......................................................................................................................................................52

Chapter 5 General Settings 55

5.1 PC Terminal Connection................................................................................................................ 58

5.2

Powering On................................................................................................................................. 59

5.2.1 Switching On and Off the Main Line Switch on the Power Distribution Unit........................................................59

5.2.2 Switching On and Off the PSU Switch on the Power Supply Unit .........................................................................60

5.2.3 Powering On .......................................................................................................................................................61

5.3 ETERNUS Web GUI Startup ............................................................................................................ 62

5.4 Storage Management (Initial Setup 1)......................................................................................... 64

5.5 LAN Cable Connection (for Operation Management).................................................................... 70

5.6 Firewall Settings........................................................................................................................... 72

5.7 RAID Configuration Settings ......................................................................................................... 74

5.7.1 RAID Group Creation ...........................................................................................................................................74

5.7.2 Operation Volume Creation.................................................................................................................................76

5.7.3 Generation Management Volume (SDV) Creation...............................................................................................79

5.7.4 Copy Data Destination Volume (SDPV) Creation .................................................................................................80

5.7.5 Hot Spare Registration........................................................................................................................................82

Chapter 6 Monitoring Settings 85

6.1 Event Notification Setup............................................................................................................... 85

6.2

Various Notification Settings ........................................................................................................ 86

6.2.1 SNMP Trap Setup ................................................................................................................................................86

6.2.2 E-mail Setup .......................................................................................................................................................93

6.2.3 Syslog Setup .......................................................................................................................................................95

12

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 13

Table of Contents

6.3 Remote Support Setup.................................................................................................................. 96

Remote Support (by AIS Connect) Setup .............................................................................................................97

6.3.1

6.3.2 Remote Support (by REMCS) Setup .....................................................................................................................98

6.4 Audit Log Setup.......................................................................................................................... 100

6.5 Monitoring Server (SNMP Manager) Settings ............................................................................. 101

6.6 Transmission Test Execution....................................................................................................... 102

6.6.1 SNMP Trap Test .................................................................................................................................................102

6.6.2 Send Test E-mail ...............................................................................................................................................103

Chapter 7 Power Control Setup 105

7.1 Setup of the Auto Power Function and/or the Power Resume Function ...................................... 105

7.2 Connection Setup for Power Synchronized Unit

.......................................................................... 107

7.3 Wake On LAN Settings................................................................................................................ 107

Chapter 8 SAN Connection Settings 109

8.1 Connection Settings for the ETERNUS AF .................................................................................... 109

8.1.1

Host Response Settings.....................................................................................................................................109

8.1.2 Host Affinity Settings ........................................................................................................................................110

8.1.3 CA Reset Group Settings....................................................................................................................................118

8.2 Server Connection Setup............................................................................................................. 119

8.2.1 iSCSI Initiator Parameter Settings (Connection Information Settings)...............................................................119

8.2.2 LUN Recognition Check.....................................................................................................................................128

8.2.3 Disk Partition Settings ......................................................................................................................................130

Chapter 9 Advanced Copy Settings 141

9.1 Advanced Copy Basic Settings .................................................................................................... 141

9.1.1 Copy Priority Settings........................................................................................................................................141

9.1.2 Copy Table Size Settings....................................................................................................................................143

9.1.3 Copy Parameter Settings ..................................................................................................................................145

9.2 Performing a Copy (SnapOPC+) .................................................................................................. 146

Chapter 10 System Status Check 152

10.1 Checking the Component Status............................................................................................... 152

10.2 Checking the RAID Groups

........................................................................................................ 153

13

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 14

Table of Contents

10.3 Checking the Volumes.............................................................................................................. 154

10.4 Checking the Copy Sessions

...................................................................................................... 155

10.5 Checking the LUNs ................................................................................................................... 155

10.6 Powering Off ............................................................................................................................ 156

Chapter 11 Solution Configuration 158

11.1 Continuous Business ................................................................................................................ 158

11.1.1 Remote Copy Operations for the Storage System (Copies between ETERNUS AF

11.1.2 Automatic Switching Operation of the Storage Systems (Storage Cluster) ......................................................160

11.2 Performance/Tuning................................................................................................................. 162

11.3 Virtualization Platform ............................................................................................................. 164

11.3.1 Oracle VM Linkage ..........................................................................................................................................164

11.3.2 VMware Linkage .............................................................................................................................................165

11.3.3 Microsoft Linkage ...........................................................................................................................................167

11.4 Security .................................................................................................................................... 168

Storage Systems) ................158

14

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 15

List of Figures

Figure 1.1 Front View of a Controller Enclosure.........................................................................................................17

Figure 1.2

Figure 1.3 Front View of a Drive Enclosure ................................................................................................................19

Figure 1.4 Rear View of a Drive Enclosure .................................................................................................................19

Figure 1.5 Power Distribution Unit (AC200-240V, 1U, 4 Outlets)...............................................................................20

Figure 1.6 Power Distribution Unit (AC200-240V, 2U, 12 Outlets).............................................................................20

Figure 1.7 Power Distribution Unit (AC200-240V, 2U, 16 Outlets).............................................................................21

Figure 3.1 System Configuration Example.................................................................................................................34

Figure 3.2 Network Setting Label..............................................................................................................................41

Figure 5.1 Example of Differential Backup Settings with SnapOPC+..........................................................................56

Figure 5.2 Example of Creating Operation Volume and Backup Volume ...................................................................57

Figure 5.3 PC Terminal Connection for Initial Setup ..................................................................................................58

Figure 5.4 ON Position (Marked "|") of the Main Line Switches on a 1U Power Distribution Unit ..............................59

Figure 5.5 ON Position (Marked "|") of the Main Line Switches on a 2U Power Distribution Unit ..............................59

Figure 5.6 ON Position (Marked "|") of the PSU Switch on a Power Supply Unit ........................................................60

Figure 5.7 RAID Group Creation.................................................................................................................................74

Figure 5.8 Operation Volume Creation ......................................................................................................................76

Figure 5.9 Generation Management Volume (SDV) Creation ....................................................................................79

Figure 5.10 Copy Data Destination Volume (SDPV) Creation.......................................................................................80

Figure 8.1 Connection Configuration with Servers...................................................................................................119

Figure 11.1 Solution — Continuous Business (Copy between ETERNUS AF storage systems)......................................158

Figure 11.2 Solution — Continuous Business (Storage Cluster) ..................................................................................160

Figure 11.3 Solution — Performance/Tuning ..............................................................................................................162

Figure 11.4 Solution — Virtualization Platform (Oracle VM Linkage)..........................................................................164

Figure 11.5 Solution — Virtualization Platform (VMware Linkage).............................................................................165

Figure 11.6 Solution — Virtualization Platform (Microsoft Linkage)...........................................................................167

Rear View of a Controller Enclosure ..........................................................................................................18

15

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 16

List of Tables

Table 3.1 Server (Host) Environment.......................................................................................................................35

Table 3.2

Table 5.1 RAID Group Creation.................................................................................................................................74

Table 5.2 Operation Volume Creation ......................................................................................................................77

Table 7.1 ETERNUS AF Operation according to the Settings of the Auto Power Function and the Power Resume

LAN Port Availability.................................................................................................................................42

Function.................................................................................................................................................105

16

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 17

Chapter 1

1

3 3

2

Component Names

This chapter provides the component names of the ETERNUS AF.

1.1 Controller Enclosure

An operation panel and drives are installed in the front of the ETERNUS AF (controller enclosure). Controllers

and power supply units are installed in the rear.

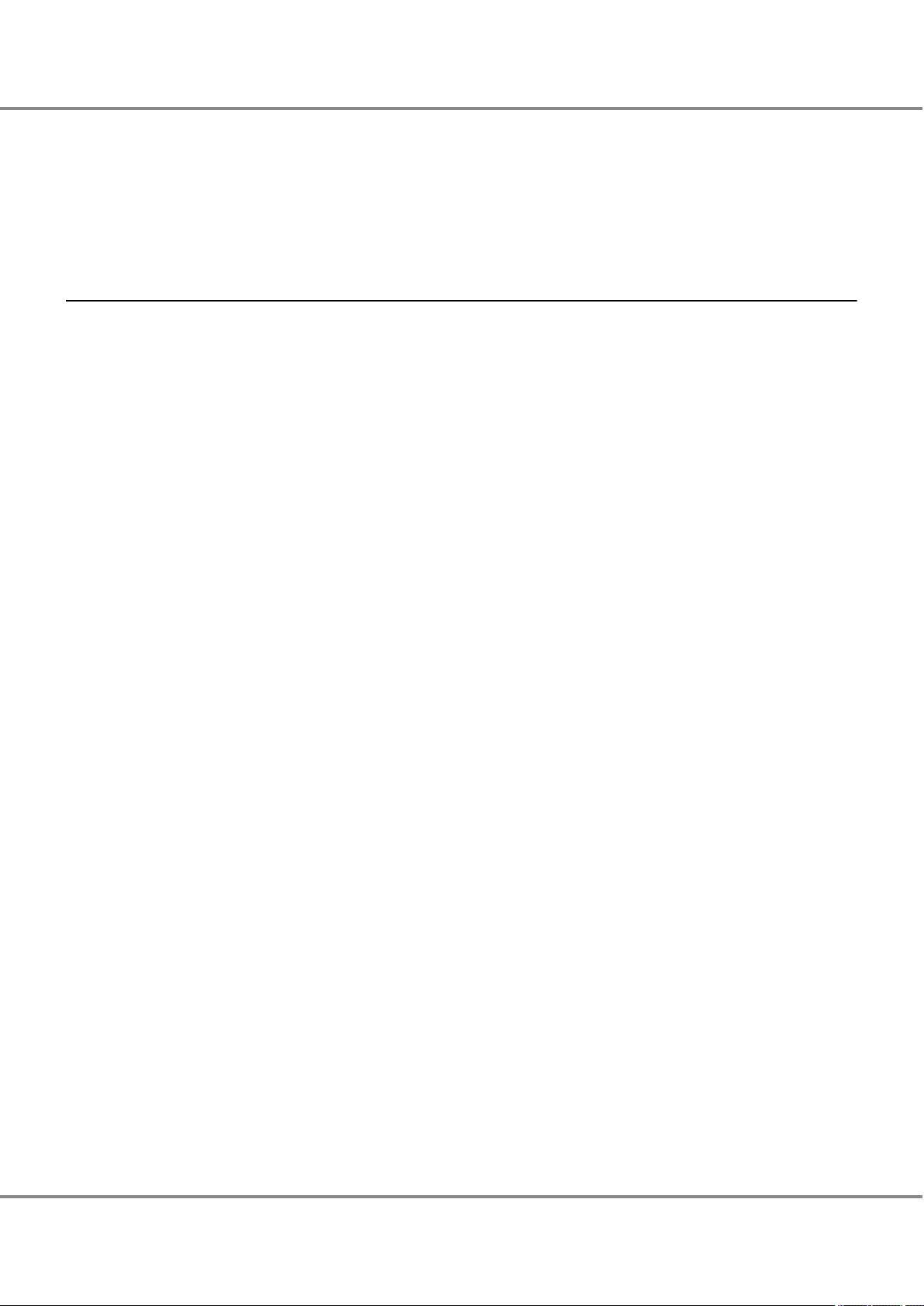

1.1.1 Front

This section provides the names of the components in the front of a controller enclosure.

