Page 1

Instruction Manual

MICRO CONTROLLER H

Z SERIES

TYPE: PYH

INP-TN3PYHd-E

Page 2

PREFACE

Congratulations on your purchase of Fuji Digital Temperature Controller (Type: PYH)

•Read this instruction manual carefully to ensure correct installation, operation and preparation.

Incorrect handling may lead to accidnt or injury.

• Specifications of this unit is subject to change without prior notice for improvement.

•Modification of this unit without permission is strictly prohibited.

Fuji will not bear any responsibility for a trouble caused by such a modification.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Co., Ltd.

Type : Shown on nameplate of main frame

Date of manufacture : Shown on nameplate of main frame

Product nationality : Japan

The product conforms to the requirements of the Electromagnetic compatibility Directive 89/336/EEC

as detailed within the technical construction file number TN510403. The applicable standards used to

demonstrate compliance are:

EN 50081-1 : 1992 Conducted and Radiated emissions

EN 50082-1 : 1992 Radiated immunity, ESD and FBT

(The unit meets Class A limits for conducted Emissions.)

The unit also complies with the part of Immunity standards.

IEC 1000-4-2 : 1995 level 3, IEC 1000-4-3 : 1995 level 3

IEC 1000-4-4 : 1995 level 3, IEC 1000-4-8 : 1993 level 4

© Fuji Electric Co., Ltd. 1993

Request

•Transcription of a part or the whole of this manual without permission is

prohibited.

•The contents of this manual are subject to change without prior notice.

Issued in November, 1993

Rev. 1st edition November, 1993

Rev. 2nd edition February, 1996

Rev. 3rd edition April, 1997

Rev. 4th edition February, 2002

INP-TN3PYH-E i

Page 3

CAUTION ON SAFETY

First of all, read this “Caution on Safety” carefully, and then use the instrument in the correct way.

The cautionary descriptions listed here contain important information about safety, so they should always be observed.

Those safety precautions are classified in 2 ranks, WARNING and CAUTION.

The following shows the meaning of WARNING and CAUTION.

Wrong handling may cause a dangerous situation, in which there is a possibility of death or

WARNING

CAUTION

1. WARNING

heavy injury.

Wrong handling may cause a dangerous situation, in which there is a possibility of injury or

physical damage.

1.1 Caution on wiring

(1) For the safe operation of the controller, where the temperature probe is to be installed into an environment where

voltage exceed 50V DC, it is essential that reinforced isolation or basic isolation and earth is maintained between

all connections to the rear of the temperature controller, and that supplementary isolation is required for the alarm

outputs.

The outputs from the controller are all less than 50V DC.

When wiring the power supply terminal, use vinyl insulated 600 volt cable or equivalent. A switch breaking both

poles of the mains supply should be installed together with a fuse with a rating of 250 volt 1 Amp. The fuse

should be installed between the mains switch and the controller.

The level of insulation provided by the temperature controller is:-

MAINS = BASIC

HEATER = BASIC

INPUTS = –––

Prior to operation of the installed system the wiring should be checked to ensure that the required levels of insulation have been provided.

(2) When a fault in the instrument is likely to lead to a serious trouble, use a suitable protective circuit on the outside

for protection against trouble.

(3) This unit is not provided with power switch, fuse, etc. These parts can be installed separately, if required (fuse

rating; 250V, 1A).

(4) Use of Fuji’s Z-Trap is recommended to protect the relay output from switching surge and to ensure a long life.

Type: ENC241D - 05A (power voltage; 100V)

ENC471D - 05A (power voltage; 200V)

Mounting position: Connected to relay control output terminals

ii INP-TN3PYH-E

Page 4

CAUTION ON SAFETY

1.2 Power source

(1) Use a power source of rated voltage to prevent damage or trouble.

(2) Do not turn ON the power until the wiring is completed to prevent shock hazard or trouble.

1.3 Prohibition of use in gas

The instrument is not an intrinsic safety explosion-proof type. Do not use it in a place exposed to combustible or

explosive gas.

1.4 Contact to unit

(1) This unit must not be disassembled, modified or repaired to prevent malfunction, shock hazard or fire accident.

(2) When the power is ON, do not touch the terminals to prevent shock hazard or malfunction.

1.5 Caution on maintenance

(1) Before mounting or removing the module or unit, turn OFF the power in advance to prevent shock hazard, mal-

function or trouble.

(2) Periodical maintenance is recommended to ensure continuous and safe operation of the instrument. Some parts of

the instrument are limited in life or are subject to secular change.

2. CAUTION

2.1 Caution on handling

(1) Do not install the unit in any of the following places.

•A place where the ambient temperature exceeds the range of -10 to 50°C

•A place where the ambient humidity exceeds the range of 45 to 85%RH

•A place where temperature changes suddenly or dew condensation occurs

•A place exposed to corrosive gases (sulfuric gas, ammonia, etc.) or combustible gases

•A place where vibration or shock is likely to be directly transmitted to the body

•A place exposed to water, oil, chemicals, vapor, steam, etc.

•A place with much dust, salt or iron component

•A place with much inductive disturbance, static electricity, magnetism or noise

•A place exposed to direct sunlight

•A place where heat such as radiant heat stays

(2) Mounting

For mounting, attach the supplied mounting brackets (2 units) on top and bottom and tighten with a screwdriver.

Tightening torque is about 147N·cm. (The case is made of plastic. Care should be taken not to tighten forcedly.)

(3) When the unit is exposed to water, it may lead to a short-circuit or fire hazard. Contact your dealer for inspection.

2.2 Caution on cable connection

(1) For thermocouple input, use a suitable compensating cable.

(2) For resistance bulb input, use a cable with a small lead wire resistance and without resistance difference between 3

wires.

(3) When external wiring has much noise, use the following step. When a conducted as load of digital output such as

relay contact output or alarm output, connect a surge absorber to the conductor coil. (Example: ENC471D-05A

for 200V AC)

INP-TN3PYH-E iii

Page 5

CAUTION ON SAFETY

(4) When the power source has much noise, use an insulating transformer together with a noise filter. Noise filter

should be mounted on a panel which has been earthed. The wiring between the noise filter output and the instrument power terminals should be as short as possible. Do not connect a fuse or switch to the noise filter output

wiring, as it affects the performance of the filter.

(5) Use of a twisted cable for the instrument power source provides better effects (short twist pitch is effective for

noise).

(6) When a heater burnout alarm is provided, the heater power and controller power should be connected using the

same power line.

(7) Time for preparation of contact output is required at power ON. When the output signal is used for an external

interlock circuit, etc., connect a delay relay to the circuit.

2.3 Other

When cleaning the instrument, do not use organic solvents such as alcohol, benzine, etc. Use neutral detergent.

3. Caution on key operation/trouble

(1) Alarm function should be set correctly. Otherwise, alarm output cannot be obtained at the time of occurrence of

trouble. Be sure to check the function prior to operation.

(2) Do not stop the device forcedly during auto-tuning, as it affects the control action. When it needs to stop forcedly,

be sure to turn OFF the power in advance.

(3) If the input cable is disconnected, the display shows UUUU or LLLL. When replacing the sensor, be sure to turn

OFF the power.

iv INP-TN3PYH-E

Page 6

CONTENTS

PREFACE .....................................................................................................................i

CAUTION ON SAFETY............................................................................................ ii

1. RATINGS.............................................................................................................1

2. PERFORMANCE.................................................................................................3

3. OPERATING PARTS AND THEIR FUNCTIONS ............................................4

4. PREPARATION FOR OPERATION, AND OPERATION................................6

4.1 Preparation for operation....................................................................................... 6

4.2 Operation ............................................................................................................... 6

4.3 Selection of operation mode................................................................................ 10

5. FAULT INDICATION.......................................................................................13

6. USE OF HEATER ALARM (OPTION)............................................................15

7. CHANGING OF FUNCTIONS .........................................................................17

7.1 Method of changing specifications...................................................................... 17

8. DUAL OUTPUT CONTROL TYPE .................................................................22

9. SV SELECTION ................................................................................................24

10. POSITION FEEDBACK CONTROL TYPE.....................................................25

11. INVERTER CONTROL TYPE..........................................................................26

12. PARAMETER SET VALUE TABLE ................................................................27

13. OUTLINE DIMENSIONS AND PANEL CUTOUT ........................................33

14. CONNECTION DIAGRAM..............................................................................34

15. PARAMETER LIST ..........................................................................................35

16. INSTALLATION AND WIRING......................................................................37

17. CODE SYMBOLS .............................................................................................39

INP-TN3PYH-E v

Page 7

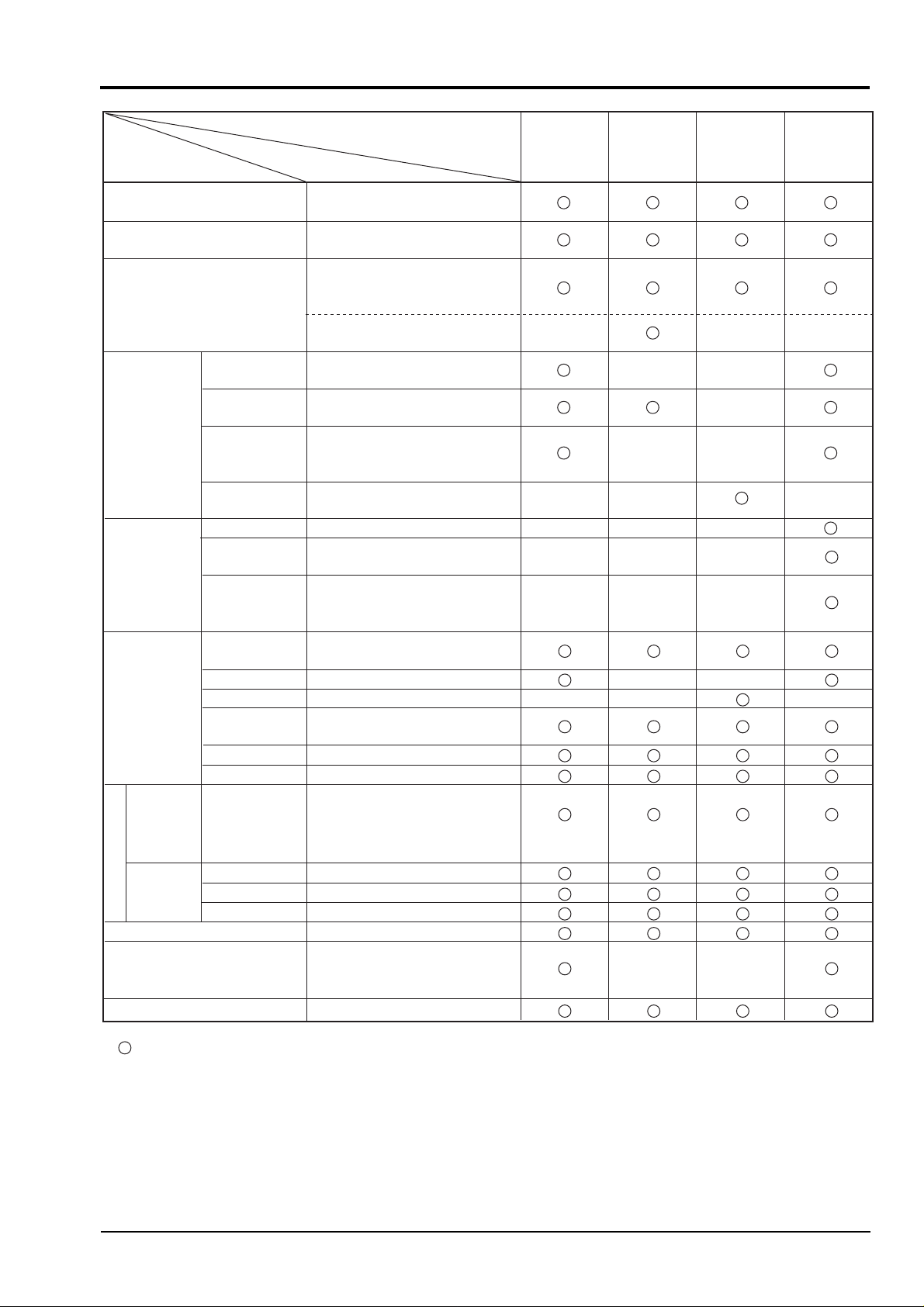

1. RATINGS

Item

Power source voltage

Power consumption

Input

(measured value)

Relay contact

Current

Control

output 1

Control

output 2

(dual control

type only)

Auxiliary

input

PV/SV/MV

transmission

output

Auxiliary

alarm

Auxiliary output

output

Main alarm output

Heater burnout alarm output

Fault output

SSR/SSC drive

Motor-driven

valve operation

Relay contact

Current

SSR/SSC drive

Analog

Heater current

Opening

Digital 1

Digital 2

Digital 3

Analog *3

Digital 1

Digital 2

Digital 3

Type

Rating

85 to 264V AC, 50/60 Hz,

free power source

About 20 VA (100V AC)/

About 30 VA (220V AC)

Thermocouple, resistance bulb,

voltage, current,

mV input (leak current=3µA typ.)

