Fujitronic UG520H-x User Manual

FUJI UGx20 SERIES PROGRAMMABLE OPERATION DISPLAY

USER'S MANUAL <HARDWARE>

TYPE: UG520H-x

UG420H-x

UG320H-x

UG221H-x

UG220H-x

FEH352c

UG Series

Preface

Thank you for selecting the Fuji Programmable Operation Display, POD UG520/420/

320/221/220 Series (called as the UG20 or POD, hereafter).

For proper set-up, you are requested to read through this booklet to understand more

about the product.

For more information about UG20 series, refer to the Reference Manual.

For further details about the PLC, see the manual attached to each PLC.

[Reference]

In addition to this manual, the following manuals on the UG20 Series are available.

Please ask your nearest dealer for the appropriate manuals and read them as required.

Name Manual No. Contents

UG Series Manual FEH375 Describes how to operate screen editor

<Operation> (UG00S-CW) for the UG Series.

UG Series Manual FEH376 Describes the functions of the UG

<Function> Series.

UG Series Manual

<CC-Link Communications> FEH355

UG Series Manual

<T-Link Communications> FEH356

UG Series Manual

<SX-BUS Communications> FEH357

UG Series Manual

<OPCN-1 Communications> FEH358

UG Series Manual <Variable

Name Cooperation Function> FEH363

UG Series Manual

<Ethernet Communications> FEH366 via the optional ETHERNET interface.

UG Series Manual

<FL-Net Communications> FEH367 via the optional FL-Net interface.

UG Series Manual

<PROFIBUS Communications> FEH368 via the optional PROFIBUS interface.

UG Series Manual <Ladder

Monitor Specifications> FEH379 Monitor are explained.

Describes the procedures for communication

with PLCs using the optional CC-Link interface.

Describes the procedures for communication

with PLCs using the optional T-Link interface.

Describes the procedures for communication

with PLCs using the optional SX-Bus interface.

Describes the procedures forcommunication

with PLCs using the optional OPCN-1 interface.

Describes the variable name cooperation function

to be used between the UG editor and D300win.

Describes the procedures for communicating

Describes the procedures for communicating

Describes the procedures for communicating

The Functions and instructions of the Ladder

[Notes]

(1)This manual may not, in whole or in part, be printed or reproduced without the prior written consent

of Fuji Electric Co., Ltd.

(2)Information in this manual is subject to change without prior notice.

(3)Windows and Excel are registered trademarks of Microsoft Corporation in the United States and other

countries.

(4)All other company names or product names are trademarks or registered trademarks of their respec-

tive holders.

(5)This manual is intended to give accurate information about POD hardware. If you have any ques-

tions, please contact your local distributor.

Notes on Safe Use of POD

In this manual, you will find various notes categorized under the following levels with

the signal words "DANGER," and "CAUTION."

DANGER

CAUTION

Note that there is a possibility that the item listed with

ramifications.

Never use the input function of POD for operations that may threaten human life or to damage

•

the system, such as switches to be used in case of emergency. Please design the system so

that it can cope with malfunction of a touch switch.

Turn off the power supply when you set up the unit, connect cables or perform maintenance

•

and inspection. Failure to do so could cause an electric shock or damage to the unit.

You must put a cover on the terminals on the unit when you turn the power on and operate

•

the unit. Without the terminal cover in place, an electric shock may occur.

The liquid crystal in the LCD panel is a hazardous substance. If the LCD panel is damaged,

•

never swallow the leaked liquid crystal. If the liquid crystal spills on your skin or clothing, use

soap and wash off thoroughly.

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury and could cause property damage.

CAUTION

DANGER

may have serious

Notes on Safe Use of POD

CAUTION

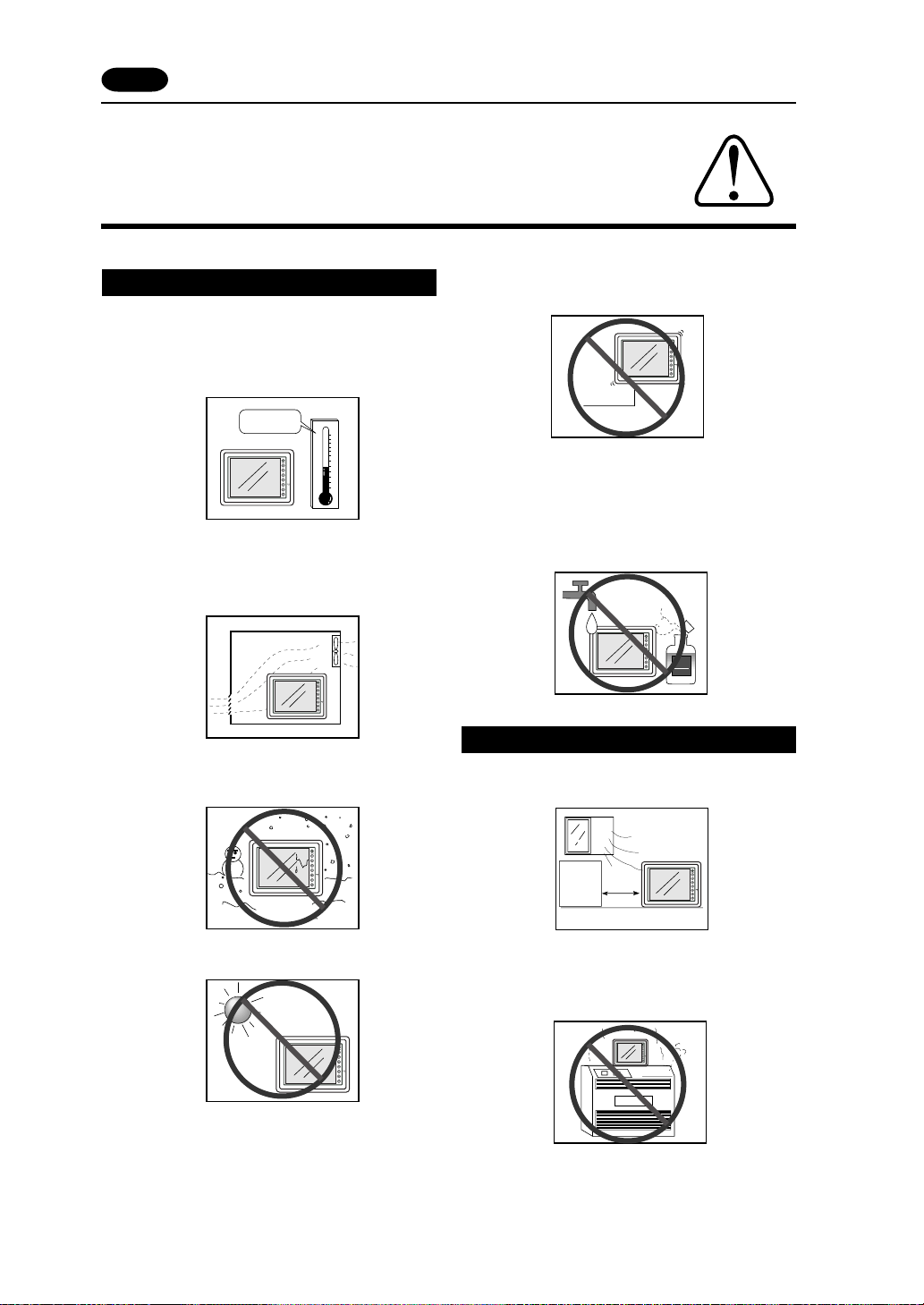

[Notes on System Design]

Never bundle control cables and input/output cables with high-voltage and large-current

•

carrying cables such as power supply cables. Keep these cables at least 200 mm away from

the power supply or high-voltage cables. Otherwise, malfunction may occur due to noise.

For use in a nuclear energy facility, or other facility of such official importance, please consult

•

your local distributor.

[Notes on Installation]

Operate (or store) POD under the conditions indicated in this manual and related manuals.

•

Failure to do so could cause fire, malfunction, physical damage or deterioration.

Understand the following environmental limits for use and storage of POD. Otherwise, fire or

•

damage to the unit may result.

-Avoid locations where there is a possibility that water, corrosive gas, flammable gas,

solvents, grinding fluids or cutting oil can come into contact with the unit.

-Avoid high temperature, high humidity, and outside weather conditions, such as wind, rain

or direct sunlight.

-Avoid locations where excessive dust, salt, and metallic particles are present.

-Avoid installing the unit in a location where vibration or physical shock may be transmitted.

Equipment must be correctly mounted so that the main terminal of POD will not be touched

•

inadvertently.

Tighten the POD mounting screws to the specified torque. Excessive tightening may distort the

•

panel surface. Loose tightening may cause POD to come off, malfunction or be short-circuited.

Tighten terminal screws on the power input terminal block equally to a torque of 0.5 Nom.

•

Check the appearance of POD when it is unpacked. Do not use the unit if any damage or

•

deformation is found.

POD has a glass screen. Do not drop or give physical shock to the unit.

•

[Notes on Cable Connection]

Connect the cables correctly to the terminals of POD in accordance with the specified voltage

•

and wattage. Over-voltage, over-wattage or incorrect cable connection could cause fire,

malfunction or damage to the unit.

Be sure to establish a ground of POD. The FG terminal must be used exclusively for the unit

•

with the level of grounding resistance less than 100W.

Prevent any conductive particles from entering into POD. Failure to do so may lead to fire,

•

damage or malfunction.

Notes on Safe Use of POD

CAUTION

[Notes on Maintenance and Operation]

Fuji Electric Co., Ltd. is not responsible for any damages resulting from repair, overhaul or

•

modification of POD that was performed by an unauthorized person.

Do not use thinners for cleaning because they may discolor the POD surface. Use alcohol or

•

benzine commercially available.

Do not use a sharp-pointed tool when pressing a touch switch.

•

Only experts are authorized to set up the unit, connect the cables or perform maintenance

•

and inspection.

If a data receive error occurs when POD and the counterpart (PLC, temperature controller,

•

etc.) are started at the same time, read the manual for the counterpart unit and handle the

error correctly.

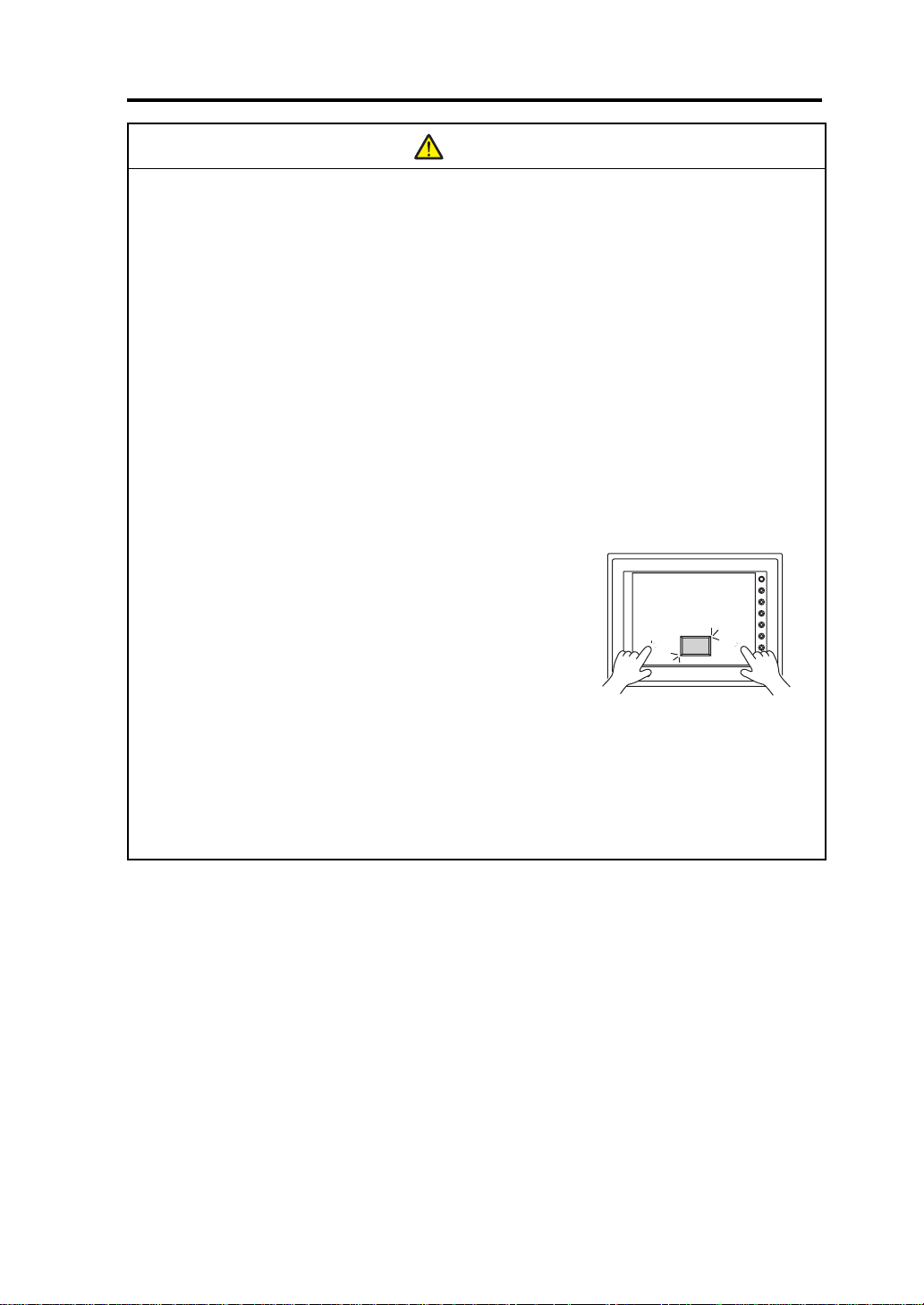

Switch resolution of the POD UG20 series is determined by the analog-type resistance film.

