Page 1

USER’S MANUAL

Conformance with Standards

FEH249

SERIES

Page 2

<Notes>

1. This manual may not be reproduced in whole or part in any form without prior written approval by the manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write then down (along with the manual

No. Shown on the cover) and contact FUJI.

Thank you very much for purchasing the FUJI MICREX-SX Series SPH.

This users' manual describes operational instructions and restrictions on MICREX-SX Series products that conform to

various standards (CE marking, Lloyd's Register of Shipping, etc.)

Please read this manual carefully to correctly use your device.

If your MICREX-SX Series product does not need to conform to CE marking or Lloyd's Register of Shipping, there is no

need to execute the content of this manual. There will be no problem with performance and functionality.

If your MICREX-SX Series product is required to conform to those standards, you must execute the content of this manual.

Note that this manual deals with MICREX-SX Series products of "basic structure," and therefore additional measures

may be necessary depending on the configuration of your system, the structure of the control panel, or the product's work

environment.

Preface

Page 3

*Manual No. is shown on the cover.

Revision

Printed on *Manual No. Revision contents

May.2000 FEH249 First edition

Page 4

Contents

Preface

Revision

Contents

Section1 Standards Conformed Product

1-1 Standards conformed products list ...................................................................................... 1-1

Section2 Conformance with CE marking

2-1 CE marking ............................................................................................................................. 2-1

2-2 Method for adapting to CE marking ..................................................................................... 2-2

2-2-1 Metal Enclosure .............................................................................................................................. 2-2

2-2-2 How to lay the SX bus cable ............................................................................................................ 2-3

2-2-3 Adaptation of individual module ...................................................................................................... 2-4

(1)T-link master / interface module (NP1L-TL1/RT1) ............................................................................. 2-4

(2)OPCN-1 master module ( NP1L-JP1) .................................................................................................. 2-5

(3)FL-net ( OPCN-2 ) module ( NP1L-FL1 ) ............................................................................................. 2-5

(4)Precautions for using the "AS-i" master module ( NP1L-AS1 ) ............................................................ 2-6

(5)DeviceNet master module ( NP1L-DN1 ) ............................................................................................ 2-6

(6)Measures for the positioning modules ................................................................................................. 2-7

Seciton3 Adaptation to UL standard / Lloyd's Resister of Shipping / NK

3-1 Adaptation to UL standard .................................................................................................... 3-1

3-2 Adaptation to Lloyd's Resister of Sipping / NK .................................................................... 3-1

Section4 Installing the PC & Wiring of power supply

4-1 Installing PC units .................................................................................................................. 4-1

4-2 Wiring of power supply ......................................................................................................... 4-2

