Page 1

SPLIT TYPE

ROOM AIR CONDITIONER

Models Indoor unit Outdoor unit

AO* G30LETL

AO* G36LETL

SERVICE

INSTRUCTION

R410A

AU* G30LRLE

AR* G30LMLE

AB* G30LRTE

AU* G36LRLE

AR* G36LMLE

AB* G36LRTE

Cassette type

Duct type

Ceiling type

INVERTER

Page 2

CONTENTS

1. DESCRIPTION OF EACH CONTROL OPERATION

1. COOLING OPERATION.............................................................................................

3. DRY OPERATION......................................................................................................

2. HEATING OPERATION..............................................................................................

5. INDOOR FAN CONTROL...........................................................................................

4. AUTO CHANGEOVER OPERATION.........................................................................

6. OUTDOOR FAN CONTROL.......................................................................................

8. TIMER OPERATION CONTROL................................................................................

7. COMPRESSOR CONTROL........................................................................................

10. TEST OPERATION CONTROL..................................................................................

9. ELECTRONIC EXPANSION VALVE CONTROL.......................................................

12. FOUR-WAY VALVE EXTENSION SELECT...............................................................

11. PREVENT TO RESTART FOR 3 MINUTES (3 MINUTES ST)..................................

18. ECONOMY OPERATION...........................................................................................

13. AUTO RESTART........................................................................................................

21. DEFROST OPERATION CONTROL..........................................................................

01-01

01-02

01-02

01-03

01-04

01-08

01-09

01-10

01-14

01-14

01-14

01-15

01-16

01-18

22. OFF DEFROST OPERATION CONTROL.................................................................. 01-20

23. VARIOUS PROTECTIONS......................................................................................... 01-21

15. FORCED COOLING OPERATION............................................................................. 01-15

24. COMPRESSOR STOP CONTROL............................................................................. 01-22

01-14

14. MANUAL AUTO OPERATION.................................................................................... 01-15

16. COMPRESSOR PREHEATING.................................................................................. 01-16

17. 10°C HEAT OPERATION........................................................................................... 01-16

19. FRESH AIR CONTROL.............................................................................................. 01-16

20. DRAIN PUMP OPERATION........................................................................................ 01-17

2-1-2 WIRED REMOTE CONTROLLER DISPLAY......................................................

2-1-1 INDOOR UNIT & WIRED REMOTE CONTROLLER DISPLAY..........................

2-1 ERROR DISPLAY......................................................................................................

2. TROUBLE SHOOTING

2-2 TROUBLE SHOOTING WITH ERROR CODE..........................................................

2-3 TROUBLE SHOOTING WITH NO ERROR CODE....................................................

2-4 SERVICE PARTS INFORMATION............................................................................

02-01

02-01

02-02

02-26

02-03

02-31

3-1-2 PROCEDURES TO CHANGE THE FUNCTION SETTING................................

3-1-1 INDOOR UNIT....................................................................................................

3-1 FUNCTION SETTING................................................................................................

3. APPENDING DATA

03-01

03-01

03-04

3-2-2 OUTDOOR UNIT................................................................................................

3-2-1 INDOOR UNIT....................................................................................................

3-2 THERMISTOR RESISTANCE VALUES.................................................................... 03-07

03-07

03-07

Page 3

1 . DESCRIPTION OF EACH

CONTROL OPERATION

R410A

Cassette/ Duct/ Ceiling type

INVERTER

Page 4

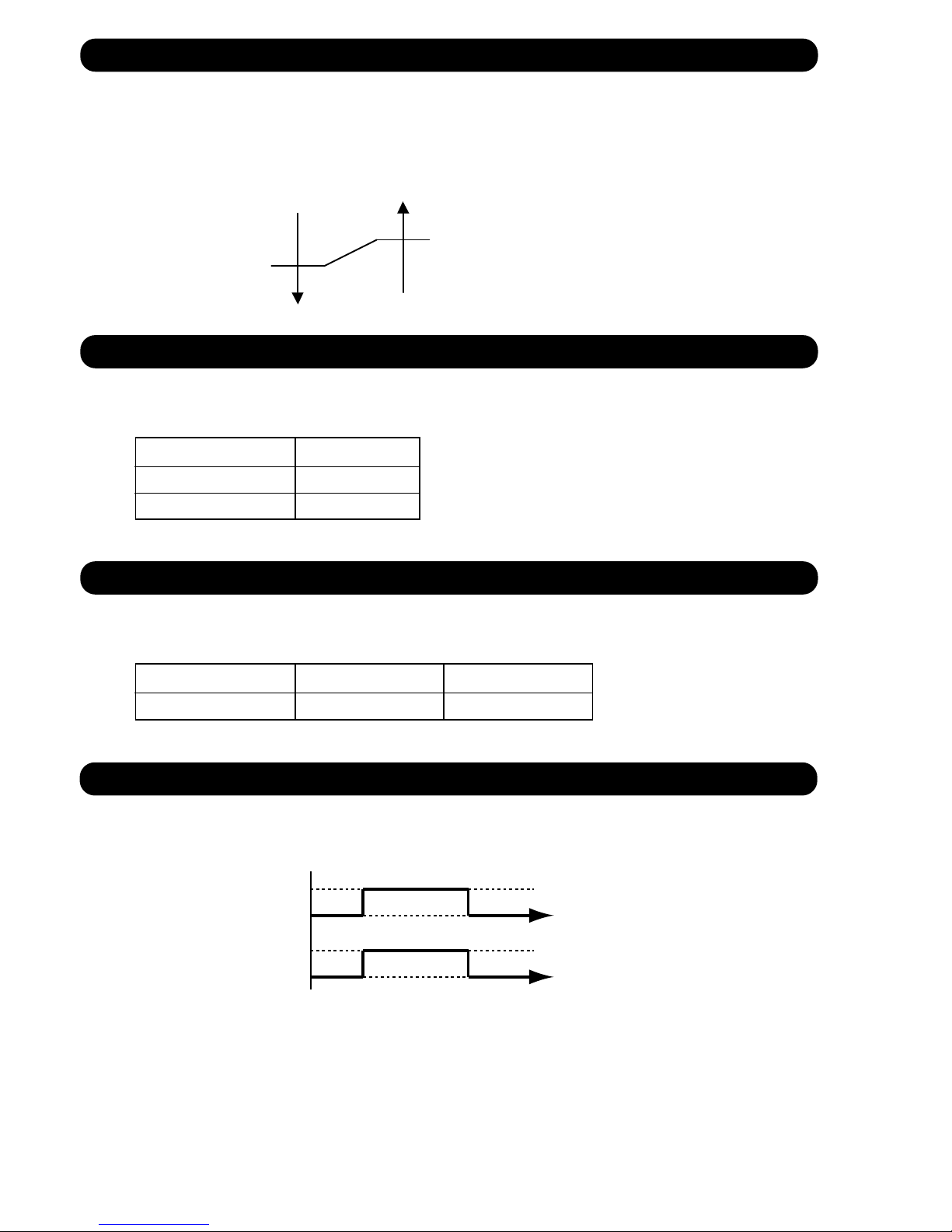

( Fig.1 : Limit of Maximum Frequency based on Outdoor Temperature )

1. COOLING OPERATION

1-1 COOLING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is 2°C higher than a set temperature, the compressor operation

frequency will attain to maximum performance.

minimum

frequency

maximum

frequency

maximum

frequency

AO* G30LETL

AO* G36LETL

16rps 72rps

56rps

61rps

Outside air Outside air

temperature drops temperature rises

36°C

A zone

34°C

32°C

B zone

30°C

21°C

C zone

19°C

D zone

Hi Me Lo Quiet

A zone 72rps

72rps

65rps

50rps

50rps

50rps

59rps

59rps

50rps

44rps

44rps

44rps

50rps

50rps

44rps

39rps

39rps

39rps

39rps

39rps

39rps

35rps

35rps

35rps

B zone

C zone

30LETL

36LETL

D zone

E zone

F zone

( Table 1 : Compressor Frequency Range )

When the compressor operates for 30 minutes continuously at over the maximum frequency ,

the maximum frequency is changed from Maximum Frequency to Maximum Frequency .

01-01

E zone

F zone

10°C

0°C

12°C

2°C

* When the room temperature is between +2°C to -2.5°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table 1.

However, the maximum frequency is limited in the range shown in Fig. 1 based on the

fan speed mode and the outdoor temperature.

* If the room temperature is some degrees lower than a set temperature,

the compressor will be stopped.

Page 5

2. HEATING OPERATION

2-1 HEATING CAPACITY CONTROL

A sensor (room temperature thermistor) built in the indoor unit body will usually perceive

difference or variation between a set temperature and present room temperature, and

controls the operation frequency of the compressor.

* If the room temperature is lower by 3°C than a set temperature, the compressor operation

frequency will attain to maximum performance.

* If the room temperature is some degrees higher than a set temperature,

the compressor will be stopped.

* When the room temperature is between +2.5°C to -3°C of the setting temperature,

the compressor frequency is controlled within the range shown in Table 2.

( Table 2 : Compressor Frequency Range )

01-02

minimum

frequency

maximum

frequency

AO* G30LETL

AO* G36LETL

16rps 90rps

3. DRY OPERATION

3-1 INDOOR UNIT CONTROL

The compressor rotation frequency shall change according to the temperature, set temperature,

and room temperature variation which the room temperature sensor of the indoor unit body has

detected as shown in the Table 3.

However, the frequency after the compressor start-up is 30rps for 60seconds.

Ts+0.5°C

Ts+1.5°C

( Table 3 : Compressor frequency )

( Fig. 2 : Compressor Control based on Room Temperature )

Operating

frequency

39rps

0rps

30LETL

36LETL

X zone

Y zone

Room

temperature drops

Room

temperature rises

X zone

Y zone

Page 6

4. AUTO CHANGEOVER OPERATION

01-03

Operation flow chart

START

Room temp.

Room temp.

>Ts+2°C ?

COOLING OPERATION

HEATING OPERATION

YES

YES

NO

NO

NO

NO

YES

YES

TS : Setting temperature

<Ts- 2°C ?

Thermostat remains

in OFF state for 6 minutes or

longer?

