Page 1

INSTALLATION MANUAL

VRF SYSTEM

INDOOR UNIT

Floor / Ceiling Type

Contents

1. SAFETY PRECAUTIONS ............................................. 2

2. ABOUT THE UNIT

2.1. Precautions for using R410A refrigerant ...............2

2.2. Special tool for R410A ........................................... 2

2.3. Accessories ...........................................................3

2.4. Optional parts ........................................................ 3

3. INSTALLATION WORK

3.1. Selecting an installation location ...........................4

3.2. Installation dimension ............................................4

3.3. Installation the unit................................................. 4

4. PIPE INSTALLATION

4.1. Selecting the pipe material .................................... 6

4.2. Pipe requirement ................................................... 7

4.3. Flare connection (pipe connection) .......................7

4.4. Installing heat insulation ........................................ 8

5. INSTALLING DRAIN HOSE ......................................... 9

6. ELECTRICAL WIRING

6.1. Electrical requirement .......................................... 11

6.2. Wiring method ..................................................... 11

6.3. Unit wiring ............................................................ 11

6.4. Connection of wiring ........................................... 13

6.5. External input and external output

(Optional parts) ....................................................13

7. FIELD SETTING

7.1. Setting the address.............................................. 16

7.2. Custom code setting ............................................ 17

7.3. Function setting ................................................... 18

8. MOUNT THE COVER PLATE AND THE INTAKE

GRILLE

8.1. Handling for the pipe take-off part ....................... 19

8.2. Mount the cover plate (Right) .............................. 19

8.3. Mount the cover plate (Left)................................. 20

8.4. Mount the intake grille .........................................20

9. TEST OPERATION

9.1. Test operation using PCB (Outdoor unit) ............. 20

9.2. Test operation using remote controller ................ 20

10. CHECK LIST ............................................................... 20

11. ERROR CODES ......................................................... 21

PART NO. 9367701070-05

For authorized service personnel only.

English

Page 2

En-2

1. SAFETY PRECAUTIONS

Be sure to read this Manual thoroughly before installation.•

The warnings and precautions indicated in this Manual •

contain important information pertaining to your safety. Be

sure to observe them.

Hand this Manual, together with the Operating Manual, to the •

customer. Request the customer to keep them on hand for

future use, such as for relocating or repairing the unit.

WARNING

This mark indicates procedures which, if

improperly performed, might lead to the

death or serious injury of the user.

• Request your dealer or a professional installer to install

the indoor unit in accordance with this Installation Manual.

An improperly installed unit can cause serious accidents

such as water leakage, electric shock, or fire. If the

indoor unit is installed in disregard of the instructions in

the Installation Manual, it will void the manufacturer’s

warranty.

• Do not turn ON the power until all work has been

completed. Turning ON the power before the work is

completed can cause serious accidents such as electric

shock or fi re.

• If refrigerant leaks while work is being carried out,

ventilate the area. If the refrigerant comes in contact with

a fl ame, it produces a toxic gas.

• Installation work must be performed in accordance with

national wiring standards by authorized personnel only.

• Except for EMERGENCY, never turn off main as well

as sub breaker of the indoor units during operation. It

will cause compressor failure as well as water leakage.

First, stop the indoor unit by operating the controller,

converter or external input device and then cut the

breaker.

Make sure to operate through the controller, converter or

external input device.

When the breaker is designed, locate it at a place where

the users cannot start and stop in the daily work.

CAUTION

This mark indicates procedures which,

if improperly performed, might possibly

result in personal harm to the user, or

damage to property.

2. ABOUT THE UNIT

1

2.1. Precautions for using R410A refrigerant

WARNING

• Do not introduce any substance other than the prescribed

refrigerant into the refrigeration cycle. If air enters the

refrigeration cycle, the pressure in the refrigeration cycle

will become abnormally high and cause the piping to

rupture.

• If there is a refrigerant leak, make sure that it does not

exceed the concentration limit. If a refrigerant leak

exceeds the concentration limit, it can lead to accidents

such as oxygen starvation.

WARNING

• Do not touch refrigerant that has leaked from the

refrigerant pipe connections or other area. Touching the

refrigerant directly can cause frostbite.

• If a refrigerant leak occurs during operation, immediately

vacate the premises and thoroughly ventilate the area. If

the refrigerant comes in contact with a fl ame, it produces

a toxic gas.

]1

2.2. Special tool for R410A

WARNING

• To install a unit that uses R410A refrigerant, use dedicated

tools and piping materials that have been manufactured

specifically for R410A use. Because the pressure of

R410A refrigerant is approximately 1.6 times higher

than the R22, fai lure to use dedicated piping material

or improper installation can cause rupture or injury.

Furthermore, it can cause serious accidents such as

water leakage, electric shock, or fi re.

Tool name Changes

Gauge manifold

The pressure in the refrigerant

system is extremely high and cannot be measured with a conventional gauge. To prevent erroneous

mixing of other refrigerants, the

diameter of each port has been

changed. It is recommended to

use a gauge manifold with a high

pressure display range of –0.1 to

5.3 MPa and a low pressure display

range of –0.1 to 3.8 MPa.

Charging hose

To increase pressure resistance, the

hose material and base size were

changed.

(The charging port thread diameter

for R410A is 1/2 UNF 20 threads per

inch.)

Vacuum pump

A conventional vacuum pump can be

used by installing a vacuum pump

adapter.

Be sure that the pump oil does

not backflow into the system. Use

one capable for vacuum suction of

–100.7 kPa (5 Torr, –755 mmHg).

Gas leakage detector

Special gas leakage detector for

R410A refrigerant.

Page 3

En-3

]1

2.3. Accessories

WARNING

• For installation purposes, be sure to use the parts

supplied by the manufacturer or other prescribed parts.

The use of non-prescribed parts can cause serious

accidents such as the unit falling, water leakage, electric

shock, or fi re.

• The following installation parts are furnished. Use them as

required.

• Keep the Installation Manual in a safe place and do not

discard any other accessories until the installation work has

been completed.

Name and Shape Q’ty Application

Operating Manual

1

Installation Manual

1

(This book)

Cover plate (Left)

1

Cover plate (Right)

1

Tapping screw

(M4

×

10mm)

2

Installation

template

1

For positioning the

indoor unit

For under ceiling type

Bracket (Left)

1

For suspending

the indoor unit from

ceiling

Bracket (Right)

1

Special nut

4

Wall bracket

2

For suspending the

indoor unit on the wall

Tapping screw

(M4

×

20mm)

6

For fi xing the wall

bracket

Coupler heat

insulation

2

For indoor side pipe

joint

Binder

Large 4

For fi xing the coupler

heat insulation

Medium 3

For power supply,

transmission and

remote controller cable

binding

Drain hose

1

For installing drain

pipe

Hose Band

1

For installing drain

hose

Drain hose insulation

1

Adhesive type

100 × 220

VT wire

1

For fi xing the drain

hose L 280 mm

Insulation (Pipe)

1

Adhesive type

160 × 110

Silencer pipe

1

Connect the silencer

pipe to the small (liquid)

pipe.

]

1

2.4. Optional parts

Description Part No. Application

Auxiliary pipe

9374714025

For indoor side pipe

joint

(For AB18, AB24)

External output wire 9379529006 For control output port

External input

(voltage) wire

9368779016 For control input port

External input

(no voltage) wire

9368779009 For control input port

Page 4

En-4

3. INSTALLATION WORK

Especially, the installation place is very important for the split

type air conditioner because it is very diffi cult to move from

place to place after the fi rst installation.

]

1

3.1. Selecting an installation location

Decide the mounting position together with the customer as

follows.

WARNING

• Select installation locations that can properly support the

weight of the indoor unit. Install the units securely so that

they do not topple or fall.

CAUTION

Do not install the indoor unit in the following areas:

• Area with high salt content, such as at the seaside. It will

deteriorate metal parts, causing the parts to fall or the

unit to leak water.

• Area fi lled with mineral oil or containing a large amount

of splashed oil or steam, such as a kitchen. It will

deteriorate plastic parts, causing the parts to fall or the

unit to leak water.

• Area that generates substances that adversely affect the

equipment, such as sulfuric gas, chlorine gas, acid, or

alkali. It will cause the copper pipes and brazed joints to

corrode, which can cause refrigerant leakage.

• Area that can cause combustible gas to leak, contains

suspended carbon fi bers or fl ammable dust, or volatile

inflammables such as paint thinner or gasoline. If gas

leaks and settles around the unit, it can cause a fi re.

