Page 1

HYBRID FLEX

INVERTER SYSTEM

Slim Duct /Compact Cassette

Compact Wall Mounted /

Wall Mounted

INVERTER MULTI

SERVICE

INSTRUCTION

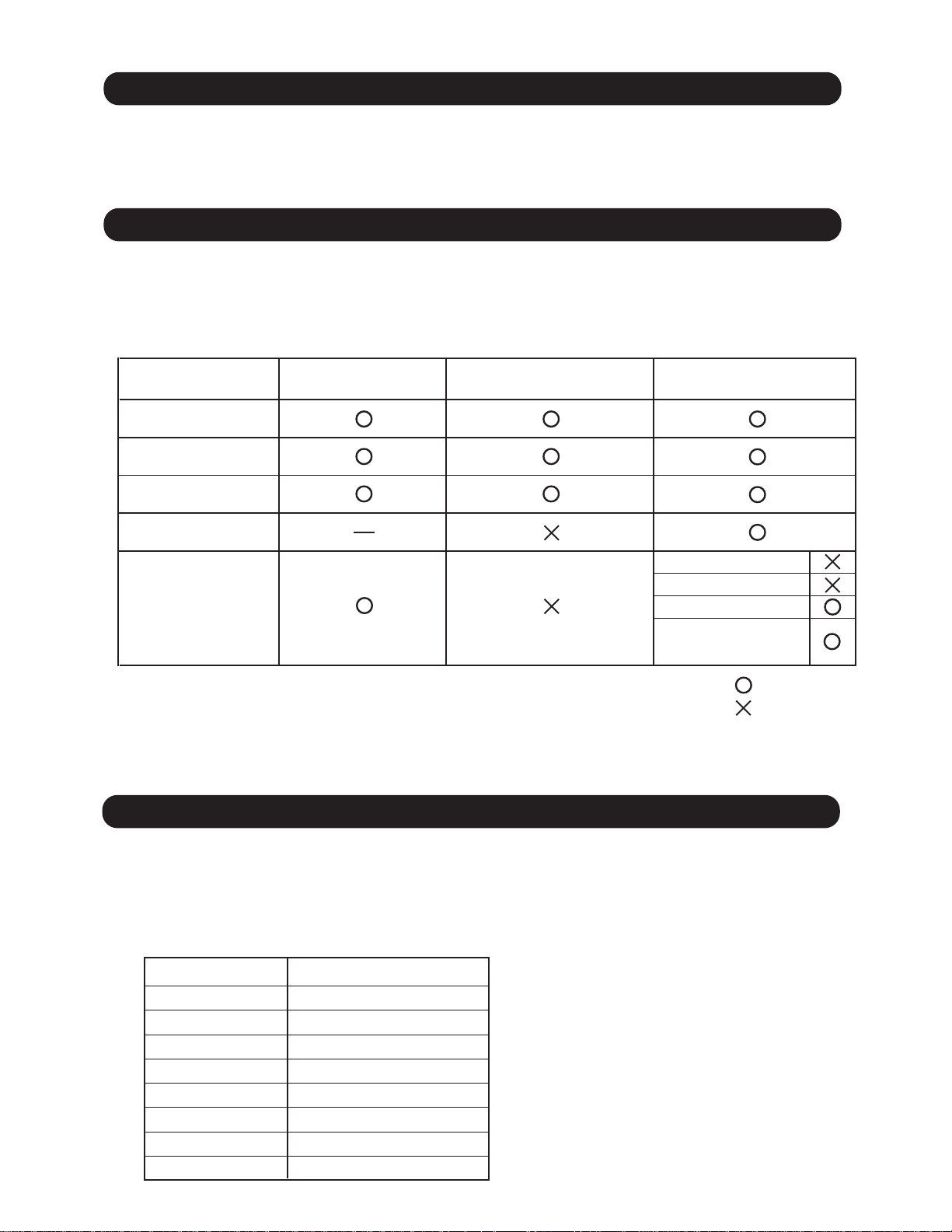

Models Indoor unit Outdoor unit

R410A

ARU9RLF

ARU12RLF

ARU18RLF

ARU24RLF

AUU9RLF

AUU12RLF

AUU18RLF

ASU7RLF

ASU9RLF

ASU12RLF

ASU18RLF

ASU24RLF

AOU48RLXFZ

Page 2

CONTENTS

1. DESCRIPTION OF EACH CONTROL OPERATION

1-1. COOLING AND DRY OPERATION.........................................................................

1-2. HEATING OPERATION...........................................................................................

1-3. AUTO CHANGEOVER OPERATION.......................................................................

1-4. INDOOR FAN CONTROL........................................................................................

1-5. LOUVER CONTROL................................................................................................ 01-09

1-6. OUTDOOR FAN CONTROL....................................................................................

1-7. COMPRESSOR CONTROL.....................................................................................

1-8. TIMER OPERATION CONTROL.............................................................................

1-9. ELECTRONIC EXPANSION VALVE CONTROL.....................................................

1-10. TEST OPERATION CONTROL..............................................................................

1-11. 4-WAY VALVE EXTENSION SELECT...................................................................

1-12. AUTO RESTART....................................................................................................

1-13. MANUAL AUTO OPERATION...............................................................................

1-14. FORCED COOLING OPERATION .......................................................................

1-15. COMPRESSOR PREHEATING.............................................................................

1-16. MINIMUM HEAT OPERATIONEHEATING............................................................

1-17. DEFROST OPERATION CONTROL.....................................................................

1-18. OFF DEFROST OPERATION CONTROL.............................................................

1-19. OIL RECOVERY OPERATION...............................................................................

1-20. FRESH AIR CONTROL(For AU / AR type)............................................................

1-21. EXTERNAL ELECTRICAL HEATER CONTROL(For AR type)..............................

1-22. DRAIN PUMP OPERATION...................................................................................

1-23. ECONOMY OPERATION.......................................................................................

1-24. ENERGY SAVING PEAK CUT FUNCTION........................................................... 01-29

1-25. LOW NOISE MODE............................................................................................... 01-29

1-26. VARIOUS PROTECTIONS.................................................................................... 01-30

01-01

01-02

01-03

01-05

01-11

01-12

01-14

01-17

01-18

01-20

01-20

01-20

01-21

01-21

01-21

01-22

01-24

01-25

01-26

01-26

01-27

01-28

2. TROUBLE SHOOTING

2-1. SERVICE MAINTENANCE FOR HYBRID FLEX INVERTER SYSTEM................

2-2. NORMAL OPERATION..........................................................................................

2-3. ABNORMAL OPERATION.....................................................................................

2-4. TROUBLE SHOOTING..........................................................................................

2-5. SERVICE PARTS INFORMATION.........................................................................

02-01

02-05

02-07

02-16

02-65

3. DISASSENBLLY PARTS

3-1. DISASSEMBLY PROCESS FOR OUTDOOR UNIT................................................

3-2. DISASSEMBLY PROCESS FOR BRANCH BOX....................................................

03-01

03-17

Page 3

Hybrid Flex Inverter System

1 . DESCRIPTION OF EACH

CONTROL OPERATION

Page 4

1-1. COOLING AND DRY OPERATION

1-1-1. COOLING AND DRY CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature,

and controls the operation speed of the compressor.

The outdoor unit operates according to the highest request capacity of indoor unit

to meet the demand capacity of all the indoor units.

The capacity control of the low request capacity indoor unit is controlled by Branch box EEV.

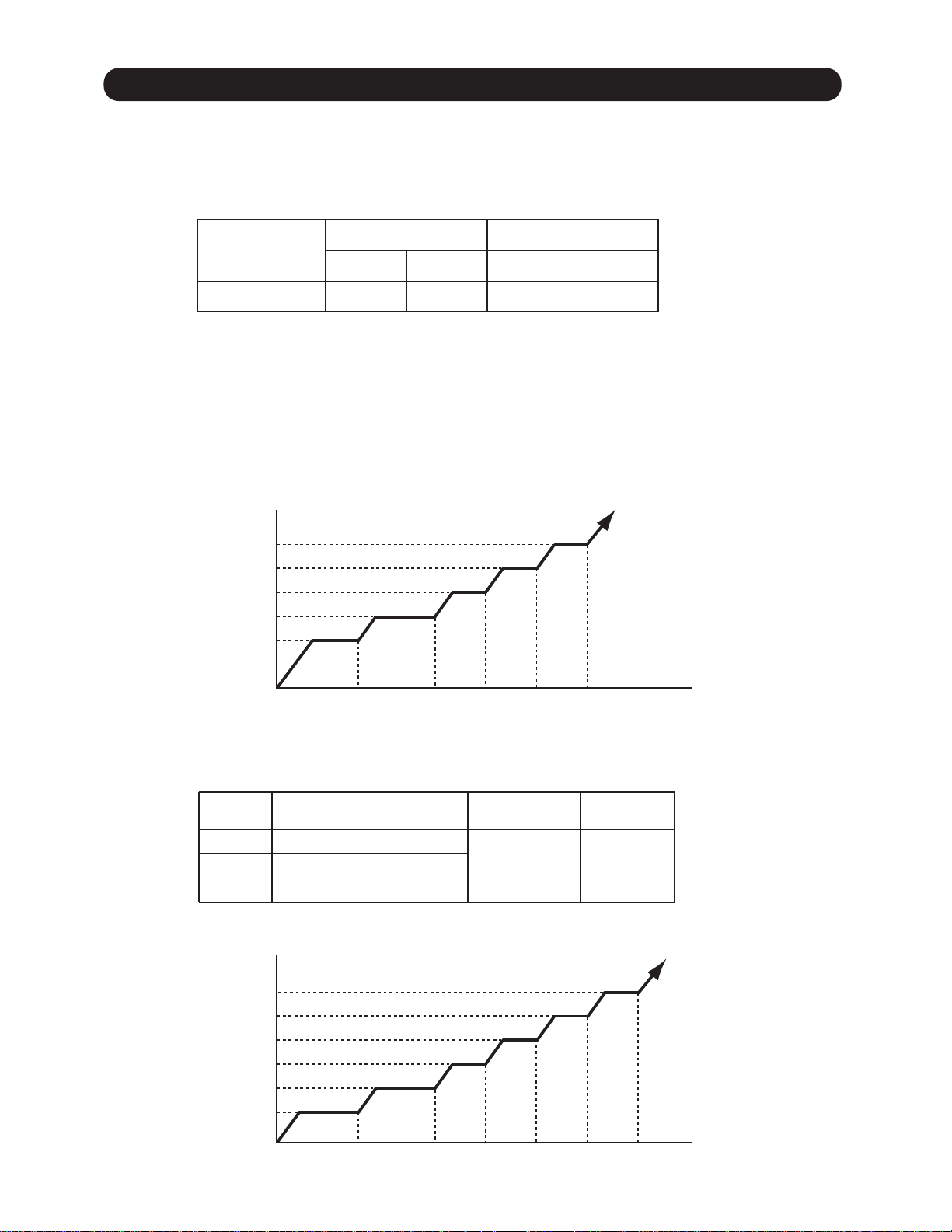

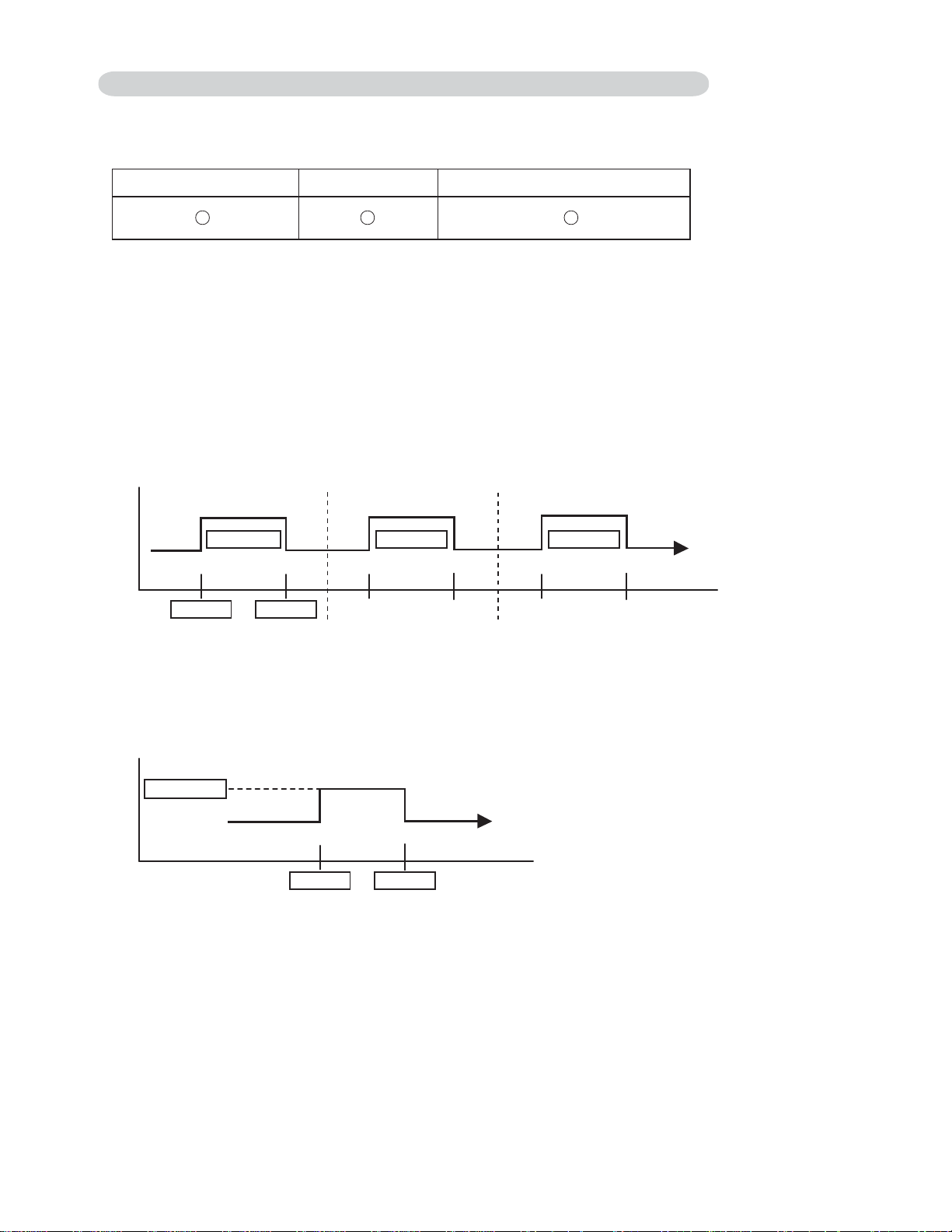

( Table 1 : Compressor speed range )

Minimum Maximum

AOU48RLXFZ

18rps

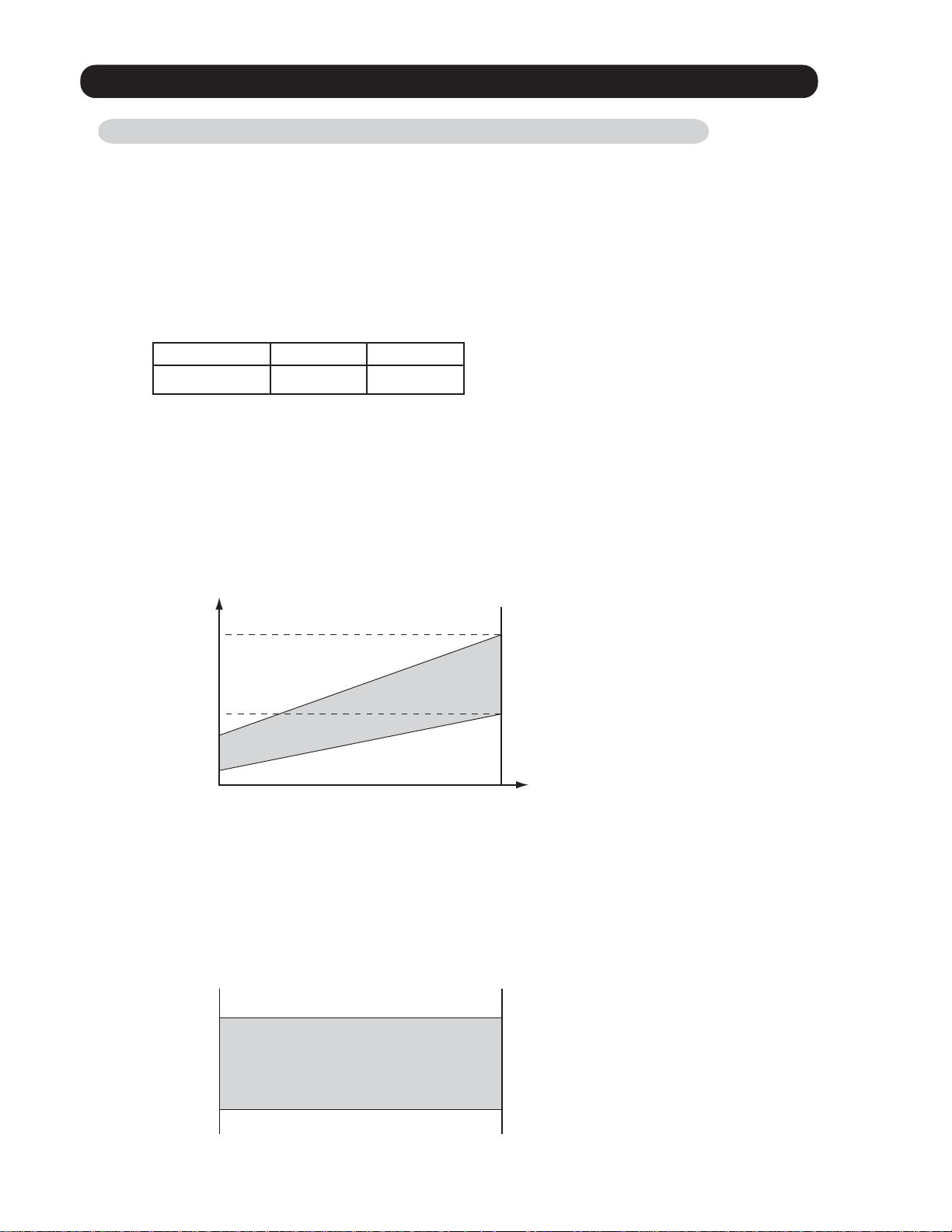

< Target high pressure control >

The outdoor fan speed is controlled to keep the high pressure to the constant range for stabilizing

the distribution performance.

90rps

High

pressure

478PSI

338PSI

275PSI

235PSI

( Fig. 1 : Target high pressure range)

Target high pressure

Outdoor

temperature

< Target low pressure control >

When the start-up control finished, the outdoor unit starts the target low pressure control.

The outdoor unit selects the target low pressure within the following range,

it is decided by the highest request capacity from indoor units.

( Fig. 2 : Target low pressure range)

184PSI

119PSI

Target low pressure

01-01

Page 5

1-2. HEATING OPERATION

1-2-1. HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature,

and controls the operation speed of the compressor.

The outdoor unit operates according to the highest request capacity of indoor unit

to meet the demand capacity of all the indoor units.

The capacity control of the low request capacity indoor unit is controlled by Branch box EEV.

