Page 1

Instruction Manual

FUZZY

CONTROLLER X

Type: PYX

PV

SV

SEL

OUT1

OUT2

ALM1

ALM2

INP-TN1PYXf-E

Page 2

Contents

I. PREPARING THE OPERATION ............................... 4

1. THE BASIC INSTALLATION PROCEDURE .................... 5

2. CHECK OF SPECIFICATIONS ........................................ 6

2.1 PYX4 MODEL CONFIGURATION ........................... 6

2.2 PYX5/9 MODEL CONFIGURATION ........................ 7

3. ACCESSORIES................................................................ 8

4. INSTALLATION ................................................................ 8

4.1 INSTALLATION PLACE ........................................... 8

4.2 INSTALLATION PROCEDURE ................................ 9

4.3 CAUTION ON SAFETY ............................................ 10

4.4 PANEL CUT DIMENSIONS ..................................... 18

5. WIRING ............................................................................ 19

5.1 PYX4 WIRING DIAGRAM

[When the output 1 is relay (SPST) output,

SSR drive output or current output].......................... 19

5.2 PYX4 WIRING DIAGRAM

[When the output 1 is relay (SPDT) output].............. 21

5.3 PYX5/9 WIRING DIAGRAM

(NOT UNIVERSAL OUTPUT) .................................. 23

5.4 PYX5/9 WIRING DIAGRAM

(UNIVERSAL OUTPUT) ........................................... 26

5.5 NOTES ..................................................................... 28

II. FRONT PANEL LAYOUT .......................................... 30

1

Page 3

III. OPERATION PROCEDURE ...................................... 33

1. OPERATION MODE/PARAMETER SETTING MODE ..... 33

2. VIEWING PARAMETERS ................................................ 33

3. CHANGING PARAMETERS............................................. 35

IV.SETTING INPUT AND OUTPUT TYPES .................. 37

Changing input ............................................................................. 37

Changing scale (voltage/current input) ......................................... 41

Changing output (universal output) .............................................. 42

V. FUNCTIONS .............................................................. 44

Lock .............................................................................................. 44

Auto-tuning ................................................................................... 47

Control function ............................................................................ 51

Alarm ............................................................................................ 55

Ramp soak ................................................................................... 60

Two set-points .............................................................................. 64

Analog output (AO) ....................................................................... 65

Digital output................................................................................. 67

Manual operation .......................................................................... 69

Remote SV ................................................................................... 71

Output monitoring ......................................................................... 72

VI.SET-UP PARAMETER .............................................. 73

Input filter ...................................................................................... 73

PV shift ......................................................................................... 74

Control type .................................................................................. 75

Output setting in input abnormal................................................... 76

Output limits.................................................................................. 77

Set point value limits..................................................................... 78

Output cycle time .......................................................................... 79

Direct/reverse control action......................................................... 81

2

Page 4

Control processing cycle time....................................................... 82

APPENDIX...................................................................... 83

1. ERROR MESSAGES........................................................ 83

2. POWER FAILURE ............................................................ 83

3. SPECIFICATIONS............................................................ 84

4. TROUBLESHOOTING...................................................... 89

5. PARAMETER LIST........................................................... 91

3

Page 5

I. PREPARING THE OPERATION

We thank you for the purchase of this PYX (Fuzzy Temperature

Controller).

Employing FUZZY LOGIC the PYX virtually eliminates system overshoot

and effectively suppresses fluctuation of the process variable due to

external disturbances.

Please read this manual, when programed and operated within the

guidelines setforth in this manual, your PYX controller will give you years of

precise, reliable control.

PYX

The product conforms to the requirements of the Electromagnetic compatibility Directive 89/336/EEC as detailed within the

technical construction file number TN510401. The applicable

standards used to demonstrate compliance are :

EN50081-1 : 1992 Conducted and Radiated emissions

EN50082-1 : 1992 Radiated immunity, ESD and FBT

(The unit meets Class A limits for Conducted Emissions.)

The unit also complies with the part of Immunity standards.

IEC1000-4-2 : 1995 level 3, IEC1000-4-3 : 1995 level 3

IEC1000-4-4 : 1995 level 3, IEC1000-4-8 : 1993 level 4

* E.U. indicates Engineering Units.

4

Page 6

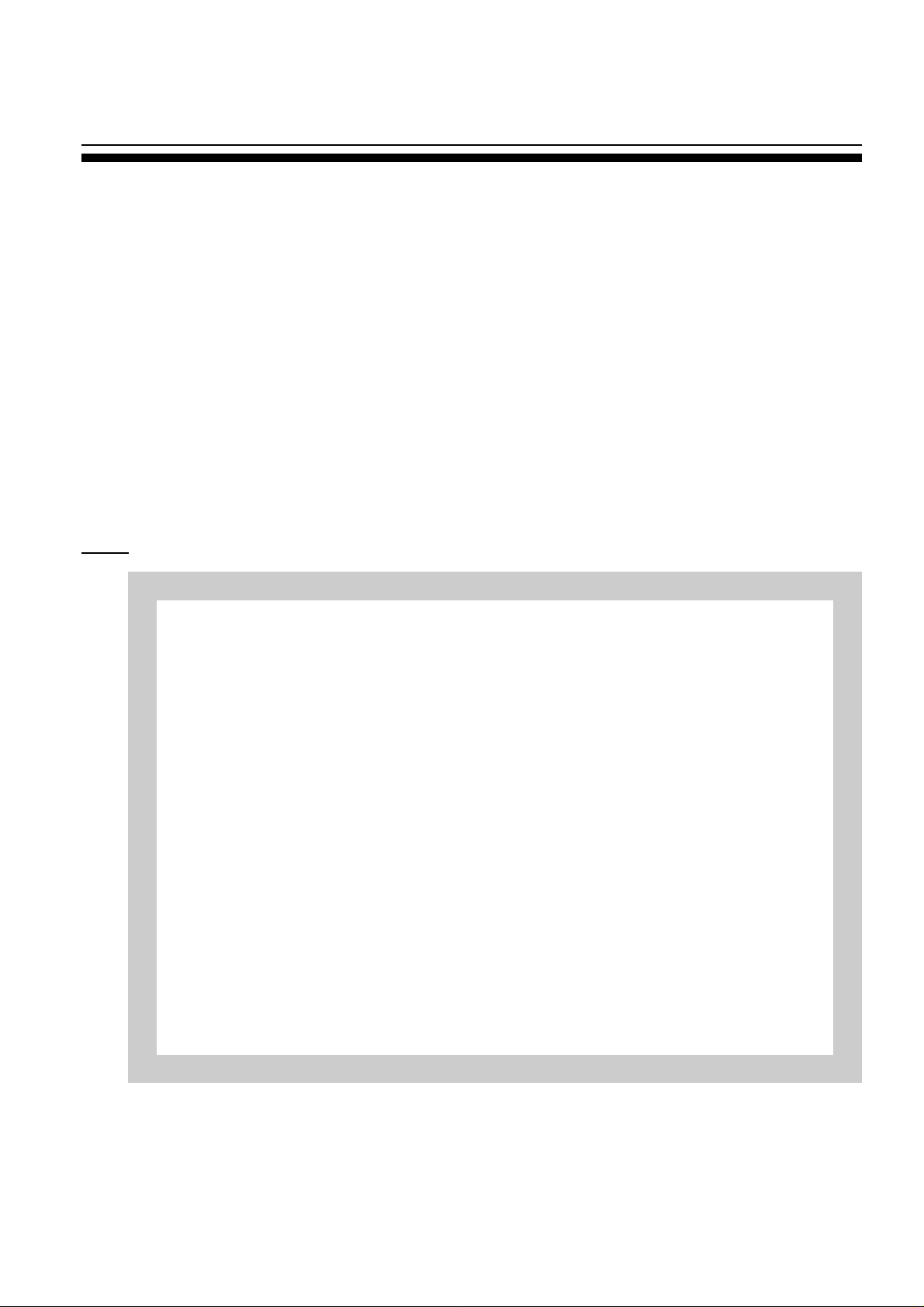

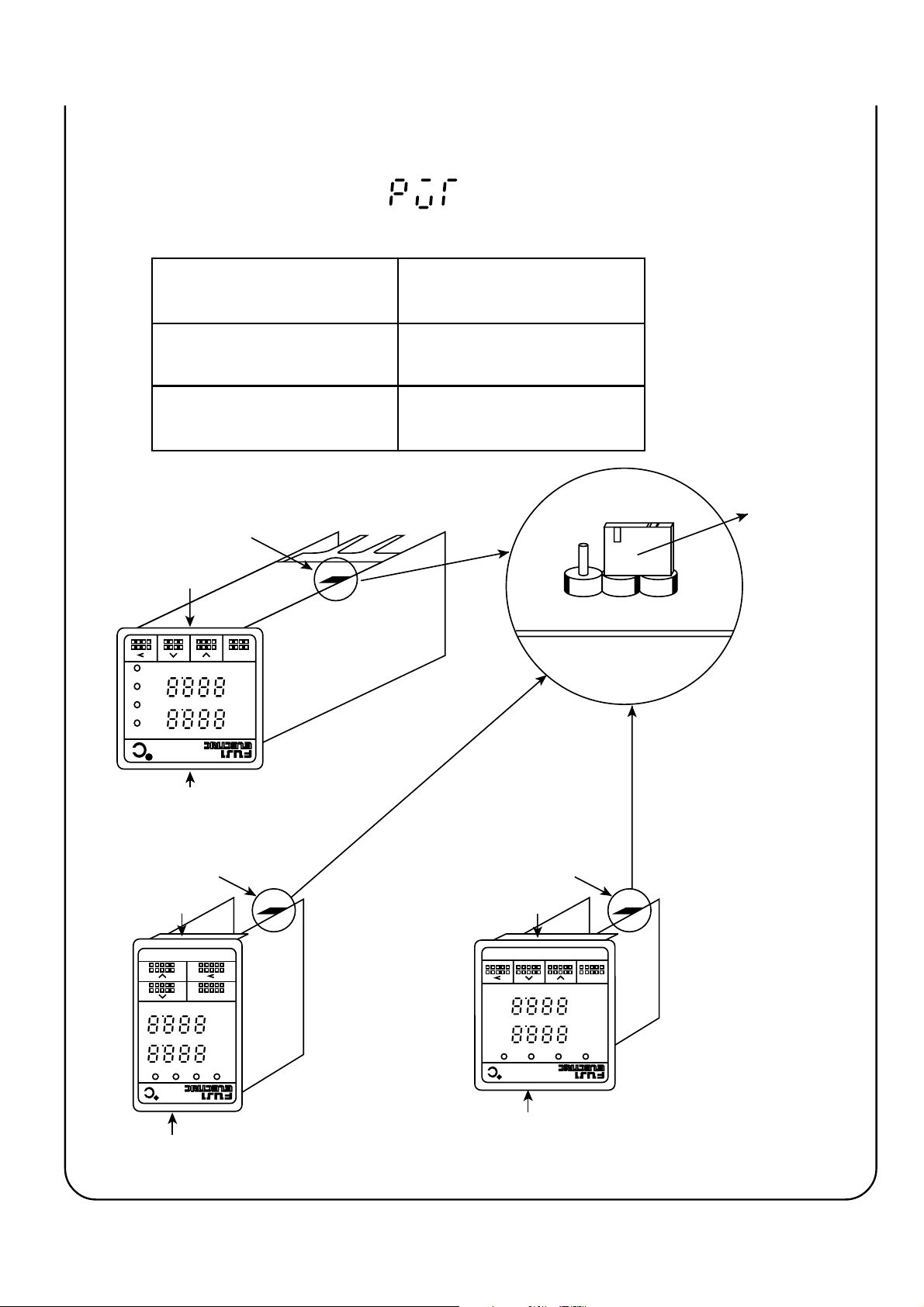

1. THE BASIC INSTALLATION PROCEDURE

Is given here as to the basic flow from the installation to operate the PYX.

For detailed description of each step, see the pages correspondent. See

the section “Operation Procedure” on the pages 33 to 36 for calls and

changes the specific parameter.

Installation of

Main Unit

Connection

Selecting Input

and Output Types

Selecting PID

or Fuzzy

Install the main unit on the panel, using the attached panel

mounting bracket. (See page 8 to 18 for details.)

Connect the unit to power supply and input and output

devices. (See page 19 to 29 for details)

Power up, then select and check input types (such as types

of sensors), input temperature range, decimal point used or

not used and so on. In case of the universal output type,

set and check the output switch pins inside the main unit.

(See page 37 to 43 for details.)

Either the conventional PID control mode or the fuzzy

control mode, which is effective in minimizing overshoot

rate and outer condition effects, can be selected. Select by

setting the parameter , where the default set is PID.

(See page 75 for details.)

Tuning

Ready

Normal

Operation

System power up then, execute auto-tuning to define the

control parameters. (See page 47 to 50 for details.)

Basic preparations are completed. Carry on settings for the

optional functions (alarm, two set points, transmission,

ramp soak, analog output etc.), following this instruction.

See page 44, as setting values (SV) can be set in the same

manner as the Lock parameter on page 44.

5

Page 7

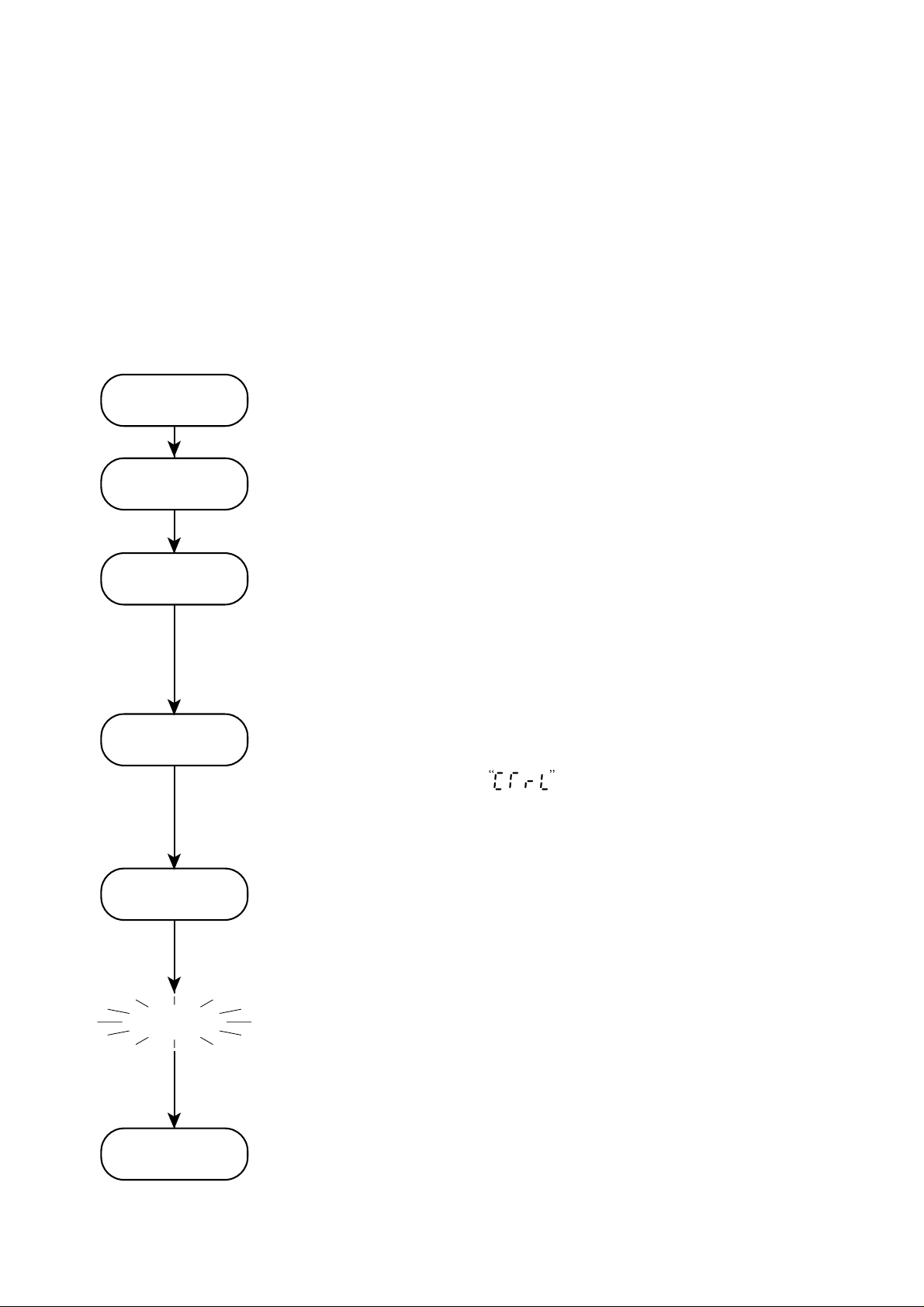

2. CHECK OF SPECIFICATIONS

Please make sure that specifications of this product is according with

your request. The product specifications are provided on the main unit

as model configuration following.

