Page 1

DESIGN & TECHNICAL MANUAL

SINGLE

INDOOR

OUTDOOR

AOA72LALT

AO

A90LALT

AR

C72LHTA ARC90LHTA

AIR CONDITIONER

Duct type

Page 2

1. INDOOR UNIT

DTR_AR061E_03

2013.11.08

DUCT TYPE :

ARC72LHTA

ARC90LH TA

Page 3

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

CONTENTS

1. INDOOR UNIT

1. FEATURES

........................................................................................................ 01 - 01

2. WIRED REMOTE CONTROLLER

................................................... 01 - 06

3. SPECIFICATIONS

........................................................................................ 01 - 08

4. DIMENSIONS

................................................................................................... 01 - 09

5. WIRING DIAGRAMS

.................................................................................. 01 - 12

6. CAPACITY TABLE

....................................................................................... 01 - 13

6-1. COOLING CAPACITY

................................................................................ 01 - 13

6-2. HEATING CAPACITY

................................................................................. 01 - 14

7. FAN PERFORMANCE AND CAPACITY

..................................... 01 - 15

8. OPERATION NOISE

................................................................................... 01 - 19

8-1. NOISE LEVEL CURVE

............................................................................... 01 - 19

8-2. SOUND LEVEL CHECK POINT

............................................................... 01 - 20

9. ELECTRIC CHARACTERISTICS

..................................................... 01 - 21

10. SAFETY DEVICES

....................................................................................... 01 - 22

11. EXTERNAL INPUT & OUTPUT

......................................................... 01 - 23

11-1. EXTERNAL INPUT

...................................................................................... 01 - 23

11-2. EXTERNAL OUTPUT

................................................................................. 01 - 24

12. FUNCTION SETTINGS

............................................................................. 01 - 29

12-1. INDOOR UNIT

.............................................................................................. 01 - 29

12-2. INDOOR UNIT (Setting by remote controller)

..................................... 01 - 31

12-3. WIRED REMOTE CONTROLLER

............................................................ 01 - 34

13. OPTIONAL PARTS

...................................................................................... 01 - 35

13-1. CONTROLLER

............................................................................................ 01 - 35

13-2. OTHERS

....................................................................................................... 01 - 35

Page 4

- (01 - 01) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

FEATUR ES1.

MODEL

ARC72LHTA / AOA72LALT

ARC90LHTA / AOA9 0 L ALT

FEATURES

Signicantly improved EER/COP

z

Signicantly improved Hi-efciency is realized by the use of a ALL-DC components, inverter

technology, and large heat exchanger.

Energy saving technology

z

OUTDOOR UNIT

INDOOR UNIT

Previous

model

Cooling Heating

New

model

EER2.0 3.00.0

Cooling EER

57%inc rease!

!

2.03

3.20

2.0 3.00.0 COP

Heat ing COP

44%increase !

2.36

3.40

(AR¾C90L) (AR¾C90L)

Surface area

1.7times!

New model

Power consumption

has been reduced

by 25% compared to

previous models by

using a compact and

high performance DC

fan motor.

High efciency

operation is

realized by

using a sine

wave DC

inverter control.

Signicantly

greater efciency

is realized by

use of a large

capacity DC twin

rotary compressor

with substantially

increased

refrigerant intake

and compression

ef ci ency.

Heat exchange ef ciency is signicantly

improved by the introduction of a new

4-face heat exchanger that increases

effective surface area.

In multiple outdoor unit installations, the

unique front intake design improves air ow

into the Heat exchanger.

Previous

model

ARC72LHTA

ARC9 0LHTA

The power consumption has

been reduced drastically by the

introduction of DC fan motors.

Page 5

- (01 - 02) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

Space saving and compact size

z

Compact size has been achieved by signicantly reducing the width of the outdoor units

compared to previous models.

Static pressure selection

z

5 Static Pressure modes are available.

Improvement and design exibility has allowed multiple fan speeds and static pressure modes.

The air ow rate has been improved to meet the requirements of complex ductwork layout designs. •

→ By introducing a new DC fan motor, the static pressure range selected by the installer can

range between 50 to 250Pa.

A three speed fan (High, Medium and Low) allows accurate airow control. •

A decrease in the power consumption of the indoor unit has been realised by optimizing the •

control of the indoor fan motor rotation frequency.

Low static pressure - High static pressure

Fan motor speed : Low speed - High speed

3900

0

50

100

150

200

250

300

4100 4300 4500 4700 4900 5100 5300 5500

Normal (72Pa)

LSP mode (50Pa)

HSP mode 1 (150Pa)

HSP mode 2 (200Pa)

HSP mode 3 (250Pa)

Static pressure (Pa)

Air flow (m3/h)

Max. 250Pa

Rating

(AR¾C90L)

]

Efciency of the indoor unit operation has

been improved in both the static pressure and

air ow design.

1,300

930

28%

reduction

Previous model

New model

Page 6

- (01 - 03) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

Outdoor unit quiet operation

z

Low noise mode (Optional parts: UTY-XWZXZ2)

Introduction of a low outdoor noise operation mode allow the outdoor unit to have two quiet mode

operation settings.

* Performance may drop depending on the outside air temperature condition, etc.

1) Level1 (Rated noise value -3dB)

2) Level2 (Rated noise value -5dB)

Peak cut operation

z

Peak cut mode (Optional parts: UTY-XWZXZ2)

The introduction of a peak power consumption mode control a 4 step outdoor operation control to

cut down energy usage at peak energy usage times.

* Performance drops by reducing the power consumption preferentially.

Level 1 ... Performs operation which suppresses the power consumption to almost 0% by stopping

the compressor.

Level 2 ... Performs operation which suppresses the power consumption to 50% of the rated

power consumption value.

Level 3 ... Performs operation which suppresses the power consumption to 75% of the rated

power consumption value.

Level 4 ... Performs operation which suppresses the power consumption to the rated power

consumption value (100%).

Page 7

- (01 - 04) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

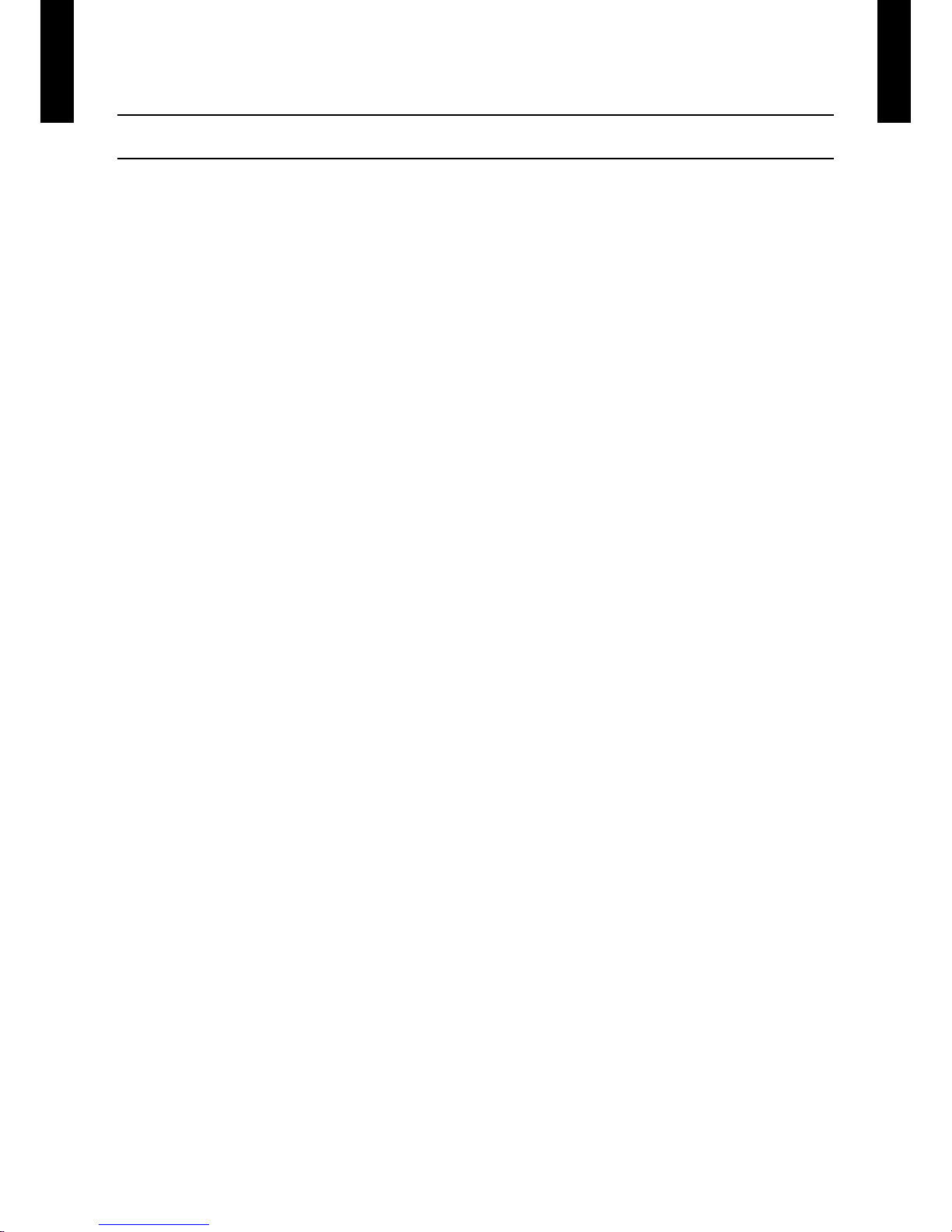

Easy service & maintenance

z

Outdoor unit

Indoor unit

Consolidated electrical

components make maintenance

easy

Maintenance of electrical

components, valves, and

compressor parts from

the front is possible.

Movable PCB panel that allows for

easier maintenance work behind

the PCB

Split front panel allows for

maintenance from top or

bottom of the outdoor unit

Easy-to-read 7-segment LED display

which explains operational and

trouble status

Fan unit

Left and Right fan motors can be removed

separately which has made servicing of

the indoor unit easier.

