Page 1

Series HMI Connection Manual

Siemens S7 300 (ISO TCP)

HMI Factory Setting:

IP Address: 192.168.0.1

COM Port: 102

Control Area / Status Area: DBW0 / DBW20

Connection

Standard Jumper Cable / Network Cable without jumper (Auto-detected by HMI)

Definition of PLC Read/Write Address

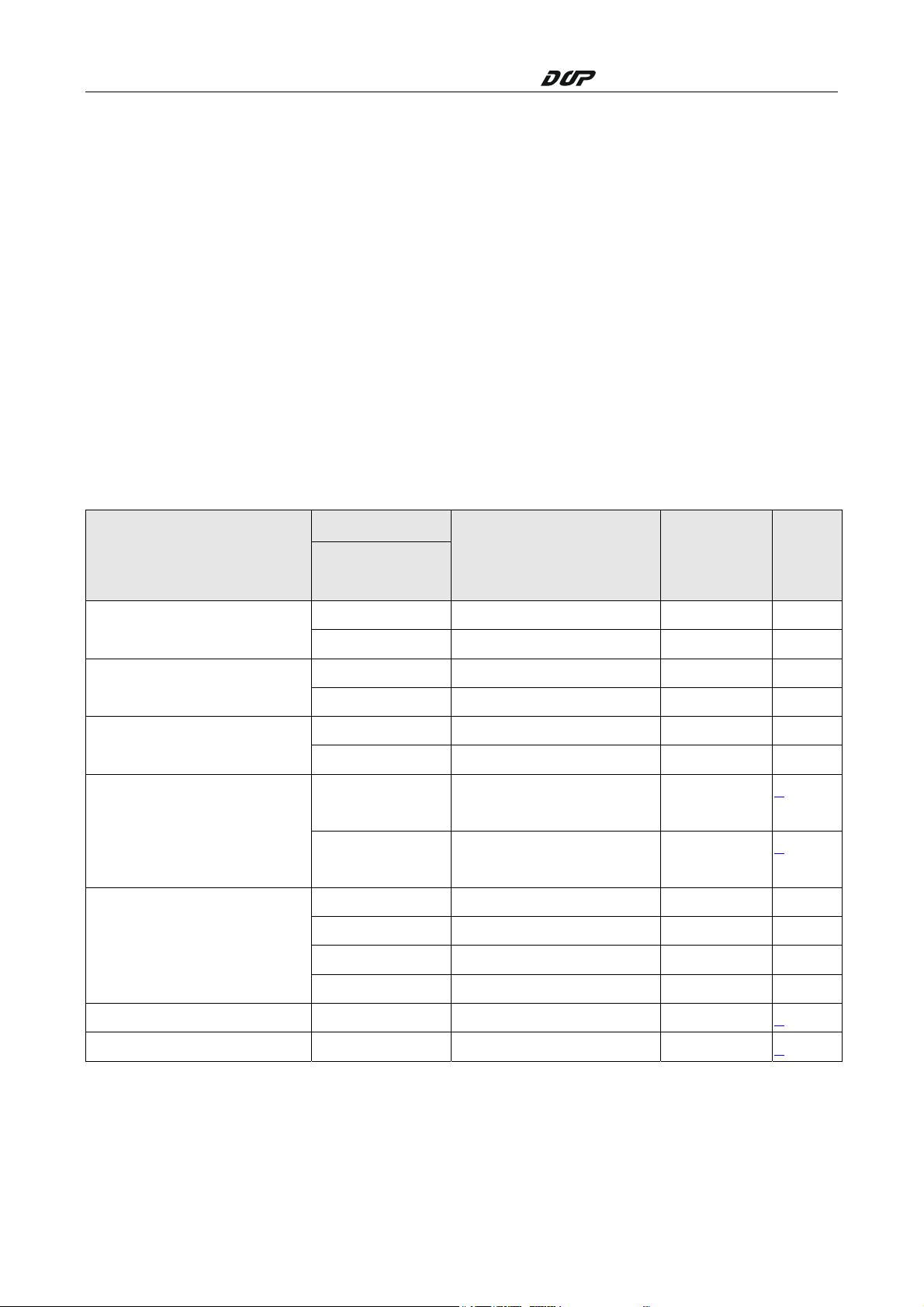

a. Registers

Format

Type

Input Image

Output Image

Internal Bits

Data Area

Data Area (DB10)

Word No.(n)

Bank No.(m)