With transmitter power 4 to

20 mA DC. (PYH9 only)

220V AC, 3A, 1c contact

(resistive load)

4 to 20mA DC, load resistance,

600Ω or less

10V to 27V DC at ON, 0.5V DC

or less at OFF, max. current,

20mA DC.

220V AC, 3A, la contact × 2

220V AC, 3A, 1c contact

4 to 20mA DC, load resistance,

600Ω or less

10V to 27V DC at ON,

0.5V DC or less at OFF,

max. current, 20mA DC.

1 to 5V DC, input resistance,

1MΩ or more *1

1 to 50A AC.

100 to 1000Ω, 3-wire system

Contact, OFF at 24V DC,

Ditto (PYH9 only)

Ditto (PYH9 only) *2

1 to 5V DC, input impedance of

connected device, 500kΩ or

more

30V DC, 0.1A, la contact *4

Ditto

Ditto (PYH9 only)

220V AC, 1A, la contact × 2

220V AC, 1A, la contact

(PYH5: Open-collector

30V DC, 0.1A, 1b contact

ON at 0V DC (15 mA)

(30V DC, 0.1A))

Fixed set

point control

type

−−

−

−

−

−

−

Inverter

control type

(PYH9 only)

−

−

−−

−

−

−−

−

Position

feedback

control type

−

−

−

−

−−

−−

−

−

Dual

control type

−

: Applicable : Not applicable

*1: If “A” or “C” is not specified in the 11th digit of PILC, do not use the instrument because it will not operate normally.

*2: Auxiliary digital input 3 can be used when it is the T-Link transmission specifications or on SV selection.

*3: If “B” or “C” is not specified in the 11th digit of PILC, do not use the instrument because it will not operate normally.

*4: Open collector in case of PYH5

INP-TN3PYH-E 1

−

Page 8

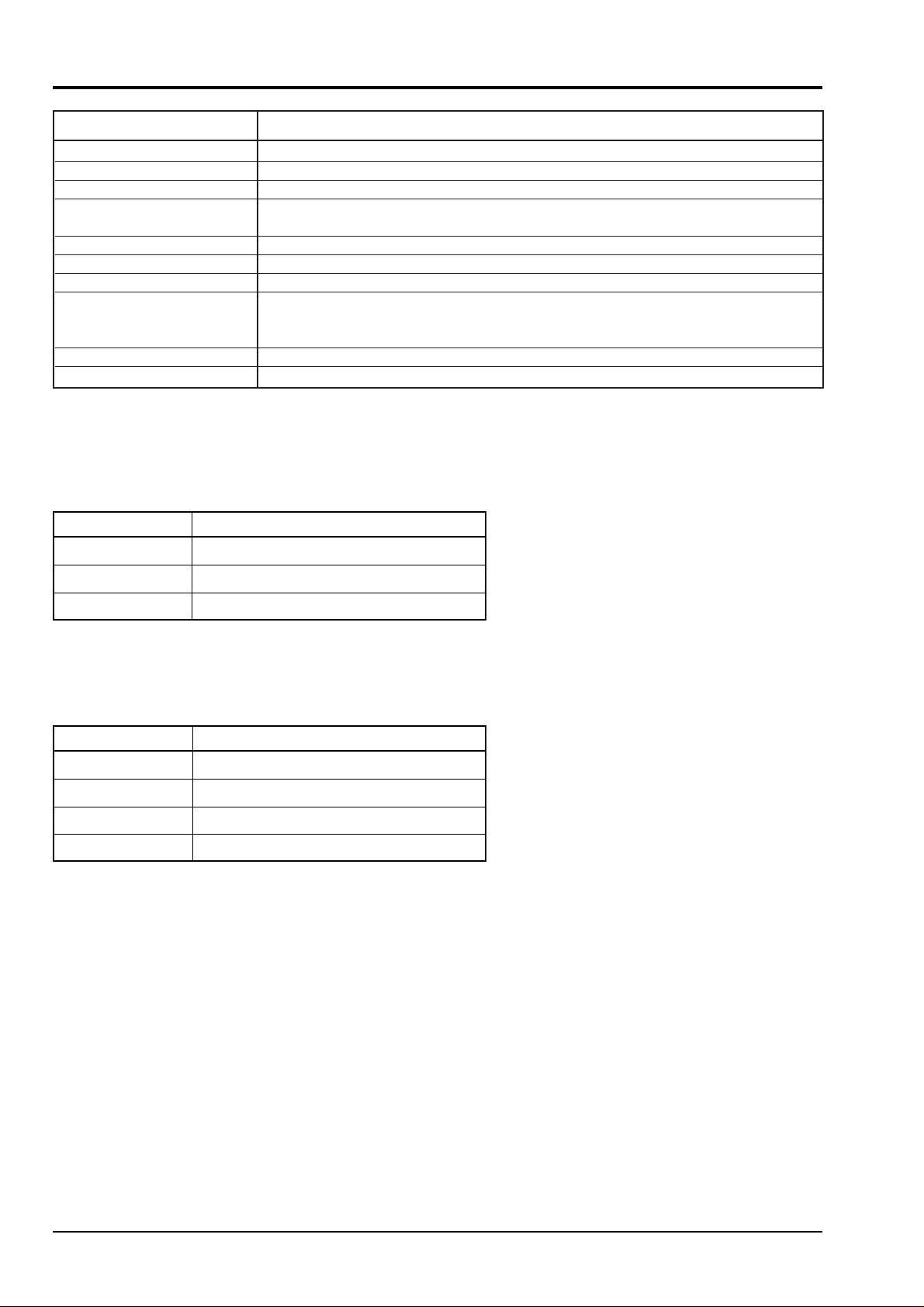

1. RATINGS

Item Rating

Setting method

Indicating method

Transmission function

Operating ambient

temperature

Operating ambient humidity

Storage temperature

Enclosure case

External dimensions

(unit: mm)

Mass

Finish color

Wiring resistance of allowable input signal

Input signal Allowable input signal wiring resistance

Thermocouple, mV 50Ω or less per wire

Resistance bulb 10Ω or less per wire

Key switch (data continuous change method)

7 segments, LED 4 digits × 2, mode indication

RS-485, T-link (PYH9 only) *5

-

10 to +50°C

90% RH or less (no condensation)

-

10 to +70°C

Plastic housing

PYH5: 96(H) × 48(W) × 150(D)

PHY7: 72(H) × 72(W) × 150(D)

PHY9: 96(H) × 96(W) × 150(D)

PYH5/PYH7, approx. 0.5kg, PYH9, approx. 0.8kg

Munsel N1.5 (black)

*5: T-Link is a name of Fuji Electric informa-

tion network.

*6: Built in the instrument (external resistor is

not required.)

1 to 5V DC 10Ω or less

Input impedance

Input signal Input impedance

Thermocouple 1MΩ

Resistance bulb ––

1 to 5V DC 1MΩ

4 to 20mA DC 250Ω *6

2 INP-TN3PYH-E

Page 9

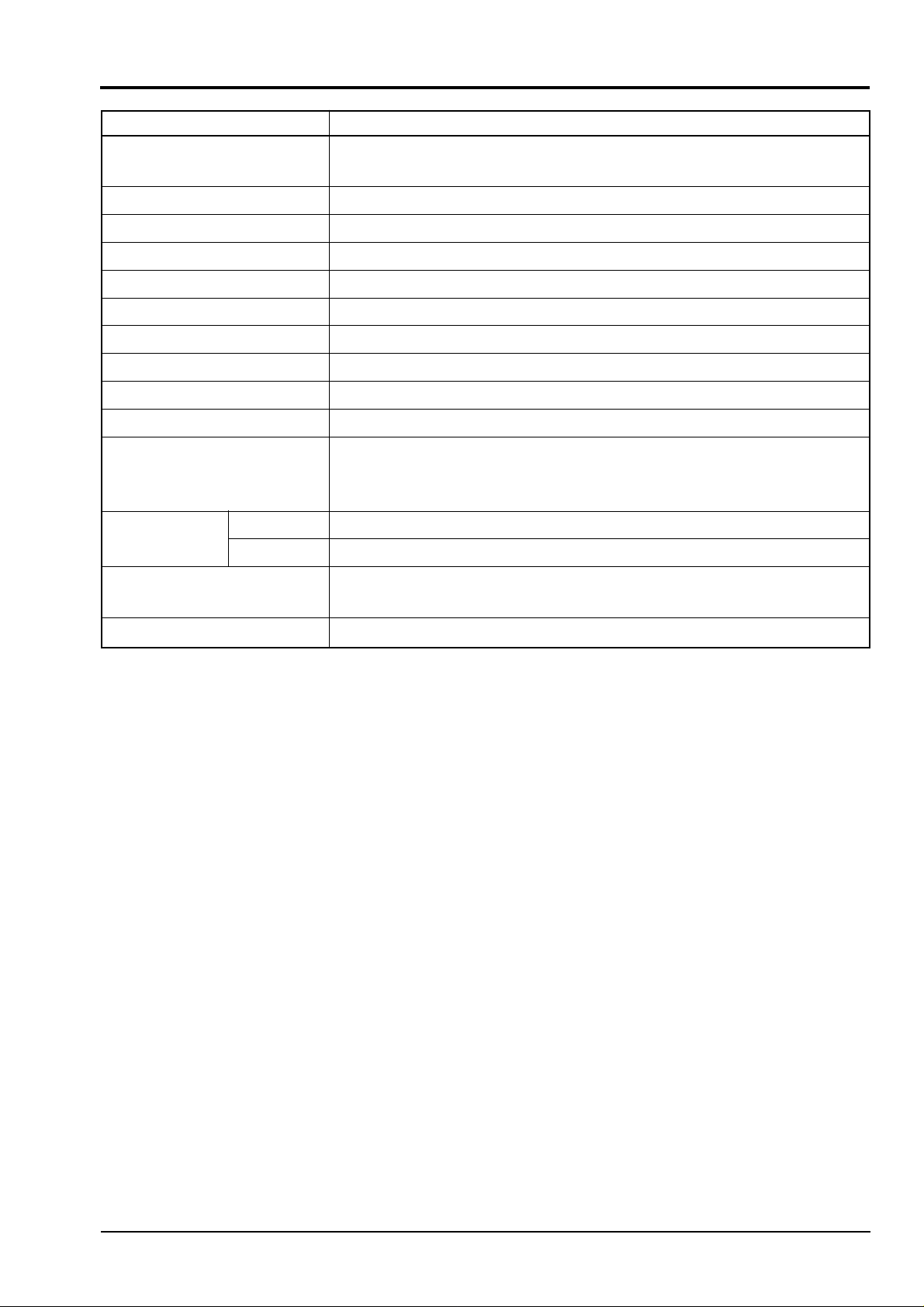

2. PERFORMANCE

Setting accuracy ±0.2% FS±1 digit

Indication accuracy ±0.2% FS±1 digit, temperature compensation ±1°C

Note) Refer to Table 1 (P.18).

Remote setting input accuracy ±0.2% FS

Proportional band (P) 0 to 3276% (with dead band ON-OFF operation at P = 0)

Integrating time (I) 0 to 3276 s

Derivative time (D) 0 to 900 s

Main alarm setting range Within full scale

Sampling cycle 100 ms

Control cycle 0.1 to 3276 s

Time proportion cycle 1 to 255 s

Insulation resistance 20MΩ or more (at 500V DC)

Withstand voltage 1500V AC for 1min. Between power supply and relay contact output, power

supply and the earth, and the earth and relay contact output

500V AC for 1 min. others

Output relay life

Mechanical 107 operations (100 ON-OFF operations/min.)