System stops

or operation command other than

auto changeover operation?

NO

NO

Thermostat remains

in OFF state for 6 minutes or

longer?

System stops

or operation command other than

auto changeover operation?

YES

YES

When the air conditioner is set to the AUTO mode by remote control, operation starts in the optimum

mode from among the HEATING, COOLING, DRY and MONITORING modes. During operation, the

optimum mode is automatically switched in accordance with temperature changes. The temperature

can be set between 18°C and 30°C in 1°C steps.

Page 7

5. INDOOR FAN CONTROL

01-04

1. Fan speed

( Table 4 : Indoor Fan Speed )

Operation mode

Air flow mode

Speed (rpm)

570

530

510

470

420

300

270

Cooling/ Fan

High

High

570

510

470

420

300

270

Med+

Med

Med

Heating

Low

Low

Quiet

Quiet

Dry

S-Low

Cool air prevention

AU* G30LRLE

*Soft Quiet

*Soft Quiet

S-Low

*Note, during Economy operation and operation mode is Fan, air flow is 1 step downs.

(High > Med, Med > Low, Low > Quiet, Quiet > Soft Quiet)

420

640

600

510

470

420

300

270

640

510

470

420

300

270

AU* G36LRLE

420

Operation mode

Air flow mode

Speed (rpm)

1270

--- 980

790

630

--- 420

420

Cooling

High

High

1130

980

790

630

420

Med+

Med

Med

Heating/ Fan

Low

Low

Quiet

Quiet

Dry

S-Low

Cool air prevention

AR* G30LMLE

S-Lo

*Note, during Economy operation and operation mode is Fan, air flow is 1 step downs.

(High > Med, Med > Low, Low > Quiet, Quiet > Soft Quiet)

630

AR* G36LMLE

Operation mode

Air flow mode

Speed (rpm)

1000

1000

910

750

650

500

250

Cooling/ Fan

High

High

1000

910

750

650

500

250

Med+

Med

Med

Heating

Low

Low

Quiet

Quiet

Dry

S-Low

Cool air prevention

AB* G30LRTE

*Soft Quiet

S-Low

*Note, during Economy operation and operation mode is Fan, air flow is 1 step downs.

(High > Med, Med > Low, Low > Quiet, Quiet > Soft Quiet)

650

1100

1100

910

750

650

500

250

1100

910

750

650

500

250

AB* G36LRTE

650

Page 8

The airflow can be switched in 5 steps such as AUTO, Quiet, Low, Med, High,

while the indoor fan only runs.

When Fan mode is set at [AUTO], it operates on [Med] Fan Speed.

01-05

2. FAN OPERATION

3. COOLING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Fig. 3.

On the other hand, if switched in [High] ~ [Quiet], the indoor motor will run at a constant airflow of [COOL]

operation modes Quiet, Low, Med, High, as shown in Table 4.

( Fig.3 : Airflow change - over ( Cooling : AUTO ) )

When the room

temperature rises

When the room

temperature drops

TR : Room temperature

Ts : Setting temperature

TR-Ts > 2°C

1°C > TR-Ts

2°C > TR-Ts > 1°C

=

TR-Ts > 2.5°C

=

1.5°C > TR-Ts

2.5°C > TR-Ts > 1.5°C

=

High mode

Med mode

Low mode

4. DRY OPERATION

Refer to the Table 4.

During the dry mode operation, the fan speed setting can not be changed.

=

5. HEATING OPERATION

Switch the airflow [AUTO], and the indoor fan motor will run according to a room temperature,

as shown in Fig. 4.

On the other hand, if switched in [High] ~ [Quiet], the indoor motor will run at a constant airflow

of [HEAT] operation modes Quiet, Low, Med, High, as shown in Table 4.

( Fig. 4 : Airflow change - over ( Heating : AUTO ) )

TR-Ts > -1.5°C

=

-2.5°C > TR-Ts

-1.5°C > TR-Ts > -2.5°C

=

TR-Ts > -1°C

=

-2°C > TR-Ts

-1°C > TR-Ts > -2°C

=

When the room

temperature rises

When the room

temperature drops

TR : Room temperature

Ts : Setting temperature

Low mode

Med mode

High mode

Page 9

The maximum value of the indoor fan speed is set as shown in Fig. 5, based on the detected

temperature by the indoor heat exchanger sensor on heating mode.

( Fig. 5 : Cool Air Prevention Control )

01-06

6. COOL AIR PREVENTION CONTROL (Heating mode)

[ AU* G30/ 36LRLE, AB* G30/ 36LRTE ]

[ AR* G30/ 36LMLE ]

*High

or setting fan mode

*Low

or setting fan mode

37°C

29°C

32°C

24°C

Indoor heat exchanger

temperature rises

Indoor heat exchanger

temperature drops

Cool air

prevention

S-Low

S-Low

42°C

30°C

34°C

Indoor heat exchanger

temperature rises

Indoor heat exchanger

temperature drops

High

*Med+

or setting fan mode

*Low

or setting fan mode

*Low

or setting fan mode

*Low

or setting fan mode

39°C

37°C

37°C

32°C

24°C

*Lower speed is selected.

42°C

30°C

34°C

Indoor heat exchanger

temperature rises

Indoor heat exchanger

temperature drops

High

*Med+

or setting fan mode

*Low

or setting fan mode

39°C

37°C

37°C

32°C

24°C

*Lower speed is selected.

*Lower speed is selected.

High

*Low

or setting fan mode

*Low

or setting fan mode

37°C

29°C

32°C

24°C

Indoor heat exchanger

temperature rises

Indoor heat exchanger

temperature drops

*Lower speed is selected.

13 min. later

13 min. later

Page 10

01-07

The indoor fan motor will run as shown in Fig. 6.

7. MOISTURE RETURN PREVENTION CONTROL (Cooling mode& Dry mode)

Switch the airflow at cooling mode, and the indoor fan motor will run as shown in Fig.6.

It depends on the Function setting "Indoor unit fan control for energy saving".

8. INDOOR UNIT FAN (CONTROL FOR ENERGY SAVING (Cooling mode))

When the defrost operation starts, the indoor fan runs according to cool air prevention control for 20 seconds.

And the fan is stopped if 20 seconds have passed.

When 60 seconds have passed after defrost operation is released,

the fan runs according to cool air prevention control

9. DEFROST OPERATION

( Fig. 6 : Indoor Fan Control )

Compressor

ON

OFF

Indoor fan

Setting air flow

Indoor fan

(as shown in Table 5)

S-Lo

OFF

10 30 60 180 60 180 60 10 30

(SEC)

( Table 5 : Indoor fan speed )

AU*G30/ 36LRLE 420 rpm 420 rpm

AR*G30/ 36LMLE 630 rpm 630 rpm

AB*G30/ 36LRTE 650 rpm 650 rpm

Dry

Cooling

Page 11

6. OUTDOOR FAN CONTROL

01-08

*

The outdoor fan speed mentioned above depends on the compressor frequency.

(When the compressor frequency increases, the outdoor fan speed also changes to the higher

speed. When the compressor frequency decreases, the outdoor fan speed also changes to the

lower speed.)

*

After the defrost control is operated on the heating mode, the fan speed keeps at the higher speed

as Table8 without relating to the compressor frequency.

( Table8 : Outdoor fan speed after the defrost )

1. Outdoor Fan Motor

2. Fan Speed

AC Motor DC Motor

AO*G30/ 36LETL

The Table 6 shows the type of the outdoor fan motor. The control method is different

between AC motor and DC motor.

( Table 6 : Type of Motor )

900rpm

( Fig.7 : Outside air temperature zone selection )

12°C

0°C

Outside air

temperature

Outside air

temperature

F zone

D zone

G zone

H zone

2°C

- 8°C

10°C

- 10°C

( Table 7 : Outdoor fan speed )

Cooling Heating

AO* G30LETL

AO* G36LETL

AO* G30LETL

AO* G36LETL

D

F

Zone

850/ 800/ 620/ 500/ 400

900/ 850/ 800/ 620/ 550/ 450

Refer to Fig. 7

(rpm)

500/ 320/ 250

G 300/ 250/ 200

H

D

F

G

H

300/ 250/ 200

Dry

550/ 450

500/ 320/ 250

300/ 250/ 200

300/ 250/ 200

900/ 800/ 620/ 500/ 400

900/ 800/ 620/ 550/ 450

500/ 320/ 250

300/ 250/ 200

300/ 250/ 200

550/ 450

500/ 320/ 250

300/ 250/ 200

300/ 250/ 200

Page 12

7. COMPRESSOR CONTROL

01-09

1. OPEARTION FREQUENCY RANGE

The operation frequency of the compressor is different based on the operation mode as

shown in the Table 9.

Cooling Heating

Min Max Min Max Min Max

Dry

AO*G30/36LETL

AO*G30/36LETL

AO*G30/36LETL

16rps 72rps 16rps 90rps 39rps 39rps

30rps 47rps 60rps

(Table 9 : Compressor Operation Frequency Range)

2. OPEARTION FREQUENCY CONTROL AT NORMAL START UP

The compressor frequency soon after the start-up is controlled as shown in the Fig. 8.