Figure 1.1 Front View of a Controller Enclosure

1. Operation panel

2. Drive

3. Flange cover

17

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 18

12

3567 6734 588

9 10

4

Chapter 1 Component Names

1.2 Drive Enclosures

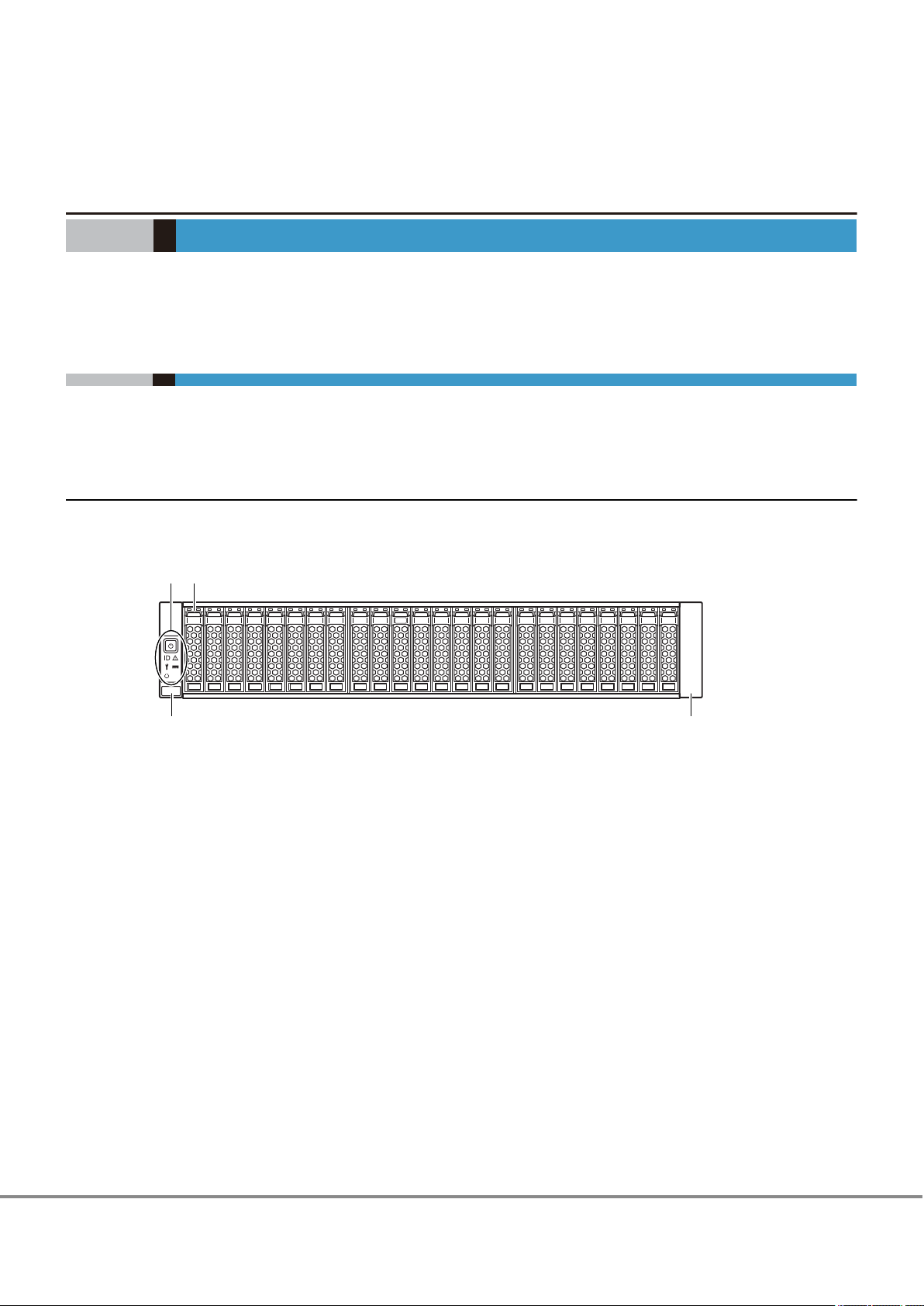

1.1.2 Rear

This section provides the names of the components in the rear of a controller enclosure.

Figure 1.2 Rear View of a Controller Enclosure

1. Controller (CM#0)

2. Controller (CM#1)

3. PWC port

4. Host interface (CA#0)

5. Drive interface (OUT) port

6. RMT (LAN) port

7. Host interface (CA#1)

8. MNT (LAN) port

9. Power supply unit (PSU#0)

10. Power supply unit (PSU#1)

1.2 Drive Enclosures

Drives and an operation panel are installed in the front of the drive enclosure. I/O modules and power supply

units are installed in the rear.

18

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 19

1

3 3

2

3

12

45

3

Chapter 1 Component Names

1.2 Drive Enclosures

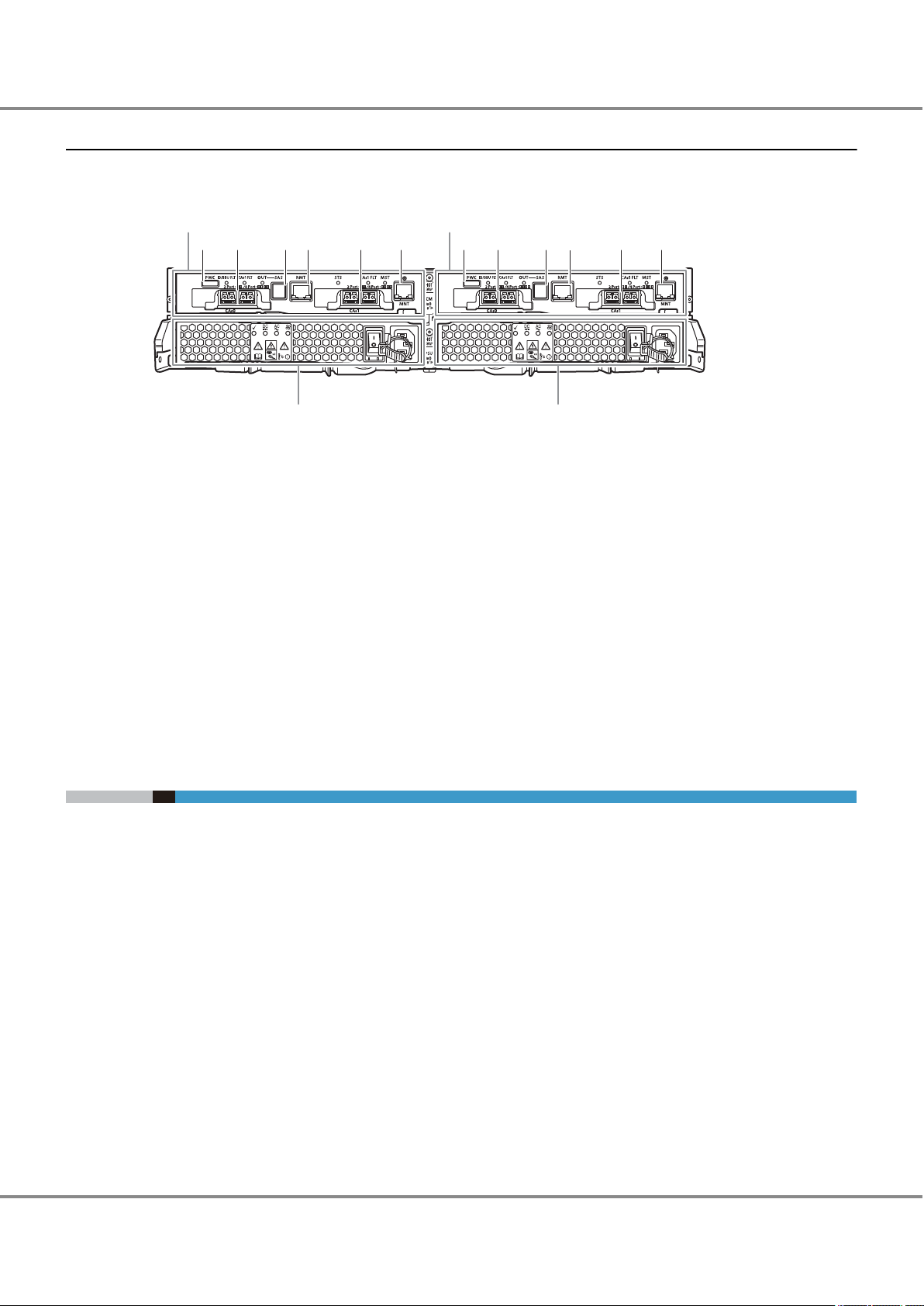

1.2.1 Front

This section provides the names of the components in the front of a drive enclosure.

