Page 1

24-wir e dot matrix printers

USER’S MANUAL

Page 2

Federal Communications Commission

Radio Frequency Interference Statement

for United States Users

Notice:

limits for a Class B digital device, pursuant to Part 15 of FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with instructions, may cause harmful

interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

• Consult the dealer or an experienced radio/TV technician for help.

FCC WARNING:

by the party responsible for compliance could void the user’s authority

to operate the equipment.

This equipment has been tested and found to comply with the

that to which the receiver is connected.

Changes or modifications not expressly approved

User’s Manual

(This equipment has been tested as M3390A/M3391A of the model

number.)

Notes:

1. The use of a nonshielded interface cable with the referenced device

is prohibited. The length of the parallel interface cable must be 3

meters (10 feet) or less. The length of the serial interface cable must

be 15 meters (50 feet) or less.

2. The length of the power cord must be 3 meters (10 feet) or less.

Page 3

Notice to Canadian Users

This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe B respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

Notice to German Users

Bescheinigung des Herstellers/Importeurs

Hiermit wird bescheinigt, daß der/die/das

• M3390B/M3391B

in Übereinsstimmung mit den Bestimmungen der

• EN 45014 (CE)

funk-entstört ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses Gerätes

angezeigt und die Berechtigung zur Überprüfung der Serie auf

Einhaltung der Bestimmungen eingeräumt.

Maschinenlärminformationsverordnung 3. GSGV, 18.01.1991:

Der höchste Schalldruckpegel beträgt 70 dB (A) oder weniger

gemäß EN 27779-1991.

User’s Manual

Page 4

CE

Manufacturer's Declaration of Conformity

According to Electromagnetic Compatibility Directive 89/336/EEC and

Low Voltage Directive 73/23/EEC, Annex

FUJITSU ISOTEC LIMITED, 135 Higashinozaki Hobara-machi Date-gun,

Fukushima, 960-0695, Japan

Declares, in sole responsibility, that the following products

III

B.

Product Type : DOT MA

Model Number : M3390B and M3391B

Approval ID Number : S1 2050720 for M3390B

Referred to in this declaration, conforms with the following directives and

standards;

Electromagnetic Compatibility Directive 89/336/EEC, 92/31/EEC, 93/68/

EEC Low Voltage Directive 73/23/EEC, 93/68/EEC

EN55022 : 1998, Class B

EN55024 : 1998 (IEC61000-4-2 : 1995, IEC61000-4-3 : 1995,

IEC61000-4-5 : 1995, IEC61000-4-6 : 1996, IEC61000-4-11 : 1994)

EN61000-3-2 : 1995

EN61000-3-3 : 1995

EN60950

TRIX PRINTER

S1 2050721 for M3391B

User’s Manual

Page 5

The contents of this manual may be revised without prior notice to

incorporate changes and improvements for units already shipped.

Every effort has been made to ensure that the information included

here is complete and accurate at the time of publication. However,

Fujitsu cannot be held responsible for errors or omissions.

Printer model specifications differ with the power supply input voltage

(100 to 120 or 220 to 240 VAC).

C147-E041-05EN May 2001

Copyright © 1998, 2000, 2001 FUJITSU LIMITED

Printed in Japan. All rights reserved. No part of this manual may be

reproduced or translated, stored in a database or retrieval system, or

transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior written

permission of the copyright owner.

Trademark Acknowledgment

FUJITSU is a registered trademark and Fujitsu Creative Faces is a

trademark of Fujitsu Limited. Centronics is a trademark of Centronics

Data Computer Corporation. IBM PC and IBM Proprinter XL24E

are trademarks of International Business Machines Corporation. ESC/

P2 is a trademark of Seiko Epson Corporation. Microsoft is a registered

trademark, and MS-DOS, Windows, and Microsoft BASIC are

trademarks of Microsoft Corporation. Bitstream is a registered

trademark of Bitstream, Inc. Nimbus Sans is a registered trademark of

URW Unternehmensberaitung Karow Rubow Weber GmbH,

Hamburg.

Other product names mentioned in this manual may also be

trademarks and are used here for identification only.

Preface

You have made a wise choice by purchasing the DL6400 Pro/DL6600

Pro printer.

To ensure that you get the maximum performance from your printer,

read this manual before attempting to use the printer.

User’s Manual

Page 6

The printer has an LED or LCD control panel. This manual describes

the operation of the printer with the LED control panel. For the

operation of the printer with the LCD control panel, see Appendix E.

As an E

NERGY STAR

that this product meets the E

® Partner, FUJITSU LIMITED has determined

NERGY STAR

® guidelines for energy

efficiency.

The International E

NERGY STAR

® Office Equipment Program is an

international program that promotes energy saving through the use of

computers and other office equipments. The program backs the

development and dissemination of products with functions that

effectively reduce energy consumption. It is an open system in which

business proprietors can participate voluntarily. The targeted products

are office equipment such as computers, displays, printers, facsimiles,

and copiers. Their standards and logos are uniform among

participating nations.

User’s Manual

Page 7

User’s Manual

Page 8

Contents

Contents

Chapter 1 Introduction

Overview ..................................................................................... 1-1

Package Contents ......................................................................... 1-2

Parts and Functions .....................................................................1-3

Chapter 2 Setting Up the Printer

Removing the Stopper and Cushion ............................................2-1

Installing the Paper Guide ........................................................... 2-2

Installing the Platen Knob ...........................................................2-3

Connecting the Power Cord ........................................................2-4

Connecting the Interface Cable .................................................... 2-5

Chapter 3 Installing the Ribbon Cassette

Choosing a Cassette ..................................................................... 3-1

Preparing the Ribbon Cassette ..................................................... 3-2

Installing the Ribbon Cassette ...................................................... 3-3

Removing the Ribbon Cassette .................................................... 3-5

Replacing the Subcassette ............................................................. 3-6

................................................................................. 1-1

FRONT ......................................................................... 1-3

BACK ............................................................................. 1-3

INSIDE .......................................................................... 1-4

SIDES (left side shown) .................................................. 1-4

.................................................................. 2-1

..................................................... 3-1

Chapter 4 Loading Paper

Loading Continuous Forms (Front) ............................................. 4-1

Loading Continuous Forms (Rear) .............................................. 4-6

Cutting Continuous Forms .......................................................... 4-6

Loading Cut Sheets ...................................................................... 4-7

Printing on Cut Sheets ............................................................... 4-10

Returning to Continuous Forms ................................................ 4-12

Chapter 5 Operating the Printer

LED type control panel ......................................................... 5-1

Using the Control Panel .............................................................. 5-1

LCD type control panel ........................................................ 5-6

Turning Printer Power On and Off ............................................. 5-8

User’s Manual i

.............................................................................. 4-1

................................................................... 5-1

Page 9

Contents

Test Printing ................................................................................5-8

Demonstration Pattern Printing ................................................. 5-11

Sensor Detection ........................................................................5-13

Chapter 6 Clearing Paper Jams

Continuous Forms (Front) ........................................................... 6-1

Continuous Forms (Rear) ............................................................6-4

Cut Sheets ....................................................................................6-4

Chapter 7 Paper Specifications

Continuous Forms .......................................................................7-1

Cut Sheets ....................................................................................7-8

Labels .........................................................................................7-10

Precautions ................................................................................7-15

Chapter 8 Setup Mode

..................................................................................8-1

Overview ......................................................................................8-1

Chapter Organization .................................................................. 8-2

Activating Setup Mode .................................................................8-2

Using Setup Mode .......................................................................8-4

Printing a List of Options ............................................................ 8-8

Setting Required Options ...........................................................8-10

Changing MENU1 and MENU2 Options ................................8-11

Changing Hardware Options .....................................................8-24

Changing Print Adjustment Options ......................................... 8-28

Changing Configuration Options ..............................................8-32

Changing Head Gap Adjustment Options .................................8-36

Exiting and Saving .....................................................................8-36

Resetting Default Values ............................................................8-37

Using Diagnostic Functions .......................................................8-38

Test printing (SELF-TST) ...................................................8-39

Hex dump printing (HEX-DUMP) .....................................8-40

Checking vertical print alignment (V-ALMNT) ..................8-42

Setup Mode Reference ...............................................................8-45

Performing Online Setup ...........................................................8-48

....................................................................6-1

...................................................................7-1

Chapter 9 Notes on Safety

Chapter 10 Troubleshooting

ii User’s Manual

............................................................................9-1

.........................................................................10-1

Page 10

Contents

Chapter 11 Daily Inspection and Maintenance

Inspection .................................................................................. 11-1

Maintenance .............................................................................. 11-1

Chapter 12 Specifications

Appendix A Consumables and Options

Appendix B Command Sets

............................................................................ 12-1

...........................................................A-1

.............................................................................B-1

Fujitsu DPL24C PLUS ................................................................B-2

Default settings at shipment ................................................B-15

IBM Proprinter XL24E Emulation ............................................B-18

EPSON ESC/P2 Emulation ......................................................B-23

Appendix C Interface Information

...................................................................C-1

Parallel Interface ..........................................................................C-1

Data Transmission Timing ..........................................................C-6

Serial Interface .............................................................................C-8

Serial Options ..............................................................................C-9

Cable Wiring .............................................................................C-10

Serial Protocols ..........................................................................C-12

Appendix D Character Sets

............................................................................D-1

........................................... 11-1

Appendix E Using the LCD/LED Type Control Panel

........................................E-1

Getting Acquainted with the Control Panel .................................E-2

Control panel components ....................................................E-2

Indicator lights ...............................................................E-3

LCD screen ....................................................................E-3

Buttons ...........................................................................E-4

Overview of menus ................................................................E-5

Points to remember about basic menus ...........................E-5

Using the basic menus ...........................................................E-5

Menus and functions ......................................................E-5

Using the Setup Menus ..............................................................E-14

Using the control panel buttons in setup mode ...................E-14

Selecting options ...........................................................E-14

Starting functions .........................................................E-15

Example of operations .........................................................E-16

Selecting options in MENU1 and MENU2 ..................E-17

User’s Manual iii

Page 11

Contents

Saving changed options .................................................E-17

Printing the self-test ......................................................E-20

Correcting vertical character displacement ....................E-21

Power-on Special Functions .......................................................E-22

Messages ....................................................................................E-23

Status messages ....................................................................E-23

Error messages .....................................................................E-27

Messages indicating user-correctable problems ..............E-27

Messages indicating fatal errors .....................................E-33

Index

..........................................................................................IN-1

Fujitsu Offices

.........................................................Inside back cover

iv User’s Manual

Page 12

CHAPTER

INTRODUCTION

1

Overview

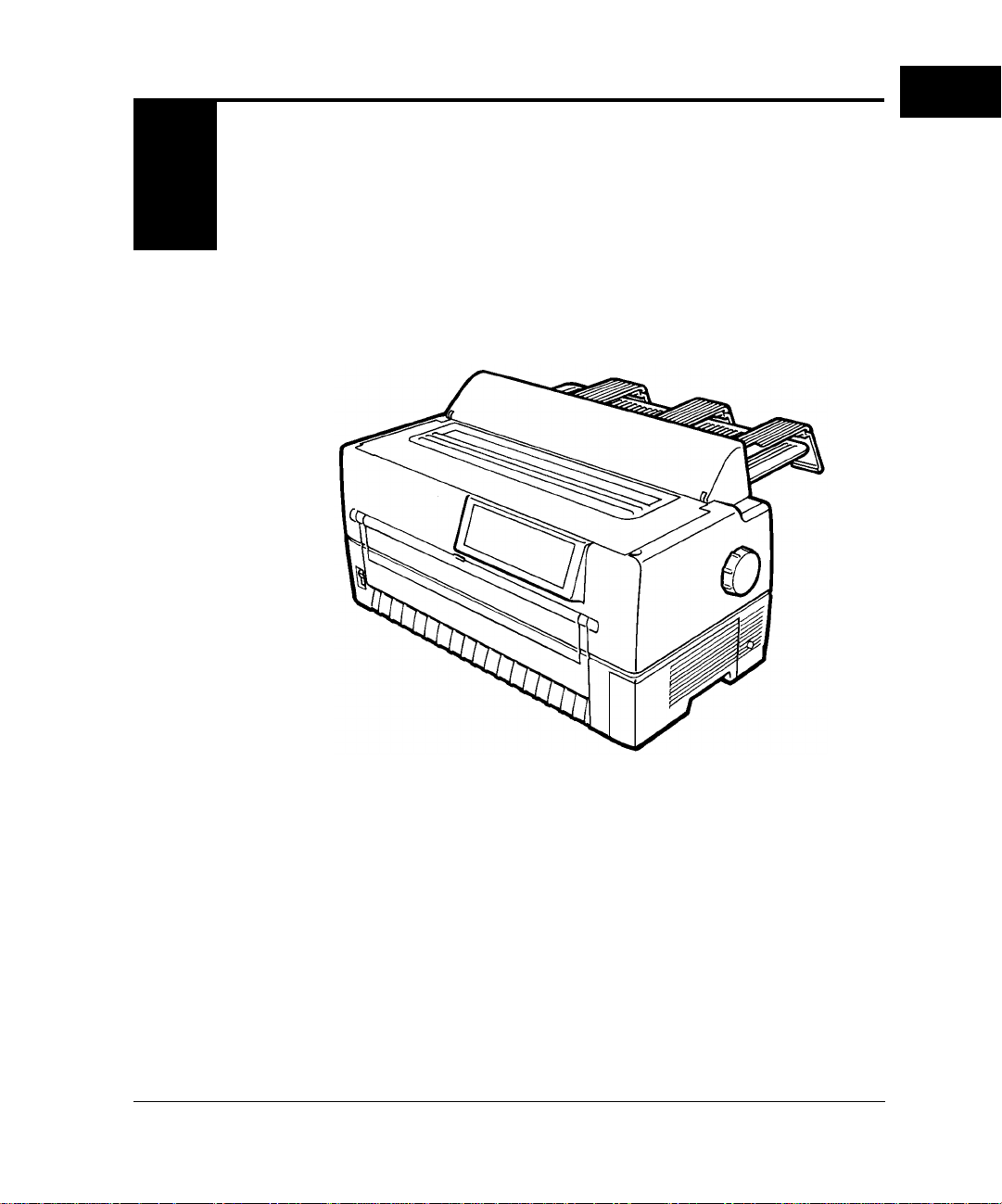

Introduction

The DL6400 Pro/DL6600 Pro is a 24-dot impact printer used for

image and graphics reproduction.

Figure 1-1 shows the printer.