Page 8

- (01 - 05) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

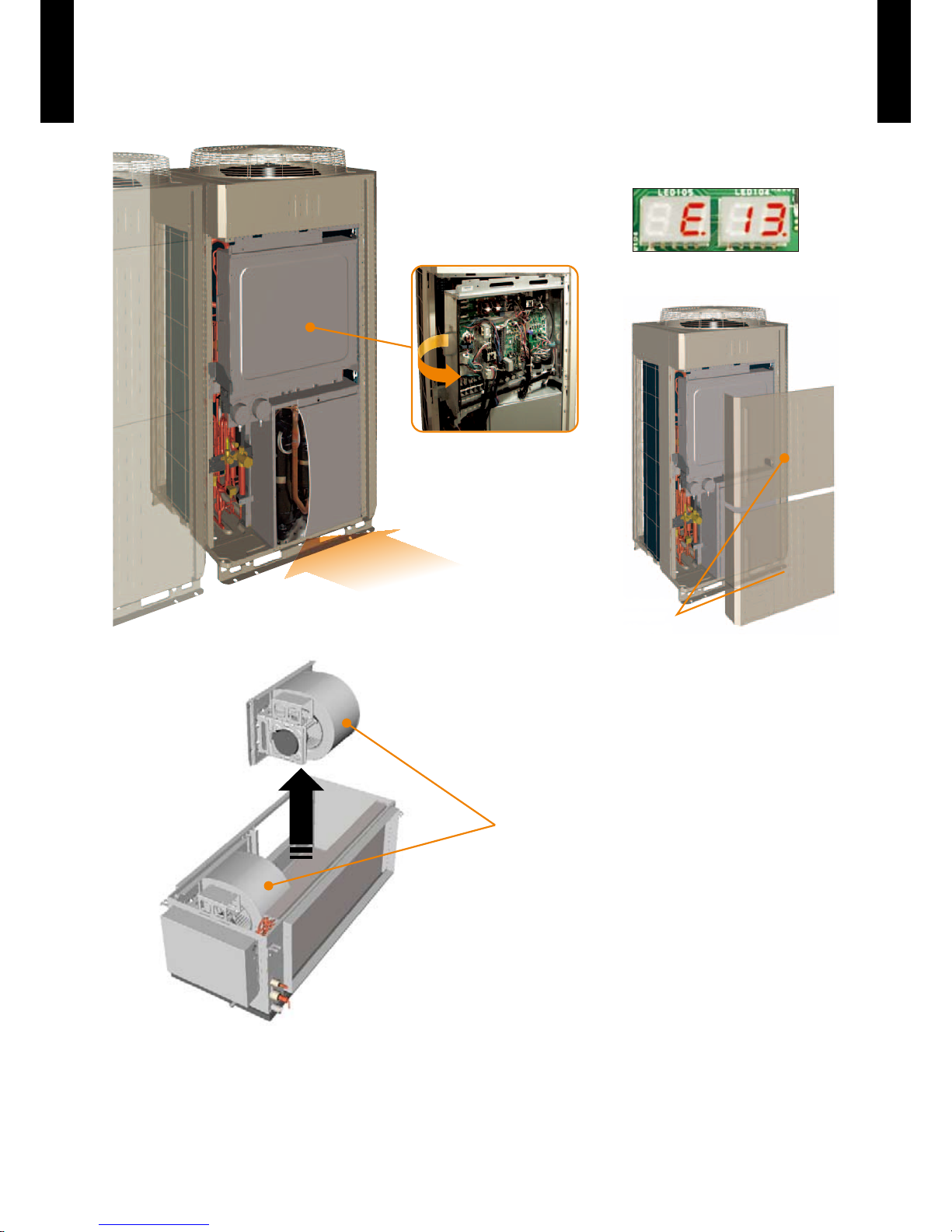

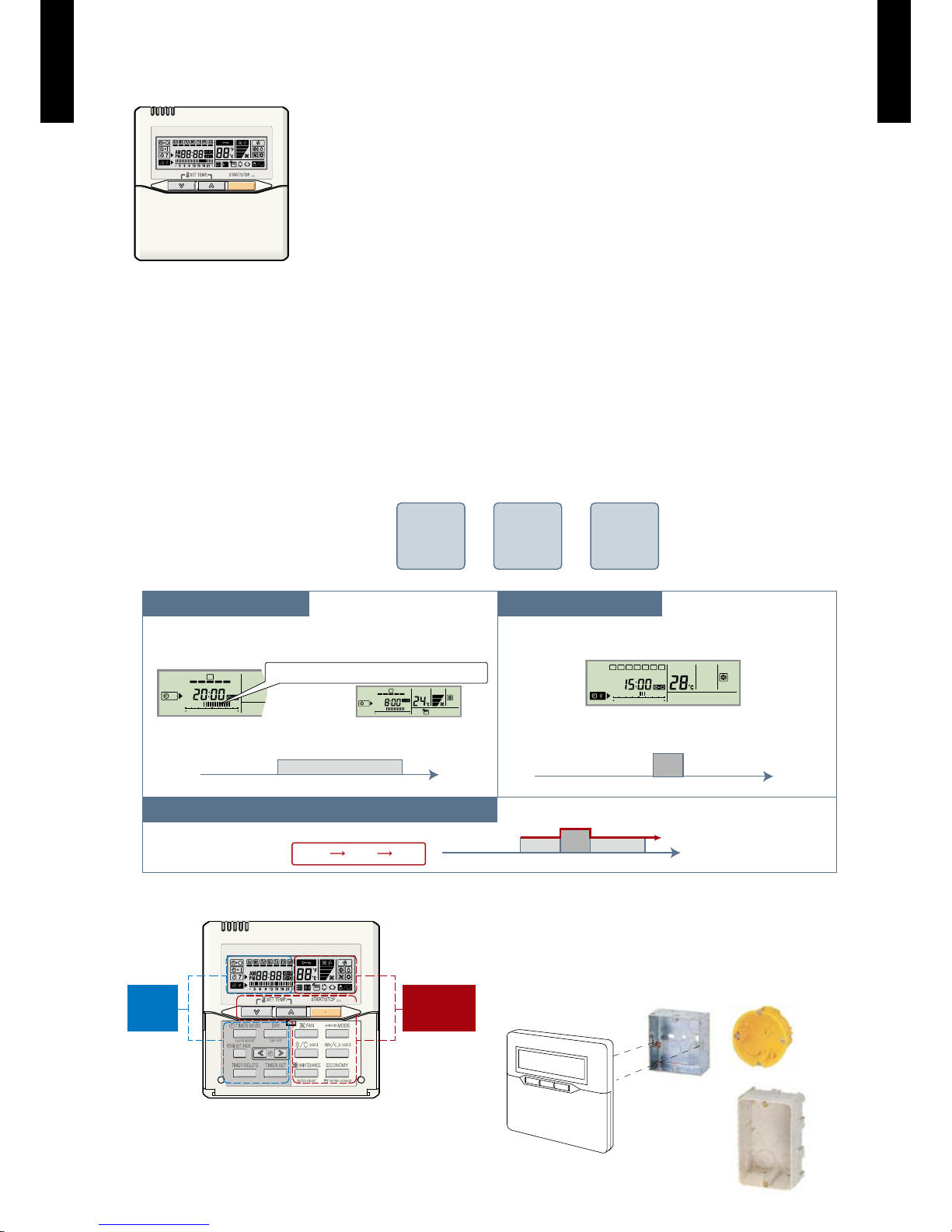

Adoption of blue n heat exchanger

z

Corrosion resistant of the heat exchanger has been improved by the introduction of blue n

treatment to the outdoor unit’s heat exchanger.

Improvement of piping length

z

Improvement of low outdoor ambient temperature performance

z

Blue fin heat exchanger

Standard chromate protec tion

Cobalt Blue protection

Aluminium base material

Hydrophilic coating

Previous model New model

50m 75m

Previous model New model

Cooling 0°C -5°C

Heating -10°C -15°C

Page 9

- (01 - 06) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

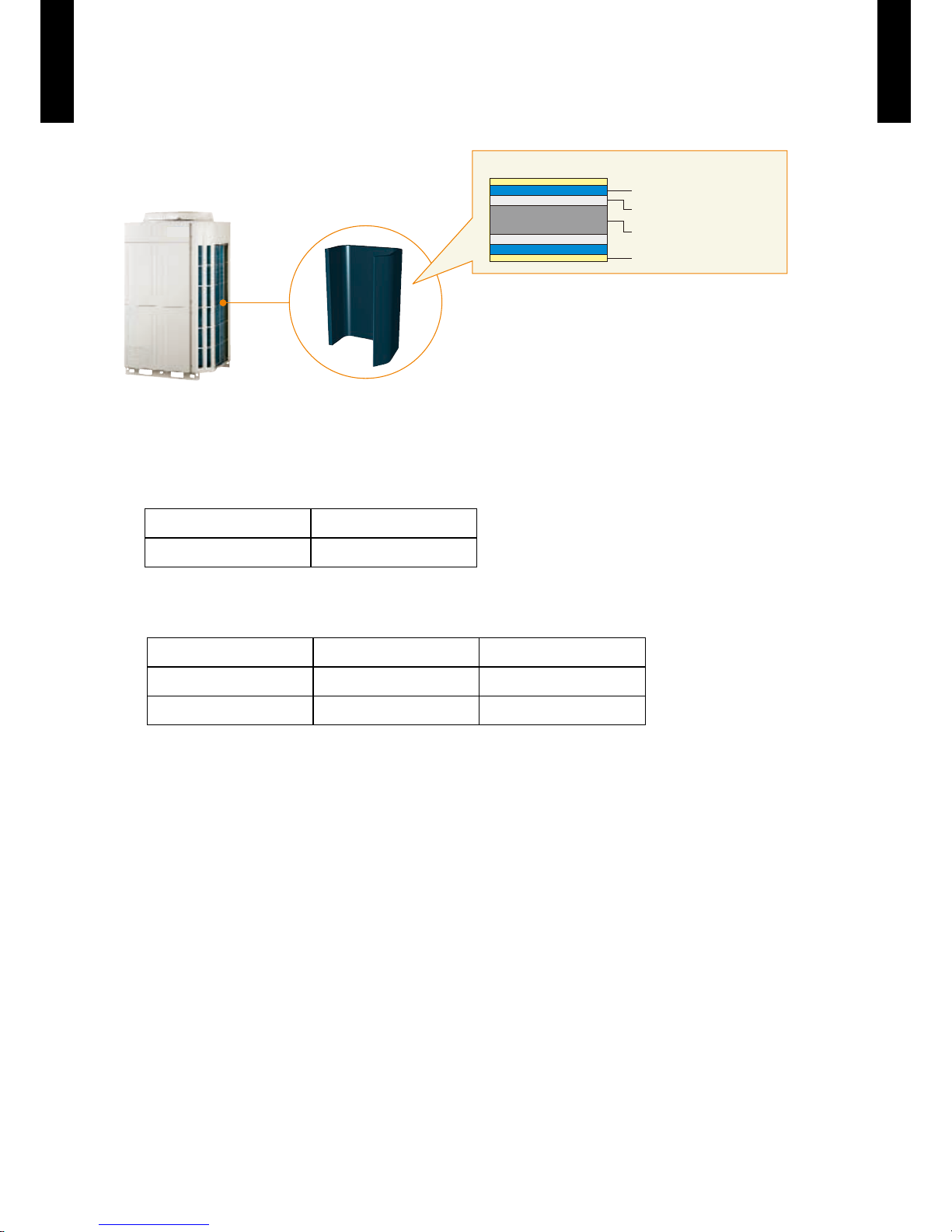

WIRED REMOTE CONTROLLER2.

FEATURES

Various timer setup (ON / OFF / WEEKLY) are possible.

Equipped with weekly timer as standard function.(2 times Start / Stop

per day for a week)

When setting up a timer, operation mode and a temperature setup

can be changed.

When a failure occurs, the error code is displayed. (Maximum of 16)

Error indication.(A maximum of 16 error histories are memorizable.)

Up to 16 indoor units can be simultaneously controlled.

The room temperature can be controlled by being detected the

temperature accurately with built-in thermo sensor.

Simple function setting

z

Setting of the air conditioner selection function is performed by remote controller.

High performance and compact size

z

Three functions are combined in

one unit.

Built-in timers

z

Wired

remote

controller

Weekly

timer

Setback

timer

+ +

Weekly timer Setback timer

At "Weekly timer" + "Set back timer" setup

Easy-to-understand operation

z

[Variable timer control]

The operation/display sections are zoned

according to time and operation, enabling

variable programming to match application.

Simple installation

z

Components are compatible with standard

switch boxes. Flat back construction allows

equipment to be installed wherever it is

needed.

SUMOTUWETH FR SA

7

3126 9

15 18 21

SUMOTUWETH FR SA

7

3126 9

15 18 21

SUMOTUWETH FR SA

3126 9

15 18 21

Possible to set ON/OFF time to operate twice each day

of the week.

Setup scr een example

(Set to Wednes day: 8:00 to 20:00.)

Screen

after setup

European

switch box

JIS box

Setup scr een example

(Set from Sunday to Saturday: 12:00 to 15:0 0, 28 °C.)

Possible to set temperature for two time spans and

for each day of the week.

Easy-to-understand time bar display

24°C

0 3 6 9 12 15 18 21 Time

28°C

0 3 6 9 12 15 18 21 Time

28°C

24°C

0 3 6 9 12 15 18 21 Time

24°C 28°C 24°C

Timer

area

Operation

area

Page 10

- (01 - 07) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

FUNCTIONS

Display panel

DIMENSION

SPECIFICATION

WIRING SPECIFICATIONS

Use Size Wire type Remarks

Remote controller

cable

0.33mm

2

( 22AWG )

Polar 3 core Use sheathed PVC cable.

15

11

10

9

8

2

1

3

5

14

4

12

13

6

7

17

16

18

19

20

21

120

120

120

18

Side ViewFront View

SIZE (H x W x D mm) 120 x 120 x 18

WEIGHT ( g ) 160

CABLE LENGTH ( m ) 10

POWER ( V ) 12

1

START/STOP button

Pressed to start and stop operation.

2

SET TEMP. button

Selects the setting temperature.

3

MODE button

Selects the operating mode (AUTO, HEAT, FAN, COOL, DRY).

4

FAN button

Selects the fan speed (AUTO, LOW, MED, HIGH).

5

ECONOMY button

Turns the economy efcient mode on and off.

6

TIMER MODE (CLOCK ADJUST) button

Selects the timer mode (OFF TIMER, ON TIMER, WEEKLY

TIMER). Set the current time.

7

DAY (DAY OFF) button

Temporarily cancels of one day timer.

8

SET BACK button

Pressed to select the set back timer.

9

Set time button

Pressed to set time.

10

TIMER DELETE button

The schedule of a weekly timer is deleted.

11

TIMER SET button

Sets the date, hour, minute and on-off time.

12

Vertical airow direction and swing button

Push for two seconds to change the swing mode.

13

Horizontal airow direction and swing button

Push for two seconds to change the swing mode.

14

FILTER RESET button

15

Operation lamp

Lights during operation and when the timer is on.

16

Timer and clock display

17

Operation mode display

18

Fan speed display

19

Operation lock display

20

Temperature display

21

Function display

Defrost display

Thermo sensor display

Economy display

Vertical swing display

Horizontal swing display

Filter display

Functions will be different due to type of indoor unit.

For details, please see operation manual.

[ Unit : mm ]

Page 11

- (01 - 08) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

SPECIFICATIONS3.

Note :

Speci cations are base d on the foll owing conditio ns.

Coolin g : Indoor te mperat ure of 27 °CD B / 19 °CWB.an d outdoo r tempera ture of 35 °C DB/24 °C WB.

Heating : I ndoor te mperatu re of 20 °CD B / 15 °CWB.an d outdoor t emperat ure of 7 °CD B/6 °CWB .

Standa rd static p ressur e : 72Pa

Pipe leng th : 7.5 m, Height di ffere nce : 0 m.(Outd oor unit - I ndoor uni t)

The prote ctive fu nction m ay work whe n using it ou tside th e tempera ture rang e mentio ned above.

Drain ho se should b e eld sup plied.

* : The maxi mum curr ent is the ma ximum value when op erated wi thin the o perati on range.

Typ e Ducted m odel inver ter heatpump

Model na me ARC72L HTA ARC9 0LH TA

Power source 230V~ 50 Hz

Available voltage r ange 198-26 4V~ 50H z

Capacity

Cooling

Rated

kW 20.3 25.0

Btu/h 69300 85300

Min. - Max.

kW 10.8 - 23.5 11.2 - 28.0

Btu/h 3680 0 - 8020 0 3 8200 - 9 550 0

Heating

Rated

kW 22.6 28.0

Btu/h 77100 95500

Min. - Max.

kW 12.0 - 26.5 12.5 - 31.5

Btu/h 4090 0 - 904 00 42600 - 107500

Input power

Cooling

Rated

kW

6.25 7. 82

Max. 9.80 12 .10

Heating

Rated 6.27 8.24

Max. 9.80 12 .10

Current

Cooling Rated

A

9.6 11.9

Heating Rated 9.6 12.5

EER Cooling

kW/kW

3.25 3.20

COP Heating 3.60 3.40

Moisture removal l/h (pints/h) 4.5 (9.5) 6.0 (12.7)

Maximum operat ing cur rent *

Cooling

A

22.8 25.8

Heating 22.8 25.8

Fan

Air ow

rate

Cooling

High

m

3

/h

4300 4850

Med 3750 425 0

Low 315 0 3600

Heating

High 4300 4850

Med 3750 425 0

Low 315 0 3600

Fan type × Q'ty Sirocco × 2

Motor out put W 700 × 2

Static pressure range Pa 50-250 (Stand ard: 72)

Sound pressure level

Cooling

High

dB (A)

47 49

Med 44 46

Low 41 4 3

Heating

High 47 49

Med 44 46

Low 41 43

Heat exchanger type

Dimensions

mm

406.4 × 125 0 × 76.2 508 × 1250 × 76. 2

Fin pitch 1. 8 1.6

Rows x stag es 4 × 16 4 × 20

Pipe typ e Copper

Fin type Aluminium

Enclosure

Material Steel

Colour

-

Dimensions (H × W × D)

Net

mm

450 × 1587 × 700 550 × 1587 × 70 0

Gross 550 × 1750 × 825 650 × 1750 × 825

Weight

Net

kg

100 110

Gross 115 125

Connec tion pipe

Size

Liquid

mm

Ø12.7 (1/2 in.)