Figure 1.3 Front View of a Drive Enclosure

1. Operation panel

2. Drive

3. Flange cover

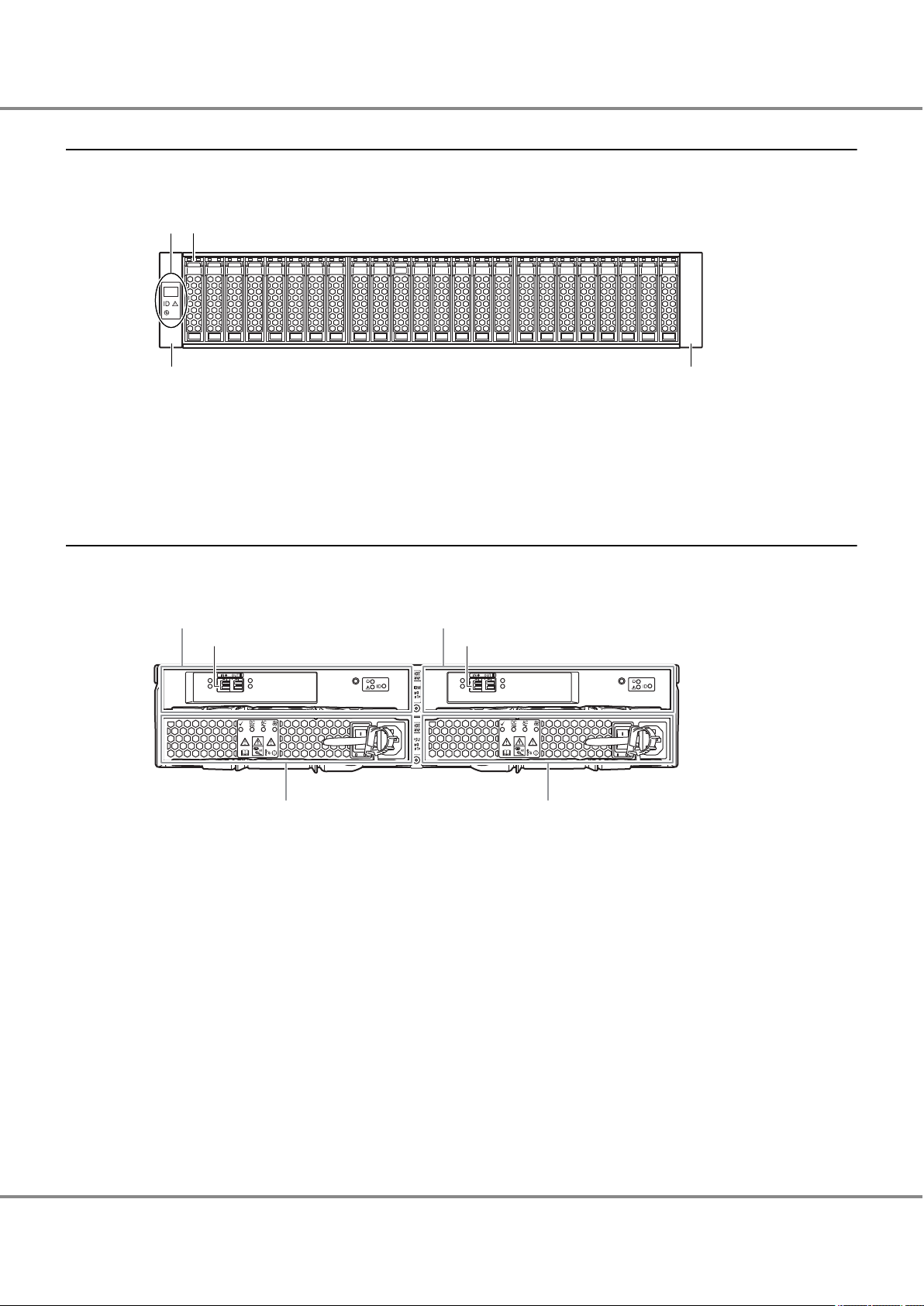

1.2.2 Rear

This section provides the names of the components in the rear of a drive enclosure.

Figure 1.4 Rear View of a Drive Enclosure

1. I/O module (IOM#0)

2. I/O module (IOM#1)

3. Drive interface (IN) port

4. Power supply unit (PSU#0)

5. Power supply unit (PSU#1)

19

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 20

3

2

1

2

1

Chapter 1 Component Names

1.3 Power Distribution Units (for Regions other than the EMEIA, Central American, and Caribbean Regions)

1.3 Power Distribution Units (for Regions other than the EMEIA,

Central American, and Caribbean Regions)

There are two sizes for power distribution units: 1U and 2U.

1.3.1 Power Distribution Units (1U)

The 1U power distribution unit has four outlets and two inlets.

1.3.1.1 Power Distribution Unit (AC200-240V, 1U, 4 Outlets)

Figure 1.5 Power Distribution Unit (AC200-240V, 1U, 4 Outlets)

1. Main line switch

2. Outlet (OUTPUT)

3. Inlet (INPUT)

1.3.2 Power Distribution Units (2U)

2U power distribution units are available in two types: a 12 outlet type and a 16 outlet type.

1.3.2.1 Power Distribution Unit (AC200-240V, 2U, 12 Outlets)

There are 12 outlets.

Figure 1.6

1. Main line switch

Power Distribution Unit (AC200-240V, 2U, 12 Outlets)

2. Outlet (OUTPUT)

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

20

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 21

2

1

Chapter 1 Component Names

1.3 Power Distribution Units (for Regions other than the EMEIA, Central American, and Caribbean Regions)

1.3.2.2 Power Distribution Unit (AC200-240V, 2U, 16 Outlets)

There are 16 outlets.

Figure 1.7

1. Main line switch

2. Outlet (OUTPUT)

Power Distribution Unit (AC200-240V, 2U, 16 Outlets)

21

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 22

Chapter 2

Do

Do Not

Rack Installation

This chapter describes the procedure for installing the ETERNUS AF in a rack.

Make sure to check "Safety Precautions" before starting the installation. Also refer to the rack manual.

Wear a wrist strap or touch a metal part to discharge the human body's natural

•

static electricity before starting each operation. Failure to discharge static electricity may cause failure in the

If components are installed in a way other as described in this chapter, damage

•

and/or device failure or electrical shock may occur.

Do not install the ETERNUS AF in the rack with cables, such as power cords, connec-

•

ted.

The ETERNUS AF contains delicate components, and should be handled gently. Do

•

not drop or knock the ETERNUS AF against the rack when installing it. Also, do not

knock the other devices installed in the rack.

The center of gravity must be taken into consideration to prevent a rack from top-

•

pling over. Enclosures should generally be installed from bottom to top to lower

the center of gravity and to ensure the safe use of racks.

ETERNUS AF.

Do not uninstall the drives that are installed by default or move them to any other

•

slot.

Contact your sales representative or maintenance engineer if drives that are installed by default need to be uninstalled or moved to another slot.

22

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

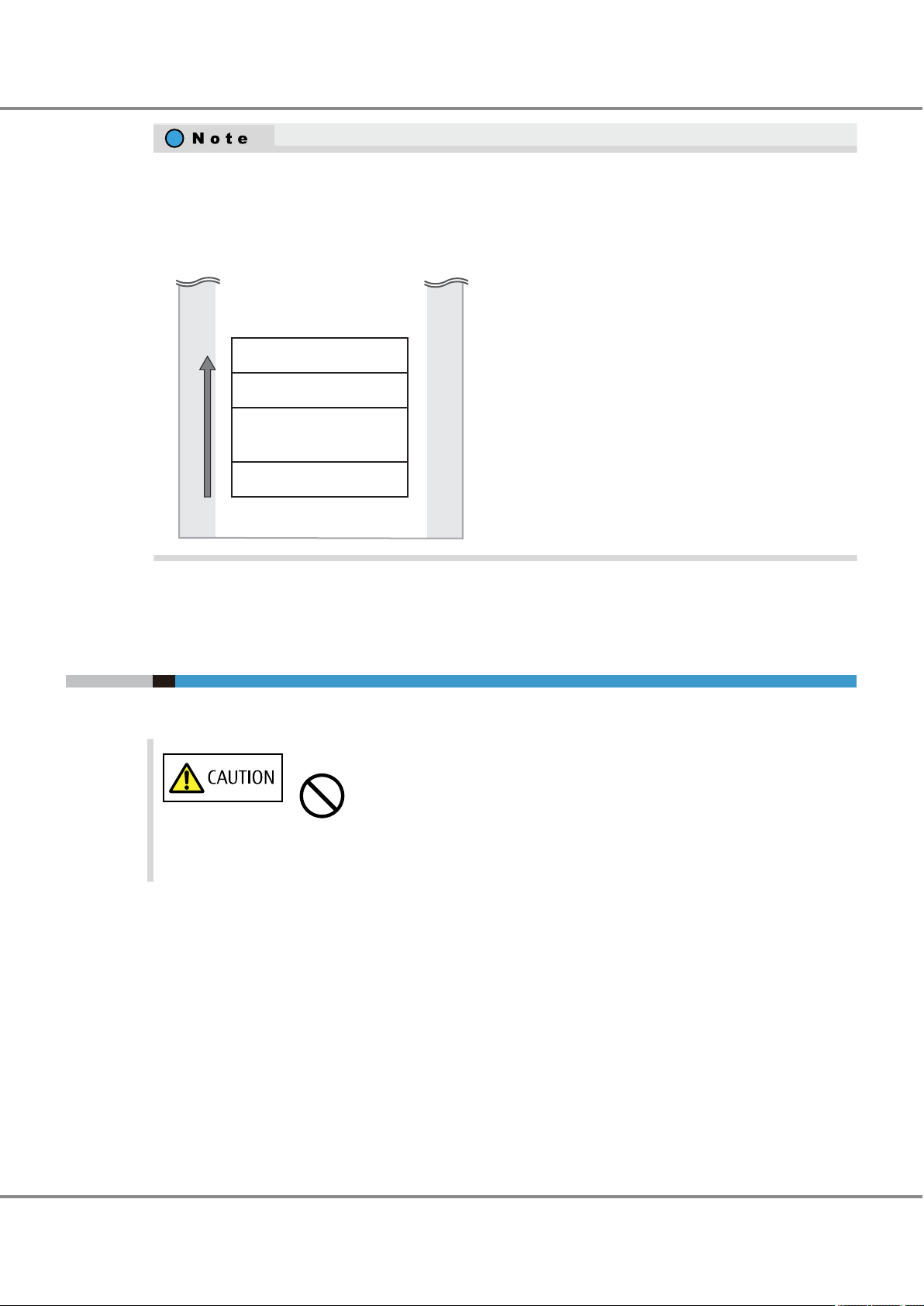

Page 23

Rack

Controller enclosure

Power distribution unit/

Power synchronized unit

Drive enclosure

UPS

1

2

3

4

Installation

order

Do Not

Chapter 2 Rack Installation

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

If the storage system is installed at the bottom of a rack, a space for the surplus of cables may not be

•

available in some racks, preventing the storage system from being pulled out when maintenance work

is required. In this case, secure a space of 1U or more at the bottom when installing the storage system.

To install an enclosure, power distribution units, power synchronized units, and UPS units in a single

•

rack, mount the devices in the following order (from bottom to top).

2.1 Power Distribution Unit Installation (for Regions other than

the EMEIA, Central American, and Caribbean Regions)

This section describes how to install the power distribution unit in a rack.

Do not connect any devices other than the

•

unit.

