Page 1

Fujitsu

ScanPartner 600C

OEM Manual

Version 1.0

Doc. No. 250-0081-0

Fujitsu Inc.

Page 2

ii

Page 3

Table of Contents

1. GENERAL.................................................................................................................................................................1-1

1.1 GENERAL ...............................................................................................................................................................1-1

1.2 DEVICE CONFIGURATION ........................................................................................................................................1-3

1.2.1 Outer View......................................................................................................................................................1-3

1.2.2 Components....................................................................................................................................................1-4

2. SPECIFICATIONS...................................................................................................................................................2-1

2.1 FUNCTIONAL SPECIFICATIONS .................................................................................................................................2-1

2.2 ENVIRONMENTAL SPECIFICATIONS ..........................................................................................................................2-2

3. OPERATION ............................................................................................................................................................ 3-1

3.1 REMOVING THE SHIPPING BRACKET......................................................................................................................... 3-1

3.2 POWER ON/OFF......................................................................................................................................................3-3

3.3 INDICATION PANEL.................................................................................................................................................3-3

3.4 SETTING THE SCSI ID AND CONNECTING THE INTERFACE CABLE............................................................................. 3-4

3.4.1 SCSI Cable Connection ..................................................................................................................................3-5

3.5 PAPER SPECIFICATIONS........................................................................................................................................... 3-7

3.5.1 Paper Size.......................................................................................................................................................3-7

3.5.2 Paper conditions............................................................................................................................................. 3-7

3.5.2.1 ADF ...........................................................................................................................................................................3-7

3.5.2.2 FIatbed.......................................................................................................................................................................3-8

3.5.2.3 Items to avoid.............................................................................................................................................................3-8

3.5.3 Readable area ................................................................................................................................................3-9

3.6 DOCUMENT SETTING METHOD..............................................................................................................................3-10

3.6.1 Flatbed.........................................................................................................................................................3-10

3.6.1.1 When the document size is of letter/A4 size or smaller .............................................................................................3-10

3.6.1.2 When the document is a thick book .......................................................................................................................... 3-11

3.6.2 ADF.............................................................................................................................................................. 3-11

3.6.2.1 Setting the ADF paper chute.....................................................................................................................................3-11

3.6.2.2 Placing the documents on the ADF paper chute ........................................................................................................ 3-12

3.7 CLEANING............................................................................................................................................................3-14

3.7.1 Cleaning the document cover and the document glass...................................................................................3-14

3.7.2 Cleaning inside the ADF............................................................................................................................... 3-15

4. INTERFACE............................................................................................................................................................. 4-1

4.1 PHYSICAL SPECIFICATIONS...................................................................................................................................... 4-3

4.1.1 Connection .....................................................................................................................................................4-3

4.1.2 Physical Specification.....................................................................................................................................4-4

4.1.3 Termination.................................................................................................................................................... 4-4

4.1.4 Pin assignments.............................................................................................................................................. 4-5

4.2 SCSI BUS ..............................................................................................................................................................4-6

4.2.1 System configuration ......................................................................................................................................4-6

4.2.1.1 System configuration..................................................................................................................................................4-6

4.2.1.2 Addresses of SCSI devices..........................................................................................................................................4-6

4.2.1.3 Peripheral equipment .................................................................................................................................................4-6

4.2.2 Bus signals .....................................................................................................................................................4-7

4.2.3 Bus signal drive conditions.............................................................................................................................4-8

4.3 BUS PHASES ...........................................................................................................................................................4-9

4.3.1 BUS FREE phase..........................................................................................................................................4-11

4.3.2 ARBITRATION phase ................................................................................................................................... 4-12

4.3.3 SELECTION phase.......................................................................................................................................4-14

4.3.4 INFORMATION TRANSFER phases............................................................................................................. 4-15

4.3.4.1 Asynchronous information transfer ...........................................................................................................................4-16

4.4 COMMANDS..........................................................................................................................................................4-18

4.4.1 RESERVE UNIT command............................................................................................................................4-19

4.4.1.1 RESERVE UNIT command: COMMAND phase (initiator Õ target)......................................................................... 4-20

4.4.2 RELEASE UNIT command............................................................................................................................4-21

4.4.2.1 RELEASE UNIT command: COMMAND phase (initiator → target).........................................................................4-21

iii

Page 4

4.4.3 INQUIRY command......................................................................................................................................4-22

4.4.3.1 INQUIRY command: COMMAND phase (initiator → target) ...................................................................................4-22

4.4.3.2 Inquiry data: DATA IN phase (target → initiator)..................................................................................................... 4-24

4.4.4 REQUEST SENSE command.........................................................................................................................4-26

4.4.4.1 REQUEST SENSE command: COMMAND phase (initiator →→ target) .....................................................................4-26

4.4.4.2 Sense data: DATA EN phase (target → initiator)......................................................................................................4-27

4.4.5 SEND DIAGNOSTIC command ....................................................................................................................4-29

4.4.5.1 SEND DIAGNOSTIC command: COMMAND phase (initiator →→ target) .................................................................4-30

4.4.5.2 Contents of self-test..................................................................................................................................................4-31

4.4.5.3 Results of self-test ....................................................................................................................................................4-31

4.4.6 TEST UNIT READY command......................................................................................................................4-31

4.4.6.1 TEST UNIT READY command: COMMAND phase (initiator → target).................................................................. 4-32

4.4.6.2 Acknowledgment......................................................................................................................................................4-32

4.4.7 SET WINDOW command ..............................................................................................................................4-33

4.4.7.1 SET WINDOW command: COMMAND phase (initiator → target) ...........................................................................4-33

4.4.7.2 Window date: DATA OUT phase (initiator → target) ...............................................................................................4-34

4.4.7.3 Update of ScanPartner 600C OEM manual...............................................................................................................4-39

4.4.7.4 B&W Scanning Vender unique parameters...............................................................................................................4-39

4.4.7.4.1 Vendor unique identification code: Byte 28 ....................................................................................................... 4-40

4.4.7.4.2 Paper size: byte 35 ............................................................................................................................................ 4-40

4.4.7.5 Color Scanning Vender unique parameters ...............................................................................................................4-41

4.4.7.5.1 Vendor unique identification code: Byte 28 ....................................................................................................... 4-41

4.4.7.5.2 Parameter length: Byte 29 ................................................................................................................................. 4-41

4.4.7.5.3 Color scanning parameters ................................................................................................................................ 4-41

4.4.8 OBJECT POSITION command......................................................................................................................4-43

4.4.8.1 OBJECT POSITION command: COMMAND phase (initator → target) ....................................................................4-44

4.4.8.2 Acknowledgment......................................................................................................................................................4-45

4.4.8.3 ADF sequence..........................................................................................................................................................4-46

4.4.9 READ command ...........................................................................................................................................4-46

4.4.9.1 READ command: COMMAND phase (initiator → target).........................................................................................4-47

4.4.9.2 DATA IN phase (target → initiator) .........................................................................................................................4-48

4.4.10 Scan command ............................................................................................................................................4-49

4.4.10.1 SCAN Command phase (initiator → target)............................................................................................................4-49

4.5 STATUS: STATUS PHASE (TARGET → INITIATOR)..................................................................................................4-50

4.6 MESSAGES ...........................................................................................................................................................4-51

4.6.1 ATN detection ...............................................................................................................................................4-51

4.6.2 Message types...............................................................................................................................................4-52

4.6.2.1 COMMAND COMPLETE (X'00'): MESSAGE IN phase (target → initiator) ............................................................4-52

4.6.2.2 INITIATOR DETECTED ERROR (X'05'): MESSAGE OUT phase (initiator → target) .............................................4-52

4.6.2.3 ABORT (X'06'): MESSAGE OUT phase (initiator → target).....................................................................................4-53

4.6.2.4 MESSAGE REJECT (X'07'): MESSAGE IN/OUT phase (initiator → target) ............................................................4-53

4.6.2.5 NO OPERATION (X'08'): MESSAGE OUT phase (initiator → target)...................................................................... 4-54

4.6.2.6 MESSAGE PARITY ERROR (X'09'): MESSAGE OUT phase (initiator → target) ....................................................4-54

4.6.2.7 BUS DEVICE RESET (X'0C'): MESSAGE OUT phase (initiator → target).............................................................. 4-54

4.6.2.8 IDENDIFY (X'80' TO X'FF'): MESSAGE OUT phase (initiator → target) .................................................................4-55

4.7 COMMAND SEQUENCE ..........................................................................................................................................4-56

4.7.1 Initial sequence ............................................................................................................................................4-56

4.7.2 Read sequence.............................................................................................................................................. 4-57

4.7.2.1 Read sequence for B&W mode.................................................................................................................................4-57

