Page 1

USER’S MANUAL

Hardware

series

FEH526c

Page 2

Preface

Thank you for purchasing Fuji Electric Programmable Controller MICREX-SX SPF Series.

This User’s Manual describes the hardware specications of the SPF series.

Read this manual carefully to ensure correct operation and also read the corresponding user’s manuals listed below.

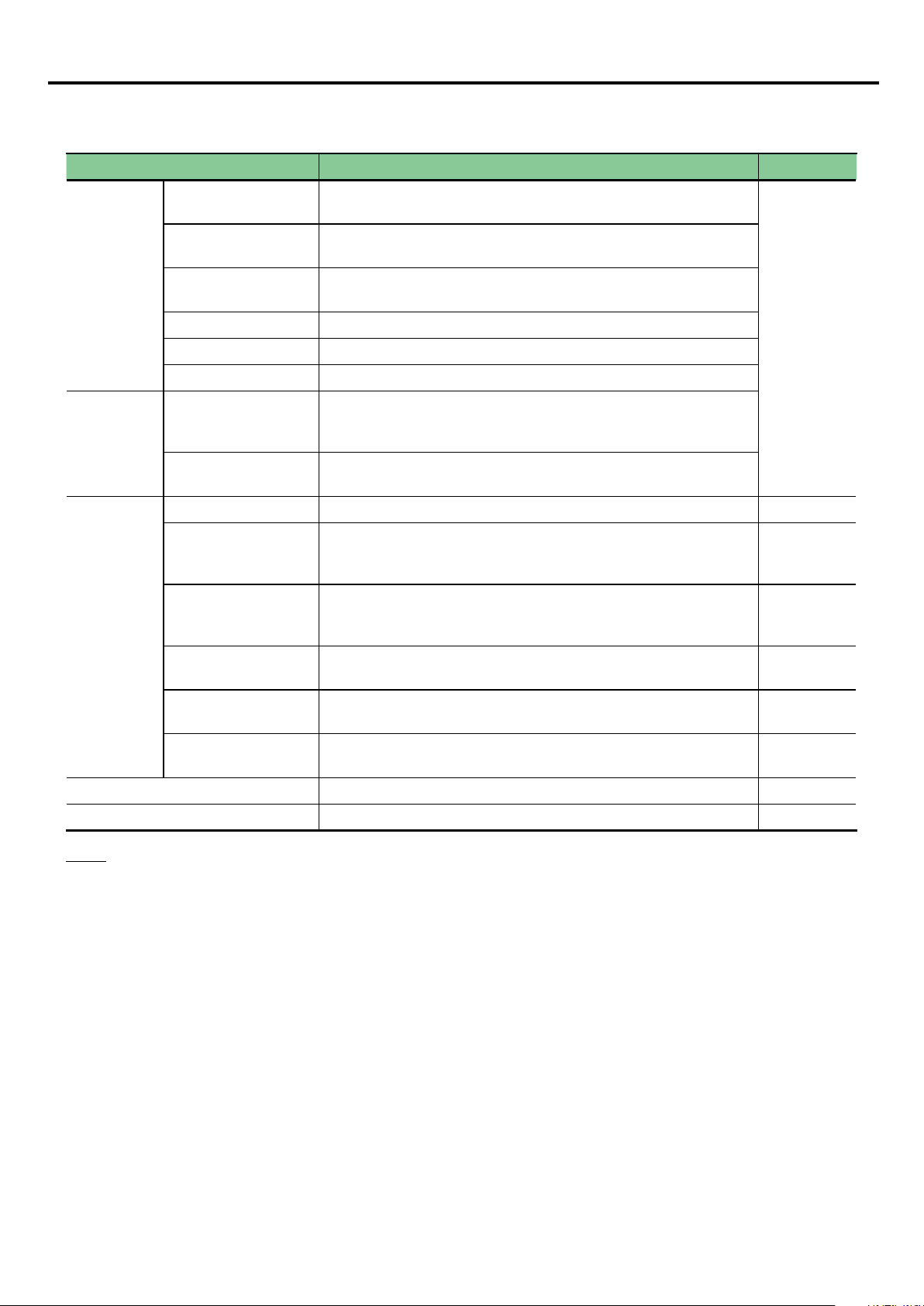

Title Manual No. Contents

User’s Manual Instructions (Standard),

MICREX-SX series SPF

User’s Manual Instructions (Standard),

MICREX-SX series SPH

User’s Manual Instructions (Expert),

MICREX-SX series SPF

User’s Manual Instructions (Expert),

MICREX-SX series SPH

User’s Manual Analog Unit,

MICREX-SX series SPF

User’s Manual Built-in High-Speed Counter,

MICREX-SX series SPF

User’s Manual

General Purpose Communication,

MICREX-SX series SPF

User’s Manual Pulse Output Instructions,

MICREX-SX series SPF

User’s Manual SX-Programmer Standard

<Reference>, MICREX-SX series

User’s Manual SX-Programmer Expert

(D300win) <Reference>, MICREX-SX series

FEH524

FEH588

FEH525

FEH200

FEH527

FEH534

FEH528

FEH529

FEH598

FEH257

Describes the memory specications and instructions specic to

the SPF series (Standard).