Electrical 105 operations (20 ON-OFF operations/min. at rated load)

Protective structure Front panel, IEC standards, IP55 (dust-drip proofing)

Terminal unit, IEC standards, IP00

Current output accuracy ±2% FS

INP-TN3PYH-E 3

Page 10

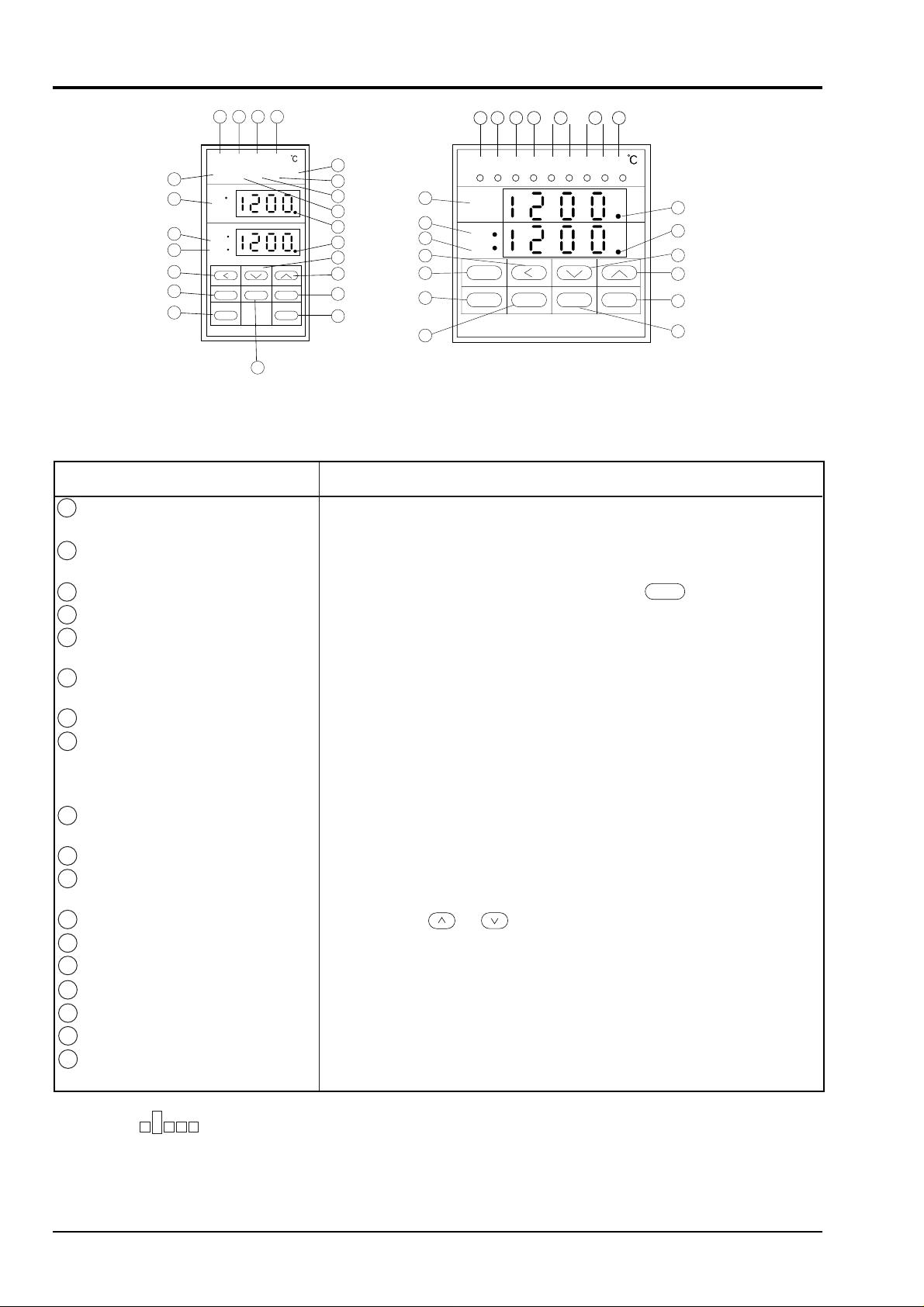

3. OPERATING PARTS AND THEIR FUNCTIONS

4 5 6 7

FLT R A M

C1 C2 H L HB

8

1

PV

2

SV

MV

3

12

11

15

SEL

SV/MV

A/M ENT

16

PYH5

Item

1

Measured value (PV) indication (red)

2

Set value (SV) indication (green)

Control output (MV) indication

3

Instrument fault lamp (red)

4

5

Remote operation lamp (green)

6

Auto operation lamp (green)

7

Manual operation lamp (green)

8

Control output lamp (green)

9

Alarm lamp (red)

10

Heater burnout alarm lamp (red)

11

SV-MV select key

12

Fast key

13

Down key

14

Up key

Auto/manual select key

15

Select key

16

17

Data key

18

Entry key

DATA

10

987654

C1

10

9

9

8

19

20

13

14

17

18

1

2

3

12

11

15

16

FLT HB

PV

SV

MV

SV/MV

A/M

MA

R

C2

SEL DATA ENT

LH

19

20

13

14

18

17

PYH 7, 9

Function

Measured value (PV) is indicated during operation.

Abbreviation of parameter is indicated when setting parameter.

Set value (SV) is indicated during operation.

Data of parameter is indicated when setting parameter.

Control output (MV) is indicated by selecting with key.

SV/MV

This lamp lights at instrument failure.

This lamp lights when operating with input of external set value

(lamp is ON during remote operation).

This lamp lights when operating with SV value set by the front key

(lamp ON during auto operation).

This lamp lights during manual operation.

C1: This lamp lights when control output 1 is given.

(not light when current output is given) *1

C2: This lamp lights when control output 2 is given.

(not light when current output is given) *1

H: This lamp lights when higher limit main alarm is output.

L: This lamp lights when lower limit main alarm is output.

This lamp lights when heater burnout alarm is output.

This key is used for selection between SV and MV indications.

By pressing the key after setting parameter, operation mode is indicated.

By pressing the or key, the data change is sent in fast-forward mode.

This key is used to decrease the value of data to be set.

This key is used to increase the value of data to be set.

This key is used for selection between auto and manual operation.

This key is used to call parameters.

This key is used to change the data of parameters.

This key is used to register the data in PYH after changing the data of

parameters.

*1: PYH lamp is set at OFF before shipment. When the ConF Ch <output terminal definition channel>

D

E

is set with Do1=0F (motor value is open) and Do2=0E (motor valve is closed), the lamp is turned ON/OFF

linked with output ON/OFF.

4 INP-TN3PYH-E

Page 11

3. OPERATING PARTS AND THEIR FUNCTIONS

Indication

Contents

This lamp lights during auto-tuning.

This lamp lights during host transmission operation.

PV

SV

• When parameter is indicated or it is left as it is after setting, operation indication is indicated automatically about

13 minutes later.

19

20

INP-TN3PYH-E 5

Page 12

4. PREPARATION FOR OPERATION, AND OPERATION

4.1 Preparation for operation

To ensure correct operation of the controller, it is necessary to set parameters before operating, according to the

procedures shown in (3) Setting method of main alarm set values (AL1, AL2) of item "4.2 Operation". While

setting parameters, be sure to stop the operation of the external system for the sake of safety.

Kinds of parameters

Refer to "15. Parameter list" on page 35. Note that some parameters in "15. Parameter list" are not used depending

on the type of PYH, which are not displayed by the indicator on the front of PYH.

4.2 Operation

(1) When power turns ON, measured value (PV) and set value (SV) are indicated a few seconds later to start operating.

The indication of measured value and set value is called the operation indication.

Heat up time of PYH is two hours. Measuring and controlling of PYH should be operated after the heat up time.

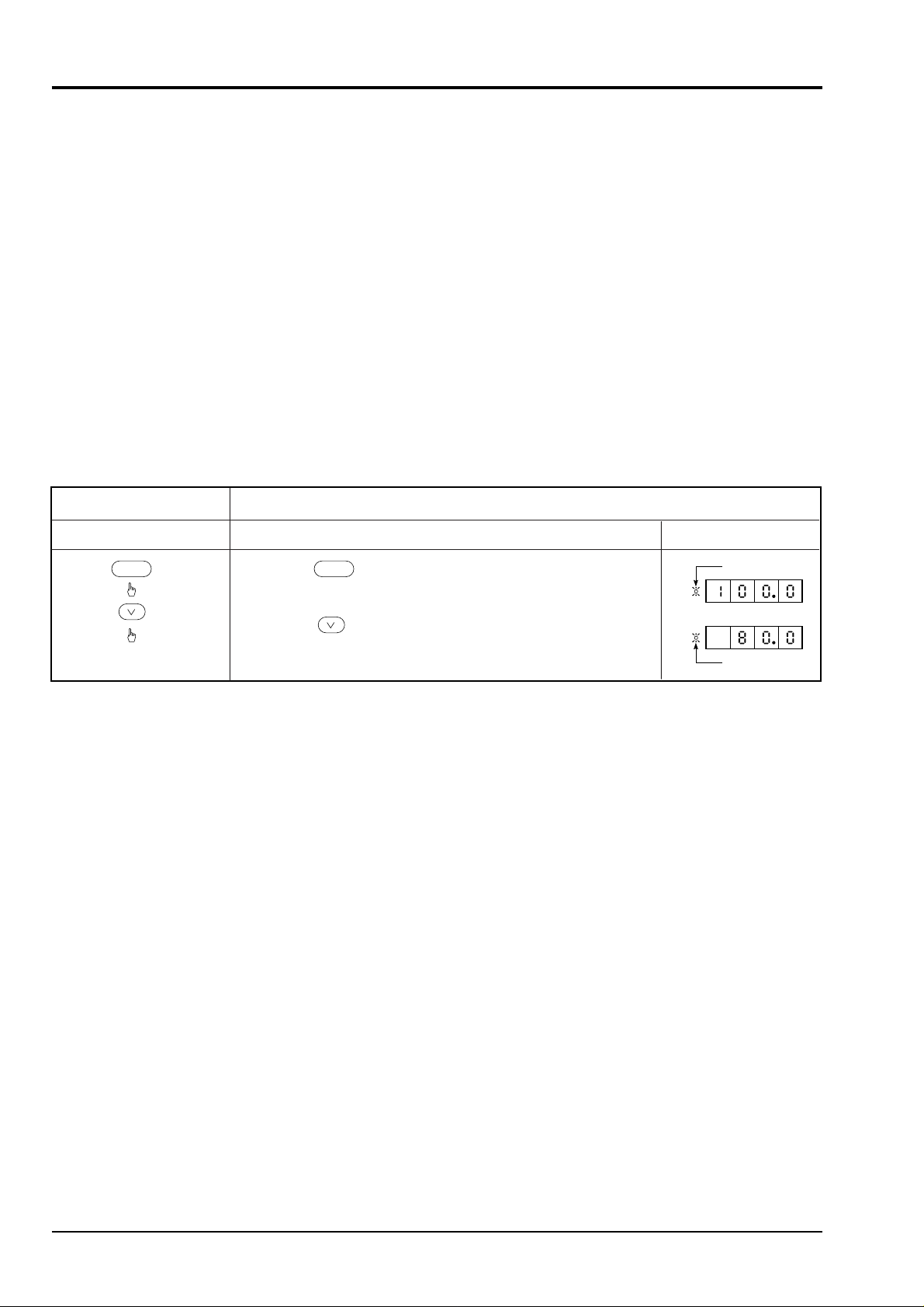

(2) Setting of set value (SV)

Contents of operation

Key operation

SV/MV SV/MV

(Note) If the power for PYH is turned OFF within 10 seconds after changing the set value, it can result in

misoperation. Be sure to turn OFF the power more than 10 seconds after the set value has been changed.

Change of set value from 100.0°C to 80.0°C

Description Indication

• Press the key to light the SV lamp.

(SV lamp should be kept lighting.)

• Using the key, set the set value (SV) to 80.0.

- Operation completed -

SV lamp

SV

SV

SV lamp

6 INP-TN3PYH-E

Page 13

• Press the key for of measured value indication.

• Press the key 3 times for of measured value

indication.

Then press the key. The indication of flickers.

• Press the key to change the data of set value indication from

800 to 850.

• Press the key for registration. stops flickering.

This completes the change of the main alarm 1.

• To reset to the operation indication, press the key.