4.7.3 READ command sequence ............................................................................................................................ 4-57

4.7.3.1 Single READ ........................................................................................................................................................... 4-57

4.7.3.2 Multiple READ ........................................................................................................................................................4-58

4.8 STATUS TRANSITION OF LOGICAL UNIT .................................................................................................................4-59

4.9 ERROR TABLE ...................................................................................................................................................... 4-60

4.10 ITEMS FOR SPECIFYING WINDOW.........................................................................................................................4-61

5. DIAGNOSTICS .........................................................................................................................................................5-1

5.1 ONLINE DIAGNOSTICS .............................................................................................................................................5-1

5.2 OFFLINE DIAGNOSTICS............................................................................................................................................ 5-2

5.3 DIAGNOSTIC FLOWCHARTS...................................................................................................................................... 5-3

5.3.1 Group 1 error flowchart (Lamp assembly).......................................................................................................5-3

5.3.2 Group 2 error flowchart (Flatbed/ADF motor) ................................................................................................5-3

5.3.3 Group 3 error flowchart (paper in ADF paper tray)........................................................................................5-4

iv

Page 5

5.3.4 Group 3 error flowchart (no paper in ADF paper tray)................................................................................... 5-5

v

Page 6

Page 7

1. General

1.1 General

1.1 General

1.2 Device Configuration

Scan Partner 600C image scanners produce excellent electronic images

from documents using the high quality optical image scanning technology

and output to the host system via SCSI interface.

On the standard flat-bed, the Scan Partner 600C can scan a single loose

page or a single page of a bound book. The standard flat-bed can

accommodate a letter size/A4 page. The Scan Partner has an automatic

document feeder (ADF) that can accommodate up to 50 pages.

The Scan Partner outputs data on the Small Computer System Interface

(SCSI). Figure 1.1 is the functional block diagram.

1-1

Page 8

To host

110/220 VAC

SCSI

controller

Mainboard

Video Circuit

Optical unit

Control

section

ADF motor ADF sensor

Flatbed

motor

Lamp unitInverter

Figure 1-1 System Block Diagram

Power supply

LED display

Sensor input

ADF section

1-2

Page 9

1.2 Device Configuration

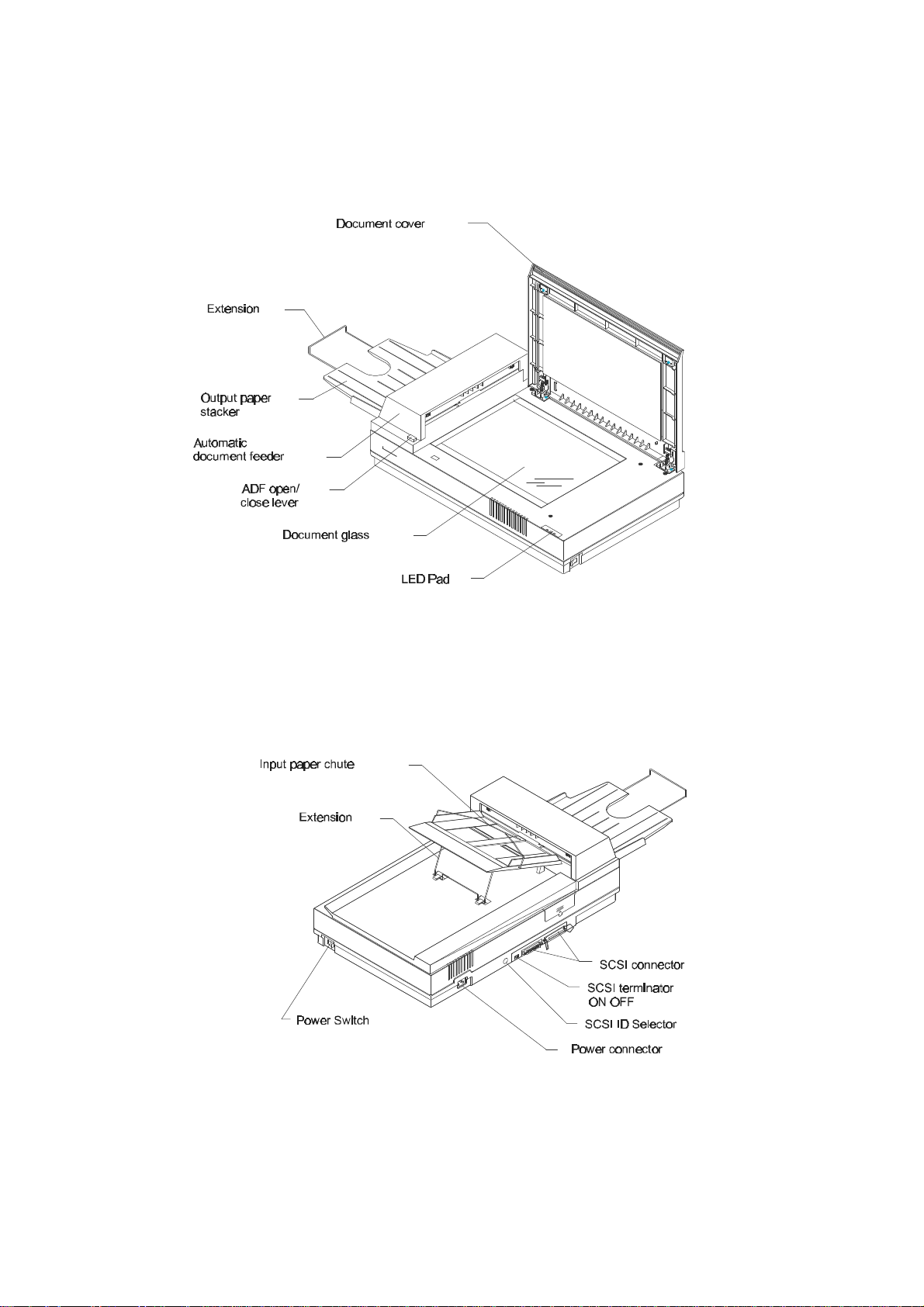

1.2.1 Outer View

Figure 1.2 shows the outer view and device configuration of the ScanPartner 600C/OEM SP600C.

Figure 1-2 ScanPartner 600C Outer View

1-3

Page 10

1.2.2 Components

1. Document Cover

The document cover holds the document in place during scanning so that the document does not move.

2. Document glass

Place the document to be read on the document glass.

3. Automatic document feeder (ADF)

The automatic document feeder (ADF) feeds documents in the scanner automatically.

4. Paper tray extension

The extension prevents documents from bending.

5. Power switch

The power switch is used to turn the scanner on and off.

6. LED panel

The LED panel indicates the status of the scanner (Power, Ready, and Jam).

7. Input paper chute

The input paper chute stacks the documents to be fed by the ADF.

8. ADF open/close lever

The ADF open/close lever is used to open and close the ADF to remove paper jammed in the ADF.

9. Power connector

The power cable is connected to the power connector to supply the scanner with AC power.

10.SCSI interface connector

The interface is connected to the interface connector. The scanner is connected to the host system

through the interface cable.

1-4

Page 11

2. Specifications

2.1 Functional Specifications

2.2 Environmental Specifications

2.1 Functional Specifications

Table 2.1 lists the functional specifications.

Table 2-1 Functional Specifications

No. Item Specifications Remarks

1 Technology CCD linear image sensor 4.2 MHz

2 Operating method Flatbed scanning/ADF scanning

3 Maximum document size Legal (11x14) for ADF

4 Light source Cold cathode fluorescent lamp

5 Optical resolution 600 x 1200 dpi

6 Scanning speed Letter: 3 sec/200 dpi

7 Gray scale 256 steps, 16 steps

8 Halftone Provides four halftone patterns

9 Automatic document feeder

1. Paper chute capacity

2. Stacker capacity

3. Reading speed

4. Paper empty detection

5. Cover open detection

10 Interface SCSI 2

Letter/A4 for flatbed

A4: 3.2 sec/200 dpi

Legal: 3.5 sec/200 dpi

Maximum 50 pages (legal, 14-28 lbs.)

Maximum 50 pages (legal, 14-28 lbs.)

Letter size paper 200 dpi = 15 ppm

Provided

Provided

2-1

Page 12

2.2 Environmental Specifications

Table 2.2 lists the environmental specifications.