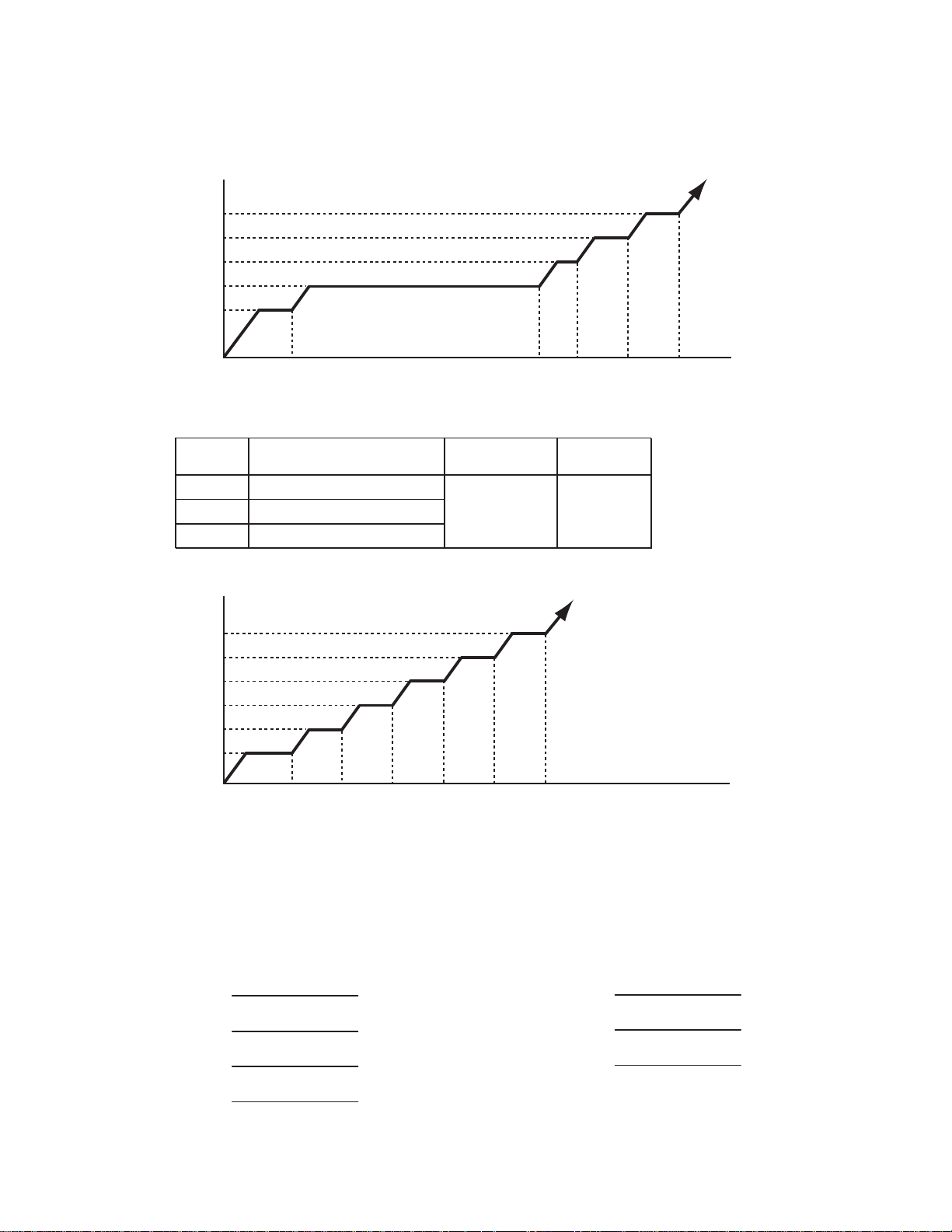

( Table 2 : Compressor speed range )

Minimum Maximum

AOU48RLXFZ

18rps

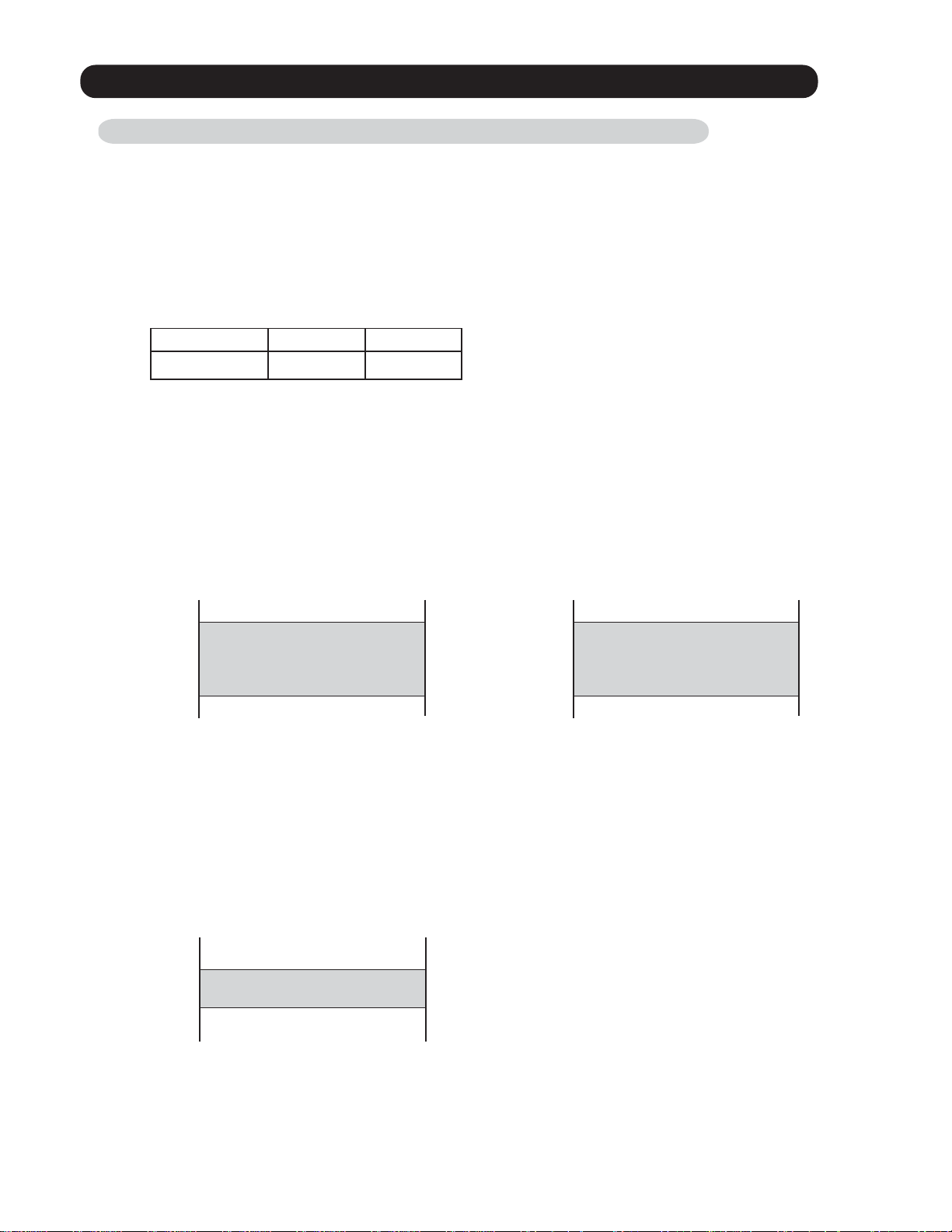

< Target high pressure control >

When the start-up control finished, the outdoor unit starts the target high pressure control.

The outdoor unit selects the target high pressure within the following range,

it is decided by the highest request capacity from indoor units.

96rps

( Fig. 3 : Target high pressure range

for NORMAL HEATING OPERATION)

451PSI

Target high pressure

328PSI

( Fig. 4 : Target high pressure range

for MIN. HEAT OPERATION)

272PSI

Target high pressure

190PSI

< Target low pressure control >

The outdoor fan speed is controlled to keep the low pressure to the constant range for the following reasons.

1. Frost prevention

2. Low pressure over rise prevention

( Fig. 5 : Target low pressure range)

123PSI

Target low pressure

109PSI

01-02

Page 6

1-3. AUTO CHANGEOVER OPERATION

When the air conditioner is set to the Auto mode by remote controller, operation starts in the optimum

mode from among the Heating, Cooling, Dry and Monitoring mode. During operation, the

optimum mode is automatically switched in accordance with temperature changes. The temperature

can be set between 64°F(18°C) and 88°F(30°C) in 2°F(1°C) steps.

When operation starts, indoor fan and outdoor fan are operated for around 3 minutes.

1

Room temperature and outdoor temperature are sensed, and the operation mode is selected

in accordance with the table below. <Monitoring mode>

( Table 3 : Operation mode selection table )

Room temperature (TR)

TR> Ts+4°F(+2°C)

Operation mode

Cooling

(Autmatic dry)

TR : Room temperature

Ts : Setting temperature

Ts+4°F(+2°C) TR Ts -4°F(-2°C)

TR < Ts -4°F(-2°C) Heating

*Middle zone

*If it's Middle zone, operation mode of indoor unit is selected as below.

(1). Same operation mode is selected as outdoor unit.

If outdoor unit is operating in Cooling, Dry, and Heating mode,

indoor unit will be operated by the same operation mode.

(2). Selected by the outdoor temperature.

If outdoor unit is operating in other than Cooling, Dry, and Heating mode,

indoor unit will be operated according to the outdoor temperature as below.

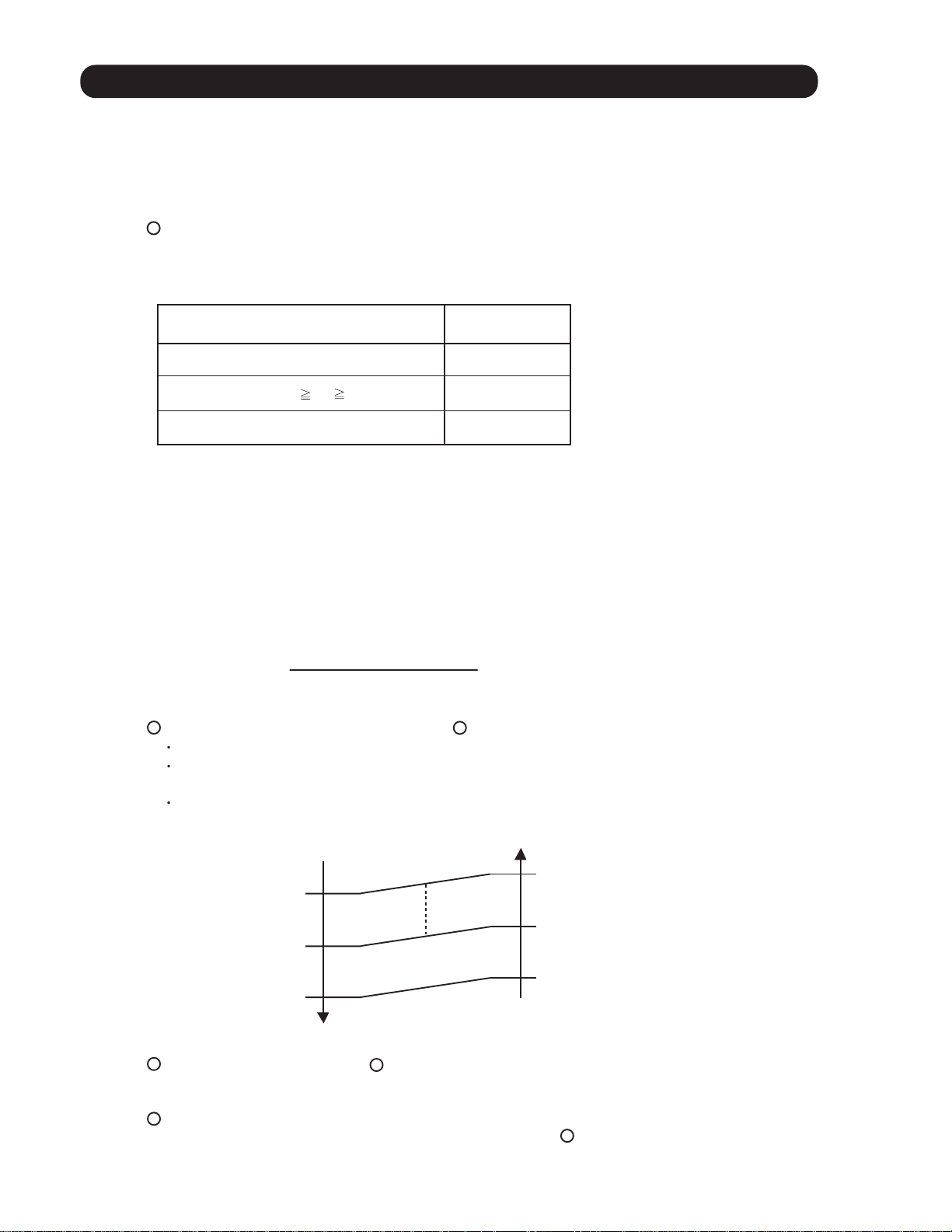

( Fig. 6 : Outdoor temperature zone selection )

Cooling mode

77°F (25°C)

Heating mode

2

When Cooling or Dry mode was selected at and air flow mode is Auto, the air conditioner operates as follow.

The same operation as COOLING OPERATION AND DRY OPERATION of page 01-01 is performed.

When the room temperature has remained at set temperature -3°F(-1.5°C), operation is automatically

switched to Dry mode.

If the room temperature reaches set temperature +4°F(+2°C) during Dry mode, operation returns to Cooling.

( Fig.7 : Auto changeover : Cooling - Dry )

( Air flow mode : Auto )

Ts +2°F(+1°C)

Cooling

Cooling

Ts -3°F(-1.5°C)

(J zone)

Ts -5°F(-2.5°C)

Compressor stop

When the room

temperature drops

3

When Heating was selected at , the same operation as HEATING OPERATION of page

1

01-02 is performed.

Dry

1

Dry

(X zone)

Ts +4°F(+2°C)

Ts -1°F(-0.5°C)

Ts -3°F(-1.5°C)

When the room

temperature rises

TR : Room temperature

Ts : Setting temperature

4

When the compressor was stopped for 6 consecutive minutes by the temperature control function

after the Cooling(Auto:Dry) or Heating mode was selected at above, operation is switched

1

to Monitoring and the operation mode is selected again.

01-03

Page 7

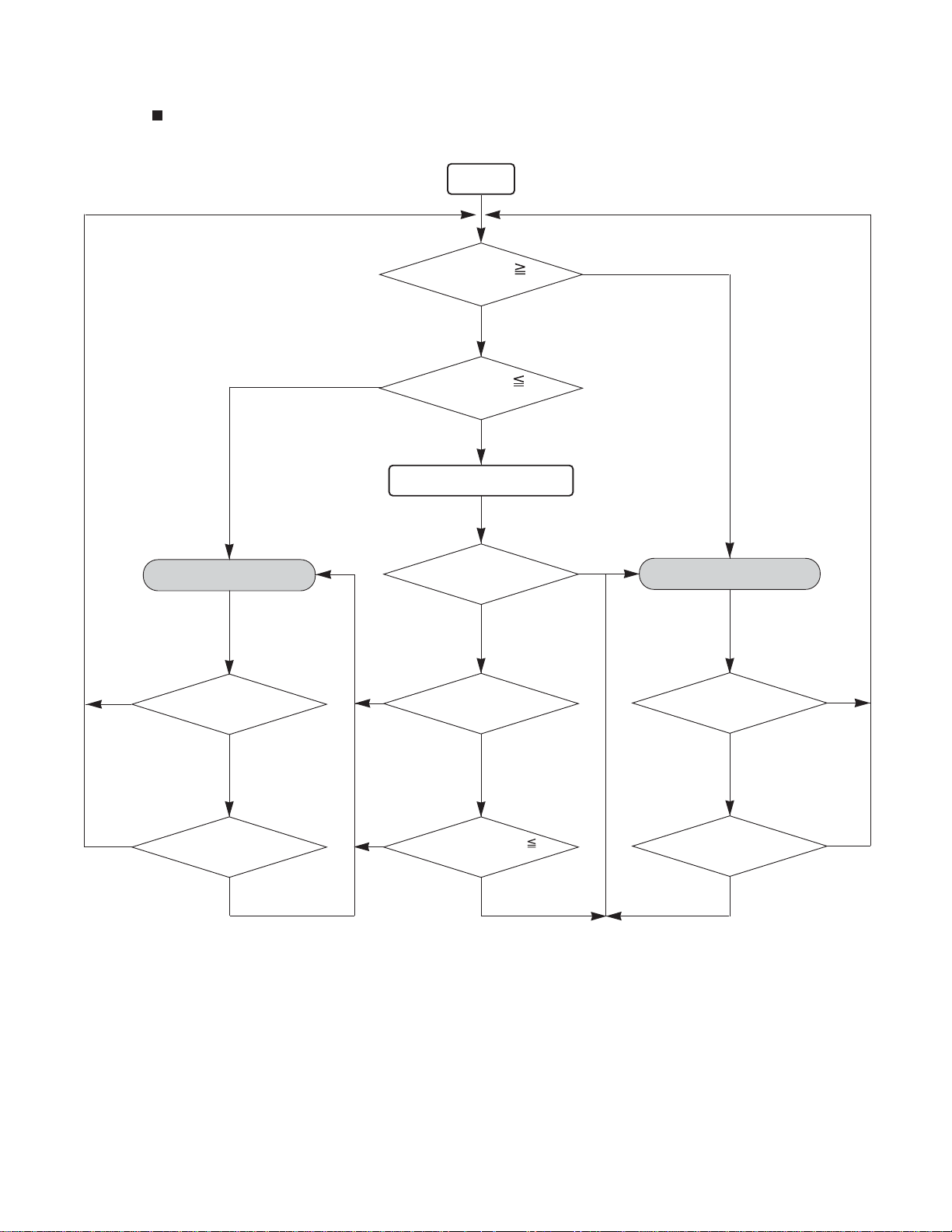

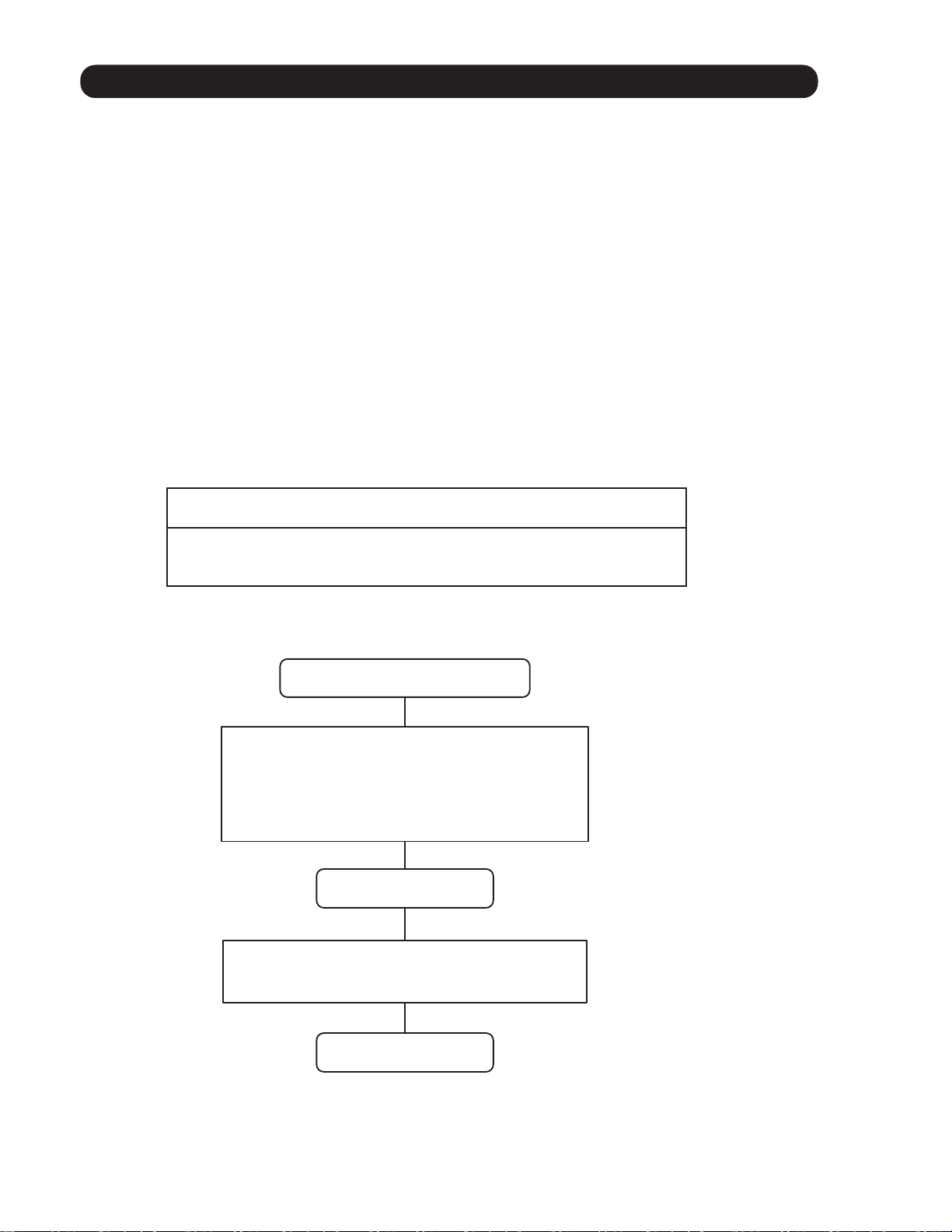

AUTO CHANGEOVER operation flow chart

HEATING OPERATION

YES

START

Room temp.

Ts+4°F(+2

°C)?

NO

Room temp.

Ts -4°F(-2

°C)?

NO

Middle zone

Operation mode of

outdoor unit : Cooling or Dry?

NO

YES

TS : Setting temperature

YES

COOLING (AUTO:DRY)

OPERATION

YES

YES

Thermostat remains

in OFF state for 6 minutes or

longer?

NO

System stops

or operation command other than

auto changeover operation?

NO

YES

YES

Operation mode of

outdoor unit : Heating?

NO

Outdoor temperature

77

°F(25°C)?

NO

Thermostat remains

in OFF state for 6 minutes or

longer?

NO

System stops

or operation command other than

auto changeover operation?