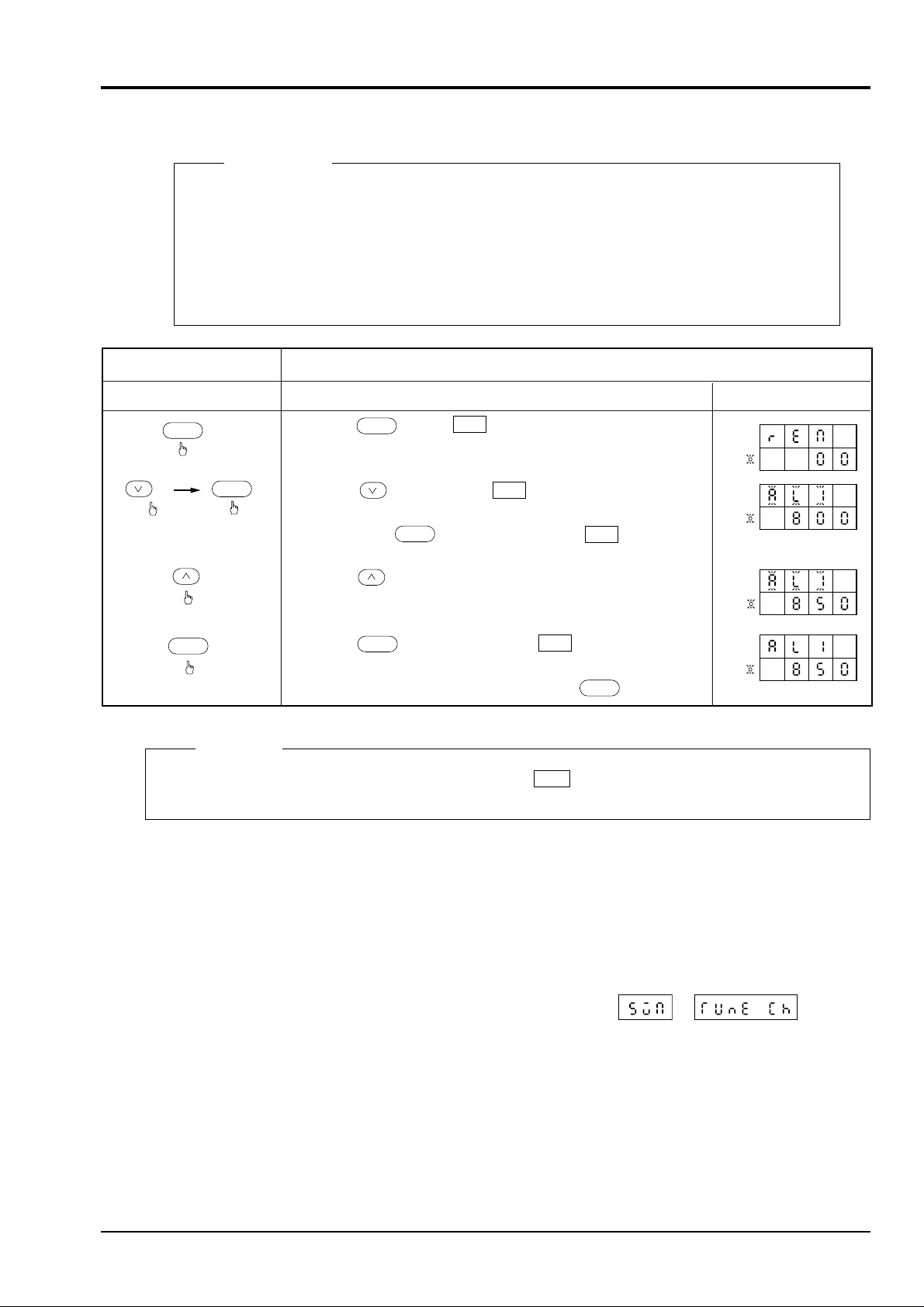

Contents of operation

Key operation

Change of set value of main alarm 1 from 800°C to 850°C

Description Indication

SEL

SEL

DATA

DATA

PV

SV

PV

SV

PV

SV

PV

SV

3 times

ENT

ENT

REM

AL1

AL1

AL1

SV/MV

(3) Setting of main alarm set value (AL1, AL2)

Description

Set data prior to delivery from the factory are as follows.

Main alarm 1 (AL1): Higher limit deviation alarm; set value is an industrial value of 50% full

scale.

Main alarm 2 (AL2): Lower limit deviation alarm with lower limit hold; set value is an indus-

trial value of 50% full scale.

4. PREPARATION FOR OPERATION, AND OPERATION

(4) Auto-tuning (AT) operation

Remarks

The setting method for AL2 is the same as above. Indicate AL2 referring to “15. parameter list” on page 35

and follow the above procedures.

Auto-tuning is a function to set up the parameter of PID automatically with PYH for operation.

a) Auto-tuning should be performed after setting the set value (SV), main alarm 1 & 2, and proportional cycle

(C1, C2 *1). *1: With control output 2 produced

b) Setting data for auto-tuning

The method of auto-tuning is set up to the standard type prior to delivery from the factory (see (4)- d)). Low

PV type (overshoot suppression) can also be selected by setting 01 in of .

(Refer to “15. Parameter list” on page 35.)

INP-TN3PYH-E 7

Page 14

4. PREPARATION FOR OPERATION, AND OPERATION

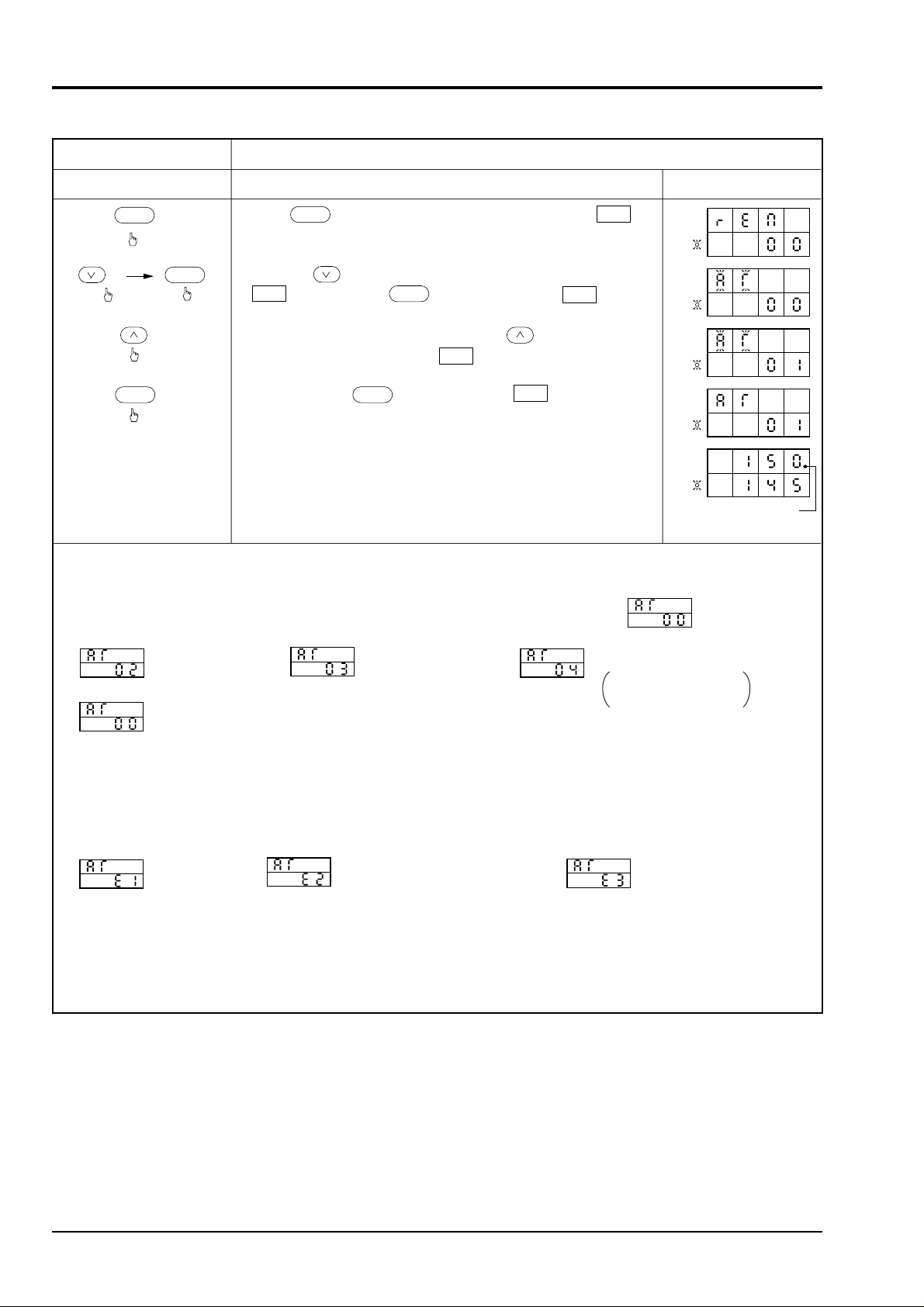

c) Auto-tuning operation method

Contents of operation

Key operation

SEL

DATA

14 times

ENT ENT

Startup of auto-tuning

Description Indication

• Press key to indicate measured value indication .

SEL

REM

• Press the key 14 times to indicate measured value indication

AT

, then press the key. The indication flickers.

DATA

AT

• When performing auto-tuning, press the key and set the

data of set value indication to .

• By pressing the key, the indication stops flickering

01

AT

and auto-tuning is started.

(The auto-tuning lamp will light in the measured value

indication.)

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Auto-tuning

• During auto-tuning, the followings are indicated. When the auto-tuning time is long (about 13 min. or more), the

indication is reset to operation indication automatically while auto-tuning continues.

• The followings are indicated in order during auto-tuning, but it is completed normally at .

at output ON

at output OFF

under calculation

Disappears almost

momentarily

completed normally

lamp

• After checking the completion of auto-tuning, the PID value calculated automatically needs to be registered.

For registration, select PID parameter and follow the procedures in “(5) Setting of PID parameter” on page 9.

At this time, the data indicated is a PID value which has been determined, so it need not be changed.

* If this registration is not made, the controller operates with PID value prior to auto-tuning.

• When auto-tuning is abnormal, the followings are indicated.

time over

PV higher/lower limit check

error (large process response)

change of SV during

auto-tuning

When these indications appear, auto-tuning is not possible. Set the PID value according to “(5) Setting of PID

parameter”.

During auto-tuning, the auto-tuning lamp lights and it goes off when auto-tuning is completed.

(Note) Auto-tuning may require several 10 minutes depending on process response characteristic.

Note 1) During auto-tuning, vibration of process is observed. It is a phenomenon of auto-tuning, which is

stabilized at the completion of auto-tuning.

Note 2) When operating conditions are changed, carry out auto-tuning once again.

Note 3) Do not use auto-tuning for the following processes.

• Process disorder due to temporary ON-OFF control output from PYH is prohibited.

• Pressure or flow process having very quick response.

8 INP-TN3PYH-E

Page 15

4. PREPARATION FOR OPERATION, AND OPERATION

AT in operation

AT in operation

AT end

(PID Setting)

AT end

(PID Setting)

Startup of AT

Startup of AT

Set value (SV)

Set value (SV)

ON 100%

OFF 0%

ON ON

OFF

PV (Measured value)

OFF

ON-OFF operation

ON-OFF operation

PID control

PID control

SV-10%

ON ON

(Control output)

(Control output)

ON 100%

OFF 0%

OFF OFF

When AT lamp lights,

ON-OFF operation

(2-position operation)

is effected and the

measured value (PV)

is oscillated.

PV (Measured value)

Contents of operation

Key operation

Description Indication

Setting of PID parameter. (Example: P=10, I=120, D=30)

SEL

DATA

DATA

DATA

15 times

ENT

ENT

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

• Press the key to indicate measured value indication REM .

• Press the key 15 times to indicate measured value indication

P , then press the key. The indication P flickers.

• Press or key to set the data of set value to 10.

• Press the key. The indication P stops flickering.

The value of P is set up.

• Press the key to indicate measured value indication I .

Press the key. The indication I flickers.

• Press or key to set the data of set value to 120.

• Press the key and the indication I stops flickering.

The value of I is now set.

• Press the key once to indicate the measured value indication

D , then press the key. The indication D flickers.

• Press the or key to set the data of set value to 30.

• Press the key and the indication D stops flickering.

The value of D is now set.

SEL

or

DATA

2 times

ENT

or

DATA

DATA

ENT

ENT

or

ENT

d) Auto-tuning comes in two types; q Standard type (with overshoot) and w Low PV type (overshoot suppres-

sion).

The type q is an overshoot where the measured value (PV) exceeds the set value (SV) during auto-tuning. Use

this type when overshoot is allowed.

The type w is for ON-OFF operation with a value lower than the set value (SV) by 10% / full scale.

Use this type when overshoot needs to be suppressed.