Table 2-2 Environmental Specifications

No. Item Specifications Remarks

1 Physical

dimension

(mm)

2 Weight 13.3 kg 24.89 lbs

3 Power

requirements

4 Power

consumption

(watts)

5 Acoustic noise (dB) Operating: 56 dBA or less

6 Temperature

(ºC)

7 Relative

humidity (%)

8 Vibration (G) Operating 0.25 5-22-500 Hz

9 Safety Regulations

10 EMC

Height

Width

Depth

Voltage (VAC) 100- 240V (Auto switching)

Frequency (Hz) 47 to 63

Power cable

length (m)

Operaing 35 watts

Non-opearting 13 watts

Operating 10 to 40ºC (50ºF to 104ºF) Gradient: 10ºC/hr.

Non-operating -40 to 60ºC(-40ºF to 140ºF)

Operating 10% to 90% RH No condensation

Non-operating 10 to 90 RH

Non-operating 1.0

165 ± 2mm 6.3 ± 0.08 inches

568 ± 2mm 22.36 ± 0.08

inches

348 ± 2mm 13.7 ± 0.08 inches

3 or less

Standby: 46 dBA or less

(18ºF/hr.)

Direction = 3 Axial

UL1950, 3rd Edition

CSA C22-2 No. 950-M93

European Norm

EN 60950: 1988+A1+ A2

FCC Part 15 Subchapter J Class B

DOC Class B (Canada)

European Directive 89/336 (CE-Mark)

2-2

Page 13

3. OPERATION

3.1 Removing the Shipping Bracket

3.2 Power On/Oft

3.3 Indication Panel

3.4 Setting the SCSI-ID and Connecting the Interface Cable

3.5 Paper Specifications

3.6 Document Setting Method

3.7 Cleaning

3.1 Removing the Shipping Bracket

The scanner has a bracket that fixes the position of the carrier unit during transportation. The bracket must be

removed from the base of the scanner.

If the power is turned on before the bracket has been removed, the Alarm lamp turns on. Before proceeding,

turn off the power, disconnect the power cable, and remove the bracket.

CAUTION

Do not turn the scanner upside down when removing the bracket.

3-1

Page 14

1. Remove the shipping retainer

2. Fasten the shipping retainer

3-2

Page 15

3.2 Power On/Off

The power switch is on the right side of the image scanner (See Figure 3.1)

Turn the power switch to the “I” side, the power LED on the indication panel will light on.

Turn the power switch to the “O” side, the power LED on the indication panel will go out.

3.3 Indication Panel

Figure 3.2 shows the indication panel, and Table 3.1 lists the names and functions of the indicator.

Figure 3-1 Power Switch

Figure 3-2 Indication Panel

3-3

Page 16

Table 3-1 Names and functions of the indicators

Name Color Function

Power Amber Lights on when the power is turned on

Ready Green Lights on when the scanner is ready to receive commands from the host computer

Paper jam Red Lights on when paper jam occurs. This indicator along with Ready indicator also indicates other

error conditions. See Chapter 5 Test Mode for details.

3.4 Setting the SCSI ID and Connecting the Interface Cable

Use the address switches to set the device address.

Figure 3-3 Signal cable connection

ID Content

0 to 7 Available

8 Offline self-test

Table 3-2 SCSI ID setting

3-4

Page 17

The devices linked to the SCSI interface are daisy-chained with one another. A terminator is attached to the

SCSI device

Scanner

Host PC

Set terminator

ends of the interface cable. User can buy the SCSI cable in computer stores. The specifications of the SCSI

cable is as shown below.

Name: SCSI Cable

Cable Specification 50 pins to 25 or 50 pins, shielded Amphenol

Cable Length: Less than or equal to 6 meters.

3.4.1 SCSI Cable Connection

There are two configurations for the connection.

Configuration I: The number of devices attached to the SCSI bus (including the host PC) is three. The

scanner is located in the middle of the connection, as shown below.

switch at “off”

position

Terminator Terminator

1. Set scanner’s SCSI terminator switch off.

2. Plug one end of the SCSI cable into the SCSI connector of the host PC, and the other end of

the cable to the scanner.

3. Plug one end of the SCSI cable into the SCSI connector of the third device, and the other end of

the cable to the other scanner.

3-5

Page 18

Configuration II: the number of devices attached to the SCSI bus (including the host PC) is three. The

Scanner

SCSI device

Host PC

scanner is located at the end of the connection, as shown below.

Set terminator switch at “on”

Terminator

If there is already another device linked to the host via SCSI cable, remove the terminator from that device. If

the terminator can not be removed, it is recommended that the connection of Configuration I be used.

1. Set scanner’s SCSI terminator switch on

2. Plug one end of the SCSI cable to one female connector of the previous device or the host.

SCSI specifications require that:

1. Only one terminator may be attached to each end of the daisy chain.

2. The total length of the daisy chain must not exceed 6 meters. The vendor suggests that the SCSI cable be two

or three meters in length to allow other devices to be attached to the SCSI bus.

3. Each device on the chain will be assigned a different ID. Devices with the same SCSI ID will cause

them to malfunction.

4. There is no restriction on the position of the devices on the daisy chain.

position

3-6

Page 19

3.5 Paper Specifications

This section provides the readable paper specifications for the automatic document feeder (ADF).

3.5.1 Paper Size

A

3.5.2 Paper conditions

3.5.2.1 ADF

a) Paper quality

Wood-free paper

PPC paper; Specified by XEROX Corporation

Feeding direction

Maximum Minimum

A B A B

216 356 100 100

Unit: mm

Figure 3-4 Paper size specifications

B

b) Paper specifications

Legal size, 14~28 lbs

3-7

Page 20

3.5.2.2 FIatbed

(a) Paper quality

No condition

(b) Ream weight

No condition

(C) Paper form

Square is preferred.

3.5.2.3 Items to avoid

Paper such as the following cannot be fed by ADF.

(a) Paper with clips or staples.

(b) Paper with ink not dry.

(C)Paper with inconsistent thickness, such as an envelope.

(d) Paper with large rumples or curls.

(e)Paper with folds or tears.

(f)Tracing paper.

(g) Coating paper.

(h) Carbonless paper.

(i) Paper smaller than A5 size or larger than A4 width.

(j) Items other than paper, such as clothes, metal sheet, or OHP film.

(k) Photographic paper.

(1) Paper that has notches on its side.

(m)Paper that has a shape other than square.

(n) Very thin paper.

(o) Important document not to be damaged.

Use the flatbed to perform scanning when reading paper of items e to o.

3-8

Page 21

3.5.3 Readable area

216

356

Feeding direction Unit: mm

Figure 3-5 ADF readable area

3-9

Page 22

3.6 Document Setting Method

3.6.1 Flatbed

Figure 3-6 Flatbed reading

3.6.1.1 When the document size is of letter/A4 size or smaller

If the document is to be read on the flat-bed, following the steps below.

1. Open the document cover.

2. Put the document on the document glass with the image face down with the upper end to the left. Correct any

curls or folded documents.

3. Position the left side and upper end of the document in line with the reference frame so that the upper-left

comer of the document coincides with the upper-left of the reference frame.

If the document is not set correctly, reading is not done correctly.

4. Close the document cover slowly.

If the document cover is closed too quickly, the document may be moved. During reading, do not press or open

the document cover.

5. Start the reading.

6. After reading ends, open the document cover and remove the document.

3-10

Page 23

3.6.1.2 When the document is a thick book

1.Open the document cover and place it on the glass surface.

2.If the document is thick, do not close the document cover.

That part of the document in close contact with the glass will be read correctly but any part that is not in contact

with the glass may be unclear or distorted so care must be taken.