Figure 1–1 DL6400 Pro/DL6600 Pro printer

User’s Manual 1-1

Page 13

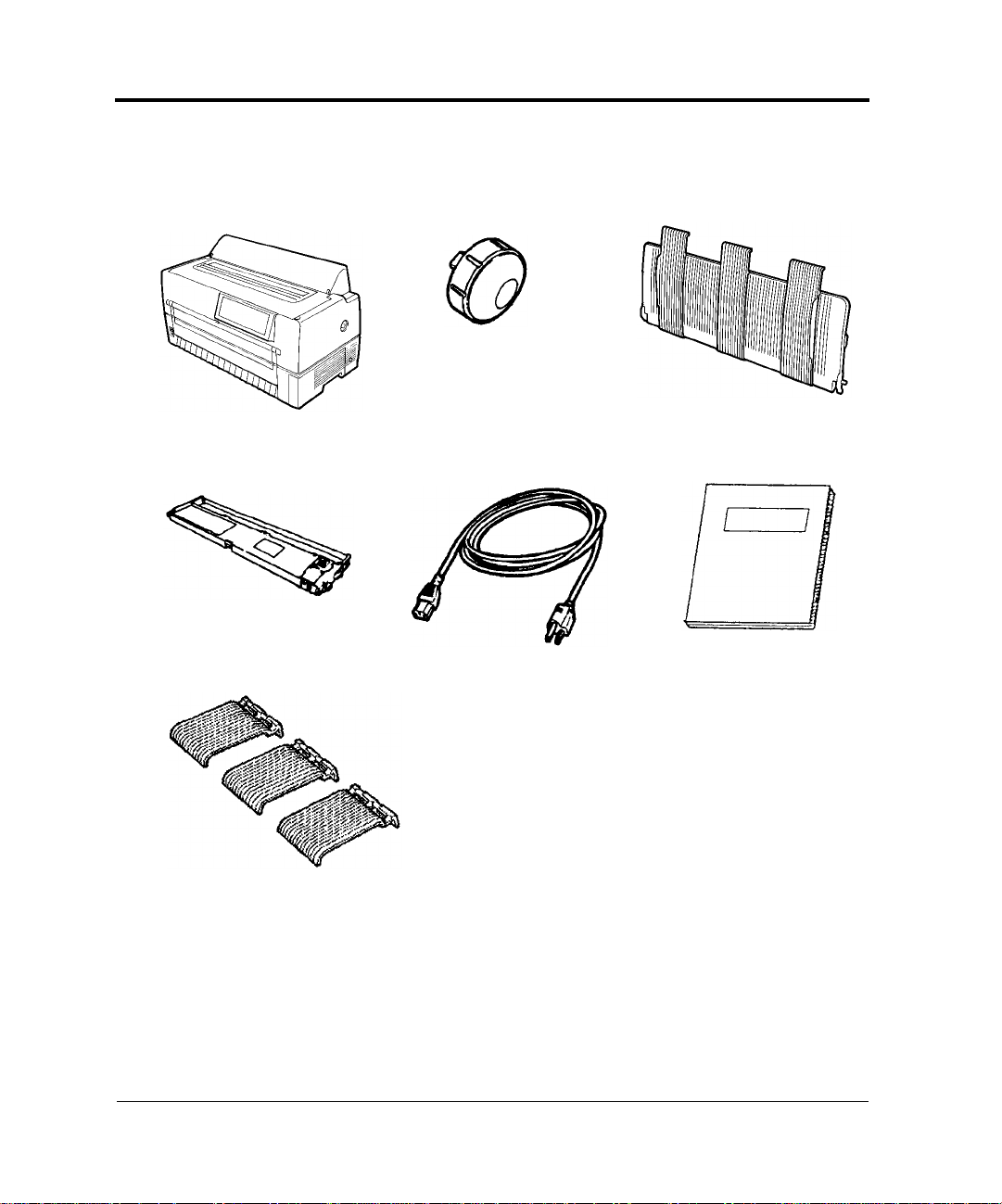

Package Contents

Package

Contents

Printer

Ribbon cassette

Check that the printer package contains the items shown in Figure 1-2.

For missing items, contact the Fujitsu sales department.

Platen knob

Paper guide

Maximum length 3 meters

Power cord

User’s manual

Paper guides

Figure 1–2 Components

1-2 User’s Manual

Page 14

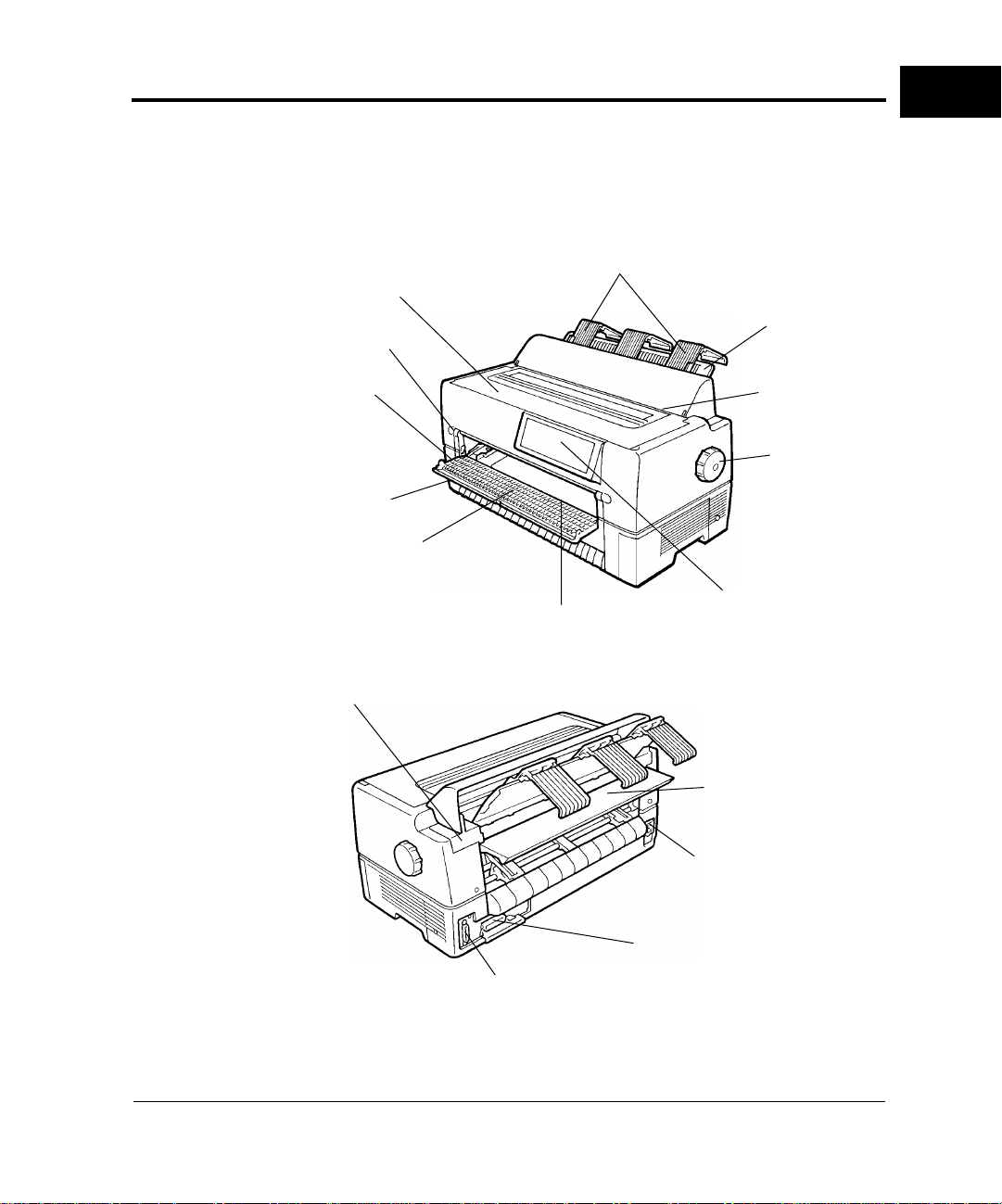

Parts and Functions

INTRODUCTION

Parts and

Functions

Figures 1-3 and 1-4 show the printer parts.

The numbers in the figures correspond to the parts listed in Table 1-1.

FRONT

q Top cover

!1 Front cover

!0 Power switch

o Front cut-sheet guide

i Front tray

BACK

!6 Back cover

w Back cut-sheet guides

u Cut-sheet tray

e Paper guide

r Paper cutter

t Platen knob

y Control panel

!2 Back auxiliary cover

!3 Power cord connector

!4 Interface cable connector

!5 Cut-sheet feeder connector

Figure 1–3 Parts (1)

User’s Manual 1-3

Page 15

Parts and Functions

!7 Ribbon cassette

INSIDE

!8 Print head

!9 Platen

@0 Paper thickness lever

SIDES (left side shown)

@1 Jam removal lever

@2 Lock lever

@3 Tractor

@4 Center guide

Figure 1–4 Parts (2)

1-4 User’s Manual

Page 16

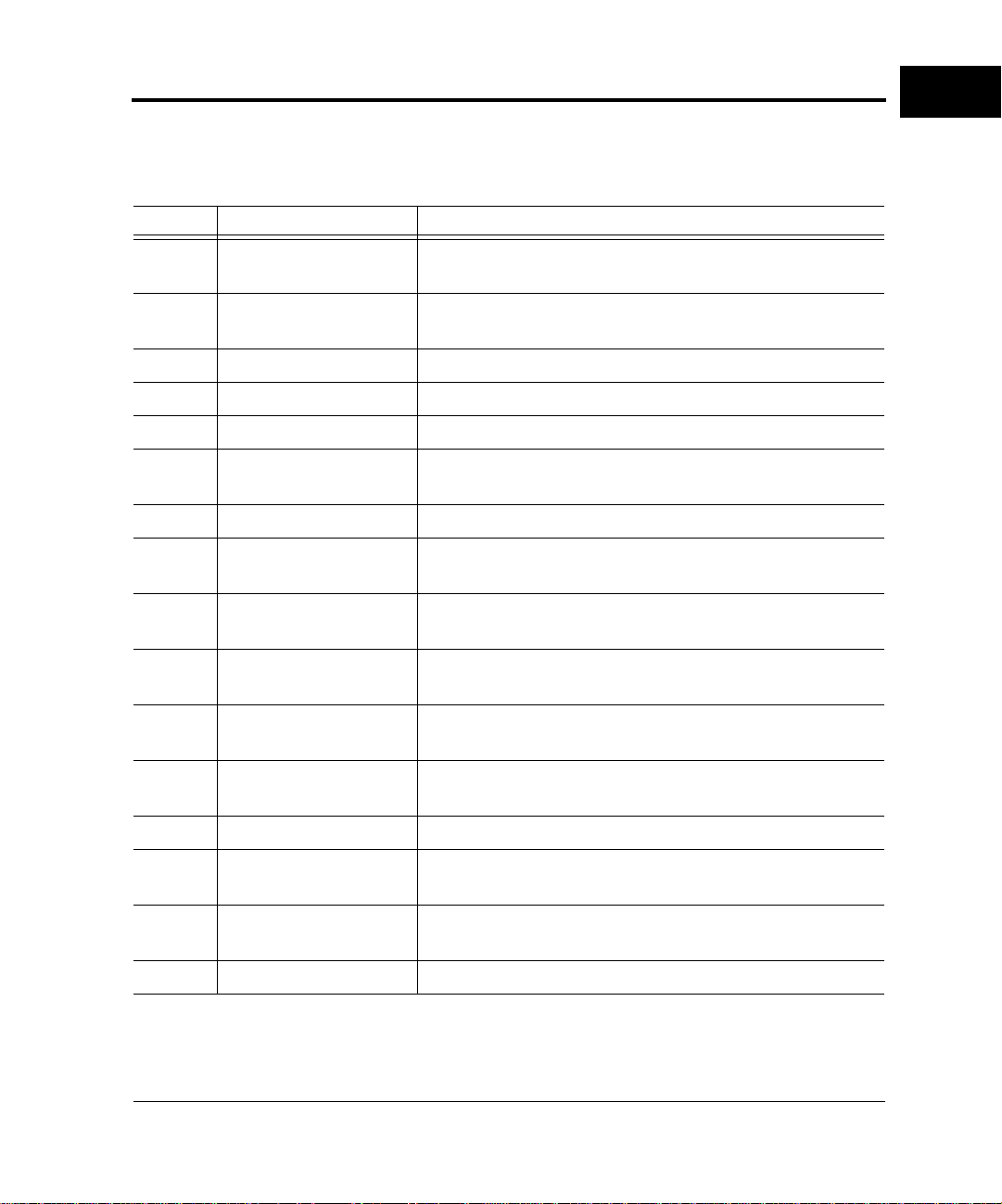

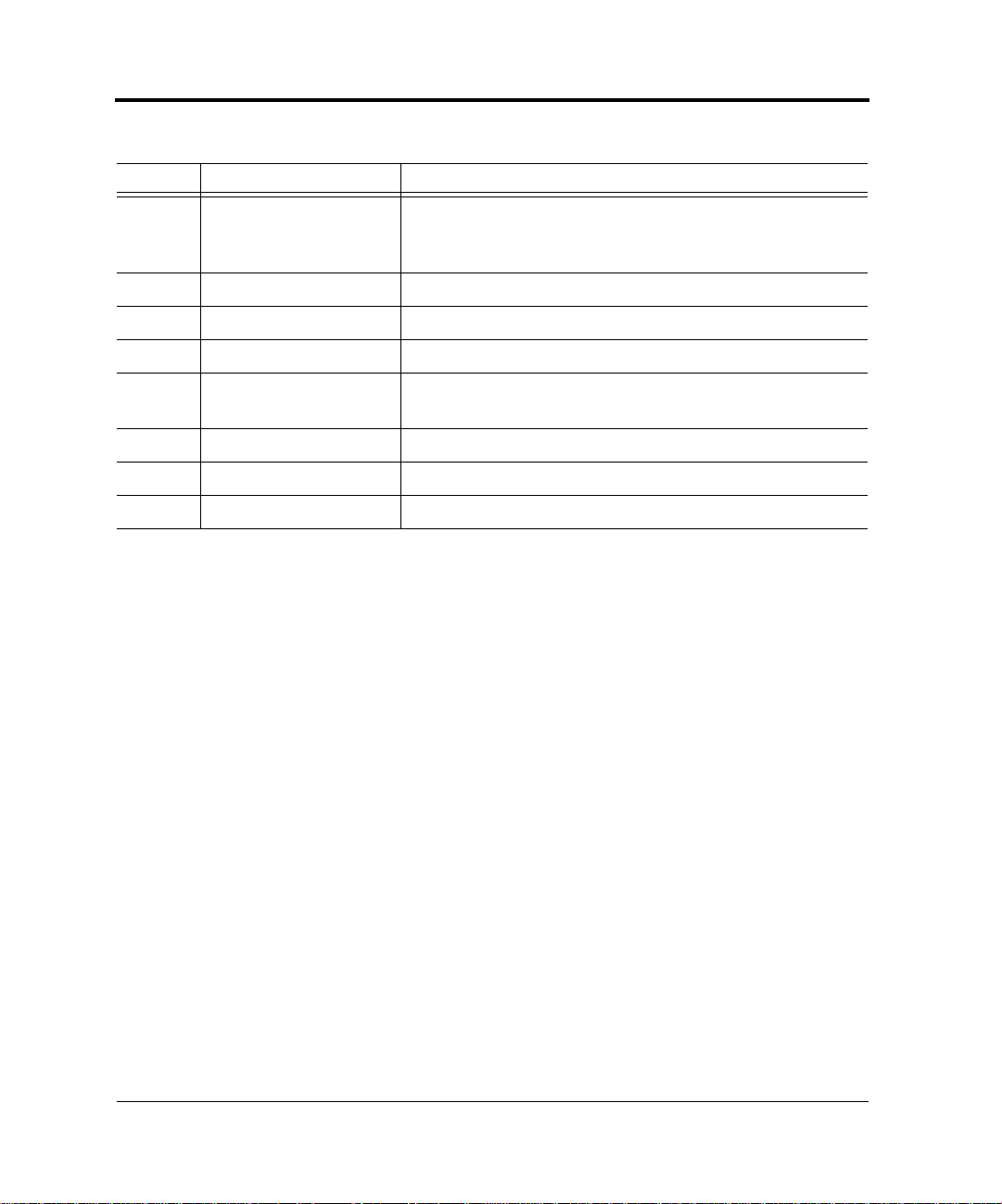

Table 1-1 lists the printer parts and functions.

