Fujitec MO-1330, MO-1350 Instruction Manual

INSTRUCTION MANUAL

Electric Screwdriver

MO-1330 MO-1350

Controller

DO-1390A CO-1390A-2

FUDOC-110630

Thank you very much for your purchasing. Electric Screwdriver (MO-1330,

MO-1350,DO-1390A,DO-1390A-2). Please study this instruction manual for

the correct use of the unit and preserve it so that you may refer to it when

you come across anything unfamiliar.

- CONTENTS -

1. Parts Identification

- - - - - - - - - - - - - - - - P1

1

Screwdriver unit(MO-1330,MO-1350A) - - - - - - - - - - - - - - P1

2

Controller(DO-1390A) - - - - - - - - - - - - - - - - P2

3

Controller(DO-1390A-2) - - - - - - - - - - - - - - - - P3

2. Precautions for Use

- - - - - - - - - - - - - - - - P4

3. Preparation

- - - - - - - - - - - - - - - - P4

【How to install】

- - - - - - - - - - - - - - - - P4

【How to connect】

- - - - - - - - - - - - - - - - P4

4. Operation

- - - - - - - - - - - - - - - - P5

【Inspection before operation start check if that】

- - - - - - - - - - P5

【Trial operation】

- - - - - - - - - - - - - - - - P5

【Operation】

- - - - - - - - - - - - - - - - P5

【Stop】

- - - - - - - - - - - - - - - - P5

5. Maintenance

- - - - - - - - - - - - - - - - P6

【Daily maintenance】

- - - - - - - - - - - - - - - - P6

【Monthly maintenance】

- - - - - - - - - - - - - - - - P6

【Adjustment】

- - - - - - - - - - - - - - - - P7

【Consumable parts replacement】