3.6.2 ADF

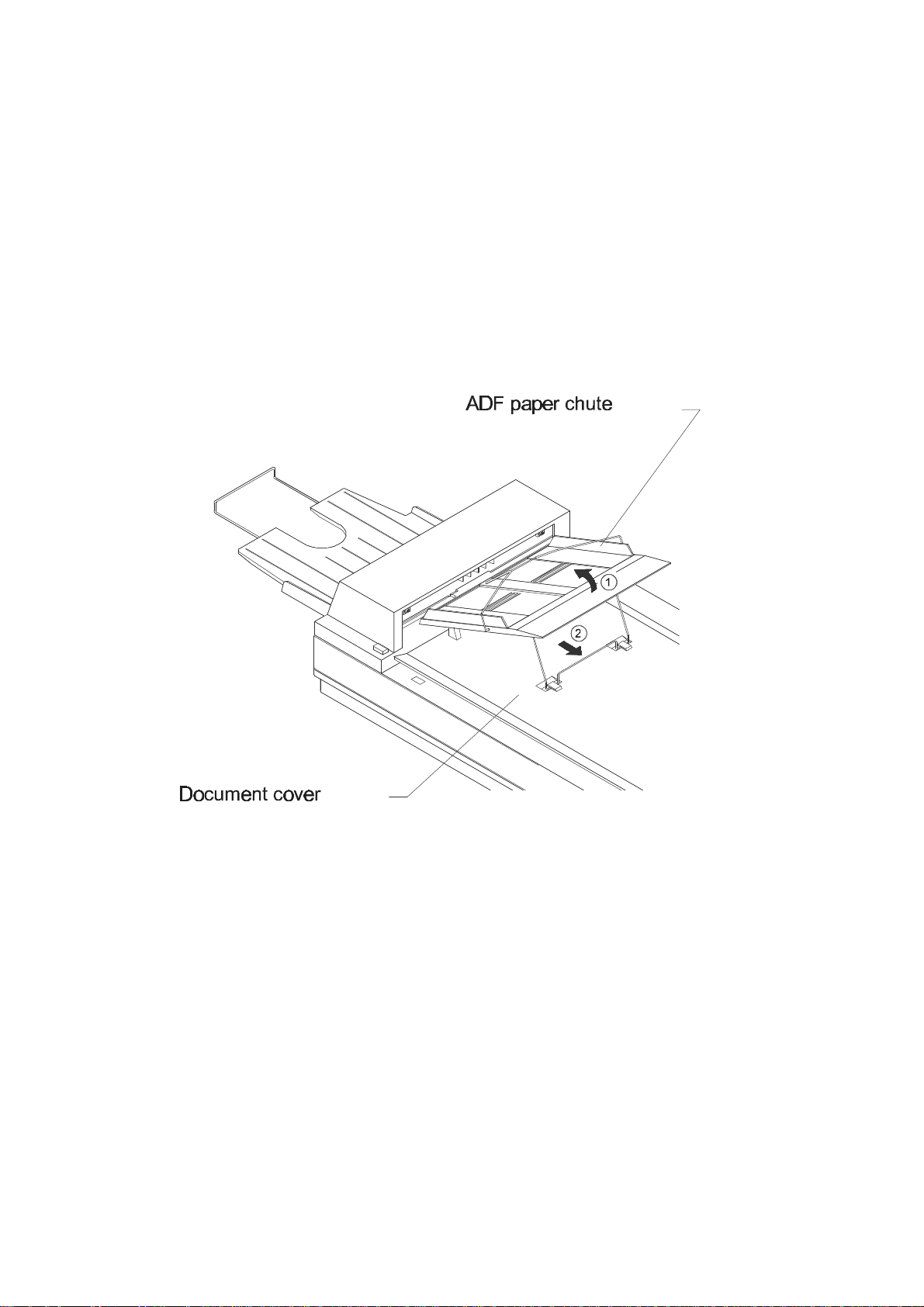

3.6.2.1 Setting the ADF paper chute

Figure 3-7 Setting the ADF paper chute

To use ADF to read the documents, set the ADF paper chute as follows:

1. Raise the unattached end of the input paper chute to about 45 degrees, as shown in Figure 3.7.

2. Pull down the metal bracket from under the paper chute.

3. Click the metal bracket into the grips on the document cover.

4. Pull the chute extension up.

3-11

Page 24

3.6.2.2 Placing the documents on the ADF paper chute

Perform the following steps to place the document in the ADF paper chute. If these steps are not followed

closely, a feed error may occur.

Figure 3-8 Placing the document on the ADF paper chute

1. Place the document upside-down.

2. Angle the document sheets as shown. (See "Angling the document sheets" that follows for an

explanation of this procedure.)

3. Spread open the right and left guides of the ADF paper chute, and set them approximately 5 mm wider

than the document width.

3-12

Page 25

4. Place the document face down on the ADF paper chute, and put the ends of the bottom 2 or 3 sheets into

the auto feeder.

5. C]ose the right and left guides against side of the document. (Skewing may occur if a gap exists between

the guides and document.)

6. Slide the pages down into the chute until they hit the far end of the auto feeder hole.

(a) Angling the document sheets

1. Place the document face down on a flat surface, with the top of the page to the left (a).

2. Lift the sheets with both hands. Take a maximum 4 mm thickness of sheets.

3. Hold the sheets tightly with your left hand and bend the sheets as shown in (b).

4. Then grip tightly with your right hand, loosen the grip of your left hand, and straighten the sheets as

shown in (c).

5. Repeat operations 3 and 4 as often as necessary with the entire document has been angled.

(b) Separating the sheets for easy feeding

Take a 2 to 4 mm thickness of sheets. Lightly hold both ends with both hands. Bend the sheets as shown.

Hold the sheets tightly with both hands then straighten the sheets. This operation separates the sheets for

easy feeding into the ADF. Repeat this operation two or three times. Turn the stack of sheets over and repeat

the entire operation.

3-13

Page 26

3.7 Cleaning

3.7.1 Cleaning the document cover and the document glass

Use a clean and soft cloth moistened with non-corrosive solvent such as alcohol (with purity above 99.5%)

and wipe the document cover and flatbed document glass slightly, as shown in Figure 3.9.

Figure 3-9

3-14

Page 27

3.7.2 Cleaning inside the ADF

Clean the ADF according to the procedure that follows when the following situations frequently occur:

• Documents are not fed smoothly.

• Several documents are fed in at the same time.

• Reading result is poor.

Cleaning Procedure:

1. Push the ADF cover release button, and open the ADF module.

2. Figure 3.10 shows the locations of pad, scrub roller, feeding rollers and follow rollers, and ADF

calibration white sheet.

Figure 3-10

3. Use a clean and soft cloth moistened with a non-corrosive solvent like ALCOHOL (with purity

above 99.5%) and wipe them slightly.

3-15

Page 28

Page 29

4. INTERFACE

4.1 Physical Specifications

4.2 SCSI Bus

4.3 Bus Phases

4.4 Commands

4.5 Status: STATUS phase (target initiator)

4.6 Messages

4.7 Command Sequence

4.8 Status Transition of Logical Unit

4.9 Error Table

4.10 Items for Specifying Window

This image scanner and the host are connected via an 8-bit parallel interface. The interface follows the

ANSI (American National Standards Institute) SCSI 2 (Small Computer System Interface 2) Revision 10c.

This chapter provides an overview of SCSI (minimum information necessary for understanding this

scanner), as well as descriptions peculiar to the scanner. For details of SCSI, refer to the ANSI standard,

The following terms are needed to understand this section.

SCSI device: A host adapter or a target controller that can he attached to the SCSI bus

Initiator: An SCSI device (usually a host system) that requests an I/O process to be performed by

another SCSI device (a target).

Target: An SCSI device that performs an operation requested by an initiator

Logical Unit: A physical or virtual peripheral device that is addressable through a target

Range of support

1. System Configuration

This scanner operates under the multiinitiator, multitarget environment. An initiator function is not

provided. This scanner incorporates an integrated target and logical unit (image scanner).

SCSI-ID:0 to 7, variable by DIP switch Logical unit number (LUN): 000, fixed

2.Bus phases

This scanner supports all phases except reselection phase.

4-1

Page 30

3. Commands

The following commands are supported by this scanner:

• INQUIRY

• OBJECT POSITION

• READ

• RELEASE UNIT

• REQUEST SENSE

• RESERVE UNIT

• SEND DIAGNOSTIC

• SET WINDOW

• TEST UNIT READY

• SCAN

A control byte is not supported. If value other than X’OO' is specified. an error is generated.

4. Statuses

The following statuses are supported by this scanner:

• BUSY

• CHECK CONDITION

• GOOD

• RESERVATION CONFLICT

5. Messages

The following messages are supported by this scanner:

• ABORT

• BUS DEVICE RESET

• COMMAND COMPLETE

• IDENTTIY

• INITIATOR DETECTED ERROR

• MESSAGE PARITY ERROR

• MESSAGE REJECT

• NO OPERATION

6. Others

The bits and fields for which the word 'Reserved" is described are checked. For a non-zero, an error is

returned.

4-2

Page 31

4.1 Physical Specifications

SCSI device

SCSI device

SCSI device

The devices linked to this interface are daisy chained with each other. A terminator is attached to the ends of

the interface cable. Interface specifications are as shown below

4.1.1 Connection

TerminatorTerminator

4-3

Page 32

4.1.2 Physical Specification

Table 4-1 SCSI physical specifications

Item Specifications

Driver/Receiver Single-ended

Connector 50 Contact Shielded Low Density

Cable Max. cable length 6 m

Characteristic impedance

Cable type 25 signal twisted pair

Stub wire

Signal level Terminator See the figure under (3).

Driver/receiver Open collector or three-state driver

Output characteristics Low level (true) = 0.0 to 0.5 VDC High Level (false)=2.5 to 5.25 VDC

Input characteristics Low level (true) = 0.0 to 0.8 VDC High level (false) = 2.0 to 5.25

Connector pin assignments for lines See (4).