• Area where animals may urinate on the unit or ammonia

may be generated.

• Do not use the unit for special purposes, such as storing

food, raising animals, growing plants, or preserving

precision devices or art objects.

It can degrade the quality of the preserved or stored

objects.

• Do not install where there is the danger of combustible

gas leakage.

• Do not install the unit near a source of heat, steam, or

fl ammable gas.

• Install the unit where drainage does not cause any

trouble.

• Install the indoor unit, outdoor unit, power supply cable,

transmission cable, and remote controller cable at least 1

m away from a television or radio receivers. The purpose

of this is to prevent TV reception interference or radio

noise. (Even if they are installed more than 1 m apart, you

could still receive noise under some signal conditions.)

• If children under 10 years old may approach the unit,

take preventive measures so that they cannot reach the

unit.

• Take precautions to prevent the unit from falling.

(1) Install the indoor unit on a place having a suffi cient

strength so that it withstands against the weight of the

indoor unit.

(2) The inlet and outlet ports should not be obstructed; the air

should be able to blow all over the room.

(3) Leave the space required to service the air conditioner.

(4) Install the unit where connection to the outdoor unit is

easy.

(5) Install the unit where the connection pipe can be easily

installed.

(6) Install the unit where the drain pipe can be easily installed.

(7) Install the unit where noise and vibrations are not

amplifi ed.

(8) Take servicing, etc., into consideration and leave the

spaces. Also install the unit where the fi lter can be

removed.

(9) Do not install the unit where it will be exposed to direct

sunlight.

]

1

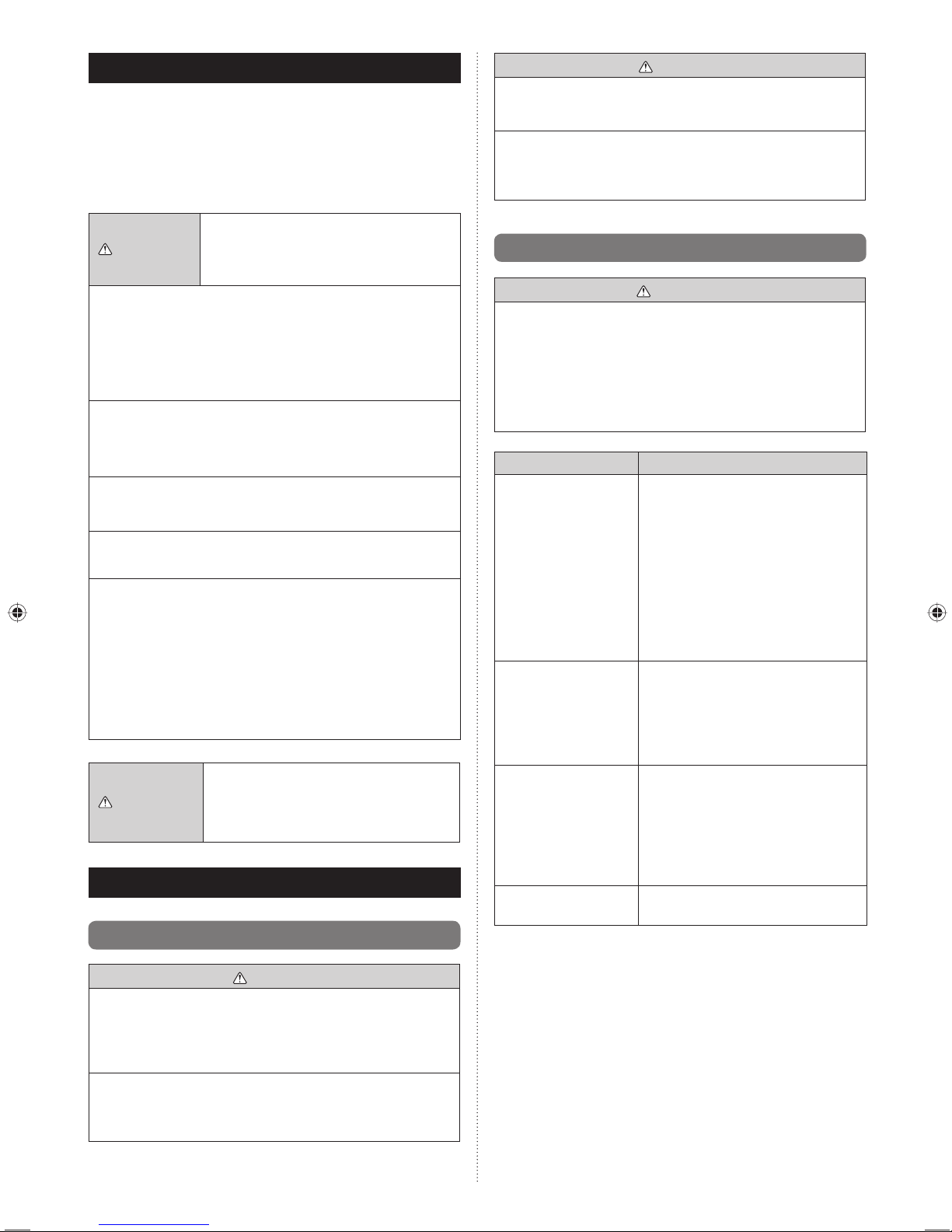

3.2. Installation dimension

Floor console

300

or more

Left Right

Unit : mm

300

or more

Under ceiling

Ceiling

Ceiling

Indoor unit

Left

150

or more

300

or more

2300

or more

Unit : mm

Floor

20 or more

Right

]

1

3.3. Installation the unit

WARNING

• Install the air conditioner in a location which can

withstand a load of at least 5 times the weight of the main

unit and which will not amplify sound or vibration. If the

installation location is not strong enough, the indoor unit

may fall and cause injuries.

Page 5

En-5

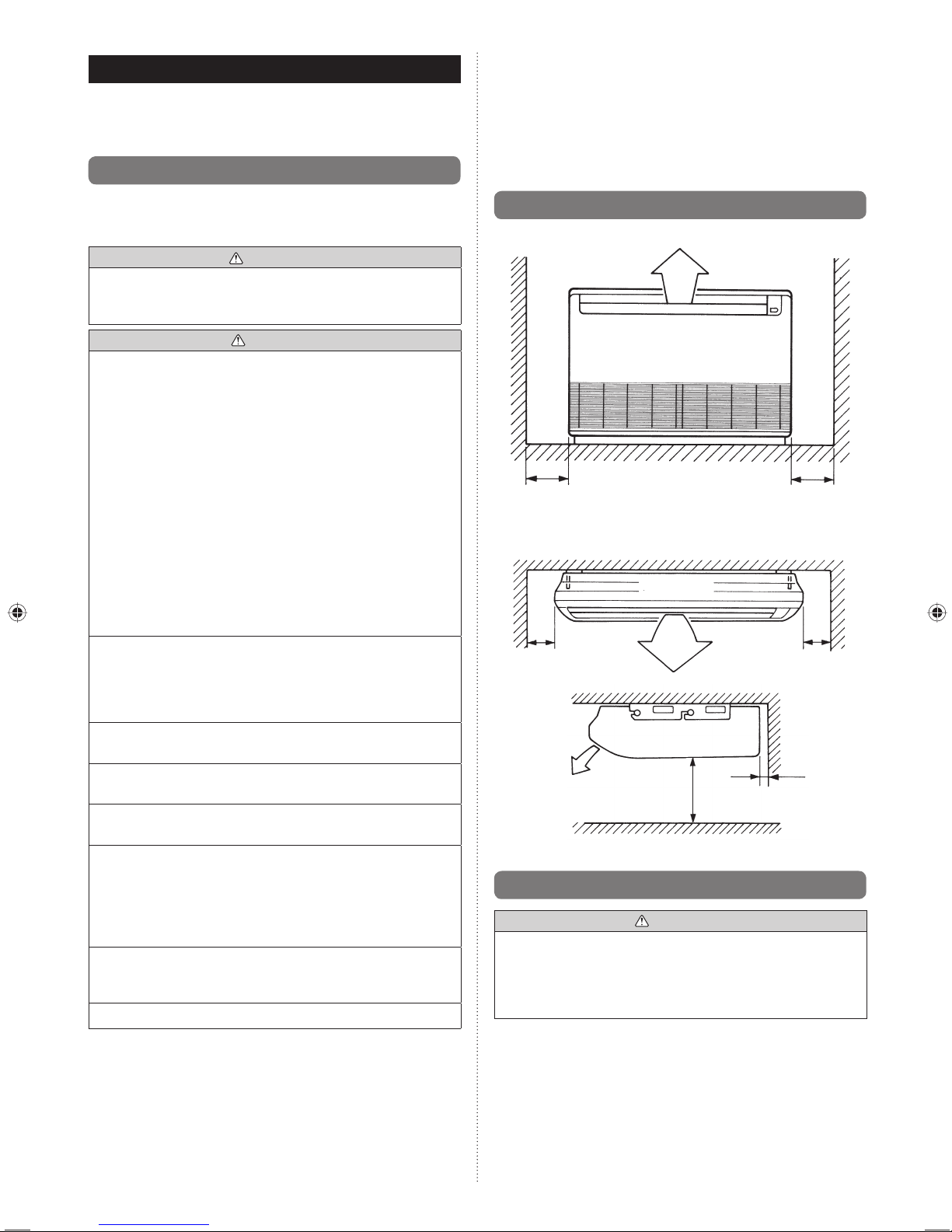

When installing set to wall install the accessory wall bracket at

the position as shown in the fi gure, and mount the set to it.

