Fujitsu AirStage AB12, AirStage AB24, AirStage AB14, AirStage AB18, AirStage AB30 Service Manual

...Page 1

R407C

Variable Refrigerant Flow System

Multi Air Conditioning System for Buildings

HEAT RECOVERY TYPE

Model : AO90

SERVICE MANUAL

Page 2

Multi Air Conditioning System

for Buildings

SERVICE MANUAL

Variable Refrigerant Flow System

R407C

Page 3

CONTENTS

1. TEST RUN

1-4 TEST RUN CONTROL................................................................................................

1-3-1 TEST RUN FROM OUTDOOR PC BOARD........................................................

2-2 MICROPROCESSOR FUNCTION LIST.....................................................................

2-1 PCB LAYOUTS...........................................................................................................

2. FUNCTION OF PRINTED CIRCUIT BOARD

3-1-3 3 MINUTES RESTART PREVENTION (3MIN ST)..............................................

3-1-2 COMPRESSOR OUTPUT PATTERN ................................................................

3-1-1 OPERATION / STOP CONDITION......................................................................

3-1 COMPRESSOR OPERATION CONTROL..................................................................

1-2 CHECK ITEM DURING TEST RUN............................................................................

1-1 CHECK ITEMS BEFORE TEST RUN.........................................................................

2-1-2 INDOOR UNIT CONTROL CIRCUIT BOARD

2-1-1 INDOOR UNIT CONTROL CIRCUIT BOARD.....................................................

2-1-3 OUTDOOR UNIT CONTROL CIRCUIT BOARD................................................. 02-03

WIRED REMOTE CONTROLLER, SIMPLE REMOTE CONTROLLER

CIRCUIT BOARD.................................................................................................

1-3-2 TEST RUN FROM REMOTE CONTROLLER.....................................................

2-1-4

2-2-1 INDOOR UNIT.....................................................................................................

2-2-2 OUTDOOR UNIT.................................................................................................

2-3 FUNCTION AND SETTING OF EACH SWITCH........................................................

2-3-1 INDOOR UNIT(EXCEPT FOR COMPACT WALL MOUNTED TYPE..................

2-3-2 INDOOR UNIT(COMPACT WALL MOUNTED TYPE).........................................

2-3-3 OUTDOOR UNIT..................................................................................................

2-3-4 WIRED, SIMPLE REMOTE CONTROLLER........................................................

2-4 EXTERNAL INPUT & OUTPUT..................................................................................

2-4-1 INDOOR UNIT(EXCEPT FOR COMPACT WALL MOUNTED TYPE).................

2-4-2 INDOOR UNIT(COMPACT WALL MOUNTED)...................................................

.2-4-3 OUTDOOR UNIT..................................................................................................

3. OUTDOOR UNIT OPERATION CONTROL

3-1-4 COMPRESSOR RECOVERY OPERATION........................................................

3-2 HEAT EXCHANGE CAPACITY CONTROL................................................................

3-3 OUTDOOR FAN MOTOR CONTROL........................................................................

01-01

01-02

1-3 TEST RUN METHOD.................................................................................................. 01-03

01-03

01-03

01-05

02-01

02-01

02-04

02-08

02-08

02-11

02-12

02-12

02-16

02-19

02-22

02-28

02-28

02-30

02-31

03-01

03-01

03-01

03-01

03-02

03-03

03-04

2-1-5 CENTRAL REMOTE CONTROLLER CIRCUIT BOARD......................................

02-05

2-3-5 CENTRAL REMOTE CONTROLLER.................................................................. 02-24

2-4-4 CENTRAL REMOTE CONTROLLER / PC CONTROLLER.................................

02-32

(COMPACT WALL MOUNTED TYPE)................................................................. 02-02

2-1-6 NETWORK CONVERTORS' CIRCUIT BOARD....................................................

02-06

2-3-6 NETWORK CONVERTOR.................................................................................. 02-26

2-4-5 NETWORK CONVERTOR...................................................................................

02-34

Page 4

3-10 PROTECTION FUNCTIONS......................................................................................

4. INDOOR UNIT OPERATION

3-9 OIL RECOVERY CONTROL......................................................................................

03-11

04-01

03-10

5. TROUBLESHOOTING

4-1 TIMER CONTROL......................................................................................................

4-2 FAN CONTROL..........................................................................................................

4-2-1 "AUTO" POSITION..............................................................................................

4-2-2 "LOW", "MED" AND "HIGH" POSITION..............................................................

4-3 MASTER CONTROL..................................................................................................

4-3-1 OPERATION MODE CONTROL..........................................................................

4-3-2 AUTO CHANGEOVER.........................................................................................

4-3-3 "COOL" POSITION..............................................................................................

4-3-4 "HEAT" POSITION...............................................................................................

4-3-5 "FAN" POSITION.................................................................................................

4-4 LOUVER CONTROL..................................................................................................

4-5 ENERGY SAVE OPERATION...................................................................................

4-6 ANTI FREEZE CONTROL.........................................................................................

4-7 ELECTRONIC EXPANSION VALVE CONTROL.......................................................

5-1 INDOOR UNIT............................................................................................................

5-1-1 NORMAL OPERATION DISPLAY.......................................................................

5-1-2 ABNORMAL OPERATION DISPLAY...................................................................

5-2 OUTDOOR UNIT........................................................................................................

5-2-1 NORMAL OPERATING DISPLAY........................................................................

5-2-2 ABNORMAL OPERATION DISPLAY...................................................................

5-3 REMOTE CONTROLLER...........................................................................................

5-5 ERROR CODE & TROUBLESHOOTING...................................................................

5-5-1 TROUBLE SHOOTING WITH ERROR CODE....................................................

6. APPENDING DATA 1 (INSTALLATION)

6-1 ADDITIONAL CHARGE..............................................................................................

6-2 ADDRESS SETTING..................................................................................................

5-5-2 TROUBLE SHOOTING WITH NO ERROR CODE..............................................

04-06

04-06

04-06

04-07

04-07

04-08

04-09

04-09

04-09

04-10

04-13

04-14

04-15

05-01

05-01

05-03

05-03

05-04

5-3-1 WIRED REMOTE CONTROLLER....................................................................... 05-05

5-3-2 SIMPLE REMOTE CONTROLLER...................................................................... 05-05

5-3-3 CENTRAL REMOTE CONTROLLER.................................................................. 05-06

05-05

05-10

05-10

05-36

05-02

06-01

06-02

5-4 NETWORK CONVERTOR.........................................................................................

05-09

5-6 CASE SUCH AS THESE ARE NORMAL...................................................................

05-46

3-4 EXPANSION VALVES 1 AND 2 CONTROL...............................................................

3-5 CIRCULATING SAVE AMOUNT CONTROL..............................................................

3-6 SOLENOID VALVE 2 CONTROL...............................................................................

3-7 DEFROSTING CONTROL..........................................................................................

3-8 OIL RETURN CONTROL............................................................................................

03-06

03-07

03-07

03-08

03-09

4-8 AUTO RESTART........................................................................................................

4-9 DRAIN PUMP OPERATION.......................................................................................

04-15

04-15

Page 5

7-1 REFRIGERANT PIPE SYSTEM DIAGRAM................................................................

7-3-1 INDOOR UNIT......................................................................................................

7-3-2 OUTDOOR UNIT..................................................................................................

7. APPENDING DATA 1 (UNIT)

7-2 CHARACTERISTICS OF SENSORS..........................................................................

7-2-1 THRMISTOR.........................................................................................................

7-2-2 PRESSURE SENSOR..........................................................................................

7-3 WIRING DIAGRAM.....................................................................................................

7-4 OUTDOOR INTERNAL LAYOUT................................................................................

07-01

07-02

07-02

07-04

07-06

07-06

07-18

07-19

6-2-1 KINDS OF ADDRESS AND SETTING RANGE....................................................

6-2-2 ADDRESS SETTING FOR COMPACT WALL MOUNTED

TYPE INDOOR UNIT.............................................................................................

6-3 PUMP DOWN METHOD.............................................................................................

6-3-1 START AND STOP OF THE PUMP DOWN.........................................................

6-4 TOOLS........................................................................................................................

06-02

06-04

06-09

06-09

6-3-2 A FLOW CHART OF PUMP DOWN.....................................................................

06-09

06-10

6-5 PRECAUTIONS FOR INSTALLATION.......................................................................

06-11

7-5 MODEL DESIGNATION ..............................................................................................

07-20

6-2-3 EXAMPLES OF SYSTEM SETTING.....................................................................

06-05

6-6 PRECAUTIONS FOR SERVICING.............................................................................

6-7 IN USE OF THE NEW REFRIGERANT R407C..........................................................

06-13

06-14

6-7-1 WHAT IS CFC/HCFC/HFC ?.................................................................................

6-7-2 CHARACTERISTICS OF R22 AND R407C..........................................................

06-14

06-14

6-7-3 DEFFERENCE FROM CONVENTIONAL MODEL(R22) AND PRECAUTIONS...

06-15

7-2-3 ELECTRIC EXPANSION VALVE..........................................................................

7-2-4 RB UNIT................................................................................................................

7-2-5 OTHERS...............................................................................................................

07-04

07-04

07-05

Page 6

1 . TEST RUN

TM

R407C

Page 7

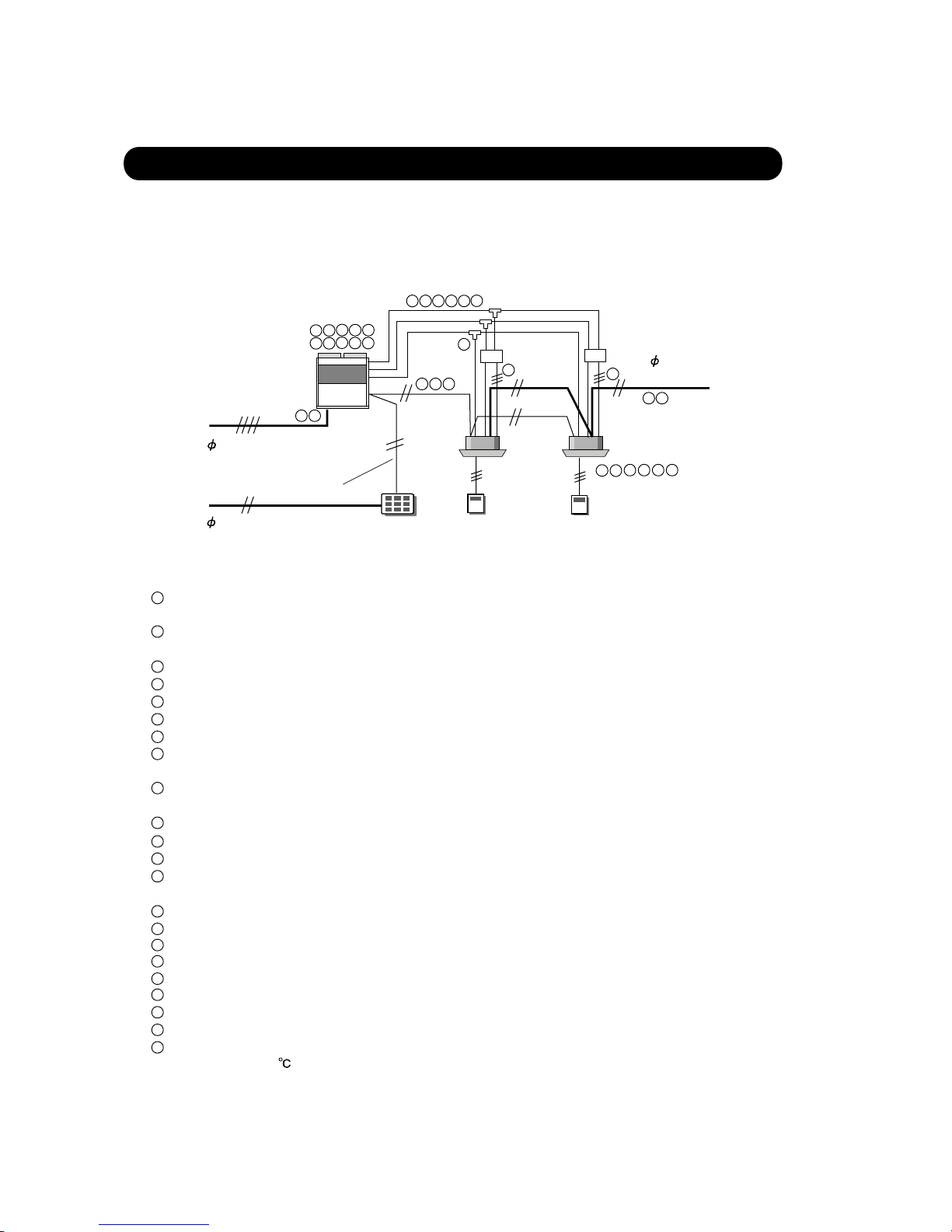

Outdoor

unit

3 4W 50Hz 380 - 415V

1 50Hz

220 - 240V

Transmission line

Indoor

unit

1

13

9

10

9

10

1

14

15 16

12

13

14

2

4

3 5 6

15

16 17 18

21

Central

remote controller

Wired

remote controller

Before test run, check the following items.

Is the selection of the outdoor unit and the indoor units correct?

(Check the number of connected indoor units, total capacity of the indoor units)

Is the piping length correct?

(Ex. Maximum piping length : 100m)

Is the diameter selected separation kit correct?

Doesn't gas leak?

Have the vaccuum process done enough time?

Is the refrigerant flow correct?

1

2

Is the additional refrigerant charge amount correct?

Are the power supply cables connected?

Is the spec. for the power supply cable correct?

Is the length of the transmission line under the limit?

Is the spec. for the transmission cable correct?

(non-polar 2-core, 0.75-1.25mm )

(Note the charge amount to control box cover)

(Power supply for the indoor unit and outdoor unit is separated.)

Is the transmission cable connected to all units?

2

Is the remote controller cable connected to units?

Is not the power supply cable connected to transmission and remote controller terminal?

Are the addresses set? (Ex. Refrigerant circuit address, indoor unit address, remote controller address, etc.)

3

4

5

6

7

8

9

Is the diameter of the selected pipe correct?

10

12

13

14

15

1. TEST RUN

16

17

Have the all settings done on the PCB?

18

Is the ball valve opened?

19

Is the pipe heat-insulated which have the enough thickness?

20

Is the drain water-flow correct?

21

Is the power supplied to crank case heater for more than 12 hours before the start of test run at outdoor

temperature of 20 or below?

22

1 50Hz 220 - 240V

1-1 CHECK ITEMS BEFORE TEST RUN

01-01

7 8

19

21

22

7 20

Is the RB unit cable connected?

11

RB unit

RB unit

11

11

Page 8

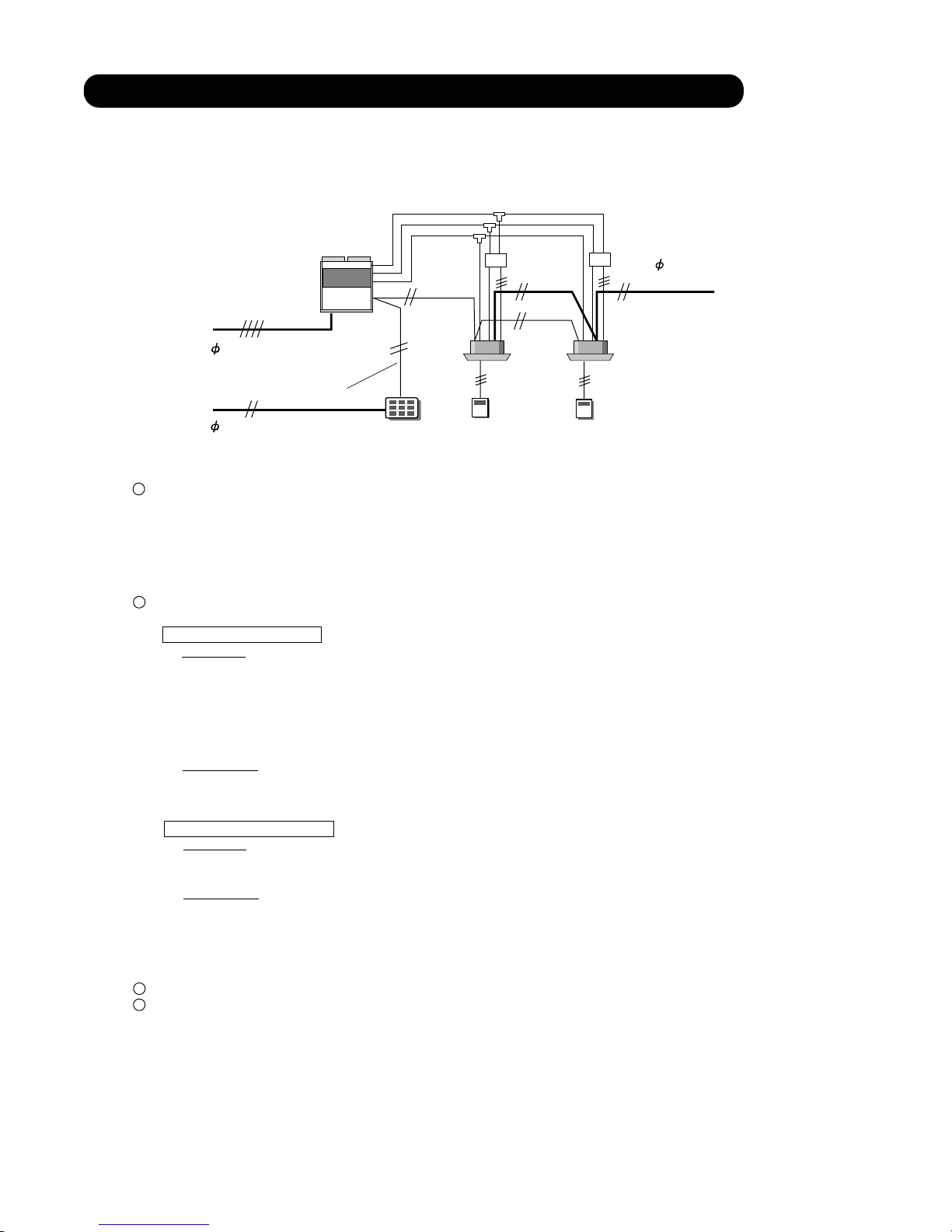

1-2 CHECK ITEM DURING TEST RUN

During the test run operation, check the following items.

When the power supply turn on,check the following items.

Outdoor unit : LED 1 lights continuously.

if LED flushing, it means error occurs ,check the eroor and solve the problem.

Indoor unit : LED RED (operation lamp) & GREEN (timer lamp) lights flush alternately.(Auto restart setting:Invalidity)

RC : Timer display indicates

When errors occur, don't advance towards the following step before a complete settlement of all these errors.

Start the Indoor unit test run from remote controller one by one (Refer to 1-3-2)

Check the following item.

Indoor unit

LED (red&green) light flush at the same time slowly.

Louver operates to open.

Fan rotates

Air flow comes

(Drain pump opration)

RC signal receive

Outdoor unit

Coresponds from indoor unit signal

Compressor start to operates

Fan rotates

Measure the following item.

Indoor unit

Air intake temp.

Air flow temp.

Outdoor unit

Outdoor temp.

Discharge pipe temp.

Suction pipe temp.

High pressure

Low pressure

Contlnue the operation about 10 minutes.

When there is no ploblem, check the next indoor unit.

After every indoor unit is check by test run, please do test run using all of the indoor units and check them.

1

2

3

4

01-02

Outdoor

unit

3 4W 50Hz 380 - 415V

1 50Hz

220 - 240V

Transmission line

Indoor

unit

Central

remote controller

Wired

remote controller

1 50Hz 220 - 240V

RB unit

RB unit

All LEDs go off.(Auto restart setting : Validity)

Page 9

1-3 TEST RUN METHOD

Supply power to the crankcase heater for 12 hours prior to the start of operation if the outdoor temperature is lower

than 20 . The following is the procedure for the test run operation.