132 Ω

≤ 0.1 mm (from main cable in scanner to internal wiring)

Output current = 48 mA (corresponding output voltage ≤ 0.5V)

VDC Input load = -0.4 mA max. (at 0.4V input voltage Input

hysteresis = 0.2 VDC min.

4.1.3 Termination

220Ω

330Ω

4-4

Page 33

4.1.4 Pin assignments

Physical Specifications

Signal Name Pin Number Signal Name

GND 1 26 -DB (0)

GND 2 27 -DB(1)

GND 3 28 -DB(2)

GND 4 29 -DB(3)

GND 5 30 -DB(4)

GND 6 31 -DB(5)

GND 7 32 -DB(6)

GND 8 33 -DB(7)

GND 9 34 -DB(P)

GND 10 35 GND

GND 11 36 GND

Reserved 12 37 Reserved

(Open) 13 38 TERMPWR

Reserved 14 39 Reserved

GND 15 40 GND

GND 16 41 -ATN

GND 17 42 GND

OND 18 43 -BSY

OND 19 44 -ACK

GND 20 45 -RST

GND 21 46 -MSG

GND 22 47 -SEL

GND 23 48 -C/D

GND 24 49 -REQ

GND 25 50 -I/O

Note: Reserved pins are connected to GND.

Figure 4-1Pin assignment

4-5

Page 34

4.2 SCSI Bus

4.2.1 System configuration

4.2.1.1 System configuration

The SCSI bus connects up to eight SCSI units, each linked with a daisy chain. Both ends of the daisy chain require a

terminator.

Each SCSI unit operates as an initiator or a target, so that a series of operations are performed between an initiator

and target pair.

The system may be configured with any combination of initiators and targets as long as the number of the initiators

and targets combined does not exceed eight.

4.2.1.2 Addresses of SCSI devices

Every SCSI device on the bus is assigned a unique address (SCSI ID) that corresponds to the data bus bit number;

ID#7 through ID#10 correspond to DB7 through DB0. The SCSI ID provides identification for specifying particular

SCSI device when an initiator selects a target or when a target reconnects an initiator.

SCSI ID also represents the priority for using the bus in the arbitration phase. (A description regarding the bus phase

is given later;) Priorities are given in the descending order of data bus bit numbers (DBn), with the highest priority

placed on ID#7(DB7) and the lowest priority on ED#0(DB0).

4.2.1.3 Peripheral equipment

With the basic specification, an initiator can designate up to eight peripheral devices (logical units) belonging tt a

single target, where the peripheral devices are used as the I/O units of the initiator; Logical units are identified and

selected by specifying their LUNs (logical unit numbers) in the IDENTIFY message or command (CDB: command

descriptor block).

This scanner is equipped with a target and a logical unit, and its LUN is 000.

4-6

Page 35

4.2.2 Bus signals

Signal name Type of signal Initiator

Data DB0

Control Signals BSY (Busy)

Table 4-2 Bus signals

Eight data-bit signals, plus a parity-bit signal that forms a DATA

DB1

DB2

DB3

DB4

DB5

DB6

DB7

(Data Bus n)

DBP

(Data Bus Parity)

SEL (Select)

RST (reset) An "ORtied" signal that indicates the RESET condition

C/D (Control/Data)

I/O (Input/Output)

MSG Message

REQ (request) A signal driven by an initiator to indicate a request for a

ACK (acknowledge) A signal driven by an initiator in indicate and acknowledgment

ATN (Attention) A signal driven by an initiator to indicate the ATTENTION

BUS. DB(7) is the most significant bit and has the highest

priority during the ARBITRATION phase. Bit number,

significance and priority decease downward to DB(O). A data bit

is defined as one when the signal value is true. A data bit is

defined as zero when the signal value is false. Data parity DB(P)

shall be odd. Parity is undefined during the ARBITRATION

phase.

An "ORtied" signal that indicates that the bus is being used

An "ORtied" signal used either by an initiator to select a target or

by a target to reselect an initiator

The C/D, I/O, and MSG signals are used to distinguish between

the different information transfer phases.

REQ/ACK data transfer handshake

for REQ/ACK data transfer handshake.

condition

⇐

⇒

Target

⇐

⇒

⇐

⇒

⇐

⇒

⇐

⇒

⇐

⇐

⇒

⇒

4-7

Page 36

4.2.3 Bus signal drive conditions

SCSI devices drive signals of the SCSI bus. The types of SCSI devices are summarized in the following table, showing

the signals that they can drive for each operating phase of the interface.

There are two kinds of signal driving methods, OR tied and NON-OR tied, as shown in Table 4.2. During an interface

operating sequence. the BSY signal could be driven simultaneously by two or more SCSI units when the data bus is in

the ARBITRATION or RESELECTION phase. This situation also occurs with the RST signs (Reset). These two signals

must be ORtied. For other signals, either of the two methods may be used: further more, different drive methods may

coexist for a signal on the bus.

Table 4-3 Bus phases vs. signal drive sources (1/2)

Signal C/D DB7 to 0

Bus phase BSY SEL '10 MSG REQ ACK DBP ATN RST

BUSFREE N N N N N N N N A

ARBITRATION A W N N N N ID N A

SELECTION I&T I N N N I I I A

RESELECTION l&T T T T T I T I A

COMMAND T N T T T I I I A

DATAIN T N T T T I T I A

DATAOUT T N T T T I I I A

STATUS T N T T T I T I A

MESSAGE IN T N T T T I T I A

MESSAGE OUT T N T T T I I I A

N: The signal shall be released, since it is not being driven by any SCSI device.

A: The signal shall be driven by all SCSI devices that are actively arbitrating.

I: If driven, this signal be driven only by the active initiation

T: If the signal is driven, it shall be driven only by the active target.

W: The signal shall be driven by the one SCSI device that wins arbitration.

ID: A unique data bit (the SCSI ID) shall be driven by each SCSI device that is actively arbitrating.

The other seven data bits shall be released (shall not be driven) by this SCSI device. The parity bit

(DB(P)) may be released or driven to the true state, but shall never be driven to the false state

during this phase.

I&T: The initiator and target drive the signal according to the interface operating sequence. The

RESELECTION phase includes a sequence in which the initiator and target simultaneously drive

the signal.

The signal shall be driven by the initiator, target, or both, as specified in the SELECTION phase and RESELECTION

phase.

4-8

Page 37

Table 4-4 Method of driving the interface signal

OR connection NON_OR connection

False No signal is driven by any

SCSI device. Signal status is

made false by the termination

resistor circuits.

True A SCSI device drives the signal true.

4.3 Bus Phases

The SCSI architecture includes the following eight distinct phases:

• BUS FREE phase

• ARBITRATION phase

• SELECTION phase

• COMMAND phase

• DATA phase

• STATUS phase

• MESSAGE phase

}

INFORMATION TRANSFER phase

The signal is driven false by

a certain SCSI device

(initiator or target), or is not

driven by any SCSI device

The SCSI bus can never be in more than one phase at any given time.

The following diagram shows how each phase transmits to another.

Reset

SELECTION

ARBITRATIONBUS FREE

MESSAGE OUT

COMMAND

DATA IN or

DATA OUT

STATUS

MESSAGE IN

Figure 4-2 Phase sequence

4-9

Page 38

The signal delay times for each bus phase are defined as follows-

Table 4-5 Signal delay times definition

No. Item Time Definition

1 Arbitration

delay

2 Assertion

period

3 Bus Clear

delay

4 Bus free delay 800 ns The minimum time that an SCSI device shall wait from

5 Bus set delay 1.8 _s The maximum time for an SCSI device to assert BSY

6 Bus settle

delay

7 Cable skew

delay

8 Data release

delay

9 Deskew delay 45 ns The minimum time required for deskew of certain

10 Disconnection 200 æs The minimum time that a target shall wait after

2.4 æs The minimum time an SCSI device shall wait from

asserting BSY for arbitration until the DATA BUS can

be examined to see if arbitration has been won. There is

no maximum time.

90 ns The minimum time that a target shall assert REQ (or

REQB) while using synchronous data transfers. Also,

the minimum time that an initiator shall assert ACK

while using synchronous data transfers.

800 ns The maximum time for an SCSI device to stop driving

all bus signals after: (1) The BUS FREE phase is

detected (BSY and SEL both false for a bus settle delay)

(2) SEL is received from another SCS] device during the

ARBITRATION phase (3) The transition of RST to true.