NO

YES

YES

01-04

Page 8

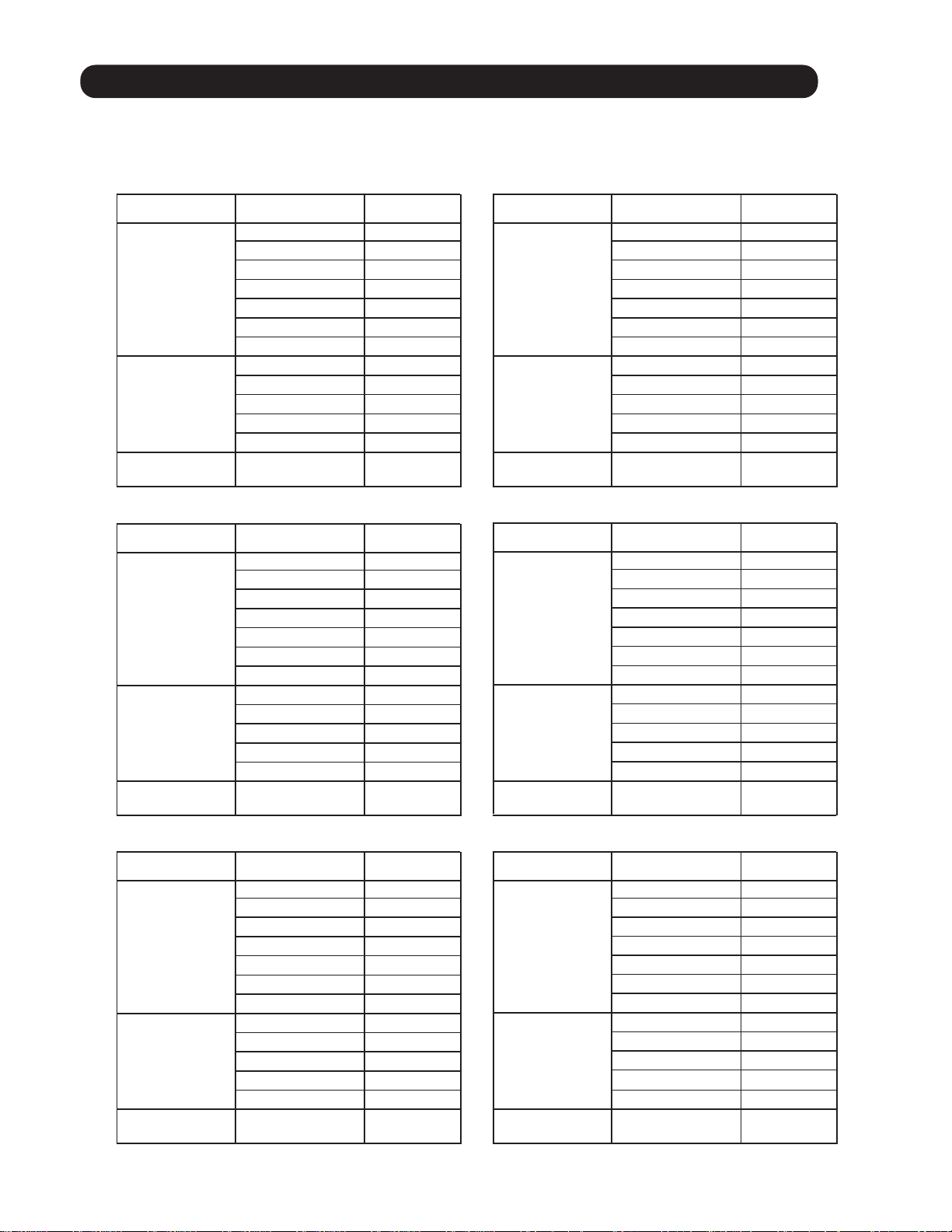

1-4. INDOOR FAN CONTROL

1. Fan speed

( Table 4 : Indoor fan speed table)

ASU7RLF

ASU9RLF

Operation mode

Heating

Cooling / Fan

Dry

ASU12RLF

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

*Soft Quiet

Auto

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

*Soft Quiet

Auto

Fan Speed

1050

1000

950

850

720

600

480

1050

950

850

710

600

X, J zone:710

Fan Speed

1200

1130

1050

910

720

600

480

1200

1050

880

710

600

X, J zone:710

Operation mode

Heating

Cooling / Fan

Dry

ASU18RLF

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

*Soft Quiet

Auto

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

*Soft Quiet

Auto

Fan Speed

1100

1040

980

850

720

600

480

1100

980

850

710

600

X, J zone:710

Fan Speed

1260

1120

1020

900

790

680

480

1260

1020

900

770

680

X, J zone:770

ASU24RLF

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

*Soft Quiet

Auto

Fan Speed

1430

1320

1220

1020

900

720

480

1480

1220

1020

900

720

X, J zone:900

AUU9RLF

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Cool Air Prevention

*Soft Quiet

*Note, during Economy operation and operation mode is Fan, air flow is 1 step downs.

(Hi > Me, Me > Lo, Quiet > Soft Quiet)

01-05

Hi

Me+

Me

Lo

Quiet

S-Lo

Hi

Me

Lo

Quiet

Auto

Fan Speed

590

570

540

490

440

400

300

590

540

490

440

400

X, J zone:440

Page 9

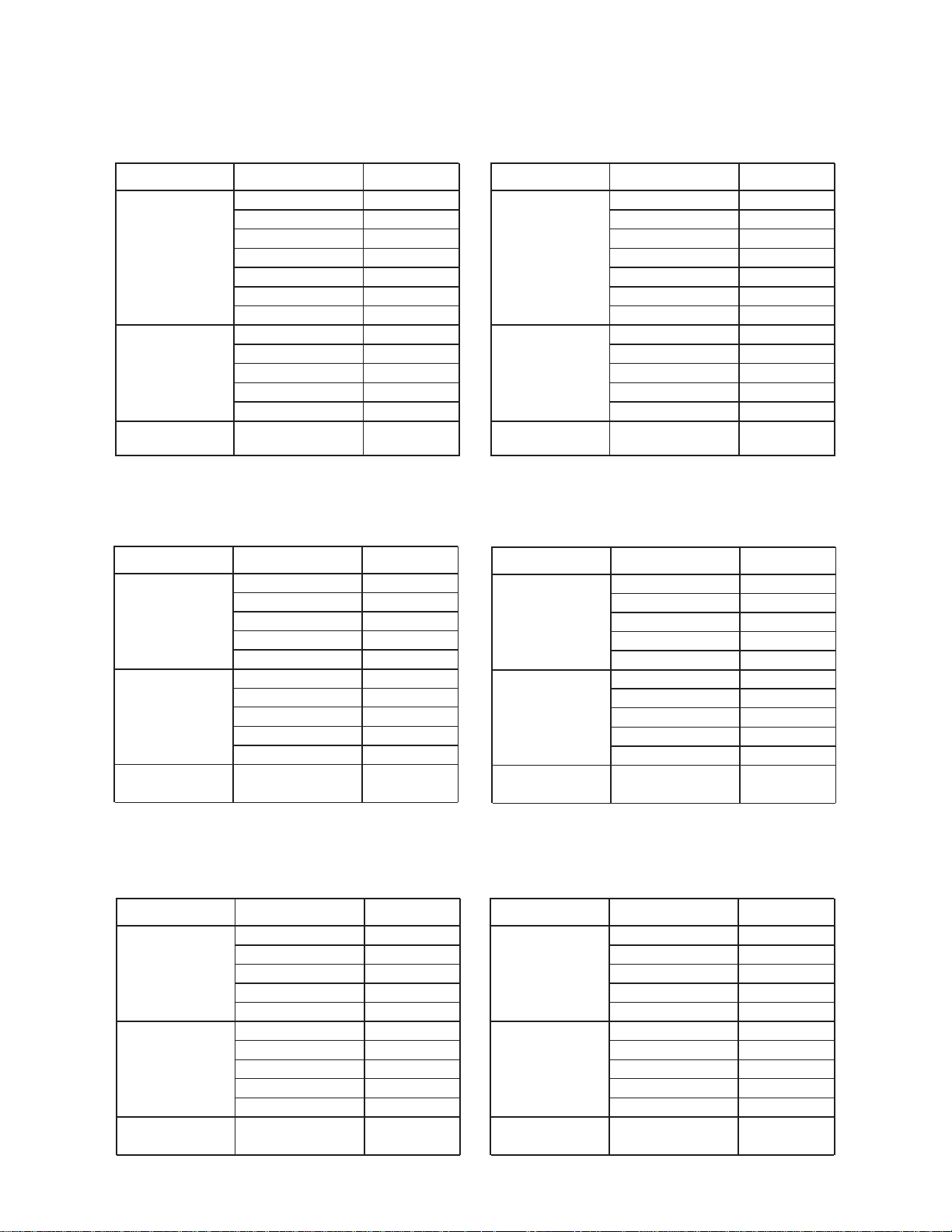

AUU12RLF

AUU18RLF

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

ARU9RLF (Static pressure:25Pa)

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me

Lo

Quiet

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

Fan Speed

650

620

580

520

460

400

300

660

580

520

460

400

X, J zone:460

Fan Speed

1260

1160

1060

960

500

1260

1160

1060

960

500

X, J zone:960

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me+

Me

Lo

Quiet

Cool Air Prevention

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

ARU12RLF (Static pressure:25Pa)

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me

Lo

Quiet

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

Fan Speed

840

800

750

650

500

400

300

790

660

570

460

400

X, J zone:460

Fan Speed

1340

1240

1140

1030

500

1340

1240

1140

1030

500

X, J zone:1030

ARU18RLF (Static pressure:25Pa)

Operation mode

Heating

Cooling / Fan

Dry

Air flow mode

Hi

Me

Lo

Quiet

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

Fan Speed

1380

1300

1220

1140

600

1380

1300

1220

1140

600

X, J zone:1140

ARU24RLF (Static pressure:25Pa)

Operation mode

Heating

Cooling / Fan

Dry

01-06

Air flow mode

Hi

Me

Lo

Quiet

S-Lo

Hi

Me

Lo

Quiet

Soft Quiet

Auto

Fan Speed

1460

1360

1260

1180

600

1460

1360

1260

1180

600

X, J zone:1180

Page 10

2. FAN OPERATION

The airflow can be switched in 5 steps such as Auto, Quiet, Lo, Me, Hi,

while the indoor fan only runs.

When Fan mode is set at (Auto), it operates on (Me) Fan Speed.

< All models >

3. COOLING OPERATION (Auto : Cooling)

Switch the airflow [Auto], and the indoor fan motor will run according to a room temperature,

as shown in Fig 8.

On the other hand, if switched in [Hi] [Quiet], the indoor motor will run at a constant airflow of [Cooling]

operation modes Quiet, Lo, Me, Hi.

( Fig.8 : Airflow change - over )

TR-Ts > +4°F(+2°C)

=

+4

°F(+2°C) > TR-Ts > +2°F(+1°C)

=

+2

=

°F(+1°C) > TR-Ts

=

When the room

temperature drops

< All models >

Hi

Me

Lo

TR-Ts > +5

+5

°F(+2.5°C) > TR-Ts > +3°F(+1.5°C)

°F(+1.5°C) > TR-Ts

+3

When the room

temperature rises

=

TR : Room temperature

Ts : Setting temperature

°F(+2.5°C)

=

=

=

4. DRY OPERATION (Auto : Dry)

During the dry operation, the fan speed setting can not be changed,

it operates automatically as shown in Fig. 8

Room temperature variation which the room temperature sensor of the indoor unit body has detected.

( Fig. 9 : Indoor fan control )

< Compressor >

ON

OFF

< Indoor fan air flow mode >

Setting air flow

S-Lo

Fan OFF

10 30 60 180 60 180 60 10 30 (sec)

< All models >

01-07

Page 11

5. HEATING OPERATION

Switch the airflow [Auto], and the indoor fan motor will run according to a room temperature,

as shown in Fig 10.

On the other hand, if switched in [Hi] [Quiet], the indoor motor will run at a constant airflow

of [Heat] operation modes Quiet, Lo, Me, Hi, as shown in Table 4.

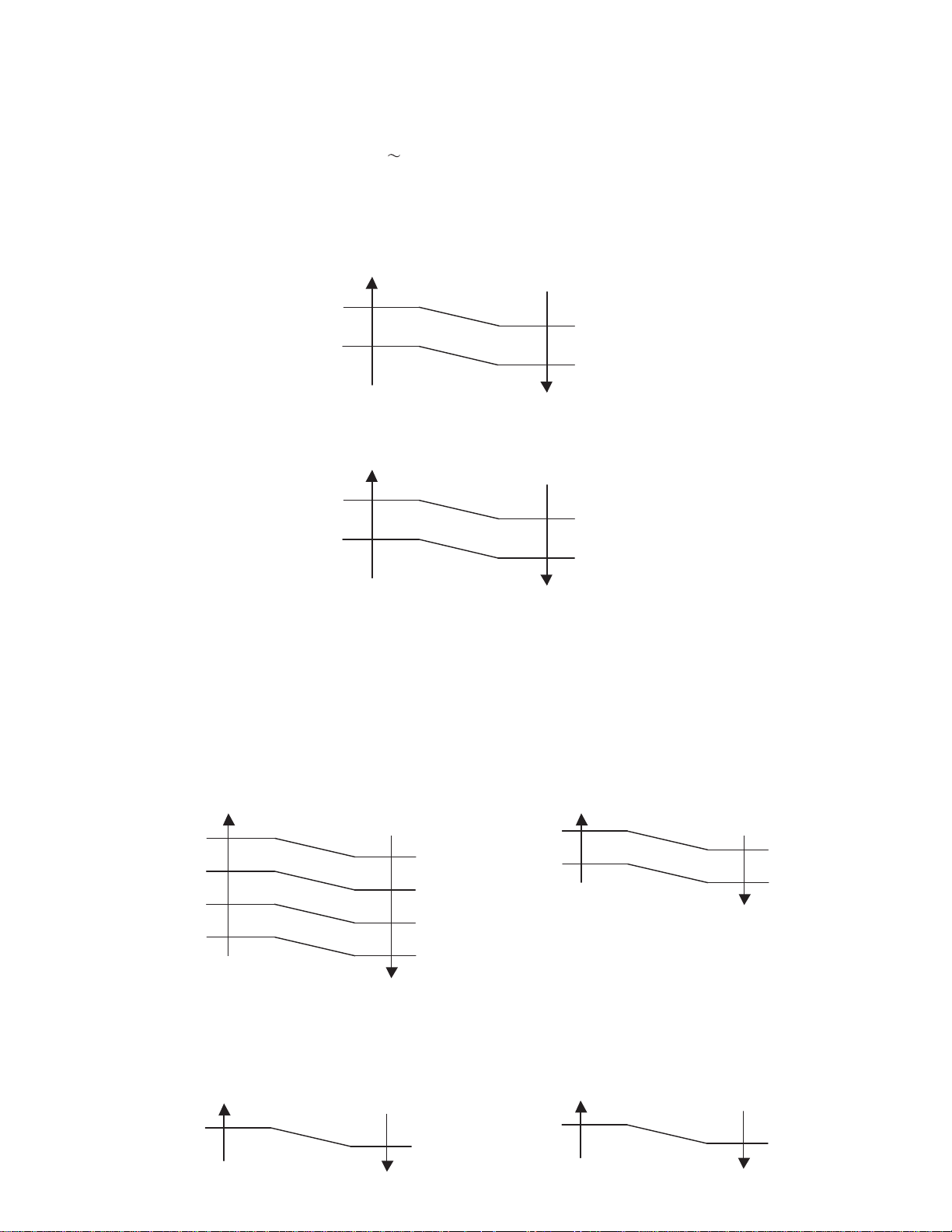

( Fig.10 : Airflow change - over ( Heating : Auto ) )

< ASU7/9/12/18/24RLF >

When the room

temperature rises

TR-Ts > -2

°F(-1°C) > TR-Ts > -4°F(-2°C)

-2

°F(-1°C) > TR-Ts > -4°F(-2°C)

-2

=

°F(-2°C) > TR-Ts

-4

TR-Ts > -2

=

-4

°F(-2°C) > TR-Ts

°F(-1°C)

=

When the room

temperature rises

°F(-1°C)

=

When the room

Lo

Me

Me+

temperature drops

TR-Ts > -3°F(-1.5°C)

-3°F(-1.5°C) > TR-Ts > -5°F(-2.5°C)

-5

°F(-2.5°C) > TR-Ts

< AUU9/12/18RLF, ARU9/12/18/24RLF >

When the room

Lo

Me

Hi

temperature drops

TR-Ts > -3°F(-1.5°C)

-3°F(-1.5°C) > TR-Ts > -5°F(-2.5°C)

°F(-2.5°C) > TR-Ts

-5

=

=

TR : Room temperature

Ts : Setting temperature

=

=

6. COOL AIR PREVENTION CONTROL (For Heating and Min. Heat operation)

The maximum value of the indoor fan speed is set as shown in Fig 10, based on the detected

temperature by the indoor heat exchanger sensor in heating mode.

Field setting is necessary at AR and AU type as "Cool air prevention : effective"

( Fig.11 : Airflow change - over for cool air prevention)

During NORMAL HEATING OPERATION

< ASU7/9/12/18/24RLF, AUU9/12/18RLF >

When Indoor

heat exchanger

temperature rises

107.6°F

(42°C)

°F

102.2

(39°C)

°F

98.6

(37°C)

86

°F

(30°C)

Hi

*Me+ or setting

FAN mode

*Lo or setting

FAN mode

Cool air

prevention

S-Lo

When Indoor

heat exchanger

temperature drops

98.6

(37°C)

93.2

(34°C)

89.6

(32°C)

82.4

(28°C)

°F

°F

°F

°F

When Indoor

heat exchanger

temperature rises

98.6°F

(37°C)

84.2°F

(29°C)

< ARU9/12/18/24RLF >

*Hi or setting

FAN mode

*Lo or setting

FAN mode

S-Lo

*Lower speed is selected

*Lower speed is selected

During MIN. HEAT OPERATION

< ASU7/9/12/18/24RLF, AUU9/12/18RLF >

When Indoor

heat exchanger

temperature rises

102.2°F

(39°C)

Auto

Lo

When Indoor

heat exchanger

temperature drops

93.2°F

(34°C)

When Indoor

heat exchanger

temperature rises

98.6

(37°C)

< ARU9/12/18/24RLF >

Auto

°F

Lo

When Indoor

heat exchanger

temperature drops

°F

89.6

(32°C)

75.2

°F

(24°C)

When Indoor

heat exchanger

temperature drops

89.6°F

(32°C)

01-08

Page 12

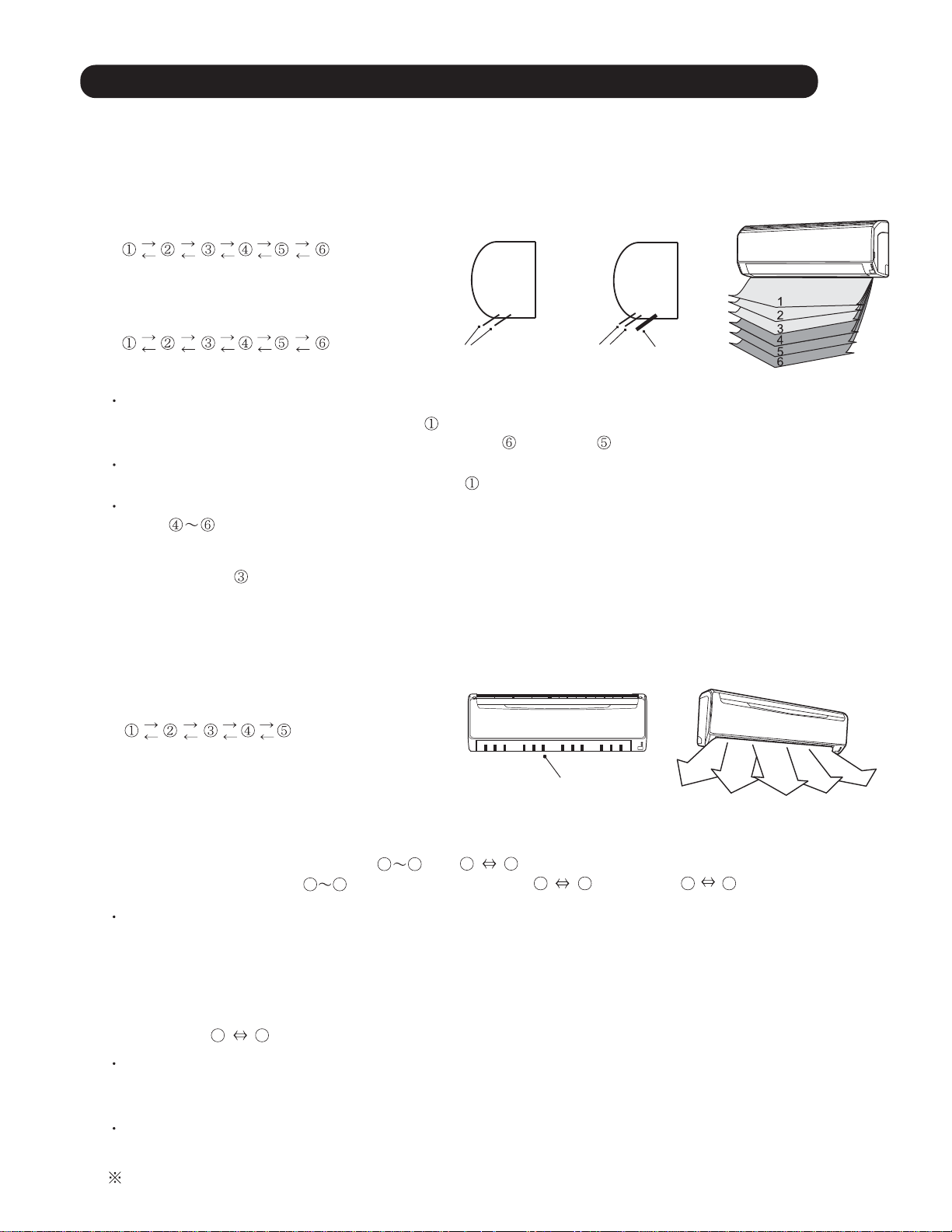

1-5. LOUVER CONTROL

For Compact Wall Mounted Type, Wall Mounted Type < ASU7/ 9/ 12/ 18/ 24RLF >

1. VERTICAL LOUVER CONTROL

(Function Range)

Each time the button is pressed, the air direction range

will change as follow:

(Table9 : Recommended Operation Range)

Cooling / Heating / Dry mode / Fan mode

(Fig.12 : Virtical Air Direction Range)

<Wall Mounted Type><Compact Wall Mounted Type>

Vertical Louver

Power DiffuserVertical Louver

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation selected.