•

Do not press two or more positions on the screen at

the same time.

If two or more positions are pressed at the same time,

the switch located between the pressed positions

activates. Please take note of this.

Avoid displaying the same patterns for hours. It may

•

cause afterimages due to the property of LCD display.

If you use the fixed patterns for hours, use the autoOFF function of the backlight.

SWITCH

POWER

Pressing two positions at the same time

activates the swith in the center.

SYSTEM

F1

F2

F3

F4

F5

F6

F7

[Notes on Disposal]

At the time of disposal, POD must be treated as industrial waste.

•

Revision

*Manual No. is shown on cover.

Printed on

October , 1999

April , 2001

November , 2002

May , 2003

*Manual No.

FEH352

FH352a

FEH352b

FEH352c

Revision contents

First edition

Second edition

New Product (UG221) specification added.

The following PLC model is added.

Mitsubishi QnH series

FX1S series

Allen-Bradley Micro Logix 1000

Siemens S7-300/400 MPI

Modicon Modbus RTU

Others , contents check

Third edition

The following PLC model is added.

SAIA PCD

MOELLER PS4

Telemecanique TSX Micro

Automationdirect Direct LOGIC

Toyo Denki uGPC sx series

Others , contents check

Fourth edition

The following PLC model is added.

VIGOR M series

DELTA DVP series

BADOR Mint

Appendix : Ladder Transfer Function

Others , contents check

Contents

Preface

Notes on Safe Use of POD

Revision

1. Hardware Specifications

1. Special Features ..........................................................................................................1-1

2. Notes on Usage ............................................................................................................1-2

3. System Composition ....................................................................................................1-4

4. Names of Components................................................................................................1-11

5. Dimensions and Panel Cut-out................................................................................... 1-13

6. Mounting Procedure................................................................................................... 1-18

7. Wiring ........................................................................................................................1-19

8. Specifications............................................................................................................. 1-21

9. Serial Connector (CN1) ...............................................................................................1-27

10. Setting of Dip Switches ..............................................................................................1-29

11. Modular Jack 1 & 2 ...................................................................................................1-30

12. Bar Code Reader Interface.......................................................................................... 1-31

13. Printer Interface (CN2) ...............................................................................................1-32

14. Video Interface ...........................................................................................................1-33

15. Analog RGB Input ......................................................................................................1-34

16. Connection ................................................................................................................1-37

17. Operation of POD Main Menu.....................................................................................1-42

18. Function Switches......................................................................................................1-59

2. Connection to Link Units

1. FUJI PLC • 1 ................................................................................................................2-1

2. FUJI PLC • 2 ................................................................................................................2-4

3. FUJI PLC • 3 ................................................................................................................2-6

4. FUJI PLC • 4 ................................................................................................................2-8

5. FUJI PLC • 5 .............................................................................................................. 2-11

6. FUJI PLC • 6 .............................................................................................................. 2-14

7. MITSUBISHI PLC • 1 ..................................................................................................2-16

8. MITSUBISHI PLC • 2 ..................................................................................................2-22

9. MITSUBISHI PLC • 3 ..................................................................................................2-26

10. MITSUBISHI PLC • 4 ..................................................................................................2-28

11. MITSUBISHI PLC • 5 ..................................................................................................2-32

12. MITSUBISHI PLC • 6 ..................................................................................................2-35

13. OMRON PLC • 1......................................................................................................... 2-37

14. OMRON PLC • 2......................................................................................................... 2-42

15. Sharp PLC • 1 ............................................................................................................ 2-43

16. Sharp PLC • 2 ............................................................................................................ 2-46

17. HITACHI PLC • 1........................................................................................................ 2-48

18. HITACHI PLC • 2........................................................................................................ 2-51

19. Matsushita PLC .........................................................................................................2-54

20. YOKOGAWA PLC • 1...................................................................................................2-57

21. YOKOGAWA PLC • 2...................................................................................................2-59

22. YASKAWA PLC • 1 ......................................................................................................2-62

23. YASKAWA PLC • 2 ......................................................................................................2-65

24. TOYOPUC PLC ........................................................................................................... 2-67

25. Koyo PLC ...................................................................................................................2-70

Contents

26. Allen-Bradley PLC • 1................................................................................................. 2-75

27. Allen-Bradley PLC • 2................................................................................................. 2-80

28. GE Fanuc PLC • 1 ......................................................................................................2-84

29. GE Fanuc PLC • 2 ......................................................................................................2-86

30. TOSHIBA PLC ............................................................................................................ 2-88

31. TOSHIBA MACHINE PLC............................................................................................ 2-90

32. SIEMENS PLC • 1 ...................................................................................................... 2-92

33. SIEMENS PLC • 2 ...................................................................................................... 2-94

34. SIEMENS PLC • 3 ...................................................................................................... 2-96

35. SIEMENS PLC • 4 ...................................................................................................... 2-97

36. SIEMENS PLC • 5 ...................................................................................................... 2-99

37. SIEMENS PLC • 6 .................................................................................................... 2-101

38. Shinko PLC .............................................................................................................. 2-103

39. SAMSUNG PLC ........................................................................................................ 2-105

40. KEYENCE PLC • 1.................................................................................................... 2-107

41. KEYENCE PLC • 2.................................................................................................... 2-109

42. KEYENCE PLC • 3.................................................................................................... 2-112

43. LG PLC .................................................................................................................... 2-114

44. FANUC PLC..............................................................................................................2-119

45. FATEK PLC .............................................................................................................. 2-121

46. IDEC PLC.................................................................................................................2-123

47. MODICON PLC......................................................................................................... 2-125

48. YAMATAKE PLC ....................................................................................................... 2-126

49. TAIAN PLC ............................................................................................................... 2-128

50. SAIA PLC ................................................................................................................. 2-130

51. MOELLER PLC......................................................................................................... 2-132

52. Telemecanique PLC .................................................................................................. 2-133

53. Automationdirect PLC .............................................................................................. 2-134

54. VIGOR PLC .............................................................................................................. 2-137

55. DELTA PLC .............................................................................................................. 2-139

56. BALDOR PLC ........................................................................................................... 2-141

57. TOYO DENKI PLC .................................................................................................... 2-143

3. Handling of Peripheral Equipment

1. Connecting the UG00P-U1 .............................................................................................3-1

2. Connecting the UG00P-U2 .............................................................................................3-3

3. Connecting the Memory Card Recorder ..........................................................................3-6

4. Connecting the Memory Extension Unit ......................................................................... 3-9

5. Connecting Communication Interface .......................................................................... 3-12

6. Connecting Dual Port Interface .................................................................................... 3-15

7. How to Replace the Backlight Unit ............................................................................... 3-19

UG520H-V ................................................................................................................. 3-20

UG420H-V ................................................................................................................. 3-26

UG420H-T ................................................................................................................. 3-31

UG420H-S ................................................................................................................. 3-36

UG320 ....................................................................................................................... 3-41

UG320HD .................................................................................................................. 3-48

UG220 ....................................................................................................................... 3-53

Appendix

Ladder Transfer Function ..................................................................................... Appendix-1

Hardware

Specifications

1. Special Features

2. Notes on Usage

3. System Composition

4. Names of Components

5. Dimensions and Panel Cut-out

6. Mounting Procedure

7. Wiring

8. Specifications

9. Serial Connector (CN1)

10. Setting of Dip Switches

11. Modular Jack 1 & 2

12. Bar Code Reader Interface

13. Printer Interface (CN2)

14. Video Interface

15. Analog RGB Input

16. Connection

17. Operation of POD Main Menu

18. Function Switches

1 Special Features

1 - 1

1

Special Features

1) 128-color Display

128-color display which makes colorful expression possible is realized. Not only drawings but also bitmap

files are clearly displayed. (UG221 and UG220 is 16-color display.)

2) Data Sheet Printing Function

It is possible to make the original data sheet screen by the panel editor (= the editing software).

Daily reports or monthly reports that the operator must fill out can be printed in an instant.

3) Sampling Function

This function makes it possible to store the sampling data in an IC card. The stored data can be edited

easily by a personal computer. It can be used widely in various fields.

4) Macro Function

With this function, UGx20 series can make programs which previously had to be produced by PLC.

5) Multi Window Function

Up to three windows can be displayed simultaneously on a screen.

It is easy to move or delete the displayed windows.

6) Video Function

UGx20 series can be connected to a video or a CCD camera, and the image which is taken by a video or

a camera can be displayed directly in a screen of UGx20 series.

7) UG221, UG220

A 5.7 inch display with 320 240 dot resolution.

8) UG320

A 7.7 inch display with VGA (640 480 dot resolution).

9) UG420

A 10.4 inch standard model display which uses the previous screen data.

10)UG520

A 12.1 inch large display with SVGA (800 600 dot resolution).

1 - 2

2 Notes on Usage

2

Notes on Usage

Environmental Limits

1. Use POD at an ambient temperature of 0 to

50ºC, and a relative humidity of 35-85 %RH.

(But, a UG420 STN multi-color display can be

used at 0 to 40ºC.)

0 to 50°C

2. Install a forced fan or an air conditioner to

maintain the ambient temperature when it is

higher than the above mentioned range.

Fan

50

40

30

20

10

0

5. Never install POD in a place where impacts or

vibrations may be transmitted.

6. Avoid any place in which there is the possibility

that water, corrosive gas, flammable gas,

solvents or coolants, grinding oil can come in

contact with the unit. Never install the unit in a

place where dust, salt and metallic particles are

present.

YOUZAI

Vent

3. Avoid places where moisture may easily

condense due to sudden temperature changes.

4. Avoid direct sunlight.

Locations

1. Secure sufficient space around POD for

ventilation.

2. Never attach POD to the top of any apparatus

generating high levels of heat (heater,

ransformer, large-capacity resistor, etc.).

2 Notes on Usage

1 - 3

3. Never install POD in the same compartment as

high-voltage equipment. The unit should be at

least 200 mm away from high-voltage lines or

power cables.

Usage

1. An emergency stop circuit must be composed of

an external relay circuit with a start signal for

POD built in. Do not create switches on POD to

be used in case of emergency.

Switch to be used

in emergency

Emergency

Stop

4. Securely fasten and lock every connector for

each cable. Double-check this before turning the

power on.

Lock !

5. In a dry environment, POD may generate a large

amount of static electricity.

Therefore, before touching the unit, touch a

grounded metallic section to discharge the static

electricity.

6. Application of thinner may discolor POD. Use

alcohol or benzine available commercially for

cleaning.

BENZINE

BENZINE

Alcohol

2. POD has a glass screen. Never drop or subject

the unit to strong impacts.

3. Tighten mounting screws with the following

torques.

Type

UG320/220

UG221

UG520/420

Screw Size

M3

M4

M4

Torque (N•m)

0.3 to 0.5

0.3 to 0.5

0.5 to 0.7

Screw

Note :Never fasten these screws too tightly,

otherwise the cover of POD may be deformed.

7. Never remove any printed circuit board from

POD. (This will harm the unit.)

8. Never operate the display by using a tool with a

sharp point like a screwdriver.

Touch the display by fingers.