Unit : mm

Wall bracket

Side of set

990

500

65

655

530

45

65

Ø

50

125 100

Ø

100

245

B. Under ceiling type

Using the installation template, drill holes for piping and

suspension bolts (for holes).

Unit : mm

Installation

template

200

Drilling position

for suspension

bolt

Ceiling

Wall

Drilling position for piping

900

B-1. Drilling for piping

Select piping and drain directions.

To p

Rear

(Install the drain hose

in this direction.)

Right

Hole

VIEW

For direction, bore the oval hole shown in the above fi gure.

CAUTION

• Install the drain hose at the rear; it should not be installed

on the top or right side.

When the directions are selected, drill 80 mm and 50 mm or

150 mm dia. hole on the wall so that the hole is tilted downward toward the outdoor for smooth water fl ow.

Unit : mm

Wall

6

Indoor side Outdoor side

3.3.1. Preparing indoor unit installation

Open the intake grille and remove the 3 screws.

Machine screw

Tapping screw

Tapping screw

Intake grille

Remark : The main unit can be wired before the indoor unit is

installed.

Select the most appropriate installation order.

3.3.2. Indoor unit installation

A. Floor console type

Drilling for piping

Select piping and drain directions.

The piping and drain can be made in 3 directions as shown

below.

VIEW

Hole

For direction, bore the oval hole shown in the above fi gure.

The drain hose can be connected to either the left or right

side.

Drain hose

(Right side)

Drain hose

(Left side)

When the directions are selected, drill a 10 cm dia. hole on

the wall so that the hole is tilted downward toward the outdoor

for smooth water fl ow.

When the pipe is led out from the rear, make a hole as shown

in the fi gure, at the position shown.

Unit : mm

6

100

Wall

Indoor side Outdoor side

Page 6

En-6

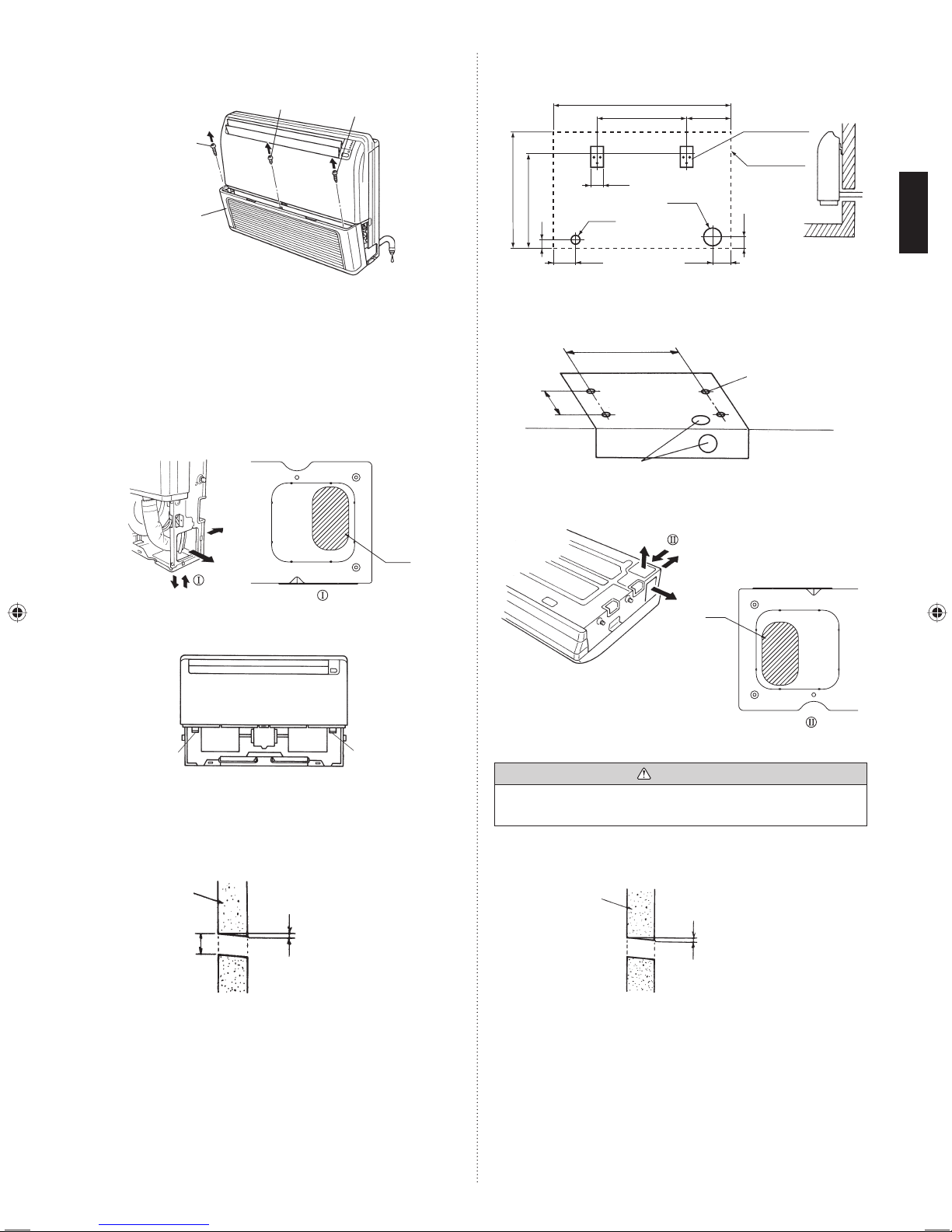

B-2. Drilling the holes and attaching the

suspension bolts

Drill Φ25 mm holes at the suspension bolt locations, then

install the bolts.

Bolt Strength 980 to 1470 N (100 to 150 kgf)

ø25 mm

Ceiling panel

20 to 50 mm

[If using anchor bolts]

Drill holes for anchor bolts at the locations at which you will

set the suspension bolts. Note that anchor bolts are M10 bolts

(to be obtained locally).

Anchor-Bolt Strength 980 to 1470 N (100 to 150 kgf)

Ceiling

20 to

50 mm

M10 Anchor bolt

(Field supply)

B-3. Installing Brackets

Install the bracket with nuts, spring washers.

Bracket (Right)

Bracket

Bracket (Left)

Special nut A

(Accessories)

Ceiling panel

Spring washer

(Field supply)

M10 Nut (Field supply)

M10 Nut (Field supply)

B-4. Installing indoor unit

Reset the hex bolts as shown in the fi gure

Unit : mm

Indoor unit

Hex bolt

8 to 13

Apply the indoor unit to the brackets.

Indoor unit

Bolt

Bracket

Now, securely tighten the hex bolts in both sides.

3.3.3. Barrier and RFM base removal and

installation

(1) Remove the barriers by removing the 4 fi xing screws

(2 screws each).

(2) Remove the RFM base by removing the 2 fi xing screws

and unhooking the 1 hook.

(3) After completing the work, install the barriers and RFM

base as they were originally.

RFM base

Fixing screw

(2 positions)

Barriers

Fixing screw

(2 positions)

Hook

Install the barriers in the correct direction.

4. PIPE INSTALLATION

]

CAUTION

• Be more careful that foreign matter (oil, water, etc.) does

not enter the piping than with refrigerant R410A models.