Cooling / Dry mode : Horizontal flow

Heating mode : Downward flow ASU7/9/12: , ASU18/24:

When the temperature of the air being blown out is low at the start of heating operation or during

defrosting, the airflow direction temporarily becomes to prevent cold air being blown onto the body.

During use of the Cooling and Dry modes, do not set the Air Flow Direction Louver in the Heating

range ( ) for long period of time, since water vapor many condense near the outlet louvers and

drop of water may drip from the air conditioner. During the Cooling and Dry modes, if the Air Flow

Direction Louvers are left in the heating range for around 30 minutes, they will automatically

return to position .

2. HORIZONTAL LOUVER CONTROL (For ASU18/ 24RLF)

(Function Range)

Each time the button is pressed, the air direction

range will change as follows.

ASU7/9/12RLF changes by manual.

Cooling / Heating / Dry mode / Fan mode

3. SWING OPERATION

Vertical Airflow Swing Operation

When the swing signal is received from the remote controller, the vertical louver starts to swing.

(Swinging Range)

Cooling mode / Dry mode / Fan mode( ) :

Heating mode / Fan mode( ) : ASU7/9/12 [ ], ASU18/24 [ ]

4

1 3

6

1

(Fig.13 : Horizontal Air Direction Range)

1

Horizontal Louver

4

6

4

36

2

3

5

4

When the indoor fan is S-Lo or Stop mode, the swing operation is interrupted

and it stops at either upper end or bottom end.

Horizontal Airflow Swing Operation (For ASU18/24RLF )

When the swing signal is received from the remote controller, the horizontal louver starts to swing.

(Swinging Range)

All mode :

1

5

When the indoor fan is S-Lo or Stop mode, the swing operation is interrupted

and it stops at either upper end or bottom end.

Vertical and Horizontal Airflow Swing Operation

When the horizontal swing signal is input from remote control, the combination of the vertical

and horizontal swing operation is performed.

Power Diffuser doesn't swing in any swing operation.

01-09

Page 13

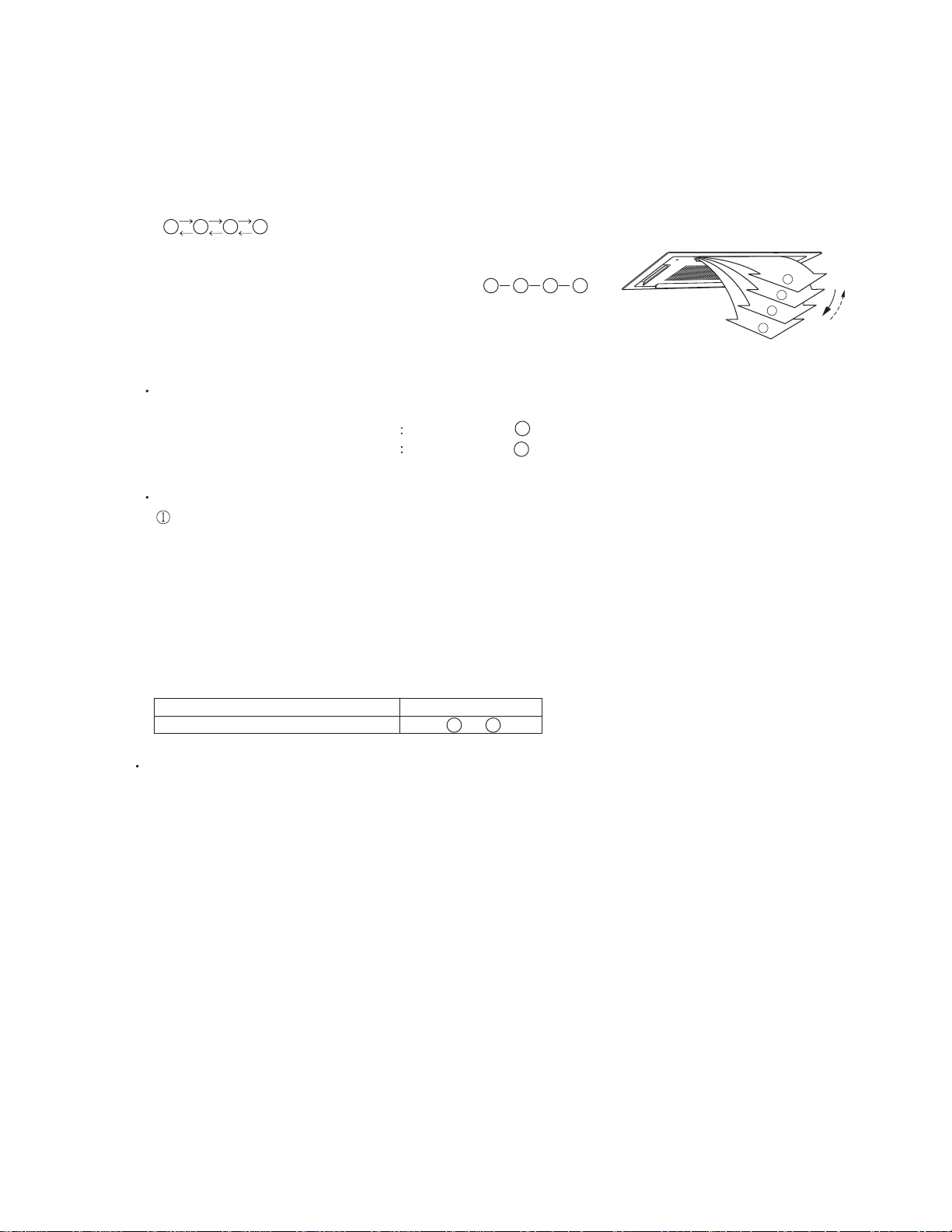

For Compact Cassette Type < AUU9/ 12/ 18RLF >

1. VERTICAL LOUVER CONTROL

(Function Range)

Each time the button is pressed, the air direction range will change as follows:

1234

(Operation Range)

During COOLING / HEATING / DRY / FAN mode :

1234

(Fig.14 : Air Direction Range)

3

4

Use the air direction adjustments within the ranges shown above.

The vertical airflow direction is set automatically as shown, in accordance with the type of operation

selected.

COOLING / DRY / FAN mode

HEATING mode

Horizontal flow

Downward flow

1

4

During AUTO mode operation, for the first minute after start-up, air-flow will be horizontal

; the air direction cannot be adjusted during this period.

2. SWING OPERATION

When the swing signal is received from the remote controller, the vertical louver starts to swing.

The range of swing depends on the set airflow direction.

1

2

The type of operation

COOLING / HEATING / DRY / FAN

Range of swing

to

14

When the indoor fan is either at S-Lo or Stop mode, the swinging operation is interrupted

and the louver stops at the memorized position.

( Stop mode means Operation stop.)

01-10

Page 14

1-6. OUTDOOR FAN CONTROL

1. Fan speed table

Table 5 shows the fan speed of the outdoor unit.

( Table 5 : Outdoor fan speed table)

AOU48RLXFZ

Fan step

0

1

2

3

4

5

6

7

8

9

10

11

Fan speed

0

250

290

340

390

460

580

690

800

890

910

950

[rpm]

2. Limit of fan speed range

Fig.15 shows the limit of fan speed range changes by outdoor temperature.

( Fig.15 : Limit of fan speed range )

Outdoor

temperature

86°F(30°C)

68°F(20°C)

50°F(10°C)

< Cooling and Dry mode >

890rpm

580 ~ 890rpm

250 ~ 890rpm

0 ~ 890rpm

Outdoor

temperature

41°F(5°C)

< Heating mode >

460 ~ 910rpm

460 ~ 950rpm

3. Initial fan speed control

Initial fan speed is decided by outdoor temperature.

( Fig.16 : Initial fan speed range )

< Cooling and Dry mode >

Outdoor

temperature

690rpm

50°F(10°C)

390rpm

If the fan motor is running over than 400rpm, it start up process is stopped in all conditions. [ Prevent the big wind operation ]

*

When the fan motor is stopped, it can not restart for 10 seconds.

*

Even if during EEV initialization, outdoor unit fan starts.

*

01-11

< Heating mode >

Fixed at 690rpm

Page 15

1-7. COMPRESSOR CONTROL

1. OPERATION SPEED RANGE

The operation speed of the compressor is different based on the operation mode as

shown in theTable 6.

( Table 6 : Compressor operation speed range )

Heating

Minimum Maximum

18rps 96rps

AOU48RLXFZ

Dry / Cooling

Minimum Maximum

18rps

90rps

2. OPERATION SPEED CONTROL AT START-UP

The compressor speed soon after the start-up is controlled for

2-1 Cooling and Dry start-up procces

< Pattern 1 >

If it does not meet the condition of pattern 2, the compressor will start at pattern 1.

( Fig.17 : Pttern 1)

(rps)

70

limit

54

47

40

33

Upper

speed

90

180 240

Elapsed time

< Pattern 2 >

If it meets one of the following conditions, the compressor will start at pattern 2.

Condition

1

2

3

Compressor control

before operation stops

Target pressure control

Start-up procces 2

Oil recovery / Defrost

Stop time of

compressor

Below 3 hours

Compressor

temperature

Over 32°C

( Fig.18 : Pattern 2)

(rps)

54

Upper

speed

limit

47

40

33

20

(sec)300 330

90

180 240

Elapsed time

01-12

(sec)300 36070390

Page 16

2-2 Heating start-up procces

< Pattern 1 >

If it does not meet the condition of pattern 2, the compressor will start at pattern 1.

( Fig.19 : Heating start-up pattern 1)

(rps)

70

limit

60

47

40

33

Upper

speed

90

Elapsed time

690 720

< Pattern 2 >

If it meets one of the following conditions, the compressor will start at pattern 2.

Condition

1

2

3

Compressor control

before operation stops

Target pressure control

Start-up procces 2

Oil recovery / Defrost

Stop time of

compressor

Below 3 hours

Compressor

temperature

Over 89.6°F

(32°C)

( Fig.20 : Heating start-up pattern 2)

(rps)

60

Upper

speed

limit

47

40

33

20

90

150 210

Elapsed time

(sec)780 840

(sec)270 33070390

3. LIMIT OF THE COMPRESSOR SPEED RANGE

The compressor speed range is limited by outdoor temperature as shown in Fig.21

( Fig.21 : Limit of the compressor speed range )

< Cooling and Dry mode >

Outdoor

temperature

21 ~ 90rps

104°F(40°C)

18 ~ 90rps

50°F(10°C)

25 ~ 90rps

23°F(-5°C)

27 ~ 90rps

14°F(-10°C)

* 0rps

*Protection stop for low outdoor temperature.

It will be released when outdoor temperature

becomes over than 14°F(-10°C)

01-13

Outdoor

temperature

53.6°F(12°C)

41°F(5°C)

5°F(-15°C)