- - - - - - - - - - - - - - - - P7

6. Motion Timing Chart

- - - - - - - - - - - - - - - - P8

7. Troubleshooting

- - - - - - - - - - - - - - - - P8

8. Specifications

- - - - - - - - - - - - - - - - P9

9. DO-1390A 1-Phase,2-Phase Torque-changing Controller

- P10

1 Adjustment for torque

- - - - - - - - - - - - - - - - P10

2 Changing Torque Wiring Diagram

- - - - - - - - - - - - - - - - P10

3 Motion Timing Chart

- - - - - - - - - - - - - - - - P11

4 Note

- - - - - - - - - - - - - - - - P11

10. Service

- - - - - - - - - - - - - - - - P11

11. Appendix

- - - - - - - - - - - - - - - - P12

-1-

1.Parts Identification

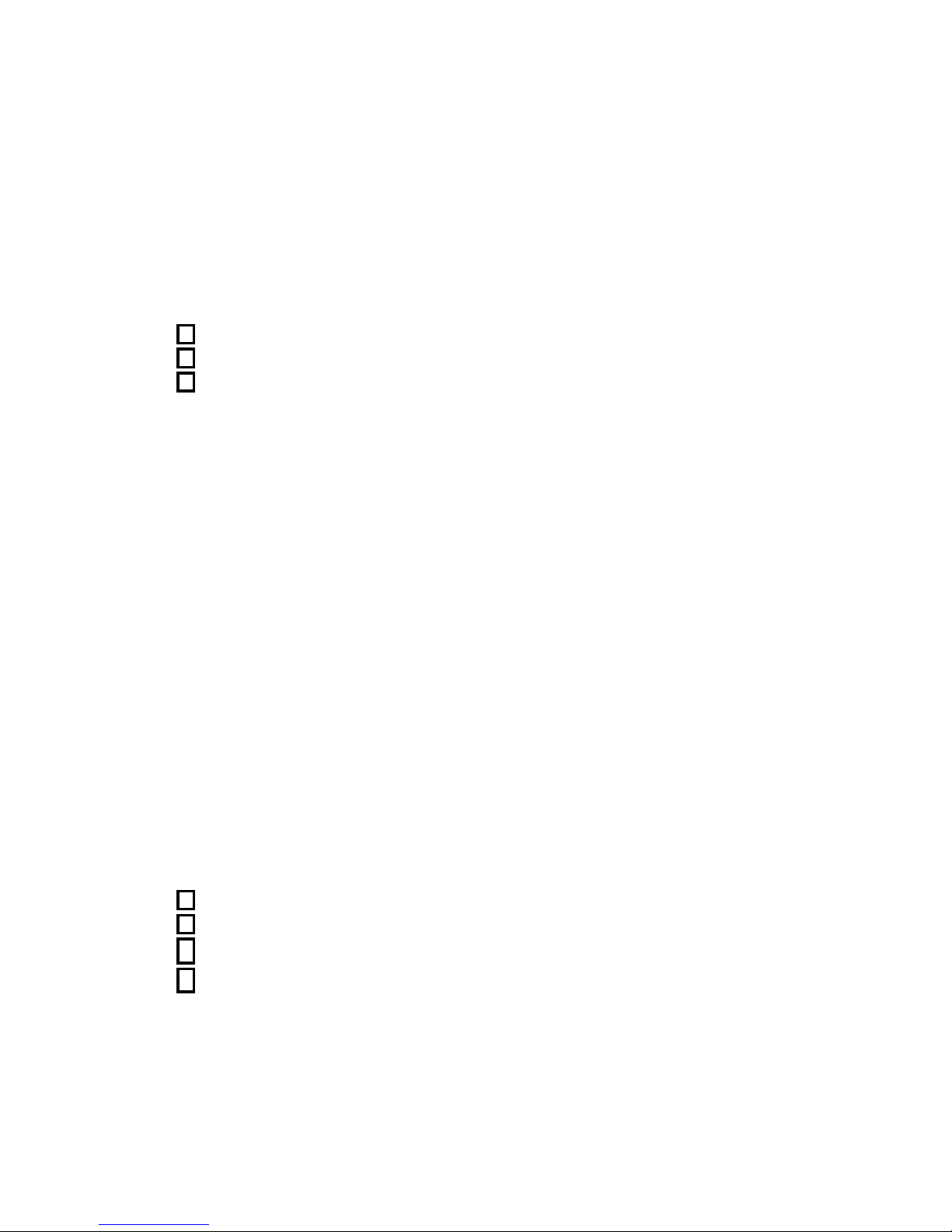

1 Screwdriver unit(MO-1330、MO-1350A)

Note)※( )The size is applied to special type MO-1330.

①Screwdriver cord 910060250(optional)

Transmits input / output signals.

driver side : surgical knife connecter 1545R / surgical knife pin 1381TR

controller side : metal outlet 2P PLT-162-R (panel side : PLT-162-P)

②Brush cap

Fixes and protects brush. If turned clockwise,brush cap tightens; if turned counterclockwise, it loosens.

③Holder

Please tighten one-page driver's center of the gripper with 5~8 N.m.

④Output shaft

Transmits screwdriver rotationn to bit.

①

(CONNECTOR FOR DRIVER)

CONNECTOR(OSU) 1545P

PIN (OSU) 1380TL

Terminal

Spanner ( opposete 32mm )

② Brush Cap

④Output shaft

③Holder

※Output axis φ6

Specification

φ3.5H7 ※(φ3H7)