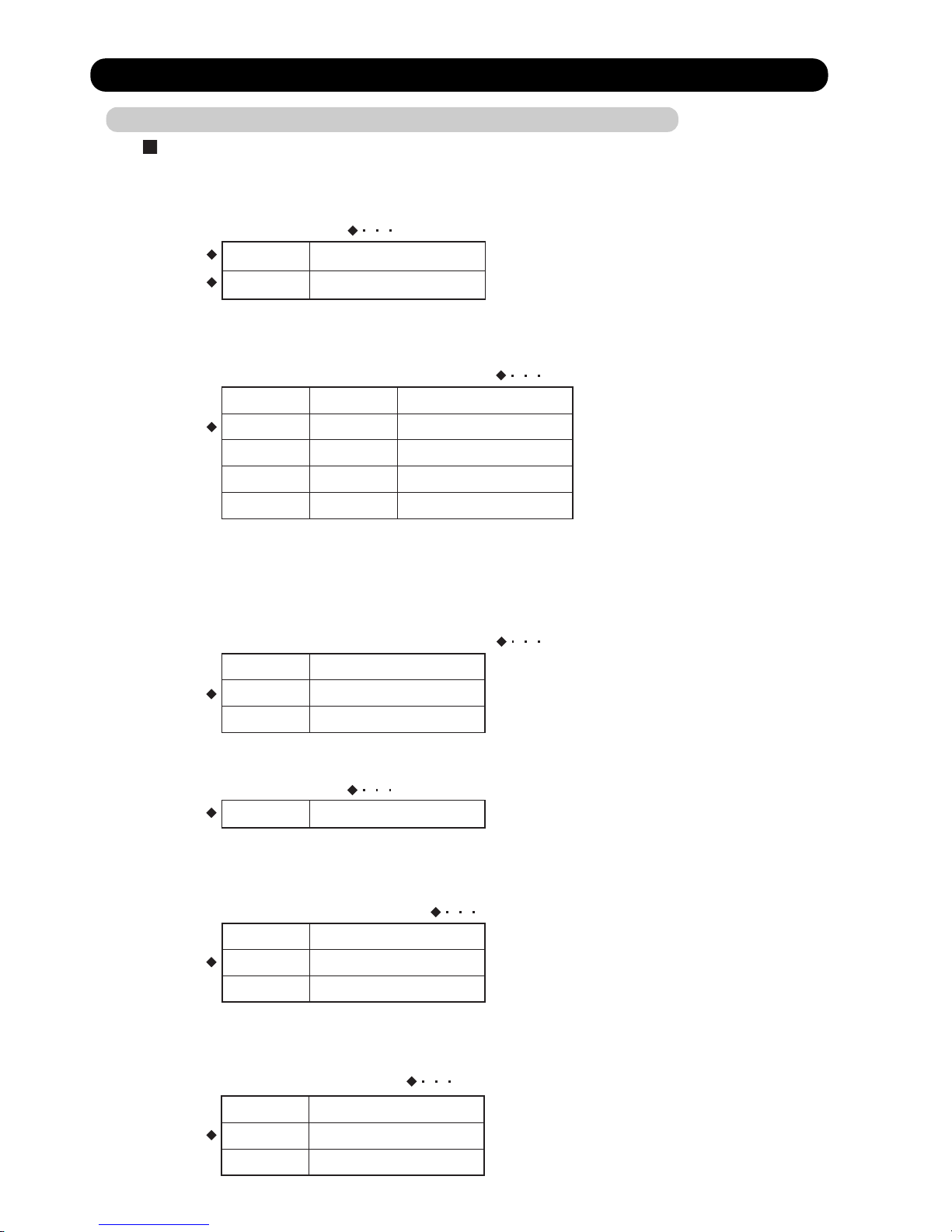

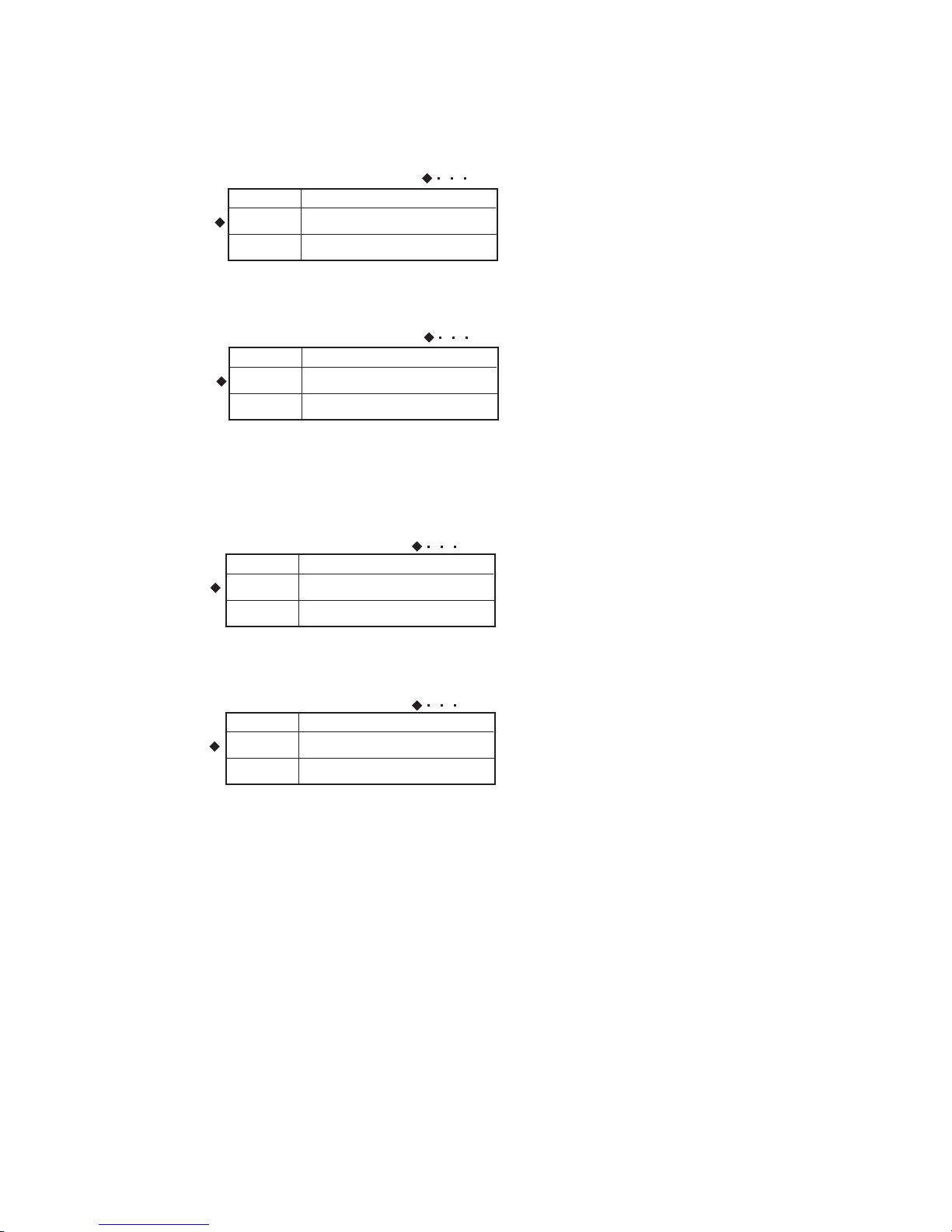

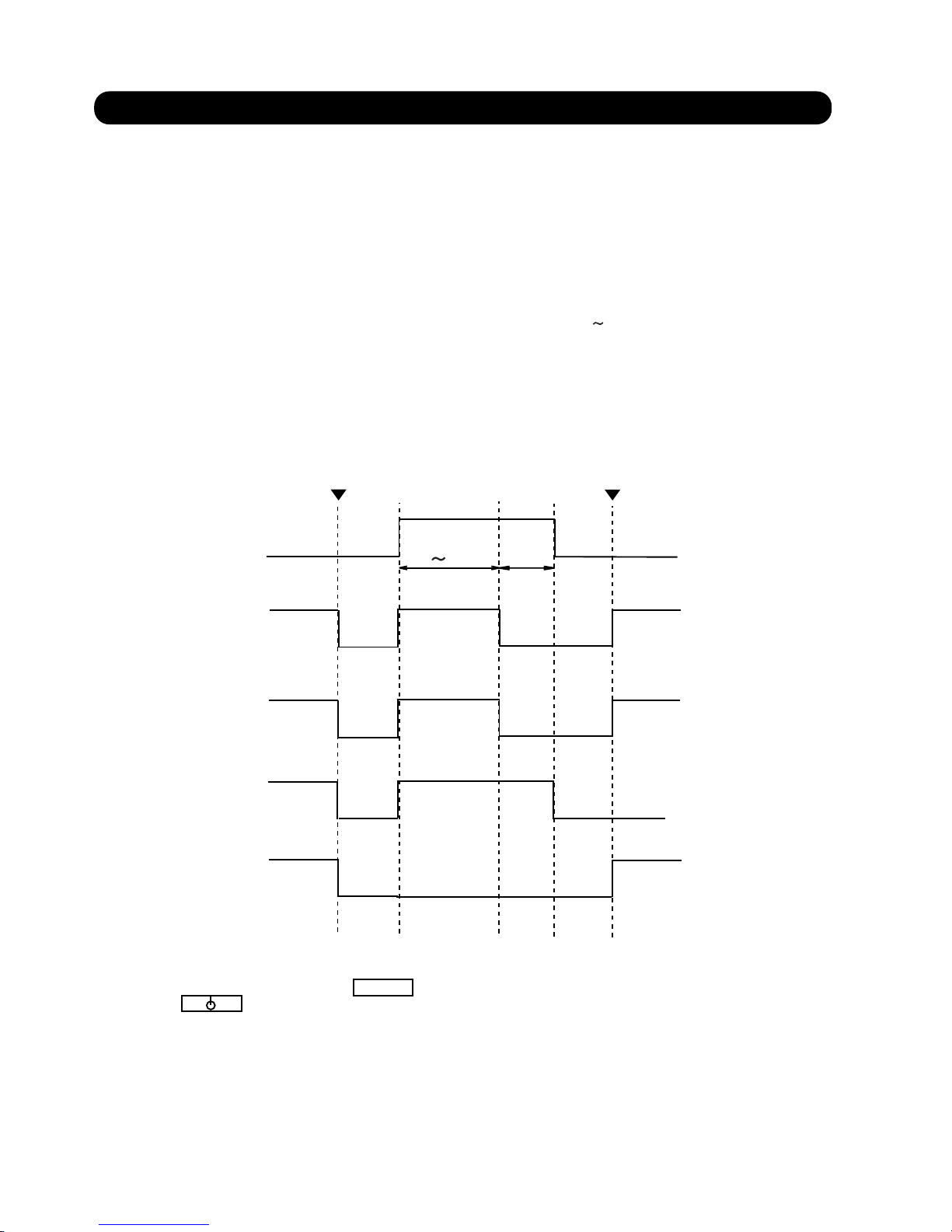

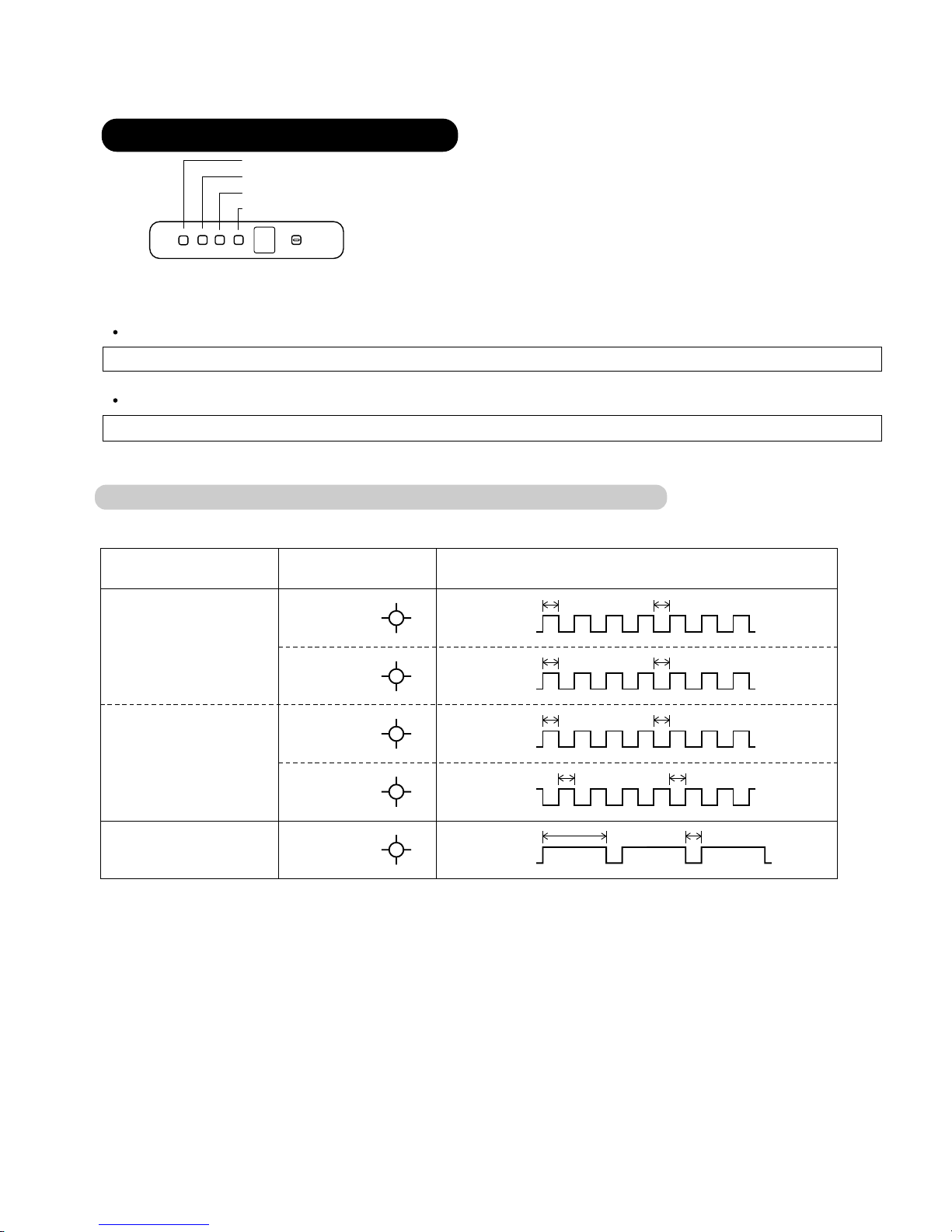

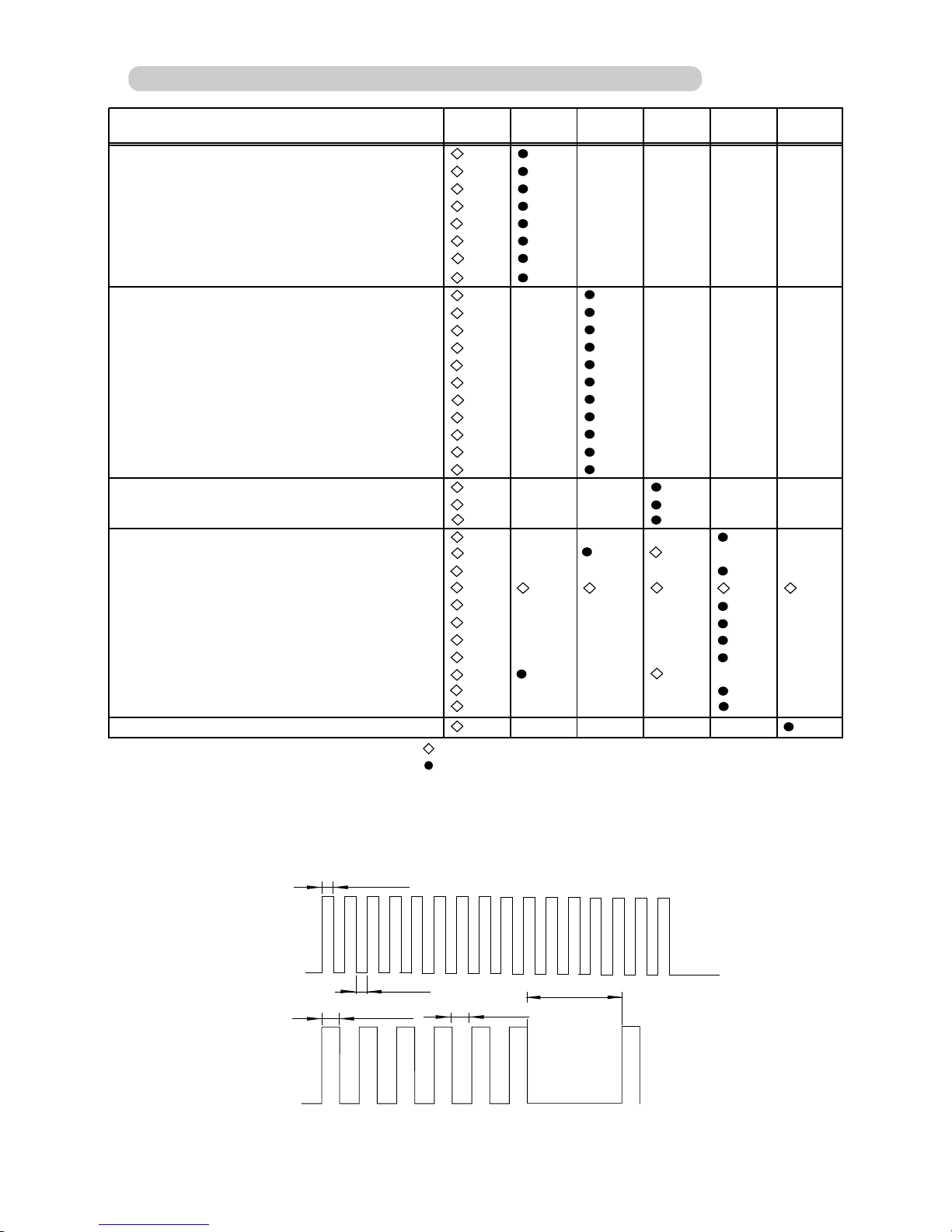

By setting DIP SW1-1 and SW1-2 on control PC board of outdoor unit, cooling test run or heating test run for all the indoor units

in the same refrigerant system can be performed.

1-3-1 TEST RUN FROM OUTDOOR PC BOARD

OFF [OFF,ON] or [ON,OFF]

SW1-2

Operation Mode

Select position of [SW1-2, SW1-1]

ON

ON

OFF

SW1-1

OFF

ON

ON

OFF

Normal Operation

Normal Operation

Heating Test Run

Cooling Test Run

[OFF,OFF]

[OFF,ON] or [ON,OFF]

[ON,ON]

[OFF,OFF]

[ON,OFF]

[OFF,OFF]

[OFF,ON]

