Page 1

1. PICTURE TUBE

Size : 17 inch (Flat Slot Mask)

DefIection Angle : 90°

Neck Diameter : 29.1mm

Stripe Pitch : 0.24mm

Face Treatment : W-ARAS(Anti-Reflection and

Anti-Static Coating)

Internal : Anti-Glare

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low=0~1.2V, High=2.5~5.5V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0 ~ 0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15-pin Attached Connector

2-4. Scanning Frequency

Horizontal : 30 ~ 72 kHz

Vertical : 50 ~ 160 Hz

3. POWER SUPPLY

3-1. Power Range

AC200~240V(PFC) 50Hz, 1.5A

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

• Max Image Size - 325.4 x 244.1mm (12.81" x 9.61")

• Preset Image Size - 310 x 230 mm (12.20" x 9.06")

4-2. Display Color : Full Colors

4-3. Display Resolution : 1280 x 1024 / 60Hz

(Non-Interlace)

4-4. Video Bandwidth : 110MHz

5. ENVIRONMENT

5-1. Operating Temperature: 10°C ~ 35°C (Ambient)

5-2. Relative Humidity : 10% ~ 90%

(Non-condensing)

5-3. Altitude : 5,000m

6. DIMENSIONS (with TILT/SWIVEL)

Width : 415.0mm (16.34 inch)

Depth : 439.0mm (17.28 inch)

Height : 435.0mm (17.13 inch)

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 17.8kg (39.24 lbs.)

Gross Weight : 20.0kg (44.09 lbs.)

- 2 -

MODE

NORMAL (ON)