1 - 4

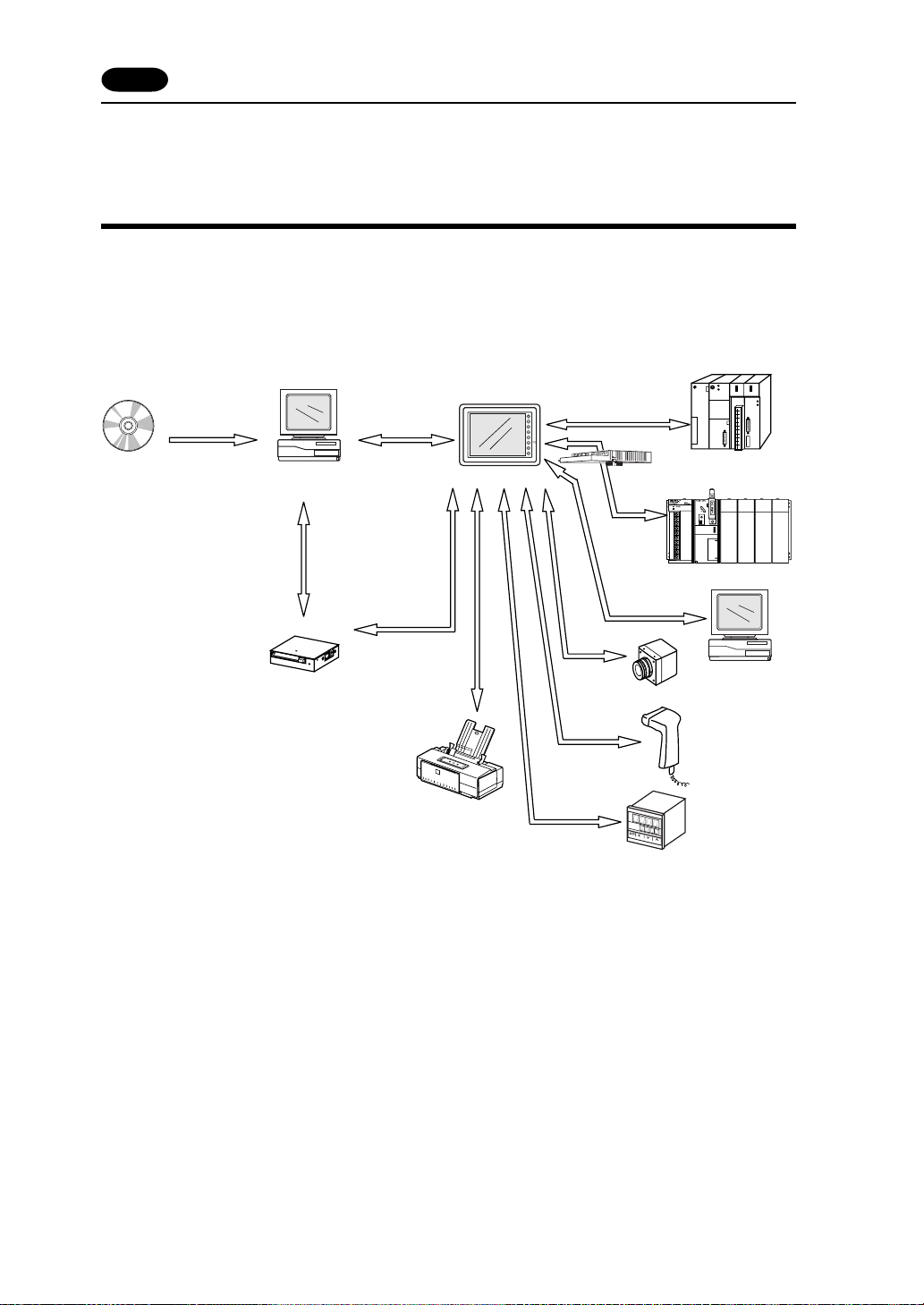

3 System Composition

3

System Composition

System Composition / Model Indication / Peripheral Equipment

System Composition

The following illustration shows possible system configurations using UG20.

Panel Editor

for UG series

UG00S-CW

Creating screens

Personal Computer (PC)

Transferring

screen data

UG00C-T

Card Recorder

UG00P-MR

*

1

Transferring

screen data

UG00C-T

Transferring

screen data

or

Memory manager

/Data logging

Printer Cable

UG00C-C

UGx20

During operation

(Link communication)

RS-232C/RS-422

UG03I-x

During operation

(TLink/OPCN-1/SXBus/ProfiBus/Ethernet)

During operation

(Universal serial

communication)

RS-232C/RS-422

Exclusive Cable

2

*

Cable

UG00C-B

Video / CCD camera

run

•••

•••

•••

•••

•••

•••

•••

•••

stop

•••

•••

•••

•••

•••

•••

•••

•••

Link Unit

Universal-purpose

computer

Bar Code Reader

Printer

1UG00P-MR is optional.

*

2 The interface for video function (using only in UG520 and UG420) is optional for Maker.

*

Cable

UG00C-H

or

UG00C-B

P

V

S

V

○

A

T

○

O

U

T

1

○

O

S

U

E

T

T

2

○

A

L

M

1

○

R

/

A

S

L

M

2

Temperature Controller

3 System Composition

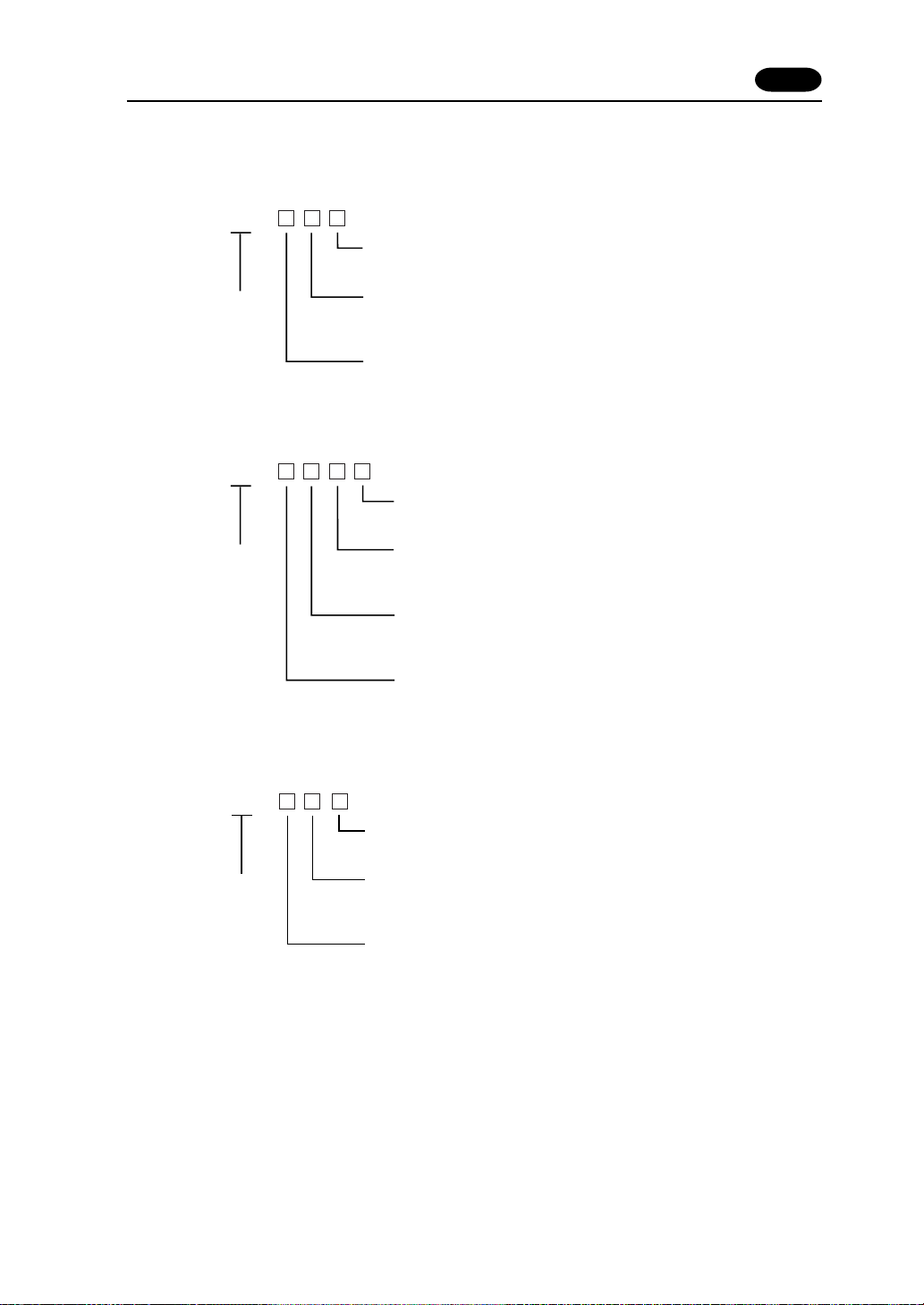

List of Models

The characters on the right of model names represent optional features and special specifications.

1 - 5

UG220H

Main unit

UG221H

Main unit

-

Power requirements

4 : 24V DC

Interface specifications

C : Serial (Link Unit Communication)

(Other interfaces can be supported using the I/F unit.)

LCD type

S : STN color LCD

L : Monochrome LCD (White mode)

-

Touch Panel Specifications

D : Matrix sw type

None : Analog sw type

Power requirements

4:24V DC

Interface specifications

C:Serial (Link Unit Communication)

(Other interfaces can be supported using the I/F unit.)

LCD type

T:TFT color LCD

S:STN color LCD

L:Monochrome LCD (Blue mode)

UG320H

Main unit

-

Power requirements

4 : 24V DC

Interface specifications

C : Serial (Link Unit Communication)

(Other interfaces can be supported using the I/F unit.)

LCD type

S : STN color LCD

1 - 6

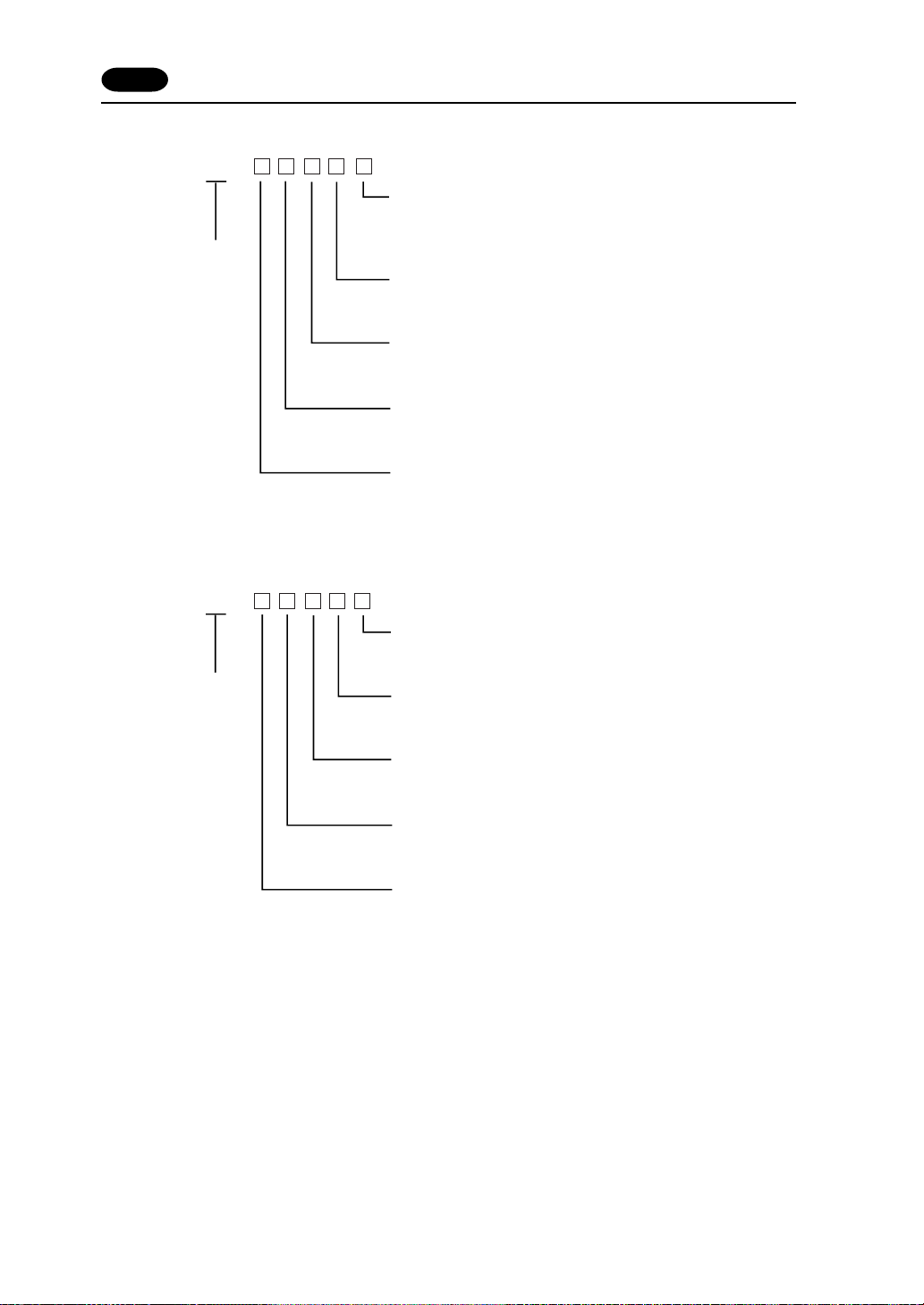

3 System Composition

UG420H

Main unit

UG520H

Main unit

-

Image input

NONE

1 : Video interface (TFT color LCD Only)

2 : RGB interface (TFT VGA only)

Memory card

None : Standard (Outside recorder)

M : Memory card interface

Power requirements

1 : 100 to 200V AC

4 : 24V DC

Interface specifications

C : Serial (Link Unit Communication)

(Other interfaces can be supported using the I/F unit.)

