Page 1

SPLIT TYPE

AIR CONDITIONER

DUCT TYPE (50Hz)

Indoor unit Outdoor unit

ARYG45LMLA AOYG45LETL

CONTENTS

SPECIFICATIONS. . . . . . . . . . . . . . . . . . .

DIMENSIONS. . . . . . . . . . . . . . . . . . . . . .

REFRIGERANT SYSTEM DIAGRAM. . . .

CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . .

INDOOR PCB CIRCUIT DIAGRAM . . . . .

OUTDOOR PCB CIRCUIT DIAGRAM

ERROR DETECTION . . . . . . . . . . . . . . .

PARTS (INDOOR UNIT) . . . . . . . . . . . .

PARTS (OUTDOOR UNIT) . . . . . . . . . .

ACCESSORIES . . . . . . . . . . . . . . . . . . .

. . .

14

18

21

24

1

2

3

4

5

8

Page 2

SPECIFICATIONS

ELECTRICAL DATA

TYPE

INDOOR UNIT

OUTDOOR UNIT

COOLING CAPACITY

HEATING CAPACITY

POWER SOURCE

RUNNING

CURRENT

INPUT WATTS

E.E.R.

C.O.P.

MOISTURE REMOVAL

AIR CIRCULATION INDOOR

AIR CIRCULATION

OUTDOOR

MAXIMUM CURRENT

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

FAN MOTOR

INDOOR UNIT, Discrimination

High

INDOOR UNIT

Medium

Low

Quiet

Cooling & Heating

ARYG45LMLA

AOYG45LETL

12.1 kW

13.3 kW

230 V, 50 Hz, single phase

16.5 A

16.1 A

3.77 kW

3.68 kW

3.21 kW/kW

3.61 kW/kW

4.0 L/hr

2,100 m3/h

6,750 m3/h

6,200 m3/h

21.0 A

MFG-45RVN

1,350 r.p.m.

1,150 r.p.m.

910 r.p.m.

770 r.p.m.

NOISE LEVEL

High

Medium

INDOOR UNIT

Low

Quiet

OUTDOOR UNIT 55 dB

42 dB

38 dB

32 dB

28 dB

COMPRESSOR AND REFRIGERANT

Hermetic type, Inverter,

TYPE

DISCRIMINATION

WEIGHT (with oil)

REFRIGERANT TYPE

PRECHARGED REFRIGERANT

MAX PIPE HEIGHT

Pipe length

FULL CHARGE

ADDITIONAL CHARGE

20 m

30 m 3,750 g

40 m

50 m

6 poles, 3 phase,

DC motor, Twin Rotary

N-TF30HD1A

15.4 kg

R410A

3,350 g

30 m

3,350 g

4,150 g

4,550 g

40 g/m

DIMENSIONS

INDOOR UNIT H x W x D

H x W x DOUTDOOR UNIT

270 x 1,135 x 700 mm

1,290 x 900 x 330 mm

OUTDOOR UNIT, Discrimination

OUTDOOR UNIT

Cooling

OUTDOOR UNIT

Heating

2013.02.18 1

Upper fan

Lower fan

Upper fan

Lower fan

MFE-45VVT

850 r.p.m.

800 r.p.m.

780 r.p.m.

750 r.p.m.

WEIGHT

INDOOR UNIT

Shipping / Net

Shipping / NetOUTDOOR UNIT

47 kg / 40 kg

94 kg / 86 kg

Page 3

DIMENSIONS

(Unit : mm)

INDOOR UNIT

OUTDOOR UNIT

139

132

264 264 264

900

31 12330

114

1,177

32

240

477

700

66

32

168

240

281

1290

283

161

173

240

121

1,015

1,135

40

107

270

16

9

21

400

air flow

2013.02.18

54

370

39

2

650

Page 4

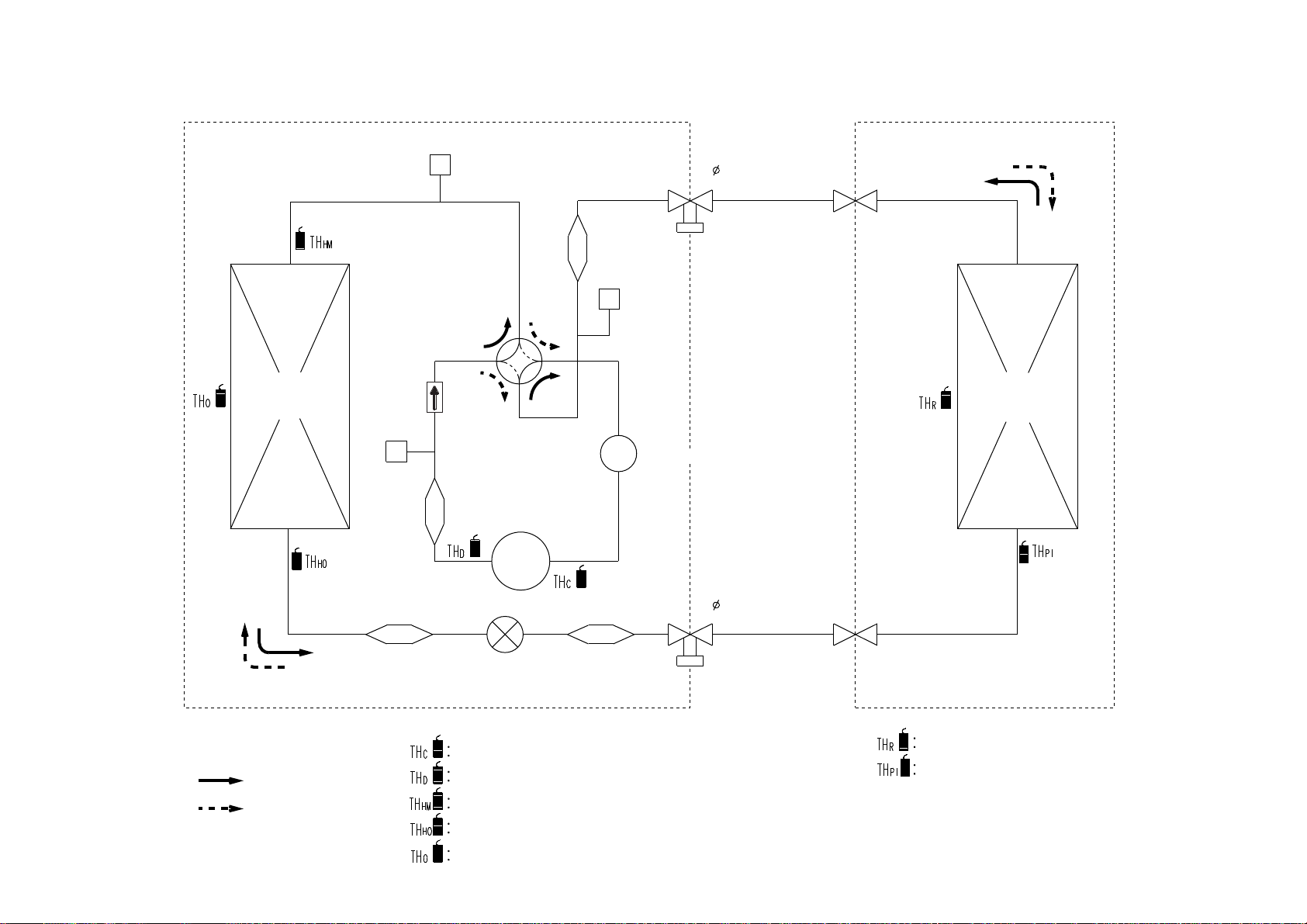

REFRIGERANT SYSTEM DIAGRAM

OUTDOOR UNIT INDOOR UNIT

Heat

Exchanger

Pressure

Check Valve

Muffler

4-way

Valve

Check

Valve

High Pressure

Switch

Muffler

Strainer Strainer

Compressor

Refrigerant Pipe

15.88mm (5/8")

3-way Valve

Pressure

Sensor

Heat

Exchanger

Accumulator

Refrigerant Pipe

9.52mm (3/8")

2013.02.15

Refrigerant direction

Cool

Heat

Expansion

Valve

3-way Valve

Thermistor (Compressor)

Thermistor (Discharge)

Thermistor (Heat Exchanger Med)

Thermistor (Heat Exchanger Out)

Thermistor (Outdoor)

3

Thermistor (Room)

Thermistor (Pipe)