Describes the memory, language and system denitions of the

MICREX-SX series SPH (Standard).

Describes the memory specications and instructions specic to

the SPF series (Expert).

Describes the memory, language and system denitions of the

MICREX-SX series SPH (Expert).

Describes the specications and operations of analog input/output

units of the MICREX-SX series SPF.

Describes the specications and operations of the high-speed

counter built in the main unit of the MICREX-SX series SPF.

Describes the specications of general purpose communication

(RS-232C/RS485) units/boards of the MICREX-SX series SPF

and how to create applications.

Describes the specications and operations of the high-speed

pulse output and high-speed positioning functions built in the main

unit of the MICREX-SX series SPF.

Describes the functions and the operations of SX-Programmer

Standard V3.

Describes the functions and the operations of SX-Programmer

Expert (D300win) V3.

* In addition to the above manuals, the following Fuji Electric Co.,Ltd.site offers various manuals and technical documents

associated with MICREX-SX series.

URL http://www.fujielectric.com

Notes

1. This manual may not be reproduced in whole or part in any form without prior written approval by the manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write them down (along with the manual No.

shown on the cover) and contact FUJI.

Page 3

Safety Precautions

: Incorrect handling of the device may result in minor injury or physical damage.

Be sure to read the "Safety Precautions" thoroughly before using the module.

Here, the safety precautions items are classied into "Warning" and "Caution".

Warning

: Incorrect handling of the device may result in death or serious injury.

Caution

Even some items indicated by "Caution" may result in a serious accident.

Both safety instruction categories provide important information. Be sure to strictly observe these instructions.

Warning

Neve touch any part of charged circuits as terminals and exposed metal portion while the power is turned ON.

It may result in an electric shock to the operator.

Turn OFF the power before mounting, dismounting, wiring, maintaining or checking, otherwise, electric shock, erratic

operation or troubles might occur.

Place the emergency stop circuit, interlock circuit or the like for safety outside the PLC. A failure of the PLC might break

or cause problems to the machine.

When using an expansion right side unit, be sure to mount a healthy unit to stop the SPF system with a fatal fault if the

expansion right side unit is dropped. Unless a healthy unit is mounted, a dropout of the expansion right side unit is not

detected and the SPF system continues operation in the state where the expansion right side unit is dropped.

Page 4

Safety Precautions

Caution

Do not use one found damaged or deformed when unpacked, otherwise, fire, failure or erratic operation might be caused.

Do not shock the product by dropping or tipping it over, otherwise, it might be damaged or troubled.

Follow the directions of the instruction manual and user’s manual when mounting the product.

If mounting is improper, the product might drop or develop problems or erratic operations.

Use the rated voltage and current mentioned in the instruction manual and user’s manual. Use beyond the rated values

might cause fire, erratic operation or failure.

Operate (keep) in the environment specified in the instruction manual and user’s manual. High temperature, high humidity,

condensation, dust, corrosive gases, oil, organic solvents, excessive vibration or shock, might cause electric shock, fire,

erratic operation or failure.

Select a wire size to suit the applied voltage and carrying current. Tighten the wire terminals to the specified torque.

Inappropriate wiring or tightening might cause fire, malfunction, failure or might cause the product to drop from its

mounting.

Contaminants, wiring chips, iron powder or other foreign matter must not enter the device when installing it, otherwise, fire,

accident, erratic operation or failure might occur.

Remove the dust-cover seals of modules after wiring, otherwise, fire, accident, erratic operation or failure might occur.

Connect the ground terminal to the ground, otherwise, electric shock or erratic operation might occur.

Periodically make sure the terminal screws and mounting screws are securely tightened.

Operation at a loosened status might cause fire or erratic operation.

Put the furnished connector covers on unused connectors, otherwise, erratic operation or failure might occur.

Sufficiently make sure of safety before program change, forced output, starting, stopping or anything else during a run.

Wrong operation might break or cause problems to the machine

Engage the loader connector in a correct orientation, otherwise, an erratic operation might occur.