01-03

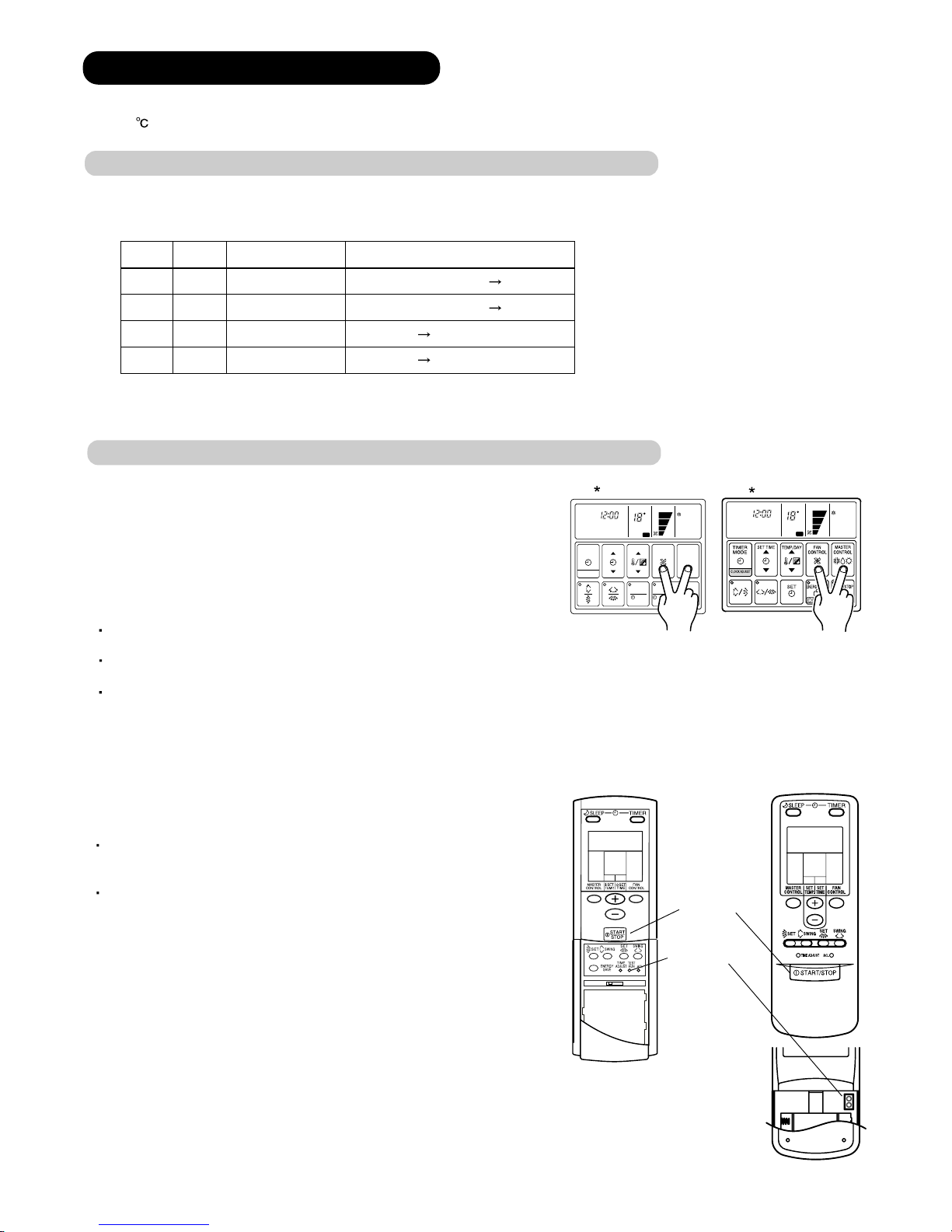

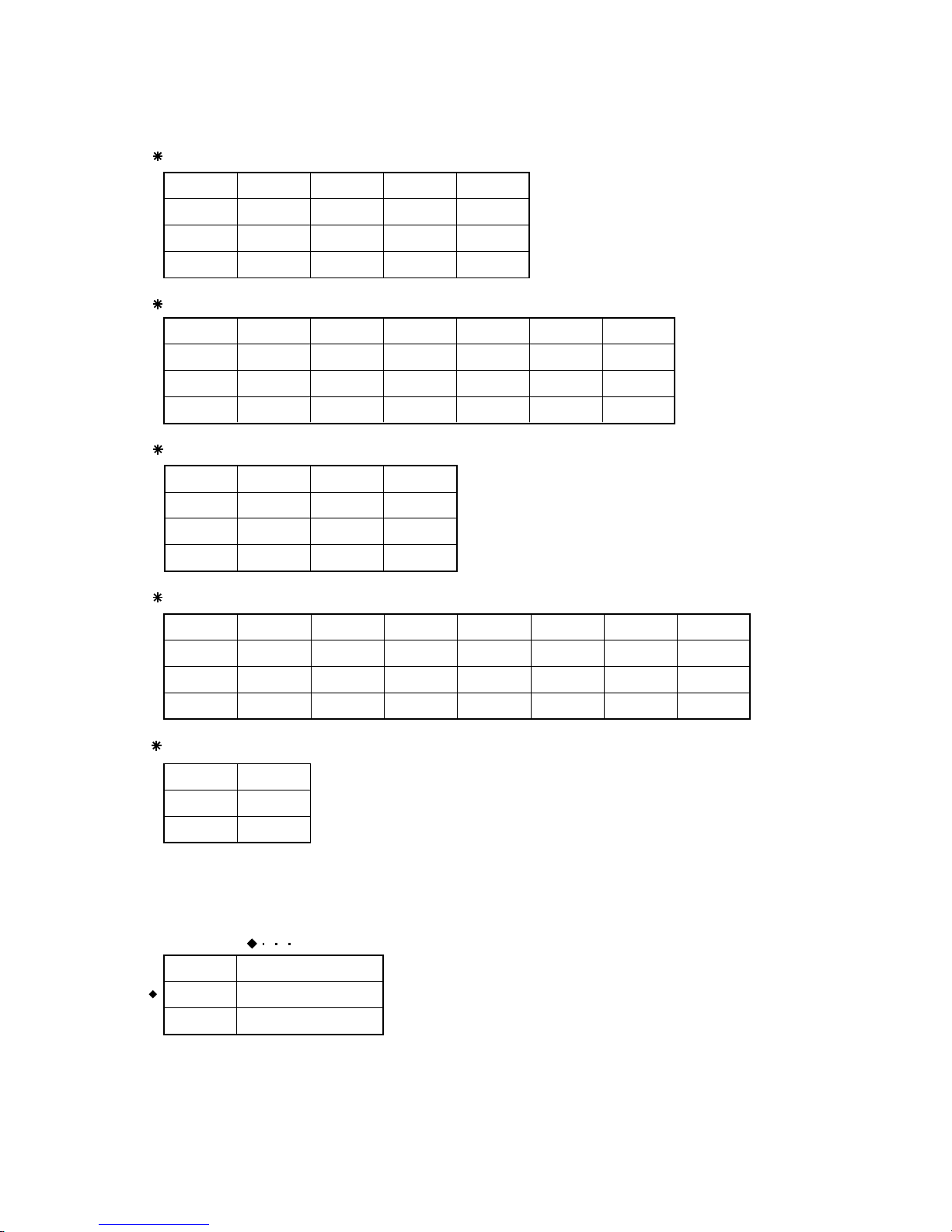

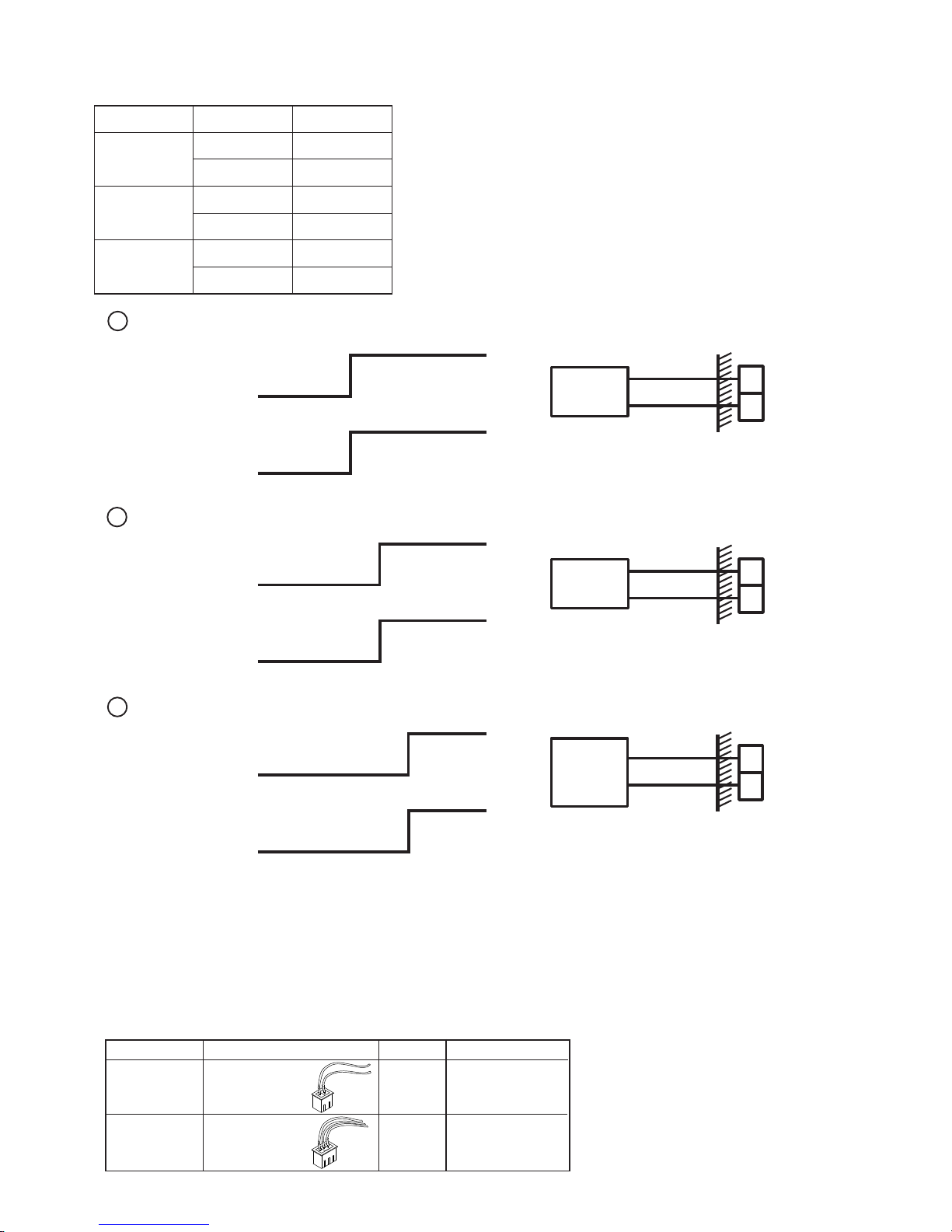

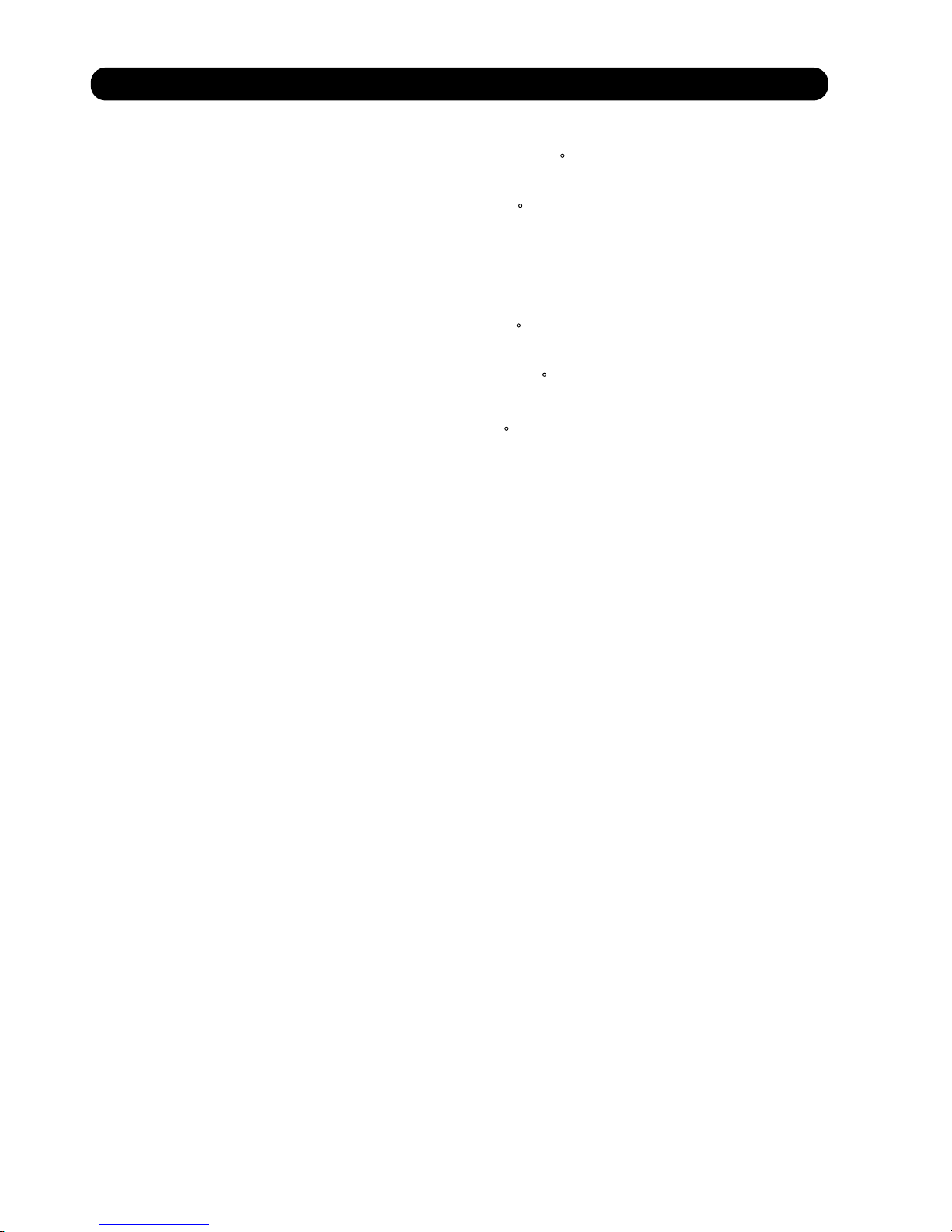

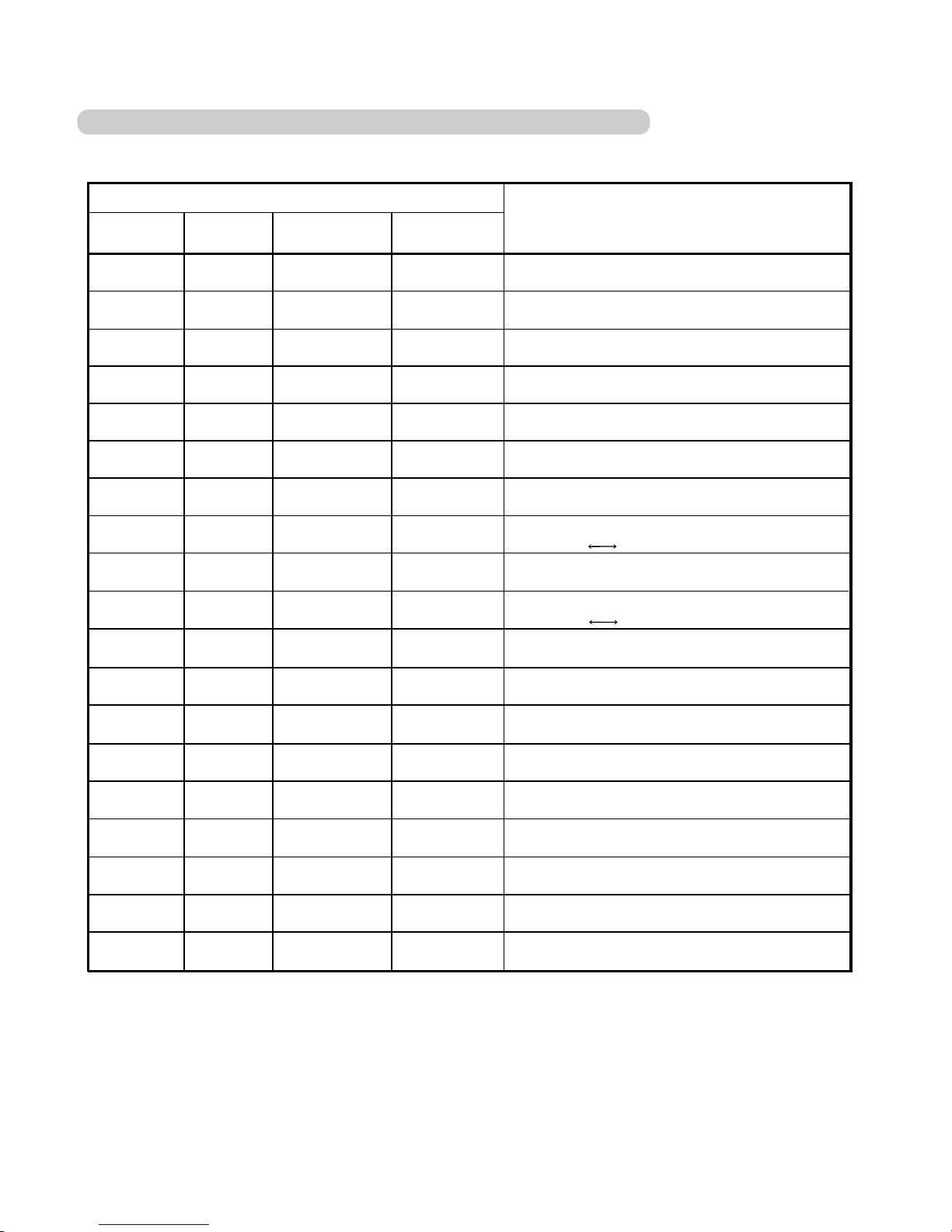

1) Standard wired remote controller

Stop the indoor and outdoor units. Push the FAN CONTROL button and

MASTER CONTROL button simultaneously for more than three seconds.

The air conditioner will start to conduct a test run and TEST will display on

the remote controller display.

However, the SET TEMP./DAY setting button does not have function,

but all other buttons, displays, and protection functions will operate.

1-3-2 TEST RUN FROM REMOTE CONTROLLER

To stop test run, push the START/STOP button of the standard wired remote

controller.

For the operation method, refer to the operating manual and perform operation

check.

Check that there are no abnormal sounds or vibration sounds during test run

operation.

2) Standard wireless remote controller

Press the test button of UTB - SA or short two pieces of metallic bodies

in the test run frame of UTB - VA, while the air conditioner is running.

To stop test run operation, push START/STOP button of the wireless

remote controller.

When the air conditioner is being test run, the OPERATION

and TIMER lamps of indoor unit flash slowly at the same time.