LCD type

S : STN color LCD

T : TFT color LCD VGA

V : TFT color LCD SVGA

-

Image input

NONE

1 : Video interface (TFT color LCD Only)

Memory card

None : Standard (Outside recorder)

M : Memory card interface

Power requirements

1 : 100 to 200V AC

4 : 24V DC

Interface specifications

C : Serial (Link Unit Communication)

(Other interfaces can be supported using the I/F unit.)

LCD type

V : TFT color LCD SVGA

E.g. : UG220H-LC4 (Monochrome LCD / Serial / 24V DC)

UG320H-SC4 (STN color LCD / Serial / 24V DC)

UG420H-TC1M1

(TFT color LCD VGA / Serial /100 to 200V AC / Memory card interface / Video interface)

UG520H-VC41 (TFT color LCD SVGA / Serial / 24V DC / Standard / Video interface)

Products conforming to overseas standards

For the products that conform to overseas standards, such as CE marking, please contact Fuji Sales

Department.

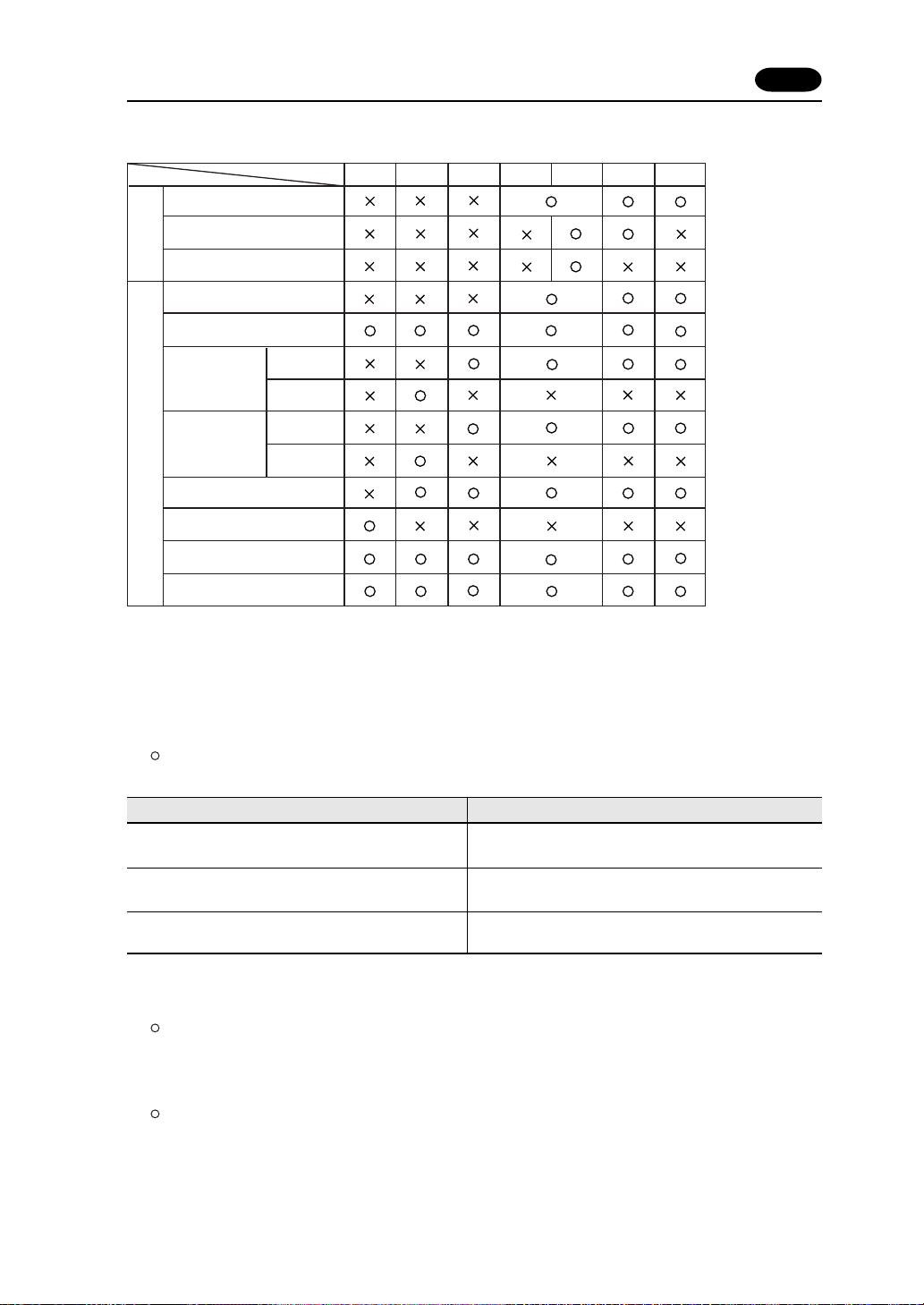

List of Options

Item

Card Interface

Video Interface

Analog RGB Input

Optional

by Manufacturer

Interface

Extension I/O Unit : UG00P-U1

(16 inputs / 16 outputs)

Serial Extension I/O : UG00P-U2

(16 inputs / 16 outputs)

Extension Memory

Cassette: (4Mbyte)

Type

1

*

UG00P-D4

UG221P-D4

UG220 UG420H-SUG320UG221 UG520H-VUG420H-VUG420H-T

2

*

2

*

3 System Composition

1 - 7

SRAM Cassette

: (512Kbyte)

Optional by User

Communication Interface Unit

: UG03I-S/J/T/C/E/P

Communication Interface Unit

: UG02I-S/J/T

Card Recorder

: UG00P-MR

Term inal Converter

: UG00P-TC

1 Prepare for UGx20 with card interface, or UGx20 and UG00P-MR (card recorder).

*

2 UG00P-U1 : Rear-side installation I/O unit, UG00P-U2 : Panel-side installation I/O unit

*

3 UG03I-T/UG02I-T : T-LINK, UG03I-J/UG02I-J : OPCN-1, UG03I-S/UG02I-S : SX BUS,

*

UG00P-SR

UG221P-SR

1

*

3

*

3

*

UG03I-C : CC-LINK, UG03I-E(2) : Ethernet or FL-net, UG03I-P : PROFIBUS

Memory Card

A SRAM card or FPROM card can be used for the memory card. The following table shows the

difference between the SRAM card and FPROM card:

SRAM

Supports the functions of POD memory manager and

data logging, and transmission of screen data.

Data is partially readable and writable at any time.

Contains a battery. Replace the battery when it runs

out.

The FROM card cannot support any functions of memory manager and data logging.

*

Supports transmission of screen data.

Data is written and read all together. Data cannot be

written or read partially.

No battery replacement is required.

FROM

The following memory cards supplied from Fuji Electric Co., Ltd. are recommended.

SRAM

UG00K-S25K(256K) UG00K-S02M(2M)

UG00K-S51K(512K) UG00K-S04M(4M)

UG00K-S01M(1M)

FROM

UG00K-F25K(256K) UG00K-F01M(1M)

UG00K-F51K(512K) UG00K-F02M(2M)

1 - 8

3 System Composition

Model Indication

UG221, UG220

Display area : 115.2 86.4 mm

(A 5.7 inch display.)

UG320

Display area : 157.4 118.1 mm

(A 7.7 inch display.)

UG420

Display area : 211.2 158.4 mm

(A 10.4 inch display.)

UG520

Display area : 246.0 184.5 mm

(A 12.1 inch display.)

Peripheral Equipment

The following options are available for using UGx20 series more effectively.

UG00S-CWV3

(Panel Editor for Windows98/NT4.0/Me/2000/XP)

Application software for editing display data for UG series.

UG00C-T (Data Transfer Cable) 3m

Connects UGx20 to a personal computer, or a personal computer to

UG00P-MR.

UG00C-C (Printer Cable) 2.5m

Connects UGx20 to a printer.

3 System Composition

1 - 9

UG00P-D4•UG221P-D4 (FPROM Cassette)

•

FROM0

1

1

M

N

C

O

R

F

1

P

J

UG00P-D4 : for UG520, UG420, UG320

•

UG221P-D4 : for UG221

Extension print circuit board to extend the memory for display data back-up.

There is 4Mbyte type.

UG00P-SR•UG221P-SR (SRAM Cassette)

•

1

N

2

-

C

2

7

1

2

0

P

SANYO

M

n

+

O

CR2430

2

-

L

i

C

E

L

L

UG00P-SR : for UG520, UG420, UG320

•

UG221P-SR : for UG221

Extension print circuit board to back-up the memory for sampling data,

N

A

P

A

J

Internal Memory and Memo Pad. There is 512kbyte type. It is also possible to

S

T

L

O

V

3

set the calendar for displaying in UGx20 at this cassette.

UG00P-MR (Card Recorder)

Reads display data created by personal computer, or works as an external

memory storage system for the memory manager and data logging functions.

UG00P-MSE (Memory Card Editor)

Application software for editing data stored in a memory card.

( For Windows 98 / Me / NT 4.0 / 2000 / XP )

UG00P-TC (Terminal Converter)

CN1

S

W

1

T

B

1

Used for connection between a UGx20 and a PLC at the RS-422/485 terminal

block.

UG00P-U1 (Extension I/O Unit)

Used as an external I/O unit for PLC. It has 16 inputs and 16 outputs.

(It can be used for UG520 and UG420.)

UG00P-U2 (Serial Extension I/O Unit)

D

C

2

4

V

IN

1

FG

IN

3IN

5IN

IN0 IN

7

IN

2IN

9IN

4

11 IN

IN6

1

3

IN8

IN

15

IN

10 IN1

O

2IN14 C

U

T

1

O

U

T

3

O

O

M

U

+

T

5

O

U

O

T

U

0

T

7

O

U

O

T

U

2

T

8

O

U

O

T

U

4

T

1

0

O

U

O

T

U

6

T

1

2

C

O

O

M

U

1

T

1

4

O

U

C

T

O

9

O

U

T

1

1

O

U

T

1

3

O

U

T

1

5

Used as an external I/O unit for PLC. It has 16 inputs and 16 outputs.

M

J

1

(It can be used for UG520,UG420,UG320,UG221 and UG220.)

M

2

1 - 10

3 System Composition

UG03I-x [x:T T-Link, x:J OPCN-1, x:S SX BUS,

Used to communicate with each network.

It makes it possible to connect multiple UGx20 series to a PLC. This system,

which enables other devices to connect to the same network, brings about

the reduction in costs of the whole system.

UG02I-x

[x:T T LINK, x:J OPCN-1, x:S SX BUS]

(Communication Interface Unit)

Used for UG220 to communicate with each network.

UG00P-DI (ACPU/QnACPU/FXCPU Dual Port Inter-

P

P

G

G

D

face)

Add-on connector with two ports, specifically designed for the connector on

the MITSUBISHI’s ACPU/QnACPU/FXCPU programmer. This can improve

operability of the ACPU/QnACPU/FXCPU programmer that is directly

connected.

x:E(2) Ethernet•FL-net, x:C

x:P PROFIBUS

]

(Communication Interface Unit)

CC-Link,

UGx20P-PS

[x:2 UG220,UG221 , 3 UG320 , 4 UG420,

5 UG520] (Protection Sheet)

Protects the operation panel surface. Five sheets are included in one

package.

UG00C-B (bar-code reader (temperature controller)

connecting cable) 3 m

Used to connect a bar-code reader to the POD.

Also used to connect a temperature controller to the POD via RS-232C.

UG00C-H (Multi-link 2 (temperature controller)

connecting cable) 3 m

Used to connect between POD master and POD slave for Multi-link 2

connection.

Also used to connect a temperature controller to the POD via RS-485.POD

slave station in the Multi-Link 2 connection.

UGxxP-Bx [UG220P/320P/420P/520P-Bx]

(Backlight for Replacement)

Placement backlight parts for UGx20 series.

