Page 1

DL9300/9400

DOT MATRIX PRINTER

PRODUCT DESCRIPTION

FUJITSU LIMITED

Communications and Electronics

Tokyo, Japan

Page 2

Page 3

REVISION RECORD

Edition

01

Date published

July 1996

Page Revised contents

First issue

Specification No. C147-C007-01EN

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 1996 FUJITSU LIMITED. Printed in Japan.

No part of this manual may be reproduced in any form without permission.

Page 4

Address your comments and inquiries on this manual to:

FUJITSU COMPUTER PRODUCTS OF

AMERICA, INC.

2904 Orchard Parkway, San Jose

CA 95134-2022, U.S.A.

TEL: (1-408) 432-6333

FAX: (1-408) 894-1709

FUJITSU CANADA INC.

2800 Matheson Boulevard East

Mississauga, Ontario L4W 4X5, CANADA

TEL: (1-905) 602-5454

FAX: (1-905) 602-5457

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue, Chatswood

N.S.W., 2067, AUSTRALIA

TEL: (61-2) 410-4555

FAX: (61-2) 411-8603

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211

80807, München, F.R. GERMANY

TEL: (49-89) 32378-0

FAX: (49-89) 32378-100

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia No. 8

20124 Milano, ITALY

TEL: (39-2) 6365-1

FAX: (39-2) 6572-257

FUJITSU KOREA LTD.

9th Floor, Korean Reinsurance Bldg.

80, Susong-Dong, Chongro-Gu

Seoul Special City, Republic of KOREA

TEL: (82-2) 739-3281

FAX: (82-2) 739-3294

FUJITSU NORDIC AB

Kung Hans Väg 12

S-191 76 Sollentuna, SWEDEN

TEL: (46-8) 626-6000

FAX: (46-8) 626-6711

FUJITSU (SINGAPORE) PTE. LTD.

75 Science Park Drive

#02-06 CINTECH II, SINGAPORE 0511

TEL: (65) 777-6577

FAX: (65) 777-8794

FUJITSU ESPAÑA, S.A.

Almagro 40, 28009 Madrid, SPAIN

TEL: (34-1) 581-8400

FAX: (34-1) 581-8125

FUJITSU EUROPE LTD.

2 Longwalk Road, Stockly Park, Uxbridge

Middlesex UB11 1AB, ENGLAND

TEL: (44-81) 573-4444

FAX: (44-81) 573-2643

FUJITSU FRANCE S.A.

Batiment Aristote, Rue Olof Palme 94006

Créteil cedex, FRANCE

TEL: (33-1) 45-13-16-16

FAX: (33-1) 43-99-07-00

FUJITSU HONG KONG LIMITED

Room 2521, Sun Hung Kai Centre

30 Harbour Road, HONG KONG

TEL: (852) 827-5780

FAX: (852) 827-4724

FUJITSU ICIM LTD.

Nagar Road, Pune 411 014, INDIA

TEL: (91-212) 681-528

FAX: (91-212) 680-238

FUJITSU SYSTEMS BUSINESS

(MALAYSIA) SDN. BHD.

Fujitsu Plaza, 1A, Jalan Tandang 204

P.O. Box 636 Pejabat Pos Jalan Sultan

46770 Petaling Jaya

Selangor Darul Ehsan, MALAYSIA

TEL: (60-3) 793-3888

FAX: (60-3) 793-0888

FUJITSU SYSTEMS BUSINESS

(THAILAND) LTD.

12th Floor, Olympia Thai Tower

444 Rachadapisek Road, Samsennok

Huaykwang, Bangkok 10310, THAILAND

TEL: (662) 512-6066

FAX: (662) 512-6068

FUJITSU TAIWAN LTD.

8th FL., NO. 170, Hung Tai Center

Tun Hwa N. RD., Taipei, TAIWAN, R.O.C.

TEL: (886-2) 545-7700

FAX: (886-2) 717-4644

FUJITSU LIMITED

Computer Products Business Group

Kamikodanaka 4-1-1, Nakahara-ku

Kawasaki-shi 211, JAPAN

TEL: (81-44) 754-8633

FAX: (81-44) 754-8510

Page 5

PREFACE

This manual gives the product specifications for the DL9300/9400 dot matrix printers. The manual provides

prospective customers with required engineering specifications.

Chapter 1: describes the main features.

Chapter 2: gives the model configuration and equipment structure.

Chapter 3: gives functional, physical, electrical, and environmental specifications. It also covers paper specifi-

cations.

Chapter 4: describes the control panel together with basic status indicated by the LED indicators and functions

of the push-button switches. It also outlines the printer remote setup utility program, DLMENU.

Chapter 5: gives information on the interface, its hardware specifications, and software specifications. It also

summarizes command sets.

Chapter 6: explains maintenance.

Chapter 7: lists options and consumables.

Appendixes: give information on character sets, resident fonts, printer dimensions, and nameplate and label

locations.

Page 6

Page 7

CONTENTS

CHAPTER 1 FEATURES ............................................................................................................................1-1

1.1 Print Quality and Copy Capability ............................................................................................................1-1

1.2 Print Modes ............................................................................................................................................... 1-2

1.3 Fonts and Character Sets ...........................................................................................................................1-3

1.4 Emulations and Compatibility with IBM PC Printers...............................................................................1-3

1.5 Printing Speed and Throughput.................................................................................................................1-4

1.6 Automatic Paper Loading, Switching, and Tearing-Off ........................................................................... 1-4

1.7 Control Panel ............................................................................................................................................. 1-5

1.8 Multiple Paper Paths and Switching (HCPP) ............................................................................................1-6

1.9 Automatic Print Head Gap Adjustment (APTC).......................................................................................1-8

1.10 Automatic Interface Switching................................................................................................................1-8

1.11 Printer Driver and DLMENU .................................................................................................................. 1-8

CHAPTER 2 MODEL CONFIGURATION AND EQUIPMENT STRUCTURE..................................2-1

2.1 Model Configuration .................................................................................................................................2-1

2.2 Block Diagram...........................................................................................................................................2-2

2.3 Structure .................................................................................................................................................... 2-4

2.3.1 Exterior components............................................................................................................................2-6

2.3.2 Printing mechanism ............................................................................................................................. 2-6

2.3.3 Bottom cover .......................................................................................................................................2-7

2.3.4 Options and consumables.................................................................................................................... 2-8

CHAPTER 3 SPECIFICATIONS................................................................................................................3-1

3.1 General Specifications...............................................................................................................................3-1

3.1.1 Print head and carriage ........................................................................................................................3-1

3.1.2 Forms feed ........................................................................................................................................... 3-2

3.1.3 Character sets and fonts.......................................................................................................................3-3

3.1.4 Forms...................................................................................................................................................3-4

3.1.5 Other printing features.........................................................................................................................3-5

3.1.6 Acoustic noise ..................................................................................................................................... 3-5

3.1.7 Interfaces .............................................................................................................................................3-5

3.1.8 Emulations...........................................................................................................................................3-5

3.1.9 Control panel .......................................................................................................................................3-5

3.2 Electrical Conditions .................................................................................................................................3-6

3.3 Environmental Conditions.........................................................................................................................3-6

3.4 Physical Specifications .............................................................................................................................. 3-7

i

Page 8

3.5 Reliability ..................................................................................................................................................3-8

3.6 Protection and Restrictions........................................................................................................................3-8

3.6.1 Protection.............................................................................................................................................3-8

3.6.2 Restrictions ..........................................................................................................................................3-9

3.7 Details on Forms Specification .................................................................................................................3-10

3.7.1 Size and thickness................................................................................................................................3-10

3.7.2 Printing areas .......................................................................................................................................3-13

3.7.3 Multipart binding and perforations......................................................................................................3-15

3.7.4 Binding holes and preprinting .............................................................................................................3-18

3.7.5 Other precautions.................................................................................................................................3-18

CHAPTER 4 CONTROL PANEL AND DLMENU ..................................................................................4-1

4.1 Control Panel .............................................................................................................................................4-1

4.2 DLMENU ..................................................................................................................................................4-2

CHAPTER 5 INTERFACE INFORMATION ...........................................................................................5-1

5.1 Overview ...................................................................................................................................................5-1

5.2 Parallel Interface Specifications ................................................................................................................5-2

5.2.1 Hardware requirements .......................................................................................................................5-2

5.2.2 Connector pin assignment ...................................................................................................................5-3

5.2.3 Data transmission timing.....................................................................................................................5-5

5.3 Serial Interface Specifications ...................................................................................................................5-7

5.3.1 Hardware requirements .......................................................................................................................5-8

5.3.2 Connector pin assignment ...................................................................................................................5-9

5.3.3 Serial data format ................................................................................................................................5-10

5.3.4 Timing diagram and cable configuration ............................................................................................5-11

5.3.5 Data protocols......................................................................................................................................5-13

5.4 Command Sets...........................................................................................................................................5-15

5.4.1 Overview .............................................................................................................................................5-15

5.4.2 DPL24C PLUS command set..............................................................................................................5-16

5.4.3 IBM Proprinter XL24E emulation command set ................................................................................5-25

5.4.4 Epson ESC/P2 emulation command set ..............................................................................................5-29

CHAPTER 6 MAINTENANCE...................................................................................................................6-1

6.1 Overview ...................................................................................................................................................6-1

6.2 Preventive Maintenance ............................................................................................................................6-1

6.3 Maintenance Philosophy ...........................................................................................................................6-1

ii

Page 9

6.4 Diagnostics ................................................................................................................................................6-1

6.4.1 ROM/RAM checking ..........................................................................................................................6-1

6.4.2 Error display ........................................................................................................................................6-1

6.5 Test and Adjustment Functions for Maintenance...................................................................................... 6-2

6.5.1 Self-diagnostics ...................................................................................................................................6-2

6.5.2 Hexadecimal dump .............................................................................................................................. 6-2

6.5.3 Vertical alignment ...............................................................................................................................6-2

6.5.4 Print position adjustment.....................................................................................................................6-2

6.6 Recommended Spare Parts ........................................................................................................................ 6-3

CHAPTER 7 OPTIONS, CONSUMABLES, AND PUBLICATIONS.....................................................7-1

7.1 Options ...................................................................................................................................................... 7-1

7.2 Consumables..............................................................................................................................................7-1

7.3 Publications ...............................................................................................................................................7-1

APPENDIX A CHARACTER SETS ........................................................................................................... A-1

APPENDIX B RESIDENT FONTS ............................................................................................................. B-1

APPENDIX C PRINTER DIMENSIONS AND LABELS ........................................................................C-1

iii

Page 10

ILLUSTRATIONS AND TABLES

Figure 1.1 Printing samples.............................................................................................................................1-2

Figure 1.2 Control panel..................................................................................................................................1-5

Figure 1.3 Cut-sheet feeders............................................................................................................................1-6

Figure 1.4 Multiple paper paths.......................................................................................................................1-7

Figure 2.1 Printer block diagram.....................................................................................................................2-2

Figure 2.2 Printer components (DL9400 printer)............................................................................................2-5

Figure 3.1 Printing area for continuous forms.................................................................................................3-13

Figure 3.2 Printing area for cut sheets.............................................................................................................3-14

Figure 4.1 Control panel..................................................................................................................................4-1

Figure 4.2 Main menu of the DLMENU .........................................................................................................4-3

Figure 5.1 Interface connectors .......................................................................................................................5-1

Figure 5.2 Parallel interface output circuit ......................................................................................................5-2

Figure 5.3 Parallel interface input circuits ......................................................................................................5-2

Figure 5.4 Parallel interface connector............................................................................................................5-3

Figure 5.5 Data transmission timing ...............................................................................................................5-6

Figure 5.6 Serial interface input circuit ...........................................................................................................5-8

Figure 5.7 Serial interface output circuit .........................................................................................................5-8

Figure 5.8 Serial interface connector...............................................................................................................5-9

Figure 5.9 Serial data format ...........................................................................................................................5-10

Table 3.1 Forms size and thickness .................................................................................................................3-10

Table 3.2 Paper thickness by part....................................................................................................................3-11

Table 4.1 Setup functions ................................................................................................................................4-3

Table 5.1 Parallel interface signals..................................................................................................................5-3

Table 5.2 Serial interface signals.....................................................................................................................5-9

iv

Page 11

CHAPTER 1 FEATURES

The DL9300/9400 printer has a small footprint, is practically maintenance-free, and is designed to provide years

of reliable service. This printer uses a 24-wire dot matrix print head. The DL9300 is an 80-column printer and

the DL9400 is a 136-column printer.

The printer's major features are detailed in the sections which follow.

1.1 Print Quality and Copy Capability

The DL9300/9400 uses a compact print head containing 24 wires, each 0.2 mm (0.008 inch) in diameter.

Its letter-quality printing nearly equals that of daisy wheel printers, thanks to the 360 (h) × 180 (v) dpi print

resolution provided by a single pass of the 24-wire print head. Double-pass unidirectional printing applies up to

360 × 360 dpi for high-resolution graphics. Curves and very fine lines print clearly, enabling bar code printing.

Bidirectional printing increases the print speed, while unidirectional printing maintains precise print alignment.

Three types of print quality are available — letter, correspondence, and draft. Letter quality has the highest

resolution. Draft quality has the lowest resolution but is easy to read and has the highest speed. Each print

quality can be made thicker in multicopy mode which can be easily set from the control panel or by DLMENU.

Choose the quality to suit the application.

