Page 1

HIGH STATIC PRESSURE

DUCT TYPE AIR CONDITIONER

TECHNICAL MANUAL

AR90

Page 2

– 1 –

CONTENTS

1. FEATURES........................................................................ 2

2. DIMENSIONS.................................................................... 4

3. WIRING DIAGRAM............................................................ 6

4. PERFORMANCE DATA..................................................... 9

5. OPERATION DETAILS .................................................... 11

6. INSTALLATION INSTRUCTIONS.................................... 12

7. SPECIFICATIONS........................................................... 13

Page 3

– 2 –

1. FEATURES

● High static pressure

• Recommended external static pressure is 200Pa (Max. 300Pa).

● Functional LCD wired remote controller (See the next page for details.)

• Weekly timer

Air conditioner ON/OFF can be set for one whole week, including 2 times a day.

• Auto restart function in case of power failure

• Zone control

Only preset air conditioners can be stopped by pressing the ZONE CONTROL button.

● Energy saving operation

• ENERGY SAVE mode uses a computer program to economically control unit operation by

raising the set temperature slightly in the cooling mode and lowering the set temperature in the

heating mode.

● Pipe length up to 50m with height differential up to 30m

● Easy maintenance

• Fan motor maintenance

Fan motor maintenance can be perfor med from top, bottom, right side, or left side. (Fig. 1)

Fan motor hooks to the panel and is safe and easy to mount and dismount. (Fig. 2)

● Remote sensor unit (Option)

• Temperature sensor unit to be placed in the room

TOP ACCESS

BOTTOM ACCESS

SIDE ACCESS

(BOTH SIDES)

Fig. 1

PILOT PLATE MOTOR

Fig. 2

Page 4

– 3 –

REMOTE CONTROLLER

WIRE REMOTE CONTROLLER WITH WEEKLY TIMER

Three kinds of timer setup (OFF/ON/WEEKLY) are possible.

Function of weekly timer

• Setting of different on-off time by day

• Setting of set on-off time twice a day

• Setting of time in 5 minute steps

• Timer operation of a reserved day can be temporarily cancelled by pushing the “DAY OFF” button.

• Time setting can be left until the next day.