ETERNUS AF to the power distribution

23

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

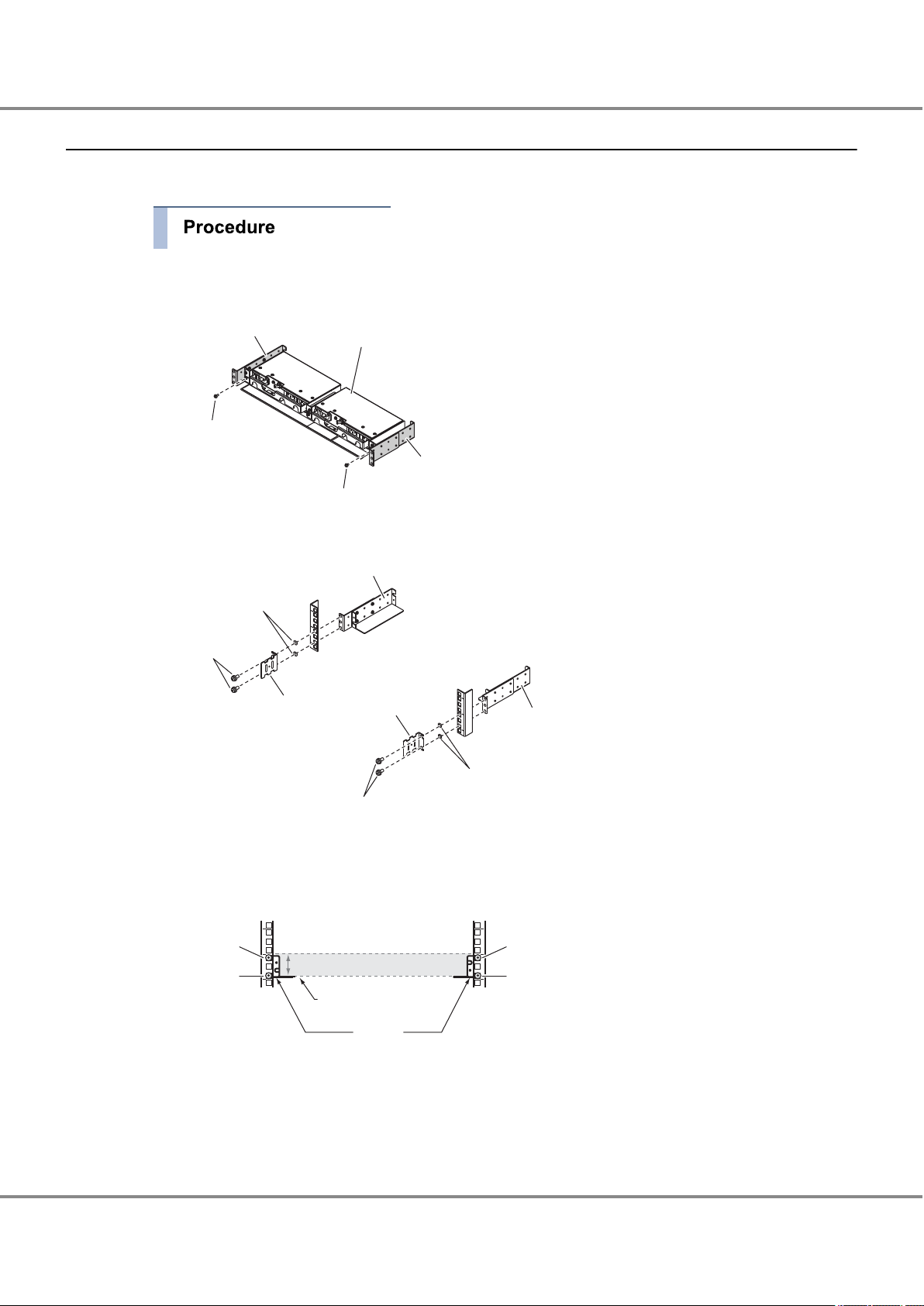

Page 24

Power distribution unit

Bracket B

Bracket A

M3 screw

M3 screw

(Rack pillar: rear)

Bracket B

Screw

holder

M6 screw

Screw

holder

Bracket A

Holder

Holder

M6 screw

Power distribution unit1U

(Rack pillar: rear)

Bracket

Power distribution unit

base line

1st hole

(M6 screw)

3rd hole

(M6 screw)

1st hole

(M6 screw)

3rd hole

(M6 screw)

[Left] [Right]

Chapter 2 Rack Installation

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2.1.1 Installing Power Distribution Unit (1U)

This section describes how to install the 1U power distribution unit in a rack.

1 Remove the two brackets temporarily attached to the power distribution unit.

Remove the two M3 screws from the front of the power distribution unit to free the brackets.

2 Attach the brackets and holders to the rack.

The four M6 screw positions for the brackets are determined relative to the power distribution unit base

line.

The four M6 screws should be inserted in the 1st and 3rd holes above the base line.

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

24

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 25

(Rack pillar: rear)

M3 screw

M3 screw

(Rack pillar: rear)

(Rack pillar: front)

Blank panel

Power distribution unit

Chapter 2 Rack Installation

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

3 Install the power distribution unit in the rack.

Fasten the power distribution unit to the bracket with the two M3 screws removed in Step 1.

4 Attach the blank panel to the front side of the rack.

The blank panel should be attached at the same height as the power distribution unit.

25

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 26

1U

1U

2U

Power distribution unit

Power distribution unit

(Rack pillar: rear)

Power distribution unit

base line

M5 cage nut M5 cage nut

1st hole

3rd hole

4th hole

6th hole

1st hole

3rd hole

4th hole

6th hole

[Left] [Right]

Side view

M5 cage nut

Rack pillar (square hole)

Chapter 2 Rack Installation

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2.1.2 Installing Power Distribution Unit (2U)

This section explains how to install a 2U power distribution unit (12 outlet type or 16 outlet type) in a rack.

This section explains how to install a 12 outlet type power distribution unit as an example. This installation method can also be applied to a 16 outlet type power distribution unit.

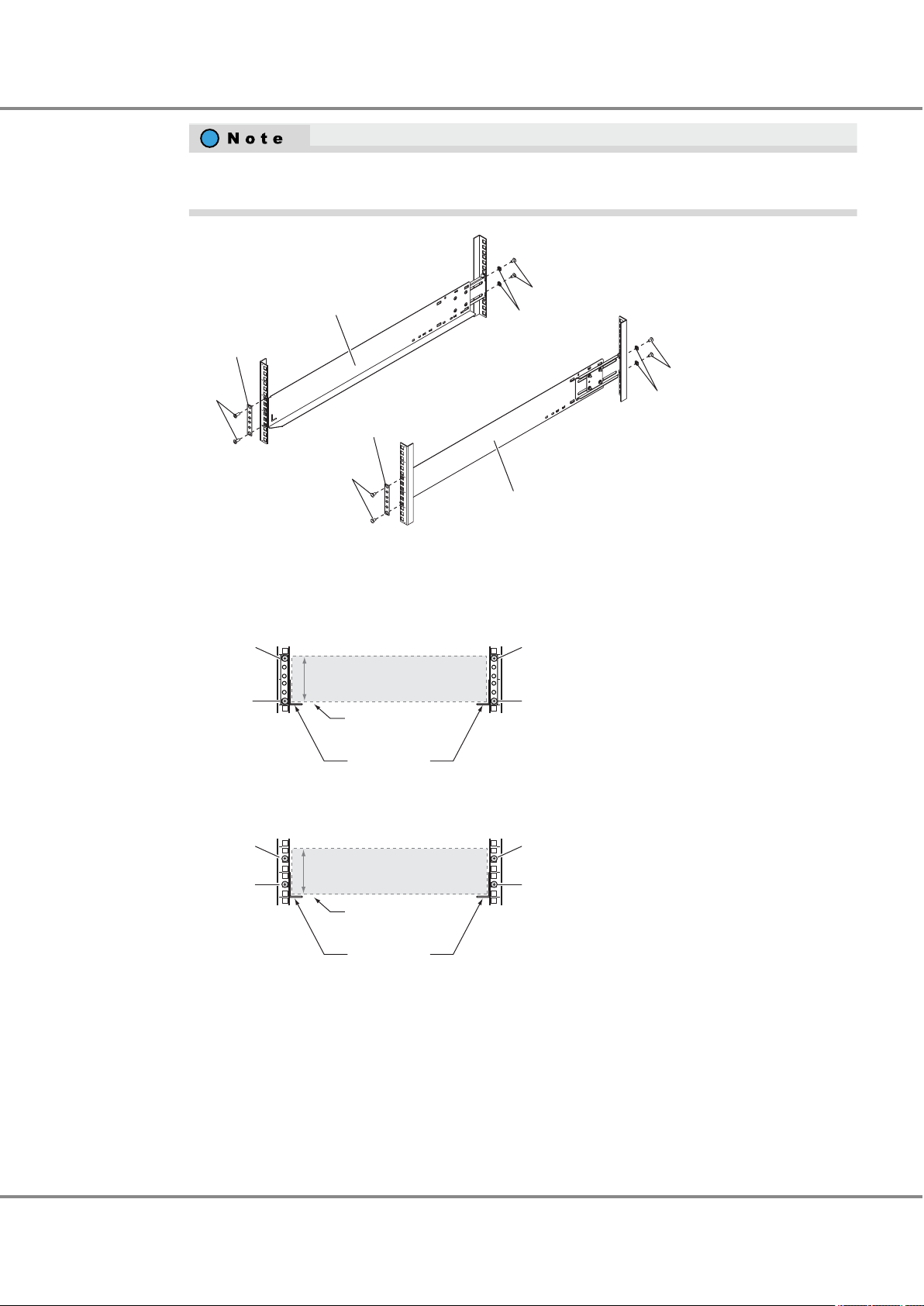

1 Attach the M5 cage nuts to the rear rack pillar.

• Attachment positions

On either side, insert eight M5 cage nuts in the 1st, 3rd, 4th, and 6th holes above the power distribution unit base line.

• Attachment procedure

Clip the M5 cage nut tabs into the desired hole from the inside.

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

26

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 27

(Rack pillar: rear)

M5 screw

M5 screw

(Rack pillar: rear)

(Rack pillar: front)

Blank panel

Power distribution unit

Chapter 2 Rack Installation

2.1 Power Distribution Unit Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2 Install the power distribution unit in the rack.

Fasten it to the prepared holes in the pillars with eight M5 screws.

3 Attach the blank panel to the rack front.

The blank panel should be attached at the same height as the power distribution unit.

27

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 28

Loosen the M4 screws to

adjust the length of the

rack rails to match the

distance between the

front and rear rack pillars.

(Rack pillar: front)

(Rack pillar: rear)

Rack rail (right)

An "R" mark is on the inner side.

[Left]

[Right]

Rack rail (left)

An "L" mark is on the

inner side.

Chapter 2 Rack Installation

2.2 Controller Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2.2 Controller Enclosure Installation (for Regions other than the

EMEIA, Central American, and Caribbean Regions)

This section describes how to install the controller enclosure in a rack.

1 Adjust the sizes of the rack rail (for left side) and the rack rail (for right side) to fit the rack.

Loosen the M4 screws to adjust the length of the rack rails to match the distance between the front and

rear rack pillars. Leave the M4 screws slightly unscrewed, as the rack rails must be attached to the rack

before they can be completely tightened.

