FujiFilm 800, 1000, Color 800, Color 1000 Specifications

Xerox® Color

Xerox® Color

800/1000 Presses

800/1000 Presses

Overview

Overview

Xerox® Color 800/1000 Presses

High definition image quality.

Fast. Vibrant. Flexible.

Digitally mastered for fine-tuned

image quality.

Xerox® Color 800/1000 Presses deliver sharp, rich, digitally mastered image

quality. Utilizing Xerox

technology, Xerox

®

can produce vibrant images with smooth sweeps that command—and hold—attention.

Running all weights at rated speeds of 80 or 100 ppm, Xerox

deliver one of the widest ranges of media handling, from a lightweight 55 gsm to a

hefty 350 gsm.

Drive more jobs through your shop. Reduce costs. Our Automated Color Quality

Suite of tools for the Xerox

®

low melt, Emulsion Aggregation (EA) Dry Ink and new fusing

Color 800/1000 Presses bring you an even wider color gamut that

®

Color 800/1000 Presses

®

Color 800/1000 Presses make it possible. These tools

are designed to expand your printing capabilities and to enhance your efficiency and

productivity. Our optional clear dry ink station, for example, enables you to apply spot

or flood creative effects that bring your prints to life. And with flexible workflow, feeding

and finishing, the Xerox

®

800/1000 Presses will suit your environment now, and as your

business volumes grow.

2

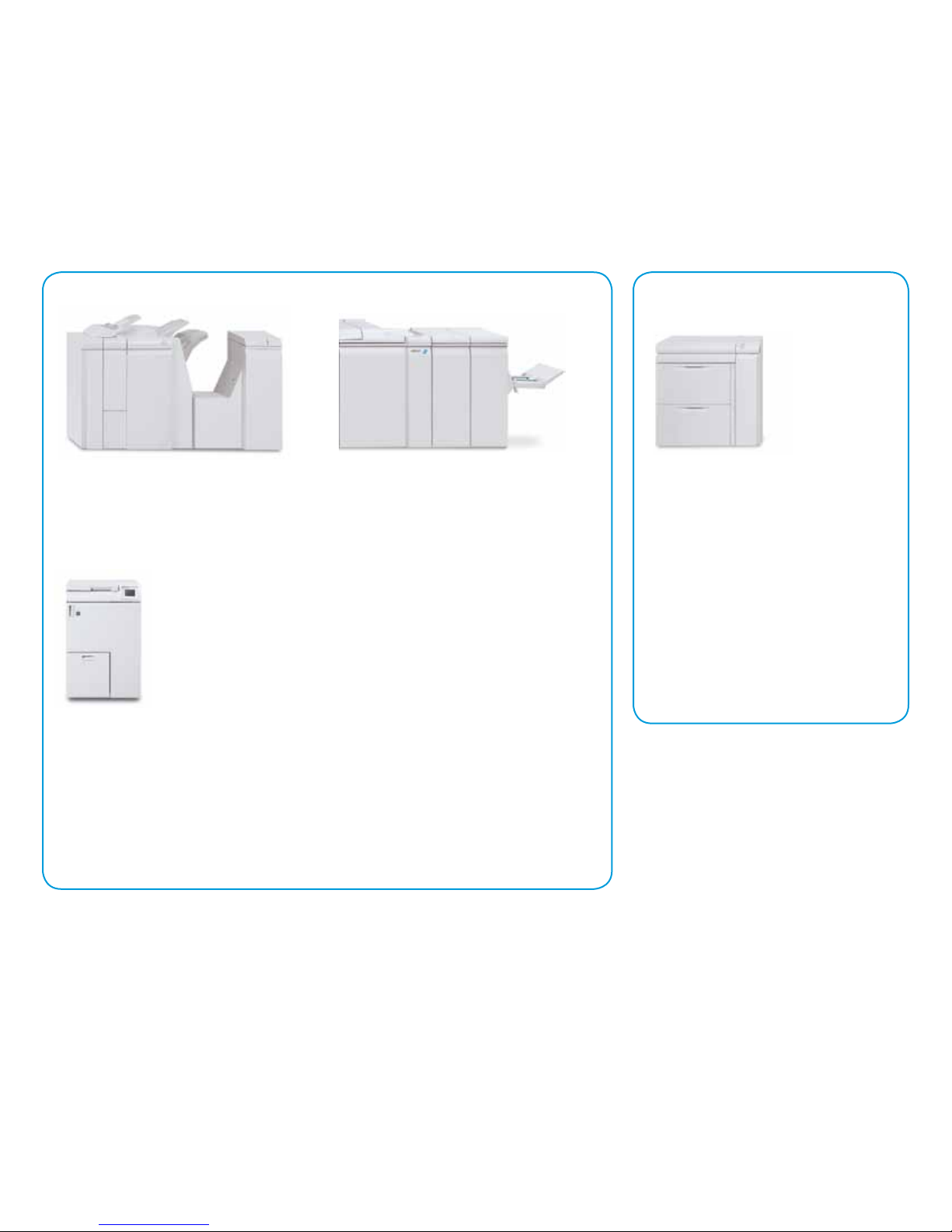

Additional Finishing Options

Feeding Option

Standard Finisher Plus

Includes Standard Finisher features with

Optional C-Z Folder plus DFA (Document

Finishing Architecture) required to support

additional finishing options.