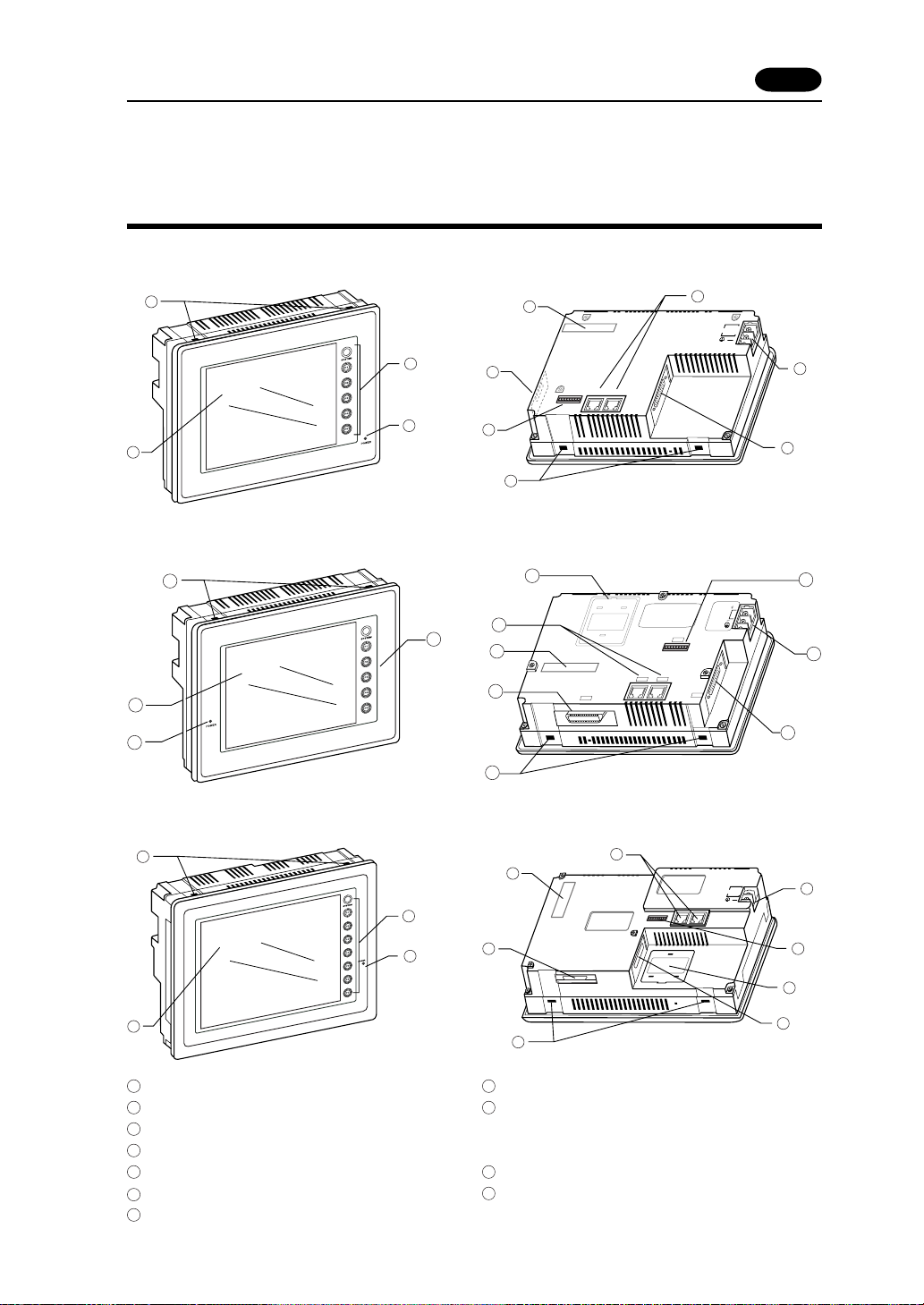

4 Names of Components

1 - 11

4

Names of Components

Front Side of UG220 Rear Side of UG220

1

3

4

2

Front Side of UG221 Rear Side of UG221

1

3

2

4

13

8

C

N

MJ2 MJ1

2

9

1

10

9

11

7

CN2

MJ2 MJ1

1

10

(+)

DC24V

(

-

)

1

N

C

5

7

8

24VDC

5

CN1

6

Front Side of UG320 Rear Side of UG320

1

2

1

Mounting holes for fixtures

2

Display

3

Function keys (Refer to P1-59)

4

Power lamp

5

DC power supply

CN1: for PLC (RS-232C, RS-422)

6

7

CN2: for printer

13

3

4

8

1

8

Dip switches

9

MJ1, 2: for data transfer, for temperature

controller, for bar-code reader, for UG00P-MR

and for UG00P-U2 (option)

10

for UG00P-D4 (option)

11

for UG03I-S/J/T/C/E/P (option)

10

1

N

CN2

C

MJ2 MJ1

(+)

DC24V

(

-

)

5

9

11

7

1 - 12

4 Names of Components

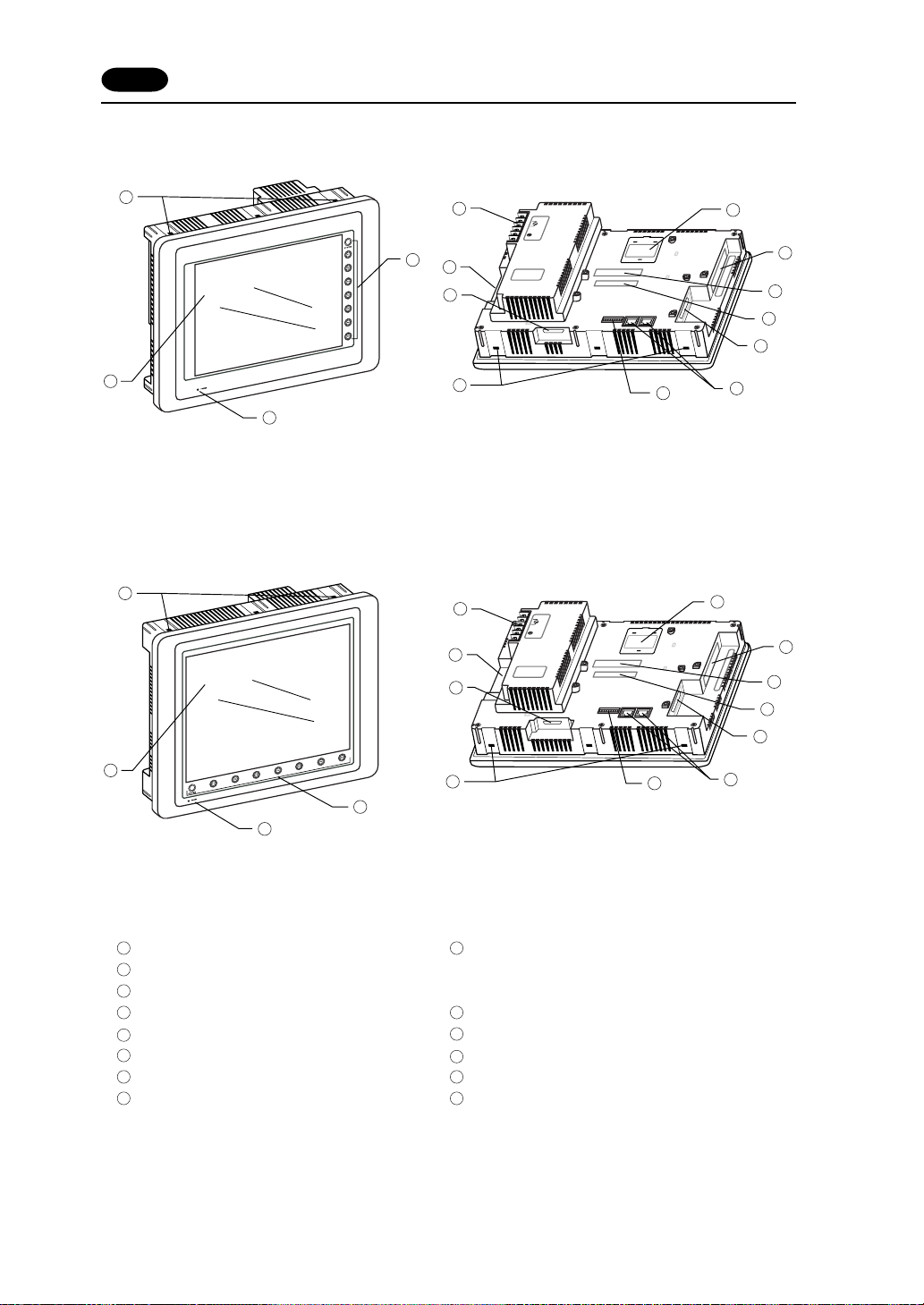

Front Side of UG420 Rear Side of UG420

1

6

3

15

L

100-

240VAC

N

NC

8

CN2

2

1

4

Front Side of UG520 Rear Side of UG520

1

6

L

100-

240VAC

N

NC

15

8

CN2

11

12

1

N

C

MJ1MJ2

13

14

7

9

10

11

12

1

N

C

MJ1MJ2

13

14

7

2

4

1

Mounting holes for fixtures

2

Display

3

Function keys (Refer to P1-59)

4

Power lamp

AC power supply / DC power supply

5

6

CN1: for PLC (RS-232C, RS-422)

7

CN2: for printer

8

Dip switches

1

9

10

3

9

MJ1, 2: for data transfer, for temperature

controller, for bar-code reader, for UG00P-MR

and for UG00P-U2 (option)

10

for UG00P-D2/D4 (option)

11

for video (option)

for UG03I-S/J/T/C/E/P (option)

12

13

for UG00P-U1 (option)

14

Card interface (option)