For the first condition listed. the maximum time for an

SCSI device to clear the bus is 1200 nanoseconds from

BSY and SEL first becoming both false. If an SCSI

device requires more than a bus settle delay to detect

BUS FREE phase, it shall clear the bus within a bus

clear delay minus the excess time

its detection of the BUS FREE phase (BSY and SEL

both false

and its SCSI ID bit on the DATA BUS after it detects

BUS FREE phase (BSY and SEL both false for a bus

settle delay) for the purpose of entering the

ARBITRATION phase

400 ns The minimum time to wait for the bus to settle after

changing certain control signals as called out in the

protocol definitions

10 ns The maximum difference in propagation time allowed

between any two SCSI bus signals measured between

any two SCSI devices.

400 ns The maximum time for an initiator to release the DATA

BUS signals following the transition of the I/O signal

from false to true.

signals

releasing BSY before participating in an

ARBITRATION phase when honoring a DISCONNECT

message from the initiator

4-10

Page 39

Table 4.5 Signal delay times definition

No. Item Time definition

11 Hold time 45 ns The minimum time added between the assertion of

REQ (Or REQB) or ACK (or ACKB) and the

changing of the data lines to provide hold time in the

initiator or target while using synchronous data

transfers. REQB and ACKIB timings only apply to

optional wide data transfers.

12 Negation 90 ns The minimum time that a target shall negate REQ (Or

REQB) while using synchronous data transfers. Also,

the minimum time that an initiator shall negate ACK

(or ACKB) while using synchronous data transfers.

REQB and ACKB timings only apply to optional

wide data transfers.

13 Power-on to

selection

time

14 Reset to

selection

time

15 Reset hold 25 æs The minimum time over which RST must be kept

16 Selection

abort time

17 Selection

timeout

delay

18 Transfer

period

10 sec

(recommended)

250 ms

(recommended)

200 æs The maximum time required from the moment when

250 ms

(recommended)

The recommended maximum time from power

application until an SCSI target is able to respond

with appropriate status and sense data to the TEST

UNIT READY, INQUIRY, and REQUEST SENSE

commands

The recommended maximum time after a hard

RESET condition until an SCSI target is able to

respond with appropriate status and sense data to the

TEST UNIT READY, INQUIRY and REQUEST

SENSE commands

asserted

selection or deselection of an initiator or target is

detected until BSY is asserted

The minimum time required for an initiator or target

in the selection or deselection phase to wait for a

BSY response before it starts the timeout procedure

The minimum allowable period, during sync data

transfer, between the start of consecutive REQ pulses

and the start of consecutive ACK pulses

4.3.1 BUS FREE phase

The BUS FREE phase is used to indicate that no SCSI device is actively using the SCSI bus. and that it is available.

SCSI devices shall detect the BUS FREE phase after the SEL and BSY signals are both false for at least a bus settle

delay.

SCSI devices shall release all SCSI bus signals within a bus clear delay after the BSY and SEL signals become

continuously false for a bus settle delay.

4-11

Page 40

Bus settle delay

Bus clear delay

BSY

SEL

others

....................................................................................................................

4.3.2 ARBITRATION phase

The ARBITRATION phase allows one SCSI device to gain control of the SCSI bus so that it can initiate or resume an

I/O process. The procedure for an SCSI device to obtain control of the SCSI bus is as follows:

1. The SCSI device shall first wait for the BUS FREE phase to occur;

Bus Free phase

2. The SCSI device shall wait a minimum of a bus free delay after detection of the BUS FREE phase (i.e. after the

BSY and SEL signals are both false for a bus settle delay) before driving any signal.

3 Following the bus free delay in Step 2, the SCSI device may arbitrate for the SCSI bus by asserting both the

BSY signal and its own SCSI ID, however, the SCSI device shall not arbitrate (i.e. assert the BSY signal and its

SCSI ID) if more than a bus set delay has passed since the BUS FREE phase was last observed.

4. After waiting at least an arbitration delay (measured from its assertion) the SCSI device shall examine the

DATA BUS. If a higher priority SCSI ID bit is true on the DATA BUS (DB(7) is the highest), then the SCSI

device has lost the arbitration and the SCSI device may release its signals and return to Step I. If no higher

priority SCSI ID bit is true on the DATA BUS, then the SCSI device has won the arbitration and it shall assert

the SEL signal. Any SCSI device other than the winner has lost the arbitration and shall release the BSY signal

and its SCSI ID bit within a bus clear delay after the SEL signal becomes true. A SCSI device that loses

arbitration may return to Step 1.

5. The SCSI device that wins arbitration shall wait at least a bus clear delay plus a bus settle delay after assert mg

the SEL signal before changing any signals.

4-12

Page 41

Bus settle

∇

Bus clear delay +

arbitration delay

arbitration delay

Bus clear delay

Bus set delay

Bus set delay

Bus free

Bus free

Bus free

Bus free

delay

delay

BSY

SCSI SEL

DB

BSY

ID7 SEL

DB(7)

ARBITRATION phase

delay

bus settle delay

delay

BSY

ID3 SEL

DB(3)

BSY

ID1 SEL

DB(1)

ID7: Succeeds in ARBITRATION

ID3: Detects the SEL signals of other SCSI unit

ID1: Detects the SCSI ID with higher priority than itself

: The point at which the BUS FREE phase is detected by each SCSI unit

delay

4-13

Page 42

4.3.3 SELECTION phase

Bus clear delay

SELECTION phase

The SELECTION phase allows an initiator to select a target for the purpose of initiating some target function (e.g.,

READ or WRITE command). During the SELECTION phase the I/O signal is negated so that this phase can be

distinguished from the RESELECTION phase.

1. The SCSI device that won the arbitration has both the BSY and SEL signals asserted and has

delayed at least a bus clear delay plus a bus settle delay before ending the ARBITRATION phase.

The SCSI device that won the arbitration becomes an initiator by not asserting the I/O signal.

2. The initiator shall set the DATA BUS to a value which is the OR of its SCSI ID but and the target's

SCSI ID bit, and it shall assert the ATN signal.

3. The initiator shall then wait at least two deskew delays and release the BSY signal.

4. The initiator shall then wait at least a bus settle delay before looking for a response from the target.

5. The target shall determine that it is selected when the SEL signal and its SCSI ID bit are true and

the BSY and I/O signals are false for a least a bus settle delay. The selected target may examine the

DATA BUS in order to determine the SCSI ID of the selecting initiator; The selected target shall

then assert the BSY signal within a selection abort time of its most recent detection of being

selected; this assertion is required for correct operation of the selection time-out procedure.

The target shall not respond to a selection if bad parity is detected. Also, if more than two SCSI ID

bits are on the DAT BUS, the target shall not respond to selection.

6. No less than two deskew delays after the initiator detects the BSY signal is true, it shall release the

SEL signal and may change the DATA BUS. The target shall wait until the SEL signal is false

before asserting the REQ signal to enter an information transfer phase.

+ bus settle delay

Deskew

delay x 2

Deskew

delay x 2

I/O

BSY

SEL

DB

4-14

Page 43

4.3.4 INFORMATION TRANSFER phases

Note:

The COMMAND, DATA, STATUS, and MESSAGE phases are all grouped together as the information transfer phases

because they are a]l used to transfer data or control information via the DATA BUS The actual content of the

information is beyond the scope of this section.

The C/D, I/O, and MSG signals are used to distinguish between the different information transfer phases (see

Table 4.5). The target drives these three signals and therefore controls all changes from one phase to another.

The initiator can request a MESSAGE OUT phase by asserting the ATN signal, while the target can cause the

BUS FREE phase by releasing the MSG, C/D, I/O, and BSY signals.

Table 4-6 INFORMATION TRANSFER phase type

Phase C/D I/O MSG DB7 to 9,P Transfer

DATA OUT 0 0 0 Data INIT ⇒TARG

DATAIN 0 1 0 Data ⇐

COMMAND I 0 0 Command ⇒

direction

STATUS I I 0 Status ⇐

* 0 0 1

* 0 1 I

MESSAGE OUT 1 0 1 Message ⇒

MESSAGEIN 1 1 1 Message ⇐

*: Reserved for future standardization

0: False

1: True

INIT: Initiator

TARG: Target

4-15

Page 44

INFORMATION

INFORMATION TRANSFER phase

Bus settle delay Bus settle delayMin. Ons

BSY

SEL

C/D,

MSG, I/O

REQ

ACK

DB

TRANSFER phase

The INFORMATION TRANSFER phases use one or more REQ/ACK handshakes to control the information

transfer Each REQ/ACK handshake allows the transfer of one byte of information. During the

INFORMATION TRANSFER phases the BSY signal shall remain true and the SEL signal shall remain

false. Additionally, during the INFORMATION TRANSFER phases, the target shall continuously envelope

the REQ/ACK handshake(s) with the C/D, I/O and MSG signals in such a manner that these control signals

are valid for a bus settle delay before the assertion of the REQ signal of the first handshake. These control

signals remain valid until after the negation of the ACK signal at the end of the handshake of the last transfer

of the phase.