GBC® eBinder 200™

Produce full 360˚, “lay flat” booklets easily

and quickly. You’ll have stack, punch and

bind functionality, all in one inline device.

Bind books of two to 100 sheets. Durable,

self-adjusting polyester bind elements let

you create professional flip presentations

and calendars as well.

PlockMatic Pro 30 Booklet Maker

(several options available including

SquareFold

Trimmer and Bleed Trim Unit)

Produce larger professional-quality

booklets—up to 30 sheets—while running

at full rated speed for top productivity.

Add optional SquareFold module to

further enhance finish. Great for offline

use as well.

®

, Cover Feeder, Face

Oversized High Capacity Feeder

Provides an additional two 2,000 sheet

tray modules that you can add to

extend your paper capacities for a

total of 8,000 sheets and four pick

points to accommodate various stocks.

Includes convenient insertion tray that

allows you to handle smaller sheets

(4” x 6”/102 mm x 152 mm)—ideal

for specialty card applications.

Auto-Tray Switching and reloadwhile-run capabilities help optimize

your productivity.

15

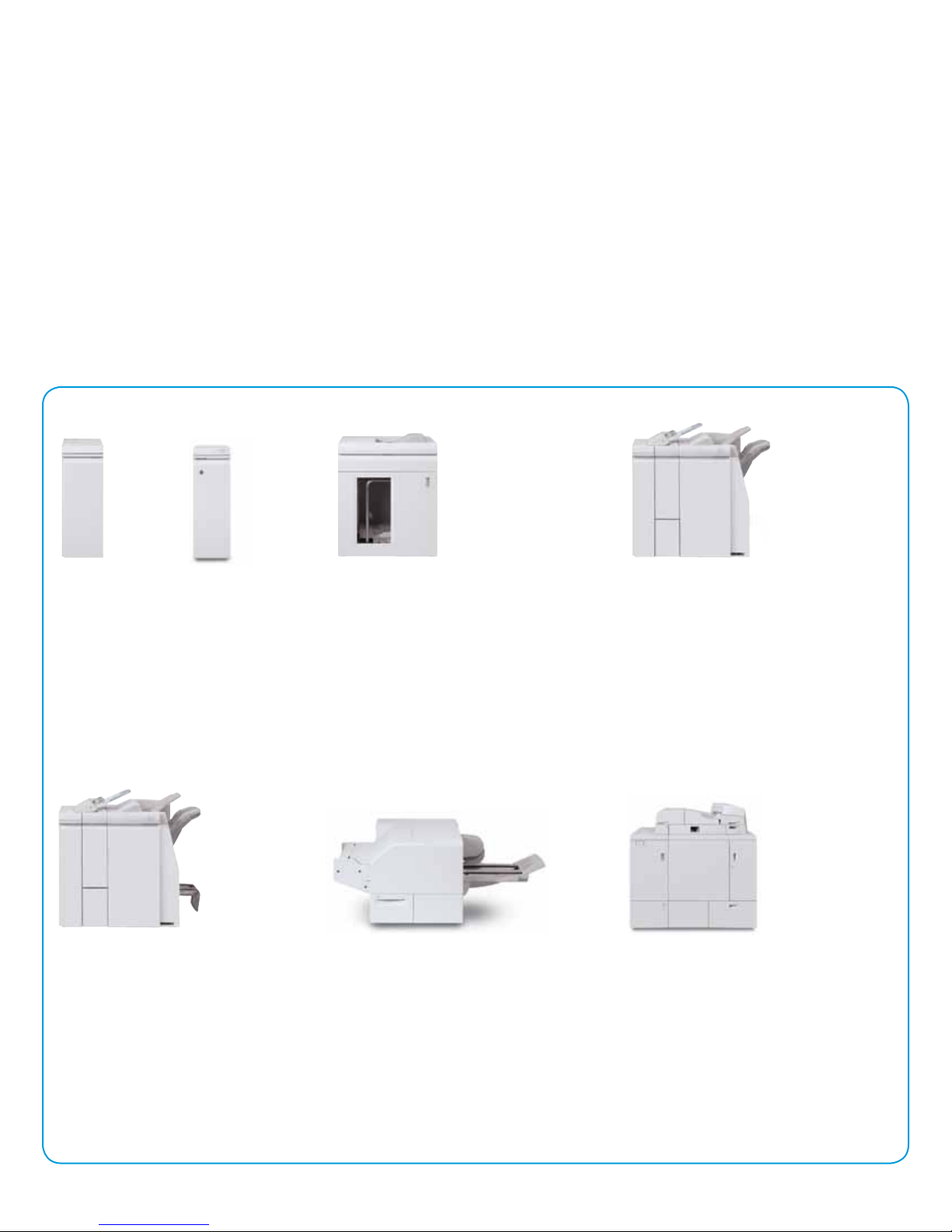

Finishing Options

From high capacity stacking, hole punching and folding to perfect-bound books,

square fold booklets and lay-flats, our array of finishing options add polish to all

your applications.