STAND-BY

SUSPEND

OFF

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

POWER CONSUMPTION

less than 105W

less than 15W

less than 15W

less than 5W

LED COLOR

GREEN

AMBER

AMBER

SPECIFICATIONS

Page 2

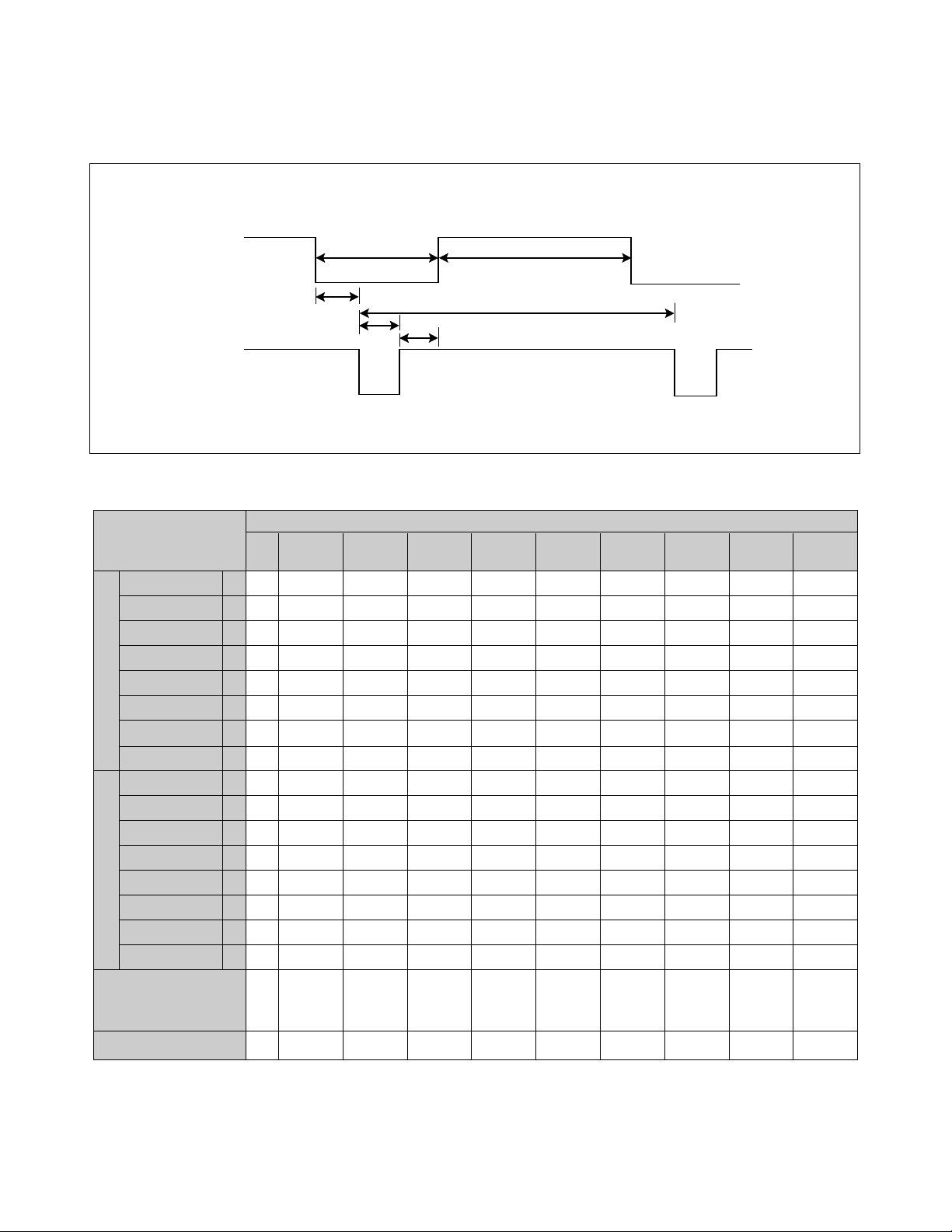

TIMING CHART

- 4 -

VIDEO

SYNC

C

E

D

F

AB

MODE

Resolution

Recall

H

O

R

I

Z

O

N

T

A

L

V

E

R

T

I

C

A

L

kHz

µs

µs

µs

µs

µs

µs

Hz

ms

ms

ms

ms

ms

ms

MODE 5

+

46.88

21.33

16.16

5.17

0.32

1.62

3.23

+

75.0

13.333

12.80

0.5333

0.021

0.064

0.448

800

x

600

75Hz

Yes

MODE 3

—

37.50

26.67

20.32

6.35

0.51

2.03

3.81

—

75.0

13.333

12.80

0.533

0.027

0.080

0.427

640

x

480

75Hz

Yes

MODE 6

+

53.67

18.63

14.22

4.41

0.57

1.14

2.70

+

85.06

11.756

11.179

0.578

0.019

0.056

0.503

800

x

600

85Hz

Yes

MODE 8

+

68.677

14.561

10.836

3.725

0.508

1.016

2.201

+

85.00

11.765

11.183

0.582

0.015

0.044

0.524

1024

x

768

85Hz

Yes

MODE 1

—

31.47

31.77

25.42

6.36

0.64

3.81

1.91

+

70.1

14.267

12.710

1.557

0.413

0.064

1.080

720

x

400

70Hz

Yes

MODE 2

—

31.47

31.78

25.42

6.36

0.64

3.81

1.91

—

59.9

16.683

15.253

1.430

0.318

0.064

1.049

640

x

480

60Hz

Yes

MODE 4

—

43.269

23.111

17.778

5.333

1.556

1.556

2.222

—

85.0

11.764

11.093

0.670

0.023

0.069

0.578

640

x

480

85Hz

Yes

MODE 7

+

60.02

16.66

13.00

3.66

0.20

1.22

2.24

+

75.0

13.328

12.795

0.533

0.017

0.050

0.466

1024

x

768

75Hz

Yes

MODE 9

+

63.98

15.63

11.85

3.78

0.44

1.04

2.30

+

60.02

16.661

16.005

0.656

0.015

0.047

0.594

1280

x

1024

60Hz

Yes

MARK

E

A

B

C

D

F

E

A

B

C

D

F

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

FACTORY PRESET MODE

Page 3

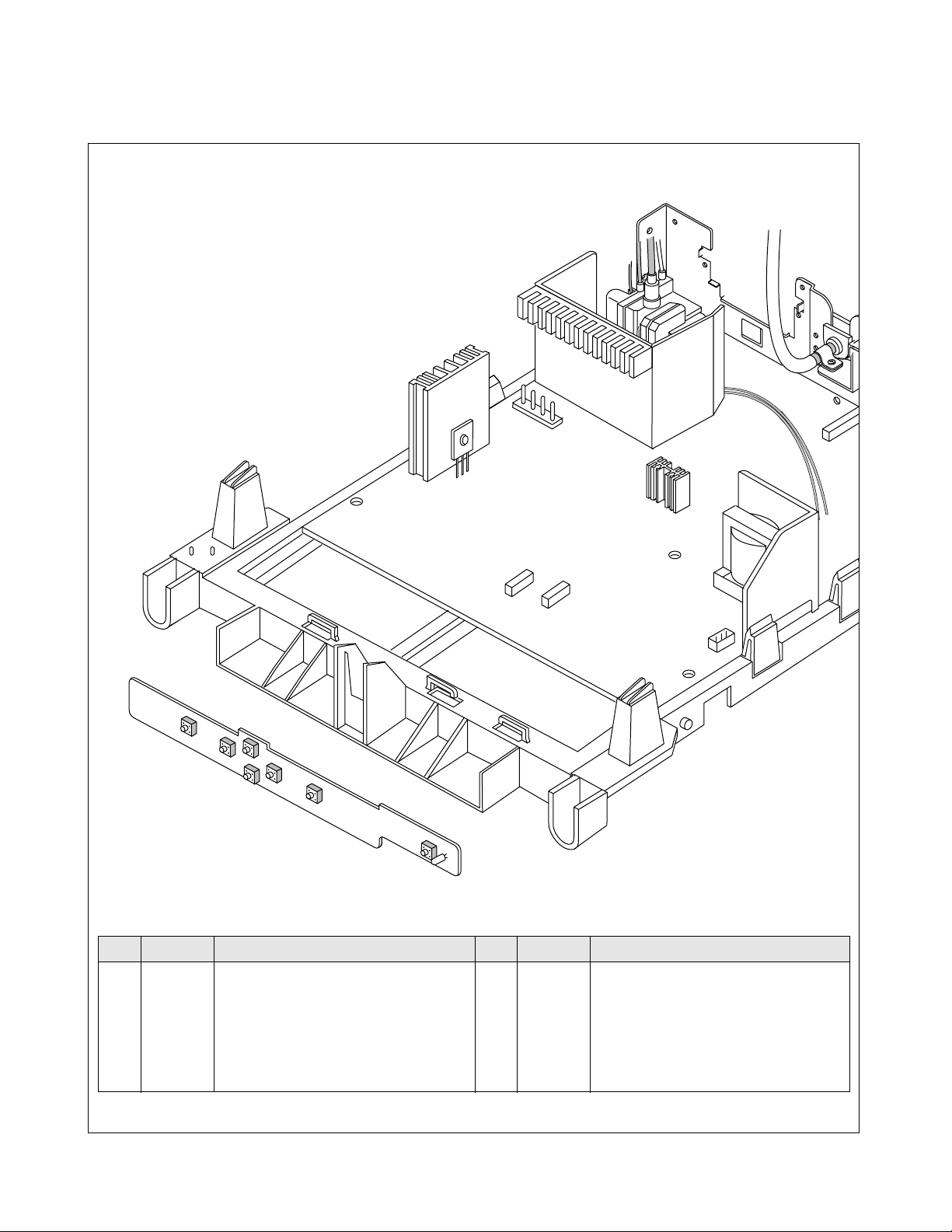

CONTROL LOCATIONS

- 8 -

1

3

6

7

4

5

CONTROL

MAIN

2

No.

1

2

3

4

No.

5

6

7

Ref. No.

SW201

SW202

SW206

SW203

Ref. No.