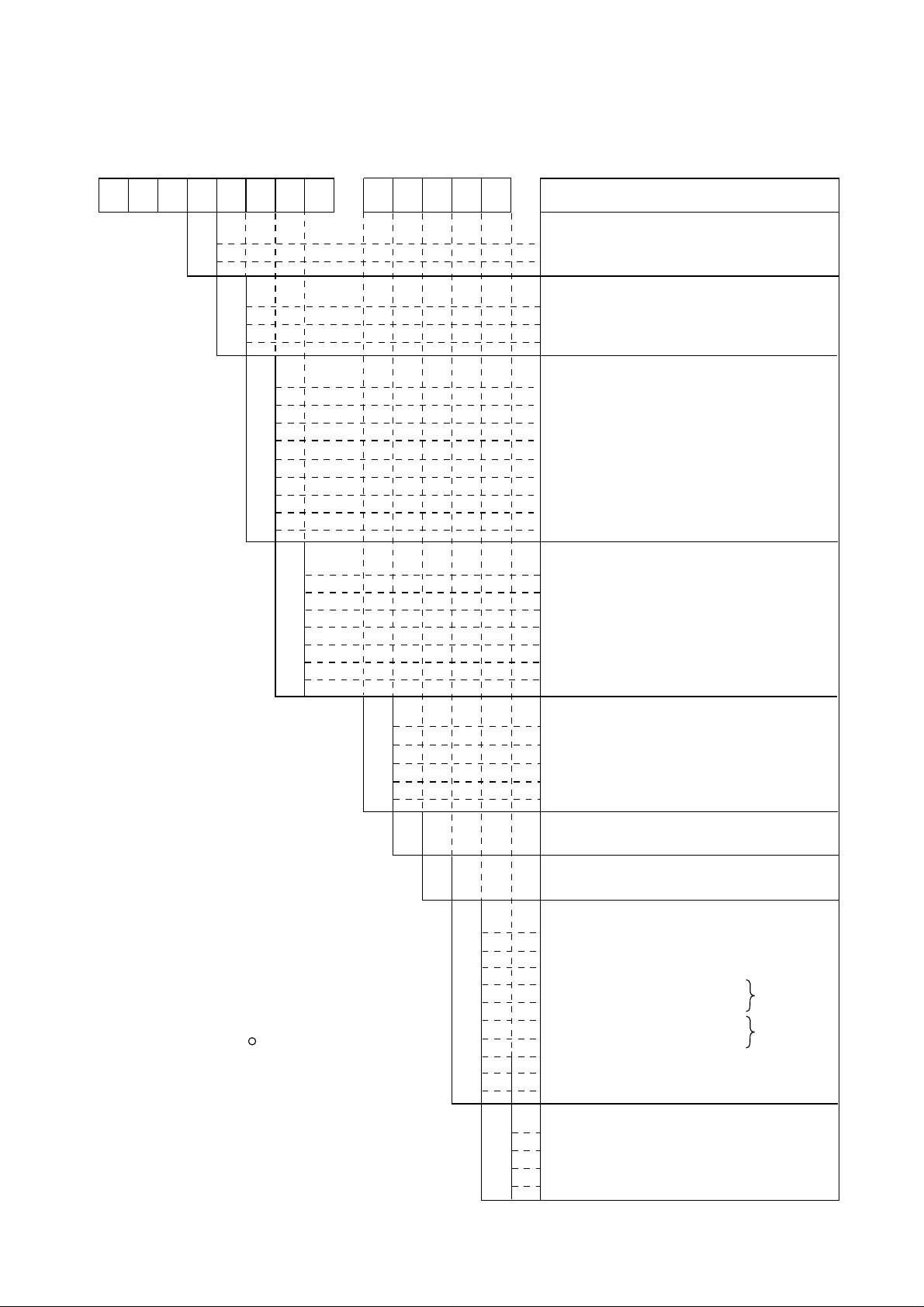

2.1 PYX4 MODEL CONFIGURATION

12345678 910111213

PYX

4 1-

T

A

M

Y

A

B

C

D

E

F

G

H

Y

A

B

C

D

0

1

2

3

4

*

Note 1: Fuji Electric CC data line protocol

Note 2: Modbus RTU protocol

R

Contents

Input type

TC/PT input

Voltage/Current input

TC/PT/Voltage/Current multi input

Control output1

Without

Relay (SPST) rev. act.

Relay (SPST) dir. act.

SSR drive rev. act.

SSR drive dir. act.

Current (DC 4~20mA) rev. act.

Current (DC 4~20mA) dir. act.

Relay (SPDT) rev. act.

Relay (SPDT) dir. act.

Control output2

Without

Relay (SPST) rev. act.

Relay (SPST) dir. act.

SSR drive rev. act.

SSR dirve dir. act.

Alarm function

Without

1pt.

2pts.

HB alarm

HB alarm + 1pt.

Input type code

See Page 21.

Input range code

*

Y

P

Q

R

S

M

N

A

B

C

J

E

F

K

See Page 21.

Additional function

Without

2 set points

4 ramp soak with start/reset

RS-485 transmission

RS-485 transmission

RS-485 transmission

RS-485 transmission + 4 ramp soak

Auxiliary analog output

Auxiliary analog output + 4 ramp soak

Remote SV

Front panel

Japanese

English (

°

C)

English (

°

F)

English (%)

+ 4 ramp soak

Note 1

Note 2

6

Page 8

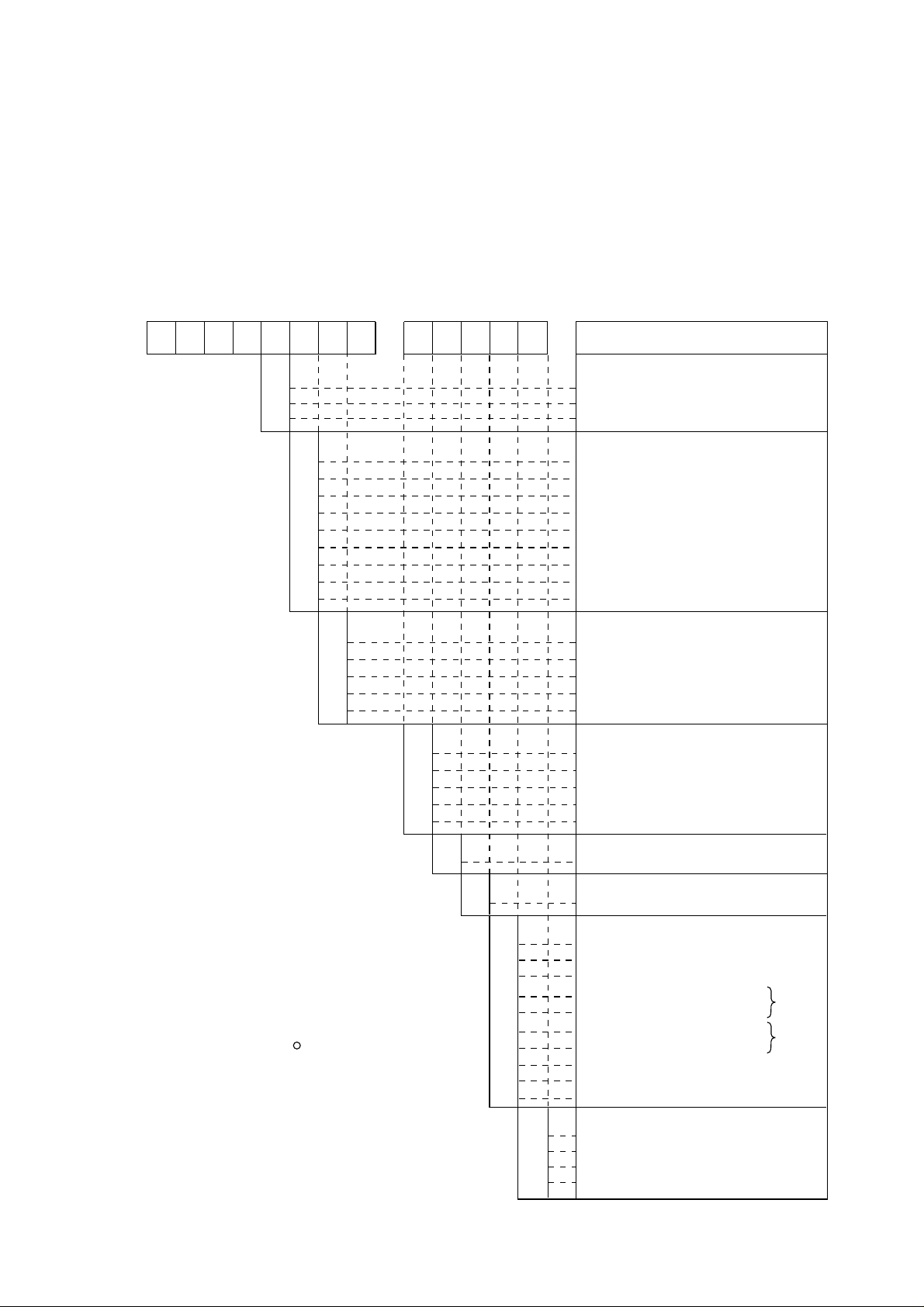

2.2 PYX5/9 MODEL CONFIGURATION

12345678 910111213

PYX

5

9

M

1-

Front panel dimensions:

48×96 mm

96×96 mm

Input type

T

A

Y

C

D

E

F

G

H

J

K

Y

C

D

E

F

G

H

0

1

2

3

4

TC/Pt input

Voltage/Current input

TC/Pt/Voltage/Current multi-input

Control output 1

Without

SSR/SSC drive rev. act.

SSR/SSC drive dir. act.

Current (DC4-20mA) rev. act.

Current (DC4-20mA) dir. act.

Relay rev. act. (SPDT)

Relay dir. act. (SPDT)

Universal output rev. act.

Universal output dir. act.

Control output 2

Without

SSR drive rev. act.

SSR drive dir. act.

Current (DC4-20mA) rev. act.

Current (DC4-20mA) dir. act.

Relay rev. act. (SPDT)

Relay rev. dir. (SPDT)

Alarm function

Without

1pt.

2pts.

HB alarm

HB alarm + 1pt.

Contents

*

*

Y

P

Q

R

S

Note 1: Fuji Electric CC data line protocol

Note 2: Modbus RTU protocol

R

M

N

A

B

C

7

Input type code

See Page 21.

Input range code

See Page 21.

Additional functions

Without

2 set points

4 ramp soak with start/reset

RS-485 transmission

RS-485 transmission + 4 ramp soak

RS-485 transmission

RS-485 transmission + 4 ramp soak

Auxiliary analog output

Auxiliary analog output + 4 ramp soak

Remote SV

Front panel

J

E

F

K

Japanese

English (

English (°F)

English (%)

°

C)

Note 1

Note 2

Page 9

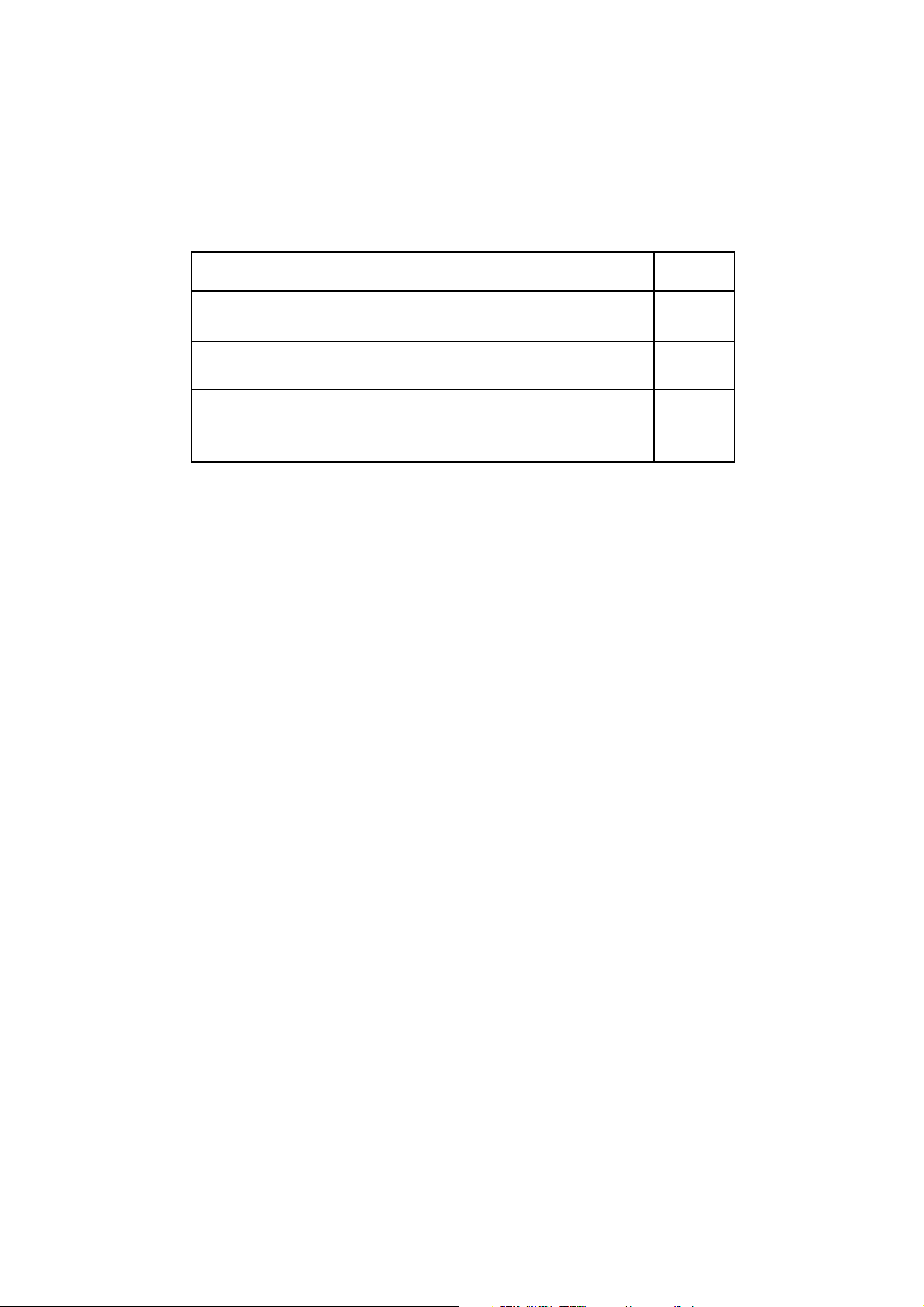

3. ACCESSORIES

In addition to the main unit, the following accessories are shipping in

the same package.

Accessories Quat.

Instruction manual (this manual) (INP-TN1PYX-E)

Panel mounting bracket set

Current input resistance (250Ω)

* Not delivered for TC/PT input type

* Suffix means revision control

4. INSTALLATION

4.1 INSTALLATION PLACE

Please verify if where the controller is mounted there is no:

(1) splash of water,

(2) mechanical vibration,

1

1

1

(3) extreme temperature

(4) no corrosive gases,

(5) dust or oil smoke,

(6) electric noise.