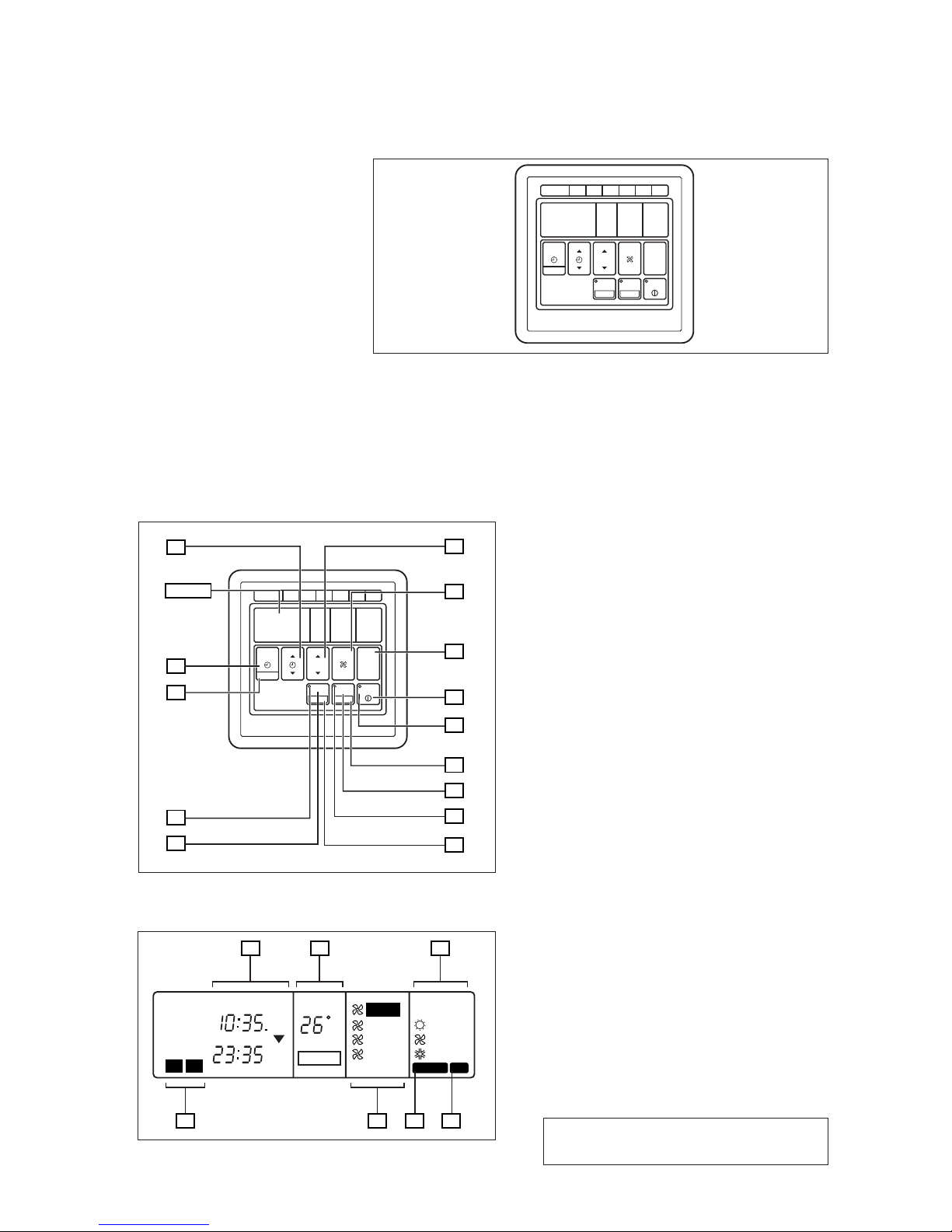

FEATURES

Display panel

COOL

FAN

HEAT

TEMP.

C

DEFROST TEST

DAY

DAY OFF

CLOCK

OFF

ON

OFF

ON

NEXT DAY

TIMER

NON STOP

OFFON

WEEKLY

TIMER

1

2

LOW

MED

HIGH

AUTO

2019

18

17

1615

21

MASTER

CONTROL

FAN

CONTROL

TIMER

MODE

DAY CODE

REMOTE CONTROLLER WITH WEEKLY TIMER

1

MON2TUE3WED4THU5FRI6SAT

TEMP./DAY

ZONE

ENERGY SAVE

SET TIME

CLOCK ADJUST

START/STOP

SET

DAY OFF

Display

12

11

9

10

8

7

13

14

1

2

3

4

5

6

MASTER

CONTROL

FAN

CONTROL

TIMER

MODE

DAY CODE

REMOTE CONTROLLER WITH WEEKLY TIMER

1

MON2TUE3WED4THU5FRI6SAT

TEMP./DAY

ZONE

ENERGY SAVE

SET TIME

CLOCK ADJUST

START/STOP

SET

DAY OFF

1 START/STOP Button

Pressed to start and stop operation.

2 OPERATION Lamp

Lights during operation and when the timer is on.

3 DAY OFF Button

Temporary cancellation of one day timer

4 ENERGY SAVE Button

Turns energy save mode on and off.

5 ENERGY SAVE Button

Lights when the unit is in the energy save mode.

6 SET Button

Sets the date, hour, minute and on-off time.

7 ZONE Button

Use to turn zone control on and off.

8 ZONE Lamp

Lights when the unit is in the zone control mode.

9 CLOCK ADJUST Button

10 TIMER MODE Button

Changes the timer mode (NON STOP, OFF TIMER,

ON TIMER, WEEKL Y TIMER).

11 SET TIME Button

Sets the current time and on-off time.

12 TEMP./DAY Button

Sets the indoor temperature / day.

13 FAN CONTROL Button

14 MASTER CONTROL Button

Selects the operating mode

(HEAT, FAN, COOL).

15 Clock Display

16 Set Temperature / Day Display (TEMP./DAY)

17 Operation Mode Display

18 Timer Mode Display

19 Fan Speed Display

20 DEFROST Display

21 TEST Display

#NOTE :

This model does not have a fan speed function.

