Page 1

FUJITSU BUSINESS

COMMUNICATION SYSTEMS

INSTALLATION

MANUAL

Package 2

Copyright 0 1995 Fujitsu Business Communication Systems

All rights reserved.

Fujitsu Business Communication Systems shall not be liable for any

commercial losses, loss of revenues or profits,

loss of goodwill, inconvenience, or exemplary, special, incidental, indirect or

consequential damages whatsoever, or

claims of third parties, regardless of the form of any claim

that may result from the use of this practice.

I

I

SECTION 123-056-002

Issue 3, May 1995

Page 2

Page 3

TABLE OF CONTENTS

Chapter Title Page

3

1

INTRODUCTION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORGANIZATION . . . .._...................................................................................................... l-l

REFERENCE DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l-2

Fujitsu Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Industry Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l-3

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM CONSTRUCTION ...........................................................................................

CABINET CONFIGURATION.. .......................................................................................

Basic Cabinet.. .........................................................................................................

Expansion Cabinets ................................................................................................. 2-l

Wall Bracket.. ........................................................................................................... 2-l

HARDWARE CONFIGURATION.. .................................................................................. 2-3

Power Units.. ............................................................................................................ 2-3

Floppy Disk Drive.. ................................................................................................... 2-3

CIRCUIT CARDS ........................................................................................................... 2-5

Common Control Cards ........................................................................................... 2-5

Interface Cards.. ....................................................................................................... 2-5

SYSTEM SPECIFICATIONS.. ........................................................................................ 2-5

SOFTWARE ................................................................................................................... 2-6

MAXIMUM CAPACITIES.. .............................................................................................. 2-7

PREPARATIONS ...........................................................................................................

LIST OF MATERIALS.. ...................................................................................................

MATERIALS NEEDED ...................................................................................................

TOOLS ........................................................................................................................... 3-l

INSTALLATION SITE REQUIREMENTS.. ..................................................................... 3-3

SPECIAL INSTALLATION INSTRUCTIONS.. ................................................................ 3-4

WALL LAYOUT ..............................................................................................................

POWER REQUIREMENTS ............................................................................................ 3-5

HEAT LOADING.. ........................................................................................................... 3-5

GROUNDING REQUIREMENTS ...................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l-1

l-l

l-2

l-3

2-1

2-l

2-l

3-l

3-l

3-l

3-4

3-5

4

CABINET INSTALLATION ............................................................................................

GENERAL ......................................................................................................................

WALL MOUNTING BRACKETS ... . .................................................................................

Attaching the Mounting Bracket.. .............................................................................

Drilling the Mounting Bolt Holes.. .............................................................................

Wall Bracket Grounding ........................................................................................... 4-l

BASIC CABINET INSTALLATION

BASIC CABINET INSTALLATION (Three-Piece Front Cover). ......................................

INSTALLING THE MPSU ............................................................................................... 4-6

INSTALLING THE BASIC CABINET ON THE WALL BRACKET ...................................

AC Power Monitor .................................................................................................... 4-7

Ring Generator .........................................................................................................

-48 Volt Power Supply ..............................................................................................

POWER AND GROUNDING. ....

Power .......................................................................................................................

Frame Ground ..........................................................................................................

Signal Ground.. ........................................................................................................

(One-Piece Front Cover)

.....................................................................................

.........................................

4-1

4-l

4-l

4-l

4-l

4-3

4-4

4-6

4-7

4-7

4-8

4-8

4-8

4-8

Installation Manual ISS 3, SECTION 123-056-002

Page 4

ii Table of Contents

Chapter Title Page

POWER BRACKETS ...................................................................................................... 4-9

AC Cord ................................................................................................................... 4-9

DC Power Cables.. ................................................................................................... 4-9

INSTALLING EXPANSION CABINETS.. ...................................................................... 4-10

Installing the First Expansion Cabinet.. .................................................................. 4-10

Installing the Second Expansion Cabinet.. ............................................................. 4-l 1

Installing the Third Expansion Cabinet.. ................................................................. 4-12

INSTALLING THE SFDC.. ............................................................................................ 4-14

Installing the Floppy Disk Drive.. ........................................................................... 4-15

POWER FAIL TRANSFER ........................................................................................... 4-16

Installing the ACPD or DCPD.. ............................................................................... 4-17

Supplemental 24V Power Supply.. ......................................................................... 4-l 8

CIRCUIT CARD INSTALLATION

GENERAL ......................................................................................................................

COMMON CONTROL CARDS.. ..................................................................................... 5-l

INTERFACE CARDS.. .................................................................................................... 5-l

LINE/TRUNK CARDS.. ................................................................................................... 5-2

16 Circuit Digital Telephone Interface Card (16DTC) .............................................. 5-7

8 Circuit Digital Telephone Interface Card (8DTC) .................................................. 5-7

8 Circuit Electronic Key Telephone Card (8EKC) .................................................... 5-8

Multi-Function Card

8 Circuit Single Line Telephone Card (8SLC). ......................................................... 5-8

16 Circuit Single Line Telephone Card (16SLC). .....................................................

4 Circuit Single Line (OPX) Telephone Card (4SLE) ............................................... 5-9

8 Circuit Central Office Bothway Trunk Card (8BWC) ........................................... 5-l 0

4 Circuit Central Office Bothway Trunk Card (4BWC) ........................................... 5-10

2 Circuit Loop Dial Tie Trunk Card (2lTL). ............................................................ 5-l 1

2 Circuit E&M Tie Trunk Card (2lTE/2TE4) .......................................................... 5-l 1

4 Circuit E&M Tie Trunk Card (4TE4)

4 Circuit Dual-Tone Multi-Frequency Receiver Card (4DMR). ............................... 5-14

4 Circuit Character Trunk Card (4CHT) ................................................................. 5-14

6 Circuit Power Failure Transfer Card (GPFA) ....................................................... 5-14

Recorded Voice Announcement Card (RVAC) ...................................................... 5-14

6 Circuit Direct Inward Dialing Trunk Card (6DID) ................................................. 5-l 5

2 Circuit Application Processor Interface Card (2APIA) ......................................... 5-15

2APIA Card Installation .......................................................................................... 5-l 6

2APIA Cross Connection ....................................................................................... 5-l 7

24 Channel Digital Trunk Interface Card (24Tl) ....................................................

24Tl Cable.. ........................................................................................................... 5-20

LED Indicators on the 24Tl Card.. ......................................................................... 5-23

ISDN Primary Rate Access Interface Card (23PT) ................................................ 5-25

LED Indicators on the 23PT Card .......................................................................... 5-25

Clock Card (CLKS) ................................................................................................. 5-27

INSERTING AND EXTRACTING ................................................................................. 5-27

To Insert and Seat Cards.. ..................................................................................... 5-27

To Unseat/Remove Card.. .....................................................................................

SYSTEM CAPACITIES ................................................................................................

Card Slots.. ............................................................................................................

EQUIPMENT NUMBERS AND CARD SLOTS.. ........................................................... 5-31

Logical Card Slots.. ................................................................................................