(Fig. 8 : Compressor Control at Start-up)

Time

Time Time

(Frequency)

Frequency

Frequency

Frequency

Frequency

Frequency

Frequency

Time

Time Time

60sec 120sec 180sec

(Time)

Page 13

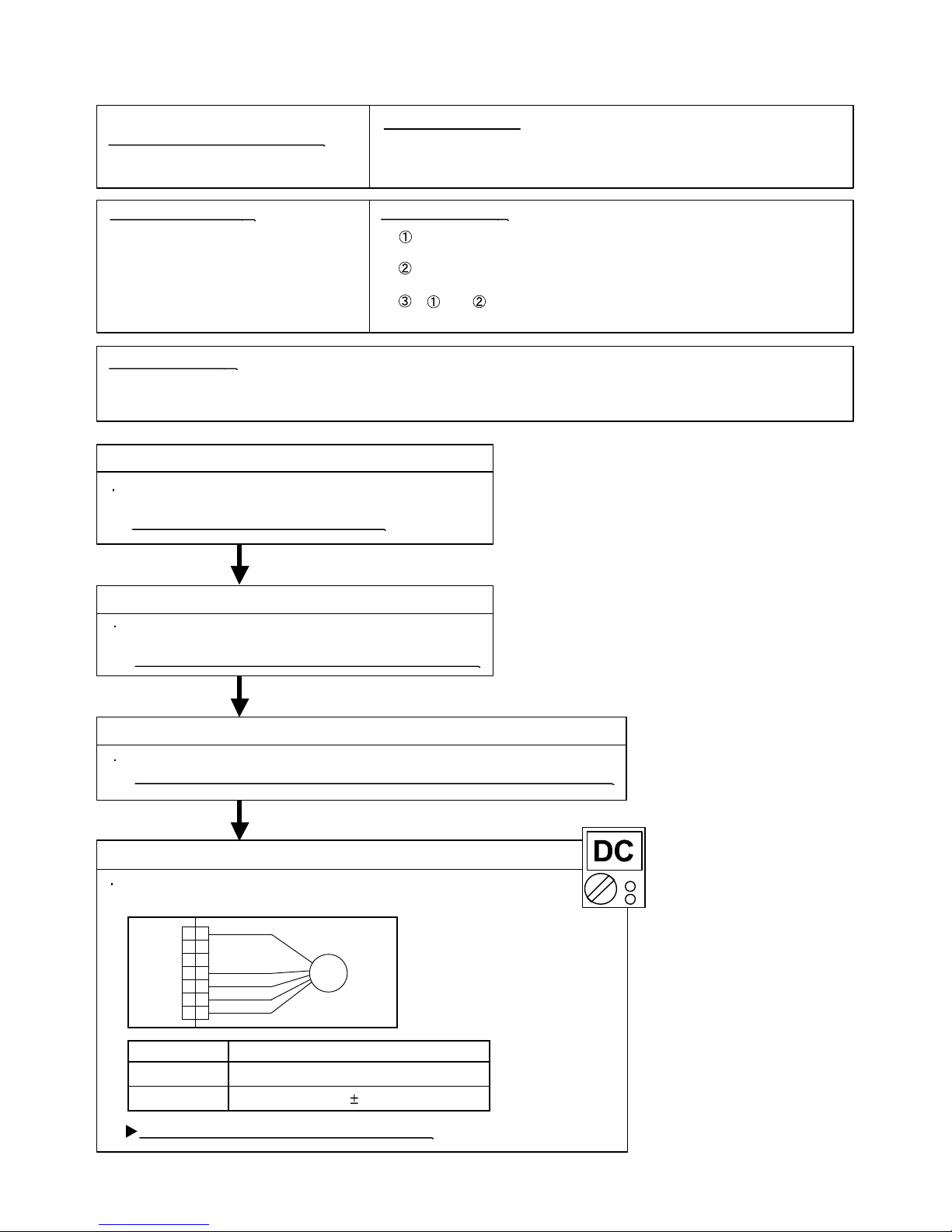

8. TIMER OPEARTION CONTROL

1. ON TIMER/ OFF TIMER

The Table 10 shows the available timer setting based on the product model.

ON TIMER / OFF TIMER

PROGRAM TIMER SLEEP TIMER

AB* G30/ 36LRTE

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

The program timer allows the OFF timer and ON timer to be used in combination one time.

Operation mode

Operation will start from the timer setting (either OFF timer or ON timer) whichever is closest

to the clock's current timer setting.

The order of operations is indicated by the arrow in the remote control unit's display.

SLEEP timer operation cannot be combined with ON timer operation.

( Table 10 : Timer Setting )

2. PROGRAM TIMER

Stop mode

Stop mode

Stop mode

Operation mode

Operation mode

Set time Set time Set time Set time

01-10

8-1 WIRELESS REMOTE CONTROLLER

Page 14

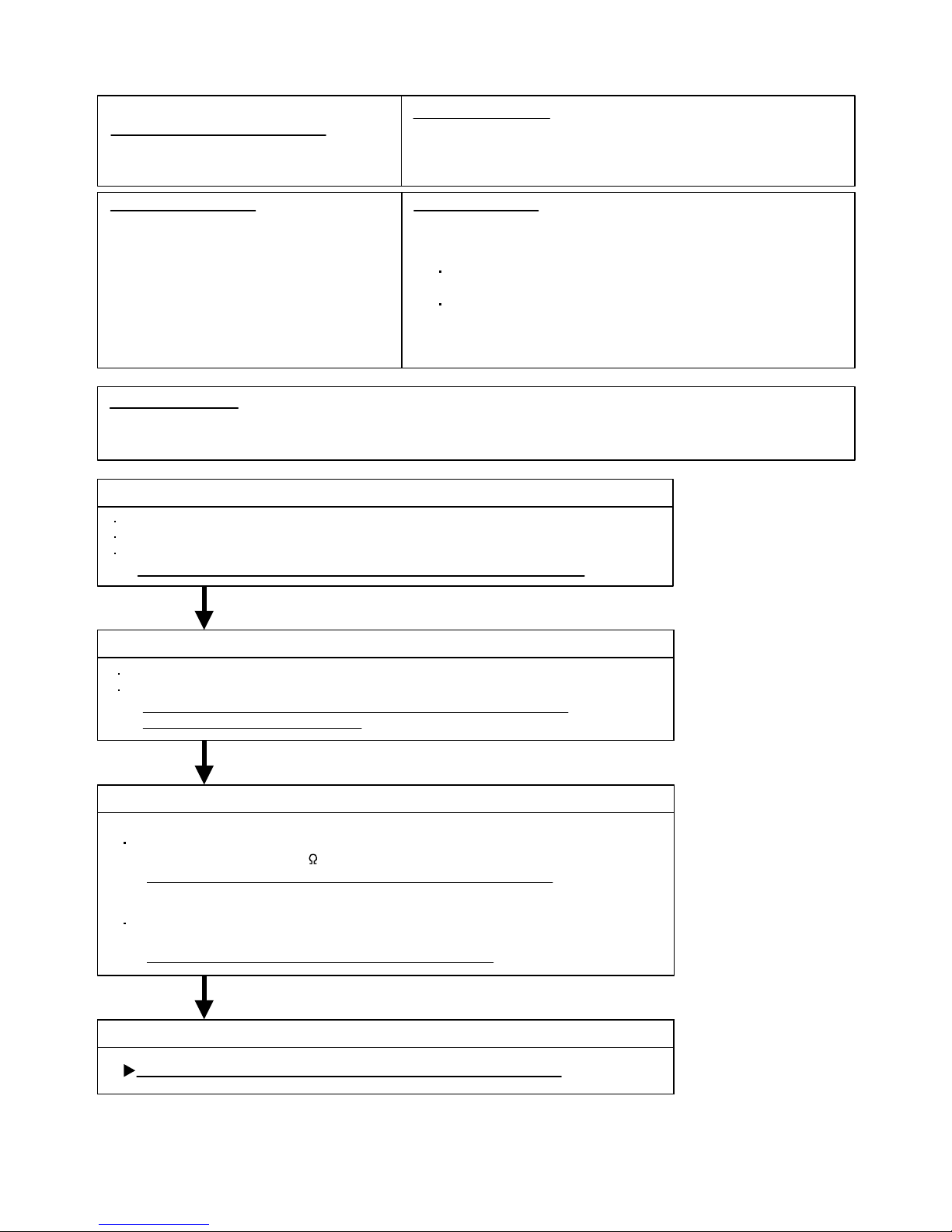

3. SLEEP TIMER

If the sleep is set, the room temperature is monitored and the operation is stopped automatically.

If the operation mode or the set temperature is change after the sleep timer is set, the operation is

continued according to the changed setting of the sleep timer from that time ON.

Set temperature rises

( Ts : Set temperature )

Stop of operation

Set temperature lowers

( Ts : Set temperature )

Ts

Stop of operation

In the cooling operation mode

When the sleep timer is set, the setting temperature is increased 1°C.

It increases the setting temperature another 1°C after 1 hour.

After that, the setting temperature is not changed and the operation is stopped at the time

of timer setting.

Ts

+1°C

+2°C

Set

60min

In the heating operation mode

When the sleep timer is set, the setting temperature is decreased 1°C.

It decreases the setting temperature another 1°C every 30 minutes.

Upon lowering 4°C, the setting temperature is not changed and the operation stops at

the time of timer setting.

-4°C

-3°C

-2°C

-1°C

Set

30min

30min

30min

01-11

Page 15

01-12

9-2 WIRED REMOTE CONTROLLER

The Table 11 shows the available timer setting based on the product model.

ON TIMER / OFF TIMER

WEEKLY TIMER

TEMPERATURE SET BACK TIMER

AR* G30/ 36LMLE

AU* G30/ 36LRLE

( Table11 : Timer Setting )

1. ON / OFF TIMER

OFF timer : When the clock reaches the set time, the air conditioner will be turned off.

Operation mode

Stop mode

Set time of timer

ON timer : When the clock reaches the set time, the air conditioner will be turned on.

Operation mode

Stop mode

Set time of timer

The weekly timer allows up to two ON and OFF time to set up per day.

Use this timer function to set operating time for each day of the week.

Operation mode

The operating time can be set in 30 min increments only.

The OFF time can be carried over to next day.

The ON timer and the OFF timer functions cannot be set with using the weekly timer.

Both ON and OFF time must be set.

2. WEEKLY TIMER

2-1. WEEKLY TIMER

Stop mode

Stop mode

Stop mode

Operation mode

Operation mode

Set time

Set time Set time Set time

Page 16

01-13

The DAY OFF setting is only available for days for which weekly settings already exist.

The SET BACK timer only changes the set temperature for 7 days, it cannot be used to start or stop

air conditioner operation.

The SET BACK timer can be set to operate up to two times per day but only one temperature setting

can be used.

During COOLING/DRY mode, the air conditioner will operate at a minimum of 18°C even if

the SET BACK temperature is set to 17°C or lower.

The DAY OFF setting can only be set one time. The DAY OFF setting is cancelled automatically

after the set day has passed.

Normal

Next day setting

If the operating time carries over to the next day (during a next day setting), the effective

DAY OFF range will be set as shown below.

