Fujitsu AS*9LSACW, AS*12LSACW, AS*14LSBCW, AS*18LSBCW, AO*9LSAC Service Instructions Manual

...Page 1

SPLIT TYPE

ROOM AIR CONDITIONER

WALL MOUNTED

type

Models Indoor unit Outdoor unit

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

AO*9LSAC

AO*12LSAC

AO*9LFBC

AO*12LFBC

AOY14LFBC

AO*18LFBC

INVERTER

SERVICE

INSTRUCTION

R410A

Page 2

CONTENTS

1. SPECIFICATION

AS*14/ 18LSBC, AO*14 / 18LFBC..................................................................................01-03

AS*9 / 12LSAC, AO*9 / 12LSAC.....................................................................................02-01

2. DIMENSIONS

AS*9 / 12LSBC, AO*9 / 12LFBC.....................................................................................01-02

AS*9 / 12LSAC, AO*9 / 12LSAC.....................................................................................01-01

AS*14 / 18LSBC, AO*14 / 18LFBC.................................................................................02-03

AS*9 / 12LSBC, AO*9 / 12LFBC.....................................................................................02-02

3. REFRIGERANT SYSTEM DIAGRAM

AS*9 / 12LSAC, AO*9 / 12LSAC.....................................................................................03-01

AS*14 / 18LSBC, AO*14 / 18LFBC.................................................................................03-03

AS*9 / 12LSBC, AO*9 / 12LFBC.....................................................................................03-02

4. CIRCUIT DIAGRAM

AS*9 / 12LSAC, AO*9 / 12LSAC.....................................................................................04-01

AS*14 / 18LSBC, AO*14 / 18LFBC.................................................................................04-03

AS*9 / 12LSBC, AO*9 / 12LFBC.....................................................................................04-02

5. DESCRIPTION OF EACH CONTROL OPERATION

1. COOLING OPERATION..............................................................................................05-01

3. DRY OPERATION......................................................................................................05-03

2. HEATING OPERATION..............................................................................................05-02

5. INDOOR FAN CONTROL...........................................................................................05-05

4. AUTO CHANGEOVER OPERATION.........................................................................05-04

7. LOUVER CONTROL...................................................................................................05-08

6. OUTDOOR FAN CONTROL.......................................................................................05-07

9. TIMER OPERATION CONTROL................................................................................05-10

8. COMPRESSOR CONTROL........................................................................................05-09

11. TEST OPERATION CONTROL..................................................................................05-12

10. ELECTRONIC EXPANSION VALVE CONTROL........................................................05-12

13. FOUR-WAY VALVE EXTENSION SELECT...............................................................05-12

12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST ).................................05-12

15. MANUAL AUTO OPERATION ( Indoor unit body operation ).....................................05-13

14. AUTO RESTART.........................................................................................................05-12

17. COIL DRY OPEARTION CONTROL..........................................................................05-13

16. COMPRESSOR PREHEATING..................................................................................05-13

Page 3

6. REFRIGERANT CAUTION -R410A-

18. DEFROST OPERATION CONTROL..........................................................................05-14

20. VARIOUS PROTECTIONS.........................................................................................05-17

19. OFF DEFROST OPERATION CONTROL..................................................................05-16

1. R410A TOOLS............................................................................................................06-01

3. PRECAUTION FOR SERVICING...............................................................................06-04

2. PRECAUTION FOR INSTALLATION.........................................................................06-02

5. DEFFERENCE FROM CONVENTIONAL MODEL(R22) AND PRECAUTIONS........06-08

4. NEW REFRIGERANT R410A.....................................................................................06-05

7. TROUBLE SHOOTING

1. WHEN THE UNIT DOES NOT OPERATE AT ALL....................................................07-01

3. TROUBLE SHOOTING METHOD

2. SELF DIAGNOSIS FUNCTION..................................................................................07-02

8. APPENDING DATA

1. JUMPER SETTING OF INDOOR UNIT AND OUTDOOR UNIT................................08-01

3. THERMISTOR RESISTANCE VALUES.....................................................................08-08

2. OUTDOOR UNIT PRESSURE VALUE AND TOTAL ELECTRIC

CURRENT CURVE...................................................................................................08-02

9. INSTALLATION MANUAL

4. SELF-DIAGNOSIS FUNCTION AND CHECKING POINTS.......................................07-03

5. SERIAL SIGNAL DIAGNOSIS....................................................................................07-08

6. IPM PROTECTION.....................................................................................................07-09

7. ACTIVE FILTER FAILURE.........................................................................................07-10

8. TROUBLE SHOOTING OF REFRIGERANT CYCLE.................................................07-11

Page 4

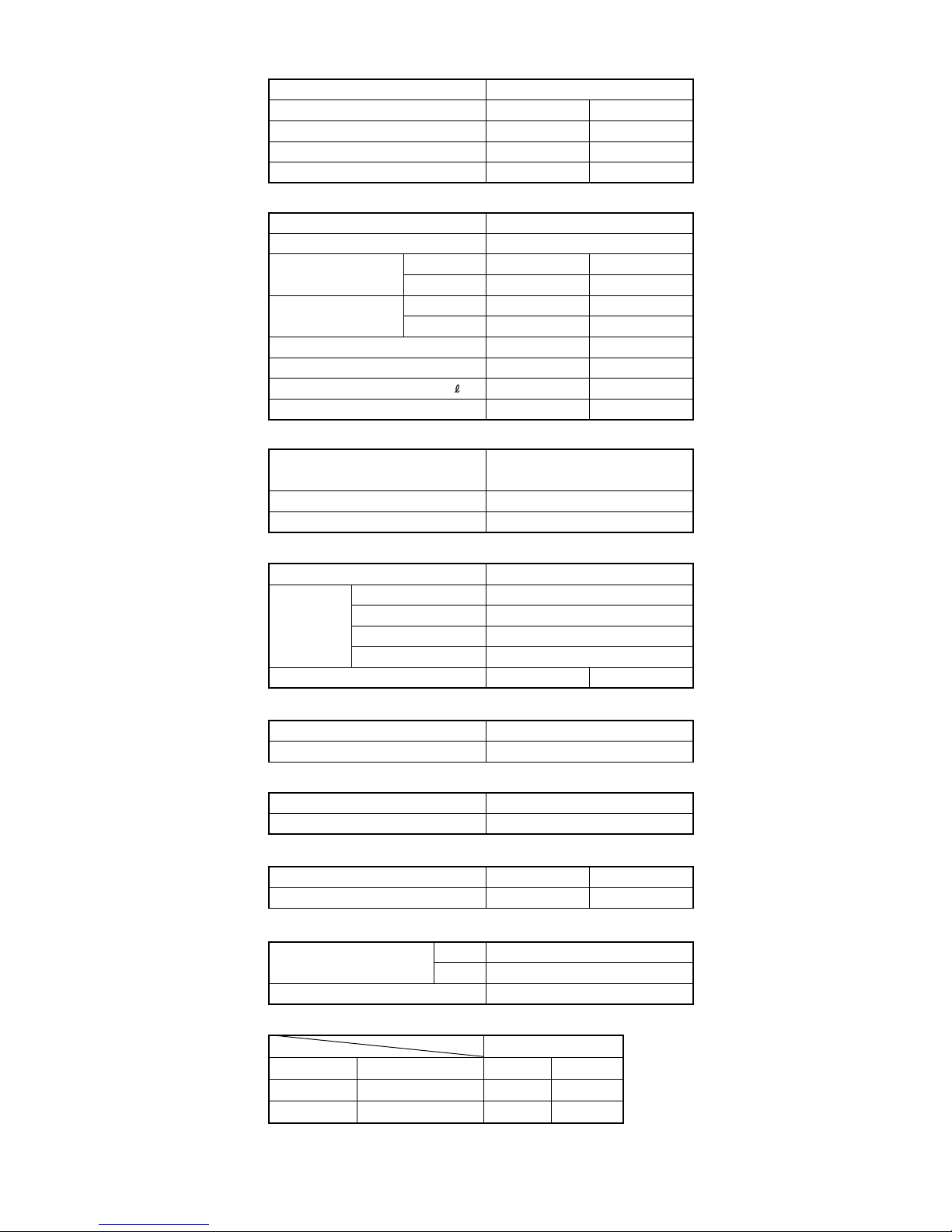

1 . SPECIFICATIONS

R410A

WALL MOUNTED type

INVERTER

Page 5

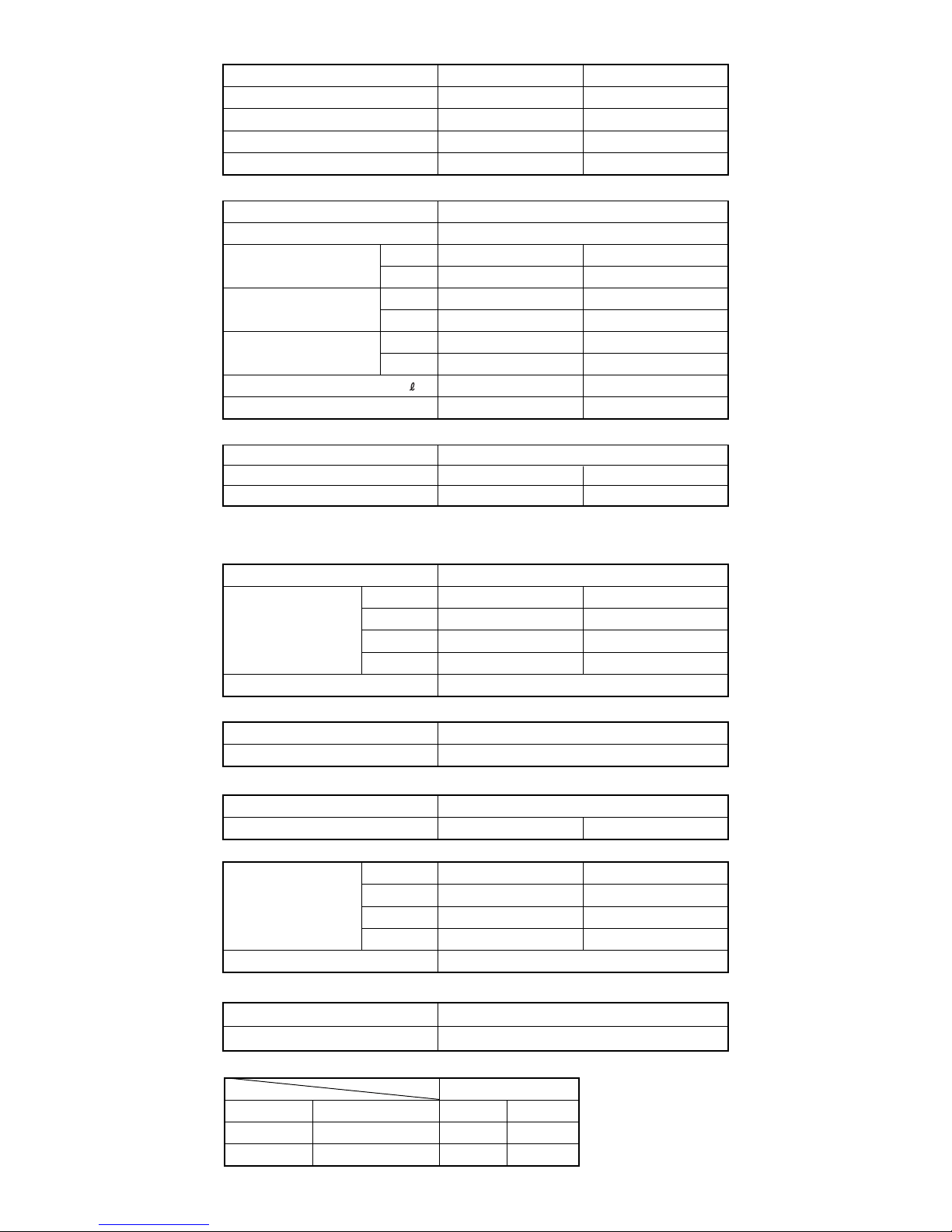

SPECIFICATIONS

TYPE

(COOL&HEAT INVERTER) (COOL&HEAT INVERTER)

INDOOR UNIT

AS*9LSACW AS*12LSACW

OUTDOOR UNIT AO*9LSAC AO*12LSAC

COOLING CAPACITY( ) : Range

(kW)

2.6 (0.5~3.6) 3.5 (0.9~4.2)

HEATING CAPACITY( ) : Range

(kW) 3.6 (0.5~6.0) 4.8 (0.9~6.6)

POWER SOURCE

(V) 230

FREQUENCY

(Hz)

50

RUNNING CURRENT

(A)

COOLING 3.0

3.6

5.8

1.33 (0.25~2.30)0.91 (0.25~1.96)

4.6

HEATING

INPUT WATTS

(kW)

COOLING

0.68 (0.25~1.38) 1.03 (0.25~1.61)

HEATING

EER

(kW/kW)

COOLING 3.82 3.40

3.96 3.61

1.8

HEATING

MOISTURE REMOVAL

1.3

AIR CIRCULATION-Hi

(m3/hr)

C 630 H665

C 630 H700

ELECTRICAL DATA

COMPRESSOR

Note : Always use a vacuum pump to purge the air.

Refrigerant for purging the air is not charged in the outdoor unit at the factory.

DIMENSIONS

TYPE Hermetic type,4 pole, 3 phase , DC brushles motor

DISCRIMINATION 80206680

REFRIGERANT R410A

(g)

(r.p.m.)

(r.p.m.)

950

1100

POWER SOURCE (V) 230

HI-SPEED

MED-SPEED

INDOOR UNIT

LO-SPEED

QUIET

C 1,350 H 1,420

C 1,150 H 1,200

C 950 H 1,000

C 740 H 900

C 1,400 H 1,470

C 1,200 H 1,290

C 1,000 H 1,110

C 820 H 980

OUTDOOR UNIT 830

INDOOR UNIT H x W x D (mm)

H x W x D (mm)

280 x 790 x 230

OUTDOOR UNIT 535 x 780 x 250

FAN MOTOR

(dB)

(dB)

HI-SPEED

MED-SPEED

INDOOR UNIT

LO-SPEED

QUIET

C 42 H 42

OUTDOOR UNIT

NOISE LEVEL

15 m

None

WEIGHTS

INDOOR UNIT

OUTDOOR UNIT

80206680

( /hr)

C 43 H 43

C 37 H 36 C 39 H38

C 31 H 30 C 32 H 33

C 23 H 26 C 26 H 29

C 47 H 49

Note : Noise was measured in accordance with JIS standards, Japan.