START/STOP button

TEST RUN button

A B C D

TEST

RUN

UTB - SA

UTB - VA

*

*

*

*

SET

MASTER

CONTROL

FAN

CONTROL

TIMER

MODE

TEMP./DAY

SET TIME

CLOCK ADJUST

OP

SET

D

ZONE

ENERG

COOL

CLOCK

C

NON STOP

TEST

COOL

CLOCK

C

NON STOP

TEST

UTB - LA

UTB - LB

Page 10

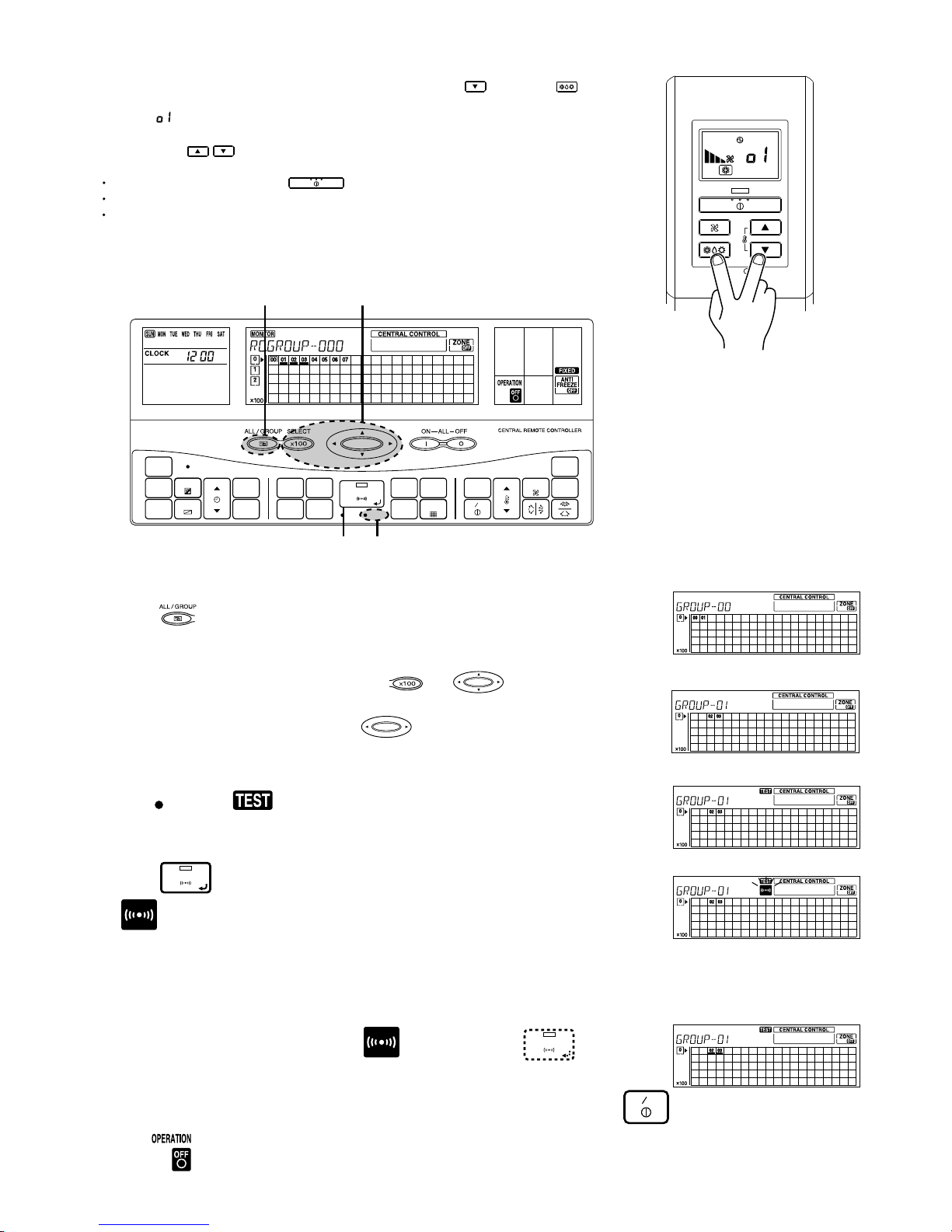

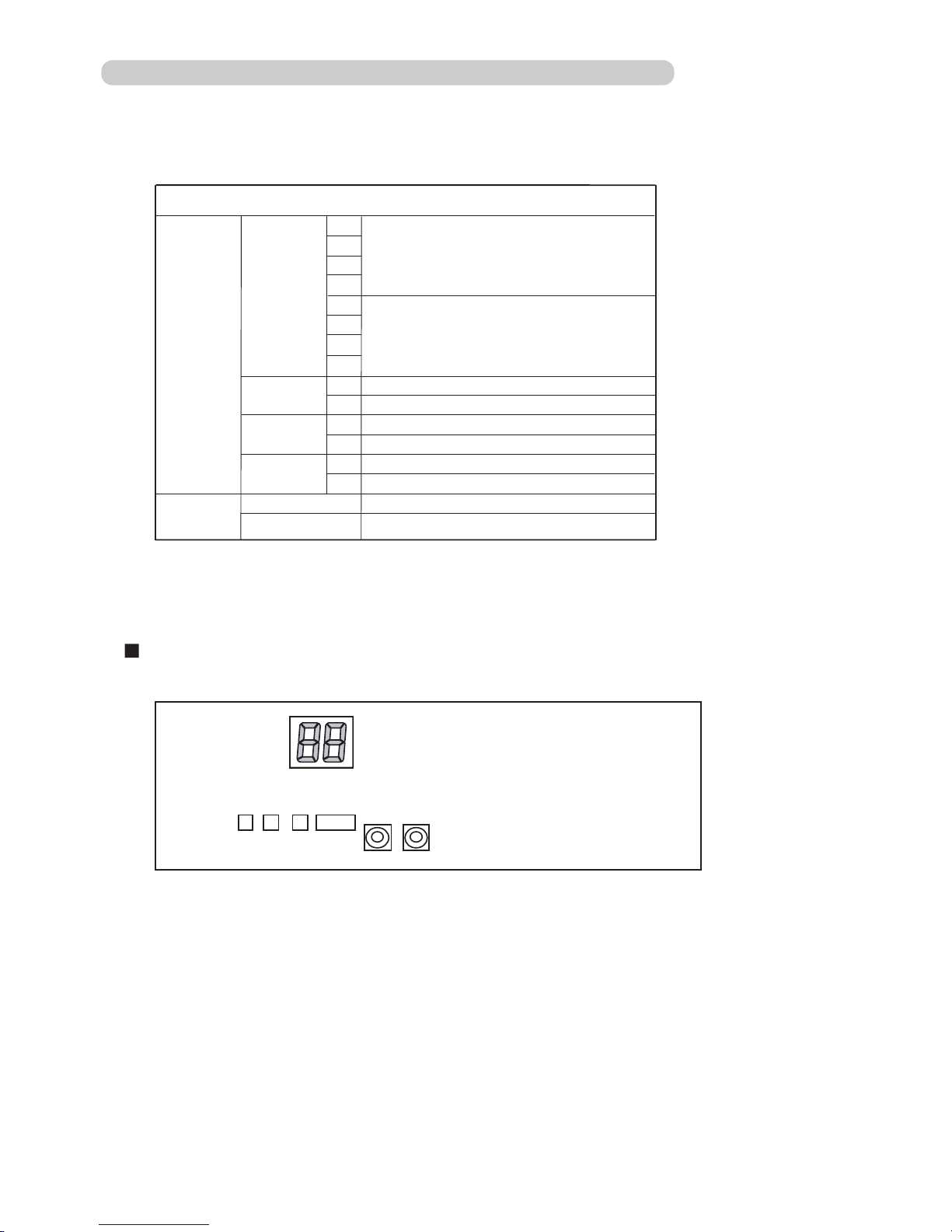

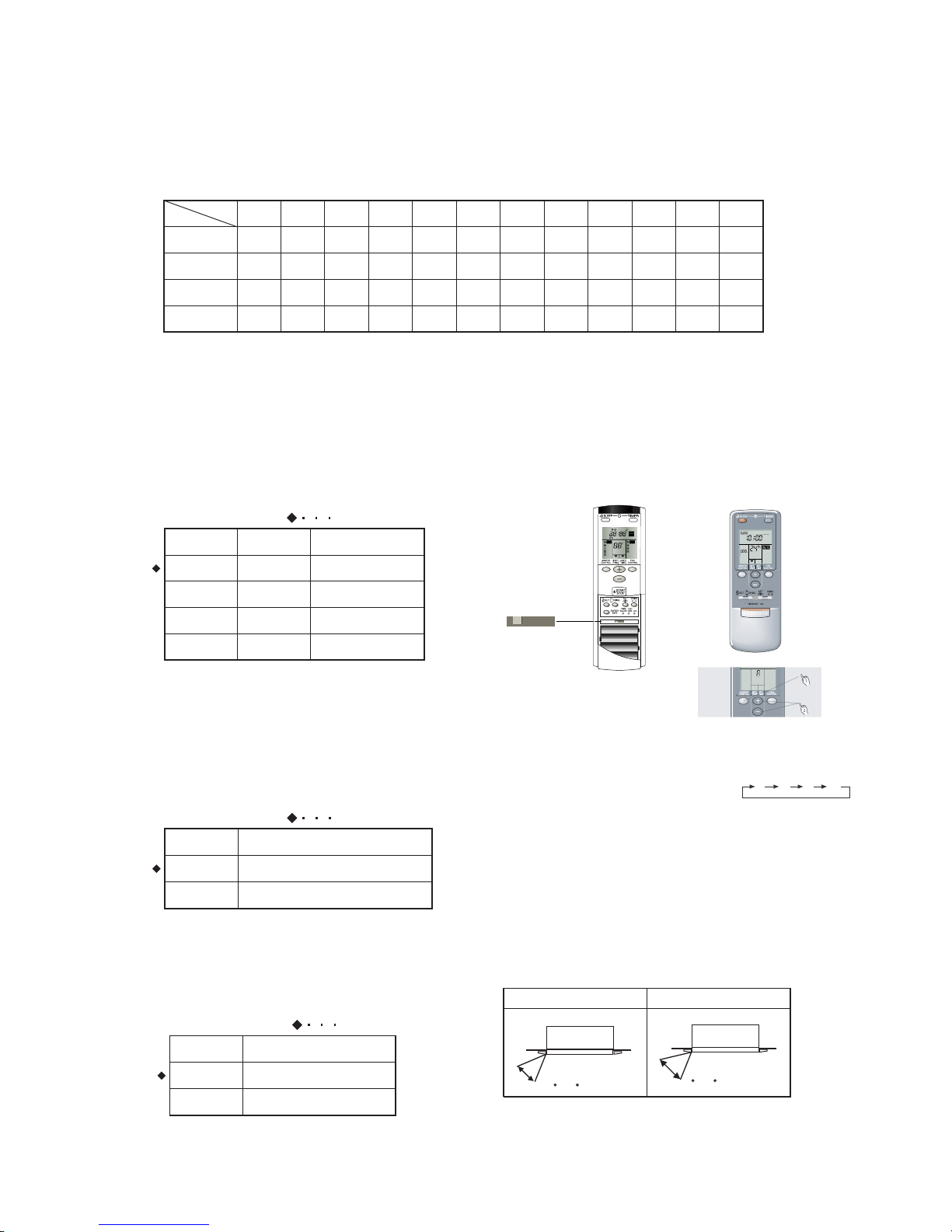

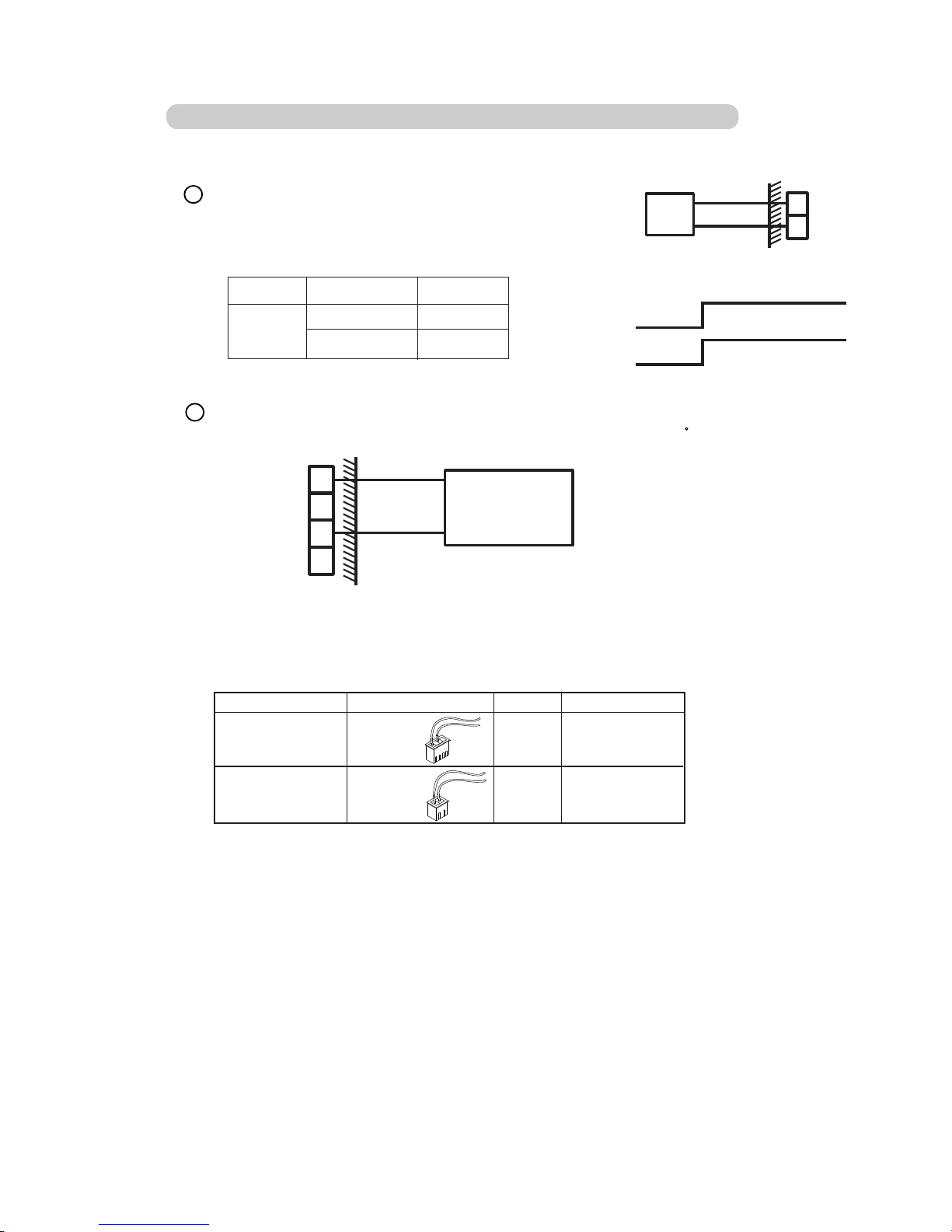

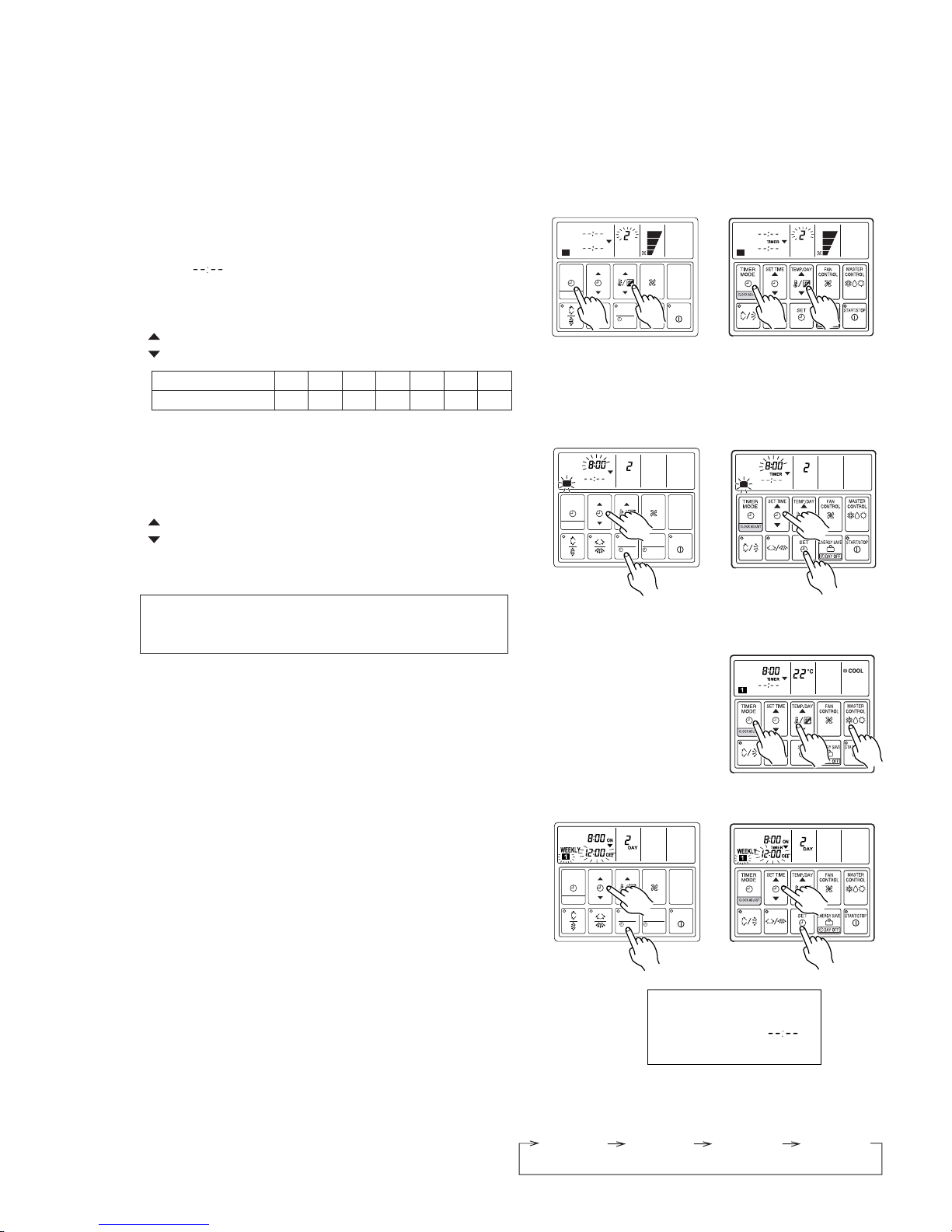

3) Simple remote controller

Stop the indoor and outdoor units. Push the remote controller

SET

button and

button

simultaneously for more than three seconds. The air conditioner will start to conduct a test

run and will display

on the temperature display.

display.

However the

setting button does not have function but all other buttons,

displays and protection functions will operate.

To stop test running press the button of the simple remote controller.

For the operation method refer to the operating manual and perform operation check.

Check that there are no abnormal sounds or vibration sounds during test run operation.

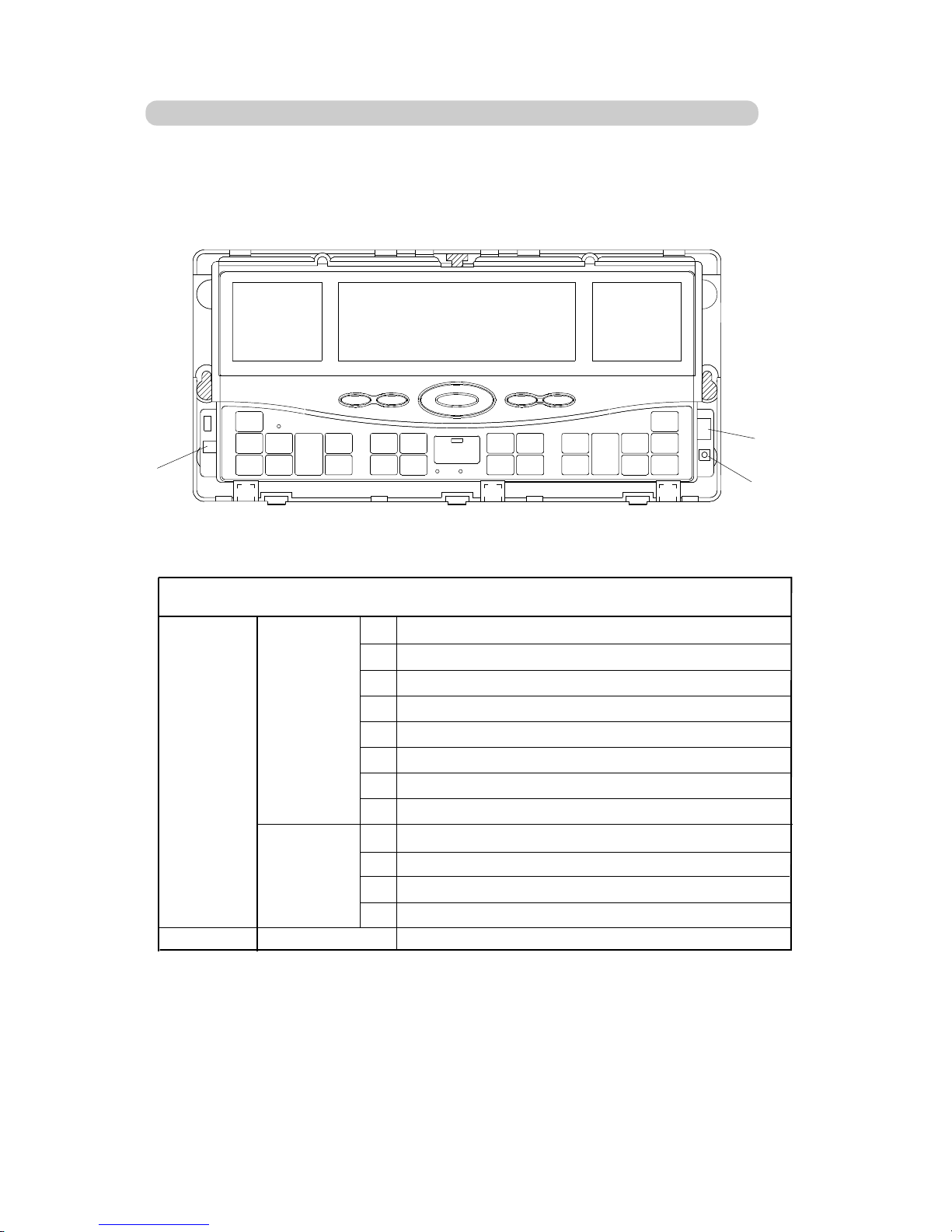

4) Central remote controller

CHECK

ACL

MASTER

ENERGY ANTI

FAN

TIMER

SET

TIMER

DELETE

TIMER

DAY

CLOCK

ADJUST

DAY OFF

TEMP.

MEMORY

OPERATION

MEMORY

TEST

SET

CENTRAL

DELETE

BACK

GROUP

ZONE

ON OFF

TIME

CONTROL

CONTROL

FILTER

RESET

CONTROL

FREEZE

COPY

TIMER

MODE

SAVE

SETTING SETTING

Remote control group operation settings are performed in the control mode. The following procedure for the setting is the same

for any of the control modes: Individual mode / Group control mode / All control grop.

Push to select control mode from among Individual control mode / Group

control mode / All control.

When Group control mode is selected use to select the desired group number,

then go to (3).

SET

60 minutes' test run starts.

To stop the test run, do the same procedure as those for stop a normal operatin.

It is possible to change the settings for the operation mode (heating / cooling) and fan setting.

Once the signal has been transmitted, the segment and LED

will go out. The indoor unit will start test run operation.

SET

If the test run is stopped midway, do the operation shown in (3) above and press ,

ON OFF

will come on, then do the operation shown in (4). Test run will stop.

When Individual control mode is selected, use and to select the desired central control number, then go to (3).

When All control mode is selected, go directly to (3).

Press TEST and will light up. The operation setting is applied to the selected

units.

Press to send the signal and test run setting is sent to the indoor unit.

will flash as the signal is being transmitted.

(1)

(2)

(3)(4)

(1)

(2)

(3)

(4)

(5)

SELECT

NOTE :