4.3.4.1 Asynchronous information transfer

The target shall control the direction of information transfer by means of the I/O signal. When the I/O

signal is true, information shall be transferred from the target to the initiator When the I/O signal is false,

information shall be transferred from the initiator to the target.

(a) Asynchronous transfer from target to initiator

If the I/O signal is true (transfer to the initiator), the target shall first drive the DB(7-O, P) signals to

their desired values, delay at least one deskew delay plus a cable skew delay then assert the REQ

signal. The DB (7-0, P) signals shall remain valid until the ACK signal is true at the target. The

initiator shall read the DB(7-0, P) signals after the REQ signal is true then indicate its acceptance of

the data by asserting the ACK signal. when the ACK signal becomes true at the target, the target

may change or release the DB(7-O P) signals and shall negate the REQ signal. After the REQ signal

is false, the initiator shall then negate the ACK signal.

After the ACK signal is false, the target may continue the transfer by driving the DB (7-0, P) signals

and asserting the REQ signal, as previously described.

4-16

Page 45

BSY

SEL

C/D,MSG

I/O

REQ

ACK

DB

Bus settle delay

deskew delay +

cable skew delay

deskew delay +

cable skew delay

(b) Asynchronous transler from initiator to target

If the I/O signal is false (transfer to the target), the target shall request information by asserting the

REQ signal. The initiator shall drive the DB (7-0, P) signals to their desired values, delay at least

one deskew delay plus a cable skew delay then assert the ACK signal. The initiator shall continue

to drive the DB (7-0, P) signals until the REQ signal is false. When the ACK signal becomes true

at the target, the target shall read the DB (7-0, P) signals then negate the REQ signal. When the

REQ signal becomes false at the Initiator, the initiator may change or release the DB (7-0, P)

signals and shall negate the ACK signal. The target may continue the transfer by asserting the

REQ signal, as previously described.

4-17

Page 46

Bus settle

delay

BSY

SEL

C/D,MSG

I/O

REQ

ACK

DB

deskew delay +

cable skew delay

deskew delay +

cable skew delay

4.4 Commands

Commands are directions issued from an initiator to a target. This image scanner supports the following

range of the commands specified by the SCSI standard.

(a) The identification number of logical unit (LUN: logical unit number) is B'000.’

If this scanner receives a value other than 000, it returns an error as follows:

• Status key: B'0000l’(CHECK CONDITION)

• Sense key: X'5’(ILLEGAL REQUEST)

(b) Relative addressing is not supported.

If this scanner receives a relative address (RelAdr) =1, it returns an error as follows:

• Status key: B'OOOOl’(CHECK CONDITION)

• Sense key: X'5’(WLEGAL REQUEST)

(c) A control byte is not supported.

If this scanner receives a control byte ≠ X'00’, it returns an error as follows:

•• Status key: B'0000l ’(CHECK CONDITION)

• Sense key: X'5’(ILLEGAL REQUEST)

4-18

Page 47

(d) A bit and field described as "Reserved" are 0.

If this scanner receives a value other than 0, it returns an error as follows:

Status key: B'00001 '(CHECK CONDITON)

Sense key: X~5'(ILLEGAL REQUES~I)

The commands supported by this scanner are listed below.

Table 4-7 Commands

Operation

Command

code (hex) Description

RESERVE UNIT 16 Declares the exclusive use of a logical unit

RELEASE UNIT 17 Cancels the declaration of the exclusive use of a logical unit

INQUIRY 12 Examines the information regarding the target and logical unit

REQUEST SENSE 03 Requests a target for sense data

SEND DIAGNOSTIC ID Requests a target for self-check

TEST UNIT READY 00 Checks whether or not a logical unit is ready

SET WINDOW 24 Sets a window

OBJECT POSITION 31 Controls the automatic document feeder

READ 28 Requests transfer of image data

SCAN 1B Requests the target to begin a scan operation

4.4.1 RESERVE UNIT command

The following table shows the normal sequence of the RESERVE UNIT command when used with this scanner.

Table 4-8 RESERVE UNIT command

Step Bus phase Initiator operation

1 BUS FREE Verifies bus free

2 ARBITRATION Obtains bus-usage right

3 SELECTION Selects target

4 MESSAGE OUT Selects logical unit

5 COMMAND Specifies RESERVE UNIT (CDB)

6 STATUS Reports GOOD status

7 MESSAGE IN

8 BUS FREE

←←→→

→

→

→

←

Target operation

Drives BSY signal

Reports message

(Command complete)

Releases ESY signal

4-19

Page 48

4.4.1.1 RESERVE UNIT command: COMMAND phase (initiator Õ target)

Where a logical unit can be accessed by two or more initiators, there could be interferences with command

sequences, data, etc. This situation can be avoided by issuing the RESERVE UNIT command before

initiating series of operations.

Once a logical unit has properly accepted the RESERVE UNIT command, it will be occupied by the

initiator that issued the RESERVE UNIT command. If the 3rd party reservation option is supported, the

logical unit might be occupied by another SCSI unit - one having an initiator function - which is specified

TPID. In this condition called "reserved;' the logical unit cannot be accessed from any other initiators. The

reserved condition remains effective until one of the following events take place:

1. The reservation is replaced by a new RESERVE COMMAND from the same initiator that has

reserved the logical unit. (issuing another RESERVE UNIT command with the reservation still

effective does not result in an error. The previously established reservation is released as a result of

2,3, or 4 described below.)

2. The RELEASE UNIT command is issued from the same initiator that has reserved the logical unit.

3. The BUS DEVICE RESET message is sent from any initiator.

4. A hardware reset condition is detected.

The condition in effect after 3 or 4 is indicated by a sense key X'6' (UNIT ATTENTION), which is

returned in response to a subsequent command.

When a logical unit is already reserved by another initiator, if a command other than RELEASE

UNIT, INQUIRY, or REQUEST SENSE is issued, the target returns the following status:

Status: B'01100' (RESERVATION CONFLICT)

The initiator having reserved a logical unit can change the reservation by issuing the RESERVE

UNIT command to the same logical unit.

The command descriptor block (CDB) of this command is shown in the following illustration.

7 6 5 4 3 2 1 0

Byte 0

1

2

3

4

5

(a) TP (third party): Byte 1

If the 3rd party reservation option is not supported, setting this bit to 1 causes the target to return

the

following error:

•Status key: B'00001 '(CIIECK CONDITION)

•Sense key: X'5' (ILLEGAL REQUEST)

This scanner does not support the 3rd party reservation option.

Logical unit number TP TPID (Reserved)

Operation code X'16'

(Reserved)

Control byte

(b) TPID (third party device ID): Byte 1

This scanner ignores TPID.

4-20

Page 49

4.4.2 RELEASE UNIT command

The following table shows the normal sequence of the RESERVE UNIT command when used with this

scanner.

Table 4-9 RELEASE UNIT command

Step Bus phase Initiator operation

1 BUS FREE Verifies bus free

2 ARBITRATION Obtains bus-usage right

3 SELECTION Selects target →

4 MESSAGE Selects local unit →

OUT

5 COMMAND Specifies RELEASE →

UNIT (CDB)

6 STATUS ← Reports GOOD status

7 MESSAGE IN ← Reports message (Command Complete)

8 BUSFREE

←←→→

Drives BSY signal

Releases BSY signal

Target operation

4.4.2.1 RELEASE UNIT command: COMMAND phase (initiator → target)

The RELEASE UNIT command releases a reserved status. If this command comes from an initiator that has

not declared reservation, the target ignores the command and responds with the GOOD status (the reserved

status is not released).

The CDB of this command is shown in the following illustration.

7 6 5 4 3 2 1 0

Byte 0

1

Logical unit number TP TPID (Reserved)

Operation code X'17'

2

3

(Reserved)

4

5

(a) TP (third party): Byte 1

Control byte

4-21

Page 50

If the 3rd party reservation option is not supported, setting this bit to 1 causes the target to return the

following error;

• Status key: B'0000I'(CHECKCONDITION)

• Sense key: X~5'(ILLEGAL REQUEST)

This scanner does not support the 3rd party reservation option.

(b) TPID (third party device ID): Byte 1 This scanner ignores TPID.

4.4.3 INQUIRY command

The following table shows the normal sequence of the INQUIRY command when used with this scanner.