GROSS / NET (kg)

GROSS / NET (kg)

12 / 9

35 / 33 37 / 34

MAX PIPE LENGTH

ADDITIONAL REFRIGERANT

THICKNESSES OF ANNEALED COPPER PIPES

Nominal diameter

1/4

3/8

Outer diameter (mm)

6.35

9.52

R410A

0.80

0.80

[ref,] R22

0.80

0.80

Thickness (mm)

01-01

Page 6

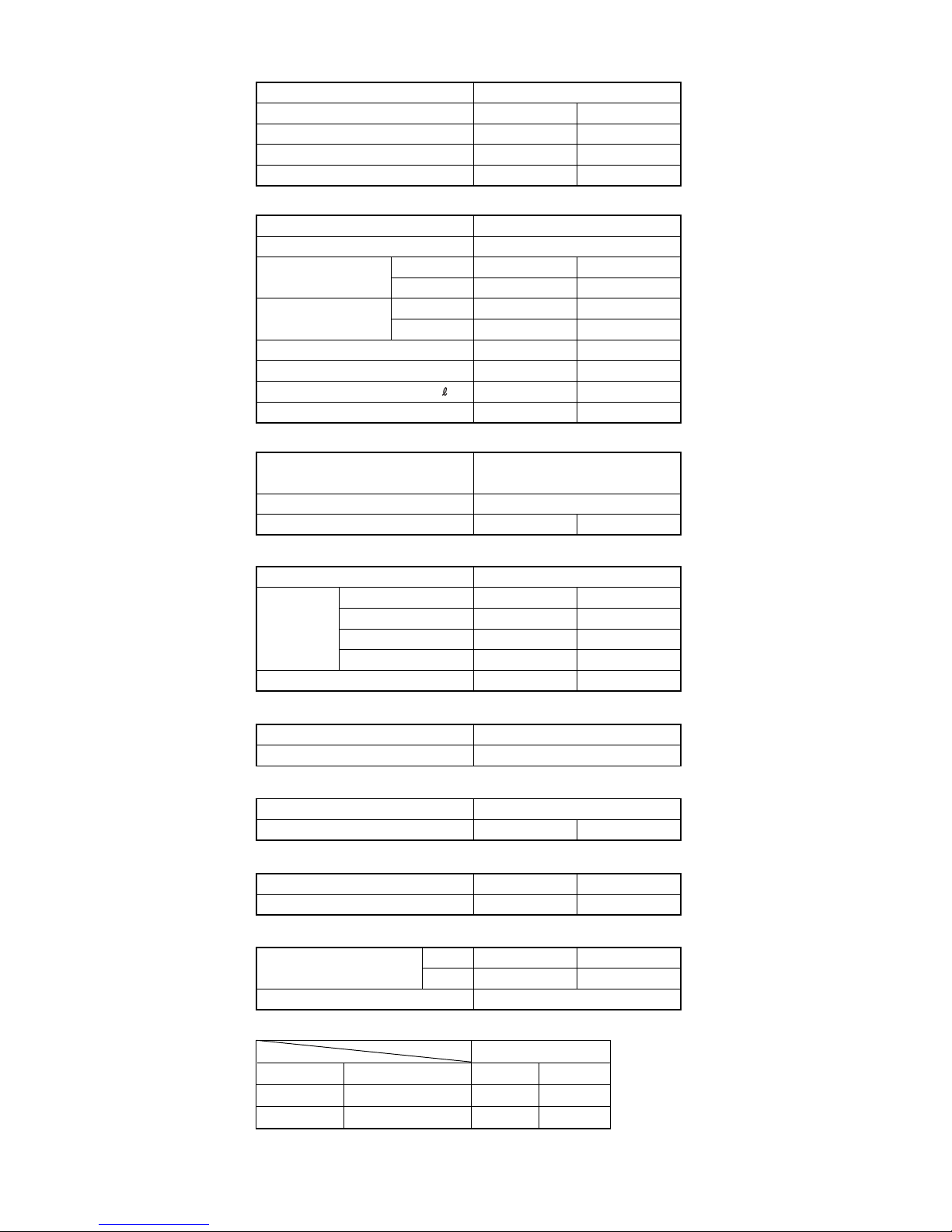

SPECIFICATIONS

INDOOR UNIT

H x W x D (mm)

H x W x D (mm)

275 x 790 x 215

OUTDOOR UNIT

540 x 790 x 290

DIMENSIONS

INDOOR UNIT

GROSS / NET (kg)

GROSS / NET (kg)

12 / 9

OUTDOOR UNIT

42 / 3839 / 35

WEIGHT

TYPE

COOL & HEAT INVERTER

INDOOR UNIT

AS*12LSBCW

OUTDOOR UNIT

AO*12LFBC

AS*9LSBCW

AO*9LFBC

COOLING CAPACITY

(kW) 3.50

HEATING CAPACITY

(kW)

4.80

POWER SOURCE (V) 230

FREQUENCY (Hz)

50

RUNNING CURRENT

COOLING 4.3

(A)

HEATING

5.6

INPUT WATTS

(kW)

COOLING 0.92

HEATING

1.23

E.E.R.

COOLING

3.80

COP HEATING

3.90

MOISTURE REMOVAL

1.8

AIR CIRCULATION-Hi (m /hr)

3

C 635 H 670C 595 H 645

2.60

3.60

3.0

3.8

0.62

0.82

4.19

4.39

1.3

FAN MOTOR

TYPE

Hermetic type, 4 pole, 3 phase,

DC inverter motor, Rotary

DISCRIMINATION DA 89 X 1F - 20F

REFRIGERANT R410A (g) 1,050950

POWER SOURCE (V) 230

HI-SPEED (r.p.m.) C 1,300 H 1,390

INDOOR

UNIT

MED-SPEED (r.p.m.) C 1,120 H 1,200

LO-SPEED (r.p.m.) C 950 H 1,000

QUIET (r.p.m.) C 700 H 760

C 1,370 H 1,440

C 1,150 H 1,200

C 950 H 1,000

C 700 H 760

OUTDOOR UNIT (r.p.m.) C 830 H 830C 840 H 840

ELECTRICAL DATA

COMPRESSOR

( /hr)

INDOOR UNIT

(dB) C 43 H 43

OUTDOOR UNIT

(dB) C 47 H 49

C 42 H 42

C 47 H 48

NOISE LEVEL

REFRIGERANT (R410A)

Pipe Length

15 m 950 g 1,050 g

FULL CHARGE AMOUNT

20 m 1,050 g 1,150 g

ADDITIONAL REFRIGERANT

20 g / m

(kW/kW)

(kW/kW)

THICKNESSES OF ANNEALED COPPER PIPES

Nominal diameter

1/4

3/8

Outer diameter (mm)

6.35

9.52

R410A

0.80

0.80

[ref,] R22

0.80

0.80

Thickness (mm)

01-02

Page 7

SPECIFICATIONS

INDOOR UNIT

H x W x D (mm)

H x W x D (mm)

275 x 790 x 215

OUTDOOR UNIT

578 x 790 x 300

DIMENSIONS

INDOOR UNIT

GROSS / NET

(kg)

GROSS / NET (kg)

12 / 9

OUTDOOR UNIT

40 / 38

WEIGHT

TYPE

COOL & HEAT INVERTER

INDOOR UNIT

AS*18LSBCW

OUTDOOR UNIT

AO*18LFBC

AS*14LSBCW

AO*14LFBC

COOLING CAPACITY

(kW) 5.20

HEATING CAPACITY

(kW)

6.25

POWER SOURCE (V) 230

FREQUENCY (Hz)

50

RUNNING CURRENT

COOLING 7.6

(A)

HEATING

7.6

INPUT WATTS

(kW)

COOLING 1.72

HEATING

1.73

E.E.R.

COOLING

3.02

COP HEATING

3.61

MOISTURE REMOVAL

2.8

AIR CIRCULATION-Hi (m /hr)

3

C 700 H700C 700 H700

4.20

5.60

4.9

6.4

1.11

1.45

3.78

3.86

2.1

FAN MOTOR

TYPE

Hermetic type, 4 pole, 3 phase,

DC inverter motor, Rotary

DISCRIMINATION DA / 30A / F-25F

REFRIGERANT R410A (g) 1,150

POWER SOURCE (V) 230

HI-SPEED (r.p.m.) C 1,480 H 1,480

INDOOR

UNIT

MED-SPEED (r.p.m.) C 1,260 H 1,300

LO-SPEED (r.p.m.) C 1,040 H 1,110

QUIET (r.p.m.) C 850 H 950

OUTDOOR UNIT (r.p.m.) C 860 H 820C 820 H 750

ELECTRICAL DATA

COMPRESSOR

( /hr)

INDOOR UNIT

(dB) C 45 H 43

OUTDOOR UNIT

(dB) C 49 H 49

C 44 H 43

C 48 H 48

NOISE LEVEL

REFRIGERANT (R410A)

PIPE LENGTH

15 m 1,150 g

FULL CHARGE AMOUNT

20 m 1,250 g

ADDITIONAL REFRIGERANT

20 g / m

(kW/kW)

(kW/kW)

THICKNESSES OF ANNEALED COPPER PIPES

Nominal diameter

1/4

1/2

Outer diameter (mm)

6.35

12.7

R410A

0.80

0.80

[ref,] R22

0.80

0.80

Thickness (mm)

01-03

Page 8

2 . DIMENSIONS

R410A

WALL MOUNTED type

INVERTER

Page 9

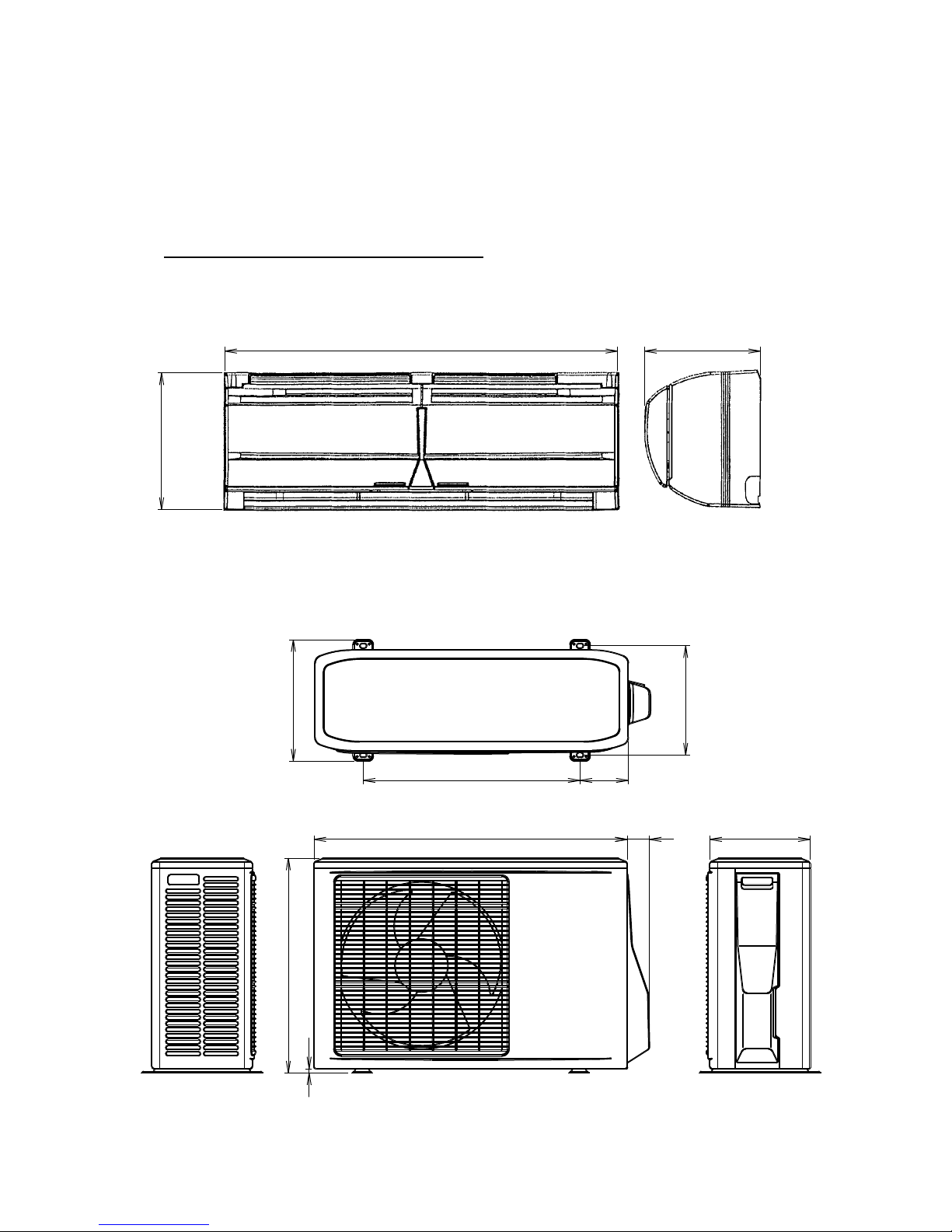

DIMENSIONS

Models : AS*9LSACW / AO*9LSAC

AS*12LSACW / AO*12LSAC

540 120

272

302

780 55

250

535

10

280

790 230

02-01

Page 10

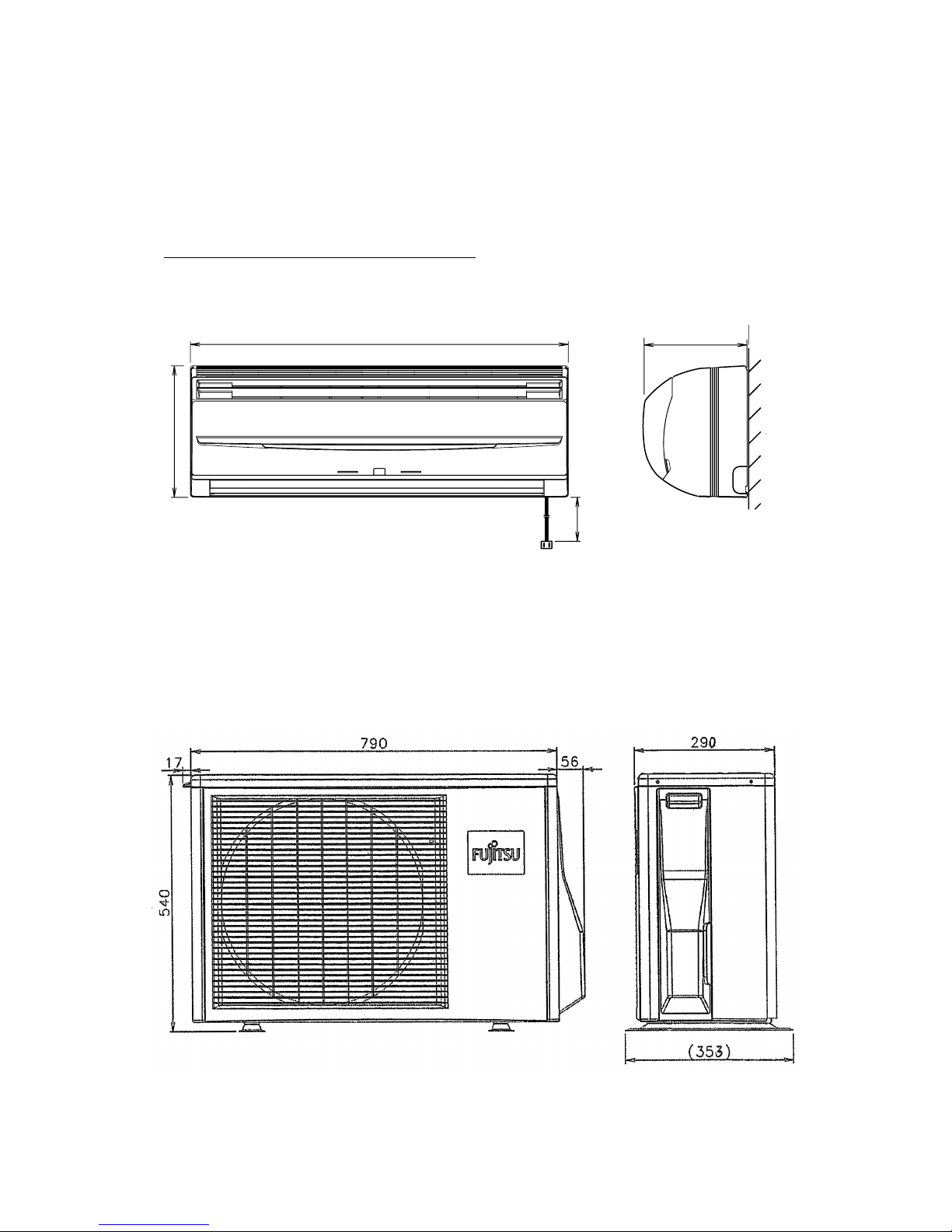

DIMENSIONS

AS*12LSBCW / AO*12LFBC

Models : AS*9LSBCW / AO*9LFBC

(unit : mm)