Gas Ø25.4 ( 1 in.)

Method Brazing

Operat ion rang e

Cooling

°C 18 to 32

%RH 80 or less

Heating °C 16 to 30

Remote co ntroller type Wired

Drain po rt

Material Steel

Size mm Ø3 5.7 (I.D.), Ø38.1 (O.D.)

Page 12

- (01 - 09) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

DIMENSIONS4.

MODEL : ARC72LHTA

(Unit : mm)

Page 13

- (01 - 10) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

MODEL : ARC90LHTA

(Unit : mm)

Page 14

- (01 - 11) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

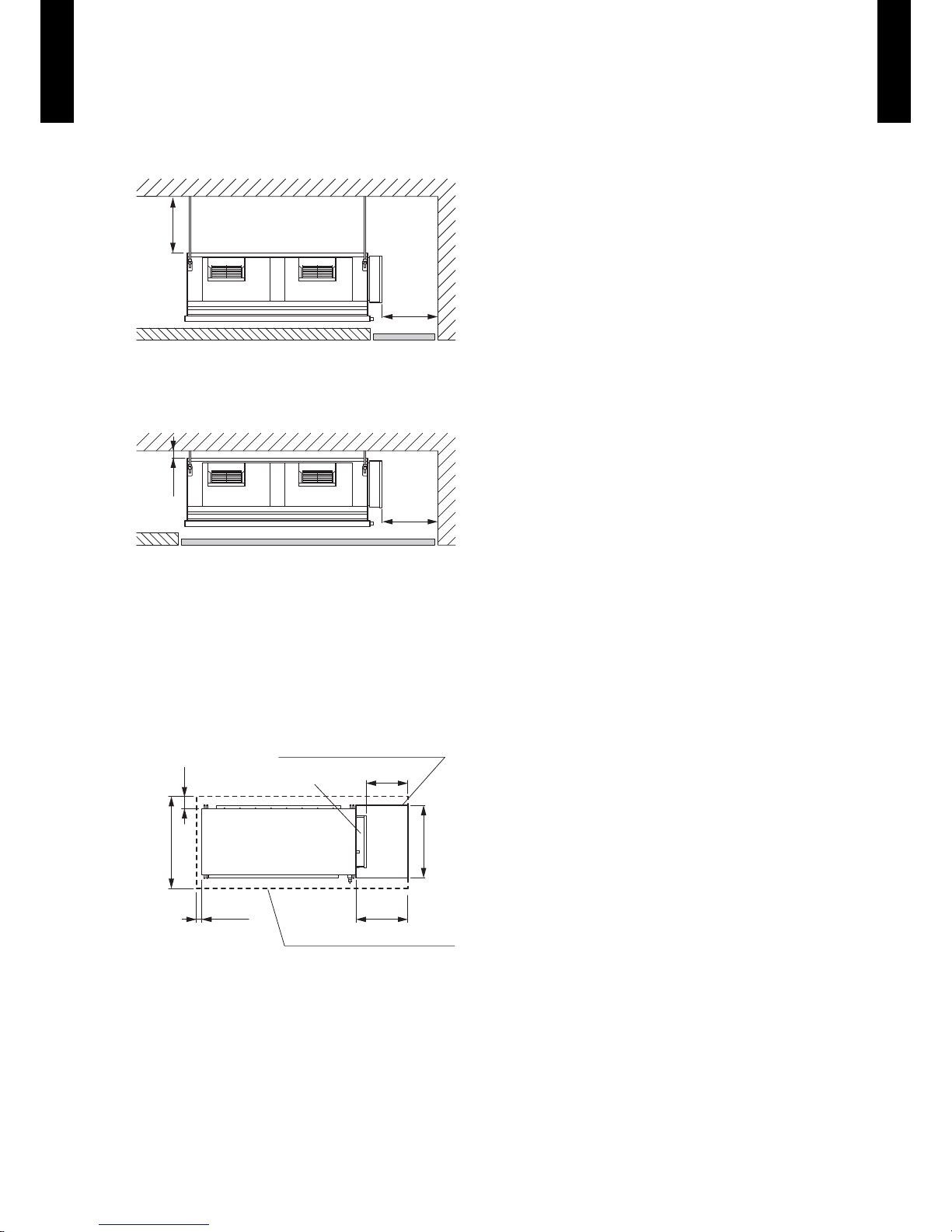

INSTALLATION PLACE

(Unit : mm)

(a) When service access will be carried out above the indoor unit a recommended installation

space of 450mm is required.

450

or

more

450

Service

space

eloh ecnanetniaM

(b) Installation by which service is carried out from the bottom of the unit

450

20 or

more

Service

space

Maintenance hole

MAINTENANCE HOLE

(Unit : mm)

(a) If maintenance work is to be done from the top, keep the space of the more than 450 mm

between the indoor unit and ceiling.

(b) If maintenance work is to be done from the bottom side, the maintenance hole needs to be

larger than the outside dimension of the indoor unit.

890

or

more

700

or

more

30 or

more

500 or

more

450 or more

200 or

more

Maintenannce hole size of (a)

Control box

Drain pan

Maintenannce hole size of (b)

Page 15

- (01 - 12) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

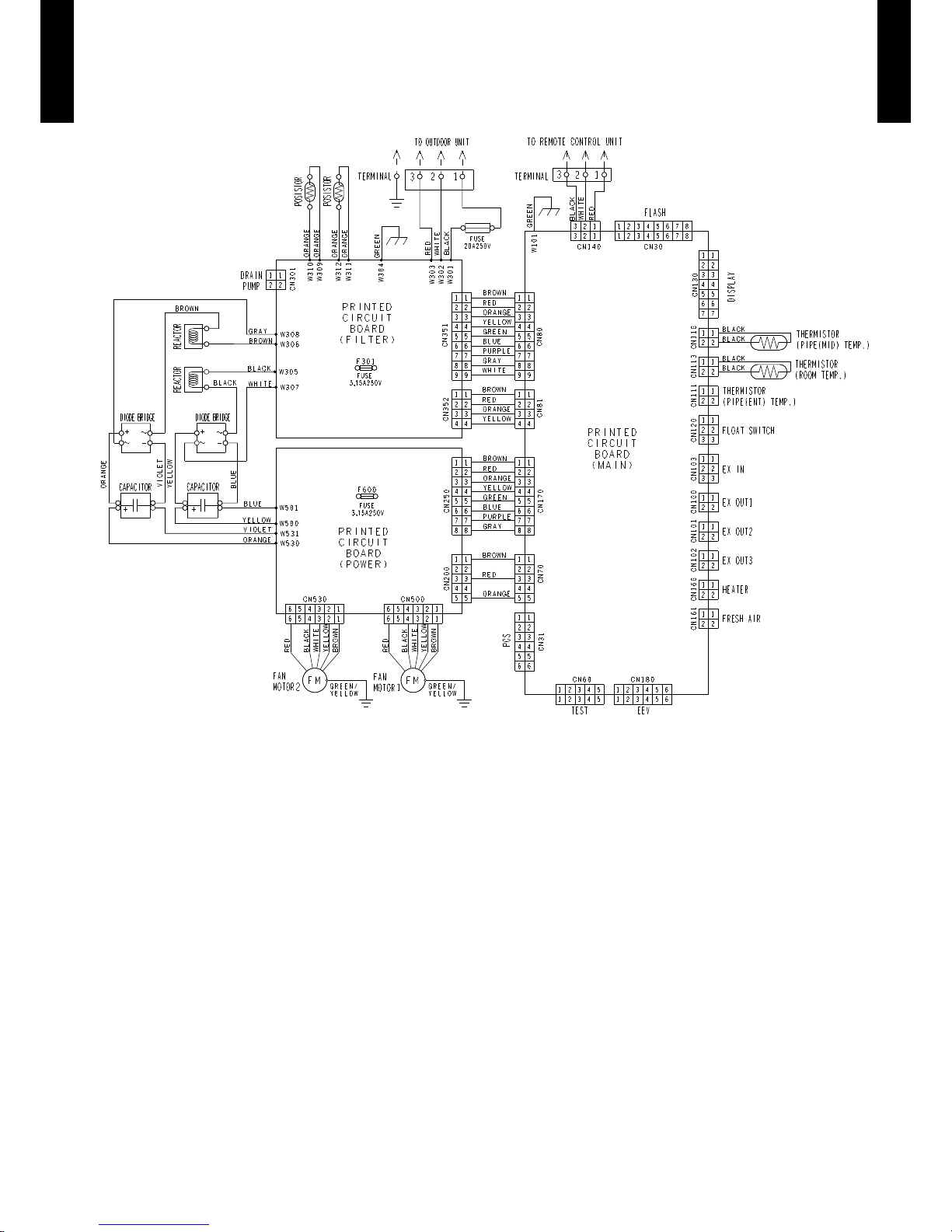

WIRING DIAGRAMS5.

MODEL : ARC72LHTA, ARC90LHTA

Page 16

- (01 - 13) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

CAPACITY TABLE6.

COOLING CAPACITY6-1.

MODEL : ARC72LHTA

MODEL : ARC90LHTA

AFR : Air o w rate (m3/min)

TC : Total capaci ty (kW)

SHC : Sensible Hea t capaci ty (kW)

IP : Input Powe r (kW)

AFR 71.7

Indoor temperature

°CDB 18 21 23 25 27 29 32

°CWB 12 15 16 18 19 21 23

Outdoor temperature

°CDB TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP

-5 17.64 15.08 3.23 19.65 15.17 3.28 20.32 16.49 3.29 21.66 16.54 3.33 22.33 17.87 3.34 23.67 17.80 3.38 25.01 18.96 3.41

0 17.61 15.05 3.28 19.61 15.14 3.33 20.28 16.46 3.34 21.62 16.51 3.38 22.29 17.83 3.40 23.63 17.76 3.43 24.96 18.92 3.46

5 17.57 15.02 3.38 19.58 15.11 3.43 20.24 16.43 3.45 21.58 16.48 3.48 22.25 17.80 3.50 23.58 17.72 3.54 24.91 18.88 3.57

10 17.39 15.05 3.69 19.37 15.14 3.75 20.03 16.46 3.77 21.35 16.51 3.80 22.01 17.83 3.82 23.33 17.76 3.86 24.65 18.92 3.90

15 17.28 14.87 4.07 19.25 14.96 4.13 19.91 16.26 4.16 21.22 16.31 4.20 21.88 17.62 4.22 23.19 17.55 4.26 24.50 18.69 4.30

20 17.27 14.85 4.69 19.24 14.93 4.76 19.90 16.24 4.78 21.21 16.29 4.83 21.86 17.59 4.86 23.17 17.52 4.91 24.49 18.66 4.95

25 17.27 14.31 5.39 19.23 14.40 5.48 19.89 15.65 5.51 21.20 15.70 5.56 21.86 16.96 5.59 23.17 16.89 5.65 24.48 17.99 5.70

30 16.90 14.19 5.90 18.82 14.28 5.99 19.46 15.52 6.02 20.75 15.57 6.08 21.39 16.82 6.11 22.67 16.75 6.17 23.96 17.84 6.24

35 16.04 14.67 6.03 17.86 14.76 6.13 18.47 16.04 6.16 19.69 16.09 6.22 20.30 17.38 6.25 21.52 17.31 6.31 22.74 18.44 6.38

40 15.97 13.83 7.67 17.79 13.92 7.79 18.40 15.13 7.83 19.61 15.18 7.91 20.22 16.39 7.95 21.43 16.33 8.03 22.65 17.39 8.10

46 15.16 14.14 8.51 16.89 14.23 8.64 17.46 15.47 8.69 18.62 15.52 8.77 19.19 16.76 8.82 20.34 16.69 8.91 21.50 17.78 8.99

AFR 80.8

Indoor temperature

°CDB 18 21 23 25 27 29 32

°CWB 12 15 16 18 19 21 23

Outdoor temperature

°CDB TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP TC SHC IP

-5 21.66 18.51 4.85 24.13 18.62 4.92 24.95 20.24 4.95 26.59 20.31 5.00 27.42 21.93 5.02 29.06 21.85 5.07 30.71 23.27 5.12

0 21.65 18.50 4.94 24.12 18.61 5.02 24.94 20.24 5.04 26.58 20.30 5.09 27.41 21.92 5.12 29.05 21.84 5.17 30.69 23.26 5.22

5 21.54 18.41 5.16 23.99 18.52 5.24 24.81 20.13 5.27 26.44 20.20 5.32 27.26 21.81 5.35 28.90 21.72 5.40 30.53 23.14 5.46

10 21.53 18.63 5.80 23.98 18.74 5.89 24.80 20.37 5.92 26.43 20.44 5.98 27.25 22.07 6.01 28.89 21.99 6.07 30.52 23.42 6.13

15 21.39 18.51 6.14 23.83 18.62 6.23 24.64 20.25 6.27 26.27 20.31 6.33 27.08 21.94 6.36 28.71 21.85 6.42 30.33 23.28 6.49

20 21.37 18.49 6.67 23.80 18.60 6.77 24.61 20.22 6.81 26.23 20.29 6.87 27.05 21.91 6.91 28.67 21.82 6.98 30.29 23.24 7.05

25 21.31 17.91 7.20 23.74 18.01 7.32 24.54 19.58 7.35 26.16 19.65 7.43 26.97 21.22 7.47 28.59 21.13 7.54 30.21 22.51 7.61

30 21.12 18.09 7.52 23.53 18.20 7.64 24.33 19.78 7.68 25.93 19.85 7.75 26.74 21.44 7.79 28.34 21.35 7.87 29.94 22.74 7.95

35 19.75 17.81 7.55 22.00 17.91 7.66 22.75 19.48 7.70 24.25 19.54 7.78 25.00 21.10 7.82 26.50 21.02 7.90 28.00 22.39 7.98

40 19.55 16.99 9.65 21.78 17.09 9.80 22.52 18.58 9.85 24.00 18.64 9.95 24.75 20.13 10.00 26.23 20.05 10.10 27.72 21.36 10.20

46 17.77 16.49 10.27 19.79 16.59 10.43 20.46 18.03 10.48 21.81 18.09 10.59 22.49 19.54 10.64 23.84 19.46 10.75 25.19 20.73 10.85

Page 17

- (01 - 14) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

HEATING CAPACITY6-2.