Also, when storing the piping, securely seal the openings

by pinching, taping, etc.

• While welding the pipes, be sure to blow dry nitrogen gas

through them.

]

1

4.1. Selecting the pipe material

CAUTION

• Do not use existing pipes.

• Use pipes that have clean external and internal sides

without any contamination which may cause trouble

during use, such as sulfur, oxide, dust, cutting waste, oil,

or water.

• It is necessary to use seamless copper pipes.

Material : Phosphor deoxidized seamless copper pipes

It is desirable that the amount of residual oil is less than

40 mg/10 m.

• Do not use copper pipes that have a collapsed,

deformed, or discolored portion (especially on the interior

surface). Otherwise, the expansion valve or capillary tube

may become blocked with contaminants.

• Improper pipe selection will degrade performance. As an

air conditioner using R410A incurs pressure higher than

when using conventional refrigerant, it is necessary to

choose adequate materials.

• Thicknesses of copper pipes used with R410A are as shown

in the table.

• Never use copper pipes thinner than those indicated in the

table even if they are available on the market.

Page 7

En-7

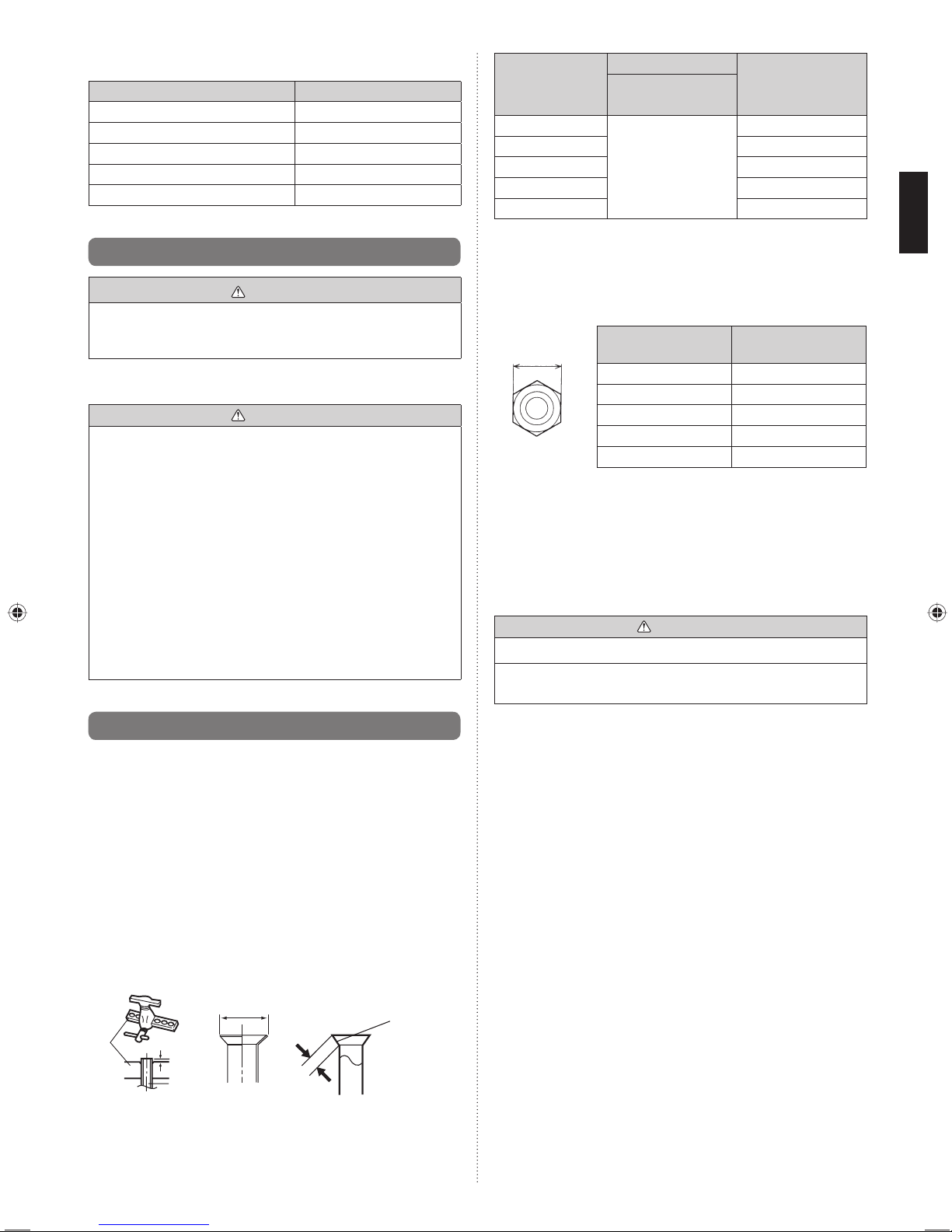

Thicknesses of Annealed Copper Pipes (R410A)

Pipe outside diameter [mm (in.)] Thickness [mm]

6.35 (1/4) 0.80

9.52 (3/8) 0.80

12.70 (1/2) 0.80

15.88 (5/8) 1.00

19.05 (3/4) 1.20

1

4.2. Pipe requirement

CAUTION

• Refer to the Installation Manual of the outdoor unit

for description of the length of connecting pipe or for

difference of its elevation.

Use pipe with water-resistant heat insulation.•

CAUTION

• Install heat insulation around both the gas and liquid

pipes. Failure to do so may cause water leaks.

Use heat insulation with heat resistance above 120 °C.

(Reverse cycle model only)

In addition, if the humidity level at the installation location

of the refrigerant piping is expected to exceed 70 %,

install heat insulation around the refrigerant piping.

If the expected humidity level is 70-80 %, use heat

insulation that is 15 mm or thicker and if the expected

humidity exceeds 80 %, use heat insulation that is 20

mm or thicker. If heat insulation is used that is not as

thick as specifi ed, condensation may form on the surface

of the insulation.

In addition, use heat insulation with heat conductivity of

0.045 W/(m·K) or less (at 20 °C).

1

4.3. Flare connection (pipe connection)

4.3.1. Flaring

• Use special pipe cutter and fl are tool exclusive for R410A.

(1) Cut the connection pipe to the necessary length with a

pipe cutter.

(2) Hold the pipe downward so that cuttings will not enter the

pipe and remove any burrs.

(3) Insert the fl are nut (always use the fl are nut attached to

the indoor and outdoor units respectively) onto the pipe

and perform the fl are processing with a fl are tool. Use the

special R410A fl are tool, or the conventional fl are tool.

Leakage of refrigerant may result if other fl are nuts are

used.

(4) Protect the pipes by pinching them or with tape to prevent

dust, dirt, or water from entering the pipes.

L

Check if [L] is fl ared uniformly

and is not cracked or scratched.

Die

Pipe

A

B

Pipe outside

diameter

[mm (in.)]

Dimension A [mm]

Dimension B

-00.4

[mm]

Flare tool for R410A,

clutch type

6.35 (1/4)

0 to 0.5

9.1

9.52 (3/8) 13.2

12.70 (1/2) 16.6

15.88 (5/8) 19.7

19.05 (3/4) 24.0

When using conventional fl are tools to fl are R410A pipes,

the dimension A should be approximately 0.5 mm more

than indicated in the table (for fl aring with R410A fl are tools)

to achieve the specifi ed fl aring. Use a thickness gauge to

measure the dimension A.

Pipe outside

diameter [mm (in.)]

Width across flats

of Flare nut [mm]

6.35 (1/4) 17

9.52 (3/8) 22

12.70 (1/2) 26

15.88 (5/8) 29

19.05 (3/4) 36

4.3.2. Bending pipes

The pipes are shaped by your hands or pipe bender. Be •

careful not to collapse them.

Do not bend the pipes in an angle more than 90°.•

When pipes are repeatedly bend or stretched, the material •

will harden, making it diffi cult to bend or stretch them any

more. Do not bend or stretch the pipes more than 3 times.

CAUTION

• To prevent breaking of the pipe, avoid sharp bends.

• If the pipe is bent repeatedly at the same place, it will

break.

Width across

fl ats

Page 8

En-8

4.3.3. Pipe connection

Connect the silencer pipe to the small (liquid) pipe.

Centering the pipe against port on the indoor unit, turn the

fl are nut with your hand.

Be sure that the small pipe is completely installed before

connecting the large pipe.