Page 5

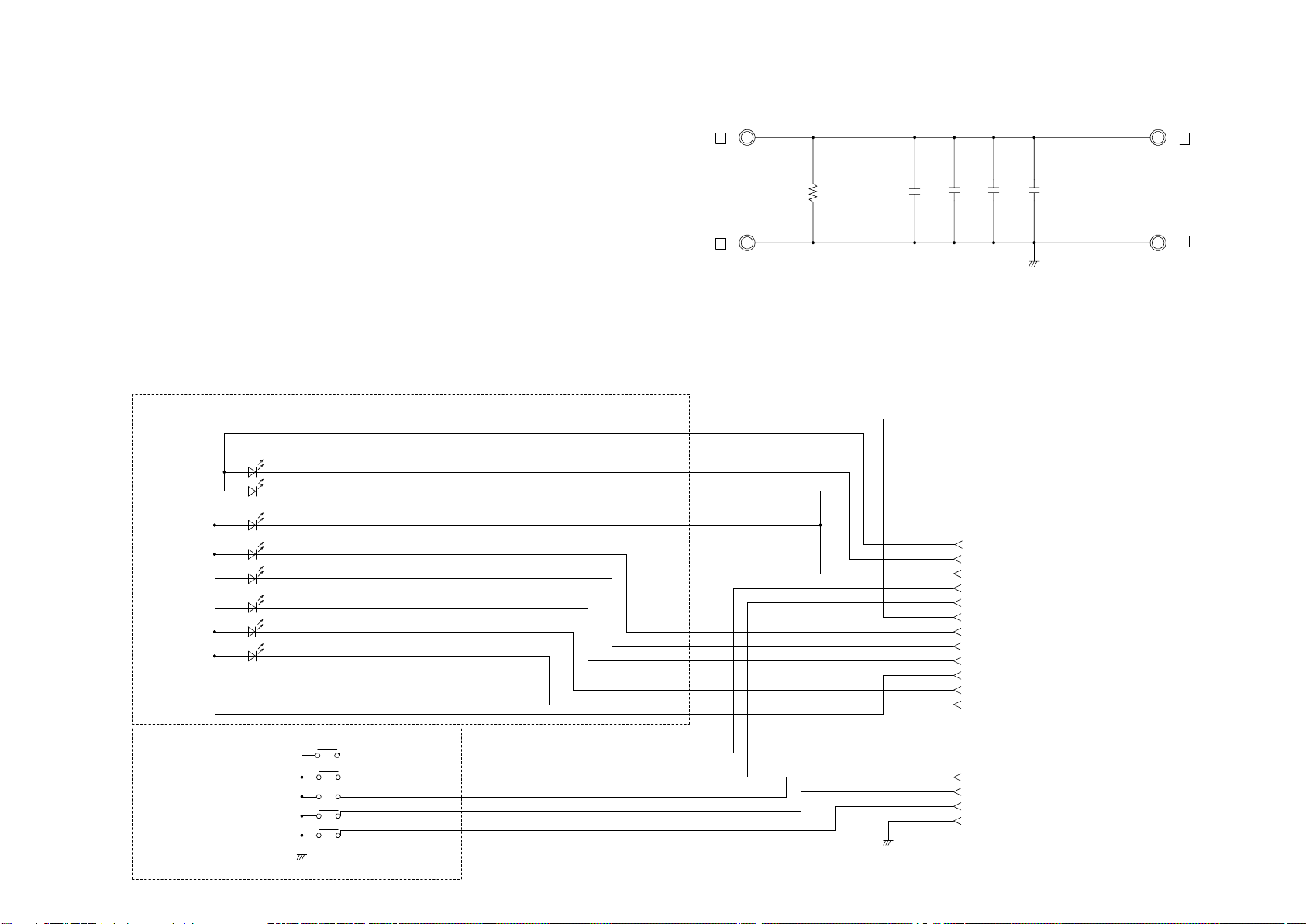

CIRCUIT DIAGRAM

INDOOR UNIT

FAN MOTOR

1

1

2

2

3

FM

3

4

4

5

5

6

6

7

7

8

8

BROWN

YELLOW

WHITE

BLACK

RED

OUTDOOR UNIT

INDICATOR PCB

CN401

RED

1

1

1

WHITE

2

2

WHITE

3

3

WHITE

4

4

WHITE

5

5

WHITE

6

6

WHITE

7

7

WHITE

8

8

WHITE

9

9

WHITE

10

10

WHITE

11

11

WHITE

12

12

WHITE

13

13

WHITE

14

14

WHITE

15

15

WHITE

16

16

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

CN40

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

2345

9

1

2345

1

78

9

78

23456

1

23456

1

MAIN PCB

1

2

1

2

CN400CN21CN20CN320

4

1

32

4

1

32

CN101

CN61

CN63

CN62

CN91

CN6

GRAY

GRAY

BLACK

BLACK

2

1

12121

CN5

CN7

1

2

3

CN12

4

5

MAIN PCB

1

2

3

CN11

4

5

1

CN9

2

3

1

CN10

2

1

1

CN105

2

2

3

3

4

4

5

5

6

6

E101

CN4 CN1

2

1

3 4 5 6 7 8

2

1

4 5 6 7 8

3

GRAY

GRAY

GRAY

GRAY

GRAY

2

1

4 5 6 7 8

3

2

1

3 4 5 6 7 8

CN104 CN101

F101

3.15A

250V

E102

POWER

SUPPLY

CN102

2

1

3

PCB

GRAY

EX. IN EX. OUT

( OPTION )

GREEN

GREEN

GRAY

GRAY

CN103

1

2

1

2

CN3

1

2

3

4

CN8

5

6

1

2

3

4

CN13

5

6

7

RED

1

1

CN14

CN6

WHITE

2

2

BLACK

3

3

1

2

2

1

3

2

1

3

GRAY

GRAY

GRAY

2

1

3

2

1

3

RED

W105

WHITE

W102

BLACK

W101

1

CN106

2

CN108

2

2

1

2

1

WHITE

WHITE

THERMISTOR

( PIPE TEMP. )

THERMISTOR

( ROOM TEMP. )

TERMINAL

1 2 3

TO WIRED

REMOTE CONTROL

TERMINAL

1 2 3

WHITE

1

32

1

32

WHITE

WHITE

1

54

154

WHITE

WHITE

WHITE

WHITE

TRANSISTOR PCB

( I P M )

TM302

TM301

W17

W16

TM102

U

V

W

TM303

TM304

TM101

TM305

RED

WHITE

BLACK

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

87654

87654

W306

9

9

32

32

CN301CN303

W307

CAPACITOR PCB

BLUE

YELLOW

BLACK

RED

BROWN

ORANGE

S

W8

W7

R

CM

T

COMPRESSOR

WHITE

BLACK

VIOLET

W13

WHITE

W12

CHOKE COIL

W103

W102

AC250V 10A

FUSE

F100

RED

ORANGE

BROWN

1

32

1

32

A C T P M

N

P

-I N

+I N

L2 L1

WHITE

FUSE

F100

AC250V 3.15A

FILTER PCB

YELLOW

654

654

WHITE

AC250V 10A

CN2 CN1

1

32

1

32

RED

WHITE

WHITE

1

32

1

32

FUSE

CN101

F101

654

654

WHITE

WHITE

WHITE

654

654

AC250V 30A

W111

ORANGE

FUSE

F103

CN111

CN800

CN802

W201

W112

1

2

1

2

BLACK

WHITE

ORANGE

W106

W113

W107

W108

W104

W101

W100

121

1

2

3

1

2

3

4

5

1

2

3

4

1

2

3

4

121

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

RED

RED

2

BLACK

1

2

BLACK

3

BLACK

1

BLACK

2

3

BLACK

4

BLACK

5

BLACK

1

BLACK

2

BLACK

3

BLACK

4

RED

1

2

WHITE

3

BLACK

4

BLACK

BLACL

2

RED

1

2

BLUE

3

ORANGE

4

YELLOW

5

WHITE

6

RED

1

2

BLACK

3

WHITE

4

YELLOW

5

BROWN

6

RED

1

2

BLACK

3

WHITE

4

YELLOW

5

BROWN

6

RED

GREEN

WHITE

BLACK

WHITE

BLACK

TERMINAL

HIGH PRESSURE SWITCH

THERMISTOR

( OUTDOOR TEMP. )

THERMISTOR ( PIPE TEMP. )

THERMISTOR

( PIPE - MID. TEMP. )

THERMISTOR ( DICHARGE TEMP. )

THERMISTOR

( COMP. SHELL TEMP. )

PS

4WV

1 2 3

4-WAY VALVE

PMV

EXPANSION VALVE

FM

FM

FAN MOTOR

( UPPER )

FAN MOTOR

( LOWER )

L N

POWER SOURCE

COIL

2013.01.22 4

Page 6

INDOOR PCB

CIRCUIT DIAGRAM

CONTROL UNIT

EZ-01229HSE

OUTDOOR UNIT

UL1015

AWG16

GREEN

UL1015

AWG16

GREEN

E101

E102

3

2(N)

1

TERMINAL

UL1015

UL1015

AWG20

BLACK

AWG20

WHITE

UL1015

AWG20

RED

W101 W102 W105

POWER SUPPLY PCB

K06AL-1106HSE-P0

2-1

CN2

2-2

2-3

B5P-SHF-1AA

2-4

WHITE

2-5

15-1

15-2

CN15

15-3

B06B-XASK-1-A

15-4

WHITE

15-5

15-6

MAIN PCB

K06AK-120WHSE-C1

3-1

3-2

CN3

3-3

B06B-PASK-1

3-4

WHITE

3-5

3-6

CN8

B02B-XASK-1-A

WHITE

CN7

B02B-XAYK-1-A

YELLOW

CN5

B02B-XAKK-1-A

BLACK

CN13

B07B-PASK-1

WHITE

CN14

B03B-XAKK-1-A

BLACK

7-1

7-2

13-1

13-2

13-3

13-4

13-5

13-6

13-7

14-1

14-2

14-3

8-1

8-2

5-1

5-2

BLACK

BLACK

GRAY

GRAY

EMI FILTER

ZCAT1518-0730

2 TURNS

THERMISTOR

( ROOM TEMP. )

THERMISTOR

( PIPE TEMP. )

DC FAN MOTOR

F M

NORMAL COIL

RLEY41-22

22mH, 2.2A

1

2

3

4

5

6

7

8

BLACK

WHITE

YELLOW

BROWN

UL1015 AWG22 x 5

DRAIN PUMP

EX. OUT

EX. IN

WHITE

WHITE

UL1015 AWG20 x 2

POWER DRIVE

104-1

RED

105-6

105-5

105-4

105-3

105-2

105-1

106-1

106-2

103-1

103-2

102-1

102-2

102-3

108-1

108-2

CN105

B5P6-VH-B

WHITE

CN106

B2P3-VH-B-E

BLUE

CN103

B2B-XH-AM

WHITE

CN102

B3B-XH-AM

WHITE

CN108

B2P3-VH-B

WHITE

B08B-PASK-1

B03B-PASK-1

CN104

WHITE

CN101

WHITE

104-2

104-3

104-4

104-5

104-6

104-7

104-8

101-1

101-2

101-3

GRAY

GRAY

GRAY

GRAY

GRAY

GRAY

GRAY

GRAY

UL1430 AWG26 x 8

DC SUPPLY

GRAY

GRAY

GRAY

UL1430 AWG26 x 3

EMI FILTER

ZCAT1518-0730

2 TURNS

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

1-1

1-2

1-3

CN4

B08B-PASK-1

WHITE

CN1

B03B-PASK-1

WHITE

CN6

B02B-PAMK-1

GREEN

CN10

B02B-PAOK-1

ORANGE

CN11

B05B-XASK-1-A

WHITE

CN12

B05B-XARK-1-A

CN9

B03B-XARK-1-A

6-1

FRESH AIR

6-2

TERMINAL 1

10-1

HEATER

10-2

11-1

11-2

11-3

11-4

11-5

12-1

12-2

12-3

12-4

RED

12-5

9-1

9-2

9-3

FLOAT SWITCH

RED

WIRED REMOTE CONTROL

EARTH WIRE

UL1430 AWG22 RED

UL1430 AWG22 BLACK

UL1430 AWG22 WHITE

2

3

2013.01.21 5

Page 7

DC SUPPLY

( TEST )