MODEL : ARC72LHTA

MODEL : ARC90LHTA

AFR : Air o w rate (m3/min)

TC : Total c apacity (kW)

IP : Input Power (k W)

AFR 71.7

Indoor temperature

°CDB 16 18 20 22 24

Outdoor temperature

°CDB °CWB TC IP TC IP TC IP TC IP TC IP

-15 -16 17.79 7.07 17.37 7.22 16.95 7.37 16.52 7.52 16.10 7.66

-10 -11 20.37 7.45 19.89 7.60 19.40 7.76 18.92 7.91 18.43 8.07

-5 -7 22.32 7.68 21.79 7.84 21.26 8.00 20.73 8.16 20.20 8.32

0 -2 23.33 7.71 22.77 7.87 22.22 8.03 21.66 8.19 21.11 8.35

5 3 23.73 6.70 23.17 6.84 22.60 6.98 22.04 7.12 21.47 7.26

7 6 23.73 6.02 23.17 6.14 22.60 6.27 22.04 6.40 21.47 6.52

10 8 27.79 6.97 27.13 7.12 26.47 7.26 25.80 7.41 25.14 7.55

15 10 28.05 6.78 27.38 6.92 26.71 7.06 26.05 7.20 25.38 7.31

20 15 29.08 6.81 28.38 6.95 27.69 7.09 27.00 7.23 26.31 7.34

24 18 29.23 6.66 28.53 6.80 27.84 6.94 27.14 7.07 26.44 7.18

AFR 80.8

Indoor temperature

°CDB 16 18 20 22 24

Outdoor temperature

°CDB °CWB TC IP TC IP TC IP TC IP TC IP

-15 -16 20.51 8.48 20.02 8.66 19.53 8.84 19.04 9.01 18.55 9.19

-10 -11 23.90 9.02 23.33 9.20 22.76 9.39 22.19 9.58 21.62 9.77

-5 -7 26.54 9.40 25.90 9.60 25.27 9.79 24.64 9.99 24.01 10.19

0 -2 28.04 9.57 27.37 9.77 26.70 9.97 26.03 10.17 25.37 10.37

5 3 29.09 8.60 28.40 8.78 27.71 8.96 27.02 9.14 26.32 9.32

7 6 29.40 7.91 28.70 8.08 28.00 8.24 27.30 8.40 26.60 8.57

10 8 34.65 9.18 33.82 9.37 33.00 9.56 32.17 9.75 31.35 9.94

15 10 35.98 9.16 35.12 9.36 34.26 9.55 33.41 9.74 32.55 9.88

20 15 36.36 8.98 35.50 9.17 34.63 9.36 33.77 9.54 32.90 9.68

24 18 36.76 8.84 35.89 9.03 35.01 9.21 34.14 9.40 33.26 9.54

Page 18

- (01 - 15) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

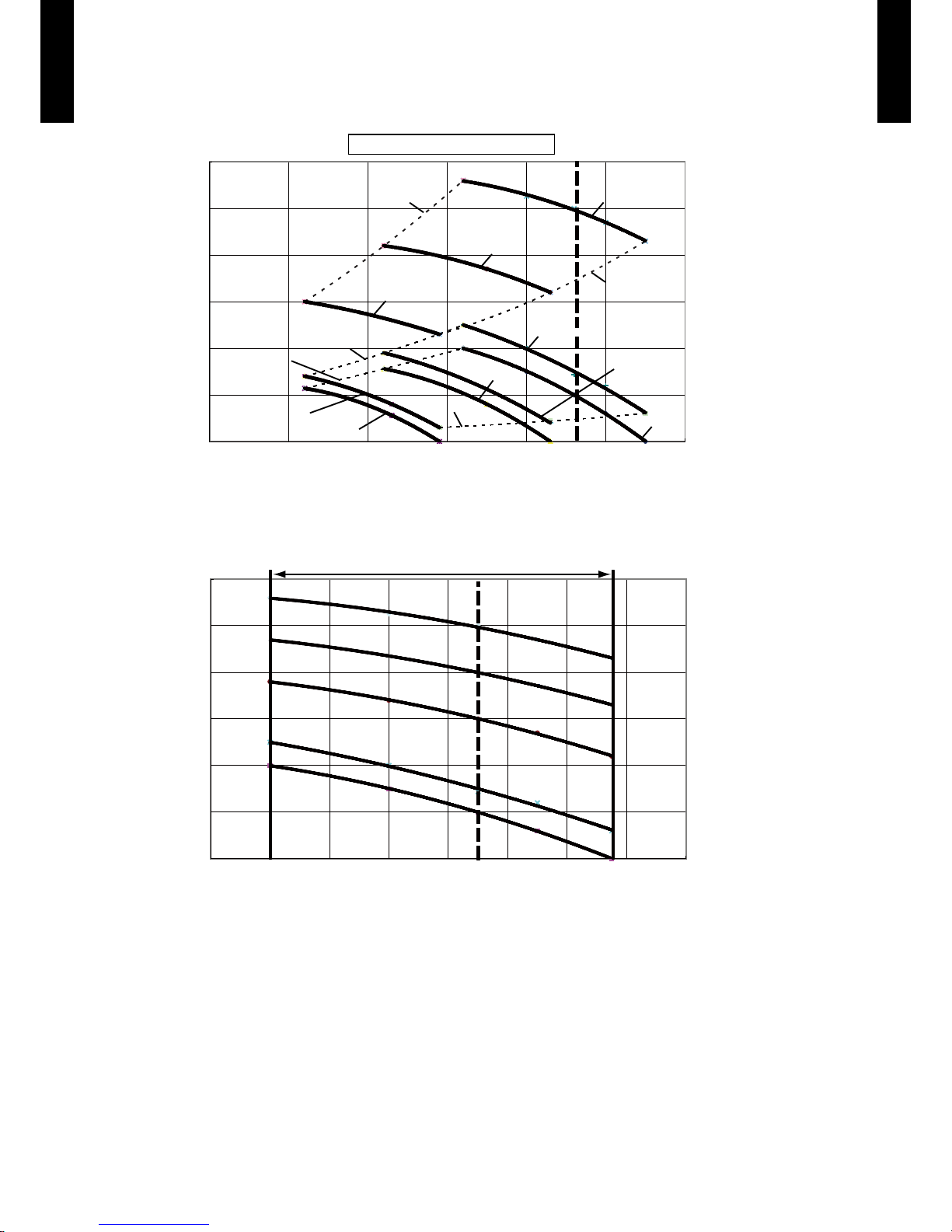

FAN PERFORMANCE AND CAPACITY7.

MODEL : ARC72LHTA

Q-h Characteristic curve

Hi(HSP mode3)

HSP mode3

Lower limit

Med(HSP mode3)

Hi(Normal SP mode)

Med(Normal SP mode)

Hi(LSP mode)

Med(LSP mode)

Normal SP

mode Lower limit

Lo(LSP mode)

Lo(Normal SP mode)

LSP mode

Upper limit

Normal SP mode

Upper limit

Lo(HSP mode3)

HSP mode3

Upper limit

300

250

200

150

100

50

0

Static pressure(Pa)

Airow

2,000 2,500 3,000 3,500 4,000 4,50 0 5,000 (m3/h)

300

250

200

150

100

50

0

Static pressure(Pa)

Airow

3,400 3,600 3,800 4,000 4,200 4,400 4,600 4,800 5,00 0 (m3/h)

Hi HSP mode3

(250Pa)

Hi HSP mode2

(200Pa)

Hi HSP mode1

(150Pa)

Hi Normal SP mode

(72Pa)

Hi LSP mode

(50Pa)

Available air flow rate range (High level)

Page 19

- (01 - 16) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

MODEL : ARC72LHTA

Cooling

z

Heating

z

92

94

96

98

100

102

3,400 3,600 3,800 4,000 4,200 4,400 4,600 4,800 5,000

capacit

䡕

(%)

Airflow

(m

3

/h)

Capacity

92

94

96

98

100

102

3,400 3,600 3,800 4,000 4,200 4,400 4,600 4,800 5,000 (m

3

/h)

Airflow

capacity(%)

Capacity

Page 20

- (01 - 17) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

MODEL : ARC90LHTA

300

250

200

150

100

50

0

Static pressure(Pa)

Airow

Q-h Characteristic curve

300

250

200

150

100

50

0

Static pressure(Pa)

Airow

2,500 3,00 0 3,500 4,000 4,500 5,00 0 5,500 (m3/h)

Hi(HSP mode3)

HSP mode3

Lower limit

Med(HSP mode3)

Hi(Normal SP mode)

Med(Normal SP mode)

Hi(LSP mode)

Med(LSP mode)

Normal SP

mode Lower limit

Lo(LSP mode)

Lo(Normal SP mode)

LSP mode

Upper limit

Normal SP mode

Upper limit

Lo(HSP mode3)

HSP mode3

Upper limit

Hi HSP mode3

(250Pa)

Hi HSP mode2

(200Pa)

Hi HSP mode1

(150Pa)

Hi Normal SP mode

(72Pa)

Hi LSP mode

(50Pa)

Available air flow rate range (High level)

3,700 3,900 4,100 4, 300 4,500 4,700 4,900 5,100 5, 300 5,500 (m3/h)

Page 21

- (01 - 18) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

MODEL : ARC90LHTA

Cooling

z

Heating

z

92

94

96

98

100

102

3,700 3,900 4,100 4,300 4,500 4,700 4,900 5,100 5,300 5,500

capacity(%)

Airflow

(m

3

/h)

Capacity

92

94

96

98

100

102

capacit

䡕

(%)

3,700 3,900 4,100 4,300 4,500 4,700 4,900 5,100 5,300 5,500

Airflow

(m

3

/h)

Capacity

Page 22

- (01 - 19) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

OPERATION NOISE8.

NOISE LEVEL CURVE8-1.

MODEL : ARC72LHTA

Condition

Static pressure : 72Pa

Static pressure mode : Normal

HIGH

LOW

Heating

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

80

70

60

50

40

30

20

10

0

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

HIGH

LOW

Cooling

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

Octave ba nd cente r frequency,Hz

80

70

60

50

40

30

20

10

0

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

HIGH

LOW

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

80

70

60

50

40

30

20

10

0

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

HIGH

LOW

Heating

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

80

70

60

50

40

30

20

10

0

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

MODEL : ARC90LHTA

Cooling

z

Octave ba nd cente r frequency,Hz

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

Octave ba nd cente r frequency,Hz

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

Octave ba nd cente r frequency,Hz

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

Page 23

- (01 - 20) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

SOUND LEVEL CHECK POINT8-2.

Microphone

Measuring duct

Measuring duct

Set the static pressure

as rating in this area

2 m 1 m

1.5 m

Microphone

AIR

Page 24

- (01 - 21) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

ELECTRIC CHARACTERISTICS9.

Model name

ARC72LHTA

ARC9 0LHTA

Power supply

Voltage V 230 ~

Frequency Hz 50

Max. operating current (Indoor unit) A 9.3

Wiring spec.

(Indoor unit to outdoor unit)

Connection cable mm

2

1.5 2.5

Limited wiring length m 50 or less 50 to 76

Note: Wiring specication

1. Selected sample

(Selected based on Japan Electrotechnical Standard and Codes Committee E0005)

2. Limited wiring length : Limit voltage drop to less than 2%. Increase cable gauge if voltage drop is 2% or more.

3. If the transmission wire is longer than 50m, use the bigger conductor size.

Page 25

- (01 - 22) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

SAFETY DEVICES10.

Protection form

Model

ARC72LHTA

ARC9 0LHTA

Circuit protection Current fuse (PCB) 250V 3.15A

Fan motor protection Thermal protection program

100°C

+15°C

OFF

-10°C

95°C

+15°C

ON

-10°C

Page 26

- (01 - 23) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

EXTERNAL INPUT & OUTPUT11.

EXTERNAL INPUT11-1.

CONTROL INPUT (Operation/Stop)

The air conditioner can be remotely operated by means of the following on-site work.

Operation is started at the following contents by adding the contact input of a commercial ON/OFF

switch to a connector on the external control PC board and turning it ON.

Unit operation Initial setting after power is ON Starting mode other than initial setting

Operation mode Auto changeover Mode at previous operation

Set temperature 24°C Temperature at previous operation

Air ow mode AUTO Mode at previous operation

Circuit diagram example

z

Indoor

control PC board

Connector

1

2

3

Signal

Field supply

* Make the distance from the PC board to the connected unit within 10 m.

Contact capacity : 5VDC or more, 15mA or more.

Please use non-polar relays and switches.

Surely insulate with

insulation tape etc. since

this wire is not used.

*10 m

Connected unit

Ex.) Switch

Operation

Stop

ON

OFF

Input signal

Indoor unit

Parts (Optional)

z

Model name

UTD-ECS5A

Wire (External input)

INPUT OUTPUT Connector REMARKS

CONTROL INPUT

(OPERATION/STOP)

— CN103

See external

input/output settings

for details.