#

#

Page 5

– 4 –

■ INDOOR UNIT

(Unit : mm)

2. DIMENSIONS

■ OUTDOOR UNIT

1,550

1,410

660

700

600

450

650

1,300 650

1,380

● SAMPLE INSTALLATION

Page 6

– 5 –

(Unit : mm)

HOOK METAL

CONTROL BOX

SAFETY DRAIN PORT

AIR FLOW OUTLET AIR FLOW INLET

COUPLING PIPE

MAIN DRAIN PORT

38.1 (DRAIN PIPE)

LIQUID : 12.7 FLARE

GAS : 28.58 FLANGE

1,550 (MAXIMUM)

1,450

713 (MAXIMUM)

600

450

25.4 (SAFETY DRAIN)

Page 7

– 6 –

3. WIRING DIA GRAM

1 2

1 2

CN. 8

1 2

CN. 6

(DRAIN PUMP)

BLACK

BLACK

THERMISTOR

(ROOM TEMP.)

TO REMOTE

CONTROL UNIT

CONTROL

BOARD

FILTER

BOARD

FAN

MOTOR

MAGNETIC RELAY

CR COMPOSITE

TERMINAL

THERMISTOR

(PIPE TEMP.)

1 2

1 2

CN. 7

GRAY

GRAY

2 31

CN. 15

(FLOAT SWITCH)

3 51

4 35

CN. 5

2 31

2 31

CN. 1

2 13

2 13

CN. 17

RED

WHITE

BLACK

WHITE

FUSE

T3.15A 250V

F101

BLACK

GREEN

WHITE

RED

BLACK

BLUE

WHITE

RED

BLACK

BLUE

BLUE

THERMAL

PROTECTOR

PURPLE

BLUE

123

N

L

TO OUTDOOR

UNIT

TERMINAL

RED

WHITE

BLACK

12

(N)

3

TO POWER

TERMINAL

BLACK

WHITE

RED

TSR

3 2 1 4 5 6

3 2 1 4 5 6

FM

Models : AR 90T

AR 90E

Note :

Y : Europe version

T : Australia version

Page 8

– 7 –

CN. 10

COMPRESSOR A

THERMISTOR

(DISCHARGE TEMP.)

THERMISTOR

(OUTDOOR TEMP.)

INTERNAL

OVERLOAD

PROTECTOR

T

1

T

3

T

2

A1

15

43

WVU32

A2TSR31

BLACK

WHITE

BLACK

PURPLE

PURPLE

BLUE

BLUE

BLACK

RED

BLACK

RED

MAGNETIC RELAY A

CR COMPOSITE

WHITE

BLACK

PURPLE

COMPRESSOR B

POWER

RELAY B

PRINTED

CIRCUIT

BOARD

EXPANSION

VALVE COIL

INTERNAL

OVERLOAD

PROTECTOR

T

1

T

3

T

2

A2

15

43

WVU32

A1TSR31

BLACK

WHITE

WHITE

BLACK

BLACK

GREEN

GREEN

WHITE

RED

RED

BLACK

BLACK

RED

BELT HEATER B

BELT

HEA TER A

MAGNETIC RELAY B

FAN MOTOR A

FAN

CAPACITOR

PRESSURE SWITCH

EARTH

CR COMPOSITE

1

POWER

RELAY A

WHITE

RED

BLACK

PURPLE

1

2

3

6

5

4

CN. 9

3

2

1

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

6

5

4

CN. 11

3

2

1

12

CN. 16

345

CN. 18

3

2

1

CN. 6

3

2

1

CN. 4

3

2

1

CN. 13

E

3

2

1

CN. 7

1

2

3

4

5

BLACK

23 RSTN

EV

FM

BLUE

RED

WHITE

BLACK

YELLOW

PINK

PINK

GREEN/YELLOW

FAN MOTOR B

FAN

CAPACITOR

12

CN. 3

345

FM

BLUE

RED

WHITE

BLACK

YELLOW

W1

RED

BLACK

PINK

RED

EARTH

POWERUNIT

TERMINAL

GREEN/YELLOW

GREEN/YELLOW

PINK

BLUE

Model : A O 90EP

Page 9

– 8 –

CN. 10

COMPRESSOR A

THERMISTOR

(DISCHARGE TEMP.)

THERMISTOR

(OUTDOOR TEMP.)

INTERNAL

OVERLOAD

PROTECTOR

T

1

T

3

T

2

A1

15

43

WVU32

A2TSR31

BLACK

WHITE

BLACK

PURPLE

PURPLE

BLUE

BLUE

BLACK

RED

BLACK

RED

MAGNETIC RELAY A

CR COMPOSITE

WHITE

BLACK

PURPLE

COMPRESSOR B

POWER

RELAY B

PRINTED

CIRCUIT

BOARD

EXPANSION

VALVE COIL

INTERNAL

OVERLOAD

PROTECTOR

T

1

T

3

T

2

A2

15

43

WVU32

A1TSR31

BLACK

WHITE

WHITE

BLACK

BLACK

THERMISTOR

(PIPE TEMP.)