( SP PCB )

POWER DRIVE

( FRESH AIR )

( HEATER )

CN1

B03B-PASK-1

CN2

B5P-SHF-1AA

CN3

B06B-PASK-1

CN4

B08B-PASK-1

CN6

B02B-PAMK-1

CN10

B02B-PAOK-1

INDOOR UNIT

MAIN PCB

K06AK-120WHSE-C1

D4

1SS355

I C8

NJM7812

I

123

O

1

2

3

1

2

3

4

5

1

2

3

4

5

6

1

2

3

4

5

6

7

8

13.5V

1

2

1

2

5V

13.5V

13.5V

5V

C1

10/

50V

R15 - R18

10k <1/10W> x 4

R24, R23, R32

5V

10k <1/10W> x 3

<1/10W>

+

I C2

NJM7805

R26

10k

G

1

I

G

2

5V

R33

10k

<1/10W>

<1/10W>

1SS355

3

O

<1/10W>

<1/10W>

<1/10W>

R27

330

12V13.5V

C2

+

10/

50V

D1

5V

C3

0.01

<F>

R19 - R22

1.0k <1/10W> x 4

R66

10k

R63 - R65

1.0k <1/10W> x 3

R67

1.0k

C35, C12, C11

1000p <R> x 3

R25

1.0k

<1/10W>

C15

0.01

<F>

R31

10k

C17

0.01

5V

<F>

R34

1.0k

<1/10W>

C4

0.01

<F>

R28

10k

<1/10W>

1

Q1

DTC124EKA

C18

0.01

<B>

5V

C14

1000p

<R>

<1/10W>

3

2

C32

100/

6.3V

C5

1000p

<R>

C37

0.1

<F>

R29

390

5V

C16

0.01

<F>

5V

1

2

1

2

1

2

C25

10/

50V

12V

R48

10k

<1/10W>

I C4

uLN2003

I 1

I 2

I 3

I 4

I 5

I 6

I 7

GND

CN8

B02B-XASK-1-A

THERMISTOR ( ROOM TEMP. )

CN7

B02B-XAYK-1-A

CN5

B02B-XAKK-1-A

THERMISTOR ( PIPE TEMP. )

5V

C26

+

0.01

<F>

D2

DAN217U

1 2

3

SK

9

O1

16

O2

15

O3

14

13

O4

O5

12

O6

11

O7

10

8

R50

10k

<1/10W>

5V

10k <1/10W> x 2

12V

D3

D1FS4A

5V

1

2

3

4

5

6

R68, R52

1

2

3

4

5

6

7

13.5V

1

2

3

4

5

1

2

3

4

5

1

2

3

CN15

B06B-XASK-1-A

( FLASH )

CN13

B07B-PASK-1

( INDICATOR PCB )

CN14

B03B-XAKK-1-A

WIRED REMOTE

CONTROL

CN11

B05B-XASK-1-A

LOUVER ( UP / DOWN )

CN12

B05B-XARK-1-A

LOUVER ( RIGHT / LEFT )

R1 - R3

5V

10k <1/10W> x 3

JM1

JM2

JM3

R4 - R6

1.0k <1/10W> x 3

C33

0.1

<F>

3

2

C28

0.1

<F>

R70

10k

<1/10W>

Q3

DTC124EKA

1

+

C7

1000p

<R>

C36

0.47

<F>

C8 - C10

0.1 <F> x 3

I C1

uPD78F0536

34

AVDD

VDD0

39

I C

36

RST*

VDD1

P00

43

P34

44

P01

P35

45

P02

P36

46

P03

P40

P41

33

P10

32

P11

P42

P43

31

P12

30

P13

P44

29

P14

P45

28

P15

P46

27

P16

P47

P50

26

P17

P51

18

P20

19

P21

P52

20

P22

P53

21

P23

P54

P55

22

P24

23

P25

P56

11

P30

P57

12

P31

P64

13

P32

P65

14

P33

P66

38

XT1

P67

37

XT2

P70

41

X1

P71

40

X2

P72

25

AGND

P73

9

GND0

P74

42

GND1

P75

35AVREF

10

24

15

16

17

57

58

59

60

61

62

63

64

1

2

3

4

5

6

7

8

53

54

55

56

47

48

49

50

51

52

3

2

1

X1

8.00MHz

<FCR>

JM5

0R0

C31

0.01

<F>

R69

10k

<1/10W>

R45

10k

<1/10W>

R46

1.0k

<1/10W>

C27

0.1

<B>

5V

R56

100k

<1/10W>

C38

0.1

<B>

R37

10k

<1/10W>

FLOAT SWITCH

CN9

B03B-XARK-1-A

1

2

3

5V

I C7

S80842

2

VDD

1

OUTNCGND

R40

10k

<1/10W>

1

VCC

CS

2

DO

SK

D I

3

NC

6

NC

GND

I C5

S-93C66BD0 I

C29

<F>

C30

<F>

C34

<F>

3

NC

4

0.1

0.1

0.1

<1/10W>

<1/10W>

<1/10W>

<1/10W>

10k <1/10W>

R41

1.0k

R57

1.0k

R58

1.0k

R62

1.0k

R43, R44

x 2

R59

10k

<1/10W>

R60

49.9k

<1/10W>

R61

49.9k

<1/10W>

5V

5V

8

C13

4

7

0.1

5

<B>

C23

0.01

<F>

5V

R55

10k

<1/10W>

C24

1000p

<R>

R42

<1/10W>

I C6-2

BA10393F

-

7

+

I C6-1

BA10393F

-

1

+

R47

390

<1/10W>

47

12V

6

5

2

3

R54

15.4k

<1/10W>

R53

28k

<1/10W>

13.5V

R35

1.0k

<1/10W>

B Z

BZ1

PKM13EPYH-4000-A0

1

2

3

4

5

6

7

13.5V

CFS-0402MC

I C3

uPA2003

9

SK

16

O1

O2

15

14

O3

13

O4

12

O5

O6

11

10

O7

8

GND

5V

SW1

8

4

7

3

6

2

5

1

1

I 1

2

I 2

3

I 3

4

I 4

5

I 5

I 6

6

7

I 7

R11 - R14

10k <1/10W> x 4

R7 - R10

1.0k <1/10W> x 4

C19

0.1

<B>

C20 - C22

0.1 <F>

x 3

Q2

DTC124EKA

1

3

2

R36

0R0

2013.01.21 6

Page 8

W101

BLACK

W102

WHITE

I C26-10

I C26-14

F101

3.15A

250V

FC51FL x 2

FH101

N

FH102

E101

GREEN

L

SA101

RA-362M

VA101

470V

<TNR>

VA102

470V

<TNR>

C101

0.22

<LE>

LF101

ELF20N030A

1 2

4

NORMAL COIL

CN108

B2P3-VH-B

2

1

D101

1

D3SB60

3

C105

0.010

C104

0.22

<R41>

3

<LE>

C106

0.010

<LE>

E102

GREEN

2

4

C107

+

270/

450V

C118

0.01

<KH>

C109

220p

<B>

R105

75

<RS-2W>

R106

1.5

<RS-2W>

340V

2

3

<1/10W>

Q101

2SC5354

Q102

2SC1815

R107

100

R104

330k

<2W>

1

1

D107

RD16

<B1>

2

3

1SR139-600

C112

330/

25V

C108

4700p

<FNS>

D102

15V

+

R110

10k

<1/10W>

R103

62k

<RS-2W>

D106

D1FL20U

D1FL20U

D104

MTZJ5.1B

D109

MTZJ5.1B

D103

T101

ZFT22B03-C

2

3

5

6

7

8

C110 0.047

<ECQV>

R108

100

<1/2W>

D105

D1FL20U

R109

330

<1/4W>

+

D2FL20U

12

10

C111

100/

25V

A

D108

C114

0.01

<KH>

C115

0.01

<KH>

+

C113

1000/

25V

R111

10k

<1/10W>

13.5V

CN105

R115

6.8k

<1/4W>

R113

330

<1/10W>

340V

B5P-VH-B

6

5

4

3

2

1

K101

G5NB-1A

4

213

5V

I C101

TLP621

<GB>

4

3 2

L103

BLm18

<AG601>

DC FAN MOTOR

13.5V

L102

BLm18

<AG601>

<1/10W>

1

C116

0.01

<B>

R112

330

CN103

B2B-XH-AM

1

2

CN102

B3B-XH-AM

3

2

1

EX. OUT

EX. IN

W105

RED

SERIAL

15V

B08B-PASK-1

POWER DRIVE

DC SUPPLY

CN104

CN101

B03B-PASK-1

I C104

5V

1

2

3

4

5

6

7

8

TLP621

<GB>

1

2

15V

4

3

R116

1.0k

<1/4W>

R117

820

<1/4W>

I C103

+

C117

100/

25V

A

A

TLP621

4

3

5V 13.5V

1

2

3

C121

0.1

<F>

C120

0.1

<F>

<GB>

1

2

A

15V

R114

4.7k

<1/10W>

2013.01.21 7

I C 1 0 5

H I 2 0 0 3 R 3

18 14 10 5

VA103

8

0.01

<F>

I C26-14

7

L

I C26-14

L

I C26-10

I C26-10

6

N

K102

G5NB-1A

3 2

1

13.5V

4

N

5

RC101

120/

0.2

4 3

4 3

2 1

2 1

5V

CN106

B2P3-VH-B-E

2

1

INDOOR UNIT

POWER SUPPLY PCB

K06AL-1106HSE-P0

DRAIN PUMP

Page 9

OUTDOOR PCB CIRCUIT DIAGRAM

INVERTER ASSEMBLY

EZ-0121HHUE

POWER SOURCE

AC230V

50Hz

INDOOR UNIT

DC FAN MOTOR 1

DC FAN MOTOR 2

EXPANSION VALVE

4-WAY VALVE

PRESSURE SWITCH

PRESSURE SENSOR HIGH

THERMISTOR

( OUTDOOR TEMP. )