SW205

SW204

SW207

Control Function

OSD BUTTON

OSD SELECT/ADJUSTMENT LEFT

OSD SELECT/ADJUSTMENT RIGHT

OSD SELECT/ADJUSTMENT UP

Control Function

OSD SELECT/ADJUSTMENT DOWN

SET BUTTON

POWER BUTTON

Page 4

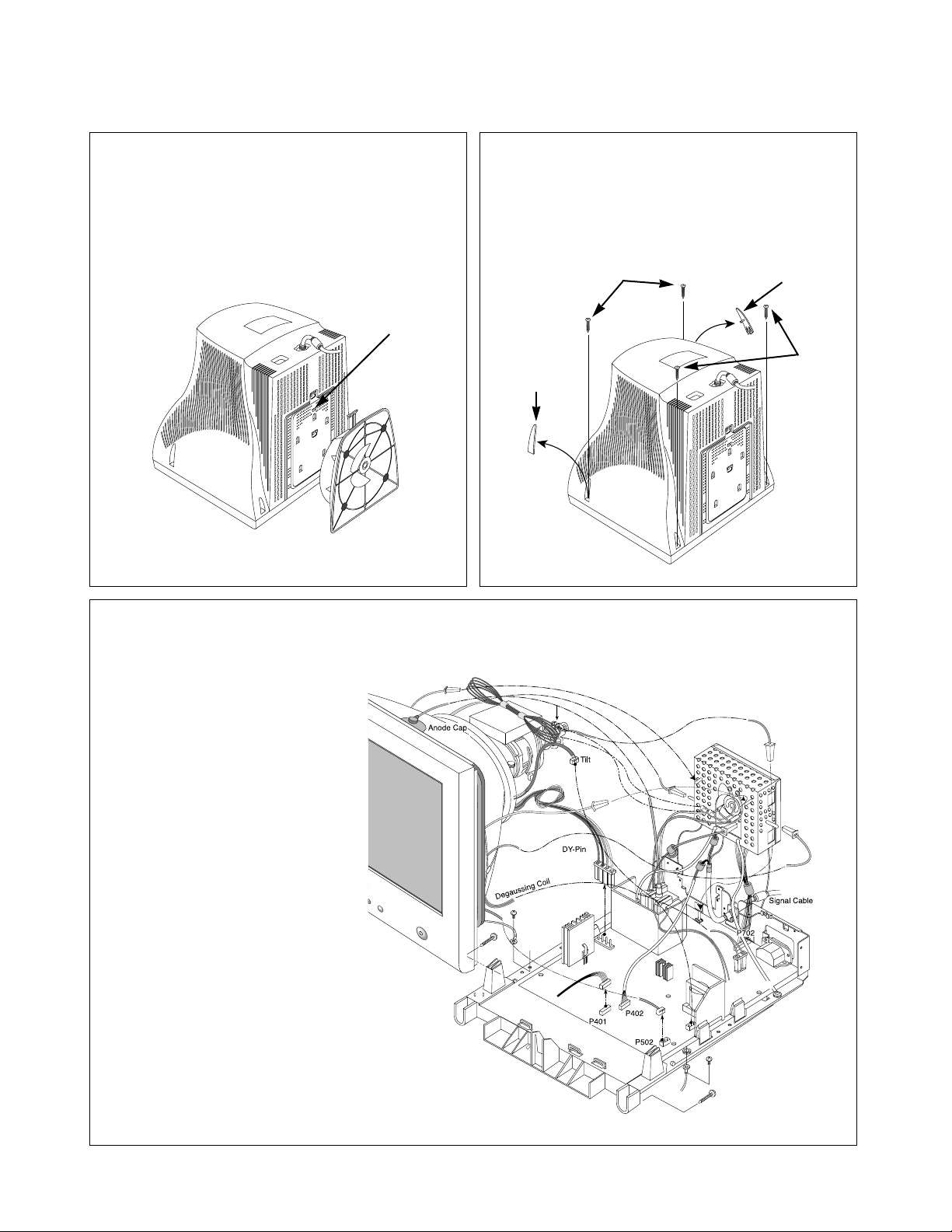

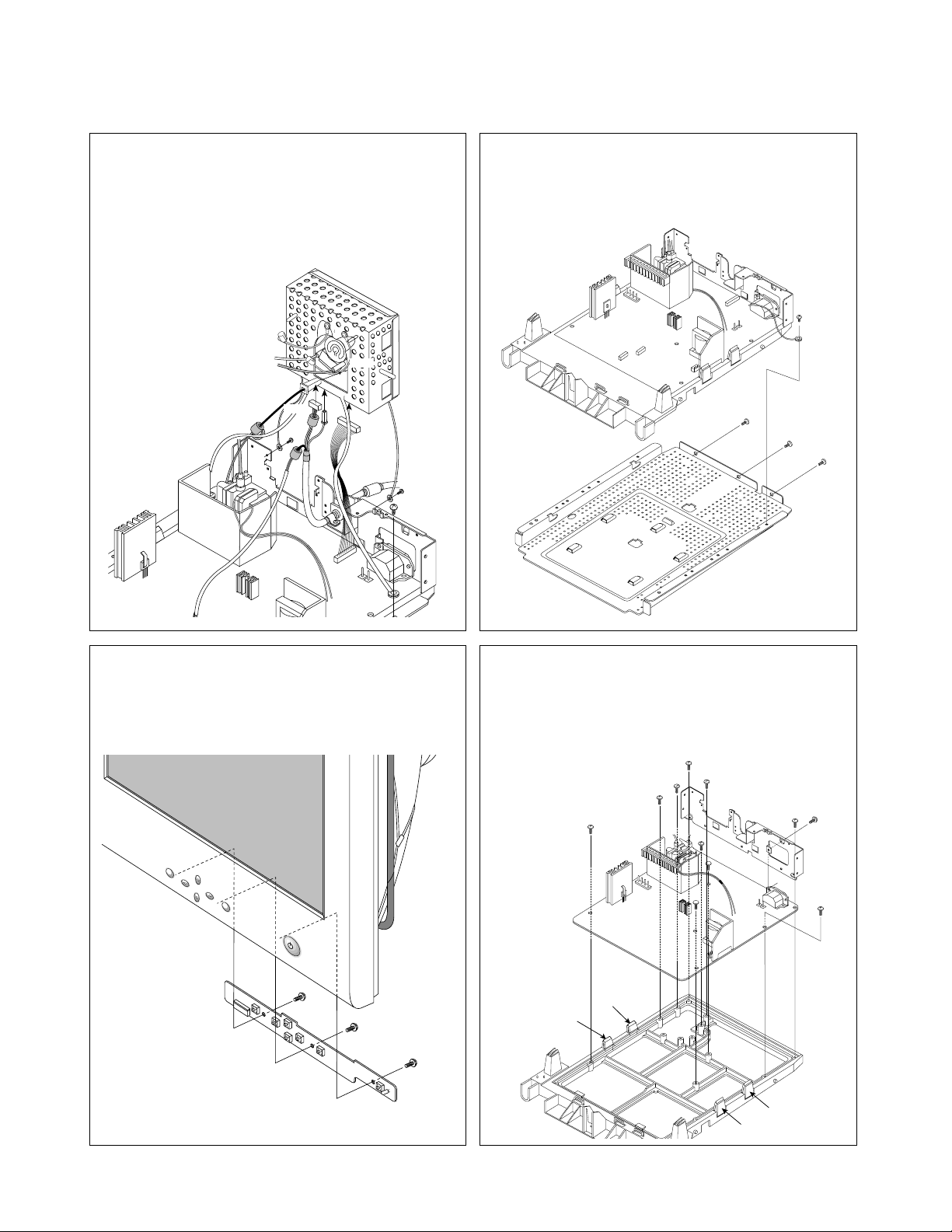

DISASSEMBLY

- 10 -

2. BACK COVER REMOVAL

1) Remove two screws cap (a).

2) Remove four screws (b) from the Back Cover.

3) Slide the Back Cover away from the Front

Cabinet of the monitor.

(a)

1. TILT/SWIVEL REMOVAL

1) Set the monitor face downward.

2) Pressing the latch (a), carefully remove

the Tilt/Swivel by pulling it upward.

(b)

(a)

(a)

(b)

P503

P703

P701

DY Assembly Screw

Control PCB

(P201)

Purity Coil

P902

(b)

(a)

(a)

(b)

SET

3. TOTAL CHASSIS ASSEMBLY

REMOVAL

1) Disconnect P903,P902(Degaussing pin),

P703(DY pin), P503(Tilt pin),

P502(Purity pin), P401

and P701 from the Main PCB.

2) Disconnect Pin four

from the Video PCB.

3) Carefully separate the CDT

Board Assembly from

the CDT neck.

4) Discharge the remaining

static electricity by shorting

between the Anode Cap

and the CDT ground.

5) Disconnect the Anode Cap

from the CDT.

6) Remove two screws (a).

7) Remove two screws (b).

8) Remove the Total Chassis

Assembly from the Main Frame.

Page 5

- 11 -

4. VIDEO PCB ASSEMBLY REMOVAL

1) Remove five screws (a).

2) Disconnect P301, P302, P303, and Pin (b).

3) Remove the Video PCB Assembly.

5. CONTROL PCB ASSEMBLY REMOVAL

1) Remove three screws (a).

2) Remove the Control PCB Assembly

from the Front Cabinet.

(a)

(a)

(a)

OSD SET

6. BOTTOM BRACKET REMOVAL

1) Remove four screws (a).

2) Remove the Bottom Bracket.

7. MAIN BRACKET REMOVAL

1) Remove three screws (a).

2) Remove the Rear Bracket.

3) Remove eight screws (b).

4) Release four latches (c),

and remove

the Bottom Bracket.

(a)

(a)

(a)

(a)

(a)

(a)

(b)

(b)

(c)

(c)

(c)

(c)

(b)

(b)

(b)

(b)

(b)

(b)

(a)

P301

(b)

(a)

P303

P302

(a)

(a)

Page 6

ADJUSTMENT

- 14 -

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then

press

DEGAUSS on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

-Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM compatible PC.

-Set external Brightness and Contrast volume to max position.

1. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 8.

2) Adjust Anode voltage to 26kV

+

0.1kV.

2. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode 8.

2) Run alignment program for FS772C on the

IBM compatible PC.

3) EEPROM→ALL CLEAR→Y(YES) command.

※ <Caution> Do not run this procedure unless the

EEPROM is changed.

All data in EEPROM (mode data and color data)will

be erased.

4) Power button of the monitor turn off → turn on.

5) COMMAND → START → Y(Yes) command.

6) DIST. ADJ. → TILT command.

7) Adjust tilt as arrow keys to be the best condition

8) DIST. ADJ. → BALANCE command.

9)

Adjust parallelogram as arrow keys to be the best

condition.

10)DIST. ADJ. → BALANCE command.

11) Adjust balance of side-pincushion as arrow keys to

be the best condition.

12)

DIST. ADJ. → FOS. ADJ command.

13)

Adjust V-SIZE as arrow keys to 230±2mm.

14)

Adjust V-POSITION as arrow keys to center of the

screen.

15)

Adjust H-SIZE as arrow keys to 310±2mm.

16)

Adjust H-POSITION as arrow keys to center of the

screen.

17)

Adjust S-PCC (Side-Pincushion) as arrow keys to be

the best condition.

18)

Adjust TRAPEZOID as arrow keys to be the best

condition.

19)

PRESET EXIT → Y (Yes) command.

3. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2)

Press the DEGAUSS on the OSD menu for demagnetization

of the CDT.

3) Set Brightness max and SUB-Brightness to 130(82)

(Decimal) position.

4) Display color 0,0 pattern at Mode 8.

5) COLOR ADJ. → LUMINANCE command of the

alignment program.

6) COLOR ADJ. → BIAS ADJ. command of the

alignment program.

7) Check whether R-BIAS and B-BIAS to min position

and G-BIAS to 0.7±0.05FL of the raster luminance.

Check it's not green color.

8) Adjust R-BIAS and B-BIAS command to x=0.283

±

0.02 and y=0.298±0.02 on the White Balance Meter

with PC arrow keys.

9) Adjust SUB-Brightness command to 0.5

±

0.1FL of the

raster luminance.

10)

Display color 15,0 window pattern (70x70mm) at Mode 8.

11)

Set Contrast max and SUB-Contrast to 127(7F)

(decimal) position.