Indoor unit side

Silencer pipe

(Accessories)

CAUTION

• Be sure to apply the pipe against the port on the indoor

unit and the outdoor unit correctly. If the centering is

improper, the flare nut cannot be tightened smoothly.

If the flare nut is forced to turn, the threads will be

damaged.

• Do not remove the fl are nut from the indoor unit pipe until

immediately before connecting the connection pipe.

• Do not use mineral oil on flared part. Prevent mineral

oil from getting into the system as this would reduce the

lifetime of the units.

If necessary, cut the silencer pipe and use it.

Silencer pipe

(Accessories)

CAUTION

• Hold the torque wrench at its grip, keeping it in the right

angle with the pipe, in order to tighten the flare nut

correctly.

• Tighten the flare nuts with a torque wrench using the

specified tightening method. Otherwise, the flare nuts

could break after a prolonged period, causing refrigerant

to leak and generate a hazardous gas if the refrigerant

comes into contact with a fl ame.

When the fl are nut is tightened properly by your hand,

hold the body side coupling with a separate spanner, then

tighten with a torque wrench.

Connection pipe

Torque wrench

Indoor unit pipe

(Body side)

Tighten with 2 wrenches.

Holding wrench

Flare nut

Flare nut [mm (in.)] Tightening torque [N·m (kgf·cm)]

6.35 (1/4) dia. 16 to 18 (160 to 180)

9.52 (3/8) dia. 32 to 42 (320 to 420)

12.70 (1/2) dia. 49 to 61 (490 to 610)

15.88 (5/8) dia. 63 to 75 (630 to 750)

19.05 (3/4) dia. 90 to 110 (900 to 1,100)

]

1

4.4. Installing heat insulation

CAUTION

• After checking for gas leaks (refer to the Installation

Manual of the outdoor unit), perform this section.

• Install heat insulation around both the large (gas) and

small (liquid) pipes. Failure to do so may cause water

leaks.

After checking for gas leaks, insulate by wrapping insulation

around the 2 parts (Gas and Liquid) of the indoor unit

coupling, using the coupler heat insulation.

After installing the coupler heat insulation, wrap both ends

with vinyl tape so that there is no gap.

Secure both ends of the heat insulation material using Binder.

And fi nally fi x connection pipe (Liquid) to connection pipe (Gas)

by rolling vinyl tape over coupler heat insulation (Gas) and

coupler heat insulation (Liquid).

Coupler heat

insulation

Indoor unit

No gap

Coupler heat

insulator

(Accessories)

Coupler heat

insulator

(Accessories)

Be sure to overlap

the insulation

Gas pipe Liquid pipe

No gap

Page 9

En-9

Insulation (pipe)

(Accessories)

No gap

Small pipe

Silencer pipe

CAUTION

• There should be no gaps between the insulation and the

unit.

5. INSTALLING DRAIN HOSE

]

CAUTION

• Install the drain hose in accordance with the instructions

in this Installation Manual and keep the area warm

enough to prevent condensation. Problems with the

piping may lead to water leaks.

Use general hard polyvinyl chloride pipe and connect it with

adhesive (polyvinyl chloride) so that there is no leakage.

Always heat insulate the indoor side of the drain hose.

Use a drain pipe that matches the size of the drain hose.

• Do not perform a rise, trap and air bleeding.

• Provide a downward gradient (1/100 or more).

• Provide supporters when long pipes are installed.

• Use an insulation material as needed, to prevent the pipes

from freezing.

• Install the pipes in a way that allows for the removal of the

control box.

O.D.

Drain pipe 32 mm (VP25)

When using the drain port on the left side of the unit, remove

the drain cap and install it to the right side drain port.

(Only when suspended from the ceiling)

Drain cap

Unit

INSTALL THE DRAIN HOSE

Working procedure

1) Install the attached drain hose to the drain port of the

body. Install the hose band from the top of the hose within

the graphic display area. Secure fi rmly with the hose

band.

2) Use vinyl adhesive agent to glue the drain piping (PVC

pipe VP25) which is prepared on site or piping socket.

(Apply color adhesive agent evenly until the gauge line

and seal)

3) Check the drainage.

4) Install the heat insulation.

5) Use the attached heat insulation to insulate the drain port

and band parts of the body.

Top view

Drain hose

(Accessories)

10~15mm

Hose Band

(Accessories)

Soft PVC side

Ensure there is no space

Drain pan

Side view

Applying

area of

adhesive

Hard PVC side

Joint pipe

(Field supply)

Drain pipe (VP25)

(Field supply)

4 mm or less

Wrap the Drain hose insulation around the drain hose

connection.

Top view

Drain pan

Drain hose

100mm

Drain hose insulation

(Accessories)

Hose opening view

Wind the attached heat insulation

around the hose band. Make sure

the alignment is on top.

A. Floor console type

Be sure to arrange the drain hose so that it is leveled lower

than the drain hose connecting port of the indoor unit.

Drain hose

OK NO GOOD NO GOOD

Arrange the drain

hose lower than

this portion.

CAUTION

• Do not install the unit so that the drain hose side is too

high. Height A should be less than 5 mm.

Drain hose

NO GOOD NO GOOD

Page 10

En-10

B. Under ceiling type

Be sure to arrange the drain hose so that it is leveled lower

than the drain hose connecting port of the indoor unit.

Drain

hose

Arrange the drain hose

lower than this portion.

OK NO GOOD

When drain hose is arranged backward.

Secure the drain hose with the VT wire.

Drain hose

VT wire

hole

VT wire

Pass the drain hose

through here.

Cut the grille

Intake grille

Base (Bottom)

6. ELECTRICAL WIRING

]

WARNING

• Electrical work must be performed in accordance with this

Manual by a person certifi ed under the national or regional

regulations. Be sure to use a dedicated circuit for the unit.

An insufficient power supply circuit or improperly

performed electrical work can cause serious accidents

such as electric shock or fi re.

• Before starting work, check that power is not being

supplied to the indoor unit and outdoor unit.

• Use the included connection cables and power cables

or ones specified by the manufacturer. Improper

connections, insufficient insulation, or exceeding the

allowable current can cause electric shock or fi re.

• For wiring, use the prescribed type of cables, connect

them securely, making sure that there are no external

forces of the cables applied to the terminal connections.

Improperly connected or secured cables can cause

serious accidents such as overheating the terminals,

electric shock, or fi re.

• Do not modify the power cables, use extension cables,

or use any branches in the wiring. Improper connections,

insuffi cient insulation, or exceeding the allowable current

can cause electric shock or fi re.

• Match the terminal board numbers and connection cable

colors with those of the outdoor unit. Erroneous wiring

may cause burning of the electric parts.

• Securely connect the connection cables to the terminal

board. In addition, secure the cables with wiring holders.

Improper connections, either in the wiring or at the ends

of the wiring, can cause a malfunction, electric shock, or

fi re.

• Always fasten the outside covering of the connection

cable with the cable clamp. (If the insulator is chafed,

electric leakage may occur.)

• Securely install the electrical box cover on the unit.

An improperly installed electrical box cover can cause

serious accidents such as electric shock or fi re through

exposure to dust or water.

• Install sleeves into any holes made in the walls for wiring.

Otherwise, a short circuit could result.

• Install a ground leakage breaker. In addition, install the

ground leakage breaker so that the entire AC main power

supply is cut off at the same time. Otherwise, electric

shock or fi re could result.

• Always connect the ground cable.

Improper grounding work can cause electric shocks.

• Install the remote controller cables so as not to be direct

touched with your hand.

• Perform wiring work in accordance with standards so that

the air conditioner can be operated safely and positively.

• Connect the connection cable fi rmly to the terminal

board. Imperfect installation may cause a fi re.

CAUTION

• Ground the unit.

Do not connect the ground cable to a gas pipe, water

pipe, lightning rod, or a telephone ground cable.

Improper grounding may cause electric shock.

• Do not connect power supply cables to the transmission

or remote controller terminals, as this will damage the

product.

• Never bundle the power supply cable and transmission

cable, remote controller cable together.

Separate these cable by 50 mm or more.

Bundling these cables together will cause miss operation

or breakdown.

• When handling PCB, static electricity charged in the body

may cause malfunction of the PCB. Follow the cautions

below:

• Establish a ground for the indoor and outdoor units and

peripheral devices.

• Cut power (breaker) off.

• Touch metal part of the indoor and outdoor units for

more than 10 seconds to discharge static electricity

charged in the body.

• Do not touch terminals of parts and patterns

implemented on PCB.