— OPERATION STATUS CN100

— ERROR STATUS CN101

— FRESH AIR CONTROL CN161

—

AUXILIARY HEATER

CN160

Page 27

- (01 - 24) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

EXTERNAL OUTPUT11-2.

OPERATION STATUS OUTPUT

An air conditioner operation status signal can be output.

Circuit diagram example

z

Field supply

Ex.)Display

Indoor

control PC board

Connected unit

Ex.)Relay unit

1

2

Signal

Relay

power

supply

V

Connector

* Make the distance from the PC board to the connected unit within 10m.

Relay spec. : Max.24VDC, 10mA to less than 500mA.

*10 m

24V DC

ON

OFF

Operation

Stop

Indoor unit

Output signal

Parts (Optional)

z

Model name

UTD-ECS5A

Wire (External output)

Page 28

- (01 - 25) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

ERROR STATUS OUTPUT

An air conditioner condition normal/error status signal can be output.

Circuit diagram example

z

Field supply

Ex.)Display

Indoor

control PC board

Connected unit

Ex.)Relay unit

1

2

Signal

Relay

power

supply

V

Connector

* Make the distance from the PC board to the connected unit within 10m.

Relay spec. : Max.24VDC, 10mA to less than 500mA.

*10 m

24V DC

ON

OFF

Error

Normal

Error status

Output signal

Parts (Optional)

z

Model name

UTD-ECS5A

Wire (External output)

Page 29

- (01 - 26) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

FRESH AIR CONTROL OUTPUT

A signal linked to air conditioner indoor fan ON can be output.

* However, signal becomes OFF during cold air prevention control operation.

Circuit diagram example

z

Field supply

Indoor

control PC board

Connector

1

12 V

on/off

2

Signal

Relay

power

supply

* Make the distance from the PC board to the connected unit within 10m.

Relay spec. : Rated 12VDC, 50mA or less.

Ex.) Fan

Connected unit

Ex.) Relay unit

*10 m

ON

OFF

Operation

Stop

Indoor fan

Output signal

Parts (Optional)

z

Model name

UTD-ECS5A

Wire (Fresh air output)

Page 30

- (01 - 27) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

AUXILIARY HEATER OUTPUT

A signal is outputed from Connector when indoor fan and compressor is turned on under heating

operation.

* Signal output performance specications are as

shown on the right

Ex. When Set Temperature(Ts) is 22°C;

▪ and Room Temperature(Tr) increase above 12°C,

signal output is on.

▪ and Room Temperature(Tr) increase above 21°C,

signal output is off.

▪ and Room Temperature(Tr) decrease below 19°C, signal output is on.

▪and Room Temperature(Tr) decrease below 10°C, signal output is off.

Jumper wire (Indoor Unit)

z

This is used to continue indoor unit fan operation for 1 minute after thermo OFF in heating mode.

1 minute delay control set by cutting jumper wire on PCB.

Circuit diagram example

z

Field supply

Indoor unit

control PC board

Connector

1

12 V

on/off

2

Signal

Relay

power

supply

* Make the distance from the PC board to the connected unit within 10m.

Relay spec. : Rated 12VDC, 50mA or less.

Ex.) Heater

Connected unit

Ex.) Relay unit

*10 m

ON

OFF

Operation

Stop

Heating

operation

Indoor unit fan

ON

OFF

Output signal

1min

OFF

OFF

ON

Tr-Ts = -1°C

Tr-Ts

Tr-Ts = -3°C

Tr-Ts = -10°C

Tr-Ts = -12°C

Page 31

- (01 - 28) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

!

CAUTION

Please place an external a heater between the indoor unit and the ductwork.

Please be sure to use delay control of the fan.

Parts (Optional)

z

Model name

UTD-ECS5A

Wire (Heater output)

Exter nal

Heater

Supply air Return air

Indooruni t

Page 32

- (01 - 29) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

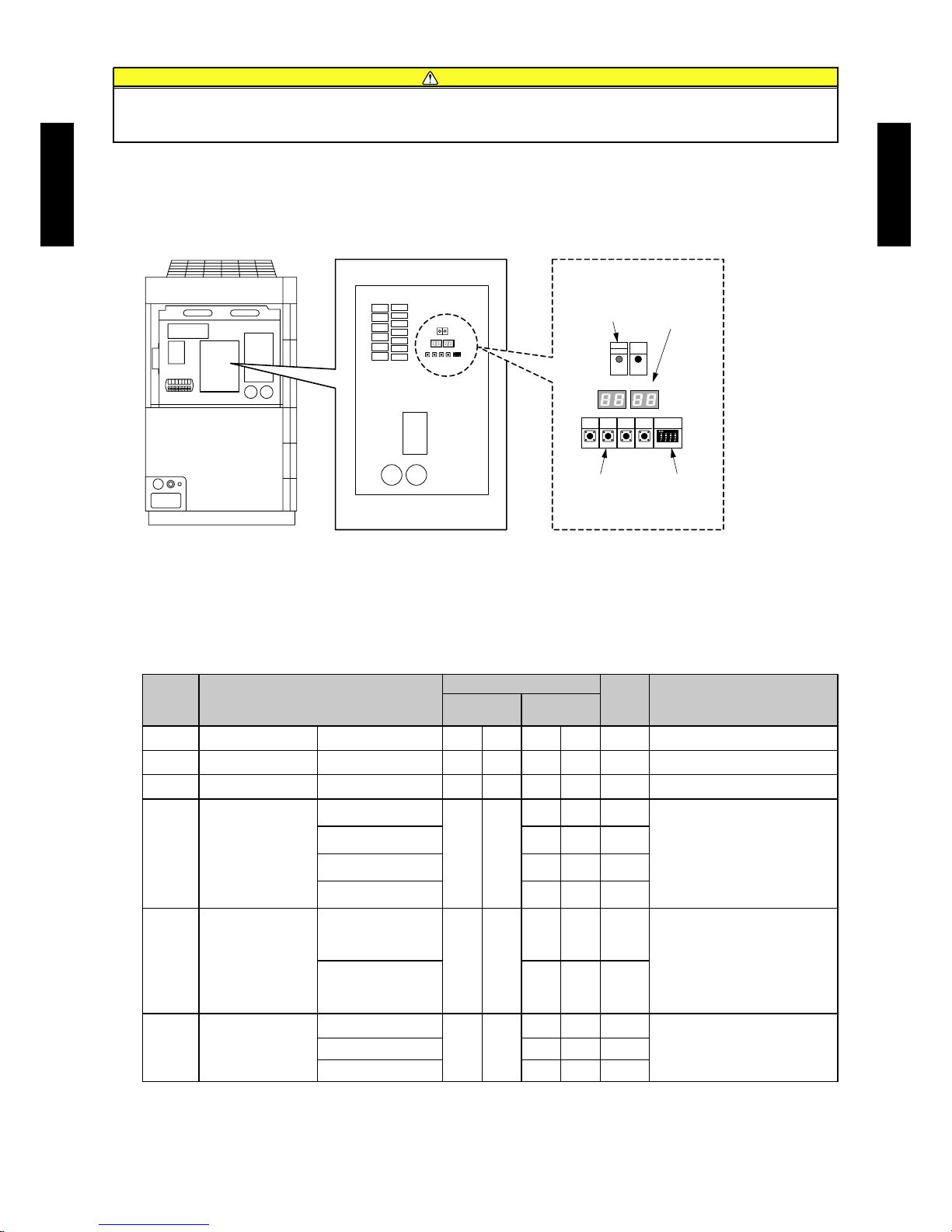

FUNCTION SETTINGS12.

INDOOR UNIT12-1.

SWITCH POSITION

DIP-SW SETTING

Remote controller address setting (SW50)

z

A number of indoor units can be operated at the same time using a single remote controller.

Set the unit number of each indoor unit using the DIP switches on the indoor unit circuit board.

(See the following table.)

The DIP switches are normally set to make the unit number 00.

(. . .Factory setting)

Remote controller address

DIP switch No.

1 2 3 4

00 OFF OFF OFF OFF

01 ON OFF OFF OFF

02 OFF ON OFF OFF

03 ON ON OFF OFF

04 OFF OFF ON OFF

05 ON OFF ON OFF

06 OFF ON ON OFF

07 ON ON ON OFF

08 OFF OFF OFF ON

09 ON OFF OFF ON

10 OFF ON OFF ON

11 ON ON OFF ON

12 OFF OFF ON ON

13 ON OFF ON ON

14 OFF ON ON ON

15 ON ON ON ON

INDOOR UNIT

DIP-SW50

1

Remote controller address setting

2

3

4

Jumper Wire

JM40

Setting forbidden

JM41

JM42 Fan delay setting

JM40

JM41

JM42

SW50

1 2 3 4

ON

OFF

MAIN PCB

Page 33

- (01 - 30) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

JUMPER WIRE SETTING

Fan delay setting (JM42)

z

When the indoor unit is stopped while operating in conjunction with auxiliary heater, the indoor unit

fan operation will continue for one minute..

(

Factory setting)

JM 42 JM state

Connect Invalidity

Disconnect Validity

Page 34

- (01 - 31) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

INDOOR UNIT (Setting by remote controller)12-2.

The function settings of the control of the indoor unit can be changed by this procedure according •

to the installation conditions. Incorrect settings can cause the indoor unit to malfunction.

After the power is turned on, perform The Function Setting according to the installation conditions •

using the remote controller.

The settings may be selected between the following two: Function Number or Setting Value. •

Settings will not be changed if invalid numbers or setting values are selected. •

PREPARATION

Turn on the power. •

* Before turning on the power of the indoor units, make sure the piping air-tight test and vacuuming

have been conducted.

* Also check again to make sure no wiring mistakes were made before turning on the power.

FUNCTION SETTING METHOD (for Wired remote controller)

Setting method

z

(1) Press the SET TEMP. buttons ( ) ( ) and FAN button simultaneously for more than 5 seconds to enter the function setting mode.

SU

MO

TU

WE

TH FR

SA

(2) Press the SET BACK button to select the indoor unit number.

SET BACK

SUMOTUWETH FR

SA

Unit number of INDOOR UNIT

3) Press the Set time buttons to select the function number.

Function number

SUMOTUWETH FR

SA

(4) Press the SET TEMP. buttons ( ) ( ) to select the setting value. The display ashes during setting value selection.

Settin g value

SUMOTUWETH FR

SA

Page 35

- (01 - 32) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

(5) Press the TIMER SET button to conrm the setting. Press the TIMER SET button for a few seconds until the setting value stops

ashing. If the setting value display changes or if “- -” is displayed when the ashing stops, the setting value has not been set correctly.

(An invalid setting value may have been selected for the indoor unit.)

(6) Repeat steps 2 to 5 to perform additional settings. Press the SET TEMP. buttons (

) ( ) and FAN button simultaneously again for

more than 5 seconds to cancel the function setting mode. In addition, the function setting mode will be automatically canceled after 1

minute if no operation is performed.

(7) After completing the FUNCTION SETTING, be sure to turn of f the power and turn it on again.

!

CAUTION

• After turning off the power, wait 30 seconds or more before turning on it again. The Function Setting will not become active

unless the power is turned off then on again.

CONTENTS OF FUNCTION SETTING

• Follow the instructions in the Local Setup Procedure, which is supplied with the remote control, in accordance with the installed

condition.

After the power is turned on, per form the Function Setting on the remote control.

• The settings may be selected between the following t wo: Function Number or Setting Value.

• Settings will not be changed if invalid numbers or setting values are selected.

1) Static pressure

2) Room temperature control for cooling

3) Room temperature control for heating

4) Auto restart

5) Room temperature sensor switching

6) Cool air prevention

7) Room temperature sensor switching (Aux

.)

1) Static pressure

Select the appropriate static pressure according to the installation conditions.

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Normal (72Pa)

21

00

Low static pressure (50Pa) 02

High static pressure 1 (150Pa) 03

High static pressure 2 (200Pa) 04

High static pressure 3 (250Pa) 05

2) Room temperature control for cooling

Depending on the installed environment, correction of the room temperature sensor may be required.

Select the appropriate control setting according to the installed environment.

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Standard

30

00

Higher control 01

Slightly higher control 02

Slightly lower control 03

Lower control 04

Page 36

- (01 - 33) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

3) Room temperature control for heating

Depending on the installed environment, correction of the room temperature sensor may be required.

Select the appropriate control setting according to the installed environment..

(. . .Factory setting)

Setting Description

Function

Numbe

Setting Value

Standard

31

00

Higher control 01

Slightly higher control 02

Slightly lower control 03

Lower control 04

4) Auto restart

Enable or disable automatic system restart after a power outage.

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Enable

40

00

Disable 01

* Auto restar t is an emergency function such as for power failure etc. Do not start and stop the indoor unit by this function in

normal operation. Be sure to operate by the control unit, or external input device.

5) Room temperature sensor switching

(Only for wired remote controller)

When using the Wired remote controller temperature sensor, change the setting to "Both" (01).

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Indoor unit

42

00

Both 01

*00: Sensor on the indoor unit is active.

01: Sensors on both indoor unit and wired remote controller are active.

*Remote controller sensor must be turned on by using the remote controller.

6) Cool air prevention

This setting is to disable the cold air prevention function during heating operation. When disabled, the fan setting will always follow the

setting on the remote controller. (Excluding defrost mode)

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Enable

43

00

Disable 01

7) Room temperature sensor switching (Aux.)

o use the temperature sensor on the wired remote controller only, change the setting to "Wired remote controller" (01). This function will

only work if the function setting 42 is set at "Both" (01)

(. . .Factory setting)

Setting Description

Function

Number

Setting Value

Both

48

00

Wired remote controller 01

Page 37

- (01 - 34) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

WIRED REMOTE CONTROLLER12-3.

SWITCH POSITION

DIP SWITCH SETTING

Dual remote controller setting

z

Set the remote controller DIP switch No.2 according to the following table.