BROWN

BROWN

GREEN

GREEN

WHITE

RED

RED

BLACK

BLACK

RED

BELT HEATER B

BELT

HEA TER A

MAGNETIC RELAY B

FAN MOTOR A

FAN

CAPACITOR

PRESSURE SWITCH

SOLENOID COIL

EARTH

CR COMPOSITE

1

POWER

RELAY A

WHITE

RED

BLACK

PURPLE

1

2

3

6

5

4

CN. 9

3

2

1

RED

BROWN

BLUE

ORANGE

YELLOW

WHITE

6

5

4

CN. 11

3

2

1

12

CN. 16

345

CN. 18

3

2

1

CN. 6

3

2

1

CN. 4

3

2

1

CN. 13

E

3

2

1

CN. 7

1

2

3

4

5

BLACK

23 RSTN

EV

4WV

FM

BLUE

RED

WHITE

BLACK

YELLOW

PINK

PINK

BLACK

BLACK

GREEN/YELLOW

FAN MOTOR B

FAN

CAPACITOR

12

CN. 3

345

FM

BLUE

RED

WHITE

BLACK

YELLOW

W1

RED

BLACK

PINK

RED

EARTH

POWERUNIT

TERMINAL

GREEN/YELLOW

GREEN/YELLOW

PINK

BLUE

Model : A O 90TP

Page 10

– 9 –

4. PERFORMANCE DATA

120

COOLING

110

100

90

90

80

80

19/13

23/16.5

27/19

19/13

31/22.5

23/16.5

27/19

31/22.5

Indoor

DB/WB (°C)

0 5 10 15 20 25 30 35 40 45 50

70

100

110

Total input (%)

Outdoor DB (°C)

Capacity (%)

120

COOLING

110

100

90

90

80

80

19/13

23/16.5

27/19

19/13

31/22.5

23/16.5

27/19

31/22.5

Indoor

DB/WB (°C)

0 5 10 15 20 25 30 35 40 45 50

70

100

110

Total input (%)

Outdoor DB (°C)

Capacity (%)

120

HEATING

110

100

90

90

80

80

15

27

20

27

20

15

Indoor

DB (°C)

-5 0 5 10 15 20

//////

-6 -2 3 7.5 12 17.5

70

100

110

Total input (%)

Outdoor DB (°C)

Capacity (%)

■ COOLING MODEL

■ REVERSE MODEL

Page 11

– 10 –

3000

30.0

25.0

20.0

4000 5000 6000

900 1000 1100

1200 1300 1400 1500 1600

(m

3

/h)

/Sec)(

Air Flow

COOLING

Capacity (kW)

3000

35.0

30.0

25.0

4000 5000 6000

900 1000 1100

1200 1300 1400 1500 1600

(m

3

/h)

/Sec)(

Air Flow

HEATING

Capacity (kW)

900

3000

30

25

20

15

10

100

150

200

250

1000 1100 1200 1300

3500 4000 4500 5000 (m

3

/h)

(Pa) (mmAq)

/Sec)(

Air Flow

External static pressure

Standard

415V

380V

3000

20.0

15.0

10.0

5.0

4000 5000 6000

900 1000 1100

1200 1300 1400 1500 1600

(m

3

/h)

/Sec)(

Air Flow

COOLING

Temp (°C)

3000

50.0

45.0

40.0

35.0

4000 5000 6000

900 1000 1100

1200 1300 1400 1500 1600

(m3/h)

/Sec)(

Air Flow

HEATING

Temp (°C)

■ FAN CURVE

■ OUTLET AIR TEMPERATURE

■ CAPACITY BY AIR FLOW

■ COOLING SENSIBLE CAPACITY

INDOOR TEMP.