(5) Setting of PID parameter

q Standard type (with overshoot)

w Low PV type (overshoot suppression)

INP-TN3PYH-E 9

Page 16

4. PREPARATION FOR OPERATION, AND OPERATION

4.3 Selection of operation mode

(1) Selection of auto/manual operation

• By pressing the

indicated, the device is changed from auto operation to

manual operation. By pressing the key once again, it is

set in auto operation.

(This selection is balanceless/bumpless.)

• During manual operation, the manual operation lamp

M

will light. (During auto operation, the auto opera-

tion lamp A will light.)

• Control output operation during manual operation is

made by pressing the

output and then pressing the key or and

keys. (When changing to control output indication,

is displayed on the manual operation indication. This is

used only for remote operation, so the

be pressed until the manual operation lamp lights.)

Control output operation speed

Normal ( or key only): About 40 s/full

scale

Fast-forward ( and keys, or and

keys): About 8 s/full scale

key when operation mode is

A/M

key to indicate control

SV/MV

SV/MV

key should

Caution

1. When transmission function is

provided, manual operation is possible

from the host system. Setting to make

manual operation invalid is also

possible from the host system. In this

case, the code 01 should be set using

in the item of parameter.

SCE

2. Setting to make A/M mode change

invalid is also possible. (Set the code

01 using in the item of

MIH

parameter.)

Caution

During remote operation, the indicating

R

lamp on the front panel lights.

However, this lamp flickers when R-ACK

signal DI1 (remote check signal) is OFF.

If “A” or “C” is not specified in the 11th

digit of PILC, the instrument will not

operate normally.

Since remote SV indication and so on

may not be displayed correctly, don’t use

it.

• Operation of the

ENT

key for data registration is not required.

10 INP-TN3PYH-E

Page 17

(2) Selection of auto/remote operation

Contents of operation

Key operation

Description Indication

SV balance prior to changing from auto to remote operation

SEL

• Press the key to indicated DSV .

• Press the or key to set the value of DSV to 0.

(Note 1)

This operation is called the balance operation.

• Press the key to reset to operation indication.

PV

SV

PV

SV

PV

SV

or

SV/MV

SV/MV

SV/MV

Contents of operation

Key operation

Description Indication

Remote operation

DATA

DATA

• Press the key to indicate the measured value indication

REM . Press the key, and the indication REM

flickers. The indication of set value 00 means auto operation.

• Press the key to indicate the set value indication 01 ,

then press the key for registration. The indication 01

means remote operation. The remote operation lamp flickers.

Apply an external signal to R-ACK (DI1) digital input signal.

The remote operation lamp stops flickering.

This completes the selection of remote operation. Remote

operation is started with the analog signal from the external

device or the set value (SV) for SV selection.

FLT R A M C1 C2 H L HB

FLT R A M C1 C2 H L HB

SEL

SEL

ENT

ENT

R

R

a) Selection of auto to remote operation

When the controller is to be changed from auto operation with the set value (SV) indicated on the front to

remote operation with analog signal from the external device or set value (SV) for SV selection, the following

procedures should be used.

(This selection is balance/bumpless, so it should be carried out after the following operation.)

4. PREPARATION FOR OPERATION, AND OPERATION

• DSV is a value obtained by subtracting the SV value of cascade input from the SV value which has

been set from the front of PYH.

• During auto operation, the auto operation lamp M on the front will light.

Note 1) In this case, don’t manipulate the

+

or +

keys. SV value changes

suddenly and control may not be performed accurately.

q Selection from auto to remote operation with keys on the front of the main unit

INP-TN3PYH-E 11

Note 1) Remote operation with external analog signal requires R-ACK signal (remote check DI

Note 2) When remote operation is selected with T-link transmission, DI1 and DI3 of the T-link

signal). Use the external terminal DI1 (auxiliary input DI) for this signal (see 14. Connection diagram on page 34).

channel should be set to 01 (see 15. Parameter list on page 35).

Page 18

4. PREPARATION FOR OPERATION, AND OPERATION

w Selection from auto to remote operation with host transmission

This selection is made by instructions from the host system through transmission functions (RS-485, T-link).

For details, refer to the technical instruction manual.

b) Selection from remote to auto operation

When changing the operation mode from remote operation with analog signal from external device or set value

(SV) of SV selection to auto operation with set value (SV) indicated on the front of the controller, the following

procedures should be used.

(This selection is balanceless/bumpless.)

q Selection from remote to auto operation by keys on the front of the main unit

Contents of operation

Key operation

SEL

DATA

ENT

Even when 01 is set in REM , auto operation is effected if R-ACK signal is removed.

w Selection from remote to auto operation with host transmission

This selection is effected by instructions from the host system through transmission functions (RS-485, Tlink).

Clear the remote operation

Description Indication

• Press the key to indicate measured value indication to

REM , then press the key. The indication REM

SEL

DATA

flickers. The set value indication 01 means remote operation.

• Press the key to set the set value indication to 00 . Then,

press the key. The set value indication 00 means auto

operation.

The auto operation lamp lights. Now, the auto operation has

ENT

A

been selected.

* When changing the set value (SV), see item 4.2 (2).

FLT R A M C1 C2 H L HB

FLT R A M C1 C2 H L HB

12 INP-TN3PYH-E

Page 19

5. FAULT INDICATION

Indication Cause

Remedy

FLT lamp is lit.

The contents of FLT light

can be indicated by using

key according to FLT

indication of input/output

data channel.

Manual

operation

Trouble with main unit

Error of DO output setting

Measured value input (PV): Over, under,

burnout

. Resistance bulb sensor is disconnected or

shorted.

. 1 to 5V DC, 4 to 20mA DC input wire is

disconnected or shorted.

. Polarity + ,

-

of the input wire is

reversed.

. Thermocouple sensor is disconnected.

No

Yes

Yes

Yes

Replace the main unit.

Correct the DO output setting

of input/output data channel.

Check measured value input.

Check the wiring of the

measured value input.

Measured value indication

is or .

(Page 36)

Condition

Disconnection

Short-circuit

Indication

Control output

Disconnection of 2

wires or 3 wires

ON or more than 24mA, OFF or more than 0mA

OFF or more than 0mA, ON or more than 24mA

ON or more than 24mA, OFF or more than 0mA

OFF or more than 0mA, ON or more than 24mA

The controller has a fault indicating function so that the cause of fault can be removed quickly.

Note) In the event of a fault, perform manual operation as an emergency measure (see item 4.3 (1)).

If the measured value input is abnormal, it is indicated as shown in the table below where the control output corresponding

to the measured value indication is output.

Resistane bulb input

INP-TN3PYH-E 13

Page 20

5. FAULT INDICATION

Thermocouple outpupt

Disconnection

Short-circuit

1 to 5V DC input

Short-circuit

4 to 20mA DC

Disconnection

Short-circuit

Condition

Condition

Condition

Indication

Indication of

temperature at

shorted point

Indication

Indication

Control output

ON or more than 24mA, OFF or 0mA

Control assuming input as temperature at shorted point

Control output

OFF or 0mA, ON or more than 24mA

Control output

OFF or 0mA, ON or more than 24mA

Note) Control output changes its action by designating burnout direction. This is effected by setting a param-

eter in "brn" (designation of burnout direction) of specification change channel.

14 INP-TN3PYH-E

Page 21

6. USE OF HEATER ALARM (OPTION)

● Heater burnout detect current and heater rated voltage need to be set according to the heater being used. These are

factory set to 100V and 50A, respectively, prior to delivery.

● Alarm operating point should be set by heater alarm current ( ) and heater rated voltage ( ).

● Current detector (CT) comes in 2 types, 0 to 30A type (CTL-6-SF) and 20 to 50 A type (CTL-12-S36-8F). Use either

one that is suited for the heater current being used.

● Setting of alarm set point

When 2 heaters of 2000W/115V are used in parallel and if one is disconnected, the rated current of 34.8A becomes

17.4A. Detection of disconnection should be set in the middle (26.1A) between the rated current and the disconnection current. (The set value of disconnection detection should be more than 15% of the rated current.)

When “N” number of heaters are connected together, the set value should be in the middle between “N” and “N-1”.

● When the heater power is also used for the instrument, the variation of alarm operating point due to power fluctuation

can be minimized.

● This method cannot be used when heaters are controlled by the thyristor phase angle control method.

● In the following power system, heater rated voltage should be 100V AC used for the instrument.

200VAC

Heater

● Connection of heater current detecting CT

Wiring to heater (inserted through CT hole)

Current detector (CT) outline diagram

Transformer

100V AC

PYH

PYH (without polarity)

Type: *CTL-6-SF (1 to 30A)

15

2.11

7.5

φ5.8

25

21

10.5

30

40

INP-TN3PYH-E 15

3

10

φ3.5 × 2

Page 22

● Connection of heater burnout alarm (for Type PYH9)

Power source

85 to 265V AC

6. USE OF HEATER ALARM (OPTION)

MG

SW

13

Power source

14

Control output

25

22

10

11 4 7

12

33

34

Heater burnout alarm output

Magnet switch

Current detector

*CTL

Thermocouple

Heater

Electric furnace

•When the heater capacity is too small and the detector error is large, the sensitivity can be improved by

winding the heater wire twice on the current detector (CT) to make the apparent current two times as large.

•When winding the current detector (CT) with many turns of wire, be sure to wind it in the same direction.

(See the figure below.)

• When the current detector (CT) is wound with many turns, the sensitivity will increase so the setting of

disconnection detecting current needs to be changed (disconnection detection setting = heater rated current ×

number of tuns).

1 turn

2 turns

Type: *CTL-12-S36-8F (20 to 50A)

φ2.36

40

φ12

M3, 4 deep

30

40

7.5

15

16 INP-TN3PYH-E

Page 23

7. CHANGING OF FUNCTIONS

Contents of operation

Key operation

Description Indication

Change of input from J thermocouple to K thermocouple

SEL

SEL

SEL

DATA

DATA

3 times

ENT

ENT

ENT

PV

SV

PV

SV

MV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

• Press the key to indicate measured value to REM .

• Press the key to indicate .

• Press the key to indicate PVF .

• Press the key 3 times to indicate PVT , then press the

key. The indication PVT flickers.

(The present input code 05 means J thermocouple.)

• Press the key to change 05 to 06 .

(06 means K thermocouple. For the type of input, refer to the

input code table (Table 1)).

• Press the key for registration. The indication stops

flickering. This completes the change of the type of input.

• Press the key and the key at the same time to indicate

RES . Then press the key. The indication RES flickers.

• Press the key once to indicate 01 , then press the

key to reset the controller.

The display returns to operation indication.

SEL

SYS

CH

•

•

•

At the

same

time

DATA

ENT

DATA

Indications shown in the following pages are required for changing the specification of PYH.

The specifications (functions) of this PYH can be changed by the user, if desired.

To change the functions, refer to “15. Parameter list” on page 35 and “12. Parameter set value list” on page 27, to ensure

correct setting.

CAUTION

PYH’s product type cannot be changed. Never change TYPE CH. on page 36.

After the functions have been changed, the parameters which were set before changing the functions become

invalid or new parameters need to be set. So, the user is requested to understand the functions thoroughly

before changing the functions.

After the functions have been changed, be sure to reset the controller. The method for resetting the controller is shown in

the example of change.

When pressing the

this is not an error.

7.1 Method of changing specifications

ENT

key with the parameter “ ” = 01, all LEDs light for a moment and the output is ON. But,

The following shows the types of measured value input, input range and the types of alarm as examples for change

of specifications.

(1) Selection of input specification (The unit is replaceable only with one of the same type.)

INP-TN3PYH-E 17

Page 24

7. CHANGING OF FUNCTIONS

Table 1 Input code table

Type of

input

A

B

C

Type of input

Resistance bulb

Thermocouple

Tungsten-rhenium (WRe5-26)

Voltage

Voltage

Current

With transmitter power

Current

supply, 4 to 20mA DC

(inverter control type only)

JPt100 (old JIS)

Pt100 (IEC)

J

K

R

B

T

E

S

PR40/20

0 to 10mV DC

0 to 50mV DC

0 to 50mV DC

4 to 20mA DC

*3

*3

*3

*3

*3

*4

Code

01

02

05

06

07

08

09

0A

0B

0C

0D

10

11

0F

0E

Measurable range

-

150 to 400°C

-

150 to 400°C

0 to 1000°C

0 to 1200°C

0 to 1600°C

0 to 1800°C

-

200 to 400°C

0 to 750°C

0 to 1600°C

0 to 1800°C

0 to 2400°C

-

999 to 9999

(Scaling range)

°C

Minimum span *2

50°C

50°C

200°C

200°C

1000°C

1500°C

200°C

200°C

1000°C

1800°C

2400°C

• Range width can be set within the range shown above (Programmable range).