2-2. DAY OFF setting

3. TEMPERATURE SET BACK TIMER

Stop mode

Stop mode

Operation mode

Stop mode

Operation mode

Preceding day Next day

DAY OFF

Stop mode

Stop mode

Operation mode

Stop mode

Operation mode

DAY OFF

Setting day

Preceding day Next daySetting day

Case of SET BACK timer on the Cooling operation.

( Setting temperature :22°C, SET BACK temperature :26°C)

SET BACK setting

Operation

temperature

Operation

temperature

26°C

22°C

26°C

22°C

24°C

*1

ON OFF OFFON

*1: During the SET BACK function,

the setting temperature is changed.

Change the setting temperature:

22°C 24°C

Page 17

9. ELECTRONIC EXPANSION VALVE CONTROL

The most proper opening of the electronic expansion valve is calculated and controlled under the

present operating condition based on the Table 12.

The compressor frequency, the temperatures detected by the discharge temperature sensor, the

indoor heat exchanger sensor, the outdoor heat exchanger sensor,

and the outdoor temperature sensor.

The expansion valve is set at 480 pulses after 120 seconds of stopping compressor.

At the time of supplying the power to the outdoor unit, the initialization of the electronic

expansion valve is operated (528 pulses are input to the closing direction).

10. TEST OPERATION CONTROL

[ Wireless remote controller ]

Under the condition where the air conditioner runs, press the TEST RUN button of the remote control,

and the test operation control mode will appear.

During test running, the operation lamp and timer lamp of the air conditioner body twinkle simultaneously.

[ Wired remote controller ]

If the operation lamp is on, press the START/STOP button to turn it off.

Press the MODE and FAN buttons at the same time for more than two seconds

to start the test operation.

The operation lamp will light up and "o1" will be displayed on the set temperature display.

[ Release ]

Perform the test operation for 60 minutes.

Pressing the START/STOP button will stop the test operation.

The compressor won't enter operation status for 3 minutes after the compressor is stopped,

even if any operation is given.

At the time when the air conditioner is switched from the cooling mode to heating mode, the

compressor is stopped, and the four-way valve is switched in 3 minutes later after

the compressor stopped.

11. PREVENT TO RESTART FOR 3 MINUTES ( 3 MINUTES ST )

12. FOUR-WAY VALVE EXTENSION SELECT

01-14

( Table 12 : The pulse range of the electronic expansion valve control )

Cooling / Dry mode

Heating mode

AO*G30LETL

AO*G36LETL

Operation mode Pulse range

between 53 to 480 pulses.

between 40 to 480 pulses.

Page 18

14. MANUAL AUTO OPERATION (Indoor unit body operation)

If MANUAL AUTO Button is set, the operation is controlled as shown in Table 13.

If the remote control is lost or battery power dissipated, this function will work without the remote control.

OPERATION MODE Auto changeover

FAN CONT. MODE Auto

TIMER MODE Continuous (No timer setting available)

SETTING TEMP. 24°C

SETTING LOUVER Standard

SWING OFF

(Table 13)

01-15

15. FORCED COOLING OPERATION

Forced cooling operation is started when pressing MANUAL AUTO button for 10 seconds or more.

During the forced cooling operation, it operates regardless of room temperature sensor.

Operation LED and timer LED blink during the forced cooling operation. They blink for 1 second ON

and 1 second OFF on both operation LED and timer LED (same as test operation).

Forced cooling operation is released after 60 minutes of starting operation.

The FORCED COOLING OPERATION will start as shown in Table 14.

Manual auto operation

OPERATION MODE

FAN CONT. MODE

TIMER MODE

SETTING TEMP.

SETTING LOUVER

SWING

( Table 14 )

Forced cooling operation

Cooling

Hi

Initial : Horizontal

(It is changed follow as setting of remote controller)

OFF

Room Temp is not controlled

-

If cooling operation is set, the operation is controlled as shown in Table 14.

When the power was interrupted by a power failure, etc. during operation, the operation contents

at that time are memorized and when power is recovered, operation is automatically started with

the memorized operation contents.

When the power is interrupted and recovered during timer operation, since the timer operation time

is shifted by the time the power was interrupted, an alarm is given by blinking (7 sec ON/2 sec OFF)

the indoor unit body timer lamp.

[ Operation contents memorized when the power is interrupted ]

13. AUTO RESTART

Operation mode

Set temperature

Set air flow

Set air flow direction

Swing

Economy operation

10°C Heat operation

Thermistor detected position

Timer mode

Wireless RC

Wired RC

(Memory Backup : Disable)

Wired RC

(Memory Backup : Enable)

OFF Timer

ON Timer

WEEKLY Timer

Temperature

SET BACK Timer

: Memorize

: Not memorize

*It is necessary to set on the DIP-SW1-No,6 of the wired remote controller, to enable the memory backup.

Refer to the installation manual of wired remote controller for details.

Page 19

01-16

When the outdoor heat exchanger temperature is lower than 0°C and the all operation mode has been

stopped for 30 minutes, power is applied to the compressor and the compressor is heated.

(By heating the compressor, warm air is quickly discharged when operation is started.)

When operation was started and when the outdoor heat exchanger temperature rises to 2°C or greater,

preheating is ended.

16. COMPRESSOR PREHEATING

( Fig. 9 : Compressor Preheating )

ON

0°C

2°C

OFF

17 . 10°C HEAT OPERATION

The 10°C HEAT operation functions by pressing 10°C HEAT button on the remote controller.

The 10°C HEAT operation is almost the same operation as below settings.

Mode Heating

Setting temperature 10°C

Fan mode AUTO

( Table 15 )

18. ECONOMY OPERATION

The ECONOMY operation functions by pressing ECONOMY button on the remote controller.

The ECONOMY operation is almost the same operation as below settings.

Mode Cooling/ Dry Heating

Target temperature Setting temp.+1°C Setting temp.-1°C

( Table 16 )

The fan motor for Fresh Air(Field supply) is operated in synchronization with the indoor fan operation

as shown in Fig. 10.

19. FRESH AIR CONTROL

(Fig. 10 : Fresh Air control)

Operation

Stop

Operation

Stop

Fan motor

(Indoor unit)

Fan motor

(for Fresh Air)

Page 20

01-17

20. DRAIN PUMP OPERATION

1. When the compressor starts, the drain pump starts simultaneously.

2. The drain pump operates continuously for 3 minutes after the compressor is turned off.

3. When the compressor stops by the "Anti- freezing protection", the drain pump is turned off

in 1 hour after the compressor stops.

4. When the water level in the drain pan rises up and then the float switch functions:

The compressor, indoor and outdoor fan motor operation are stopped.

Drain pump operates continuously for 3 minutes after the float switch is turned off.

(Almost condensing water may be drained)

5. When the float switch turns ON continuously for 3 minutes, "FAILURE INDICATION" operates.

(It is necessary to turn off power for release it. )

6. When the float switch turns OFF less than 3 minutes, the unit starts Cooling operation.

1

2

1.When the water level in the drain pan rises up and then the float switch functions:

Drain pump operates continuously for 3 minutes after the float switch is turned off.

(Almost condensing water may be drained)

2. When the float switch turns ON continuously for 3 minutes, "FAILURE INDICATION" operates.

Thereafter, even if the float switch turns OFF, the "FAILURE INDICATION" is not released.

(It is necessary to turn off power for release it. )

During Cooling / Dry mode

3 minutes

ON

OFF

ON

OFF

Compressor

Drain Pump

3 minutes

3 minutes ST

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Float Switch

Compressor

Indoor Fan

Drain Pump

3 minutes

ON

OFF

ON

OFF

Float Switch

Drain Pump

During Heating / Fan mode / Stop operation

<Float Switch turns OFF less than 3 minutes>

Less than 3 minutes

.

.

The indoor unit fan motor operates after the float switch is turned off.

3

(Fig. 11 : Detail of Drain Pump Operation)

Page 21

01-18

2. CONDITION OF THE DEFROST OPERATION COMPLETION

Release Condition

Outdoor heat exchanger temperature sensor value is higher than +13°C or

Compressor operation time has passed 15 minutes.

21. DEFROST OPERATION CONTROL

1. CONDITION OF STARTING THE DEFROST OPERATION

The defrost operation starts when the outdoor heat exchanger temperature sensor detects

the temperature lower than the values shown in Table 17.

(Table 17 : Condition of starting Defrost Operation)

1st time defrosting after starting operation

Less than 22 min.

22 to 62 min.

62 min. to 4 hours

More than 4 hours

Does not operate

- 9°C

- 5°C

- 3°C

Compressor integrating

operation time

Compressor contiguous

operation time

Defrost operation is released when the conditions become as shown in Table 18.

(Table 18 : Defrost Release Condition)

Operation

temperature

Below 10 min.

Above 10 min.

Less than 35 min.

35 min. to 215min

215 min. to 4 hours

Does not operate

- 6°C

- 5°C

More than 4 hours

- 3°C

Compressor integrating

operation time

Compressor contiguous

operation time

Operation

temperature

Below 10 min.

Above 10 min.

Defrosting after 2nd time upon starting operation

Compressor integrating

operation time

Operating condition

Integrating defrost for intermittent operation

Less than 10 min.

If the compressor continuous operation time is less than 10 minutes,

the OFF number of the compressor is counted.

If any defrost operated, the compressor OFF count is cleared.

OFF count of the compressor

40 times

More than 210 min.

Compressor OFF

(at outside air temp.< 2°C)

=

Page 22

(Not defrosted for 10 minutes)

Outdoor fan : OFF

Compressor : OFF

EEV : 480pulse

4-way valve : OFF

Compressor: ON

(Frequency : 55rps)

Heating operation start : Compressor ON

Defrost Indicator:

[Operation lamp]

7 sec ON / 2 sec OFF

Outdoor heat exchanger temperature: Over 13°C

or

Compressor ON time: Over 15 minutes

Defrost end

01-19

3. Defrost Flow Chart

The defrosting shall proceed by the integrating operation time

and outdoor heat exchanger temperature as follows.