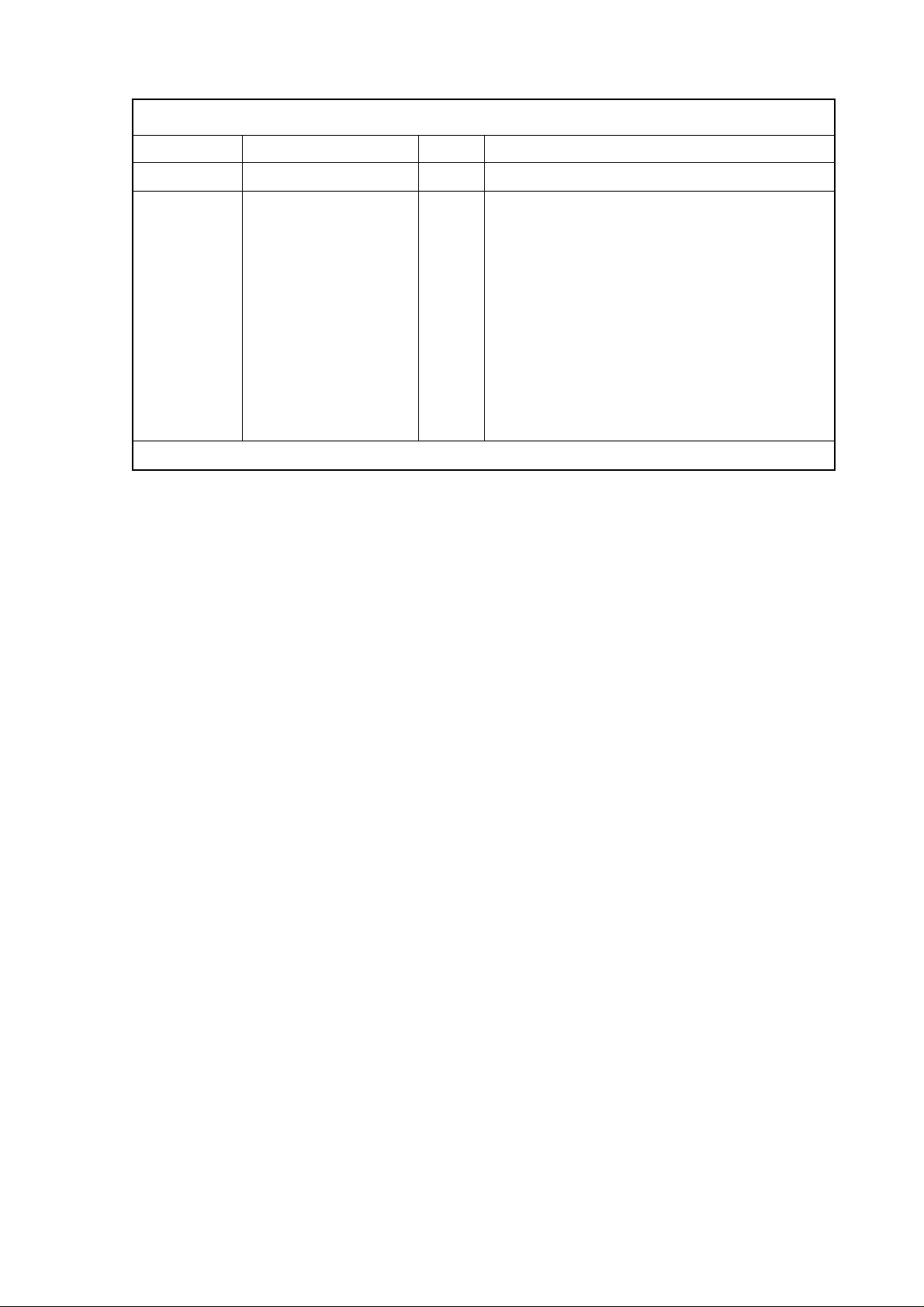

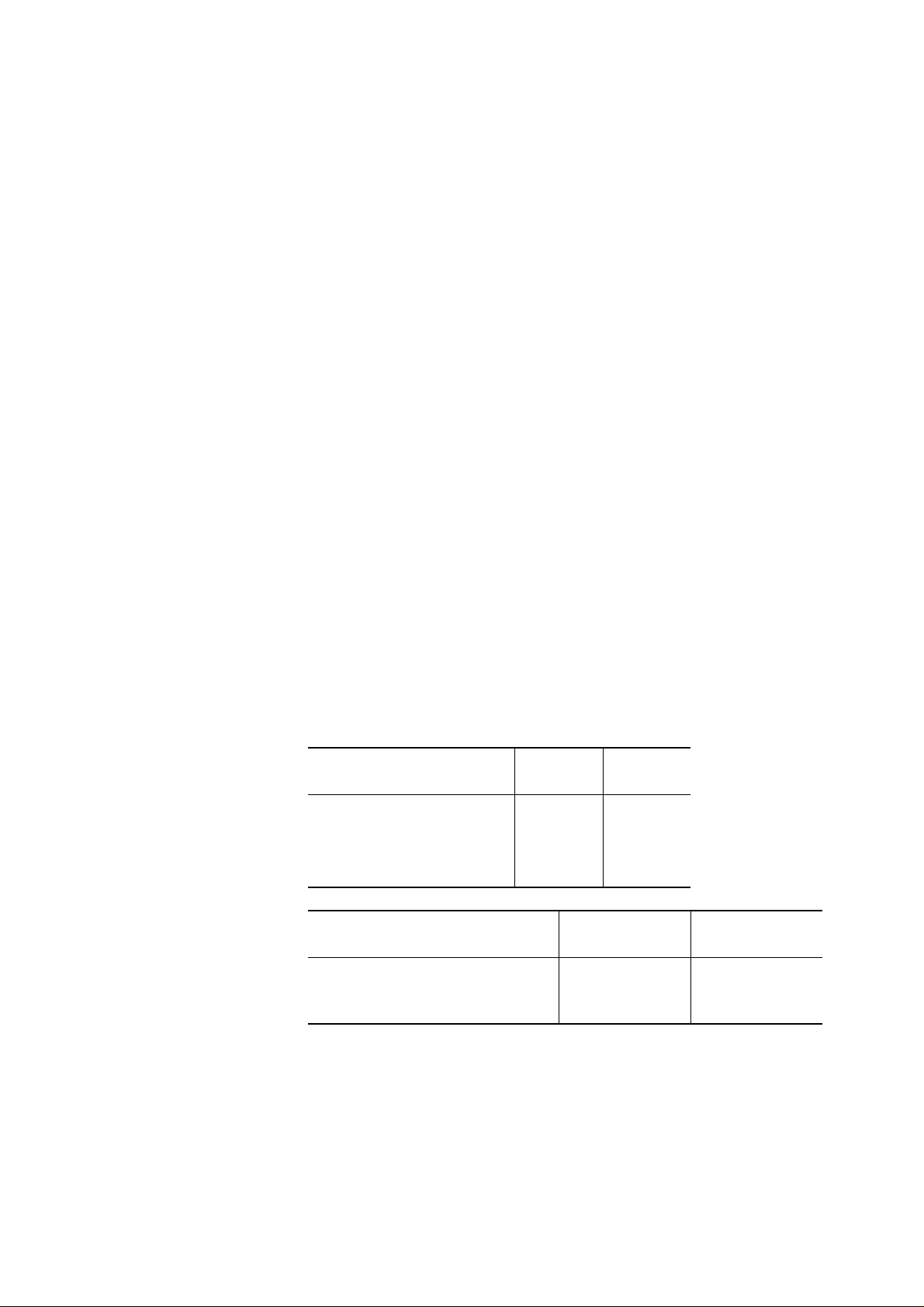

Quality

Letter

Correspondence

Draft

dpi: Dots per inch

cps: Characters per second

Paper type

Continuous forms or cut sheets

Continuous forms

Cut sheets

Resolution (dpi: h × v)

360 × 180

180 × 180

120 × 180

Paper path

Fed from the front

Fed from the rear

Fed from the CSF

Normal mode

5 copies

5 copies

5 copies

Speed (cps at 10 cpi)

100

200

360

Multicopy mode

8 copies

6 copies

5 copies

Number of copies includes the original.

1-1

Page 12

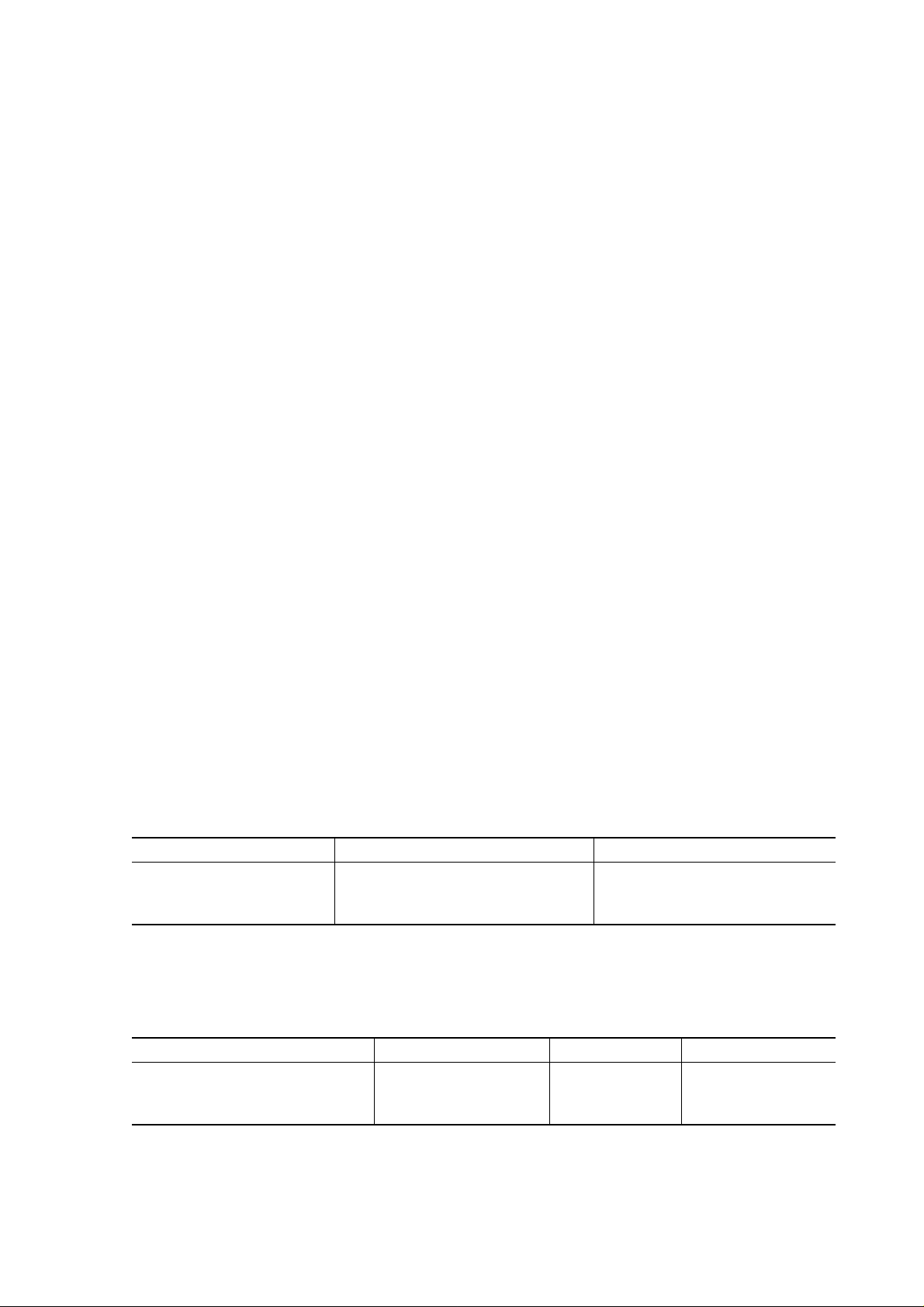

1.2 Print Modes

Multiple print modes enable word processing with great flexibility.

The DL9300/9400 has the following print modes and line spacing:

Print modes: Bold, shadow, double-width, double-height, condensed, superscript, subscript,

underline, justified, and proportional. Other modes, such as italic, multisize, outline,

shaded, and overlay are available depending on the emulation used.

Line spacing: 1, 2, 3, 4, 5, 6, 7, or 8 lines per inch

Programmable in 1/360 inch and other increments for image graphics

Both 8-bit and 24-bit graphics are available. The dot density is up to 1/360 × 1/360 inch.

Figure 1.1 shows printing samples.

1-2

Figure 1.1 Printing samples

Page 13

1.3 Fonts and Character Sets

The DL9300/9400 has 18 resident fonts which are supported by a maximum of 58 national character sets. See

Appendix B for printing samples of resident fonts.

The following 15 resident fonts are letter-quality:

Bit map fonts: Courier 10, Pica 10, OCR-A 10, OCR-B 10, Prestige Elite 12, and Boldface PS

Scalable fonts: Courier (upright, italic, and bold)

Nimbus Sans

Timeless (upright, italic, and bold)

*1 Nimbus Sans is a registered trademark of URW Unternehmensberatung Karow Rubow

Weber GmbH, Hamburg.

The following three resident fonts are used for speed or condensed printing:

Correspondence, Draft, and Compressed

For downloadable fonts, up to 96K bytes of user-designed fonts can be downloaded to RAM.

(*1)

(upright, italic, and bold)

The DL9300/9400 has 56 or 58 national character sets (depending on the emulation) besides the basic character

sets. This makes the printer be adaptable to various languages. Note that some character sets cannot be used

with some fonts. See Appendix A for details.

1.4 Emulations and Compatibility with IBM PC Printers

The DL9300/9400 has two emulations in addition to the Fujitsu DPL24C PLUS command set. These are all

resident in ROM:

Fujitsu DPL24C PLUS, including bar code commands

IBM Proprinter XL24E emulation

Epson ESC/P2 emulation

The user can run many software applications without changing computer or application software, just by selecting an emulation using the printer control panel or the DLMENU.

When the IBM Proprinter XL24E emulation is selected, the command set and aspect ratio of the graphics are

exactly the same as the IBM Proprinter when alternate graphics mode (AGM) is selected from the printer control

panel in setup mode.

Many 24-wire printers produce graphics having a different aspect ratio than other manufacturers' printers

because of different spacing of the print head wires. The DL9300/9400 produces the same aspect ratio as IBM

PC printers, including 9-wire printers. This offers the advantage of full compatibility with graphics software for

IBM printers.