275

2,000

215

790

02-02

Page 11

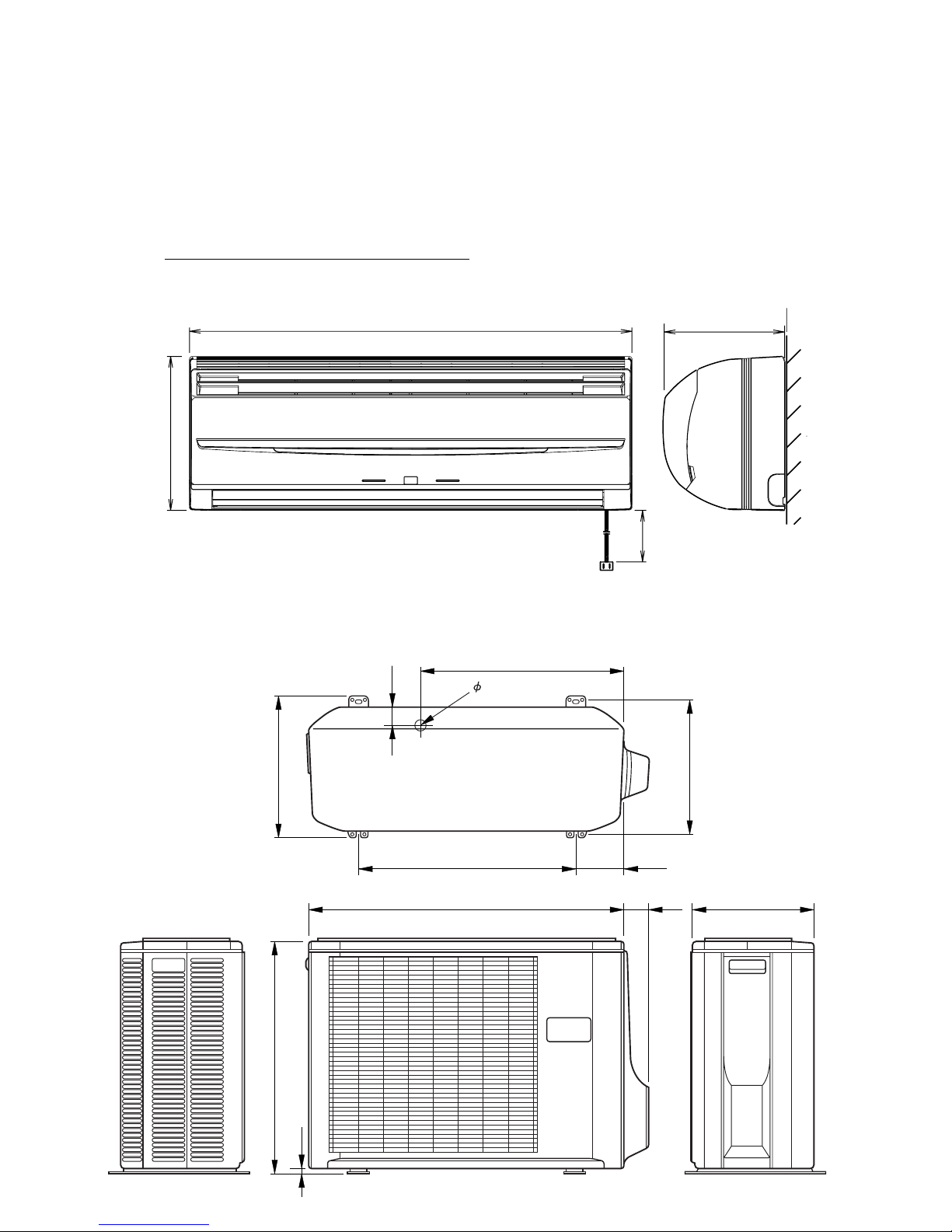

DIMENSIONS

AS*18LSBCW / AO*18LFBC

Models : AS*14LSBCW / AO*14LFBC

(unit : mm)

275

2,000

215

790

347

578

48

10

320

508

540

20

300

125

60

790

02-03

Page 12

3 . REFRIGERANT SYSTEM DIAGRAM

R410A

WALL MOUNTED type

INVERTER

Page 13

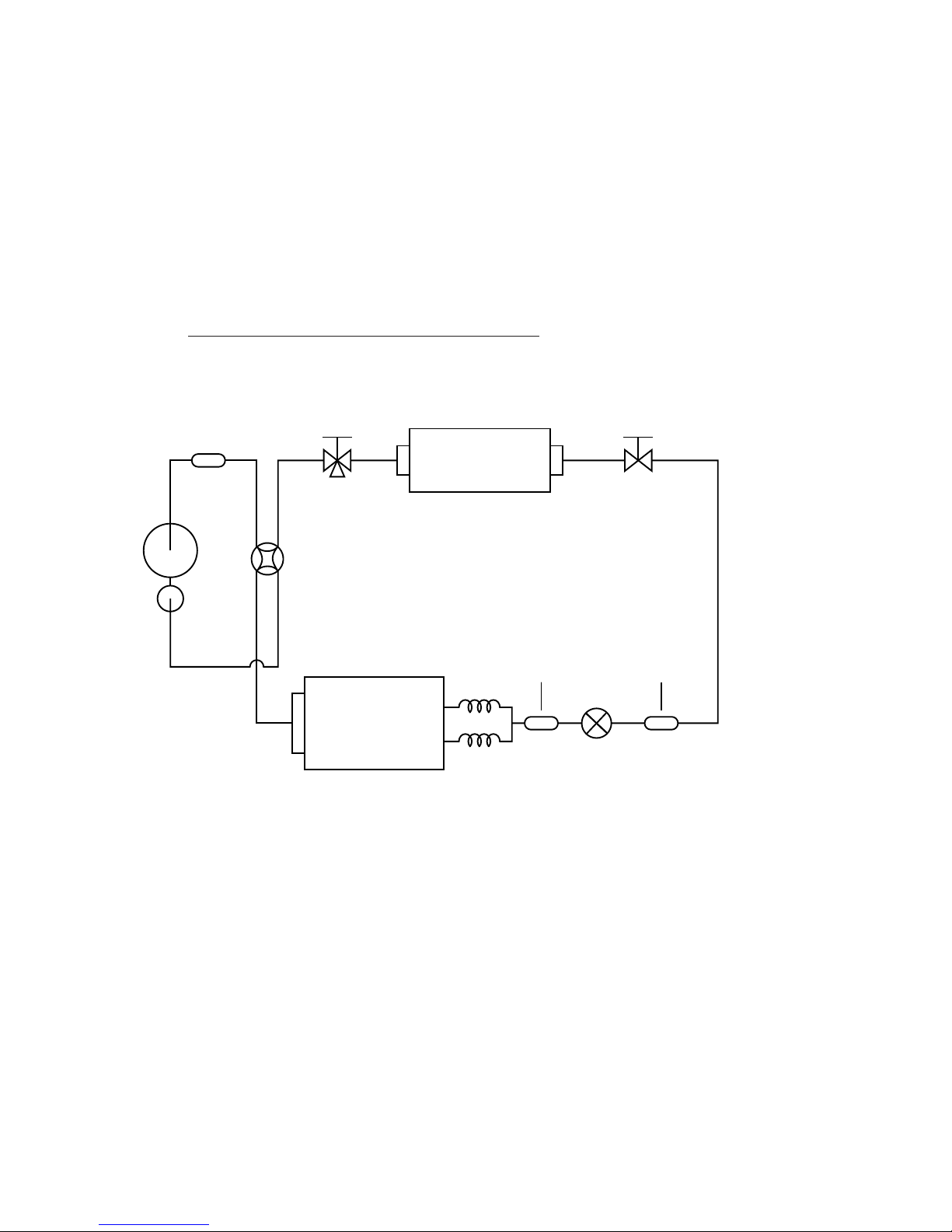

REFRIGERANT SYSTEM DIAGRAM

Models : AS*9LSACW / AO*9LSACW

AS*12LSACW / AO*12LSACW

(2 pass)

(2 pass)

Indoor heat exchanger

Outdoor heat exchanger

Capillary

tube

Pulse motor valve

2way-valve3way-valve

Muffler

Compressor

Accumulator

4way-valve

Strainer Dryer

03-01

Page 14

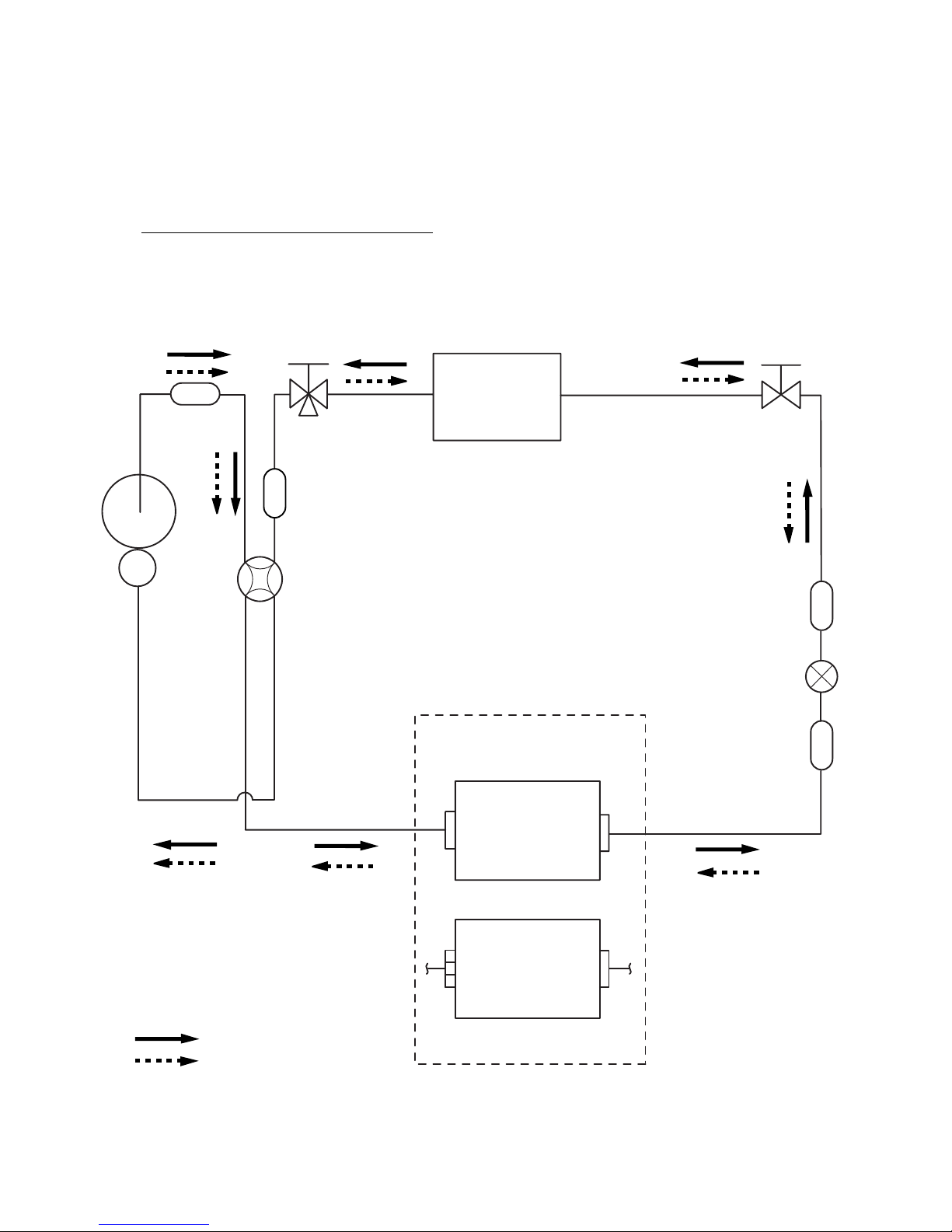

REFRIGERANT SYSTEM DIAGRAM

2-Way

valve

Strainer

Strainer

3-Way

valve

Muffler

Muffler

4-Way valve

Expansion valve

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

AOY9LFBC

(2Pass)

AOY12LFBC

(4Pass)

Compressor

Cooling

Heating

AS*12LSBCW / AO*12LFBC

Models : AS*9LSBCW / AO*9LFBC

03-02

Page 15

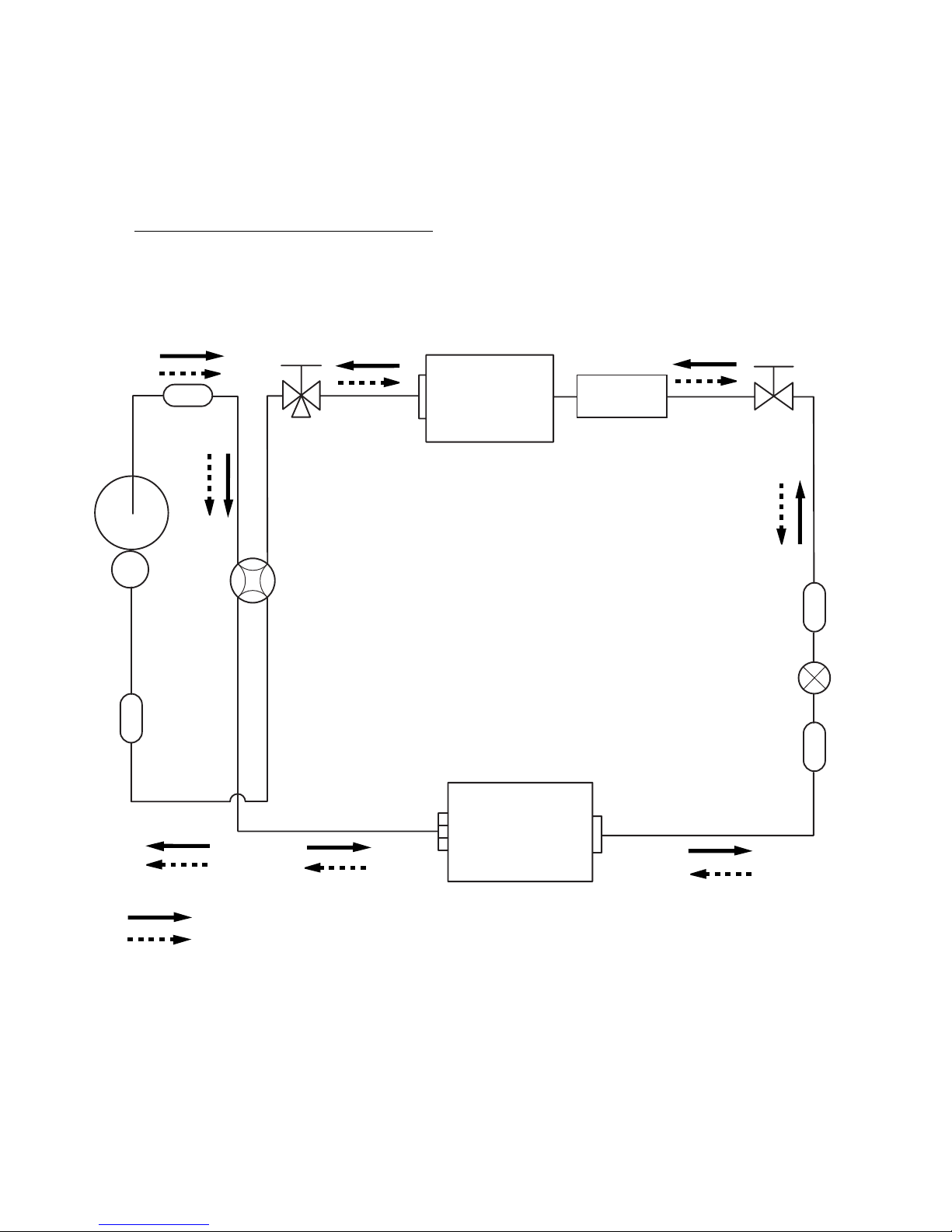

REFRIGERANT SYSTEM DIAGRAM

2-Way

valve

Strainer

Strainer

Sub-heat

exchanger

( INDOOR )

3-Way

valve

Muffler

4-Way valve

Expansion valve

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

Sub-accumulator

Compressor

Cooling

Heating

AS*18LSBCW / AO*18LFBC

Models : AS*14LSBCW / AO*14LFBC

03-03

Page 16

4 . CIRCUIT DIAGRAM

R410A

WALL MOUNTED type

INVERTER

Page 17

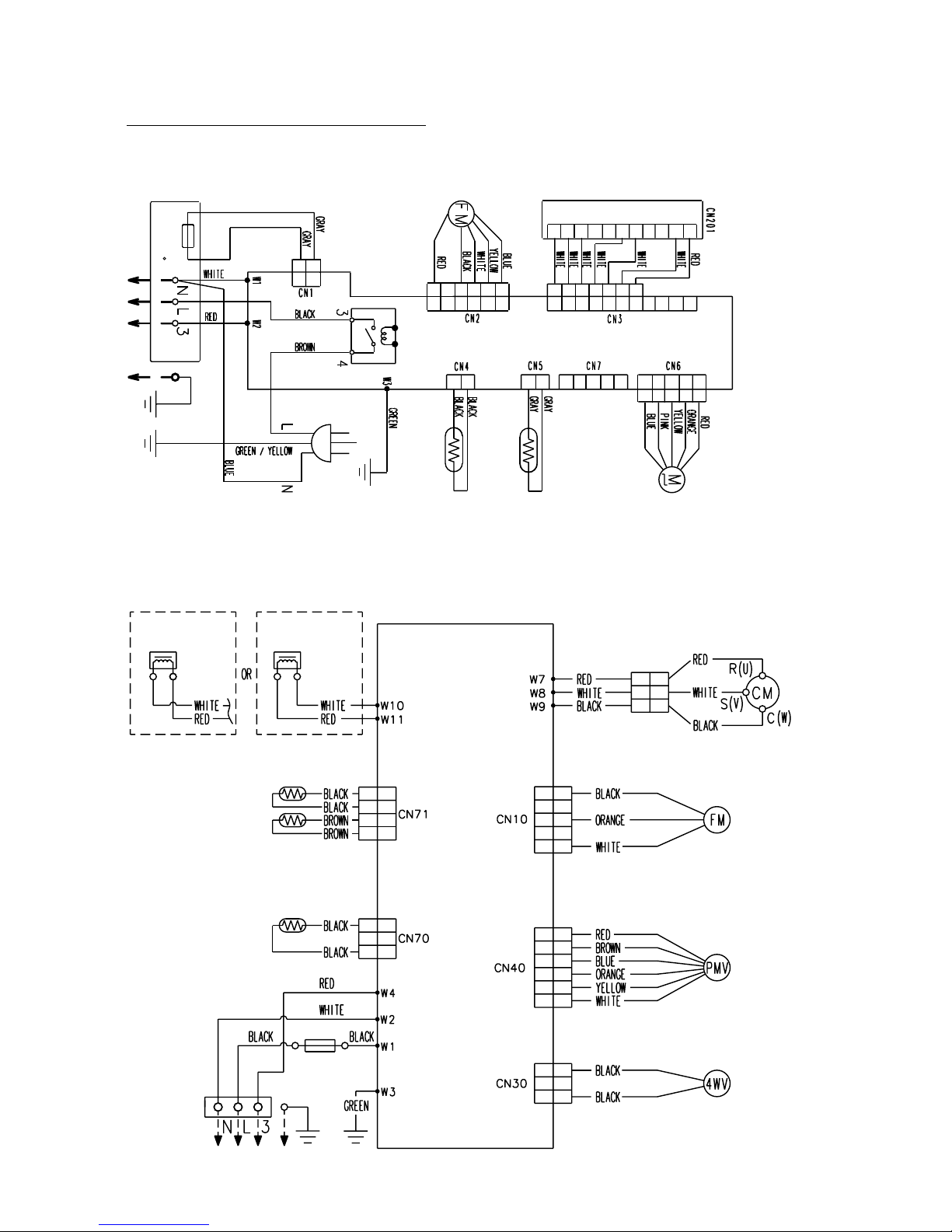

CIRCUIT DIAGRAM

INDOOR UNIT

OUTDOOR UNIT

Models : AS*9LSACW / AO*9LSAC

AS*12LSACW / AO*12LSAC

Controller PCB

Thermistor

(pipe)

Thermistor

(discharge pipe)

Thermistor

(outdoor temp.)