01-04

Page 11

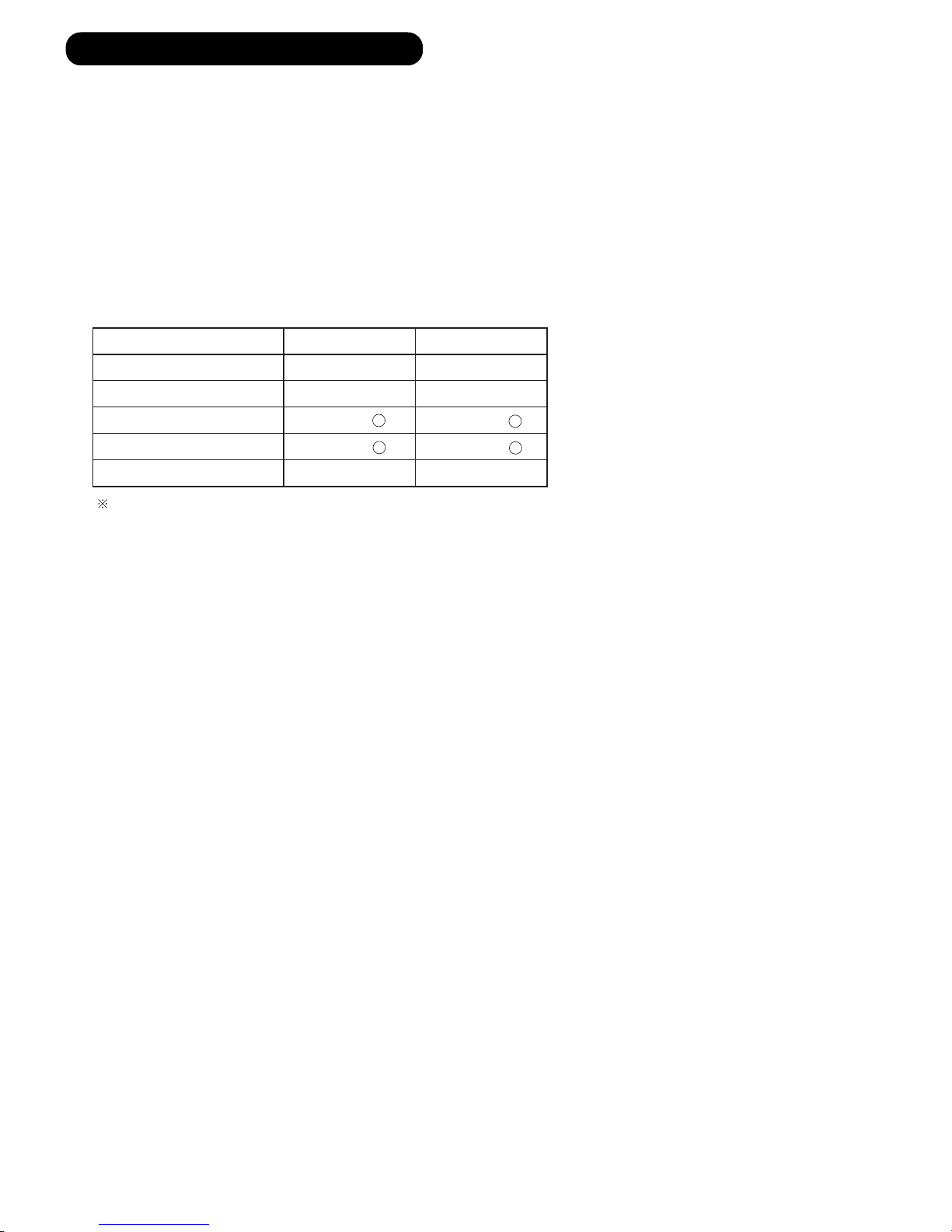

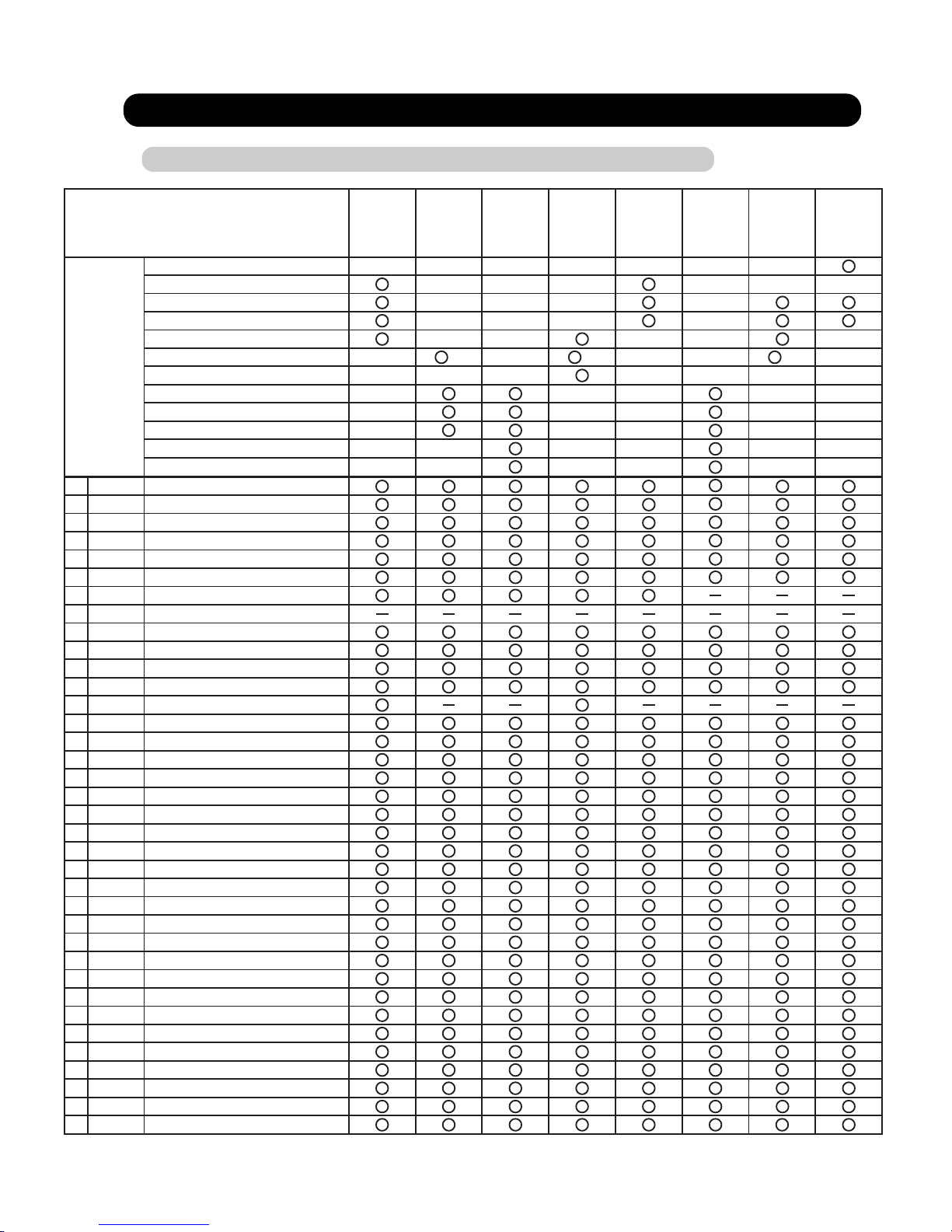

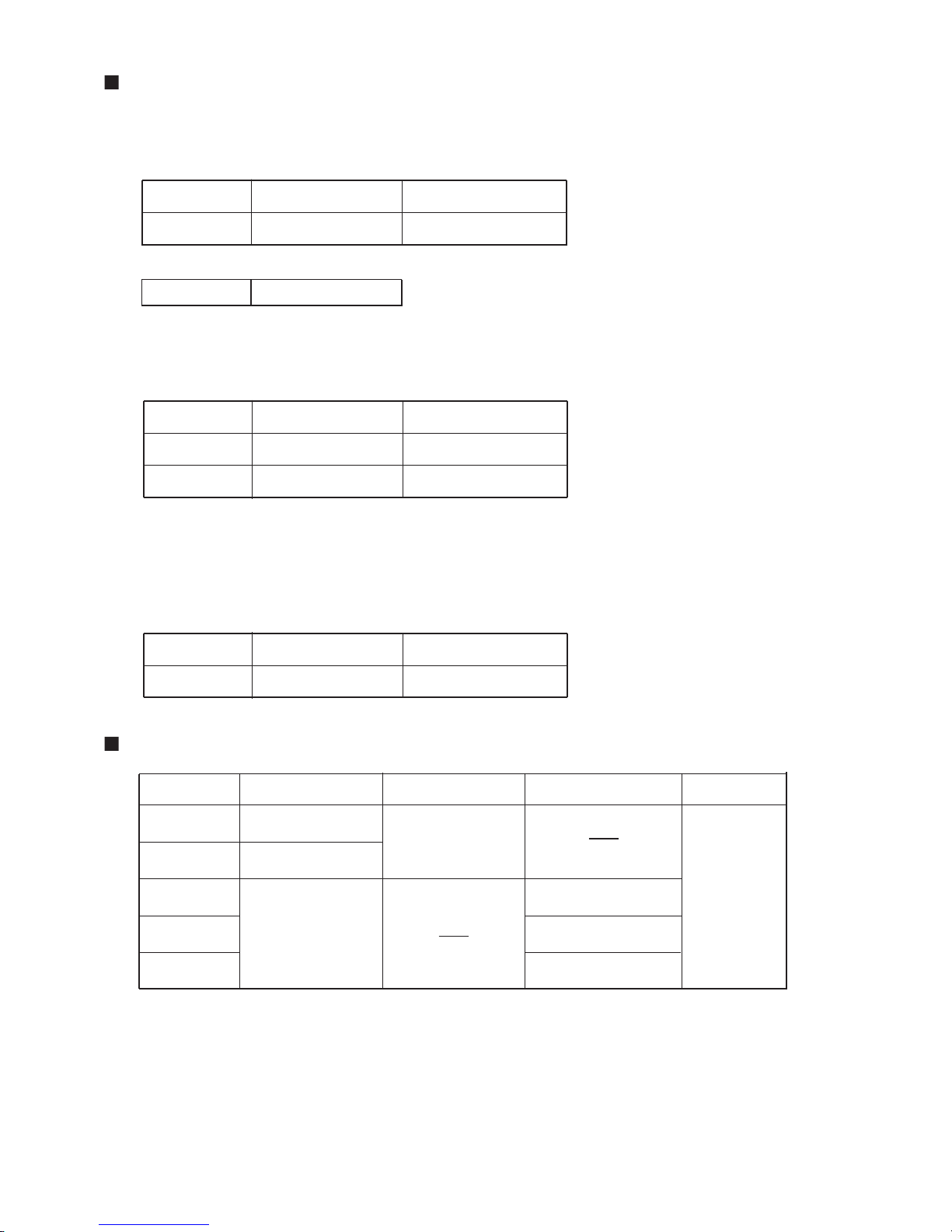

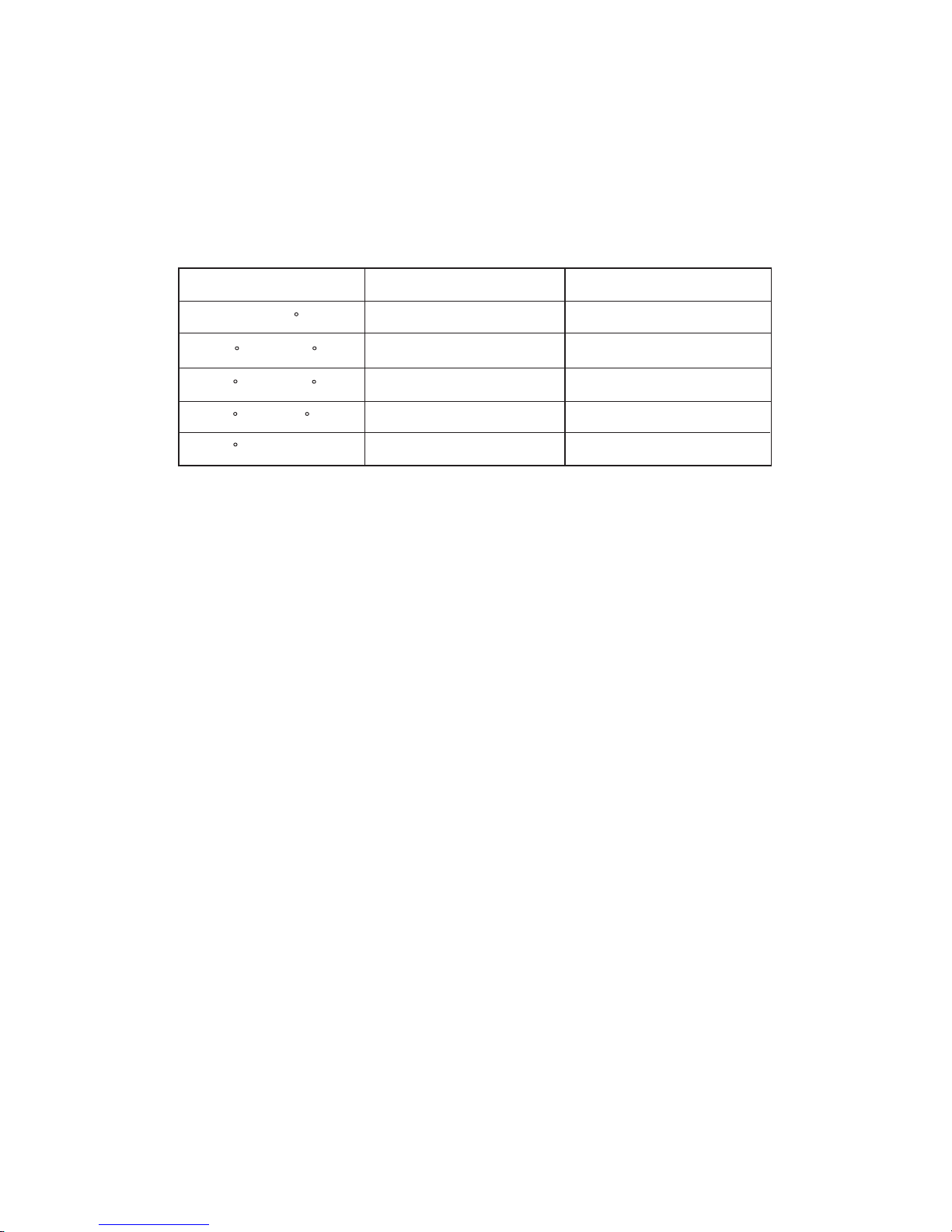

1) When the test run signal is transmitted from standard wired, wireless remote controller, simple remote controller

and central remote controller.

(1) The test runn operation starts and the electric expansion valve is controlled to a maximum flow, regardless of

the temperature condition.

(2) De-frosting and frost prevention operation has priority over item(1).

(3) After 60 minutes passes, the test run stops. However, the operation continues in same operating mode.

2) When the test run signal is transmitted from the outdoor unit.

(1) Whether state of the indoor unit operates or stops, All units in the same refrigerant system will start to conduct a

test run in accordance with the operation

mode set by DIP SW 1-1 and SW 1-2 of outdoor unit ( see 1 - 3 - 1 ).

(2) Test running initialization is shown below.

Fan speed Hi Hi

Room Temperature Indication 18 30

Vertical Air Direction Panel

Horizontal Air Direction Panel

Swing

Operating Mode Cooling Heating

OFF OFF

1-4 TEST RUN CONTROL

Position

1

Position

4

Position

3

Position

3

Please refer to '4-4 LOUVER CONTROL' in this manual and find the definition

for air direction panel position.

01-05

Page 12

2 . FUNCTION OF PRINTED CIRCUIT

BOARD

TM

R407C

Page 13

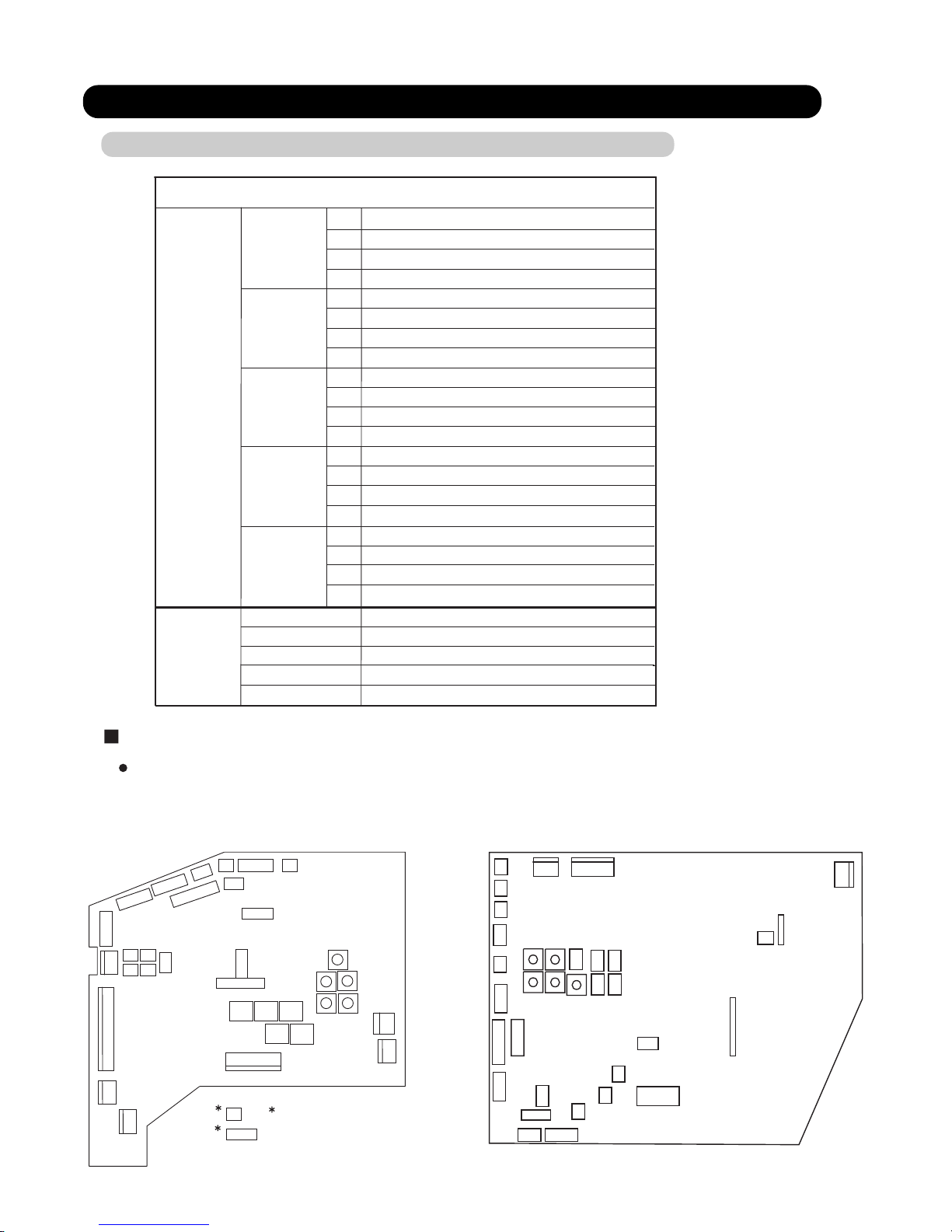

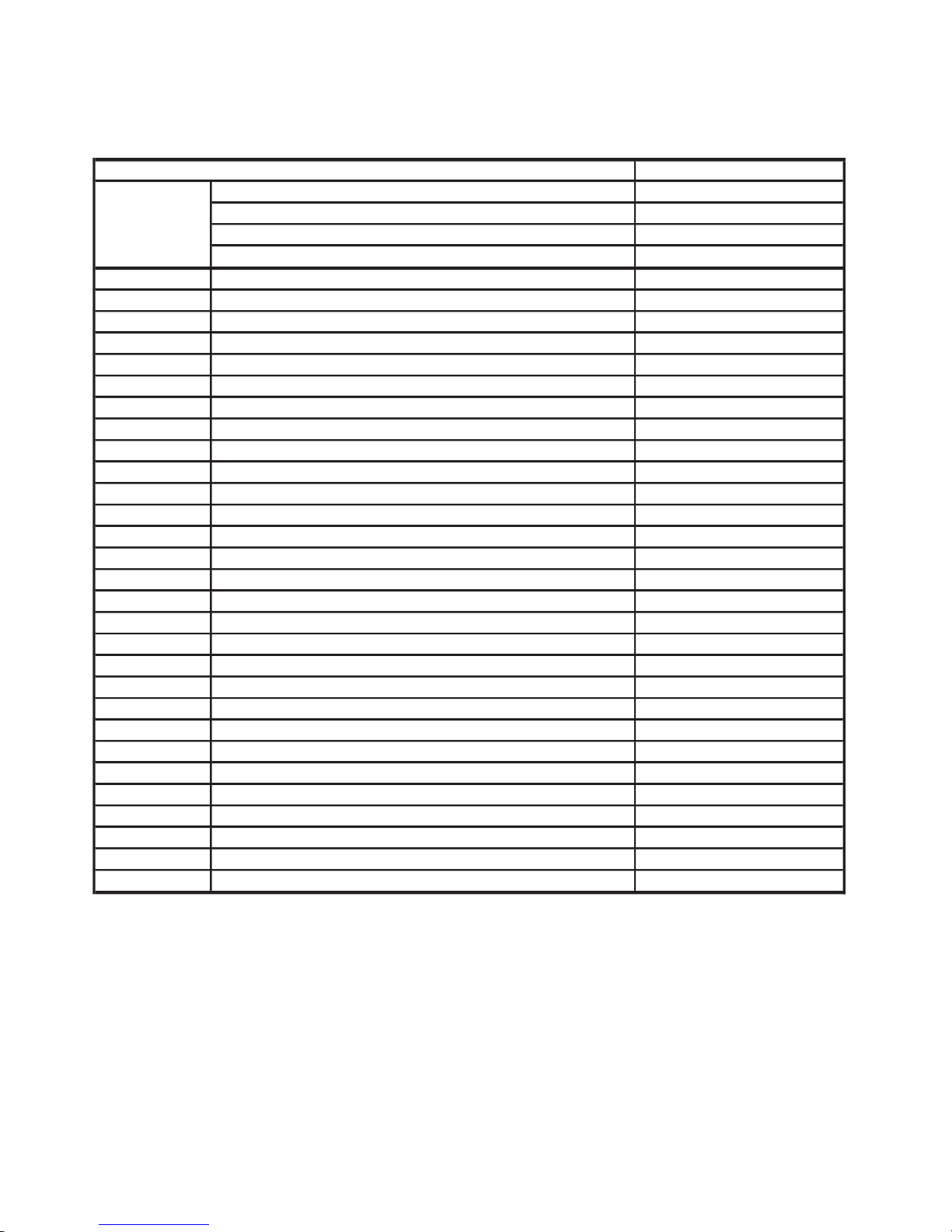

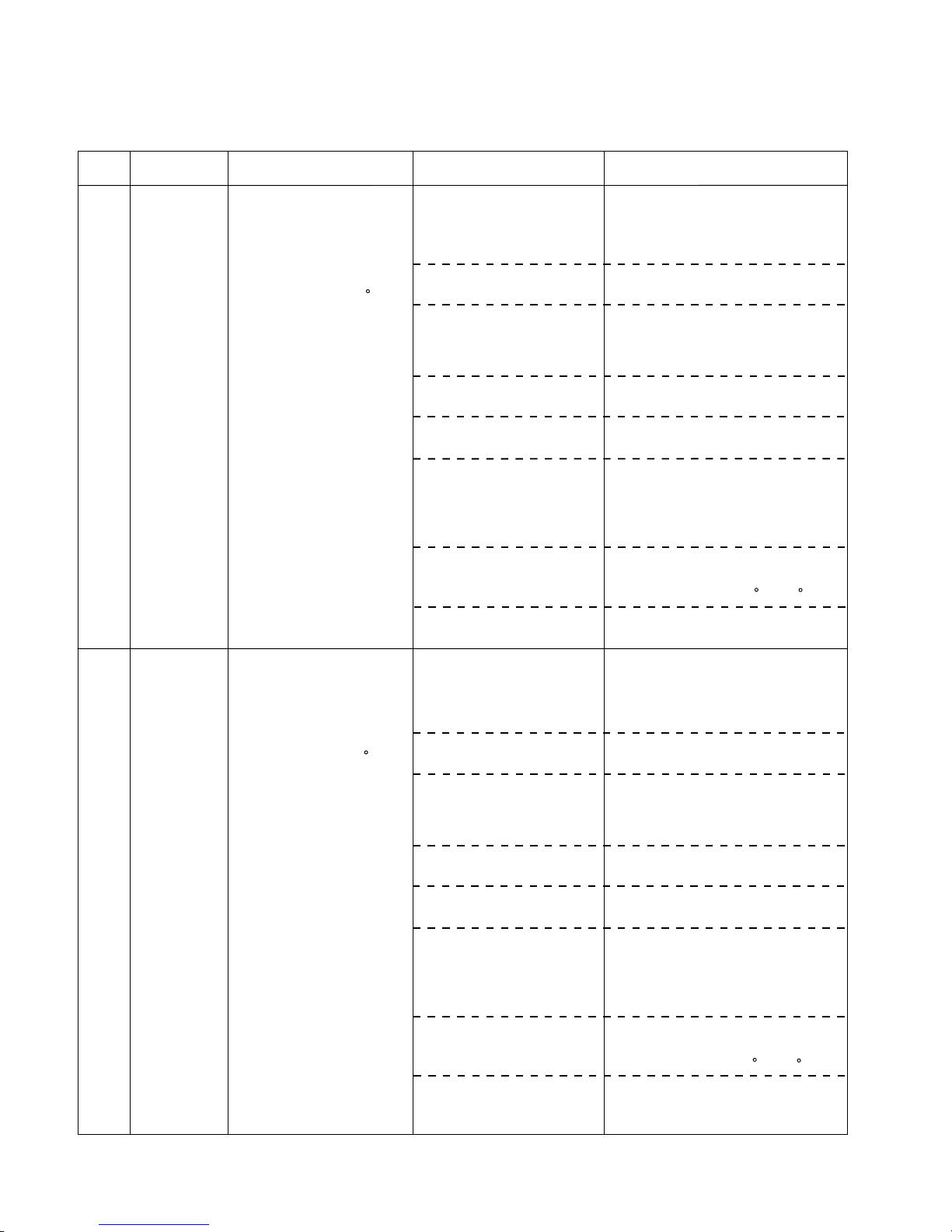

2-1 PCB LAYOUTS

2-1-1 INDOOR UNIT CONTROL CIRCUIT BOARD

2. FUNCTION OF PRINTED CIRCUIT BOARD

02-01

Indoor unit

SW 1

SW 2

DIP SW

SW 3

SW 4

Room temp correct coefficient of heating 1

Room temp correct coefficient of heating 2

Room temp correct coefficient of cooling

Forbidden(Indoor unit fan speed switch 1)

Forbidden(Indoor unit fan speed switch 2)

Forbidden(Indoor unit fan speed switch 3)

Extermal input select edge / pulse

Forbidden(Indoor unit model code)

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Filter check validity / invalidity

Forbidden(Indoor unit model code)

Forbidden(Indoor unit model code)

Forbidden(Indoor unit model code)

SW 6

SW 7

SW 8

SW 9

SW 10

Indoor unit address switch

Forbidden

Rotary SW

Forbidden

Forbidden

Forbidden

Auto restart validity / invalidity

Refrigeration circuit address 1

Refrigeration circuit address 2

Remote controller address

Indoor unit control circuit board

SWITCH POSITION

Wireless remote controller custom code switch 1

1

2

3

4

Wireless remote controller custom code switch 2

Frost prevention temperature shift switch

Draft prevention setting switch

SW 5

CN27

CN18

CN19 CN20 CN21

CN22 CN23

CN24

CN25

CN26

CN11

CN12

CN13

CN14

CN1

CN2

CN4

CN5

CN10

CN6

CN3

CN17

CN16

CN15

SW1

SW2

SW3 SW4

SW5

SW7

SW9

SW6

SW8

SW10

CN201

CN101

CN23

CN1

CN9

CN16

CN7

CN4

CN13

CN11

CN6

CN5

CN19

CN12

CN8

CN22

CN24

CN21

CN20

CN17

CN18

CN14

CN3

CN25

CN15

CN26

SW1

SW2

SW3

SW4

SW5

SW7

SW9

SW6

SW8

SW10

For AB / AU / AR types indoor unit

For AS / AW types indoor unit

CN101 and CN201 exist

in the PCB of power supply.