1-3

Page 14

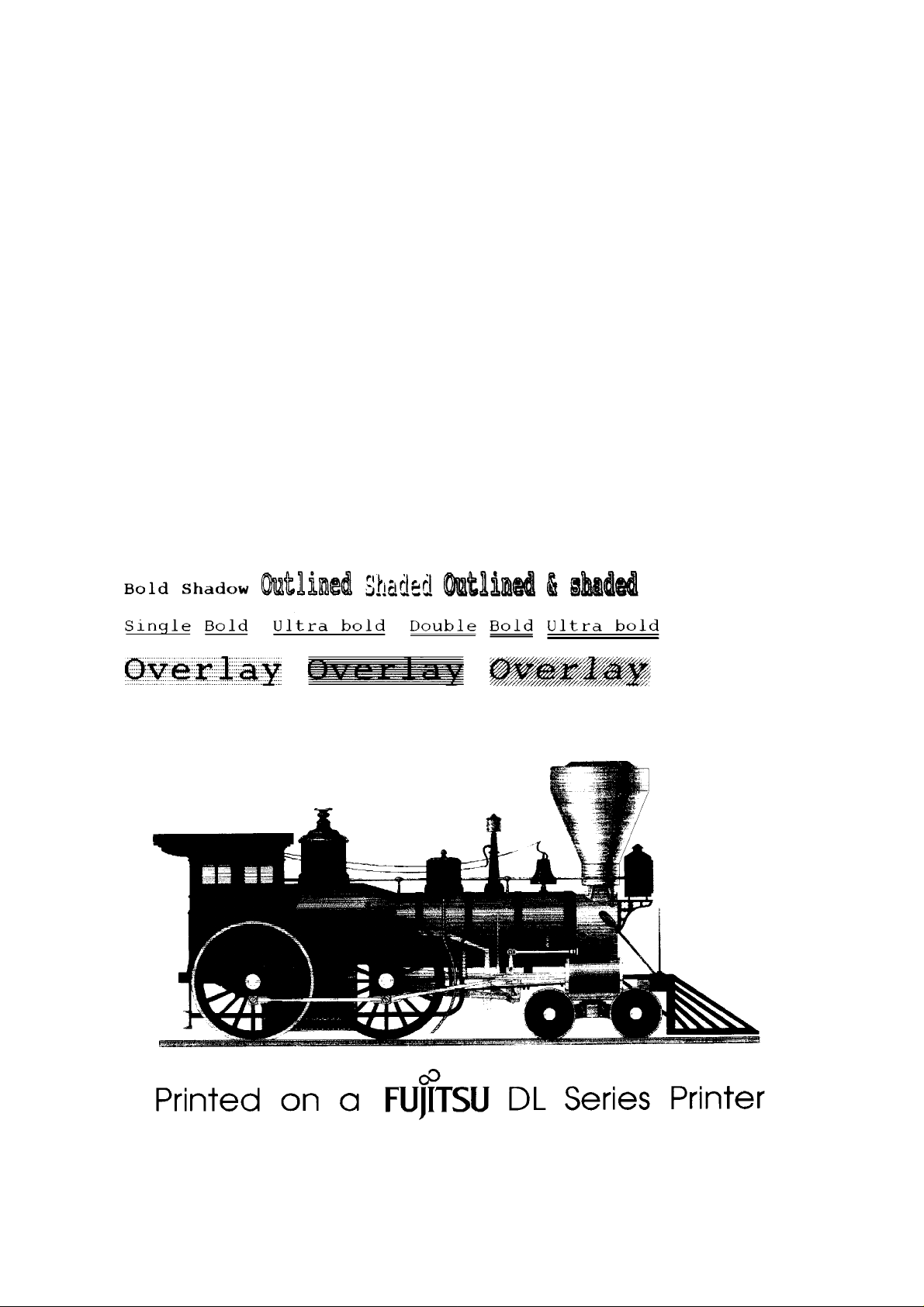

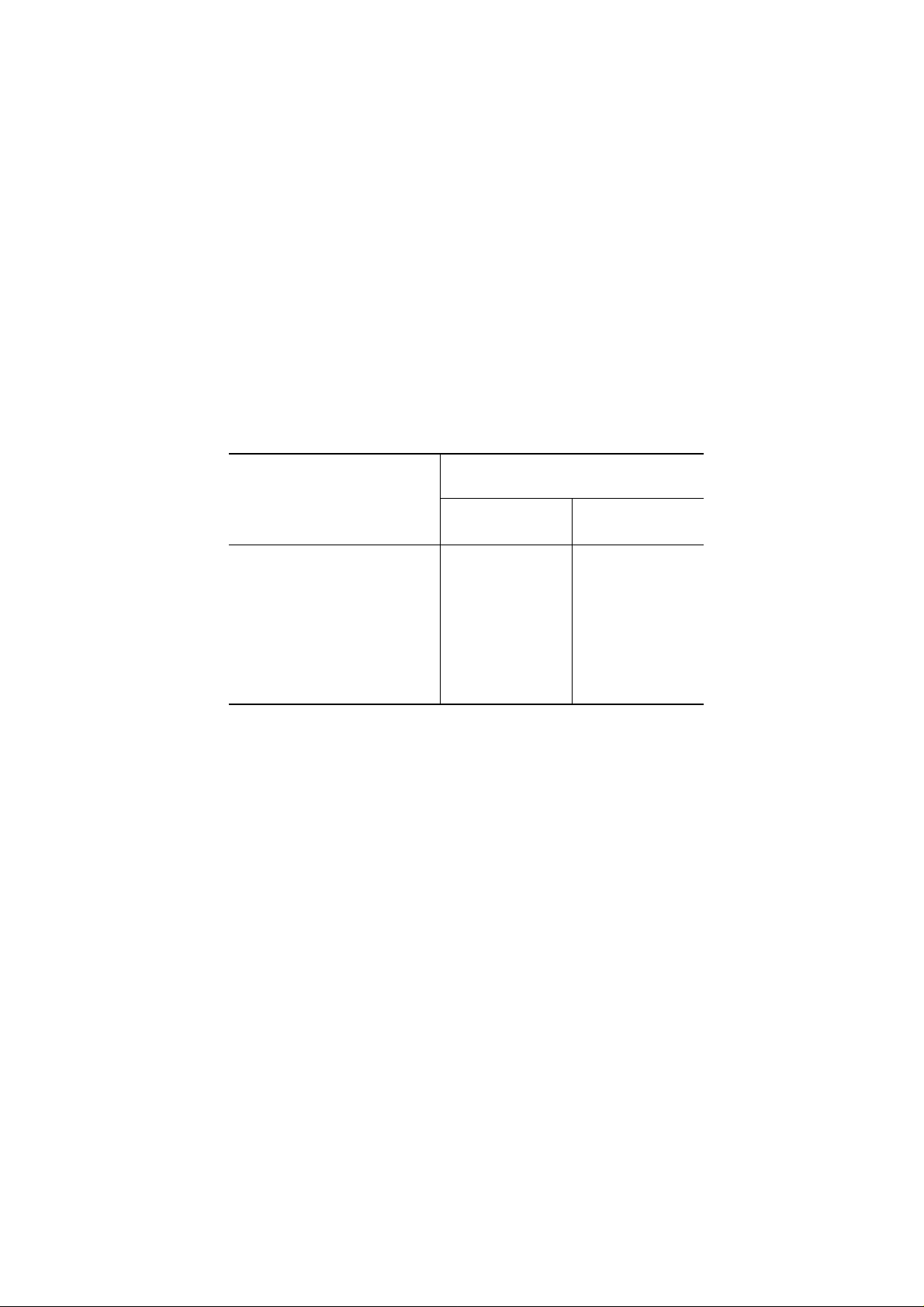

1.5 Printing Speed and Throughput

The DL9300/9400 prints text at the following speeds:

Quality

Letter

Correspondence

Draft

cpi: Characters per inch

cps: Characters per second

The DL9300/9400’s buffer control enables data reception while other data is being printed. Other features, such

as logical seek, bidirectional printing, and horizontal and vertical tabulation also improve printer throughput.

The printer throughput, based on ECMA 132 (letter test pattern), is listed in the following table:

Quality

Letter

Draft

Speed at 12 cpi

120 cps

240 cps

432 cps

DL9300

156 pages/h

320 pages/h

Speed at 10 cpi

100 cps

200 cps

360 cps

DL9400

156 pages/h

320 pages/h

1.6 Automatic Paper Loading, Switching, and Tearing-Off

Paper handling is automated as follows:

Paper is loaded or unloaded automatically using the LOAD button on the control panel. The print position can

be adjusted for each paper type and path beforehand in setup mode.

Cut sheets can be used without removing continuous forms currently loaded. Pressing the LOAD button moves

the loaded continuous forms from the platen to the parking position (forms tractor). After pressing the PAPER

PATH button so as to turn on the CUT SHEET indicator, pressing the LOAD button loads a cut sheet up to the

platen. After the cut sheet is printed, pressing the PAPER PATH button so as to turn on the FRONT TRACTOR

or REAR TRACTOR indicator and pressing the LOAD button reloads the continuous forms from the parking

position.

There is no waste of paper in tearing off the continuous forms printed. Pressing the TEAR OFF button on the

control panel positions the bottom perforation of the last printed page at the tear-off edge provided at the front

cover or upper cover of the printer. After tearing off the last page, pressing any button backs the new first page

to the print position. This back-and-forth feeding is called tear-off feeding. Tear-off feeding saves pages.

Automatic tear-off feeding can be specified in setup mode; the printer waits for a while between jobs instead of

requiring the TEAR OFF button to be pressed. If a job ends and no data is sent from the computer, the printer

automatically feeds the last page to the tear-off edge.

1-4

Page 15

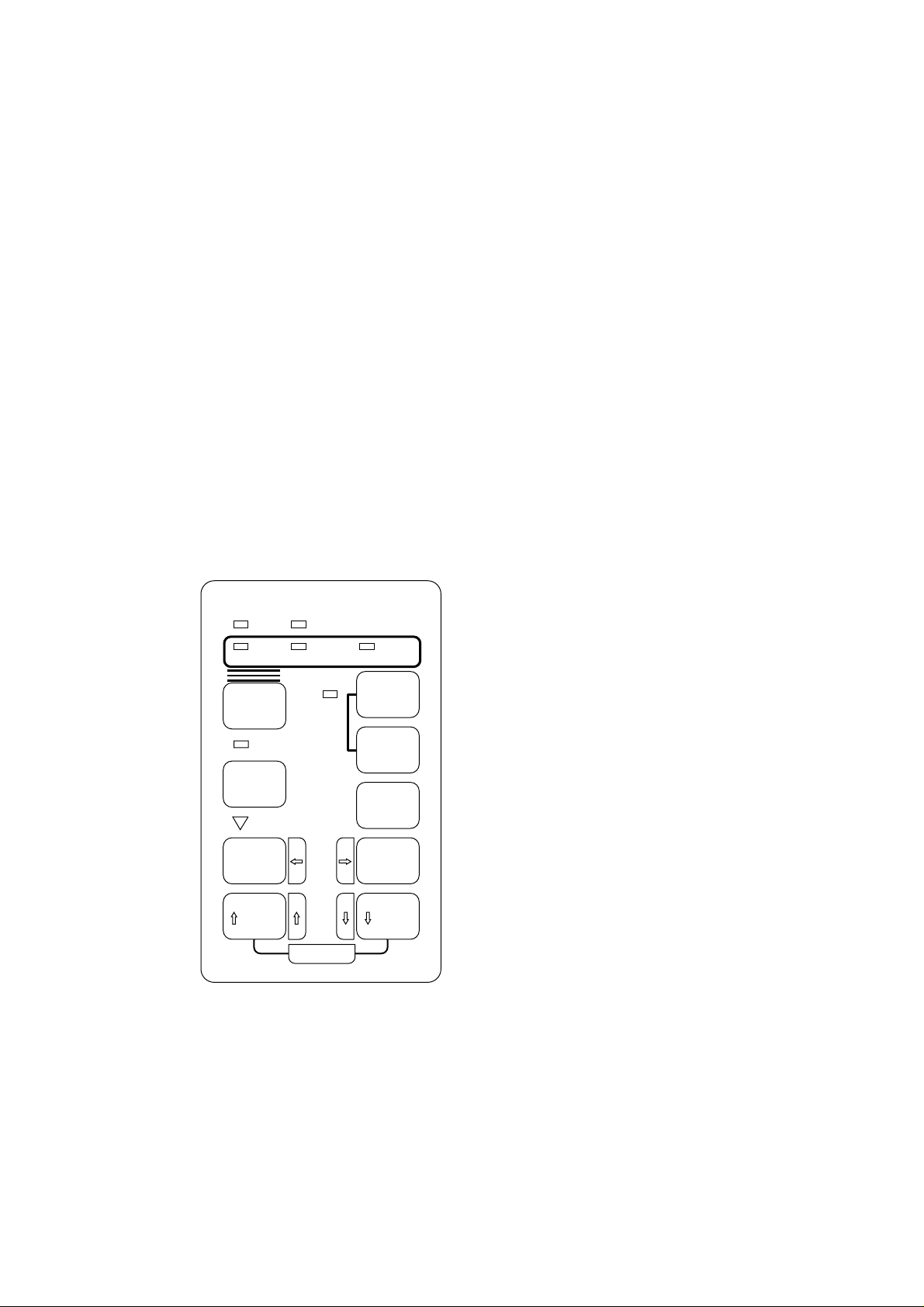

1.7 Control Panel

The control panel has nine push-button switches, eight LED indicators, and a buzzer. Indication of functions and

statuses are easy to understand.

The control panel operates in two modes: normal and setup.

• Normal mode is used in daily operation such as paper path selection, paper loading and unloading, forms feed,

and line feed. It also enables copy control, tear-off feed, and top-of-form adjustment.

• Setup mode is used in customizing the printer to the user environment when first connecting the printer to the

computer or when printing special documents. It is also set using the DLMENU. Setup mode enables the

user to select printer features such as font settings, line and character spacing, page margins, serial interface

parameters, and other infrequently used functions.

See Chapter 4 for details.