2 Attach the rack rails to the rack.

Use the two plates to fasten the rack rails to the front rack pillars. Use the washers to fasten the rack

rails to the rear rack pillars.

28

Configuration Guide (Basic)

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 29

(Rack pillar: front)

(Rack pillar: rear)

Washer

M5 screw

M5 screw

Washer

M5 screw

Plate

M5 screw

Plate

Rack rail (right)

Rack rail (left)

Controller enclosure: front

Controller enclosure: rear

2U

Rack rail

Controller

enclosure base line

Rack rail

Controller

enclosure base line

[Right]

[Left]

6th hole

(M5 screw)

1st hole

(M5 screw)

6th hole

(M5 screw)

1st hole

(M5 screw)

2U

[Right][Left]

5th hole

(M5 screw)

2nd hole

(M5 screw)

5th hole

(M5 screw)

2nd hole

(M5 screw)

Chapter 2 Rack Installation

2.2 Controller Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

Make sure to attach the rack rails to rack pillars so that they fit exactly together without any space

between them.

3 Tighten the M4 screws of the rack rails that were slightly unscrewed in Step 1.

The M5 screw positions for the rack rails are determined by the controller enclosure base line.

Insert the M5 screws in the 1st and 6th holes on the front rack pillars above the base line and in the

2nd and 5th holes on the rear rack pillars above the base line to fasten the rack rails.

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

29

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 30

Do

M5 screw

M5 screws

Chapter 2 Rack Installation

2.2 Controller Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

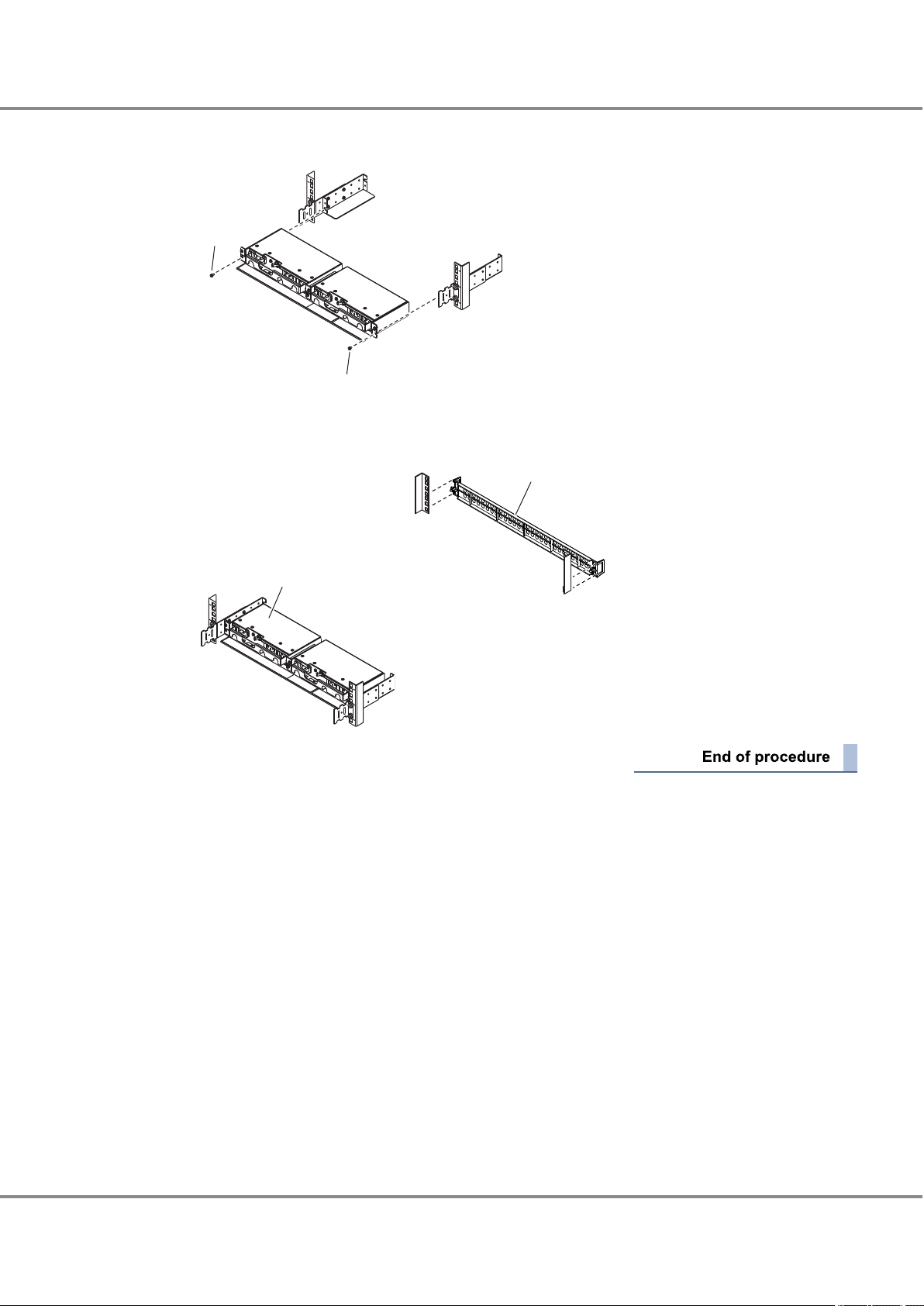

4 Install the controller enclosure in the rack.

• When installing or removing the controller enclosure to or from the rack,

make sure that the sides and the bottom of the controller enclosure are held

by two or more people. Failure to do so may cause injury.

5 Fasten the controller enclosure in the rack.

Use three M5 screws to fasten it in the rack pillar.

6 Attach the flange cover.

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

30

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 31

Loosen the M4 screws to

adjust the length of the

rack rails to match the

distance between the

front and rear rack pillars.

(Rack pillar: front)

(Rack pillar: rear)

Rack rail (right)

An "R" mark is on the inner side.

[Left]

[Right]

Rack rail (left)

An "L" mark is on the

inner side.

Chapter 2 Rack Installation

2.3 Drive Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

2.3 Drive Enclosure Installation (for Regions other than the

EMEIA, Central American, and Caribbean Regions)

This section describes how to install a drive enclosure in a rack.

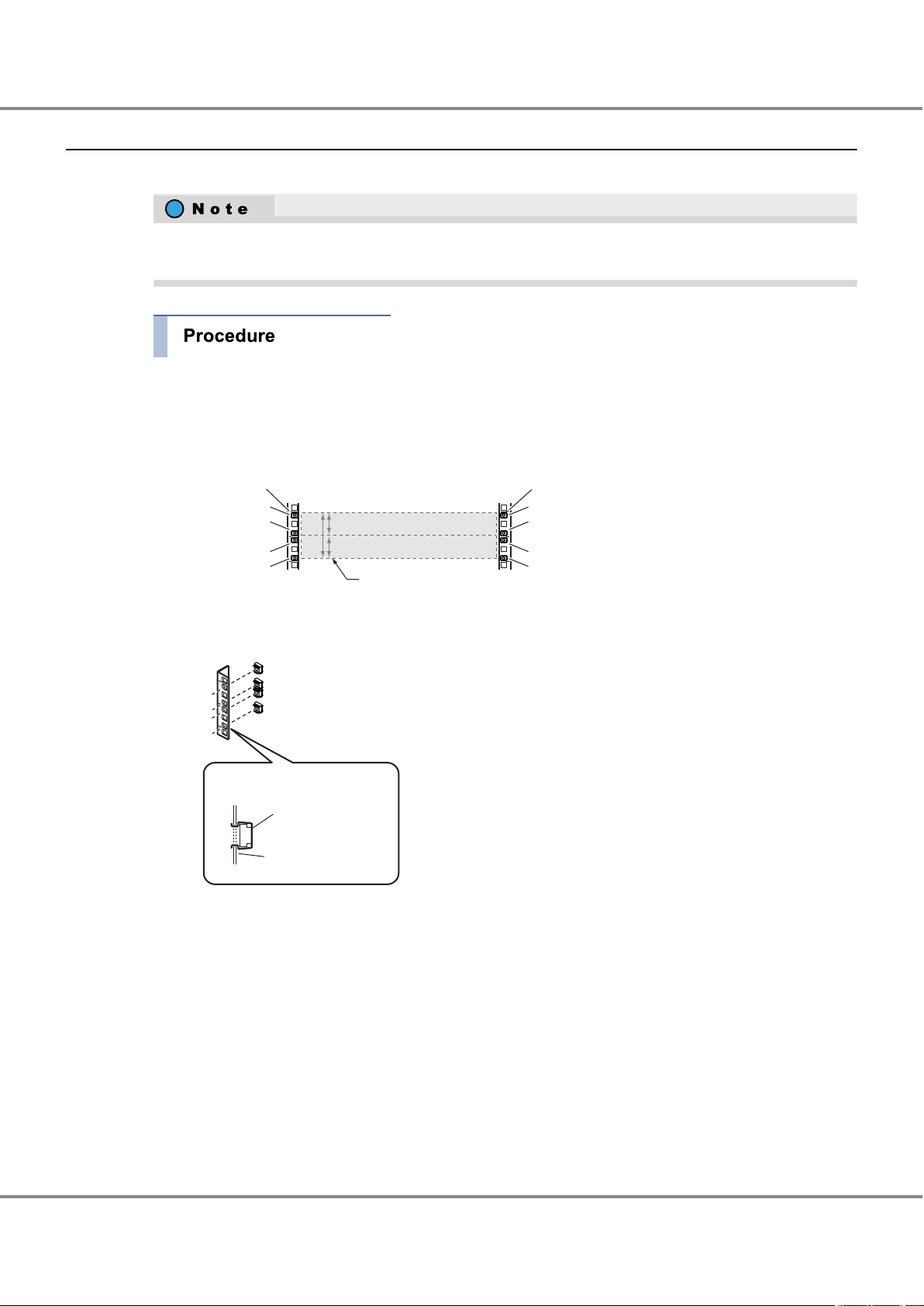

1 Adjust the sizes of the rack rail (for left side) and the rack rail (for right side) to fit the rack.

Loosen the M4 screws to adjust the length of the rack rails to match the distance between the front and

rear rack pillars. Leave the M4 screws slightly unscrewed, as the rack rails must be attached to the rack

before they can be completely tightened.

2 Attach the rack rails to the rack.

Use the two plates to fasten the rack rails to the front rack pillars. Use the washers to fasten the rack

rails to the rear rack pillars.