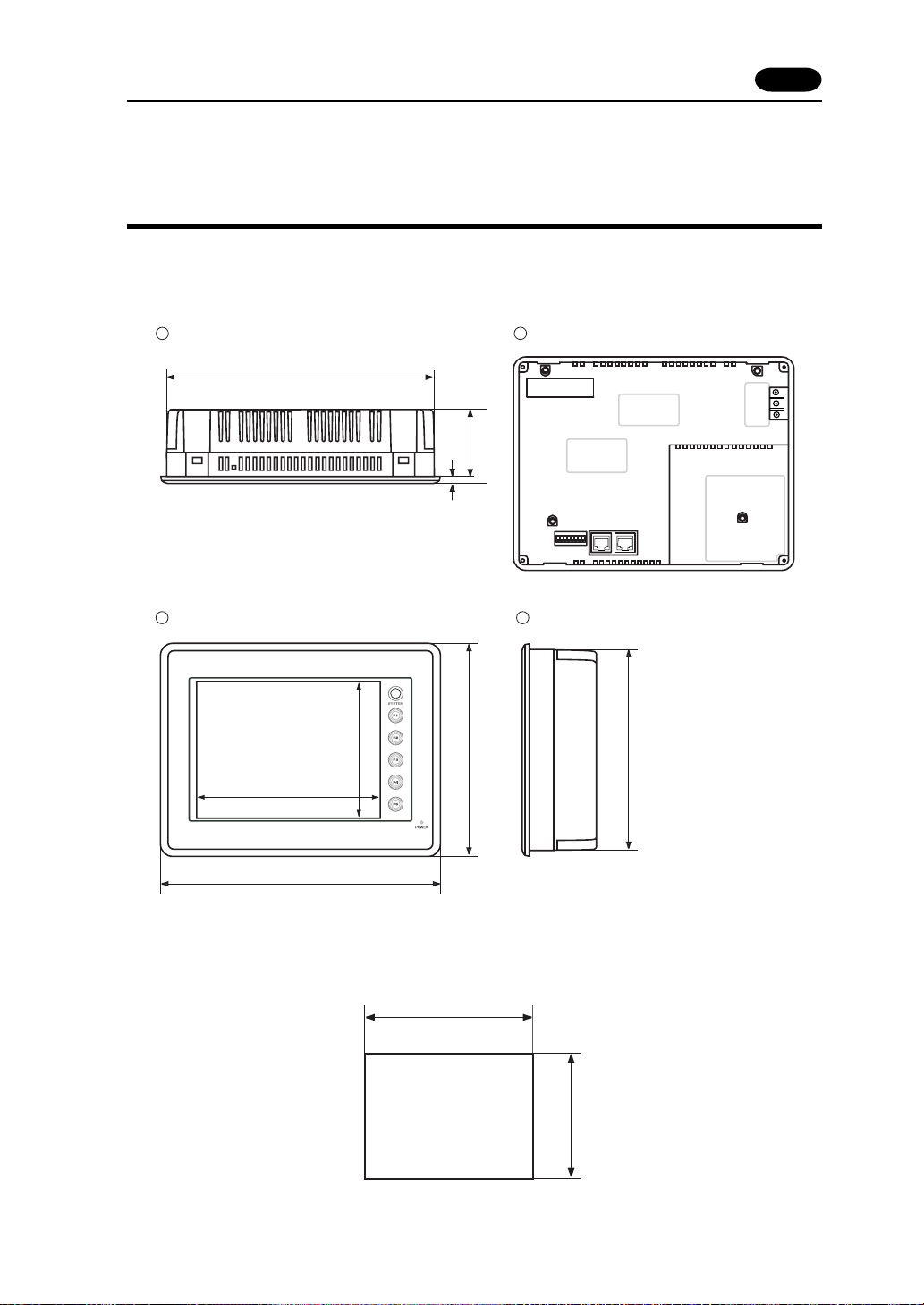

5 Dimensions and Panel Cut-out

1 - 13

5

Dimensions and Panel Cut-out

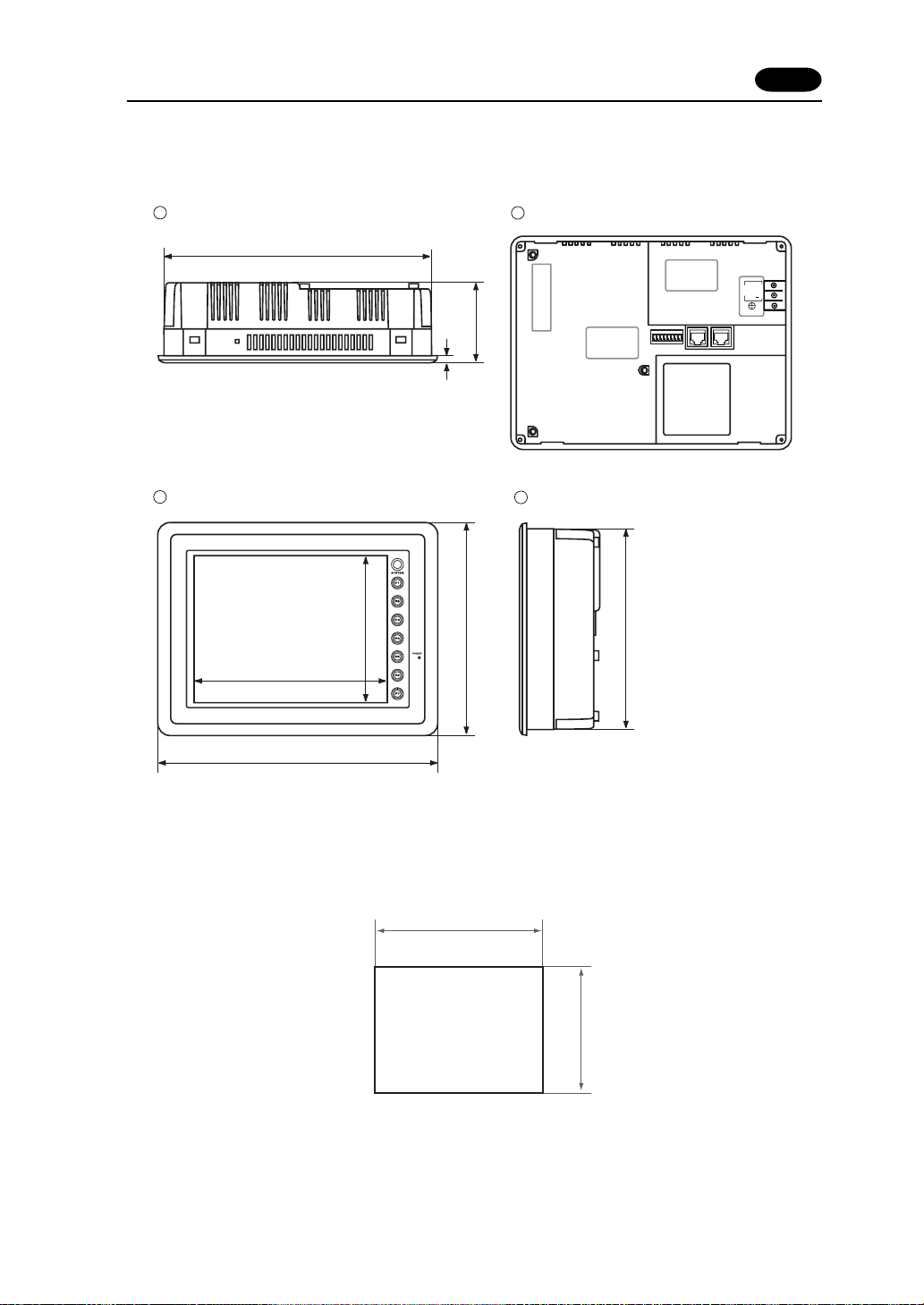

Dimensions of UG220

Unit : mm

Top View

173.6

45

5

Front View Side View

Rear View

CN2

CN1

MJ2 MJ1

117.2

182.5

Panel Cut-out of UG220

88.4

Unit : mm

174

138.8

+0.5

- 0

+0.5

130.8

- 0

131

1 - 14

5 Dimensions and Panel Cut-out

Dimensions of UG221

Unit : mm

Side View Front View

130.8

Rear View Under View

POWER

182.5

SYSTEM

F1

F2

F3

F4

F5

138.8

Do not remove this seal.

unless the optional unit is mounted.

CN2

Panel Cut-out of UG221

MJ1MJ2

Unit : mm

24V DC

CN1

+

-

6

4 47.3

+

0.5

174

-

0

0.5

0

+

-

131

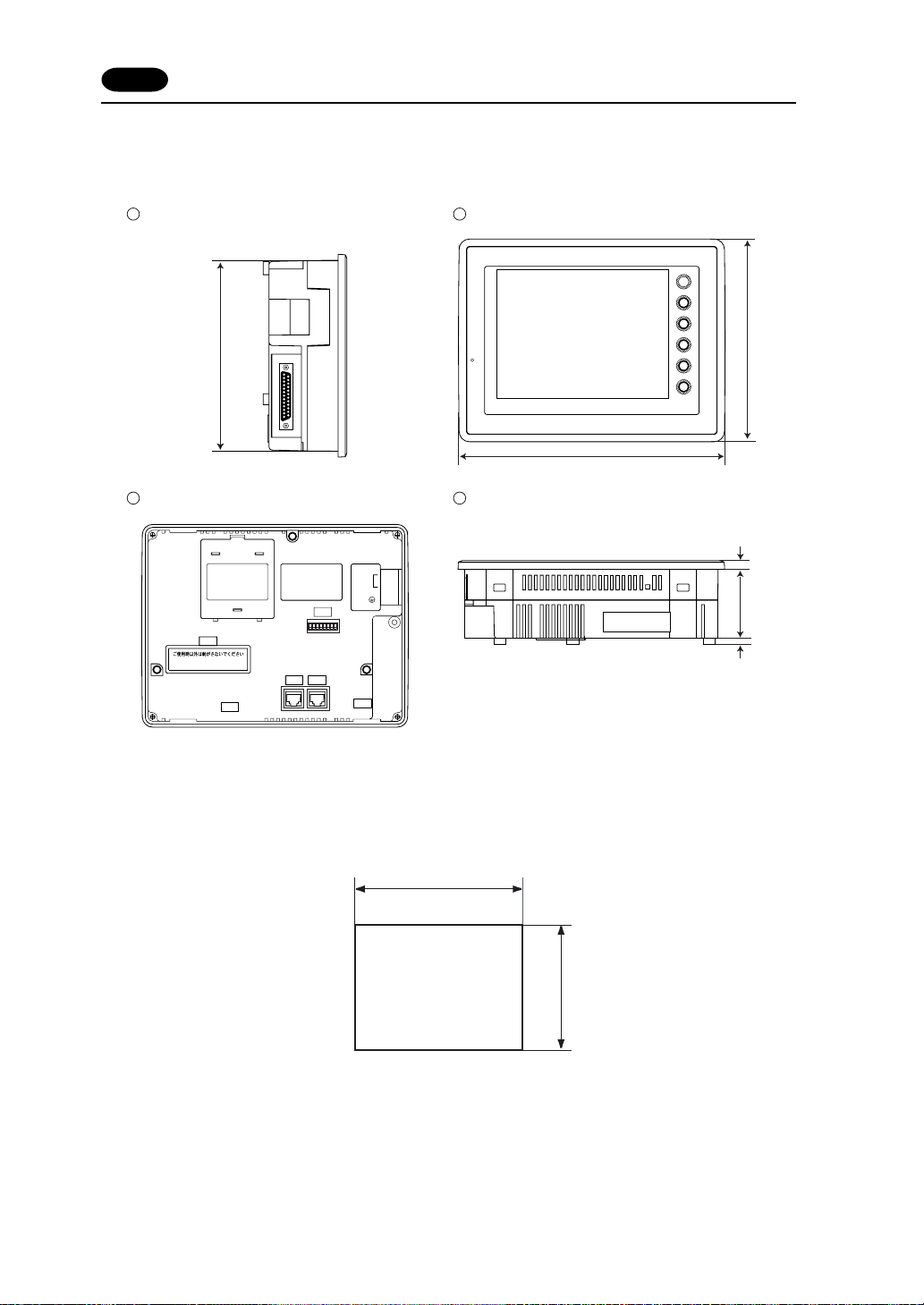

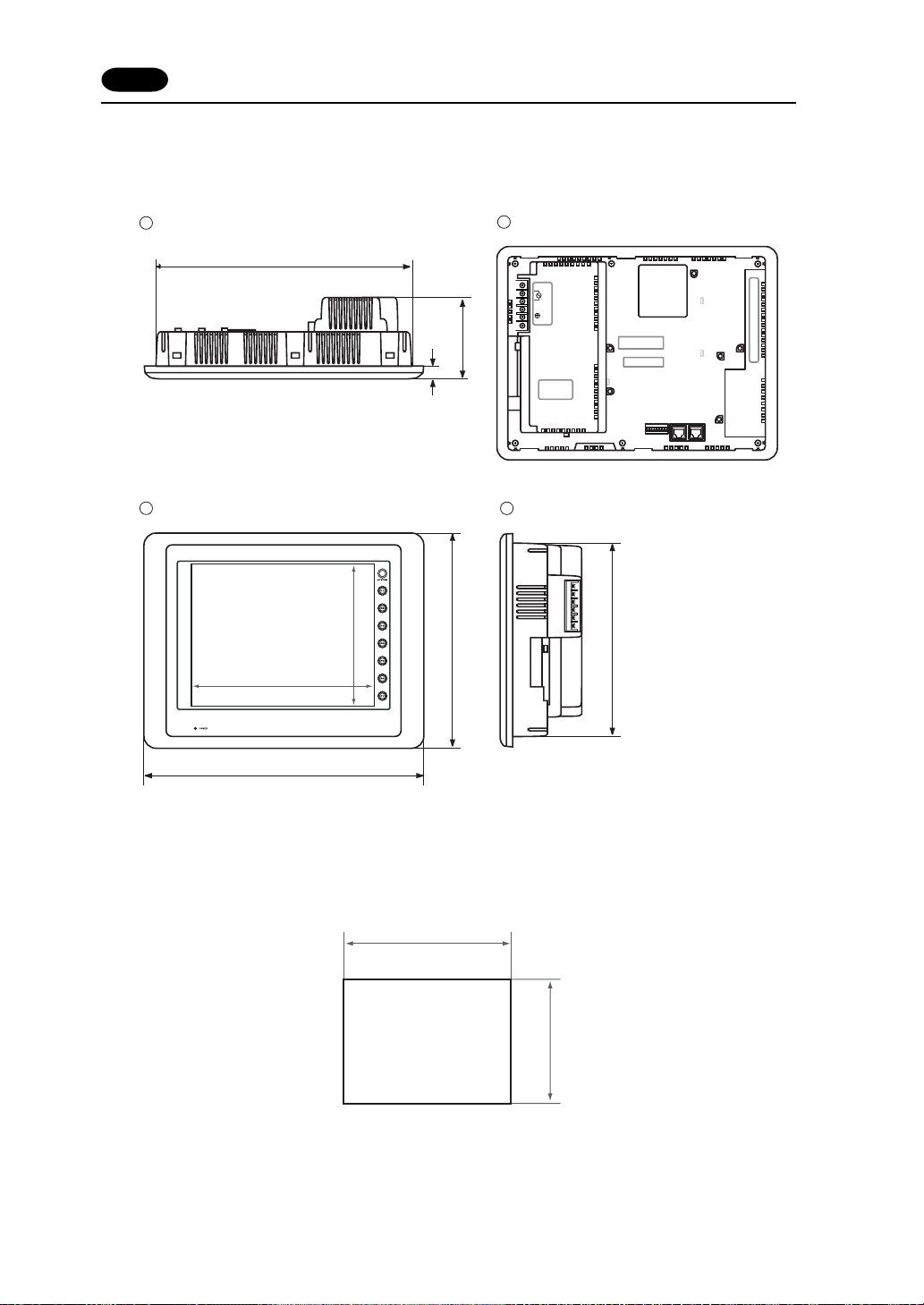

Dimensions of UG320

Unit : mm

5 Dimensions and Panel Cut-out

1 - 15

Top View

Front View

220

160

121

Rear View

TB1

(+)

DC 24V

( )