Page 5

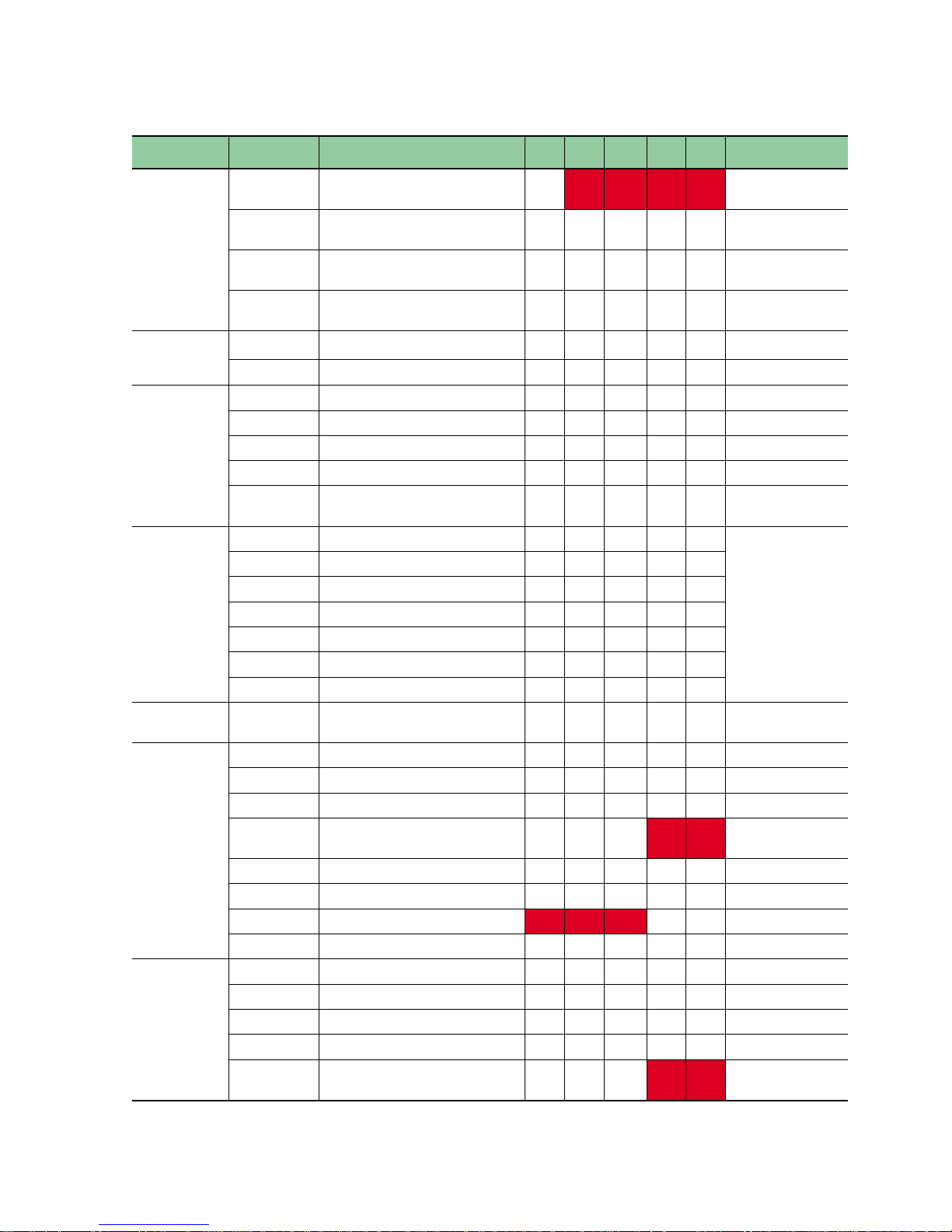

1-1

1-1 Standards conformed products list

( Continued on next page )

Section1 Standards Conformed Product

Component Typ e Specification

CE UL cUL LR NK

CPU module

NP1PS-74 High-performance CPU module

Program memory:74K steps

yes no no no no

NP1PS-32 High-performance CPU module

Program memory:32K steps

yes yes yes yes yes

NP1PH-08 Standard CPU mod ule

Program memory:8K steps

yes yes yes yes yes

NP1PH-16 Standard CPU mod ule

Program memory:16K steps

yes yes yes yes yes

Power supply

module

NP1PS-22 100/200V AC yes yes yes yes yes

NP1PS-42 24V DC yes yes yes yes yes

Base board NP1BS-06 No.of slots:6 yes yes yes yes yes

NP1BS-08 No.of slots:8 yes yes yes yes yes

NP1BS-11 No.of slots:11 yes yes yes yes yes

NP1BS-13 No.of slots:13 yes yes yes yes yes

NP1BP-13 No .of s lots:13

No.of processor buses:10

yes yes yes yes yes

SX bus

expansion

cable

NP1C-P3 Cable leng th:30cm yes yes ye s yes yes To adapt to CE

marking, the

measures described

in 2-2-2 need to be

taken.