Equipment Numbers ..............................................................................................

HIWAYS .......................................................................................................................

(MUFN)

..................................................................................

.................................................................................... 5-8

....................................................................

5-1

5-l

5-8

5-l 1

5-17

5-28

5-29

5-29

5-31

5-31

5-32

SECTION 123-056-002

Installation Manual

Page 5

Table of Contents

Chapter

6

9

TERMINAL AND LINE CONNECTION .......................................................................... 6-1

PIN ASSIGNMENT OF

CROSS CONNECTION. ................................................................................................. 6-l

METHOD OF WIRING ... ... .............................................................................................. 6-l

ATTENDANT CONSOLE..

DATA INTERFACE UNIT..

WALL MOUNTING PROCEDURE FOR PROPRIETARY TELEPHONE..

DATA TERMINAL ADAPTER

DIGITAL STATION.. ..... ................................................................................................ 6-18

DSS 30 ............................. ............................................................................................ 6-l 8

MAIN DISTRIBUTION FRAME

ROUTING THE MDF CABLES..

SYSTEM START-UP ......................................................................................................

SYSTEM START..

DEFAULT DATA..

INITIAL PROGRAM LOADING..

START-UP

IPL AFTER ODDB LOADING HAS BEEN STORED ON DISK..

BAlTERY BACK-UP

GENERAL ......................................................................................................................

HARDWARE.. .................................................................................................................

Cabinet Hardware ....................................................................................................

Battery Plant.. ...........................................................................................................

Battery Sizing ...........................................................................................................

PROCEDURE.. ............................................................................................

MDF TERMINAL.. .....................................................................

............................................................................................

...........................................................................................

................... 6-l 1

(DTA)

............................................................................

...................................................................................... 7-l

.....................................................................................

..........................................................................................................

...........................................................................................................

.....................................................................................

.................................... 8-3

.....................................................................................................

6-l

6-l 0

6-10

6-15

7-l

8-I

8-l

8-l

8-l

8-3

9-I

9-l

9-l

9-l

9-l

9-3

-

10

PERIPHERAL EQUIPMENT

STATION MESSAGE DETAIL RECORDING (SMDR)

XON/XOFF Flow Control Option.. .......................................................................... 10-l

Power On/off Option..

REQUIREMENTS FOR CABLE ................................................................................... 10-2

DTE Mode Printer .................................................................................................. 1 o-2

DCE Mode Printer ... ............................................................................................... 10-2

RS-232C PORTS IN THE BASIC CABINET.. ..............................................................

SMDR INSTALLATION ................................................................................................

SMDR SCREENING.. ...................................................................................................

SMDR FORMAT.. .........................................................................................................

SMDR Message per Call.. ......................................................................................

SYSTEM MESSAGES .................................................................................................. 10-7

Time and Date Change.. ........................................................................................ 10-7

System Restart.. ................. .................................................................................... 10-7

Power Failure.. ....................................... ................................................................

Printer Failure .........................................................................................................

Clock Failure ................... . . . ....................................................................................

PRIORITY ... ..................................................................................................................

RESPONSE PROCEDURES. ......................................................................................

Paper End.. ............................................................................................................

Printer with XONIXOFF Option ..............................................................................

Printer with Line Disconnect Option

Printer without Paper End Alerting Function

OTHER PROBLEMS ..................................................................................................

........................................................................................ IO-I

PRINTER.. .............................. 10-l

.............................................................................................

....................................................................... 1 o-9

..........................................................

1 O-2

104

1 O-5

1 O-5

10-6

10-6

1 o-7

1 o-7

10-7

1 o-9

1 o-9

10-g

1 o-9

1 o-9

10-10

Installation Manual ISS 3, SECTION 123-056-002

Page 6

iv

Table of Contents

Chapter

Title

HOTEL/MOTEL PRINTER.. ....................................... . ................................................

XONIXOFF Option ............................................................................................... 10-I 1

Power On/Off Option ............................................................................................ 10-I 1

CABLE REQUIREMENTS

Hotel/Motel Printer Cable Connection ..................................................................

Hotel/Motel Printer Installation ...................... .......................................................

HOTEL/MOTEL PRINTER SCREENING.. ........... ... . ..................................................

HOTEL/MOTEL PRINT OUT FORMAT.. .................................................................... IO-1 3

RESPONSE PROCEDURES FOR MALFUNCTIONS ............................................... 10-I 8

Paper End ............................................................................................................

Printer with XONIXOFF Option ............................................................................

Printer with Line Disconnect Option .....................................................................

Printer without Paper End Alerting Function ........................................................ 1 O-l 9

OTHER PROBLEMS.. .............. . . . ...............................................................................

ACD CALLS WAITING INDICATOR.. ................... ......................................................

Operational Checks

DIAGNOSIS.. .............................................................................................................. lo-22

MUSIC SOURCE EQUIPMENT. ................................................................................

DICTATION MACHINE.. .............................................................................................

EXTERNAL ALARM UNIT.. ...... . . . . ..............................................................................

APPLICATION PROCESSOR APPLIQUE.. ............................................................... 1 O-22

..........................................................................................

..............................................................................................

Page

1 O-1 0

1 O-l 2

10-12

10-13

10-13

lo-18

lo-18

10-19

10-19

10-19

1 O-20

1 o-22

lo-22

1 o-22

11

PROPERTY MANAGEMENT SYSTEM INTERFACE (PMSI)

INTRODUCTION ..........................................................................................................

GENERAL CONDITIONS. ............................................................................................

SYSTEM INTERFACE SPECIFICATIONS.. .................................................................

SOFTWARE INTERFACE SPECIFICATIONS.. ...........................................................

Message Format ....................................................................................................

Control Codes ........................................................................................................

Protocol .......... ........................................................................................................

Error Codes..

TRANSMISSION

MESSAGE SPECIFICATIONS.. .........

PMSI FEATURES

Maid Status - Dialed from Guest Room

Message Waiting..

Multi-Language Wake-Up

Check-In/Out..

Room Restriction . .

Room Data Image

Wake-Up.. ............................................................................................................

Wake-Up Attempt .................................................................................................

Set and Change Guest Information

Status Inquiry..

Message Format

..........................................................................................................

CODE..

......................................................................................................... 1 l-7

....................... ...............................................................................

.............................................................................................

..........................................................................

.................................................................

..................................................................................................

....................................................................................

................................................................................................ 11-14

................................................................................................

......................................................................

.....................................................................................................

..................................................................................................

.....................................