Compressor

integrating operation:

Over 22 minutes to

below 62 minutes

Compressor

integrating operation:

Over 240 minutes

Compressor

integrating operation:

Over 62 minutes to

below 240 minutes

Outdoor HEX temp.:

Below - 9°C

Outdoor HEX temp.:

Below - 5°C

Outdoor HEX temp.:

Below - 3°C

In case of 1st defrost

In case of 2nd

and later defrost

Outdoor temp Outdoor HEX temp.

: Above 5 °C

Compressor

integrating operation:

Over 35 minutes to

below 215 minutes

Outdoor HEX temp.:

Below - 6°C

Compressor

integrating operation:

Over 215 minutes to

below 240 minutes

Outdoor HEX temp.:

Below - 5°C

Compressor

integrating operation:

Over 240 minutes

Outdoor HEX temp.:

Below - 3°C

Compressor OFF:

Outside air temp.< 2°C

(More than 210 min.)

Compressor

OFF count :

40 times

(Less than 10min.)

In case of Integrating defrost

for intermittent operation

Defrost start

=

*HEX : Heat EXchanger

Page 23

22. OFF DEFROST OPERATION CONTROL

1. OFF DEFROST OPERATION CONDITION

When operation stops in the [Heating operation] mode, if frost is adhered to the outdoor unit heat

exchanger, the defrost operation will proceed automatically. In this time, if indoor unit operation

lamp flashes slowly (7 sec ON / 2 sec OFF), the outdoor unit will allow the heat exchanger to defrost,

and then stop.

In heating operation, the outdoor heat exchanger temperature is less than -4°C,

compressor continuous operation more than 10 minutes, and

compressor operation integrating time lasts for more than 30 minutes.

OFF Defrost Flow Chart

Heating operation stop

Outdoor heat exchanger temperature :

Below -4°C

Compressor continuous operation :

Over 10 minutes

Compressor integrating operation :

Over 30 minutes

Defrost start

Defrost Indicator:

[Operation lamp]

7 sec ON / 2 sec OFF

Outdoor heat exchanger temperature :

Over +13°C

or

Compressor ON time : Over 15 minutes

Defrost end

2. OFF DEFROST END CONDITION

Release Condition

Outdoor heat exchanger temperature sensor value is higher than +13°C or Compressor

operation time has passed 15 minutes.

01-20

Page 24

23. VARIOUS PROTECTIONS

1. DISCHARGE GAS TEMPERATURE OVERRISE PREVENTION CONTROL

The discharge gas thermosensor (discharge thermistor : Outdoor side) will detect discharge gas temperature.

When the discharge temperature becomes higher than Temperature , the compressor frequency

is decreased 10rps and it continues to decrease the frequency

for 10rps every 120 seconds until the temperature becomes lower than Temperature .

When the discharge temperature becomes lower than Temperature , the control of the

compressor frequency is released.

When the discharge temperature becomes higher than Temperature , the compressor is stopped

and the indoor unit LED starts blinking.

AO* G30/ 36LETL

104°C 101°C 110°C

( Table 19 : Discharge Temperature Over Rise Prevention Control / Release Temperature )

Temperature

Temperature

Temperature

2. CURRENT RELEASE CONTROL

The compressor frequency is controlled so that the outdoor unit input current does not exceeds

the current limit value that was set up with the outdoor temperature.

The compressor frequency returns to the designated frequency of the indoor unit at the time

when the frequency becomes lower than the release value.

( Table 20 : Current Release Operation Value / Release Value )

01-21

[ Heating ]

T0 : Outdoor Temperature

[ Cooling ]

AO* G30LETL AO* G30LETL

T0 (Control / Release)

9.0A / 8.5A

10.0A / 9.5A

12.5A / 12.0A

14.5A / 14.0A

50°C

46°C

40°C

T0 : Outdoor Temperature

T0 (Control / Release)

10.0A / 9.5A

11.5A / 11.0A

14.5A / 14.0A

14.5A / 14.0A

17°C

12°C

5°C

3. ANTIFREEZING CONTROL (Cooling and Dry mode)

The compressor frequency is decrease on cooling & dry mode when the indoor heat exchanger

temperature sensor detects the temperature lower than Temperature .

Then, the anti-freezing control is released when it becomes higher than Temperature .

( Table 21 : Anti-freezing Protection Operation / Release Temperature )

Outdoor temperature

Over than 10°C *1

or 12°C *2

Less than 10°C *1

or 12°C *2

*1. When the temperature drops.

*2. When the temperature rises.

4°C

7°C

13°C

Temperature Temperature

12°C

2°C

14.5A / 14.0A

14.5A / 14.0A

T0 : Outdoor Temperature

AO* G36LETL

T0 (Control / Release)

9.0A / 8.5A

10.0A / 9.5A

13.0A / 12.5A

16.5A / 16.0A

50°C

46°C

40°C

12°C

2°C

16.5A / 16.0A

16.5A / 16.0A

AO* G36LETL

T0 : Outdoor Temperature

T0 (Control / Release)

10.0A / 9.5A

11.5A / 11.0A

16.0A / 15.5A

18.0A / 17.5A

17°C

12°C

5°C

Page 25

01-22

4. COOLING PRESSURE OVERRISE PROTECTION

When the outdoor unit heat exchange sensor temperature rises to 67°C or greater,

the compressor is stopped and trouble display is performed.

5. HIGH TEMPERATURE AND HIGH PRESSURE RELEASE CONTROL ( HEATING MODE )

On heating mode, the compressor frequency is controlled as following based on the detection value of the indoor

heat exchanger temperature sensor.

Indoor heat exchange

temperature rises

Indoor heat exchange

temperature drops

[ Control System ]

It returns to the normal operation

Compressor is stopped

53°C

55°C

63°C

50°C

The compressor frequency is

decreased 2rps every 120seconds.

The compressor frequency is

decreased 15rps every 120seconds.

6. COMPRESSOR TEMPERATURE PROTECTION

When the compressor temperature sensor detects higher than 108°C, the compressor is stopped.

The protection is released when the compressor temperature sensor detects 80°C

after 3 minutes of compressor stop.

7. HIGH PRESSURE PROTECTION

When the pressure switch becomes OFF (Open : higher than 4.2 MPa), the compressor is stopped.

It is released when the pressure switch becomes ON (Close : lower than 3.2 MPa)

after 3 minutes of compressor stop.

24. COMPRESSOR STOP CONTROL

When the detection value of outdoor temperature sensor is lower than Temp in the Table 22,

the compressor is stopped.

( Table 22 : Operation temperature of compressor stop control )

Temperature

AO* G30/ 36LETL

Cooling Heating

-15°C

Stable zone

Page 26

Page 27

2 . TROUBLE SHOOTING

R410A

Cassette/ Duct/ Ceiling type

INVERTER

Page 28

Manual Auto Switch Error

Indoor Room Thermistor Error

Indoor Unit Model Information Error

EEPROM Access Abnormal

Wired Remote Controller

Communication Error

Error Contents

Continuous

Continuous

4 times

Continuous2 times

3 times

3 times

5 times

Continuous2 times1 times

Continuous1 times1 times

Trouble

shooting

Economy

(Green)

Timer

(Orange)

Operation

(Green)

02-01

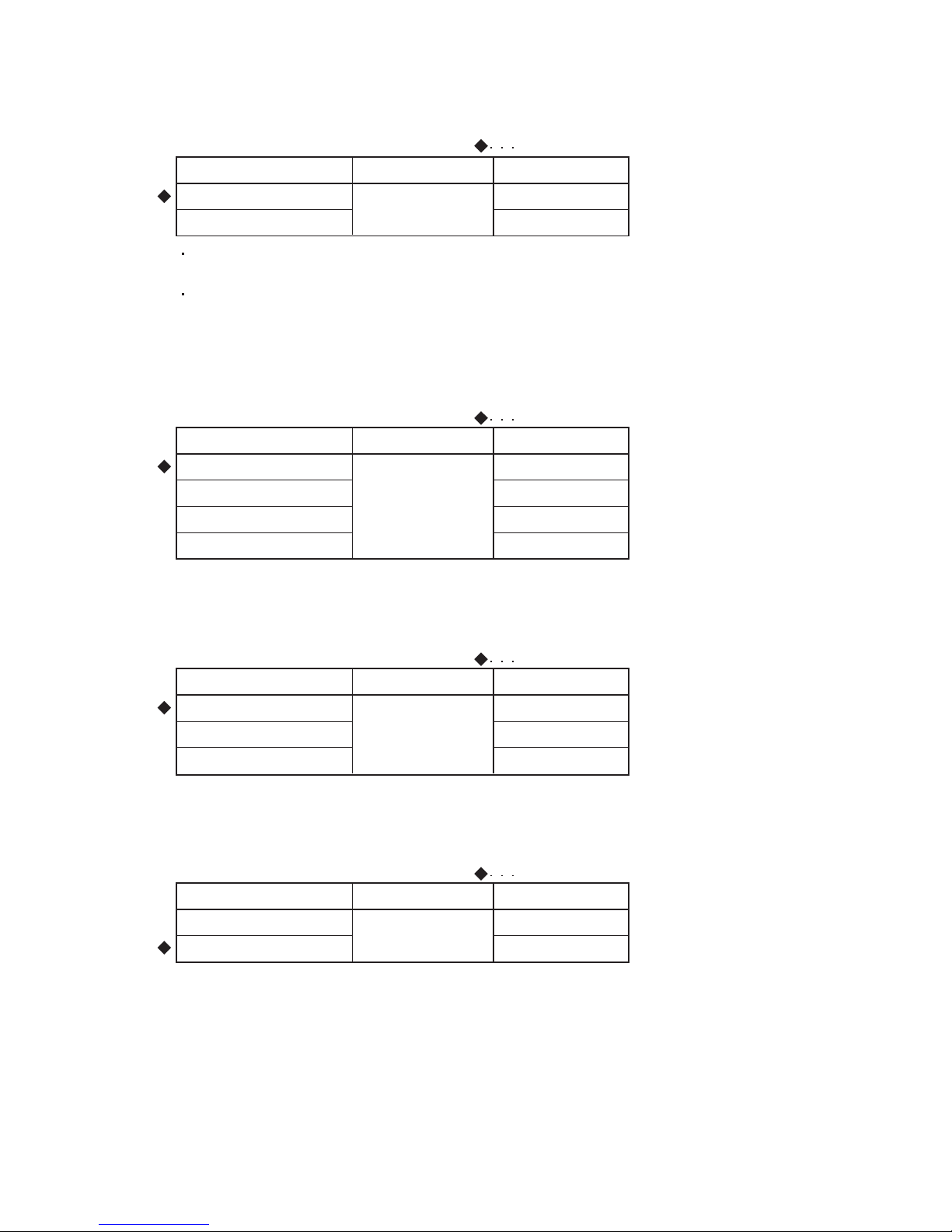

2-1 ERROR DISPLAY

2-1-1 INDOOR UNIT AND WIRED REMOTE CONTROLLER DISPLAY

1 times

Serial Communication Error

Indoor Unit Fan Motor Error

Indoor Heat Ex. Thermistor Error

Continuous4 times 2 times

Continuous1 times5 times

Continuous

Continuous3 times

7 times

5 times

1 times

Continuous

7 times 3 times

Continuous

7 times 4 times

Continuous

2 times

7 times

Drain Pump Error

Discharge Thermistor Error

Heat Ex. Liquid Outlet

Thermistor Error

Outdoor Thermistor Error

Compressor Thermistor Error

Please refer the flashing pattern as follows.