Table 1–1 Printer parts and functions

Number Part Function

Parts and Functions

INTRODUCTION

q

Top cover Protects the print head and other internal printer

components.

w

Back cut-sheet guides Guides paper into the printer . Set based on the cut-sheet

or continuous forms width.

e

r

t

y

Paper guide Set down for continuous forms and up for cut sheets.

Paper cutter Cuts continuous forms.

Platen knob Turned to feed paper manually.

Control panel Contains the switches and status lamps used to operate

the printer.

u

i

Cut-sheet tray Supports cut sheets during feeding.

Front tray Holds cut sheets for insertion into the printer. Open for

cut sheets and closed for continuous forms.

o

Front cut-sheet guide Set based on the cut-sheet width to guide paper into the

printer.

!0

Power switch Set to "|" to turn power on and to "❍" to turn power

off. When power is on, the power lamp is on.

!1 Front cover Protects components inside the printer. Opened to

replace continuous forms.

!2 Back auxiliary cover Protects components inside the printer. Opened to

replace continuous forms.

!3 Power cord connector Power cord connection.

!4 Interface cable

Cable connection between the printer and processor.

connector

!5 Cut-sheet feeder

connector

Cable connection between the printer and the optional

cut-sheet feeder.

!6 Back cover Removed when the optional cut-sheet feeder is installed.

User’s Manual 1-5

Page 17

Parts and Functions

Table 1–1 Printer parts and functions (Continued)

Number Part Function

!7 Ribbon cassette Contains the printing ribbon. If characters do not print

clearly , replace the ribbon or cassette. A F ujitsu ribbon is

recommended.

!8 Print head Performs actual printing.

!9 Platen Controls and feeds paper.

@0 Paper thickness lever Used to manually adjust paper thickness.

@1 Jam removal lever Turned down to allow jammed paper to be removed

more easily.

@2 Lock lever Locks the tractor.

@3 Tractor Feeds continuous forms.

@4 Center guide Controls continuous forms feeding.

1-6 User’s Manual

Page 18

CHAPTER

SETTING UP

THE PRINTER

2

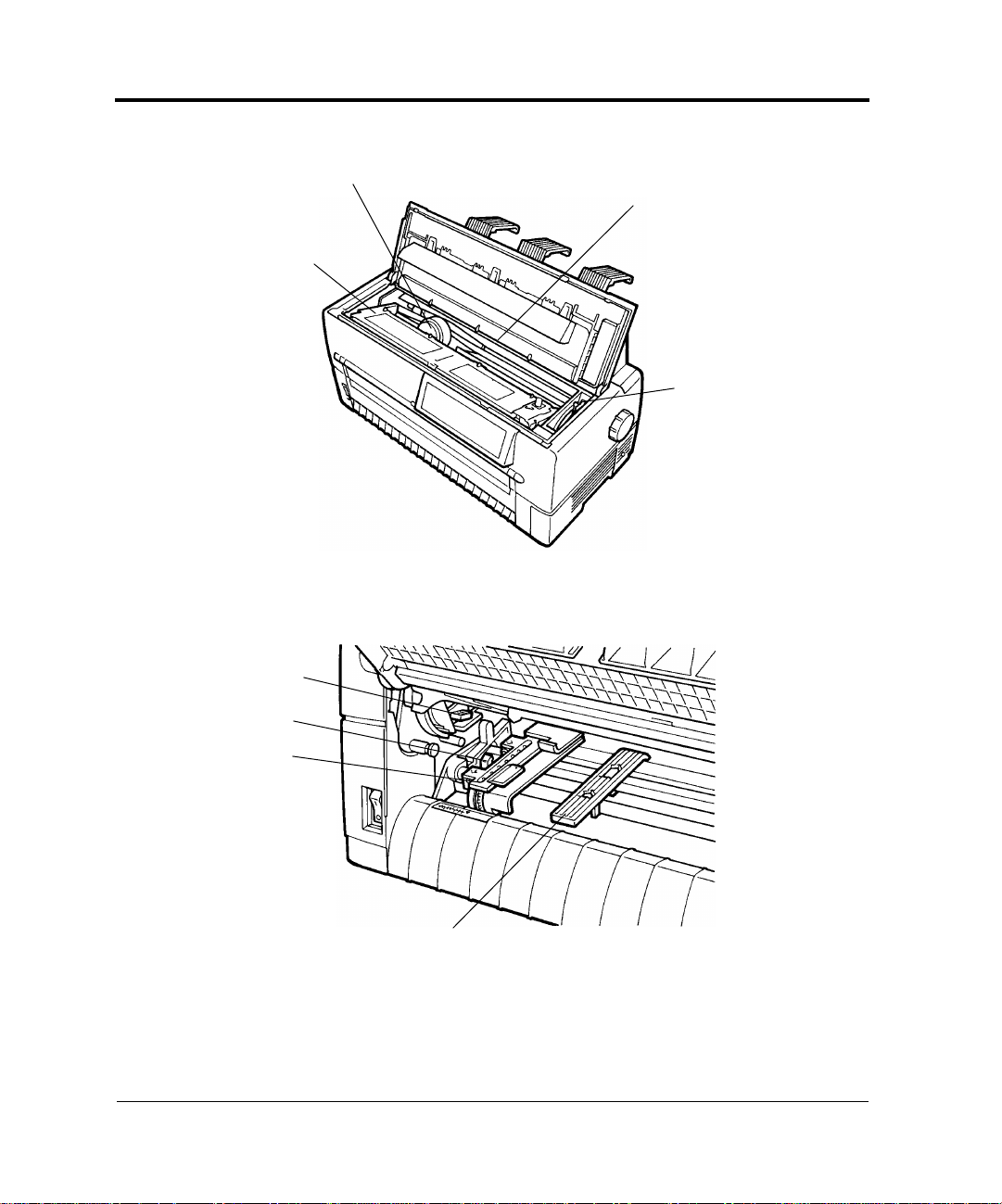

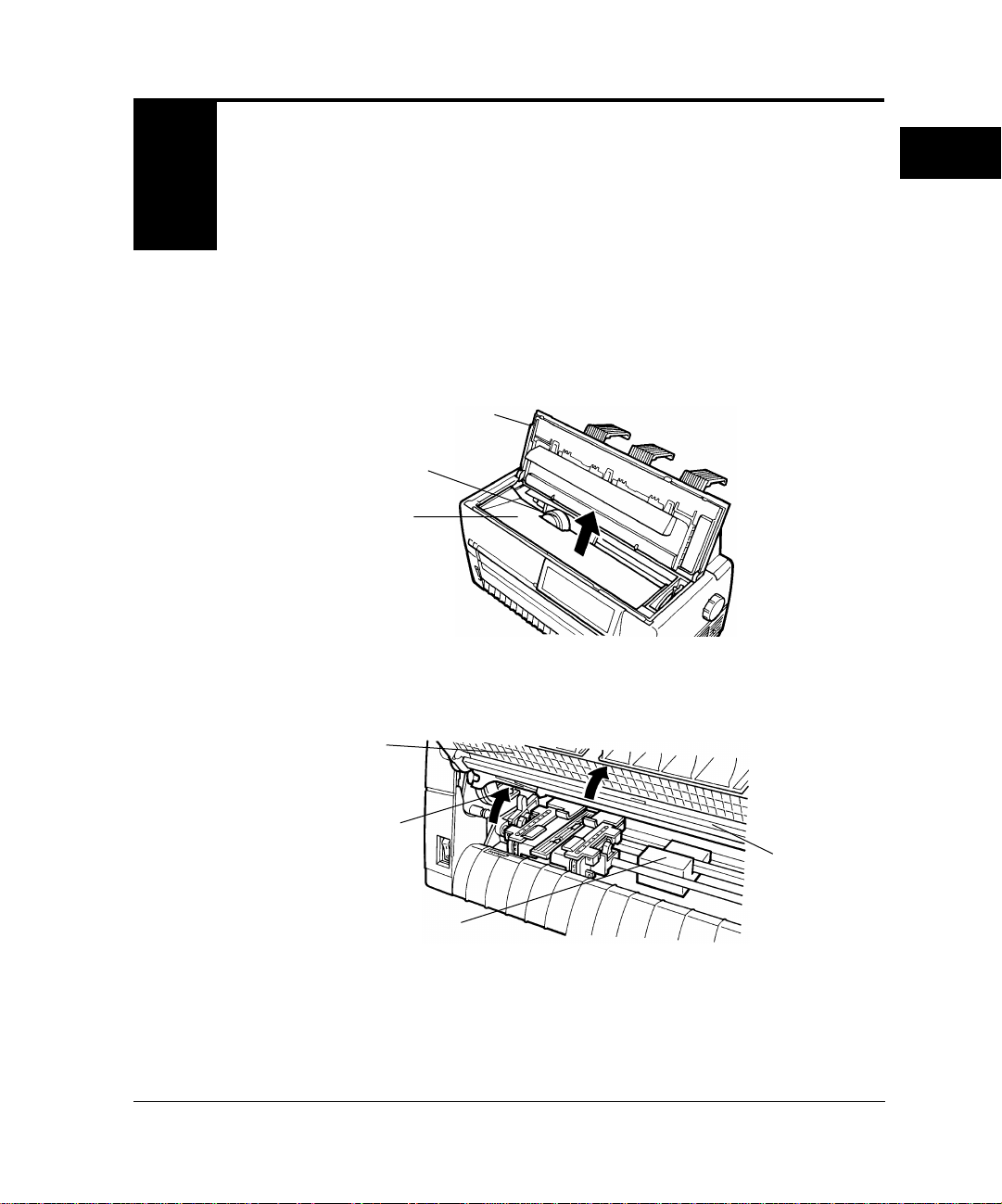

Removing the

Stopper and

Cushion

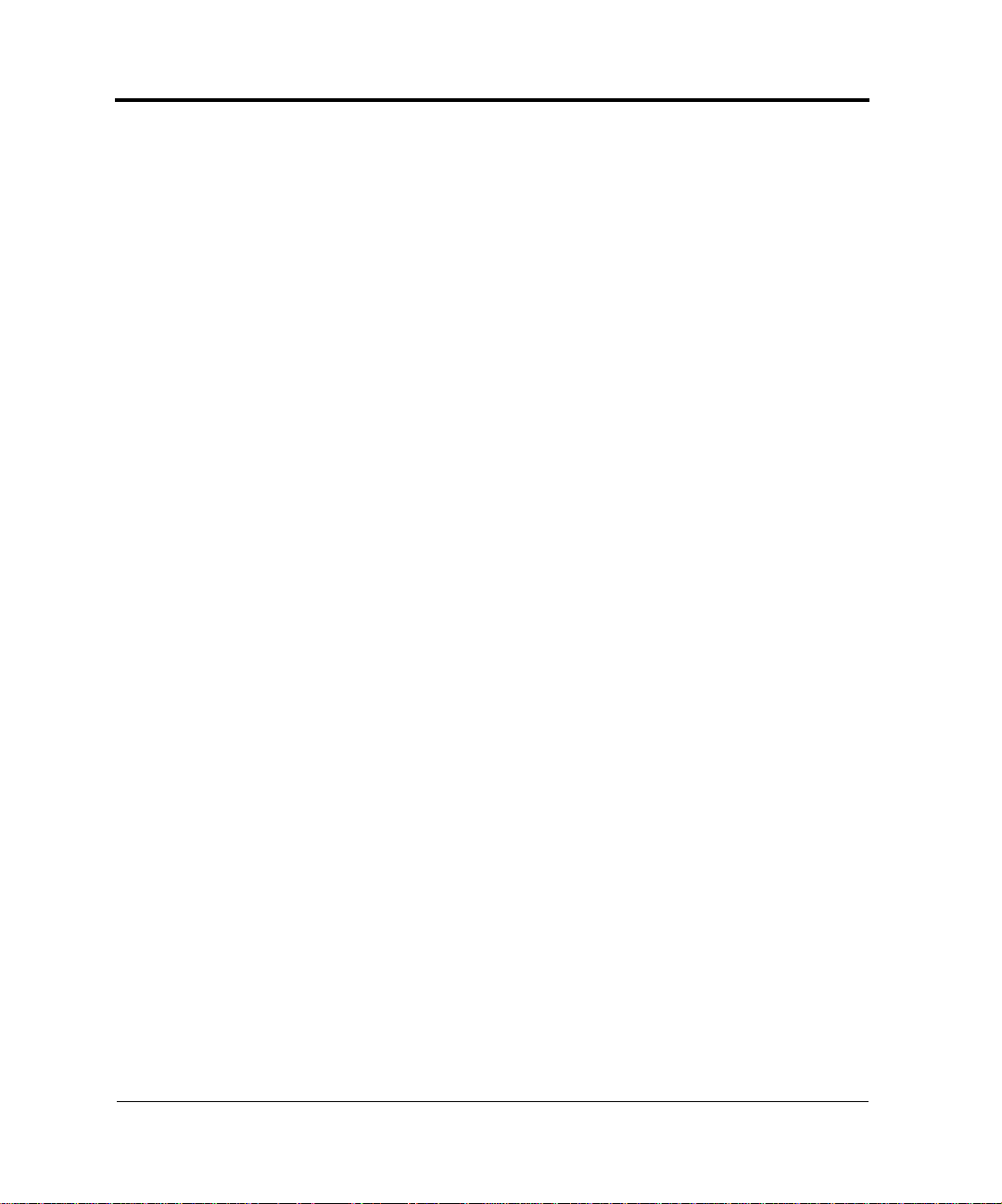

Setting Up the Printer

The printer is shipped with a stopper and cushion inside that prevent

vibration and other movement that could cause damage during

shipment.