NP1C-P6 Cable leng th:60cm yes yes ye s yes yes

NP1C-P8 Cable leng th:80cm yes yes ye s yes yes

NP1C-02 Cable leng th:2m yes yes ye s yes yes

NP1C-05 Cable leng th:5m yes yes ye s yes yes

NP1C-10 Cable leng th: 10m yes yes ye s yes yes

NP1C-25 Cable leng th: 25m yes yes ye s yes yes

SX bus T-branch

uint

NP8B-TB For SX bus T-branch yes yes yes yes yes

Digital input

module

NP1X1606-W 24V DC, 16 p oints yes yes ye s ye s ye s

NP1X3206-W 24V DC, 32 points ye s yes yes yes yes

NP1X3202-W 5/12V DC, 32 points yes yes ye s ye s ye s

NP1X3206-A 24V DC, 32 points

High-speed counter 4 channels 20kHz

yes yes yes

no no

NP1AX6406-W 24V DC, 64 points ye s ye s yes y es yes

NP1X0810 100 to 120V AC, 8 points yes yes yes yes yes

NP1X1610 100 to 120V AC, 16 points

no no no yes yes

NP1X0811 200 to 240V AC, 8 points yes yes yes ye s ye s

Digital

output

module

NP1Y08T0902 Tr sink 12 to 24V DC, 8 points yes yes ye s yes yes

NP1Y16T09P6 Tr sink 12 to 24V DC, 16 points yes yes yes yes yes

NP1Y32T09P1 Tr sink 12 to 24V DC, 32 points yes yes yes ye s ye s

NP1Y64T09P1 Tr sink 12 to 24V DC, 64 points yes yes yes ye s ye s

NPY32T09P1-A Tr sink 24V DC, 32 points

Pulse train output function

yes yes yes

no no

Page 6

1-2

Section1 Standards Conformed Product

( Continued on next page )

( Note )To adapt to CE marking, the measures described in 2-2-3 need to be taken.

Component Typ e Specification CE UL cUL LR NK

Digital output

module

NP1Y08U0902 Tr sourc e 12 to 24V DC, 8 points yes yes ye s ye s yes

NP1Y16U09P6 Tr source 12 to 24V DC, 16 points yes yes yes yes yes

NP1Y32U09P1 Tr source 12 to 24V DC, 32 points yes yes ye s ye s yes

NP1Y64U09P1 Tr source 12 to 24V DC, 64 points yes yes ye s ye s yes

NP1Y06S Triac 100 to 200V AC, 6 points yes yes ye s ye s yes

NP1Y08S Triac 100 to 200V AC, 8 points

no no no yes yes

NP1Y08R-04 Ry 110V DC,240V AC, 8 p oints yes yes ye s ye s yes

NP1Y16R-08 Ry 110V DC,240V AC, 16 p oints

no no no yes yes

Digital input/output

module

NP1W1606T input : sourse typ e24V DC, 8 points

output : Tr sink12 to 24V DC, 8 points

yes yes yes yes yes

NP1W3206T input : source typ e24V DC, 16 points

output : Tr sink12 to 24V DC, 16 points

yes yes yes yes yes

NP1W1606U input : sink type24V DC, 8 points

output : Tr source12 to 24V DC, 8 points

yes yes yes yes yes

NP1W3206U input : sink type24V DC, 16 points

output : Tr source12 to 24V DC, 16 points

yes yes yes yes yes

Multi-range Analo g

input module

NP1AXH4-MR 4 channels, Resolution : 14bits yes yes ye s ye s yes

NP1AX04-MR 4 channels, Res olution : 10bits yes yes ye s ye s yes

NP1AX08-MR 8 channels, Res olution : 10bits yes yes ye s

no no

Multi-range Analo g

output module

NP1AYH2-MR 2 channels, Resolution : 10bits yes yes ye s ye s yes

NP1AY02-MR 2 channels, Res olution : 10bits yes yes ye s ye s yes

Gene ral purpose

communication

module

NP1L-RS1 RS-232C : 1 channel, RS-485 : 1 channel yes yes ye s ye s yes

NP1L-RS2 RS-232C : 1 channel yes yes ye s ye s yes

NP1L-RS4 RS-485 : 1 channel yes yes ye s ye s yes

FL-net ( OPCN-2 )

module

NP1L-FL1 FL-net (OPCN-2 ) : 1 channel yes

no no no no ( Note )