Up to the first decimal place can be indicated *1. (To be used with the span of 1000°C or less.)

• “°C” is based on IEC standards.

• Accuracy

B: 0 to 400°C, ± 5%

R: 0 to 500°C, ± 1%

PR40/20: Less than 1000°C; not guaranteed, more than 1000°C ; ±1%

*1: Voltage/current input is indicated up to the third decimal place.

*2: Range setting below minimum span is out of accuracy assurance.

*3: Inhibit the minus temperature input

*4: 250Ω resistor is built in, and external resistor is not required.

Note) The input range of this table means the range that PYH can measure the input.

This means overrange and underrange should be included in this range. You should set your range including overrange and underrange within the table range.

(2) Change of input (measurement) range

Description

The lower limit (minimum range) and upper limit (maximum range) of measuring range should be set up.

Caution

Measuring range and the type of input are factory-set prior to delivery. When changing the measuring

range and the type of input, other parameters need to be changed.

18 INP-TN3PYH-E

Page 25

q Change of upper/lower limit of measuring range

Contents of operation

Key operation

Description Indication

Change of measuring range from -50 to 100°C to 0 to 200°C

PV

SV

PV

SV

MV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

• Press the key to indicate measured value to REM .

• Press the key to indicate .

• Press the key once to indicate PVF , then press the

key. The indication PVF flickers. PVF is the upper

limit of the measuring range.

• Press the key and key at the same time to change 100

to 200.

• Press the key for registration. The indication stops

flickering. This completes the setting of the upper limit of the

measuring range.

• Press the key once to indicate PVB , then press the

key. The indication PVB flickers.

• PVB is the lower limit of the measuring range. Press the

key to change

-

50 to 0.

• Press the key for registration. The indication stops

flickering. This completes the setting of the lower limit of the

measuring range.

• Press the key and the key at the same time to indicate

RES , then press the key. The indication RES flickers.

• Press the key once to indicate 01 , then press the

key to reset the controller.

The indication returns to operation indication.

SEL

SEL

SEL

SEL

DATA

DATA

DATA

DATA

ENT

ENT

ENT

ENT

ENT

ENT

•

•

•

At the

same

time

DATA

DATA

SYS

CH

Press at the

same time to

obtain 200.

Press to obtain 0.

7. CHANGING OF FUNCTIONS

w Measured value full scale (PVF) – measured value base scale (PVb) must be larger than the minimum range width

(deviation alarm setting cannot be performed accurately.)

INP-TN3PYH-E 19

Page 26

7. CHANGING OF FUNCTIONS

(3) Change of alarm operation

Description

The type of main alarm is factory-set prior to delivery as shown below.

Main alarm 1: Upper limit deviation alarm (code 02)

Main alarm 2: Lower limit deviation alarm (code 04) with lower limit hold

Setting of absolute alarm (upper limit) to main alarm 1 and absolute alarm (lower limit) to main alarm 2.

Contents of operation

Key operation

SEL

•

•

•

SEL

7 times

DATA

ENT

DATA

Change of main alarm 1 code 02 to 01 and main alarm 2 code 04 to 08

Description Indication

• Press the key to indicate measured value to REM .

• Press the key to indicate .

• Press the key to indicate PVF , then press the key

7 times. When 1TP is indicated, press the key. The

indication 1TP flickers.

SEL

SEL

SYS

CH

DATA

PV

SV

MV

PV

SV

MV

PV

SV

MV

(The present main alarm 1 code 02 is indicated.)

• Press the key to change main alarm 1 code 02 to 01 .

(Main alarm 1 code is set as shown in the main alarm code table

(see Table 2).)

• Press the key. The indication stops flickering and the

ENT

setting of main alarm 1 is completed.

Next, set main alarm 2.

• Press the key to indicate 2TP , then press the key.

DATA

The indication 2TP flickers.

(The present main alarm 2 code 4 is indicated.)

PV

SV

MV

PV

SV

MV

PV

SV

MV

ENT

At the

same

time

ENT

• Press the key to change main alarm 2 code 04 to 08 .

(Main alarm 2 code is set as shown in the main alarm code table

(see Table 2).)

• Press the key. The indication stops flickering and setting

ENT

of main alarm 2 is completed.

• Press the key and the key at the same time to indicate

RES , then press the key. The indication RES flickers.

• Press the key once to indicate 01 , then press the

DATA

ENT

key to reset the controller.

The indication returns to operation indication.

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

20 INP-TN3PYH-E

Page 27

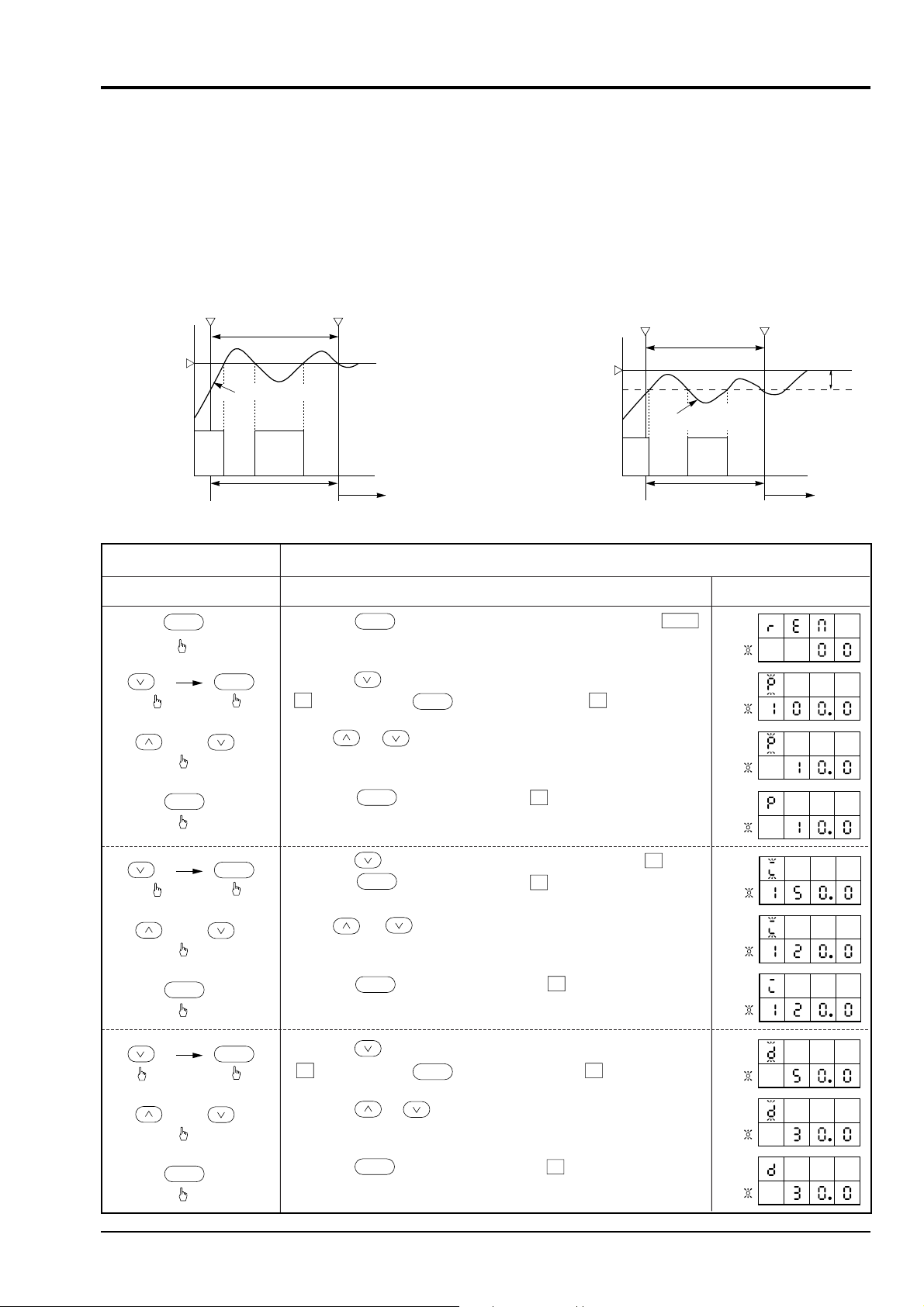

Table 2 : Type of main alarm code table

7. CHANGING OF FUNCTIONS

Type of main alarm

Without alarm

Absolute alarm (upper limit)

(Set by absolute value without regard to main setting.)

Absolute alarm (lower limit)

(Set by absolute value without regard to main setting.)

Upper limit deviation alarm

(Set by deviation value of output from main setting.)

Lower limit deviation alarm

(Set by deviation value of output from main setting.)

With lower limit hold*

Lower limit deviation alarm

Upper/lower limit deviation alarm (non-discriminate)

(The value of lower limit and upper limit deviations are

the same.)

With lower limit hold

Upper/lower limit deviation alarm (non-discriminate)

(The values of lower limit and upper limit deviations are

the same.)

Upper/lower limit alarm

(The values of lower limit and upper limit deviations are

the same.)

Absolute alarm (with lower limit hold)

(Set by absolute value without regard to main setting.)

Code

00

01

08

02

03

04

05

06

07

09

Alarm setting

(absolute value)

Deviation

Alarm

setting

Deviation

Alarm

setting

Deviation Deviation

Alarm

setting

Deviation Deviation

Alarm

setting

Deviation Deviation

Alarm

setting

Alarm setting

(absolute value)

Main alarm output

Operation chart

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

(SV)

Main setting

Alarm setting

(absolute value)

Deviation

(SV)

Alarm

setting

Alarm

setting

Alarm

setting

Alarm

setting

* Lower limit hold is an action not to emit output until the alarm exceeds the lower limit after power is ON.

INP-TN3PYH-E 21

Page 28

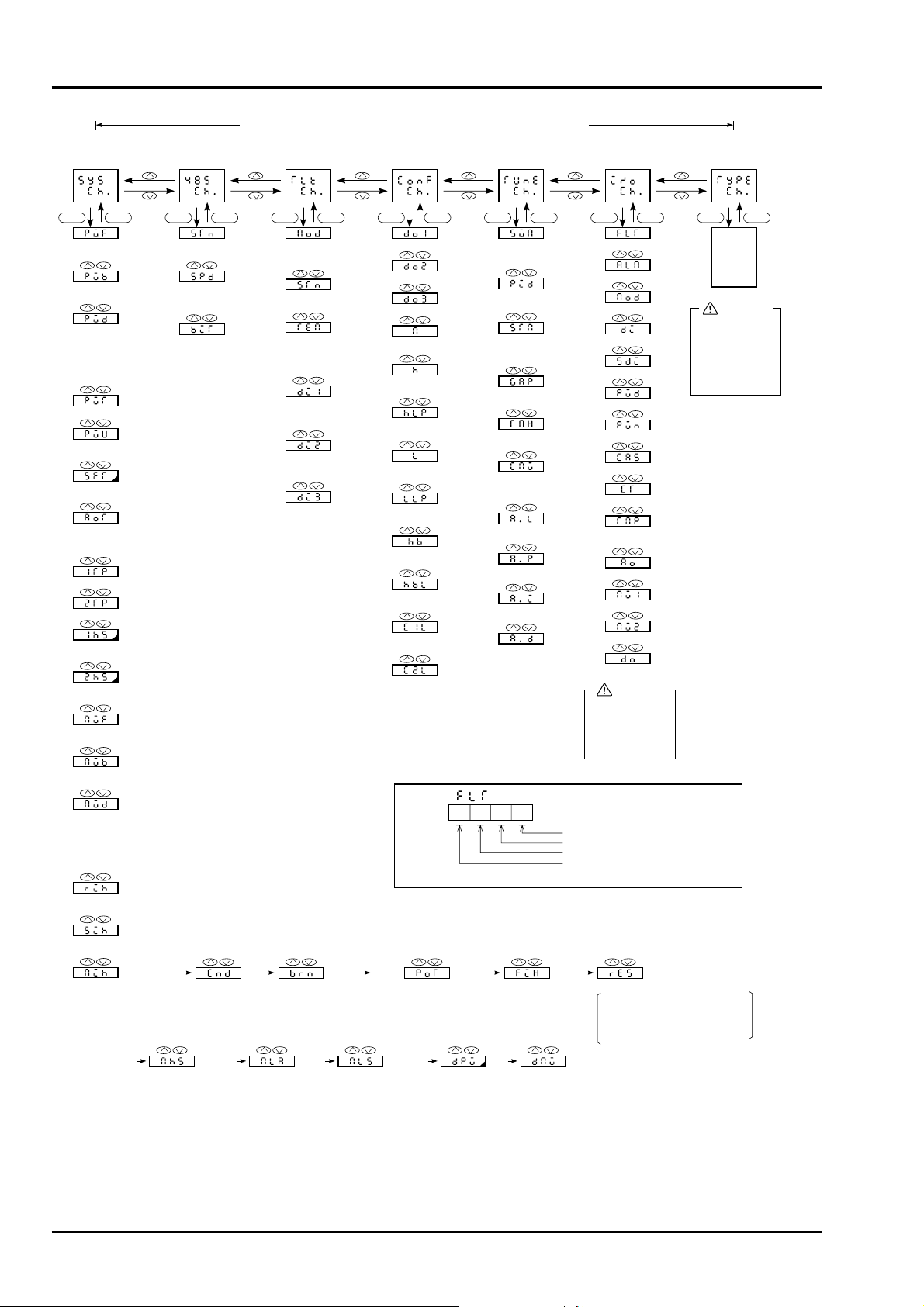

8. DUAL OUTPUT CONTROL TYPE

< PYH dual output control >

Dual calculation

MV

proportional band

Cooling side

PC

<C1>

Output 1(heating)

<C2>

Output 2(cooling)

PV

Dead band

calculation

DV DV’

GAP

SV

PiD

calculation

PYH

When the process tends to generate heat of itself, cooling control is required in addition to heating control. Dual output

control is used to control the temperature of such a process. As another example, it is used in the PH control process.