The OPERATION, TIMER, ECONOMY lamps operate as follows according to the error contents.

1,2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Continuous8 times 4 times

Current Sensor Error

Continuous8 times 6 times

High Pressure Switch Error

Continuous10 times 3 times

Compressor Temp. Error

Continuous

Continuous5 times

9 times

9 times

7 times

Compressor Control Error

Outdoor Unit Fan Motor Error

Continuous4 times9 times

Continuous9 times 9 times

4 Way Valve Error

Continuous1 times10 times

Discharge Temp. Error

Over Current Error

Continuous5 times6 times

IPM Error

Indoor Unit Display

Wired Remote

Controller

Display

11

12

32

35

41

42

51

53

64

65

71

72

73

74

84

86

94

95

97

99

A1

A3

Continuous4 times6 times

A. F. Voltage Error

[ ]

[ ]

[ ]

Page 29

02-02

When " " in Temperature Display is displayed, inspection of the air conditioning system is necessary.

Please consult authorized service personnel.

2-1-2 WIRED REMOTE CONTROLLER DISPLAY

1. SELF - DIAGNOSIS

SU MOTUWETH FR SA

Unit number (usually 0)

Error code

ex. Self-diagnosis check

2. ERROR CODE HISTORY DISPLAY

Up to 16 memorized error codes may be displayed for the indoor unit connected to the remote controller.

1. Stop the air conditioner operation.

2. Press the SET TEMPERATURE buttons , simultaneously for 3 seconds

or more to start the self-diagnosis.

4. Press the SET TEMPERATURE buttons , simultaneously for 3 seconds or more

or there is no key input for 60 seconds to stop the display.

3. Press the SET TEMPERATURE button to select the error history number.

SU MOTU WETH FR SA

Error code

Error history number

0 1 2 3 4 5 6 7

F E d c b A 9 8

Lower

Raise

Page 30

Trouble shooting 1

OUTDOOR UNIT Error Method:

Detective Actuators: Detective details:

Forecast of Cause:

OK

Indicate or Display:

Refer to error code table.

YESYES

NO

Serial Communication Error

(Serial Reverse Transfer Error)

Outdoor unit Main PCB

Outdoor unit Fan motor

1. Connection failure 2. External cause 3. Main PCB failure 4. Outdoor unit Fan motor failure

Check Point 1-1 : Reset the power and operate

Does error indication reappear?

Check Point 1-2 : Check external cause such as noise

Check if the ground connection is proper.

Check if there is any equipment that causes harmonic wave

near the power cable (Neon light bulb or any electronic

equipment which causes harmonic wave).

Check Point 2 : Check connection

Check any loose or removed connection line of

between indoor unit and outdoor unit.

>> If there is an abnormal condition, correct it by

referring to Installation Manual or Data &

Technical Manual.

Check connection condition in control unit.

(If there is loose connector, open cable or mis-wiring)

Check Point 3 : Check the voltage of power supply

Check the voltage of power supply

>> Check if AC216V(AC240V-10%) - 264V(AC240V+10%) appears

at outdoor unit terminal L - N.

When the indoor unit cannot receive the serial signal from Outdoor unit

more than 2minutes after power ON, or the indoor unit cannot receive

the serial signal more than 15seconds during normal operation.

02-03

2-2 TROUBLE SHOOTING WITH ERROR CODE

OK

Check Point 4 : Check serial signal (Reverse transfer signal)

Check serial signal (Reverse transfer signal)

>> Check if indicated value swings between AC90V and AC270V at outdoor unit terminal 1 - 3.

>> If it is abnormal, Check the parts as follows.

- Outdoor unit fan motor (PARTS INFORMATION 5)

>> If Outdoor fan motor is abnormal, replace Outdoor unit fan motor and Main PCB.

>> If the parts are normal, replace Main PCB.

1

2

3

L

N

RED

WHITE

BLACK

BLACK

WHITE

+

-

Page 31

Trouble shooting 2

INDOOR UNIT Error Method:

Detective Actuators: Detective details:

Forecast of Cause:

OK

Indicate or Display:

Refer to error code table.

YESYES

NO

OK

Serial Communication Error

(Serial Forward Transfer Error)

Indoor unit Controller PCB

Indoor unit Fan motor

Outdoor unit Main PCB

1. Connection failure 2. External cause 3. Controller PCB failure 4. Indoor unit fan motor failure

5. Outdoor unit Main PCB

Check Point 1-1 : Reset the power and operate

Does error indication reappear?

Check Point 1-2 : Check external cause such as noise

Check if the ground connection is proper.

Check if there is any equipment that causes harmonic wave

near the power cable (Neon light bulb or any electronic

equipment which causes harmonic wave).

Check Point 2 : Check connection

Check any loose or removed connection line of

between indoor unit and outdoor unit.

>> If there is an abnormal condition, correct it by

referring to Installation Manual or Data &

Technical Manual.

Check connection condition in control unit.

(If there is loose connector, open cable or mis-wiring)

Check Point 3 : Check the voltage of power supply

Check the voltage of power supply

>> Check if AC216V(AC240V-10%) - 264V(AC240V+10%) appears

at outdoor unit terminal L - N.

Check Point 4 : Check serial signal (Forward transfer signal)

Check serial signal (Forward transfer signal)

>> Check if indicated value swings between AC30V and AC130V at outdoor unit terminal 2 - 3.

>> If it is abnormal, replace Controller PCB.

>> If it is abnormal, Check Indoor unit fan motor. (PARTS INFORMATION 4)

>> If Indoor unit fan motor is abnormal, replace Indoor unit fan motor and Controller PCB.

>> If it is abnormal, replace Outdoor unit Main PCB.

When the outdoor unit cannot properly receive the serial signal from

indoor unit for 10 seconds or more.

02-04

1

2

3

L

N

RED

WHITE

BLACK

BLACK

WHITE

+

-

Page 32

Trouble shooting 3

INDOOR UNIT Error Method:

Detective Actuators: Detective details:

Forecast of Cause:

Check Point 2 : Check Wired Remote Controller and Controller PCB

Check Point 1 : Check the connection of terminal

OKOK

Indicate or Display:

Wired Remote Controller

Communication Error

Indoor unit Controller PCB

Wired Remote Controller (Option)

1. Connection failure 2. Wired Remote Controller failure 3. Controller PCB failure

Check & correct the followings.

Check the connection of terminal between Wired Remote Controller and indoor unit,

and check if there is a disconnection of the cable.

When the indoor unit cannot properly receive the signal from

Wired Remote Controller for 1 minute or more.

02-05

Refer to error code table.

>> If it is DC12V, Remote Control is failure. (Controller PCB is normal) >> Replace Remote Control

>> If it is DC 0V, Controller PCB is failure. (Check Remote Control once again) >> Replace Controller PCB

Check Voltage at CN14 (terminal 1-3) of Controller PCB.

(Power supply to Remote Control)

Page 33

02-06

Trouble shooting 4

INDOOR UNIT Error Method:

Indicate or Display:

Indoor Unit Model Information Error

EEPROM Access Abnormal

Refer to error code table.

Detective Actuators:

Detective details:

Forecast of Cause:

Check Point 3 : Replace Controller PCB

Check Point 2 :

Check Indoor unit electric components

YESYES

NO

Indoor unit Controller PCB

1. External cause 2. Defective connection of electric components 3. Controller PCB failure

Check Point 1-1 : Reset Power Supply and operate

Does Error indication show again?

Check Point 1-2 :

Check external cause such as noise

Check if the ground connection is proper.

Check if there is any equipment that causes harmonic wave

near the power cable (Neon light bulb or any electronic

equipment which causes harmonic wave).

Note : EEPROM

EEPROM(Electronically Erasable and

Programmable Read Only Memory) is a nonvolatile memory which keeps memorized

information even if power is turned off. It can

change the contents electronically.

To change the contents, it uses higher

voltage than normal, and it can not change a

partial contents. (Rewriting shall be done

upon erasing the all contents.)

There is a limit in a number of rewriting.

Change Controller PCB.

Check all connectors.

(loose connector or incorrect wiring)

Check any shortage or corrosion on PCB.

When power is on and there is some below case.

1. When model information of EEPROM is incorrect.

2. When the access to EEPROM failed.

Page 34

Trouble shooting 5

INDOOR UNIT Error Method:

Indicate or Display:

Detective Actuators: Detective details:

Forecast of Cause :

OKOK

Manual Auto Switch Error

Indoor Unit Controller PCB

Indicator PCB

Manual Auto Switch

When the Manual Auto Switch becomes ON for consecutive 60 or

more seconds.

1. Manual Auto Switch failure 2. Controller PCB and Indicator PCB failure

Check Point 1 : Check the Manual Auto Switch

Check if Manual Auto Switch is kept pressed.

Check ON/OFF switching operation by using a meter.

>> If Manual Auto Switch is disabled (on/off switching), replace it.

Check Point 2 : Replace Controller PCB and Indicator PCB

If Check Point 1 do not improve the symptom, replace Controller PCB and Indicator PCB

and execute the check operation again.