P-link mo dule NP1L-PL1 P-link : 1channel

no yes ye s no no

PE-link mod ule NP1L-PE1 PE-link : 1 channel

no yes ye s no no

OPCN-1 maste r

module

NP1L-JP1 OPCN-1 : 1 channel yes yes ye s yes yes To adapt to CE

marking, the

measure s

described in 22-3 need to be

taken.

OPCN-1 interface

module

NP1L-RJ1 interface module to expansion OPCN-1 yes yes yes yes yes

Dev iceNet maste r

module

NP1L-DN1 Devic eNet : 1 channel yes

no no no no

AS-i master mod ule NP1L-AS1 AS-i master : 1 channel y es

no no no no

T-link master

module

NP1L-TL1 T-link master : 1 channel yes yes ye s ye s yes

T-link interface

module

NP1L-RT1 interface module to expansion T-link yes yes yes yes yes

PC c ard interface

module

NP1F-PC2 General purp ose PC card : 1 channel

memory card : 1 channel

yes

no no no no

Memory card

interface module

NP1F-MM1 SRAM memory card : 1 channel yes

no no no no

Page 7

1-3

Section1 Standards Conformed Product

Component Type Specification CE UL cUL LR NK

Dummy mo dul e NP1F-DMY sub stitute fo r the faile d module y es no no no no

To adapt to

CE

marking,

the

measures

described

in 2-2-3

need to be

taken.

High-speed counter

module

NP1F-HC2 2 channels 500kHz yes

no no no no

NP1F-HC8 8 channels 50kHz yes

no no no no

Pulse train output

module

NP1F-HP2

Pulse train command, 2 c hannels 250kHz

Forward pulse + reverse pulse

yes

no no no no

Pulse train multiple

module

NP1F-MP2

Positioning control multiple module

2 axes, Pulse train command

yes

no no no no

Analo g

multiplemodule

NP1F-MA2

Positioning control multiple module

2 axes, Analog command

yes

no no no no

Sig nal converter NP2F-LEV

Convert signal level, From open collector signal to

RS-485 or vice versa

yes

no no no no

D300win cable

NP4H-CNV Personal computer cable for loader with converter yes yes yes yes yes

NP4H-CA2 Personal computer cable for loader yes yes yes yes yes

Simulative-input swich NP8X-SW 16 points yes yes yes yes yes

Data backup battery NP8P-BT Lithium primary battery yes yes yes yes yes

User ROM card NP8PMF-16

User ROM card 16k steps Dedicated to standard

CPU

yes yes yes yes yes

CPU mode selection

key swich

NP8P-KY For CPU mode selection yes yes yes yes yes

Base board mounting

stud

NP8P-ST For DIN rail (in pairs) yes yes yes yes yes

SX bus terminating

plug

NP8P-BP For SX bus terminating yes yes yes yes yes

T-link connector,

JPCN-1 connector

FCT120T yes yes yes yes yes

P/PE-link connector FTC120P yes yes yes yes yes

T-link/JPCN-1

terminating resistor

FRT120A100 100Ω/1W yes yes yes yes yes

P/PE terminating

resister

FRT220A75 75Ω/1W yes yes yes yes yes

I/O connec tor,

Positioning control

module connector

NP8V-CN

Soldered socket type,connector cover

(Fujitsu Co .,Ltd.)

yes yes yes yes yes

Page 8

2-1

Section2 Conformance with CE marking

2-1 CE marking

<Product standard>

IEC 61131-2

EMI = CISPR11, Gr. 1, Class A

EMS = IEC 61000-4-2 to -6, -8 and -12

<Classification of product>

Enclosed type equipment, which is defined as follows:

"To prevent accidents due to a charged or operating part coming into contact with the human body, the

product should be installed in a metal enclosure when used."