12)

DRIVE ADJ command.

13)

Set G-DRIVE to 170(AA) (decimal) at DRIVE of the

alignment program.

14)

Adjust R-DRIVE and B-DRIVE command to white

balance x=0.283

±

0.02 and y=0.298±0.02 on the

White Balance Meter with PC arrow keys.

15)

Adjust SUB-CONTRAST command to 52±1FL of the

raster luminance at the save in color 1.

Page 7

- 15 -

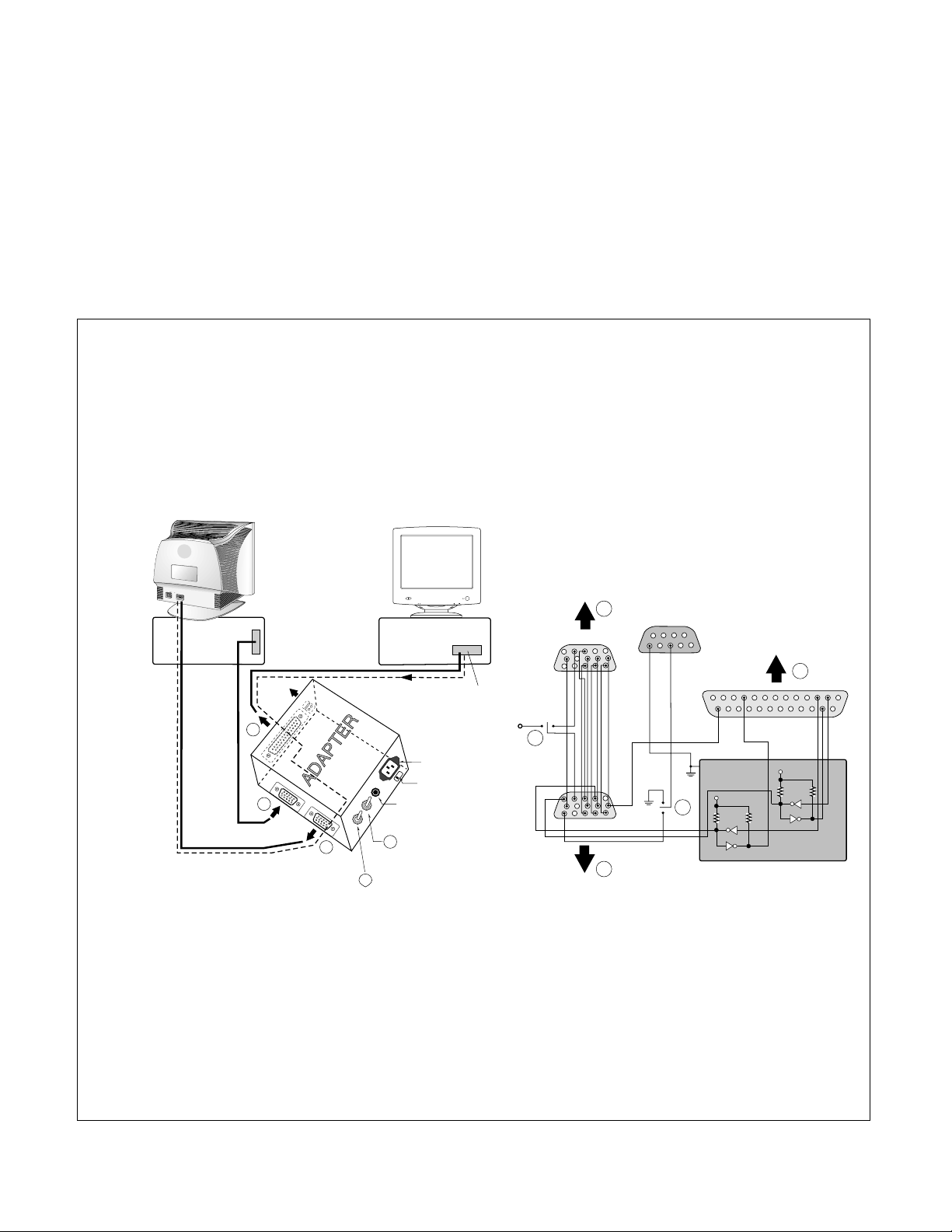

Figure 1. Cable Connection

220

IBM

Compatible PC

PARALLEL PORT

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

V-Sync On/Off Switch

(Switch must be ON.)

F

A

B

C

E

F

A

B

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

VIDEO

SIGNAL

GENERATOR

16)

Display color 15,0 full white patten at Mode 8.

17)

COLOR ADJ. → LUMINANCE → ABL command.

18)

Adjust ABL to 34±1FL of the luminance.

19)

Exit from the program.

4. Adjustment for Focus.

1) Display “mE” character in full screen at Mode 8.

2) Adjust two Focus control on the FBT that focus

should be the best condition.