POWER PAPER OUT

FRONT

TRACTOR

PAPER PATH

MULTI

MULTI

COPY

FRONT

FRONT DIR

MICRO

SAVE TOP

SET UP

REAR

TRACTOR

CUT

SHEET

ONLINE

LOAD

LF / FF

TEAR OFF

MICRO

Figure 1.2 Control panel

1-5

Page 16

1.8 Multiple Paper Paths and Switching (HCPP)

The DL9300/9400 has a wide variety of paper feed paths for both continuous forms and cut sheets. These paths

are almost straight so that the printer can use various types of paper and be adapted to various user environments.

The DL9300/9400 uses a friction feed platen, a standard tractor unit, and an optional tractor unit as the paper

feed mechanism for continuous forms. The optional tractor unit is exactly the same with the standard one. The

tractor unit is removable and installable at the front or rear of the printer. It pushes continuous forms toward the

platen. When the printer is shipped, the tractor unit is installed at the front of the printer.

The 9300/9400 uses a mechanism that switches these three paper paths by a command. This is called hostcontrolled paper path (HCPP) mechanism. The HCPP mechanism switches power transmission to the tractors.

Three states are possible: front tractor selected, rear tractor selected, and cut sheet selected. Switching is

possible through software or by the control panel. The paper on the platen is unloaded to the park position or

ejected, and then the paper feed path is switched. When switching from a cut sheet to continuous forms, the

continuous forms are automatically loaded to the print position.

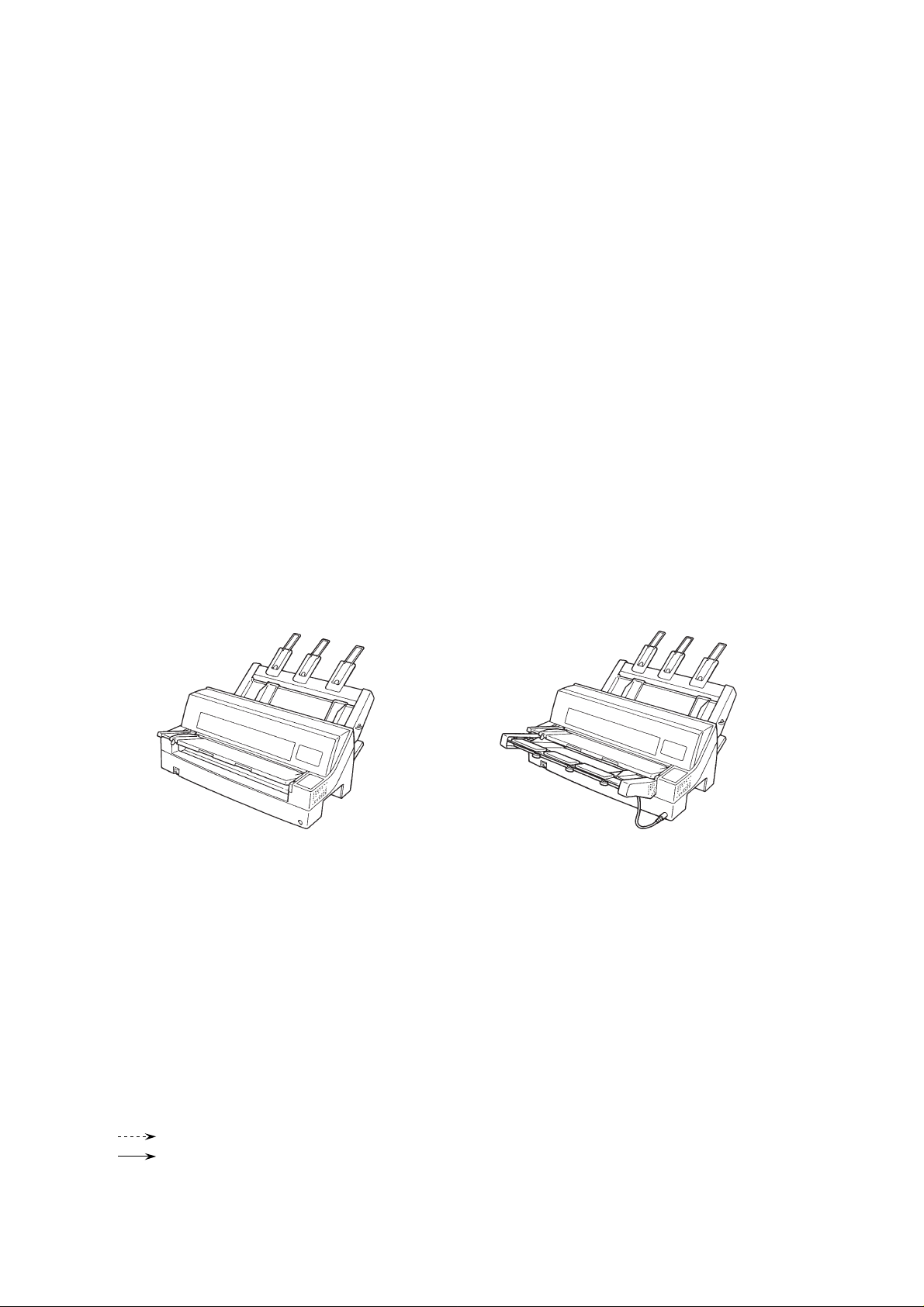

As the cut-sheet feed mechanism, the DL9300/9400 uses the platen and an optional single-bin cut-sheet feeder

which is also installable at the front or rear of the printer. The SF930 is available for the DL9300, and the SF940

for the DL9400.

SF940 mounted at rear of printer SF940s mounted at both front and rear of printer

Figure 1.3 Cut-sheet feeders

Two tractor units can be used at the same time. Two cut-sheet feeders can be used at the same time. However,

at the front of the printer, the tractor unit cannot be used with the cut sheet feeder at the same time.

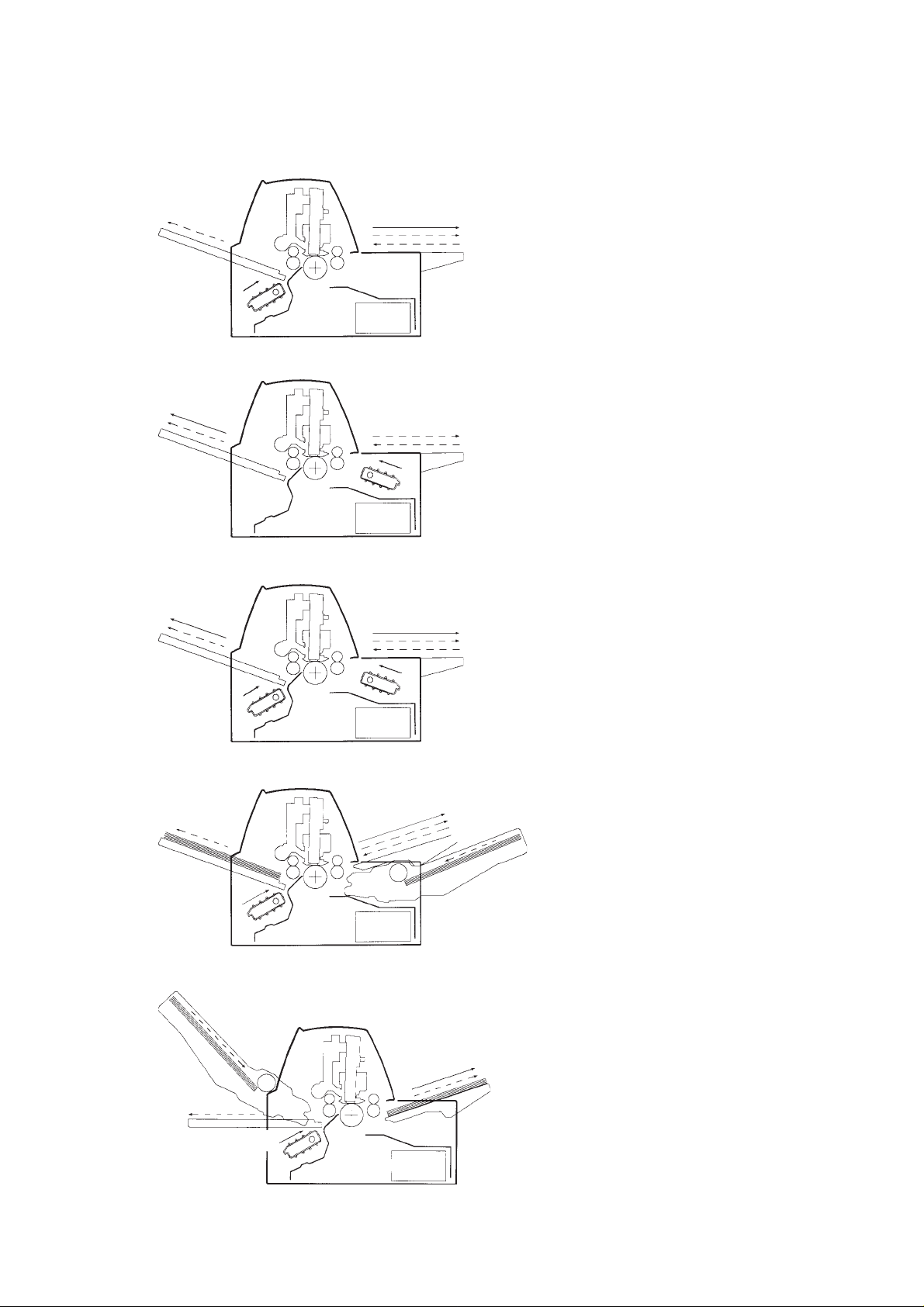

The 9300/9400 has eight paper feed paths depending on combinations of feed mechanisms. Figure 1.4 shows

these paper paths. At the right side of each illustration are listed available paper feed paths.

Legend:

: Cut sheet

: Continuous forms

(n) : Input

[n] : Output

1-6

Page 17

a. Rear tractor

[2]

(3)

b. Front tractor

[4]

[2]

c. Front and rear tractors

(4)

[3]

[1]

[1]

(1) (2)

(1) (2)

(1) Paper table → Print → Paper table

(2) Paper table → Print → Rear stacker

(3) Rear tractor → Print → Front eject

(1) Paper table → Print → Paper table

(2) Paper table → Print → Rear stacker

(4) Front tractor → Print → Rear eject

[4]

[2]

(3)

(4)

d. Rear tractor and front cut sheet feeder

[6]

(3)

e. Rear tractor and rear cut sheet feeder

(7) (8)

[3]

[3]

[1]

(1)

[3]

[1]

(1) (2)

[5]

[7]

(5) (6)

(1) Paper table → Print → Paper table

(2) Paper table → Print → Rear stacker

(3) Rear tractor → Print → Front eject

(4) Front tractor → Print → Rear eject

(1) Paper table → Print → Paper table

(3) Rear tractor → Print → Front eject

(5) Front cut sheet feeder → Print → Paper table

(6) Front cut sheet feeder → Print → Rear stacker

(3) Rear tractor → Print → Front eject

(7) Rear cut sheet feeder → Print → Paper table

(8) Rear cut sheet feeder → Print → Rear stacker

[8]

(3)

Figure 1.4 Multiple paper paths (to be continued)

1-7

Page 18

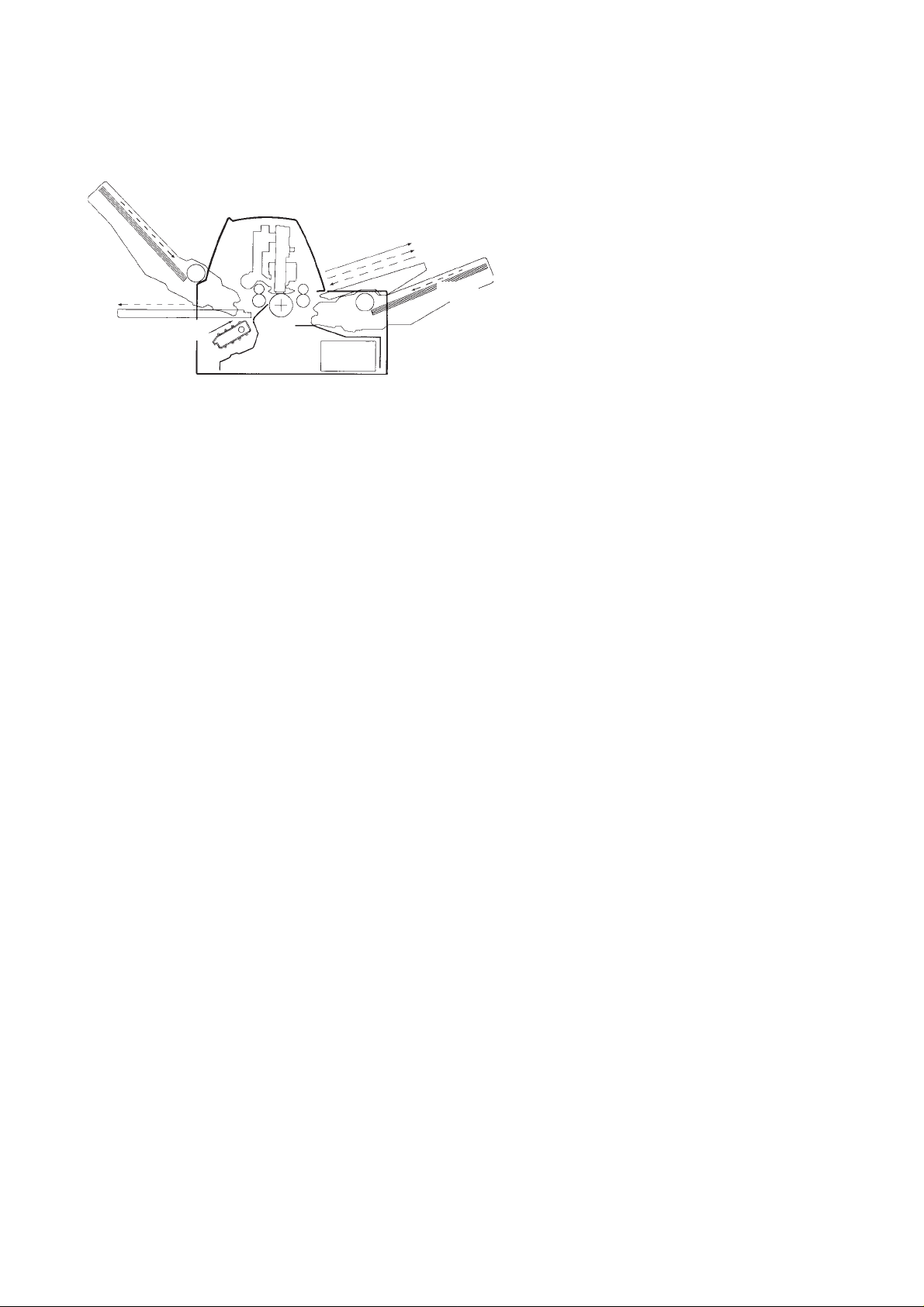

f. Rear tractor and front and rear cut sheet feeders

(7) (8)

[2] [6] [8]

(3)

[3]

[1] [5] [7]

(1) (2)

(5) (6)

(1) Paper table → Print → Paper table

(2) Paper table → Print → Rear stacker

(3) Rear tractor → Print → Front eject

(5) Front cut sheet feeder → Print → Paper table

(6) Front cut sheet feeder → Print → Rear stacker

(7) Rear cut sheet feeder → Print → Paper table

(8) Rear cut sheet feeder → Print → Rear stacker

Figure 1.4 Multiple paper paths (continued)

1.9 Automatic Print Head Gap Adjustment (APTC)

The 9300/9400 automatically adjusts the gap between the print head and the platen for paper thickness when

paper is loaded. This function is usually called APTC (abbreviated from automatic paper thickness control). It

is useful for users who often change paper types.