04-01

Page 18

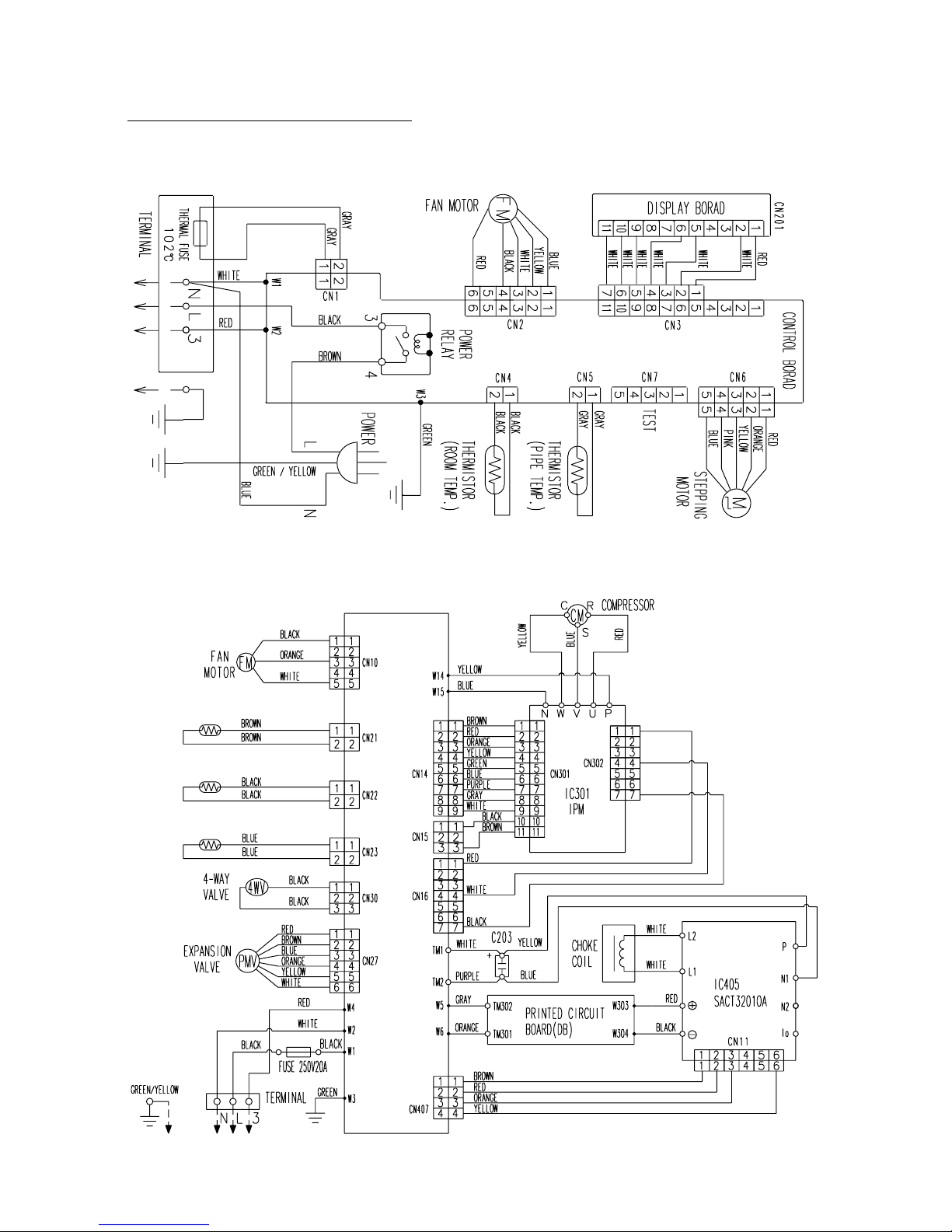

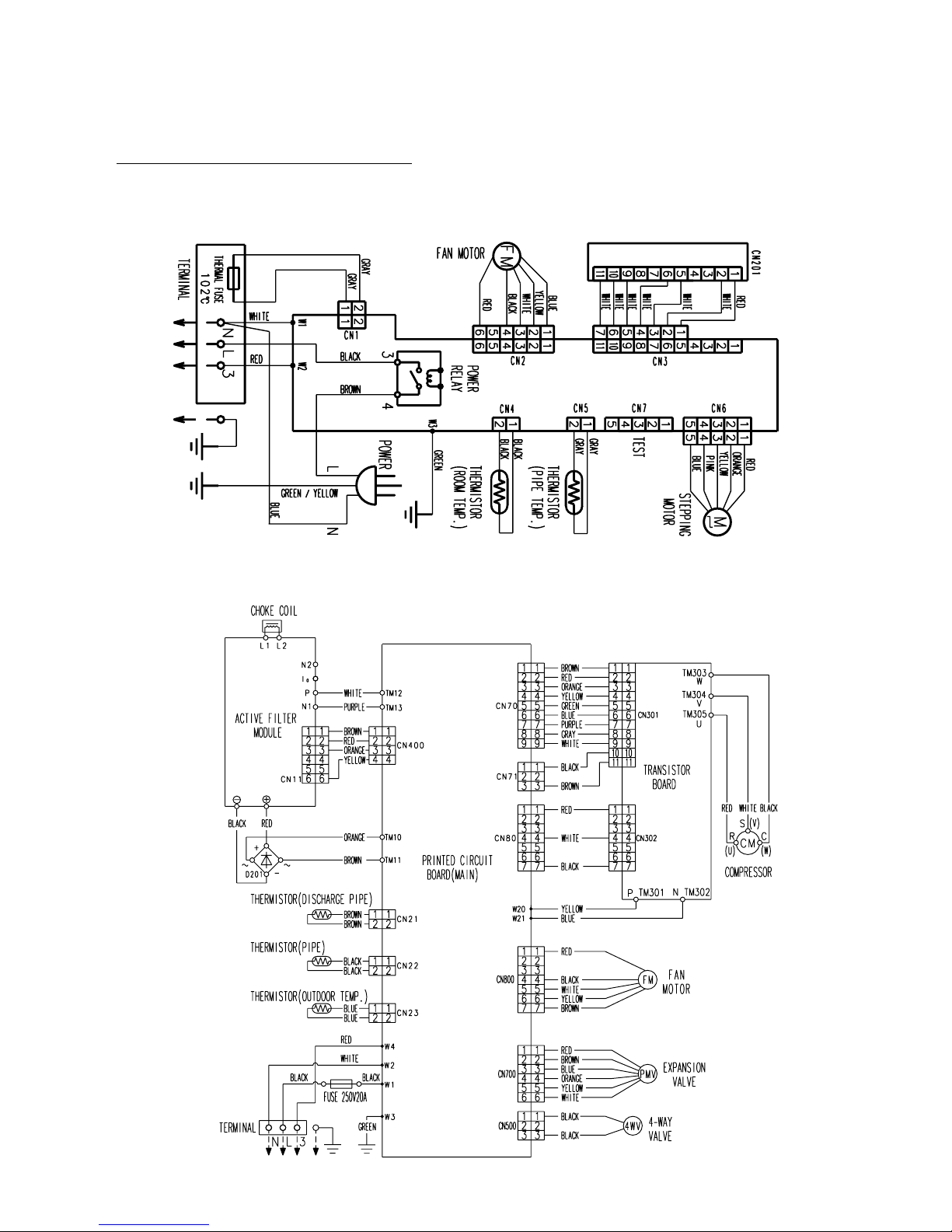

CIRCUIT DIAGRAM

INDOOR UNIT

OUTDOOR UNIT

AS*12LSBCW / AO*12LFBC

Models : AS*9LSBCW / AO*9LFBC

Fan Motor

Stepping

Motor

Thermistor

(room temp.)

Terminal

Terminal

Fuse 250V20A

Reactor Reactor

Fan Motor

Expansion

Valve

4-Way

Valve Assy

PCB (MAIN)

Power

Relay

Compressor

Thermistor

(pipe temp.)

Test

Thermistor (pipe)

Thermistor (Discharge Pipe)

Thermistor (outdoor temp.)

Display Board

Controller PCB

Power

102 C

Thermal Fuse

1

2

3

4

5

6

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

4

5

1

2

3

4

5

1

2

3

1

2

3

1

2

3

4

1

2

3

4

1

2

3

4

5

6

1

2

3

4

5

1

2

3

4

5

1

2

1

2

1

2

3

4

5

1

2

3

4

5

6

7

1

2

3

4

5

6

1

2

3

4

5

6

1

2

2

1

2

1

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

04-02

Page 19

CIRCUIT DIAGRAM

INDOOR UNIT

OUTDOOR UNIT

AS*18LSBCW / AO*18LFBC

Models : AS*14LSBCW / AO*14LFBC

DISPLAY BOARD

CONTROL BOARD

04-03

Page 20

5 . DESCRIPTION OF EACH

CONTROL OPERATION

R410A

WALL MOUNTED type

INVERTER

Page 21

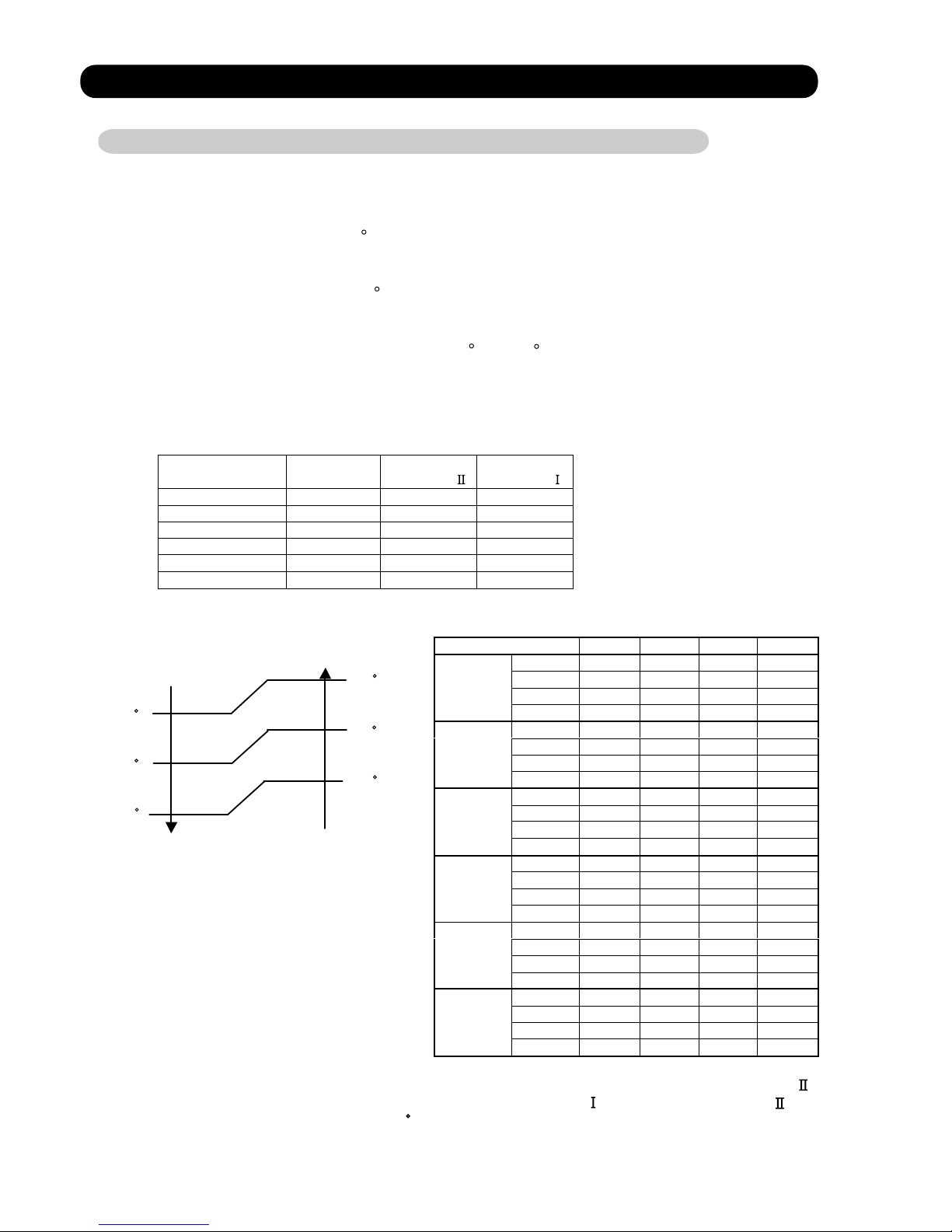

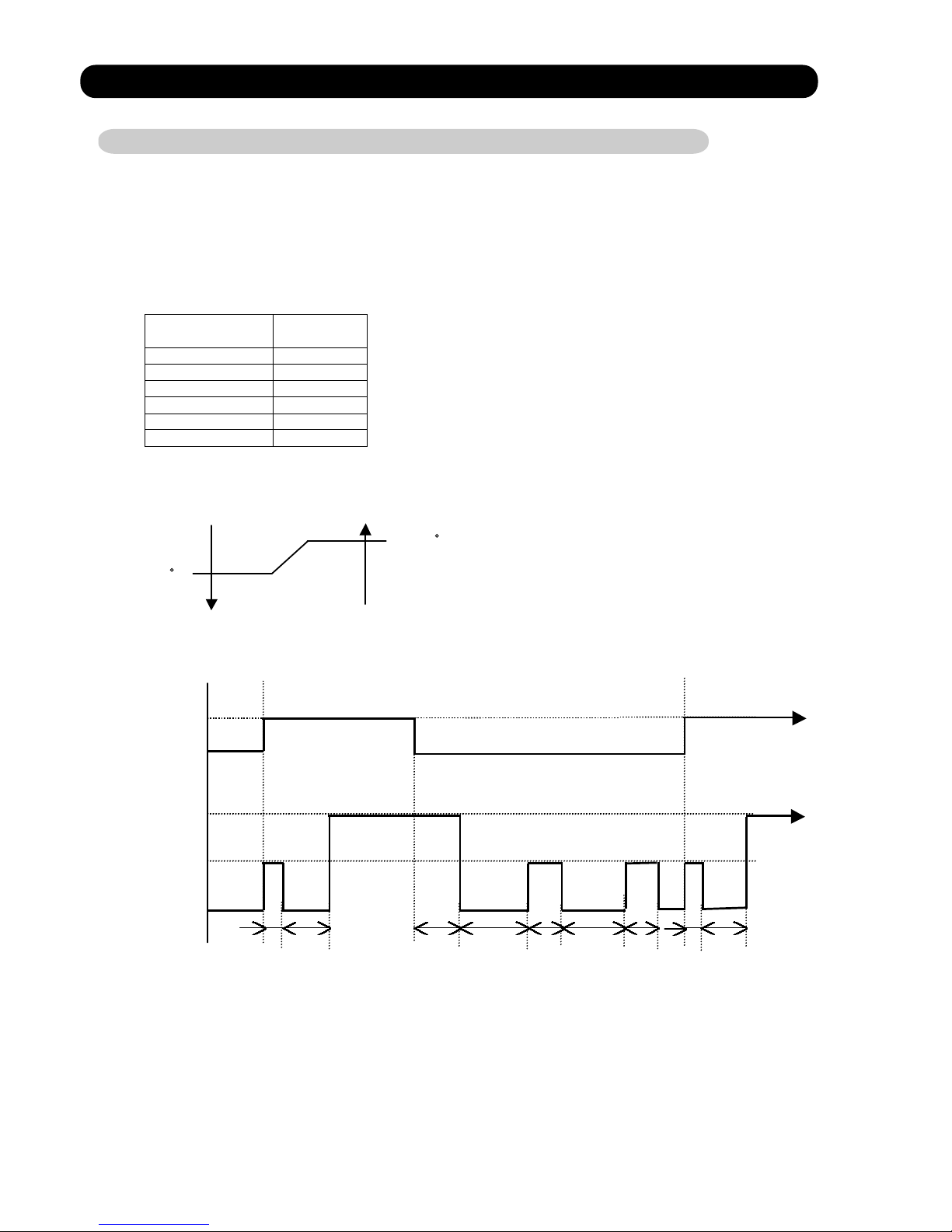

1. COOLING OPERATION

1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is 2 C higher than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is 2.5 C lower than a set temperature, the compressor will be

stopped.