Monitor to be

adjusted

Page 8

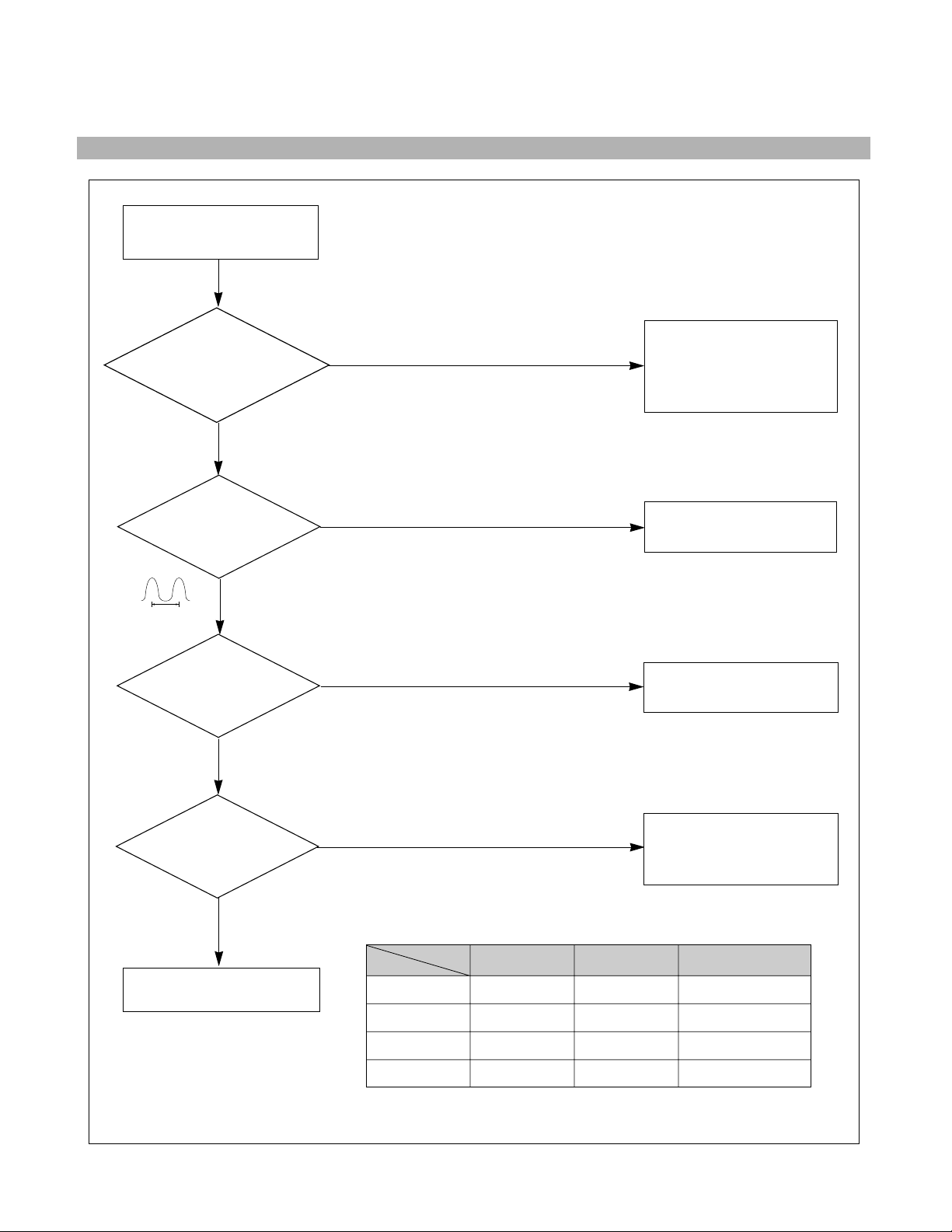

TROUBLESHOOTING GUIDE

- 16 -

NO POWER

(POWER INDICATOR OFF)

TROUBLE IN

D901

TROUBLE IN FUSE

(F901)

TROUBLE IN

IC901

TROUBLE IN

D931, D961, D991,

D951, D941,D971

TROUBLE IN

IC901

CHECK

FUSE OK?

CHECK

C908 VOLTAGE?

(AC220V: 310VDC)

NO

YES

YES

YES

YES

NO

NO

NO

CHECK

IC901 PIN 3

WAVEFORM

(SQUARE WAVE

COMES OUT?)

CHECK

D931, D961, D991,

D951, D941,D971

VOLTAGE?

1. NO POWER

Page 9

- 17 -

2. NO CHARACTER

NO CHARACTER

CHECK

IC302 PIN 7, 15, 18,

21(8V) ?

CHECK

IC302 PIN 6, 8, 10 ?

CHECK

IC302 PIN 16, 19, 22 ?

CHECK

IC303

PIN 1, 2, 3 ?

CHECK

IC303 PIN 4 (80V)

8 (12V) ?

TROUBLE IN

P302 12V LINE, IC304

TROUBLE IN

PC SIGNAL,

P301 SIGNAL CABLE

TROUBLE IN

IC302

TROUBLE IN

P302 12V LINE/80V LINE

TROUBLE IN IC303

NO

YES

NO

NO

YES

YES

YES

YES

NO

NO

CHECK

R, G, B CATHODE

VOLTAGE?

TROUBLE IN

R338~R341,

R344, R345, L302~L304,

D307~D310, D312, D313

TROUBLE IN

CRT SOCKET

YES

NO

Page 10

- 18 -

NO VIDEO

(POWER INDICATOR ON)

CHECK

POWER INDICATOR

GREEN or ORANGE?

CHECK

D712 ANODE

(-120V)?

CHECK

G1VOLTAGE?

(-5~25V)

TROUBLE IN

D712

TROUBLE IN

D941, Q941, Q942 (6.3V)

TROUBLE IN

Q703, Q704

DPM MODE

(NO H and/or V SYNC)

ORANGE

NO

GREEN

YES

YES

NO

3. NO RASTER

Page 11

- 19 -

4. TROUBLE IN H-LINEARITY

UNBALANCED OF H-LIN.

CHECK

IC401

PIN 19, 20, 21,

22, 23, 24?

CHECK

Q714~Q716, Q735, Q737

Q711~Q713, Q739

Q710?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q714~Q716, Q735, Q737

Q711~Q713, Q739, Q710

TROUBLE IN

RL701

NO

NO

YES

YES

Cs SIGNAL TABLE

HORIZONTAL

FREQUENCY(fH)

66K ~ 73K

62K ~ 66K

57K ~ 62K

49K ~ 57K

46K ~ 49K

43K ~ 46K

36K ~ 43K

33K ~ 36K

30K ~ 33K

Cs0

H

H

H

H

L

L

L

L

L

Cs1

H

H

L

L

H

L

H

H

L

Cs2

H

L

H

L

H

H

H

H

L

Cs3

H

H

H

H

H

H

L

L

L

Cs4

H

H

H

H

H

H

H

L

L

Page 12

- 20 -

5. NO VERTICAL DEFLECTION

NO V-DEFLECTION

(ONE HORIZONTAL LINE)

CHECK

IC601 PIN 2

(15V)?

CHECK

IC601 PIN 4

(-12V)?

CHECK

IC601 PIN 1 ?