8

Page 10

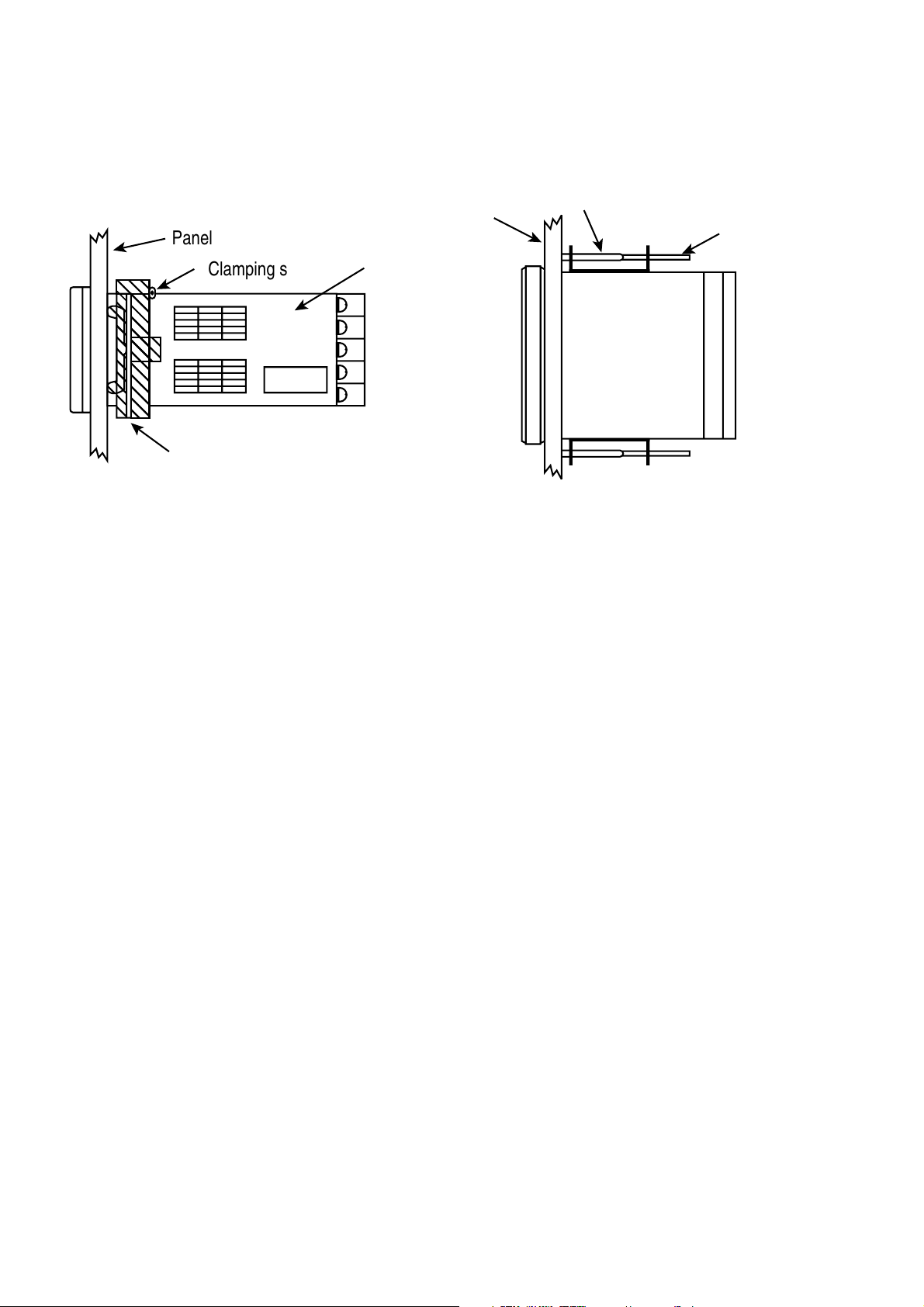

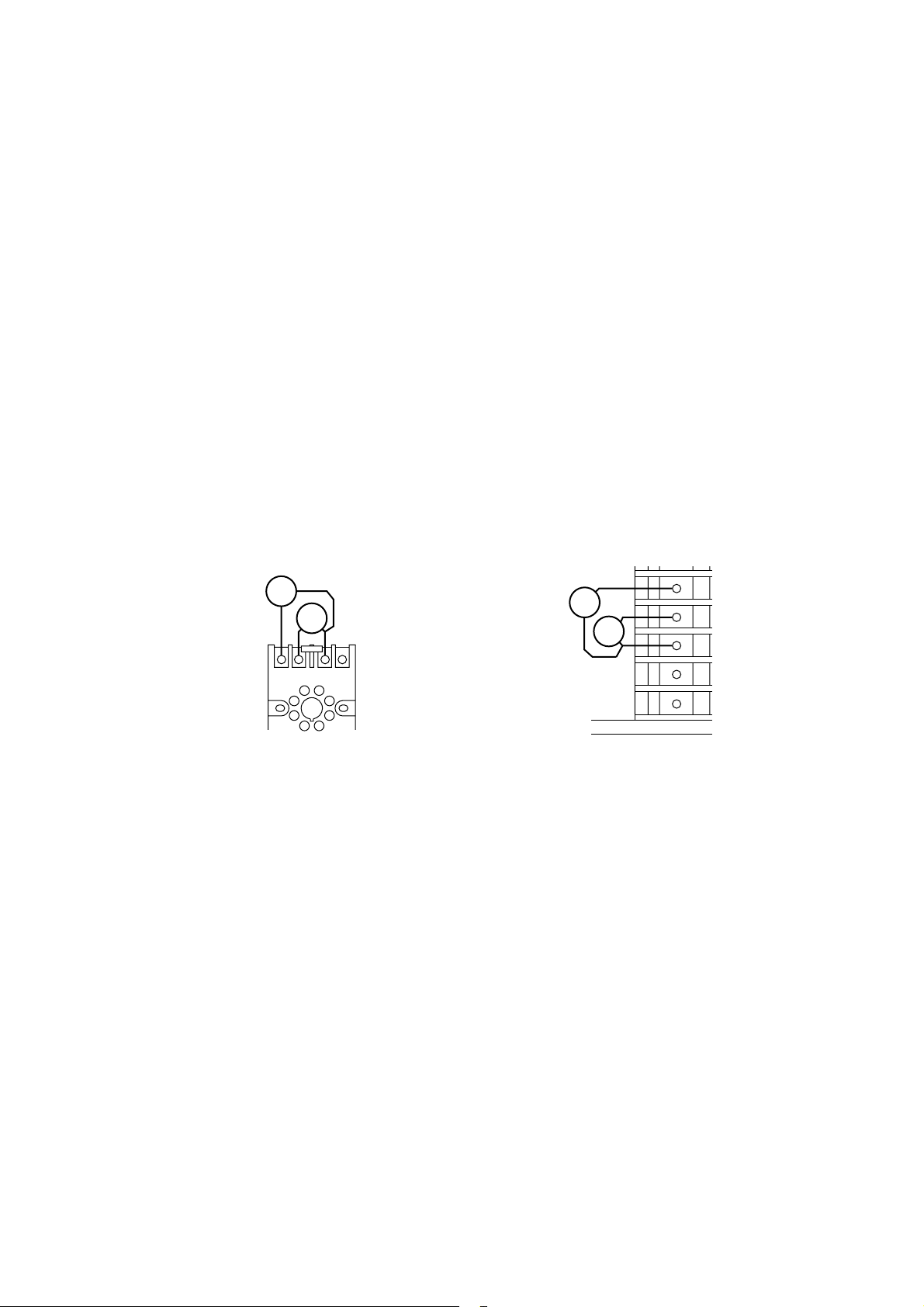

4.2 INSTALLATION PROCEDURE

;

Panel mounting bracket (accessorie)

Panel

Panel

Clamping screw Main unit

Panel mounting bracket (accessorie)

Clamping screw

For PYX4

For PYX5/9

• For PYX4

Slide the enclosed plastic panel mounting bracket (shipped with

every PYX4) up the back of the controller until it makes contact

with the back of the panel. Push the mounting bracket until the

tabs seat themselves in the molded tab ridges, located on the

front of the controller’s outer case. Tighten the two screw on the

mounting bracket for added pressure; do not use excessive

force.

• For PYX5/9

The mounting bracket’s tabs fit into the two holes on both the top

and bottom of the controller’s outer case. With an instrument

screwdriver, turn the screw in the mounting bracket until the end

of it touches the back of the panel. Do this to both brackets.

Making sure that the face of the controller is flush and straight,

tighten both mounting bracket screws. Your controller should

now be firmly set. If the controller is still loose, tighten the

mounting bracket screw a little more. Do not use excessive

force.

9

Page 11

4.3 CAUTION ON SAFETY

First of all, read this "Caution on Safety" carefully,

and then use the instrument in the correct way.

The cautionary descriptions listed here contain important information about

safety, so they should always be observed. Those safety precautions are

classified in 2 ranks, WARNING and CAUTION.

The following shows the meaning of WARNING and CAUTION.

Wrong handling may cause a dangerous situation,

WARNING

CAUTION

1. WARNING

1.1 Caution on wiring

1) For the safe operation of the controller, where the temperature probe is to

be installed into an environment where voltage exceed 50VDC, it is essential that reinforced isolation or basic isolation and earth the maintained between all connections to the rear of the temperature controller, and that

supplementary isolation is required for the alarm outputs.

in which there is a possibility of death or heavy

injury.

Wrong handling may cause a dangerous situation,

in which there is a possibility of injury or physical

damage.

The outputs from the controller are all less than 50VDC.

When wiring the power supply terminal, use vinyl insulated 600 volt cable

or equivalent. A switch breaking both poles of the mains supply should be

installed together with a fuse with a rating of 250 volt 1 Amp. The fuse

should be installed between the mains switch and the controller.

The level of insulation provided by the temperature controller is:-

MAIN = BASIC

HEATER = BASIC

INPUTS = BASIC

10

Page 12

Prior to operation of the installed system the wiring should be checked to

ensure that the required levels of insulation have been provided.

2) When a fault in the instrument is likely to lead to a serious trouble, use a

suitable protective circuit on the outside for protection against trouble.

3) This unit is not provided with power switch, fuse, etc. These parts can be

installed separately, if required (fuse rating; 250V, 1A).

4) Use of Fuji's Z-Trap is recommended to protect the relay output from switching surge and to ensure a long life.

Type: ENC241D - 05A (power voltage; 100V)

ENC471D - 05A (power voltage; 200V)

Mounting position: Connected to relay control output terminals

ex) PYZ4

Socket (ATX2PSB)

65 43

1.2 Operating condition

Operating temperature : -10 to 50°C

Operating humidity : 90%RH or less (non condensing)

Installation category :

Pollution degree : 2

PYZ9

5

6

7

8

9

Ⅱ

1.3 Power source

1) Use a power source of rated voltage to prevent damage or trouble.

2) Do not turn ON the power until the wiring is completed to prevent shock

hazard or trouble.

11

Page 13

1.4 Prohibition of use in gas

The instrument is not an intrinsic safety explosion - proof type. Do not use

it in a place exposed to combustible or explosive gas.

1.5 Contact to unit

1) This unit must not be disassembled, modified or repaired to prevent malfunction, shock hazard or fire accident.

2) When the power is ON, do not touch the terminals to prevent shock hazard

or malfunction.

1.6 Caution on maintenance

1) Before mounting or removing the module or unit, turn OFF the power in

advance to prevent shock hazard, malfunction or trouble.

2) Periodical maintenance is recommended to ensure continuous and safe

operation of the instrument. Some parts of the instrument are limited in life

or are subject to secular change.

WARNING

It is essential that, when the controller is introduced into a system

which uses or generates a hazardous voltage, the minimum creepage

and clearances specified in the table below are maintained on the

temperature probe. A hazardous voltage is one that exceeds 42.4V

peak AC or 60V DC. If you have any doubt, seek advice from a

competent engineer before installing the controller into the host

equipment.

The equipment must be installed such that with the exception of the

connection to the mains, creepage and clearance distances shown in

the table below are maintained between the temperature probe and

any other assemblies which use or generate a voltage shown in the

12

Page 14

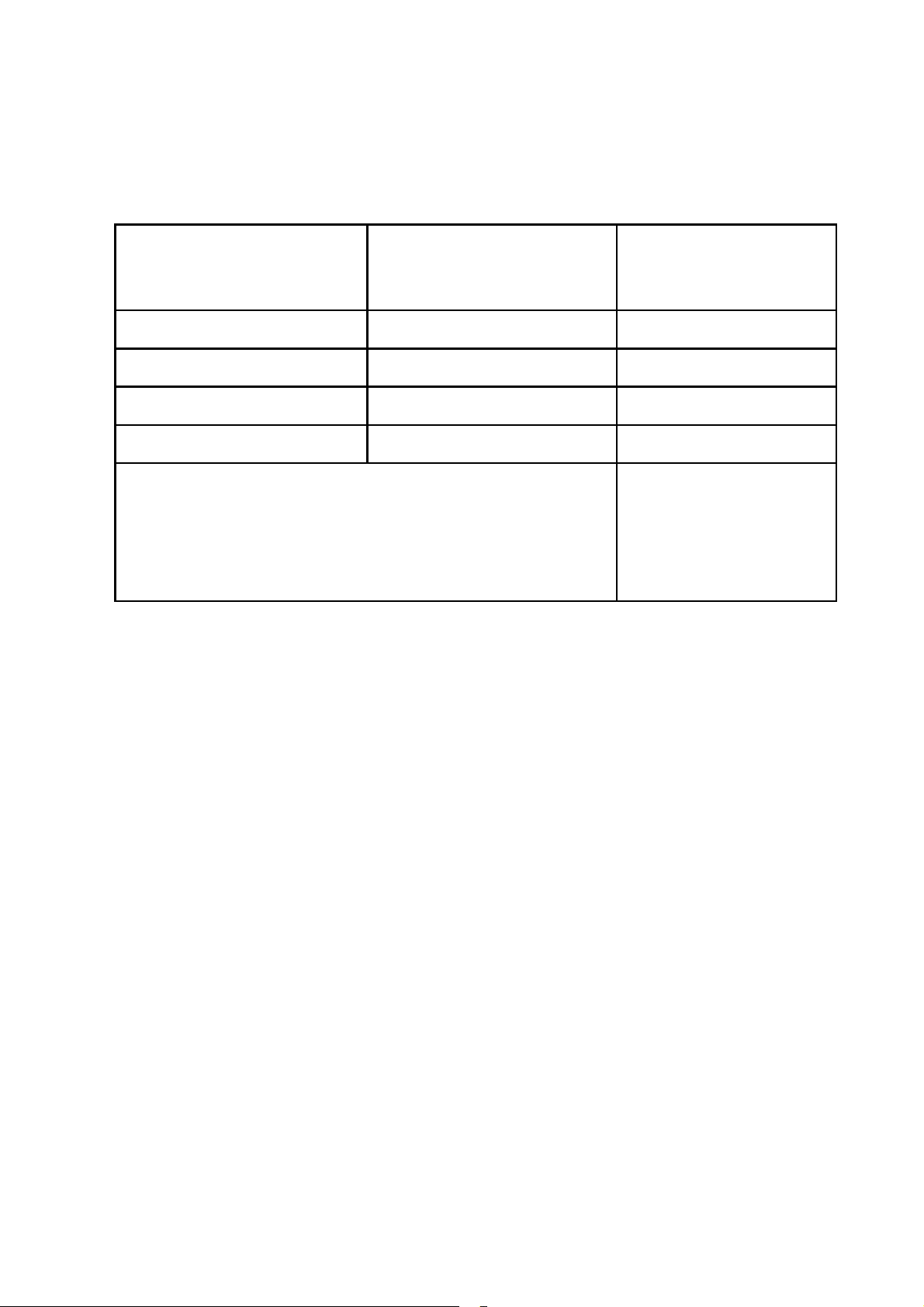

table below. Failure to maintain these minimum distances would

Clearance (mm) Creepage (mm) Voltage used or generated

by the other assemblies

0.2 1.2 Up to 50V

rms or V DC

0.2 1.4 Up to 100Vrms or V DC

0.5 1.6 Up to 150Vrms or V DC

1.5 3.0 Up to 300Vrms or V DC

Above 300Vrms or V DC

For a host or other assemblies fitted in the system, using or

generating voltages greater than 300V(rms or DC),advice from

a competent engineer must be obtained before installation of

the relevant equipment.

invalidate the EN61010 safety approval.

It is essential that following the installation of the system, and prior to

powering the system up that it is tested to determine that the correct

level of isolation is present to protect the user and other equipment

against the hazards of electric shock and fire.

An explanation of creepage and clearance is given in the following

diagram.

13

Page 15

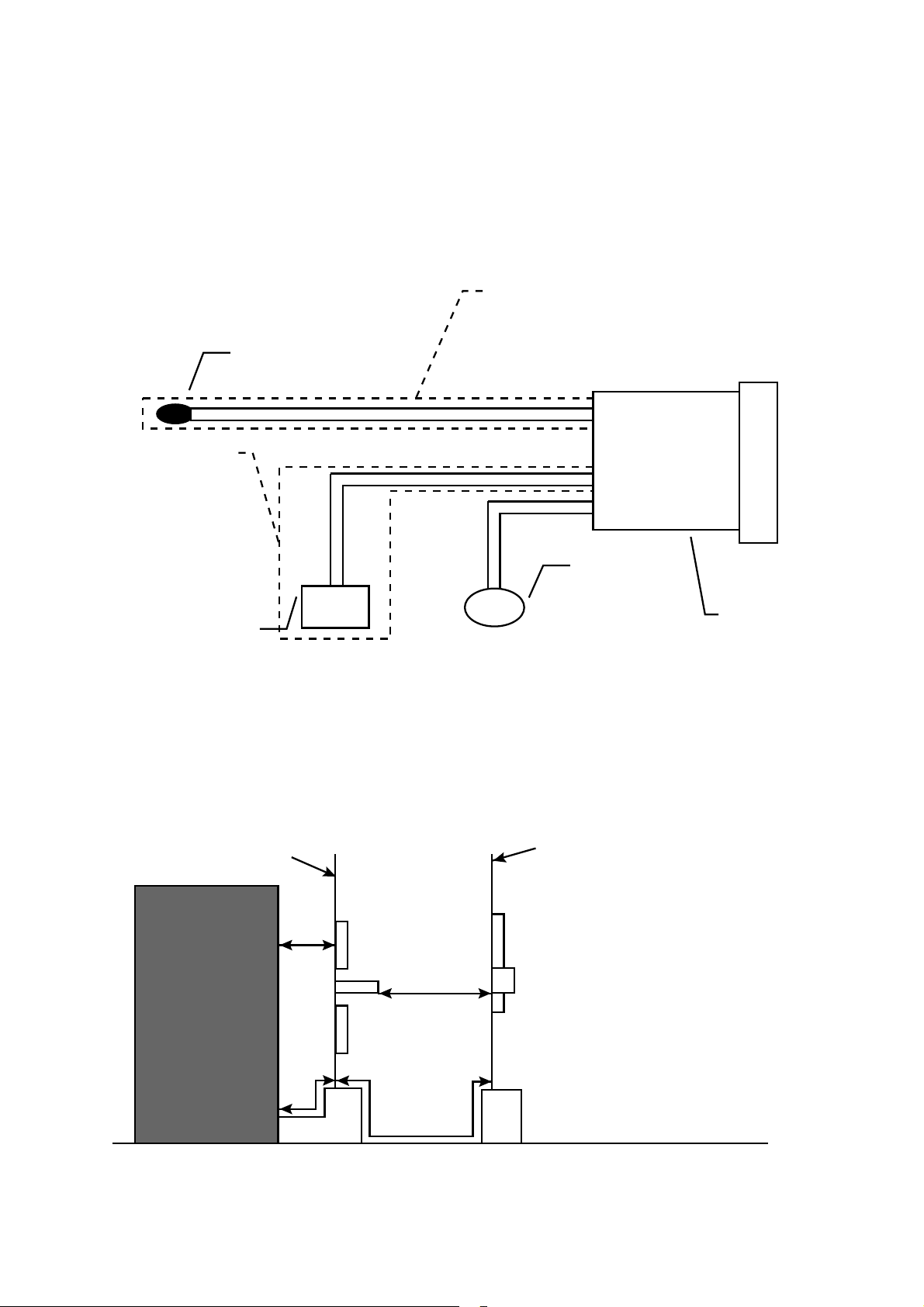

EXAMPLE INSTALLATION DIAGRAM

TO MAINTAIN SAFETY OF CONTROLLER

Example of how to install Controller into an environment where

hazardous voltages may exist is shown below.

Make sure installed system

has basic insulation around

Thermocouple, RTD,

Voltage or Current

Make sure

installed

system has

basic

insulation

Heater Break

Circuit

this connection

24V mains

supply

Controller

Example Diagram To Explain The Meaning Of Creepage and

Clearance Distances Is Shown Below

Communication card

X

X

Y

Y

Expansion card

Except for the edge connector which

plugs into the host's expansion slot,

clearance distance (X mm) and

creepage distance (Y mm) as given in

the table above, must be maintained

between the controller and any other

assemblies which use or generate a

hazardous voltage.

14

Page 16

2.

CAUTION

2.1 Caution on handling

1) Do not install the unit in any of the following places.

• A place where the ambient temperature exceeds the range of -10

50°C

• A place where the ambient humidity exceeds 90%RH

• A place where temperature changes suddenly or dew condensation

occurs

• A place exposed to corrosive gases (sulfuric gas, ammonia, etc.) or

combustible gases

• A place where vibration or shock is likely to be directly transmitted to

the body.