Table 4-10 INQUIRY command

Step Bus phase Initiator operation

1

2

3

4

5

6

7

8

9

BUS FREE Verifies bus free

ARBITRATION ON Obtains bus-usage right

SELECTION Selects target

MESSAGE OUT Selects logical unit

COMMAND Specifies INQUIRY (CBD)

DATA IN

STATUS

MESSAGE IN

BUS FREE

←←→→

→

→

→

←

←

←

Target operation

Drives BSY signal

Reports inquiry data

Reports GOOD status

Reports message (Command Complete

Releases BSY signal

4.4.3.1 INQUIRY command: COMMAND phase (initiator → target)

The INQUIRY command checks information regarding a target and logical unit.

The CDB of this command is shown in the following illustration.

4-22

Page 51

Byte 0

7 6 5 4 3 2 1 0

Operation code X'12'

1

2

3

Logical unit number (Reserved) EVPD

Page Code

(Reserved)

4

5

(a) EVPD (enable vital product data): Byte 1

This scanner does not support EVPD. If this bit is set to 1, the scanner returns the following error:

• Status key: B'OOOO1 '(CHECK CONDITION)

• Sense key: X'5'(ILLEGAL REQUEST)

(b) Page code: Byte 2

This scanner does not support page code. If this bit is set to 1, the scanner returns the following error:

• Status key: B'00001'(CHECK CONDITION)

• Sense key: x'5'(ILLEGAL REQUEST)

(C)Allocation length: Byte 4

This field specifies the storage area in bytes that the initiator allocates for inquiry data. If a 0 is set here,

inquiry data is not transferred, but this is not regarded as an error. The target terminates the DATA IN

phase when it has transferred either the bytes of inquiry data specified in this field or all of effective

inquiry data.

Allocation length

Control byte

4-23

Page 52

4.4.3.2 Inquiry data: DATA IN phase (target → initiator)

7 6 5 4 3 2 1 0

Byte 0

1

2

3

4

5

6

7

8

Peripheral qualifier Peripheral device type

RMB Device type qualifier

ISO version ECMA version ANSI approved version

AENC Reserved Response data format

Additional length (n-4)

(Reserved)

Rel Adr Wbus32 Wbus16 SYNC LINKED CACHE CMDQUE SftRst

(MSB)

Vendor identification

F

(MSB)

10

1F

20

(MSB)

23

24

5F

(a) Peripheral qualifier: Byte 0

Indicates the connection status of the devices under control of the target This scanner returns B' 000'.

(b) Peripheral device type: Byte 0

Indicates the type of the devices under control of the target. This scanner returns B'00110' (scanner).

(c) Removable medium (RMB): Byte 1

This scanner does not support RMB. This scanner returns B'0'.

ADF Color mode Color plane sequence

Product identification

Product revision level

(Reserved)

LSB

LSB

LSB

(d) Device type qualifier: Byte 1

This scanner does not support this field. This scanner always returns B'0000000'.

4-24

Page 53

(e) ISO version, ECMA version, ANSI approved version: Byte 2

Indicates the version number of the governing standard. This scanner returns X'02' (SCSI-2).

(f) Asynchronous event notification capability (AENC): Byte 3

This scanner does not support this field, so it returns B'0'.

(g) Response data format: Byte 3

Indicates the standard, and its version number, that governs the format of inquiry data. This scanner returns

B'0010' (SCSI-2).

(h) Additional length (n-4): Byte 4

Specifies the number of bytes, from byte 5 to the last byte. This value will not change with the allocation length

value specified in CDB. This scanner returns ~5B' (the 91 bytes from byte 5 to byte SF).

(i) RelAdr, Wbu~2, Wbusl6: Byte 7

This scanner does not support ReIAdrIwbus32(Wbusl6. This scanner returns B' 000'.

(j) SYNC (synchronous transfer): Byte 7

This scanner returns B'0' ("synchronous transfer not supported").

(k) Linked, cache, CMDQUE: Byte 7

This scanner does not support linked/cache/CMDQUE. This scanner returns B'000'.

(l) sftRst (Soft Reset): Byte 7

This scanner performs Hardware Reset. This scanner returns B'0'.

(m) Vendor identification: Bytes 8 to F

Indicates the vendor of the logical unit in ASCII code. The vendor name is left-justified, with the blank filled

with spaces (x'20'). This scanner returns "FCPA".

(n)Product identification: Bytes 10 to 1F

Indicates the product name in ASCII code. The name is left-justified, with the blank filled with spaces (X'20').

This scanner returns one of the following names:

Scan Partner 10

(o) Product revision level: Bytes 20 to 23

Indicates the version number of the product in ASCII code. This number is left-justified, with the blank filled

with spaces (X'20').

(p) ADF mode: Byte 24, bit 7

0: No built-in ADF module

1: With built-in ADF module

(q) Color mode: Byte 24, bit 6 to 4

000: B&W image only

001: 3-pass color scan mode

101: 1-pass color scan mode

(r) Color plane sequence: Byte 24, bit 3 to 0

0000: RGB

4-25

Page 54

4.4.4 REQUEST SENSE command

The following table shows the normal sequence of the REQUEST SENSE command when used with this scanner.

Table 4-11 REQUEST SENSE command

Step Bus phase Initiator operation

1 BUS FREE Verifies bus free

2 ARBITRATION Obtains bus-usage right

3 SELECTION Selects target →→

4 MESSAGE OUT Selects logical unit →→

5

6 DATA IN ←← Reports sense data

7 STATUS ←← Reports GOOD status

8 MESSAGE IN

9 BUS FREE

COMMAND Specifies REQUEST

SENSE (CDB)

Target operation

←←→→

Drives BSY signal

→→

Reports message

←←

(Command Complete)

Releases BSY signal

4.4.4.1 REQUEST SENSE command: COMMAND phase (initiator →→ target)

The REQUEST SENSE command requests the sense data that shows the status of a logical unit. On receiving this

command, the target sets the unit's status in the sense data and returns it to the initiator.

The CDB of this command is shown in the following illustration.

7 6 5 4 3 2 1 0

Byte 0

1

Logical unit number (Reserved)

2

Operation code X'03'

(Reserved)

3

4

5

Allocation length

Control byte

4-26

Page 55

(a) Allocation length: Byte 4

Specifies the storage area in bytes that tile initiator allocates for sense data If a 0 is set here, sense data is not

transferred, but this is not treated as an error. The target terminates tile DATA IN phase when it has

transferred either the bytes of sense data specified in this field or all of effective sense data.

4.4.4.2 Sense data: DATA EN phase (target → initiator)

The target creates sense data if its status is B'00001 ' (CHECK CONDITION) or if a BUS FREE error has occurred.

This scanner creates sense data when any of tile errors described later is encountered.

The sense data on this scanner is shown in tile following illustration.

7 6 5 4 3 2 1 0

Byte 0

Valid Error code

C

D

E

F

10

11

1

2

FM EOM ILI (Reserved) Sense key

3

(MSB)

Segment number

Information bytes

6

7

8

(MSB)

Additional sense length

Command-specific information byte

Additional sense code

Additional sense code qualifier

Field replaceable unit code

SKSV

Sense-key specific bytes

(LSB)

LSB

(a) Valid: Byte 0

Indicates whether or not the INFORMATION BYTES field is as specified by ANSI. This scanner

returns B'1' ("specified by ANSI").

(b) Error code: Byte 0

Differentiates between current error or deferred error. This scanner returns X'70' ("CURRENT ERROR").

(c) Segment number: Byte 1

This scanner does not support SEGMENT NUMBER. This scanner returns X'00'.

4-27

Page 56

(d)FM (file mark): Byte 2

This scanner does not support FM. This scanner returns B'0'.

(e) EOM (end of medium): Byte 2

Indicates the completion of window reading: 1 when completed, 0 when not completed.

(f) ILI (incorrect length indicator): Byte 2

Indicates that an error in logical block length has been detected.

(g) Sense key: Byte 2

Indicates the logical unit status using a sense key. This scanner supports the sense keys shown in the

following table:

Table 4-12

Sense key status of logical unit

0 NO SENSE

The logical unit has no information to be specifically described in a sense key.

This status occurs because either a command has succeeded, or because a

command has terminated in the CHECK CONDITION status since tile ILI bit has

been set to 1.

2

3 MEDIUM ERROR

4 HARDWARE ERROR

5 ILLEGAL REQUEST

6 UNIT ATTENTION

B

NOT READY

The specified logical unit cannot be accessed.

A command has terminated because of a trouble with tile medium. Typical

causes of this error with this scanner are that tile ADF paper chute is empty,

paper is jammed in the ADF, or the ADF cover has been opened.

An unrecoverable error was detected

An illegal parameter exists either in a command (CDB), or in a group of

parameters sent in the DATA OUT phase following a command.

The target has been reset.

ABORTED COMMAND

The target has aborted a command.

(h)Information bytes: Bytes 3 to 6