Page 11

En-11

]

1

6.1. Electrical requirement

Voltage rating

230 V

Operating range

198 - 264 V

Recom-

mended cable

size (mm2)

Cable type Remark

Power

supply cable

2.5

Type245 IEC57

or equivalent

1ø 50 Hz

198 - 264 V

2 Cable + ground

Transmission

cable

0.33

LONWORKS

compatible cable

22 AWG

LEVEL 4 (NEMA)

non-polar 2 core,

twisted pair solid

core diameter

0.65 mm

Remote

controller

cable

0.33

Sheathed

PVC cable*

Polar 3 core

Twisted pair

*: Use shielded cable in accordance with local rules for

remote controller cable.

Fuse capacity (A) Breaker for leakage current

15 30 mA 0.1 sec. or less

]

1

6.2. Wiring method

(EXAMPLE)

POWER SUPPLY

OUTDOOR UNIT

BREAKER

POWER SUPPLY

TRANSMISSION

TRANSMISSION

POWER

SUPPLY

POWER

SUPPLY

REMOTE

CONTROLLER

(Primary)

REMOTE

CONTROLLER

POWER

SUPPLY

REMOTE

CONTROL

TRANSMISSION TRANSMISSION

POWER

SUPPLY

POWER

SUPPLY

REMOTE

CONTROL

REMOTE

CONTROL

INDOOR UNIT

POWER

SUPPLY

REMOTE

CONTROLLER

(Secondary)

INDOOR UNIT

INDOOR UNIT

BREAKER

BREAKER BREAKER

*Ground the remote controller if it has a ground wire.

]

1

6.3. Unit wiring

• Before attaching the cable to terminal block.

6.3.1. Power supply cable

Power supply

cable

15 mm

Earth

cable

70 mm

A. For solid core wiring

(1) To connect the electrical terminal, follow the below

diagram and connect after looping it around the end of the

cable.

(2) Use the specifi ed cables, connect them securely, and

fasten them so that there is no stress placed on the

terminals.

(3) Use an appropriate screwdriver to tighten the terminal

screws. Do not use a screwdriver that is too small,

otherwise, the screw heads may be damaged and prevent

the screws from being properly tightened.

(4) Do not tighten the terminal screws too much, otherwise,

the screws may break.

(5) See the table for the terminal screw tightening torques.

(6) Please do not fi x 2 power supply cables with 1 screw.

Strip 25 mm

Loop

Screw with

special washer

Cable

Cable end (Loop)

Terminal block

Screw with

special

washer

Cable end

(Loop)

Cable

WARNING

• When using solid core cables, do not use the ring

terminal. If you use the solid core cables with the ring

terminal, the ring terminal’s pressure bonding may

malfunction and cause the cables to abnormally heat up.

Page 12

En-12

6.3.2. Transmission and Remote controller cable

Transmission cable

Shielded

cable

(No fi lm)

50 mm

30 mm

Remote controller cable

30 mm

• Connect remote controller and transmission cables as shown

in Fig. B.

• When the 2 cables are attached.

Fig. B

Different

diameter

Connect to

1 side

OK

NO GOOD NO GOOD

WARNING

• Tighten the terminal screws to the specified torques,

otherwise, abnormal overheating may be produced and

possibly cause heavy damage inside the unit.

Tightening torque

M3 screw

(Transmission/X1, X2)

(Remote controller/Y1, Y2, Y3)

0.5 to 0.6 N·m

(5 to 6 kgf·cm)

CAUTION

• To peel the fi lm from the lead cable, use a dedicated tool

that will not damage the conductor cable.

• When installing a screw on the terminal block, do not cut

the cable by overtightening the screw. On the other hand,

an undertightened screw can cause faulty contact, which

will lead to a communication failure.

]

B. For strand wiring

(1) Use ring terminals with insulating sleeves as shown in the

fi gure below to connect to the terminal block.

(2) Securely clamp the ring terminals to the cables using an

appropriate tool so that the cables do not come loose.

(3) Use the specifi ed cables, connect them securely, and

fasten them so that there is no stress placed on the

terminals.

(4) Use an appropriate screwdriver to tighten the terminal

screws. Do not use a screwdriver that is too small,

otherwise, the screw heads may be damaged and prevent

the screws from being properly tightened.

(5) Do not tighten the terminal screws too much, otherwise,

the screws may break.

(6) See the table for the terminal screw tightening torques.

(7) Please do not fi x 2 power supply cables with 1 screw.

Ring terminal

Sleeve

Screw with

special washer

Cable

Ring terminal

Terminal block

Screw with

special

washer

Cable

Ring

terminal

Strip 10 mm

WARNING

• Use ring terminals and tighten the terminal screws to the

specifi ed torques, otherwise, abnormal overheating may

be produced and possibly cause heavy damage inside

the unit.

Tightening torque

M4 screw

(Power supply/L, N, GND)

1.2 to 1.8 N·m

(12 to 18 kgf·cm)

Page 13

En-13

1

6.4. Connection of wiring

(1) Remove the electric component box.

Electric component box

Electric component box

RFM

CAUTION

• Do not remove the RFM fixing screws. If the stays are

removed, the electric component box will fall.

• If you use as “Floor console”, you must remove screws

and RFMs (2 position).

When removing the electric component box, remove the

clamp from the cables.

After completing the work, fasten the cables as they were

originally by installing the clamp.

Cables

Clamp

Remove the clamp.

Install the clamp.

(2) Pull out the electric component box.

Electric component box

(3) Remove the electric component box cover.

Remove the 3 tapping screws.

Electric component box cover

Base

CAUTION

• Be careful not to pinch the lead cables between the

electric component box and base.

(4) Wiring

* When there is 1 transmission cable or remote controller

cable, fasten it the same way as shown in the fi gure with a

binder (medium).

Binder (Medium)

(Accessories)

L, N: Power supply cable

Remote controller cable

Y1: Red, Y2: White, Y3: Black

X1, X2: Transmission cable

]

1

6.5. External input and external output

(Optional parts)

Controller PCB

Input No Voltage terminal (CN17)

Input Voltage terminal (CN6)

Output terminal (CN16)

GND

Page 14

En-14

(1) External input terminals

• Indoor unit can be Start/Stop or Emergency stop, Forced

stop by using indoor unit PCB CN6 or CN17.

Wiring methods and specifi cations

• A twisted pair cable (22AWG) should be used. Maximum

length of cable is 150 m.

* Use an external input and output cable with appropriate

external dimension, depending on the number of cables to

be installed.

• The wire connection should be separate from the power

cable line.

• Input selection

Use either one of these types of terminal according to the

application. (Both types of terminals cannot be used

simultaneously.)

• Voltage terminal ([CN6])

When a power supply must be provided at the input device

you want to connect, use the voltage terminal ([CN6]).

1

2

3

+

+

-

-

-

Input device 1Input device 2

Load

resistance

Load

resistance

*1

DC power supply

12 - 24V

connected unit

*a

*a

P.C .B

CN6

*b

*1 Make the power supply DC12 to 24V. Select a power supply

capacity with an ample surplus for the connected load.

Do not impress a voltage exceeding 24V across pins 1-2, and

1-3.

*a The allowable current is DC5~10mA. (Recommended:

DC5mA)

Provide a load resistance such that the current becomes

DC10mA or less.

Select very low current use contacts (usable at DC12V,

DC1mA or less).

*b The polarity is [+] for pin 1 and [-] for pin 2 and 3.

Connect correctly.

When connected to voltage terminals of multiple indoor units

with a connected unit, be sure to make a branch outside the

indoor unit using a pull box, etc. as shown on below example.

DC power

supply 12-24V

connected unit

Load

resistance

P.C .B

P.C .B

CN6

CN6

CN6

P.C .B

Input device 1Input device 2

Indoor unitIndoor unitIndoor unit

Load

resistance

• No voltage terminal ([CN17])

When a power supply is unnecessary at the input device you

want to connect, use the no voltage terminal ([CN17]).

1

2

3

P.C .B

GND

Ch 1

*c

*c

*d

Ch 2

CN17

connected unit

*c Select very low current use contacts (usable at DC12V,

DC1mA or less).

*d The wiring is different from voltage terminals. Be suffi ciently

careful when wiring.

When connected to no voltage terminals of multiple indoor

units with a connected unit, insulate each indoor unit with

relay, etc. as shown on below example.

When connected to multiple indoor units directly, it will cause

breakdown.