• A place exposed to water, oil, chemicals, vapor, steam, etc.

• A place with much dust, salt or iron component

• A place with much inductive disturbance, static electricity, magnetism

or noise

〜

• A place exposed to direct sunlight

• A place where heat such as radiant heat stays

2) Mounting

• PYX5/9

For mounting, attach the supplied mounting brackets (2 units) on top

and bottom and tighten with a screwdriver. Tightening torque is about

147N.cm (1.5kg.cm). (The case is made of plastic. Care should be

taken not to tighten forcedly)

15

Page 17

• PYX4

Insert the supplied mounting frame from the rear side and push it in

until the main unit is secured firmly to the panel. If it has a slight play,

tighten the 2 screws until the play is eliminated. (If the screws are tightened forcedly, the mounting frame may be slipped off the stopper)

3) When the unit is exposed to water, it may lead to a short-circuit or fire

hazard. Contact your dealer for inspection.

2.2 Caution on cable connection

1) For thermocouple input, use a suitable compensating cable.

2) For resistance bulb input, use a cable with a small lead wire resistance and

without resistance difference between 3 wires.

3) When external wiring has much noise, use the following step. When a

conducted as load of digital output such as relay contact output or alarm

output, connect a surge absorber to the conductor coil. (Example:

ENC471D-05A for 200V AC)

4) When the power source has much noise, use an insulating transformer

together with a noise filter. Noise filter should be mounted on a panel which

has been earthed. The wiring between the noise filter output and the instrument power terminals should be as short as possible. Do not connect a

fuse or switch to the noise filter output wiring, as it affects the performance

of the filter.

5) Use of a twisted cable for the instrument power source provides better effects (short twist pitch is effective for noise).

6) When a heater burnout alarm is provided, the heater power and controller

power should be connected using the same power line.

7) Time for preparation of contact output is required at power ON. When the

output signal is used for an external interlock circuit, etc., connect a delay

relay to the circuit.

16

Page 18

2.3 Other

When cleaning the instrument, do not use organic solvents such as alcohol,

benzine, etc. Use neutral detergent.

3. Caution on key operation / trouble

(1) Alarm function should be set correctly. Otherwise, alarm output

cannot be obtained at the time of occurrence of trouble. Be sure to

check the function prior to operation.

(2) Do not stop the device forcedly during auto - tuning, as it affects the

control action. When it needs to stop forcedly, be sure to turn OFF

the power in advance.

(3) If the input cable is disconnected, the display shows UUUU or LLLL.

When replacing the sensor, be sure to turn OFF the power.

17

Page 19

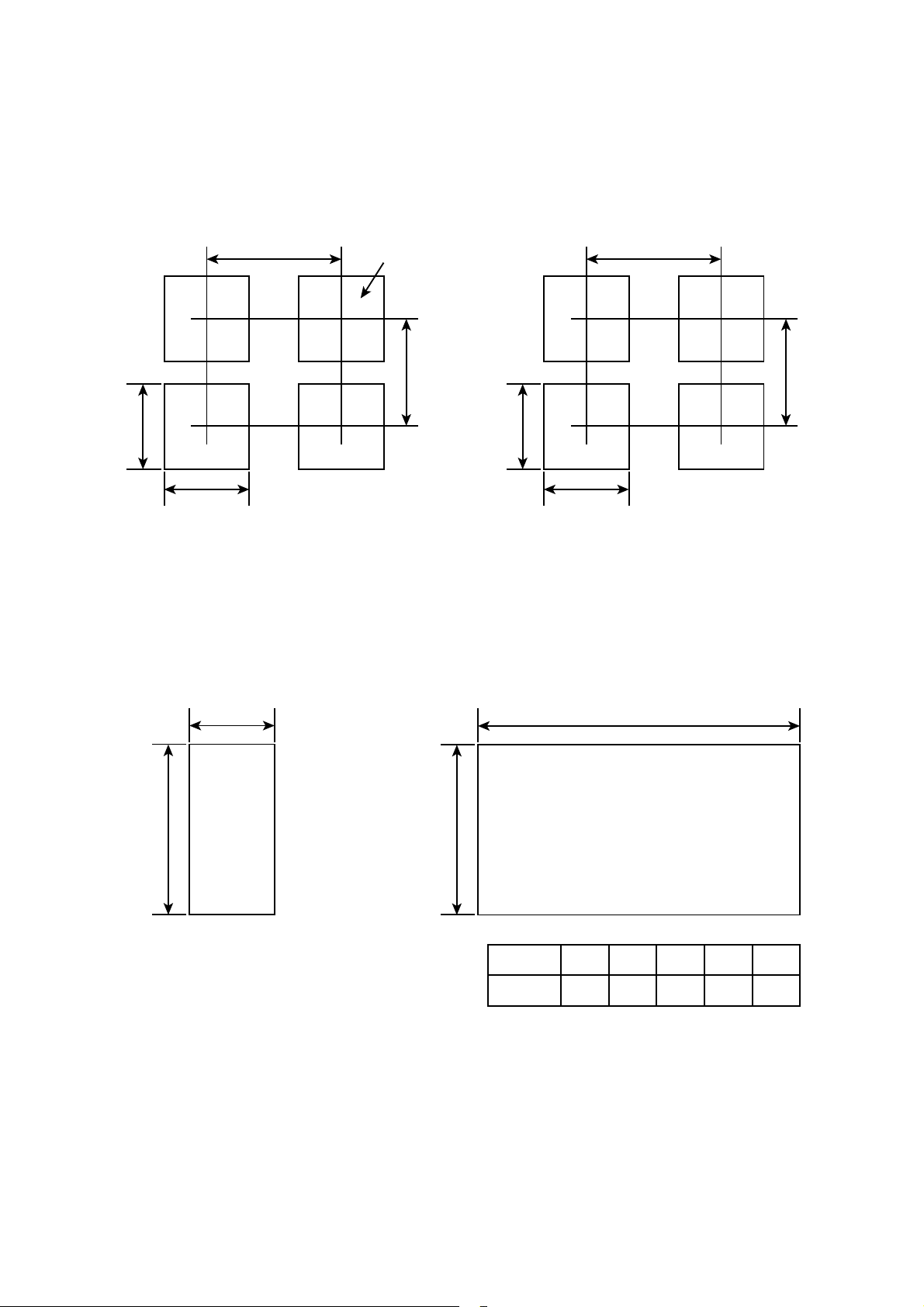

4.4 PANEL CUT DIMENSIONS

65 or more

100 or more

65

or more

45

+0.5

-0

+0.5

45

-0

For PYX4

92

+0.8

-0

+0.8

92

-0

For PYX9

When mounting one unit When mounting multiple n units (2

45

+0.8

-0

+0.8

a

-0

≤

n ≤ 6)

115

or more

92

+0.8

-0

+0.8

92

-0

For PYX5

18

Unitsa2

933141418952376285

Units (mm)

Page 20

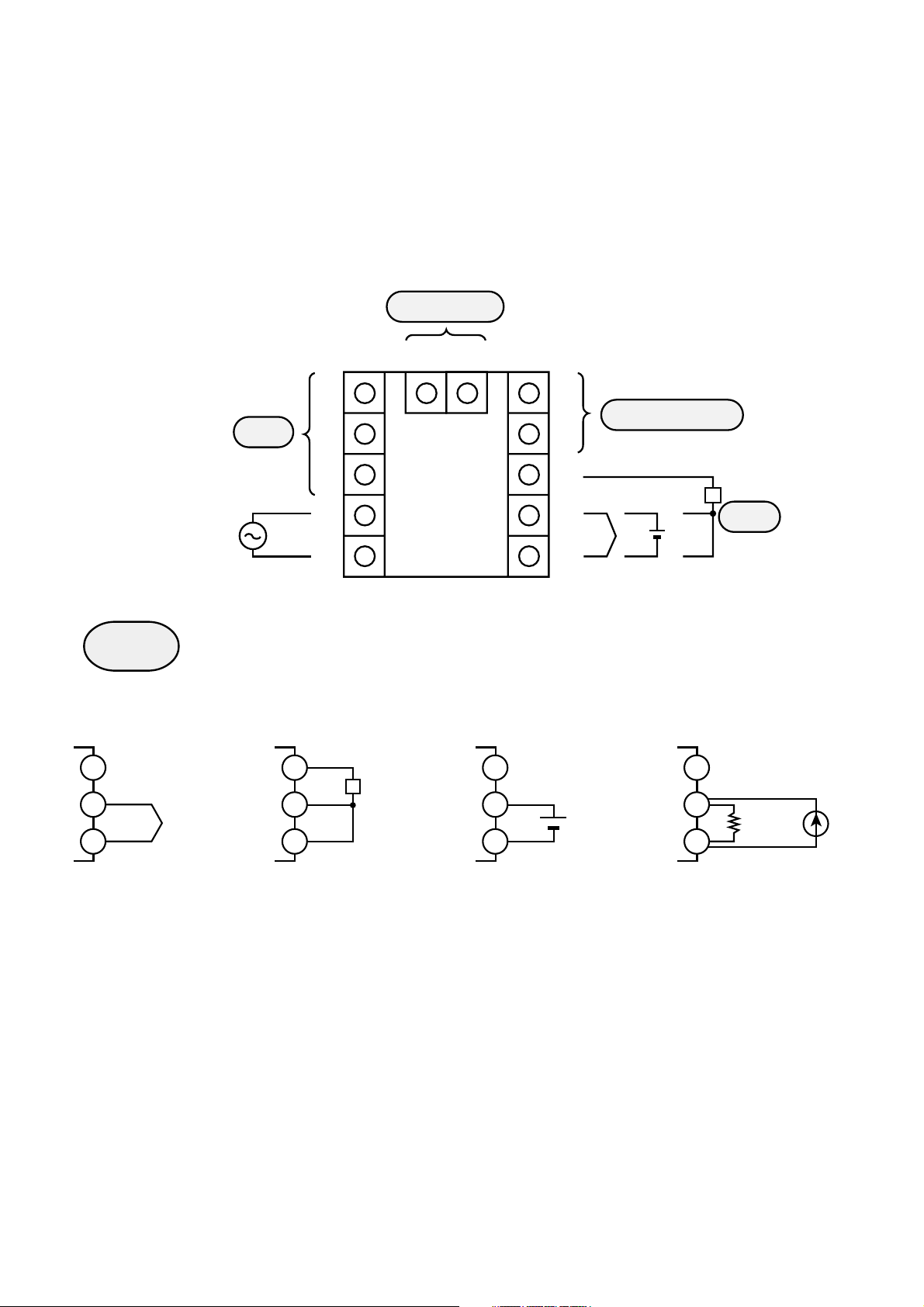

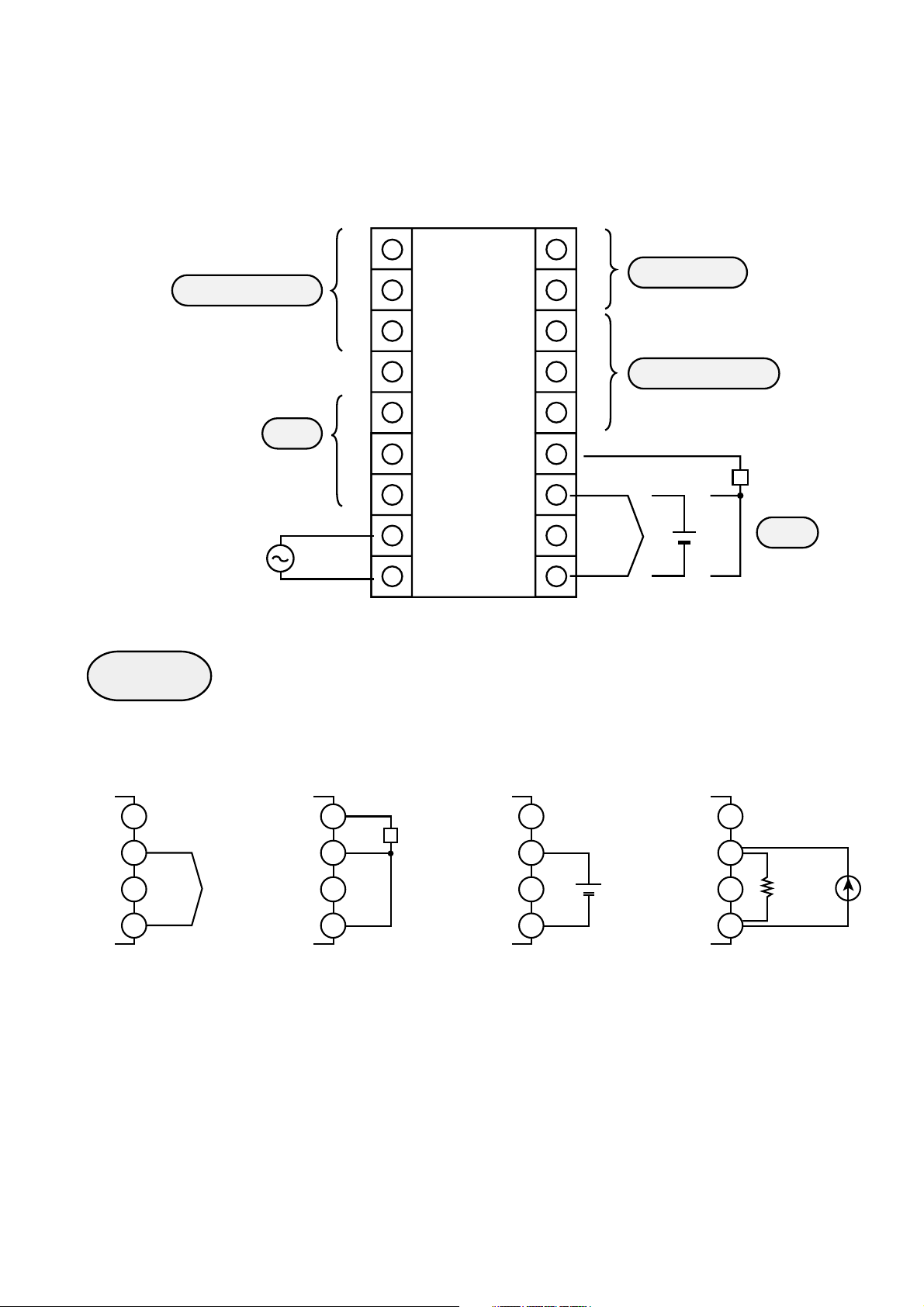

5. WIRING

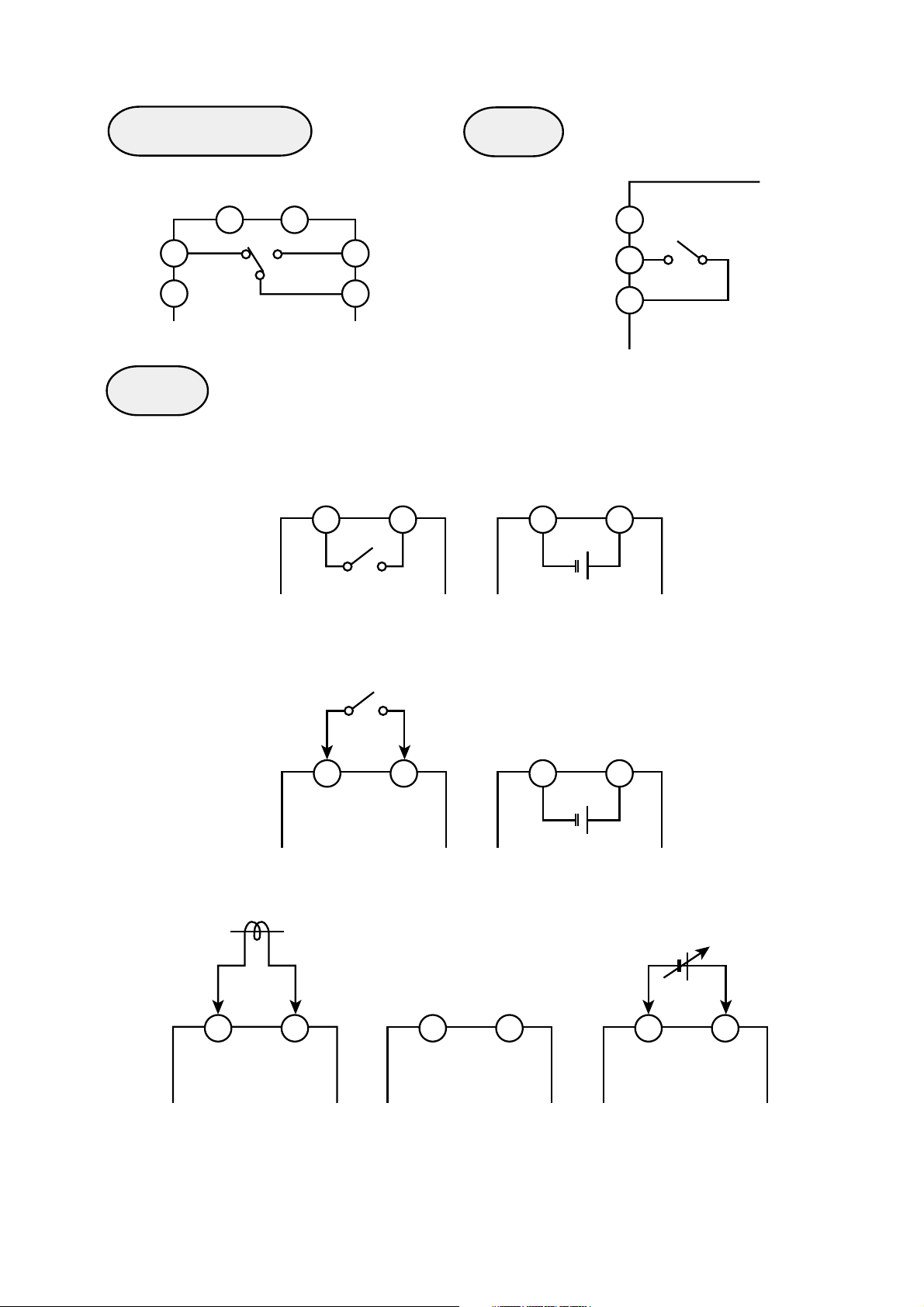

5.1 PYX4 WIRING DIAGRAM

[When the output 1 is relay (SPST) output, SSR drive output or

current output]

Option

11 12

6

7

8

9

10

Control output 1

+

–

+

AC100-240V

50/60H

z

Alarm

1

2

3

4

5

Input

TC input Pt input Voltage input

N.C. N.C. N.C.