THERMISTOR ( DISCHARGE )

THERMISTOR ( COMP. TEMP. )

THERMISTOR ( PIPE TEMP. )

THERMISTOR

( PIPE - MID. TEMP. )

PRES

SENSOR

H I

N

L

3

2

1

FM

FM

M

UL1430 AWG22 RED

UL1430 AWG22 RED

NO MARKING

BROWN

GRAY

RED

NO MARKING

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

EMI FILTER

RFC-13

2T

UL1015

AWG20

WHITE

EMI FILTER

ZCAT2132-1130

2T

RED

BLACK

WHITE

YELLOW

BROWN

RED

BLACK

WHITE

YELLOW

BROWN

RED

BLUE

ORANGE

YELLOW

WHITE

BLACK

BLACK

RED

WHITE

BLACK

UL1015

AWG16

GREEN

EARTH

UL1015

AWG12

BLACK

UL1015

AWG12

WHITE

UL1015

AWG20

BLACK

CN800

B6P-VH-B

1

WHITE

2

3

4

5

6

CN802

1

B6P-VH-B-C

2

BLACK

3

4

5

6

CN111

1

B06B-XARK-1-A

2

RED

3

4

5

6

CN6

1747052-1

1

WHITE

2

CN9

1

B4P-VH-B-C

2

BLACK

3

4

CN101

1-1871843-2

1

RED

2

CN91

1871843-4

1

WHITE

2

3

4

CN61

B03B-PASK-1

1

WHITE

2

3

CN62

B04B-PASK-1

1

WHITE

2

3

4

CN63

1

B05B-PASK-1

2

WHITE

3

4

5

W100

B

W101

B

W104

B

W113

B

W106

B

F100

AC250V 10A

F101

AC250V 10A

UL1015

AWG20

BLACK

UL1015

AWG20

RED

W201

B

RED

SERIAL

AC250V 3.15A

FLASH ( MAIN )

CN5

B06B-PASK-1

WHITE

6 543 2 1

F103

AC250V 30A

AC250V 3.15A

FILTER PCB

K10BR-1000HUE-FL0

MAIN-POWER PCB COM.

CN101

B06B-XN I SK-A-1

WHITE

W107BW108

B

1 2

CN1

3-1747052-4

YELLOW

AC I N

F202

UL1015

AWG20

WHITE

1 234 5 6

RED

WHITE

WHITE

WHITE

WHITE

1 234 5 6

CN2

B06B-XN I SK-A-1

WHITE

MAIN-POWER PCB COM.

FLASH ( INV )

CN350

B06B-PAKK-1

BLACK

6 543 2 1

F104

WHITE

UL1007 AWG24 x 6

B02B-XAYK-1-A

B02B-XAMK-1-A

B02B-XAKK-1-A

B02B-XAEK-1-A

UL3271

AWG20

ORANGE

BLACK

BLUE

W112

1

2

1

2

1

2

1

2

W111

B

PTC THERMISTOR

ZPR0YCE400A300

CN10

YELLOW

CN11

GREEN

CN12

CN13

K10BS-1203HUE-C1

W102

B

W103

B

B

UL3271

AWG20

ORANGE

EX I N 1

EX I N 2

EX OUT 1

EX OUT 2

MAIN PCB

UL1015

AWG12

ORANGE

UL1015

AWG12

BROWN

CHOKE COIL A

L=0.32mH 30A

UL1015

AWG12

WHITE

L1 L2

ACTPM

( PM-601BSG )

6 543 2 1

ACTPM CONTROL

YELLOW

ORANGE

RED

CN400

B04B-PAKK-1

BLACK

EMI FILTER

ZCAT2132-1130

1T

UL1015

AWG12

WHITE

+

-

UL1015

AWG14

WHITE

P

UL1015

AWG14

VIOLET

N

EMI FILTER

TFC-25-15-12A

1T

BROWN

UL1430 AWG26 x 4

CAPACITOR PCB

K05FB-1000HUE-P0

W12

B

W13

B

WHITE

BLACK

UL1015 AWG20 x 2

CN21

1-1747052-2

RED

DC VOLT I N

I PM CONTROL

B09B-PL I SK-1

9 8 7

WHITE

WHITE

WHITE

1 2 31 24 3 2 1

B09B-PL I SK-1

I PM CONTROL

W7

B

W8

B

CN301

WHITE

6 543 2 1

WHITE

WHITE

WHITE

WHITE

WHITE

4 567 8 9

CN20

WHITE

UL1015

AWG14

RED

UL1015

AWG14

BLACK

UL1015

AWG14

YELLOW

UL1015

AWG14

BLUE

WHITE

TM101

TM102

W16

B

W17

B

K10AY-1003HUE-TR0

TM301

TM302

W306

B

W307

B

MAIN-I NV PCB COM.

CN303

B05B-PL I RK-1

RED

5 4 3 2 1

WHITE

WHITE

UL1007 AWG26 x 9

1 2 3 4 5

CN320

B05B-PL I RK-1

RED

MAIN-I NV PCB COM.

+

-

D100

LL25XB60

1

4

2

3

TRANSISTOR PCB

( I P M )

WHITE

WHITE

WHITE

UL1007 AWG26 x 5

CN40

WHITE

CN14

RED

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

B16B-PASK-1

B6 ( 7-3 ) B-XN I RK-B-2

TM305

TM304

TM303

UL1007 AWG24 x 16

RED

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

RED

WHITE

BLACK

UL3271 AWG12 x 3

EMI FILTER

ZCAT2132-1130

1T

CM

CN401

1

B16B-PASK-1

WHITE

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

INDICATOR PCB

K10BC-1000YUE-D0

COMPRESSOR

2013.01.22 8

Page 10

OUTDOOR UNIT

MAIN PCB - 1

K10BS-1203HUE-C1

CN1

3-1747052-4

YELLOW

AC I N

CN6

1747052-1

WHITE

4-WAY VALVE

CN9

B4P-VH-B-C

BLACK

BASE HEATER

W201

SERIAL

CN21

1-1747052-2

RED

DC VOLT I N

CN350

B06B-PAKK-1-A

BLACK

FLASH ( I NV )

B06B-XN I SK-A-1

CN2

WHITE

MAIN-POWER PCB COM.

R233

180

<1/4W>

L232

L151

330p <CH> x 2

5V-2

5V-3

+

C167, C168

330p <CH>

x 2

D153

RF101L2S

C231

+

470/

C235, C236

330p <CH> x 2

D232 RF101L2S

C162, C163

330p <CH> x 2

1

3

D151

RF601T2D

C164, C165

D152

RF101L2S

S-93C66BD0 I

1

CS

D I

3

2

SK

5

GND

<1/10W>

P_RESET

L300

BLm18AG601

C302

+

4.7/

50V

C306

0.1

<B>

340V

D200

D3F60

L152

BLm31PG121

15V

1

2

R215 - R218

1.0M <1/4W>

x 4

C211

+

33/

450V

12V

2

1

CR6

RE1201

0.1/120

4

3

2

CR9

1

RE1201

B

RED

1

2

JM210

F202

3.15A

250V

FH203

TP00351-31

x 2

FH204

JM209

18 14

8

I PS-1124

2

1

K6

FTR-F3

2

1

K9

FTR-F3

H Y I C 2 0 1

H U 2 0 0 1 R 2

10 54321

7 6 5 4 3

PIN 1

340V

C23

+

33/

450V

4

3

5V

P_RXD_I NV

5V-2

5V-2

R350

1

2

3

4

5

6

12V

6

5

4

5V-2

3

2

1

<1/10W>

<1/10W>

R600

1.0M

<1/10W>

10k

R351

10k

5V-2

2

3

RESET_I N

P_FLMD0

P_TEST_S I

P_TEST_SO

D600

1

DAN217U

C600

0.1

<B>

P_AN_CT

uLN2003

16

15

uLN2003

I C42-1

I C42-2

P_ON_AVAILABLE

P_TXD_I NV

1

2

3

4

12V

16 1

P_RUSH_R

P_PR

I C10-4

uLN2003

13 4

I C10-1

uLN2003

2 1

C330

0.01

<B>

C331

0.01

<B>

R338

10k

<1/10W>

P_4WV

P_BH

R141

47k

<1/10W>

R330

1.0k

<1/10W>

R331

1.0k

<1/10W>

JM332

0R0

D

R340, R341

10k <1/10W>

x 2

R342 - R345

10k <1/10W>

<1/10W>

2SC2412K

x 4

R140

27k

Q142

<BQ>

5V-2

1

JM330

0R0

JM331

0R0

R332

1.0k

<1/10W>

TOP256PN

8

7

6

5

C212

47/35V

5V

3

R144

2

<1/10W>

I C10-5

uLN2003

12 5

C332

I C2

S

S

S

S

C213

0.1 <B>

+

R142

4.7k

<1/10W>

1.0k

0.01

<B>

4

D

2

C

1

M

R211

47 <1/10W>

R143

1.0k

<1/10W>

C142

R336

10k

<1/10W>

R337

10k

<1/10W>

P_HS

P_SCK

P_S I

P_SO

P_FLMD0

P_FLMD1

BLm21AG601

0.01

<B>

D203

1SS355

D204

UDZS8.2B

L202

0R0

L203

D205

1SS355

BLm31PG121

C141

0.1

<B>

P_MAIN_SO1

P_MAIN_SO2

P_MAIN_S I

R203

1.0k

<1/10W>

L291

C292, C293

330p <CH>

P_SERIAL_RXD

P_I NT_POWER

P_SERIAL_TXD

R301

10k

<1/10W>

R219, R220

1.8k <1/4W>

R223, R224

22 <1/4W>

C204 - C206

1.0 <B> x 3

D290

UF4005

x 2

C361

10k

<1/10W>

5V-2

P_MAIN_SO2

x 2

x 2

R293

180

<1/4W>

JM60

R294

8.2k

<1/4W>

C310

0.1

<B>

P_MODEL1

P_MODEL0

P_RTR I P

P_TR I P

P_CP_POS

P_TEST_SO

P_TEST_S I

P_S I

P_SO

P_SCK

P_UP

P_UN

P_VP

P_VN

P_WP

P_WN

P_AN_I L

P_AN_DC

P_AN_CT

C214

2200p

<D>

D211

ST03D-82

C291

+

100/

50V

A

C19

0.1

<B>

I C310

S80842

3

NC

4

GND

RESET_OUT

12

13

14

15

16

17

18

22

23

24

25

26

27

19

20

21

28

29

30

31

34

35

64

63

62

61

60

59

58

57

56

55

ZTF0608

1

2

3

4

5

6

8

D12 1SS355

I C5

BA17818

1

2

<1/10W>

2

VDD

1

OUT

RESET_I N

( I NV. )