Finishing Options

Interface Module (required to support

finishing modules) [Left]

GBC® AdvancedPunch™ [Right]

Create professionally bound documents

in-house by combining printing, punching

and collating in one convenient step. Ideal

for punched applications such as manuals,

guides and planners.

Booklet Maker Finisher with Optional C-Z

Folder (25 sheets or 100 page booklets)

Incorporating all of the features of the

Standard Finisher, plus booklet-making

capabilities. Ideal for large booklets and

calendars, up to 25 sheets with 100 imposed

pages, 100 imaged sides. Excellent handling

of approved coated stocks along with

saddle-stitch and bi-fold capabilities.

High Capacity Stacker (Single or Dual) up

to 5,000 Sheet Removable Cart (Top Tray

500 Sheets)

Your choice for long production runs,

removable carts make it easy to unload your

large jobs. Dual stackers support unloadwhile-run capability so you can be even

more productive.

Xerox® SquareFold® Trimmer Attaches

to the optional Booklet Maker Finisher

Enhance your professional finishing even

further with creased cover sheets, face

trimming and control of trim and square

fold thickness. Create crisp, sharp square

spine booklets that can be opened flat and

are easy to handle, stack and store.

Standard Finisher with Optional C-Z

Folder (2-100 sheets, 3-position variable

length stapler)

Enhance your standard finishing

applications with convenience and

flexibility. Variable length stapling for up to

100 sheets delivers neat output, regardless

of your document size. Hole-punching saves

time and money, while the optional folder

enables you to create applications featuring

bi-fold, C-, Z- and Engineering Z-folding.

®

Xerox

Perfect Binder*

Say “yes” to more applications—novelty

books, manuals, textbooks, course books,

magazines, catalogs, trade books and

selected photo books and yearbooks. Use

inline or offline, you’ll have big capabilities

in a small footprint. You can use mixed

media to create these higher-value books,

inserting pre-printed covers or covers

printed in your workflow.

*Available post-launch.

14

Image quality so outstanding,

you won’t want to look away

Our Xerox® “low melt” EA (Emulsion

Aggregation) Dry Ink technology uses no

fuser oil, giving all your applications a smooth

offset like finish. Chemically grown, its small,

consistent particles produce great quality

with less EA dry ink, for smooth transitions.

The unique properties of EA Dry Ink are also

environmentally friendly.

Advanced Xerox

technology with closed loop process controls

enable vivid and consistent color rendition.

®

Xerox

Color 800/1000 Presses print at

2400 x 2400 dpi for excellent sharpness

and uniformity. They deliver outstanding

midtones, crisp text, pure neutrals, detailed

shadows, bright highlights and excellent

photo rendering, perfect for today’s hot

specialty photo applications. And Xerox

Color 800/1000 Presses maintain benchmark

color consistency, from page to page and job

to job.

®

color management

®

Productivity and efficiency

to the max

We’ve listened to our customers and

leveraged our experience and heritage in

the production print industry to develop this

newest member of our family. Expanding on

our proven success, we’ve packed design and

technology innovations into the Xerox

800/1000 Presses, making them the image

quality and productivity powerhouses that

fit your production schedules as well as your

workspace. For instance:

• Advancedimagingtechnologywithlonglife

photo receptors and dual wire, auto-cleaning

corotrons lasts longer and provides more

uniform print quality.

• TheseamlessIntermediateBeltTransfer

(IBT) provides even greater versatility, speed

and reliability.

• Tightfront-to-backregistrationwithin+/-0.5

mm with electronic controls and sensors that

automatically adjust to sheet conditions.

• Highlyprocientbeltfusertechnology

efficiently transfers energy and supports

wide media latitude to deliver smooth, crisp,

clean output at production print speeds.

®

Color

• Oursingle-passdecurlerintegratesboth

belt and roll technologies for optimal sheet

flatness, while the advanced inline cooling

module ensures outstanding stack quality.

Automated Color Quality Suite

(ACQS)

You can also opt for our Full Width Array

technology, which delivers the Automated

Color Quality Suite (ACQS), a set of color

management tools unique to our entire

portfolio of digital color production presses.

These productive tools automate timeconsuming daily tasks so color-critical jobs can

be completed faster. Routine tasks such as

color calibration and profiling become simple

and quick for your operators.

In addition to those color management

tools, Full Width Array also delivers

Image-to-Media Alignment, allowing

an operator to automatically adjust for

front-to-back registration, perpendicularity,

skew and magnification. You can create and

store custom paper and alignment profiles

for paper stocks to ensure proper alignment.

Delivering outstanding

midtones, crisp text, pure

neutrals, detailed shadows,

bright highlights and excellent

®

photo rendering, the Xerox

Color 800/1000 Presses

are perfect for today’s hot

specialty photo applications.

3

Loading...

Loading...