02-07

Refer to error code table.

Page 35

Detective Actuators:

Indoor unit Controller PCB

Room temperature thermistor

Detective details:

Room temperature thermistor is open or short is detected always.

Forecast of Cause :

1. Connector failure connection 2. Thermistor failure 3. Controller PCB failure

Check Point 2 : Remove connector and check Thermistor resistance value

Thermistor Characteristics (Rough value)

If Thermistor is either open or shorted, replace it and reset the power.

Check Point 1 : Check connection of Connector

Check if connector is loose or removed

Check erroneous connection

Check if thermistor cable is open

>>Reset Power when reinstalling due to removed connector or incorrect wiring.

6.58.0

10.012.515.820.225.933.6

4.35.3Resistance value (k )

OK

OK

Check Point 3 : Check voltage of Controller PCB (DC5.0V)

Make sure circuit diagram of each indoor unit and check terminal voltage at Thermistor (DC5.0V)

If the voltage does not appear, replace Controller PCB and execute the check operation again.

02-08

Trouble shooting 6

INDOOR UNIT Error Method:

Indicate or Display:

Indoor Room Thermistor Error

Refer to error code table.

Temperature (°C )

Temperature (°C )

0

40 45

5

44.0

-5 10

58.2

-10 15 20 25

30 35

Resistance value (k )

H/E (MID) Thermistor

Room Temp. Thermistor

AR*G30/ 36LMLE

BLACK

BLACK

121

2

1 1

2 2

1 1

2 2

CN5

CN8

GRAY

GRAY

1

2

CN7

H/E (MID) Thermistor

Room Temp. Thermistor

AU*G30/ 36LRLE

RED

RED

121

2

1 1

2 2

CN5

CN8

BLACK

BLACK

1

2

CN7

121

2

121

2

1

2

H/E (MID) Thermistor

Room Temp. Thermistor

BLACK

BLACK

CN5

CN8

GRAY

GRAY

CN7

BLACK

BLACK

AB*G30/ 36LRTE

Page 36

Thermistor Characteristics (Rough value)

If Thermistor is either open or shorted, replace it and reset the power.

Detective Actuators:

Indoor unit Controller PCB

Heat exchanger (MID) Thermistor

Detective details:

Heat exchanger (MID) thermistor is open or short is detected always.

Forecast of Cause :

1. Connector failure connection 2. Thermistor failure 3. Controller PCB failure

Check Point 1 : Check connection of Connector

Check if connector is loose or removed

Check erroneous connection

Check if thermistor cable is open

>>Reset Power when reinstalling due to removed connector or incorrect wiring.

OK

Check Point 2 : Remove connector and check Thermistor resistance value

OK

Check Point 3 : Check voltage of Controller PCB (DC5.0V)

Make sure circuit diagram of each indoor unit and check terminal voltage at Thermistor (DC5.0V)

If the voltage does not appear, replace Controller PCB and execute the check operation again.

02-09

Trouble shooting 7

INDOOR UNIT Error Method:

Indicate or Display:

Indoor Heat Ex. Thermistor Error

Refer to error code table.

31.739.649.762.9

80.3103.3134.2176.0

17.120.825.6Resistance value (k )

Temperature (°C )

Temperature (°C )

0

40 45 50

14.1

55

5 10

1131.9

-30

804.5

-25

579.6

-20

422.9

-15

312.3

-10

233.2

-5 15

20 25 30 35

11.66010.4

63

Resistance value (k )

H/E (MID) Thermistor

Room Temp. Thermistor

AR*G30/ 36LMLE

BLACK

BLACK

121

2

1 1

2 2

1 1

2 2

CN5

CN8

GRAY

GRAY

1

2

CN7

H/E (MID) Thermistor

Room Temp. Thermistor

AU*G30/ 36LRLE

RED

RED

121

2

1 1

2 2

CN5

CN8

BLACK

BLACK

1

2

CN7

121

2

121

2

1

2

H/E (MID) Thermistor

Room Temp. Thermistor

BLACK

BLACK

CN5

CN8

GRAY

GRAY

CN7

BLACK

BLACK

AB*G30/ 36LRTE

Page 37

02-10

Trouble shooting 8

INDOOR UNIT Error Method:

Indicate or Display:

Indoor unit Fan Motor Error

Refer to error code table.

Detective Actuators:

Detective details:

Forecast of Cause:

Check Point 1 : Check rotation of Fan

Check Point 2 : Check ambient temp. around motor

OK

OK

OK

Indoor unit Controller PCB

Indoor unit fan motor

1. Fan rotation failure 2. Fan motor winding open 3. Motor protection by surrounding temperature rise

4. Control PCB failure 5. Indoor unit fan motor failure

Rotate the fan by hand when operation is off.

(Check if fan is caught, dropped off or locked motor)

>>If Fan or Bearing is abnormal, replace it.

Check excessively high temperature around the motor.

(If there is any surrounding equipment that causes heat)

>>Upon the temperature coming down, restart operation.

When the condition that actual frequency of Indoor Fan is

below 1/3 of target frequency is continued more than 56 seconds.

Check Point 4 : Replace Controller PCB

If Check Point 1- 3 do not improve the symptom, replace Controller PCB.

Check Point 3 : Check Indoor unit fan motor

Check Indoor unit fan motor. (PARTS INFORMATION 4)

>>If Indoor unit fan motor is abnormal, replace Indoor unit fan motor.

Page 38

Indicate or Display:

Refer to error code table.

Trouble shooting 9

INDOOR UNIT Error Method:

Drain Pump Error

Detective Actuators:

Indoor unit Controller PCB

Float switch

Detective details:

When Float switch is ON for more than 3 minutes.

Check Point 1 : Check Float switch

Check operation of float switch. (any blocking by dust, etc.)

Remove Float switch and check ON/OFF switching operation

by using a meter.

>>If Float switch is abnormal, replace it.

ON OFF

OK

Forecast of Cause :

1. Float switch failure 2. Shorted connector/wire 3. Controller PCB failure

4. Drain pump failure 5. Hose clogging

Check Point 2 : Check Connector (CN 9) / Wire

Check loose contact of CN9 /shorted wire (pinched wire).

>>Replace Float switch if the wire is abnormal

Check Point 4 : Check Controller PCB

If Check Point 1 ~ 3 do not improve the symptom, change

Controller PCB and execute the check operation again.

OK

OK

Check Point 3 : Check Drain hose

Check Drain hose .

>>If there is Hose clogging. Please clear the clog.

02-11

Page 39

Trouble shooting 10

OUTDOOR UNIT Error Method:

A.F Voltage Error

02-12

Indicate or Display:

Refer to error code table.

Detective Actuators:

Detective details:

Forecast of Cause :

OKOK

OKOK

Outdoor unit Main PCB

1. External cause 2. Connector connection failure 3. Main PCB failure

Check Point 2 : Check connection of Connector

Check if connector is removed.

Check erroneous connection.

Check if cable is open.

>>Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 3 : Replace Main PCB

If Check Point 1 - 2 do not improve the symptom, change Main PCB.

Check Point 1 : Check external cause at Indoor and Outdoor (Voltage drop or Noise)

Instant drop : Check if there is a large load electric apparatus in the same circuit.

Momentary power failure : Check if there is a defective contact or leak current

in the power supply circuit.

Noise : Check if there is any equipment causing harmonic wave near electric line.

(Neon bulb or electric equipment that may cause harmonic wave)

Check the complete insulation of grounding.

When inverter input DC voltage is higher than 425V or

lower than 80V.

When a momentary power cut off occurred on low voltage

Page 40

Detective Actuators:

Detective details:

Forecast of Cause :

Check Point 3 : Check Outdoor Fan

OK

OK

Check Point 5 : Replace Main PCB

Check Point 1 : Check connections of Outdoor Unit Electrical Components

Outdoor unit Main PCB

Compressor

1. Defective connection of electric components 2. Outdoor Fan Operation failure

3. Outdoor Heat Exchanger clogged 4. Compressor failure 5. Main PCB failure

Check if connector is removed.

Check if the terminal connection is loose.

Check erroneous connection.

Check if cable is open.

>>Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 2 : Check Outdoor Fan, Heat Exchanger

Is there anything obstructing the air distribution circuit?

Is there any clogging of Outdoor Heat Exchanger?

Is the Fan rotating by hand when operation is off ?

>> If the Fan Motor is locked, replace it.

Check Outdoor Fan Motor. (Refer to Trouble shooting 20)

>> If the Fan Motor is failure, replace it.

Check Point 4 : Check Compressor

(PARTS INFORMATION 2)

Check Compressor.

If Check Point 1 4 do not improve the symptom, change Main PCB.

When more than normal operating current to IPM in Main PCB flows,

the compressor stops.

After the compressor restarts, if the same operation is repeated within 40sec,

the compressor stops again.

If and repeats 5 times, the compressor stops permanently.

02-13

Trouble shooting 11

OUTDOOR UNIT Error Method:

IPM Error

Indicate or Display:

Refer to error code table.

OK

OK

Page 41

Trouble shooting 12

OUTDOOR UNIT Error Method:

Indicate or Display:

Detective Actuators: Detective details:

Forecast of Cause :

OKOK

OKOK

17.826.3

20

40.0

62.579.1100.9129.8168.6Resistance value (k )

1510

1013.1

-30

531.6

-20

292.9

-10

221.1

-5 50Temperature (°C )

12.3

30 5040 60

2.03.44.66.38.7Resistance value (k )

120100908070Temperature (°C )

Discharge Thermistor Error

Outdoor unit Main PCB

Discharge pipe temperature thermistor

When Discharge pipe temperature thermistor open or short-circuit

is detected at power ON or while running the compressor.

1. Connector connection failure 2. Thermistor failure 3. Main PCB failure

Check Point 1 : Check connection of connector

Check if connector is removed.

Check if connector is erroneous connection.

Check if thermistor cable is open.

>> Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 2 : Remove connector and check thermistor resistance value

Thermistor characteristics (Approx. value)

If Thermistor is either open or shorted, replace it and reset the power.

Check Point 3 : Check voltage of Main PCB (DC5.0V)

Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

If the voltage does not appear, replace Main PCB.