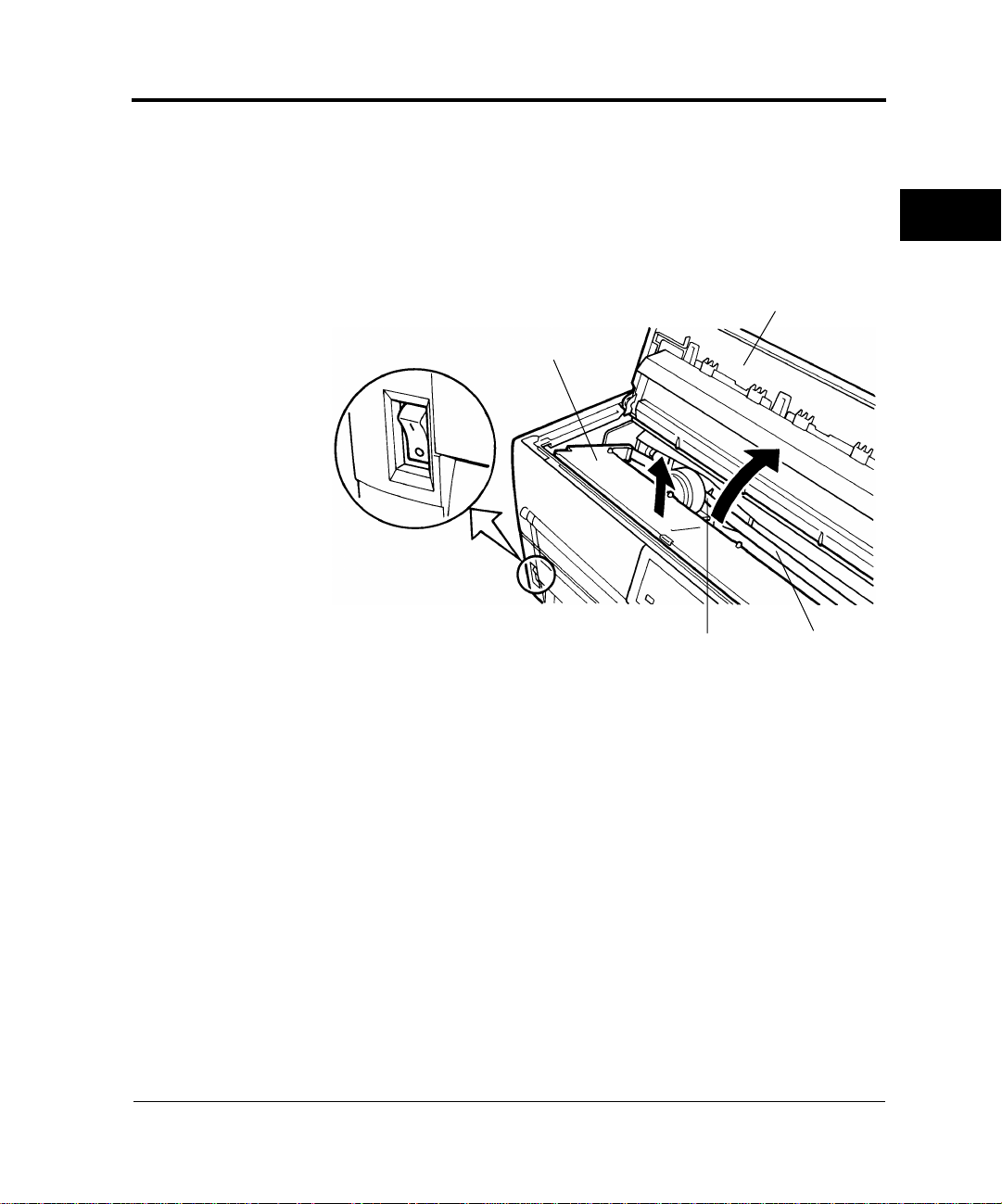

1. Open the top cover and lift out the stopper as shown by the arrow

in the figure.

Top cover

Print head

Stopper

2. Open the front cover and cut-sheet tray and remove the cushion

from between the tractor shafts.

Front cover

Jam removal lever

Cut-sheet tray

Cushion

3. Check that the jam removal lever is locked.

User’s Manual 2-1

Page 19

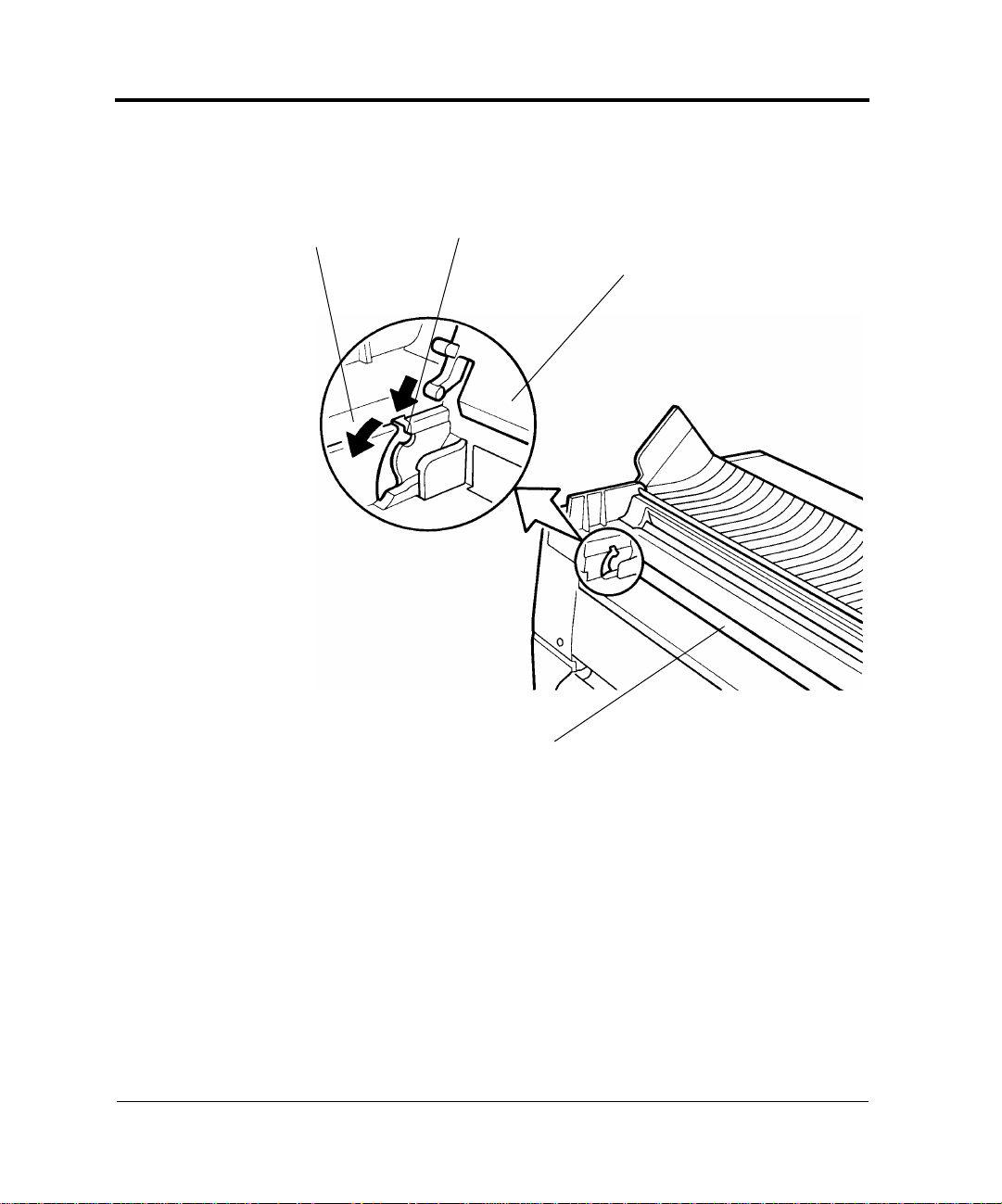

Installing the Paper Guide

Installing the

Paper Guide

Insert the paper guide, at an angle, into the left and right guide grooves

on the back cover and slide it back into place.

Back cover

Guide groove

Paper guide

Back of printer

Paper exit

2-2 User’s Manual

Page 20

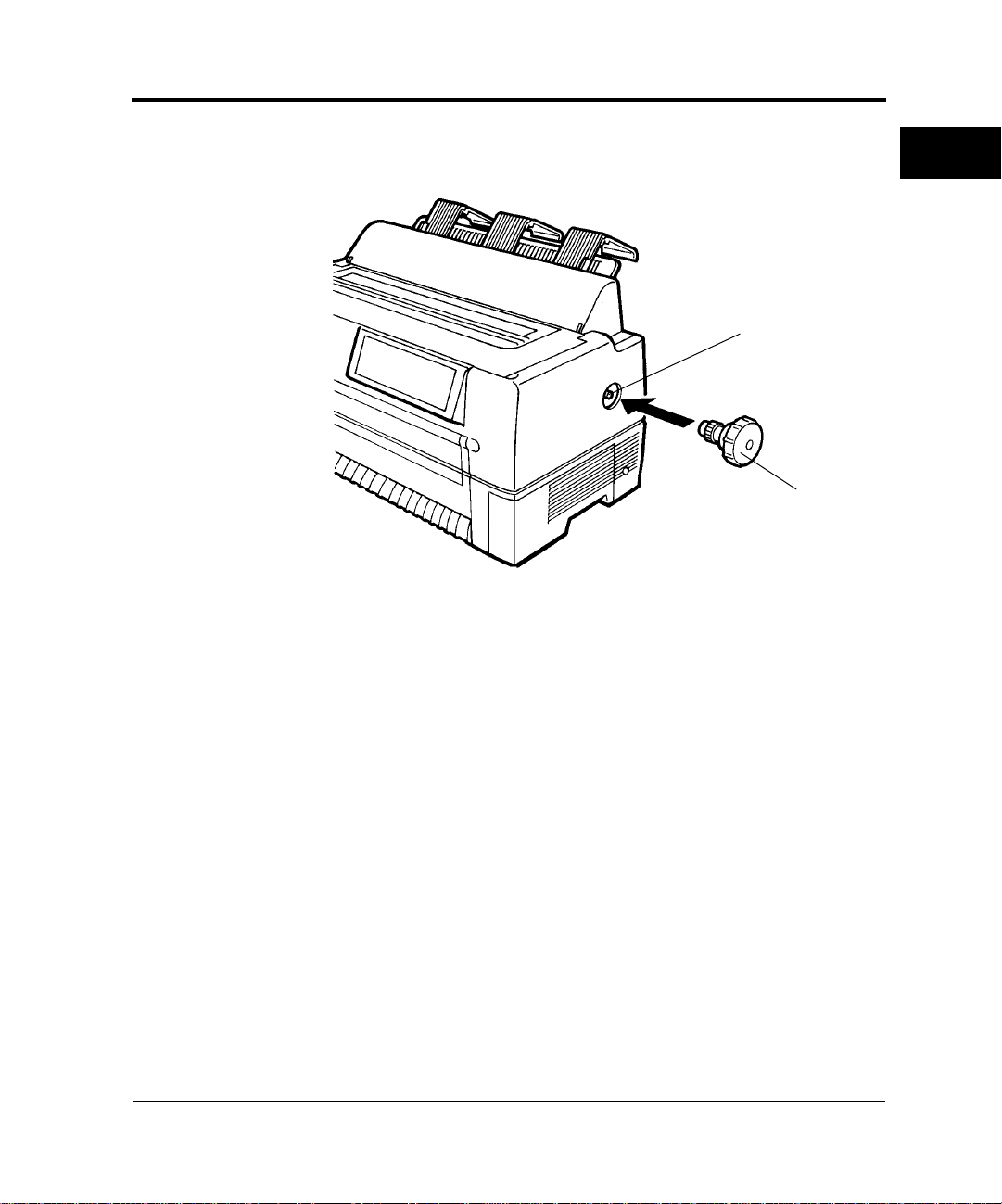

Installing the Platen Knob

Installing the

Platen Knob

Insert the platen knob and align it with the gear teeth.

Platen shaft

SETTING UP

THE PRINTER

Platen knob

User’s Manual 2-3

Page 21

Connecting the Power Cord

Connecting the

Power Cord

1. Turn off printer power (❍).

2. Connect the power cord to the connector on the back of the printer,

at the right side.

Power cord connector

Power cord

3. Plug the power cord into an outlet.

2-4 User’s Manual

Page 22

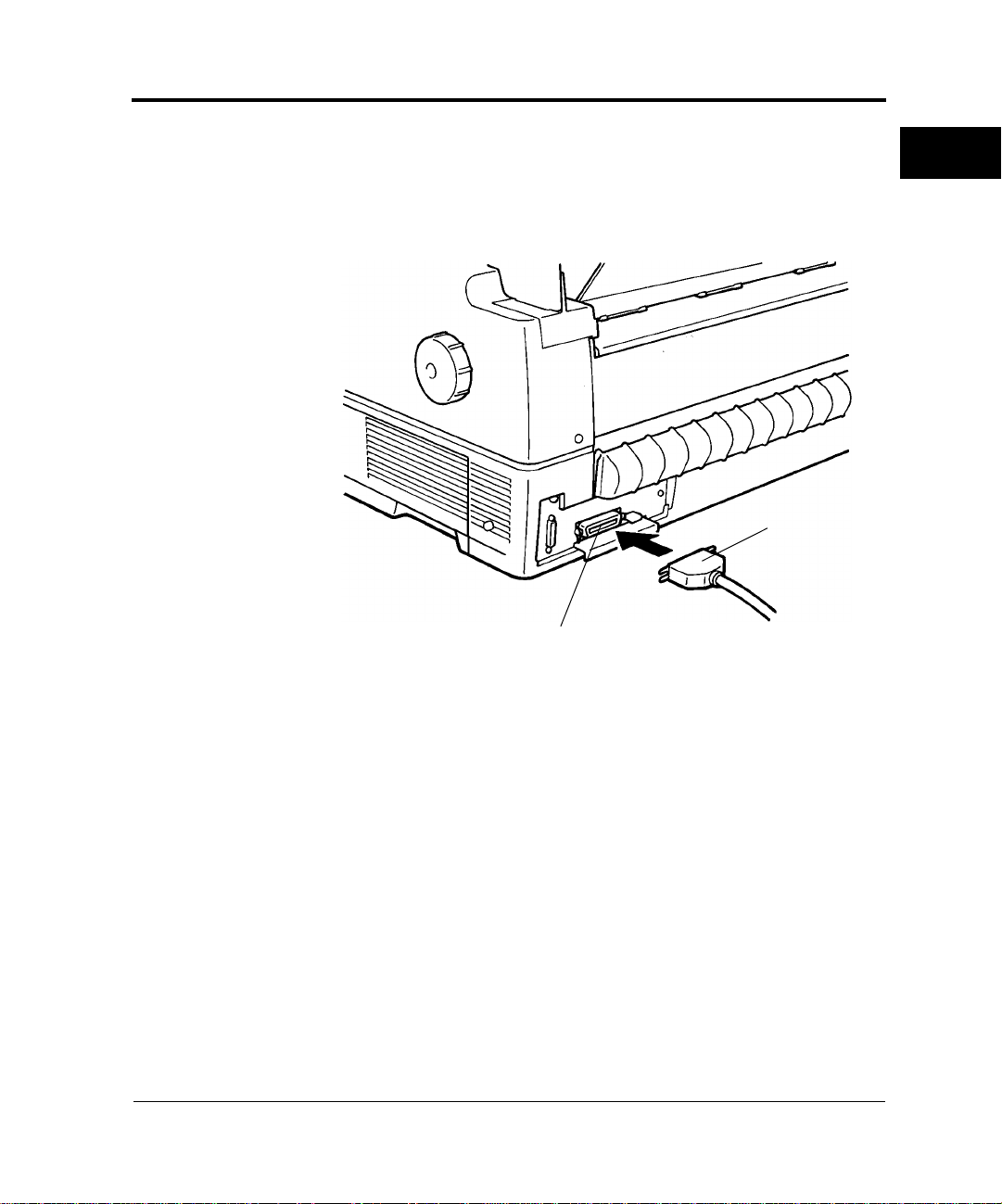

Connecting the Interface Cable

Connecting the

Interface Cable

1. Turn off printer and processor power.

2. Connect the interface cable to the connector at the back of the

printer, on the left side. Make sure the orientation is correct. Press

the left and right lock pins down to secure the cable.

Interface cable

Interface cable connector

SETTING UP

THE PRINTER

3. Connect the cable to the computer. For more information, refer to

the computer user's manual.

User’s Manual 2-5

Page 23

2-6 User’s Manual

Page 24

CHAPTER

Ch

3

oosing a

Cassette

Installing the Ribbon Cassette

The ribbon cassette contains a folded ribbon. Handle the ribbon

cassette carefully to ensure that the ribbon is not disordered or

damaged.

Notice:

A Fujitsu ribbon cassette is recommended. Other cassettes may cause

☞

operating problems or damage the print head. Fujitsu takes no

responsibility for print head faults caused by such cassettes.