①

-2-

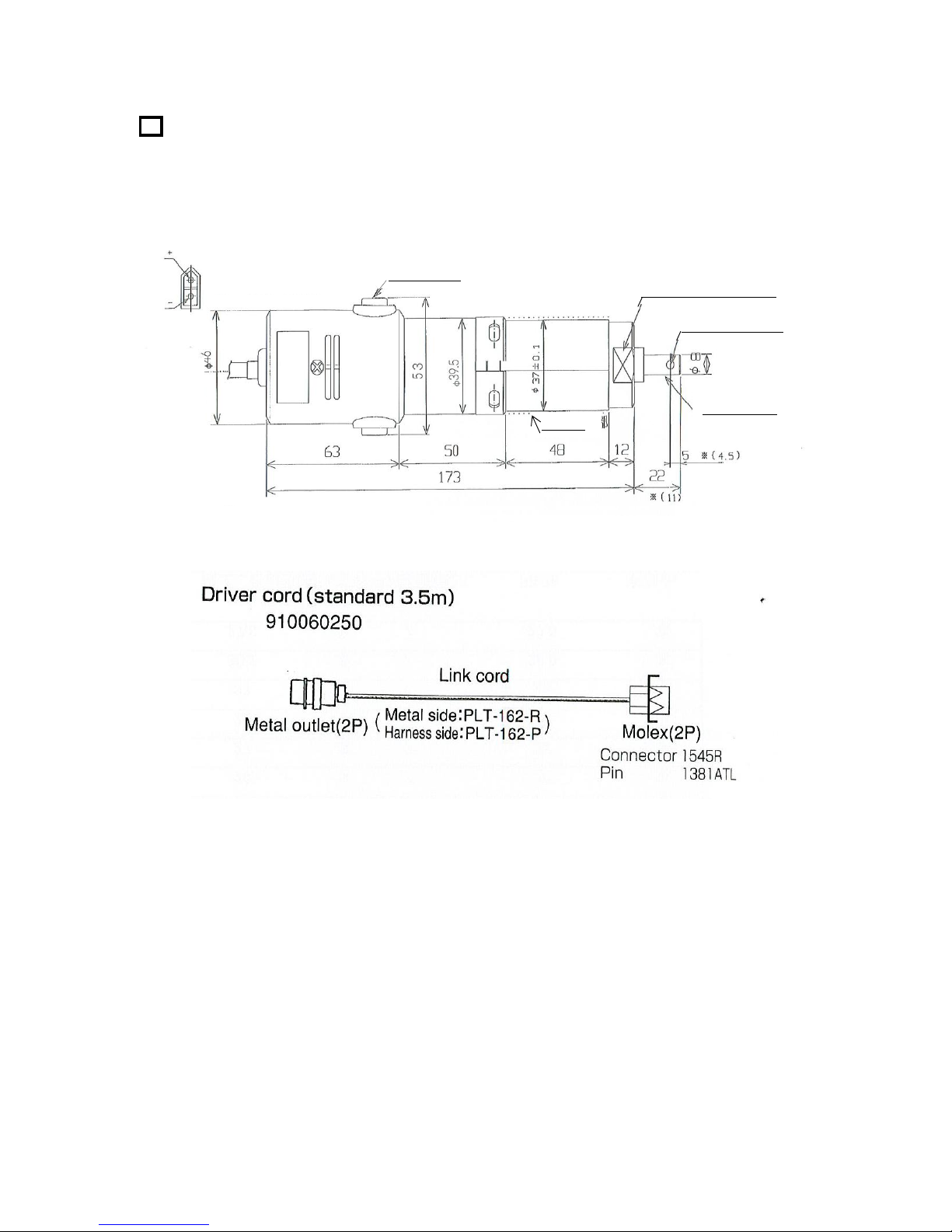

2

Controller(DO-13390A)For MO-1330・1350

①Screwdriver select switch

Set to screwdriver model No.

②Torque volume

Used to change torque.

③Power switch(POWER)

Used to ON/OFF power of control unit.

④Power indicator

Light while power control unit is ON.

⑤Overcurrent indicator lamp(OCP)

⑥Metal outlet(2P)

Used to connect to screwdriver.

Panel side :PLT-162-R Harness side : PLT-162-P

⑦Fuse holder (3A)

Used to protect and replace fuse.

⑧Metal outlet(5P)

Connecter to input/output signals.

Panel side :PLT-165-R Harness side : PLT-165-P

⑨Power cord

Plugged into AC100V power source.

⑩Adjustment at motor lock time

Can it tighten and the following maintenance officer be adjusted.