I C300

uPD70F3747

P00

VDD

P01

EVDD

P02

P03

P04

P913

P05

P914

P06

P915

P30

P31

P32

P33

P34

PCM0

P35

PCM1

P40

PDL0

P41

PDL1

P42

PDL2

P50

PDL3

P51

PDL4

P52

PDL5

P53

PDL6

P54

PDL7

P55

AVREF0

P70

FLMD0

P71

REGC

P72

P73

P74

RESET*

P75

P76

P77

AVSS

P78

EVSS

P79

VSS

R311

22k

P90

P91

P96

P97

P98

P99

X1

X2

XT1

XT2

T1

3IGO

23V

C10

+

10/

50V

A

5V-2

C311

1000p

<B>

C313

1000p

<B>

4

33

36

37

42

43

44

38

39

40

41

45

46

47

48

49

50

51

52

53

54

1

3

5

7

8

9

10

11

2

32

6

R300

<1/10W>

16

15

13

12

11

10

9

<1/10W>

C301

0.1

<B>

P_MAIN_SO1

P_MAIN_S I

P_PR

P_AF_EN

P_HS

P_RUSH_R

P_E2P_D I

P_E2P_SK

P_E2P_CS

P_FLMD1

P_FLMD0

P_RESET

10k

18V

R310

10k

C233, C234

P_E2P_CS

P_E2P_D I

P_E2P_SK

R313

1.0k

<1/10W>

R302

0R0

3 1

D231

RF301B2S

330p <CH>

x 2

BLm31PG121

BLm31PG121

<1/10W>

5V-3

C300

+

4.7/

50V

C303

<B>

C305

0.1

<B>

X300

2

8.00MHz

<CSTS>

R308

0.1

C304

4.7/

50V

10k

L155

0R0

25V

2

I C307

R307

10k

P_RTR I P

P_TR I P

R234 180

<1/10W>

R162 180

<1/10W>

8

VCC

4

DO

7

NC

6

TEST

R163

180

<1/10W>

C152

220/

50V

R161 180

<1/10W>

C151

470/

25V

P_LED

P_AN_I L

C322

1000p

<B>

P_AN_DC

P_CP_POS

12V-2

+

D

C232

+

100/

50V

12V

+

C155

0.1

<B>

5V-2

10k <1/10W> x 2

I C41-7

uLN2003

7

C320

10k

<1/10W>

C321

0.1

<B>

<1/10W>

C323

<B>

C324

470p

<CH>

<1/4W>

R232

62k

<1/10W>

-10V

C307

0.1

<B>

R303, R304

P_MODEL0

P_MODEL1

10

R322

1.0k

0.1

15V

R231

33k

C15

100/

25V

P_AF_EN

12V

R321

1.0k

<1/10W>

R323

1.0k

<1/10W>

R324

4.7k

<1/10W>

1SS355

1

+

5V-2

D38

SLR-325VC

<RED>

R38, R39

1.0k <1/10W>

x 2

5V-2

R326

10k

<1/10W>

5V-2

R329

1.0k

<1/10W>

D13

I C4

7805

I

G

2

I C42-4

uLN2003

4

2

3

O

C16

0.1

<B>

3

5V

13

<1/10W>

R328

10k

<1/10W>

5V-2

1

D321

DAN217U

R325

1.0M

<1/10W>

R400

1.0k

5V-2

C17

+

4.7/

50V

R404

<1/10W>

1.0k

R401

12V

<1/10W>

1 4

2

I C400

PS2561L-1-V

R403, R402

270 <1/10W>

1.0k

P_UP

P_VP

P_WP

P_UN

P_VN

P_WN

1%

x 2

RD24FM

18V

3

D400

18V

C400

0.01

<B>

A

C401

0.01

<B>

A

A

15V-2

C46

0.1

<B>

-10V

1

2

3

4

1

2

3

4

5

6

7

8

9

5

4

3

2

1

CN400

B04B-PAKK-1

BLACK

ACTPM CONTROL

CN20

B09B-PL I SK-1

WHITE

I P M CONTROL

CN320

B05B-PL I RK-1

RED

MAIN-I NV PCB COM.

2013.01.21 9

Page 11

CN800

B6P-VH-B

WHITE

DC FAN MOTOR 1

CN802

B6P-VH-B-C

BLACK

DC FAN MOTOR 2

CN111

B06B-XARK-1-A

EXPANSION VALVE

CN91

1871843-4

WHITE

PRESSURE SENSOR HIGH

CN101

1-1871843-2

PRESSURE SWITCH

CN61

B03B-PASK-1

WHITE

THERMISTOR ( OUTDOOR TEMP. )

CN62

B04B-PASK-1

THERMISTOR ( DISCHARGE TEMP. )

WHITE

THERMISTOR ( COMP. TEMP. )

CN63

B05B-PASK-1

THERMISTOR ( PIPE TEMP. )

WHITE

THERMISTOR ( PIPE - MID. TEMP. )