Use a cassette or subcassette (ribbon only) listed in Table 3-1.

Table 3–1 Ribbon cassette and subcassette

Product Product number Product description

Ribbon cassette CA02460-D115 Ribbon in cassette

Subcassette CA02460-D215 Ribbon only

INSTALLING

THE RIBBON

CASSETTE

User’s Manual 3-1

Page 25

Preparing the Ribbon Cassette

P

reparing the

Ribbon Cassette

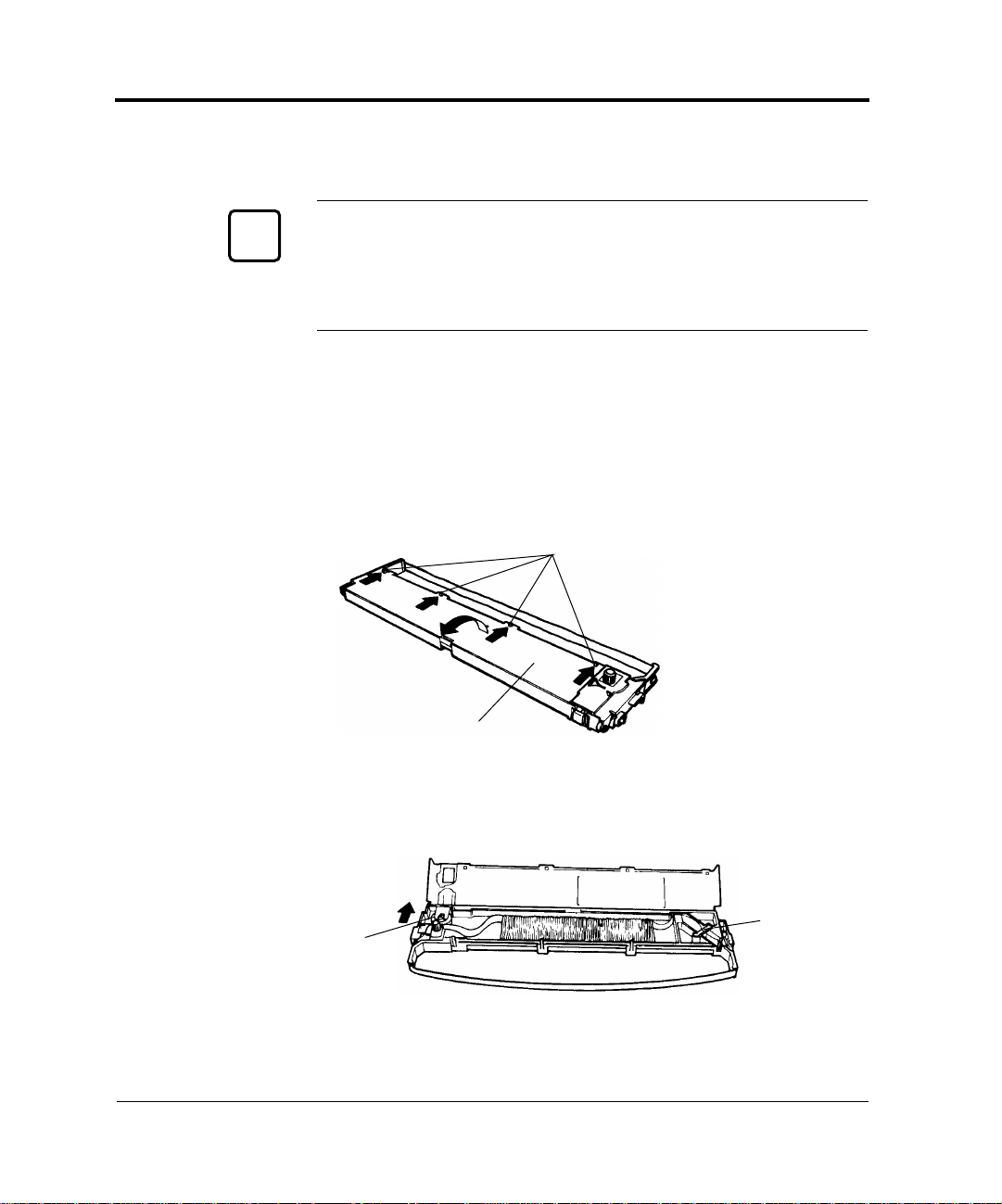

1. Remove the two protective tabs used in shipment.

2. Release the ribbon lock.

3. Turn the knob clockwise to check that the ribbon moves smoothly.

Remove the protective tabs

Knob

Lock tabs B

Release the ribbon lock

Notice:

Adjust the paper thickness lever on the printer appropriately for the

☞

forms used. Otherwise, the ribbon may come loose or paper may be

smeared by ink from the ribbon.

3-2 User’s Manual

Page 26

Installing the Ribbon Cassette

I

lli

nsta

ng the

Ribbon Cassette

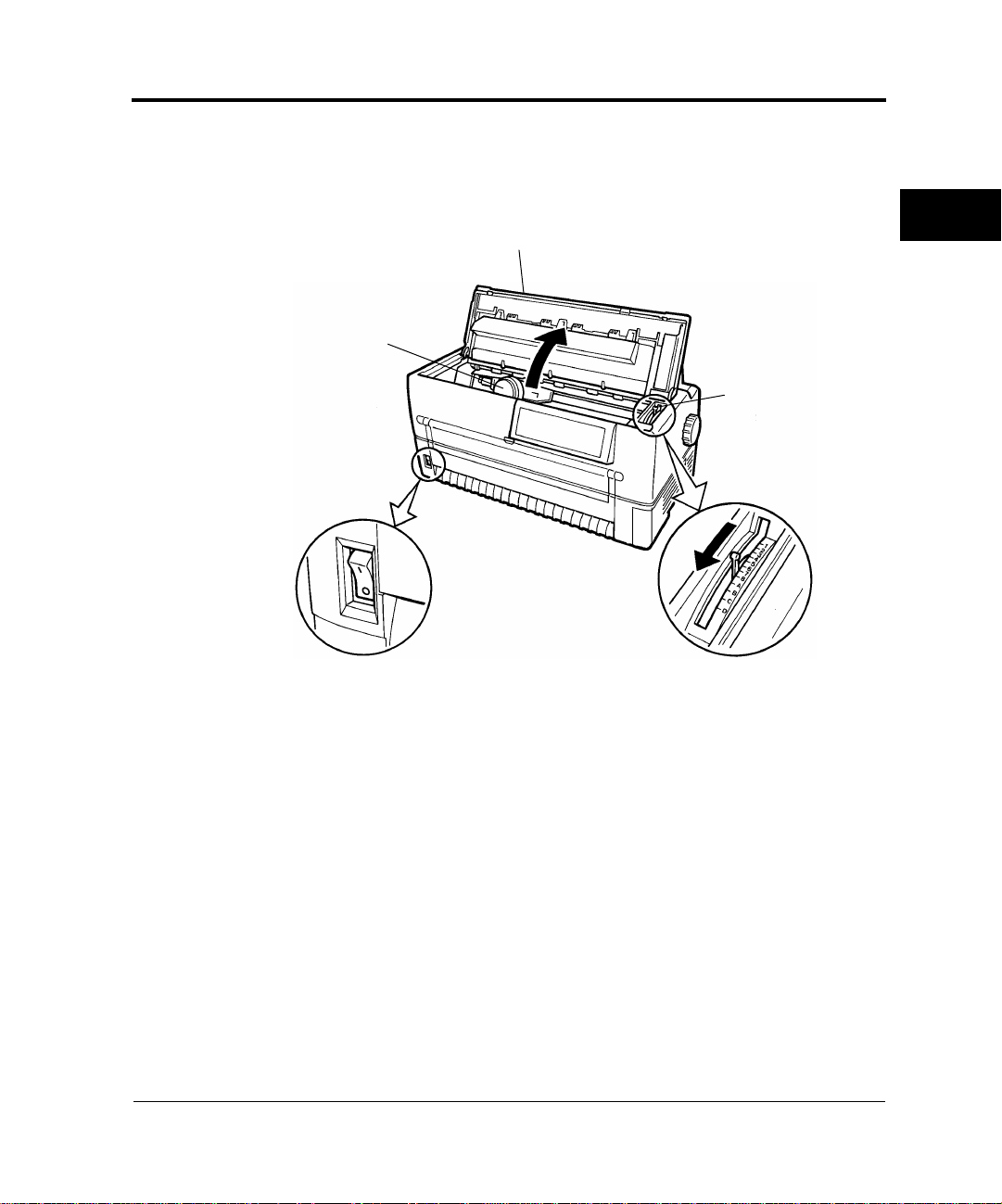

1. Turn off printer power (❍).

2. Open the top cover of the printer and move the paper thickness

lever to D.

Top cover

Print head

Paper thickness lever

Power switch off (❍)

INSTALLING

THE RIBBON

CASSETTE

3. Manually move the print head to the left side so that it is one third

of the printer width from the left side.

User’s Manual 3-3

Page 27

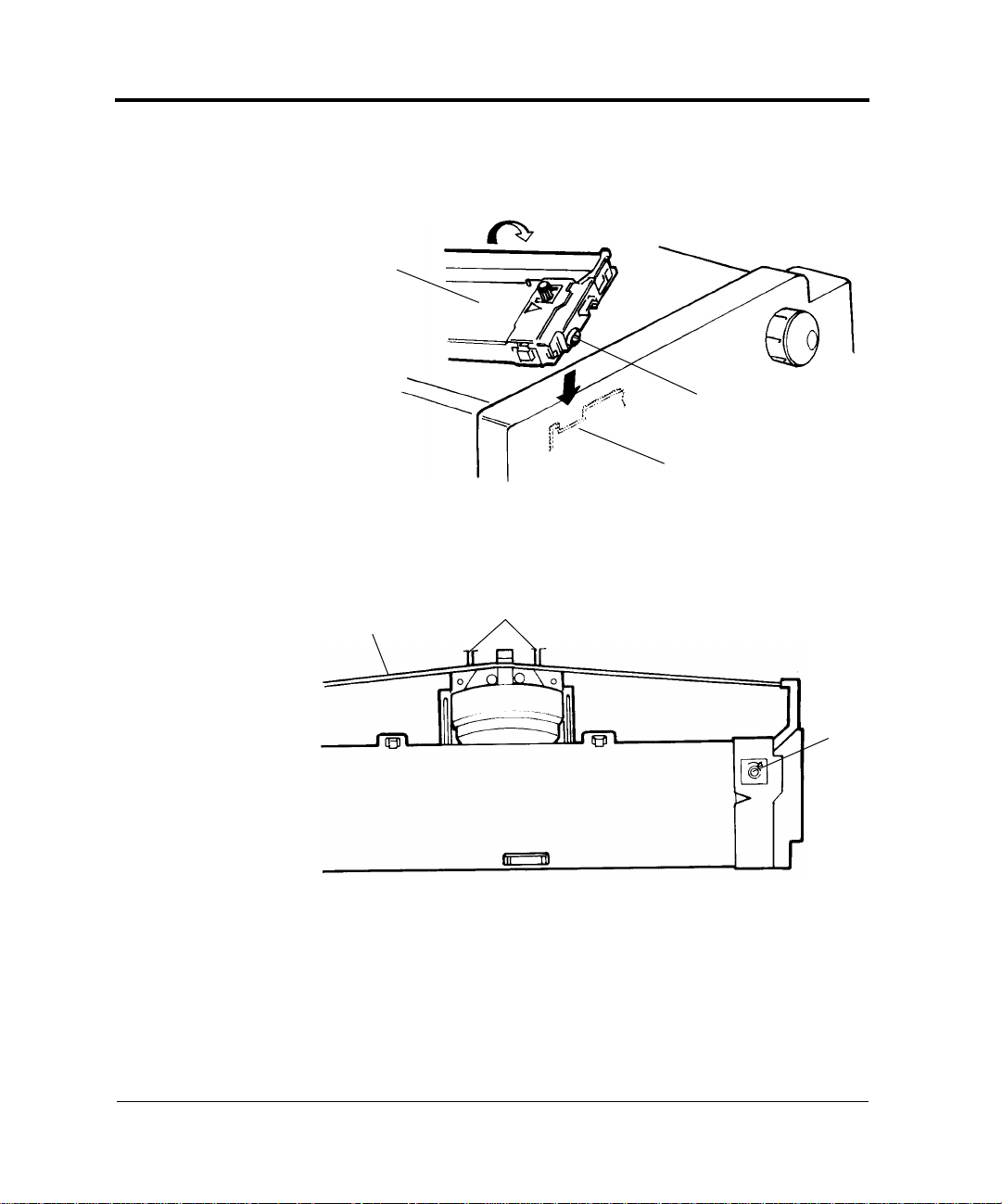

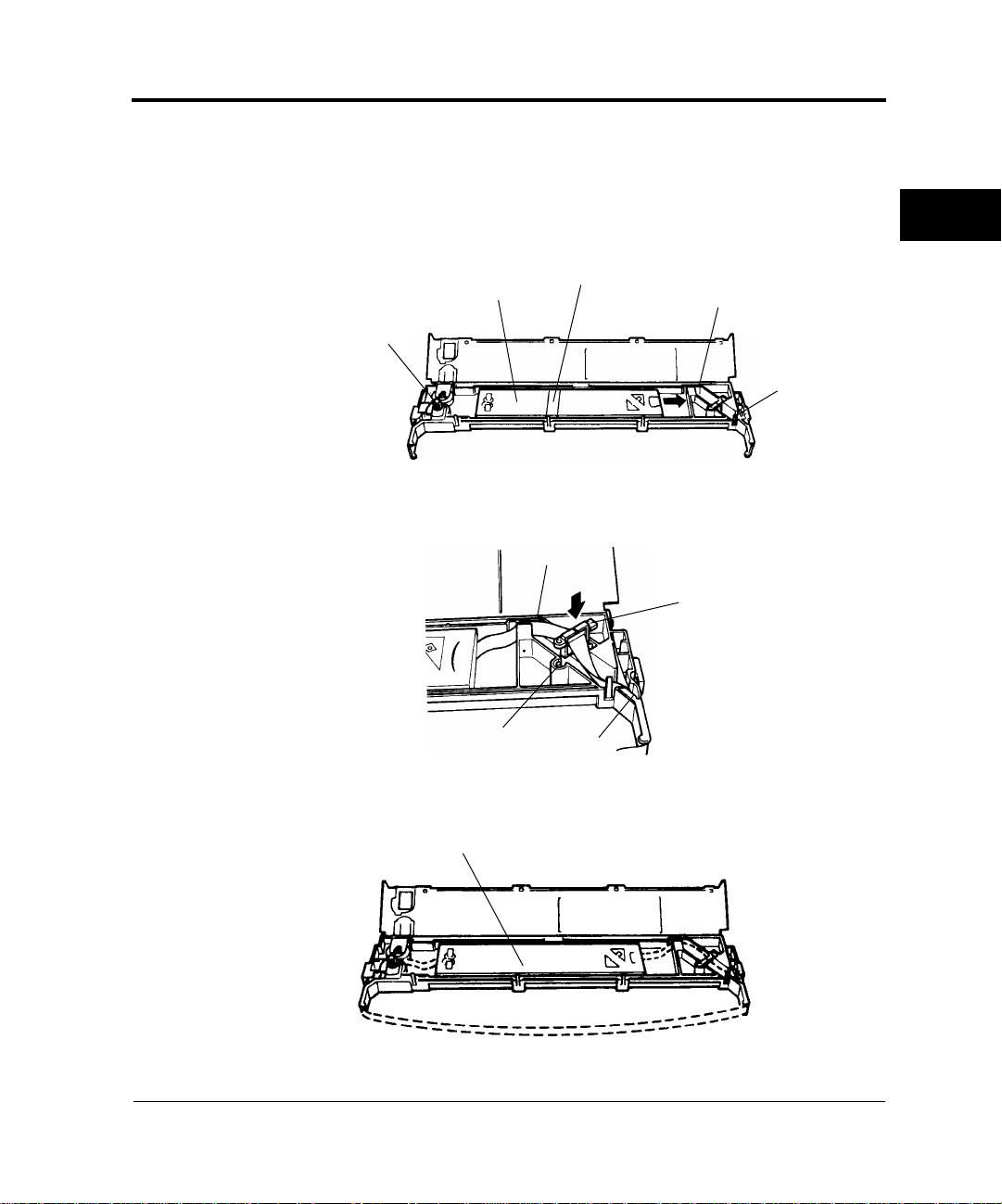

Installing the Ribbon Cassette

4. Align the pins on both ends of the ribbon cassette with the guide

Ribbon cassette

5. Hook the ribbon over the ribbon guide.

6. Turn the ribbon cassette knob clockwise to remove any slack.

Ribbon

grooves inside the printer. Then press the ribbon cassette down to

install it.