Before touching the PLC, discharge any static electricity that may have been collected on your body. To discharge it, touch

a grounded metallic object. Static electricity might cause erratic operation or failure.

Be sure to install the electrical wiring correctly and securely, observing the directions of the instruction manual and user’s

manual. Wrong or loose wiring might cause fire, accident or failure.

When disengaging the plug from the outlet, do not pull the cord, otherwiase, break of cable might cause fire or failure.

Do not attempt to change system configurations (such as installing or removing expansion block) while the power is ON,

otherwise, failure or erratic operation might occur.

Do not attempt to repair the module by yourself, but contact your Fuji Electric agent, otherwise, fire, accident or failure

might occur.

To clean the module, turn power off and wipe the module with a cloth moistened with warm water. Do not use thinner or

other organic solvents, as the module surface might become deformed or discolored.

Do not remodel or disassemble the product, otherwise, failure might occur.

Follow the regulations of industrial wastes when the device is to be discarded.

The products covered in this user’s manual have not been designed or manufactured for use in equipment or systems

which, in the event of failure, can lead to loss of human life.

Do not use the products covered in this user’s manual for special applications, such as power plant, radiation facilities,

railroad, space/flight equipments, lifeline facilities, or medical equipments, where a great effect on human life, body,

society, major property or rights may be anticipated and high degree of safety is required.

Be sure to provide protective measures when using the products covered in this manual in equipment which, in the event

of failure, can lead to loss of human life or other grade results.

External power supply (such as 24 V DC power supply) which is connected to DC I/O should be strongly isolated from AC

power supply, otherwise, accident or failure might occur. (Use of EN60950 conforming power supply is recommended.)

Do not use the peoducts covered in this user’s manual in a residential environment.

Page 5

Revision

* The manual No. is printed at the bottom right of the cover of this manual.

Printed on * Manual No. Revision contents

Jan. 2017 FEH526 First edition (preliminary edition)

Jan. 2017 FEH526a Ofcial edition

June 2017 FEH526b • The specications of new models were added.

(NA0E08T-3, NA0E08T-0, NA0E16R-0, NA0AX02-TC, NA0AX16-TC, NA0AX06-PT,

NA3AY02-MR, NA3AW03-MR, NA0LA-RS3)

• The structure of the manual were altered.

Oct. 2017 FEH526c • The specications of new models were added.

(NA3LA-ET1, NA0LA-ET1, NA0FA-LC1)

• The description of a memory pack was added.

• The contents were revised.

Page 6

Contents

Preface

Safety Precautions

Revision

Contents

Section 1 Overview

1-1 Features .............................................................................................................................................1-1

1-1-1 Overview of system conguration .................................................................................................................1-1

1-1-2 Function list ...................................................................................................................................................1-2

1-2 Type Code .......................................................................................................................................... 1-3

1-3 Product Type List ................................................................................................................................1-5

1-4 Supported Versions ............................................................................................................................ 1-7

1-4-1 Program loader version .................................................................................................................................1-7

1-4-2 Main unit version ...........................................................................................................................................1-7

Section 2 System Conguration

2-1 System Conguration Specications ..................................................................................................2-1

2-1-1 Expansion specications ...............................................................................................................................2-2

2-1-2 Calculation of current consumption ...............................................................................................................2-3

2-2 System denition ................................................................................................................................2-7

2-3 I/O address assignment .....................................................................................................................2-8

2-3-1 Rules for assigning I/O addresses ................................................................................................................2-8

2-3-2 Example of address assignment ...................................................................................................................2-9

Section 3 Specications

3-1 General Specications .......................................................................................................................3-1

3-2 Main Unit Specications .....................................................................................................................3-2

3-2-1 Performance specications ...........................................................................................................................3-2

3-2-2 Memory backup and internal battery specications ......................................................................................3-3

3-2-3 Calendar specications .................................................................................................................................3-3

3-3 Power supply specications ...............................................................................................................3-4

3-3-1 AC power supply type ...................................................................................................................................3-4

3-3-2 DC power supply type ...................................................................................................................................3-4

3-4 Input specications .............................................................................................................................3-5

3-4-1 DC input specications..................................................................................................................................3-5

3-5 Output Specications .........................................................................................................................3-7

3-5-1 Transistor output specications .....................................................................................................................3-7

3-5-2 Relay output specications ...........................................................................................................................3-10

3-5-3 Output device protection and noise suppression in DO circuit......................................................................3-12

3-6 Analog Unit/Board Specications .......................................................................................................3-15

3-6-1 Analog input unit (NA0AX06-MR) .................................................................................................................3-15

3-6-2 Analog output unit (NA0AY02-MR) ...............................................................................................................3-16