Page 14

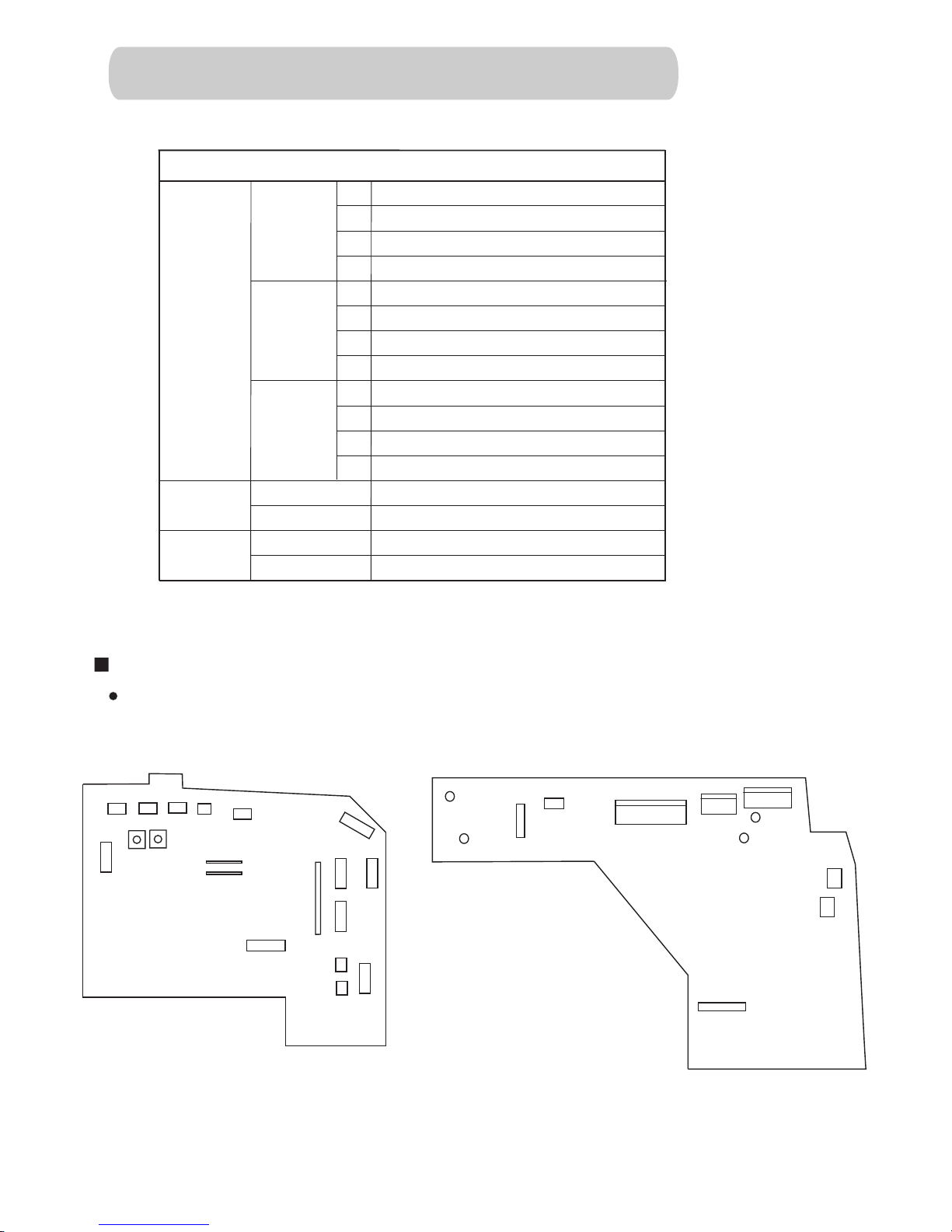

SWITCH POSITION

Compact wall mounted type indoor unit control circuit board

CN7

CN4

CN101

CN6

CN9

CN1

CN108

CN12

CN2

CN107

CN8

CN10

CN3

CN11

SW4

W101

SW5

SW1 SW2

SW3

JM1

JM2

CN104

CN105

CN102

CN103

CN106

W102

W103

W104

Controller PCB

Power supply PCB

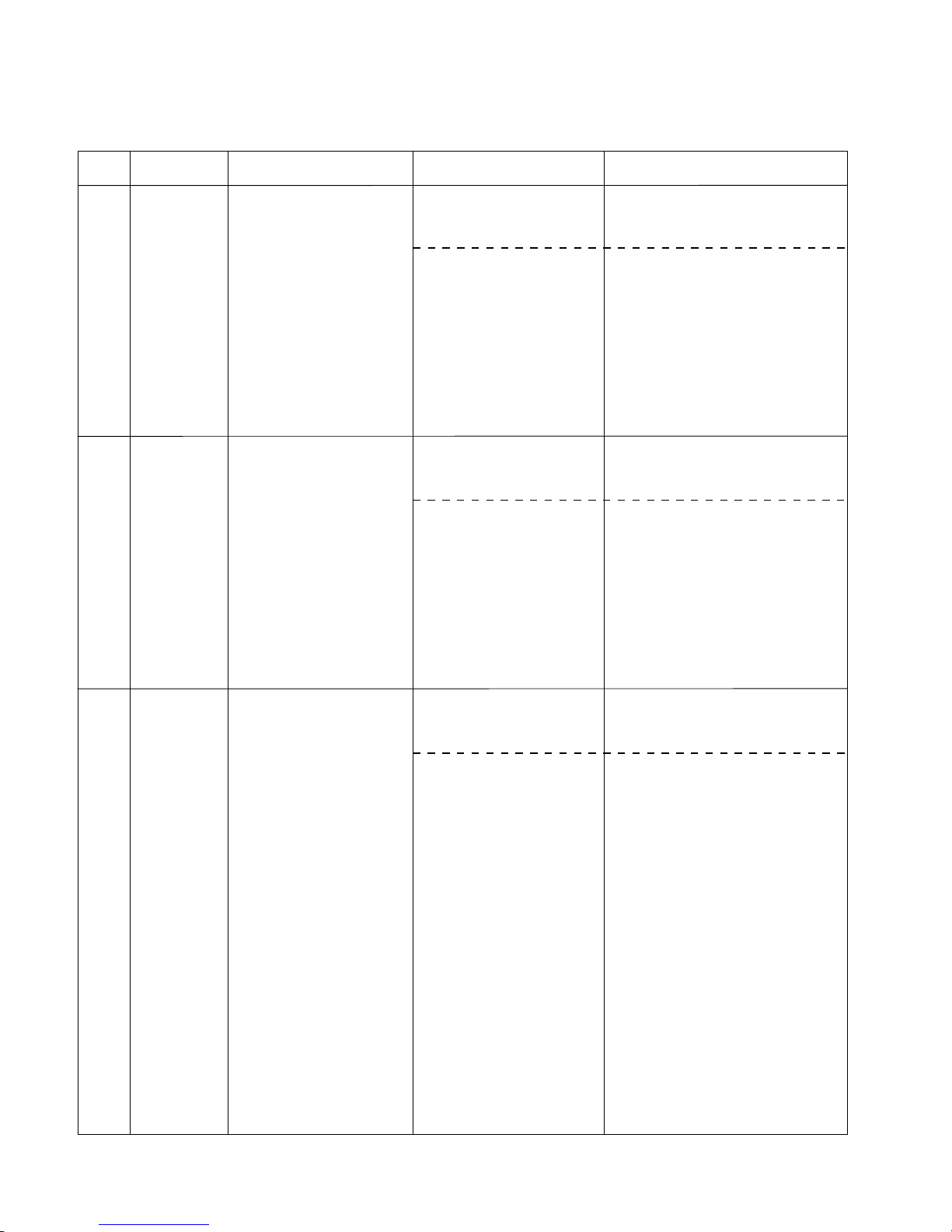

2-1-2 INDOOR UNIT CONTROL CIRCUIT BOARD

(COMPACT WALL MOUNTED TYPE)

Indoor unit

SW 1

SW 2

DIP SW

SW 3

SW 4

Forbidden(Indoor unit fan speed switch 1)

Forbidden(Indoor unit fan speed switch 2)

Forbidden(Indoor unit model code)

1

2

3

4

1

2

3

4

1

2

3

4

Forbidden(Indoor unit model code)

Wireless remote controller custom code

Indoor unit address switch

Forbidden

Rotary SW

Forbidden

Auto restart validity / invalidity

Refrigerant circuit address switch

Refrigerant circuit address switch

SW 5

Indoor unit address switch

Refrigerant circuit address switch

Indoor unit address switch

Refrigerant circuit address switch

JM 1

JM 2

Jumper

wire

Wireless remote controller custom code

02-02

Page 15

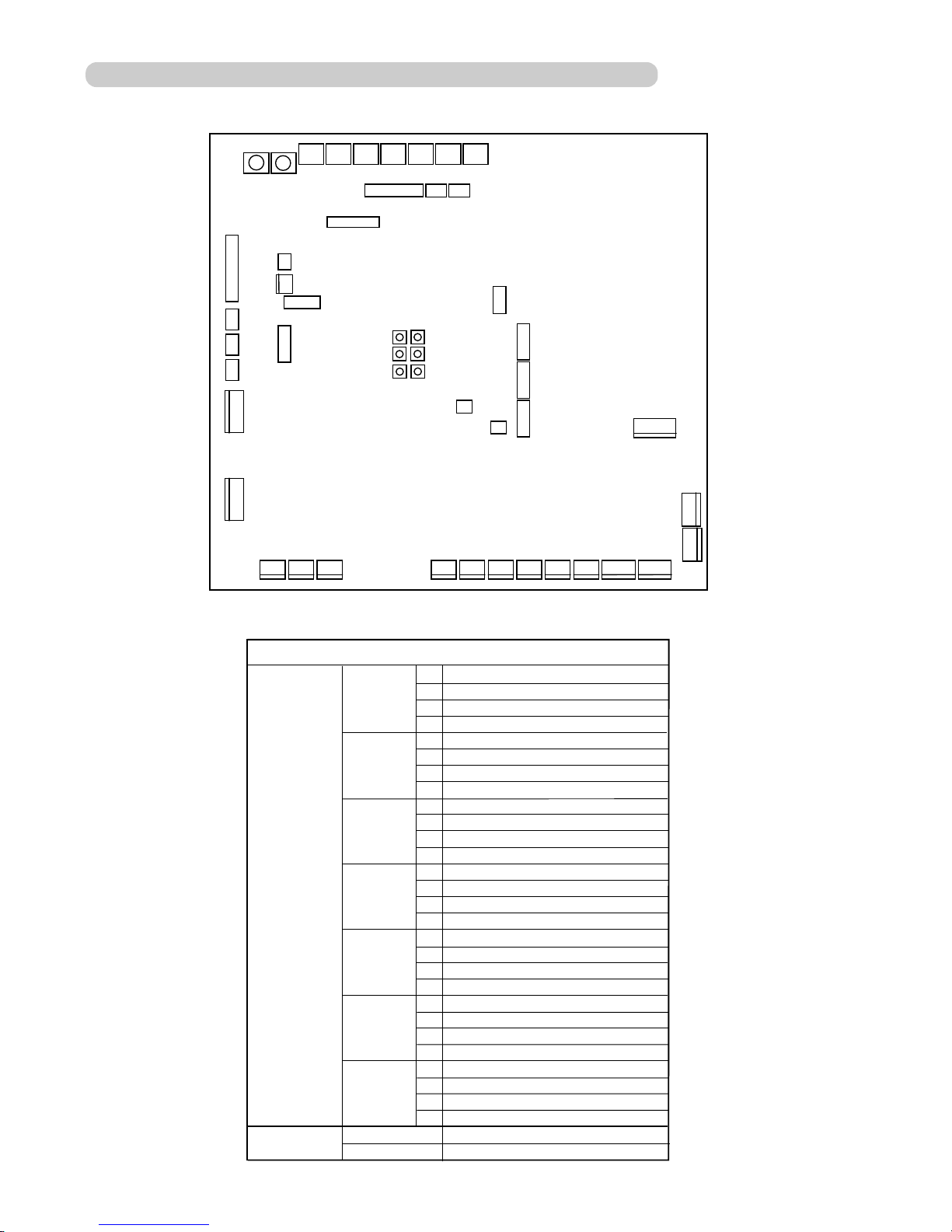

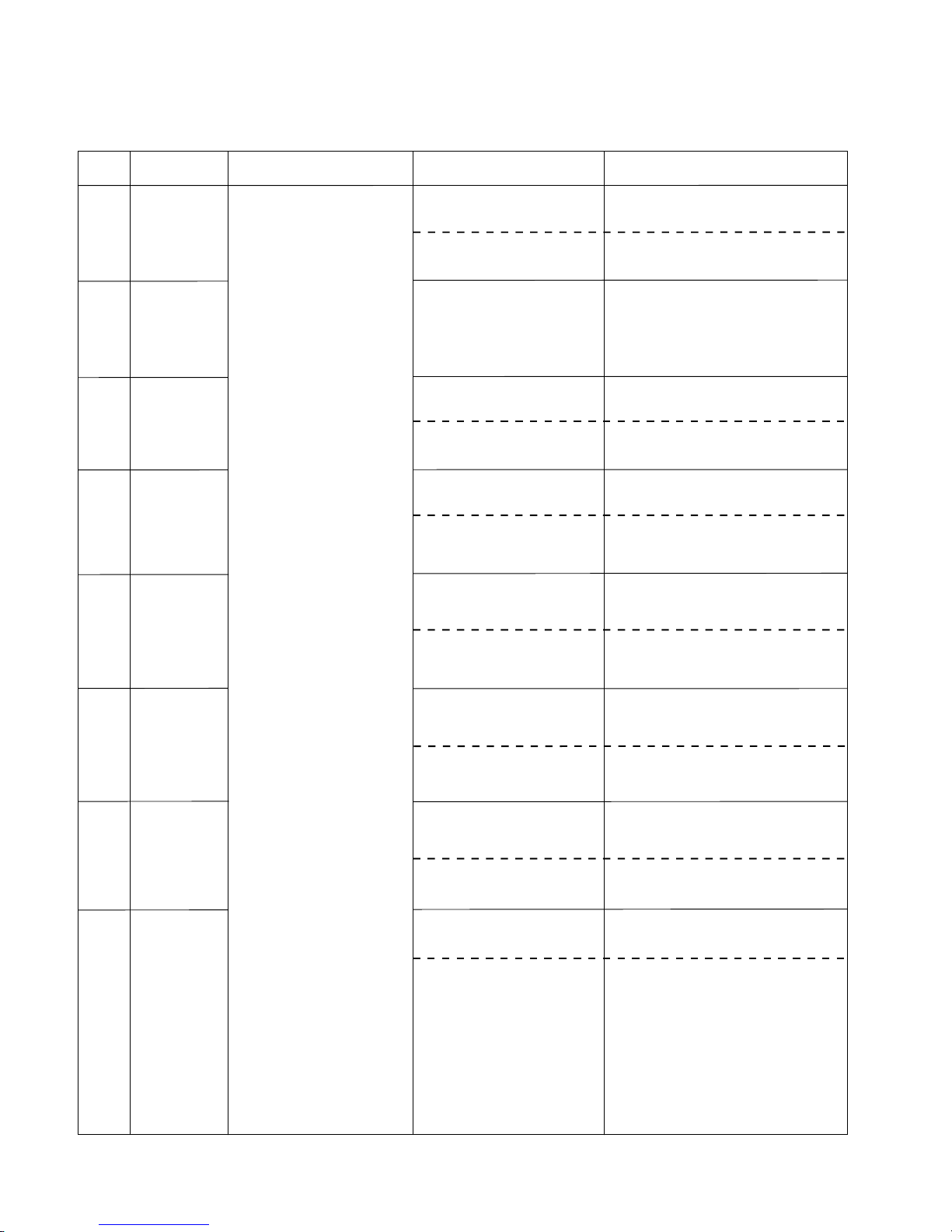

2-1-3 OUTDOOR UNIT CONTROL CIRCUIT BOARD

02-03

SW9 SW8

SW6SW7 SW5 SW4SW3 SW2 SW1

CN27 CN34

CN33

CN45

CN24

CN25

CN26

CN4

CN3

CN28

CN44

CN22

CN2

CN35

CN29

CN30

CN31

CN1

CN42

CN48

CN20

CN19

CN18 CN14

CN13 CN11 CN9 CN7

CN12 CN10 CN8

CN6

CN5

CN51

LED1

LED2

LED3

LED4

LED5

LED6

Outdoor unit

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

SW 7

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Forced oil recovery operation

Forbidden

Silent operation mode

Snow falling protection fan mode

EEV initialization

System type switch 1

System type switch 2

Forbidden

SW 8

SW 9

Base heater validity / invalidity

Forbidden

Forbidden

Forbidden

Defrost temperature setting SW1

Defrost temperature setting SW2

Forbidden

Forbidden

Forbidden

Forbidden

Forbidden

Forbidden

Forbidden

Forbidden

Forbidden

DIP SW

ROTARY SW

Test run(Heating)

Test run(Cooling)

Pump down operation

Forced defrost operation

Refrigerant circuit address switch 1

Refrigerant circuit address switch 2

Forbidden

Page 16

1

2

3

4

5

6

1

2

3

4

5

6

DIP SW1

DIP SW2

O

N

O

N

Wired & Simple remote controller

SW 1

SW 2

DIP SW

Remote controller switch 1(Terminator)

Indoor unit connection (One / multiple)

Forbidden

Remote controller switch 2(Master / Slave)

Forbidden

Back ground light validity / invalidity

Maintenance switch

Forbidden

Battery backup switch

1

2

3

4

5

6

1

2

3

4

5

6

Forbidden

Cooling / Heat pump

Auto change over validity / invalidity

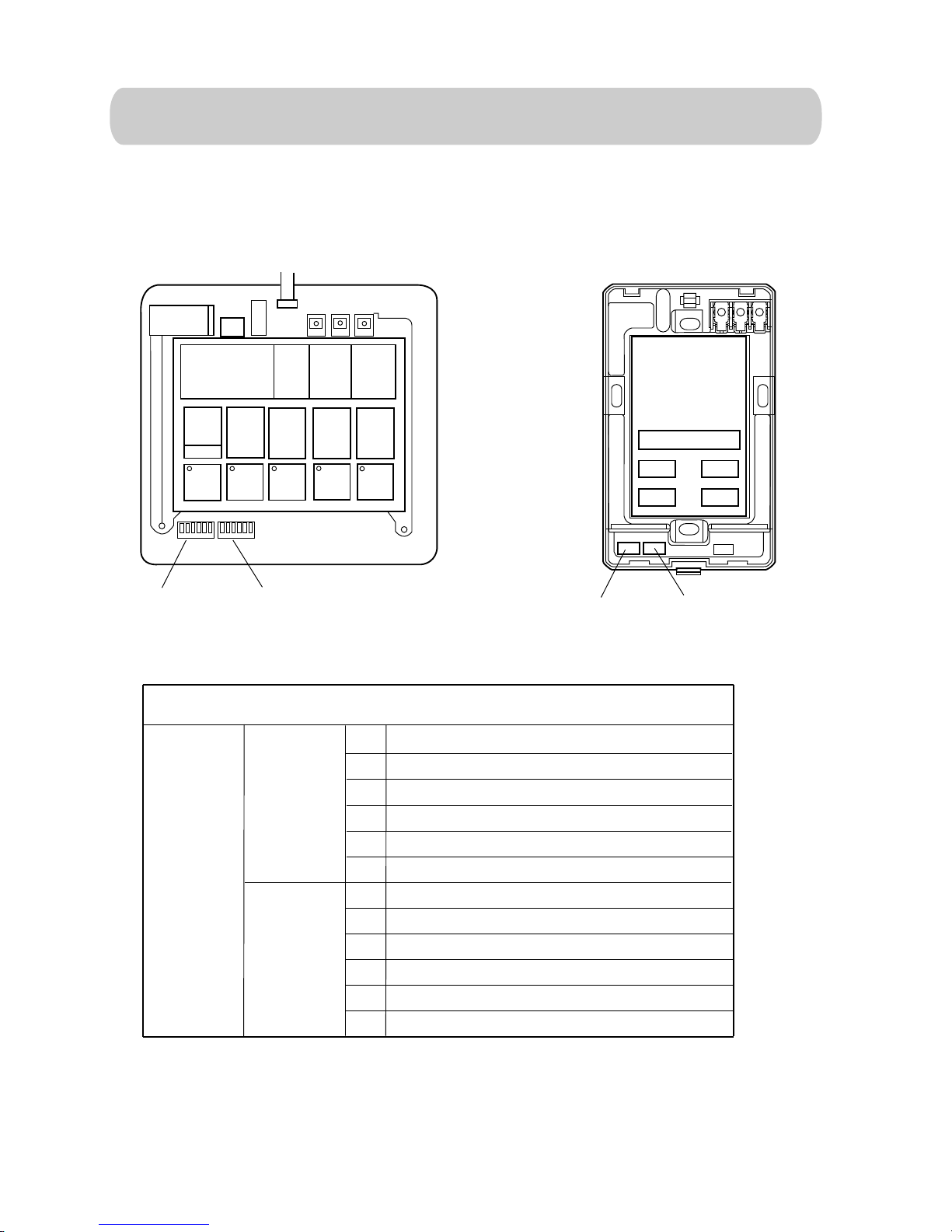

2-1-4 WIRED REMOTE CONTROLLER,SIMPLE REMOTE CONTROLLER

CIRCUIT BOARD

*

Simple remote

controller only

*

Wired remote

controller only

Wired remote controller

Simple remote controller

DIP SW1 DIP SW2

02-04

Page 17

DIP SW3

DIP SW2

SWITCH 42

Central remote controller

SW 2

SW 3

1

2

3

4

5

6

7

8

1

2

3

4

Filter sign indication ON / OFF

C / F switch

RC operation prohibit function validity/invalidity

Forbidden

Forbidden

SRAM battery ON / OFF

Forbidden

Forbidden

Forbidden

Forbidden

Initial setting

External input validity / invalidity

External input select edge / pulse

SW 42

DIP-SW

o

o

2-1-5 CENTRAL REMOTE CONTROLLER CIRCUIT BOARD

02-05

Page 18

2-1-6 NETWORK CONVERTORS' CIRCUIT BOARD

02-06

Network Convertor (UTR-YSSA)

SW 103

DIP SW

SW 107

SW 109

Forbidden

Wired remote controller validity / invalidity

External input validity / invalidity

External input select edge / pulse

Auto changeover validity / invalidity

1

2

3

4

1

2

5

6

7

8

1

2

1

2

Auto restart validity / invalidity

Refrigerant circuit address 1

SWITCH POSITION

(1) NETWORK CONVERTOR (UTR-YSSA)

Remote controller type

Number of connected indoor units

SW 108

* Set to OFF for duct type indoor unit

SW 110

SW 111

ROTARY

SW

Refrigerant circuit address 2

SW111

SW109

SW103

SW107

SW110

SW108

D129

Page 19

02-07

(Switch)

SWITCH AND LED POSITION

(2) NETWORK CONVERTOR (UTR-YLLA)

Switch No.

SW1

SW2

SW3

SW4

SW5

SW6

SW7

Push switch

Push switch

Push switch

Push switch

Rotaly switch (0-15)

Rotaly switch (0-15)

Push switch

CPU Reset

Selection of setting mode

Contents

(LED)

LED No.