TROUBLE IN

Q951, Q952, D951

15V LINE

TROUBLE IN

SMPS, D991

TROUBLE IN

IC701

TROUBLE IN

IC601, V-CIRCUIT

NO

NO

YES

YES

YES

NO

Page 13

- 21 -

TROUBLE IN

OSD PERIPHERAL

CIRCUIT

NO OSD

TROUBLE IN

5V LINE

TROUBLE IN

IC601 PIN6 (V-FBP),

T701 40V LINE

TROUBLE IN

IC302, IC301

TROUBLE IN

IC301, IC302

NO

YES

DC 5V

YES

YES

YES

NO

NO

NO

Pin 5

5V

Pin 10

5V

H+V

5V

H+V

CHECK

IC301 B

+

?

CHECK

IC301 PIN 12

WAVEFORM ?

(ENTER BUTTON MUST BE PRESSED.)

6. TROUBLE IN OSD

CHECK

IC301 PIN 5, 10

WAVEFORM?

CHECK

IC301 PIN 13, 14, 15 ?

Page 14

- 22 -

CHECK

IC401 (MICOM)

PIN 1, 42 (H/V INPUT)

SIGNAL?

CHECK

IC401 PIN 6

WAVEFORM?

CHECK

IC401 (MICOM)

PIN 3, 4 ?

CHECK

B+LINE

(6.3V,15V) ?

CHECK PC,

(PC IS NOT GOING INTO

DPM OFF MODE)

TROUBLE IN

X401

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q941, Q942, Q951, Q952

TROUBLE IN PC

OFF MODE FAILURE

INPUT H/V SYNC SIGNAL

NO H/V SYNC

(NO OFF MODE.)

NO

NO

NO (DPMF: 0V)

DPM TABLE

Mode

Item

NORMAL

STAND-BY

SUSPEND

OFF

DPMS

H

L

L

L

LED

GREEN

AMBER

AMBER

AMBER

DPMF

H

H

H

L

YES

SEE DPM TABLE

YES

YES

5V

6MHz

7. TROUBLE IN DPM

Page 15

- 23 -

CHECK

IC401 PIN 31

(0V)?

CHECK

Q920 COLLECTOR

(15V)VOLTAGE?

CHECK

P902, P905?

CHECK

RL901?

TROUBLE IN

IC401 (MICOM)

TROUBLE IN

Q921

TROUBLE IN

P902, P905

TROUBLE IN

RL901

TROUBLE IN

TH901,

DEGAUSSING COIL

NO DEGAUSSING

DC 5V

NO

NO

NO

NO

YES

YES

YES

YES

(DEGAUSS ON THE OSD MENU MUST BE PRESSED.)

8. NO DEGAUSSING

Page 16

- 24 -

9. NO TILT (NO ROTATION)

NO TILT (NO ROTATION)

TROUBLE IN

IC401 (

MICOM)

TROUBLE IN

15V LINE, 6.3V LINE

TROUBLE IN

Q501~Q503

TROUBLE IN

P503, TILT COIL

NO

YES

YES

YES

CHECK

15V LINE

AND 6.3V LINE ?

CHECK

Q503 EMITTER

VOLTAGE ?

NO

NO

CHECK

Q504

WAVE FORM ?

Page 17

BLOCK DIAGRAM

- 12 -

POWER INPUT

200~240VA

C

(50Hz)

Line

Filter

Degaussing

Circuit

[ OSD Control ]

SMPS

CONTROL

(IC901)

120V

80V

50V

TILT

Control

Circuit

6.3V

15V

E

2

PROM

(IC402)

5V

OSD IC

(IC301)

H-Sync Sig

V-Sync Sig

I

2

C DATA(SDA )

I

2

C CLOCK(SCL)

VIDEO

PRE-AMP

(IC302)

Signal

Cable

RGB

VIDEO

MAIN AMP

(IC303)

8V REG.

(IC304)

8V

-12V

12V

CUT OFF

CONTROL

120V

12V

5V

H/V Sync P rocessor

( IC701 )

TDA9112

V-OUT

( IC601)

TDA8172

H-OUT

( Q706)

H-Linearity

Correction

DC/DC Converter

X-RAY

Protection

Circuit

Dynamic

Focus

Circuit

Auto

Beam

Limit

Vertical Blanking,

Brightness Control

- 120V

40V

15V

D/D Feed Back

30V

12V

MICOM

(IC401)

SCL / SDA

H/V Sync,

PWM Control

Sig

12V

15V

50V

DY CDT

Heater ( 6.3V )

I

2

C

I

2

C

I

2

C

H/V

Sync

Screen

Dynamic Focus

Static Focus

H.V

R/G/B

Bias

R/G/B

Contrast

H-DRV

B-DRV

B+

15V

TILT

COIL

DEGAUSSING

CO

REACTOR

IL

I

2

C

BRIGHTNESS/CO

NTRAST

COLOR CURVE

H / V POSITION

H / V SIZE

SPCC

TRAPIZODE

PIN BALANCE

PA RALLELOGRAM

ROTA TION

TOP CORNRE

BOTTOM CORMOR

RECALL

DEGAUSSING

MOIRE

PURITY

LANGUAGE

RECALL

DPM

CONTROL

CIRCUIT

850V

FBT

( T701 )

15V

SMPS

TRANS

(T901)

G

1

G

2

15V

IC992

12V REG.

6.3V

-12V

15V

12V 80V

12V

Voltage

feedback

Voltage

feedback

PURITY

Control

Circuit

PURITY

COIL

15V

6.3V

Page 18

DESCRIPTION OF BLOCK DIAGRAM

- 13 -

1. SMPS(Switching Mode Power Supply)

When you turn on the power switch, the operating

procedure is as follows:

1) The AC line voltage is rectified by the bridge diodes

D901 and C908

2) The control IC(IC901) starts switching and generates

switching pulses in the primary turns of the SMPS

transformer (T901)

3) The switching pulses of the primary turns are induced the

secondary turns of the transformer by the turn ratio.

These pulses are rectified by each diode (D971,D961,

D951, D931, D941 ,D991)

4) Each rectified DC voltage (120V, 50V, 15V, 80V, 6.3V,12V and 5V) is supplied to the main circuit.