< Heating mode >

21 ~ 90rps

18 ~ 96rps

23 ~ 96rps

25 ~ 96rps

Page 17

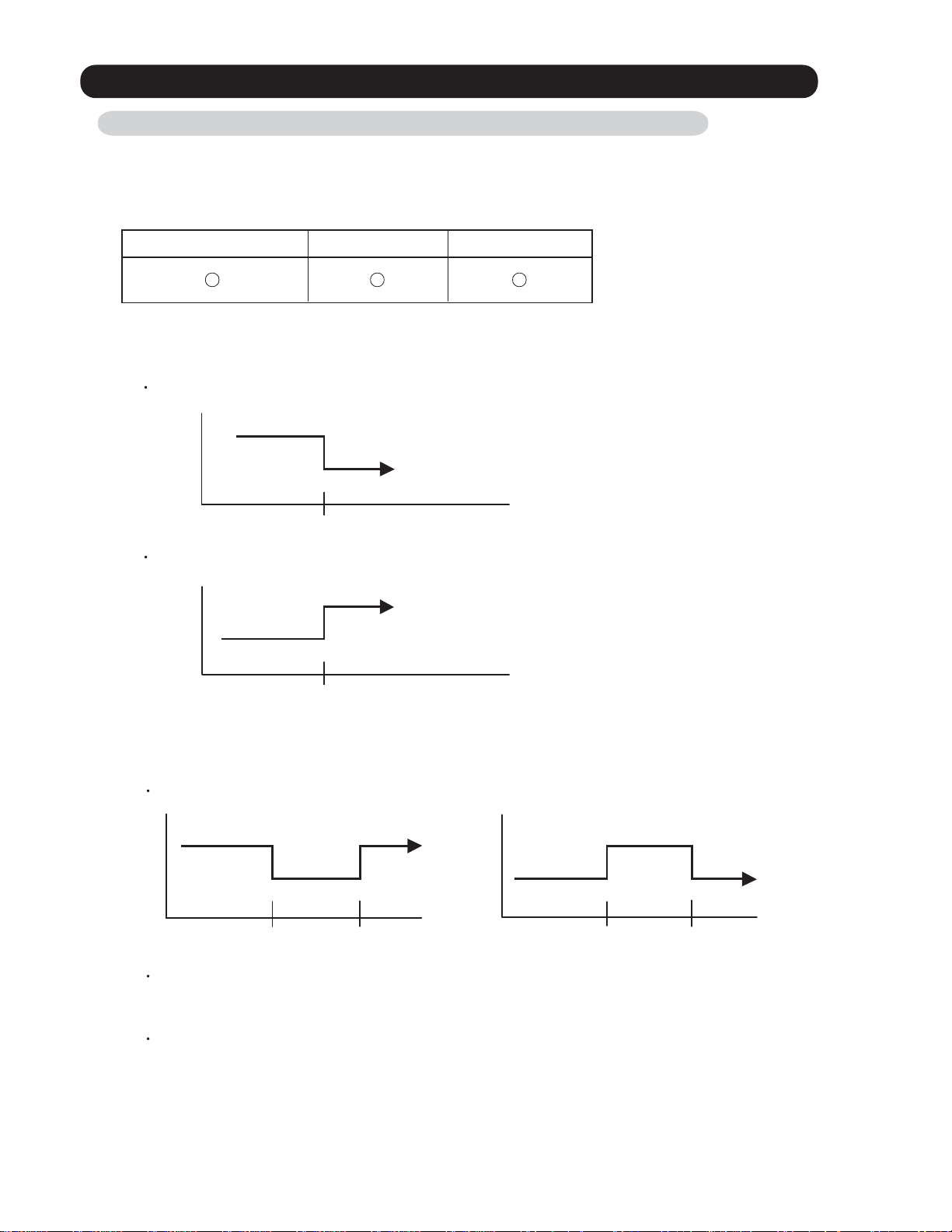

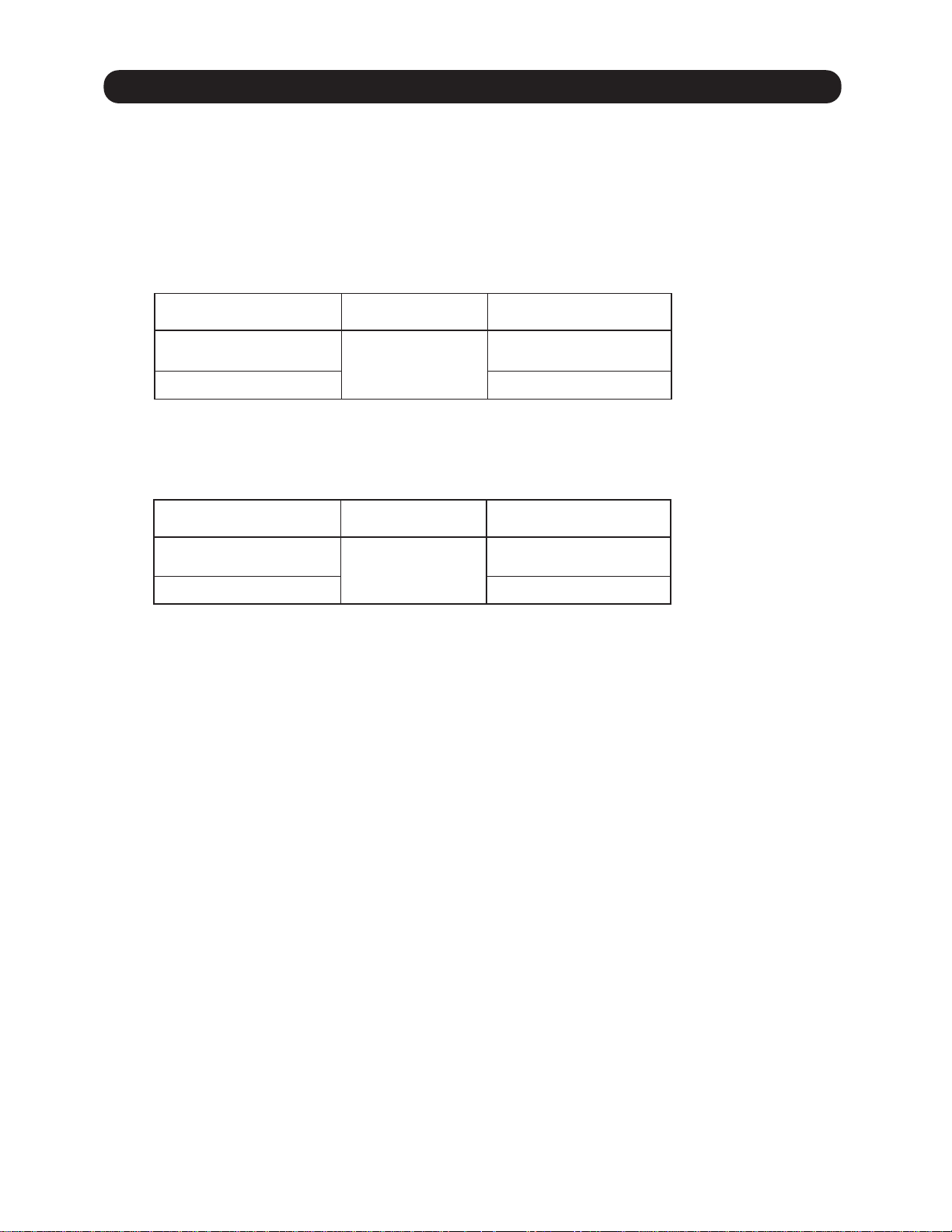

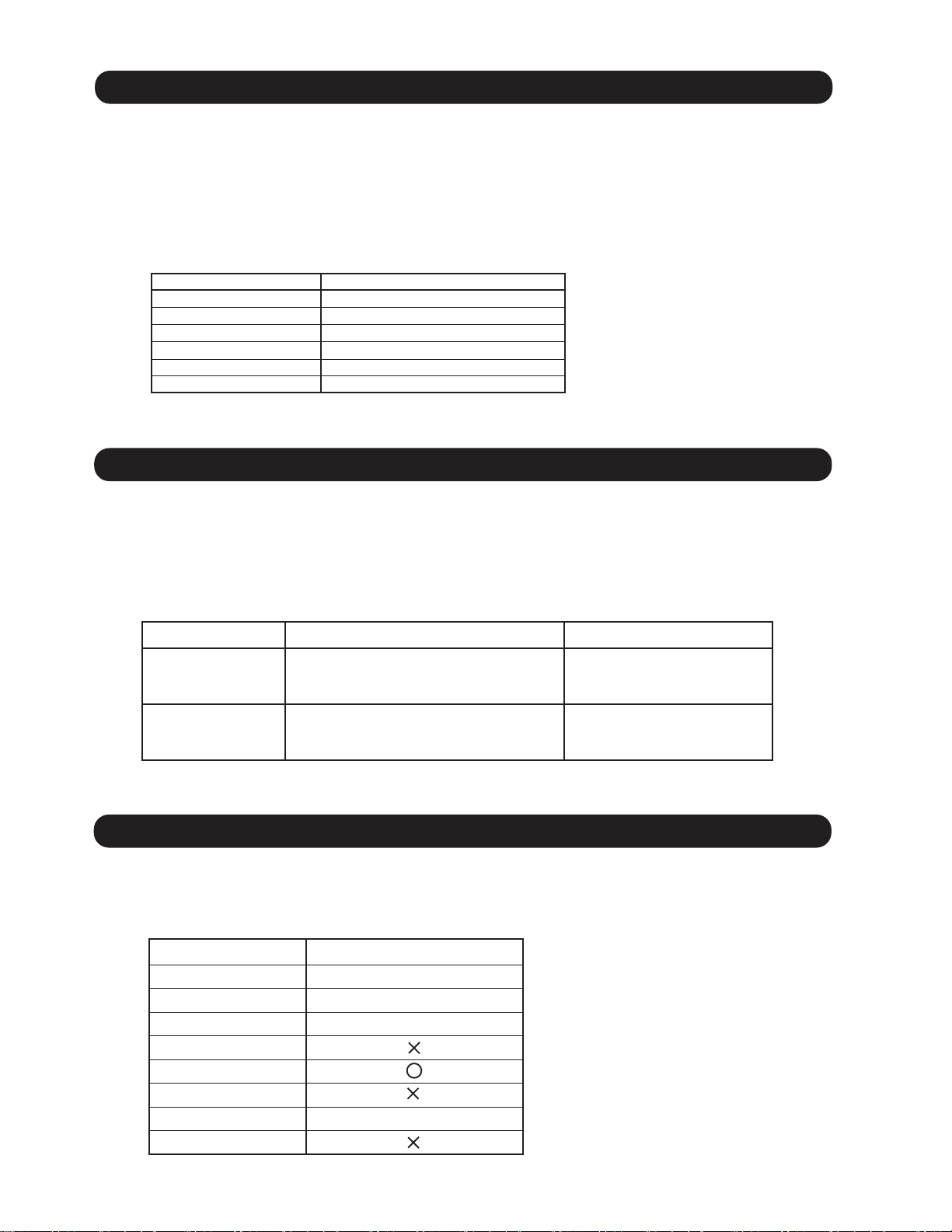

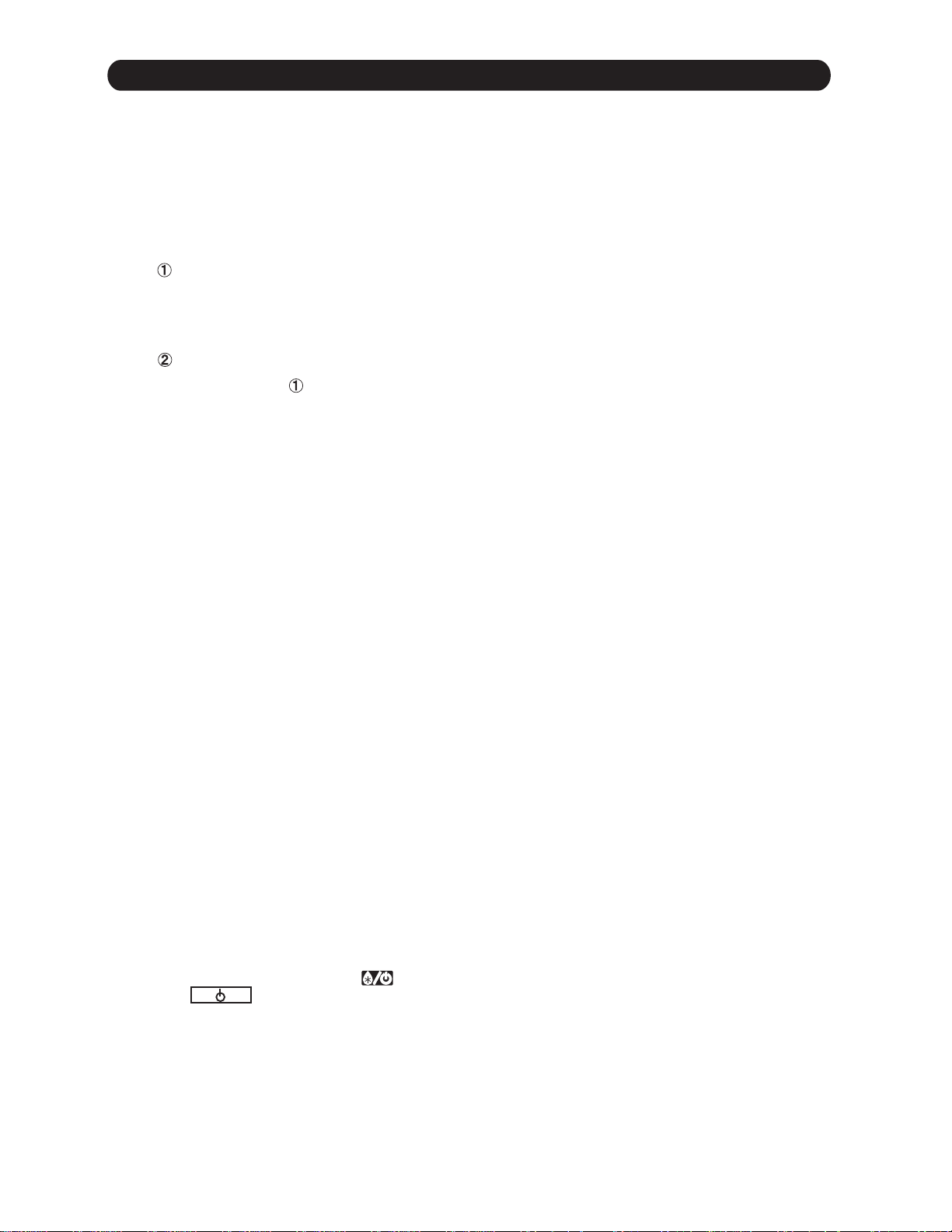

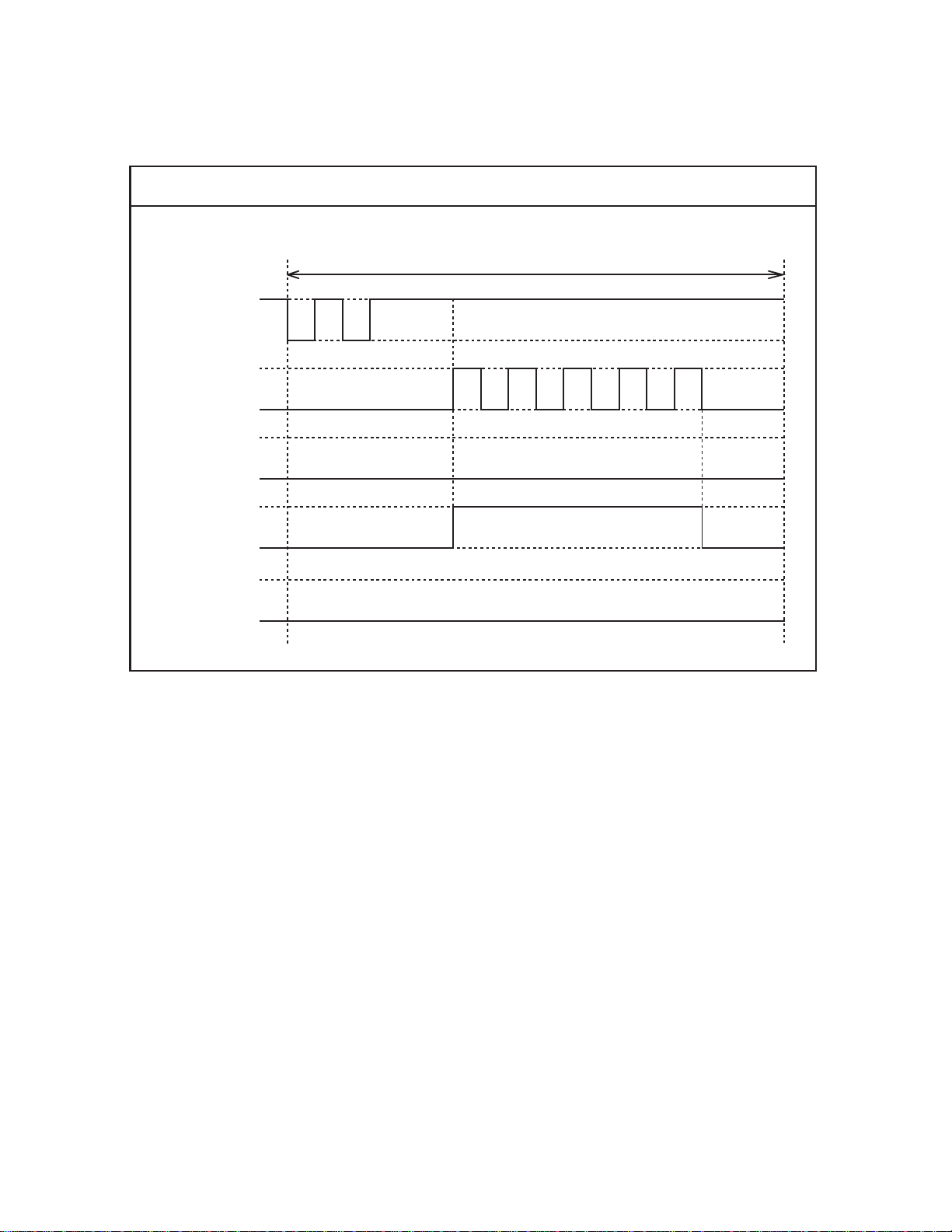

1-8. TIMER OPEARTION CONTROL

1-8-1 WIRELESS REMOTE CONTROLLER

The table 7 shows the available timer setting based on the product model.

( Table 7 : Timer setting )

ON TIMER / OFF TIMER PROGRAM TIMER SLEEP TIMER

1. ON / OFF TIMER

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

2. PROGRAM TIMER

The program timer allows the OFF timer and ON timer to be used in combination one time.

Operation mode

Stop mode

Set time Set time Set time Set time

Operation will start from the timer setting (either OFF timer or ON timer) whichever is closest

to the clock's current timer setting.

The order of operations is indicated by the arrow in the remote control unit's display.

Operation mode

Operation mode

Stop mode

Stop mode

SLEEP timer operation cannot be combined with ON timer operation.

01-14

Page 18

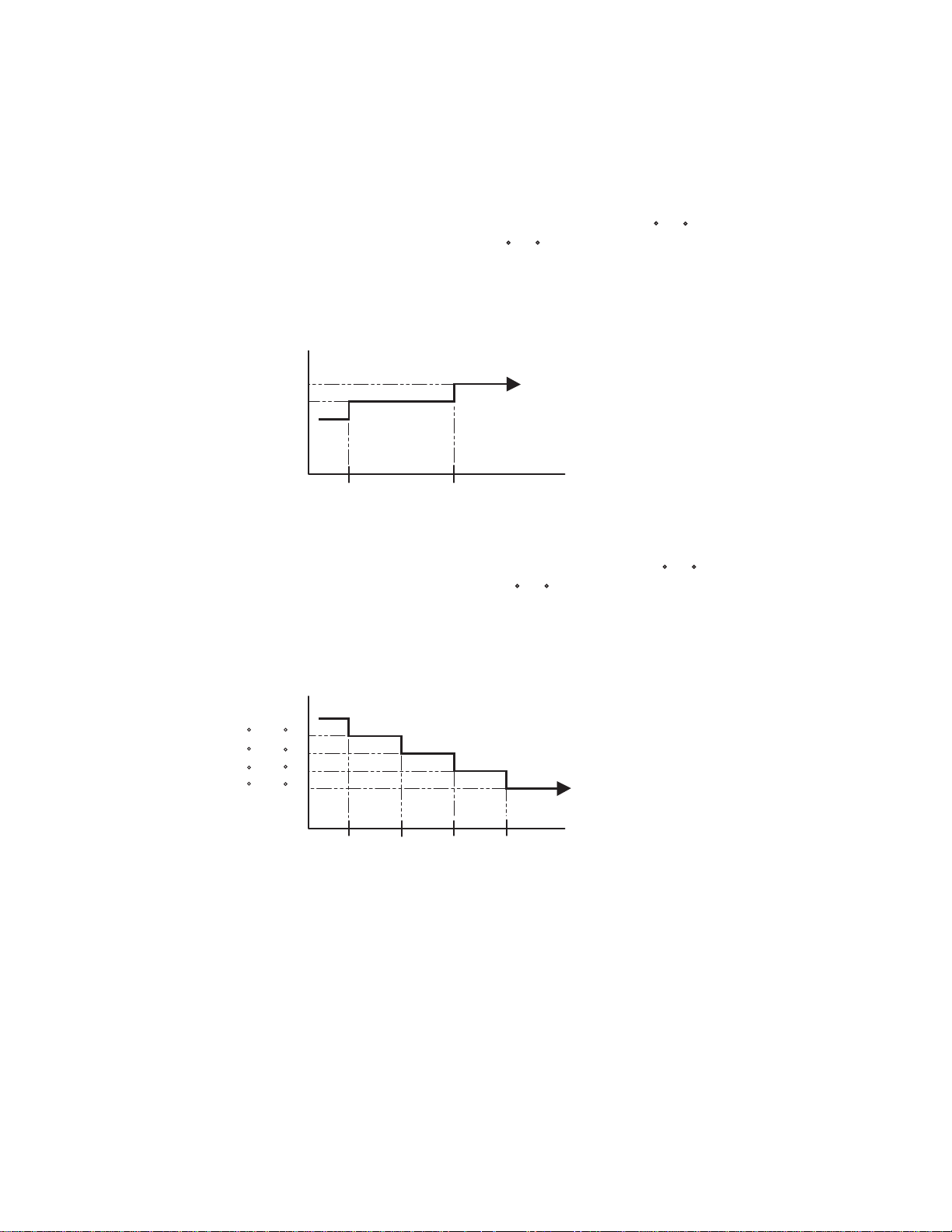

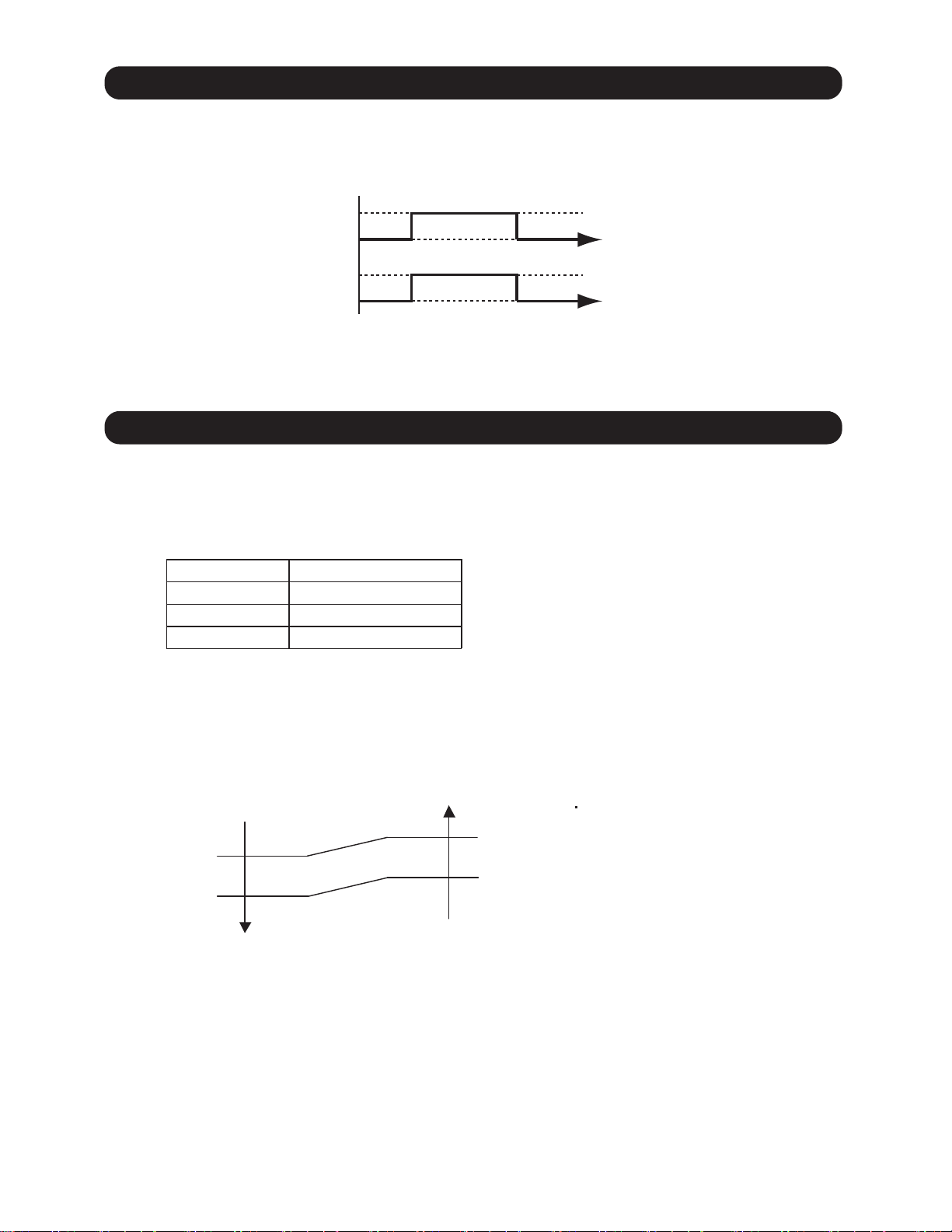

3. SLEEP TIMER

If the sleep is set, the room temperature is monitored and the operation is stopped automatically.

If the operation mode or the set temperature is change after the sleep timer is set, the operation is

continued according to the changed setting of the sleep timer from that time ON.

In the cooling operation mode

When the sleep timer is set, the setting temperature is increased 2 F(1 C).

It increases the setting temperature another 2 F(1 C) after 1 hour.

After that, the setting temperature is not changed and the operation is stopped at the time

of timer setting.

Set temperature rises

( Ts : Set temperature )

+4°F (+2°C)

+2°F (+1°C)

Ts

Stop of operation

Set

60min

In the heating operation mode

When the sleep timer is set, the setting temperature is decreased 2 F(1 C).

It decreases the setting temperature another 2 F(1 C) every 30 minutes.

Upon lowering 4deg C, the setting temperature is not changed and the operation stops at

the time of timer setting.