3-6-3 Analog input/output unit (NA0AW06-MR) .....................................................................................................3-17

3-6-4 Analog output board (NA3AY02-MR) ............................................................................................................3-19

3-6-5 Analog input/output board (NA3AW03-MR) ..................................................................................................3-20

3-6-6 Thermocouple input unit (NA0AX02-TC/NA0AX06-TC/NA0AX16-TC) .........................................................3-21

3-6-7 Resistance thermometer element input unit (NA0AX06-PT).........................................................................3-24

3-7 Communication Unit/Board Specications .........................................................................................3-25

3-7-1 RS-232C/RS-485 general purpose communication board (NA3LA-RS1) .....................................................3-25

3-7-2 RS-232C general purpose communication unit (NA0LA-RS3) .....................................................................3-26

Page 7

Contents

3-7-3 RS-485 general purpose communication unit (NA0LA-RS5) ........................................................................3-27

3-7-4 Ethernet communication board (NA3LA-ET1) / Ethernet communication unit (NA0LA-ET1) .......................3-28

3-8 Function Unit Specications ...............................................................................................................3-29

3-8-1 Load cell unit (NA0F-LC1).............................................................................................................................3-29

3-8-2 High-precision load cell unit (NA0FA-LC1)....................................................................................................3-31

3-9 Temperature derating of main unit .....................................................................................................3-32

3-10 Terminal Arrangement ......................................................................................................................3-34

3-10-1 Main unit .....................................................................................................................................................3-34

3-10-2 Expansion unit ............................................................................................................................................3-37

3-11 Names and Functions ......................................................................................................................3-39

3-11-1 Main unit .....................................................................................................................................................3-39

3-11-2 Expansion unit ............................................................................................................................................3-42

3-12 Dimensions ......................................................................................................................................3-44

3-12-1 Main unit .....................................................................................................................................................3-44

3-12-2 Expansion unit ............................................................................................................................................3-46

3-13 Mass ................................................................................................................................................. 3-49

Section 4 Installation and Wiring

4-1 Installation Precautions ......................................................................................................................4-1

4-1-1 Installation Environment ................................................................................................................................4-1

4-1-2 Before installation..........................................................................................................................................4-2

4-1-3 Control panel mounting (protection against noise)........................................................................................4-3

4-1-4 Environmental condition for mounting PLC on panel ....................................................................................4-5

4-1-5 Mounting methods.........................................................................................................................................4-6

4-2 Wiring .................................................................................................................................................4-11

4-2-1 Wiring and cables..........................................................................................................................................4-12

4-2-2 Wiring to power-supply, I/O and ground terminals ........................................................................................4-13

Section 5 Maintenance and Inspection

5-1 General Inspection Items ...................................................................................................................5-1

5-1-1 Inspection frequency .....................................................................................................................................5-1

5-1-2 Cautions on using the product ......................................................................................................................5-1

5-1-3 Inspection items ............................................................................................................................................5-2

5-2 Actions to be Taken When Battery Voltage Drop is Detected ............................................................5-3

5-3 Maintenance Services ........................................................................................................................5-4

5-3-1 Ordering notes ..............................................................................................................................................5-4

5-3-2 Free-of-charge warranty period and scope of warranty ................................................................................5-4

5-3-3 Service costs .................................................................................................................................................5-4

Appendix 1 Installing USB Driver ..............................................................................................App.1-1

Appendix 2 Automatic Update of System Software .................................................................App.2-1

Page 8

Section 1 Overview

1-1 Features .................................................................................................... 1-1

1-1-1 Overview of system conguration ...............................................................1-1

1-1-2 Function list ................................................................................................1-2

1-2 Type Code ................................................................................................. 1-3

(1) Main unit ..................................................................................................... 1-3

(2) DIO expansion unit (expansion right side unit) ........................................... 1-3

(3) Analog unit (expansion right side unit) ....................................................... 1-3

(4) Function unit (expansion right side unit) ..................................................... 1-4

(5) Analog board .............................................................................................. 1-4

(6) Communication board ................................................................................ 1-4

(7) Communication unit (expansion left side unit) ............................................ 1-4

(8) Function unit (expansion left side unit) ....................................................... 1-4

(9) Expansion power supply unit ...................................................................... 1-4

1-3 Product Type List ..................................................................................... 1-5

1-4 Supported Versions ................................................................................. 1-7

1-4-1 Program loader version .............................................................................. 1-7

1-4-2 Main unit version ........................................................................................1-7