31

Configuration Guide (Basic)

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 32

(Rack pillar: front)

(Rack pillar: rear)

Washer

M5 screw

M5 screw

Washer

M5 screw

Plate

M5 screw

Plate

Rack rail (right)

Rack rail (left)

Front view of drive enclosure

Rear view of drive enclosure

2U

Rack rail

[Right][Left]

2U

Rack rail

[Right][Left]

Sixth screw

(M5 screw)

First screw

(M5 screw)

First screw

(M5 screw)

Fifth screw

(M5 screw)

Fifth screw

(M5 screw)

Second screw

(M5 screw)

Second screw

(M5 screw)

Sixth screw

(M5 screw)

Bottom position of

drive enclosure

Bottom position of

drive enclosure

Do

Chapter 2 Rack Installation

2.3 Drive Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

Make sure to attach the rack rails to rack pillars so that they fit exactly together without any space

between them.

The M5 screw positions for the rack rails are determined by the drive enclosure base line.

Insert the M5 screws in the 1st and 6th holes on the front rack pillars above the base line and in the

2nd and 5th holes on the rear rack pillars above the base line to fasten the rack rails.

3 Tighten the M4 screws of the rack rails that were slightly unscrewed in Step 1.

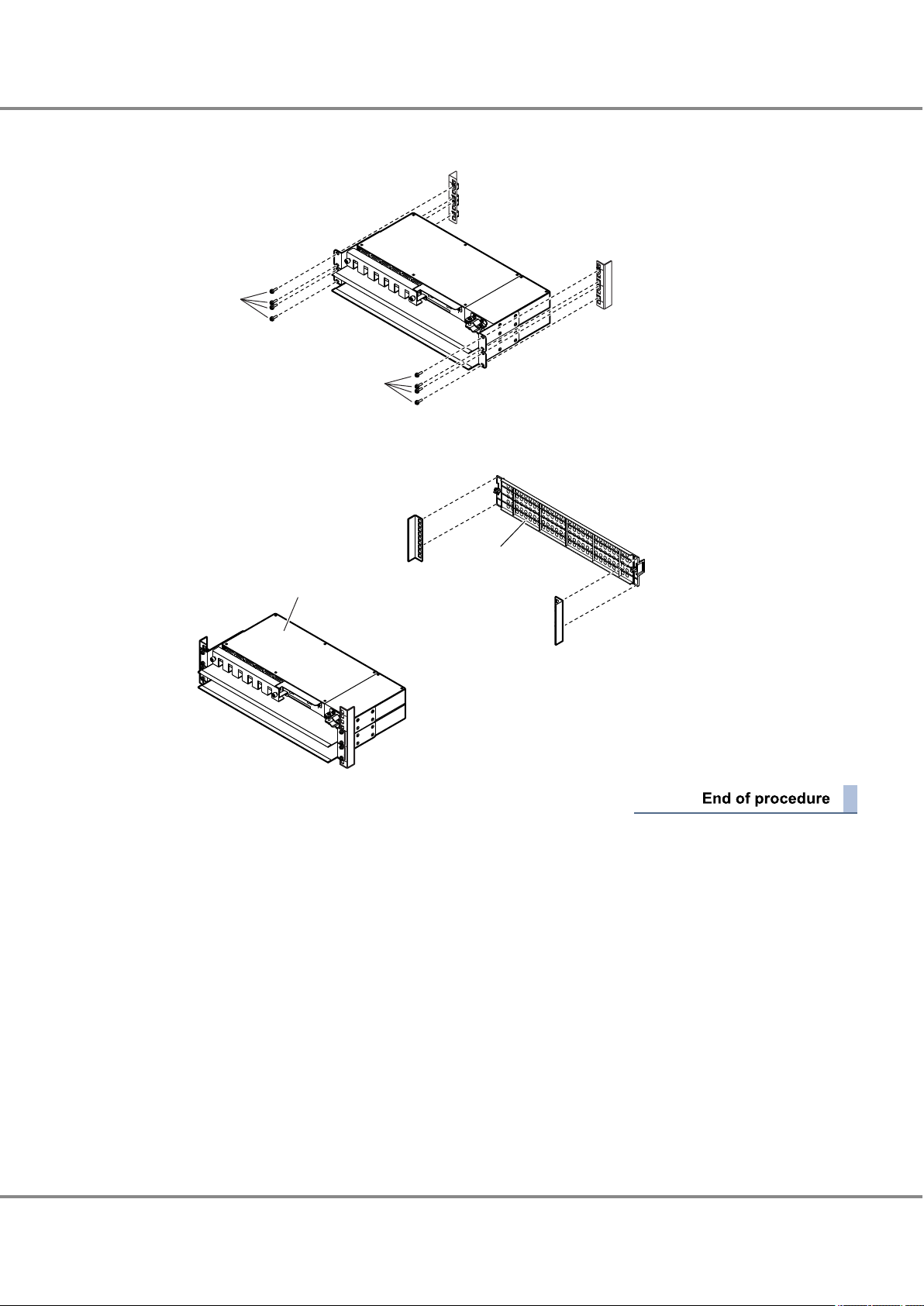

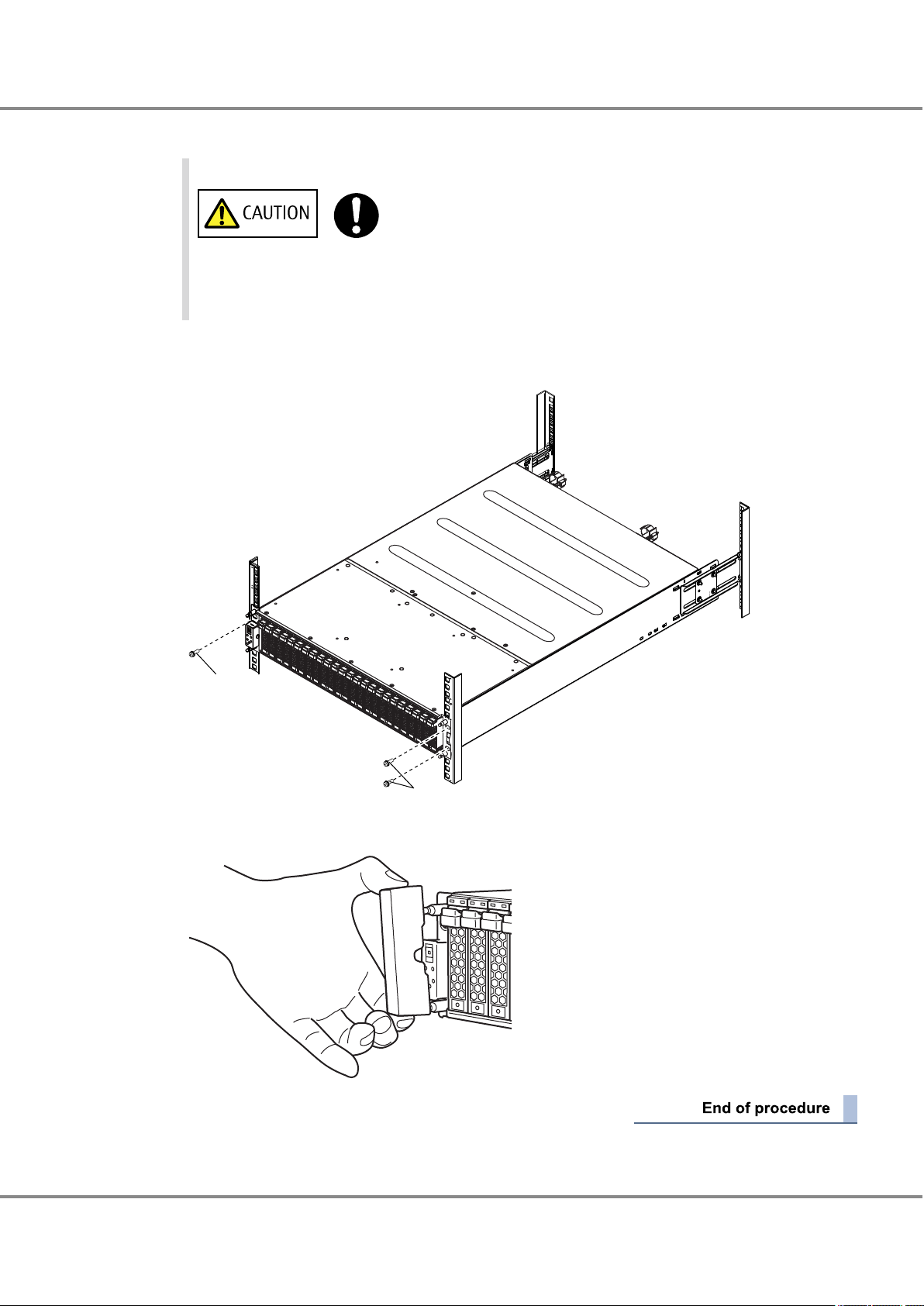

4 Install the drive enclosure in the rack.

• When installing or removing the drive enclosure to or from the rack, make

sure that the sides and the bottom of the drive enclosure are held by two or

more people. Failure to do so may cause injury.

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

32

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 33

M5 screws

M5 screws

Chapter 2 Rack Installation

2.3 Drive Enclosure Installation (for Regions other than the EMEIA, Central American, and Caribbean Regions)

5 Fasten the drive enclosure in the rack.

Use four M5 screws to fasten it in the rack pillar.

6 Attach the flange cover.

33

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 34

Chapter 3

ETERNUS AF

Remote support center

iSCSI SAN

Multipath

LAN for Operation Management

Server

SNMP manager

Mail server

Syslog server

PC for Operation

Management/

PC for setup

Checking the Configuration Environment

This manual explains how to configure the system with the ETERNUS AF, taking a basic configuration as an

example.

3.1 System Configuration Example

This section describes the procedure for the following system configuration as an example.

iSCSI interface connection

•

Multipath connection using the ETERNUS Multipath Driver

•

Event notification (SNMP trap transmission, email notification, syslog notification, and remote support) via

•

LAN

Generation management of data by acquisition of backup based on the day of the week with generation

•

copy using SnapOPC+

■

Configuration Diagram

The following diagram shows a system configuration example.

Figure 3.1 System Configuration Example

34

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 35

Do

Chapter 3 Checking the Configuration Environment

3.2 Server Connection Preparation

■

Server (Host) Environment

Table 3.1 Server (Host) Environment

Item Explanation

Server OS Windows Server 2008

Connection Configuration iSCSI connection, duplicated with multipath connection

Multipath Driver ETERNUS Multipath Driver

To connect the server and the ETERNUS AF via a switch, setting up of the switch must be performed. For details on this setting, refer to relevant manuals of the switch.

3.2 Server Connection Preparation

Prepare the server to connect to the ETERNUS AF.

A host bus adapter (HBA) that matches the connection interface that is to be used and a driver for the HBA

are required. Some types of HBA require utility software. Prepare the required environment for the HBA that

is to be used by referring to the HBA manual.

This section uses an iSCSI connection as an example to explain the required preparation for server connection.

3.2.1 Driver Preparation

Prepare required drivers and utilities.