11-l

11-l

11-2

? l-3

1 l-3

11-4

1 l-4

11-4

1 l-5

1 l-5

11-6

11-7

11-8

II-IO

11-12

1 I-16

11-18

11-19

11-20

11-23

11-24

SECTION 123-056-002

Installation Manual

Page 7

Table of Contents

V

Chapter

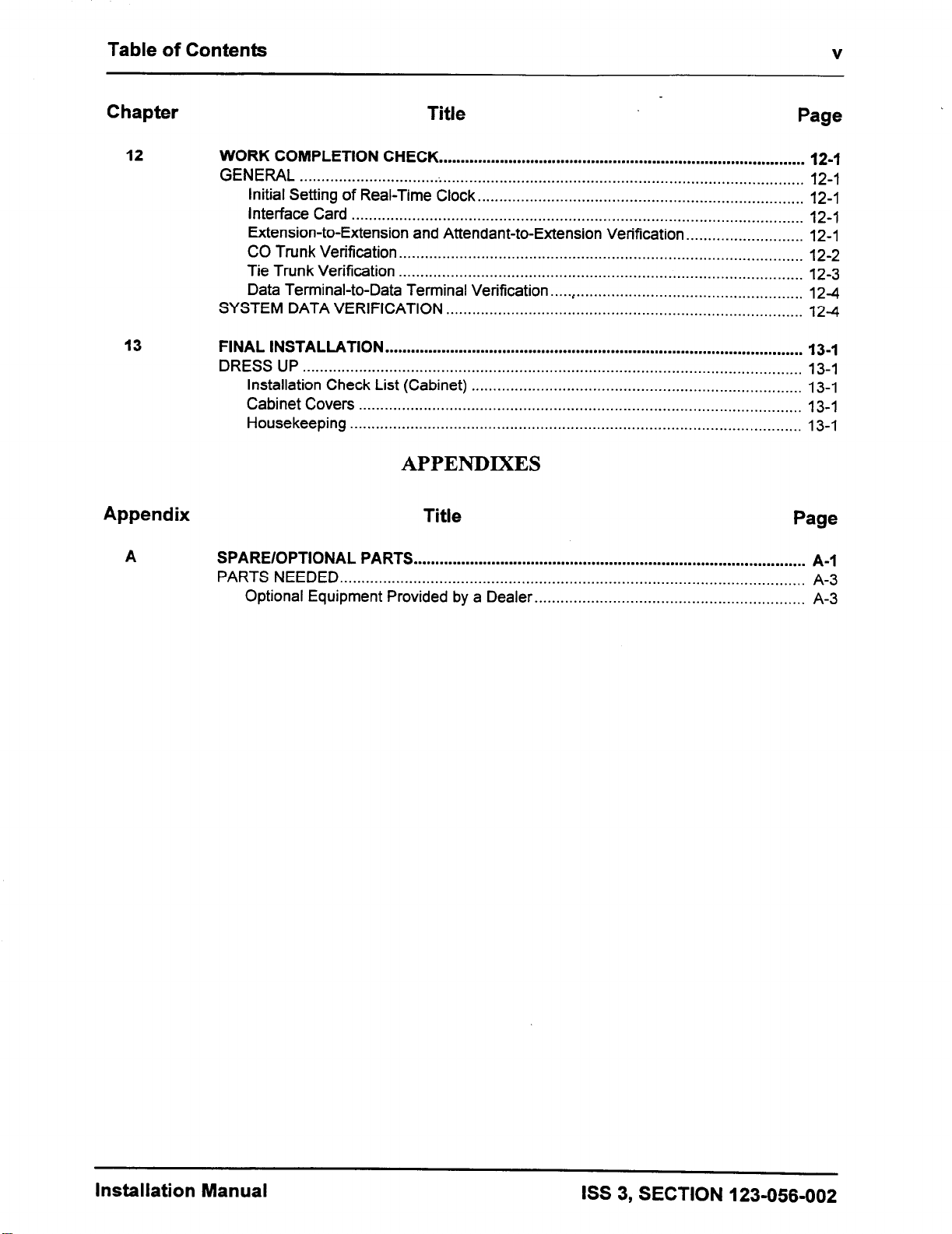

12 WORK COMPLETION CHECK

13

GENERAL .

Initial Setting of Real-Time Clock . . . . .._......................................._......_............._....... 12-l

Interface Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extension-to-Extension and Attendant-to-Extension Verification . . . . . . . . . . . . . . . . . . . . . . .._..

CO Trunk Verification _ _

Tie Trunk Verification .

Data Terminal-to-Data Terminal Verification.

SYSTEM DATA VERIFICATION

FINAL INSTALLATION ................................................................................................

DRESS UP . . .................................................................................................................

Installation Check List (Cabinet) ............................................................................

Cabinet Covers ........

Housekeeping.. ......................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

A

SPARE/OPTIONAL PARTS

PARTS NEEDED.. ..............

Optional Equipment Provided by a Dealer

Title

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . ..~....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..............................................................................................

APPENDIXES

Title

..........................................................................................

...........................................................................................

..............................................................

Page

12-1

12-1

12-1

12-1

12-2

12-3

12-4

12-4

13-1

13-l

13-1

13-l

13-1

Page

A-l

A-3

A-3

Installation Manual

ISS 3, SECTION 123-056-002

Page 8

vi

-

Table of Contents

LIST OF TABLES

Table

2-l

2-2

3-l

3-2

3-3

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-l 1

5-12

5-13

5-14

5-15

6-l

6-2

7-1

7-12

8-1

8-2

9-1

9-2

9-3

9-4

IO-1

1 o-2

1 o-3

IO-4

1 o-5

11-l

II-2

11-3

11-4

11-5

11-6

11-7

11-8

Title Page

Power Supply Front Panel Indicators, Switch, and Fuse Labels..

System Maximums ......................................................................................................... 2-7

Basic Cabinet Parts Lists.. ..............................................................................................

Expansion Cabinet Parts Lists.. .......................... ............................................................ 3-6

SSDEC Kit.. ....................................................................................................................

Maximum Number of Cards per Cabinet..

System Controls and Indicators.. ....................................................................................

IPL Select Switch ............................................................................................................

Line Card Specifications..

Trunk Card Specifications ..............................................................................................

Combination of Proprietary Telephones and Line Cards..

Combination of Long/Short Lines ...................................................................................

24Tl Card Strapping ....................................................................................................

Adapter Location ..........................................................................................................

Card in Slot 0, 3, or 6; Digital Trunk Output on Connector JO3

Card in Slot 1, 4, or 7; Digital Trunk Output on Connector JO4

Card Slot Usage

Equipment Numbers.

Cabinet Zero (Basic) Hiways ........................................................................................

Cabinet One Hiways.. ...................................................................................................

Power Fail Transfer Cross Connect.

Loop Limit of Terminals ................................................................................................

MDF Cable Pin Configurations.. .....................................................................................

16 Circuit Card MDF Cable Pin Configurations.. .........................................................

IPL Mode Selection Switch.. ...........................................................................................

7-Segment LED Display on the CPU Cards ...................................................................

Typical Power Consumption.. .........................................................................................

Recommended Battery Capacity and Minimum Recharge Time..

Worst Case Power Consumption.. ..................................................................................

Recommended Battery Capacity and Minimum Recharge Time for Worst Case

SMDR Printer Requirements ........................................................................................

Default Attributes for I/O Ports.. ....................................................................................

Screening Capability .....................................................................................................

Default Data for Screening Capability

Hotel/Motel Printer Requirements ...............................................................................