D9

D14

D25-D18

D29-D26

Contents

Type

Service Pin SW (VRF side)

Service Pin SW (Lon works side)

Confirmation of setting

Setting up the value at the each setting mode (D25-D22)

Setting up the value at the each setting mode (D21-D18)

Light up when SW1 is pressed (Neuron ID Transmission)

Light up when SW2 is pressed (Neuron ID Transmission)

Indicates the setting mode selected with SW3

Indicates the setting value specified with SW5 and SW6

SW3

SW4

SW5

SW6

SW7

SW1

SW2

D9

D14

D29,28,27,26(From left)

D25,24,23,22,21,20,19,18(From left)

Page 20

2-2 MICROPROCESSOR FUNCTION LIST

2-2-1 INDOOR UNIT

02-08

Large

Ceiling

Universal

Compact

Cassette

Thin

Cassette

Large

Cassette

Compact

Duct

Low

Static

Pressure

Duct

High

Static

Pressure

Duct

60,000

54,000

45,000

36,000

30,000

24,000 (25,000)

24 25 25

20,000

18,000

14,000

12,000

9,000

7,000

CN1 AC IN

CN2 TH. FUSE

CN3 FAN CAPA

CN4 FAN MOTOR

CN5 D. PUMP

CN6 S. VALVE

CN10 SP-M (U,D)

CN11 SP-M (R,L)

CN12 HEATER

CN13 DISPLAY

CN14 E.E.VALVE

CN15 FLOAT SW

CN16 MOTOR F. BACK

CN17 REMOCON

CN18 TEST

CN19 R. TH

CN20 P. TH

CN21 S. TH

CN22 EX. OUT1

CN23 EX. OUT2

CN24 EX. OUT3

CN25 FLASH

CN26 COMMUNICATION-PWB

CN27 EX. IN

CN101 NETWORK

CN201 COMMUNICATION

SW1 FUNCTION 1

SW2 FUNCTION 2

SW3 FUNCTION 3

SW4 FUNCTION 4

SW5 FUNCTION 5

SW6

INDOOR UNIT ADDRESS 1

SW7 FORBIDDEN

SW8

REFRIGERANT ADDRESS 1

SW9

REFRIGERANT ADDRESS 2

SW10

REMOTE CONTROLLER ADDRESS

INDOOR UNIT TYPE

CAPACITY

(BTU/h)

Page 21

02-09

Wall Mounted Ceiling Wall

30,000

24,000

18,000

14,000

CN1 TH. FUSE

CN2 FAN MOTOR

CN3 FAN MOTOR

CN4 D. PUMP

CN5 S. VALVE

CN6 DIFFUSER/SP-M(U,D)

CN7 SP-M(L/R)

CN8 DISPLAY-1

CN9 DISPLAY-2

CN10 F. BACK

CN11 TEST

CN12 E.E.VALVE

CN13 REMOCON

CN14 FLOAT

CN15 NETWORK

CN16 R.-TH

CN17 P-TH

CN18 S-TH

CN19 FLASH

CN20 HEATER

CN21 EX. IN

CN22 EX. OUT1

CN23 EX. OUT2

CN24 EX. OUT3

CN25 COMMUNICATION-PWB

CN26 COMMUNICATION

SW1 FUNCTION 1

SW2 FUNCTION 2

SW3 FUNCTION 3

SW4 FUNCTION 4

SW5 FUNCTION 5

SW6 INDOOR UNIT ADDRESS 1

SW7 FORBIDDEN

SW8 REFRIGERANT ADDRESS 1

SW9 REFRIGERANT ADDRESS 2

SW10 REMOTE CONTROLLER ADDRESS

INDOOR UNIT TYPE

CAPACITY

(BTU/h)

Page 22

02-10

Compact Wall Mounted

14,000 ○

CAPACITY 12,000 ○

(BTU/h) 9,000 ○

7,000 ○

CN1 POWER-PWB ○

CN2 FAN F. BACK ○

CN3 E. E. VALVE ○

CN4 SP MOTOT(U,D) ○

CN5 DISPLAY ○

CN6 ROOM TH. ○

CN7 PIPE TH. ○

CN8 TEST ○

CN9 FLASH ○

CN10 EX. IN ○

CN11 EX. OUT ○

CN12 COMMUNICATION-PWB ○

CN101 MAIN-PWB ○

CN102 FAN MOTOR ○

CN103 TRANS-P ○

CN104 TRANS-S ○

CN105 TH. FUSE ○

CN106 S. VALVE ○

CN107 NETWORK ○

CN108 COMMUNICATION ○

W101-102 POWER SUPPLY ○

W103-104 FAN CAPACITOR ○

SW1 FUNCTION ○

SW2 FUNCTION & INDOOR UNIT ADDRESS ○

SW3 REFRIGERANT CIRCUIT ADDRESS ○

SW4 INDOOR UNIT ADDRESS ○

SW5 REFRIGERANT CIRCUIT ADDRESS ○

JM1

WIRELESS REMOTE CONTROLLER CUSTOM CODE

○

JM2

WIRELESS REMOTE CONTROLLER CUSTOM CODE

○

INDOOR UNIT TYPE

Page 23

AO*90MPCMFOUTDOOR UNIT TYPE

CN1

AC IN

CN2

NET

CN3

FAN.1

CN4

FAN.2

CN5

BASE HEATER

CN6

CRANK CASE HEATER

CN7

CN8

S.V.1

CN9

S.V.2

CN10

S.V.3

CN11

S.V.4

CN12

S.V.5

S.V.8

S.V.6

S.V.7

CN13

CN14

CN19

CN20

TERMINATOR

CN22

COMP.1

CN24

COMP.2

CN25

COMP.3

CN26

TH.1

CN27

FLASH W/R M

FLASH W/R S

CN28

CN29

E.E.V.3

E.E.V.1

E.E.V.2

CN30

P.SEN-H

P.SEN-M

CN31

P.SW-H

CN33

TEST

CN34

TH.2

CN35

CN42

CN44

EXT.OUTPUT

CN45

CN48

COMMUNICATION PWB

CN51

SW 1

FUNCTION 1

SW 2

FUNCTION 2

SW 3 FUNCTION 3

SW 4 FUNCTION 4

SW 5 FUNCTION 5

SW 6 FUNCTION 6

SW 7

2-2-2 OUTDOOR UNIT

SW 8

SW 9

REFRIGERANT

ADDRESS 2

REFRIGERANT

ADDRESS 1

CN18

4WV.2

4WV.3

4WV.4

FUNCTION 7

02-09

Page 24

2-3 FUNCTION AND SETTING OF EACH SWITCH

2-3-1 INDOOR UNIT

02-12

1-2 Room temperature correct coefficient of heating.

Decide the heating temperature correct coefficient value of heating.

2-1 Room temperature correct coefficient of cooling.

Decide the cooling temperature correct coefficient value of cooling.

HEATING TEMPERATURE CORRECTION

Coefficient value

OFF

ON

+ 4 deg

SW1-3

SW1-4

+ 8 deg

OFF

ON OFF

0 deg

OFF

+ 12 degON ON

COOLING TEMPERATURE CORRECTION

Coefficient value

0 deg

SW2-1

ON + 2 deg

OFF

2-2 Dip SW 2-2 setting forbidden

OFF

SW2-2

2-3 Filter check validity / invalidity.

Filter check is set with Dip SW 2-3

FILTER CLEANING FUNCTION

Filter check

Invalidity

SW2-3

ON Validity

OFF

DIP SWITCH SETTING

1. SW1 setting

2. SW2 setting

( Factory setting)

( Factory setting)

( Factory setting)

( Factory setting)

2-4 Auto restart validity / invalidity.

Control the auto restart function by turning this switch ON/OFF.

AUTO RESTART SETTING

Auto restart

Validity

SW2-4

ON

Invalidity

OFF

( Factory setting)

1-1 DIP SW 1-1 and SW 1-2 setting forbidden

OFF

SW1-1

( Factory setting)

OFF

SW1-2

Page 25

02-13

3-1 Indoor unit fan speed switch

This switch can select fan speed corresponding to each model.

Large ceiling type

OFF

OFF

OFFSW3-1

SW3-2

OFF ON

OFF ON

OFF

OFF ON

OFF

SW3-3

ON

Cassette type

OFF

AB30

AB36 AB45

AB54

SW3-1

SW3-2

SW3-3

AU54

AU45

AU36 AU30

AU25

OFF

OFF

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

OFF

ON

ON

AU20

ON

ON

ON

3. SW3 setting (Never change at the site)

Wall mounted type

OFF OFFSW3-1

SW3-2

ON

OFF ON

SW3-3

AS18

AS24 AS30

Ceiling wall type

OFF

OFFSW3-1

SW3-2

ON

OFF ONON

OFF

SW3-3

ON

AW14

AW18 AW24

AW30

ON

ON

ONON

ONON

ON

ON

SW3-1

SW3-2

SW3-3

OFF

OFF

OFF

Other model (Default)

3-2 DIP SW 3-4 setting

SW3-4

External input select

OFF

ON

Edge

Pulse

( Factory setting)

This switch is used to select the format of external input command as shown in

the table below.

OFF

OFF

OFF ON

OFF

AW7

AW9 AW12

ON

OFF

OFF

OFF

Page 26

02-14

Indoor unit model code.

This switch for changing the model code information of indoor unit PCB.

INDOOR UNIT MODEL CODE

SW4-1

SW4-2

Type

SW4-3

60

ON

OFF

ON

ON

54

OFF

OFF

ON

ON

45

ON

OFF

OFF

ON

36

OFF

OFF

OFF

ON

30

ON

ON

ON

OFF

25(24)

OFF

ON

ON

OFF

20

ON

ON

OFF

OFF

18

OFF

ON

OFF

OFF

14

ON

OFF

ON

OFF

12

OFF

OFF

ON

OFF

9

ON

OFF

OFF

OFF

7

OFF

OFF

OFF

OFF

SW4-4

Capacity

5-2 Frost prevention temperature shift switch

4. SW4 setting (Never change at the site)

5. SW5 setting

5-1 Wireless remote controller custom code switch

Decid the custom code and restrict the type of infrared control signal, in order to prevent

mixing of multiple indoor unit signals.

Remote controller custom code switch

OFFOFF

SW5-1

OFFON

Type A

Custom code

ON

ON

ON

SW5-2

Type B

Type C

Type D

( Factory setting)

5-3 Draft prevention setting switch (only for cassette type)

Set the frost prevention temperature for indoor

unit.

Frost prevention temperature shift switch

NormalOFF

SW5-3

HighON

Frost prevention temperature

( Factory setting)

OFF

C

O

O

L

FA

N

H

E

A

T

A

U

T

O

A

U

T

O

H

I

G

H

M

E

D

LO

W

T

I

M

E

R

T

I

M

E

R

R

E

S

E

T

C

L

O

C

K

S

L

E

E

P

E

N

E

R

G

Y

S

A

V

E

C

A

M

P

M

O

N

O

F

F

O

F

F

O

N

H

M

A B C D

A B C D

D

R

Y

ABCD

Remote controller

Remote controller

signal selector

switch

Set the flap angle of cassette type unit.

Draft prevention switch

Normal positionOFF

SW5-4

Draft prevention positionON

flap angle

( Factory setting)

Normal position Draft prevention position

35 - 65

25 - 65

Flap angle Flap angle

*If air conditioning cooling operation is performed in

long time and a humid place, there is a possibility

that waterdrop may hang down from a blow-off mouth.

An air flow direction, by moving the flap angle horizontally,

It can prevent that a cold wind directly hits.

1. Press the MASTER CONTROL button for

more than five seconds to start the code

change.

2. Press the (+) or (-) button to select the

desired code.

3. Press the MASTER CONTROL button again

to end the code change.

A B C D

Page 27

02-15

ROTARY SWITCH SETTING

EXTERNAL INPUT AND OUTPUT

Indoor unit address switch

Sets the indoor unit addresses.

INDOOR UNIT ADDRESS SWITCH

Refrigerant circuit address switch

Sets the refrigerant circuit.

REFRIGERANT CIRCUIT ADDRESS SWITCH (Factory setting SW 8: 0 SW 9: 0)

Remote controller address switch

REMOTE CONTROLLER ADDRESS SWITCH (Factory setting : 0)

When the indoor unit is wired by remote controller group, to identity the indoor unit in the remote

controller group, the number (remote controller address) in the remote controller group is set.

Set the remote controller address in the 0.1.2,~,15 order (Blank is not allowed)

1.SW6 setting

2.SW7 setting forbidden

Rotary SW7 0

Rotary SW

6

Description Remarks

Indoor unit

address SW

Indoor unit address

( 0~15 )

Rotary SW

8

9

Description Remarks

Refrigerant circuit

address 1

Refrigerant circuit

address 2

Refrigerant circuit

address (the first digit)

Refrigerant circuit

address (the second digit)

Rotary SW

10

Description Remarks

Remote controller

address SW

Remote controller

address

3.SW8,9 setting

4.SW10 setting

(Factory setting : 0)

Connector

CN21

CN27

Input

Output

OPERATION DISPLAY

(DC12V)

Remarks

Indoor unit type

Wall mounted /

Ceiling wall types

CN22

CN23

CN24

Other types

All types

CONTROL INPUT

(OPERATION / STOP)

ERROR DISPLAY

(DC12V)

INDOOR UNIT FAN

STATUS DISPLY(DC12V)

See 2-4-1

for details

Page 28

1-2 Model code setting switch

The model code infomation corresponding to each model is provided with the switch.

2-1 Dip SW 2-1,2-2 setting forbidden

OFF

SW2-1

2-3 DIP SW 2-4 setting forbidden.

DIP SWITCH SETTING

1. SW1 setting (Never change at the site)

2. SW2 setting

1-1 Fan speed setting switch

( Factory setting)

( Factory setting)

The fan speed corresponding to each model is set with the switch.

OFFSW1-1

SW1-2

OFF

ON ONOFF

ON

OFF ON

AS7

AS9 AS12

AS14

OFFSW1-3

SW1-4

OFF

ON ONOFF

ON

OFF ON

AS7

AS9 AS12

AS14

OFF

SW2-2

2-2 Auto restart validity / invalidity.

The auto restart function be comes validity by changing the switch position from OFF to ON.

AUTO RESTART SETTING

Auto restart

Validity

SW2-3

ON

Invalidity

OFF

( Factory setting)

OFF

SW2-4

2-3-2 INDOOR UNIT ( COMPACT WALL MOUNTED TYPE )

02-16

Page 29

3-1 Refrigrant circuit address switch

By combined with Rotary SW5 , the refrigerant circuit address (0-99) can be set.

Please see "6-2 ADDRESS SETTING" for refrigerant address conversion table.

OFF

OFF

16 - 31

32 - 47

ON

OFF

OFF

ON

OFF

48 - 63

Remarks

3. SW3 setting

( Factory setting)

SW3-1 SW3-2 SW3-3

Refrigerant

circuit address

0 - 15

64 - 79

80 - 95

96 - 99

ON

ON

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

About Rotary

SW5,

see next page

3-2 DIP SW 3-4 setting forbidden.

( Factory setting)

OFF

SW3-4

02-17

Page 30

ROTARY SWITCH SETTING

JUMPER WIRE

Indoor unit address switch

Set the indoor unit addresses.

INDOOR UNIT ADDRESS SWITCH

Refrigerant circuit address switch

By combined with DIP switch 3-1,3-2 and 3-3,the refrigerant circuit address(0 - 99)can be set.

Please see "5-3-3 ADDRESS SETTING" for the refrigerant address conversion table.

REFRIGERANT CIRCUIT ADDRESS SWITCH (Factory setting SW 5: 0)

1.SW4 setting

Rotary SW

4

Description Remarks

Indoor unit

address SW

Indoor unit address

( 0~15 )

Rotary SW

5

Description Remarks

Refrigerant circuit

address SW

About DIP switch 3-1,3-2

and 3-3 see previous page

2.SW5 setting

(Factory setting : 0)

Wireless remote controller custom code switch

Limit the type of infrared control signal which the indoor unit is controlled,in order to prevent

misoperation of the unit due to the signal from other wirless remote controller.

Remote controller custom code switch

ConnectConnect

JM 1

ConnectDisconnect

Type A

Custom code

Disconnect

Disconnect

Disconnect

JM 2

Type B

Type C

Type D

( Factory setting)

Connect

C

O

O

L

FA

N

H

E

A

T

A

U

T

O

A

U

T

O

H

I

G

H

M

E

D

L

O

W

T

I

M

E

R

T

I

M

E

R

R

E

S

E

T

C

L

O

C

K

S

L

E

E

P

E

N

E

R

G

Y

S

A

V

E

C

A

M

P

M

O

N

O

F

F

O

F

F

O

N

H

M

A B C D

A B C D

D

R

Y

ABCD

Remote controller

Remote controller

signal selector

switch

1. Press the MASTER CONTROL button for

more than five seconds to start the code

change.

2. Press the (+) or (-) button to select the

desired code.

3. Press the MASTER CONTROL button again

to end the code change.

A B C D

02-18

EXTERNAL INPUT AND OUTPUT

Control Input

CN10

Connector

CN11

See 2-4-2

for details.

Remarks

Operation Display

Input or Output

(Operation / Stop)

(DC12V)

Page 31

2-3-3 OUTDOOR UNIT

02-19

1. SW1 setting

1-1 Test run

By setting DIP SW1-1 and SW1-2 on control PC board of outdoor unit, cooling test run or heating test run for all the indoor

units in the same refrigerant system can be performed.

SELECTOR SWITCH FOR TEST RUN AND NORMAL OPERATION

1-2 Pump down operation

Pump down operation is set with SW1-3

1-3 Forced defrost operation

PUMP DOWN OPERATION

FORCED DEFROST OPERATION

2-1 Silent operation mode (cooling mode only)

Noise level can be reduced using silent operation mode when the outdoor temperature decreases

decreases below 30 C.

2. SW2 setting

SILENT OPERATION MODE

Silent operation mode

Release

SW 2-1

ON Oparate

OFF

2-2 Snow falling protection fan mode

When snowing , to prevent the unit from being covered with snow , the outdoor fan is periodically

operated by this switch even when the compressor is stopped.

SNOW FALLING PROTECTION SW

Snow falling protection fan mode

Release

SW2-2

ON

Operate

OFF

SW1-2 SW1-1 Test Run Remarks

OFF OFF Normal operation

OFF ON Cooling test run

ON OFF Heating test run

ON ON Normal operation

SW1-3 Pump down operation Remarks

OFF Release

ON Operate

OFF ON and be kept at ON position

for more than 30 sec.

SW1-4 Forced defrost Remarks

OFF Release

ON Operate

DIP SWITCH SETTING

( Factory setting)

( Factory setting)

( Factory setting)

( Factory setting)

( Factory setting)

[OFF,OFF] [OFF,ON] and be kept at

[OFF,ON] position for more than 1 min.

[OFF,OFF] [ON,OFF] and be kept at

[OFF,ON] position for more than 1 min.

OFF ON and be kept at ON position

for more than 10 sec.

Page 32

02-20

2-3 Expansion valve initialization

This switch initializes the number of pulses of the expansion valve when the outdoor unit is stopped.

3. SW3 setting

ELECTRONIC EXPANSION VALVE INITIALIZATION

Initialization

Release

SW2-3

ON Operate

OFF

2-4 Forced oil recoverry operation.

Oil recovery is started manually by DIP SW 2-4 on the PCB.

FORCED OIL RECOVERY

Forced oil recovery

Release

SW2-4

ON Operate

OFF

( Factory setting)

( Factory setting)

Dip SW3-1,3-2,3-3 and SW3-4 setting forbidden

4.SW4 setting

4-1 Defrost temperature setting SW

OFF

SW3-1

SW3-4

SW3-2

OFF

OFF

SW3-3 OFF

The thershold temperature for starting a defrosting operation can be selected by setting up the switches.

SW4-1

SW4-2

ON

OFF

OFF

ON

OFF ON

ON OFF

Temperature

Standard

Low

High

Lower

DEFROST TEMPERATURE

( Factory setting)

4-2 Dip SW4-3 and SW4-4 setting forbidden.

OFF

OFF

SW4-3

SW4-4

5. SW5 setting

5-1 Dip SW 5-1,SW5-2 and SW5-4 setting forbidden

5-2 Base heater validity/invalidity

This switch sets the output of the base heater (CN5) on the PCB.

Base heater

Invalidity

SW5-3

ON validity

OFF

BASE HEATER SWITCH

The base heater output turns ON at an outside temperature of 2 C or less

during heating operation.

Base heater : 220-240V AC , 35W , field supplied.

( Factory setting)

Remarks

OFF ON and be kept at ON position

for more than 10 seconds

Page 33

02-21

DIP SW 6-1,SW6-2,SW6-3 and SW6-4 setting forbidden

6. SW6 setting

7. SW7 setting

7-1 System type switches

ON

ON

OFF

OFF

SW7-1 System type SW7-2

ON

OFF

OFF

ON

Forbidden

Heat recovery

Forbidden

SYSTEM TYPE SWITCHES

7-2 Dip SW 7-3 and SW 7-4 setting forbidden

( Factory setting)

Forbidden

OFF

OFF

SW7-3

SW7-4

SW8,9 setting

Rotary SW

8

9

Description Remarks

Refrigerant circuit

address 1

Refrigerant circuit

address 2

Refrigerant circuit

address (the first digit)

Refrigerant circuit

address (the second digit)

ROTARY SWITCH SETTING

CN48

OutputConnector

Error Display

(DC12V)

EXTERNAL OUTPUT

OFF

OFF

SW6-1

SW6-2

OFF

OFF

SW6-3

SW6-4

Page 34

2-3-4 WIRED , SIMPLE REMOTE CONTROLLER

1. SW1 setting

1-1 Remote controller switch 1

1-4 Remote controller switch 2

1-3 DIP SW1-3 setting forbidden

REMOTE CONTROLLER SWITCH 2

Setting for Master/Slave

OFF Master

SW1-4

ON Slave

REMOTE CONTROLLER SWITCH 1

Terminator setting

Not terminated

SW1-1

ON

Terminated

OFF

1-2 Number of indoor unit connection (One/Multiple)

This is switched according to the number of connected indoor units.

NUMBER OF INDOOR UNIT CONNECTION

Number of indoor unit

One unit connection

SW1-2

ON Multiple unit connection

OFF

DIP SWITCH SETTING

SW 1-5 OFF

SW 1-6 OFF

SW 1-3 OFF

This is used to set up the terminated resistance of the wired remote controller.

When 1 remote controller is connected to remote controller group, set this ON all the time.

When 2 remote controllers are connected to remote controller group, set the Master one OFF, and set the Slave one ON.

If it is used to set up Master/Slave setting of wired remote control.

When 1 remote control is connected to 1 remote control group, always set the Master OFF.

When 2 remote controls are connected to remote control group, set one side to Master, and the other side to Slave.