The print head carriage has a pressure sensor on the card guide which faces the platen. When paper is loaded,

the card guide is first set to the widest gap, pressed against the platen over the paper, and then backed for the

proper gap. The gap can be also adjusted by the paper thickness indicator in manual mode (the indicator is

accessible at the left of the printer when the front cover is open).

1.10 Automatic Interface Switching

The 9300/9400 has two interfaces: Centronics parallel and RS-232C serial. The dual interface allows the user to

connect the printer to both a network environment and a PC environment at the same time. The printer will

automatically switch to the proper interface (parallel or serial) when an AUTO option is selected for the

<INTRFCE> item by the HARDWRE function in setup mode.

1.11 Printer Driver and DLMENU

The 9300/9400 is delivered with two floppy disks.

One floppy disk contains printer drivers for Windows 3.x and Windows 95. The printer driver is a control

program to be installed on the computer for controlling document printing on the user printer. This printer driver

allows the application programs to make the best use of the DL9300/9400's functions. The printer driver for

Windows 95 has the plug and play detection capability.

The other floppy disk contains the DLMENU. The DLMENU is a printer remote setup utility program which

controls printer features in setup mode from the computer display in place of the printer control panel. This

greatly releases the user from tedious operation of setting up the printer from the control panel.

1-8

Page 19

CHAPTER 2 MODEL CONFIGURATION AND

EQUIPMENT STRUCTURE

This chapter gives the model configuration and equipment structure.

2.1 Model Configuration

The printer model differs with two specifications: print line and power supply.

DL9300/9400

Basic specification

Print line at 10 cpi: 80 columns (DL9300)

136 columns (DL9400)

Alternative specification

Power supply: 100-120 VAC or 220-240 VAC input

Add-on installable at factory

Front cover (transparent type)

Add-ons installable by user

Cut-sheet feeder

Tractor unit

cpi: characters per inch

Notes:

The following three emulations are standard for all versions.

• DPL24C PLUS: Fujitsu proprietary command set for DL-series serial printers

• IBM Proprinter XL24E

• Epson ESC/P2

The following two interfaces are standard and automatically switched for all versions (dual interface).

• Centronics parallel

• RS-232C serial

The printer is shipped with the standard tractor unit installed at the front of the printer.

This manual covers all models. An understanding of equipment structure helps relate the information in this

chapter to a particular model.

2-1

Page 20

2.2 Block Diagram

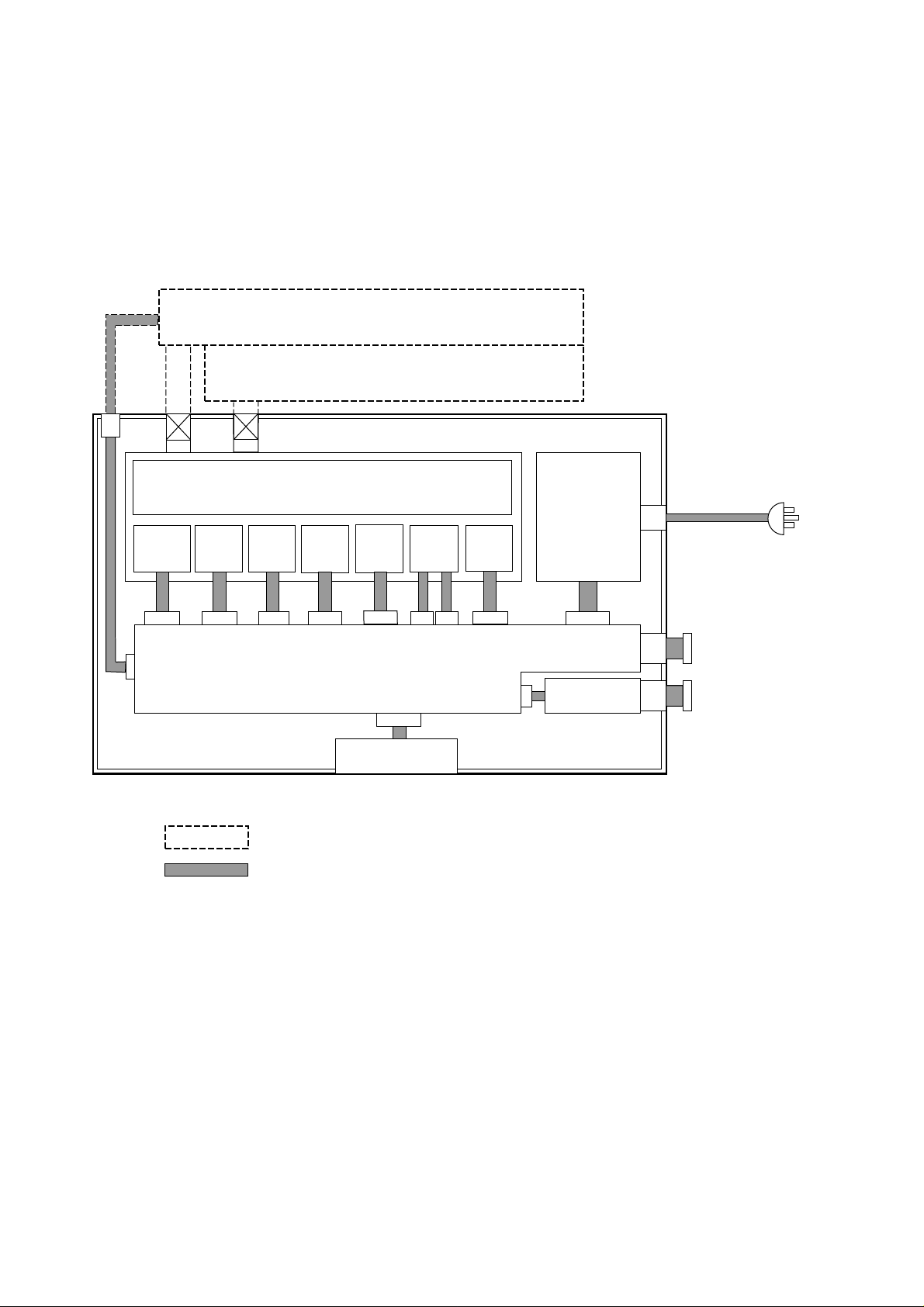

Figure 2.1 is a block diagram of the DL9300/9400 printer.

Cut-sheet feeder

Additional tractor unit

Printer

Sensors

Note:

Gears

Standard tractor unit and platen

LF

motorTRmotor

APTC

motor

Printer control board

Option

Cable

Printing mechanism

HCPP

motor

Control panel

Print

head

100-120 VAC or

220-240 VAC

Power supply

SP

motor

Centronics

To computer

RS-232C

(1) Printing mechanism

The DL9300/9400 printing mechanism consists of a print head and carriage, a carriage drive mechanism, a

paper feed mechanism, a paper path selection mechanism, an automatic print head gap adjustment mechanism, and sensors. The carriage includes a ribbon feed mechanism and the other sensors.

The printing mechanism uses five motors for driving the mechanism components so as to distribute the load.

The five motors each correspond to the platen, the tractor unit, the APTC mechanism, the HCPP mechanism,

and the print head carriage.

2-2

Figure 2.1 Printer block diagram

Page 21

(2) Printer control board

The printer control board consists of a main controller, memory, sensor receivers, drivers, a Centronics

parallel interface controller, and an RS-232C serial interface controller. This board governs the computer

interface, control panel, and printing mechanism using the main controller and memory that holds resident

character patterns and firmware including resident emulation programs.

(3) Control panel

The control panel is used by the user for operations such as changing or feeding paper, resetting the printer,

and selecting printer features in setup mode. The control panel indicates the printer status using a buzzer

and LED indicators.

(4) Power supply

The power supply provides power for operating the printer. Its specifications depend on the input AC

voltage.

(5) Cut-sheet feeder (user option)

The cut-sheet feeder is driven by a gear on the platen shaft. It has a cable to be connected to the printer for

controlling the feed rollers in the cut-sheet feeder. The feeder enables cut sheets to be fed and printed

continuously.

(6) Tractor unit (user option)

A second tractor unit can be installed if the user requires dual tractor feeding capability.

2-3

Page 22

2.3 Structure

DL9300/9400 printer

Upper cover assembly

Front cover assembly

Paper table assembly

Rear stacker assembly

Tractor unit

Printer unit

ROM board [control board with ROM]

RS-232C board

Power supply (100-120 or 220-240 VAC)

OP board [control panel]

Printer lower unit Bottom cover

Printer mechanism assembly

AC inlet assembly

Front CSF board

Frame assembly Upper stay assembly

Front stay assembly FPSS PCA (front paper set or

Rear stay assembly RTRPE unit (rear tractor paper end)

Platen roll assembly

DV roller unit

Nip roller assembly

LF motor assembly

TR motor assembly

SW subassembly

HCPP motor assembly

Carrier unit [carriage unit]

Card guide assembly

Ribbon feed assembly

Timing belt

SP motor unit

APTC unit APTC motor unit

Print head (consumables)

Ribbon cartridge (black, consumables)

front tractor paper end sensor)

2-4

Notes:

[ ] indicates a general name of the component or the subassembled component referred frequently

in this manual or the user's manual.

( ) shows options that determine the specification of the component.

Page 23

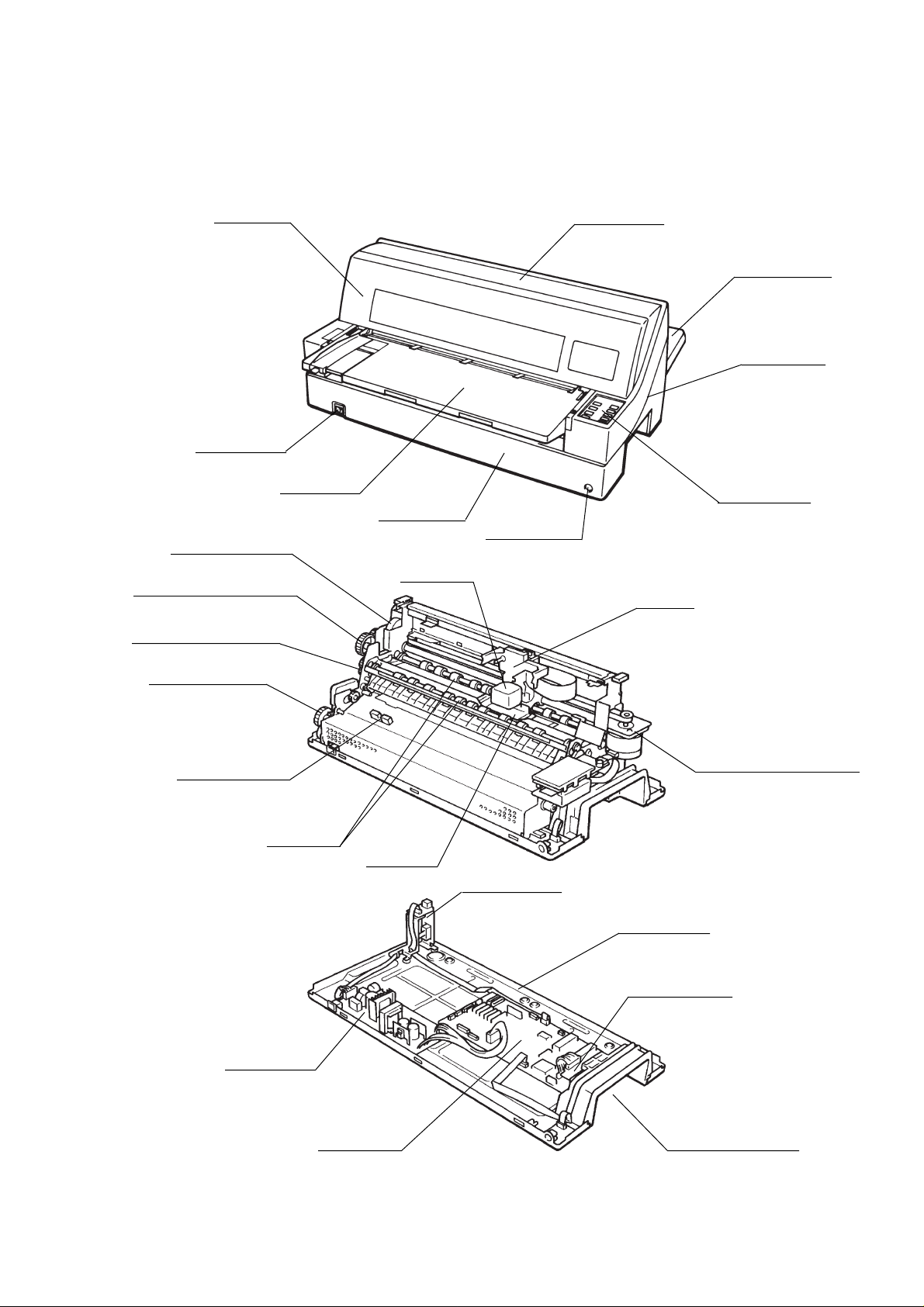

Figure 2.2 shows printer components of the DL9400. (DL9300 is the same except for width.)