<Safety level>

Overvoltage Category II

<EMC classification when installing PLC defined in IEC 61131-2>

Zone B, which is defined as follows:

"An environment where power from an external power supply, which supplies power to the factory (the build-

ing in which the device is installed), is used after doubly protecting against surge voltage with an insulating

transformer or the like.

3-phase power supply

Primary

protection

Secondary

protection

Factory

Zone C

Zone B

Lightning

PLC

MICREX-SX

An environment that is doubly protected against surge voltage, but in

which the superimposition of industrial environment noise may occur.

Page 9

Section2 Conformance with CE marking

2-2

2-2 Method for adapting to CE marking

2-2-1 Metal Enclosure

MICREX-SX Series products are classified as "enclosed type" equipment. "Enclosed type" means equip-

ment that is designed on the condition that it is installed in an enclosure such as a metal enclosure, so that

electric shock or other accidents do not occur due to the human body coming into contact with the product

(MICREX-SX). In other words, there may be danger of an electric shock, etc., if the product is not accom-

modated in an enclosure. (For example, a steel wire may be inserted in one of the cooling slots provided

on the product body.)

MICREX-SX Series products also need to be installed in a metal enclosure in order to control the electro-

magnetic radiation noise (EMI) they emit. Basic specifications for the metal enclosure are as follows.

Material : SPCC (high-tensile-strength steel)

Plate thickness: Min. 1.6 mm

Power supply : Power supplied to the control panel should be protected from external surge voltage with

an insulating transformer.

Remarks : Should be structured so that an electromagnetic radiation noise does not leak from the

enclosure.

For example, in the figure below, a box-type door is used, and the enclosure has an eave-

like protrusion that overlaps on the side faces of the door when closed.

The important point here is that the overlap of the door and the enclosure's main body

effectively prevents electromagnetic radiation noise from leaking out of the enclosure.

扉

ひさし

Door

Eave

Page 10

2-3

Section2 Conformance with CE marking

2-2-2 How to lay the SX bus cable

<Mounting the ferrite core>

A high-speed electric signal flows through the SX bus cable. Therefore, high-frequency noise is emitted

from the SX bus cable, making it impossible for the product to conform to the EMC directive concerning CE

marking.

To solve this problem, a ferrite core is mounted at the base of the SX bus cable.

Mount the ferrite core according to the figure below.

<How to affix the cable to the metal enclosure>

When affixing the SX bus cable to the metal enclosure, be sure to secure a 1-cm or wider gap so that the

SX bus cable does not come into contact with the metal plate.

On the one hand, the metal enclosure provides an effective shield fromelectromagnetic radiation noise; on

the other hand, it becomes an effective antenna that electromagnetic radiation noise if a cable as a noise

source is nearby or comes into actual contact with it. Not only the SX bus cable, but also other high-speed

signal transmission cables need to be kept away from the metal walls of the enclosure.

Commendable ferrite core

: ZCAT 3035-1330 from TDK

Page 11

Section2 Conformance with CE marking

2-4

2-2-3 Adaptation of individual module

(1) T-link master/interface module (NP1L-TL1 / RT1)

When a T-link master module is used, it is necessary to mount the ferrite core at the base of the communi-

cation cable as well as affix insulating sheet. When the T-link interface module is used, it is necessary to

mount the ferrite core at the base of the communication cable.

1) Mount the ferrite core at the root of the communication cable.

2) Affix the static electricity preventive insulating sheet to the station number-setting switch

When a station number needs to be changed while the module is operating, it is once necessary to remove

the insulating sheet for this work. For this operation, the operator must remove static electricity accumu-

lated on his body by means of a static elimination band or the like before touching the station number-set-

ting switch. This is necessary only for the T-link master module (NP1L-TL1), and not necessary for the T-

link interface module (NP1L-RT1).