1-5 DIP SW 1-5 and SW 1-6 setting forbidden.

( Factory setting)

( Factory setting)

( Factory setting)

02-22

Page 35

02-23

2-1 Cooling only / heat pump

Switching cooling only / heat pump.

COOLING ONLY / HEAT PUMP SWITCH

Operation system

Heat pump/Heat recovery

SW2-1

ON Cooling only

OFF

2-2 Auto change over validity/invalidity

Selecting auto change over validity/invalidity.

Never turn it on in the case of Heat pump type.

2. SW2 setting

AUTO CHANGE OVER

Auto change over

Invalidity

SW2-2

ON Validity

Invalidity

Validity

OFF

2-4 Maintenance switch

Used to indicate of the refrigerant system, indoor unit address.

MAINTENANCE SWITCH

Mode

Normal mode

SW2-4

ON Maintenance mode

OFF

2-6 Battery backup switch (Wired remote controller only)

When installing, turn the SW2-6 ON.

2-5 DIP SW 2-5 setting forbidden.

SW 2-5 OFF

2-3 Back ground Light validity (simple remote controller only)

Selecting to use internal background light validity/invalidity.

The background light can turn on during indoor unit operation.

BATTERY BACKUP SWITCH

Battery backup

SW2-6

ON

OFF

Never turn it ON in the case of simple remote controller.

SW 2-3

OFF

ON

Background light

Invalidity

Validity

Never turn it ON in the case of wired remote controller.

( Factory setting)

( Factory setting)

( Factory setting)

( Factory setting)

( Factory setting)

Page 36

02-24

1-1 DIP SW2-1 setting .

For validity / invalidity the external input function.

1-4 DIP SW2-4 setting.

SW2-4

ON

OFF

1-3 DIP SW2-3 setting.

Filter check sign indication

Non-Display

SW2-3

ON Display

OFF

1-5 DIP SW2-5 setting

SW 2-1 External input function

OFF Invalidity

C / F

C

F

RC operation prohibit function

Validity

SW2-5

ON Invalidity

OFF

1. DIP-SW2 SETTING

2-3-5 CENTRAL REMOTE CONTROLLER

Filter check sign indication or not when filter check come from indoor unit.

C / F switch

Temperature display is centigrate( ) / Fahrenheit( )

C

F

For validity / invalidity the wired and wireless remote controller operation prohibit function.

( Factory setting)

( Factory setting)

( Factory setting)

ON

Validity

( Factory setting)

1-2 DIP SW2-2 setting .

Select the external input command function.

SW 2-2 External input select

OFF Edge

ON

Pulse

( Factory setting)

(Refer to 2-4-4 about external input & output)

Page 37

02-25

1-6 DIP SW2-6 and 2-7 setting forbidden.

1-7 DIP SW2-8 setting.

SRAM Battery

SW2-8

ON

OFF

SW 2-6 OFF

SW 2-7 OFF

SRAM Battery ON / OFF

When installing the control remote controller, this switch must be set to ON.

(factory setting:OFF)

OFF

ON

At the time of shipment,the battery is turned off to avoid electricity consumption.

Be sure to set this switch to ON.

1-8 SW42 Initial setting button

( Factory setting)

This switch is used when initializing the central remote controller.

Page 38

2-3-6 NETWORK CONVERTOR

02-26

2. DIP- SW103 (5, 6, 7, 8) setting

Number of the connected indoor units

Number of

connected the

Indoor unit

OFF

OFF

OFF OFF

OFF OFF

OFF ON

OFF OFF

ON OFF

1

2

3

4

5

6

OFF

OFF

ON ON

OFF ON

OFF OFF

OFF ON

OFF ON

DIP-SW 103

5

6

7

8

Number of

connected the

Indoor unit

OFF

ON

ON OFF

OFF ON

ON ON

ON OFF

OFF OFF

7

8

9

10

11

12

ON

OFF

OFF ON

ON OFF

ON OFF

ON OFF

ON ON

DIP-SW 103

5

6

7

8

Number of

connected the

Indoor unit

ON

ON

OFF OFF

ON ON

OFF ON

ON ON

ON OFF

13

14

15

16

ON

ON

ON ON

DIP-SW 103

5

6

7

8

3. DIP SW 107 Setting

3-1 DIP SW 107-1 setting forbidden

Select the wired remote controller validity / invalidity

Wired remote controller

SW 107-2

OFF

ON

Wired remote controller

Invalidity

validity

( Factory setting)

( Factory setting)

Set the DIP-SW 103 (5, 6, 7, 8) according to number of the connected indoor units.

3-2 Wired remote controller validity / invalidity

SW 107-1 OFF

( Factory setting)

(1) Network convertor (UTR-YSSA)

1. Dip SW103 ( 1, 2, 3, 4) setting

Indoor unit model type and remote controller type

Indoor unit type

Heat pump of big multi type

Heat pump of single spilt type

Cooling only of single spilt type

Cooling only of big multi type

Cooling only of single spilt type

Wall mounted with wired RC

RC type

With weekly timer

With weekly timer

Without weekly timer

With weekly timer

With weekly timer

Without weekly timer

RC number

EZ-099DHSE-*,EZ-000DHSE-*,EZ-0001HSE-*,

EZ-000GHSE-*,EZ-00004HSE-*,

EZ-00005HSE-*,EZ-0015HSE-*,EZ-0019HSE-*

EZ-0994HSE-*,EZ-000EHSE-*

EZ-09503HSE-*,EZ-0950DHSE-*

EZ-099CWSE-*,EZ-000AWSE-*,EZ-0001WSE-*,

EZ-000FWSE-*,EZ-0012WSE-*

EZ-09906WSE-*,EZ-000FWSE-*

EZ-095YWSE-*

EZ-098VWSE-*

OFF OFF

OFF OFF

Without weekly timer

Heat pump of single spilt type

DIP-SW103

1

2 3

4

OFF OFF

OFF ON

OFF OFF

ON OFF

ON

OFF

OFF OFF

ON OFF

OFF ON

ON OFF

ON OFF

ON ON

OFF OFF

Set Dip SW103 ( 1, 2, 3, 4) according to indoor unit type and remote

controller (packaged together with the unit) type. You can also set

DIP-SW103 (1, 2, 3, 4) using the remote controller number that is

shown on the rear surface of the remote controller.

Rear View

EZ-########-R

RC Number

Instead of using the remote controller that was packaged together

with the unit, a VRF type remote controller must be used to

connected to network.

( Factory setting)

Asterisks (*) are used in place of variable characters.

Page 39

02-27

4. DIP SW 108 setting

4-1 External input validity / invalidity

Select the external input function validity / invalidity

SW 108-1

OFF

ON

External input function

Invalidity

validity

4-2 External input command type

Select the external input command type

SW 108-2

OFF

ON

External input command type

Edge

Pulse

( Factory setting)

( Factory setting)

5. DIP SW109 setting

5-1 Auto changeover validity / invalidity

Select auto changeover function validity / invalidity

SW 109-1

OFF

ON

Auto changeover function

Invalidity

validity

5-2 Auto restart validity / invalidity

Select auto restart function validity / invalidity

SW 109-2

OFF

ON

Auto restart function

Invalidity

validity

( Factory setting)

( Factory setting)

Page 40

2-4 EXTERNAL INPUT & OUTPUT

2-4-1 INDOOR UNIT ( EXCEPT FOR COMPACT WALL MOUNTED TYPE

02-28

(1) Control input (Operation/Stop)

Indoor unit can be operated or stopped by using indoor unit PCB

CN 21 (Wall mounted type / ceiling wall type) or CN27 (other types)

Dip SW3-4 Input select

OFF

ON

Edge

Pulse

1 Input select

2 In the case of "Edge" input

CONNECTOR INPUT SIGNAL COMMAND

Ch1 of

CN21 (RED)

or

CN27 (RED)

OFF ON

ON OFF

Operation

Stop

*1)

*2)

1

2

CN 21(RED) *1)

or

CN 27(RED) *2)

3

Ch 2

Ch 1

*1) For Wall mounted type / Ceiling wall type.

*2) For other types

Ch1 of

CN21 or

CN27

*1)

*2)

3 In the case of "pulse" input

CONNECTOR INPUT SIGNAL COMMAND

OFF ON Operation

Stop

CN21 (RED)

or

CN27 (RED)

*1)

*2)

Ch1

Ch2

OFF ON

On

On

Off

Remote

Controller

Indoor

Unit

NOTE

1. The last command has priority.

2. The indoor units within the same

remote controller group operates

in the same mode.

3.The wire connection shall be

separate from the power cable line.

Operation

Stop

CN21

or

CN27

*1)

*2)

On

Off

Indoor

Unit

Operation

On

Off

Ch1

Ch2

The width of pulse must be longer than 200ms.

Stop

Page 41

02-29

(2) Output

1 Operation display

CONNECTOR OUT VOLTAGE STATUS

Operation12V

0V

12V Error

Stop

CN22

CN23

CN24

0V

12V

0V

Normal

Fan stop

Fan run

1

2

CN 23

(WHITE)

+

-

Error

Indicator

1

2

CN 24

(WHITE)

+

-

Indoor unit

fan status

Indicator

Operation

Stop

CN 22

CN 23

CN 24

Indoor

unit

Indoor

unit

Indoor

unit

1

2

CN 22

(WHITE)

+

-

Operation

Indicator

12V

0V

Error

Normal

12V

0V

Fan run

Fan stop

12V

0V

(3) Parts

Following cord (service parts) is required. Please use the parts number shown below

to order the cord from your sales representative.

Name and shapes Q'ty Parts No.

1

1

EXTERNAL

INPUT WIRE

EXTERNAL

INPUT WIRE

9368778002

9368779009

2 Error display

3 Inter locking output with indoor unit fan

EX) Used for inter lock energize for exhaust fan.

Usage

For output port

For control

input port

Page 42

(1) Control input (Operation/Stop)

Indoor unit can be operated or stopped by using the connector CN10(RED) ON indoor unit PCB.

1

CN 10

(RED)

3

Ch 1

Ch1 of

CN10

*1)

On

On

Off

Remote

Controller

Indoor

Unit

NOTE

1. The last command has priority.

2. The wire connection shall be

separate from the power cable line.

Operation

Stop

(2) Output

1 Operation display

CONNECTOR OUT VOLTAGE STATUS

Operation12V

0V Stop

CN11

Operation

Stop

CN 11

Indoor

unit

1

2

CN 11

(WHITE)

+

-

Operation

Indicator

12V

0V

(3) Parts

Following cord (service parts) is required. Please use the parts number shown below

to order the cord from your sales representative.

Name and shapes Q'ty Parts No.

1

1

EXTERNAL

INPUT WIRE

EXTERNAL

INPUT WIRE

9368778002

9368779009

Usage

For output port

For control

input port

2

2-4-2 INDOOR UNIT (COMPACT WALL MOUNTED)

02-30

(WHITE)

INPUT SIGNAL COMMAND

OFF ON

CONNECTOR

CN10

(RED)

ON OFF

Operation

Stop

Page 43

02-31

2-4-3 OUTDOOR UNIT

(1) Output

This output indicates the outdoor unit and connected indoor

unit's "Normal" or "Error" status.

1

2

CN 48

(BLACK)

+

-

Error

Indicator

1 Error display

P.C.B

CONNECTOR OUTPUT VOLTAGE STATUS

2 Base heater output

Turn ON when the ambient temperature is low in heating mode.(2 C or less)

1

2

CN 5

(GREEN)

Following cord (service parts) is required. Please use the parts number shown below

to order the cord from your sales representative.

Name and shapes Q'ty Parts No.

1 9368776008

(2) Parts

1 9368777005

EXTERNAL

INPUT

WIRE

BASE

HEATER

WIRE

CN48

(BLACK)

Normal

Error

0V

12V

Normal

12V

0V

CN48

Error

3

4

Usage

For base heater

output port

For error display

output port

Base heater

(Field supply)

AC220-240V,35W

Page 44

02-32

(1) Input

Indoor units which stored into Central R.C. or PC controller can be operated

or stopped by this input.

CN9

Ch1

Indoor

Unit

Control input (All on / All off)

All ON

CN9

(RED)

DipSW2-1

a) Input select

Central remote controller

PC controller

Input select can be set in environmental set up.

(Please refer to PC Controller's setting manual.)

b) In the case of "Edge" input

CONNECTOR INPUT SIGNAL COMMAND

CN9

(RED)

All ON

All OFF

OFF ON

ON OFF

On

Off

CN9

Ch1

Indoor

Unit

All ON

All OFF

c) In the case of "Pulse" input

DipSW2-2 Input select

"Edge"

"Pulse"

ON

ON

CN9

Ch2

1

OFF

ON

Ch1

CONNECTOR INPUT SIGNAL COMMAND

CN9

(RED)

All ON

All OFF

OFF ON

Ch1

Ch2

OFF ON

All ON

On

Off

On

Off

The width of pulse must be longer than 300ms.

Ch1

1

2

3

P.C.B

Ch2

2-4-4 CENTRAL REMOTE CONTROLLER / PC CONTROLLER

Page 45

02-33

(2) Output

This output indicates the indoor unit's "Operate" or "Stop" status.

Indoor

Unit

ON

OFF

Short

Open

CN1

Ch1

Operation display

Ch1

1

2

3

CN1

(WHITE)

P.C.B

Open

Short

CN1

(WHITE)

All of indoor units "OFF"

At least one more indoor units "ON"

Ch2

CONNECTOR

OUTPUT

SIGNAL

STATUS

Ch1

ON /OFF

Indicator

Error

Indicator

Com

Error display

This output indicates the indoor unit's "Normal" or "Error" status.

CN1

(WHITE)

All of indoor units "Normal"

At least one more indoor units "Error"

CONNECTOR STATUS

Ch2

Indoor

Unit

Error

Normal

CN1

Ch2

1

2

(3) Parts

Following cord (service parts) is required. Please use the parts number shown below

to order the cord from your sales representative.

9368779009

Name and shapes Q'ty Parts No.

1

EXTERNAL

INPUT

WIRE

* 1

* 2

* 1 Always insert a diode on both ends of relay coil.

* 2 Pin 1 - Pin 3 Max 15V

Pin 2 - Pin 3 70mA

OUTPUT

SIGNAL

Open

Short

Short

Open

Usage

For input and

output port

Page 46

02-34

(1) Control input

(Operation / Stop)

Indoor units that connected to network convertor can be controlled (all operation / all stop

by this input.

CN105

Ch1

Indoor

Unit

All operation

CN105

(RED)

DipSW108-1

a) Input select

b) In the case of "Edge" input

CONNECTOR INPUT SIGNAL COMMAND

CN105

(RED)

All operation

All stop

OFF ON

ON OFF

ON

OFF

CN105

Ch1

Indoor

Unit

All operation

All stop

c) In the case of "Pulse" input

DipSW108-2 Input select

"Edge"

"Pulse"

ON

ON

CN105

Ch2

OFF

ON

Ch1

CONNECTOR INPUT SIGNAL COMMAND

CN105

(RED)

All operation

All stop

OFF ON

Ch1

Ch2

OFF ON

All stop

On

Off

On

Off

The width of pulse must be longer than 200ms.

Ch2

3

2

1

P.C.B

Ch1

2-4-5 NETWORK CONVERTOR

SW111

SW109

SW103

SW107

SW110

SW108

D129

. . .

. . .

. . .

CN105(RED)

CN108(BLK) CN109

EXT IN

EXT OUT1

EXT OUT2

3 2 1

1 2 3

1 2 3

The connector positions and pin number of

network convertor (UTR-YSSA) for external

input and output are shown in the right figure.

Page 47

02-35

(2) Output

This output indicates the indoor unit's "Operation" or "Stop" status.

Indoor

Unit

Operation

Stop

Short

Open

CN108

(BLK)

Operation display (EXT OUT1)

CN108

(BLK)

P.C.B

Open

Short

CN108

(BLACK)

Indoor units "Stop"

Indoor units "Operation"

CONNECTOR

OUTPUT

SIGNAL

STATUS

ON /OFF

Indicator

Com

Error display (EXT OUT2)

This output indicates the indoor unit's "Normal" or "Error" status.

CN109

(WHITE)

All of the indoor units "Normal"

At least one more indoor units "Error"

CONNECTOR STATUS

Indoor

Unit

Error

Normal

CN109

(WHITE)

1

2

(3) Parts

Following cord (service parts) is required. Please use the parts number shown below

to order the cord from your sales representative.

9368779009

Name and shapes Q'ty Parts No.

1

EXTERNAL

INPUT

WIRE

* 1

* 2

* 1 Always insert a diode on both ends of relay coil.

* 2 Pin 2 - Pin 3 Max 15V, 50mA

OUTPUT

SIGNAL

Open

Short

Short

Open

2

1

3

CN109

(WHITE)

P.C.B

Error

Indicator

Com

* 1

* 2

* 1 Always insert a diode on both ends of relay coil.

* 2 Pin 2 - Pin 3 Max 15V, 50mA

2

1

3

Usage

For control

input and output port

Page 48

3 . OUTDOOR UNIT OPERATION

CONTROL

TM

R407C

Page 49

3-1 COMPRESSOR OPERATION CONTROL

3. OUTDOOR UNIT OPERATION CONTROL

3-1-1 OPERATION / STOP CONDITION

Compressor operation condition

When cooling requirement capacity or heating requirement capacity from either of the indoor units in the same

refrigerant system is input, the compressor operates.

But in the following case, the compressor operates in accordance with operation of each mode.

During 3 minute restart prevention operation

During compressor recovery operation

During deicing operation

Failure (except for a part)

Defrosting

Oil recovery

Under expansion valve initialization

At protective operation

Central discharge temperature protection

High pressure protection

Compressor stop condition

When all the indoor units in no "cooling requirement capacity" or "heating requirement capacity ",

all the compressors

are stopped.

But, in the following case, the compressor operates in accordance with operation of each mode.

Defrosting

Oil recovery

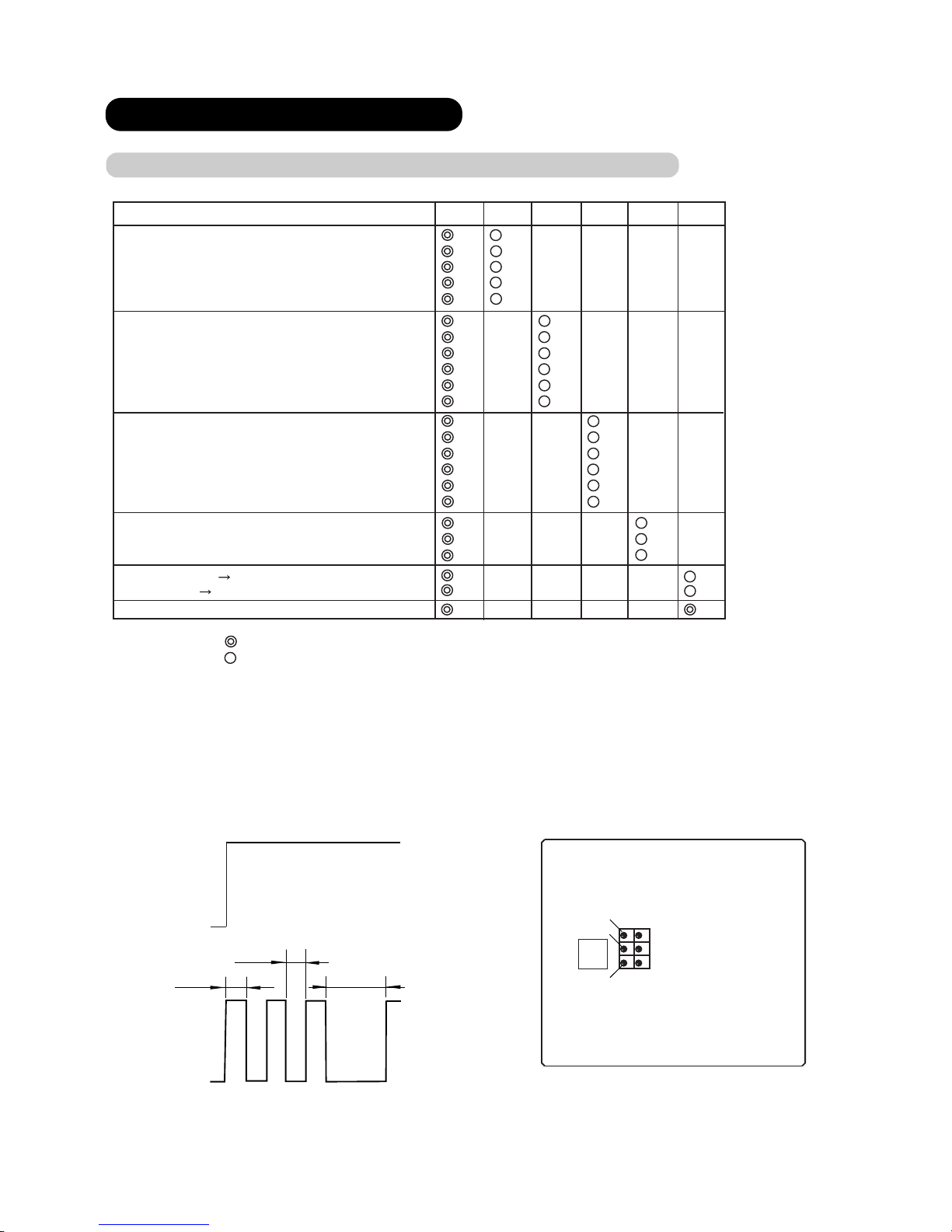

3-1-2 COMPRESSOR OUTPUT PATTERN

The output pattern of a compressor is defined as below.

OUTPUT PATTERN

COMPRESSOR 1

(2HP)

COMPRESSOR 2

(4HP)

COMPRESSOR 3

(6HP)

Step 0

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Compressor output pattern

3-1-3 3 MINUTES RESTART PREVENTION (3 MIN ST)

When the compressor is stopped, the compressor does not start on any condition for 3 minutes afterwards.

But, this function is excluded when defrosting, oil recovery is performed and the power is turned on.

03-01

Page 50

If compressor 1, 2, or 3 fails, or if two compressors fail at the same time, the remaining compressor(s)

perform recovery operation to prevent interruption of air conditioning system operation by a failure.

When compressor 1, 2, or 3 is judged to be faulty, the system is operated by switching the compressor output

pattern (compressors 0 to 6) as shown in the following table.

Compressor failure is displayed by LEDs on the PCB of the outdoor unit and by output ERROR to the

communication bus line (standard wired remote controller, central remote controller, PC controller).