8

9

10

8

+

–

9

10

Pt

8

9

10

+

Pt

Input

Current input

8

9

250Ω

10

+

NOTE: • For current input (4-20mA), use the accessorie

Ω

resistance (250

).

• Make sure that the setting pin is in the appropriate

position according to page 40.

19

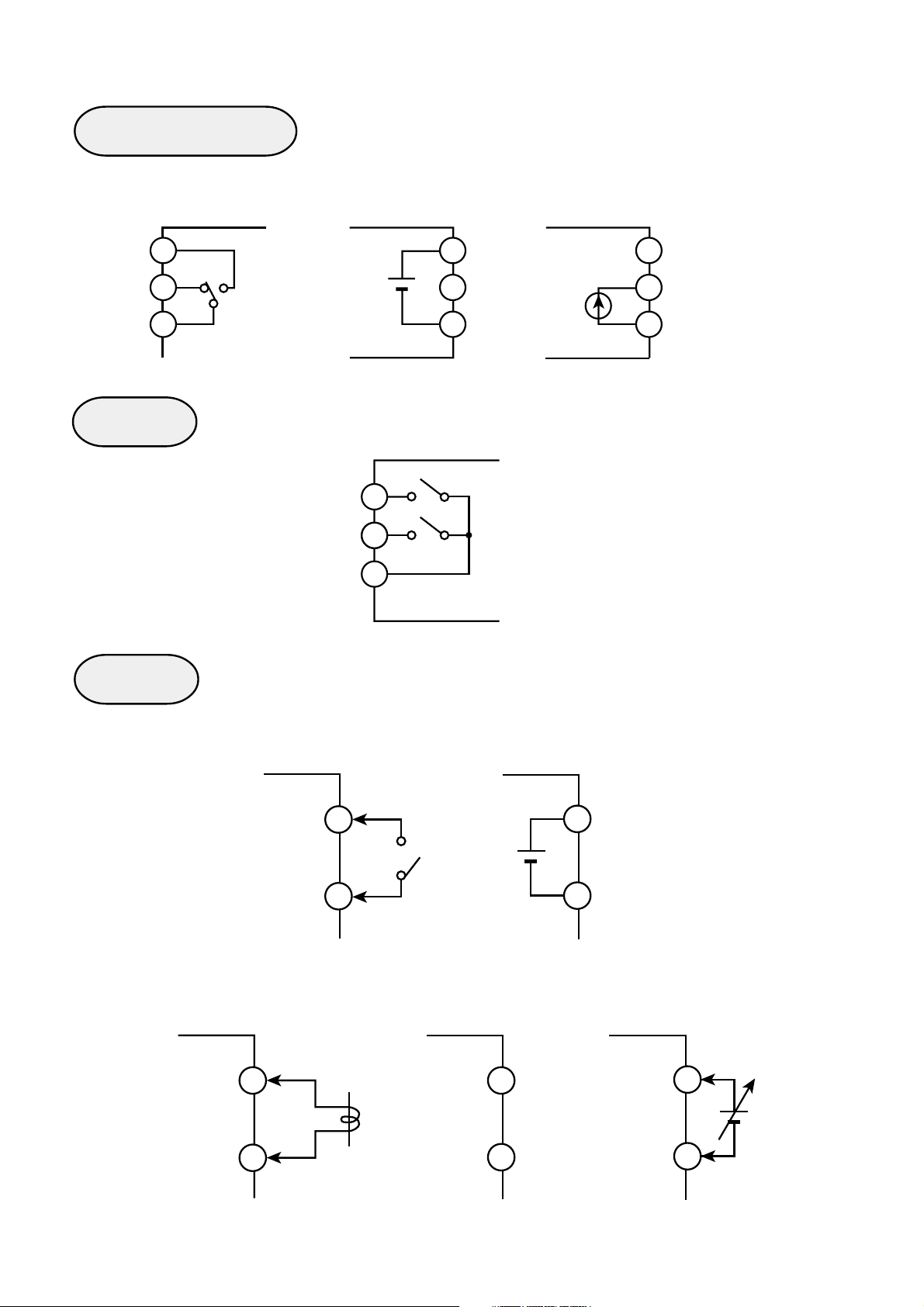

Page 21

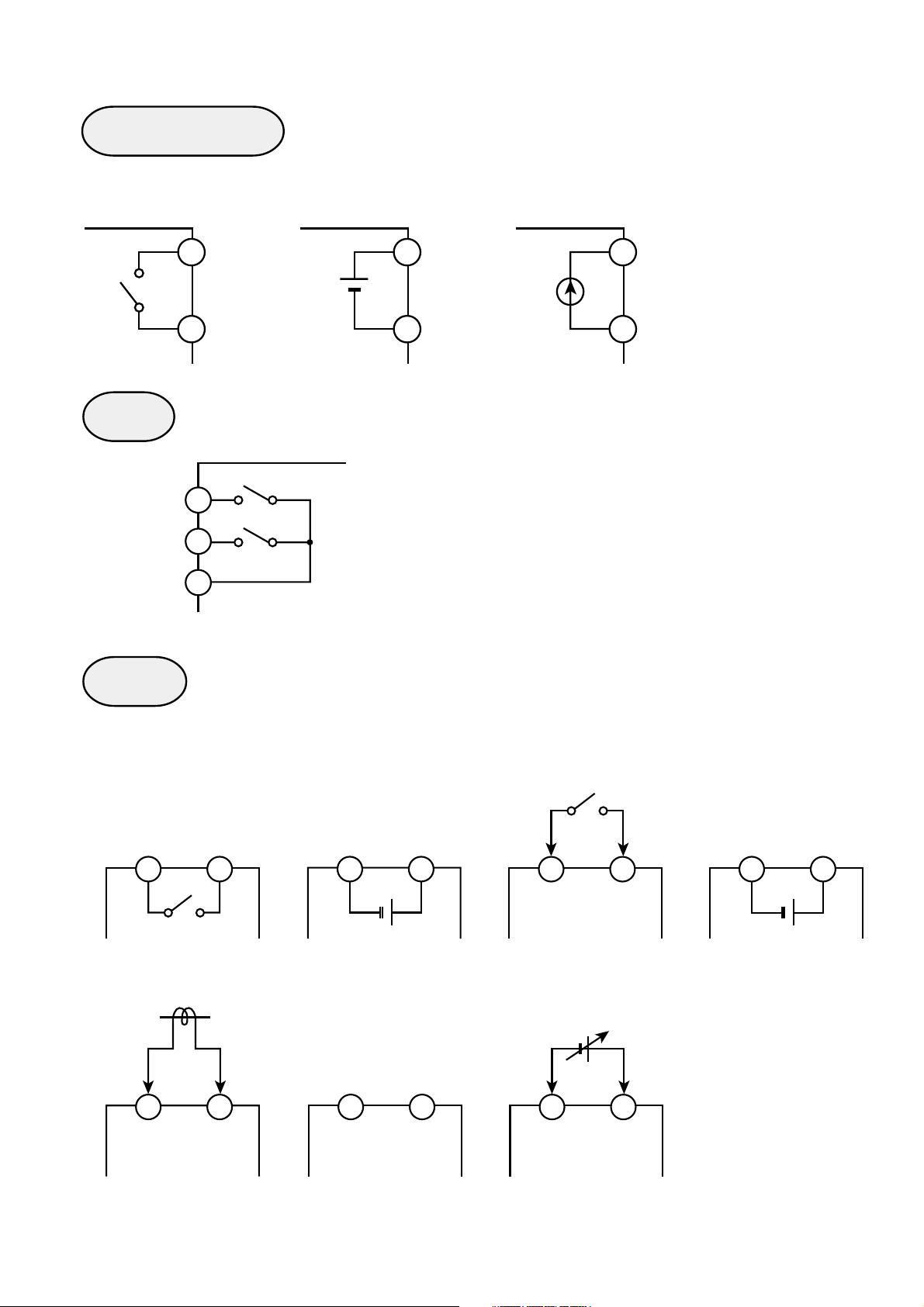

Control output 1

For relay output For SSR drive output For current output

Alarm

ALM2

ALM1

ALM-COM

Option

6

++

7

1

2

6

DC-V DC 4-20mA

7

6

7

NOTE: Only ALM 1 is available in the case of

3

the digital output type.

For control output 2

(relay output)

11

For current transformer input For RS485 transmission

11 12

12 11 12

For control output 2

(SSR drive output)

+

TRX– TRX+

11 12

For digital input

11 12

For remote SV input

+

11 12

For AO output

11 12

+

20

Page 22

5.2 PYX4 WIRING DIAGRAM

[When the output 1 is relay (SPDT) output]

Option

11 12

Control output 1

AC100-240V

50/60H

z

1

2

Alarm

3

4

5

6

7

8

9

10

Control output 1

+

+

–

–

Input

TC input Pt input Voltage input

N.C. N.C. N.C.

8

9

10

8

+

–

9

10

Pt

10

8

9

+

Pt

Current input

8

9

250Ω

10

Input

+

NOTE: • For current input (4-20mA), use the accessorie

Ω

resistance (250

).

• Make sure that the setting pin is in the appropriate

position according to page 40.

21

Page 23

Control output 1 Alarm

N.C. N.O.

1

2

Option

11 12

For control output 2

6

7

(relay output)

11

For digital input

12 11 12

1

ALM

ALM-COM

For control output 2

(SSR drive output)

For AO output

2

3

+

11 12

For current transformer input For RS485 transmission

TRX– TRX+

11 12

11 12

11 12

+

For remote SV input

+

11 12

22

Page 24

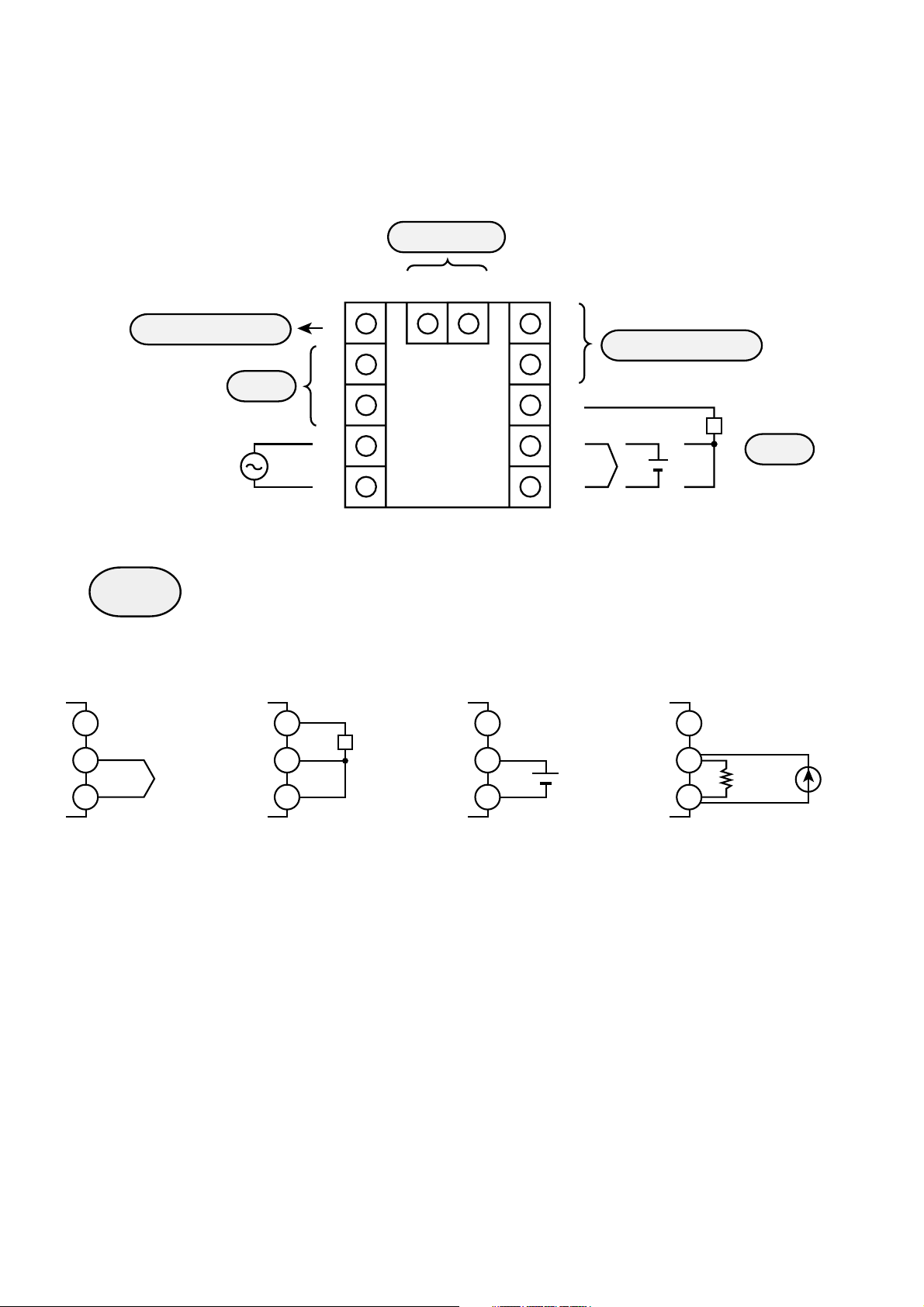

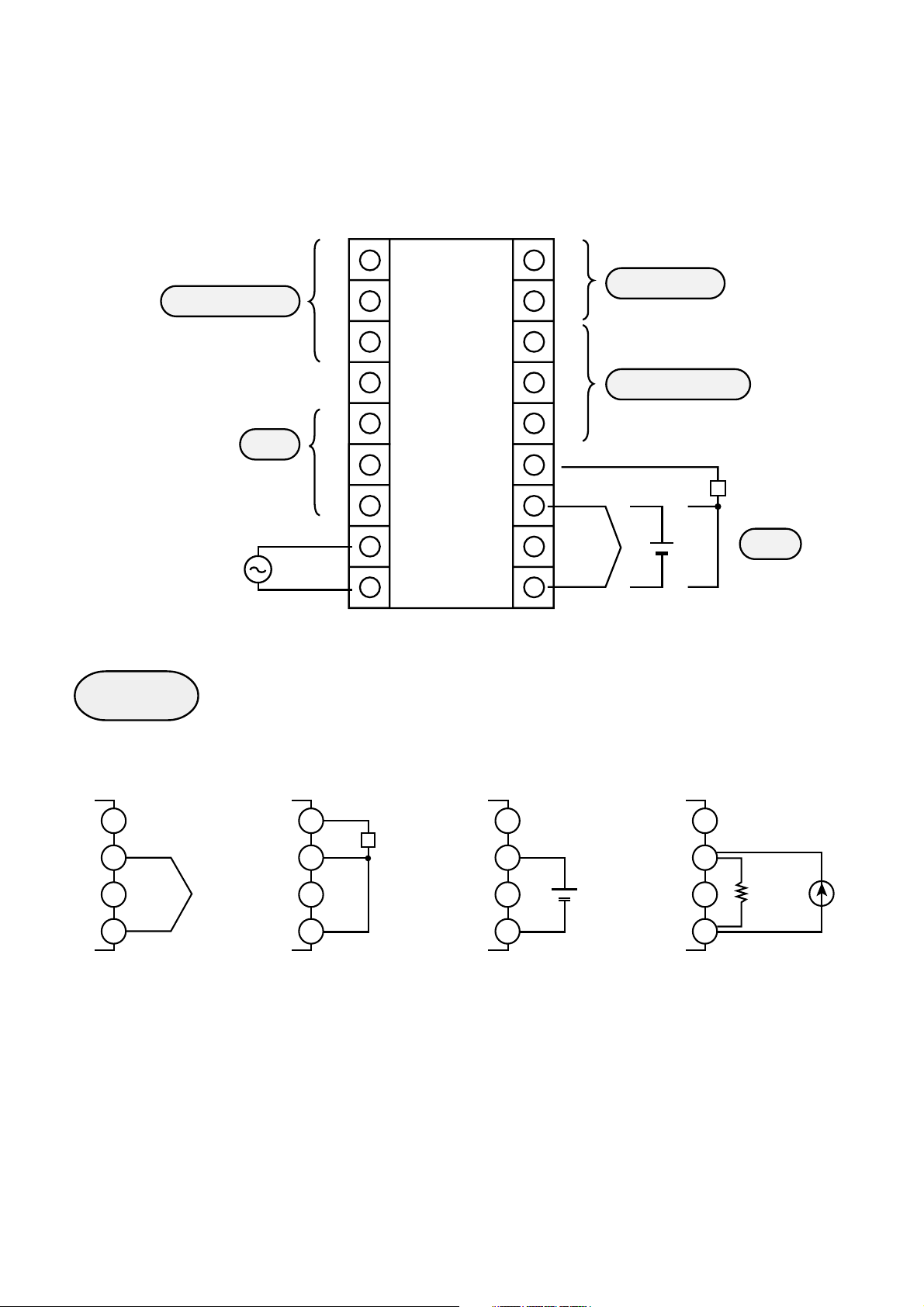

5.3 PYX5/9 WIRING DIAGRAM

(Not universal output)

Control output 1

AC100~240V

50/60H

z

Output

Alarm

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

Option

Control output 2

Pt

+

+

Input

–

For TC input For Pt input For voltage input For current input

15

N.C. N.C. N.C.