MJ2 MJ1

60.1

6

CN1

CN2

Side View

175

165

230

Panel Cut-out of UG320

Unit : mm

220.5

+0.5

- 0

+0.5

- 0

165.5

1 - 16

310

5 Dimensions and Panel Cut-out

Dimensions of UG420

Unit : mm

Top View

Front View

288

211

158

16

240

76.3

Rear View

L

100-

240VAC

N

NC

Side View

CN1

MJ1MJ2

CN2

215.2

Panel Cut-out of UG420

Unit : mm

289

+0.5

- 0

+0.5

- 0

216.2

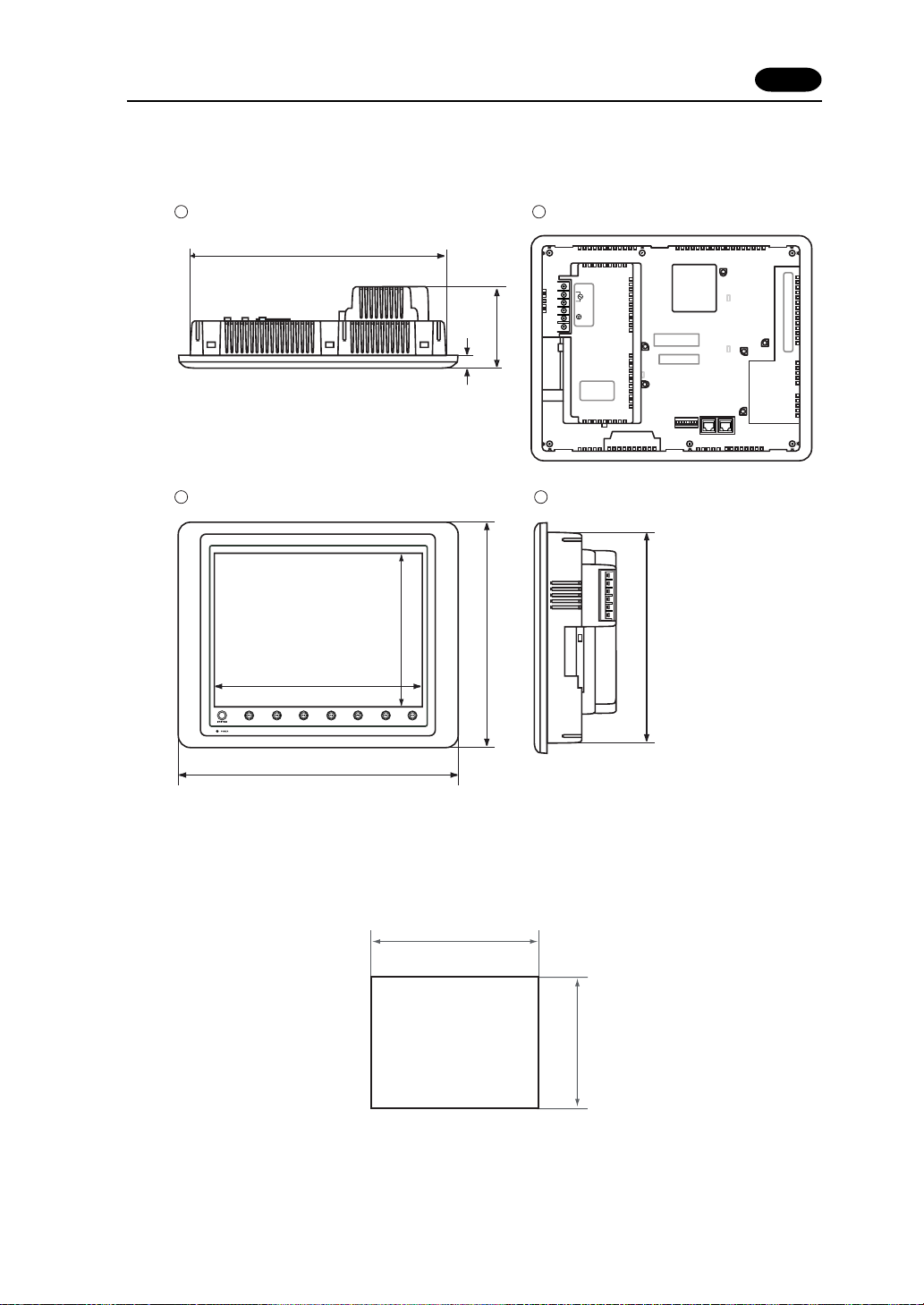

Dimensions of UG520

Unit : mm

312

Front View Side View

5 Dimensions and Panel Cut-out

Rear ViewTop View

L

100-

240VAC

N

NC

79.8

16

CN2

1 - 17

CN1

MJ1MJ2

247

334

Panel Cut-out of UG520

185

Unit : mm

313

270

+0.5

- 0

+0.5

- 0

245.2

246.2

1 - 18

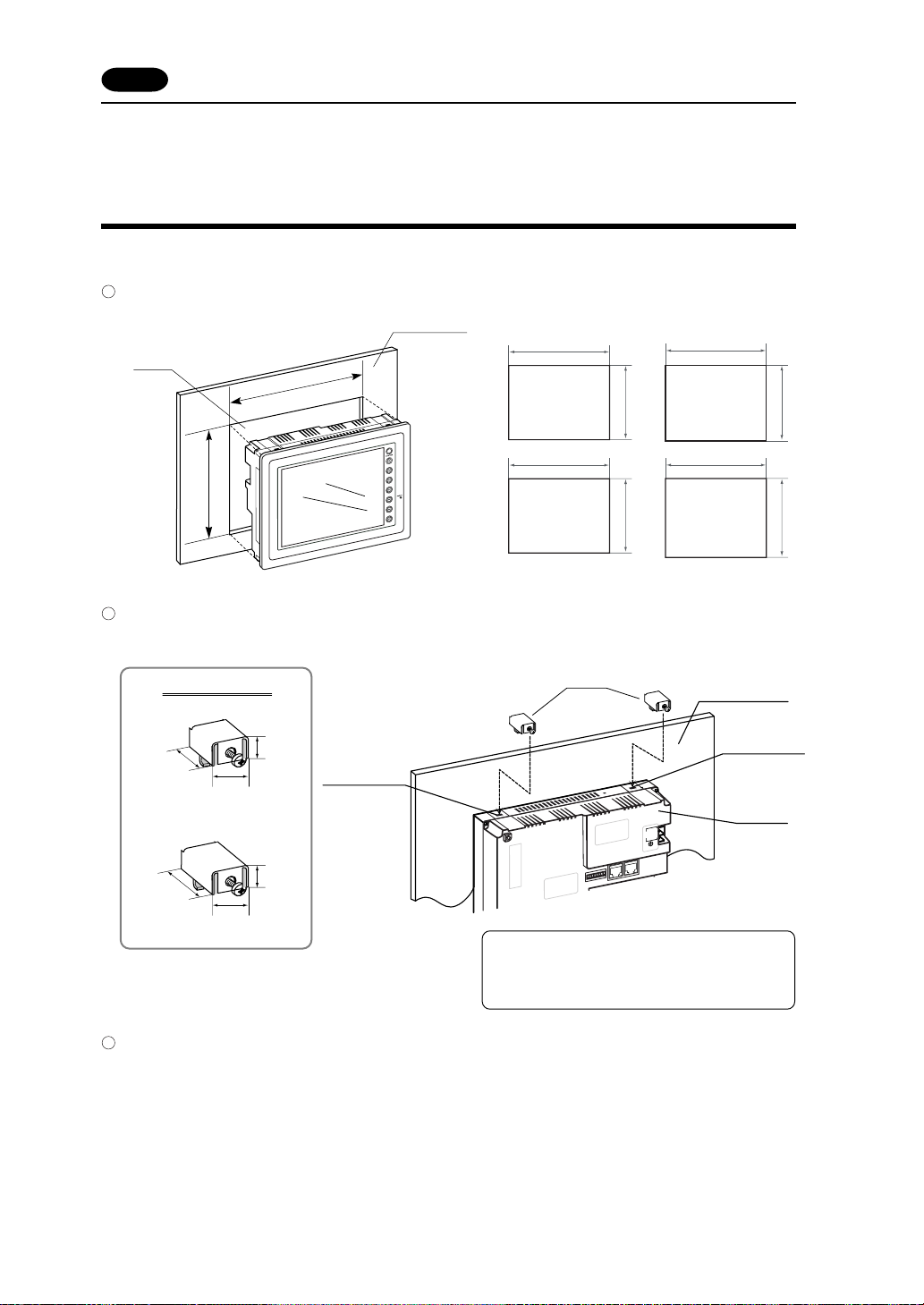

6 Mounting Procedure

6

Mounting Procedure

Mounting Procedure

1

Cut out the mounting panel (Max. thick: 3.2 mm) to match the dimensions shown below.

Mounting panel

Cut-out

1

6

5

.5

- 0

+0.5

2

Insert the fixtures attached to UGx20 into the mounting holes on UGx20. Tighten them with the locking

220.5

5

.

0

+

0

-

screws. (Number of the fixtures: all series 4 pcs,)

Dimensions of Fixtures

(Unit : mm)

Unit : mm

174

UG220

UG221

289

UG420

+0.5

- 0

+0.5

- 0

Fixture

+0.5

- 0

131

+0.5

- 0

216.2

220.5

UG320

313

UG520

Mounting panel

+0.5

- 0

+0.5

- 0

165.5

+0.5

- 0

+0.5

- 0

246.2

20.0

17.8

10.5

Mounting hole

Mounting hole

for UG220/320

1

B

T

)

+

(

V

4

2

C

D

)

-

(

1

J

M

2

J

M

30.0

10.5

17.8

for UG221/420/520

torque:

UG320/UG221/UG220 0.3 to 0.5 N • m

UG520/UG420 0.5 to 0.7 N • m

3

The waterproof packing mounted on the UG221 main unit shall come in close contact with the mounting

panel so that it is surely caught between the mounting panel and UG221.

UGx20

7 Wiring

1 - 19

7

Wiring

Caution

Do not remove the dust-proof seal till you finish wiring in the panel. If the seal is removed, conductor chips or other

•

foreign matter may enter the device to cause failure.

When you finished wiring in the panel, be sure to remove the dust-proof seal.

•

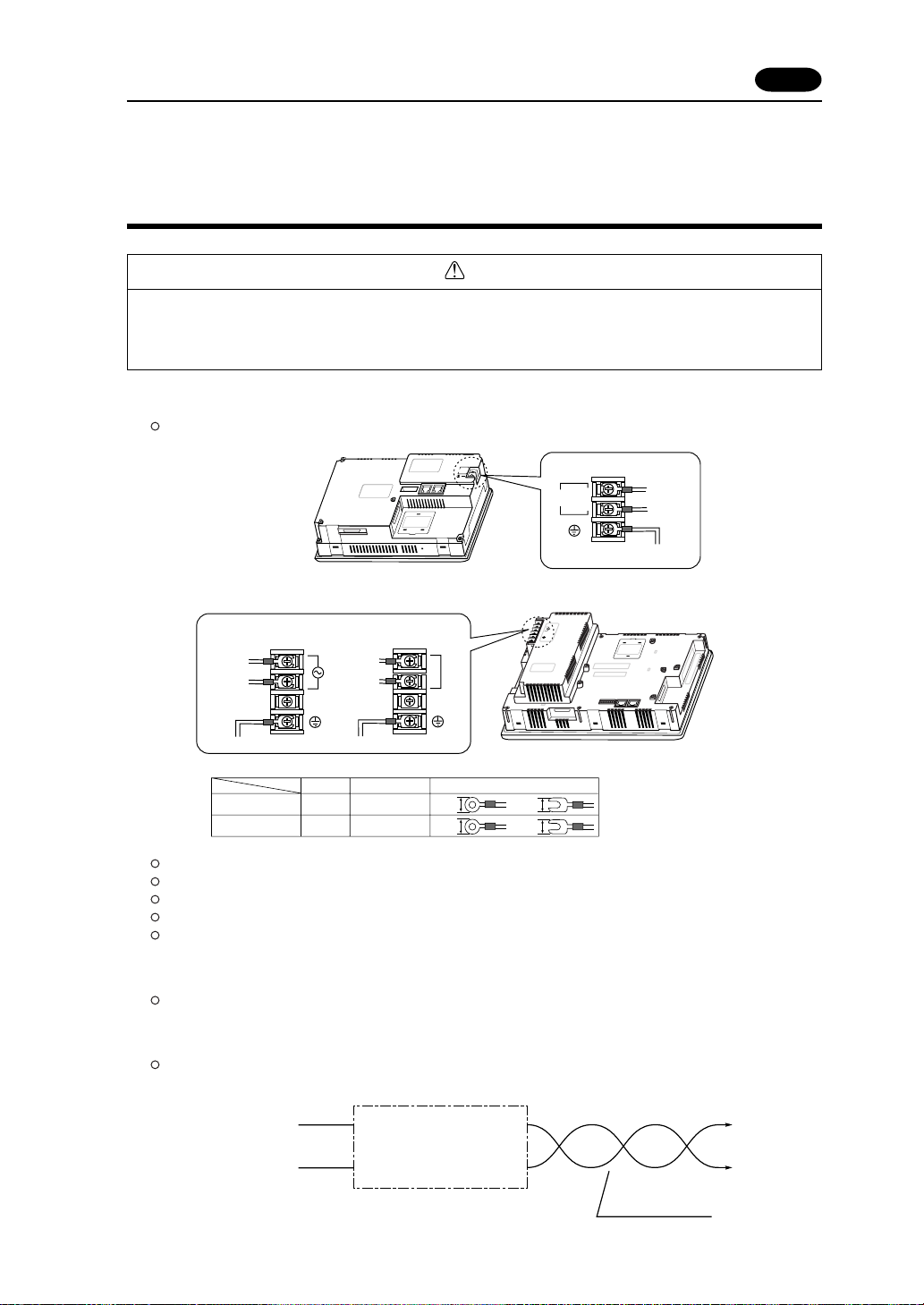

Electrical Wiring

Connects the cable for power supply to TB1 on the rear side of UGx20.

