FUJI-IMVAC BT-32EI Operator’s Manual

Operator’s Manual for BT-32EIS

SPECIFICATIONS

Displacement: 1.95 cu in [34cc]

Horsepower: 2.2 hp @ 10,000 rpm

Ignition Style: Electronic Ignition

RPM: 1,200 – 10,000 rpm

Fuel: Gas/2-cycle engine oil

Weight w/Muffler: 3.6 lb, [1.7 kg]

Manufactured by FUJI-IMVAC INC.

YOKOHAMA, 235-0005 JAPAN

Worldwide Distributor (except Japan): Hobbico, Inc.

Champaign, IL 61826 USA

Fuji-Imvac is not related to the original Fuji Engines sold by Mecoa.

www.fuji-imvac.com

™

SAFETY TIPS AND WARNINGS

Always use a balanced spinner and a balanced prop. An unbalanced spinner

·

and prop combination will cause high levels of vibration and may cause the

propeller shaft to break.

Always use a lightweight spinner on your engine. Lightweight spinners are

·

considered to be those with a cone wall of 1mm or less. Heavy spinners could

cause the propeller shaft to break.

Securely tighten the spinner and prop on the engine to prevent it from being

·

thrown off the engine while running.

Never use a prop that has hit the ground. Even though it may look good from

·

the outside, it may be cracked on the inside which may cause it to disintegrate

while in use. Do not use a nicked, cracked or split propeller.

Keep foreign objects away from the propeller. Make sure that nothing can be

·

“sucked in” by the propeller. Never start the engine on loose gravel or sand.

Keep onlookers away from the running engine, especially small children.

·

Do not attempt to stop the engine by throwing anything into the path of the propeller.

·

Make sure the fuel line is well-secured to the engine and to the fuel tank so that

·

it won’t come off in flight.

FJIZ1205 for FJIG0132 V2Entire Contents © Copyright 2009

Do not use silicone fuel line because it will be attacked by the fuel. Use vinyl or

·

neoprene rubber fuel line.

Always secure the fuel line away from the cylinder head. The engine’s heat can

·

damage the fuel line.

Never touch the engine after a run. The engine will be hot and it may burn you.

·

Before transporting your model, remove all the fuel from the fuel tank and fuel lines.

·

Always use high-quality oil intended for 2-stroke engines.

·

Use only low-octane, alcohol-free gasoline. The carburetor diaphragm will

·

gradually deteriorate if you use gasoline with alcohol (ethanol, gasohol, etc.).

You will need to replace the diaphragm in about 80 hours of operation if you use

gasoline with alcohol.

Muffler pressure to the fuel tank is not required.

·

Do not install your throttle servo or kill switch servo inside the engine compartment.

·

Doing so could cause radio interference. Install all electronic radio devices at least

305mm [12"] away from the engine. The throttle pushrod should be non-metallic.

If the engine is not to be used for more than a month, drain the fuel tank and

·

remove any fuel from inside the carburetor. Do this by running the engine at idle

until it quits by running out of fuel. Keeping gasoline inside the carburetor over

an extended period of time will damage the diaphragm valve and clog passages

inside the carburetor.

Because the carburetor is more complicated than those used in glow engines,

·

keep the fuel clean by using a fuel filter. Use a filter intended to be used with

gasoline engines. Metal filters intended for glow engines are too coarse and will

not screen out finer particles. Always filter your fuel by using an appropriate filter

before putting it into the airplane’s fuel tank.

If you intend to run this engine on an engine stand, or on any other rigid mount,

·

use rubber mounts. The crankcase and other parts of the engine may crack if

you do not provide some kind of vibration absorption mechanism. A rubber

mount is not necessary if the engine is mounted on a model airplane.

Do not operate the engine in a closed room or where ventilation is not adequate.

·

Gasoline is extremely flammable. Keep it away from an open flame, excessive

·

heat or sources of sparks. Do not smoke near the engine or the fuel tank.

This engine was designed for use in a model aircraft. Do not attempt to use it

·

for any other purpose.

Always install a kill switch that can be operated both manually and with the R/C

·

transmitter.