+

16

–

18

15

16

18

Pt

15

16

18

15

16

+

250Ω

18

NOTE: • For current input (4-20mA), use the accessorie

Ω

resistance (250

).

• In the case of multi-input, make sure that the setting

pin is in the appropriate position according to page

40.

+

23

Page 25

Control output 1

For relay output For SSR drive output For current output

N.O.

1

N.C.

2

1

++

DC-V DC 4-20mA

2

1

2

3

3

Control output 2

For relay output For SSR drive output For current output

N.O.

N.C.

12

+

13

14

12

+

13

DC-V DC 4-20mA

14

Alarm

3

12

13

14

ALM1

ALM2

ALM-COM

5

6

7

24

Page 26

Option

For digital input

10

11

For AO output

+

For current transformer input For RS485 transmission

10 10

TRX+

10

11

For remote SV input

+

10

11

11

TRX–

11

25

Page 27

5.4 PYX5/9 WIRING DIAGRAM

(universal output)

Control output 1

AC100~240V

50/60H

z

Input

Alarm

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

Option

Control output 1

Pt

+

+

Input

–

For TC input For Pt input For voltage input For current input

15

N.C. N.C. N.C.

+

16

–

18

15

16

18

Pt

15

16

18

15

16

+

250Ω

18

NOTE: • For current input (4-20mA), use the accessorie

Ω

resistance (250

).

• In the case of multi-input, make sure that the setting

pin is in the appropriate position according to page

40.

+

26

Page 28

Control output 1

For relay output For SSR drive output For current output

1

2

3

Alarm

Option

N.O.

N.C.

ALM1

ALM2

ALM-COM

12

+

13

DC-V DC 4-20mA

14

5

6

7

12

13

+

14

For digital input

10

11

For AO output

+

For current transformer input For RS485 transmission

10 10

11

11

TRX+

TRX–

10

11

For remote SV input

+

10

11

27

Page 29

5.5 NOTES

Connection:

• No power switch and fuse are provided on this product. Install

them separately if necessary.

• Use designated compensating wire in the case of thermocouple input.

• Use wire with line resistance lower that 10

thermoresistance input.

• To avoid noise induction to input wires separate from the

power and output wires also connected to your controller.

• In case of model equipped with heater break alarms, the

power supply used should be the same for the PYX and

Heater.

Ω

for

• Use shielded wires for input wires. Keep them away from

output wires.

Noise:

Take the following measures when there is serious noise

induction in the external wiring:

• When using a contactor as a load on digital output such as

relay contact output and alarm output, supplement a serge

absorber to the coil side of the contactor.

Z-Trap (ENB461D-14A for AC220V) manufactured by Fuji

Electric

• In the case of noise induction from the power supply, the use

of an insulated transformer and a noise filter is recommended.

Noise Filter (ZMB22R5-11) manufactured by TDK

• It is efficacious against noise induction to twist the power

wires.

28

Page 30

Connection of Load Circuit:

• When the frequency of operation is rather high, in the case of

proportional operation for instance, maximum load with

respect to the capacity of the output relay will result in shorter

life. Use an auxiliary relay in such a case. Type SSR is

recommended.

electromagnetic switch: proportion cycle 20 sec. and above

SSR: proportion cycle 2 sec. and above

(approximately)

contact output life: mechanical: 10 million times (no load)

electrical: 100 thousand times (nominal

load)

• Relay contacts will be worn out with time. After certain period

has passed, locking (a phenomenon in which a contact cannot

be released once switched on) may happen. It is advisable to

provide an external safety device to protect the system just in

case locking happens.

29

Page 31

II. FRONT PANEL LAYOUT

➀

PV value display

➁

Set point value display

➀

➁

PV

SV

SEL

OUT1

➂

OUT2

➃

ALM 1

➄

ALM 2

➅

➂

Control output 1 monitor lamp

➃

Control output 2 or remote operation monitor lamp

➄

Alarm 1 lamp

➅

Alarm 2 lamp

➆

SELECT/Registration

➇

DOWN key

➈

UP key

➀

➁

➆

➉

➆➇➈➉

➉

CARRIAGE/Registration

PYX4

➂

➃ ➄ ➅

OUT1

OUT2 ALM 1 ALM 2 OUT1 OUT2 ALM 1 ALM 2

PV

➀

SV

➁

SEL

➈

➇

PYX-5

➂➃➄➅

PV

SV

SEL

➆➇➈➉

PYX-9

PYX5

PYX9

30

Page 32

➀

PV value display

PV Displays the measured value, as well as

the failure information. When more than

one failure occurs simultaneously, the

failure information of the highest priority

alone will be displayed.

➁

Set point value display

Display Priority

Main unit failure

Heater disconnected

Control loop failure

Meaning

High

Low

SV Displays the set point value.

(During auto-tuning or manual operation,

the display of

or

and set point value alternate.)

➂

Control output-1 monitor lamp

Output 1(OUT1) Lights when Output 1 is ON. (it does not

●

➃

Control output 2 or remote operation monitor lamp

●

light for the current output type.)

This lamp lights when Output 2 is ON or

during remote operation. (it does not

light for the single output type.)

Dual Control type

Output 2(OUT2) Acts as the control output 2 monitor lamp.

●

Remote SV type

REM Acts as the remote operation monitor lamp.

●

31

Page 33

➄

Alarm-1 monitor lamp

ALM 1 Lights when the alarm-1 relay operates

●

➅

Alarm 2 monitor lamp

ALM 2 Lights when the alarm-2 relay operates

●

➆

SELECT/Registration

Used to switch from the operation mode

SEL

to parameter setting mode, to select

parameters, and to Registration set

values.

Keeping pressing this key for about 3

➇

DOWN key

➈

UP key

sec switches between the operation

mode and parameter setting mode.

Used to select parameters and to

decrease set values.

Continuing to press this key results in

auto-repeat.

Used to select parameters and to

increase set values.

Continuing to press this key results in

auto-repeat.

➉

CARRIAGE/Registration

Used for preset value digit carrying or for

preset value Registration.

32

Page 34

III. OPERATION PROCEDURE

1. OPERATION MODE/PARAMETER SETTING MODE

The operation of this device includes the Operation Mode where

measured and set values are displayed and the Parameter Setting

Mode where various parameters are set.

To switch between the operation and parameter setting modes,

SEL

continue to press the

key for about 3 sec.

Continue to press

Operation Mode Parameter Setting Mode

Displays measured and set

point.

Displays information on loop*

break, heater break

error, auto-tuning, and manual

operation.

Changes set point.

*

, main-unit

SEL

key for about 3 sec

Make no operation

for 1 min

Displays and changes

various parameters.

*

indicates an option.

2. VIEWING PARAMETERS

1. Enter the parameter setting mode. (continue to press

SEL

key for

about 3 sec)

SEL

2. Display the target parameter with the

, , or key.

NOTES: No parameter is displayed if its parameter lock setting is

illegal or if its corresponding option has been mounted in the

system.

33

Page 35

PV

SV

PV

* The numeric value shown in the

left-hand figure is only an example.

Continue to

press

SEL

key for about

3 sec

SEL

Parameter Setting Mode Operation Mode

SEL

SV

parameter

or

PV

SV

parameter

or

•

•

•

•

SEL

or

PV

SV

parameter

*Not displayed unless the transmission option is provided.

34

Page 36

3. CHANGING PARAMETERS

1. Display the parameter to be set (to be changed) on the screen, as

described in the Section 2. “Viewing Parameter” (page 33).

2. Select the digit to be set (to be changed ), with the

key (the

selected digit flickers).

3. Set (to be changed ) the data with the

SEL

4. Press the

key, or repeat pressing the key until it stops

and keys.

flickering (the set (changed) data is registered).

NOTES: If no operation is made for about one minute during data

setting (changing), control automatically returns to the

operation mode. The data being changed (set) at this time is

invalidated.

35

Page 37

Example

<<Changing “Lock” from 1 to 2>>

PV

SV

Display the target

➀➁➂

Press

parameter.

PV

SV

The leftmost digit

flickers, and data of that

digit is changeable.

PV

SV

The center right digit

➃➄

flickers, and data of that

digit is changeable.

PV

SV

The center left digit

flickers, and data of that

digit is changeable.

PV

SV

The rightmost digit

flickers, and data of that

digit is changeable.

PV

SV

Increment data by 1 to 2. Flickering stops, and is the

➅➆

SEL

or

PV

SV

registered.

36

Page 38

IV. SETTING INPUT AND OUTPUT TYPES

After completing wiring, make sure that the measured value is of the right

type before operating the device.

Parameter to be used

Changing input

Setting the Input type ( )

It refers to setting the input type (range), presence or absence of decimal-

°C/°

point, and units of display (

Setting procedure

F).

PV

SV

PV

SV

1. Turn the power of PYX

(LEDs go on after a few sec).

SEL

2. Continue to press the key for about 3 sec (parameter

is displayed).

At that time, if is displayed steps 3 and 4 need not

be executed.

3. Press the key 4 times (the right most digit flickers).

37

Page 39

PV

SV

PV

SV

PV

4. Change the lower display to with the

and keys, and stop flickering and

register the value with the and keys.

SEL

5. Repeat pressing the key until parameter

is displayed.

SV

6. Set parameter to the desired specifications

following.

Example: Setting of K thermocouple for 0.0-400.0 °C range

Display unit

0

°

C display

1

°

F display

Decimal-point display

0

No decimal point

0.1

1

°C/°

F display

Input type code

38

Page 40

Input signal and measurement range

Input signal

Thermoresistance

JIS

Thermoresistance

old JIS

Thermocouple

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

JPt100

JPt100

JPt100

JPt100

JPt100

JPt100

JPt100

J

J

K

K

K

R

B

T

T

E

E

S

N

U

WRe5-26

PL-II

Input type

code

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

Measurement

range (°C)

0~150°C

0~300°C

0~500°C

0~600°C

–

50~100°C

–

100~200°C

–150~600°C

–150~850°C

0~150°C

0~300°C

0~500°C

0~600°C

–

50~100°C

–

100~200°C

–150~600°C

0~400°C

0~800°C

0~400°C

0~800°C

0~1200°C

0~1600°C

0~1800°C

–199.9~200°C

–

150~400°C

0~800°C

–199.9~800°C

0~1600°C

0~1300°C

–199.9~400°C

0~2300°C

0~1300°C

Measurement

°

range (

–

–

238~1112°F

–

238~1562°F

–

–

238~1112°F

–

–

–

328~1472°F

–

F)

32~302°F

32~572°F

32~932°F

32~1112°F

–

58~212°F

148~392°F

32~302°F

32~572°F

32~932°F

32~1112°F

–

58~212°F

148~392°F

32~752°F

32~1472°F

32~752°F

32~1472°F

32~2192°F

32~2912°F

32~3272°F

328~392°F

238~752°F

32~1472°F

32~2912°F

32~2372°F

328~752°F

32~4172°F

32~2372°F

0.1°C

display

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

Ο

×

×

×

Ο

Ο

Ο

Ο

×

×

Ο

×

×

0.1°F

display

Ο

Ο

Ο

×

Ο

Ο

×

×

Ο

Ο

Ο

×

Ο

Ο

×

Ο

×

Ο

×

×

×

×

×

×

×

×

×

×

×

×

×

Power

supply

voltage

Power

supply

current

NOTES:

DC1-5V

DC0-5V

40

41

–1999

(Possible scaling range)

to

9999

Ο: Enabled

×: Disabled

DC4-20mA

40*

* For current input, mount the

250Ω resistance on input

terminals, and apply the 1-5V

voltage input.

•The 0.1°C/F display is impossible for all over the 1000°C/F span.

39

Page 41

NOTES: Make sure to switch the input selection SW referencing the

following table when changing the type of input by changing

the parameter “

Switching from Pt or TC input

to voltage/current input

Switching from voltage/current

input to Pt/TC input

Other types of switching

Input selection SW

Lower

”.

Re-position the input switch pin

on "V" side.

Re-position the input switch pin

on Pt/TC side.

Input pin re-positioning is not

necessary.

V

J4

Input select SW

TC. Pt

ALM2

ALM1

OUT2

OUT1

Upper

Input selection SW

Lower

PYX-5

SEL

SV

PV

OUT1

OUT2 ALM1 ALM2

SEL

SV

PV

PYX4

Input selection SW

Lower

PYX-9

SEL

SV

PV

OUT1 OUT2 ALM1 ALM2

PYX5 PYX9

Upper

Upper

40

Page 42

Parameter to be used

Changing scale (voltage/current input)

If it is used for voltage or current input, input scaling is possible.

Input scaling

Engineering dimensions can be set to voltage or current input.

Setting procedure

maximum value on scale

(

): Engineering value

equivalent to the 100% input is set

(-1999 ~ 9999).

minimum value on scale

(

): Engineering value

equivalent to the 0% input is set (1999 ~ 9999).

(decimal-point location):Decimal point location is set (see

below). (0 ~ 2)

(No decimal point)

0

1

2

NOTES: When setting the scale, set it so that the difference between

and (span) does not exceed 9999. The

following condition must always be satisfied when setting is

made:

is larger than .

41

Page 43

Parameter to be used

Changing output (universal output) none

In case of the universal output type, the type of the control output 1 can

be selected from the relay (SPDT) output, the SSR drive output and

the current (4-20mA) output. Follow the table below when switching.

Desire type of control output 1 Switching

Relay (SPDT) output

SSR drive output

Current (4-20mA) output

Output selection SW

Upper

OUT1

OUT2 ALM1 ALM2

PV

SV

SEL

PYX-5

PYX5

Switch the pin “J2” in the figure below to the

“RY” position.

Switch the pin “J2” in the figure below to the

“SSR” position.

No swtching required.

Output

selection SW

SSR

J2

RY

Lower

Output selection SW

Upper

OUT1 OUT2 ALM1 ALM2

PV

SV

SEL

PYX-9

Lower

PYX9

42

Page 44

NOTES:

1. The output terminal for each output type is independent in the case

of the universal output. Make sure that connections are properly

made according to the page 27.

2. The current (4-20mA) output is made regardless of the position of

the switching pin “J2” in the case of the universal output. However,

only one type of output can be concurrently used among the relay

output, the SSR drive output and the current output.

43

Page 45

V. FUNCTIONS

Parameter to be used

Lock

The lock function is to suppress display of those parameters which are not

used frequently in normal operations, and thereby to prevent parameter

miss-settings.

There are four lock levels: 0 to 3. Parameters corresponding to each lock

level are displayed. Setting the lock level to 0 disables changing of all

parameters other than

.

<Parameters for each lock level>

PV

SV

Lock level

0

Lock level

1

Operation screen

Lock level

2

Lock level

3

44

Page 46

45

Page 47

NOTE: Some parameters may not be displayed, depending

upon the option composition.

Lock level Use

0

1

2

3

(Setting of no parameter allowed)

Use this level to lock all parameters.

(Setting of only set point allowed)

Use this level when no parameter other than the set point is changed.

(Setting of normally set parameters allowed)

Use this when normal parameters are set or changed.

(Setting of all parameters allowed)

Use this when the set-up parameters are set or changed.

46

Page 48

Parameter to be used

Auto-tuning

Autotuning function

This is the function implemented by the controller itself to automatically

perform ON/OFF control, identify the process, and determine control

constants (P, I, D, Cool, Ar).

Operating procedure

(Autotuning Command)

Setting Operation

Provides normal control.

Perform auto-tuning while

(Standard

type)

targeting the present [set

point value (SV)].

(Autotuning command) Setting

or in the autotuning

command starts autotuning (during

autotuning,

value alternate in display on the run

Performs auto-tuning while

(Low PV

type)

targeting the present [set

point value (SV) - 10%FS].

screen). Autotuning terminates

automatically.

Supplementary descriptions

1. There are two types of auto-tuning (AT):

➁

over-shoot) and

➀

Type

is the system in which the measured value (PV) exceeds

Low PV type (suppressing overshoot).

➀

and the set

Standard type (including

the set point value (SV) (overshoot) during autotuning. Use this type

where overshoot is permitted.

➁

Type

is the system in which ON-OFF control is provided by

centering upon the value 10% (/full-scale) lower than the set point

value (SV). Use this type where overshoot is to be suppressed.

47

Page 49

For single output

➀

Standard type (including overshoot)

AT started AT terminated

AT arithmetic being made

Set point value (SV)

PV (Measured value)

(PID determined)

ON 100%

ON ON

OFF 0%

(Control output)

➁

Low PV type (suppressing overshoot)

AT started AT terminated

Set point value (SV)

OFF OFF

ON-OFF operation

(PID determined)

AT arithmetic being made

During AT, the ON-OFF

operation (2-point operation) is

provided where the measured

value (PV) vibrates.

PID control

SV-10%FS

ON 100%

OFF 0%

(Control output)

PV (Measured value)

ON ON

OFF OFF

ON-OFF operation

48

During AT, the ON-OFF

operation (2-point operation) is

provided where the measured

value (PV) vibrates.

PID control

Page 50

For dual output

➀

Standard type (including overshoot)

AT started AT terminated

AT arithmetic being made

Set point value

(SV)

PV (Measured value)

(Control output 1)

(Control output 2)

ON 100%

OFF 0%

ON 100%

ON ON

OFF OFF

OFF OFF

ON ON

(PID determined)

During AT, the ON-OFF

operation (2-point operation) is

provided where the measured

value (PV) vibrates.

PID control

➁

Low PV type (suppressing overshoot)

AT started AT terminated

AT arithmetic being made

Set point value

(SV)

PV (Measured value)

(Control output 1)

(Control output 2)

ON 100%

OFF 0%

ON 100%

ON ON

OFF OFF

OFF OFF

ON ON

(PID determined)

SV-10%FS

During AT, the ON-OFF

operation (2-point operation) is

provided where the measured

value (PV) vibrates.