Page 9

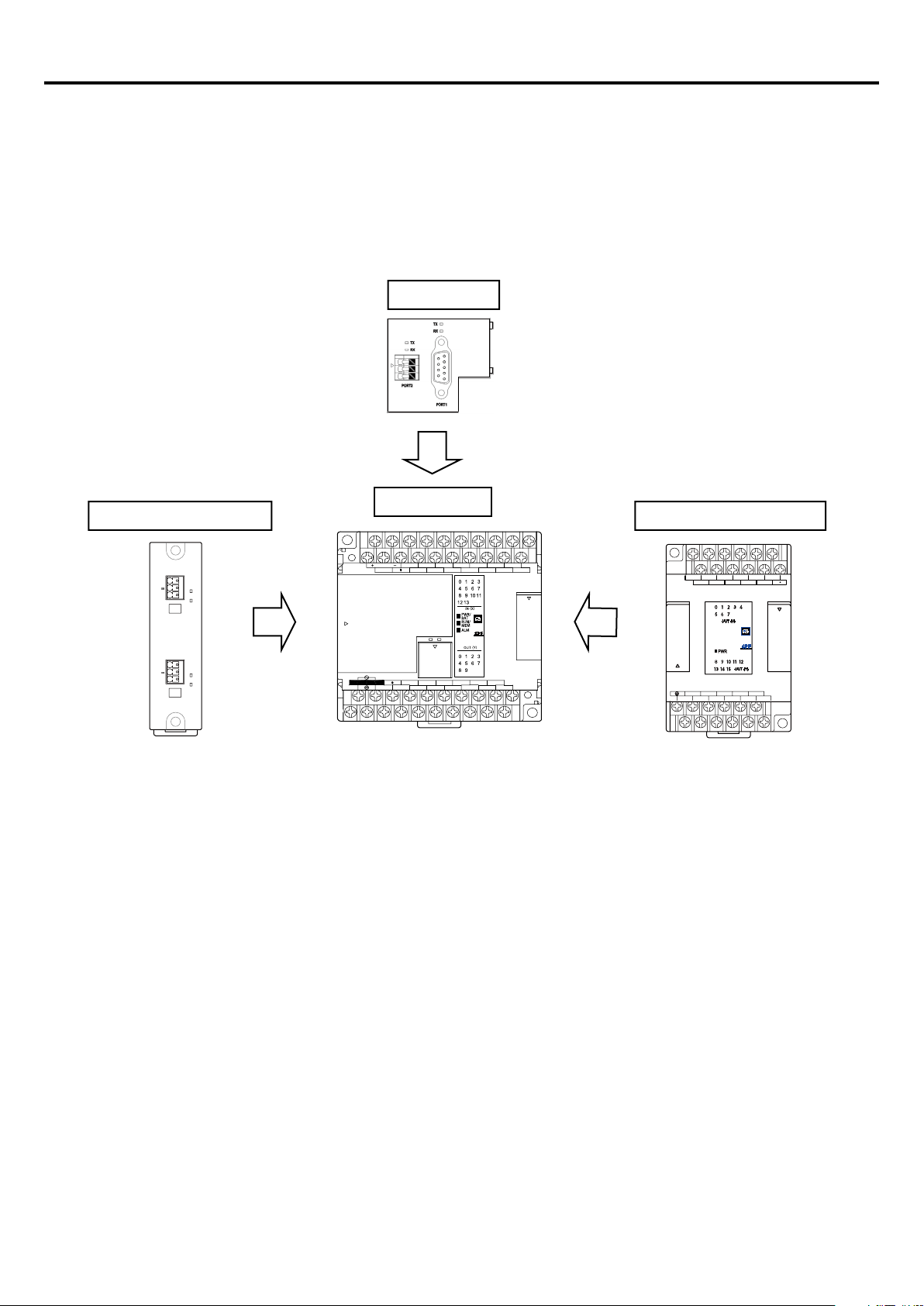

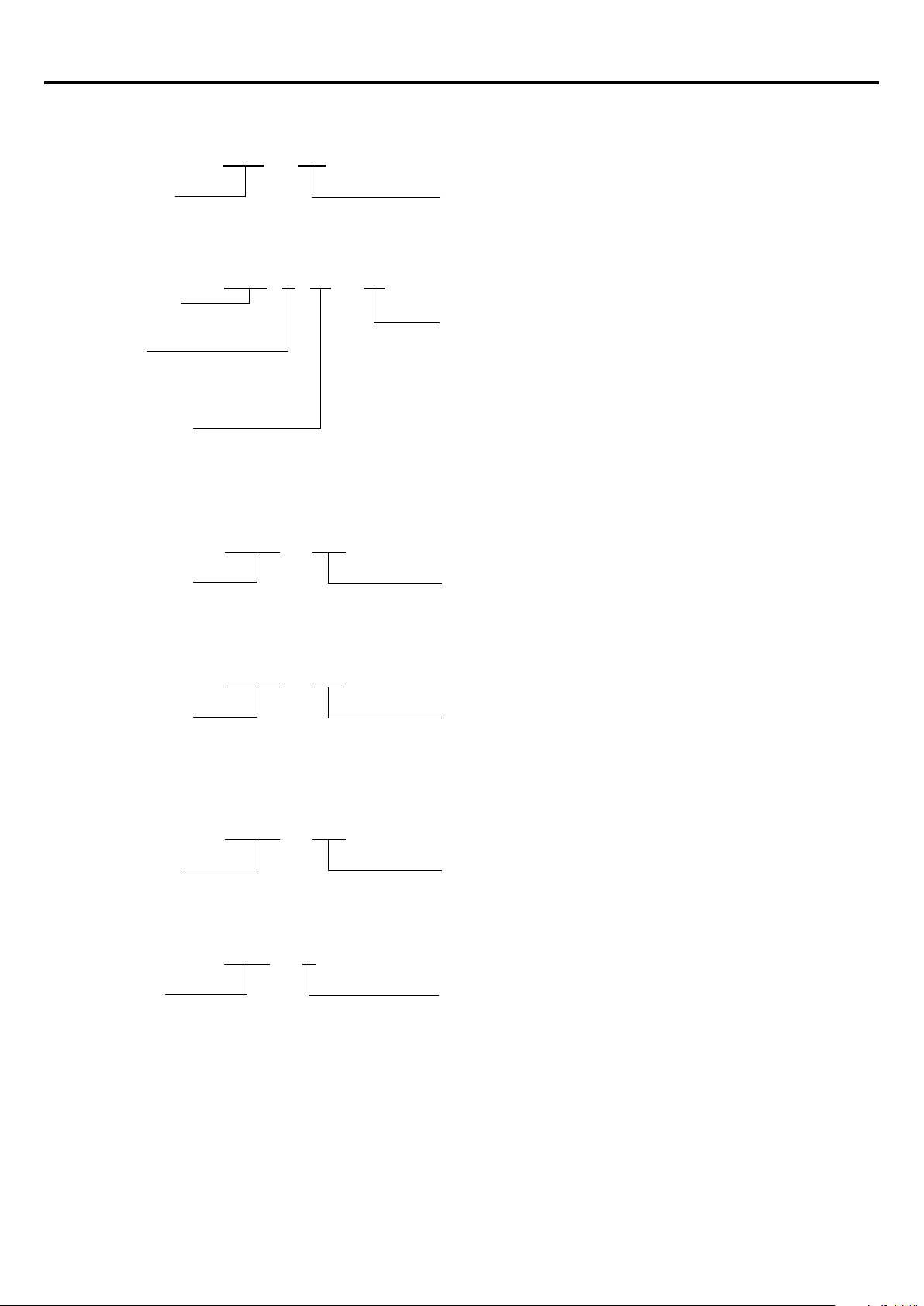

Section 1 Overview

• Expansion power supply unit

1-1 Features

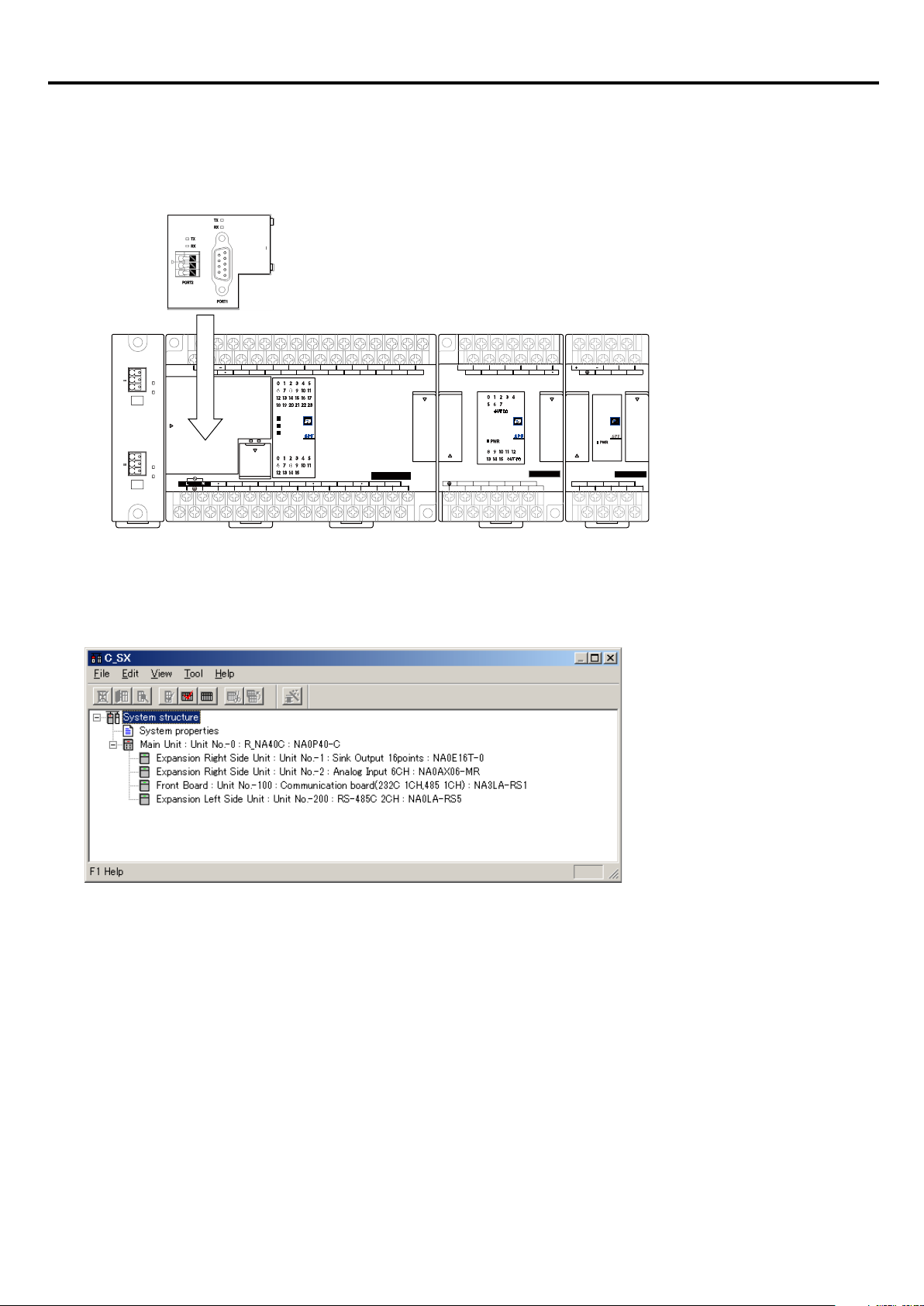

1-1-1 Overview of system conguration

The SPF series units are small controllers equipped with excellent functions comparable to medium-sized controllers and

maximum ve communication ports.

Various types of expansion units are available. One unit can be connected on the front of or on the left side of the main unit and

six units on the right side. In addition, interface options such as RS-232C, RS-485, and Ethernet enable you to use peripheral

communication devices.

PORT4 (RS485)

+

G

TNN

PORT3 (RS485)

+