* When the room temperature is between +2 C to -2.5 C of the setting temperature,

the compressor frequency is controlled within the range shown in Table1.

However, the maximum frequency is limited in the range shown in Figure 1 based on the

fan speed mode and the outdoor temperature.

minimum

frequency

maximum

frequency

maximum

frequency

AS*9LSACW 18Hz 60Hz 80Hz

AS*12LSACW 18Hz 80Hz 96Hz

AS*9LSBCW 18Hz 61Hz 80Hz

AS*12LSBCW 18Hz 80Hz 96Hz

AS*14LSBCW 18Hz 70Hz 90Hz

AS*18LSBCW 18Hz 70Hz 90Hz

Outside air Outside air

temperature temperature

36 C

A zone

34 C

32 C

B zone

30 C

21 C

C zone

19 C

D zone

Hi Me Lo Quiet

A zone 80Hz 51Hz 45Hz 33Hz

B zone 80Hz 51Hz 45Hz 33Hz

C zone 80Hz 51Hz 45Hz 33Hz

9LSACW

D zone 51Hz 39Hz 33Hz 27Hz

A zone 96Hz 60Hz 51Hz 33Hz

B zone 96Hz 60Hz 51Hz 33Hz

C zone 80Hz 60Hz 51Hz 33Hz

12LSACW

D zone 51Hz 42Hz 36Hz 27Hz

A zone 80Hz 61Hz 51Hz 33Hz

B zone 80Hz 61Hz 51Hz 33Hz

C zone 80Hz 61Hz 51Hz 33Hz

9LSBCW

D zone 51Hz 42Hz 36Hz 22Hz

A zone 96Hz 61Hz 51Hz 33Hz

B zone 96Hz 61Hz 51Hz 33Hz

C zone 96Hz 61Hz 51Hz 33Hz

12LSBCW

D zone 51Hz 42Hz 36Hz 22Hz

A zone 90Hz 45Hz 42Hz 30Hz

B zone 90Hz 45Hz 42Hz 30Hz

C zone 90Hz 45Hz 42Hz 30Hz

14LSBCW

D zone 49Hz 38Hz 34Hz 24Hz

A zone 90Hz 45Hz 42Hz 30Hz

B zone 90Hz 45Hz 42Hz 30Hz

C zone 90Hz 45Hz 42Hz 30Hz

18LSBCW

D zone 49Hz 38Hz 34Hz 24Hz

( Table 1 : Compressor Frequency Range )

( Fig. 1 : Limit of Maximum Frequency based on Outdoor Temperature )

When the compressor operates for 30 minutes continuously at over the maximum frequency ,

the maximum frequency is changed from Maximum Frequency to Maximum Frequency .

The room temperature is controlled 1 C lower than the setting temperature for 40 minutes

after starting the operation.

After 40 minutes, it is controlled based on the normal setting temperature.

05-01

Page 22

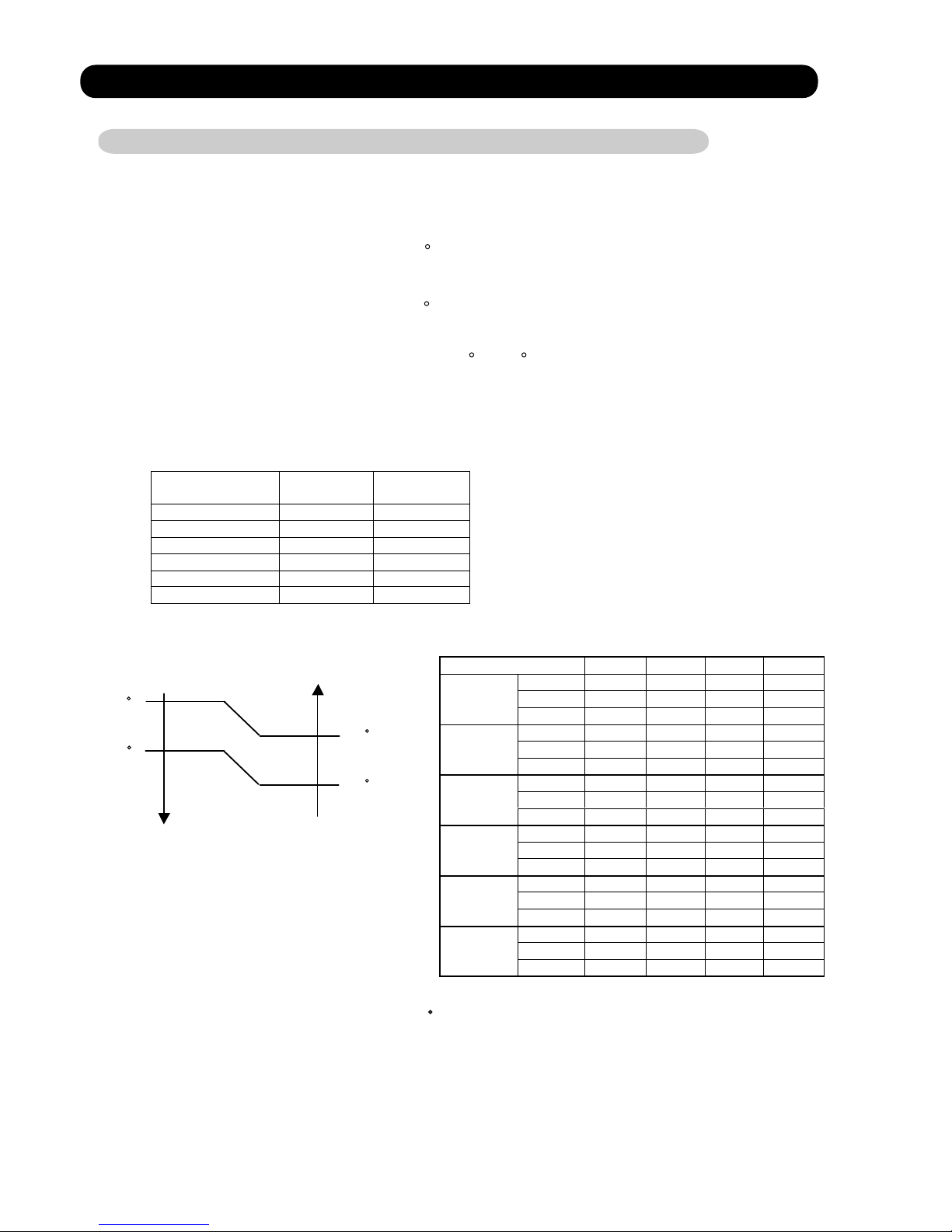

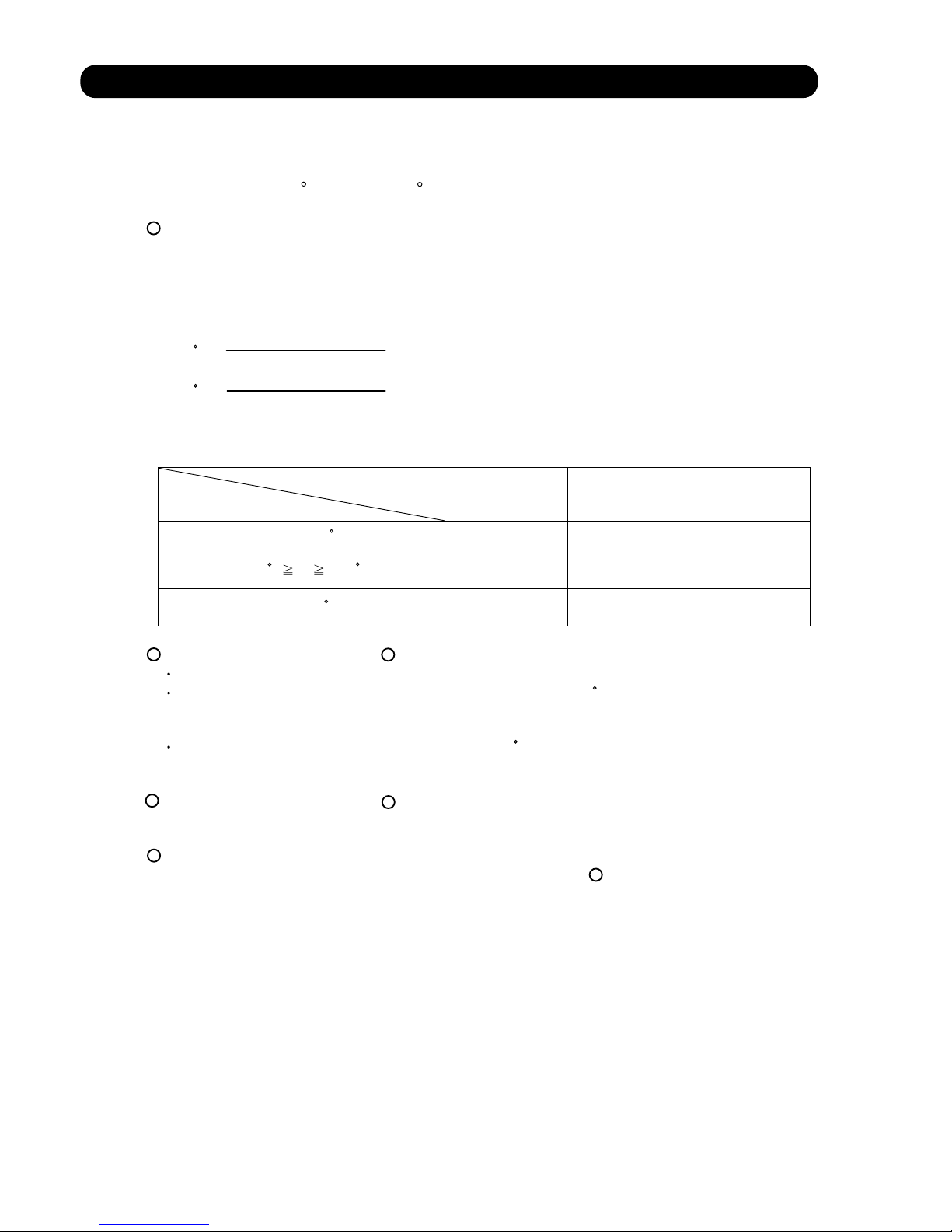

2. HEATING OPERATION

2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is lower by 3 C than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is higher 2.5 C than a set temperatire, the compressor will be

stopped.

minimum

frequency

maximum

frequency

AS*9LSACW 18Hz 130Hz

AS*12LSACW 18Hz 130Hz

AS*9LSBCW 18Hz 130Hz

AS*12LSBCW 18Hz 130Hz

AS*14LSBCW 18Hz 119Hz

AS*18LSBCW 18Hz 119Hz

Outside air Outside air

temperature temperature

19 C

C zone

17 C

14 C

B zone

12 C

A zone

Hi Me Lo Quiet

A zone 130Hz 92Hz 80Hz 68Hz

B zone 130Hz 80Hz 60Hz 54Hz

9LSACW

C zone 96Hz 68Hz 54Hz 51Hz

A zone 130Hz 96Hz 80Hz 68Hz

B zone 130Hz 96Hz 64Hz 57Hz

12LSACW

C zone 96Hz 96Hz 64Hz 54Hz

A zone 130Hz 96Hz 80Hz 68Hz

B zone 130Hz 96Hz 80Hz 54Hz

9LSBCW

C zone 130Hz 96Hz 80Hz 45Hz

A zone 130Hz 96Hz 80Hz 68Hz

B zone 130Hz 96Hz 80Hz 54Hz

12LSBCW

C zone 130Hz 96Hz 80Hz 45Hz

A zone 119Hz 90Hz 70Hz 58Hz

B zone 119Hz 90Hz 70Hz 58Hz

14LSBCW

C zone 119Hz 90Hz 70Hz 58Hz

A zone 119Hz 90Hz 70Hz 58Hz

B zone 119Hz 90Hz 70Hz 58Hz

18LSBCW

C zone 119Hz 90Hz 70Hz 58Hz

* When the room temperature is between +2 C to -3 C of the setting temperature,

the compressor frequency is controlled within the range shown in Table2.

However, the maximum frequency is limited in the range shown in Figure 2 based on the

fan speed mode and the outdoor temperature.

( Table 2 : Compressor Frequency Range )

( Fig.2 : Limit of Maximum Frequency based on Outdoor Temperature )

* The room temperature is controlled 2 C higher than the setting temperature for 60 minutes

after starting the operation.

After 60 minutes, it is controlled based on the normal setting temperature.

05-02

Page 23

3. DRY OPERATION

3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to the temperature, set temperature,

and room temperature variation which the room temperature sensor of the indoor unit body has

detected as shown in the Table 3. However, after the compressor is driven, the indoor unit shall

run at operation frequency of 58Hz, for a minute.

Operating

frequency

AS*9LSACW 33Hz

AS*12LSACW 33Hz

AS*9LSBCW 33Hz

AS*12LSBCW 33Hz

AS*14LSBCW 24Hz

AS*18LSBCW 24Hz

room room

temperatu re temperature

compressor ON

Ts+1.5 C

Ts+0.5 C

compressor OFF

Compressor

ON

OFF

Indoor fan

Dry air flow

S-Lo

OFF

10 30 60 180 60 180 60 10 30 (sec)

( Table 3 : Compressor frequency )

( Fig.3 : Compressor Control based on Room Temperature )

( Fig.4 : Indoor Fan Control )

05-03

Page 24

4. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the AUTO mode by remote cintrol, operation starts in the optimum

mode from amoung the HEATING, COOLING, DRY and MONITORING modes. During operation, the

optimum mode is automatically swiched in accordance with temperature changes. The temperature

can be set between 18 C and 30 C in 1 C steps.

.When operation starts, only the indoor and outdoor fans are operated for 1 minute. After 1 minute,

the room temperature and outside air temperature are sensed and the operation mode is

selected in accordance with the table below.

C zone

32 C

B zone

10 C

A zone

( Table.4 Operation mode selection table)

Outside air temperature (TO)

Room temperature(TB)

A zone B zone C zone

TB > TS+ 2 C

Monitoring

Cooling

(automatic dry)

Cooling

(automatic dry)

TS+2 C TB TS-2 C

Monitoring Monitoring Monitoring

TB TS-2 C Heating Heating Monitoring

.When COOING was selected at , the air conditioner operates as follow:

The same operation as COOLING OPERATION of item 1 above is performed.

When the room temperature has remained at (set tempareure -1 C) for 8 minutes, operation is

automatically switched to DRY and the same operation as DRY OPERATION of item 3 above

is performed.