OUTDOOR UNIT

MAIN PCB - 2

K10BS-1203HUE-C1

1

2

3

4

5

6

1

2

3

4

5

6

12V

1

RED

2

3

4

5

6

5V

1

2

3

4

RED

1

2

1

2

3

1

2

3

4

1

2

3

4

5

C60

0.1

<B>

C91

0.1

<B>

L91

BLm18AG601

R101

2.2k

<1/10W>

L60

BL02Rn1

R65 38.3k

R63 4.75k

<1/10W>

R69 4.75k

<1/10W>

5V

<1/10W>

1%

R61

13k

<1/10W>

R67

13k

<1/10W>

1%

1%

340V

340V

5V

C802

0.1

<B>

D801

RD24FM

R801

22k

<1/10W>

C805

0.1

<B>

16

16

15

15

C93

1000p

<B>

C101

0.1

<B>

BL02Rn1

BL02Rn1

1

1

2

2

DAN217U

R64

10k

<1/10W>

R60

10k

<1/10W>

R66

10k

<1/10W>

R62

10k

<1/10W>

R68

10k

<1/10W>

L800

<1/10W>

C800

+

4.7/

50V

L801

D803

RD24FM

C803

+

4.7/

50V

I C111-1

uLN2003

I C112-1

uLN2003

I C111-2

uLN2003

I C112-2

uLN2003

D91

<1/10W>

15V-2

R800

27k

2

D800

DAN217U

15V-2

R804

27k

<1/10W>

2

3

D802

DAN217U

3

R91

10k

C63

0.1

<B>

C61

0.1

<B>

C64

0.1

<B>

C62

0.1

<B>

C65

0.1

<B>

5V

3

5V

21

5V

1

15V-2

5V

1

15V-2

1

3

R802

10k

<1/10W>

R803

1.0k

<1/10W>

1

3

R806

10k

<1/10W>

R807

1.0k

<1/10W>

R93

10k

<1/10W>

R102

10k

<1/10W>

P_AN_TH1

P_AN_TH2

P_AN_TH3

P_AN_TH4

P_AN_TH5

Q801

DTA143EUA

2

3

2

Q800

1

DTC143EUA

C801

0.01

<B>

Q803

DTA143EUA

2

3

2

1

DTC143EUA

C804

0.01

<B>

P_EEV1_P4

P_EEV1_P3

P_EEV1_P2

P_EEV1_P1

Q802

RESET

P_FM1_PWM

P_FM1_FB

P_FM2_PWM

P_FM2_FB

P_AN_PS_HP

C95

0.01

<B>

C102

0.01

<B>

P_RXD_PCS

P_TXD_PCS

P_JM

MODE

P_PSW

C4

0.01

<B>

EEP_CS

EEP_I O

EEP_SK

1000p

<1/10W>

R22

10k

<1/10W>

R27

10k

<1/10W>

R34

1.0k

<1/10W>

C31

<B>

R2

1.0k

C28

<B>

5V

0.1

S-93C66BD0 I

1

3

2

5

<1/10W>

R26

47k

<1/10W>

5V

C26

0.1

<B>

C3

0.1

<B>

<1/10W>

5V

<1/10W>

I C21

CS

D I

SK

GND

R24

10k

C66

10k

R1

10k

VCC

DO

NC

TEST

S80842

2

1

8

4

7

6

I C26

VDD

OUTNCGND

P_SW_MODE

MODE

RESET

P_AN_TH5

P_AN_TH3

P_LED

P_AN_TH1

P_AN_TH4

P_AN_TH2

P_I NT_POWER

P_SERIAL_RXD

P_DEMAND2

P_DEMAND1

P_LED3

P_LED2

P_4WV

P_FM1_PWM

P_LED1

P_JM

P_FM2_PWM

P_BH

P_EX_I N2

P_EX_I N1

P_FM2_FB

P_SW_SELECT

P_EX_OUT1

P_EX_OUT2

P_FM1_FB

5V

C21

0.1

<B>

3

4

R35

1.0k

<1/10W>

CN12

B02B-XAKK-1-A

BLACK

10

I C11

I C12

R95

4.7k

<1/10W>

R96

4.7k

<1/10W>

R97

4.7k

<1/10W>

R98

4.7k

<1/10W>

R99

4.7k

<1/10W>

R72

3.3k

<1/10W>

R73

3.3k

<1/10W>

R74

3.3k

<1/10W>

12V

7

I C10-7

uLN2003

6

I C10-6

uLN2003

C11

0.01

1

<B>

2

C12

0.01

1

<B>

2

R83

1.0k

<1/10W>

R84

1.0k

<1/10W>

P_DEMAND3

12V-2

12V-2

12V-2

12V-2

12V-2

12V-2

I C6

PS2561L-1-V

1

2

I C7

PS2561L-1-V

1

2

I C8

PS2561L-1-V

1

2

11

12V-2

R12

4.7k

<1/10W>

R13

4.7k

<1/10W>

5V

R80

10k

<1/10W>

5V

R81

10k

<1/10W>

C82

R85

0.01

1.0k

<B>

<1/10W>

R103, R108, R113

560 <1/10W> x 3

R104, R109, R114

560 <1/10W> x 3

R105, R110, R115

560 <1/10W> x 3

R106, R111, R116

560 <1/10W> x 3

R107, R112, R117

560 <1/10W> x 3

I C40-1

uLN2003

1

16

I C40-2

uLN2003

15

2

I C40-3

uLN2003

3

14

R20

4.7k

<1/10W>

4

3

R23

D

4.7k

<1/10W>

4

3

R25

D

4.7k

<1/10W>

4

3

D

3

12V

4

FTR-F3

3

12V

4

FTR-F3

12V-2

5V

R82

10k

<1/10W>

R42, R41

1.0k <1/10W>

x 2

R44, R43

1.0k <1/10W>

x 2

R46, R45

1.0k <1/10W>

x 2

12V-2

1

2

DTA143

3

1

2

3

1

2

3

1

2

K11

1

2

K12

R14, R29, R36

560 <1/10W> x 3

R15, R30, R37

560 <1/10W> x 3

Q1

EUA

Q2

DTA143

EUA

Q3

DTA143

EUA

12V-2

P_EX_OUT1

5V

C2

( MAIN )

I C1

R5F212C

1

P3_3

6

MODE

9

RESET*

11

VSS

75

VSS

77

VREF

66

P0_0

67

P0_1

68

P0_2

69

P0_3

70

P0_4

73

P0_5

74

P0_6

76

P0_7

57

P1_0

56

P1_1

55

P1_2

54

P1_3

P1_4

34

P1_5

33

32

P1_6

31

P1_7

30

P2_0

29

P2_1

28

P2_2

P2_3

27

26

P2_4

25

P2_5

P2_6

24

23

P2_7

51

P3_0

50

P3_1

53

P3_2

2

P3_4

80

P3_5

52

P3_6

79

P3_7

P4_3

7

8

P4_4

44

P4_5

5V

0.1

<B>

13

VCC

78

VCC

P4_6

12

10

P4_7

18

P5_0

17

P5_1

16

P5_2

15

P5_3

14

P5_4

5

P5_5

4

P5_6

3

P5_7

43

P6_0

72

P6_1

P6_2

71

P6_3

49

48

P6_4

47

P6_5

P6_6

45

46

P6_7

P7_0

65

P7_1

64

63

P7_2

P7_3

62

P7_4

61

60

P7_5

59

P7_6

58

P7_7

42

P8_0

41

P8_1

40

P8_2

39

P8_3

38

P8_4

37

P8_5

36

P8_6

35

P8_7

22

P9_0

19

P9_3

20

P9_2

21

P9_1

R31 - R33

10k <1/10W> x 3

C32

1000p

<B>

L1

BLm18AG601

C1

+

4.7/

50V

EEP_SK

EEP_CS

EEP_I O

P_SW_PUMP_DOWN

P_SW_EXIT

P_SW_ENTER

P_PSW

P_TXD_I NV

P_RXD_I NV

P_SERIAL_TXD

P_TXD_PCS

P_RXD_I NV

P_AN_PS_HP

P_DEMAND3

P_EEV1_P1

P_EEV1_P2

P_EEV1_P3

P_EEV1_P4

P_LED_COM3

P_LED_COM1

P_LED_COM2

P_ON_AVAILABLE

P_SW_PUMP_DOWN

P_SW_EXIT

P_SW_ENTER

P_SW_SELECT

P_SW_MODE

1

3

R3

0R0

C96

10k

<1/10W>

C40

0.01

<B>

C41

0.01

<B>

C42

0.01

<B>

C43

0.01

<B>

C44

0.01

<B>

P_LED1

P_LED2

P_LED3

CN5

B06B-PASK-1

WHITE

1

2

3

4

5

6

X1

2

8.00MHz

<CSTLS>

P_EX_I N1

P_EX_I N2

R52

1.0k

<1/10W>

R53

1.0k

<1/10W>

R54

1.0k

<1/10W>

R55

1.0k

<1/10W>

R56

1.0k

<1/10W>

I C41-4

uLN2003

4

I C41-5

uLN2003

5

I C41-6

uLN2003

6

FLASH ( MAIN )

C13

0.01

<B>

C14

0.01

<B>

R47

10k

<1/10W>

R48

10k

<1/10W>

R49

10k

<1/10W>

R50

10k

<1/10W>

R51

10k

<1/10W>

R78, R173

1.0k <1/10W>

x 2

13

R79, R174

1.0k <1/10W>

x 2

12

R86, R175

1.0k <1/10W>

x 2

11

I C41-1

uLN2003

P_LED_COM1

I C41-2

uLN2003

P_LED_COM2

I C41-3

uLN2003

P_LED_COM3

R18

1.0k

<1/10W>

R19

1.0k

<1/10W>

5V

5V

5V

5V

5V

R75

4.7k

<1/10W>

R76

4.7k

<1/10W>

R77

4.7k

<1/10W>

1 16

2

3

R16

10k

<1/10W>

R17

10k

<1/10W>

P_DEMAND1

P_DEMAND2

I C48

PS2561L-1-V

4

3

I C49

PS2561L-1-V

4

3

I C50

PS2561L-1-V

4

3

I C51

PS2561L-1-V

4

3

I C52

PS2561L-1-V

4

3

12V

R7, R170

1.0k <1/10W>

x 2

R8, R171

1.0k <1/10W>

x 2

15

R9, R172

1.0k <1/10W>

x 2

14

P_EX_OUT2

5V

5V

1

2

C48

0.01

<B>

1

C49

2

0.01

<B>

1

C50

2

0.01

<B>

1

C51

2

0.01

<B>

1

C52

2

0.01

<B>

I C13

PS2561L-1-V

1

2

I C14

PS2561L-1-V

1

2

I C15

PS2561L-1-V

1

2

R4

4.7k

<1/10W>

R5

4.7k

<1/10W>

R6

4.7k

<1/10W>

PS2561L-1-V

4

3

PS2561L-1-V

4

3

C80

0.01

<B>

C81

0.01

<B>

4

3

4

3

4

3

1

2

EX. OUT 1

CN13

B02B-XAEK-1-A

BLUE

1

2

EX. OUT 2

CN10

B02B-XAYK-1-A

YELLOW

1

2

EX. IN 1

CN11

B02B-XAMK-1-A

1

GREEN

2

EX. IN 2

D

CN14

B6 ( 7-3 ) B-XNIRK-B-2

RED

1

2

D

3

DEMAND OF RESPONSE

4

5

6

( CN40-4 )

( CN40-5 )

( CN40-13 )

( CN40-14 )

( CN40-15 )

D

( CN40-16 )

CN40

B16B-PASK-1

WHITE

INDICATOR PCB

( CN40-1 )

( CN40-2 )

( CN40-3 )

( CN40-6 )

( CN40-7 )

( CN40-8 )

( CN40-9)

( CN40-10 )

( CN40-11 )

( CN40-12 )

2013.01.21 10

Page 12

TM101

86028

TM102

86028

OUTDOOR UNIT

TRANSISTOR PCB ( I P M )