G

T

NA0LA-RS5

Front board

* Mounted on the front of the main unit.

• Communication board

• Analog board

Main unit

Expansion right side unitExpansion left side unit

X12X10

24V OUT

S/S

AC100~240V

C0

X0

X1 X3

PORT0

Y2

Y0

C2

max.

400mA

TX

RX

TX

RX

IN

X8

X4X2

X6

X5 X7

RXTX

Y4

Y3

C4 C6

X11 X13

X9

Y5

Y6Y1

SINK

Y8

SRCE

Y7

Y9

Y1Y2C2 C4C0

Y0

Y10Y8 Y11 Y12 Y14

Y9C8 C10 C12 Y13 Y15

Y3 Y4 Y6

Y5 Y7

• Communication unit

• High-accuracy load cell unit

• Advance main unit

(High-speed counter, positioning function)

• Basic main unit

(High-speed counter)

• Digital input/output unit

• Analog unit

• Temperature measuring unit

• Load cell unit

1-1

Page 10

Section 1 Overview

1-1-2 Function list

Item Specication

External interrupt input function Max. 16 points (Rising edge / falling edge / both edges)

Pulse catch function Max. 36 points (Rising edge / falling edge)

No. of channels Max. 8 channels (single phase)

High-speed counter

0.1ms high-speed timer When using high-speed counter in high-speed timer mode

High-speed pulse

output

&

High-speed

positioning

Communication port

Diagnostic function

Security function Password (Set by the support tool)

Calendar function

Count frequency

Count mode U/D, U/D×2, P/R, P/R×2, A/B, A/B×2, A/B×3, A/B×4 (Note 1)

No. of axes Max. 4 axes

Output frequency Max. 200kHz

Output pulse mode U/D, P/R, A/B, PLS, PWM (Note 1) (Note 2)