Set temperature lowers

( Ts : Set temperature )

Ts

-2 F(-1 C)

-4 F(-2 C)

-6 F(-3 C)

-8 F(-4 C)

Stop of operation

Set

30min

30min

30min

01-15

Page 19

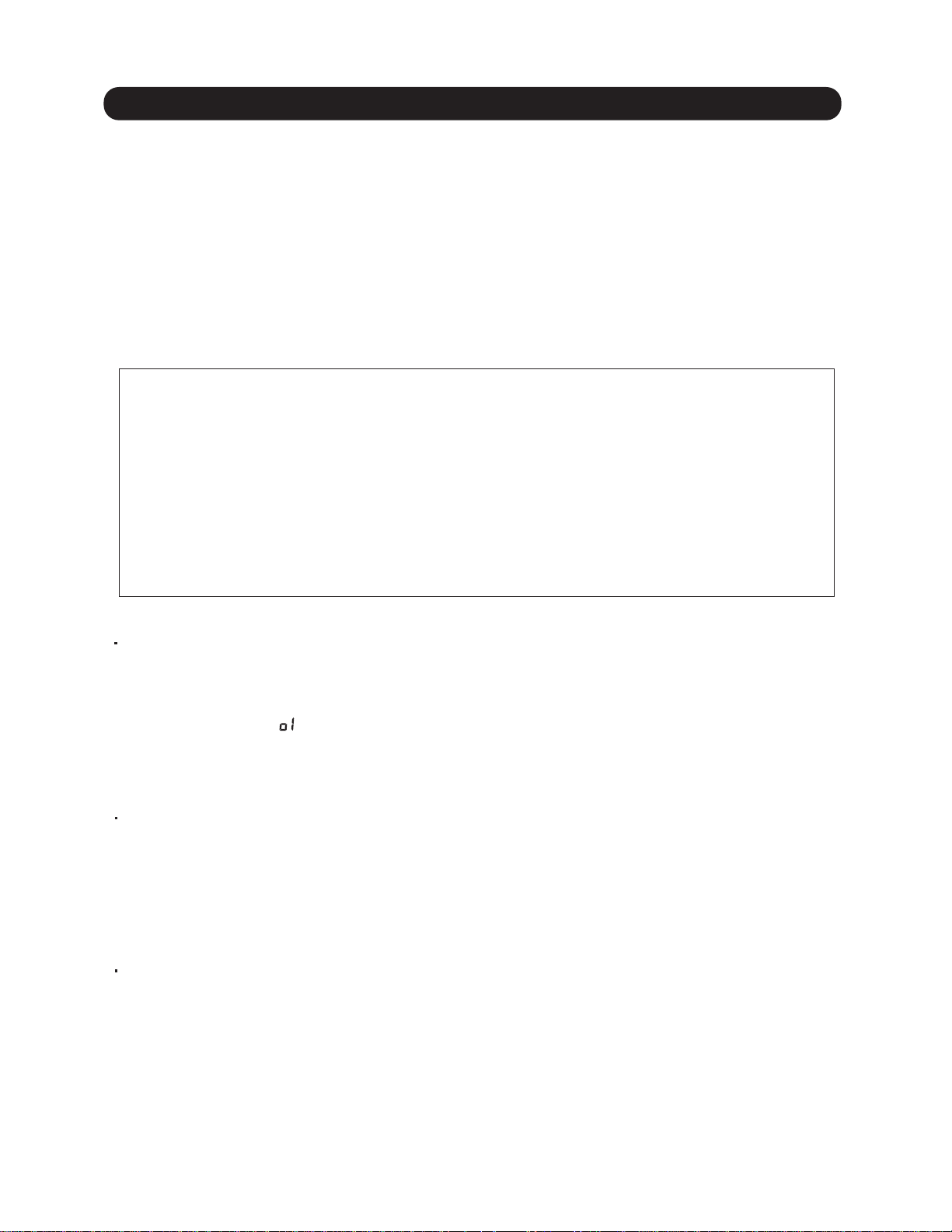

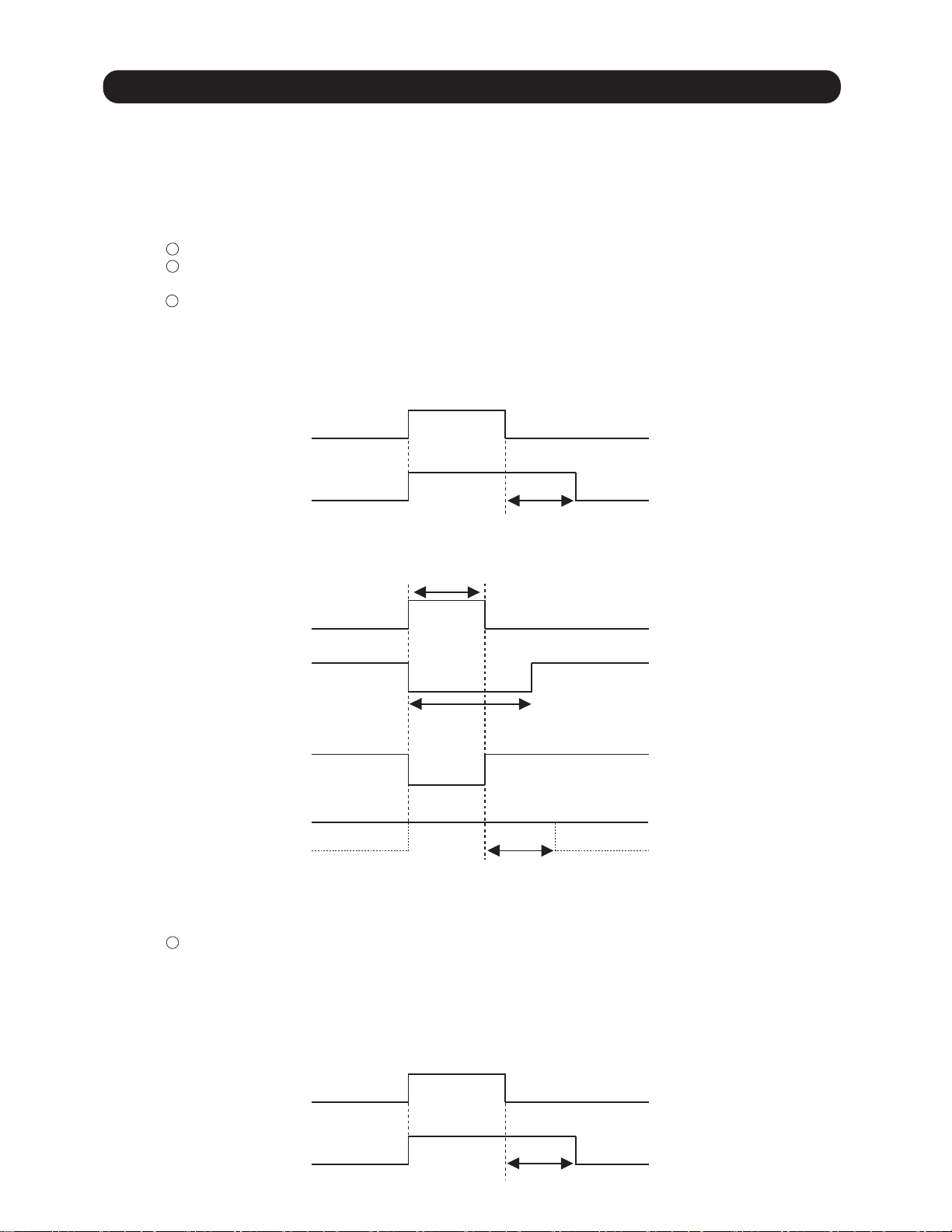

1-8-2 WIRED REMOTE CONTROLLER

The Table 8 shows the available timer setting based on the product model.

( Table 8 : Timer setting )

ON TIMER / OFF TIMER WEEKLY TIMER TEMPERATURE SET BACK TIMER

1. ON TIMER / OFF TIMER

Same to 1-8-1 ON / OFF TIMER and shown in those.

2. WEEKLY TIMER

This timer function can set operation times of the each day of the week.

All days can be set together,the weekly timer can be used to repeat the timer setting for all of the days.

ON OFF ON OFF ON OFF

Setting day Setting day Setting day

Set time Set time

3. TEMPERATURE SET BACK TIMER

This timer function can change setting temperature of setting operation times of the each day of the week.

This can be together with other timer setting.

Set back tmp.

Normal tmp.

ON

Set time Set time

OFF

01-16

Page 20

1-9. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the following values.

The compressor frequency, the temperatures detected by the discharge temperature sensor, the

indoor heat exchanger sensor, the outdoor heat exchanger sensor, and the outdoor temperature

sensor.

1. Pulse range

(Table 9 : Pulse range of outdoor unit EEV)

Outdoor unit

Main EEV

Subcool EEV

Operation mode

Dry / Cooling

Heating

During heating operation, lower limit is 0 pulse.

Pulse range

40 ~ 480

35 ~ 480

(Table 10 : Pulse range of branch box EEV)

Branch box

Main EEV

Bypass EEV

Operation mode

Dry / Cooling

Heating

There is a case that EEV is full close at 32 10 pulse.

Pulse range

32 ~ 480

0 ~ 480

+

-

2. Initialization

Initialization (Input of 528 pulses toward closing direction) is operated under the following conditions.

It apply to all of EEV.

< Initialization conditions >

.

Power-on.

.

4 hours has passed from the last initialization, and when the compressor starts.

.

If 12 hours has passed from the last initialization, the compressor is compulsorily stopped.

.

3 minutes has passed from the protection stop of outdoor unit.

01-17

Page 21

1-10. TEST OPERATION CONTROL

< Pre-test run check items >

Before the test run, refer to the figure and check the following items.

1. Is check run performed? Test run doesn't operate if check run is not performed.

After checking that the above items are all in order, refer to Test run method "to test run the unit.

If there are problems, adjust immediately and recheck.

< Test run method >

Be sure to configure test run settings only when the outdoor unit has stopped operating.

Depending on the communication status between the indoor and outdoor units, it may take several minutes for •

the system to start operating after settings for the test run are complete.

After the test run settings are complete, all the outdoor units and the connected indoor units will start operating. •

Room temperature control will not activate during test run (continuous operation).

Test run set with the outdoor unit doesn't stop automatically. Be sure to stop the operation according to the •

operation method.

All indoor units will operate when test run is performed from the outdoor unit. At this time, the remote controller of •

the indoor unit is unavailable.

Operation mode cannot be changed during the test run. To change the operation mode, please stop the test run •

first, and then perform the test run again. At this time, the compressor cannot be restarted for three minutes after

it stops in order to protect the indoor unit. Please restarte it after three minutes.

With Wired Remote Controller

Under the condition where the air conditioner stops, press the MODE button and the FAN button

simultaneously for 2 seconds or more, and the test operation control mode will appear.

During test running, " " will display on the remote controller display.

Set the test operation mode, and the compressor will continue to run regardless of whatever

the room temperature sensor detects.

With Wireless Remote Controller

Under the condition where the air conditioner runs, press the TEST RUN button, and

the test operation control mode will appear.

During test running, the Operation LED and Timer LED of the air conditioner body blinks simultaneously.

Set the test operation mode, and the compressor will continue to run regardless of whether the room

temperature sensor detects.

With Outdoor Unit

All the indoor units connected to the outdoor unit can be test-operated by push button as next page.

01-18

Page 22

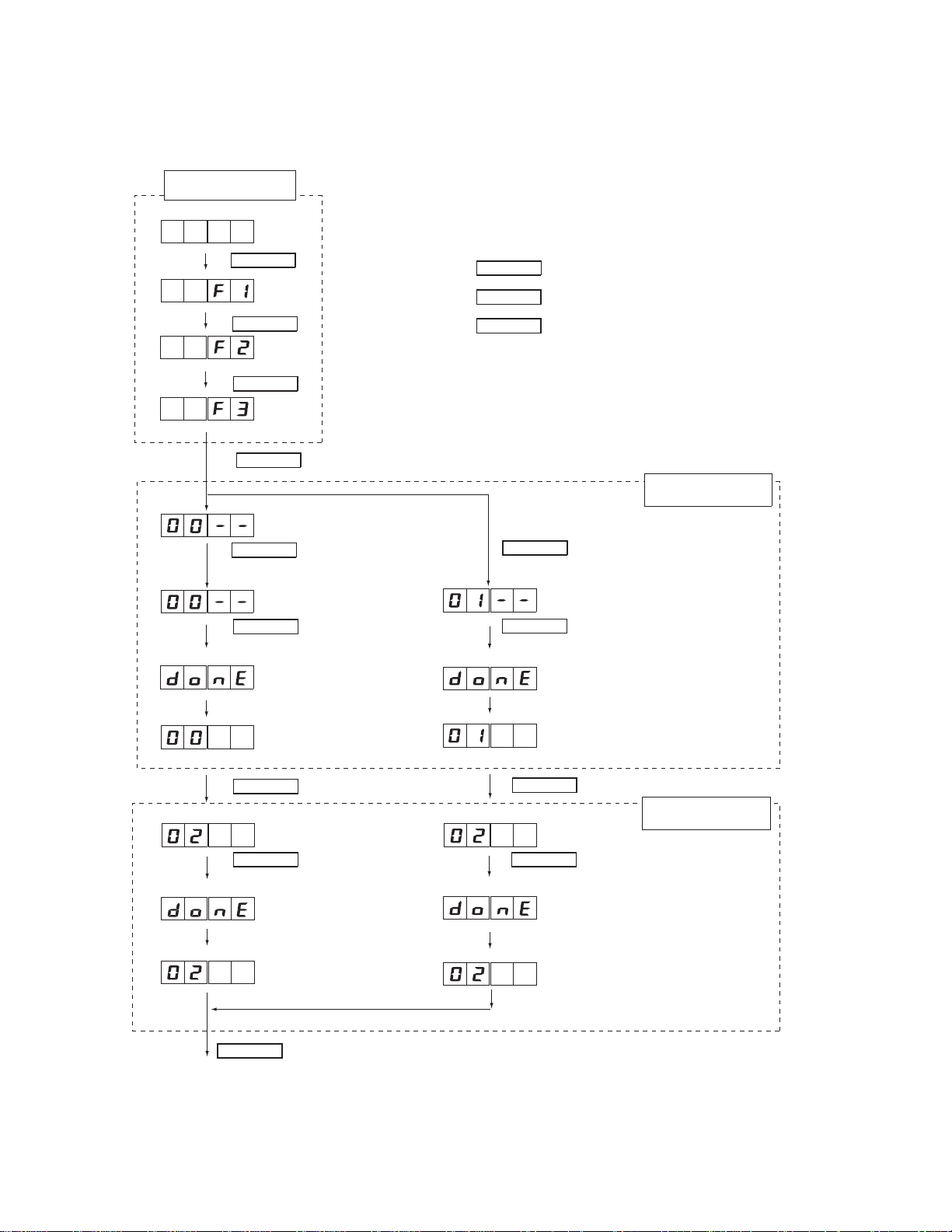

Perform test run for refrigerant system.

You can set “cooling test run” or “heating test run” with the push-button switch on the outdoor unit print circuit board.

Test run setting method

Function settings

First 2 digits

(Blinking)

(Blinking)

(Blinking)

Last 2 digits

MODE/EXIT

(Blinking)

SELECT

(Blinking)

SELECT

ENTER

SELECT

For cooling operation, press the

SELECT button until

ENTER

Press the ENTER button for

more than 3 seconds.

This will be displayed when the

cooling test run starts.

(It takes approximately 30 seconds for

the outdoor unit to start its operation.)

This will be displayed

after 5 seconds.

MODE/EXIT

SELECT

ENTER

(When [F4] to [F9] are displayed, continue to press

the SELECT button until [F3] is displayed.)

SELECT

For heating operation, press the

is displayed.

“00”

(Blinking)

(Blinking)

SELECT button until

ENTER

Press the ENTER button for

more than 3 seconds.

This will be displayed when the

heating test run starts.

This will be displayed

after 5 seconds.

: Press the “MODE/EXIT” button.

: Press the “SELECT” button.

: Press the “ENTER” button.

Settings for starting

test run operation

is displayed.

“01”

(It takes approximately 30 seconds for

the outdoor unit to start its operation.)

SELECT

SELECT

Settings for stopping

test run operation

(Blinking)

(Blinking)

ENTER

Press the ENTER button for

more than 3 seconds.

This will be displayed when the

cooling operation mode is canceled.

(It takes approximately 30 seconds for

the outdoor unit to stop its operation.)

This will be displayed

after 5 seconds.

MODE/EXIT

(Blinking)

(Blinking)

ENTER

Press the ENTER button for

more than 3 seconds.

This will be displayed when the heating

operation mode is canceled.

(It takes approximately 30 seconds for

the outdoor unit to stop its operation.)

This will be displayed

after 5 seconds.

EXIT

After the test run is complete, turn off the power. Attach the cover of the electrical component box and the front panel

of the outdoor unit.

01-19

Page 23

1-11. 4-WAY VALVE EXTENSION SELECT

At the time when the air conditioner is switched from the Cooling mode to Heating mode,

the compressor is stopped, and the 4-way valve is switched in 3 minutes later

after the compressor stopped.

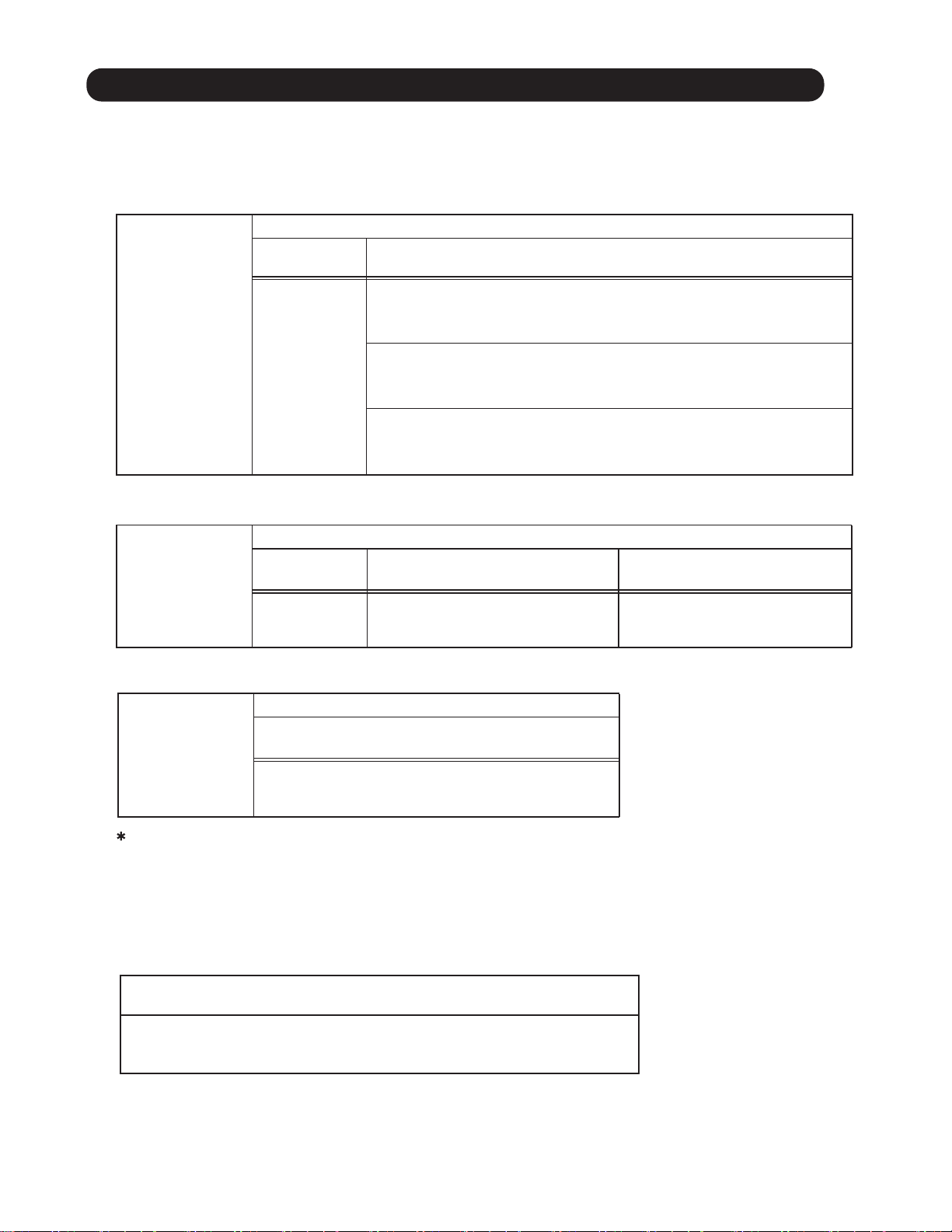

1-12. AUTO RESTART

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically resumed with

the memorized operation contents.

(Table 11 : Operation contents memorized when the power is interrupted)

Wireless remote controller

Wired remote controller

(When Memory Backup : Disable)

Wired remote controller

(When Memory Backup : Enable)

Operation mode

Set temperature

Set air flow

Thermistor detected position

OFF TimerON Timer

WEEKLY Timer

Timer mode

Temperature

SET BACK Timer

: Memorize

: Not memorize

*It is necessary to set on the DIP-SW1-No,6 of the wired remote controller, to enable the memory backup.

Refer to the installation manual of wired remote controller for details.

1-13. MANUAL AUTO OPERATION

If MANUAL / AUTO Button is pushed continuous from 3 seconds to 10 seconds,

manual auto operation will starts.

If the remote control is lost or battery power dissipated, this function will work without the remote

control.

(Table 12 : Manual auto operation control)

Functions

OPERATION MODE

SETTING TEMP.

FAN MODE

VERTICAL LOUVER

HORIZONTAL LOUVER

TIMER MODE

SWING OPERATION

ECONOMY

All models

Auto changeover

75.2°F(24°C)

Auto

NORMAL

NORMAL

Continuous

(No timer setting available)

OFF

OFF

01-20

Page 24

1-14. FORCED COOLING OPERATION

Forced cooling operation is started when pressing MANUAL AUTO button for 10 seconds or more.

During the forced cooling operation, it operates regardless of room temperature sensor.

Operation LED and timer LED blink during the forced cooling operation. They blink for 1 second ON

and 1 second OFF on both operation LED and timer LED (same as test operation).

Forced cooling operation is released after 60 minutes of starting operation.

FORCED COOLING OPERATION will start as shown in Table12.

( Table 13 : Detail of forced cooling operation)

Forced cooling operation

OPERATION MODE

FAN CONT. MODE

TIMER MODE

SETTING TEMP.