PID control

49

Page 51

NOTES

1. Avoid applying the auto-tuning to the following processes.

(a) The process must not be disturbed due to temporary ON-OFF

control output from PYX.

(b) Process featuring very quick response such as pressure/flow

rate process.

(c) Process where overshoot must not be generated

2. Auto-tuning cannot be executed under the following conditions. If

the auto-tuning is already being executed, stop it.

(a) Manual operation

(b) Measured value (PV) error occurring

(c) When the set value (SV) has changed by more than 0.5%FS

per 0.5 second during auto-turning

(d) Auto-tuning not terminated within 12 hours

3. Do not execute auto-tuning when the ramp soak function is being

used (i.e. when the parameter “

” is not ), since it

may result in incorrect tuning.

4. When the operation condition is changed, restart the auto-tuning

5. When the auto-tuning terminates abnormally, the PID value takes

the value prior to auto-tuning, in such cases as abnormal

termination of auto-tuning. The same applies when the auto-tuning

command is switched to

50

during auto-tuning.

Page 52

Control function

Normal PID control

1.

(Proportional band) Set the proportional band using the

Parameter to be used

ratio (%) with respect to the input

full scale (0.0-999.9%).

Setting

to 0.0 provides the 2point (ON-OFF) control. The 2-point

control is not available in the fuzzy

control mode. This parameter is

automatically set with auto-tuning.

(Integral time) Set the integral time in sec units (0-

3200 sec).

Setting

to 0 provides no integral

operation.This parameter is

automatically set with auto-tuning.

(Derivative time) Set the derivative time in 0.1-sec

units (0.0-999.9 sec).

Setting

to 0.0 provides no

derivative operation. This

parameter is automatically set with

auto-tuning.

51

Page 53

(Anti-reset wind up) When control operation involves

integral operation, the initial overintegral causes overshoot to occur.

Overshoot is prevented by limiting

the integral range. Set setting value

(SV) high and low limits with

engineering units. (0~100%FS

E.U.)

This parameter is automatically set

by executing auto-tuning.

PV

AR

SV

AR

Integral value truncated

Integral value truncated

(Manual resetting value) When control includes only the P

operation, it generates offset. To

eliminate this, add the manual

resetting value to the manipulated

value (MV). (-100.0~100.0%)

SV

PV

PID arithmetic

52

MV

+

+

Manual resetting

Manipulated value (MV)

Page 54

2. 2-POINT (ON-OFF) CONTROL

When PID control is specified as the control type, setting P to 0.0

provides the 2-point (ON-OFF) control operation.

(2-point operation hysteresis)

Set the 2-point operation hysteresis

with engineering values. (0~100%

FS D.E.U.)

HYS

Output ON

Output OFF

Set point

PV

3. FUZZY CONTROL

Employing Fuzzy Logic control eliminates system overshoot and

effectively suppresses fluction of the process variable due to external

disturbances. See the section describing control type setting (page75).

NOTES

1. The dual output type does not allow use of fuzzy control.

2. Though the fuzzy control also requires setting of parameters P, I,

and D, these values can be set to those being used in PID control.

Auto tuning is also available.

4. DUAL CONTROL

* This function is an option.

If the process heats itself, cooling control is needed in addition to

heating control. The dual control is used for control of that process.

53

Page 55

(Cooling-side proportional band coefficient )

Set the cooling-side proportion

band coefficient (0.1~10.0). This

parameter is automatically set with

auto-tuning.

= 50%

Heating side

Output

Cooling side

COOL=0.5

COOL=1.0

COOL=2.0

Offset (–) Offset (+)

Set point value (SV)

Heating-side

proportion band

Proportion band (P)

Cooling-side

proportion band

(Dead/overlap band) Used to separate (dead) and

overlap the heating and cooling

side output as shown in the figure

below (-50 ~ +50%)

Output

Heating side

Cooling side

Offset (–) Offset (+)

Overlap

band

Set point value

Dead

band

(SV)

54

Page 56

Parameter to be used

Alarm

* This function is an

option.

This device provides the multi-alarm function (option) that allows

simultaneous detection of a maximum of 4 types of alarming.

Multi-alarming

It allows a maximum of 4 types of alarm settings (among which, one is

dedicated to loop/heater disconnection), detects those types of alarm

individually, and makes logical OR before outputing it to the alarm

relay.

(Multi-alarm)

Alarm setting 1

Alarm setting 2

Alarm setting 3

Alarm setting 4

(dedicated to loop/

heater break Alarms)

Operation procedure

(Alarm-1 type)

(Alarm-2 type)

Decision of Alarm 1

Decision of Alarm 2

Decision of Alarm 3

Decision of loop/

heater break Alarms

OR

Alarm relay

Setting 1Setting 2Setting 3Setting 4

Selection from

B-group

* For the setting in the above figure, the result of ORing of the heater break alarm,

“holding”-featured low-limit deviation alarm, and high-limit absolute alarm is output.

Each one selected

from A-group

55

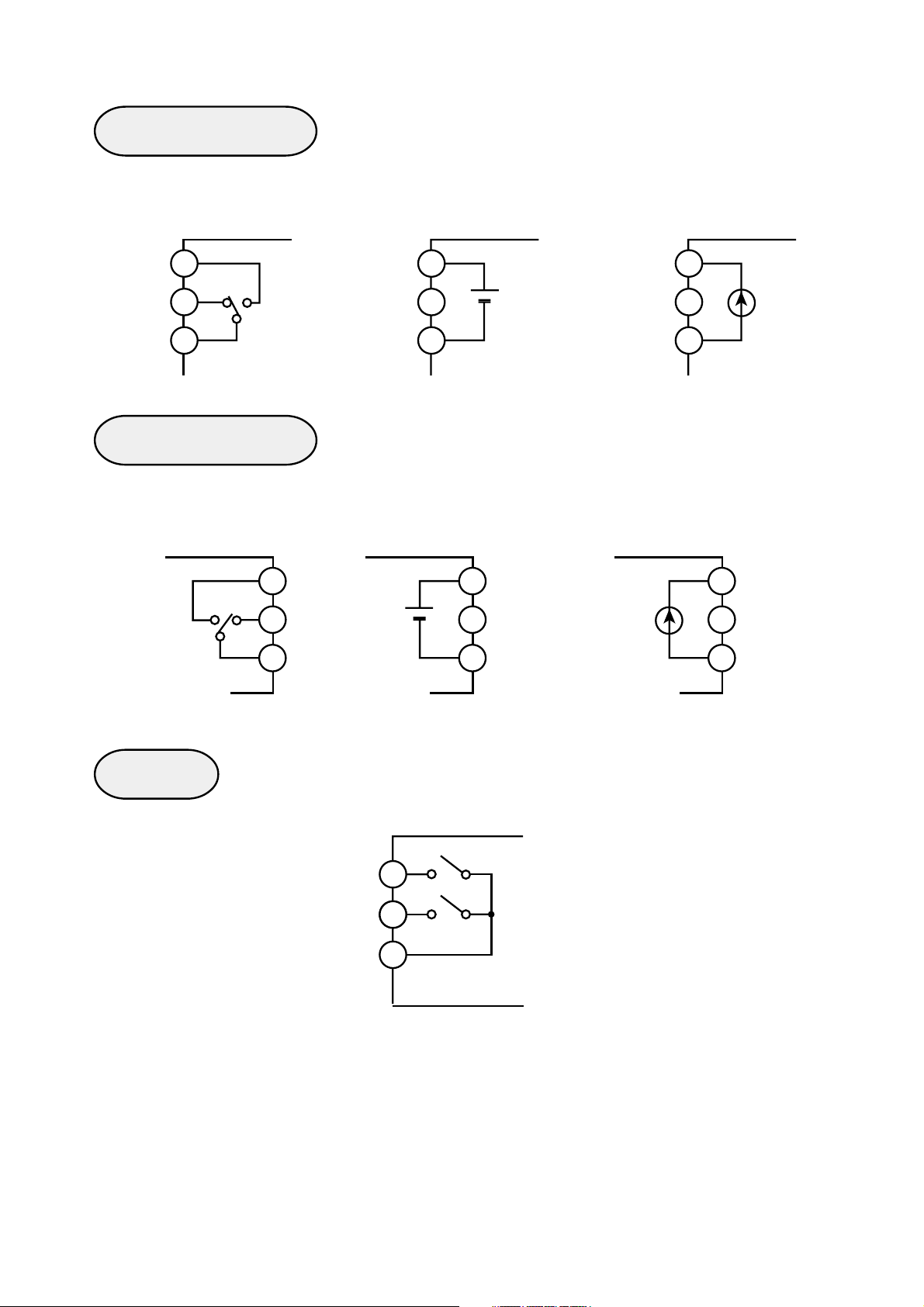

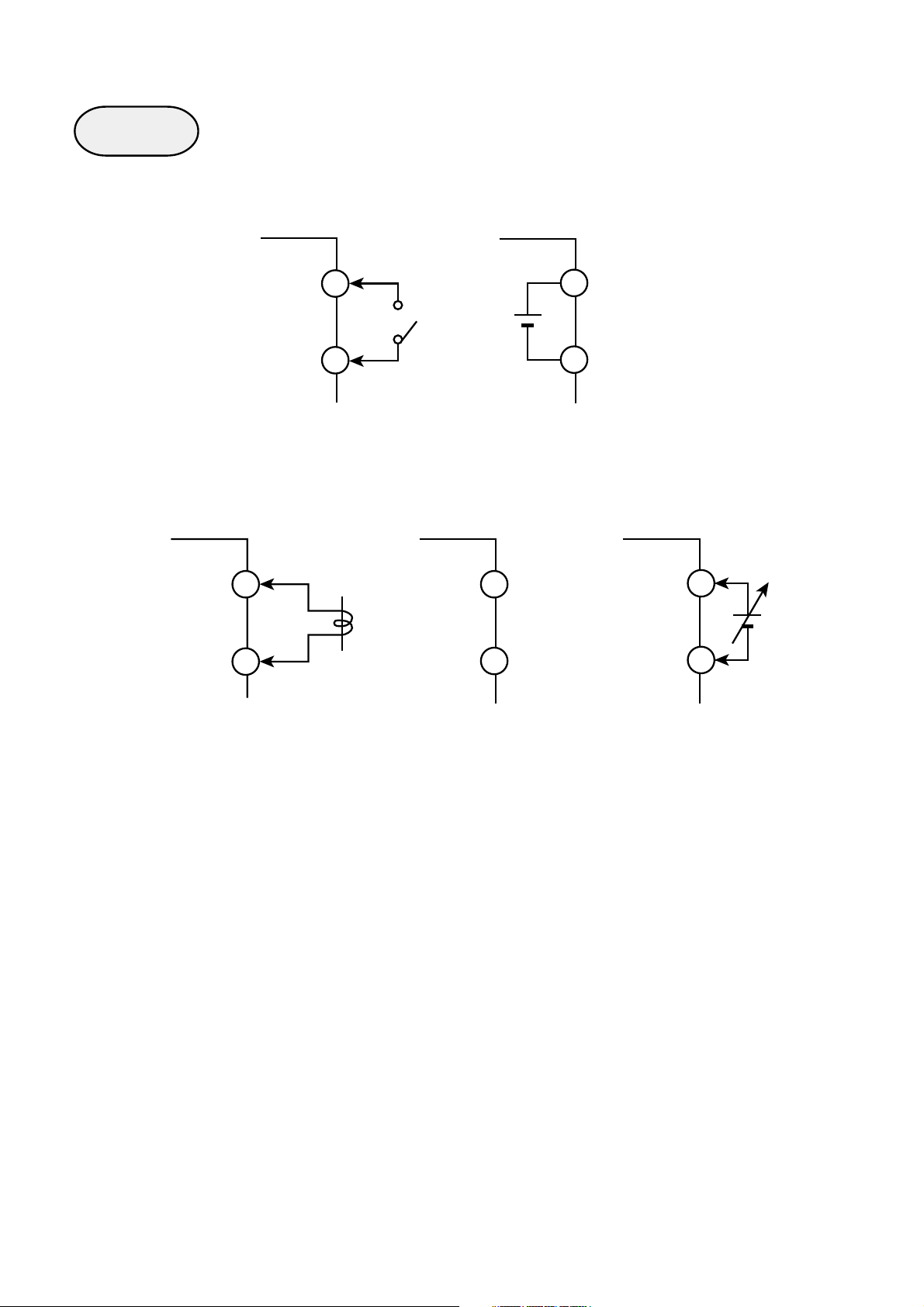

Page 57

Set one type code in each digit (settings 1 to 4). When a code that is

not in the table is specified, it will be regarded as “no alarm (code: 0)”.

(A-group alarm)

Code Type

0

1

2

9

3

4

A

5

6

B

7

C

8

D

No alarm

High limit absolute value

Low limit absolute value

Low limit absolute value

with holding feature

High limit deviation

Low limit deviation

Low limit deviation with

holding feature

High limit deviation

(inverted)

Low limit deviation (inverted)

Low limit deviation (inverted)

with holding feature

High/low limit deviation

High/low limit deviation with

holding feature

High/low limit deviation (inverted)

High/low limit deviation

(inverted) with holding

feature

No alarm used

PV

Alarm Set point

PV

Alarm Set point

Alarm Set point

PV

Set point

Alarm Set point

PV

Set point

Alarm Set point

PV

Set point

Alarm Set point

PV

Set point

Alarm Set point

PV

Set point

Alarm Set point

PV

E

SV high limit absolute value

SV low limit absolute value

F

Alarm Set point

SV

SV

Alarm Set point

NOTE: SV high limit absolute and SV low limit absolute alarms can be

set only in the remote SV type.

56

Page 58

(B-group alarm)

Code Type

0

1

2

3

No alarm

Heater break detection

Loop break detection

Heater break detection

+

Loop break detection

NOTES: Any code setting does not result in heater break detection

unless the heater break option is provided.

(alarm 1 - set point 1) Sets the value for alarm.

(alarm 1 - set point 2)

(alarm 1 - set point 3)

(alarm 2 - set point 1)

(alarm 2 - set point 2)

(alarm 2 - set point 3)

(alarm 1-hysteresis 1) Sets the hysteresis for alarm.

(alarm 1-hysteresis 2)

(alarm 1-hysteresis 3)

(alarm 2-hysteresis 1)

(alarm 2-hysteresis 2)

(alarm 2-hysteresis 3)

57

Page 59

(loop break detection time)

The loop break detection time is set in

minutes and seconds. By setting 00.00,

the alarm will turned ON only at an

abnormal input (overrange/

underrange, burn-out etc.). (00.00

~99.59)

(heater break detection current value)

The heater break detection current

value is set in the unit of ampere.

(1~50A)

(heater current value)

Displays the current in the heater.

This parameter cannot be changed.

(0~50A)

Supplementary descriptions

1. If during normal operation, the output (MV value) to switch to less 0% or

±

more 100%, and the input (PV value) not moved more than

elapsed the time defined in

parameter, then the

3%FS

message will appear and loop break alarm turns ON.

2. This device provides the heater current monitor function (for only the

heater break option-fitted type). The current value is displayed in parameter

. This can be used as reference when determining the heater break

detection current value.

3. The heater current measured value is read only when the control output-1

relay is on. When that relay is off, the value at the point immediately before

the relay is set off is retained.

58

Page 60

4. Detection of the heater current requires the following current

transformer (to be purchased separately).

Heater current value

For 1~30A

For 20~50A

Types

CTL-6-SF

CTL-12-S36-8F

5. Heater break alarm is not available in the following cases.

1) Control output 1 is SSR drive output or current output.

2) Control output 1 is relay (1c contact) output and the heater is ON

on the contact N.C. (normally close) side.

3) The output proportion cycle time of control output 1 is lower than

20 seconds.

59

Page 61

Parameter to be used

Ramp soak

* This function is an option.

Ramp soak function

Function to automatically change the set point value (SV) with elapsing

of time, in accordance with the preset pattern, as shown below. This

device allows a maximum of 4 ramp soak programs.

The first ramp starts at the value measured immediately before the

program is executed (PV).

After the program ends, the manipulate value is output according to

(“

”) setting. If you want to continue the control with the

setting value (SV) immediately prior to the end of the program, set the

parameter “

” to 0 (control continue). Note that, with this

setting, the control will be continued even if abnormal input takes

place.

Set point

Set point 3

Set point 2

Set point 1

Set point 4

PV

First ramp First soak

0

TM1R TM1S

Second

ramp

TM2R

Second

soak

TM2S

Third

ramp

TM3R

Third soak

TM3S

Fourth

ramp

TM4R

Fourth soak

Time

TM4S

Ramp···· Region in which the SP changes toward the target value.

Soak····· Region in which the SP keeps unchanged at the target value.

Powering on can automatically trigger the program run (power-on start

function). External contact signals (option) also run the program (start/

reset).

60

Page 62

Operating procedure

(ramp soak command) Switches the program

(power-on start command) Set this to determine whether

(first-ramp target value) Sets the target value (SV)

operation modes.

Local operation

Program run

Program temporary halt

the power-on start should be

made. (Yes/No)

during each ramp. (0~100%FS

E.U.)

(second-ramp target value)

(third-ramp target value)

(fourth-ramp target value)

(first ramp segment time) Sets the duration (in hours and

minutes) of each time segment

(first soak segment time)

(second ramp segment time)

(second soak segment time)

(third ramp segment time)

61

Page 63

(third soak segment time)

(fourth ramp segment time)

(fourth soak segment time)

(time for rest of the program) The time for rest of the

program is displayed as

follows. This parameter cannot

be set.

When the time for rest is 100 hours or more:

(example: for 100 hours)

When the time for rest is less than 100 hours:

(example: for 99 hours and 59 min)

(present point of program) It displays the program run

status as shown in the

following table. This parameter

cannot be set.