If the room temperature reaches (set temperature+2 C during DRY operation, operation returns to

COOLING operation.

.When HEATING was selected at , the same operation as HEATING OPERATION of item 2

above is performed.

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the COOLING or HEATING operation mode was selected at above, operation is switched

to MONITORING and the operation mode is selected again.

1

<

1

2

3

1

4

1

( Fig.5 : Outside air temperature zone selection )

05-04

Page 25

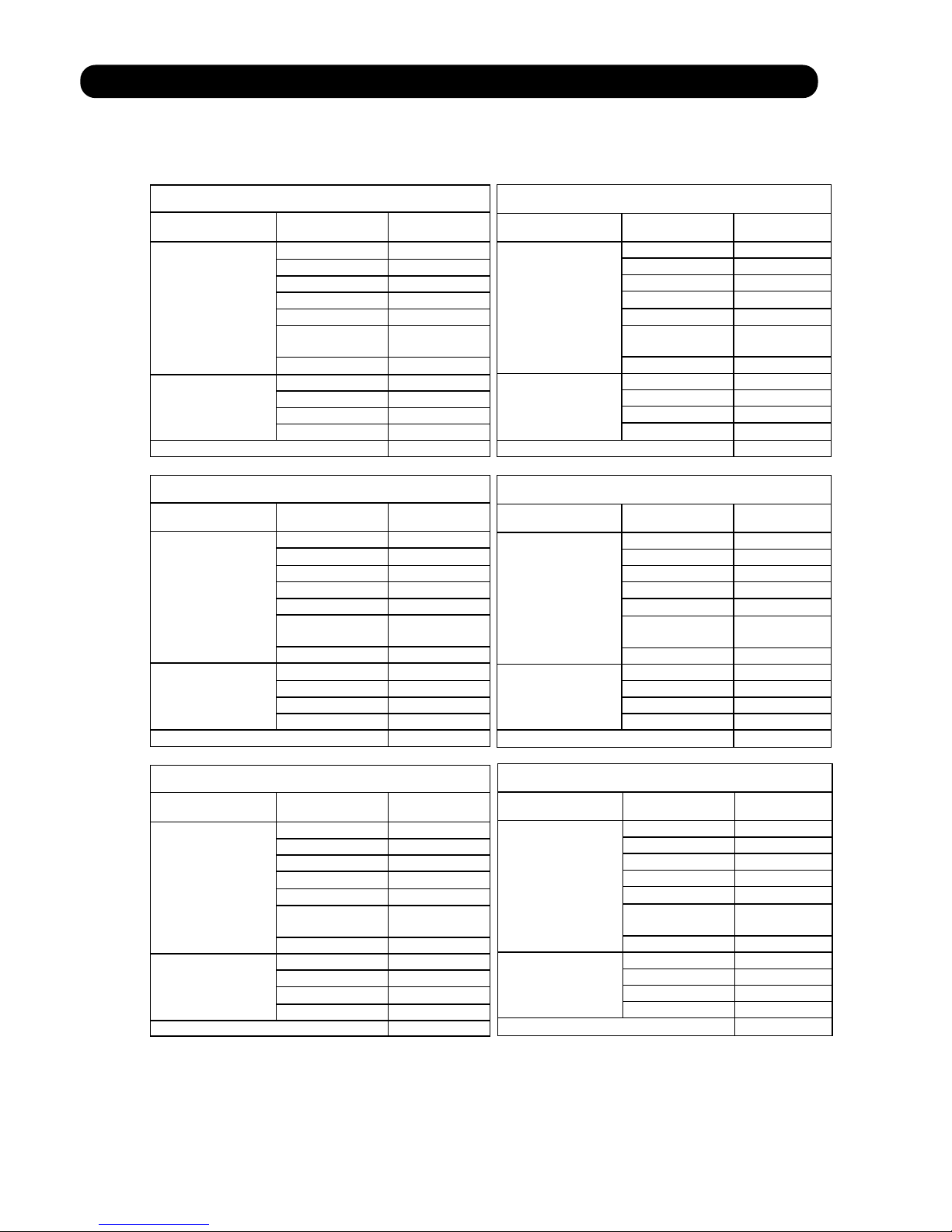

5. INDOOR FAN CONTROL

(1).Fan speed

( Table 5 : Indoor Fan Speed )

AS*9LSACW

Operation mode Air flow mode Speed (rpm)

Hi 1420

Me+ 1370

Me 1200

Lo 1000

Quiet 900

Cool air

prevention

850

Heating

S-Lo 480

Hi 1350

Me 1150

Lo 950

Cooling

Fan

Quiet 740

Dry 740

AS*9LSBCW

Operat ion mode Air flow mode Speed (rpm)

Hi 1390

Me+ 1350

Me 1200

Lo 1000

Quiet 760

Cool air

prevention

760

Heating

S-Lo 480

Hi 1300

Me 1120

Lo 950

Cooling

Fan

Quiet 700

Dry 700

AS*14LSBCW

Operation mode Air flow mode Speed (rpm)

Hi 1480

Me+ 1420

Me 1300

Lo 1110

Quiet 950

Cool air

prevention

850

Heatin g

S-Lo 480

Hi 1480

Me 1260

Lo 1040

Cooling

Fan

Quiet 850

Dry 850

(2).FAN OPERATION

The airflow can be switched in 5 steps such as AUTO, QUIET, LOW, MED, HIGH, while the indoor

fan only runs.

When Fan mode is set at (Auto), it operates on (MED) Fan Speed.

AS*12LSACW

Operation mod e Air flow mode Speed (rpm)

Hi 1470

Me+ 1420

Me 1290

Lo 1110

Quiet 980

Cool air

prevention

850

Heating

S-Lo 480

Hi 1400

Me 1200

Lo 1000

Cooling

Fan

Quiet

820

Dry 820

AS*12LSBCW

Operation mode

Air flow mode Speed (rpm)

Hi 1440

Me+ 1350

Me 1200

Lo 1000

Quiet 760

Cool air

prevention

760

Heating

S-Lo 480

Hi 1370

Me 1150

Lo 950

Cooling

Fan

Quiet

700

Dry 700

AS*18LSBCW

Operation mode Air flow mode Speed (rpm)

Hi 1480

Me+ 1420

Me 1300

Lo 1110

Quiet 950

Cool air

prevention

850

Heating

S-Lo 480

Hi 1480

Me 1260

Lo 1040

Cooling

Fan

Quiet

850

Dry 850

05-05

Page 26

(3).COOLING OPERATION

Switch the airflow [AUTO], and the (Fig.6)

indoor fan motor will run according airflow change - over ( Cooling:AUTO )

to a room temperature, as shown in When the room

Figure 6. temperature rises

On the other hand, if switched in HIGH mode

[HIGH] [QUIET], the indoor motor +2.5

will run at a constant airflow of [COOL] +2.0

operation modes QUIET, LOW, MED, MED mode

HIGH, as shown in Table 5. +1.5

+1.0

LOW mode

When the room

temperature lowers

(Room temperature) D (Setting temperature)

(4).DRY OPERATION

(5).HEATING OPERATION

Switch the airflow [AUTO], and the (Fig.7)

indoor fan motor will run according airflow change - over ( Heating:AUTO)

to a room temperature, as shown in When the room

Figure 7. temperature rises

On the other hand, if switched

LOW mode

[HIGH] [QUIET], the indoor motor -1.0

will run at a constant airflow of [HEAT] -1.5

operation modes QUIET, LOW, MED, MED mode

HIGH, as shown in Table 5. -2.0

-2.5

MED + mode

When the room

temperature lowers

(Room temperature) D (Setting temperature)

(6).COOL AIR PREVENTION CONTROL (Heating mode)

Indoor heat exchanger Indoor heat exchanger

temperature temperature

47 Hi

40 Me+ 40

37

Lo 34

Cool air prevention 32

30

28

S-Lo

Refer to the table 4.

Durring the dry mode operation, the fan speed

setting can not be changed.

The maximum value of the indoor fan speed is set as shown in Figure 8, based on the detected

temperature by the indoor heat exchanger sensor on heating mode.

(Fig.8 : Cool Air Prevention Control)

05-06

Page 27

6. OUTDOOR FAN CONTROL

(1). Outdoor Fan Motor

AC Motor

DC Motor

AS*9/12LSACW

AS*9/12LSBCW

AS*14/18LSBCW

(2). Fan Speed

Cooling Dry Heating

AS*9LSACW 830rpm 830rpm 830rpm

AS*12LSACW 820rpm 820rpm 820rpm

AS*9LSBCW 840rpm 840rpm 840rpm

AS*12LSBCW 830rpm 830rpm 830rpm

Cooling Dry Heating

AS*14LSBCW 860/820/670/500rpm 500rpm 820/750/670/550/450rpm

AS*18LSBCW 860/820/670/500rpm 500rpm 820/750/670/550/450rpm

Following table shows the type of the outdoor fan motor. The control method is different

between AC motor and DC motor.

( Table 6 : Type of Motor )

( Table 7 : AC Motor )

In conjunction with the compressor ON/OFF, the fan speed operates at around the speed

shown above.

*

( Table 8 : DC Motor )

*

The outdoor fan speed changed in the range mentioned avobe depending on the compressor

frequency.

(When the compressor frequency increases, the outdoor fan speed also changes to the higher

speed. When the compressor frequescy decreases, the outdoor fan speed also shanges to the

lower speed.)

*

It runs at 500rpm for 20 seconds after starting up the outdoor fan.

*

After the defrost control is operated on the heating mode, the fan speed keeps at 950rpm

without relating to the compressor frequency.

05-07

Page 28

7. LOUVER CONTROL

(1). VERTICAL LOUVER CONTROL

Each time the button is pressed, the air direction range will change as follow:

Cooling / Dry mode

Heating mode

Fan mode

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation

selected.

Cooling / Dry mode Horizontal flow

Heating mode Downward flow

When the temperature of the air being blown out is low at the start of heating operation or during

defrosting, the airflow direction temporarily becomes to prevent cold air being blown onto the body.

During use of the Cooling and Dry modes, do not set the Air Flow Direction Louver in the Heating

range ( ) for long period of time, since water vapor many condense near the outlet louvers and

drop of water may drip from the air conditioner. During the Cooling and Dry modes, if the Air Flow

Direction Louvers are left in the hating range for more than 30minutes, they will automatically

return to position .

During Monitor operation in AUTO CHANGEOVER mode, the airflow direction automatically

becomes , and it cannot be adjusted.

Cooling mode / Dry mode / Fan mode( )

Heating mode / Fan mode( )

(Function Range)

(Fig 9: Air Direction Range)

(Operation Range)

(2). SWING OPERATION

When the swing signal is received from the remote controller, the vertical louver starts to

swing.

(Swinging Range)

When the indoor fan is either at S-lo or Stop mode, the swinging operation is interrrupted

and the louver stops at the memorized position.

05-08

Page 29

8. COMPRESSOR CONTROL

(1). OPEARTION FREQUENCY RANGE

The operation frequency of the compressor is different based on the operation mode as

shown in the table 9.

Cooling Heating

Min Max Min Max

Dry

AS*9LSACW 18Hz 80Hz 18Hz 130Hz 33Hz

AS*12LSACW 18Hz 96Hz 18Hz 130Hz 33Hz

AS*9LSBCW 18Hz 80Hz 18Hz 130Hz 33Hz

AS*12LSBCW 18Hz 96Hz 18Hz 130Hz 33Hz

AS*14LSBCW 18Hz 90Hz 18Hz 119Hz 24Hz

AS*18LSBCW 18Hz 90Hz 18Hz 119Hz 24Hz

AS*9LSACW 56Hz 64Hz 74Hz 87Hz 108Hz 120Hz

AS*12LSACW 56Hz 64Hz 74Hz 87Hz 108Hz 120Hz

AS*9LSBCW 56Hz 74Hz 87Hz 97Hz 108Hz 119Hz

AS*12LSBCW 56Hz 74Hz 87Hz 97Hz 108Hz 119Hz

AS*14LSBCW 40Hz 59Hz 72Hz 80Hz 101Hz 110Hz

AS*18LSBCW 40Hz 59Hz 72Hz 80Hz 101Hz 110Hz

AS*9LSACW 80sec 30sec 30sec 30sec 50sec 60sec

AS*12LSACW 80sec 30sec 30sec 30sec 50sec 60sec

AS*9LSBCW 80sec 60sec 60sec 180sec 60sec 60sec

AS*12LSBCW 80sec 60sec 60sec 180sec 60sec 60sec

AS*14LSBCW 60sec 40sec 40sec 60sec 150sec 60sec

AS*18LSBCW 60sec 40sec 40sec 60sec 150sec 60sec

(Table 9 : Compressor Operation Frequency Range)

(2). OPEARTION FREQUENCY CONTROL AT START UP

The compressor frequency soon after the start-up is controlled as shown in the figure 10.

(Fig.10 : Compressor Control at Start-up)

Time

Time Time Time

Time

Time

(Frequency)

(Time)

Frequency

Frequency

Frequency Frequency

Frequency

Frequency

Time Time

Time Time Time Time

Frequency

Frequency

Frequency

Frequency

Frequency

Frequency

05-09

Page 30

9. TIMER OPEARTION CONTROL

(1). OPEARTION FREQUENCY RANGE

The table 10 shows the available timer setting based on the product model.

ON TIMER / OFF TIMER PROGRAM TIMER SLEEP TIMER

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : Depending on the difference between the actual room temperature and the set

temperature value, the unit will start operation automatically in order to bring the room

temperature to the desired set temperature value by the timer previously set.

Operation mode

Stop mode

Before the operation start

Set time of timer

At the ON timer when [Heating/Auto time:45 min] [Cooling/dry time:20 min] are reduced, the

indoor fan motor runs with S-Lo for 1 minute, and detects the room temperature. The [Operation

start time] is determined according to the Table 11 as shown below, and the operation is started.

Differential of set temperature and room temperature

Operation Start Time

Heating Cooling Dry

Before 44 minutes 20 C or larger

Before 30 minutes 15 C 20 C

Before 19 minutes 10 C 15 C 10 C or larger 10 C or larger

Before 15 minutes 5 C 10 C 5 C 10 C

Before 10 minutes Less than 10 C Less than 5 C Less than 5 C

The program timer allows the OFF timer and ON timer to be used in combination one time.

Operation mode

Operation will start from the timer setting (either OFF timer or ON timer) whichever is closest

to the clock's current timer setting. The order of operations is indicated by the arrow in the remote

control unit's display.

SLEEP timer operation cannot be combined with ON timer operation.

(Table 10 : Timer Setting)

(Table 11)

(2). PROGRAM TIMER

Stop mode

Stop mode

Stop mode

Operation mode

Operation mode

Set time

Set time Set time Set time

05-10

Page 31

(3). SLEEP TIMER

If the sleep is set, the room temperature is monitored and the operation is stopped automatically.

If the operation mode or the set temperature is change after the sleep timer is set, the operation is

continued according to the changed setting of the sleep timer from that time ON.

Set temperature rises

( Ts : Set temperature )

Stop of operation

Set temperature lowers

( Ts : Set temperature )

Ts

Stop of operation

In the cooling operation mode

When the sleep timer is set, the setting temperature is increased 1 degC.

It increases the setting temperature another 1degC after 1 hour.

After that, the setting temperature is not changed and the operation is stopped at the time

of timer setting.

Ts

+1.0

+2.0

Set

60min

In the heating operation mode

When the sleep timer is set, the setting temperature is decreased 1 degC.

It decreases the setting temperature another 1degC every 30 minutes.

Upon lowering 4degC, the setting temperature is not changed and the operation stops at

the time of timer setting.

-4.0

-3.0

-2.0

-1.0

Set

30min

30min

30min

05-11

Page 32

10. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the following values.

The compressor frequency, the temperatures detected by the discharge temperature sensor, the

indoor heat exchanger sensor, the outdoor heat exchanger sensor, and the outdoor temperature

sensor.

The pulse range of the electronic expansion valve control is between 60 to 480 pulses.

The expansion valve is set at 480 pulses after 110 seconds of stopping compressor.

At the time of supplying the power to the outdoor unit, the initialization of the electronic

expansion valve is operated (528 pulses are input to the closing direction).

11. TEST OPERATION CONTROL

Under the condition where the air conditioner runs, press the test operation button of the remote

control, and the test operation control mode will appear. During test running, the operation lamp

and timer lamp of the air conditioner body twinkle simultaneously. Set the test operation mode,

and the compressor will continue to run regardless of whether the room temperature sensor detects.