PARTS LIST

BT-32 EIS Engine w/Muffler

EIS Ignition Module

Propeller Flange with Propeller Washer

Propeller Bolt

Friction Ring

Right Engine Mount

Left Engine Mount

(4) 5 x 12mm SHCS with Lock

Washers and Flat Washers

(4) 5 x 22mm SHCS with Lock

Washers and Flat Washers

Spark Plug Wrench

4mm Allen Wrench

2

FEATURES

Automatic Ignition Timing: The BT-32EIS features an electronic ignition system

·

that advances the ignition timing as the engine rpm increases. This ensures a

delayed ignition timing at low rpm for easy starts and good low-end engine

performance, and advanced timing at high rpm for good high-end power.

The ignition module is waterproof and vibration proof.

·

The ignition module runs on any 4.8V battery. The current consumption is

·

approximately 188mAh.

An optional Digital Tachometer (FJIP9920) is available to monitor rpm and

·

ignition battery voltage.

SPARK PLUG

The recommended spark plug is a Champion RCJ-6Y or 7Y. To avoid improper

operation or possible engine damage, do not use any other type of spark plugs.

The plug gap should be 0.4mm to 0.6mm [0.016" to 0.024"]. If the plug gap is

incorrect, adjust it with a spark plug gapping tool, wash it with gasoline and allow

it to dry completely before you reinstall the plug in the engine.

Note: If you want to check if the spark plug works, remove the spark plug from

the engine, connect it to the coil and make sure the metallic threaded end of the

spark plug touches the engine. Spin the propeller rapidly through top dead center

and check for a spark. This procedure only works in a dark room as there is too

much light outside to see the spark.

The various spark plug manufacturers have much information on their web sites

regarding spark plug performance and health. For more information, check:

http://www.championsparkplugs.com/sparkplug411.asp

PROPELLER

Always use a well-balanced, high-quality propeller.

The recommended propellers are:

High Performance Wood Prop: 18" x 8"

16" x 12"

Carbon Prop: 18" x 10"

During our tests, our BT-32EIS turned a Bolly 18" x 10" carbon prop at 7700 rpm.

The Fuji-Imvac engine was new with 90 minutes of breaking in. The test conditions

were: Temperature 10°C [50°F], humidity 40%, elevation at sea level. Performance

may vary depending on atmospheric conditions.

3

OIL

Fuji-Imvac engines has developed a special oil, Super Lube Oil (FJIP9910 – 250cc),

to work with their engines. This oil is of extremely high quality and it has exceptional

lubricating properties. This oil can be mixed with gasoline at much higher ratios than

other engine oils which allows the engine to develop more horsepower and last longer.

It is recommended that you use Fuji-Imvac Engine oil with all your Fuji-Imvac engines.

Break-in procedures are slightly different than those when using standard oils. Please

refer to the table below for oil contents. Fuji-Imvac Oil is available from your Fuji-Imvac

distributor or hobby shop.

Break-in (Stage 1): 1 gallon of gasoline with 50:1 (2%) oil content.

·

Break-in (Stage 2): 1 gallon of gasoline with 100:1 (1%) oil content.

·

Normal running: In un-cowled or well-cooled installations 150:1 (0.65%) oil

·

content.

In-cowled or not-so-good cooling installations 100:1 (1%) oil content.

·

Do not try to use these engine oil ratios with any other brand of oil other than

·

the Fuji-Imvac oil.

Do not use the Fuji-Imvac oil with any other brand of engines.

·

If you have been running the engine on other oil and wish to switch to Fuji-Imvac

·

oil, follow the break-in procedure for Fuji-Imvac oil.

If Fuji-Imvac oil is not available, or if you prefer to use a different brand of oil, use

the standard fuel/oil ratios as shown below. Never experiment with cheap oil or

with obscure brand names. Be certain to select only high-quality oil that is

intended for use in gasoline R/C model airplane engines.

Break-in: 1 gallon of gasoline with 25:1 (4%) oil content.

·

Normal running: 40:1 (2.5%) oil content.

·

PREPARE THE ENGINE

1. Check to see that all screws and bolts are tight. Check carefully for any cracks,

broken or missing parts. Tighten or replace before proceeding.