PMS Feature Support.. .................................................................................................

System Interface Specifications ...................................................................................

Software Interface Specifications.. ............................................................................... 11-3

State Transition Diagrams (Receive Side). ................................................................... 11-4

State Transition Diagrams (Send Side) ........................................................................ 11-5

Code Representation .................................................................................................... 11-6

Feature Message Summary

ASCII Nibbles Conversion for Guest Name..

........................................................................................................... 5-29

............................................................................................... 5-6

.................................................................................................... 5-32

......................................................................................... 11-6

...................................................................... 5-3

.............................................. 5-7

............................................................................... 6-8

..........................................................................

..............

. ............................................... 1 l-21

.................................. 2-3

....................................

....................................

.................................. 9-3

........... 9-4

3-6

3-6

5-5

5-5

5-6

5-9

5-18

5-21

5-22

5-22

5-32

5-33

6-10

7-4

7-12

8-2

8-3

9-3

94

1 O-l

1 O-5

1 o-5

IO-6

1 O-l 0

1 l-2

1 l-3

SECTION 123-056-002 Installation Manual

Page 9

Table of Contents vii

LIST OF ILLUSTRATIONS

Figure

2-l

2-2

2-3

3-l

3-2

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-l 0

4-l 1

4-12

4-13

4-14

4-l 5

4-16

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-l 0

5-l 1

5-12

5-13

6-l

6-2

6-3

6-4

6-5

6-6

6-7

6-8

6-9

6-10

6-l 1

6-12

6-13

6-14

6-15

6-16

Title

Series 3 Cabinet.. ..... ... . ..................................................................................................

Four Cabinet Configurations..

Series 3 Cabinet internal View ................................... .................................................... 2-4

Unpacking the Cabinet

Series 3 Wall Arrangements.. ......................................................................................... 3-4

Wall Bracket Detail ........ ................................................................................................. 4-2

One Piece Front Cover..

Three-Piece Front Cover.

Access Port Covers..

Bottom Cover Plate

Cabinet Installation .........................................................................................................

Power Distribution Unit, -48 VDC and

Power and Ground Connections .................................................................................... 4-8

DC Cable and G Ground Installation ..............................................................................

Ground Cable, Address Extension Cable..

Extended Cable

Mounting the SFDC..

Floppy Disk

Power Fail Transfer Card Installation ........................................................................... 4-16

ACPD/DCPD Installation .............................................................................................. 4-l 7

24V Supplemental Power Supply Installation ...............................................................

Front View of the CPU Cards .........................................................................................

4SLE Card Switch Positions..

8BWC Card Jumper Configuration ...............................................................................

2TE4 Card Jumper Configuration.. ...............................................................................

4TE4 Card Jumper Configuration.. ...............................................................................

Power Fail Transfer Card .............................................................................................

6DID Card Jumper Configuration .................................................................................

DB-25 Pin Connection to the MDF Terminal

2APIA Cross Connect Diagram (ASYNC)

24Tl Card

24Tl / 23PT Adapter

24Tl Cable

23PT Card Jumper Configuration.. ...............................................................................

Card Slot to

Interface of E & M Tie Trunks ......................................................................................... 6-2

Cross-Connection

Cross-Connection for Type I and Type II Signaling.. ...................................................... 6-5

Cross-Connection for Type II Signaling.. ........................................................................ 6-6

Cross-Connection for GPFA..

Configuration of Connector Blocks..

Rear View of the Data Interface Unit (DIU) ...................................................................

DIU with Modern

Typical Connection for Proprietary Telephone Paired with DIU

Wall Mounting of Proprietary/Digital Telephone..

BLF/DSS Console Mounting.. ....................................................................................... 6-14

Attendant to DSS 100 Connecting Procedure

Installation of DTA in the Digital Telephone

Digital Station and DSS 30 Wiring..

Digital Station and DSS 30 Connectors

Drive

Jumper Configuration .................................................................................

Configurations.. .........................................................................................

MDF Connector Wiring..

...................................................................................................... 4-5

........................................................................................................

Installation.. ........................................................................................ 4-l 3

....................................................................................................

Installation

....................................................................................................

of Lines and Trunks ..........................................................................

PoolinglDlU with CSD Connection.. .................................................. 6-12

......................................................................................... 2-2

...................................................................................................

..... ............................................................................................

...............................................................................................

RGMW Installed ................................................. 4-7

...................................................................

....................................................................................... 4-l 5

......................................................................................... 5-9

Block

.......................................................

....................................................................

.............................................................................

........

..................................................................................

...............................................................................

................................... 6-12

......................................................... 6-13

..............................................................

.................................................................

..............................................................................

........................................................................

Page

2-l

3-2

4-3

4-4

4-5

4-6

4-9

4-l 1

4-14

4-l 8

5-4

5-l 0

5-12

5-l 3

5-14

5-l 5

5-16

5-17

5-l 9

5-2 1

5-23

5-26

6-l

6-3

6-7

6-9

6-l 1

6-16

6-17

6-l 8

6-l 9

Installation Manual ISS 3, SECTION 123-056-002

Page 10

. . .

VIII

Table of Contents

Figure

7-l

7-2

7-3

7-4

9-l

9-2

1 o-1

1 o-2

1 o-3

10-4

10-5

10-6

1 o-7

1 O-8

1 o-9

10-10

10-11

10-12

10-13

10-14

10-15

lo-16

10-17

lo-18

10-19

1 O-20

1 o-21

1 o-22

1 O-23

11-l

11-2

11-3

12-1

12-2

12-3

12-4

LIST OF ILLUSTRATIONS

Title

Clamp-On Ferrite Core RFI Filter ...

Clamp-On Ferrite Core On MDF Cable ... .......................................................................

Card Slots and

Card Slots and Hiways

Battery Back Up ..............................................................................................................

Battery Plant Construction

RS-232C Cable for DTE Mode SMDR Printer..

RS-232C Cable for Modem / DCE Mode SMDR Printer ............................................... 10-3

Position of I/O Ports #0 and #l .....................................................................................

SMDR Message Formats

Hotel/Motel Printer Configuration

RS-232C Cable for Hotel/Motel

Automatic Wake-Up Registration Message

Automatic Wake-Up Cancellation Message

Automatic Wake-Up Execution Message

Automatic Wake-Up Report.. ...................................................................................... 1 O-l 5

Call Charge Addition Message ................................................................................... 1 O-l 5

Call Charge Clear Message .......................................................................................

Call Charge Verification Message

Call Charge Report..

Short Power Failure Message

Printer Failure Message .............................................................................................

Real Time Clock

Real Time Clock Repair Message

Real Time Clock Changed by Command Message

SMDR Printout for Single Guest

SMDR Printout for all Guest Rooms.. .........................................................................

ACD Calls Waiting Indicator..

ACD Calls Waiting Indicator Terminal Block..

Property Management System Interface Configuration..

Message Format ........................................................................................................... 1 l-4

Message Text Format

Extension-to-Extension Verification ..............................................................................