Pin

Guide groove

Ribbon guides

Knob

Ribbon cassette

7. Close the top cover of the printer.

3-4 User’s Manual

Page 28

Removing the Ribbon Cassette

R

emoving the

Ribbon Cassette

1. Turn off printer power (❍).

2. Open the top cover of the printer.

3. Remove the ribbon from the ribbon guide.

4. Pull the ribbon cassette towards you to unlock it and remove the

cassette from the printer.

Top cover

Ribbon cassette

Power switch off (❍)

Ribbon guide

Ribbon

INSTALLING

THE RIBBON

CASSETTE

User’s Manual 3-5

Page 29

Replacing the Subcassette

Replaci

ng the

Subcassette

The ribbon can be replaced up to five times before the entire ribbon

cassette itself must be replaced.

Notice:

A Fujitsu ribbon cassette is recommended. Other cassettes may cause

☞

operating problems or damage the print head. Fujitsu takes no

responsibility for print head faults caused by such cassettes. Replace the

cassette carefully to avoid getting ink on your hands.

Replace the ribbon as follows:

1. Turn off printer power (❍).

2. Remove the ribbon cassette from the printer as explained in

“Removing the Ribbon Cassette” on page 3-5.

3. Sequentially press each of the four lock tabs A in the directions of

the arrows, starting from either end. Then open the cassette lid.

Lock tabs A

Lid

4. Press feed roller A in the direction of the arrow until it clicks into

place. This procedure loosens the ribbon holder.

Reverse guide

Feed roller A

5. Lift the reverse guide and remove the old ribbon.

3-6 User’s Manual

Page 30

Replacing the Subcassette

6. When loading the new subcassette into the ribbon cassette, check

that the orientation of the new subcassette is correct. After loading

remove the paper tape.

7. Holding the subcassette casing, slide the bottom of the casing to the

right to remove it.

Casing

Feed roller A

Paper tape

Ribbon path A

Ribbon path B

8. Route the ribbon through paths A and B and insert the reverse

guide.

Ribbon path A

Reverse guide

INSTALLING

THE RIBBON

CASSETTE

Reverse guide insertion

Ribbon path B

9. Thread the ribbon through the cassette as shown by the dotted line

in the figure. Then raise the casing to remove it.

Casing

User’s Manual 3-7

Page 31

Replacing the Subcassette

10. Press lock tabs B in the direction of the arrows to return feed roller

A to its original position. Then close the cassette lid. Turn the knob

clockwise to check that the ribbon moves smoothly.

Knob

Lock tabs B

11. Check off the subcassette replacement column on the cassette label.

12. Install the ribbon cassette (see “Installing the Ribbon Cassette” on

page 3-3).

3-8 User’s Manual

Page 32

CHAPTER

4

Loading

Continuous

Forms (Front)

Loading Paper

1. Turn on the printer power switch ( | ).

2. Press the PAPER PATH button on the control panel to select

FRONT TRACTOR. The FRONT TRACTOR lamp lights.

3. Move the paper guide back as indicated by the arrow in the figure.

(See “Installing the Paper Guide” on page 2-2.)

4. Open the front cover of the printer.

Front cover

Power switch on ( | )

Paper guide

LOADING

PAPER

User’s Manual 4-1

Page 33

Loading Continuous Forms (Front)

5. Raise the cut-sheet tray.

6. Turn the lock levers of the left and right tractors in the direction indicated by the arrow to unlock them.

Lock lever

7. Move the left tractor to the reference point on the lower cover.

Then press the lock lever in the direction of the arrow in the figure

below to lock it.

Cut-sheet tray

Tractor

8. Move the right tractor in alignment with the paper width.

9. Adjust the center guide to the paper width to remove slack in the

paper.

Lock lever

Reference point

Center guide

Tractors

4-2 User’s Manual

Page 34

Loading Continuous Forms (Front)

10. Open the paper holders of the left and right tractors. Align the

forms feed holes with the tractor pins and close the paper holders.

Tractor pins

Paper holders

Tractors

Continuous forms

11. Move the right tractor to add slight tension to the paper. Then press

the lock lever in the direction of the arrow to lock it.

LOADING

PAPER

Lock lever

Tractor

User’s Manual 4-3

Page 35

Loading Continuous Forms (Front)

12. Lower the cut-sheet tray.

13. Close the front cover of the printer.

Cut-sheet tray

Front cover

4-4 User’s Manual

Page 36

Loading Continuous Forms (Front)

14. Press the ONLINE button on the control panel to place the printer

offline. The ONLINE lamp should not be lit.

15. Press the LOAD button (or LOAD/UNLOAD button) on the control panel to load a continuous form automatically.

16. Adjust the position of the print line

To adjust the print line to the position that you require, open the

top cover of the printer and align the red mark of the indicator with

the position you require the bottoms of characters to be.

• Fine forward feed: Holding the ONLINE button down, press

the LF/FF button to feed paper forward in small increments.

• For the operation of the printer with the LCD control panel, see

Appendix E.

• Fine reverse feed: Holding the ONLINE button down, press the

TEAR OFF button to feed paper in reverse in small increments.

Indicator Red mark

LOADING

PAPER

17. Press the ONLINE button on the control panel to place the printer

online. The ONLINE lamp lights.

User’s Manual 4-5

Page 37

Loading Continuous Forms (Rear)

Loading

Continuous

Forms (Rear)

Cutting

Continuous

Forms

Refer to the Rear-Feed Tractor User’s Manual for information on the

rear-feed tractor option.

Forms are cut at perforations 23.3 mm (11/12 inch) above the print

head center when the print head center is on the sixth line. A single line

feed is 4.2 mm (1/6 inch)..

Perforations

23.3 mm

(11/12 in)

Print head center

1. Press the TEAR OFF button on the control panel. The continuous

forms are then automatically loaded to where they are to be cut.

For the operation of the printer with the LCD control panel, see

Appendix E.

2. Open the noise-proof cover.

3. Check that the perforations are at the paper cutter.

4. Cut the continuous forms as shown in the figure below.

4-6 User’s Manual

Page 38

Loading Cut Sheets

Important:

Continuous forms cannot be cut where there are no perforations.

Paper cutter

LOADING

PAPER

Loading Cut

Sheets

1. Turn on printer power ( | ).

2. Press the PAPER PATH button on the control panel to select

FRICTION (friction feed). The FRICTION lamp lights.

3. Raise the paper guide. (See “Installing the Paper Guide” on page

2-2.)

User’s Manual 4-7

Page 39

Loading Cut Sheets

4. Open the front tray.

Paper guide

Power switch on ( | )

Front tray

5. Align the cut-sheet guide with the reference point.

Cut-sheet guide

Reference point

Front guide

4-8 User’s Manual

Page 40

Loading Cut Sheets

6. Insert paper while aligning its left edge with the cut-sheet guide.

Cut-sheet guide

Cut sheet

7. Press the LOAD button (or LOAD/UNLOAD button). The paper

is then loaded to the print start position.

LOADING

PAPER

Notice:

If paper is not loaded correctly, a paper feed error or skewed loading

☞

may occur. Once a cut sheet has been inserted, it is loaded

automatically.

8. Adjust vertical printing as described in step 16 in “Loading Continuous Forms (Front)” on page 4-1.

User’s Manual 4-9

Page 41

Printing on Cut Sheets

Printing on Cut

Sheets

You can print on cut sheets without removing continuous forms from

the tractor section.

1. Press the PAPER PATH button on the control panel to select

FRICTION (friction feed). The FRICTION lamp lights.

Important:

1. Retract continuous forms, if any, from the paper path to the tractor

section. The FRICTION lamp lights.

2. If the lamp does not light to indicate FRICTION, continuous

forms remain in the paper path. Cut the continuous forms and

select FRICTION again.

Continuous forms

4-10 User’s Manual

Page 42

Printing on Cut Sheets

2. Load cut sheets as explained in “Loading Cut Sheets” on page 4-7

without removing the continuous forms.

Cut sheet

Continuous forms

LOADING

PAPER

User’s Manual 4-11

Page 43

Returning to Continuous Forms

Returning to

Continuous

Forms

After printing on cut sheets with continuous forms loaded, you can

easily return to printing continuous forms.

1. Remove cut sheets, if any.

2. Tip back the paper guide.

Paper guide

Front tray

3. Close the front tray.

4. Press the PAPER PATH button on the control panel to select

FRONT TRACTOR or REAR TRACTOR, whichever you want

to use. The FRONT TRACTOR or REAR TRACTOR lamp

lights. Continuous forms are then loaded automatically.

The REAR TRACTOR lamp is for the optional rear-feed tractor.

5. Check the vertical printing position. See “Loading Continuous

Forms (Front)” on page 4-1.

4-12 User’s Manual

Page 44

CHAPTER

5

Using the

Control Panel

Operating the Printer

LED type control panel

1. Layout

Figure 5-1 shows the LED type control panel layout.

Figure 5–1 Control panel layout (LED type)

2. Lamps

Control panel lamps indicate the printer status.

Table 5-1 lists the lamp functions.

OPERATING

THE PRINTER

Table 5–1 Lamp functions (LED type)

*1

Lamp

ONLINE Lights when the printer is online.

PAPER OUT (amber) Changes to red when a paper outage is

1 Lights when MENU 1 is selected.

2 Lights when MENU 2 is selected.

User’s Manual 5-1

Function

detected.

Switched by pressing the MENU button.

Switched by pressing the MENU button.

Page 45

Using the Control Panel

Table 5–1 Lamp functions (LED type) (Continued)

*1

Lamp

Function

FRICTION Lights when cut sheets can be used.

Switched by pressing the PAPER PATH

button.

FRONT TRACTOR Lights when the FRONT tractor can be

used for continuous forms.

Switched by pressing the PAPER PATH

button.

REAR TRACTOR Lights when the REAR tractor can be

used for continuous forms.

Switched by pressing the PAPER PATH

button.

LOCKED Lights when lock mode is on.

Switched by pressing the LOCK button.

Fonts are selected by pressing the FONT

button.

COUR10 Courier (10 cpi)

PRESTG12 Prestige Elite (12 cpi)

COMPRESS17 Compression (17 cpi)

Bold PS Boldface (proportional spacing)

Time PS Timeless (proportional spacing)

N. Sans PS Nimbus Sans (proportional spacing)

DRAFT10 Draft (10 cpi)

DRAFT12 Draft (12 cpi)

MENU FONT The font selected in menu mode becomes

valid in this state.

*1 Lamps glow green unless otherwise indicated.

5-2 User’s Manual

Page 46

Using the Control Panel

3. Buttons (when printer is online)

ONLINE: Places the system offline after it prints the current

line.

LF/FF: Line feed/forms feed button. Feeds forms forward.

Pressing this button continuously for 3 seconds or

more feeds lines forward to the feed point for the

next page (forms feed).

When the cut-sheet feeder is used, pressing this

button continuously for 3 seconds or more unloads

forms. If forms are not at the platen, forms are not

loaded, but a line feed occurs.

TEAR OFF: Places the system in tear off mode and feeds lines to

the forms cutting point. Tear off mode is valid for

continuous forms only.

When this button is pressed, the printer performs

centering, and the ONLINE lamp blinks.

If any button is pressed after forms are cut, the buzzer

sounds, the ONLINE lamp stops blinking, and

forms are fed back to their previous location.

OPERATING

THE PRINTER

LOAD: Loads or unloads forms as follows, depending on the

situation:

• Continuous forms at the platen

Forms are fed backward on the tractor until a paper

outage is detected. If a paper outage has not been

detected when forms have been fed 22 inches,

forms feeding stops.

• Cut sheets at the platen

Cut sheets are unloaded if printing has not started,

and the TOP MARGIN value is made the current

vertical location.

• Cut-sheet feeder set and cut sheets at the platen

Cut sheets are unloaded if printing has not started,

and the next cut sheet is loaded from the cut-sheet

feeder. The TOP MARGIN value is made the

current vertical location.

• Continuous forms or cut sheets being used, cutsheet feeder set, and no forms at the platen

User’s Manual 5-3

Page 47

Using the Control Panel

Forms are loaded, and the TOP MARGIN value is

made the current vertical location.

4. Buttons (when printer is offline)

LOCK: Switches lock mode on or off. The lock mode takes

effect when the offline status changes to online. When

the LOCKED lamp is on, lock mode is on.

When lock mode is on, the font selected on the control

panel is in effect, even if a host command sends an

instruction to change it.

FONT: Selects a font. The font lamps light sequentially each

time the FONT button is pressed. The font lamp that

is on indicates which font is selected.

The font setting takes effect when the offline status

changes to online.

If a command changes the font when lock mode is off,

the font lamp indication does not change.

The font, pitch, and quality for each font selection are

shown here.

Table 5–2 Font button values

Font Quality Characters per inch

COUR10 Courier Letter 10

PRESTG12 Prestige Letter 12

COMPRESS17 Compression CQ 17

Bold PS Boldface Letter Proportional spacing

Time PS Timeless Letter Proportional spacing

N. Sans PS Nimbus Sans Letter Proportional spacing

DRAFT10 Draft Draft 10

DRAFT12 Draft Draft 12

Sequence in which lamps light

MENU FONT The font, quality , and pitch for the font selected in

menu mode are used.

5-4 User’s Manual

Page 48

Using the Control Panel

ONLINE: Places the system online.

MENU: Selects Menu 1 or 2. This button is a toggle.

LF/FF: Feeds lines or forms (same as in online mode).

TEAR OFF: Places the system in tearoff mode (same as in

online mode).

LOAD: Loads or unloads forms (same as in online

mode).

PAPER PATH: Selects FRICTION, FRONT TRACTOR, or

REAR TRACTOR.

ONLINE + LF/FF: Feeds lines forward by 1/180 inch.

ONLINE + TEAR OFF:

Feeds lines backward by 1/180 inch.

ONLINE + LOAD: Permanently stores the load position adjusted

by fine line feeding.

LOCK + FONT: Initializes the printer.

MENU + FONT: Places the system in Setup mode.

See Chapter 8, “Setup Modes,” for more

information.