(+)

DC24V

1

N

C

CN2

UG320/UG221/UG220

Type : 100-200V AC Type : 24V DC

Power supply

100-200VAC

TB1

L

Power supply

24V ±10% DC

N

NC

(-)

MJ2 MJ1

24V DC

L

N

TB1

+

24VDC

-

NC

NC

TB1

(

+)

(

-

)

100240VAC

CN2

Power supply

24V ±10% DC

Earth

MJ1MJ2

1

N

C

Earth

Type

UG320/UG221/UG220

UG520/UG420

Screw

Earth

Screw Size

M3.5

M3.5 0.5

Torque (N • m)

0.5

Clamp Terminal (Unit : mm)

7.0MAX

8.0MAX

UG520/UG420

7.0MAX

8.0MAX

When TB1 is used for wiring, refer to the following table.

The power source used must be within the allowable voltage fluctuation.

Use a power source with low noise between the cables or ground and the cable.

Use as thick a power cable as possible to minimize any drop in voltage.

Keep cables of 100V AC and 24V DC sufficiently away from high-voltage, large-current cables.

Notes on Usage of UG520/UG420 100-200V AC Specifications

Generally, an isolating transformer improves noise resistance. However, if the display unit is far away

from the secondary port of the transformer and noise gets mixed in, an isolating transformer becomes

unnecessary.

If any power voltage fluctuation caused by noise is expected, it is recommended that a voltage stabilizer

be used.

Power Supply

Insulation transformer

or

Stabilized transformer

1.25

mm

2

twisted

to UG520/UG420

1 - 20

7 Wiring

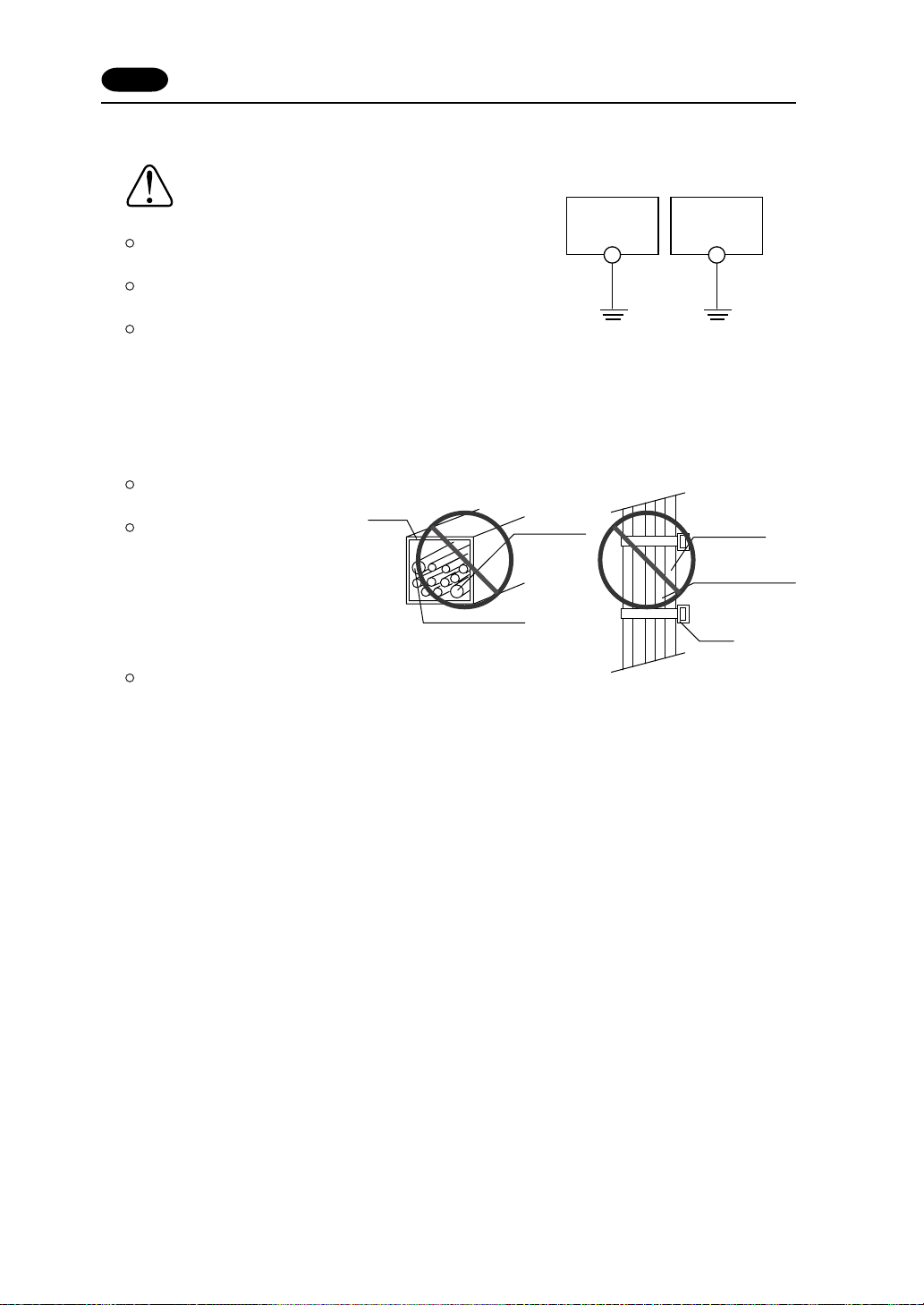

Grounding

This equipment must be earthed.

An independent earth pole shall be used for POD. (The

level of grounding resistance should be less than 100 Ω.)

Use a cable which has a nominal cross section of more than

2mm2 for grounding.

Grounding point shall be near the POD to shorten the

distance of grounding wires.

Wiring for Communication

Never place the communication

cable with electric circuits.

Never bundle these cables together

with other wires in ducts or electric

boxes using cord locks. Although it

is tempting to bundle all the cables

neatly together, this does not

necessarily lead to a noise-resistant

configuration.

It is recommended that the

communication cable be independently wired.

Wiring duct

Power cable and control cable

UGx20

Grounding resistance : less than 100Ω

Communication cable

equipment

Communication cable

Power cable and control cable

Cord lock

other

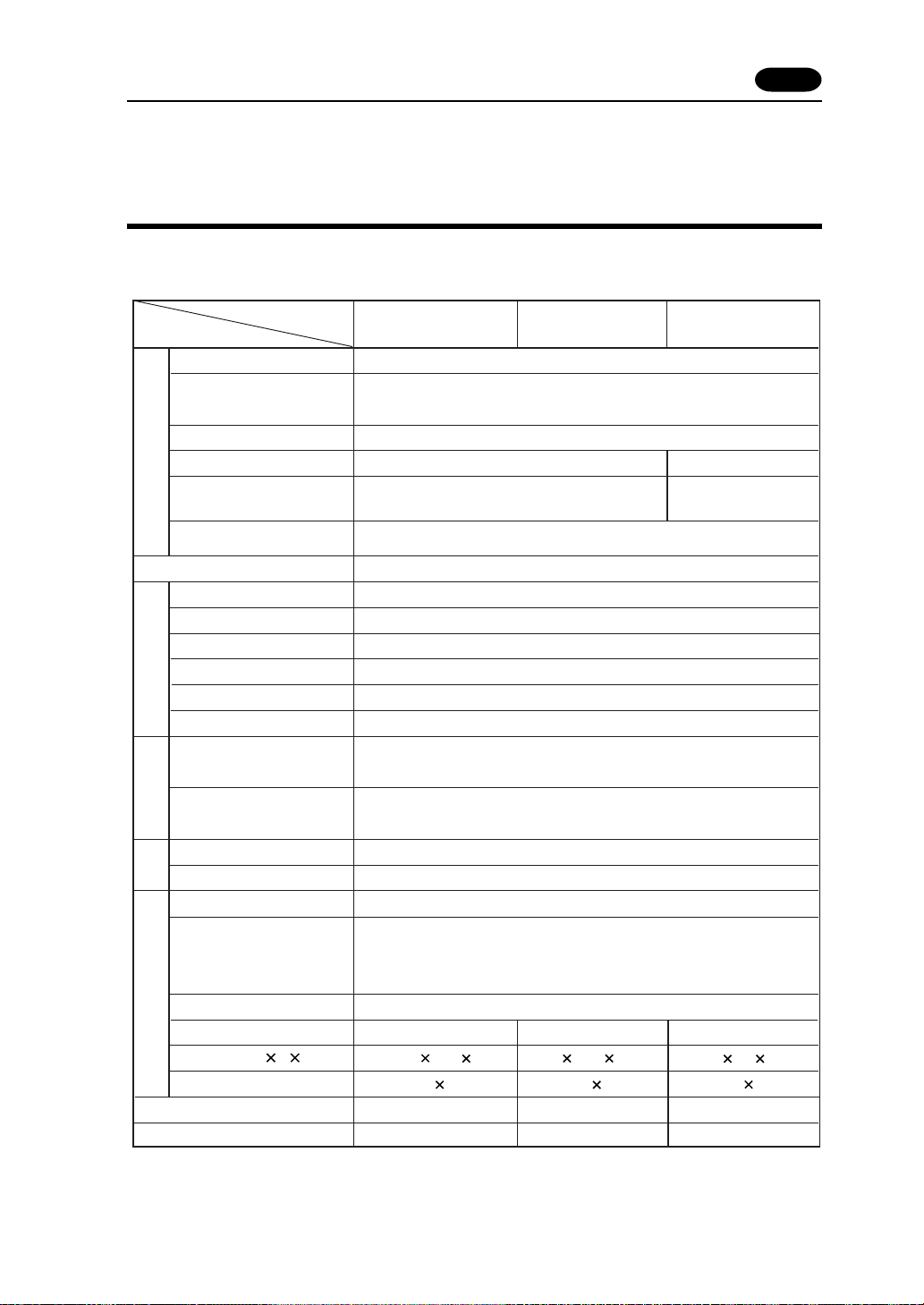

8 Specifications

1 - 21

8

Specifications

General Specifications

Type

Item

Rated Voltage

Permissible Range

of Voltage

Permissible Momentary Power Failure

Demand

Power SupplyPhysical Environment

Rushed Electric Current

With-stand voltage

Insulation Resistance

Ambient T emperature

Storage Ambient Temperature

Ambient Humidity

Dust

Solvent Resistance

Corrosive Gas

Vibration Resistance

Shock Resistance

Conditions

Mechanical

Working

Noise Resistance

Static Electricity Discharge Resistance

Conditions

Electrical

Working

Grounding

Structure

Cooling System

Weight

Mounting Conditions

Dimensions W H D (mm)

Panel Cut-out (mm)

Case Color

Material

1 including 4mm, the size of boss for communication unit

*

2 equivalent to the Munsell color system N-2.0

*

Protection structure: front panel complies with IP65 (when using gasket)

UG220

Vibration frequency: 10 to 150Hz, Acceleration: 9.8m/s

Single amplitude:0.075mm ,3 directions of X, Y and Z: one hour

Peak acceleration: 147m/s

Approx. 0.8kg

182.5 138.8 50

+0.5

174 131

-0

DARK GREY

PC/ABS

UG221

24V DC

±

10% DC

24V

10ms or less

10W or less

15A

1ms

DC external terminals to FG : 500V AC per min.

500V DC, 10MΩ or more

85% RH or less (without dew condensation)

No cutting oil or no organic solvent to cling to the unit

Pulse shape: Sine half wave,

Noise voltage: 1500Vp-p, noise width: 1µs

Contact: 6kV , Air: 8kV

Grounding resistance: less than 100Ω

rear panel complies with IP20

Mounting procedure: inserted in a mounting panel

182.5

+0.5

-0

0°C to +50°C

-

10°C to +60°C

No conductive dust

No corrosive gas

2

, 3 directions of X, Y and Z: six times

Form: in a body

Cooling naturally

Approx. 0.8kg

1

131

*

57.3

2

*

+0.5

-0

138.8

+0.5

174

-0

BLACK

PC/PS

UG320

20W or less

15A

1.5ms

Approx. 1.1kg

230175 66.1

+0.5

220.5 165.5

-0

DARK GREY

PC/ABS

2

,

+0.5

-0

Loading...

Loading...