⑩Adjustment

at motor lock

⑥ Metal outlet

⑦Fuse holder

⑨

Power

⑧Metal outlet

③Power switch

④Power indicator

⑤

Overcurrent

indicator

①Screw driver select switch

②Torque

volume

-3-

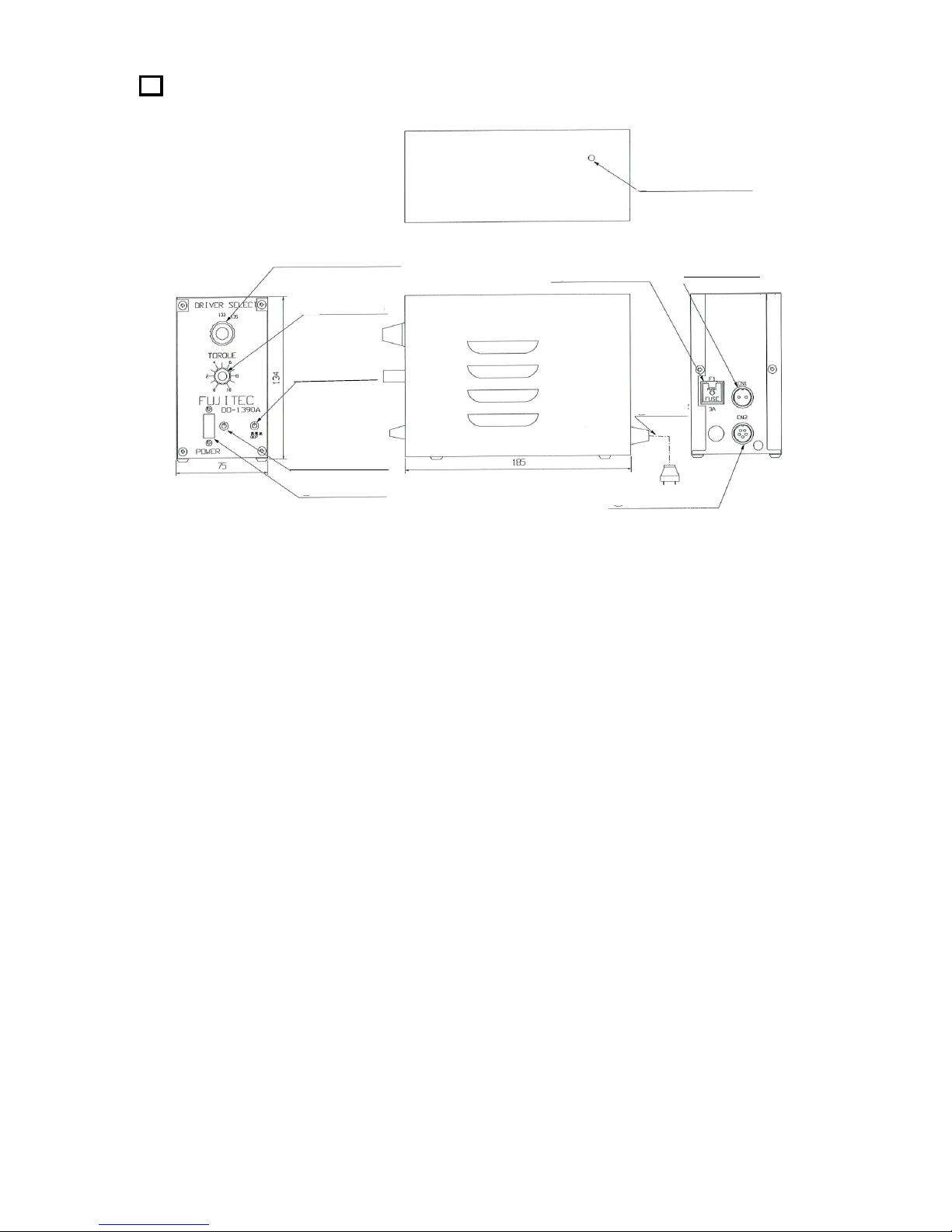

3

Controller(DO-1390A-2) For MO-1330・1350

①Screwdriver select switch

Set to screwdriver model No.

②Torque volume 1

Use to change torque.

③Torque volume 2

Use to change torque.

④Power switch(POWER)

Use to turn ON / OFF power of control unit.

⑤Power indicator

Light while power of control unit is ON.

⑥Overcurrent indicator lamp(OCP)

⑦Torpue change switch connector(3P)

Torque 1 and torque 2 can be switched.

⑧Metal outlet(2P)

Connected to input/output signals.

Panel side : PLT-162-R Harness side : PLT-162-P

⑨Fuse holder(3A)

Used to protect and replace fuse.

⑩Metal outlet(5P)

Connected to input/output signals.

Panel side : PLT-165-R Harness side : PLT-165-P

⑪Power cord

Plugged into AC100V power source.

⑫Adjustment at motor lock time

Can it tighten and the following maintenance officer be adjusted.

⑫Adjustment at motor lock

⑨Fuse holder

⑧ Metal outlet(2p)

⑦Torque switch

⑩Metal outlet

⑪Power cord

①Screwdriver select switch

②Torque volume1

⑥Overcurrent

indicator lamp

③Torque volume2

④Power switch

⑤Power

indicator

-4-

2.Precautions for Use

① Do not drop screwdriver unit and control unit or hit them against other substances.

② Keep the screwdriver free form water and oil.

③ Do not operate screwdriver select switch while screwdriver is working.

④ Never short-circuit screwdriver output terminal.

⑤ Be sure to perform daily inspection and maintenance. If any trouble should occur, please repair the unit

as soon as possible.

⑥ No modification is allowed.To ensure safe use, never provide screwdriver unit and controller with any

modification.

3.Preparation before Use

■

How to install

①

Installation requirements

Do not install the unit near Heating element.

Do not subject it to direct sunrays.