Upper coverFront cover

Power switch

Rear stacker

Upper cover

APTC mechanism

Paper thickness indicator

Paper feed mechanism

HCPP mechanism

Paper end sensor

(Front tractor)

Nip rollers

Paper table

Control panel

Upper cover

CSF connector

Print head

Carriage

Print head

Ribbon feed mechanism

Sensors

Carriage drive mechanism

Card guide

AC inlet and

CSF connector

Bottom cover

Power supply

Figure 2.2 Printer components (DL9400 printer)

ROM board

RS-232C board

Interface connectors

2-5

Page 24

2.3.1 Exterior components

This section gives information on exterior components of the printer: covers, removable mechanism units, etc.

The upper cover is fastened with screws at the back (two for the DL9300 and three for the DL9400).

(1) Upper cover

The interface cable connector is on the right side of the printer, as seen from the front of the upper cover, so

the interface cable does not interfere with the paper feed path.

(2) Front cover

The front cover is opened to replace the ribbon cartridge.

(3) Paper table

The paper table guides a cut sheet manually fed by the user. It can also stack printed cut sheets when it is set

at the "down" position.

(4) Rear stacker

The rear stacker holds printed cut sheets. It must be set at the "down" position when an optional cut-sheet

feeder is installed at the back of the printer.

(5) Control panel

The control panel consists of an LSI, nine push-button switches, eight LEDs, and a buzzer. The switches are

used for operations such as loading and feeding paper and controlling printing pressure. Some switches are

also used in setup mode in place of the DLMENU. The LEDs indicate printer basic statuses and paper feed

path conditions. The buzzer sounds to indicate certain operating and printer statuses.

2.3.2 Printing mechanism

The two screws secure the printing mechanism to the bottom cover. The two hooks on the bottom cover hold the

mechanism in position.

(1) Carriage

The carriage supports the print head and ribbon cartridge, and slides left and right on the stay shaft. The

ribbon feed gear system moves the ribbon in one direction regardless of carriage movement. It has three

sensors: LRES, TOF, and APTC. The LRES detects both left and right ends of the carriage movement. The

TOF detects the top edge of paper. The APTC detects the gap between the print head and the platen.

(2) Carriage drive mechanism

The stay shaft and the stay guide support the carriage; the stepping motor and timing belt move the carriage

horizontally.

(3) Paper feed mechanism

The stepping motor drives the platen and/or tractors through gears to feed paper. See also the HCPP mechanism.

2-6

Page 25

(4) Host-controlled paper path (HCPP) mechanism

The HCPP mechanism switches power transmission to the tractors. Three states are possible: front tractor

selected, rear tractor selected, and cut sheet selected. Switching is possible through software or by the

control panel. The paper on the platen is unloaded to the park position or ejected, and then the paper feed

path is switched. When switching from a cut sheet to continuous forms, the continuous forms are automatically loaded to the print position.

(5) Paper sensors

There are six paper sensors for controlling paper feeding:

Function Paper sensed Sensor type

Front paper set Cut sheet, continuous forms, and CSF Lever and transparent type photo-interrupter

Top-of-form Cut sheet, continuous forms, and CSF Reflective type photointerrupter

End of paper Continuous forms on the rear tractor Lever and transparent type photointerrupter

End of paper Continuous forms on the front tractor Lever and transparent type photointerrupter

Paper empty Cut sheets in the front CSF Microswitch

Paper empty Cut sheets in the rear CSF Microswitch

(6) Automatic paper thickness control (APTC) mechanism

The APTC mechanism adjusts the gap between the print head and the platen. When paper is loaded, the

print head is pressed against the platen and the sensor issues a signal when the print head is stopped by the

paper. The print head is then returned by a certain distance so that the gap (actually between the print head

and the paper) is properly adjusted regardless of the paper thickness.

2.3.3 Bottom cover

(1) Bottom cover

The bottom cover supports the printer mechanism.

(2) ROM board (control board with ROM)

The ROM board controls the host interface, control panel, and printing mechanism using an MPU and an

LSI circuit. Memory holds the resident character patterns and firmware, including resident emulation

programs. This board also has drivers and receivers for other components. The separate RS-232C serial

board is connected to this board through the cable.

(3) Power supply

The power supply outputs a constant voltage, regardless of the input AC line voltage, within ranges of 100 to

120 VAC or 220 to 240 VAC. The power supply is at the front of the printer and includes an AC line switch

and noise filter.

2-7

Page 26

(4) AC inlet and CSF connector (rear CSF)

The AC inlet consists of the power input connector, the wiring cable, and the bracket on which the connector

for the rear CSF is mounted.

(5) CSF connector (front CSF)

The connector board for the front CSF is mounted at the front right of the bottom cover.

2.3.4 Options and consumables

(1) Cut-sheet feeders

A cut-sheet feeder allows both single-part cut sheets and multi-part cut sheets to be fed automatically.

The SF930 single-bin feeder is available for DL9300, and the SF940 single-bin feeder for DL9400.

(2) Tractor unit

An additional tractor unit can be installed in the printer. Because the standard tractor unit is installed at the

front of the printer at shipment, the additional tractor is installed at the rear of the printer. However, both

tractor units are the same, and installable at either position.

(3) Front cover (transparent type)

This type of front cover has the transparent window so that printed characters are visible without opening the

cover.

(4) Ribbon cartridge

The black ribbon cartridge contains a continuous inked ribbon and is installed on the print head carriage.

(5) Print head

The 24-wire print head is easily installed on and removed from the print head carriage.

2-8

Page 27

CHAPTER 3 SPECIFICATIONS

This chapter details DL9300/9400 specifications.

3.1 General Specifications

3.1.1 Print head and carriage

Printing method: 24-wire dot matrix

Wire diameter: 0.2 mm (0.008 in.)

Wire spacing (vertical): 0.141 mm (1/180 in.)

Printing direction: Bidirectional, logic-seeking or unidirectional seeking

Character cell: Letter quality 36 × 24 (10 cpi)

(horiz × vert) 30 × 24 (12 cpi)

Correspondence quality 18 × 24

Draft quality 12 × 24

Printing speed: Print quality 10 cpi 12 cpi

Letter quality 100 cps 120 cps

Correspondence quality 200 cps 240 cps

Draft quality 360 cps 432 cps

Throughput: Print quality DL9300 DL9400

(ECMA 132,

letter test pattern) Letter quality (continuous forms) 156 pages/h 156 pages/h

Draft quality (continuous forms) 320 pages/h 320 pages/h

3-1

Page 28

Resolution: Letter quality 360 × 180 dots/inch

(horiz × vert) Correspondence quality 180 × 180 dots/inch

Draft quality 120 × 180 dots/inch

Graphics 360 × 360, 360 × 180, 180 × 180,

120 × 180, 90 × 180, 60 × 180 dots/inch

240 × 72, 120 × 72, 60 × 72 dots/inch

200 × 60, 100 × 60, 90 × 60,

200/3 × 60, 60 × 60, 50 × 60 dots/inch

Character spacing: 2.5, 3, 5, 6, 10, 12, 15, 17.1, 18, and 20 cpi and proportional spacing

Programmable in 1/360-inch and other increments for image graphics

Character expansion: Double or quadruple width and height (control panel or DLMENU)

Multiwidth and height (DPL24C PLUS printer command)

Characters per line:

Characters per inch (cpi)

(Character spacing)

10 80 136

12 96 163

15 120 204

17.1 136 232

18 144 244

20 160 272

3.1.2 Forms feed

Feeding: Continuous forms:

Standard tractor unit installed at front of printer at shipment, but installable at rear of printer

Optional tractor unit installable at rear or front of printer

Cut sheets:

Friction-feed platen (standard)

Cut-sheet feeder (option) installable at rear and front of printer

Note that front and rear tractor units or front and rear cut-sheet feeders can be used at the

same time. However, the front tractor unit cannot be installed with the front cut-sheet

feeder at the same time.

Characters per line (cpl)

DL9300 DL9400

Feed direction: Bidirectional (push-feed tractor)

Line spacing: 1, 2, 3, 4, 5, 6, 7, and 8 lines per inch

Programmable in 1/360-inch and other increments for image graphics

Line feed speed: Less than 60 ms/line (at 6 lines per inch)

Forms feed speed: 6 inches per second

Paper detection: 6 sensors: front paper set, top-of-form, end of paper (front and rear tractors), paper empty

(front and rear CSFs)

3-2

Page 29

3.1.3 Character sets and fonts

Character sets: DPL24C+/XL24E IBM PC character sets 1 and 2

IBM PS/2 character sets (code pages) and other

national character sets (56 languages

in total)

Fujitsu character set (692 characters)

ESC/P2 Italic character set

Graphics character sets 1 and 2

IBM PS/2 character sets (code pages) and other

national character sets (58 languages

in total)

National character sets: USA (=code page 437), United Kingdom,

(All emulations) German, Swedish, ISO 8859-1, ECMA 94,

Code pages 437, 850, 852, 855, 860, 863, 865,

and 866,

Hungarian, Slovenian, Polish, Mazowian, Latin 2,

Kamenicky, Turkish, Cyrillic, IBM 437, IBM

851,

ELOT 928, Latin Polish, ISO Latin, Lithuanian 1,

Lithuanian 2, MIK, Macedonian, ABG, ABY,

Code page MAC, ELOT 927, DEC Greek, Greek

11,

Code page 862, Hebrew Old, and Hebrew DEC

Note:

Some national character sets do not support

some

resident fonts. See Appendix A for details.

Resident fonts: Letter quality

Bit map fonts 6 fonts

Courier 10, Pica 10, Prestige Elite 12, Boldface PS,

OCR-B 10, and OCR-A 10

Scalable fonts 9 fonts

Courier (upright, italic, bold)

Nimbus Sans (upright, italic, bold)

Timeless (upright, italic, bold)

Correspondence (*1) 1 font

*1 The correspondence font has the same print quality but higher printing speed

compared to letter quality fonts.

Draft quality 1 font

Compressed 1 font

Note:

Italic, shadow, bold, outlined, screened, enlarged, and super/subscript can be specified

by commands.

Downloadable RAM: 0, 64K, 72K, 88K, 94K, 95.75K, or 96K bytes

3-3

Page 30

3.1.4 Forms

Width: Forms type DL9300 DL9400

Continuous forms

Cut sheets (sheet feeder)

Cut sheets (paper table)

Length: Forms type DL9300 DL9400

Continuous forms 102 mm (4 in.) or more 102 mm (4 in.) or more

Cut sheets (sheet feeder)

Cut sheets (paper table)

Thickness: Up to 0.65 mm (0.025 in.)

Thickness control: Automatic print head gap control (manual control possible)

Loading: Autoloading for continuous forms and cut sheets

Parking: Cut sheets are loaded without removing continuous forms from the printer;

continuous forms are unloaded to the parking position and stand by for the next

loading.

102 to 267 mm (4 to 10.5 in.) 102 to 420 mm (4 to 16.5 in.)

102 to 257 mm (4 to 10.1 in.) 102 to 420 mm (4 to 16.5 in.)

55 to 267 mm (2.2 to 10.5 in.) 55 to 420 mm (2.2 to 16.5 in.)

70 to 364 mm (2.8 to 14.3 in.) 70 to 420 mm (2.8 to 16.5 in.)

70 to 364 mm (2.8 to 14.3 in.) 70 to 420 mm (2.8 to 16.5 in.)

Cut-sheet feeder (option): DL9300 DL9400

SF930 SF940

Forms cutting: 25.4-mm (1-in.) margin tear-off

Paper detection: Left and right edges of paper

Top and bottom edges of paper

Feed path: Nearly flat

See Section 3.7 for details on forms specifications.

3-4

Page 31

3.1.5 Other printing features

Multiple copies: Original + 4 copies (depending on paper) in normal mode

Original + 7 copies (depending on paper) in multicopy mode

3.1.6 Acoustic noise

Average: 55 dB (A)

Measurement conditions: ECMA-74 Section IV, ISO 7779, bystander position-front

Printing conditions: 60 g/m2 thick, 13 inches wide, continuous paper, and letter quality printing

3.1.7 Interfaces

Types: Centronics parallel + RS-232C serial

Parallel: Bi-directional, complying with the IEEE 1284 standard

RS-232C: 150, 300, 600, 1200, 2400, 4800, 9600, and 19200 baud

X-ON/X-OFF (DC1/DC3), DTR, and RC protocols. The ETX/ACK protocol is not

applicable to IBM character set 2.

Input buffer: 0, 256, 2K, 8K, 24K, 32K or 96K bytes

3.1.8 Emulations

Resident: Fujitsu DPL24C PLUS

IBM Proprinter XL24E

Epson ESC/P2

3.1.9 Control panel

Switches: Nine push-button switches: ONLINE, PAPER PATH, FRONT DIR, LOAD, LF/FF,

TEAR OFF, MULTI COPY, ⇑MICRO, and ⇓MICRO

Indicators: Three LEDs for basic status: POWER, PAPER OUT, and ONLINE

Five LEDs indicating the currently selected paper path and multicopy mode

See Chapter 4 for details.