SETTING LOUVER

SWING

Cooling

Hi

-

Room temperature is not controlled

Horizontal

OFF

1-15. COMPRESSOR PREHEATING

The compressor temperature is maintained more than ambient temperature (other refrigerant cycle parts)

for the following reasons.

⅙

⅙1.To Prevent the compressor damage by the cold start.

2.Speed up the ascent rate of the refrigerant, and the separation of the refrigerant and oil is furthered.

( Table 14 : Detail of compressor preheating operation )

Judgment condition Operation

Start condition

Outdoor temperature 89.6

and

>

°F (32°C)

=

Crankcase heater : ON

30 minutes after the compressor stop

Release condition

Outdoor temperature 93.2

Operating instruction to outdoor unit

>

°F (34°C)

=

or

Crankcase heater : OFF

1-16. MINIMUM HEAT OPERATION

MINIMUM HEAT OPERATION functions by pressing MIN HEAT button on the remote controller.

It is almost the same operation as below settings.

( Table 15 : Detail of MINIMUM HEAT OPERATION )

Operation mode

Setting temperature

Defrost operation

Oil recovery operation

Fan mode

Louver setting

Swing setting

LED indication

ON / OFF timer

Only ECONOMY LED (Green)

Heating

50°F (10°C)

Normal operation

Normal operation

01-21

Page 25

1-17. DEFROST OPERATION CONTROL

1. CONDITION OF STARTING THE DEFROST OPERATION

The defrost operation starts as shown in the following Table 16, 17 and 18.

( Table 16 : Condition of normal defrost operation)

Compressor integrating operation time

Less than

35 minutes

Does not operate

Normal defrost

Outdoor temperature 14°F (-10°C)

Heat exchanger temperature 23°F (-17°C )

Outdoor temperature 14°F (-10°C)

Heat exchanger temperature -14°F (7°C )

Over 35 minutes

>

=

and

>

and

<

=

<

=

and

>

<

=

Outdoor temperature 14°F (-10°C)

Heat exchanger temperature -4°F (-20°C )

( Table 17 : Condition of integrating defrost operation)

Compressor integrating operation time

Integrating defrost

Less than

210 minutes

Does not operate

Outdoor temperature 35.6°F (2°C)

Over 210 minutes

Compressor stop

and

<

=

Over 240 minutes

Outdoor unit

heat exchanger

temperature

<

26.6°F (-3°C)

=

( Table 18 : Condition of Integrating (OFF count) defrost operation)

Compressor continuous operation time

Integrating defrost

(OFF count defrost)

Less than 10 minutes

and

<

=

Outdoor temperature 35.6°F (2°C)

Compressor OFF count : 40 times

If any defrost operated, "compressor integrating operation time" and "compressor OFF count" are cleared.

2. CONDITION OF THE DEFROST OPERATION COMPLETION

Defrost operation is released when the conditions becomes as shown in Table 19.

( Table 19 : Condition of defrost release )

Release Condition

Outdoor heat exchanger temperature is higher than 53.6°F(12°C)

or

Compressor operation time has passed 15 minutes.

01-22

Page 26

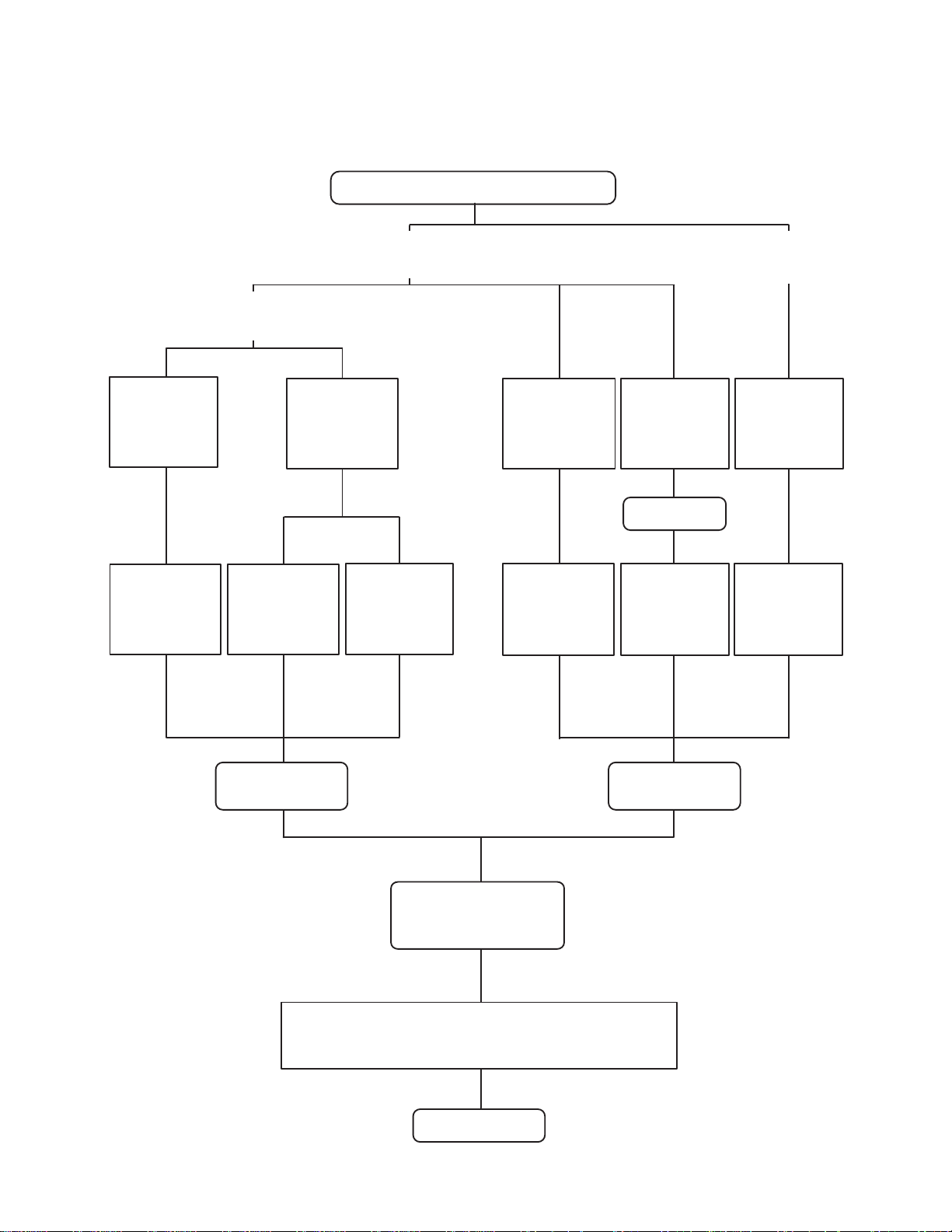

3. Defrost Flow Chart

The defrosting shall proceed by the integrating operation time, outdoor temperature

and outdoor heat exchanger temperature as follows.

Outdoor unit operation mode : Heating mode

Compressor integrating

Outdoor

temperature [Ta]

Ta > 14°F(-10°C)

=

Outdoor

heat exchanger

temperature [Tn]

Tn < 1.4°F(-17°C)

=

operation time :

Over 35 minutes

Outdoor

heat exchanger

temperature [Tn]

Tn < Ta - 14°F(7°C)

=

Compressor continuous

operation time

Over 10 minutes

Outdoor

temperature [Ta]

Ta < 14°F(-10°C)

Outdoor

heat exchanger

temperature [Tn]

Tn < -4°F(-20°C)

=

Compressor

integrating

operation time

Over 240 minutes

Outdoor

heat exchanger

temperature [Ta]

Below 26.6°F(- 3°C)

Compressor

integrating

operation time

Over 210 minutes

Compressor

stop

Outdoor

temperature [Ta]

Ta < 35.6°F(2°C)

Compressor continuous

operation time

Less than 10 minutes

Outdoor

temperature [Ta]

Ta < 35.6°F(2°C)

Compressor

OFF count

40 times

Normal defrost

start

Outdoor heat exchanger temperature (Outlet): Over 53.6° F(12°C)

Compressor : 70rps

Outdoor fan motor : OFF

Defrost Indicator:

[Operation lamp]

7 sec ON / 2 sec OFF

Main EEV : 480Pulse

4-way valve : OFF

Solenoid valve : OFF

Indoor fan : OFF

or

Compressor ON time: Maximum 15 minutes

Defrost end

01-23

Integrating defrost

start

Page 27

1-18. OFF DEFROST OPERATION CONTROL

When operation stops in the [Heating operation] mode, if frost is adhered to the outdoor unit heat

exchanger, the defrost operation will proceed automatically. In this time, the outdoor unit will allow

the heat exchanger to defrost, and then stop.

1. OFF DEFROST OPERATION CONDITION

When heating operation stops, all of following conditions are met, OFF defrost operation starts.

1. Compressor operation integrating time lasts for more than 30 minutes.

2. Compressor countinuous operation time lasts for more than 10 minutes.

3. Outdoor unit heat exchenger temperature is less than 24.8°F(-4°C).

If the operation stops in defrost operation, defrost operation is kept untill the it is completed.

2. OFF DEFROST RELEASE CONDITION

OFF defrost operation is released when the conditions becomes as shown in Table 31

( Table 20 : OFF Defrost Release Condition )

Release Condition

Outdoor heat exchanger temperature is higher than 53.6°F(12°C)

or

Compressor operation time has passed 15 minutes.

OFF Defrost Flow Chart

Heating operation stop

Compressor integrating operation : Over 30 minutes

and

Compressor countinuous operation time : Over 10 minutes

and

Outdoor heat exchanger temperature : Below

Defrost start

Outdoor heat exchanger temperature : Over 53.6°F(12°C)

or

Compressor ON time : Maximum 15 minutes

24.8°F(-4°C)

Defrost end

01-24

Page 28

1-19. OIL RECOVERY OPERATION

Outdoor unit operates by cooling refrigerant cycle for recover the refrigerant oil to the compressor

1. Cooling oil recovery operation

< Start condition >

It operates forcibly from the compressor integrating time in Cooling and Dry mode.

Condition of the oil recovery operates after 1 hour

(1). First time after power ON

(2). When the operation mode changes from Heating to Cooling. (only first time)

Condition of the oil recovery operates after 3 hour

Without condition

< Operation >

Compressor : Over 50rps

Outdoor fan : Normal operation

4 way valve : OFF

< Release condition >

*2~7 minutes has passed from the start of oil recovery operation.

2. Heating oil recovery operation

< Start condition >

It operates forcibly when the compressor integrating operation time becomes 12 hours.

< Operation >

Refrigerant cycle is changed to the cooling cycle temporarily.

Compressor : Fixed 50rps

Outdoor fan : Step2 (290rpm)

4 way valve : OFF

< Release condition >

*1~5 minutes has passed from the start of oil recovery operation.

During the oil recovery operation, appears on the display of wired and central remote controller,

and appears on the simple remote controller.

The operation indicators (LED) of the indoor units flash slowly.

*Operation time changes from the progress status of oil recovery.

01-25

Page 29

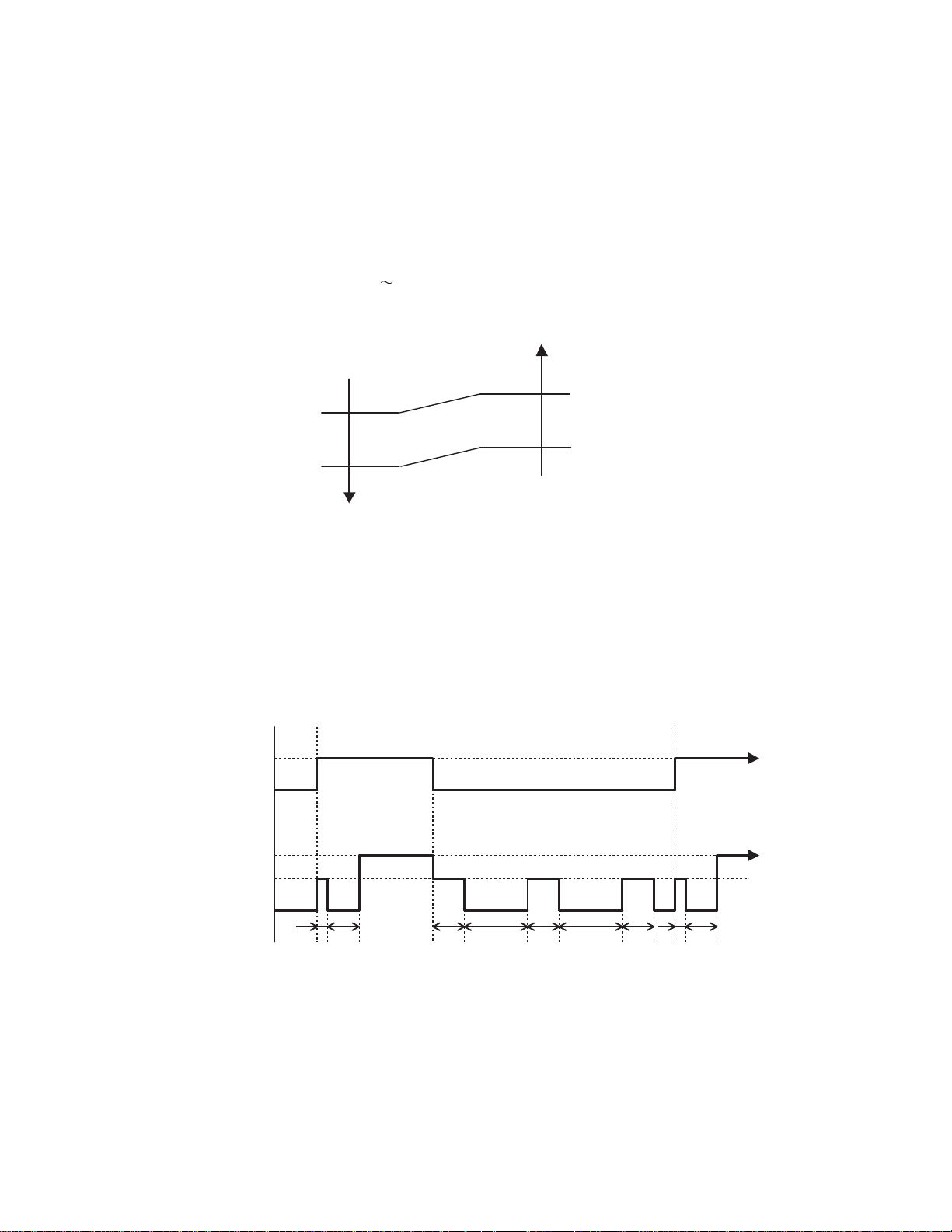

1-20. FRESH AIR CONTROL( For AU / AR type)

The fan motor for Fresh Air is operated in synchronization with the indoor fan operation

as shown in Figure 22.

(Fig. 22 : Fresh Air control)

Fan motor

(Indoor unit)

Fan motor

(for Fresh Air)

Operation

Stop

Operation

Stop

*It needs the external relay and power supply.

1-21. EXTERNAL ELECTRICAL HEATER CONTROL (For AR type)

The External Electrical Heater is operated as below.

< Heater : ON condition >

When all of the following conditions are met, external elecrtical heater will operate according to Figure 23.

System type

Operation mode

Compressor

Indoor fan

Heatpump

Heating

ON

ON (S-Lo is excluded)

< Heater : OFF condition >

1). When one of the ON conditions is not met.

2). When Defrost operation or Oil recovery operation starts

(Fig. 23 : External electrical heater control)

Heater : OFF

Ts -6°F(-3°C)

Ts -24°F(-12°C)

When the room

temperature drops

Heater : ON

Heater : OFF

When the room

temperature rises

Ts : Setting temperature

Ts -2°F(-1°C)

Ts -20°F(-10°C)

01-26

Page 30

1-22. DRAIN PUMP OPERATION

During Cooling / Dry mode

1. When the compressor starts, the drain pump starts simultaneously.

2. The drain pump operates continuously for 3 minutes after the compressor is turned off.

3. When the compressor stops by the "Anti- freezing protection", the drain pump is turned off

in 1 hour after the compressor stops.

4. When the water level in the drain pan rises up and then the float switch functions:

1

The compressor, indoor and outdoor fan motor operation are stopped.

2

Drain pump operates continuously for 3 minutes after the float switch is turned off.

(Almost condensing water may be drained)

3

The indoor unit fan motor operates after the float switch is turned off.

5. When the float switch turns ON continuously for 3 minutes, "FAILURE INDICATION" operates.

(It is necessary to turn off power for release it. )

6. When the float switch turns OFF less than 3 minutes, the unit starts Cooling operation.

( Fig. 24 : Detail of Drain Pump Operation in Cooling / Dry )

Compressor

Drain Pump

ON

OFF

ON

OFF

3 minutes

<Float Switch turns OFF less than 3 minutes>

Less than 3 minutes

Float Switch

Compressor

Indoor Fan

Drain Pump

ON

OFF

ON

OFF

3 minutes ST

ON

OFF

ON

OFF

3 minutes

During HEATING / FAN mode / Stop operation

1.When the water level in the drain pan rises up and then the float switch functions:

Drain pump operates continuously for 3 minutes after the float switch is turned off.

1

(Almost condensing water may be drained)

2. When the float switch turns ON continuously for 3 minutes, "FAILURE INDICATION" operates.

Thereafter, even if the float switch turns OFF, the "FAILURE INDICATION" is not released.

(It is necessary to turn off power for release it. )

( Fig. 25 : Detail of Drain Pump Operation in Heating )

Float Switch

Drain Pump

ON

OFF

ON

OFF

01-27

3 minutes

Page 31

1-23. ECONOMY OPERATION

ECONOMY OPERATION functions by pressing ECONOMY button on the remote controller or

Home controller, it is almost the same operation as below settings.

( Table 20 : Detail of ECONOMY OPERATION)

Operation

mode

Cooling

Heating

Dry

Auto

Outdoor unit

limit current

value

*17.0A

Setting temperature

correction

Ts + 2°F (Ts+1°C)

Ts - 2°F (Ts-1°C)

Ts + 2°F (Ts+1°C)

Cooling : Ts + 2°F (Ts+1°C)

Heating : Ts -2°F (Ts-1°C)

Indoor fan

speed

Normal

operation

(When only fan mode,

air flow downs 1 step)

Indoor unit LED

OPERATION : Lighting

ECONOMY : Lighting

Ts : Setting temperature

Wired remote

controller display

: Lighting

ECO

During ECONOMY OPERATION,

*limit current value of outdoor unit is changed to 17.0A

When also "ENERGY SAVING PEAK CUT FUNCTION" mode is effective, the outdoor unit will operate

by lower current.

ECONOMY OPERATION does not operate in following conditions.

.

Compressor start-up process

.

Defrost operation

.

Oil recovery operation

.

Minimum heat operation

< Release conditions of ECONOMY OPERATION >

1, When the ECONOMY button on the remote controller is pressed.

2, When the indoor unit start-up by MANUAL AUTO button on the indoor unit.

(When the operation is stopped by MANUAL AUTO button, it is not released.)

01-28

Page 32

1-24. ENERGY SAVING PEAK CUT FUNCTION

The current value is limited to reduce the power consumption by external input terminal 3(CN933).

When

and "LOW NOISE OPERATION" are effective, the

(Table 21 : Outline of ENERGY SAVING PEAK CUT FUNCTION)

this function, "CURRENT OVERLOAD OPERATION", "ECONOMY OPERATION"

outdoor unit will operate by lowest current of them.

MODE1

0%

MODE2

50%

MODE3

75%

(Forced thermostat-OFF)

Cooling mode

Dry mode

Compressor stop

11.0A 17.0A

Heating mode

*Percentage is rated electrical power ratio

ENERGY SAVING PEAK CUT OPERATION does not operate in following conditions.

.

Compressor start-up process

.

Defrost operation

.

Oil recovery operation

.

Check run

1-25. LOW NOISE MODE

The outdoor unit operation changes from the capacity priority to the low noise priority

by external input 1(CN931).

The compressor speed and outdoor fan speed are limited as following table.

MODE4

100%

(Rated)

22.5A

When "CURRENT OVERLOAD OPERATION", "ECONOMY OPERATION" and "PEAK CUT OPERATION"

are effective, the outdoor unit will operate by lowest current of them.

( Table 22 : Detail of LOW NOISE OPERATION)

MODE1 MODE2 MODE3

Cooling mode

Dry mode

Limit compressor speed

Limit fan speed

Limit compressor speed

52rps 36rps

690rpm 390rpm

55rps 42rps

45rps

580rpm

49rps

Heating mode

Limit fan speed

690rpm

580rpm 390rpm

(Relative to the rated sound pressure level)

*The performance drops when operating in the LOW NOISE OPERATION.

LOW NOISE OPERATION does not operate in following conditions.

.

Compressor start-up process

.

Defrost operation

.

Oil recovery operation

.