OUTDOOR TEMP. (°C)

(°C) 25 30 35 40 45

DB WB Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

19 13 22.9 17.3 21.8 16.9 20.9 16.4 19.9 15.8 18.5 14.9

23 16.5 24.7 17.9 23.6 17.5 22.9 17.0 21.7 16.4 20.3 15.7

27 19 27.0 21.4 26.1 21.1 25.4 20.9 24.2 20.2 22.7 19.4

31 22.5 29.3 24.8 28.7 24.7 27.9 24.5 26.7 24.1 25.4 23.3

(Unit : kW)

Page 12

– 11 –

Actual pipe length

30m 40m 50m Additional

(99ft) (132ft) (164ft) refrigerant (R407C)

Full charge amount 7,000g 8,000g 9,000g 100g/m

HEAT & COOL MODEL

(247 oz) (282 oz) (317 oz) (3.5 oz / 3.3 ft)

Full charge amount 6 ,000g 6,500g 7,000g 50g/m

COOLING MODEL (212 oz) (229 oz) (247 oz) (1.8 oz / 3.3 ft)

Cooling Mode *Heating Mode

COOLING MODEL Approx. 00 to 52°C –––––

HEAT & COOL MODEL

Approx. 00 to 46°C Approx. -10 to 21°C

(Reverse Cycle)

INDOOR TEMPERATURE Approx. 18 to 30°C Approx. below 30°C

INDOOR HUMIDITY Approx. 80% or less –––––

■ REFRIGERANT CHARGE

■ TEMPERATURE AND HUMIDITY RANGE

OUTDOOR

TEMPERATURE

• Do not use this unit for any purpose other than the cooling, (*) heating,

dehumidifying and circulating air of rooms in ordinary dwellings.

5. OPERATION DETAILS

Do not purge the air with refrigerants but use a vacuum

pump to vacuum the installation! There is no extra refrigerant in the outdoor unit for air purging!

Use a vacuum pump for R407C exclusively. Using the

same vacuum pump for different refrigerant may damage the vacuum pump or the unit.

When moving and installing the air conditioner, do not

mix gas other than the specified refrigerant R407C

inside the refrigerant circuit.

When charging the refrigerant R407C, always use an

electronic balance for refrigerant charging (to measure

the refrigerant by weight).

When charging the refrigerant,

take into account the slight change

in the composition of the gas and

liquid phases, and always charge

from the liquid phase side whose

composition is stable.

Add refrigerant from the charging valve after the

completion of the work.

Use a brand-new refrigerant piping when replacing the

air conditioner using the refrigerant except R407C and

R410A.

Gas

Liquid

LO

HI

Gauge manifold

Service hose

Vacuum pump

Use a clean gauge manifold and charging hose

for R407C exclusively.

Page 13

– 12 –

6. INSTALLATION INSTRUCTIONS

■ INDOOR UNIT

• SERVICE SPACE

Leave the space reguired to service the air conditioner. (Fig.1)

(1) If a service hole is provided at the bottom of the product.

(2) If the service hole referenced in (1) is not provided.

• INSTALLING DRAIN PIPE

Position of drain piping and refrigerant piping.

The installed drain pipe should have a downward gradient of 1/50

to 1/100. Make sure that the drain pipe is installed without rises.

Use general hard polyvinylchloride pipe (VP25) and connect

it with adhesive (polyvinylchloride) so that there is no leakage. Do not perform air bleeding.

Main drain

On the main drain, provide one trap near the indoor unit.

Safety drain

There is no need to provide a trap for the safety drain. If the

safety drain is connected to the main drain, make the connection below the main trap.

Once installation is complete, check the flow of drain water.

• INSTALLING THE DUCT

Follow the procedure in the following figure to install the duct.

Flange positions for connecting the duct.

Unit : mm

1,250

Inlet port flange

*20 370 14

*25

15

35

350

2 x 160 pitch = 320

75 Outlet port flange

7 x 150 pitch = 1,050

*Spacing between flange and drain pan

Install the air inlet grille for air circulation.

The correct temperature cannot be detected.

Unit

Air Outlet Grille

(Room)

■ OUTDOOR UNIT

Provide the space shown in Fig.2 so that the air flow is not

blocked.

• Installing the unit individually

L1 L2

Top blower

outlet

Front air

intake

Rear

air

intake

H (1,200 mm or less) h

H (1,200 mm or less) h

• There is no limit to the height of the side wall.

• The height of the wall (H) at the front and rear should be

1,200mm or less.

• If the wall height exceeds 1,200mm, add dimension (h) to

the respective service space dimensions L1 and L2.