Power supply for relay

Indoor unit Indoor unit Indoor unit

Input device 2

Input device 1

K1~ K6: Re lay

P.C .B

K1

P.C .B

P.C .B

CN17

CN17

CN17

K2

K3

K4

K5

K6

Operation behavior

• Input signal type

The input signal type can be selected.

Pulse

Edge

The width of pulse

must be longer than

200msec.

It is switched by Dip-sw on the indoor

unit PCB.

Dip-sw [Set 2-2] Input signal type

OFF Edge

ON Pulse

• When function setting is “Start/Stop” mode

In the case of “Edge” input

Connector Input signal Command

Ch1 of

CN6 or CN17

OFF → ON Operation

ON → OFF Stop

In the case of “Pulse” input

Connector Input signal Command

CN6 or CN17

Ch1 OFF → ON Operation

Ch2 OFF → ON Stop

(Device for DC Current)

Page 15

En-15

* The last command has priority.

* The indoor units within the same remote controller group

operates in the same mode.

• When function setting is “Emergency stop” mode

In the case of “Edge” input

Connector Input signal Command

Ch1 of

CN6 or CN17

OFF → ON Emergency stop

ON → OFF Normal

In the case of “Pulse” input

Connector Input signal Command

CN6 or CN17

Ch1 OFF → ON

Emergency

stop

Ch2 OFF → ON Normal

* All indoor units of same refrigerant system stops when

Emergency stop operates.

• When function setting is “Forced stop” mode

In the case of “Edge” input

Connector Input signal Command

Ch1 of

CN6 or CN17

OFF → ON Forced stop

ON → OFF Normal

In the case of “Pulse” input

Connector Input signal Command

CN6 or CN17

Ch1 OFF → ON Forced stop

Ch2 OFF → ON Normal

* When the forced stop is triggered, indoor unit stops and

Start/Stop operation by a remote controller is restricted.

* When forced stop function is used with forming a

remote controller group, connect the same equipment

to each indoor unit within the group.

• Selection method of functions

“Start/Stop” mode or “Emergency stop” mode, “Forced stop”

mode can be selected with function setting of indoor unit.

(2) External output terminals

• When picking up output signals for operating status,

abnormal conditions or indoor unit status.

Wiring methods and specifi cations

1

2

3

4

P.C .B

CN16

*4

+

+

-

-

-

-

DC power supply

12 - 24V *2

Connected load

*3

connected unit

Connected load

*3

Connected load

*3

*2 Provide a DC12 to 24V power supply. Select a power

supply capacity with an ample surplus for the connected

load.

*3 The allowable current is 30mA or less. Provide a load

resistance such that the current becomes 30mA or less.

*4

Polarity is [+] for pin 1 and [-] for pins 2-4. Connect correctly.

Do not impress a voltage exceeding 24V across pins 1-2, 1-3,

and 1-4.

Operation behavior

Connector Output voltage Status

CN16

External

output1

Pins 1-2

0V Stop

DC 12-24 V *2 Operation

External

output2

Pins 1-3

0V Normal

DC 12-24 V *2 Error

External

output3

Pins 1-4

0V Indoor unit fan stop

DC 12-24 V *2

Indoor unit fan

operation

A twisted pair cable (22AWG) should be used. Maximum

length of cable is 150 m.

* Use an external input and output cable with appropriate

external dimension, depending on the number of cables to

be installed.

Page 16

En-16

(3) Connection methods

• Wire modifi cation

Use a tool to cut off the terminal on the end of the wire, and

then remove the insulation from the cut end of the wire.

Connect the wire with connecting wire with solder.

Important: Be sure to insulate the connection between the

wires.

Option parts

External input /output wire

Insulated connection

Field supply

Input Voltage terminal

(CN6)

Controller PCB

Input No Voltage terminal (CN17)

Output terminal (CN16)

Binder

Switch PCB

Controller PCB

Power supply PCB

Terminal PCB

7. FIELD SETTING

There are 3 methods for address setting by FIELD SETTING

as follows.

Set by either of the methods.

Each setting method is described (1) to (3) below.

(1)

IU AD, REF AD SW settings

....This section (7.1. Setting

the address)

(2) Remote controller settings .... Refer to the wired or

wireless remote controller

manual for detailed setting

information. (Set IU AD,

REF AD SW to 0)

(3) Automatic address settings ... Refer to the outdoor unit

manual for detailed setting

information. (Set IU AD,

REF AD SW to 0)

]1

7.1. Setting the address

Manual address setting method

• The indoor unit address and the refrigerant circuit address

can also be set up through the wireless remote controller.

CAUTION

• Be sure to turn OFF the power before performing the

fi eld setting.

• Set it according to the following procedures when setting

manually.

It can be set manually if the cover (small) is removed under

the condition that the electric component box cover is

attached.

Cover (small)

Electric component box

Rotary switch

Example: “0”

Rotary switch

Example: “0”

Page 17

En-17

CAUTION

• Use an insulated screwdriver to set the dip switches.

Setting

Setting

range

Type of switch

Indoor unit

address

0–63

Setting

example

2

IU AD x 10 IU AD x 1

Refrigerant

circuit

address

0–99

Setting

example

63

REF AD x 10 REF AD x 1

(1) Indoor unit address

Rotary switch (IU AD × 1) .........Factory setting “0”

Rotary switch (IU AD × 10) .......Factory setting “0”

When connecting multiple indoor units to 1 refrigerant sys-

tem, set the address at IU AD SW as shown in the Table A.

(2) Refrigerant circuit address

Rotary switch (REF AD × 1) .....Factory setting “0”

Rotary switch (REF AD × 10) ...Factory setting “0”

In the case of multiple refrigerant systems, set REF AD

SW as shown in the Table A for each refrigerant

system.

Set to the same refrigerant circuit address as the outdoor

unit.

Table A

Address

Rotary

Switch Setting

Address

Rotary

Switch Setting

Refrigerant

circuit

REF AD SW

Indoor unit

IU AD SW

×

10

×

1

×

10

×

1

000000

101101

202202

303303

404404

505505

606606

707707

808808

909909

10 1 0 10 1 0

11 1 1 11 1 1

12 1 2 12 1 2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

99 9 9 63 6 3

Do no

t set the indoor unit address (IU AD SW) at 64 to 99. It

may result

failure.

(3) Remote controller address

Rotary switch (RC AD SW)....Factory setting “0”

When connecting multiple indoor units to 1 standard wired

remote controller, set the address at RC AD SW in

sequence from 0.

Setting

Setting

range

Type of switch

Remote con-

troller

address

0–15

Setting

example

0

RC AD

Example If 4 indoor units are connected.

Remote

controller

Indoor unit

Indoor unit

Indoor unitIndoor unit

RC AD SW0RC AD SW1RC AD SW2RC AD SW

3

RC AD SW

01234567

Address 01234567

RC AD SW

89ABCDEF

Address 8 9 10 11 12 13 14 15

]1

7.2. Custom code setting

Selecting the custom code prevents the indoor unit mix-up.

(Fig. B)

(Up to 4 codes can be set.)

Perform the setting for both the indoor unit and the remote

controller.

Fig. B

Code change

Indoor unit

Remote

controller

Confusion

A B C D

A B C D

• Custom code setting for indoor unit

Set the DIP SW SET 3 SW1, SW2, referring to the Table B.

sw1sw2sw3sw

4

Dip switch

“SET 3”

ON

OFF

Table B

Custom code

A (Factory setting) B C D

DIP SW

SET 3 SW1

OFF ON OFF ON

DIP SW

SET 3 SW2

OFF OFF ON ON

Page 18

En-18

]1

7.3. Function setting

• FUNCTION SETTING can be performed with the wired or

wireless remote controller.

(The remote controller is optional equipment)

• Refer to the wired or wireless remote controller manual for

detailed setting information. (Set IU AD, REF AD SW to 0)

• Refer to “7.1. Setting the address” for indoor unit address

and refrigerant circuit address settings.

•

Turn the power of the indoor unit ON before starting the setting.

* Turning on the power indoor units initializes EEV, so make

sure the piping air tight test and vacuuming have been

conducted before turning on the power.

* Also check again to make sure no wiring mistakes were

made before turning on the power.

Function details

Function

Function

number

Setting

number

Default Details

Filter

indicator

interval

11

00 Default

○

Adjust the fi lter cleaning interval

notifi cation. If the notifi cation is

too early, change to setting 01. If

the notifi cation is too late, change

to setting 02.