2. Over Voltage Protection Circuit

When the input voltage of IC901 Vin(pin 4) is more than

22.5V(typical), all the secondary Voltages of the SMPS

transformer (T901) down to low value.

3. Display Power Management Circuit

1) Stand-by and Suspend mode.

When no input of horizontal or vertical sync, Q951 and

Q952 are turned off.

Then input power consumption is below 15 watts

2) OFF mode

When no input of horizontal and vertical sync,

Then input power consumption is below 5 watts

4. X-ray Protection Circuit

If the high voltage of the FBT reaches up to 29KV IN an

abnormal case, Q807 operates and IC401 pin 41 came

to low level, Then IC401 control IC701 to stop Horizontal

drive pulse and stop Horizontal Deflection.

5. Microprocessor Control Circuit.

1) Horizontal and Vertical sync signals are supplied to the

microprocessor (IC401).

2) Microprocessor(IC401) discriminates the operating mode

from the sync polarity and resolution.

3) After microprocessor reads these adjusted mode data

stored at EEPROM, it controls operating mode data

through IIC

4)

Users can control screen condition by the OSD, SET, UP,

DOWN, RIGHT, LEFT, and Audio and Audio Mute buttons.

6. D/D Convert Circuit.

To obtain constant high voltage, this circuit supplies

controlled DC voltage for FBT and Horizontal deflection

circuit according to the horizontal sync frequency.

7. Horizontal and Vertical Sync Processor Circuit.

The horizontal and vertical sync processor IC (IC701)

has a sync detector, a saw-tooth generator, and drive

function. So output horizontal and vertical drive signal

control screen distortions.

8. Horizontal linearity Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

9. Horizontal drive and Output Circuit.

This circuit is a horizontal deflection amplifier for raster

scan.

10. ABL Circuit.

This circuit limits the beam-current for the reliability of the

CDT.

11. Vertical Output Circuit.

This circuit takes the vertical ramp wave from the

TDA9112(IC701) and performs the vertical deflection by

supplying the saw-tooth wave current to the vertical

deflection yoke.

12. Blanking and Brightness Control Circuit.

Blanking circuit eliminates the retrace line by supplying a

negative pulse wave to the G1 of the CDT.

Brightness control circuit is used for control of the screen

brightness by changing the DC level of the G1.

13. Video Processor Circuit.

Video processor circuit consists of the video drive output

block. The video drive IC(IC302) receives the video

signal from PC. The gain of each channel is controlled by

the voltage of contrast pin. The cut-off circuit compensate

different voltage of each channel between the cathode

and the G1 of the CDT.

14. OSD (On-Screen-Display) Circuit.

This circuit displays on the screen information of the

monitor’s status.

15. Dynamic Focus Output Circuit.

This circuit takes the horizontal and the vertical parabola

waves from the TDA9112(IC701) and amplifies it to

maintain constant focus on center and comers in the

screen.

17. Image Rotation (Tilt) Circuit.

This circuit corrects the tilt of the screen by supplying the

image rotation signal to the tilt coil which is attached near

the deflection yoke of the CRT.

18. Earth Margnetic Correction(Purity) Circuit

This circuit corrects the convergence of screen by

suppling the convergence signal to the coil which is

attached to the CRT near the deflection.

Page 19

WIRING DIAGRAM

- 9 -

P503

P703

P701

P902

DY Assembly Screw

Page 20

3.11V

0.5V

42.8V

45V

4.5V

-7V

4.5V

19.1V

0.4

51.2V

11.4ms

340V

130V

60V

17.8V

12V

247

400 210

14.6V

-2.0V

1098V

14.54

1.3~1.94V

Page 21

EXPLODED VIEW

1

2

4

6

9

10

15

11

12

7

3

B

A

C

13-2

14-1

14-2

13-1

OSD SET

5

8

EXPLODED VIEW PARTS LIST

Ref. No.

1

2

3

4

5

6

7

8

9

10

11

12

13-1

13-2

14-1

14-2

15

A

B

C

Part No.

3091TKC040B

2423GC3E41M

339-002D

6140TC2007D

6174Z-1044A

6620TKB002A

6871TST225B

4950TKK171B

4810TKM037L

332-102G

4814TKK077B

3809TKC034E

3550TKK061L

3550TKK061M

332-102P

332-102J

3043TKK040U

6871TMT225B

6871TVT225B

3313T17226B

Description

CABINET ASSY FS772C FUJITSU SIMENS 039

CDT SET, M41QBF423X 31NPLD

SCREW ASSY, PHP+5*30BP(FZMY)+GW18 #(4)CDT FIX

COIL,DEGAUSSING, 1410MM 18.5OHM 0.45MM 120T 17" 220V, PURITY

FBT (FLY BACK TRANSFORMER), FMMTC91 M1044A (LIM SANG IL)

SOCKET (CIRC),POWER, BCP-03A-3 BAE EUN AC UNIVERSAL 3PIN BLACK

PWB(PCB) ASSY,SUB FS772C KZFSED FUJITSU SIMENS CA-87 LGEDI TOTAL

METAL REAR KFB775B

BRACKET, KFB775C MAIN J-CKD

SCREW, PTP 4*30 FZMW

SHIELDBOTTOM KFB775B

BACK COVER ASSY, FS772C 016 F-SIEMENS

COVER FS772C SCREW F-SIEMENS (RIGHT)

COVER FS772C SCREW F-SIEMENS (LEFT)

SCREW, PTP 4*30[MSWR/FZMCWY-1] #C/A+B/C (UP)

SCREW, PTP 4*20 (FZMW) #C/A+B/C (DOWN)

TILT SWIVEL ASSY, FS772C T032B029B F-SIEMENS

PWB(PCB) ASSY,MAIN FS772C KZFSED FUJITSU SIMENS CA-87 LGEDI TOTAL

PWB(PCB) ASSY,VIDEO FS772C KZFSED FUJITSU SIMENS CA-87 LGEDI TOTAL

MAIN TOTAL ASSY, FS772C FUJITSU SIMENS CA-87 LGEDI

Loading...

Loading...