* Ferrite core mounting may be unnecessary if all of

the communication cable is laid only inside the

metal enclosure, or even when it is laid outside the

metal enclosure, if it is laid in EMI shielding tube or

metal tube so that no noise leaks out.

Commendable ferrite core

: ZCAT 3035-1330 from TDK

Note:

If vibration or shock is applied to the product, a

strong force due to the weight of the ferrite core

may act on the cable to damage it. Be sure to af-

fix the cable to a firm object such as a duct so

that the cable does not swing under vibration.

Affix the insulating sheet supplied with the product on the station number-

setting switch.

Note: For the purpose of explanation, a colored sheet is used in the

photo at left. The actual insulating sheet supplied with the prod-

uct is transparent.

Page 12

2-5

Section2 Conformance with CE marking

(2)OPCN-1 master module (NP1L-JP1)

When a OPCN-1 master module is used, it is necessary to the stick-insulating sheet.

1) Affix the static electricity preventive insulating sheet to the station number-setting switch

When a station number needs to be changed while the module is operating, it is once nec-

essary to remove the insulating sheet for this work. For this operation, the operator must

remove static electricity accumulated on his body by means of a static elimination band or

the like before touching the station number-setting switch.

(3) FL-net ( OPCN-2 ) module (NP1L-FL1)

When the "FL-net ( OPCN-2 )" module is used, in order to control electromagnetic radiation noise emitted

from the communication cable, a ferrite core needs to be mounted at the base of the cable.

1) Mount the ferrite core at the base of the communication cable.

Affix the insulating sheet supplied with the product on the station number-

setting switch.

Note: For the purpose of explanation, a colored sheet is used in the photo

at left. The actual insulating sheet supplied with the product is

transparent.

Commendable ferrite core

: ZCAT 3035-1330 from TDK

Note:

If vibration or shock is applied to the product, a

strong force due to the weight of the ferrite core

may act on the cable to damage it. Be sure to af-

fix the cable to a firm object such as a duct so

that the cable does not swing under vibration.

* Ferrite core mounting may be unnecessary if all of the communication cable is laid only inside the metal

enclosure, or even when it is laid outside the metal enclosure, if it is laid in EMI shielding tube or metal

tube so that no noise leaks out.

Page 13

Section2 Conformance with CE marking

2-6

Static discharge to the termi-

nal block does not occur.

(4) Precautions for using the "AS-i" master module (NP1L-AS1)

When the "AS-i" module is used, the operator who works on the terminal block for connecting the signal

cable must discharge static electricity accumulated on his body by means of a static elimination band or

the like before touching the terminal block so that static discharge to the terminal block does not occur.

Commendable ferrite core

: ZCAT 3035-1330 from TDK

Note:

If vibration or shock is applied to the product, a

strong force due to the weight of the ferrite core

may act on the cable to damage it. Be sure to af-

fix the cable to a firm object such as a duct so

that the cable does not swing under vibration.

* Ferrite core mounting may be unnecessary if all of the communication cable is laid only inside the metal

enclosure, or even when it is laid outside the metal enclosure, if it is laid in EMI shielding tube or metal

tube so that no noise leaks out.

(5) DeviceNet master module (NP1L-DN1)

When the "DeviceNet" master module is used, be sure to take the following measure.

1) Mount the ferrite core at the base of the communication cable.

Page 14

2-7

Section2 Conformance with CE marking

(6) Measures for the positioning modules

When one of the following modules is used, a ferrite core needs to be mounted at the base of all the cables

connected to the module as well as the power and FG cables leading to the power module mounted on the

baseboard on which the positioning module is also mounted.

NP1F-HC2/NP1F-HC8

NP1F-HP2/NP1F-MP2/NP1F-MA2

Wire to a power supply and grounding wire

Affix the insulating sheet supplied with the product on the station number-

setting switch.