K10AY-1003HUE-TR0

D100

2

3

POW_GND

1

1

+

4

-

DCV

I P M CONTROL

W

<1/10W>

W306

B

WHITE

P

TM301

86028

TM302

86028

N

W307

B

BLACK

REVERSE CURRENT

15V

I C70-3

BA2903F

I PM-GND

15V

I C70-1

BA2903F

3

+

1

2

-

C70

10/

25V

I PM-GND

VCC

G / V

8

4

+

C71

0.1

<F>

C72

330p

<B>

CN303

B05B-PL I RK-1

WHITE

R66, R63, R60

R67, R64, R61

R68, R65, R62

330k <1/3W>

1% x 9

D70, D71

DAN217U x 2

231

C73

220p

4.7k <1/10W>

<B>

2

3

LL25XB60

1

2

3

4

5

U V

R76, R77

1%

x 2

C161

<X7R>

R80

5.1k

1%

R108

13k

<1/10W>

1%

0.1

CN301

B09B-PL I SK-1

WHITE

R71, R70, R69

330k <1/3W>

1%

x 3

R81

22k

<1/10W>

1%

R107

39.2k

<1/10W>

1%

15V

C332

0.1

<F>

10

11

12

13

14

15

16

17

18

19

20

CSC

CFOD

I PM-GND

C302

100/

35V

+

I PM-G

I C301

FSBB30CH60

1

VCC

2

COM

3

I N

NV

4

I N

5

I N

6

VFO

NW

7

CFOD

8

CSC

9

I N

VCC

U

VB

VS

V

I N

VCC

VB

W

VS

I N

VCC

P

VB

VS

C330

100p

<CH>

BL02Rn1

21NU

22

23

24

25

26

27

R312

0R0

L300

D307

RD24FM

W V U

C307

0.1

<HCP>

R284, R285

0.03 <5W>

x 2

R304

820

<1/10W>

DCV

C306

0.1

<X7R>

TM303

86028

TM304

86028

TM305

86028

R302

0.03

<5W>

W

V

U

CSC

CFOD

C222

1.0

<F>

I PM-GND

C327

0.022

<F>

C209 - C211, C221

0.1 <F>

W16

B

RED

W17

B

BLACK

C304

C322

47/

0.1

35V

<F>

R316 - R321

C50

0R0

+

I PM-GND

+

C305

C323

47/

0.1

35V

<F>

C301

15V

0.1

C308

<F>

+

7

C300

0.1 <F>

5

+

6

-

47/

35V

R55

0R0

390 <1/10W> x 6

9

8

7

6

5

4

3

2

1

DCV

I PM-G

-12V

I C70-2

BA2903F

C303

C321

47/

0.1

35V

<F>

C311 - C316

2200p <B> x 6

+

x 4

I PM-G

I PM-GND

2013.01.21 11

Page 13

L

POWER SOURCE

AC230V

50Hz

N

L

TO INDOOR UNIT

N

EARTH

OUTDOOR UNIT

POWER SUPPLY PCB

K10BR-1000HUE-FL0

TM100

86028

VA100, VA101

W100

B

BLACK

W101

B

WHITE

W104

BLACK

W113

B

WHITE

W106

GREEN

W107

BLACK

W108

WHITE

B

B

B

B

FH101 FH100

PFC5000-0702F

x 2

470V <TNR>

F100

10A

250V

F101

10A

250V

FH103 FH102

PFC5000-0702F

x 2

VA104

470V

<TNR>

FH109

PFC5000-0702F

x 2

F104

3.15A

250V

x 2

FH108

FH106 FH107

H-0017-2 x 2

F103

30A

VA102

250V

470V

<TNR>

SA100

RA-302M

C100

3.3

<LE>

L100

RCH3818-022PF07

4

3

12

C103

3.3

<LE>

T100

CT-1B

5

1 3

JM100 - JM102

TM103

86028

12V

DAN217U

1

2

K100

DW12D1-O (M)

3

4

1

2

K100 - 3

D100

3

C111

220/

16V

+

R104

3.74k

<1/10W>

1%

P-PR1

L102

n200500K

VR100

VG067TL1

<0.2W>

B2K

2

3

1

P-PR2

P-PR1

R106

22k

<1/10W>

C112

0.1

<B>

C110

3.3

<LE>

5V

C113

0.1

<B>

L101

RCH3818-022PF07

3

C104

0.022

<YE>

C105

0.022

<YE>

4

4

C106

0.015

C108

<YE>

3.3

<LE>

C107

0.015

<YE>

2

1

5V

R103 1.0k

<1/10W>

1%

12V

W111

ORANGE

W112

ORANGE

W102

ORANGE

W103

B

ORANGE

6

5

4

3

2

1

CN101

B06B-XN I SK-A-1

WHITE

MAIN PCB

2013.01.21 12

Page 14

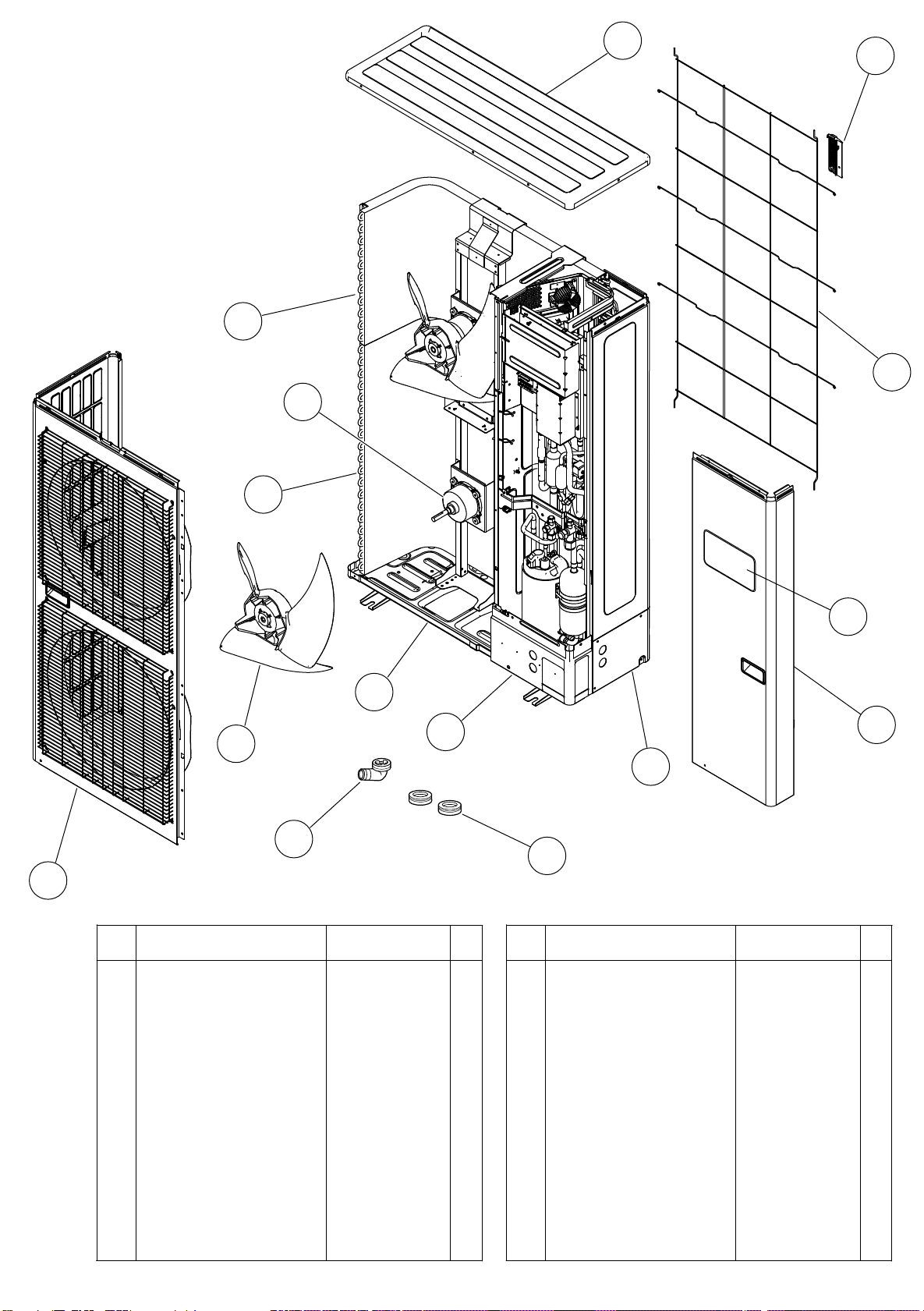

OUTDOOR UNIT

CAPACITOR PCB

K05FB-1000HUE-P0

OUTDOOR UNIT

INDICATOR PCB

K10BC-1000YUE-D0

D401 SLR-325 <ORANGE> L6

D402 SLR-325 <ORANGE> L5

D403 SLR-325 <ORANGE> L4

D404 SLR-325 <ORANGE> L3

D405 SLR-325 <ORANGE> L2

D406 SLR-325 <ORANGE> PUMP DOWN L1

D407 SLR-325 <RED> ERROR

D408 SLR-325 <GREEN> POWER / MODE

W12

B

WHITE

W13

B

VIOLET

R200

220k

<2W>

C200 - C203

660/

450V

x 4

P

+

+

+

+

N

POWER_G

( CN401-1 )

( CN401-2 )

( CN401-3 )

( CN401-4 )

( CN401-5 )

( CN401-6 )

( CN401-7 )

( CN401-8 )

( CN401-9 )

( CN401-10 )

( CN401-11 )

( CN401-12 )

W7

B

YELLOW

W8

B

BLUE

PUMP DOWN

EXIT

ENTER

SELECT

MODE

SW5

SW4

SW3

SW2

SW1

KSM8WBTS x 5

2013.01.21 13

( CN401-13 )

( CN401-14 )

( CN401-15 )

( CN401-16 )

Page 15

ERROR DETECTION

INDOOR UNIT

and WIRED REMOTE CONTROL

If you use a wireless remote control, the lamp

on the photo detector unit will output error codes

by way of blinking patterns.

If you use a wired type remote control, error

codes will appear on the remote control display.

See the lamp blinking patterns and error codes

in the table. An error display is displayed only

during running.

Remote control

This is possible only on a wired remote control.

If an error occurs, the following display will be shown.

(“Er” will appear in the set room temperature display.)

indoor unit

EX. Self-diagnosis

Receiver unit (option)

( ) : Number of flashing

.

Error codeUnit number of

OPERATION lamp (green)

TIMER lamp (orange)

ECONOMY lamp (green)

: 0.5s on / 0.5s off

: 0.1s on / 0.1s off

Receiver unit

OPERATION

lamp

(green)

(1) (1)

(1) (2)

(1)

(2)

(2) (2)

(2) (3)

(2)

(2)

(3)

(3)

(3) (5)

(4) (1)

(4) (2)

(5)

(5)

(5) (7)

(5) (15)

(6)

(6) (3)

(6)

(6) (5)

(6)

TIMER

lamp

(orange)

(5)

(1)

(4)

(7)

(1)

(2)

(1)

(3)

(2)

(4)

(10)

ECONOMY

lamp

(green)

Wired

remote

control

Description

Serial communication error

Wired remote control communication error

Check run unfinished

Unit number or Refrigerant circuit address setting error

[Simultaneous Multi]

Indoor unit capacity error

Combination error

Connection unit number error (indoor slave unit)•

[Simultaneous Multi]

Connection unit number error (indoor unit or branch unit)

•

[Flexible Multi]

Master unit, slave unit set-up error

[Simultaneous Multi]

Power supply interruption error

Indoor unit PCB model

information error

Manual auto switch error

room temp. sensor error

Indoor unit Heat Ex. Middle temp. sensor error

Indoor unit fan motor error

Drain pump error

Damper error

Indoor unit error

Outdoor unit main PCB model information error

or communication error

Inverter error

Active filter error, PFC circuit error

Trip terminal L error

Display PCB microcomputers communication error

Receiver unit

OPERATION

lamp

(green)

(7)

(7) (2)

(7) (3)

(7) (4)

(7)

(7) (6)