Memory backup setting

z

Set to ON to use batteries for the memory backup. If batteries are not used, all of the settings

stored in memory will be deleted if there is a power failure.

DIP SW

1 Can not be used. (Do not change)

2 Dual remote controller setting

3 Can not be used. (Do not change)

4 Can not be used. (Do not change)

5 Can not be used. (Do not change)

6 Memory backup setting

ON

ON

OFF

1

2

3

4

5

6

Front case (back side)

Do not use this

DIP Switch

DIP Switch

(

Factory setting)

Number

of remote

controller

Primary unit Secondary unit

DIP-SW No.2 DIP-SW No.2

1 (Normal) OFF ―

2 (Dual) OFF ON

(

Factory setting)

DIP-SW

No.6

Memory backup

OFF Invalidity

ON Validity

Page 38

- (01 - 35) -

DUCT TYPE

AR

C72-90LHTA

DUCT TYPE

AR

C72-90LHTA

OPTIONAL PARTS13.

CONTROLLER13-1.

Exterior Parts name Model No. Summary

Wired

remote

controller

UTY-

RVNM

Large and full-dot liquid crystal

screen, wide and large keys

easy to press, user-intuitive

arrow key.

Wired

remote

controller

UTY-

RNNM

The room temperature can be

controlled by being detected

the temperature accurately

with built-in thermo sensor.

Simple

remote

controller

UTY-

RSNM

Compact remote controller

concentrates on the basic

functions such as Start/Stop, Fan

Control, Temperature Setting and

Operation mode.

OTHERS13-2.

Exterior Parts name Model No. Summary

Remote

sensor

UTY-XSZ X

New amenity space can be

offered by installing the Remote

sensor in the remote controller.

( x 1 ) ( x 2 )

( x 1 ) ( x 2 )

External

control set

UTD-ECS5A

Use to connect with various

peripheral devices and air

conditioner PC board.

(Set of 6)

Page 39

SINGLE TYPE :

AOA7 2 L A LT

AOA90LALT

2. OUTDOOR UNIT

DTR_AO133E_02

2013.11.08

Page 40

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

CONTENTS

2. OUTDOOR UNIT

1. SPECIFICATIONS

............................................................................................. 02 - 01

2. DIMENSIONS

........................................................................................................ 02 - 02

3. INSTALLATION PLACE

............................................................................... 02 - 07

3-1. WHEN INSTALL NEAR BY LIMITED HEIGHT WALL

........................... 02 - 07

3-2. WHEN INSTALL NEAR BY UNLIMITED HEIGHT WALL

..................... 02 - 08

3-3. WHEN THERE IS AN OBSTRUCTION ABOVE THE PRODUCT

........ 02 - 09

4. REFRIGERANT CIRCUIT

........................................................................... 02 - 10

5. WIRING DIAGRAMS

........................................................................................02 - 11

6. CAPACITY COMPENSATION RATE FOR PIPE LENGTH AND

HEIGHT DIFFERENCE

...................................................... 02 - 12

7. PIPE SIZE SELECTION & LIMITATION

........................................... 02 - 14

8. ADDITIONAL CHARGE CALCULATION

........................................ 02 - 14

9. AIR FLOW

............................................................................................................... 02 - 15

10. OPERATION NOISE

........................................................................................ 02 - 16

10-1. NOISE LEVEL CURVE

................................................................................. 02 - 16

10-2. SOUND LEVEL CHECK POINT

.................................................................. 02 - 17

11. ELECTRIC CHARACTERISTICS

.......................................................... 02 - 18

12. SAFETY DEVICES

........................................................................................... 02 - 19

13. EXTERNAL INPUT & OUTPUT

.............................................................. 02 - 20

13-1. EXTERNAL INPUT

........................................................................................ 02 - 20

13-2. EXTERNAL OUTPUT

................................................................................... 02 - 22

Page 41

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

CONTENTS

14. FUNCTION SETTING

..................................................................................... 02 - 25

14-1. FIELD SETTING SWITCHES

...................................................................... 02 - 25

14-2. FUNCTION SETTINGS

................................................................................. 02 - 25

14-2-1. SETTING METHOD ................................................................................... 02 - 26

14-2-2. PEAK CUT MODE ..................................................................................... 02 - 28

14-2-3. LOW NOISE MODE ................................................................................... 02 - 28

15. OPTIONAL PARTS

........................................................................................... 02 - 29

16. LOCALLY PROCURED PARTS

............................................................. 02 - 30

16-1. AIR DISCHARGE DUCT

.............................................................................. 02 - 30

16-2. SNOW HOOD

................................................................................................. 02 - 32

16-3. CENTRAL DRAIN PAN

................................................................................ 02 - 35

2. OUTDOOR UNIT

Page 42

- (02 - 01) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

SPECIFICATIONS1.

Note :

Specications are bas ed on the fo llowin g conditions.

Coolin g : Indoor temperature of 27 °CDB / 19 °CWB.a nd outdoor temperature of 35 °CDB/24 °CWB.

Heating : Indoor te mperat ure of 20 °CD B / 15 °CWB.and outdoo r temper ature of 7 °CDB/6 °CWB.

Pipe leng th : 7.5 m, Height difference bet ween outd oor unit and indoo r unit : 0 m.

The prote ctive fu nction may work wh en using it outside the tempe rature range ment ioned ab ove.

Typ e INVERTER HEATPUMP

Model name AOA7 2L ALT AOA90 LA LT

Power source 3N ~ 400V, 50Hz

Available voltage range 3N ~ 342V - 457 V, 50Hz

Starting current 9.6 12.5

Fan

Type × Quantity Propeller fan × 1

Airow

rate

Cooling

m

3

/h

9,300 10,700

Heating 9,300 10,800

Motor

Type × Quantity DC motor × 1

Output W 600

Sound pressure level

Cooling High

dB (A)

57 58

Heating High 57 59

Heat exchanger

Length

mm

1750 1750

Fin pitch 1.45 1. 45

Rows × Stages 3 × 60 3 × 60

Face area m

2

2.2 2.2

Pipe type (Material) Grooved H-pin (Copper)

Fin

Type (Material) Corrugate (Aluminium)

Surface treatment Corrosion resistance (Blue n)

Compressor

Type × Quantity Twin rotary × 1

Motor output kW 3.9

Crankcase heater W 25

Refrigerant

Typ e R410A

Charge kg 11.2

Refrigerant oil Typ e PVE

Enclosure

Material Painted galbanized steel

Colour

BEIGE

Approximate colour of MUNSELL 10YR 7.5/1.0

Dimensions

(H × W × D)

Net

mm

1690 × 930 × 765

Gross 1811 × 1002 × 847

Weight

Net

kg

215

Gross 243

Connection pipe

Size

Liquid

mm

Ø12.7 (Ø1/2in.)

Gas Ø25.4 (Ø1in.)

Method

Liquid Brazing

Gas Brazing

Pre-charge length

m

20

Max. length 75

Max. height difference 30

Operation temperature range

Cooling

°CDB

-5 to 46

Heating -15 to 24

Defrost method Reversed cycle

Page 43

- (02 - 02) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

DIMENSIONS2.

MODEL : AOA72LALT, AOA9 0 L ALT

(Unit : mm)

Top view

690 (Bolt pitch)

732 (Bolt pitch)

8-12x17 (Hole)

765

930

1690

1576

1339

530 (Bolt pitch)

80

Front view

A, C

B

Right view

Left view

Rear view

Page 44

- (02 - 03) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

(Unit : mm)

KNOCKOUT HOLE POSITION

Detail A : Front view

Detail B : Left view

Detail C : Top view

Power supply

cable port

Pipe port

Transmission cable port

Transmission

cable port

73

43

Ø 43.7

Ø 22.2

Ø 22.2

95

75

10

100

125

199

Ø 34.5

Ø 50

Power supply cable port

Power supply cable port

19742

82 80

Transmission

cable port

Transmission

cable port

Ø 43.7

Ø 22.2

Ø 22.2

Ø 34.5

Power supply cable port

Power supply cable port

Power supply

cable port

Ø 50

Pipe port

Page 45

- (02 - 04) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

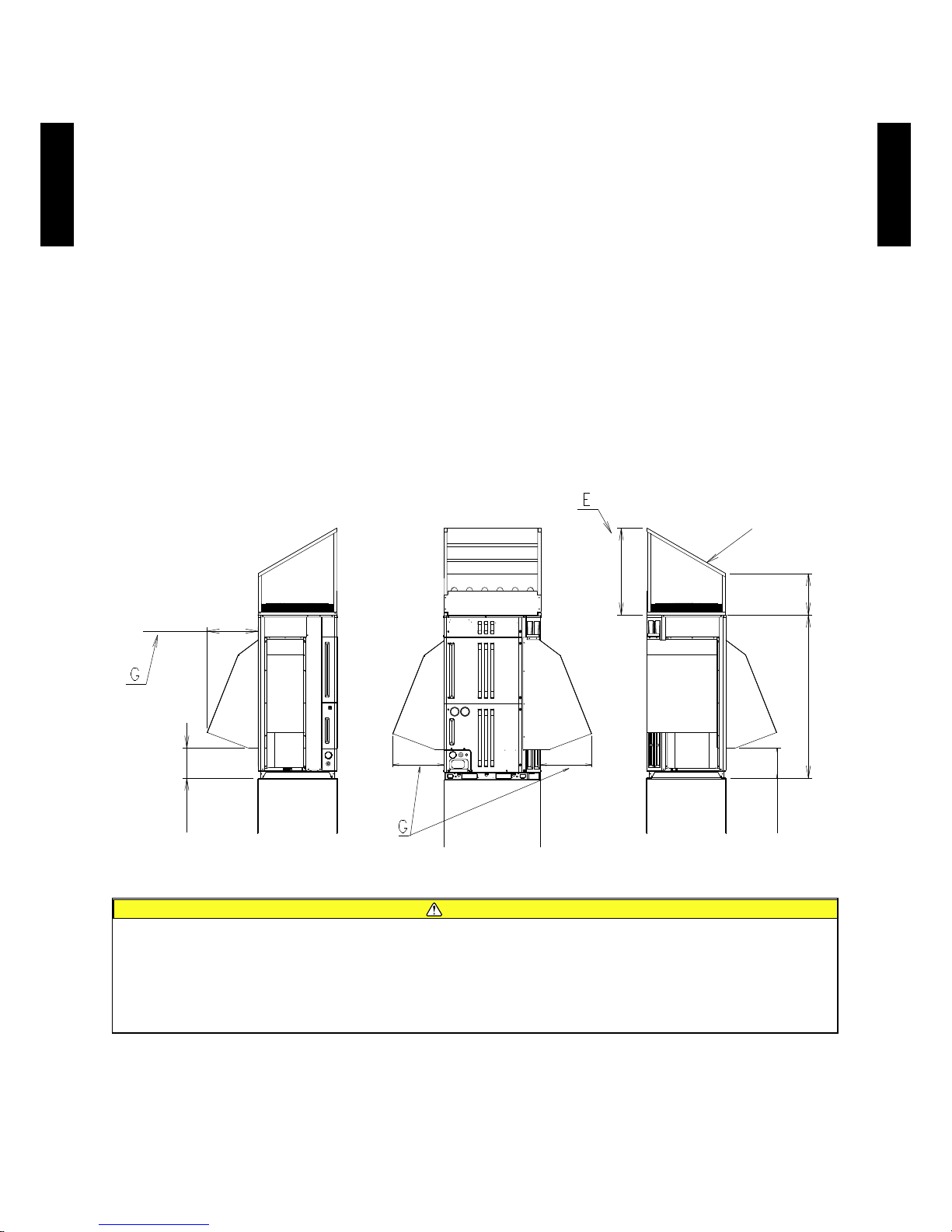

VALVE POSITION

ACCESSORY PIPE

(Unit : mm)

(Unit : mm)

Liquid valve

Gas valve

Ø 25.4

Ø 12.7

247.4

208.9

100

96

65

Liquid valve

Gas valve

128

123

D : Front view E : Left view

F : Left view

(Accessory pipe A setting)

G : Left view

(Accessory pipe B setting)