OPERATING

THE PRINTER

User’s Manual 5-5

Page 49

Using the Control Panel

LCD type control panel

1. Layout

Figure 5-2 shows the LCD type control panel layout.

Figure 5–2 Control panel layout (LCD type)

2. Lamps

Control panel lamps indicate the printer status.

Table 5-3 lists the lamp functions.

Table 5–3 Lamp functions (LCD type)

*1

Lamps

Function

POWER Lights when power is on.

ONLINE

ALARM

*2

Lights when the printer is online.

Changes to red to indicate an alarm.

(amber)

FRICTION

*2

Lights when cut sheets can be used.

Switched by pressing the PAPER PATH button.

FRONT

TRACTOR

*2

Lights when the FRONT tractor can be used for

continuous forms.

Switched by pressing the PAPER PATH button.

REAR

TRACTOR

*2

Lights when the REAR tractor can be used for

continuous forms.

Switched by pressing the PAPER PATH button.

*1 Lamps glow green unless otherwise indicated.

*2 Same as the LED control panel.

5-6 User’s Manual

Page 50

Using the Control Panel

3. LCD

The LCD control panel displays printer status, messages, and

control items on the screen using alphanumeric characters. The

LCD control panel is 24 columns × 2 lines.

4. Buttons

*1

ONLINE

: When the system is online, pressing ONLINE

puts the printer offline after the current lines

are printed. When the printer is offline,

pressing ONLINE puts the printer online.

F1, F2, and F3: Programmable function buttons numbered 1

to 3. The functions depend on the LCD

screen contents.

*2

OPERATING

THE PRINTER

↑ ↓: Switches the direction of an arrow displayed

on the LCD screen.

NEXT DISPLAY: Displays the next LCD screen.

*2

*2

LOAD/UNLOAD: Loads or unloads forms. The operation

depends on the situation.

This button performs the same function as the

LOAD button on the LED control panel. For

details, see 3 and 4 under “LED Type Control

Panel” on pages 5-3 and 5-4.

*1

PAPER PATH

: Selects FRICTION, FRONT TRACTOR, or

REAR TRACTOR.

*1 Same as the LED control panel.

*2 For basic operation information, see Appendix E, “Using the LCD Type Control

Panel.”

User’s Manual 5-7

Page 51

Turning Printer Power On and Off

Turning Printer

Power On and

Off

Test Printing

Turn power on or off as follows:

1. On

Press the power switch at the left on the front of the printer to turn

the printer on ( | ). Depending on the switch settings, lamps will

light.

Notice:

Do not touch any other control panel button when turning power on

☞☞

or off. Otherwise, you may activate a maintenance mode for other than

test printing.

2. Off

Press the power switch to turn the printer off (❍). Lamps go out.

Notice:

Wait at least 3 seconds before turning on power again after turning it

off. Otherwise, a printer fault may occur.

The printer's built-in self-test program prints the firmware version

number, the names of resident emulations, and all available characters.

The test prints 80 characters per line.

For the operation of the printer with the LCD control panel, see

Appendix E.

Make sure paper is loaded. Check that the paper thickness lever is set

to the appropriate position (see “Installing the Ribbon Cassette” on

page 3-3. Then follow these steps to print a self-test page.

1. Turn off the printer.

2. Holding down the LF/FF button, turn the printer back on.

Hold LF/FF down until the printer beeps. Test printing will start

then.

3. To stop printing, press the FONT or MENU button. To remove

the test page, turn the platen knob clockwise.

5-8 User’s Manual

Page 52

Notice:

Do not attempt to use the LF/FF (line feed/forms feed) button to eject

☞

paper in test mode.

4. Check that the printed page resembles the sample in Figure 5-3.

Check that printing is uniform and free of light, dark, or smudged

areas. When printing quality is satisfactory, go to step 5. Otherwise,

correct problems as follows:

a. Check that the ribbon is installed correctly.

b. Check that the paper thickness lever is set to the appropriate po-

sition.

c. Put a new sheet in the cut-sheet tray. Then manually turn the

platen knob to advance the top edge of the paper past the top

roller.

d. Press FONT or MENU to restart printing. If printing quality

does not improve, turn off the printer and contact your dealer.

Test Printing

OPERATING

THE PRINTER

User’s Manual 5-9

Page 53

Test Printing

Figure 5–3 Test printing sample

5. To exit test printing mode, press ONLINE. The printer goes online.

5-10 User’s Manual

Page 54

Demonstration Pattern Printing

Demonstration

Pattern Printing

The printer prints a demonstration pattern showing some printing

features, as shown in Figure 5-4. To print a demonstration pattern,

follow the steps below.

For the operation of the printer with the LCD control panel, see

Appendix E.

1. Load a sheet of letter- or A4-size paper.

2. Turn off the printer.

3. Holding down the FONT button, turn the printer back on.

The printer will start printing the demonstration pattern.

4. For cut sheets, the demonstration stops after printing a page. If a

cut-sheet feeder or continuous forms are used, the demonstration

pattern is repeated. To stop or restart the demonstration during

printing, press ONLINE.

5. To exit demonstration mode, turn off the printer.

OPERATING

THE PRINTER

User’s Manual 5-11

Page 55

Demonstration Pattern Printing

Figure 5–4 Demonstration pattern

5-12 User’s Manual

Page 56

Sensor Detection

Sensor

Detection

The printer has sensors to detect the following conditions:

• Top cover open

The printer goes offline if the top cover is open.

• Paper out

The printer stops printing when it detects a paper outage, cut-sheet

search, or cut-sheet loading.

• Paper jam

The printer stops printing when it detects a paper jam while paper is

being ejected.

• Print head overheating

The printer prints each line in three passes to protect the print head

when overheating is detected.

• Skewed feeding

When the printer detects skewed feed during loading from the front

table, the printer ejects a cut sheet by reverse line feeding.

• Internal lock switch (not available in some countries)

If the top cover is opened during printing, the printer will

automatically stop, and the remainder of the print data from the line

being printed will be lost. Therefore, do not open the top cover

during printing.

• Jam lever open

OPERATING

THE PRINTER

User’s Manual 5-13

Page 57

5-14 User’s Manual

Page 58

CHAPTER

6

Clearing Paper Jams

Continuous

Forms (Front)

When using front-fed continuous forms, remove jammed paper as

follows:

1. Turn off printer power ( ❍ ).

2. Open the front cover.

Front cover

Power switch off ( ❍ )

3. Raise the cut-sheet tray.

4. Lower the green left and right jam removal levers.

CLEARING

PAPER JAMS

Cut-sheet tray

Jam removal lever

User’s Manual 6-1

Page 59

Continuous Forms (Front)

5. Turn the tractor lock levers in the direction indicated by the arrows

in the figure to unlock them. Then open the paper holders.

Lock levers

Paper holders

Tractors

6. Cut the forms just in front of the tractors.

7. Remove jammed continuous forms from the tractors as follows:

a. Remove paper from the paper guide, at the back of the printer.

b. Remove other paper from the front of the printer.

Paper guide

Back of printer

6-2 User’s Manual

Page 60

Print head

Continuous Forms (Front)

c. Remove jammed paper in the printing section as follows:

1. Open the top cover.

2. Slide the paper thickness lever down to D.

3. Move the print head away from the paper.

4. Remove the paper.

Top cover

CLEARING

PAPER JAMS

Paper thickness lever

8. Lift the green left and right jam removal levers and return them to

their original locations.

9. Lower the cut-sheet tray.

10. Reload forms.

Important:

To prevent paper jams when using continuous forms, align the left and

right holes with the tractor feed holes and ensure that the forms have

no slack.

User’s Manual 6-3

Page 61

Continuous Forms (Rear)

Continuous

Forms (Rear)

Cut Sheets

Refer to the Rear-Feed Tractor User’s Manual for information on the

rear-feed tractor option.

Remove jammed cut sheets as follows:

1. Turn off printer power ( ❍ ).

2. Open the front cover.

Front cover

Power switch off ( ❍ )

3. Raise the cut-sheet tray.

4. Lower the green left and right jam removal levers.

Cut-sheet tray

Jam removal lever

6-4 User’s Manual

Page 62

5. Lower the cut-sheet tray.

Cut-sheet tray

Cut Sheets

6. Remove the jammed cut sheet as follows:

a. Remove paper in the paper guide from the back of the printer.

b. Remove paper other than paper in the paper guide from the

front of the printer.

Paper guide

Back of printer

c. Remove paper in the printing section as explained in step 7 of

“Continuous Forms (Front)” on page 6-3.

CLEARING

PAPER JAMS

Important:

When loading forms after clearing a jam, be sure to insert cut sheets

with the left edge aligned with the paper guide.

User’s Manual 6-5

Page 63

6-6 User’s Manual

Page 64

CHAPTER

7

Continuous

Forms

Paper Specifications

This chapter describes paper that the printer can use.

Any other paper should be tested carefully before use.

1. Size

Figure 7-1 shows the size range for continuous forms.

PAPER

SPECIFICATIONS

T

Y

Measurement Dimensions in mm (in)

Paper width Y 101.6 to 419 (4 to 16.5)

Length between folds T 101.6 (4) or more

Figure 7–1 Size range for continuous forms

User’s Manual 7-1

Page 65

Continuous Forms

2. Number of parts

The printer can handle multipart paper. Table 7-1 lists allowable

combinations for the total number of parts, including the original,

and the ream weight.

Table 7–1 Number of parts and ream weight for continuous forms

Type Number of parts Ream weight in g/m

Single part 1 46, 52, 64, 81

Pressure sensitive

*1

2

3

4

5

[6]

[7]

[8]

39, 50, 64, (81)

39, 50, (64, 81)

39, (50, 64, 81)

39, (50, 64)

39, (50, 64)

39, (50, 64)

39, (50, 64)

2

Carbon-backed

multipart

*1

2

3

4

5

[6]

[7]

[8]

Multipart with car-

*2

bons

2

3

[4]

*1 Ream weights for pressure-sensitive and carbon-backed multipart

forms may differ slightly according to the manufacturer. Select forms

of the weight closest to those in Table. 7-1.

*2 The maximum number of parts for multipart forms with carbons

counts each carbon as one part; that is, the maximum is four.

Important:

39, 52, 64, (81)

39, 52, (64, 81)

39, (52, 64, 81)

39, (52, 64)

39, (52, 64)

39, (52, 64)

39, (52, 64)

34, 46, 52, (64, 81)

34, 46, (52, 64)

34, 46, (52, 64)

1. For specifications for continuous forms loaded from the back of the

printer, refer to the Rear-Feed Tractor User’s Manual.

2. The printer can use only the bottom copy layer of paper with its

weight in parentheses ( ).

7-2 User’s Manual

Page 66

Continuous Forms

3. Characteristics of paper with the number of parts in brackets [ ]

may differ slightly with the manufacturer and should be tested

carefully before use.

4. Paper used for continuous forms differs depending on whether it is

loaded from the front or from the back of the printer. The paper

specifications in Table 7-1 are for forms loaded from the front.

5. The total thickness of multipart paper must not exceed 0.65 mm

(0.025 in).

3. Binding

Select a binding type from Table 7-2.

Table 7–2 Binding for continuous forms with two to six parts

Binding Remarks

Double-sided glued multipart

forms (zigzag spot gluing)

Recommended because:

• Forms remain flexible.

• Parts do not separate or

become misaligned easily.

25.4 mm (1 in) or less

Double-sided paper staples The more parts, the easier the

parts separate or become

misaligned.

76.2 mm (3 in) or less

PAPER

SPECIFICATIONS

User’s Manual 7-3

Page 67

Continuous Forms

Table 7–2 Binding for continuous forms with two to six parts (Continued)

Binding Remarks

Single-sided zigzag spot gluing

and paper staples from back

25.4 mm (1 in) or less

76.2 mm (3 in) or less

Combination of the other two

types of binding

Important:

To avoid paper feed problems, do not bind as shown in the figure.

Line pasting

Staple

Pasted

Stapling

Check that the height of unfolded pasted forms at perforations is 2 mm

(0.08 in) or less.

2 mm (0.08 in)

or less

7-4 User’s Manual

Page 68

4. Binding holes in the scanning area of the sensor

The shaded area shown in the figure indicates the scanning area of

the sensor in which binding holes may lie. Their size is subject to

the following restrictions as described and illustrated.

Any binding hole completely in the shaded area must be 7 mm

(0.28 in) or less in diameter.

Caution:

Always avoid printing on the binding holes. This could damage the

☞

print head.

30 mm

(1.2 in)

10 mm (0.4 in)

First character

Binding holes

Continuous Forms

PAPER

SPECIFICATIONS

5. Perforations

The perforations in continuous forms must meet the following

conditions:

The ratio of cut to uncut areas for single-part continuous forms

must be 3:1.

User’s Manual 7-5

Page 69

Continuous Forms

The uncut dimension at C on each end of horizontal perforations

shown below must be 1 mm or more.

3 mm (0.12 in)

cut

Vertical perforations (middle)

1 mm (0.04 in)

uncut

C

Vertical

perforations

Horizontal perforations

Edge

C

Cut

1 mm (0.04 in) or more

Uncut

When a cross-point cut occurs at the juncture of vertical and horizontal

perforations, printing is inhibited in the shaded area shown in the

figure below. Printing is not allowed in this area to prevent damage to

forms and also to prevent printer faults.

3 mm

(0.12 in)

3 mm

(0.12 in)

Inhibited area

28 mm

(1.1 in)

Cross-point cut

28 mm

(1.1 in)

Cross-point uncutCross-point cut

Notice:

This restriction also applies when the print head moves without

☞

printing.

7-6 User’s Manual

Page 70

Continuous Forms

6. Print area

The figure below shows the print area on continuous forms.

A

F

(in)

A 4.2 (0.17) Characters printed in this

Area Size in mm

Remarks

area may not be neat. A line

spacing of 4.2 mm (1/6 in) or

more prevents characters on

adjacent lines from

Print area

Perforations

(fold)

A

F

B 5.08 to 30

(0.2 to 1.18)

overlapping.

Depending on the paper

width, this size varies as

follows:

101.6 to 119.4 mm (4 to 4.7

in) wide: 5.08 to 9 mm (0.2

PAPER

SPECIFICATIONS

to 0.35 in)

A

F

388.6 to 419 mm (15.3 to

16.5 in) wide: 15 to 30 mm

(0.6 to 1.18 in)

Print area

C 5.08 (0.2)

or more

This size varies with the

paper width and number of

print columns, but must be at

least 5.08 mm (1/5 inch).

D 152 (6.0) This area feeds off the

D

tractors and prevents reverse

line feed.

G

BC

101.6 to 419 mm

(4 to 16.5 in)

E

E Appropriately

29 (1.1)

This value indicates the

paper-end detection point.

F 3.5 (0.14) Do not move the printing

unit horizontally in this area

as paper may be smeared by

the ink ribbon or the printing

unit may be caught at bulges.

G 4.2 (0.17)

User’s Manual 7-7

Page 71

Cut Sheets

Cut Sheets

For cut sheets, use high-quality paper with a light reflection factor of

60 percent or more. Ordinary high-quality white paper has a light

reflection factor of approximately 70 percent. The darker or thinner

the paper, the lower the reflection factor.

1. Size

Width: 90 to 420 mm (3.5 in to A3 horizontal)

Length: 90 to 420 mm (3.5 in to A3 horizontal)

2. Number of parts

The printer can handle multipart paper. Table 7-3 lists allowable

combinations for the total number of parts, including the original,

and the ream weight.