For the dual output control type, the following settings are required.

q MV 2 proportional cycle (to be set according to the type

of cooling side terminal device)

Setting range: 1 to 255 s (factory-set prior to

delivery; contact output 30 s, SSR/

SSC 2 s, not indicated at DC 4 to 20

mA)

Set to

(

w Cooling side proportional band (setting of the propor-

tional band on the cooling side)

Setting range: 0.0 to 3276.0 (factory-set prior to

of operating condition change channel

).

Heating side

Output

50%

Cooling side

proportional band

100%

200%

MV (%)

50%

delivery; 100.0)

Set to of normal operation channel.

e Dead band (used to overlap the heating side propor-

tional band and the cooling side proportional band, or

separate (dead) them from each other.)

Setting range: -50.0 to +50.0% (factory set prior to

delivery; 0.1%)

Set to of normal operation channel.

• Set value of DB is a percentage (%) of MV full

scale.

r Limiter function

• Heating manipulated value upper limit (

• Heating manipulated value lower limit (

• Cooling manipulated value upper limit (

• Cooling manipulated value lower limit (

, , ,

Set to

of auxiliary alarm channel (

)

)

)

)

Heating side

Overlap band

(dB= –50 to 0%)

*4mA and 20mA are output current.

Output denotes both output 1 and output2.

Proportional band P

Output

20mA

4mA

50%

).

Varies with parameter “ ”

Cooling side

MV(%)

Dead band

(dB= 0 to 0%)

22 INP-TN3PYH-E

Page 29

■ Auto-tuning

•For operation, refer to "Auto-tuning operation" on page 7.

•During auto-tuning, the cooling side output is ON-OFF controlled as shown in the diagram below, to obtain

optimum PID and cooling side proportional band (PC).

(Values of I and D are the same for heating/cooling.)

• At the completion of auto-tuning, register the values of PID and PC referring to page 9.

q Standard type (with overshoot)

8. DUAL OUTPUT CONTROL TYPE

AT start

Set value (SV)

Heating side

(control output)

Cooling side

(control output)

ON 100%

OFF 0%

ON 100%

ON

OFF

w Low PV type (overshoot suppression)

AT start

Set value (SV)

AT end (PID setting)

AT under operation

PV (measured value)

ON

OFF

ON

OFF

AT end (PID setting)

AT under operation

OFF

ON

PID control

While AT lamp is lights,

measured value (PV) is

oscillated by ON-OFF

action (2-position action).

SV-10%

PV (measured value)

Heating side

(control output)

Cooling side

(control output)

INP-TN3PYH-E 23

ON 100%

OFF 0%

ON 100%

ON

OFF

OFF

ON

ON

OFF

OFF

ON

PID control

Page 30

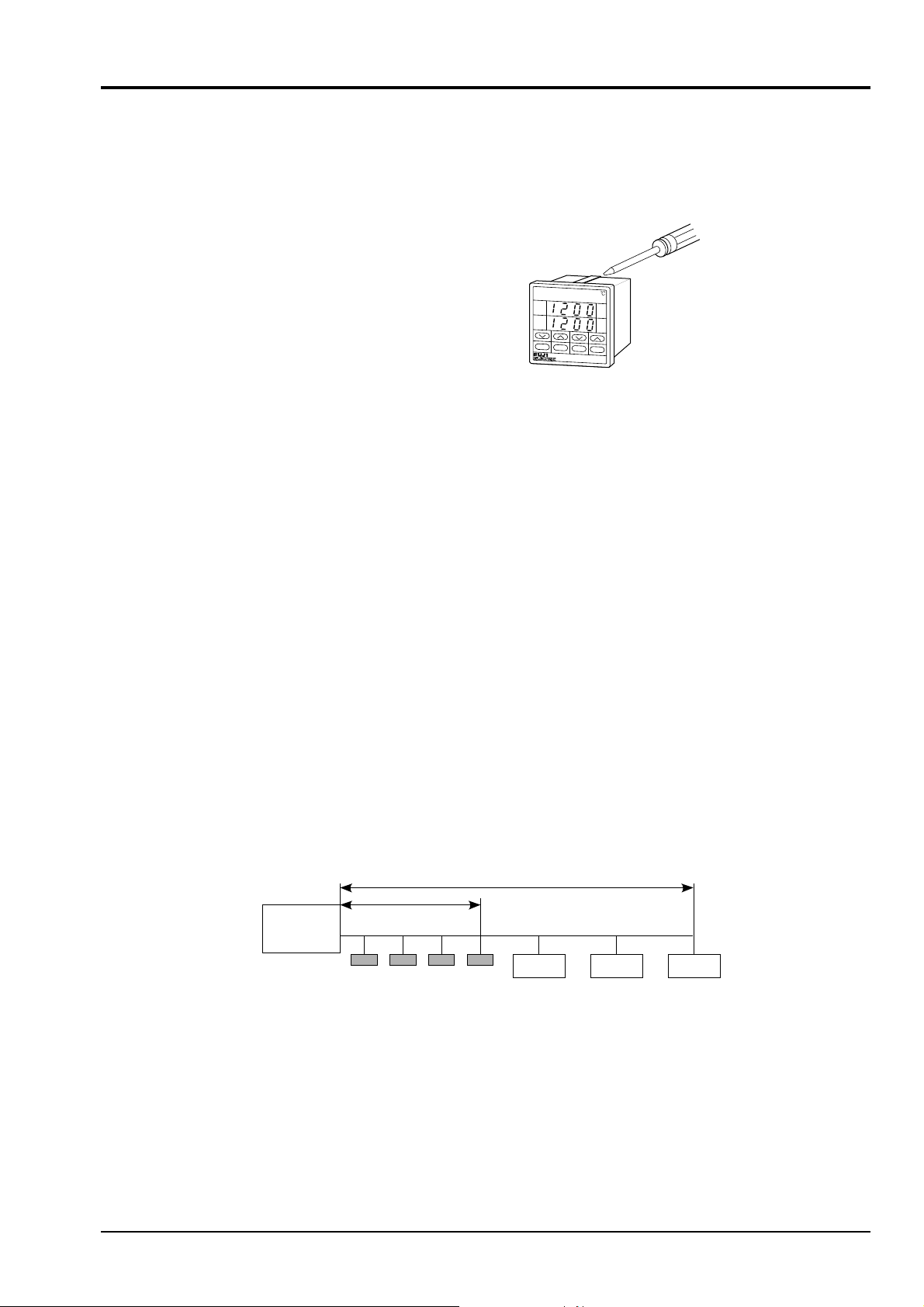

9. SV SELECTION

This function is used to control set values (SV) of 1 to 7 types set by the keys on the front of the controller using external

contact input (DI).

Note) The number of set values (SV) varies with the type of PYH.

• For setting the set values (SV1 to SV7), use

Auxiliary input

Digital 1 Digital 2 Digital 3

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Note) All can be used by PYH9 type. Only the item shown in can be used by

PYH7, PYH5 and inverter control types.

Note) When operating PYH with any set value of SV1 to SV7, remote operation is effected. When digital 1, 2

and 3 are at OFF, PYH is set in auto-operation mode using the set value obtained from the front of PYH.

When changing the operation (remote operation) with set values of SV1 to SV7 to auto-operation, the set

values of the remote operation is still valid so they need to be changed.

OFF

OFF

ON

ON

OFF

OFF

ON

ON

to

OFF

OFF

OFF

OFF

ON

ON

ON

ON

of normal operation channel.

Set value

SV0 (Auto-operation is effected.)

SV1

SV2

SV3

SV4

SV5

SV6

SV7

24 INP-TN3PYH-E

Page 31

10. POSITION FEEDBACK CONTROL TYPE

Contents of operation

Key operation

Description Indication

DATA

DATA

DATA

DATA

DATA

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

PV

SV

MV

• Set the valve opening to 0%, then set 01 to the data.

• Press the key. When the indication is changed from 01 to

00, zero point has been adjusted.

• Next, set the valve opening to 100%, then set 02 to the data.

• Press the key and when the indication is changed from

02 to 00, adjustment at 100% point is completed.

• Next, press the key once to indicate FIX , then press the

key.

Example of tuning

of 100% point

Example of tuning

of 0% point

• Finally, press the key to indicate RES , then press the

key to indicate 01 . Press the key to reset the

controller.

The indication returns to operation indication.

PV

SV

MV

PV

SV

MV

• Press the key once to indicate 01 . Then, press the

key and when the indication is changed from 01 to 00,

registration is completed.

DATA

Position feedback control is a function to control by feeding back valve opening signal with a motor-driven valve connected to a terminal device.

• To adjust zero and span of valve opening signal (potentiometer), call the specification change channel (SYS CH.)

to select the item of POT and use the following procedures.

Note) Valve opening indication

Accuracy: ± 0.2% FS

Resolution: max. ± 1.0% FS

INP-TN3PYH-E 25

Page 32

11. INVERTER CONTROL TYPE

Inverter control is a control system with inverter used for terminal device. In the inverter control type, transmitter power

supply built in PYH is also available.

This controller is able to select frequency indication in addition to normal operation indication (PV/SV indication).

1. Selection of frequency indication

SV/MVSV/MVSV/MV

Frequency

SV/MV

SEL

Setting of full scale

Setting of base scale

PV

SV

PV

SV

PV

SV

SEL

Setting of decimal point

DATA

ENT

Note) MV output is not stabilized for the time (FLT output) until it is raised a few seconds after power for

PYH is closed.

2. On the scale value setting of frequency indication, the following is factory-set prior to delivery.

• Full scale (MVF) : 600

•Base scale (MVB) : 0

• Decimal point (MVD) : 01

When changing, use procedures as shown above.

Note) Frequency is indicated down to MV = -25%, so it may be indicated in negative value.

3. Connection to pressure transmitter

• Connection to FC series pressure transmitter (FBC)

0+

0––+65

•Connection to FCX pressure transmitter (FHG) or small type pressure sensor (FCP)

–

–

+

+65

PYH

PYH

26 INP-TN3PYH-E

Page 33

12. PARAMETER SET VALUE TABLE

Channel

Indication

REM

SCE

LOC

AL1

AL2

HBA

HBV

SV1

SV2

SV3

SV4

SV5

SV6

SV7

AT

P

PC

I

D

GAP

PGP

DB

PAS

PSS

Remote mode

SCC operation

Setting lock

Main alarm 1 setting *

Main alarm 2 setting *

Heater burnout setting

Heater rated voltage

SV select type

SV setting 1 *

SV select type

SV setting 2 *

SV select type

SV setting 3 *

SV select type

SV setting 4 *

SV select type

SV setting 5 *

SV select type

SV setting 6 *

SV select type

SV setting 7 *

Auto-tuning start

Proportional band

Cooling side proportional

band

Integral time

Derivative time

Dead band *

Position feedback dead band

Dead band

Pass board

Pass code

Setting range

Name/item

Preset

value

Remarks

Entry

column

00: Auto-operation

01: Remote operation

00: Inhibit

01: Acceptable

00: Parameter setting

possible

01: Parameter setting

not possible

02: Setting other than

SV not possible

-

25.0 to 125.0

-

25.0 to 125.0

0 to 50A

0 to 300V

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

00: None

01: Start

0.0 to 3276%

0.0 to 3276%

0.0 to 3276 s

0.0 to 900.0 s

0.0 to 100.0

0.0 to 100.0%

-

50.0 to 50.0%

0000 to FFFF

0000 to FFFF

Upper limit deviation

(preset)

Lower limit deviation with

hold (preset)

Indicated only for heater

burnout alarm type.