Gas

Liquid

30

147.3

121.5

Gas

Liquid

Page 46

- (02 - 05) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

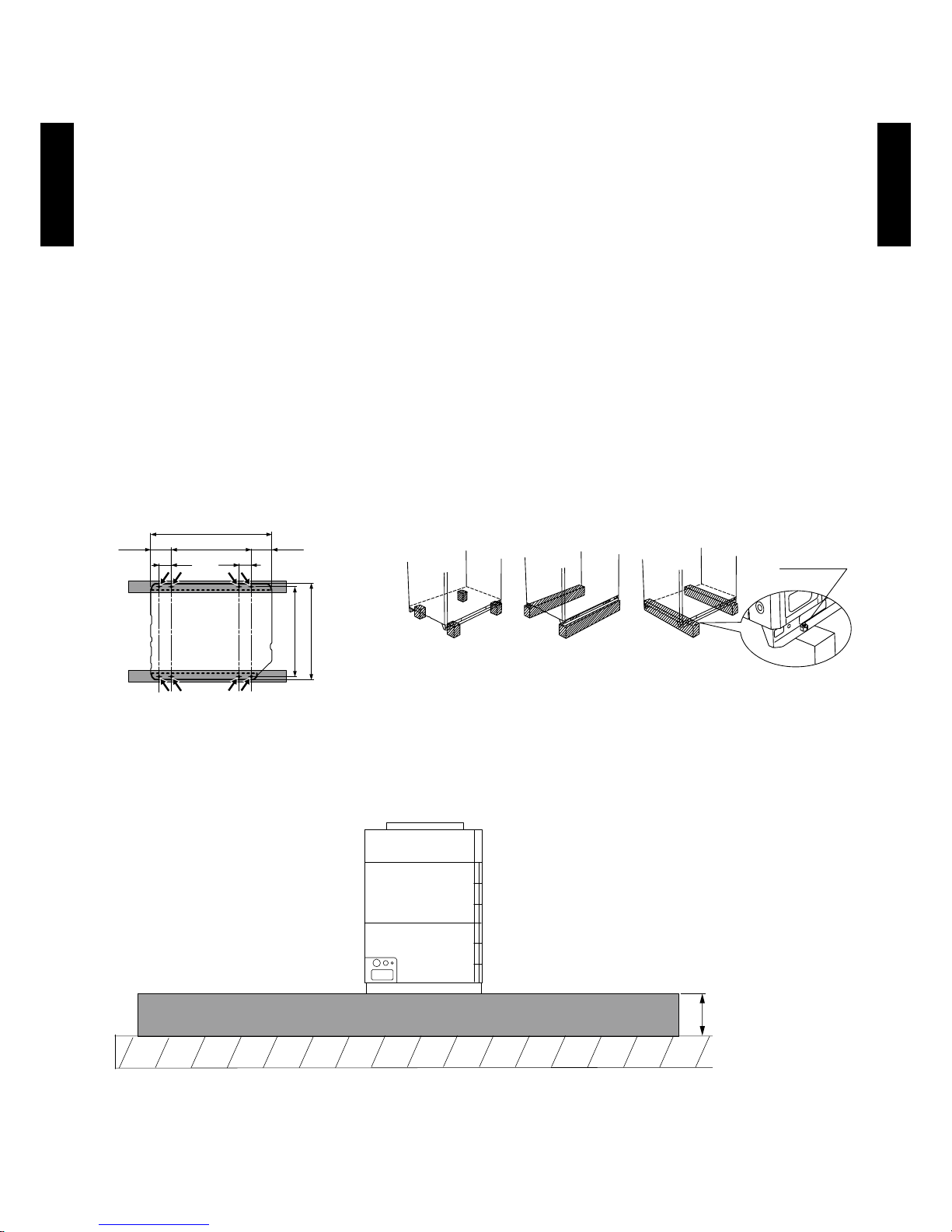

INSTALLATION (FOUNDATION)

Install the unit horizontally (within 3 degrees). •

Install 4 or more anchor bolts at the 8 locations indicated by arrows (Fig. A). •

Place the left and right anchor bolts at a distance further away than 610 mm. •

(Excluding the case where anchor bolts are installed at 8 locations.)

To minimize vibration, do not install the outdoor unit directly on the ground. Instead, install it on •

top of a rm platform (such as concrete block) (Fig. B).

Keep the height of foundation base over 200 mm from the oor surface (Fig. C). •

The foundation base should be able to support the product and the foot width of the product •

should be more than 46.5 mm.

Depending on the installation condition, vibration during the operation of the unit may cause •

noise and vibration.

Install vibration-proong materials (such as rubber pads). •

Consider the removal space of the connection piping when installing the foundation. •

• Secure the equipment rmly with anchor bolts, washers, and nuts.

More than

200mm

(Unit : mm)

Bottom view 8 - 12 x 17 (hole)

732

765

160

160610

930

80 80

Fig. A

Fig. C

*Do not use a four-cornersupport foundation.

Bolt (M10)

No good OK OK

Fig. B

Page 47

- (02 - 06) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

CENTER OF GRAVITY POSITION

Models : zAOA72LALT, AOA9 0L ALT

(Unit : mm)

● :

Center of gravity

Page 48

- (02 - 07) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

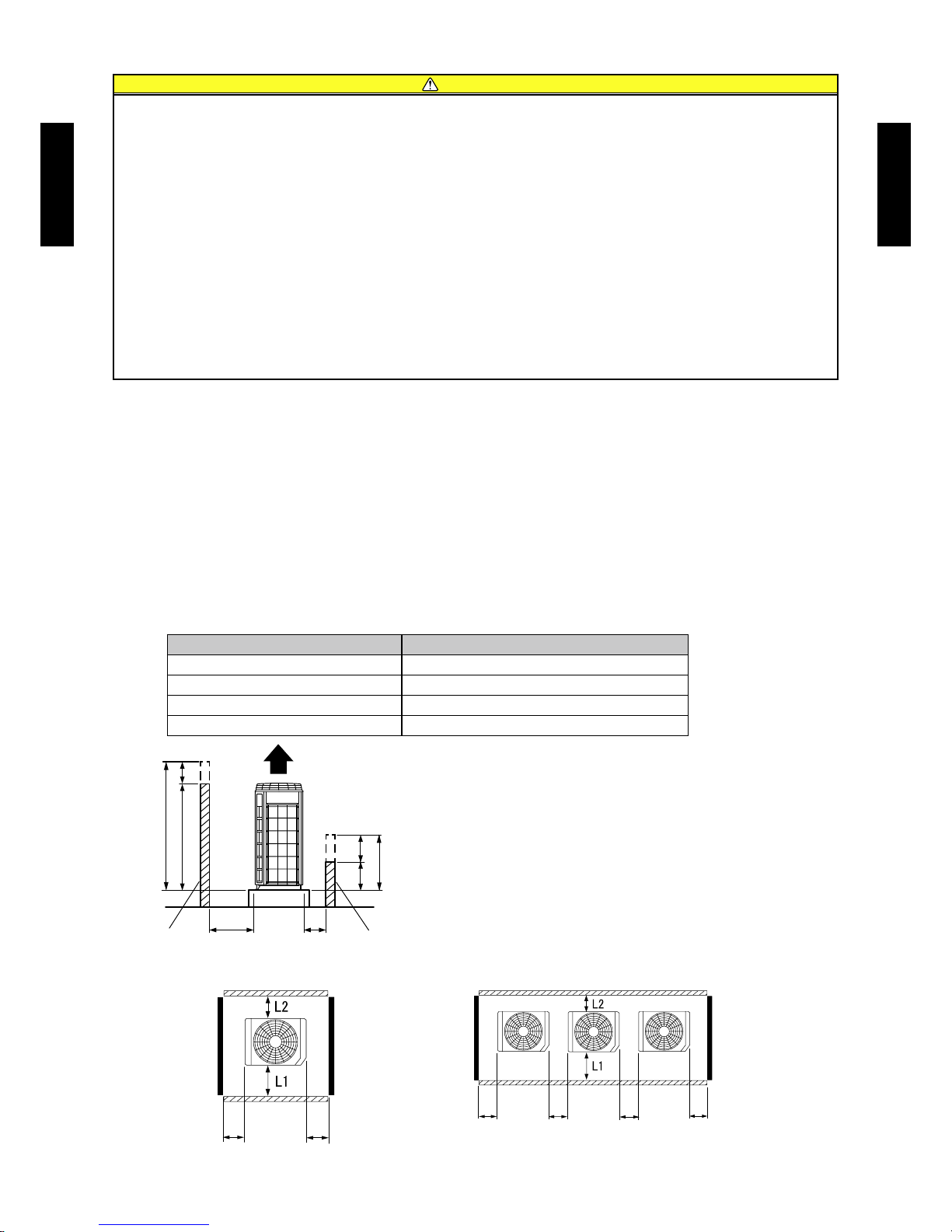

INSTALLATION PLACE3.

WHEN INSTALL NEAR BY LIMITED HEIGHT WALL3-1.

SINGLE AND MULTIPLE INSTALLATIONS

There are no restrictions on the height of the side wall.

●

Provide installation spaces L1 and L2 in accordance with the table below according to the

●

wall height (front side, rear side) conditions.

Provide installation spaces other than L1 and L2 in accordance with the conditions shown in

●

the gure below.

Ventilation resistance can be ignorable when the distance from a wall or product, etc. is

●

larger than 2m.

Wall height condition Necessary installation space

When H1 is 1500(mm) or less L1 ≥ 500 (mm)

When H1 is 1500(mm) or more L1 ≥ 500 + h1 ÷ 2 (mm)

When H2 is 500(mm) or less L2 ≥ 300 (mm)

When H2 is 500(mm) or more L2 ≥ 300 + h2 ÷ 2 (mm)

Caution

When installing the outdoor unit, pay attention to the following items.

To prevent stopping of operation by short circuit and worsening of performance and high pressure ●

protection, refer to the installation space shown in the figure and secure enough space.

Install in sufficient space considering the carrying in route, installation space, maintenance space, ●

passage of people, etc.

Do not place obstructions in the air flow outlet direction. If there is an obstruction in the outlet ●

direction, install an outlet duct.

When there is a wall in front of the unit, provide a space of 500mm or more as maintenance space. ●

When there is a wall at the side of the unit, provide a space of 30mm or more as maintenance ●

space.

An outdoor temperature of 35 degrees in air-conditioned operation is assumed for the installation ●

space in this item. If the outdoor temperature exceeds 35 degrees, provide a larger inlet space.

When installing, also consider the refrigerant piping space. ●

h1

1500

H1

L1

L2

500

h2

H2

30 mm

or more

30 mm

or more

<Front>

<Rear>

30 mm

or more

30 mm

or more

30 mm

or more

<Front>

<Rear>

30 mm

or more

<Side view>

<Top view>

Wall Wall

<Top view>

Front Rear

Page 49

- (02 - 08) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

WHEN INSTALL NEAR BY UNLIMITED HEIGHT WALL3-2.

SINGLE AND MULTIPLE INSTALLATIONS

There are no restrictions on the height of the wall.

●

The wall (without height restrictions) must not exist on the both sides (left / right) of outdoor

●

unit. Also, must not exist on the both sides (front / rear) of outdoor unit.

Provide installation spaces other than L3 in accordance with the conditions shown in the

●

gure below.

Ventilation resistance can be ignorable when the distance from a wall or product, etc. is

●

larger than 2m.

When installing with the REAR of the outdoor unit facing the wall side

z

Condition Necessary installation space

When B ≥ 400 (mm) L3 ≥ 200 (mm)

When 30 ≤ B < 400 (mm) L3 ≥ 200 + (400 - B) x 3 (mm)

Single installation Multiple installations

<Top view>

<Front>

<Rear>

300 mm

or more

200 mm

or more

200 mm

or more

<Front>

<Rear>

300 mm

or more

<Top view>

<Front>

<Rear>

300 mm

or more

B

L3

B

300 mm

or more

200 mm 200 mm

800 mm

or more

Example:

When B is made 200 mm

L3

>

=

200+(400-200)×3=800 mm

Page 50

- (02 - 09) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

When there are obstacles above the product, keep the minimum installation height as shown

in the gure and install the outlet duct.

The efciency might decrease when the outlet duct etc. are installed.

When an outlet duct is not installed, install the product as shown below.

z

1) Make the ceiling height after setting 1m or greater.

2) Be sure there is no wall at the rear side.

3) When installing products adjacently, install up to 3 units.

WHEN THERE IS AN OBSTRUCTION ABOVE THE PRODUCT3-3.

500mm

or more

Outlet

duct

1000mm

or more

500mm

or more

front rear

Page 51

- (02 - 10) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

REFRIGERANT CIRCUIT4.

MODEL : AOA72LALT, AOA9 0 L ALT

Page 52

- (02 - 11) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

WIRING DIAGRAMS5.

MODEL : AOA72LALT, AOA9 0 L ALT

Page 53

- (02 - 12) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

CAPACITY COMPENSATION RATE FOR PIPE LENGTH 6.

AND HEIGHT DIFFERENCE

MODEL : AOA72LALT

COOLING

Pipe length (m)

5 7. 5 10 20 30 40 50 60 75

Height

difference

H

(m)

1

Indoor unit is

higher than

outdoor unit

30 - - - - 0.901 0.878 0.855

0.832 0.798

20 - - - 0.939 0.916 0.892 0.869

0.846 0.811

10 - - 0.978 0.954 0.931 0.907 0.884

0.860 0.825

7. 5 - 0.988 0.982 0.958 0.935 0.911 0.887

0.864 0.828

5 0.992 0.992 0.986 0.962 0.938 0.915 0.891

0.867 0.831

0 1.000 1.000 0.994 0.970 0.946 0.922 0.898

0. 874 0.838

2

Indoor unit is

lower than

outdoor unit.

-5 1.000 1.000 0.994 0.970 0.946 0.922 0.898

0. 874 0.838

-7. 5 - 1.000 0.994 0.970 0.946 0.922 0.898

0. 874 0.838

-10 - - 0.994 0.970 0.946 0.922 0.898

0. 874 0.838

-20 - - - 0.970 0.946 0.922 0.898

0. 874 0.838

-30 - - - - 0.946 0.922 0.898

0. 874 0.838

HEATING

Pipe length (m)

5 7. 5 10 20 30 40 50 60 75

Height

difference

H

(m)

1

Indoor unit is

higher than

outdoor unit

30 - - - - 0.977 0.966 0.956

0.946 0.930

20 - - - 0.987 0.977 0.966 0.956

0.946 0.930

10 - - 0.997 0.987 0.977 0.966 0.956

0.946 0.930

7. 5 - 1.000 0.997 0.987 0.977 0.966 0.956

0.946 0.930

5 1.000 1.000 0.997 0.987 0.977 0.966 0.956

0.946 0.930

0 1.000 1.000 0.997 0.987 0.977 0.966 0.956

0.946 0.930

2

Indoor unit is

lower than

outdoor unit.