The compressor won't enter operation status for 2 minutes and 20 seconds after the compressor is

stopped, even if any operation is given.

At the time when the air conditioner is switched from the cooling mode to heating mode, the

compressor is stopped, and the four-way valve is switched in 2 minutes and 20 seconds later after

the compressor stopped.

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically started with

the memorized operation contents.

When the power is interrupted and recovered during timer operation, since the timer operation time

is shifted by the time the power was interrupted, an alarm is given by blinking (7 sec ON/2 sec OFF)

the indoor unit body timer lamp.

[Operation contents memorized when the power is interrupted]

Operation mode

Set temperature

Set air flow

Timer mode and timer time

Set air flow Direction

Swing

The test operation mode is released if 60 minutes have passed after setting up the test operation.

12. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )

13. FOUR-WAY VALVE EXTENSION SELECT

14. AUTO RESTART

05-12

Page 33

15. MANUAL AUTO OPERATION (Indoor unit body operation)

If MANUAL AUTO Button is set, the operation is controlled as shown in Table 12.

If the remote control is lost or battery power dissipated, this function will work without the remote

control.

OPERATION MODE Auto changeover

FAN CONT. MODE Auto

TIMER MODE Continuous

SETTING TEMP. 24 C

SETTING LOUVER Standard

SWING OFF

When the outdoor heat exchanger temperature is lower than temperature and the heating operation has

been stopped for 30 minutes, power is applied to the compressor and the compressor is heated.

(By heating the compressor, warm air is quickly discharged when operation is started.)

When operation was started, and when the outdoor temperature rises to temperature or greater, preheating

is ended.

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

AS*9LSACW

900rpm 36Hz

AS*12LSACW

900rpm 36Hz

AS*9LSBCW

900rpm 36Hz

AS*12LSBCW

900rpm 36Hz

AS*14LSBCW

900rpm 24Hz

AS*18LSBCW

900rpm 24Hz

(Table 12)

(No timer setting available)

16. COMPRESSOR PREHEATING

(Table 13 : Preheating Operation / Release Temperature)

Temperature

Temperature

5 C

5 C

5 C

5 C

5 C

5 C

7 C

7 C

7 C

7 C

7 C

7 C

17. COIL DRY OPERATION CONTROL

The coil-dry operation functions by pressing Coil Dry operation button on the remote controller.

The coil-dry operation is consisted of 3 cycles of [Fan operation 3 minutes / Heating operation

2 minutes], and Fan operates for 3 minutes at last before ending the air conditioner operation.

(It takes 18 minutes to complete the coil-dry operation.)

Following table indicates the indoor unit setting on the coil-dry operation.

(Table 14 : Coil-dry Operating Functions)

Indoor Fan Speed

Compressor

Frequency

Louver

Position

Main Unit

Indocation

Coil-dry indication : ON

Other indication : OFF

05-13

Page 34

18. DEFROST OPERATION CONTROL

(1). CONDITION OF STARTING THE DEFROST OPERATION

The defrost operation starts when the outdoor heat exchanger temperature sensor detects

the temperature lower than the values shown in Table 15.

(Table 15 : Condition of starting Defrost Operation)

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

1 time defrosting

after starting

operation

ST

Defrosting after 2

time upon starting

operation

ST

Compressor operating time

Less than 20 minutes 20 to 60 minutes

60 minutes to 4 hours

After 4 hours

Does not operate

- 9 C

- 9 C

- 9 C

- 9 C

- 9 C

- 9 C

- 5 C

- 5 C

- 5 C

- 5 C

- 5 C

- 5 C

- 3 C

- 3 C

- 3 C

- 3 C

- 3 C

- 3 C

Less than 35 minutes

35 minutes to

4 hours

Does not operate

Compressor operating time

After 4 hours

- 3 C

- 3 C

- 3 C

- 3 C

- 3 C

- 3 C

- 6 C

- 6 C

- 6 C

- 6 C

- 6 C

- 6 C

(2). CONDITION OF THE DEFROST OPERATION COMPLETION

Defrost operation is released when the conditions become as shown in Table 16.

(Table 16 : Defrost Release Condition)

Release Condition

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 16degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 16degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

05-14

Page 35

Defrost Flow Chart

The defrosting shall proceed by the integrating operation time and outdoor heat exchanger

temperature as follows.

(Not defrosted for 10 minutes)

(In case of 1st defrost) (In case of 2nd and later defrost)

Compressor OFF

Outdoor fan motor OFF

30 sec later four - way valve OFF

36 sec later compressor ON

Heating operation start : Compressor ON

Compressor integrating

operation:

Over 20 minutes to

below 60 minutes

Compressor integrating

operation:

Over 60 minutes to

below 240 minutes

Compressor integrating

operation:

Over 240 minutes

Compressor integrating

operation:

Over 35 minutes to

below 240 minutes

Compressor integrating

operation:

Over 240 minutes

Outdoor heat exchanger

temperature:

Below - 9 C

Outdoor heat exchanger

temperature:

Outdoor heat exchanger

temperature:

Outdoor heat exchanger

temperature:

Outdoor heat exchanger

temperature:

Defrost start

Defrost Indicator:

[Operation lamp]

7 sec ON / 2 sec OFF

Outdoor heat exchanger temperature:

Over 10 C / 16 C

or

Compressor ON time:

Over 15 minutes

Defrost end

Below - 5 C

Below - 3 C

Below - 6 C

Below - 3 C

05-15

Page 36

19. OFF DEFROST OPEARTION CONTROL

(1). OFF DEFROST OPERATION CONDITION

When operation stops in the [Heating operation] mode, if frost is adhered to the outdoor unit heat

exchanger, the defrost operation will proceed automatically. In this time, if indoor unit operation

lamp flashes slowly (7 sec ON / 2 sec OFF), the outdoor unit will allow the heat exchanger to defrost,

and then stop.

In heating operation, the outdoor heat exchanger temperature is less than - 4 C, and compressor

operation integrating time lasts for more than 30 minutes.

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

OFF Defrost Flow Chart

Heating operation stop

Outdoor heat exchanger temperature:

Below - 4 C

and

Compressor integrating operation:

Over 30 minutes

Defrost start

Defrost Indicater:

[Operation lamp]

Outdoor heat exchanger temperature:

Over 10 C / 16 C

or

Compressor ON time:

Over 15 minutes

Defrost end

(2). OFF DEFROST END CONDITION

Release Condition

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 16degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 16degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

Outdoor heat exchanger temperature sensor value is higher than 10degC or

Compressor operation time has passed 15 minutes.

7 sec ON / 2 sec OFF

05-16

Page 37

20. VARIOUS PROTECTIONS

(1). DISCHARGE GAS TEMPERATURE OVERRISE PREVENSION CONTROL

The discharge gas thermosensor (discharge thermistor : Outdoor side) will detect discharge gas

temperature.

AS*9LSACW 104 C 101 C 110 C

AS*12LSACW 104 C 101 C 110 C

AS*9LSBCW 104 C 101 C 110 C

AS*12LSBCW 104 C 101 C 110 C

AS*14LSBCW 104 C 101 C 110 C

AS*18LSBCW 104 C 101 C 110 C

AS*9LSACW AS*12LSACW AS*9LSBC W AS*12LSBCW AS*14LSBCW AS*18LSBCW

OT (Control / Release)

6.5A / 6.0A

17 C

8.0A / 7.5A

12 C

8.0A / 7.5A

8.0A / 7.5A

6.5A / 6.0A

8.0A / 7.5A

8.5A / 8.0A

9.5A / 9.0A

6.5A / 6.0A

8.0A / 7.5A

8.0A / 7.5A

8.0A / 7.5A

6.5A / 6.0A

8.0A / 7.5A

8.5A / 8.0A

9.5A / 9.0A

7.0A / 6.5A

9.0A / 8.5A

10.5A / 10.0A

12.0A / 11.5A

7.0A / 6.5A

9.0A / 8.5A

10.5A / 10.0A

12.0A / 11.5A

AS*9LSACW AS*12LSACW AS*9LSBCW AS*12LSBCW AS*14LSBCW AS*18LSBCW

3.5A / 3.0A

46 C

4.0A / 3.5A

40 C

5.5A / 5.0A

4.0A / 3.5A

5.0A / 4.5A

6.5A / 6.0A

3.5A / 3.0A

4.0A / 3.5A

5.5A / 5.0A

4.0A / 3.5A

5.0A / 4.5A

6.5A / 6.0A

4.5A / 4.0A

6.0A / 5.5A

8.5A / 8.0A

4.5A / 4.0A

6.0A / 5.5A

8.5A / 8.0A

When the discharge temperature becomes higher than Temperature ,the compressor frequency

is decreased 20 Hz, and it continues to decrease the frequency for 20 Hz every 120 seconds until

the temperature becomes lower than Temperature .

When the discharge temperature becomes lower than Temperature ,the control of the control of the

compressor frequency is released.

When the discharge temperature becomes higher than Temperature ,the compressor is stopped

and the indoor unit LED starts blinking.

(Table 17 : Discharge Temperature Over Rise Prevension Control / Release Temperature)

Temperature

Temperature

Temperature

(2). CURRENT RELEASE CONTROL

The compressor frequency is controlled so that the outdoor unit input current does not exceeds

the current limit velue that was set up with the outdoor temperature.

The compressor frequency returns to the designated frequency of the indoor unit at the time

when the frequency becomes lower than the release value.

(Table 18 : Current Release Operation Value / Release Value)

[ Heating ]

[ Cooling / Dry ]

OT : Outdoor Temperature

OT (Control / Release) OT (Control / Release)

OT (Control / Release)

OT (Control / Release)

OT (Control / Release)

OT : Outdoor Temperature

OT (Control / Release) OT (Control / Release)

OT (Control / Release)

OT (Control / Release) OT (Control / Release)

OT (Control / Release)

5 C

17 C

12 C

5 C

17 C

12 C

5 C

17 C

12 C

5 C

17 C

12 C

5 C

17 C

12 C

5 C

46 C

40 C

46 C

40 C

46 C

40 C

46 C

40 C

46 C

40 C

05-17

Page 38

(3). ANTIFREEZING CONTROL (Cooling and Dry mode)

The compressor frequency is decrease on cooling & dry mode when the indoor heat exchanger

temperature sensor detects the temperature lower than Temperature .

Then, the anti-freezing control is released when it becomes higher than Temperature .

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

(Table 19 : Anti-freezing Protection Operation / Release Temperature)

TemperatureTemperature

4 C

4 C

4 C

4 C

4 C

4 C

7 C

7 C

7 C

7 C

7 C

7 C

(4). COOLING PRESSURE OVERRISE PROTECTION

(Table 20 : Cooling Pressure Over Rise Protection Function Temperature)

When the outdoor unit heat exchange sensor temperature rises to temperature or greater, the

compressor is stopped and trouble display is performed.

AS*9LSACW 65 C

AS*12LSACW 65 C

AS*9LSBCW 67 C

AS*12LSBCW 67 C

AS*14LSBCW 65 C

AS*18LSBCW 65 C

Temperature

AS*9LSACW

AS*12LSACW

AS*9LSBCW

AS*12LSBCW

AS*14LSBCW

AS*18LSBCW

Indoor heat exchange

temperature

[ AS*9/12LSBCW ]

52Hz or greater 51Hz

26 51Hz

18 25Hz OFF

AS*9LSACW 52 C 48 C 54 C 50 C

AS*12LSACW 52 C 48 C 54 C 50 C

(5). HIGH TEMPERATURE RELEASE CONTROL ( HEATING MODE )

On heating mode, the compressor frequency is controlled as following based on the

detection value of the indoor heat exchanger temperature sensor.

(The control system is different depending on the product model)

Control system

(Fig 11 : Heating Overload Protection Control)

[ Control System ]

Temperature

Temperature

Refer to below

The frequency increase every

60 seconds gradually.

It returns to the normal operation

after 5 minutes.

Fan Hi

Other than Hi

Temp

Temp Temp

Temp

Compressor Operation

Frequency down evry 60 seconds

05-18

Page 39

Indoor heat exchange

temperature

[ AS*9/12LSBCW ]

52Hz or greater 51Hz

26 51Hz

18 25Hz OFF

AS*9LSACW 52 C 48 C 54 C 50 C

AS*12LSACW 52 C 48 C 54 C 50 C

[ Control System ]

Temperature

Temperature

Refer to below

The frequency increase every

60 seconds gradually.

It returns to the normal operation

after 5 minutes.

Fan Hi

Other than Hi

Temp

Temp Temp

Temp

Compressor Operation

Frequency down evry 60 seconds

[ AS*9/12LSBCW ]

[ AS*14/18LSBCW ]

46Hz or greater 45Hz

39Hz or greater 38Hz

39 45Hz

38Hz

26 38Hz 25Hz

19 29Hz 18Hz

18 25Hz OFF

OFF

AS*9LSBCW 55 C 53 C 52 C 50 C

AS*12LSBCW 55 C 53 C 52 C 50 C

AS*14LSBCW 55 C 53 C 52 C 50 C

AS*18LSBCW 55 C 53 C 52 C 50 C

Indoor heat exchange

temperature

[ Control System ]

Temperature

Temperature

Refer to below

Temperature

Temperature

The compressor frequency is

precisely controlled so that

it does not exceeds Temperature .

It returns to the normal operation

Compressor Operation

18Hz

30

Frequency down every 120 seconds

Frequency down every 120 seconds

Temp

Temp Temp

Temp

05-19

Page 40

6 . REFRIGERANT CAUTION -R410A-

R410A

WALL MOUNTED type

INVERTER

Page 41

1. R410A TOOLS

Gauge manifold . . . . . . . . . . . . . . . . . . . . . (Fig.4-1)

Since the normal pressure is high, the connection pipe size

is also different.

Charge hose . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-2)

Refrigerant cylinder . . . . . . . . . . . . . . . . . (Fig.4-3)

Confirm the refrigerant type before charging. Always

charge liquid-phase refrigerant.

Electronic balance for refrigerant

charging . . . . . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-4)

Electronic balance is recommended as in the case of

R410A.

Vacuum pump with adapter to prevent

reverse flow . . . . . . . . . . . . . . . . . . . . . . . .(Fig.4-5)

Conventional pump can be used.

Vacuum holder . . . . . . . . . . . . . . . . . . . . . (Fig.4-6)

Conventional pump can be used if adapter for preventing

vacuum pump oil from flowing back is used.

Gas leakage tester . . . . . . . . . . . . . . . . . . (Fig.4-7)

Exclusive for HFC

Refrigerant cleaner . . . . . . . . . . . . . . . . . . (Fig.4-8)

Brown paint as designated by the ARI, USA

Flare tool . . . . . . . . . . . . . . . . . . . . . . . . . . (Fig.4-9)

Torque wrench . . . . . . . . . . . . . . . . . . . . (Fig.4-10)

Refrigerant recovering

equipment (Collector) . . . . . . . . . . . . . . (Fig.4-11)

The type which can be used for any refrigerant is available

Nitrogen cylinder . . . . . . . . . . . . . . . . . . . (Fig.4-12)

This prevents an oxide film from forming in the pipe silveralloy brazing work by turning the air out of the pipe and

preventing the inside combustion.

Safety charger . . . . . . . . . . . . . . . . . . . . . (Fig.4-13)

It is always compulsory to change the liquid, because

R410A is a mixed refrigerant and there is some fear that a

mixing ratio changes. In order to avoid the refrigerant from

returning to the compressor in a liquid state, the refrigerant

can be charged instead of giving a load to the compressor

with a safety charger.

Control valve . . . . . . . . . . . . . . . . . . . . . . (Fig.4-14)

The control valve prevents the refrigerant from spouting

when it is removed, as the charging hose side and the service port side are possible to open and close at the same

time.

Thermistor vacuum gauge . . . . . . . . . . . (Fig.4-15)

To remove moisture from the refrigerating cycle completely, it is necessary to perform appropriate vacuum drying.

For that reason, vacuum conditions can be confirmed certainly.

Vacuum valve . . . . . . . . . . . . . . . . . . . . . (Fig.4-16)

This valve builts in a check valve, and it is easily possible

to vacuum a refrigerating cycle or check for degree of vacuum with it.

TOOLS AND EQUIPMENT (R410A)

Refrigerant cylinder

Gauge Manifold

R410A

R22, R407C

High

pressure

gauge

Compond

gauge

Port size

-0.1 5.3

Mpa

-0.1 3.8

Mpa

1/2UNF

5/16"

-0.1 3.5

Mpa

-0.1 1.7

Mpa

7/16UNF

1/4"

*

1

Charge hose

R410A

R22, R407C

Normal

pressure

Port size

5.1 Mpa

27.4 Mpa

1/2UNF

3.4 Mpa

17.2 Mpa

7/16UNF

*

2

Breaking

pressure

This air conditioner used R410A.