CO Trunk Verification

Tie Trunk Verification

Extension-to-Extension Verification

Cable Connectors.. ................................................................................ 7-3

................................................................................................... 7-3

..............................................................................................

.............................................................................................

................................................................................................... lo-16

Failure

Message..

................................................................................................... 11-5

...................................................................................................

....................................................................................................

. . .............................................................................. 7-2

............................................................................... 10-11

Printer .......................................................................

................................................................ 10-14

...............................................................

...................................................................

..............................................................................

....................................................................................

............................................................................

.............................................................................. lo-16

Room ...................................................................... 1 O-l 7

..................................................................................... 1 o-21

............................................................. lo-21

..............................................................................

(Cont’d)

...................

.................................................... lo-17

.........................................

.............................................. 1 l-1

Page

7-2

9-l

9-2

1 o-3

1 O-4

1 O-8

10-12

1 O-14

1 O-14

1 O-l 5

1 O-l 5

1 O-l 6

1 O-16

1 O-l 6

1 O-l 8

12-1

12-2

12-3

12-4

SECTION 123-056-002

Installation Manual

Page 11

CHAPTER 1 _

INTRODUCTION

INTRODUCTION

ORGANIZATION

This document contains information for the installation of Series 3

system hardware. This document assumes that the user is familiar

with the operating principles of telecommunications systems and

possesses the skills required for installing, configuring, and

validating those systems.

The organization of this manual is as follows:

Chapter 1, Introduction:

of the manual. Includes a list of Reference Documents.

Chapter 2, System Construction:

characteristics and operation principals of the Series 3 system.

Chapter 3, Preparations:

instructions, and hardware inspection and handling instructions.

Chapter 4, Cabinet Installation:

mounting, power unit installation, floppy disk drive installation, and

inter-cabinet cables.

Chapter 5, Circuit Card Installation:

locations and inter-card connections.

Chapter 6, Terminal and Line Connection:

terminal equipment, including proprietary telephones, the Attendant

Console, and other devices.

Describes the purpose and organization

Describes the physical

Describes site requirements, unpacking

Describes bracket and cabinet

Describes card mounting

Describes installation

Chapter 7, Main Distribution Frame:

connections, I/O connectors, Attendant Console wiring, T-l and

23PT cabling.

Chapter 8, System Start-Up:

power-down, and data save procedures.

Chapter 9, Battery Back-Up:

battery back-up equipment.

Chapter 10, Peripheral Equipment:

peripheral equipment.

Chapter 11, Property Management System Interface (PMSI):

Describes the installation of PMSI equipment.

Chapter 12, Work Completion Check:

testing to verify system operation after installation.

Chapter 13, Final Installation:

lists for use after installation.

Appendix A, Recommended Spares/Quantities:

cards and equipment that may be needed as spares.

Describes system power-up, IPL,

Describes sizing and installation of

Describes MDF cable

Describes the installation of

Describes precutover

Provides work completion check

Provides a list of

installation ISS 3, SECTION 123-056-002

Page 12

Introduction

REFERENCE

DOCUMENTATION

Fujitsu Documentation System Description/Features (Section 123-001-002). Describes

The following is a list of available documents:

.

in detail all of the features available in the system.

Applications Manual (Section 123-015-002). Used to assist in the

installation, programming, and maintenance of the system.

Attendant Console User Guide (Section 123-040-002). Describes

basic attendant console operating instructions.

Digital Station User Guide (Section 123-050-002). Describes

Digital Station operating instructions.

CT-10120130 User Guide (Section 123-052-002). Describes CT-lo,

CT-20, and CT-30 telephone operating instructions.

Single Line Telephone User Guide (Section 123-063-002).

Describes single line telephone operating instructions.

Maintenance Manual (Section 123-060-002). Provides complete

instructions for maintaining the Series 3 system.

Data Base Manual (Section 123-080-002). Provides information

necessary to interface with the system and implementation

procedures for each command.

Site Log Manual (Section 123-200-002). Provides configuration

forms used for entering data base information.

It is recommended that pre-cutover tests be performed. This testing

information is located in the Maintenance Manual and the Data

Base. A brief test is also recommended to assure telephone

operation. Such tests may require referencing the System

Description/Features and User Guides.

For overall system information, consult the System Description/

Features.

SECTION 123-056-002

Installation

Page 13

Introduction

1-3

Industry Standards

GENERAL INFORMATION

The following additional documents may be helpful when installing

the Series 3 system:

EIA Standard RS232C Interface Between Data Terminal Equipment

and Data Communications Equipment Employing Serial Binary Data

Interchange.

EIA RS-464

“Private Branch Exchange Switching Equipment for

Voiceband Applications.”

EIA RS-464-1

“PBX Switching Equipment for Voiceband

Applications, Addendum Number 1 .‘I

EIA PN-1429

EIA RS-478

“Proposal Addition” to RS-464.

“Multi-Line Key Telephone Systems (KTS) for

Voiceband Applications.”

The Series 3 meets FCC Rules and Regulations, Part 68, and

l

Part 15Class A.

.

FCC Registration:

- Key System: BJ885Z-60084-KF-E

- PBX System: BJ8USA-75355-PF-E

- Hybrid (Multifunction) System: BJ8USA-60083-MF-E

Installation ISS 3, SECTION 123-056-002

Page 14

This page intentionally left blank

Page 15

CHAPTER 2

SYSTEM CONSTRUCTION

CABINET CONFIGURATION

Basic Cabinet The basic cabinet, referred to as cabinet zero, houses one of the

Expansion Cabinets

Wall Bracket The bracket is mounted on the wall, and the cabinet is then secured

Figure 2-I. Series 3 Cabinet

The Series 3 system is made up of one to four wall mounted

cabinets. A two cabinet Series 3 system is shown in Figure 2-l.

Figure 2-2 shows an exterior view of Series 3 four cabinet

configurations; a basic cabinet and three expansion cabinets.

The Series 3 consists of the following hardware components:

power distribution boxes (ACPD or DCPD), the common control

card (SC2P2B / SC2P2E or SC4P2B / SC4P2E), and various line

and trunk cards

The expansion cabinets are physically the same as the basic

cabinet. Each expansion cabinet is equipped with a Main Power

Supply Unit (MPSU). The third cabinet, in three and four cabinet

systems, contains the SSDEC (switching expansion) card and a

power distribution box (ACPDIDCPD).

to the bracket. The Series 3 system require a minimum of 12 inches

clearance above and below each cabinet.

Installation

ISS 3, SECTION 123-056-002

Page 16

2-2 System Construction

Fiaure 2-2. Four Cabinet Confiaurations

BASIC

BASIC

EXTENSION EXTENSION EXTENSION

2 3 BASIC

EXTENSION EXTENSION EXTENSION SERIES 3 CABINET MOUNTING

1

I I

EXTENSION EXTENSION

1 2 3

I

2

OR

3

NOTE: There must be a

EXTENSION

I

1

CONFIGURATIONS

minimum of 12 inches

clearance above and

below all cabinets.