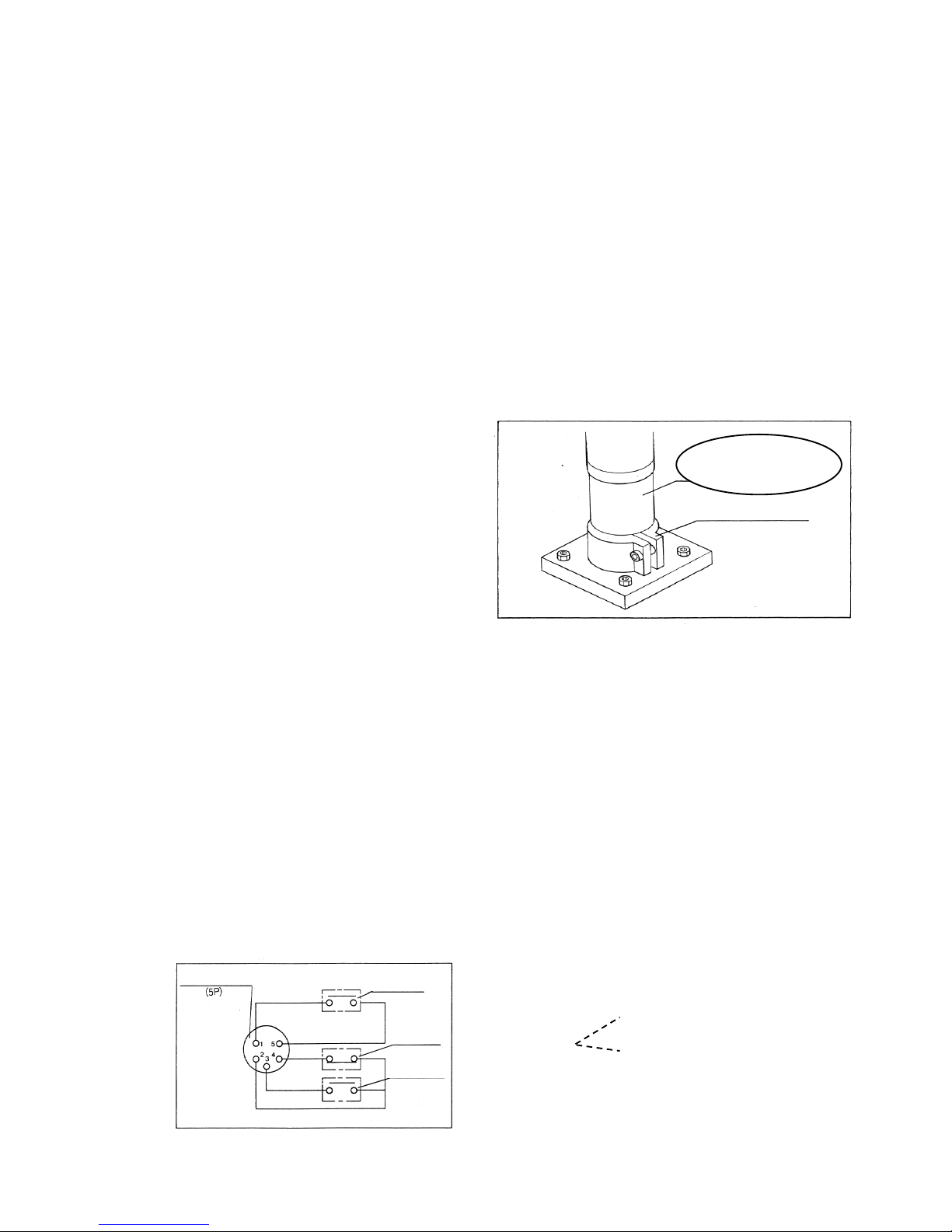

② Fixing screwdriver unit

Fixing screwdriver unit to screwdriver holder

using screwdriver grip.

※Use split type screwdriver holder.

■

How to connect

①

Check that power switch on controller is OFF.

② Plug power cord on the back of controller into AC100V power supply outlet.

③ Plug screwdriver cord into metal outlet (2P) on the back of controller.

【Caution】Be sure to use exclusive controller.

※DO-1390A,DO-1390A-2 : 2P metal outlet (For MO-1330・1350)

④ Connect input signal (start signal ) to input/output terminal (metal outlet ,5P )

on the back of controller. Input signal must be no-voltage contact signal.

【Caution】If several-units are used at a time each input signal must be provided through respective contact.

⑤ Complete signal can be obtained through input/output terminal.

Load capacity for complate signal must be kept below AC100V 0.1A.

⑥Input/output signal connection diagram

Start Signal・・・

Input signal terminal (1-5)

Output signal terminal (2-3)

(Relay A contact)

Input signal terminal (2-4)

(Relay B contact)

Metal outlet (5P)

Panel side : PLT-165-R

Harness side : PLT-165-P

Complete

Signal

Please tighten one-page

driver's center of the gripper

with 5~8 N.m

Holder

Start signal

extermal

Complete

B contact

Complete

A contact

-5-

Loading...

Loading...