Note: For the purpose of explanation, a colored sheet is used in the photo

at left. The actual insulating sheet supplied with the product is

transparent.

Static discharge to the termi-

nal block does not occur.

Commendable ferrite core

: ZCAT 3035-1330 from TDK

Note:

If vibration or shock is applied to the product, a

strong force due to the weight of the ferrite core

may act on the cable to damage it. Be sure to af-

fix the cable to a firm object such as a duct so

that the cable does not swing under vibration.

2) Affix the static electricity-preventive insulating sheet on the station number-setting switch.

Take measures to prevent static discharge to the terminal block for the signal cable.

Affix the static electricity preventive insulating sheet to the station number-setting switch.

When a station number needs to be changed while the module is operating, it is once necessary to remove

the insulating sheet for this work. For this operation, the operator must remove static electricity accumu-

lated on his body by means of a static elimination band or the like before touching the station number-set-

ting switch.

Page 15

3-1

Section3

Adaptation to UL standard / Lloyd's Register of Shipping / NK

3-1 Adaptation to UL standard

No restriction

3-2 Adaptation to Lloyd's Register of Shipping / NK

Ship standards such as Lloyd's Register of Shipping and NK (Nippon Kaiji Kyokai) are almost the same as that for CE

marking, except that vibration- related rules are more severe in the former than in the latter.

Therefore, when a MICREX-SX Series product is used for marine equipment, tightly wind a strong nylon band around the

entire PLC so that the modules come in close contact with each other, as shown in the figure below.

A guideline for checking the propriety of the contact is whether or not a name card can be inserted in between the mod-

ules.

Fix by tightly winding a nylon band

around the SX.

After fixing with a nylon band, check to see that a

name card cannot be inserted in the gap be-

tween the modules.

Page 16

4-1

4-1 Installing PC uints

1) Keep an open space of 110mm (vertical) or 10mm (horizontal) between the PC unites, between remote I/O modules the

PC unit and remote I/O module.

Note:When the base board is mounted on a DIN rail, keep an open space of 80mm in consideration of mounting bracket

dimensions and the workability.

2) Keep an open space of 50mm between the PC unit and other device and between the PC unit and the wall to obtain

sufficient ventilation.

3) Avoid installing heat generating devices (heaters, transformers, or resistors) underneath the PC unit.

4) Shield or separate the PC unit as far from high voltage device, high-voltage cables, or power equipment as possible.

Avoid installing PC I/O cables unit and high-voltage or power equipment cables in parallel.

5) Install the PC unit perpendicular to the panel floor.

6) The PC must be installed in a vertical position. Do not install the PC in other position.

Section4 Installing the PC & Wiring of power supply

80mm or more

Unite

Unite

Unite

Other

device

1)

110mm or more

10mm or more

1)

110mm or more

1)

10mm or more

2)

2)

50mm or more

3) Heat generating

device

4)

High-

voltage

device

5)

MICREX-

SX

MICREX-

SX

110mm

or more

1)

Duct

50mm or more

Duct

Mounting angle

0°

90°

50mm or more

50mm or more

50mm or more

Remote I/O

Remote I/O

Remote I/O

Keep an open space as follows:

Incorrect

Incorrect

Incorrect

Incorrect

Page 17

4-2

4-2 Wiring of power supply

Section4 Installing the PC & Wiring of power supply

AC power

supply

Keep the distance between the insulating transformer

(or the noise filter) and the power supply module as

short as possible, and the cable must be twisted

densely.

Do not bundle up and di not close

100V AC:85 to132V AC

200V AC:170V to 264V AC

(Note) Be sure to use crimp terminals.

( Tightening torque:1.2N·m)

3)

Grounding

ground resisstance of 100

or less

2)

Votage selection

Short:100V AC

Open:200V AC

M4 screw

3)

DC pwer

supply

24V DC:22.8-26.4V DC

Breaker

Insulating transformer,

Noise filter

Keep the distance between the DC power suplly

and the the power supply module as short as

possible, and the cable must be twisted densely.