T

12”TO24”

I

BASIC

I

SECTION 123-056-002

EXTENSION

1 t UPTO24” +

I

EXTENSION EXTENSION

2 3

I

Installation

Page 17

System Construction 2-3

HARDWARE

CONFIGURATION

Power Units

l

ACPDIDCPD: The power distribution unit is the primary power

input to the Series 3 system. It is available in two versions: the

ACPD for AC only operation; and the DCPD for AC with battery

back up operation. Installed in the basic and second expansion

cabinets.

.

MPSU: The Main Power Supply Unit (MPSU) provides

+/- 5VDC and -24VDC power for each cabinet. Each cabinet

includes its own MPSU. Refer to Table 2-l.

.

RGMW: The Ring Generator supplies 20Hz ring voltage and

DC message waiting voltage for single line phones. One RGMW

mounted in cabinet zero supplies ring voltage and message

waiting power for cabinets zero and one. One RGMW in cabinet

two supplies cabinets two and three. The RGMW is never

installed in cabinets one or three.

.

48V PS: The -48V PS supplies -48 volts for 4SLE, 6DID and

4TE4 cards and for recharging the back-up batteries. The

cabinets are connected by a power bus. When two or more 48V

PS units are installed in a system, all units load share equally.

Refer to Figure 2-3. Each 48V PS has a capacity of 3.0 Amps

(A). The 6DID and 4TE4 cards draw an average of 0.3 A each.

Any surplus current capacity can be used to charge external

back up batteries. Refer to Chapter 9 for battery back up

information, and to Table 2-l below.

.

24V PS: This power supply is mounted beneath the card shelf

and has no switches. There is a green LED on the front edge.

Floppy Disk Drive The optional floppy disk drive stores the customer data base.

Table 2-1. Power Supply Front Panel Indicators, Switch, and Fuse Labels

POWER SUPPLY LABEL

OPE

uv

MPSU

-48V PS

24V PS

INT

RES

FUSE

OPE

SYNC

(none)

MPSU is operating correctly.

Under Voltage, the output of the MPSU is under the

specifications.

Momentary loss of AC input power. An interruption longer than

10 ms, but less than one second. Must be manually reset. INT is

disabled if battery back-up is installed.

Reset switch for INT indicator.

48 volts output fuse. The -48 volts for 6DID and 4TE4 cards.

-48V PS is operating correctly.

Sync signal is being received correctly from the MPSU.

24V PS is operating correctly.

FUNCTION

Installation

ISS 3, SECTION 123-056-002

Page 18

System Construction

MPSU

r

ir

:

T

r

:

T

lr

4

i

:

T

LA J

r-m

: L

T :

4 5 6 7 8 9 10

nnr

L L L L L

: : : : i

ir

63

1

* This slot is not available in the Basic Cabinet and is used only in the

expansion cabinets for the 4DMR, CACH, and CACC cards. Refer to

Chapter 5.

SECTION 123-056-002

Installation

Page 19

System Construction

CIRCUIT CARDS

Common Control Cards

l

SCPNZM: Combined processor, memory, switch network, and

(optional) floppy disk controller for use in one and two cabinet

systems. installed in the basic cabinet.

l

SCPN4M: Combined processor, memory, switch network,

floppy disk controller (optional), and switching extender for three

and four cabinet systems. Installed in the basic cabinet.

l

SSDEC: Switching extender card for three and four cabinet

systems. Mounts in the processor slot of the third cabinet.

2-5

-

Interface Cards

SYSTEM SPECIFICATIONS

IGDTC, IGSLC, 8EKC, 8DTC 8SLC 8PDL, 4SLE, 4BWC, 8BWC

2lTL, 2lTE, 2TE4,4TE4,4DMR, 4CHT, 6DID, RVAC, 2APIA,

MUFN, 24Tl,23PT, CLKS, GPFA, CACC, and CACH cards can be

ordered depending on the customers requirements.

The system specifications are listed below. For additional

information refer to Table 2-l.

l

Cabinet dimensions:

- Wrdth: 14.61 in. (37.11 cm)

- Height: 19.91 in. (50.57 cm)

- Depth: 14.675 in. (37.27 cm) includes door

- Weight: 5 lb. (25 kg) fully equipped

.

Mounting bracket dimensions:

- Width: 20.89 in (53 cm)

- Height: 19.8 in. (50.4 cm)

l

Central Controller (MBL 80186)

- 8 Mhz; one and two cabinet systems (SCPN2M)

- 16 MHz; three and four cabinet systems (SCPN4M)

.

l/O interface:

- 2 ports

- RS-232C compatible

- Full duplex mode

- Stop bits; 1 or 2

- ASCII characters: 7 or 8

- Asynchronous clock

- Baud rate: 110 to 4800

- Panty: none, odd, or even

Installation

.

Maintenance:

- Remote with optional modem

- Local

ISS 3, SECTION 123-056-002

Page 20

2-6

System Construction

SYSTEM SPECIFICATIONS

(Cont’d)

SOFTWARE

l

Digital switching network bus:

- Time Division Multiplex (TDM) non-blocking

- 512 time slots in one and two cabinets (SCPN2M)

- 1024 time slots in three and four cabinets (SCPN4M)

.

One 3.5 inch floppy disk drive (optional):

- Capacity of 1.44 MB formatted (IBM format)

- Customer data base back up

The features provided include:

.

Basic Calls (Business Package)

.

Station Message Detail Recording (SMDR) (Business Package)

.

Direct Inward Dial (DID) (Business Package)

.

Direct Inward System Access (DISA) (Business Package)

.

Automatic Call Distribution (ACD) (Business Package)

.

Hotel/Motel Features (Business Package)

.

Least Cost Routing (Business Package)

.

Property Management System Interface (Business Package)

.

T-l Interface (Enhanced Package)

.

ISDN PRI Interface (Enhanced Package)

.

FIPN Interface (Enhanced Package)

.

Data Switching (Enhanced Package)

.

ACD Report Manager Application Processor (Enhanced

Package)

The features of the software are described in more detail in the

System Description/Features Manual.

SECTION 123-056-002 Installation

Page 21

System Construction 2-7

MAXIMUM CAPACITIES Some system maximum capacities are set by the number of

available card slots in the cabinets; others are set by the system

software. Table 2-2 lists all the maximum capacities. Not all of the

maximums can be configured in the same system. For example; the

maximum total number of DSS buttons in a system is 640.

Table 2-2. System Maximums

DTMF Receivers

Mixers*

SLT Ringing

SLT MW Lamps Lit

Proprietary

Telephone

Speaker Use

* Determined by SCPN2M or SCPN4M card not by the number of cabinets.

32 32 32

10 10

6/ring phase 12/ring phase 18lring phase 24/ring phase

50 100 150

96

192 288 384

15 15

32

200

Installation

ISS 3, SECTION 123-056-002

Page 22

This page intentionally left blank

Page 23

CHAPTER 3

PREPARATIONS

LIST OF MATERIALS

Observe the following rules when unpacking and inspecting the

system hardware:

.

Inspect all shipping containers for evidence of damage that may

have occurred during shipment. If such evidence is found,

advise the carrier and distributor.