3-5

Page 32

3.2 Electrical Conditions

Input voltage: 100 to 120 VAC ±10% (100 V models)

220 to 240 VAC –10%, +6% (200 V models)

Frequency: 50 or 60 Hz +2%, –4%

Insulation resistance: AC-FG 10 MΩ or more

Dielectric strength: AC-FG 1 min. at 1.25 kVAC (100 V models)

1 min. at 1.5 kVAC (200 V models)

Power consumption:

(average)

Condition

Operating

Standby

Input voltage

100–120

60 W

15 W

220–240

70 W

15 W

3.3 Environmental Conditions

Temperature: Operating 5 to 38°C (41 to 100°F)

Storage –15 to 60°C (–4 to 140°F)

In transit –25 to 60°C (–13 to 140°F)

Gradient 15°C/h or less

Note:

Print quality is guaranteed from 10 to 30°C.

Humidity: Operating 30 to 80% RH

Storage 10 to 95% RH (no condensation)

Gradient 30% RH/day or less

Maximum wet bulb 29°C (84°F)

Note:

Print quality is guaranteed from 30 to 70% RH.

Remarks

Printing letter quality H

Vibration: Operating 0.2 G. The printer is not damaged, but printing quality is not

guaranteed.

Storage 0.5 G

Packaged 1.25 G (5 to 55 Hz, vertical; 2 min./cycle, 10 min.)

0.75 G (5 to 55 Hz, horizontal; 2 min./cycle, 10 min.)

Shock: Operating 3 G. The printer is not damaged, but printing quality is not

guaranteed.

Storage 10 G

Packaged Withstanding a 60 cm (23.6 in.) drop test

3-6

Page 33

Tilt: Operating 5° (left and right)

7° (back and front)

Electrostatic strength: 9 kV minimum, no errors during test printing under the following conditions:

Contact cycle and period: 10 Hz and 3 min.

Capacitor-resistor circuit: 150 pF and 150 Ω

Safety: Model Regulation Region

100-120 VAC UL 1950-D3 United States

CSA C22.2/950 Canada

220-240 VAC TÜV EN 60 950 Germany

RFI regulation: Model Regulation Region

100-120 VAC Class B, FCC Part 15B United States

3.4 Physical Specifications

Dimensions: DL9300 DL9400

Width 456 mm (17.9 in.) 598 mm (23.5 in.)

Depth (*) 300 mm (11.8 in.) 300 mm (11.8 in.)

Height 250 mm (9.8 in.) 250 mm (9.8 in.)

* Excluding the paper table and the rear stacker

Weight: DL9300 DL9400

12 kg (26.4 lb) 14 kg (30.8 lb)

3-7

Page 34

3.5 Reliability

MTBF: 8,000 hours using a 25% duty cycle, 25% page density, and three hours of power-on

operation per day.

MTTR: 0.5 hours

Printer service life: 5 million lines or 5 years

Consumables Print head 300 million strokes for each wire (90% confidence level)

This corresponds to about 110 million characters for draft quality or 70

million characters for letter quality.

Ribbon 5.0 million characters for draft quality (black ribbon cartridge)

3.6 Protection and Restrictions

3.6.1 Protection

To protect the print head, controller, and power supply, the printer checks for the following conditions:

• High temperature of the print head

• Damage to the carriage motor driver and the line feed motor driver or a short circuit in the motors

• Overvoltage of +34 V

To ensure printing quality, the 24 dot wires of the print head are divided into three groups and 3-pass

unidirectional printing is done when one of the following overload conditions is detected:

• +34 V power falls below the predetermined voltage.

• The print head’s thermal sensor detects a high temperature.

• Image data has a dot density higher than the prescribed printing duty.

Note:

No overload condition occurs when the printing load is smaller than printing 66 lines at 33% duty.

3-8

Page 35

3.6.2 Restrictions

To avoid damaging the printer, do not:

• Feed lines continuously more than 3 minutes.

• Continue character spacing without printing more than 5 minutes.

• Continuously print lines of 5 characters or less (at 10 cpi) more than 5 minutes.

• Continuously print at 50% duty more than 1 minute.

Note:

If the above limits are exceeded, the printer’s service life may be greatly shortened.

3-9

Page 36

3.7 Details on Forms Specification

The DL9300/9400 processes a variety of forms: letter paper, typewriter paper, copy paper, business stock forms,

labels, and ordinary envelopes. This section gives general specifications for continuous forms and cut sheets.

Before using paper, check that it satisfies the requirements below. For nonstandard forms such as envelopes and

labels, paper of nonstandard size or thickness, or cut sheets for autofeeding using cut-sheet feeders, consult your

Fujitsu representative.

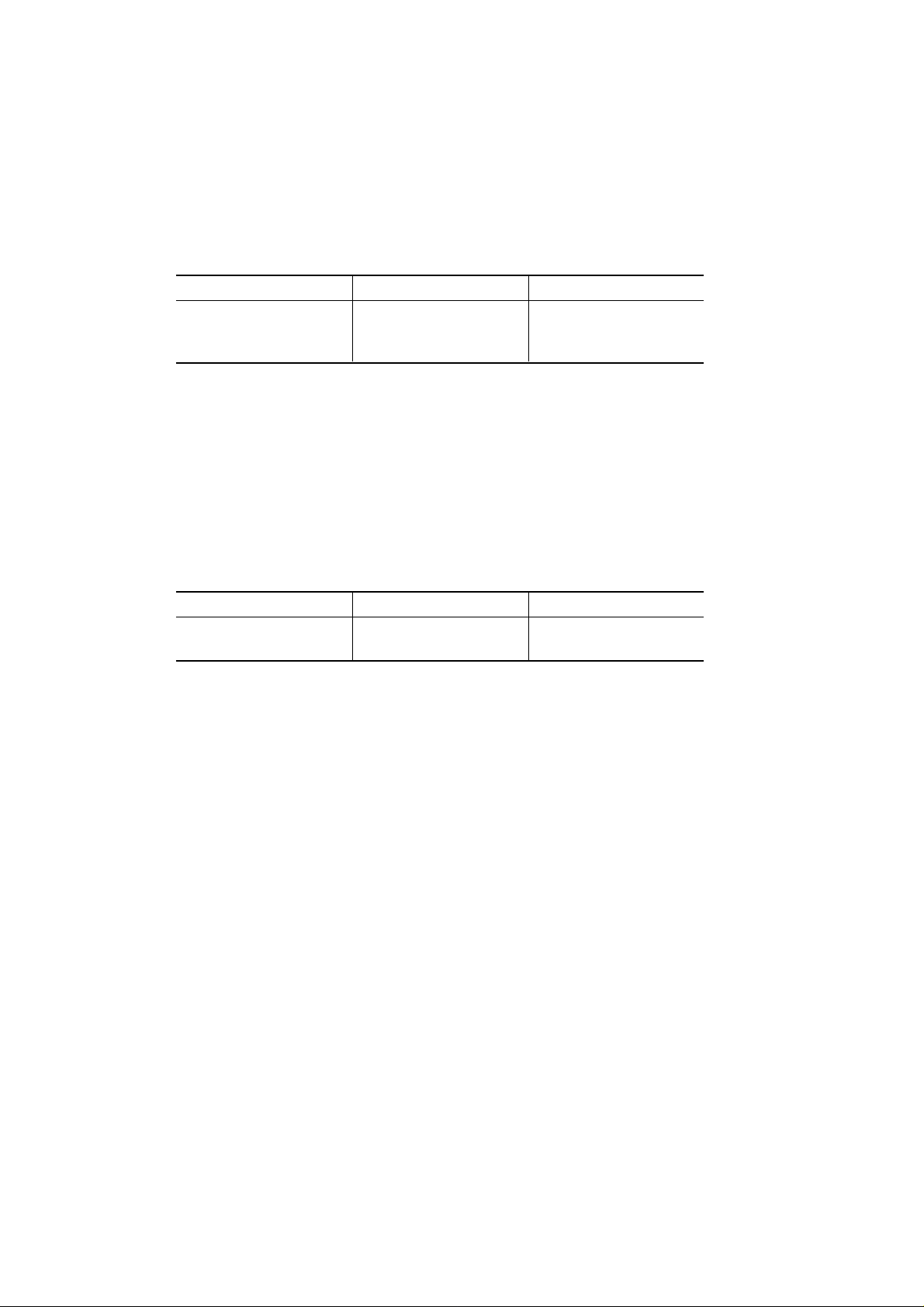

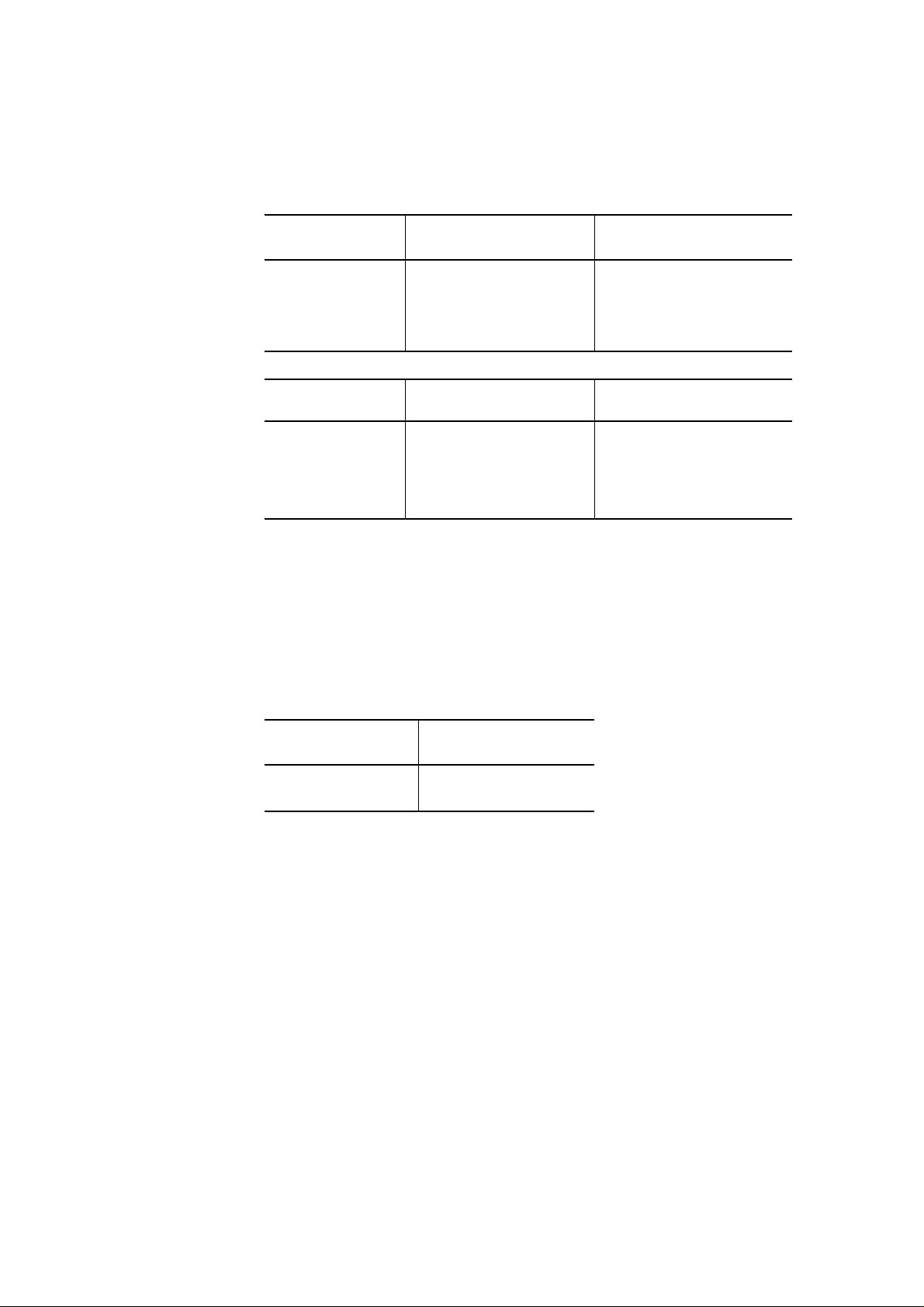

3.7.1 Size and thickness

Table 3.1 Forms size and thickness

Item

Width

Length

Thickness (*1)

Requirements

DL9300 DL9400

Cut sheets (paper table)

Cut sheets (sheet feeder)

Continuous forms: 102 to 267 mm (4 to 10.5 in.) 102 to 420 mm (4 to 16.5 in.)

Cut sheets (paper table)

Cut sheets (sheet feeder)

Continuous forms: 102 mm (4 in.) or greater Same as left

Up to 0.65 mm (0.025 in.)

See Table 3.2 for details.

Notes:

1. The total thickness of multipart paper must not exceed 0.65 mm (0.025in.), with each

part the same size and the part thickness uniform.

2. Multipart paper with a thickness or part count differing from specifications must be

tested before use.

3. The accuracy of line spacing cannot be guaranteed when using multipart paper.

4. Carbon interleaving is used for continuous forms only.

5. Because the carbon inserted between sheets of paper counts as one part, the number of

copies necessarily becomes 3 (in normal mode) or 4 (in multicopy mode) including the

original.

55 to 267 mm (2.2 to 10.5 in.) 55 to 420 mm (2.2 to 16.5 in.)

102 to 257 mm (4 to 10.1 in.) 102 to 420 mm (4 to 16.5 in.)

70 to 364 mm (2.8 to 14.3 in.) 70 to 420 mm (2.8 to 16.5 in.)

70 to 364 mm (2.8 to 14.3 in.) 70 to 420 mm (2.8 to 16.5 in.)

3-10

*1 The thickness is indicated by the paper weight in grams per square meter or in pounds per bond.

Page 37

Table 3.2 Paper thickness by part

Type of copy Part Thickness

One-part Single 47-81 g/m2 (40-70 kg or 12-22 lb)

Carbonless multipart

Top 40-64 g/m2 (34-55 kg or 11-17 lb)

2P

3P

4P

5P

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

Top 40-50 g/m2 (34-43 kg or 11-13 lb)

Middle 40-50 g/m2 (34-43 kg or 11-13 lb)

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

Top 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 3P 40 g/m2 (34 kg or 11 lb)

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

Top 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 4P 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 5P 40 g/m2 (34 kg or 11 lb)

6P

6P

7P

7P

8P

8P

Carbon-backed Do not use in high-humidity environments.