1)

1)

1) Wiring of power supply

For AC power supply

Wire to a 100 to 120V AC or 200 to 240V AC power supply.

The thickness of the wire must be 2mm2, and the wire must ne twisted densely.

For DC power supply

Wire to a 24V DC power supply (22.8-26.4V DC).

The thickness of the wire must be 2mm

2

, and the wire must ne twisted densely.

[Tips]

The tolerance range of MICREX-SX AC power supply is 85 to 132V AC for 100V AC, and 170 to 264V AC for 200V AC. But

the voltage is recommended to be as near the rated voltage (100 to 110V AC, 200 to 220V AC) as possible.

In the case of the lower voltage, a small voltage drop will cause a power failure. In the case of the higher voltage, the heat-

ing value of the power supply module increases and it reduces the life of the module. If power supply voltage fluctuation

exceeds the specified range, connect a voltage stabilizer to the power supply.

For noise reduction of the power supply, an insulating transformer or a noise filter is effective between the breaker and the

power supply module. Take care of the following points:

• Do not bundle up or do not close the insulating transformer or the noise filter.

• Keep the distance between the insulating transformer (or the noise filter) and the power supply module as short as

possible, and the cable must be twisted densely.

Breaker

AC power supply

DC power supply

ΩΩ

ΩΩ

Ω

M4 screw

Grounding

ground resisstance of 100

or less

ΩΩ

ΩΩ

Ω

Page 18

4-3

2) Voltage selection (for only AC power supply)

100V AC : Short (using a jumper cable)

200V AC : Open

3) Grounding

• Connect the FG terminal to the integrated ground section of each control panel (FG bus, FG integrated terminal block, or

stud) in branch-type configuration. The thickness of the ground wire must be 2mm

2

. Allocate the grounding point as near

the module as possible, and keep the ground wire as short as possible.

• The integrated ground section of each control panel must be connected to the integrated ground board, which is installed

according to the distribution of devices in a branch-type configuration. The thickness of the ground wire must be 5.5mm

2

or more.

• Separate the ground wire as far from the lines of high-voltage circuits and main circuit as possible. In addition, keep the

distance at which they run in parallel as short as possible.

• For grounding, use an exclusive ground pole and wire which are separated from the ground system of other power cir

cuits.

• The grounding should be exclusive. The grounding resistance is 100 or less. Separate the ground pole 10m or more

from that of other power circuit.

• When installing in a place affected by frequent lighting surges, all the CPU modules and input/output modules should be

electrically insulated from the control panel. Also, modules and units should be earthed to ground individually.

Do not open the FG terminal with LG-FG short circuited. (It must be grounded, otherwise it might cause electric

shock.)

Warning

Section4 Installing the PC & Wiring of power supply

PC

Other

device

PC

PC

Grounding

resistance

100 or less

ΩΩ

ΩΩ

Ω

Other

device

Other

device

ΩΩ

ΩΩ

Ω

Grounding

resistance

100 or less

ΩΩ

ΩΩ

Ω

Exclusive grounding....Best Common grounding....Good Common grounding ....Not acceptable

Page 19

4-4

<Grounding example>

SX bus

Control panel

LG

LG

FG

FG

T-link master

2mm

2

FG bus

Operator panel

Remote

I/O

FG

POD

FG bus

5.5mm

2

or more

Integrated ground board

Grounding

Section4 Installing the PC & Wiring of power supply

Power supply

Power supply

Integrated ground sectionIntegrated ground section

Page 20

Fuji Electric Co.,Ltd

ED & C Division,Electrical Components & Drive Systems Company

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo 141-0032, Japan

Phone: 3-5435-7135 / 3-5435-7136

Fax: 3-5435-7456 / 3-5435-7457

Information in this manual is subject to change without notice.

Loading...

Loading...