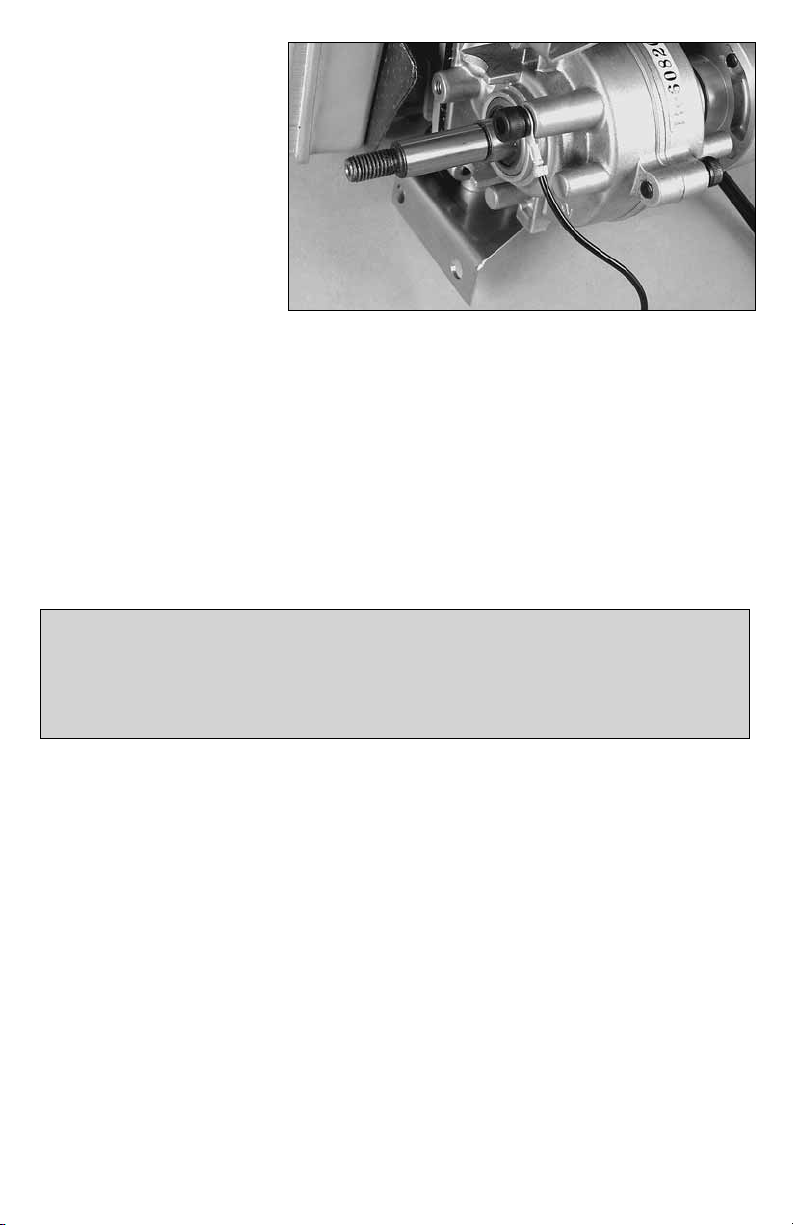

2. Install the prop shaft on the flywheel using three

5 x 22mm [3/16" x 7/8"] SHCS with lock washers

and flat washers. Use threadlocking compound on

the screws.

3. Install the engine mounts on the engine using four

5 x 12mm [3/16" x 15/32"] SHCS.