.

Open the shipping containers and remove the contents

carefully. Refer to Figure 3-l.

.

Inspect the contents of the containers for any damage; if found,

advise the carrier and distributor.

l

When handling cards, do not remove them from antistatic bags

until card installation. Take normal precautions for electrostatic

damage to CMOS devices (antistatic spray, grounding, etc.)

Account for all system parts before discarding packing materials.

Table 3-l at the end of this chapter contains a list of parts that

should be shipped with each system.

You should have the following (customer provided) materials for

installation:

.

Mounting bolts; expansion bolts, or No. 10 bolts with insert

sleeves, or No. 10 x 98 inch wood screws (minimum)

.

Ground wire from cabinets to MDF ground bar (12 AWG

stranded or solid)

TOOLS

l

Signal ground wire from MDF to utility entrance ground (6 AWG

or larger, stranded)

.

AC power outlet, 110 VAC, 15 Amps

.

DC wire from battery plant to cabinet (10 AWG stranded or solid)

No special tools are required for installation.

All of the screws in the Series 3 cabinet are metric. Use a #2 Phillips

or “Reed and Prince” head screwdriver to avoid damage to the

screw heads.

Installation ISS 3, SECTION 123-056-002

Page 24

Figure 3-1. Unpacking the Cabinet

Preparations

--...’

. . . ::y.:..p,

‘.Y ,... ;‘..

: . . . .;.:,. . . . .

u

SECTION 123-056-002

Installation

Page 25

Preparations

3-3

INSTALLATION SITE

REQUIREMENTS

A stable, clean, and uncluttered area should be carefully considered

when selecting an installation site. The equipment cabinets are

designed to fit easily in the installation site. The cabinets are

compact and operate quietly, so they can be placed in an office or

work area.

Before the system can be installed, the operations in this chapter

must have been completed.

Keep in mind the following environmental considerations in the

selection of an installation site:

.

The installation site should be clean, dry, and uncluttered to limit

the intake of dust and dirt into the cabinet.

.

The installation site should e well ventilated to dissipate warm

air vented from the equipment cabinets.

.

The installation site should be well lighted to make installation

and maintenance easier.

.

The installation site ambient temperature must be maintained

between 32” and 104” Fahrenheit (0’ to 40” Celsius).

.

The installation site should be maintained at a relative humidity

between 10% and 90% (non-condensing) over the specified

temperature range.

.

The minimum wall load requirement for mounting a Series 3

cabinet is 55 pounds per cabinet.

.

The equipment location should be subject to very little vibration

l

There should be enough AC power outlets and circuits for the

system and its peripheral hardware.

.

The equipment location should be free of overhead water pipes

which might rupture and damage the equipment.

l

The equipment location should be free of strong magnetic fields,

such as those created by large transformers. Also, avoid an

area where there is apt to be static electricity.

l

The equipment location must be free of corrosive fumes or

machine exhaust which might cause deterioration of circuit

components.

.

The equipment location should not have heating ducts or

adjacent windows which could cause the ambient temperature

to rise above or fall below the rated operating range.

.

The equipment location must allow adequate air circulation

through the cabinet.

.

Moving machinery or vehicles should not be permitted in the

equipment location.

Installation

ISS 3, SECTION 123-056-002

Page 26

Preparations

SPECIAL INSTALLATION

INSTRUCTIONS

WALL LAYOUT

igure 3-2. Series 3 Wall Arrangements

l

.

.

.

Figure 3-2 shows wall arrangements for the Series 3 system.

Never install telephone wiring during a lighting storm.

Never install telephone jacks in wet locations unless the jack is

designed for wet locations.

Never touch bare telephone wires or terminals unless the

telephone has been disconnected at the network interface.

Use caution when installing or modifying telephone lines.

CEILING

12” min.

Alternate expansion or

application processor

location

20” REF

r-----

’ Alternate application

I processor location

l

EXP

#l

EXP EXP

#2 #3

Alternate application ’

processor location I

-Ll

Standard

expansion or

application processor

mounting location

Alternate expansion or

application processor

location

FLOOR

12” min

24” max.

20” REF

I

----- J

12” min

24” max.

20” REF

12” min.

SECTION 123-056-002 Installation

Page 27

Preparations

POWER REQUIREMENTS The power requirements are as follows:

l

Voltage: 96 to 127 VAC

.

Frequency: 60 Hz f 5 Hz

.

Phase: Single phase only

.

Maximum current:

- 3.8 A rated current for single cabinet system

- 7.2 A for a two cabinet system

- 11 .O A for a three cabinet system

- 14.4 A for a four cabinet system

.

Power consumption (max):

- About 418 W for a single cabinet system

About 792 W for a two cabinet system

About 1210 W fora three cabinet system

-

- About 1584 W for a four cabinet system

3-5

HEAT LOADING

GROUNDING

REQUIREMENTS

.

Typical heat generated:

About 956 BTU (single cabinet/70 lines)

-

- About 1853 BTU (two cabinet systeIl50 lines)

- About 2809 BTU (three cabinet system/220 lines)

- About 3703 BTU (four cabinet system)

Although standard power provides an acceptable level of

performance for most installations, some will require the power

failure transfer feature which switches designated stations to

assigned outgoing trunks during power outages.

Some facilities (particularly those with computer installations) are

equipped with an Uninterruptable Power Supply (UPS). This is the

preferred power source since it provides automatic switchover to

120 VAC back up in case of a loss of power. If a UPS is available at

the facility, the installer should verify that the Series 3 system power

outlet is connected to the UPS system.

Battery back up for the Series 3 is described in Chapter 8.

.

Signal ground: A single wire is connected to the G (center)

terminal of the terminal block in the bottom of cabinet zero

(Basic). Refer to Chapter 4. This wire must be 12 AWG,

stranded or solid copper conductor. The resistance of the

connection from the terminal block to the Utility Entrance

Ground must not be greater than 5 ohms.

.

Frame ground: Frame ground is provided by the third wire

ground in the AC power cable. The brackets of cabinets

mounted side by side are connected with clips. Refer to

Chapter 4.

Installation

ISS 3, SECTION 123-056-002

Page 28

Table 3-1. Basic Cabinet Parts Lists

Preparations

SPECIFICATION

I

Cabinet

Wall Mount Bracket

MPSU (Power Supply) (old)

-or-

EMPSU (Power Supply) (new)

RGMW (Ring Generator)

ACPD (AC only)

DCPD (AC/DC)

Modem (2400 BPS Modem)

Music on Hold Adapter

4DMR* (4 circuit DTMF receiver) 1 E20B-4505-R350

48V PS (-48~ Power Supply) I

AC Power Monitor I E20B-9900-R370 I First and third cabinets only

* As an option, customers may order a 4DMR or a MUFN card.

Table 3-2. Expansion Cabinet Parts Lists

E2 IO-990-V02 1 1 Includes covers

I

E2 10-9900-X1 56 1

I

710036-01

710036-02

710038-01

E08B-1034-CO01

E08B-1034-Cl01

735077-05

I

360456-01 1 Shipped in a separate box

710037-01 I Shipped in a separate box

I

Shipped in a separate box. Requires

supplemental 24V supply.