Fig. 2

10mm or more

200mm

or more

500mm

or more

10mm or more

Front

Air Inlet Grille

200

890

40030

1,920

Unit : mm

Service hole

Fig.1

900 900

Unit H1=100 mm (Approx.)

H2=50 to 100 mm

Drain pipe

Trap

H1H2

Unit

Main

Safety

Drain Pipe

95

40

60

50

50

200

427

404

318

235

Safety drain pipe

ø25.4mm (O.D.)

Main drain pipe

ø38.1mm (O.D.)

Unit : mm

Page 14

– 13 –

TYPE

DUCT TYPE AIR CONDITIONER

COOLING ONLY TYPE COOLING & HEATING TYPE

Model

Indoor Unit AR

90E AR 90T

Outdoor Unit AO 90EP AO 90TP

Input Power V/ /Hz 380 - 415 / 3 / 50 380 - 415 / 3 / 50

Cooling

kW 24.8 - 25.4 24.8 - 25.4

Capacity

BTU/h 84,500 - 86,500 84,500 - 86,500

Heating

kW ––– 28.9 - 29.5

BTU/h ––– 98,500 - 100,500

Ampacity

Cooling

A

18.3 - 17.6 19.5 - 19.5

Heating ––– 19.5 - 19.5

Input Watts

Cooling

kW

11.0 - 11.0 12.2 - 12.5

Heating ––– 12.2 - 12.5

Starting Current A 63 63

Moisture Removal /h 7.5 7.5

E.E.R.

Cooling

kW/kW

2.25 - 2.31 2.03 - 2.03

Heating ––– 2.36 - 2.36

Fan Speed

Indoor

r.p.m.

1,140 When static pressure is 200Pa

Outdoor 730

Air Flow

Indoor

m

3

/h

4,300 (1,194) When static pressure is 200Pa

Outdoor

(

/s)

5,800 (1,611)

Standard Static Pressure Pa 200

Net

Indoor 450 x 1,550 x 700

Dimensions

Outdoor

mm

1,380 x 1.300 x 650

H x W x D

Gross

Indoor 550 x 1,750 x 825

Outdoor 1,535 x 1,400 x 700

Weights Net / Gross

Indoor

kg

85 / 100

Outdoor 243 / 280 245 / 282

Refrigerant Type –– R407C

Connection Method / Pipe Size –– Flange / 28.58 (Large) Flare / 12.70 (Small)

Max. Pipe Length / Height m 50 / 30

Operation Range

Cooling

°C

0 to 52 0 to 46

Heating –– -10 to 21

7. SPECIFICATIONS

Note :

Y : Europe version

T : Australia version

Page 15

0009J-903-1749

September 2000 Printed in Japan

ACN 001 229 554

FUJITSU GENERAL (Euro) GmbH

A SUBSIDIARY OF FUJITSU GENERAL LIMITED

Werftstraße 20, D-40549 Düsseldorf, F.R. Germany TEL : (49) 211 50098 0

FUJITSU GENERAL (U.K.) CO. LIMITED

A SUBSIDIARY OF FUJITSU GENERAL LIMITED

Ground Floor, Elstree House, Elstree Way, Borehamwood, Herts WD6 1LS United Kingdom

TEL : (44) 181 421 7000

FUJITSU GENERAL(AUST.) PTY LIMITED

A SUBSIDIARY OF FUJITSU GENERAL LIMITED

HEAD OFFICE

SYDNEY : 100 Holbeche Road, Arndell Park, N.S.W. 2148 TEL: (02) 8822 2500

MELBOURNE : Unit 7, 14 Lionel Road, Mount Waverley, VIC. 3149 TEL: (03) 9543 5899

(also all Tasmanian enquiries)

BRISBANE : Suite 1, Level 5, 301 Coronation Drive, Milton, QLD. 4064 TEL: (07) 3367 2008

ADELAIDE : 146 Fullarton Road, Rose Park, S.A. 5067 TEL: (08) 8364 0588

PERTH : Suite 3, 5 Mumford Place, Balcatta W.A. 6021 TEL: (08) 9240 5877

FUJITSU GENERAL NEW ZEALAND LIMITED

A SUBSIDIARY OF FUJITSU GENERAL LIMITED

HEAD OFFICE

WELLINGTON : Level 1, 8-10 Fitzherbert Street, Petone, New Zealand TEL: (04) 568 8761

Loading...

Loading...