4

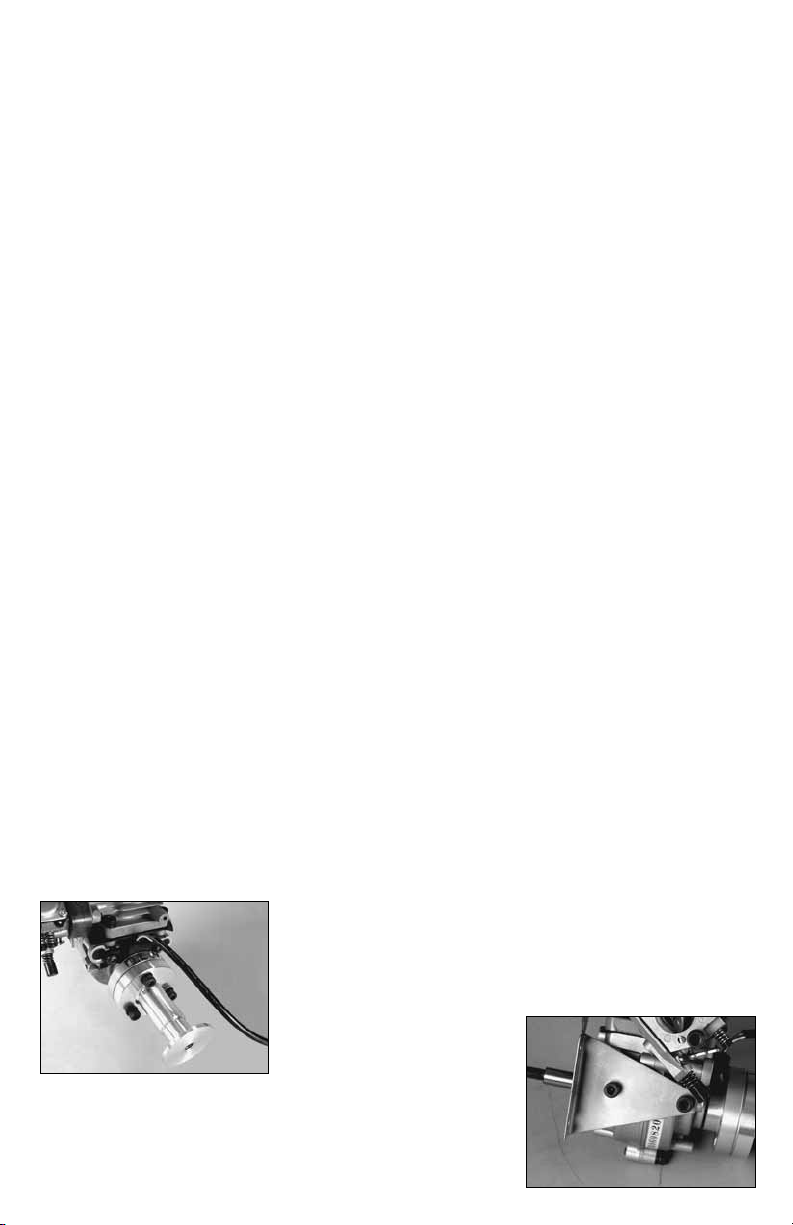

4. Secure the ignition

control module ground

wire to the engine using

one of the 5 x 22mm

[3/16" x 7/8"] SHCS.

5. Connect the ignition control module to the pick up sensor. The connector is

polarized and will only plug in one way.

6. Connect a kill switch to the ignition control module. It is recommended to

install a manual switch and a servo operated switch. This can be accomplished

using two receiver On/Off switches.

7. Connect the ignition module battery. Any 4.8V, 500mAh and above battery will

work well for this. The approximate current consumption of the ignition switch

module is 188mAh.

INSTALLING THE FUJI-IMVAC BT-32EIS ON YOUR AIRPLANE

Note: The Fuji-Imvac BT-32EIS must be installed on a 9mm [3/8"] lite-ply firewall or

on a 6.4mm [1/4"] birch ply firewall. The firewall must be securely glued to the

airplane. Use triangle stock and pin the firewall with hardwood dowels to reinforce

the firewall glue joints. Never install the Fuji-Imvac BT-32EIS onto a firewall thinner

than specified because it may fail due to the power of the engine.

Note: The length of the engine from the back on the engine mount to the propeller

washer is 166mm [6.5"] when using the stock (62.5mm [2.46"]) prop flange.

1. Use the supplied mounting template (on the back cover of this manual) to drill the

engine mounting bolt holes and the necessary clearance hole on the firewall.

2. Install the engine on the firewall using four 6.4 x 19mm or [10-24" x 3/4"] socket

head cap screws, four #10 flat or lock washers and four #10 blind nuts. Use

some threadlocking compound, such as Great Planes® Pro™ Threadlocker.

3. Install a manual and radio operated kill switch (GPMG2150). Install a kill switch

servo at least 305mm [12"] away from the engine.

4. Install the throttle servo at least 305mm [12"] away from the engine. Make sure

that you get the carburetor’s full range of rotation with your servo travel.

5. Install the ignition module securely in the airplane forward area. It is

recommended that a thin piece of foam rubber be placed between the module

and the mounting surface and that rubber bands are used to hold the module

in place. 4mm [5/32"] screws and washers can also be used to secure it in

place, but soft mounting the module is always the best choice.

6. Secure all connections with shrink tubing.

5

Loading...

Loading...