IWn IW0 – IW65534 Word

IDn ID0 – ID65532 Double Word

QWn QW0 – QW65534 Word

QDn QD0 – QD65532 Double Word

MWn MW0 – MW65534 Word

MDn MD0 – MD65532 Double Word

DBm.DBWn DB1.DBW0 –

DBm.DBDn DB1.DBD0 –

DBWn DBW0 – DBW65534 Word

DBDn DBD0 – DBD65532 Double Word

VWn VW0 – VW65534 Word

VDn VD0 – VD65532 Double Word

Read/Write Range Data Length Note

Word 1

DB255.DBW65534

Double Word

DB255.DBW65532

1

Timer Tn T0 – T65535 Word 2

Counter

V1.02 Revision January, 2012 203

Cn C0 – C65535 Double Word

3

Page 2

Series HMI Connection Manual

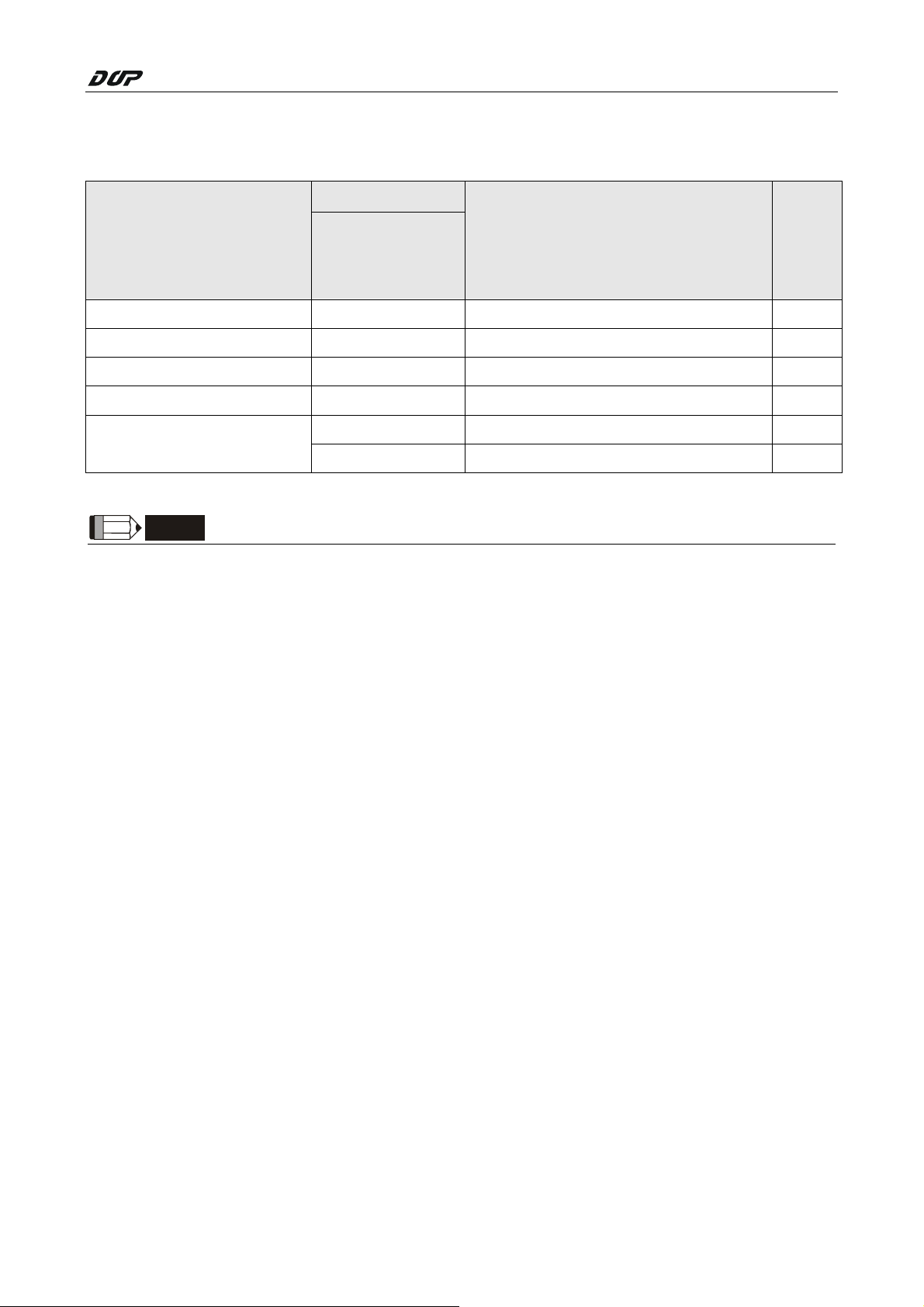

b. Contacts

Format

Type

Input Image In.b I0.0 - I65535.7

Output Image Qn.b Q0.0 - Q65535.7

Internal Bits Mn.b M0.0 - M65535.7

Data Area DBm.DBXn.b DB1.DBX0.0 – DB255.DBX65535.7

Data Area (DB10)