-5 0.995 0.995 0.992 0.982 0.972 0.961 0.951

0. 9 41 0.925

-7. 5 - 0.993 0.990 0.980 0.970 0.959 0.949

0.939 0.923

-10 - - 0.987 0.977 0.967 0.956 0.946

0.937 0.921

-20 - - - 0.967 0.957 0.947 0.937

0.927 0.911

-30 - - - - 0.948 0.937 0.927

0.918 0.902

Outdoor unit

Indoor unit

Connec tion pipe

2 Indoor unit is lower than outdoor unit.

H

Indoor unit

Outdoor unit

Connec tion pipe

1 Indoor unit is higher than outdoor unit.

H

Height difference H

Page 54

- (02 - 13) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

MODEL : AOA9 0 L ALT

Outdoor unit

Indoor unit

Connec tion pipe

2 Indoor unit is lower than outdoor unit.

H

Indoor unit

Outdoor unit

Connec tion pipe

1 Indoor unit is higher than outdoor unit.

H

Height difference H

COOLING

Pipe length (m)

5 7. 5 10 20 30 40 50 60 75

Height

difference

H

(m)

1

Indoor unit is

higher than

outdoor unit

30 - - - - 0.898 0.874 0.850 0.826 0.790

20 - - - 0.938 0.913 0.889 0.864 0.840 0.803

10 - - 0.978 0.953 0.928 0.903 0.879 0.854 0.817

7. 5 - 0.988 0.982 0.957 0.932 0.907 0.882 0.858 0.820

5 0.992 0.992 0.986 0.961 0.935 0.911 0.886 0.861 0.823

0 1.000 1.000 0.994 0.969 0.943 0.918 0.893 0.868 0.830

2

Indoor unit is

lower than

outdoor unit.

-5 1.000 1.000 0.994 0.969 0.943 0.918 0.893 0.868 0.830

-7. 5 - 1.000 0.994 0.969 0.943 0.918 0.893 0.868 0.830

-10 - - 0.994 0.969 0.943 0.918 0.893 0.868 0.830

-20 - - - 0.969 0.943 0.918 0.893 0.868 0.830

-30 - - - - 0.943 0.918 0.893 0.868 0.830

HEATING

Pipe length (m)

5 7. 5 10 20 30 40 50 60 75

Height

difference

H

(m)

1

Indoor unit is

higher than

outdoor unit

30 - - - - 0.977 0.966 0.956 0.946 0.930

20 - - - 0.987 0.977 0.966 0.956 0.946 0.930

10 - - 0.997 0.987 0.977 0.966 0.956 0.946 0.930

7. 5 - 1.000 0.997 0.987 0.977 0.966 0.956 0.946 0.930

5 1.000 1.000 0.997 0.987 0.977 0.966 0.956 0.946 0.930

0 1.000 1.000 0.997 0.987 0.977 0.966 0.956 0.946 0.930

2

Indoor unit is

lower than

outdoor unit.

-5 0.995 0.995 0.992 0.982 0.972 0.961 0.951 0.941 0.925

-7. 5 - 0.993 0.990 0.980 0.970 0.959 0.949 0.939 0.923

-10 - - 0.987 0.977 0.967 0.956 0.946 0.937 0.921

-20 - - - 0.967 0.957 0.947 0.937 0.927 0.911

-30 - - - - 0.948 0.937 0.927 0.918 0.902

Page 55

- (02 - 14) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

PIPE SIZE SELECTION & LIMITATION7.

MODEL : AO

A72LALT, AOA9 0 L ALT

ADDITIONAL CHARGE CALCULATION8.

MODEL : AO

A72LALT, AOA9 0 L ALT

Refrigerant charge

z

Refrigerant type R410A

Refrigerant amount g 11, 20 0

Refrigerant pipe size

[mm (in.)]

Piping length

Standard ~20 m 30 m 40 m 50 m 60 m 70 m 75 m g/m

Liquid

Gas

12.70 (1/2)

25.40 (1)

None 1,100 g 2,200 g 3,300 g 4,400 g 5,500 g 6,050 g 110 g/m

Size down ~20 m 30 m 40 m 50 m 60 m 70 m 75 m g/m

Liquid

Gas

12.70 (1/2)

22.22 (7/8)

None 1,100 g 2,200 g 3,300 g 4,400 g 5,500 g 6,050 g 110 g/m

Size up ~20 m 30 m 40 m 50 m g/m

Liquid

Gas

12.70 (1/2)

28.58 (9/8)

None 1,100 g 2,200 g 3,300 g 110 g/m

Size down Standard Size up

Pipe diameter

Liquid pipes 12.70 (1/2)

[mm (in.)] Gas pipes

22.22

(7/8)

25.40

(1)

28.58

(9/8)

Piping length

Max. piping length (L1)

(Max. chargeless length)

[m (m)] 75 (20) 75 (20) 50 (20)

Min. piping length (L1) [m] 5

Max. height difference (H1)

<Indoor unit to outdoor unit>

[m]

30

L1

H1

Page 56

- (02 - 15) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

AIR FLOW9.

MODEL : AOA72LALT

Cooling

z

Heating

z

MODEL : AOA9 0 L ALT

Cooling

z

Heating

z

Number of

rotations

(r.p.m)

Air ow

730

m

3

/h 9300

l/s 2583

CFM 5474

Number of

rotations

(r.p.m)

Air ow

730

m

3

/h 9300

l/s 2583

CFM 5474

Number of

rotations

(r.p.m)

Air ow

830

m

3

/h 10700

l/s 2972

CFM 6298

Number of

rotations

(r.p.m)

Air ow

840

m

3

/h 108 00

l/s 3000

CFM 6357

Page 57

- (02 - 16) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

OPERATION NOISE10.

NOISE LEVEL CURVE10-1.

MODEL : AOA72LALT

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

Octave ba nd cente r frequency,Hz

80

70

60

50

40

30

20

10

0

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

Cooling

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

Octave ba nd cente r frequency,Hz

80

70

60

50

40

30

20

10

0

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

Heating

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

Octave ba nd cente r frequency,Hz

80

70

60

50

40

30

20

10

0

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

Heating

z

Octave ba nd sound p ressur e level, dB:(0 dB= 0.00 02µbar)

Octave ba nd cente r frequency,Hz

80

70

60

50

40

30

20

10

0

63 125 250 50 0 1,000 2 ,000 4 ,000 8,000

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC -15

MODEL : AOA9 0 L ALT

Cooling

z

Page 58

- (02 - 17) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

SOUND LEVEL CHECK POINT10-2.

Microphone

1 m

1 m

Page 59

- (02 - 18) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

ELECTRIC CHARACTERISTICS11.

*1) The maximum current is the total current of indoor unit and outdoor unit.

*2) Wiring spec. :

Selected sample

(Selected based on Japan Electrotechnical Standard and Codes Committee E0005)

Model AOA72LALT AOA90LALT

Power supply

Voltage V 400

Frequency Hz 50

*1) Max. operating current A 22.8 25.8

Starting current A 9.6 12.5

Breaker

MCCB

Capacity

A 30

ELCB

Leakage current

30mA

0.1sec or less

Outdoor unit power

supply cable

Power supply cable

mm

2

6

Ground wire

mm

2

6

Page 60

- (02 - 19) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

SAFETY DEVICES12.

Protection form

Model

AOA72LALT AOA90LALT

Circuit protection

Fuse (Main PCB)

AC400V 15A

AC250V 3.15A

Protector (FILTER PCB) AC500V 25A

Indoor unit protection Fuse AC250V 20A

Compressor protection

Thermal protection program

(Compressor temp.)

OFF : 112°C

ON : 80°C

Thermal protection program

(Discharge temp.)

OFF : 115°C

ON : After 7 minutes.

High pressure protection Pressure switch

OFF : 4.2MPa

ON : 3.2MPa

Low pressure protection Pressure sensor

OFF : 0.02MPa

ON : 0.05MPa

Fan motor protection Thermal protection program

OFF :100

+15

°C

-10

ON : 95

+15

°C

-10

Page 61

- (02 - 20) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

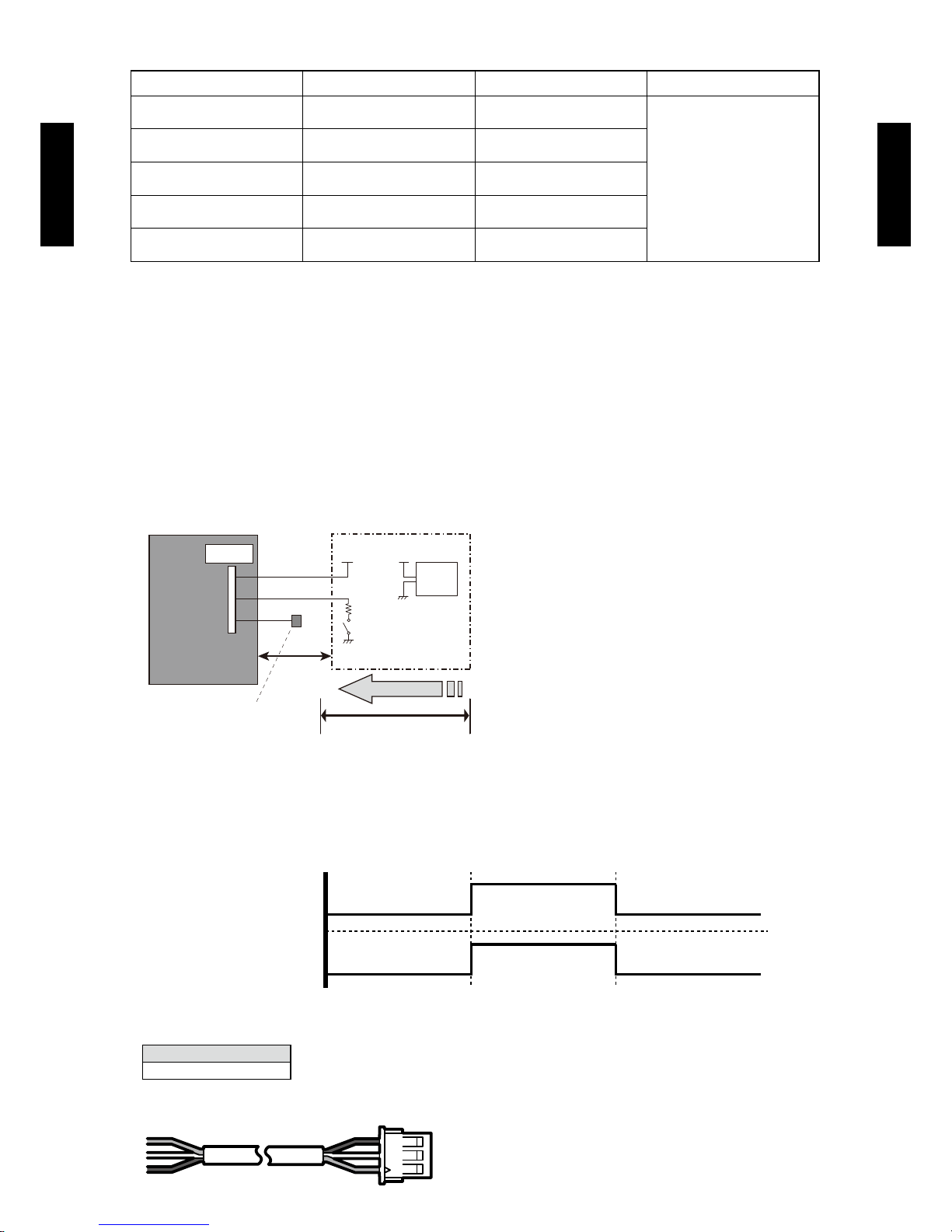

EXTERNAL INPUT & OUTPUT13.

EXTERNAL INPUT13-1.

ON/OFF of the "Low noise mode" and "Peak cut mode" functions can be specied by external

signal.

LOW NOISE MODE

On-site work like the following also reduces the operating sound of the outdoor unit from the •

normal sound.

The air conditioner is set to the "Low noise mode" by applying the contact input of a commercial

timer or ON/OFF switch to a connector on the outdoor control PC board.

* Performance may drop depending on the outside air temperature condition, etc.

Circuit diagram example

z

Use the following parts and construct a circuit like that shown above. •

Input Signal •

ON : Low noise mode / OFF : Normal operation

* Set the "Low noise mode" level by "Push switch" on the outdoor control PC board.

Parts (Optional)

z

Model name

UT Y-XWZ X Z2

Wire (External input)

Input Output Connector Remarks

Low noise mode ― CN131

See external

input/output settings

for details.

Peak cut mode ― CN131

― Error status CN136

― Compressor status CN136

― Base heater CN115

Outdoor

control PC board

Connected unit

Connector

1

2

3

Signal

Field supply

* Make the distance from the PC board to the connected unit within 10 m.

Surely insulate with

insulation tape etc. since

this wire is not used.

*10 m

Red

White

Black

Vcc

R

SW

Vcc

Power

supply

ON

OFF

ON

OFF

Input Signal

Low noise mode

1) Power supply

●Voltage (Chart sign=Vcc) : DC 5V to 24V

●The current capacity : About 100m A

2) Switch (Char t sign=SW)

● Toggle switch or Rocker switch, etc : Switch which maintains the

states.

● Prep ar e swit ch es w hi ch a re enoug h capa ble for DC 10m A

current or more

3) Resistance (Chart sign=R)

●Adjust the resistance for current to about DC 10mA

(Example)

●In case of Vcc= DC 5V : Rated resistance value 470Ω 1/4W

●In case of Vcc= DC 12V : Rated resistance value 1kΩ 1/4W

●In case of Vcc= DC 24V : Rated resistance value 2.2kΩ 1/4W

Page 62

- (02 - 21) -

OUTDOOR UNIT

AO

A7 2-90LALT

OUTDOOR UNIT

AO

A7 2-90LALT

PEAK CUT MODE

Operation that suppressed the current value can be performed by means of the following on- •

site work. The air conditioner is set to the Peak cut mode by applying the contact input of a

commercial ON/OFF switch to a connector on the outdoor control PC board.

Circuit diagram example

z

Outdoor

control PC board

Connected unit

Connector

1

2

3

Signal

Field supply

* Make the distance from the PC board to the connected unit within 10 m.

Surely insulate with

insulation tape etc. since

this wire is not used.

*10 m

Red

White

Black

Vcc

R

SW

Vcc

Power

supply

Use the following parts and construct a circuit like that shown above. •

Input Signal∙∙∙ON : Peak cut mode/OFF : Normal operation •

*Set the "Peak cut mode" level by "Push switch" on the outdoor control PC board.

ON

OFF

ON

OFF

Input Signal

Peak cut mode