Shipped in a separate box.

Supplemental supply not required.

Shipped in a separate box

AC operation

AC operation with battery back up

Attached to I/O port in cabinet

I Shipped in a separate box

COMMENTS

‘able 3-3. SSDEC Kit

PART

SSDEC El 6B-3020-R130

SSDEC Cable E660-2507-T673#00-01

E Ground Extender (short) E660-9900-T108 #I

E Ground Extender (long) E660-9900-T108 #2

E Ground Extender (short) E660-9900-T115 #I

E Ground Extender (lona)

SPECIFICATION

E660-9900-T115 #2

COMMENTS

SECTION 123-056-002 Installation

Page 29

CHAPTER 4

CABINET INSTALLATION

GENERAL

WALL MOUNTING

BRACKETS

Mounting Bracket

Drilling the Mounting

Attaching the

Bolt Holes

The following procedures detail the mounting of wall brackets,

cabinets, and the connection of the inter-cabinet cables.

Each bracket will support one cabinet.

When planning the layout for a system with expansion cabinets

located above or below the basic cabinet allow a minimum 12

inches between the top and bottom mounting brackets. The space is

required for MDF cable clearance and cooling air flow. The

maximum spacing is 24 inches. Refer to Chapter Two.

Each mounting bracket has four sets of bolt holes. Refer to Figure

4-l. Bolt Hole Set One is used to attach the bracket for the first

cabinet in a row. Bolt Hole Set Two is used to attach the second

cabinet bracket. The basic cabinet (cabinet zero) is always the first

cabinet; expansion cabinet one mounts to the right of the basic

cabinet. Attach the mounting bracket to the wall using either

expansion bolts, or bolts and insert sleeves. The bolts must be at

least 114 in. diameter; or, if mounting the bracket on wood, the

minimum size wood screw permitted is a 114 x 5/8 inch. The method

used to secure the bracket must be capable of supporting 55

pounds (25 kg).

Drill the bolt holes as follows:

1. Find and mark the stud locations behind the walls where the

bracket is to be mounted. The mounting bracket provides holes

for 16-inch center-to-center stud distance.

Wall Bracket Grounding

2. Mark the positions of the four holes to be drilled in the wall for

the mounting bracket. For the basic cabinet use Bolt Hole Set

One.

3. Mark the center of the holes using a drill or punch.

4. Drill each marked hole to the correct depth and width for the

bolts/sleeves or screws to be used.

5. If sleeve inserts are used, drive one into each of the holes.

6. If another bracket is to be installed to the right; attach the FIRST

bracket to the wall. Set the right bracket in place, next to the left

bracket. Notice that two right side tabs fit under the main plate of

the left mounting bracket. Align the Set Two holes in the new

bracket tabs with the Set One hole in the right side of the first

bracket. Ensure that the left bracket frame ground tab is over the

hole in the right bracket. Mark the wall through the Bolt Hole Set

Two holes.

Connect adjacent brackets together with the frame ground tab on

the lower right corner of each bracket. Refer to Figure 4-l.

Installation ISS 3, SECTION 123-056-002

Page 30

4-2 Cabinet Installation

Figure 4-1. Wall Bracket Detail

Mounting Holes

set #4

MOUNTING BRACKETS

NOTE: 4 SETS OF MOUNTING

HOLES. HOLES ARE SPACED

TO ALLOW MOUNTING TO

WALL STUDS ON 16” CENTERS

USE HOLES SET #l FOR THE

FIRST BRACKET

SECTION 123-056-002

GND

CUP

123-056-001-05A

Installation

Page 31

Cabinet Installation

4-3

BASIC CABINET

INSTALLATION (One-Piece

Front Cover)

igure 4-2. One Piece Front Cover

1. Unpack the basic cabinet as described in Chaoter 3.

2. To remove the front cover, turn key clockwise, swing top out to

clear to locking tab, lift the cover up and out of the cabinet. Refer

to Figure 4-2.

3. Tip cabinet onto its back. Loosen the screws holding the bottom

plate. Slide bottom plate off of the screws. Refer to Figure 4-5.

CAUTION: All covers must be replaced at the end of the

installation procedures to meet FCC Part 15

requirements.

Installation

ISS 3, SECTION 123-056-002

Page 32

4-4

Cabinet Installation

BASIC CABINET

INSTALLATION (Three-Piece

Front Cover)

2. Remove two screws from the top front cover. Remove top cover.

3. Remove the power supply shelf access port covers from the top

4. Tip cabinet onto its back. Loosen the screws holding the bottom

CAUTION: All visible covers must be replaced at the end of the

Figure 4-3. Three-Piece Front Cover

1. Unpack the basic cabinet as described in Chapter 3. To remove

the front cover, open the small lock cover, turn key clockwise,

swing top out, lift the cover up and out of the cabinet. Refer to

Figure 4-3.

Remove the bottom front cover the same way.

of the cabinet. Refer to Figure 4-4.

plate. Slide bottom plate off of the screws. Refer to Figure 4-5.

installation procedures to meet FCC Part 15

requirements.

SECTION 123-056-002

Installation

Page 33

Cabinet Installation 4-5

Fiaure 4-4. Access Port Covers

Power supply shelf access

extender cable access

Ground cable access

Figure 4-5. Bottom Cover Plate

;---------- ---- ---- ----------

--L;-.---------- ..-..--.-- -

/

Installation ISS 3, SECTION 123-056-002

Page 34

4-6

INSTALLING THE EMPSU A Main Power Supply Unit (EMPSU or MPSU) is mounted in each

cabinet. An MPSU (P/N 710036-01) requires a supplemental 24V

power supply. When installing an EMPSU (P/N 71036-02) the

supplemental power supply must not be installed.

1.

Set the MPSU on the right side of the power supply shelf in the

basic cabinet.

2.

Align the MPSU with the connector on the backplane. Remove

the access cover on the left side of the cabinet in order to see

the connectors. Replace the cover after the MPSU is installed.

3.

Slide the MPSU back until the connectors are seated.

4.

Secure the MPSU with the M4xlO screw provided.

Cabinet Installation

INSTALLING THE BASIC

CABINET ON THE WALL

BRACKET

Fiaure 4-6. Cabinet Installation

The basic cabinet is ready to be installed on the wall bracket when

the MPSU has been installed in the power supply shelf.

1. Lift and attach the cabinet by lining up the mounting slots in the

top of the cabinet back with the tabs on the bracket and lowering

the cabinet onto the mounting bracket as shown in Figure 4-6.

2. Use two screws and washers to fasten the equipment cabinet to

the mounting bracket as shown.

SECTION 123-056-002

Installation

Page 35

Cabinet Installation

AC Power Monitor Install the AC Power Monitor plug in the backplane connector as

Ring Generator If a Ring Generator Message Waiting power supply is required to

4-7

shown in Figure 4-10.