Stop

First ramp running

First soak running

Second ramp running

Second soak running

Third ramp running

Third soak running

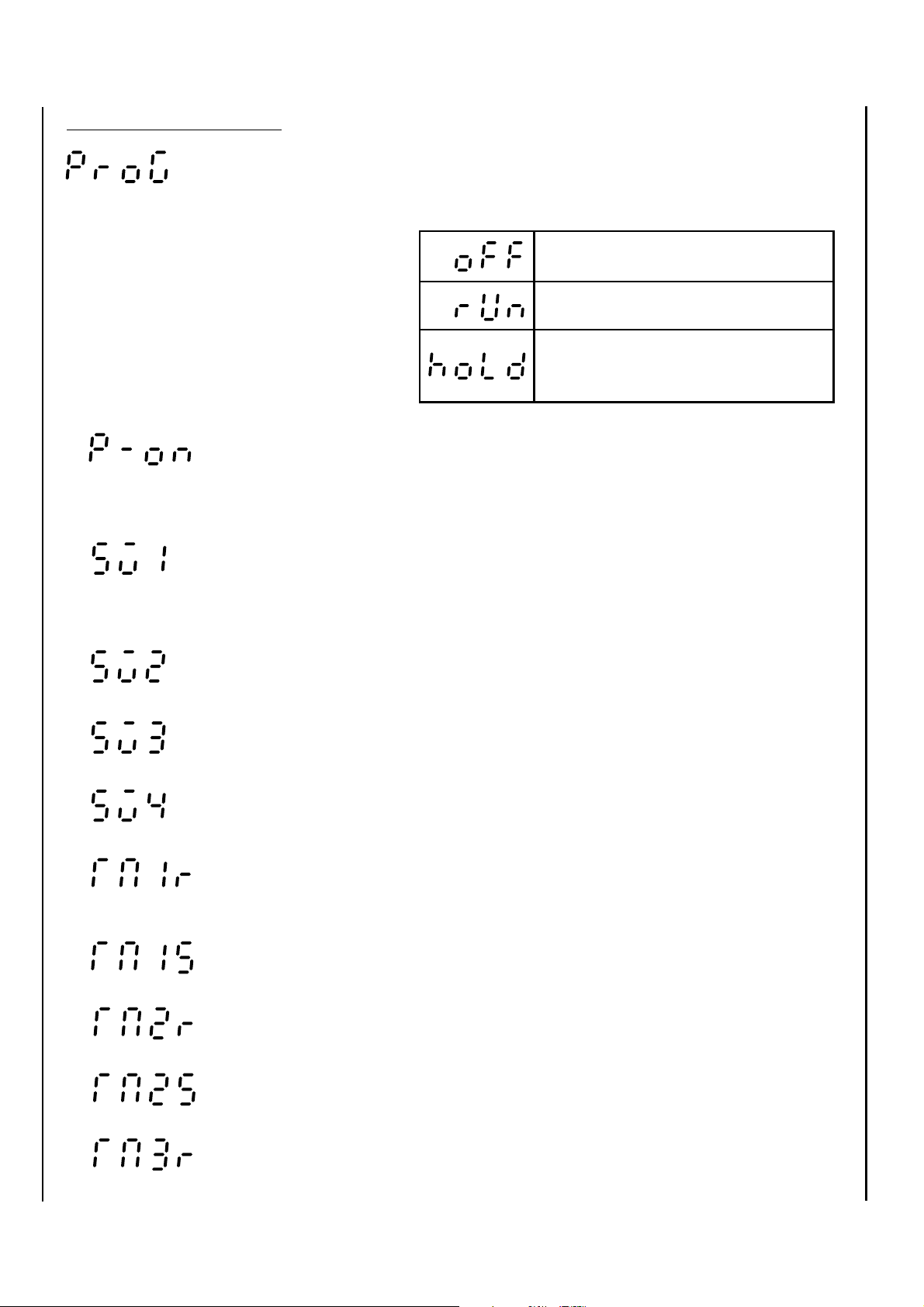

Fourth ramp running

Fourth soak running

Program end

62

Page 64

When using the start/reset function, connect an external terminal with

reference to the section “5. Wiring” starting on the page 19. The

operations will be as follows. External contact input takes place at the

time when the contact status (ON/OFF) changes (edge detection).

External contact

(digital input DI)

ON → OFF

OFF → ON

Program stops.

Program runs.

Operation

NOTE:

1. Do not use the auto-tuning function while the ramp soak function is

ON (“

2. The ramp soak command “

supply is switched

” is not ).

” will be set off, once the power

.

63

Page 65

Parameter to be used

Two set-points

* This function is an option.

Two set-points

Changes setpoint with external contact input (Digital Input). See “5.

Wiring” starting on the page 19 for connection of an external contact.

Main Set point

(SV)

Target point

Sub-Set point

( )

Operating procedure

(sub-set point) Set the sub-Set point in parameter

Target value

DI input

sub-Set point value while DI input is

on and, while it is off, the main Set

point value is the target value.

Main

Set point

OFF OFFON

Sub-Set point

DI input

. The target value is the

Main

Set point

64

Page 66

Parameter to be used

Analog output (AO)

* This function is an option.

AO output function

Function to externally output the PV, SV, or MV value with DC1~5V

signals. AO output can be scaled.

Operating procedure

(AO output type) Set the parameter

the desired output signal type.

Measured Value

Setting Value

Manipulated Value

(scale high limit)

(scale low limit) Set the parameters

and to the signal type

values (%) corresponding to the 5V

and 1V output respectively of AO.

(Percentage against the input

range is set when the signal type is

to

PV or SV, the % value with respect

to the input range is set.)

65

Page 67

Example: Input....K thermocouple, 0 ~ 800

°

C range

1~5V signals are to be output when PV values are at 200 -

°

600

Measured

value

800

(°C)

600

(°C)

C.

AO output

5(V)

AO signal type . . . PV value

600°C → 75% of input range

200°C → 25% of input range

(Setting)

200

(°C)

1(V)

0

• • •

• • •

• • •

75.0%

25.0%

NOTE:

1. must be greater than .

66

Page 68

Parameter to be used

Digital output

* This function is an option.

Digital transmission function

Using the RS-485 communication, this function allows remote control

for parameter settings and process monitoring. This employs the multidrop system, and allows connection of a maximum of 31 units. The

communication protocol conforms to the Fuji Electric CC data line

R

protocol or Modbus

RTU (Radio Terminal Unit) protocol. Select

model configuration when you order (See page 6 or 7). For details,

refer to the Fuji Electric PYX Transmission Protocol Specifications

(TN508165-E).

Operating procedure

(station No.) Set the station number (1~31).

Perform transmission in accordance with the PYX Transmission

Protocol Specifications. In case of Fuji Electric CC data line protocol,

the available commands are for polling (parameter read), selecting

(parameter write) and control (parameter save). In case of Modbus

R

RTU (Radio Terminal Unit) protocol, they are for polling (parameter

read) and selecting (parameter write, including parameter save <fix>).

Communication settings are fixed as described below. Make sure that

the host side has the same settings.

Transmission signal ..... RS-485

Transmission rate ........ 9600 bps

Parity ........................... Odd

Stop bit ........................ 1 bit

67

Page 69

NOTES:

1. For the control (parameter save) operation, a maximum of 5 sec is

required for the interval from receiving a command to completing the

operation.

Before ending of that interval, never turn the power

for this device off (otherwise, the memory contents are destroyed

and disabled).

2. This unit requires a time length of 100 to 120mS as the interval from

completing reception of a command from the host before returning

the response. It also requires 20mS before it is able to receive the

next command after completing a reply.

This device

100~120mS

Host Command

Response

20mS

Host Command

Time

Modbus R is a registered trademark of Gould Modicon.

68

Page 70

Manual operation /Set Point value (MV)

Manual mode

Direct manipulation

Operating procedure

(control mode) Switches the control mode

Parameter to be used

Automatic control

Manual control

(During manual mode, the Set point

value and

alternate in

display on the Run screen.)

Set point value Set the manipulated variable to be

output in “%” units into the SP field

of the operation screen. (-3.0-

103.0%)

Supplementary descriptions

1. The normal PID or fuzzy control status is called the auto mode

(

manual mode (

), and manual operation status is referred to as the

).

69

Page 71

NOTE:

1. For the dual control type, the manual control mode is not available.

2. Though the display of manual output can be set in 0.1% unit, the

actual output resolution is 1%.

3. Autotuning cannot be executed in the manual mode.

4. Power supply is off during manual operation, the value of

becomes 0.0%.

5. When the manipulated variable is changed during manual operation,

the proportion cycle being output at that changing point is followed

by the next proportion cycle which starts the actual output of

changed MV.

Present cycle Next cycle

Output changed from

50%~20%

20% output started

70

Page 72

Parameter to be used

Remote SV Set value

* This function is an option.

Remote SV function

This function is used to input a signal of 1 to 5 VDC externally, and

changes and controls the set value (SV) according to the input voltage.

This is useful for cascade control etc.

Operating procedure

Set value

(Select the control mode)

Sets the control mode

The set value (SV) by remote input is displayed

during remote control. (The keys on the front panel

are disabled during remote control.)

(Remote control set value)

The set value (SV) by remote input, regardless of

the current mode. This parameter cannot be

changed.

(Scale high limit)

The remote set values (SV) corresponding

remote input 5V and 1V as the parameter

(Scale low limit)

(0 to 100% FS E.U.)

Enables automatic control.

(See Page 69 for details.)

Enables manual control.

(See Page 69 for details.)

Enables remote control.

to the

and respectively.

Supplementary descriptions

1. See Page 69 for and (automatic and manual modes).

2. When the mode is switched to

(the automatic mode) during

(remote operation), the set value (SV) of the automati c mode will be the same as

the set value of the remote control. (The set value will be switched by bumpless).

3. The set value will be the low limit when the remote input is disrupted.

4. Fuzzy control can be used for set value (SV) changes in steps.

NOTES:

1. must be greater than .

2. Caution is required when executing auto-tuning during remote operation,

since auto-tuning will be disrupted if the set value (SV) changes by more

than 0.5%FS per 0.5 second before the completion of auto-tuning.

71

Page 73

Parameter to be used

Output monitoring

Output monitor function

Numerically displays the MV being output.

Operating procedure

(MV for output1) The currently output value of single-

output or dual-output heating-side

MV is displayed in percent.

(-3.0 to 103.0%)

(MV for output2) The currently output value of dual-

NOTES:

1. Neither

2.

output cooling-side MV is displayed

in percent. (-3.0 to 103.0%)

nor can be set.

is not displayed with the single-output type.

72

Page 74

VI. SET-UP PARAMETER

Parameter to be used

Input filter

Input filter

When a PV value becomes unstable due to effects of noise, the filter

helps suppress the unstable status.

Setting procedure

(input filter constant) Set the filter time constant in sec

units (0.0 ~ 900.0 (sec)).

=0, input filter function is not active.

The filter effects increase as this setting becomes larger, and decrease

as it becomes smaller.

Time constant LargerSmaller

Response SlowerFaster

Effect GreatLittle

73

Page 75

Parameter to be used

PV shift

PV shift

Shifts the PV. Use this function when the PV is to be adjusted

according to a recorder or an indication instrument, or when the sensor

is not in the right position and therefore the PV must be adjusted.

Setting procedure

(PV shift value) Set the shift value to be added to

PV. (-50 ~ 50%FS E.U.)

+

PV Processor

+

74

Page 76

Parameter to be used

Control type

Control type

In addition to PID control, this device is fitted with the fuzzy control

suitable for suppressing overshoot. One of the two can be selected as

the control type.

Setting procedure

(control type) Select the control type.

PID control

Fuzzy control

NOTES:

1. When control is made with the fuzzy, the PID parameter must be set

as with PID control. However, it need not be tuned particularly for

the fuzzy. (The values are allowed to be the same as those for PID

control.)

2. The fuzzy control mode also allows use of the autotuning function.

3. Fuzzy control cannot be used in the dual output type.

4. The two-set-point function is not available in the fuzzy control mode.

5. Fuzzy control can only be used when the set values change in

steps. Attention is required when the ramp soak function or remote

SV function is used.

75

Page 77

Parameter to be used

Output setting in input abnormal

Input abnormal-time output

In the event of an input PV error (e.g. thermocouple burn-out, sensor

disconnection or short-circuit, over-input, under-input etc.), or after the

ramp soak function (option) program ends, the value specified in

advance as the parameter “

value.

Setting procedure

(input abnormal-time output selection code)

Code No. Control output 1

” is out put as the manipulated

Set the code number (0 ~ 4) by

referencing the following table.

Control output 2

0

1

2

3

4

Going on control

-3%

103%

-3%

103%

Going on control

-3%

103%

103%

-3%

Supplement:

1. Set the parameter

to “0” when the control is desired to

be continued after the ramp soak function (option) program

terminates, with the set value prior to the program termination.

NOTES:

1. The parameter “

” specifies only one type of output for

both cases of abnormal input and program end. In other words, the

same operation will be made after an input error and after the

program ends.

76

Page 78

Parameter to be used

Output limits

Output limit

Function to limit the manipulated variable. Used to limit the output

range to favor conditions of the process or operation terminal.

Setting procedure

(MV high limit)

(MV low limit) Set the manipulated-variable high

and low limits (-3.0 ~ 103.0%).

Set point

Set point 3

Set point 2

Set point 1

Set point 4

PV

First ramp First soak

0

TM1R TM1S

Ramp···· Region in which the SP changes toward the target value.

Soak····· Region in which the SP keeps unchanged at the target value.

Second

ramp

TM2R

Second

soak

TM2S

Third

ramp

TM3R

Third soak

TM3S

Fourth

ramp

TM4R

Fourth soak

Time

TM4S

NOTES 1: Setting must always be made to satisfy the condition of

> .

2: Limiting is not valid during manual operation.

3: Auto-tuning provides the 0-100% range output regardless

of limiting.

4: The limiter is not valid for the 2 point (ON/OFF) control.

5: The loop break detection cannot be performed when

“

” exceeds 100.0% or does not reach 0.0%.

77

Page 79

Parameter to be used

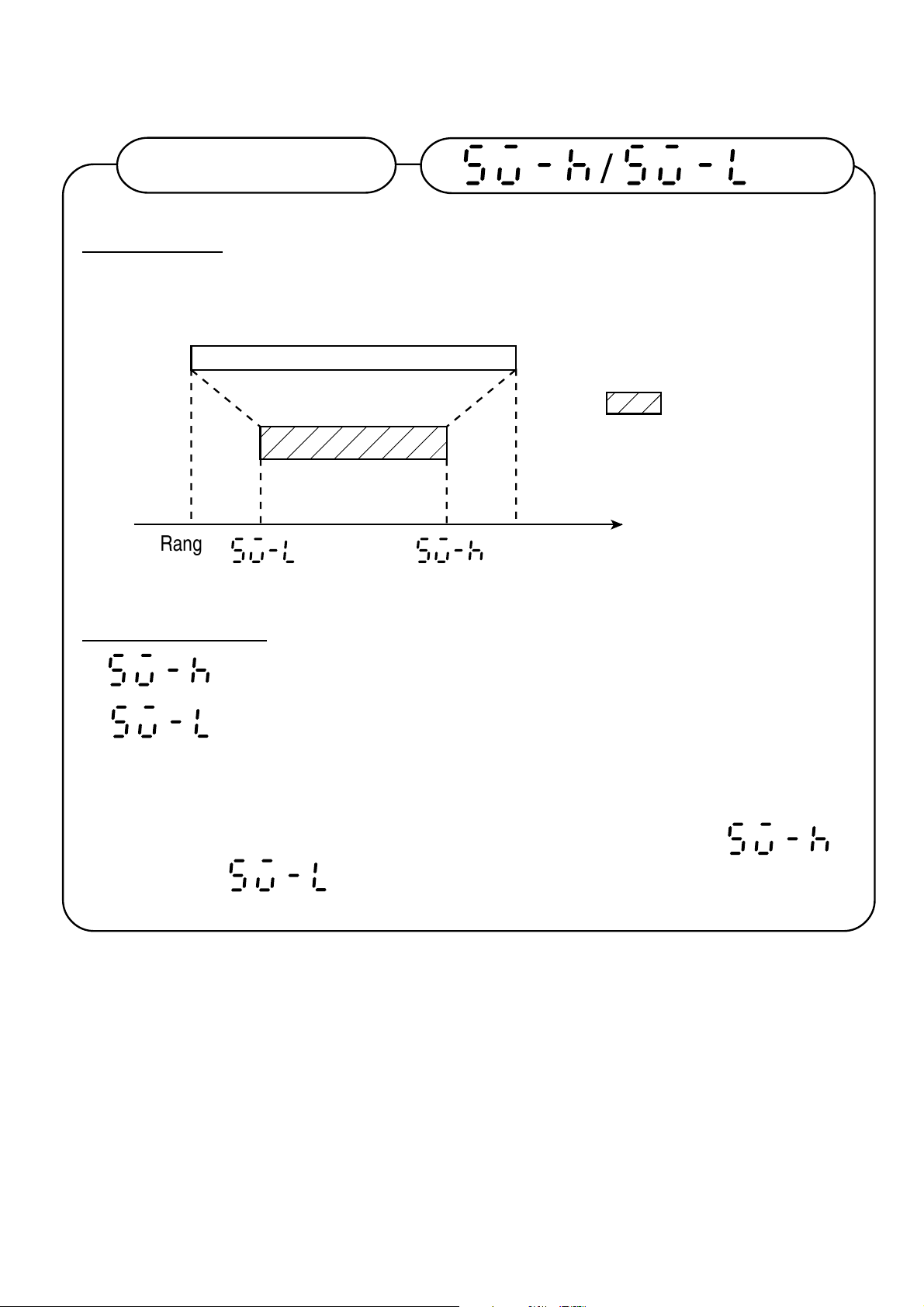

Set point vlaue limits

Set point limit