Indicated only for heater

burnout alarm type.

1) Used for SV select type.

2) Indicated only for SV

select type.

3) SV1 to SV7 setting

possible for PYH9 type

4) SV1 to SV3 setting

possible for PYH5/7 type

0.0 for ON/OFF control

Indicated only for dual

output type.

00 not integrated

(2-position type or P action)

Indicated only for position

feedback type.

Indicated only for dual

output type.

Normal operation channel

00

00

00

50

50

50A

100V

0

0

0

0

0

0

0

00

0.5%

0.5%

3276 s

0.0 s

0.0

3.0%

0.1%

0000

0000

on page 4 lights

with “01”.

20

(Note) * can be set in industrial values.

Setting range is shown in industrial value %.

Example) For 0 to 400°C range, 0 is 0°C and 100 is 400°C.

INP-TN3PYH-E 27

Page 34

12. PARAMETER SET VALUE TABLE

Channel

Auxiliary alarm channel

Indication

DH

DHS

DL

DLS

SH

SL

PH

PHS

PL

PLS

PHH

HHS

PLL

LLS

MH

ML

HMH

HML

CMH

CML

MHA

MHS

MLA

MLS

DPV

DMV

Name/item

Deviation (+) alarm *

Deviation (+) alarm

hysteresis *

Deviation (-) alarm *

Deviation (-) alarm

hysteresis *

Set value upper limit *

Set value lower limit *

Measured value upper limit

alarm *

Measured value upper limit

alarm hysteresis *

Measured value lower limit

alarm *

Measured value lower limit

alarm hysteresis *

Measured value upperupper limit alarm *

Measured value upper-upper

limit alarm hysteresis *

Measured value lowerlower limit alarm *

Measured value lower-lower

limit alarm hysteresis *

Manipulated value (MV)

upper limit

Manipulated value (MV)

lower limit

Heating manipulated value

lower limit

Heating manipulated value

lower limit

Cooling manipulated value

upper limit

Cooling manipulated value

lower limit

Manipulated value (MV)

upper limit alarm

Manipulated value upper

limit alarm hysteresis

Manipulated value lower

limit alarm

Manipulated value lower

limit alarm hysteresis

Measured value variation

rate alarm *

Manipulated value variation

rate alarm

Setting range

0.0 to 100.0

0.0 to 100.0

0.0 to 100.0

0.0 to 100.0

-

25.0 to 125.0

-

25.0 to 125.0

-

25.0 to 125.0

0.0 to 100.0

-

25.0 to 125.0

0.0 to 100.0

-

25.0 to 125.0

0.0 to 100.0

-

25.0 to 125.0

0.0 to 100.0

-

25.0 to 125.0%

-

25.0 to 125.0%

-

25.0 to 125.0%

-

25.0 to 125.0%

-

25.0 to 125.0%

-

25.0 to 125.0%

-

25.0 to 125.0%

0.0 to 100.0 %

-

25.0 to 125.0%

0.0 to 100.0%

0.0 to 100.0

0.0 to 100.0%

Preset

value

100.0

100.0

100.0

100.0

125.0

-

25.0

125.0%

-

25.0%

125.0%

-

25.0%

125.0%

-

25.0 %

125.0%

0.0%

-

25.0 %

0.0%

100.0

100.0%

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Entry

column

Remarks

Set PL < PH.

If PL>PH, the device is not

operated properly.

Set PL < PH.

If PL>PH, the device is not

operated properly.

Indicated only for dual

}

output type.

28 INP-TN3PYH-E

Page 35

12. PARAMETER SET VALUE TABLE

Channel

Indication

TF

KNL

CUT

DT

REV

ARH

ARL

TON

Operating condition change channel

TOFF

EXM

C1

C2

MAN

Name/item

Measured value filter time

constant

Non-linear gain

Router cut point

Sampling cycle

Reverse action setting

Integration cut point upper

side *

Integration cut point lower

side *

Intermittent PID

(with control)

Intermittent PID

(without control)

EXT-MV setting

MV 1 proportional cycle

MV 2 proportional cycle

Manual reset

Setting range

10.0 to 900.0 s

0.0 to 327.7%

-

25.0 to 125.0%

0.1 to 3276 s

00: Normal 01: Reverse

0.0 to 125.0

0.0 to 125.0

0 to 9999 s

0 to 9999 s

-

25.0 to 125.0%

1 to 255 s

1 to 255 s

-

25.0 to 125.0%

Preset

value

10 s

0.0%

-

0.01%

0.1 s

Reverse: 01

100.0

100.0

0 s

0 s

0.0%

Relay contact

output 30 s,

SSR/SSC

drive output

2 s.

0.0%

Entry

column

Remarks

When the router is unused,

set PV to –0.01%. When

input is made from resistance

bulb or thermocouple, be

sure to set PV to –0.01%.

Setting of industrial

value for set value (SV)

Indicated only for dual output

type.

Effective only when I = 0.0.

PVF

PVB

PVD

PVT

PVU

Specification change channel

SFT

AOT

1TP

2TP

Measured value full scale

Measured value base scale

Measured value decimal

point position

PV input type

PV unit

PV zero shift *

AO output type

Main alarm 1 type

Main alarm 2 type

Input range upper

limit setting

Input range lower

limit setting

00: Without decimal

point

01: 2nd digit from end

02: 3rd digit from end

03: 4th digit from end

See page 17.

00: °C 02: Other

-

50.0 to 50.0

00: Measured value

(PV) output

01: Set value

(SV) output

02: Control output

value (MV) output

See page 17.

See page 17.

Specified

when

ordering

Specified

when

ordering

Specified

when

ordering

Specified

when

ordering

Specified

when

ordering

0.0

0.0

02

04

00 and 01 only for

thermocouple and resistance

bulb

02: Upper limit deviation

04: Lower limit deviation

with hold

1HS

2HS

INP-TN3PYH-E 29

Main alarm 1 hysteresis *

Main alarm 2 hysteresis *

0.0 to 100.0

0.0 to 100.0

0.0

0.0

Page 36

12. PARAMETER SET VALUE TABLE

Channel

Specification change channel

Indication

MVF

MVB

MVD

RIH

SIH

MIH

CND

BRN

Name/item

Manipulated value full scale

Manipulated value base

scale

Manipulated value decimal

point position

Remote setting indication

inhibit

SCC setting indication

inhibit

A/M mode change inhibit

Startup control condition

Burnout direction

Setting range

-

999 to 9999

-

999 to 9999

00: Without decimal

point

01: 2nd digit from end

02: 3rd digit from end

03: 4th digit from end

00: Release

01: Inhibit

00: Release

01: Inhibit

00: Release

01: Inhibit

00: Automatic

01: Manual

00: Hold

Lower limit scale out

01:

02:

Upper limit scale out

Preset

value

600

0

01

Specified

when

ordering

Specified

when

ordering

00

00

01

Entry

column

Remarks

Indicated only for inverter

control type.

With external set value

input, T -link transmission

and SV select: 00

Without above: 01

Not specified: 00

Designation of manipulated

out (MV) burnout direction

RS485

transmission channel

Potentiometer zero/span

POT

adjustment

Trace fix command

FIX

Reset command

RES

Station No.

STN

Transmission speed

SPD

Bit format

BIT

00: No adjustment

01:

Zero point adjustment

02:

Span point adjustment

01 registered for

adjustment of

potentiometer

01 registered when

changing parameters

other than SYS CH

00 to FF

03: 9600 BPS

04: 19200 BPS

01: No-parity stop bit 1

02: No-parity stop bit 2

11: Parity odd number

stop bit 1

12: Parity odd number

stop bit 2

21: Parity even number

stop bit 1

22: Parity even number

stop bit 2

00

00

00

01

03

01

Indicated only for position

feedback type.

Hexadecimal setting

Connected to transmission

interface board.

(type PYY): 04

Connected to transmission

interface board.

(type PYY): 12

30 INP-TN3PYH-E

Page 37

12. PARAMETER SET VALUE TABLE

Channel

T-link

transmission channel

Indication

MOD

STN

TEM

DI1

DI2

DI3

Name/item

T-link operation mode

Station address

EX-MV T-link setting

DI1 T -link setting

DI2 T -link setting

DI3 T -link setting

Table 3. Types of auxiliary alarm outputs

Setting range

00: 8W (PYH mode)

01: 4W (PYK mode)

00 to FF

00: Use main unit data.

01: Use T-link transmi ssion data.

00: Settable from main

unit

01: Settable through

T-link

00: Settable from main

unit

01: Settable through

T-link

00: Settable from main

unit

01: Settable through

T-link

Preset

value

00

01

00

00

00

00

Entry

column

Remarks

Hexadecimal setting

Code

10

11

12

13

14

15

16

17

1A

1B

1C

1D

Type

SV-H (Set value upper limit alarm)

SV-L (Set value lower limit alarm)

PV-H (Measured value upper limit alarm)

PV-L (Measured value lower limit alarm)

PV-HH (Measured value upper-upper limit alarm)

PV-LL (Measured value lower-lower limit alarm)

DV-H (Deviation "+" side alarm)

DV-L (Deviation "-" side alarm)

MV-H (Manipulated output upper limit alarm)

MV-L (Manipulated output lower limit alarm)

DMP (Manipulated variable variation rate alarm)

DPV (Measured value variation rate alarm)

INP-TN3PYH-E 31

Page 38

12. PARAMETER SET VALUE TABLE

Channel

Output terminal define channel

Indication

DO1

DO2

DO3

M

H

HLP

L

LLP

HB

HBL

C1L

C2L

Name/item

DO1 output setting

DO2 output setting

DO3 output setting

AL1 terminal output

setting

H lamp setting

AL2 terminal output setting

L lamp setting

HB terminal output setting

HB lamp setting

C1 lamp setting

C2 lamp setting

Setting range

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

00 to FF

Preset

value

12: PV-H

13: PV-L

16: DV-H

1E: Main

alarm 1 output

Indication of

above output

1F: Main

alarm 2 output

Indication of

above output

0D: Heater

burnout alarm

output

Indication of

above output

5F

5E

Entry

column

Remarks

See Table 3 for code

symbols.

SVM

PID

STM

GAP

TMX

CMV

A.L

Auto-tuning define channel

A.P

A.D

SV mode

PID selection

Start mode

Auto-tuning dead band

Maximum standby time

Cooling side output setting

Indication of L value after

tuning

Indication of P value after

tuning

Indication of I value after

A.I

tuning

Indication of D value after

tuning

00: Standard type

(SV value 100%)

01: Low PV type

(SV value -10%)

00: PI 01: PID

Auto-tuning not

00:

started at power ON

01:

Auto-tuning started

at power ON

0.0 to 100%

0.0 to 9999 min.

-

25.0 to 125.0%

00

01

00

0.3%

720 min.

100.0%

32 INP-TN3PYH-E

Page 39

13. OUTLINE DIMENSIONS AND PANEL CUTOUT

■ PYH7/PYH9 type

A12150

10

C1

MA

FLT HB

PV

SV

B

MV

SV/MV

A/M

R

SEL DATA ENT

LH

C2

■ PYH5 type

Panel cutout

Note 3)

Type

PYH7 PYH9

Min. 30

A72 96

B91 115

C Min. 92 Min. 116

D Min. 82 Min. 100

E68

+0.7

0

0

+0.8

92

48

PV

SV

96

MV

115

DATA

SEL

SV/MV

A/M ENT

C

12 150

Q'ty 23456

a93141 189 237 285

(When two or more controllers are

mounted together and used at power

supply of 200 to 265V AC, provide a

fan for ventilation.

Also, when a single controller is used

or two or more controllers are mounted

on top of one another, provide a fan.)

D

Panel cutout

Note 3)

Min.

Min.

30

60

Min. 150

45+

Note 3)

Min. 30

Note 3)

Min.

30

0.6

0

E

Note 3)

Min.

30

0.8

0

92+

a+

0.8

0

10

Note 3)

Min.

30

0.8

92+