(7) (7)

(8) (2)

(8) (3)

(8) (4)

(8) (6)

(9) (4)

(9) (5)

(9) (7)

(9) (8)

(9) (9)

(9) (10)

(10) (1)

(10) (3)

(10) (4)

(10) (5)

(13) (2)

TIMER

lamp

(orange)

(1)

(5)

ECONOMY

lamp

(green)

Wired

remote

control

Description

Discharge temp. sensor error

Compressor temp. sensor error

Outdoor unit Heat Ex. liquid temp. sensor error

Outdoor temp. sensor error

Suction Gas temp. sensor error

2-way valve temp. sensor error•

3-way valve temp. sensor error•

Heat sink temp. sensor error

Sub-cool Heat Ex. gas inlet temp. sensor error•

Sub-cool Heat Ex. gas outlet temp.sensor error•

Liquid pipe temp. sensor error

Current sensor error

Discharge pressure sensor error•

Suction pressure sensor error•

High pressure switch error•

Trip detection

Compressor rotor position detection error

(permanent stop)

Outdoor unit fan motor 1 error

Outdoor unit fan motor 2 error

4-way valve error

Coil (expansion valve) error

Discharge temp. error

Compressor temp. error

High pressure error

Low pressure error

Branch boxes error

[Flexible Multi]

2012.04.26 14

Page 16

OUTDOOR UNIT

Indicator PCB

LEDs

Buttons

ERROR DETECTION

Display when an error occurs.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

On

ERROR

Blink

(Hi speed)

PUMP

DOWN

Check that the “ERROR” LED blinks, then press the [Enter] button once.

For details, refer to the following table.

DESCRIPTION REMARK

Serial communication error

Indoor unit capacity error Indoor unit capacity error

Indoor unit error Indoor unit error

Outdoor unit main PCB error Outdoor unit PCB model information error

Inverter PCB error Inverter error

IPM error Trip terminal L error

Discharge temp. sensor error Discharge temp. sensor 1 error

Compressor temp. sensor error Compressor temp. sensor 1 error

Outdoor unit Heat Ex. sensor error

Outdoor temp. sensor error Outdoor temp. sensor error

Heat sink temp. sensor error Heat sink temp. sensor error

Current sensor error Current sensor 1 error (stoppage permanently)

Pressure sensor error

Trip detection Trip detection

Compressor motor control error Rotor position detection error (stoppage permanently)

Outdoor unit fan motor 1 error Duty abnormal

Outdoor unit fan motor 2 error Duty abnormal

4-way valve error 4-way valve error

Discharge temp. 1 error Discharge temp. 1 error

Compressor temp. error Compressor 1 temp. error

Pressure error 2 Low pressure error

LOW

NOISE

PEAK

CUT

OffOffOffOffOffOff

Serial forward transmission error immediately after

operation

Serial forward transmission error during operation

Heat Ex. centre temp. sensor error

Outdoor unit Heat Ex. liquid temp. sensor error

High pressure switch 1 error

Pressure sensor error

POWER

MODE

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

Blink

(2 times)

ERROR

On On On

On On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

On

LED display

PUMP

DOWN

(L1) (L2) (L3) (L4) (L5) (L6)

Blink

(1 time)

Blink

(1 time)

Blink

(2 times)

Blink

(5 times)

Blink

(6 times)

Blink

(6 times)

Blink

(6 times)

Blink

(7 times)

Blink

(7 times)

Blink

(7 times)

Blink

(7 times)

Blink

(7 times)

Blink

(7 times)

Blink

(8 times)

Blink

(8 times)

Blink

(8 times)

Blink

(9 times)

Blink

(9 times)

Blink

(9 times)

Blink

(9 times)

Blink

(9 times)

Blink

(10 times)

Blink

(10 times)

Blink

(10 times)

LOW NOISE PEAK CUT

Blink

(1 time)

Blink

(1 time)

Blink

(2 times)

Blink

(15 times)

Blink

(2 times)

Blink

(3 times)

Blink

(5 times)

Blink

(1 time)

Blink

(2 times)

Blink

(3 times)

Blink

(3 times)

Blink

(4 times)

Blink

(7 times)

Blink

(4 times)

Blink

(6 times)

Blink

(6 times)

Blink

(4 times)

Blink

(5 times)

Blink

(7 times)

Blink

(8 times)

Blink

(9 times)

Blink

(1 time)

Blink

(3 times)

Blink

(5 times)

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

On

On

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

Off

On

Off

Off

On

On

Off

Off

Off

Off

On

Off

Off

On

On

Off

Off

Off

Off

Off

On

On

On

On

On

On

On

Off

On

On

On

On

Off

Off

On

On

On

On

On

On

On

On

2010.12.17 15

Page 17

OUTDOOR UNIT

TEST RUN

Before the test run, refer to he figure and

check the following items.

Is the outdoor unit securely installed?

Have you performed gas leakage inspection?

(Connection joints of various pipes (flang connection, brazing))

Is the heat insulation done completely?

(Gas pipe, liquid pipe, drain hose extension on indoor unit side etc)

Is the water discharging from drain without any problems?

Are the cables connected correctly?

Are the cables as per specif cations?

Is the earth wire connected accurately?

Are there any obstacles blocking the suction gate, and outlet of

the indoor/outdoor units?

Have you filled the specified amount of refrigerant?

Are the stop valves of gas pipe and liquid pipe fully open?

Has the power been supplied to crankcase heater for more than 6 hours?

If there are problems, adjust immediately and recheck.

Test run method

Be sure to configure test run settings only when the outdoor unit has stopped

operating.

Depending on the communication status between the indoor and outdoor units,

it may take several minutes for the system to start operating after settings for the

test run are complete.

After the test run settings are complete, the outdoor units and the connected

indoor units will start operating. Room temperature control will not activate during

test operation (continuous operation).

If a knocking sound can be heard in the liquid compression of the compressor,

stop the unit immediately and then energize the crank case heater for a sufficient

length of time before restarting the operation.

Test run setting method (it can be performed in the following two ways)

Set with test run setting (refer to installation instructions manual of indoor unit

for further details) available in the remote control.

Cooling Operation” and Heating Operation” can be set using , SELECT button and

ENTER button available on the board of display unit.

(*Make sure to perform the first test run with cooling operation.)

Set as per the procedure given below.

Setting method

(1)

Turn on the power of the outdoor unit and enter standby mode.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

PUMP

DOWN

OffOn Off Off OffOff Off Off

(2)

Press the ENTER button for more than 3 seconds.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

Blink

Press the SELECT button,

(3)

ERROR

Off Off Off Off Off Off

PUMP

DOWN

LED of the test run mode Switched between "COOL" and "HEAT".

Cooling test mode

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

Blink

ERROR

Off Off Off Off Off Off

PUMP

DOWN

Heating test mode

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

Blink

ERROR

Off Off OffOff Off Off

PUMP

DOWN

After confirmin the operation mode, Press ENTER button.(4)

The display changes as follows, and Air conditioner starts operation.

Cooling test mode

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

Blink

ERROR

Off Off Off On Off Off Off

PUMP

DOWN

Heating test mode

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

PUMP

DOWN

Blink Off Off On Off Off Off Off

Blink

LOW

NOISE

LOW

NOISE

LOW

NOISE

LOW

NOISE

LOW

NOISE

LOW

NOISE

PEAK

CUT

PEAK

CUT

Blink

PEAK

CUT

Blink

PEAK

CUT

PEAK

CUT

PEAK

CUT

Check items during test run

Is the outdoor unit making any abnormal noise or vibrating significantly?

Is the cold air or hot air blowing from indoor unit according to the operation

mode?

Check that the “ERROR” LED blinks.

If it has displayed, check the error content as per 12.2. described later.

Operate the unit according to the operating manual provided with the indoor

unit, and check that it is operating normally.

(5)

2013.03.05 16

Press [ENTER] button.

Air conditioner stopped operation.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

PUMP

DOWN

LOW

NOISE

PEAK

CUT

OffOn Off OffOff Off Off Off

Page 18

OUTDOOR UNIT

PUMP DOWN

WARNING

Never touch electrical components such as the terminal blocks except the button on

the display board. It may cause a serious accident such as electric shock.

During the pump-down operation, make sure that the compressor is turned off before

you remove the refrigerant piping.

Do not remove the connection pipe while the compressor is in operation with 2-way or

3-way valve open. This may cause abnormal pressure in the refrigeration cycle that

leads to breakage and even injury.

Procedure

(1) Check the 3-way valves (both the liquid side and gas side) are opened.

(2) Turn the power on.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

PUMP

DOWN

Off Off Off Off

LOW

NOISE

PEAK

CUT

Off Off OffOn

CAUTION

Perform the pump down operation before disconnecting any refrigerant pipe or electric

cable.

Collect refrigerant from the service port or the 3-way valve if pump down cannot be

performed.

In case of a group control system installation, do not turn the power off pump down is

completed in all outdoor units.

(Group control system installation described in SPECIAL INSTALLATION METHODS”

in the installation manual of the indoor unit.)

• Operate [PUMPDOWN] button on the display board in the manner described

below.

Preparation for pump down

Confirm that the power is off,

and then open the service panel.

(3) Press [PUMP DOWN] button for 3 seconds or more after 3 minutes after power on.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

LED display lights on as shown in the above figure and the fans and the

compressor start operating.

• If the [PUMP DOWN] button is pressed while the compressor is operating, the

compressor will stop, then start again in about 3 minutes.

(4) LED display will change as shown below about 3 minutes after the compressor

starts. Fully close the 3-way valve on the liquid pipe side at this stage.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

On On On On On

Off Off Off

ERROR

PUMP

DOWN

PUMP

DOWN

LOW

NOISE

LOW

NOISE

PEAK

CUT

PEAK

CUT

OffOff Off OffOn On On On

If the valve on the liquid pipe side is not closed, the pump down cannot be •

performed.

(5) When LED display changes as shown in the below figure close the 3-way valve on

the gas pipe side tightly.

POWER

MODE (L1) (L2) (L3) (L4) (L5) (L6)

ERROR

PUMP

DOWN

On On