NOTE

1) PLC needs to enable DB memory (DBm.DBWn、DBm.DBDn、DBm.DBXn.b) before DB data

Word No.(n)

Bank No.(m)

Bit No.(b)

DBXn.b DBX0.0 – DBX65535.7

Vn.b V0.0 – V65535.7

Read/Write Range Note

can be read.

2) Timer reads only up to 3 digits. If a value input is more than 3 digits, the Timer will

regards the highest 3 (decimal) and replace the rest by 0. For example, a value 12345

will be written as 12300 in PLC.

3) Counter reads only up to 3 digits. If a value input is more than 3 digits, the Counter will

regards the first 3 digits and leave out the rest. For example, a value 12345 will be

written as 123 in PLC.

4) Except register Tn and Cn,data type of register is Byte and its order is opposite to usual

controller , for example :

1、 IW3 is a word which combined from IB3 and IB4,High Byte of IW3 is IB3;Low Byte of

IW3 is IB4.

2、 ID3 is Double Word which combined from IB3, IB4, IB5 and IB6, and its order from

highest to lowest is IB3, IB4, IB5 andIB6.

And please be attentive to use these registers, because their Data type is different with

Data Length, it will need more than one register for each access, for example:

1、 AIW6 which Data Type is Byte and Data Length is 1 Word, when it used for one word

Numeric Entry , it will occupy two addresses AIB6 and AIB7。

204 V1.02 Revision January, 2012

Page 3

Series HMI Connection Manual

2、 MD12 which Data Type is Byte and Data Length is Double Word,when it used for one

word Numeric Entry, it will occupy four addresses MB12,MB13,MB14 and MB15; But

data only stored in MB14 and MB15.

3、 IW3 which Data Type is Byte and Data Length is 1 Word , when it used for double word

Numeric Entry, it will occupy for addresses IB3,IB4,IB5 and IB6,order from highest to

lowest byte is IB5,IB6,IB3 和 IB4.

V1.02 Revision January, 2012 205

Page 4

Series HMI Connection Manual

Settings

Screen Editor:

1. HMI Ethernet Setting

206 V1.02 Revision January, 2012

Page 5

2. PLC Ethernet Setting

Series HMI Connection Manual

Simatic (V5.4):

1. Right click on “CP343-1 Lean” module and select "Object Properties", on this page set up “IP

address” and “Subnet mask” for CP343-1 Lean Module. Please be aware that the “IP

address” setting must be the same as PLC Ethernet setting in Screen Editor and the “Subnet

mask” setting must be the same as the HMI Ethernet setting in Screen Editor.

2. To add a new "Other station", right click on “Object Properties", add a new Interface and set

the “Type” as “Industrial Ethernet”. To set up HMI “IP address” and “Subnet mask”, go to

“Ethernet interface" > "Properties", please be aware that this setting must be the same as the

HMI Ethernet setting in Screen Editor. As the setting is completed, left click on the green box

above “Other station” and drag to link with the green line above.

V1.02 Revision January, 2012 207

Page 6

Series HMI Connection Manual

3. Right click on the CPU module and select "Insert New Connection", for “Connection Partner”

select “Unspecified” and for “Type” select “TCP connection”. Then go to "Properties - TCP

connection" >"Options", and set “Mode” to “Fetch passive”; please follows the restriction for

“Address” setting, set “Address” to Local Port No. must be the same as PLC Ethernet setting

in Screen Editor, to Partner’s IP must be the same as HMI Ethernet setting in Screen Editor,

but Port No. can be any Port No. depending on the structure of network connection.

4. Right click on another CPU to add a new “TCP connection” and repeats setting 3, except the

“Mode”, go to “Options” > “Mode” and select “Write passive”.

5. After setting 1~4 is done, you will see two “TCP connection” at the bottom of PLC Ethernet

setting page. PLC Ethernet setting is completed.

6. For detail on parameter setting, please refer to Siemens PLC user manual.

HSA

208 V1.02 Revision January, 2012

Loading...

Loading...