01 Longer

02 Shorter

Filter

indicator

action

13

00 Enable

○

Enable or disable the fi lter

indicator. Setting 02 is for use

with a central remote controller.

01 Disable

02

Display

only on

central

remote

controller

Horizon-

tal swing

airfl ow

direction

24

00 Default

○

Adjust the horizontal swing airfl ow

direction.

(For horizontal swing equipped

models)

01 Left half

02 Right half

Cool air

tem-

perature

trigger

30

00 Default

○

Adjust the cool air trigger

temperature. To lower the trigger

temperature, use setting 01. To

raise the trigger temperature, use

setting 02.

01 Adjust (1)

02 Adjust (2)

Hot air

tem-

perature

trigger

31

00 Default

○

Adjust the hot air trigger

temperature. To lower the trigger

temperature by 6 degrees C, use

setting 01. To lower the trigger

temperature by 4 degrees C, use

setting 02. To raise the trigger

temperature, use setting 03.

01 Adjust (1)

02 Adjust (2)

03 Adjust (3)

Auto

restart

40

00 Enable

Enable or disable automatic

system restart after a power outage.

*

Auto restart is an emergency function such as for power failure etc.

Do not start and stop the indoor

unit by this function in normal

operation.

Be sure to operate by the control

unit, converter or external input

device.

01 Disable

○

External

control

46

00 Start/Stop

○

Allow an external controller to

start or stop the system, or to

perform an emergency stop.

* If an emergency stop is

performed from an external

controller, all refrigerant systems

will be disabled.

*

If forced stop is set, indoor unit

stops

by the input to the external

input terminals, and Start/Stop by

a remot

e controller is restricted.

01

Emergency

stop

02

Forced

stop

Error

report

target

47

00 All

○

Change the target for reporting

errors. Errors can either be

reported in all locations, or only

on the central remote controller.

01

Display only

on central

remote controller

7.3.1. Button name and function

OPERATION indicator lamp (Green)

TIMER indicator lamp (Orange)

FILTER indicator lamp (Red)

MANUAL AUTO button

7.3.2. Checking the function settings

• Press and hold the “MANUAL AUTO” button on the indoor

unit for 3 seconds to check the function settings. It is

necessary to disconnect the power in order to return to

normal operation mode.

(1) Indoor unit and refrigerant address indication

Indication pattern

Indicator name

Indication pattern

Indoor unit

address

Refrigerant address

OPERATION

indicator lamp (Green)

ON

Flash

(1.0s ON/1.0s OFF)

TIMER indicator lamp

(Orange)

Address: tens place (0.5s ON/0.5s OFF)

FILTER indicator lamp

(Red)

Address: ones place (0.5s ON/0.5s OFF)

• Indoor unit address example

(Example) ADDRESS : 24

OPERATION

indicator lamp

(Green)

TIMER

indicator lamp

(Orange)

FILTER

indicator lamp

(Red)

10 sec

1 cycle 12 sec

8 sec

ON

OFF

0.5s

0.5s 0.5s 0.5s

0.5s

0.5s

0.5s 0.5s

0.5s

0.5s

0.5s 0.5s

ON

OFF

ON

OFF

ON

Page 19

En-19

• Refrigerant address example

(Example) ADDRESS : 30

OPERATION

indicator lamp

(Green)

TIMER

indicator lamp

(Orange)

FILTER

indicator lamp

(Red)

9 sec

1 cycle 12 sec

ON

OFF

1.0s 1.0s 1.0s

1.0s 1.0s 1.0s 1.0s

0.5s

0.5s

0.5s 0.5s 0.5s 0.5s

ON

OFF

ON

OFF

OFF

• Setting details

Function

number

Item Setting number

01 Indoor unit address 00~63

02 Refrigeration address 00~99

For use with a remote controller, set all rotary switches to 0,

and refer to “7.1. Setting the address” for details.

All switches are set to 0 at the factory.

(2) Others

Indication pattern

Indicator Name Indication pattern

OPERATION

indicator lamp (Green)

Function number; tens place

(0.5s ON/0.5s OFF)

TIMER

indicator lamp (Orange)

Function number; ones place (0.5s

ON/0.5s OFF)

FILTER

indicator lamp (Red)

Setting number: (0 - 9) (0.5s ON/0.5s

OFF)

(Example) Function : 31, Setting number : 2

OPERATION

indicator lamp

(Green)

TIMER

indicator lamp

(Orange)

FILTER

indicator lamp

(Red)

11 sec

10 sec

9 sec

1 cycle 12 sec

ON

OFF

0.5s

0.5s

0.5s

0.5s

0.5s

0.5s

0.5s

0.5s

0.5s

0.5s 0.5s 0.5s

ON

OFF

ON

OFF

8. MOUNT THE COVER PLATE AND

THE INTAKE GRILLE

]

1

8.1. Handling for the pipe take-off part

When the pipe is pulled out in the direction shown in the fi gure

below, cover the take-off part with material (putty or the like)

that will block it off.

UNDER CEILING TYPE

To p

Right

Rear

FLOOR CONSOLE TYPE

]

1

8.2. Mount the cover plate (Right)

(1) Cut a pipe exit hole in the right plate. This is only when

the pipe exits from the right side. (This operation is not

required when the protrusion is on the top or rear.)

Cover plate (Right) (Accessories)

Page 20

En-20

(2) Join the cover plates (right) and mount with screws.

Tapping screw (ø4 × 10)

(Accessories)

]

1

8.3. Mount the cover plate (Left)

(1) Join the cover plates (left) and mount with screws.

Tapping screw (ø4 × 10)

(Accessories)

Cover plate (Left)

(Accessories)

8.4. Mount the intake grille

(1) Cut the right side of the intake grille. This is only when the

pipe exits from the right side.

(2) Insert the hinges on the bottom of the intake grille into the

holes in the base assembly. Then mount the arms to the

3 areas on the top of the intake grille.

9. TEST OPERATION

]

1

9.1. Test operation using PCB (Outdoor

unit)

• Refer to the Installation Manual for the outdoor unit if the

PCB for the outdoor unit is to be used for the test operation.

]

1

9.2. Test operation using remote controller

• Refer to the Installation Manual for the remote controller to

perform the test operation using the remote controller.

• When the air conditioner is being test run, the OPERATION

and TIMER indicator lamps fl ash slowly at the same time.

10. CHECK LIST

]1

Pay special attention to the check items below when

installing the indoor unit(s). After installation is complete, be

sure to check the following check items again.

Check items

If not performed

correctly

Check

box

Has the indoor unit

been installed correctly?

Vibration, noise,

indoor unit may drop

Has there been a

check for gas leaks

(refrigerant pipes)?

No cooling, No heating

Has heat insulation

work been completed?

Water leakage

Does water drain easily

from the indoor units?

Water leakage

Is the voltage of the

power source the same

as that indicated on the

label on the indoor unit?

No operation, heat

or burn damage

Are the wires and

pipes all connected

completely?

No operation, heat

or burn damage

Is the indoor unit

grounded?

Short circuit

Is the connection cable

the specifi ed thickness?

No operation, heat

or burn damage

Are the inlets and outlets

free of any obstacles?

No cooling, No heating

Does start and stop air

conditioner operation

by remote controller

or external device?

No operation

After installation is

completed, has the

proper operation

and handling been

explained to the user?

Page 21

En-21

11. ERROR CODES

1

If you use a wired type remote controller, error codes will

appear on the remote controller display. If you use a wireless

remote controller, the lamp on the photodetector unit will

output error codes by way of blinking patterns. See the lamp

blinking patterns and error codes in the table below.

Error display

Wired

Remote

Controller

Error CODE

Error contents

OPERATIOR

indicator

lamp

(green)

TIMER

indicator

lamp

(orange)

FILTER

indicator

lamp

(red)

(1) (2)

Remote

controller

communication

error

(1) (4)

Anomalous

network

communications

(1) (6)

Parallel

communication

error

(3) (1)

Power

frequency error

(3) (2)

Model

information

error/EEPROM

accession error

(4) (1)

Room

temperature

thermistor error

(4) (2)

Indoor heat

exchanger

temperature

thermistor error

(5) (1)

Indoor fan

motor error

(5) (3) Drainage error

(9) (15)

Outdoor unit

error

Display mode

: 0.5s ON / 0.5s OFF

: 0.1s ON / 0.1s OFF

( ) : Number of fl ashing

Wired Remote Controller Display

Error code

Loading...

Loading...