Check run

01-29

Page 33

1-26. VARIOUS PROTECTIONS

1. DISCHARGE GAS TEMPERATURE OVER RISE PREVENTION CONTROL

During the compressor in operation,

the discharge thermistior will detect discharge gas temperature.

The discharge gas temperature is controlled in the following protections.

Discharge temperature protection 1

<Start condition>

Discharge temperature becomes more than 221°F(105°C).

<Operation>

The compressor speed -20rps every 120 seconds.

If the compressor operates at minimum speed for 120 seconds,

and the release condition isn't met, it will be stopped.

<Release condition>

When the discharge temperature becomes lower than

212°F(100°C), the compressor returns to the normal operation.

If the compressor was stopped by protection, it will restart

after 3 minutes ST.

(Fig. 26 : Discharge temperature control)

Discharge

temperature

239°F

(115°C)

Comp. speed -20rps every 120 sec.

221°F

(105°C)

158°F

(70°C)

Comp. stop

Release protection 2

Hold

Discharge temperature protection 2

<Start condition>

Discharge temperature becomes more than 239°F(115°C).

<Operation>

The compressor is stopped, and it does not restart for 7 minutes.

<Release condition>

When the discharge temperature becomes lower than 158°F(70°C), the compressor restarts.

If the

Discharge temperature protection 2 operates 2 times within 24 hours,

discharge temperature error will occur. <Permanent stop>

An error code is displayed each controller, it is reset by only the main power supply reset.

2. COMPRESSOR TEMPERATURE PROTECTION CONTROL

<Start condition>

When the compressor temperature thermistor detects more than 233.6°F (112°C).

<Operation>

The compressor is stopped at once.

<Release condition>

The compressor temperature becomes lower than 176°F(80°C) after 3 minutes ST.

If the Compressor temperature protection operates 2 times within 24 hours,

discharge temperature error will occur. <Permanent stop>

An error code is displayed each controller, it is reset by only the main power supply reset.

01-30

Page 34

3. HEAT SINK TEMPERATURE PROTECTION CONTROL

During the compressor in operation,

heat sink temperature thermistor (Built-in IPM) will detect heatsink temperature.

It is controlled in the following protections.

Heat sink protection 1 and 2 operates at the same time, if each conditions are met.

Heatsink temperature protection 1

<Start condition>

When the heat sink temperature becomes more than 185°F(85°C).

<Operation>

Outdoor unit fan +1 STEP (rise) every 30 seconds.

<Release condition>

When the h

eat sink temperature becomes lower than 176°F(80°C).

and the outdoor fan returns to the normal operation.

Heat sink

temperature

(100°C)

Heatsink temperature protection 2

<Start condition>

When the heat sink temperature becomes more than 194°F(90°C).

<Operation>

Compressor speed -10rps every 30 seconds.

If the compressor operates at minimum speed for 120 seconds,

and the release condition isn't met, it will be stopped.

<Release condition>

When the h

If the compressor was stopped by protection, it will restart after 3 minutes ST.

eat sink temperature becomes lower than 185°F(85°C), the outdoor fan to the normal operation.

(Fig. 27 : Heat sink temperature control)

Comp. stop

212°F

Comp. speed -10rps every 120 sec.

194°F

(90°C)

Outdoor unit fan +1 step every 30 sec.

185°F

(85°C)

Release protection 2,3

176°F

(80°C)

Release protection 1

Heatsink temperature protection 3

<Start condition>

When the heat sink temperature becomes more than 212°F(100°C).

<Operation>

Compressor is stopped

<Release condition>

When the h

the compressor restarts.

eat sink temperature becomes lower than 185°F(85°C) and after 3 minutes ST,

01-31

Page 35

4. CURRENT RELEASE CONTROL

The compressor speed is controlled so that the outdoor unit input current does not exceeds

the current limit value is decided by the outdoor temperature.

When "ECONOMY OPERATION" or "PEAK CUT OPERATION" are effective,

the outdoor unit will operate by lowest current.

When the outdoor unit input current reaches to the control value, the compressor speed

-1rps every 1 second till the release value.

Then, if the compressor operates at minimum speed and the input current doesn't reach

to the release value, the compressor is stopped.

( Table 23 : Current release operation value / Release value )

Outdoor

Cooling

Dry

Heating

temperature [ Ta ]

122°F(50°C) < Ta

116.6°F(47°C) < Ta < 122°F(50°C)

104°F(40°C) < Ta < 116.6°F(47°C)

104°F(35°C) < Ta < 104°F(40°C)

86°F(30°C) < Ta < 104°F(35°C)

20°F(30°C) < Ta < 86°F(30°C)

50°F(10°C) < Ta < 20°F(30°C)

23°F(-5°C) < Ta < 50°F(10°C)

75.2°F(24°C) < Ta

62.6°F(17°C) < Ta < 75.2°F(24°C)

53.6°F(12°C) < Ta < 62.6°F(17°C)

41°F(5°C) < Ta < 53.6°F(12°C)

30.2°F(-1°C) < Ta < 41°F(5°C)

5°F(-15°C) < Ta < 30.2°F(-1°C)

=

=

=

=

=

=

=

=

Ta < 23°F(-5°C)

=

=

=

=

=

=

Ta < 5°F(-15°C)

Normal

17.0 / 16.5

18.0 / 17.5

22.0 / 21.5

26.0 / 25.5

22.0 / 21.5

22.0 / 21.5

*20.5 / 20.0

*20.5 / 20.0

*20.5 / 20.0

19.0 / 18.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

Current value [ A ]

(Conrtol / Release)

Low noise

mode 1

14.0 / 13.5

16.5 / 16.0

17.0 / 16.5

22.0 / 21.5

22.0 / 21.5

22.0 / 21.5

*20.5 / 20.0

*20.5 / 20.0

*20.5 / 20.0

19.0 / 18.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

Ta : Outdoor temperature

Low noise

mode 2

13.0 / 12.5

15.0 / 14.5

15.5 / 15.0

17.0 / 16.5

17.0 / 16.5

19.0 / 18.5

*20.5 / 20.0

*20.5 / 20.0

*20.5 / 20.0

19.0 / 18.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

26.0 / 25.5

Low noise

mode 3

10.5 / 10.0

12.5 / 12.0

13.0 / 12.5

14.0 / 13.5

14.0 / 13.5

16.0 / 15.5

*20.5 / 20.0

*20.5 / 20.0

*20.5 / 20.0

19.0 / 18.5

23.5 / 23.0

23.5 / 23.0

23.5 / 23.0

23.5 / 23.0

23.5 / 23.0

23.5 / 23.0

*Current value(Control / Release) is different from the operating fan step of the outdoor unit.

(Above case is more than 4 STEP, refer to outdoor unit fan table.)

Cooling

Dry

50°F(10°C) < Ta < 20°F(30°C)

23°F(-5°C) < Ta < 50°F(10°C)

=

=

< Ta < 23°F(-5°C)

=

01-32

STEP 0, 1 : 11.0 / 10.5

STEP 2 : 13.5 / 13.0

STEP 3 : 16.5 / 16.0

Page 36

5 . HIGH PRESSURE PROTECTION CONTROL

During the compressor in operation,

When the discharge high pressure sensor will detect the high pressure sensor.

The high pressure is controlled in the following protections.

HIGH PRESSURE PROTECTION 1

.

During Cooling / Dry mode

<Start and Release condition>

When the compressor speed meets following conditions.

( Table 24 : Cooling / Dry high pressure protection control)

High pressure

HP < 451PSI

HP < 551PSI

Release

=

=

=

Cooling

Dry

Compressor speed [rps]

rps < 20

=

20 < rps < 30

=

30 < rps

Control

HP > 478PSI

=

HP > 543PSI HP < 530PSI

=

HP > 580PSI

=

<Operation>

The compressor speed -5rps every 60 seconds.

If the compressor operates at minimum speed for 60 seconds and the release condition isn't met,

it will be stopped.

.

During Heating mode

<Start and Release condition 1>

When the compressor speed meets following conditions.

( Table 25 : Heating high pressure protection control)

High pressure

Heating

Compressor speed [rps]

rps < 20

=

20 < rps < 90

90 < rps

=

Control

HP > 478PSI

=

HP > 507PSI HP < 530PSI

=

HP > 478PSI

=

HP < 451PSI

HP < 451PSI

<Operation>

The compressor speed -5rps every 60 seconds.

If the compressor operates at minimum speed for 60 seconds.

<Release condition 2>

If the compressor was stopped by protection, it will restart after 3 minutes ST

and high pressure is lower than 435PSI.

Release

=

=

=

01-33

Page 37

HIGH PRESSURE PROTECTION 2

( Fig. 28 : High pressure protection 2 )

<Start condition>

High pressure sensor detects more than 594PSI.

<Operation>

High

pressure

594PSI

Compressor stop

Compressor is stopped.

<Release condition>

When the high pressure sensor detects lower than 435PSI

435PSI

Release of protection

and after 3 minutes ST, the compressor restarts.

HIGH PRESSURE PROTECTION 3

<Start condition>

When the pressure switch becomes OFF (Open : more than 609.2 PSI), the compressor is stopped.

<Operation>

Compressor is stopped.

<Release condition>

When the pressure switch becomes ON (Close : lower than 464.1 PSI) and after 3 minutes ST,

the compressor restarts.

6. LOW PRESSURE PROTECTION CONTROL

Hold

LOW PRESSURE PROTECTION 1 (For Cooling, Dry and Heating mode)

<Start condition>

After the compressor operates for 1 minute, and low pressure sensor

detects lower than 7.25PSI for 5 minutes.

<Operation>

Compressor is stopped.

<Release condition>

Compressor restarts after 3 minutes ST.

( Fig. 29 : Low pressure protection 1 )

Low

pressure

7.25PSI

(When continues for 5 minutes)

If the Low pressure protection 1 operates 5 times within 2 hours,

Low pressure error will occur. <Permanent stop>

An error code is displayed each controller, it is reset by only the main power supply reset.

LOW PRESSURE PROTECTION 2 (For Heating mode)

<Start condition>

The compressor operates for 10 minutes, and low pressure sensor

detects lower than 23.2PSI for 1 minute.

( Fig. 30: Low pressure protection 2 )

<Operation>

The compressor speed -5rps every 60 seconds till the

release condition.

If the compressor operates at minimum speed for 60 seconds,

and the release condition isn't met, the compressor is stopped.

<Release condition>

Low pressure sensor detects more than 26.0PSI,

and after 3 minutes ST.

Low

pressure

26.0PSI

Compressor speed -5 every 60 sec.

23.2PSI

(When continues for 1 minutes)

Release protection 1

Compressor stop

Release protection 2

Compressor stop

01-34

Page 38

LOW PRESSURE PROTECTION 3 (For Cooling / Dry mode)

<Start condition>

During the compressor in operation, low pressure sensor detects

lower than 21.7PSI.

<Operation>

Main EEV of Branch Box opens untill the release condition.

<Release condition>

Low pressure sensor detects more than 24.6PSI.

If the compressor stopped, it restarts after 3 minutes ST.

7. ANTIFREEZING CONTROL (Cooling and Dry mode)

To prevent the indoor unit heat exchenger freezing.

<Start condition>

When the indoor heat exchanger temperature sensor detects lower than 37.4

<Operation>

Main EEV of branch box is closed.

<Release condition>

When indoor heat exchanger becomes more than 44.6

°F(7°C).

Low

pressure

24.6PSI

21.7PSI

(Fig. 31 : Low pressure protection 3)

Release protection 3

Hold

Main EEV of Branch Box opens

°F(3°C).

8. EEV FULL CLOSE PROTECTION CONTROL (Heating mode)

Operation condition of EEV is checked from the temperature difference

indoor heat exchanger and room temperature.

<Start condition>

When all the following conditions are met for the 2 times in a row.

1. During compressor in operation

2. After 20 minutes from compressor start-up.

3. Indoor unit heat exchanger temperature - Room temperature < 8°F( 4°C)

<Operation>

Outdoor unit is stopped and EEV is initialized.

<Release condition>

After 3 minutes ST, compressor will restart.

01-35

Page 39

Hybrid Flex Inverter System

2. TROUBLE SHOOTING

Page 40

2. TROUBLESHOOTING

2-1 Service maintenance for Hybrid Flex Inverter System

2-1-1 Features

Enhanced installability and maintenance.

<Product>

1) Multi-room --> Many pipes and lines

2) Branch box --> Pipes and line

3) Increased power supply points --> Outdoor units and branch boxes

<Functions>

- The conditions of each lines are automatically checked.

- Controller in outdoor units.

- 7-segment lamp in outdoor units.

Check operation

- Lines and pipes of branch boxes are automatically checked.

- Check result (Fault and right lines) is shown.

Controller in outdoor units

[Available]

- Cooling and heating test running

- Refrigerant recovery mode

- Local setteing function (Outdoor unit function)

Display in outdoor units

[Available]

- Cooling and heating running condition

- Detail and unit number of error

- Speed of compressor and outdoor fan

- Value detected from sensor

2-1-1 Error code

1) New error codes are adopted.

Lamp flashing, wired remote control, outdoor unit 7-segment (number).

Checked by alphabet.

Current "EE" --> New "Er"

Shown in wired remote control, temperature setting.

02-01

Page 41

2) Hybrid Flex Inverter System, error codes

Error code display Defective component Appearance Object person

Indoor unit

Indoor units lamps,

flashing of operation

and timer lamps.

and continuous

flashing of economy

lamp.

Wired remote

control

LCD, 7-segment

display

- Indoor unit error

- Abnormal units

except indoor units

OPERATION (Green)

TIMER (Orange)

ECONOMY (Green)

- End user

- Installer

- Service

engineer

Outdoor unit

Four 7-segment lamps

on PCB

- Outdoor unit error

- Abnormal units

except outdoor units

(Indoor

unit, Branch-

box)

Branch box

Four lamps on PCB

- Branch box error,

*No exception

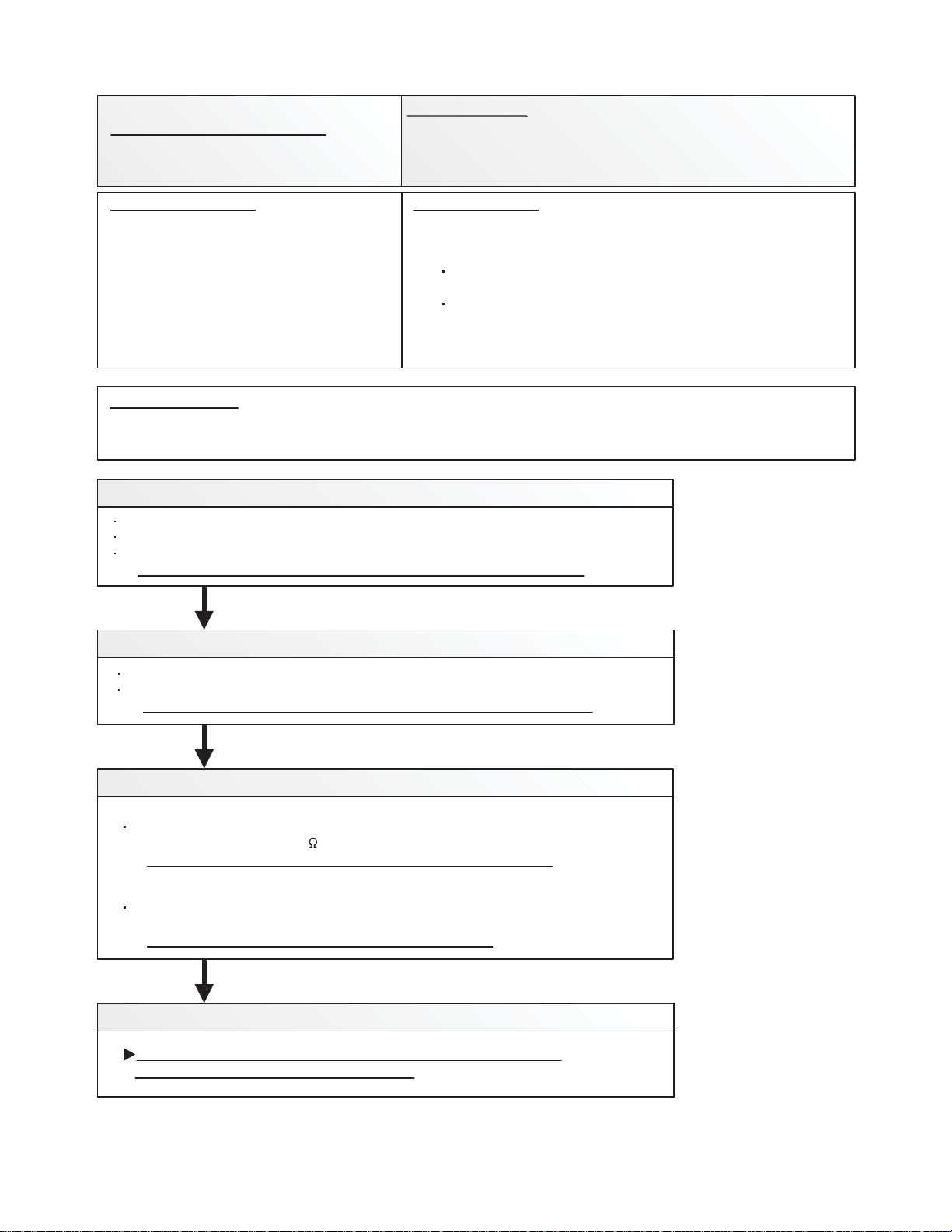

2-1-3 Response procedure at error code display

Case1 : End user

Occurrence of an error

Indoor unit lamp is flashing.

Case2 : Service Engineer

Site visit

Check outdoor ‚7-seg

to find defectives

LED981

LED982

POWER

ERROR

/ MODE

LED961 LED962

MODE /

SELECT

EXIT

SW932

SW931

ENTER

CHECK

SW933

SW934

LED401

LED402

LED403

LED404

LED405

Amount of errors

- Service

engineer

- Installer

Inform object person of

the number of flashing.

Indoor unit error

(7-seg : E5U1)

Branch box error

(7-seg : EJ2U)

Outdoor unit error

02-02

Check indoor unit,

Branch Box

Check indoor unit,

Branch Box

Page 42

Case3 : Error at construction

After performing the below-described work, repairs, inspections etc., always carry out the Check operation. Normal

operation will not be possible without performing the Check operation.

1. Things to comfirm before starting the Check operation

To ensure safety, check that the following work, inspections and operations have been completed.

1 Check that all work on the piping connecting the outdoor unit , indoor units and branch box

has been completed

2 Check that all work on the wiring connecting the outdoor unit, indoor units and branch box

has been completed

3 Is there a gas leakge? (At pipe connections flang connections and brazed areas )

4 Is the system changed with the specifed volume of refrigera

5 Is a breaker installed at the power supply cable of outdoor unit and every branch boxes?

6 Are the wires connected to the terminals without looseness, and in accorodance with the specifications?

7 Is the 3-way valve of the outdoor unit open?(Gas pipe and liquid pipe)

8 Is power supplied to the crank case heater for more than 12 hours?

9 Has the power supply of the all indoor units turned of

2. Restrictions applicable when performing the Check operation

When the Check run starts, all indoor units connected to the outdoor unit will start to run automatically. During

the Check run, you cannot check the operation of the indoor units separately. After the Check run, check the

operation of the indoor units separately in normal operation.

The operable temperature ranges for the Check run are: external temperature -15 to 46ºC(5 to 115°F); room

rature for cooling 18 to 46ºC(64 to 114°F); room temperature for heating -15 to 37ºC(5 to 98°F).

tempe

In the check run, the conditioner will automatically switch between cooling and heating depending on the

external temperature and internal temperature.

If the external temperature or internal temperature is outside the above operable temperature range, wait until

the temperature is within the operab

The Check run can be completed within 1 hour, but may take several hours depending on the external and

internal temperature conditions etc.

Please do not conduct the Check run with all the windows in the room closed. Otherwise the room temperature

could get too low or too high.

Depending on the difference of the room temperature of each room, a judgment may be impossible.

3. Operating procedure for Check run

(1)

Turn power on to the outdoor unit, indoor units and branch boxes.

After the displayed number of “8888.” has been turned off, press

the “CHECK” button.(approximately 2 minutes)

{

}

nt?

f?(Remote controller)

le range and then perform the Check run.

7 seg.display

( : On, : Blinking, : Off)

POWER

ERROR

(LED982)

MODE

(LED981)

(2)

Press and hold the "CHECK" BUTTO for

more than 3 seconds.

(3)

The number of connected branch boxes and indoor units will be

displayed on the 7 seg. display. Check that the displayed number

matches the actual number of connected units. Do not perform the

Check run if the displayed number of units is in error. If the Check run

was performed with the number of units in error, check the state of the

units and then perform the Check run again.

If the displayed number of units matches the installed number,

1

go to (4)

If the displayed number does not match the installed number,

2

check the following.

Are all the Branch boxes tume

Branch boxes are turned on, and go to (4).

d on?

Check that the