LAN card driver for iSCSI

•

LAN driver

-

Supported version of iSCSI Software Initiator

-

This is already installed in a server that runs Windows Server 2008 or later.

ETERNUS Multipath Driver

•

•

Before installing the ETERNUS Multipath Driver, make sure that the server is not

connected to the ETERNUS AF. If the server is connected, shut down the server, remove the cable, and then restart the server.

35

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 36

Chapter 3 Checking the Configuration Environment

3.2 Server Connection Preparation

3.2.2 Driver Installation

Install the LAN driver and the ETERNUS Multipath Driver.

■

LAN Driver Installation

The following procedure explains how to install the LAN driver.

When using the onboard LAN card, skip this procedure.

1 To install a LAN driver, refer to the instructions for the LAN card.

2 Check that the driver has correctly been installed.

■

ETERNUS Multipath Driver Installation

The following procedure explains how to install the ETERNUS Multipath Driver.

1 Insert the CD-ROM into the server, then from Windows Explorer double-click on "setup.msi" in the "Eng-

lish" folder of the CD-ROM.

A screen to confirm the start of installation appears.

2 Click the [Next] button.

A screen to specify the installation directory of the ETERNUS Multipath Driver and which user installs the

driver appears.

3 To change the installation directory, click the [Browse] button and select the installation directory. To

leave the settings unchanged, click the [Next] button.

36

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 37

Chapter 3 Checking the Configuration Environment

3.2 Server Connection Preparation

For the user who installs the driver, select [Everyone] for normal operations.

If [Just me] is selected, users other than the one who installed the driver are not allowed to uninstall

or overwrite the installation of it.

The option that is selected here does not affect the operation of the ETERNUS Multipath Driver after

installation.

A screen to confirm execution of the installation appears.

4 Click the [Next] button.

When installation is complete, a message appears.

5 Click the [Close] button.

A screen to confirm whether to restart the computer appears.

6 Restart the server.

3.2.3 iSCSI Initiator Parameter Settings

The following procedure explains how to set the iSCSI initiator parameters. This section shows how to set an

iSCSI initiator name.

1 In [Administrative Tools], click [iSCSI Initiator].

2 For the first startup, the following dialog appears.

If there is no problem with service startup settings, click the [Yes] button.

37

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 38

Chapter 3 Checking the Configuration Environment

3.2 Server Connection Preparation

3 On the [iSCSI Initiator Properties] screen, click the [Configuration] tab.

38

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 39

Chapter 3 Checking the Configuration Environment

3.2 Server Connection Preparation

4 The currently set initiator name is displayed.

Click the [Change] button.

5 On the [iSCSI Initiator Name] screen, specify the initiator name and click the [OK] button.

To leave the initiator name unchanged, click the [OK] button.

To use the default initiator name, also click the [Change] button.

This allows you to continue to use this initiator name even after changing the "server name".

39

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 40

Chapter 3 Checking the Configuration Environment

3.3 Preparing the PC Terminal for Setup

6 Shut down the server.

After this, the settings for the ETERNUS AF must be completed before connecting the ETERNUS AF to

the server. In order to perform these settings, turn off the server.

3.3 Preparing the PC Terminal for Setup

The initial settings are performed by using a Web browser on the PC terminal.

Prepare and set up the PC terminal before the initial settings.

Preparing the PC terminal

Prepare the PC terminal that contains the following environment:

Web browser

•

Usable Web browsers are shown below. Using Web browsers other than the following is possible, but proper operation is not guaranteed.

Microsoft Internet Explorer 7.0, 8.0, 9.0, 10.0 (desktop version), 11.0 (desktop version)

-

Mozilla Firefox 3.6.x, ESR 10.0.x, ESR 17.0.x, ESR 24.0.x

-

Setting up the PC terminal

Set up the PC terminal with the following procedure:

1 Set the IP address and subnet mask of the PC terminal.

Set the following values.

IP address: 192.168.1.2

Subnet mask: 255.255.255.0

2 Check the settings of the Web browser.

For details on the required settings, refer to "Configuration Guide (Web GUI)".

40

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 41

Network Setting

:

: . . .

: . . .

:

IP address of MNT port

IP address of FST port

Subnet Mask of FST port

IP address of RMT port

Chapter 3 Checking the Configuration Environment

3.4 LAN Connection Preparation for Operation Management

3.4 LAN Connection Preparation for Operation Management

3.4.1 Completing and Attaching the Network Setting Label

Enter the network setting information on the Network Setting label. Attach the Network Setting label on the

rack wall near the controller enclosure to avoid losing it.

Figure 3.2 Network Setting Label

Complete the following items in the Network Setting label.

IP address of MNT port

•

Enter the IP address for the MNT port of the ETERNUS AF. The MNT port is a LAN port that is used to perform

operation management connection.

IP address of FST port

•

This item is not used. No information needs to be entered for this item.

Subnet Mask of FST port

•

This item is not used. No information needs to be entered for this item.

IP address of RMT port

•

Enter the IP address for the RMT port of the

initial setup and to connect to the remote support center.

ETERNUS AF. The RMT port is a LAN port that is used during

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

41

Configuration Guide (Basic)

Copyright 2017 FUJITSU LIMITED

P3AG-1832-04ENZ0

Page 42

Chapter 3 Checking the Configuration Environment

3.4 LAN Connection Preparation for Operation Management

3.4.2 LAN Related Specifications

■

Network Communication Protocols

The usable LAN ports and functions are different depending on the usage and protocol.

The following table shows how the LAN ports may be used (by usage and protocol).

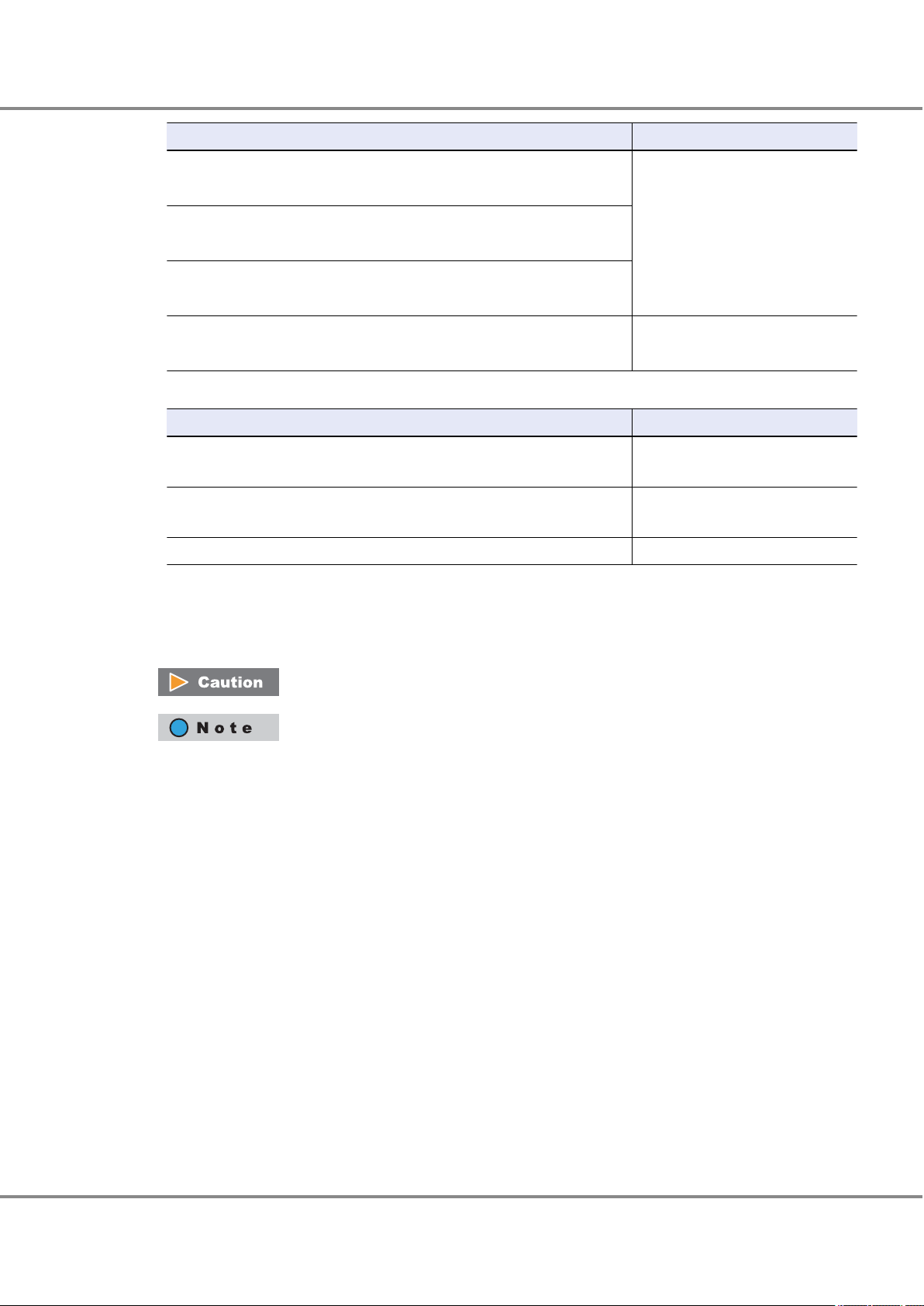

Table 3.2 LAN Port Availability

Usage Protocol tcp / udp

ETERNUS Web GUI http /

https

ETERNUS CLI telnet /

ssh

ftp (client)

SNMP agent snmp udp 161 from

trap snmp

trap

SMI-S http /

https

http /

https

SLP tcp 427 from/to

E-mail smtp (cli-

ent)

NTP NTP (cli-

ent)

tcp 80 / 443 from

tcp 23 / 22 from

tcp 21 to

udp Must be

tcp 5988 /

tcp Must be

tcp 25 (*3) to

udp 123 to

Port

number

set

5989

set

Direction

to

from

to

Master CM Slave CM

MNT RMT MNT RMT

¡ ¡

¡ ¡

¡ ¡

¡ ¡ ¡ ¡

¡ (*2) ¡ (*2)

¡

¡

¡

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

´ ´ ´

´ ´ ´

´ ´ ´

△ (*1) △ (*1) Accessed

△ (*1) △ (*1) −

△ (*1) △ (*1) −

´ ´

´ ´

´ ´

Remarks

from a

Web

browser

−

−

Used for

SMI-S client communication

Used for

event

communications

with the

SMI-S listener,

etc.

Used for

service

inquiry

communication

from the

SMI-S client

Used for

failure

notification, etc.