For installation and servicing, it is necessary to prepare the

tools and machines that are different from the previous

refrigerant.

Mark shows the exclusive use for R410A.

The specification of the gauge is different due

to higher pressure.

The size of connection pipe is also different to

prevent mis-use.

The shape of flare is different for

high pressure condition.

06-01

Page 42

2. PRECAUTION FOR INSTALLATION

Precaution for installation

Selection of pipe

Pipe thickness

Outer diameter Thickness

1/4” (6.35mm) 0.8 mm

3/8” (9.52mm) 0.8 mm

1/2”(12.7mm) 0.8 mm

Be sure to use this pipe thickness and over

for countermeasure against higher

pressure.

Flare and flare nuts

Diameter 1/4”(6.35mm) 3/8”(9.52mm) 1/2”(12.7mm)

Refrigerant

R410A

R22

/R407C

R410A R410A

A 9.1 9.0 13.2 13.0 16.6

16.2

B 13 12 20 15 13 20

C 12 11 16 12.5 19 16

Nut width 17 22 26 24

Always use the flare nut that is packed

with the product.

Do not use existing (for R22) pipes

• Be sure to use new pipes when replacing

conventional (R22) model with HFC

(R407C, R410A) model.

• If you use existing pipes, it may cause

resolution of compressor oil by remaining

mineral oil.

R22

/R407C

R22

/R407C

06-02

Page 43

Be careful not to mix moisture and

contamination into the pipe

Moisture and contamination

in the pipe is a cause of

trouble.

Air purge

Always use a

vacuum pump

to purge air.

Refrigerant charge

Do it always from the liquid phase

side.

Don't charge from the gas phase side.

Compressor oil is changed

Be careful to handle synthetic oil, since it

resolves easily by moisture and

contamination.

Don't mix new synthetic oil and mineral oil.

It may cause trouble.

We developed new synthetic oil, since HFC

refrigerant doesn't dissolve in mineral (for R22)oil.

06-03

Page 44

3. PRECAUTION FOR SERVICING

Feature 1 Refrigerant oil is different from before.

Refrigerant oil for

New Refrigerant

Synthetic oil

Ether

Esther

Different point from

previous one

Previously it was

mineral oil.

Absorbent character

is high.

Contamination occurs

when mixed withe other

kind of oil.

Use the gauge manifold and charge hose

for New Refrigerant(HFC), which shall

be segregated from those of R22.

Attach the stop valve on the vacuum pump

and avoid the oil from reverse frow.

It is necessary to use the vacuum pump

which can obtain the high vacuum condition.

Precaution on Tools

Feature 2 New Refrigerant has Approx 1.6 times higher pressure than previous refrigerant.

R410A

High Pressure

Different point from

previous one

Diameter of Service port

has been changed from

1/4 Flare to 5/16 Flare.

It requires the gauge manifold and charge

hose exclusively for R410A.

It requires the flare tool and torque wrench

that satisfies New JIS standard.

Precaution on Tools

R410A R22

1.6 times of R22.

JIS standard of flare

process It became lager

To keep thethickness of

copper tube.

(1/4,3/3=more than 0.8mm)

Previous flare tool + flare adapter can be used as well.

06-04

Page 45

4. NEW REFRIGERANT R410A

What is HFC ?

Phase-out schedule of HCFC

according to Montreal protocol

1996 20102000 2004 2015 2020 2030

60

40

20

100

(Year)

(%)

80

(HCFC consumption of 1989) +

(CFC consumption of 1989) x 2.8%

65%

35%

10%

0.5%

started control

only service use

total abolition

100% =

0

*

06-05

Page 46

Page 47

Page 48

OIL

• Use new synthetic oils such as ester because HFC series refrigerant has less solubility with mineral oils

conventionally used for R22.

• As these new synthetic oils are easily influenced by moisture and dusts, they must be treated more care-

fully than the conventional lubricating oils.

CAUTION

For installation/servicing, take more precautions than the case of conventional refrigerants to avoid moisture

and dusts entering the refrigerant circuit. Also, for storing parts, more precautions must be taken.

2, 3-WAY VALVE

• Review material O-ring, valve core seal for securing suitability with oil.

CAUTION

Check if the valve is suitable for the refrigerant (model) when replacing.

CAUTION

Check if the compressor is suitable for the refrigerant (model) when replacing. Complete welding within 15

minutes after opening the cap when replacing.

COMPRESSOR

• Use better grade of material for sliding parts for securing good lubrication of sliding part as HFC

refrigerant does not contain chloride.

• Review insulating materials

• Increase pressure resistance strength

CAUTION

During storage, due care must be taken so that foreign matters such as dust and water do not enter.

HEAT EXCHANGER

• Review the water,contaminants controlling level

• Use thinner tube to increase pressure Increase capacity for resistance strength (only outdoor unit)

improving performance

CAUTION

Check if the valve is suitable for the refrigerant (model) when replacing.

4-WAY VALVE

• Review materials

5. DEFFERENCE FROM CONVENTIONAL MODEL (R22) AND PRECAUTIONS

06-08

Page 49

7 . TROUBLE SHOOTING

R410A

WALL MOUNTED type

INVERTER

1. When the unit does not operate at all (Operation lamp and Timer lamp do not light up)

2. Self Diagnosis Function (Either Operation lamp or Timer lamp is blinking)

* How to operate the self-diagnosis function

* Self- diagnosis table and Check points

3. Trouble shooting method

* Serial signal check

* IPM protection check

* Active filter error check

* Refrigeration cycle diagnosis

Page 50

Does not operate at all (Operation Lamp and Timer Lamp do not light up)

[Check Point]

(1) Is the input power voltage from the exclusive circuit AC outlet normal?

(2) Is the AC plug inserted to the AC outlet securely and not loose?

(3) Check if each connector is inserted securely.

[Checking Flow Chart]

Is AC input voltage from AC outlet normal ?

Is AC voltage between VA 1 normal?

Is DC voltage between terminal of C5 normal?

Is DC voltage between terminals of C7 and C12

Is DC voltage between terminal 1 & 2 of IC6 normal?

YES (AC220/230V)

YES (AC220/230V)

YES (AC220/230V)

Is DC voltage between terminals of C9

YES (C7:DC20V)

(C12:DC13.5 1V)

YES (DC12 14V)

Terminal board temperature

fuse is blown or CN1 is loose

(IC2, T1 or IC3 defective)

IC4 defective

YES (DC15V)

Is DC voltage between terminals 3 & 4 of IC7 normal?

YES (Pulse wave of DC5Vp-p)

IC7 defective

(F1, VA1 defective)

Input power supply failure

Controller PCB defective

NO

NO

NO

NO

NO

NO

NO

Switching power circuit

Switching power circuit

Switching power circuit

(F2, D1, R1 defective)

07-01

Page 51

SELF-DIAGNOSIS FUNCTION

This function memorizes the self-diagnosis function (lamp display) in the in door control P.C.Board

when trouble occurs.

(The memory contents are not destroyed even when the power cord is unplugged from the AC outlet.)

The self-diagnosis function (lamp display) can also be switched between major classification display

and minor classification display and precise diagnosis can be made.

Self-diagnosis function [lamp display] (memory reading)

(1) When error occurs, it is indicated by blinking [Operation lamp (Red)] and [Timer lamp (Green)].

(2) Upon pulling out and inserting the AC plug, the starts to operates from remote control.

(At this state, a normal operation indication is performed.)

(3) By pressing [TEST] button of remote control, [Large Division Error Indication] is indicated only

during

[3 minutes ST].

(3 minutes ST : 2 minutes 20 seconds from the timing AC plug is ON)

[Lamp display]

3 minutes delay

Turn off Operating Large Div. Error Indication Normal indication after

3min.ST

Indication

AC Plug ON Start operation Input TEST signal

(4) By pressing [TEST] button of remote control while [Large Division Error Indication], it switches

to

[Small Division Error Indication].

(5) Every time [TEST] button of remote control is pressed, it switches between [Large Division Error

Indication] and [Small Division Error Indication] alternately.

How to erase Memory

(1) While [Large Division Error Indication] or [Small Division Error Indication] is ON by the

self-diagnosis function, the memorized contents can be erased by pressing [Forced Auto

Button] on the main unit.

(Indoor unit buzzer beeps 3 seconds.)

07-02

Page 52

Self - diagnosis function and Checking points

Large Division Error

Indication

Small Division Error

Indication

Operation

Timer

Large Div.

Contents

Opera

tion

Timer

Small Div. Contents

(Protection)

Diagnosis Method

0.1

sec.

blinki

ng

0.5 sec

2 times

Serial reverse transfer

error at starting up

operation

At the start up, the indoor unit does not receive the signal for 10 consecutive seconds from the time when the

power relay was ON. > Permanent stop after 30 seconds.

[Diagnosis Point]

- Check the indoor/outdoor cable connection (in order). If the cable wiring is not abnormal, measure the

voltage of the outdoor unit terminals and diagnose the defective location.

(Refer to the after mentioned [Serial Signal Diagnosis] for the voltage measuring method and diagnosis

method.)

0.1

sec.

blinki

ng

0.5 sec

3 times

Serial reverse transfer

error during the

operation

When the indoor unit does not receive the signal for 10 consecutive seconds during the operation > Permanent

stop after 30 seconds.

[Diagnosis Point]

- Check the indoor/outdoor cable connection (in order). If the cable wiring is not abnormal, measure the

voltage of the outdoor unit terminals and diagnose the defective location.

(Refer to the after mentioned [Serial Signal Diagnosis] for the voltage measuring method and diagnosis

method.)

0.1

sec.

blinki

ng

0.5 sec

4 times

Serial forward transfer

error at starting up

operation

The outdoor unit does not receive the signal for 10 consecutive seconds from the time when the power relay was

ON. > Outdoor unit stops.

[Diagnosis Point]

- Check the indoor/outdoor cable connection (in order). If the cable wiring is not abnormal, measure the

voltage of the outdoor unit terminals and diagnose the defective location.

(Refer to the after mentioned [Serial Signal Diagnosis] for the voltage measuring method and diagnosis

method.)

ON 1 sec.

blinking

Transmission

Error

0.1

sec.

blinki

ng

0.5 sec

5 times

Serial forward transfer

error during the

operation

When the outdoor unit does not receive the signal for 10 consecutive seconds during the operation >

Outdoor unit stops.

[Diagnosis Point]

- Check the indoor/outdoor cable connection (in order). If the cable wiring is not abnormal, measure the

voltage of the outdoor unit terminals and diagnose the defective location.

(Refer to the after mentioned [Serial Signal Diagnosis] for the voltage measuring method and diagnosis

method.)

07-03

Page 53

0.1

sec.

blinki

ng

0.5 sec

2 times

Room temperature

thermistor defective

The room temperature thermistor detected a abnormal temperature when the power was turned on.

> Remote control does not operate.

[Diagnosis Point]

- Check Thermistor resistance value (Refer to “Thermistor characteristics table”).

- Controller PCB defective.

0.5 sec

2 times

0.1 sec.

blinking

Indoor Unit

Thermistor

Error

0.1

sec.

blinki

ng

0.5 sec

3 times

Indoor Heat Exchanger

Thermistor Error

The detection value of the indoor heat exchanger thermistor is either open or shorted when the power is ON.

> Remote control does not operate.

[Diagnosis Point]

- Check Thermistor resistance value (Refer to “Thermistor characteristics table”).

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

2 times

Discharge Thermistor

Error

The detection value of the discharge thermistor is either open or shorted

> Compressor, Outdoor Fan : OFF (It automatically releases when the normal value is detected.)

[Diagnosis Point]

- Check Thermistor resistance value (Refer to “Thermistor characteristics table”).

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

3 times

Outdoor Heat Exchanger

Thermistor Error

The detection value of the outdoor heat exchanger thermistor is open.

> Compressor, Outdoor Fan : OFF (It automatically releases when the normal value is detected.)

[Diagnosis Point]

- Check Thermistor resistance value (Refer to “Thermistor characteristics table”).

- Controller PCB defective

0.5 sec

3 times

0.1 sec.

blinking

Outdoor Unit

Thermistor

Error

0.1

sec.

blinki

ng

0.5 sec

4 times

Outdoor Temperature

Thermistor Error

The detection value of the outdoor temperature thermistor is either open or shorted

> Compressor, Outdoor Fan : OFF (It automatically releases when the normal value is detected.)

[Diagnosis Point]

- Check Thermistor resistance value (Refer to “Thermistor characteristics table”).

- Controller PCB defective.

0.5 sec

4 times

0.1 sec.

blinking

Indoor Unit

Controller

Error

0.1

sec.

blinki

ng

0.5 sec

2 times

Forced Auto Switch

Error

Forced Auto Switch becomes ON for 10 consecutive seconds.

> It indicates the error but the operation continues.

[Diagnosis Point]

- Check if Forced Auto Switch is kept pressed.

- Forced Auto Switch defective.

- Controller PCB defective.

07-04

Page 54

0.1

sec.

blinki

ng

0.5 sec

3 times

Main Relay Error

After 2 minutes 20 seconds of stopping operation, the signal from outdoor unit is received even though the main

relay is OFF.

> Main Relay OFF continues (Outdoor Unit OFF Command)

[Diagnosis Point]

- Main Relay defective

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

4 times

Power Supply

Frequency Detection

Error

The power supply frequency can not be recognized after 4 seconds of power ON.

> Permanent stop.

[Diagnosis Point]

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

2 times

IPM Protection

Abnormal current value of IPM is detected > Permanent stop.

[Diagnosis Point]

- Heat radiation is blocked (Inlet/Outlet)

- Check if Outdoor Fan is defective (does not rotate).

- Controller PCB defective (Refer to after mentioned “IPM diagnosis”)

- Refrigeration cycle defective (Refer to after mentioned “Refrigeration cycle diagnosis”).

0.1

sec.

blinki

ng

0.5 sec

3 times

CT Error

The current value during the operation after 1 minute from starting up the compressor is 0 A.

> Permanent stop.

[Diagnosis Point]

- Check if CT wire is open.

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

5 times

Compressor Location

Error

The compressor speed does not synchronize with the control signal. (Including start up failure of the compressor)

> Permanent stop.

[Diagnosis Point]

- Check if 2 way valve or 3 way valve is left open.

- Check the compressor (Winding resistance value, Loose lead wire).

- Refrigeration cycle defective (Refer to after mentioned “Refrigerant cycle diagnosis”).

0.5 sec

5 times

0.1 sec.

blinking

Outdoor Unit

Controller

Error

0.1

sec.

blinki

ng

0.5 sec

6 times

Outdoor Fan Error

(DC Motor)

Either the outdoor fan motor abnormal current or location error was detected.

> Permanent stop.

[Diagnosis Point]

- Fan motor connector loose/ defective contact.

- Fan motor defective.

- Controller PCB defective.

07-05

Page 55

0.1

sec.

blinki

ng

0.5 sec

2 times

Indoor Fan Lock Error

The indoor fan speed is 0 rpm after 56 seconds from starting operation or from the time the fan mode was

changed. > Operation stops. (It releases by sending the operation stop signal from the remote controller.)

[Diagnosis Point]

- Fan motor connector loose/ defective contact.

- Fan motor defective.

- Controller PCB defective.

0.5 sec

6 times

0.1 sec.

blinking

Indoor Fan

Motor Error

0.1

sec.

blinki

ng

0.5 sec

3 times

Indoor Fan Speed Error

The indoor fan speed is 1/3 of the target frequency after 56 seconds from starting operation or from the time the

fan mode was changed. > Operation stops. (It releases by sending the operation stop signal from the remote

controller.)

[Diagnosis Point]

- Fan motor connector loose/ defective contact.

- Fan motor defective.

- Controller PCB defective.

0.1

sec.

blinki

ng

0.5 sec

2 times

Discharge Temperature

Error

The discharge temperature error is activated. > Permanent stop.

[Diagnosis Poijnt]

- Check if 2 way valve or 3 way valve is left open.

- Heat radiation is blocked (Inlet/Outlet)

- Check if Outdoor Fan is defective (does not rotate).

- Refrigeration cycle defective (Refer to after mentioned “Refrigerant cycle diagnosis”).

0.5 sec

7 times

0.1 sec.

blinking

Refrigerant

Cycle Error

0.1

sec.

blinki

ng

0.5 sec

3 times

Excessive High Pressure

Protection on Cooling