2P

3P

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 6P 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 7P 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40-64 g/m2 (34-55 kg or 11-17 lb)

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

Top 40-52 g/m2 (34-45 kg or 11-14 lb)

Middle 40-52 g/m2 (34-45 kg or 11-14 lb)

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

3-11

Page 38

Type of copy Part Thickness

Top 40 g/m2 (34 kg or 11 lb)

4P

5P

6P

7P

8P

Bottom 40-81 g/m2 (34-70 kg or 11-22 lb)

Top 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Top 40 g/m2 (34 kg or 11 lb)

Bottom 40-64 g/m2 (34-55 kg or 11-17 lb)

Middle, 2P to 3P 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 4P 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 5P 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 6P 40 g/m2 (34 kg or 11 lb)

Middle, 2P to 7P 40 g/m2 (34 kg or 11 lb)

Carbon-interleaved Avoid using carbon-interleaved single sheets.

Top 35-52 g/m2 (30-45 kg or 9-14 lb)

2P

3P

4P

Carbon Counted as one sheet

Bottom, 2P 35-81 g/m2 (30-70 kg or 9-22 lb)

Top 35-46 g/m2 (30-40 kg or 9-12 lb)

Carbon Counted as one sheet

Middle, 2P 35-46 g/m2 (30-40 kg or 9-12 lb)

Carbon Counted as one sheet

Bottom, 3P 35-64 g/m2 (30-55 kg or 9-17 lb)

Top 35-46 g/m2 (30-40 kg or 9-12 lb)

Carbon Counted as one sheet

Middle, 2P 35-46 g/m2 (30-40 kg or 9-12 lb)

Carbon Counted as one sheet

Middle, 3P 35-46 g/m2 (30-40 kg or 9-12 lb)

Carbon Counted as one sheet

Bottom, 4P 35-64 g/m2 (30-55 kg or 9-17 lb)

3-12

P: Abbreviation for part. 3P, for example, means 3-part copy paper.

kg: Kilogram weight of 1000 sheets of 788 × 1091 mm paper (1.16 g/m2)

lb: Pound weight of 500 sheets of 17 × 22 inch paper (3.76 g/m2)

Page 39

3.7.2 Printing areas

Figures 3.1 and 3.2 detail valid printing areas.

Continuous forms:

DL9300: 102-267 mm (4-10.5 in.)

DL9400: 102-420 mm (4-16.5 in.)

4.73 mm (0.19 in.)

Min. 102 mm

(4 in.)

Perforation

5.08-38 mm

(0.2-1.5 in.)

Print area

Print area

Paper end

May be decreased to 4.23 mm (1/6 in.).

Ηowever, line spacing may be uneven.

4.73 mm (0.19 in.)

4.73 mm (0.19 in.)

Approx. 102 mm (4 in.) for front-tractor feed.

Approx. 93.6 mm (3.7 in.) for rear-tractor feed.

5.08 mm or more

(0.2 in. or more)

Print area may be off the paper, depending on

paper setting or width.

Figure 3.1 Printing area for continuous forms

3-13

Page 40

Cut sheet paper:

DL9300: 55-267 mm (2.2-10.5 in.)

DL9400: 55-420 mm (2.2-16.5 in.)

DL9300:

70-364 mm

(2.8-14.3 in.)

DL9400:

70-420 mm

(2.8-16.5 in.)

May be decreased to 4.23 mm (1/6 in.).

However, line spacing may be uneven.

4.73 mm (0.19 in.)

HH

Print area

HH

4.73 mm (0.19 in.)

5.08-38 mm

(0.2-1.5 in.)

5.08 mm (0.2 in.)

or more

Print area may be off the paper, depending on

paper setting or width.

Figure 3.2 Printing area for cut sheets

3-14

Page 41

3.7.3 Multipart binding and perforations

To avoid paper jams when using multipart paper, note the following:

Binding continuous forms:

Multipart paper must be pasted or crimped (paper-stapled) at margins only. Metal staples and bar pasting must

not be used. Incorrect multipart paper may reduce print quality and make forms difficult to fold.

Procedure

(1) Point-pasting on two sides

(zigzag pasting)

25.4 mm (1 in.)

or less

Printing surface

(2) Crimping on both sides

(double-gathered)

76.2 mm (3 in.)

or less

Pros and cons

Preferred because:

• Forms remain flexible.

• Copy parts do not displace each other.

The greater the number of copies, the greater

the displacement.

Printing surface

(3) Point-pasting on one side and

crimping on the other side

25.4 mm (1 in.)

or less

76.2 mm (3 in.)

or less

Combination of (1) and (2)

3-15

Page 42

Notes:

1. To prevent paper jams, avoid the following:

• Bar-pasting that makes forms stiff.

• Metal staples that cause forms to catch in the paper feed path. The print head may also be damaged in

printing on staples.

Metal staple

Bar pasting

2. The raised fold of the top part at the perforation (fold) must be 1 mm (0.04 in) or less, with the bottom layer

flat as shown below.

Example: 3-part

Bottom layer flat

3. When using continuous forms, the rear stacker must be down as shown below.

Rear stacker position for continuous forms

1 mm (0.04 in.) or less

3-16

Page 43

Binding cut sheets:

When using carbonless or carbon-backed paper, be sure forms are pasted at the top. Paste must be applied

evenly and must not cause wrinkles, creases, or discoloration.

Glued top of sheets

Feed direction

Binding carbon-interleaved multipart paper (continuous forms only):

Process carbon-interleaved multipart paper as follows:

• Paste each carbon to the paper at the left and right margins at spots other than sprocket hole areas.

• Paste each carbon to the paper at the left and right margins including the sprocket hole areas while aligning

the carbon’s sprocket holes with those of the paper.

Perforations:

Poor or incomplete horizontal and vertical perforations cause paper jams. The tie-to-cut ratio for both types of

perforation must be 1 to 3.

Cut

3 mm

(0.12 in.)

Tie

1 mm

(0.04 in.)

Vertical

perforation

Tie

Paper

edge

Horizontal

perforation

1 mm

(0.04 in.)

The paper edge must be tied.

3-17

Page 44

3.7.4 Binding holes and preprinting

To ensure that paper is detected, do not let binding holes enter the paper sensing area.

Binding holes must be less than 8 mm (0.32 in.) in diameter.

Preprinting in the paper sensing area should be avoided.

Binding hole

8.0 mm (0.32 in.) or less

First

character

Printing

area

60 mm (2.4 in.) 5 mm (0.2 in.)

Not recommended

Paper sensing area

Binding hole and

preprinting inhibited

3.7.5 Other precautions

• Use high-quality paper.

• Make sure that cut sheets are not curled.

• Handle and store forms carefully. Make sure that they are not wrinkled or damaged.

• Never store forms where humidity is high.

• When using multipart forms, envelopes, or labels, test-print before actual use.

3-18

Page 45

CHAPTER 4 CONTROL PANEL AND DLMENU

The control panel is mainly concerned with printer basic status display and paper feeding in normal mode. The

DLMENU is used for remotely setting up the printer in setup mode.

4.1 Control Panel

The control panel has nine push buttons and eight LED indicators as shown in Figure 4.1. Except paper handling, capability of copying can be changed by a touch of a button.

In setup mode, the four arrow buttons can be used to set up the printer in place of DLMENU. The printer prints

the setup menu and the help menu that shows how to use the buttons to select parameters for printer operating

conditions. The red cursor engraved on the paper guide of the print head carriage indicates the active position.

POWER PAPER OUT

FRONT

TRACTOR

PAPER PATH

MULTI

MULTI

COPY

FRONT

FRONT DIR

MICRO

REAR

TRACTOR

SAVE TOP

SET UP

and ∇: LED indicators

: Push buttons

CUT

SHEET

ONLINE

LOAD

LF / FF

TEAR OFF

MICRO

Indicators

POWER, PAPER OUT, and ONLINE: Printer basic status

FRONT TRACTOR, REAR TRACTOR, and CUT SHEET:

Paper path currently selected

MULTI: Multicopy mode (high printing pressure)

FRONT: Selected direction of ejecting paper

Buttons

ONLINE: Selecting online or offline

LOAD, LF/FF, and TEAR OFF: Controlling paper feed

PAPER PATH and FRONT DIR: Selecting paper path and

paper eject direction

MULTI COPY: Selecting multicopy mode

⇑MICRO and ⇓MICRO: Feeding paper in 1/180 inch for fine-

adjusting TOF position

SAVE TOP (ONLINE and LOAD): Storing TOF position in

permanent memory

SETUP (⇑MICRO and ⇓MICRO): Setting printer in setup mode

⇐, ⇒, ⇑, and ⇓: Moving cursor in setup mode

Figure 4.1 Control panel

4-1

Page 46

4.2 DLMENU

Generally, the printer features are controlled by the printer driver through application programs. These are also

controlled by the remote setup utility program, DLMENU, stored in the DLMENU floppy disk which is furnished with the printer.

The DLMENU allows the user to change printer’s features directly from the computer display and keyboard.

Operations are easy enough that the user's manual need not be referenced once the user is familiar with the printer.

The DLMENU is useful to configure the printer to suit the requirements of user's computer, software, and

documents to be printed. It also has maintenance-aid functions which allows the user to print self-test reports

and print commands and data in hexadecimals.

The parameters changed using the DLMENU affect page layout, font, and printer control. If software programs

have printer drivers, the printer drivers control these parameters for the user. The user may never need to change

the settings manually using the DLMENU.

The DLMENU first displays the opening screen then the main menu. The main menu offers functions to select

print options for user documents. It also offers an operation guide of some keys and a help message line. If the

printer is not ready or has an error, a status message is displayed. The top menu bar offers pull-down menus for

file functions, emulation selection and interface setting, and maintenance. The user can select options or

perform a function by using the main menu and top menu bar accessed through the mouse or keyboard. One of

the six languages is selectable for messages when installing the DLMENU.

To use the DLMENU, the following are required:

• IBM PC/AT or compatible or PS/2

• PC DOS 5.02, MS-DOS 3.3, or higher

• VGA (640 x 400) or higher display

• Hard disk driver installed (1 MB essential for DLMENU)

• 3.5-inch 2HD floppy disk drive (1.44 MB)

The following main menu is displayed if the printer has no error after the opening screen is displayed.

4-2

Page 47

File(F)

Key Guide

ALT+( ) : Short cut key

Enter :

TAB :

ESC : Cancel

Cursor :

F5 : Cuctum setup

Option(O) Help(H)

Menu function 1

Menu function 2

Hardware function

Adjust function

Config function

(Help windows : discribes item Indicated by cursor)

Figure 4.2 Main menu of the DLMENU

Table 4.1 Setup functions

Menu function 1

FONT : COUR 10

QUALITY : LETTER

PITCH : 10CPI

LINE SP : 6 LPI

CHAR-W : NORMAL

CHAR-H : NORMAL

ATTRIB : NONE

PAGE LG : 11.0IN

COLOR : AUTOSEL

LFT-END : 1 COLM

TOP-MRG : 1 LINE

LANGUGE : USA

CHR-SET : SET 1

AGM : OFF

SEND Exit

Function Description

SAVE & END Stores selected options in nonvolatile memory and exits setup mode.

MENU 1 or 2 Selects options for font styles, page format, command compatibility, etc. See the

description below. Two menus enable setting different options for two applications.

HARDWARE Selects options for hardware conditions such as input buffer capacity selection. See

the description below.

ADJUSTMENT Adjusts the top-of-form location where paper is loaded.

CONFIGURATION Defines the printer's primary condition such as tearing off continuous forms.

DEFAULT Restores printer features to their factory defaults.

LIST Prints out currently saved setup options in table form.

SELF-TEST Prints firmware versions and self-test pages.

HEX DUMP Prints received data and commands in hexadecimal.

V-ALIGNMENT Prints vertical bars for aligning printing locations between odd and even lines in

bidirectional printing.

MENU 1 and 2 functions:

Emulation, font style, print quality, character spacing, line spacing, character width, character height,

character attribute, page length, left-end offset, top margin, language, character set, perforation skip, paper

width, zero character typeface, DC1/DC3 code specification, CR code definition, LF code definition, and

right-end auto CR

HARDWARE functions:

Paper-outage detection, print direction, buzzer activation, interface data word length, print data/download

data buffer allocation, parallel interface +5V source pin assignment, interface type, serial data format, baud

rate, protocol, DSR signal control, and duplex mode

4-3

Page 48

Page 49

CHAPTER 5 INTERFACE INFORMATION

5.1 Overview

The DL9300/9400 has a dual interface feature which allows the printer to communicate with a host through

Centronics parallel and RS-232C serial interfaces. The printer automatically selects the interface proper to the

occation.

Parallel interface

(lower connector)

Serial interface

(upper connector)

Figure 5.1 Interface connectors

5-1

Page 50

5.2 Parallel Interface Specifications

This parallel interface supports the bi-directional data transfer in nibble mode of the IEEE 1284 standard. It is

also compatible with the conventional Centronics interface.

5.2.1 Hardware requirements

Signal levels:

TTL-compatible

0.0 to +0.4 V for low level

+2.4 to +5.0 V for high level

Output circuit:

SN74LS07 or equivalent

+5 V

1 kΩ

Input circuit:

SN74LS14 or equivalent

DSTB

INPRM

DATA 1-8

Auto Feed XT

SLCT-IN

Figure 5.2 Parallel interface output circuit

+5 V

3.3 kΩ

100 Ω

1000 pF

+5 V

R

Signal

DATA 1-8

Auto Feed XT

SLCT-IN

R

3.3 kΩ

1 kΩ

3.3 kΩ

5-2

Figure 5.3 Parallel interface input circuits

Page 51

5.2.2 Connector pin assignment

Connector (cable):

Amphenol DDK 57FE-30360 shielded male connector or equivalent

Signals:

Connector pin

number

1

2

3

4

5

6

7

8

9

10

Return

line pin

number

19

20

21

22

23

24

25

26

27

28

1

19

Figure 5.4 Parallel interface connector

Table 5.1 Parallel interface signals

Signal

Compati mode

Nibble mode

Data Strobe

(DSTB)

Host Clock

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8