02-14

Refer to error code table.

BROWN

BROWN

Thermistor

(Discharge pipe)

Thermistor

(Heat exchanger)

Thermistor

(Outdoor temp.)

Thermistor

(Compressor temp.)

3

2

1

3

2

1

CN64

BLUE

BLUE

3

2

1

3

2

1

CN62

BLACK

BLACK

3

2

1

3

2

1

CN65

BROWN

BROWN

3

2

1

3

2

1

CN63

Page 42

Trouble shooting 13

OUTDOOR UNIT Error Method:

Indicate or Display:

Detective Actuators: Detective details:

Forecast of Cause :

OKOK

Compressor Thermistor Error

Outdoor unit Main PCB

Compressor temperature thermistor

When Compressor temperature thermistor open or short-circuit

is detected at power ON or while running the compressor.

1. Connector connection failure 2. Thermistor failure 3. Main PCB failure

Check Point 1 : Check connection of connector

Check if connector is removed.

Check if connector is erroneous connection.

Check if thermistor cable is open.

>> Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 2 : Remove connector and check thermistor resistance value

Thermistor characteristics (Approx. value)

If Thermistor is either open or shorted, replace it and reset the power.

02-15

Refer to error code table.

17.826.3

20

40.0

62.579.1100.9129.8168.6Resistance value (k )

1510

1013.1

-30

531.6

-20

292.9

-10

221.1

-5 50Temperature (°C )

12.3

30 5040 60

2.03.44.66.38.7Resistance value (k )

120100908070Temperature (°C )

OKOK

Check Point 3 : Check voltage of Main PCB (DC5.0V)

Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

If the voltage does not appear, replace Main PCB.

BROWN

BROWN

Thermistor

(Discharge pipe)

Thermistor

(Heat exchanger)

Thermistor

(Outdoor temp.)

Thermistor

(Compressor temp.)

3

2

1

3

2

1

CN64

BLUE

BLUE

3

2

1

3

2

1

CN62

BLACK

BLACK

3

2

1

3

2

1

CN65

BROWN

BROWN

3

2

1

3

2

1

CN63

Page 43

Trouble shooting 14

OUTDOOR UNIT Error Method:

Indicate or Display:

Detective Actuators: Detective details:

Forecast of Cause :

OKOK

Heat Ex. Liquid Outlet Thermistor Error

Outdoor unit Main PCB

Heat exchanger temperature thermistor

When Heat exchanger temperature thermistor open or

short-circuit is detected at power ON or while running the compressor.

1. Connector connection failure 2. Thermistor failure 3. Main PCB failure

Check Point 1 : Check connection of connector

Check if connector is removed.

Check if connector is erroneous connection.

Check if thermistor cable is open.

>> Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 2 : Remove connector and check thermistor resistance value

Thermistor characteristics (Approx. value)

If Thermistor is either open or shorted, replace it and reset the power.

02-16

Refer to error code table.

7.7

5

9.712.416.120.927.549.2Resistance value (k )

0-5-10-20

92.3

-30Temperature (°C ) 10 15

0.91.21.82.63.9Resistance value (k )

70

0.6

80

0.5

9060504030

6.1

20Temperature (°C )

OKOK

Check Point 3 : Check voltage of Main PCB (DC5.0V)

Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

If the voltage does not appear, replace Main PCB.

BROWN

BROWN

Thermistor

(Discharge pipe)

Thermistor

(Heat exchanger)

Thermistor

(Outdoor temp.)

Thermistor

(Compressor temp.)

3

2

1

3

2

1

CN64

BLUE

BLUE

3

2

1

3

2

1

CN62

BLACK

BLACK

3

2

1

3

2

1

CN65

BROWN

BROWN

3

2

1

3

2

1

CN63

Page 44

Trouble shooting 15

OUTDOOR UNIT Error Method:

Indicate or Display:

Detective Actuators: Detective details:

Forecast of Cause :

OKOK

16.1

5

20.726.935.246.662.3115.2Resistance value (k )

0-5-10-20

224.3

-30Temperature (°C ) 10 15

1.62.43.55.28.0Resistance value (k )

70

1.2

8060504030

12.6

20Temperature (°C )

Outdoor Thermistor Error

Outdoor unit Main PCB

Outdoor temperature thermistor

When Outdoor temperature thermistor open or short-circuit

is detected at power ON or while running the compressor.

1. Connector connection failure 2. Thermistor failure 3. Main PCB failure

Check Point 1 : Check connection of connector

Check if connector is removed.

Check if connector is erroneous connection.

Check if thermistor cable is open.

>> Upon correcting the removed connector or mis-wiring, reset the power.

Check Point 2 : Remove connector and check thermistor resistance value

Thermistor characteristics (Approx. value)

If Thermistor is either open or shorted, replace it and reset the power.

02-17

Refer to error code table.

OKOK

Check Point 3 : Check voltage of Main PCB (DC5.0V)

Make sure circuit diagram of outdoor unit and check terminal voltage at thermistor (DC5.0V)

If the voltage does not appear, replace Main PCB.

BROWN

BROWN

Thermistor

(Discharge pipe)

Thermistor

(Heat exchanger)

Thermistor

(Outdoor temp.)

Thermistor

(Compressor temp.)

3

2

1

3

2

1

CN64

BLUE

BLUE

3

2

1

3

2

1

CN62

BLACK

BLACK

3

2

1

3

2

1

CN65

BROWN

BROWN

3

2

1

3

2

1

CN63

Page 45

Trouble shooting 16

OUTDOOR UNIT Error Method:

Current Sensor Error

02-18

Indicate or Display:

Refer to error code table.

Detective Actuators:

Detective details:

Forecast of Cause :

Check Point 3 : Replace Main PCB

YES

NO

OK

Outdoor unit Main PCB

Check Point 2 :

Check connections of Outdoor Unit Electrical Components

Check if connector is removed.

Check if the terminal connection is loose.

Check erroneous connection.

Check if cable is open.

>>Upon correcting the removed connector or mis-wiring,

reset the power.

Check Point 1-2 :

Check external cause at Indoor and Outdoor

(Voltage drop or Noise)

1. Defective connection of electric components 2. External cause 3. Main PCB failure

Instant drop : Check if there is a large load electric

apparatus in the same circuit.

Momentary power failure : Check if there is a defective

contact or leak current in the

power supply circuit.

Noise : Check if there is any equipment causing harmonic

wave near electric line.(Neon bulb or electric

equipment that may cause harmonic wave)

Check the complete insulation of grounding.

Check Point 1-1 : Reset Power Supply and operate

Does Error indication show again?

When Input Current Sensor has detected 0A, while Inverter Compressor is

operating at higher than 56rps, after 1minute upon starting the Compressor.

(Except during the defrost operation)

If Check Point 1, 2 do not improve the symptom,

change Main PCB.

Page 46

Trouble shooting 17

OUTDOOR UNIT Error Method:

Detective Actuators: Detective details:

Indicate or Display:

02-19

Refer to error code table.

High Pressure Switch Error

Forecast of Cause :

Check Point 1 : Check the high pressure switch connection state

OK

Outdoor unit Main PCB

High Pressure Switch

1. High pressure switch connector disconnection, open

2. High pressure switch characteristics failure

3. Main PCB failure

When pressure switch open is detected in 10 seconds

after the power is turned on.

Connector and wiring connection state check

Cable open check

Check Point 2 : Check the high pressure switch characteristics

Switch characteristics check

* For the characteristics of high pressure switch, refer to below.

OK

Check Point 3 : Replace Main PCB

Change Main PCB, and execute the check operation again.

Type of contact

Characteristics of high pressure switch

C

H

Pressure

high pressure switch

4.2 0.1MPa

3.2 0.15MPa

Contact : Short Open

Contact : Open Short

(CN74)

Page 47

02-20

Trouble shooting 18

OUTDOOR UNIT Error Method:

Indicate or Display:

Over Current Error

Refer to error code table.

Detective Actuators:

Detective details:

Forecast of Cause :

OKOK

Check Point 2: Replace Main PCB

Outdoor unit Main PCB

Compressor

Transistor PCB (IPM)

If Check Point 1 do not improve the symptom, change Main PCB.

OKOK

Check Point 3: Replace Compressor

If Check Point 3 do not improve the symptom, change Compressor.

1. Outdoor unit fan operation defective, foreign matter on hear exchanger,

excessive rise of ambient temperature

2. Main PCB

3. Inverter compressor failure (lock, winding short)

4. Transistor PCB (IPM) failure

"Protection stop by overcurrent generation after inverter compressor start

processing completed'' generated consecutively 10 times.

* The number of generations is reset if the start-up of

the compressor succeeds.

No obstructions in air passages?

Heat exchange fins clogged

Outdoor unit fan motor check

Ambient temperature not raised by the effect of other heat sources?

Discharged air not sucked in?

Check Point 1 : Check the outdoor unit fan operation, heat exchanger, ambient temperature

Page 48

Trouble shooting 19

OUTDOOR UNIT Error Method:

Compressor Control Error

02-21

Detective Actuators:

Detective details:

Forecast of Cause :

Check Point 2 : Check connection of around the Compressor components

OKOK

Check Point 3: Replace Main PCB

Outdoor unit Main PCB

Compressor

1. Defective connection of electric components 2. Main PCB failure 3. Compressor failure

If Check Point 1,2 do not improve the symptom, change Main PCB.

Check if connector is removed.

Check erroneous connection.

Check if cable is open.

>>Upon correcting the removed connector or mis-wiring, reset the power.

(Refer to PARTS INFORMATION 2)

For Compressor Terminal, Main PCB

While running the compressor, if the detected rotor location is out of

phase with actual rotor location more than 90°,

the compressor stops.

After the compressor restarts, if the same operation is repeated

within 40sec, the compressor stops again.

If and repeats 5 times, the compressor stops permanently.

Check Point 1 : Check Noise from Compressor

Turn on Power and check operation noise.

If an abnormal noise show, replace Compressor.

OKOK

Check Point 4: Replace Compressor

If Check Point 3 do not improve the symptom, change Compressor.

OKOK

Indicate or Display:

Refer to error code table.

Page 49

02-22

Trouble shooting 20