−

42

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 43

Chapter 3 Checking the Configuration Environment

3.4 LAN Connection Preparation for Operation Management

Usage Protocol tcp / udp

REMCS

(remote support)

AIS Connect (remote

support)

Syslog

(event notification

and audit log sending)

RADIUS Radius udp Must be

ping ICMP − − from

KMIP (key management)

ETERNUS DX Discovery

smtp tcp Must be

http (client)

https (client)

Syslog udp Must be

SSL tcp 5696

Unique

protocol

tcp Must be

tcp 443 to

udp 9686 from

Port

number

set

set

set

set

(*3)

Direction

to

to

to

to

to

Master CM Slave CM

MNT RMT MNT RMT

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡ (*2) ¡ (*2)

¡

´ ´ ´

´ ´

´ ´

´ ´

´ ´

´ ´

´ ´

´ ´

Remarks

Used for

failure

notification, etc.

Used for

firmware

download, etc.

—

−

−

−

−

−

¡: Possible / △: Partially possible / ´: Not possible

*1: Only the following functions are available:

• Checking the ETERNUS AF status

• Switching the Master CM

*2: May use either the MNT port or RMT port.

*3: Modifiable

For details on the port numbers for the ETERNUS SF Software, refer to the manual of each Storage Foundation

Software ETERNUS SF.

■

Communication Modes

The default LAN operation mode is "Auto Negotiation" which allows the

ETERNUS AF to automatically recognize 1000BASE-T/100BASE-TX/10BASE-T and Full/Half-Duplex connections. However, some devices may require that a fixed communication mode be set.

43

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 44

Chapter 4

Do

Connecting Cables

This chapter explains how to connect various cables to the ETERNUS AF.

Wear a wrist strap or touch a metal part to discharge the human body's natural

•

static electricity before starting each operation. Failure to discharge static electricity may cause failure in the

4.1 Host Interface Cable Connection

ETERNUS AF.

Connect the ETERNUS AF to the connection destination using host interface cables. The connection procedure

varies depending on the type of host interface that is used for the ETERNUS AF

If the host interface is iSCSI 10Gbit/s (10GBASE-SR), and an FC cable is used for the connection, the SFP+

module must be installed in the host interface port before the cable is connected.

Prepare the same number of host interface cables as the number of host interface ports.

To help with host interface cable management and prevent incorrect connections, attach labels to the

•

cables that show which end is for the connection origin and which end is for the connection destination.

When connecting a host interface cable, check the direction of the connector tab and insert it all the

•

way in firmly.

When disconnecting a host interface cable, pull out the connector while holding its tab.

If the host interface ports and host interface cable connectors have covers, remove the covers. Keep the

•

removed covers in a safe place where they will not be lost.

When connecting the cables, position them so that they will not obstruct replacement of the power sup-

•

ply unit or controllers by the maintenance engineer.

.

44

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 45

Do

Do

Do Not

Chapter 4 Connecting Cables

4.1 Host Interface Cable Connection

■

SFP+ Module Handling Instructions

The following shows instructions for handling an SFP+ module.

● About Condensation

When moving an SFP+ module from a cold place, such as an unconditioned store

•

house in winter, to a warmer place such as an air-conditioned room, the severe

temperature change may result in condensation forming.

To avoid this, allow the packed SFP+ modules sufficient time in the warmer place

(one hour for each 15

ture.

°C of temperature difference) to adapt to the new tempera-

● About Static Electricity

● About Shock

When handling SFP+ modules, wear a wrist strap or touch a metal part to discharge

•

the human body's natural static electricity. Failure to discharge static electricity

may cause failure in the ETERNUS AF.

Leave the SFP+ module in its package until ready to install it.

•

Do not handle the SFP+ module roughly or subject it to physical shocks when lay-

•

ing it down.

Do not place any objects on top of SFP+ modules.

•

Do not knock or drop the SFP+ module on hard objects.

•

This section uses an iSCSI 10Gbit/s host interface (CA) as an example to show the connection procedure.

1 Install an SFP+ module in the host interface port.

This procedure is required only when an SFP+ module must be installed.

45

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 46

SFP+ module

Lever

Host interface

(CA#0)

Host interface

(CA#1)

Controller 0

(CM#0)

Port#0 Port#1 Port#0 Port#1

Port#0 Port#1 Port#0 Port#1

Host interface

(CA#0)

Host interface

(CA#1)

Controller 1

(CM#1)

SFP+ module (Insertion direction)

Topside

Chapter 4 Connecting Cables

4.1 Host Interface Cable Connection

Step 1 is not required if the host interface (CA) is iSCSI 10Gbit/s (10GBASE-T).

(1) Remove the connector cover attached to the port of the SFP+ module and open the lever.

Keep the removed connector cover in a safe place where it will not be lost.

(2) Check the direction of the SFP+ module and insert it all the way into the port cage of the host

interface.

Install the SFP+ module in Port#0 first, and then Port#1.

(3) Close the SFP+ module's lever.

46

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 47

Do

Chapter 4 Connecting Cables

4.2 Drive Enclosure Connection

2 Connect a host interface cable to the

ETERNUS AF.

Insert the host interface cable connectors in the host interface ports (iSCSI) of Controller 0 (CM#0) and

Controller 1 (CM#1).

• When connecting the host interface cables, position them so that they will

not obstruct replacement of the power supply unit or controllers by the maintenance engineer.

3 Connect the host interface cable to the connection destination.

Connect the other end of the cable to the connection destination.

4.2 Drive Enclosure Connection

When a drive enclosure is installed, connect the drive enclosure to the controller enclosure with a mini SAS

HD cable between enclosures.

0.75m mini SAS HD cables between enclosures are provided with drive enclosures.

The following procedure explains how to connect the mini SAS HD cable between enclosures.

47

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 48

Tab

Chapter 4 Connecting Cables

4.2 Drive Enclosure Connection

To help with management of the mini SAS HD cable between enclosures and prevent incorrect connec-

•

tions, make sure to attach the destination labels to the connectors of the cables.

When connecting the mini SAS HD cable between enclosures, check the direction of the connector (the

•

tab must be pointed downward) and firmly insert all the way in.

To disconnect the mini SAS HD cables between enclosures, hold the tab and then pull out the connector.

1 Check the connection destination of the mini SAS HD cables between enclosures.

• The connectors on the cable with the "n" symbol are connected to the DI (OUT) ports on the controller

enclosure.

• The connectors on the cable with the "l" symbol are connected to the DI (IN) ports on the drive en-

closure.

48

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 49

Controller

enclosure

Drive

enclosure

Controller

enclosure

Drive

enclosure

Chapter 4 Connecting Cables

4.3 Power Synchronized Unit Connection

2 Connect the controller enclosure to the drive enclosure.

(1) Connect Controller 0 first.

Connect the DI (OUT) port of Controller 0 (CM#0) in the controller enclosure to the DI (IN) port of

I/O module 0 (IOM#0) in the drive enclosure with the mini SAS HD cable between enclosures.

(2) Connect Controller 1 next.

Connect the DI (OUT) port of Controller 1 (CM#1) in the controller enclosure to the DI (IN) port of

I/O module 1 (IOM#1) in the drive enclosure with the mini SAS HD cable between enclosures.

4.3 Power Synchronized Unit Connection

When using a power synchronized unit for power control, connect the power synchronized unit to the ETERNUS AF.

Refer to "Configuration Guide (Power Synchronized Unit)" for details about power synchronized units, the procedure for connecting power synchronized units to the

ETERNUS AF, and required settings.

4.4 Power Cord Connection

Connect the power cords to the ETERNUS AF.

49

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 50

Chapter 4 Connecting Cables

4.4 Power Cord Connection

The controller enclosure and drive enclosure have two power supply units (PSU#0 and PSU#1).

Make sure that the power cords are connected to all the power supply units.

4.4.1 When No Power Distribution Units Are Installed

The following procedure explains how to connect the power cords when no power distribution units are installed.

To help with power cord management and prevent incorrect connections, attach labels to the power cords

and make a note of connection origins and destinations.

1 Connect the power cord to the ETERNUS AF

.

(1) Connect the power cord plugs to the power inlets of the power supply units.

(2) Fasten the plug of the power cord with the release tie.

Wrap the release tie around the power cord and fasten the release tie from either side. Make sure

that the release tie is not loose.

2 Connect the power cords to the socket.

Connect the plug at the other end of each power cord to the socket.

Connecting two power cords for each enclosure to different two power supply facilities improves the

availability of the power supply facilities against failures.

50

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 51

Do Not

Power distribution unit

Power cord clamp

Chapter 4 Connecting Cables

4.4 Power Cord Connection

• Do not use the server service outlet to connect a power cord for the ETERNUS

AF

.

4.4.2 When 1U Power Distribution Unit Is Installed (for Regions other than the EMEIA, Central American, and Caribbean Regions)

The following procedure explains how to connect the power cord when a 1U power distribution unit is installed.

To help with power cord management and prevent incorrect connections, attach labels to the power cords

and make a note of connection origins and destinations.

1 Remove the power cord clamp from the power distribution unit.

51

FUJITSU Storage ETERNUS AF250 S2, ETERNUS AF250 All-Flash Arrays

Copyright 2017 FUJITSU LIMITED

Configuration Guide (Basic)

P3AG-1832-04ENZ0

Page 52

Drive enclosure 1

Controller enclosure

: Connect

OUTPUT#0-n of the Power distribution unit to the PSU#0 inlet of the ETERNUS storage system.

: Connect

OUTPUT#1-n of the Power distribution unit to the PSU#1 inlet of the ETERNUS storage system.

Power distribution unit

Outlet

OUTPUT #0-1

Outlet

OUTPUT #0-2

Outlet

OUTPUT #1-2

Outlet

OUTPUT #1-1

PSU#1 Inlet

PSU#1

Inlet

PSU#0

Inlet

PSU#0 Inlet

Inlet

INPUT #0

Inlet

INPUT #1

Power distribution unit

Chapter 4 Connecting Cables

4.4 Power Cord Connection

2 Connect the power distribution unit outlets and power supply unit inlets with the power cords (AC out-

put cables).

The procedures to connect the power supply unit is same as Step 1 in "4.4.1 When No Power Distribu-

tion Units Are Installed" (page

The following figure shows an example of AC output cable connection:

50).

3 Connect the power cord (AC input cable) plugs to the inlets of the power distribution unit.

4 Use the power cord clamps to prevent the power plugs from coming unplugged.

Attach the power cord clamps removed in Step 1.

5 Connect the plugs on the other end of the power cords (AC input cables) that were connected in Step 3

to the sockets.

Power supply failure can be prevented by connecting the power cords (AC input cables) on the INPUT#0 side and the INPUT#1 side to different power sources.

4.4.3 When 2U Power Distribution Unit Is Installed (for Regions other than the EMEIA, Central American, and Caribbean Regions)

The following procedure explains how to connect the power cords when a 2U power distribution unit (12 outlet type or 16 outlet type) is installed.