Table 7–3 Number of parts and ream weight for cut sheets

Type Number

of parts

Single

1 <35>, 46, 52, 64, 81

part

Ream weight in g/cm

2

35, 46, 52, 64, 81, 104,

Front Rear

*1

127

Pressure

sensi-

*2

tive

2

3

4

5

[6]

[7]

[8]

39, 50, 64, (81)

39, 50, (64, 81)

39, (50, 64, 81)

39, (50, 64)

39, (50, 64)

39, (50, 64)

39, (50, 64)

Carbonbacked

multi-

*3

part

2

3

4

5

[6]

[7]

[8]

*1 For DL6600 only.

*2 Ream weights for pressure-sensitive and carbon-backed multipart

forms may differ slightly according to the manufacturer. Select forms

of the closest weight to those in the table.

*3 Do not use carbon paper with cut sheets.

7-8 User’s Manual

39, 52, 64, (81)

39, 52, (64, 81)

39, (52, 64, 81)

39, (52, 64)

39, (52, 64)

39, (52, 64)

39, (52, 64)

Page 72

Cut Sheets

Important:

1. Paper with its weight in angle brackets < > must be at least 254

mm (10 in) wide.

2. For multipart forms the ream weight of the bottom sheet being

used must be one of the values in parentheses ( ).

3. Characteristics of paper with the number of parts in brackets [ ]

may differ slightly according to the manufacturer and should be

tested carefully before use.

4. The total thickness of multipart paper must not exceed 0.65 mm

(0.025 in).

3. Binding

Paste sheets at the top.

Important:

Pasted portions must be flexible and free of curl.

Paste here.

Front

Side

PAPER

SPECIFICATIONS

User’s Manual 7-9

Page 73

Labels

4. Print area

The figure below shows the print area on cut sheets.

A

Area Size in mm (in)

Front Rear

Print area

A 4.2 (0.17) 8.5 (0.33)

B 4.2 (0.17) 8.5 (0.33)

*1

5.1 (0.2) to 38 (1.5) or

C

more

B

D 5.1 (0.2) or more

C

90 to 419 mm

(3.5 to 16.5 in)

D

(DL6600 Pro only)

*1 For wide paper, this specification is as follows:

406.4 mm (16 in) wide: 22.5 to 38.5 mm (0.9 to 1.5 in)

419 mm (16.5 in) wide: 36 to 38.5 mm (1.4 to 1.5 in)

Labels

Only labels on the front of continuous forms backing sheets can be

printed.

1. Size

Paper size specifications are the same as for general continuous

forms.

2. Paper thickness

The label and backing sheet together must be 0.2 mm (1/27 in) or

less.

7-10 User’s Manual

Page 74

Label

Labels

Important:

1. The thickness of the backing sheet must be 0.1 mm (1/254 in) or

less.

2. The thickness of the label must be 0.1 mm (1/254 in) or less.

3. Label adhesion

Labels must satisfy the conditions below and not peel off easily.

Winding drum diameter 27 mm

(1.06 in)

Winding angle 180°

PAPER

SPECIFICATIONS

Winding time 24 hours

Drum diameter:

27 mm (1.06 in)

Ambient temperature 40°C

Ambient humidity 30% RH

4. Print area

The figure below shows the print areas on labels.

Fold

Area Size in mm (in)

A 2.54 (0.1) or more

A

C

D

B 6.35 (0.25) or more

C 2.54 (0.1) or more

Print area

C

B

CC

Label

Print area

D 25.4 (1)

B

*1

*1 Lines may not be fed neatly in the print area of D. A line spacing of 1/6 inch or more pre-

vents characters on adjacent lines from overlapping.

User’s Manual 7-11

Page 75

Labels

5. Formats

Use the formats shown below to prevent peeled labels from causing

feed failures, print head damage, and other serious problems.

Example 1:

Leave the four corners and sides uncut between cut portions and do

*1

not remove nonlabel areas

.

This procedure completely prevents label peeling.

Enlarged label:

Leave several cuts on

each of the four sides.

Label

Label

Label

Backing

sheet

Label

Label

Label

Label

Label

Leave uncut portions

on the four corners.

7-12 User’s Manual

Page 76

Example 2:

Labels

Mount

If nonlabel areas

Label

Label

Label

Label

*1 Areas in which no labels adhere to the backing sheet.

*2 R stands for radius. R2 and R3 should be between 2 mm and 3 mm.

*1

must be removed, round label corners.

Label

Label

Label

Enlarged label:

Rounded (R2 to R3)*2 corners

Label

Figure 7–2 Recommended label formats

PAPER

SPECIFICATIONS

User’s Manual 7-13

Page 77

Labels

6. Restriction on APTC option

The printer performs automatic paper thickness detection on the

printing side. For forms with backing sheets removed, the thickness

differs between the label and backing sheet. Measure the thickness

at a label as shown in Figure 7-13.

Front end (or fold)

First printed character

38 mm (1.5 in) 44 mm (1.7 in)

16.93 mm

ABC

12.7 mm

(2/3 inch)

(1/2 inch)

Important:

Ensure that characters are printed in the shaded area.

Figure 7–3 Label arrangement

7-14 User’s Manual

Page 78

Precautions

Precautions

1. Preprinting

When printing using a color with a reflection factor of 60 percent

or less, such as black, do not print in the shaded area shown in the

figure below.

30 mm

(1.18 in)

First character

Important:

10 mm (0.4 in)

Preprinting-inhibited area

The printer uses an autosensor to detect loaded paper in the shaded

area. If the area is preprinted in black, the sensor may fail to detect the

paper because of decreased light reflection.

PAPER

SPECIFICATIONS

Perform preprinting as follows:

a. Do not print horizontal lines thicker than 8 mm (0.3 in)

8 mm (0.3 in) or less

User’s Manual 7-15

Page 79

Precautions

b. When consecutively printing lines that satisfy the specification

in (a), leave an interval of 8 mm (0.3 in) or greater between

lines.

Leave an interval of 8 mm (0.3 in) or greater.

Important:

If the line thickness is 0.5 mm (0.02 in) or less, the interval can be

4 mm (0.16 in) or more.

c. When printing near a paper edge, leave a margin of 8 mm

(0.3 in) or greater.

Top or bottom end of paper

Leave a margin of

8 mm (0.3 in)

or greater.

Important:

If the line thickness is 0.5 mm (0.02 in) or less, the interval can be

4 mm (0.16 in) or more.

d. When printing vertical lines in the shaded area in Figure 7-##,

make lines 0.5 mm (0.02 in) thick or less and do not print more

than one line.

Before printing characters in the shaded area in Figure 7-14, use a

sample to check that the characters can be printed.

7-16 User’s Manual

Page 80

Precautions

2. Binding hole

The shaded area on page 7-15 also places restrictions on binding

holes punched in that area. If punching is necessary, make the holes

7 mm (0.28 in) or less in diameter.

3. Smearing caused by paper feed roller

If the percentage of printing in the shaded areas in the figure below

is high, the paper feed roller may smear paper at loading or ejection.

Design the format to make areas as far away from the printed area

as possible or print a color or pattern on the paper to make smearing

unnoticeable.

Smeared areas in the figure below assume that the left margin is

25.4 mm (1 in). If the left margin is changed, smear areas move

proportionally.

Unit: mm (in)

PAPER

SPECIFICATIONS

24.5

(0.96)

24.5

(0.96)

22 (0.87)

89.5

(3.52)

H

First column

22 (0.87)

144.5

(5.69)

22 (0.87)

199.5

(7.85)

22 (0.87)

284.5

(11.2)

22 (0.87)

345.5

(13.6)

22 (0.87)

User’s Manual 7-17

Page 81

Precautions

4. Miscellaneous

When using special paper that does not conform to specifications,

prepare samples for full trials before using the paper.

Store and handle paper with care to prevent deformation or

damage. Do not store paper where humidity is high.

7-18 User’s Manual

Page 82

CHAPTER

8

Overview

Setup Mode

The printer provides two modes: normal mode, for everyday printer

operations, and setup mode, for selecting printer options and helping

diagnose printer problems.

Setup is performed offline using the printer control panel, an approach

called offline setup, or remotely using a processor or software, an

approach called setup program online setup. This chapter focuses on

offline setup. The section “Performing Online Setup” on page 8-48

applies to all emulations.

Optional printer settings include emulation, font, spacing, page length

and width, serial interface, and top-of-form. Saving settings in the

printer's permanent memory makes them the default settings. Default

settings are activated whenever the printer is turned on. If DPL24C

PLUS is saved as the default emulation, for example, DPL24C PLUS

is activated when the printer is next turned on.

Printer diagnostic functions include SELF-TST, HEX-DUMP, and

V-ALMNT, used in troubleshooting. HEX-DUMP is mainly used by

programmers.

For printers that use the LED control panel, perform offline setup as

follows. Firstly, print setup function, item, and option. Press the

FONT, MENU, or LOCK button to move the yellow arrow on the

print head beneath the desired selection.

SETUP MODE

For printers that use the LCD control panel, perform offline setup as

follows. Firstly, display the setup function, item, and option on the

LCD screen. Press F1, F2, or F3 to select the desired function. On the

LCD display, options can be easily set, and functions un be easily

executline setup function using the LCD control panel, see

Appendix E, “Using the LCD Type Control Panel.”

User’s Manual 8-1

Page 83

Chapter Organization

Chapter

Organization

Activating

Setup Mode

If you are using setup mode for the first time, read “Activating Setup

Mode” on page 8-2 and “Using Setup Mode” on page 8-4 to learn how

setup mode works. Once you understand the basics, read the following

sections to learn how to select printer options compatible with your

processor hardware and software.

To restore printer default values set at shipment, see “Resetting Default

Values” on page 8-36.

For information on using SELF-TST, HEX-DUMP, and V-ALMNT,

see “Using Diagnostic Functions” on page 8-37.

Experienced users can turn to the flowchart at the end of this chapter,

which lists the printer setup functions and options for quick reference.

Before entering setup mode, load continuous forms paper. For

information, see “Loading Continuous Forms (Front)” on page 4-1.

You will need approximately eight sheets of paper to print all setup

selections.

Enter setup mode as follows:

1. Check that forms are loaded.

2. Press ONLINE to place the printer offline.

3. Press FONT and MENU together until the printer beeps.

If a beep does not sound, you are not in setup mode. Place the

printer offline and try again.

Upon entering offline setup mode, the printer prints the

information shown in Figure 8-1.

8-2 User’s Manual

Page 84

Activating Setup Mode

SETUP MODE

(GAP-ADJ is printed only with APTC installed.)

Figure 8–1 Initial setup mode printout

The initial printout contains a header, help menu, and

<<FUNCTION>> menu. The header shows that the printer is offline

and in setup mode. The help menu summarizes setup mode

operations. The <<FUNCTION>> menu lists all functions available in

setup mode. Note that the yellow arrow on the print head is initially

below the SAVE&END function.

Another way to enter setup mode is to turn off the printer and then

turn it on again while pressing the FONT and MENU buttons.

Continue pressing the buttons until the printer beeps.

User’s Manual 8-3

Page 85

Using Setup Mode

Using Setup

Entering setup mode prints the <<FUNCTION>> menu.

Mode

<<FUNCTION>>

SAVE&END MENU1 MENU2 HARDWRE ADJUST CONFIG DEFAULT LIST SELF-TST HEX-DUMP

V-ALMNT GAP-ADJ

Table 8-1 summarizes the setup mode functions.

Table 8–1 Setup mode functions

Function Purpose

SAVE&END Exits setup mode and saves changes made in

MENU1 and

MENU2

HARDWRE Changes hardware options.

ADJUST Changes print adjustment options.

CONFIG Changes configuration options.

GAP-ADJ Sets the head gap, and is displayed when the

(GAP-ADJ is printed only with APTC installed.)

setup mode.

Assigns print features to MENU1 and

MENU2 on the control panel.

printer is equipped with the APTC function.

DEFAULT Resets MENU1 and MENU2 default values

set at shipment.

LIST Prints all currently selected options.

SELF-TST Run the self-test.

HEX-DUMP Prints hexadecimal data dumps.

V-ALMNT Checks and corrects vertical printing

alignment.

To select a function from the <<FUNCTION>> menu, do the

following:

1. Repeatedly press LOCK to position the yellow arrow on the print

head beneath the required function.

2. Press FONT or MENU to select a function. If the function has

items and options, the printer prints the first item and its options.

8-4 User’s Manual

Page 86

Using Setup Mode

MENU1, MENU2, HARDWRE, ADJUST, CONFIG, and

GAP-ADJ contain items with selectable options.

The first three MENU1 items shown in angle brackets < > and

options, for example, are as follows:

<EMULATE> DPL24C+ XL24E ESC/P2

<FONT>

UR 10 PRSTG12 COMPRSD BOLDFCE PICA10 CORRESP OCR-B OCR-A COUR-N COUR-B

CO

COUR-I N.SAN-N N.SAN-B N.SAN-I TIMLS-N TIMLS-B TIMLS-I DOWNLD0 DOWNLD1

<QUALITY> LETTER REPORT DRAFT

To select an option from an item menu, do the following:

1. Repeatedly press LOCK to position the yellow arrow on the print

head beneath the required option.

2. Press FONT to select the option. The printer prints the next function and its options.

3. After selecting options, press ONLINE to reprint the

<<FUNCTION>> menu.

Underlined options are current default settings—that is, the

settings saved in the printer’s permanent memory. In the preceding

example, the default options are Fujitsu DPL24C PLUS emulation,

Courier 10 font, and letter-quality printing.

SETUP MODE

Figure 8-2 summarizes option selection and button use for functions

that do not have options.

The following example illustrates the use of setup mode. The example

shows how to change the font and spacing in MENU2 to Prestige Elite

12 and 12 cpi.

1. Load continuous forms.

2. Enter setup mode.

Press FONT and MENU together until the printer beeps.

3. Select the MENU2 function.

Wait for the printer to stop printing and press LOCK twice to

position the yellow arrow on the print head beneath MENU2. Press

FONT or MENU to select MENU2 and print <EMULATE> and

its options.

User’s Manual 8-5

Page 87

Using Setup Mode

Press FONT

or MENU

Enter setup mode:

Press FONT and MENU

Reprint <<FUNCTION>> menu

Printer prints <<FUNCTION>> menu

Select function: Press LOCK to position

the cursor; then press FONT or MENU

The desired function is selected.

SAVE&END

Printer saves

changes and

exits setup

mode

Press ONLINE

: Functions with items and options

MENU1, MENU2,

HARDWRE, ADJUST,

CONFIG, and GAP-ADJ

LIST, DEFAULT

SELF-TST, HEX-DUMP

V-ALMNT

Select options: Press LOCK

to position cursor; then press

FONT or MENU

Press ONLINE

Press FONT or MENU to

pause or resume

Press LOCK

See “Using Diagnostic Functions”

on page 8-37 for details.

Figure 8–2 Setup mode summary

8-6 User’s Manual

Page 88

Using Setup Mode

4. Select the current emulation.

To leave the emulation unchanged, press FONT to select the

current emulation and print <FONT> and its options.

5. Change the font to Prestige Elite 12.

Press LOCK once to position the yellow arrow on the print head

beneath PRSTG12. Press FONT to select PRSTG12 and print

<QUALITY> and its options.

6. Select the current print quality.

To leave print quality unchanged, press FONT to select the current

print quality and print <PITCH>.

7. Change spacing to 12 cpi and exit MENU2.

Press LOCK once to position the yellow arrow beneath 12 CPI. To