Pulse output instruction By SPF-specic instruction

PORT0 (RS-232C) Loader port built in main unit

PORT1, PORT2

(Communication board)

PORT3, PORT4

(Communication unit)

Max. 200kHz (Advance main unit)

Max. 100kHz (Basic main unit)

Communication mode:

Loader communication, general-purpose communication, simplied CPU link

communication (only one port among them),

Modbus RTU master communication

Communication speed:

1200/2400/4800/9600/19200/38400/57600/115200 bps

Self-diagnosis (memory check, ROM sum check), System conguration

supervising

Available up to 31 Dec. 2069 23:59:59

Precision: ±20 sec/day (at 25°C)

Program memory,

system denition

Backup

(Note 2)

User ROM function

Notes:

1) U/D: Up/Down pulse mode, P/R: Pulse / Direction signal mode, A/B: A/B phase mode, x2: 2 multiplication, x3: 3

multiplication, x4: 4 multiplication

2) PLS: Single pulse output mode, PWM: PWM output mode

3) The backup time is 10 years or more (ambient temperature: 55°C)

4) Notes on rewriting programs

When rewriting the program in the main unit from the loader while the PLC is running, the built-in RAM is changed,

however, the built-in ash memory is unchanged. As a result, the contents of the RAM does not match those of the ash

memory and the RUN/MEM LED blinks to prompt the user to transfer the contents of the RAM to the ash memory.

After rewriting the program, be sure to transfer the contents of the RAM to the ash memory. When the transfer is

completed normally, the RUN/MEM LED turns OFF.

<Method 1>

Perform transfer by using the loader.

<Method 2>

After rewriting the program, turn OFF the main unit and then ON again. When the power supply is turned ON, the contents

of the RAM is automatically transferred to the ash memory.

ZIP le Built-in ash memory

Data memory Built-in RAM: Built-in lithium primary battery

Calendar Calendar IC: Built-in lithium primary battery

Built-in RAM: Built-in primary lithium battery

Built-in ash memory (Note 4)

Programs, system denitions, and zipped les can be stored in the external

memory pack (NA8PMF-20).

1-2

Page 11

Section 1 Overview

Main unit

Ty

B: Basic

No. of I/O points

14: 14 points (Input 8 points / Output 6 points)

24: 24 points (Input 14 points / Output 10 points)

32: 32 points (Input 20 points / Output 12 points)

40: 40 points (Input 24 points / Output 16 points)

60: 60 points (Input 36 points / Output 24 points)

AC)

T: Transistor sink output

NA0P AT-31C24

DIO expansion uni

No. of I/O points

08: 8 points

16: 16 points

24: 24 points

3: Input is provided. (24V DC, Non-polarity)

T: Transistor sink output

NA0E 24 R-31

NA0A X06-MR

No. of channels

02: 2CH

06: 6CH

16: 16CH

: Resistance thermometer element input

A

1-2 Type Code

This subsection describes the rule of type codes.

(1) Main unit

Calendar

C: Calendar is provided.

pe

A: Advance

(2) DIO expansion unit (expansion right side unit)

t

Power supply specifications

1: AC power supply (100 to 240V

4: DC power supply (24V DC)

Input specifications

3: 24V DC (Non-polarity)

Output specifications

R: Relay output

Power supply specifications

1: AC power supply (100 to 240V AC)

4: DC power supply (24V DC)

None: No power supply is provided.

Input specifications

0: No input is provided.

Output specifications

X: No output is provided. (all points input)

R: Relay output

(3) Analog unit (expansion right side unit)

nalog unit

I/O type

X: Input

Y: Output

W: Input/output

MR: Multi-range

TC: Thermocouple input

PT

1-3

Page 12

Section 1 Overview

NA0F

Function unit LC1: Load cell unit

LC1-

NA0S

Expansion

power supply unit

2-

AC)

4: DC power supply (24V DC)

NA0LA

Communication

unit

RS3: RS-232C 2CH

ET1: Ethernet

RS5-

NA3LA

Communication

board

RS1: RS-232C 1CH, RS-485 1CH

ET1: Ethernet

RS1-

NA3A Y02-MR

No. of channels

02: 2CH

03: 3CH

MR: Multi-range

A

NA0FA

Function unit

LC1: High-precision load cell unit

LC1-

(4) Function unit (expansion right side unit)

(5) Analog board

nalog board

I/O type

Y: Output

W: Input/output

(6) Communication board

(7) Communication unit (expansion left side unit)

(8) Function unit (expansion left side unit)

(9) Expansion power supply unit

RS5: RS-485 2CH

Power supply specifications

2: AC power supply (100 to 240V

1-4

Page 13

Section 1 Overview

1-3 Product Type List

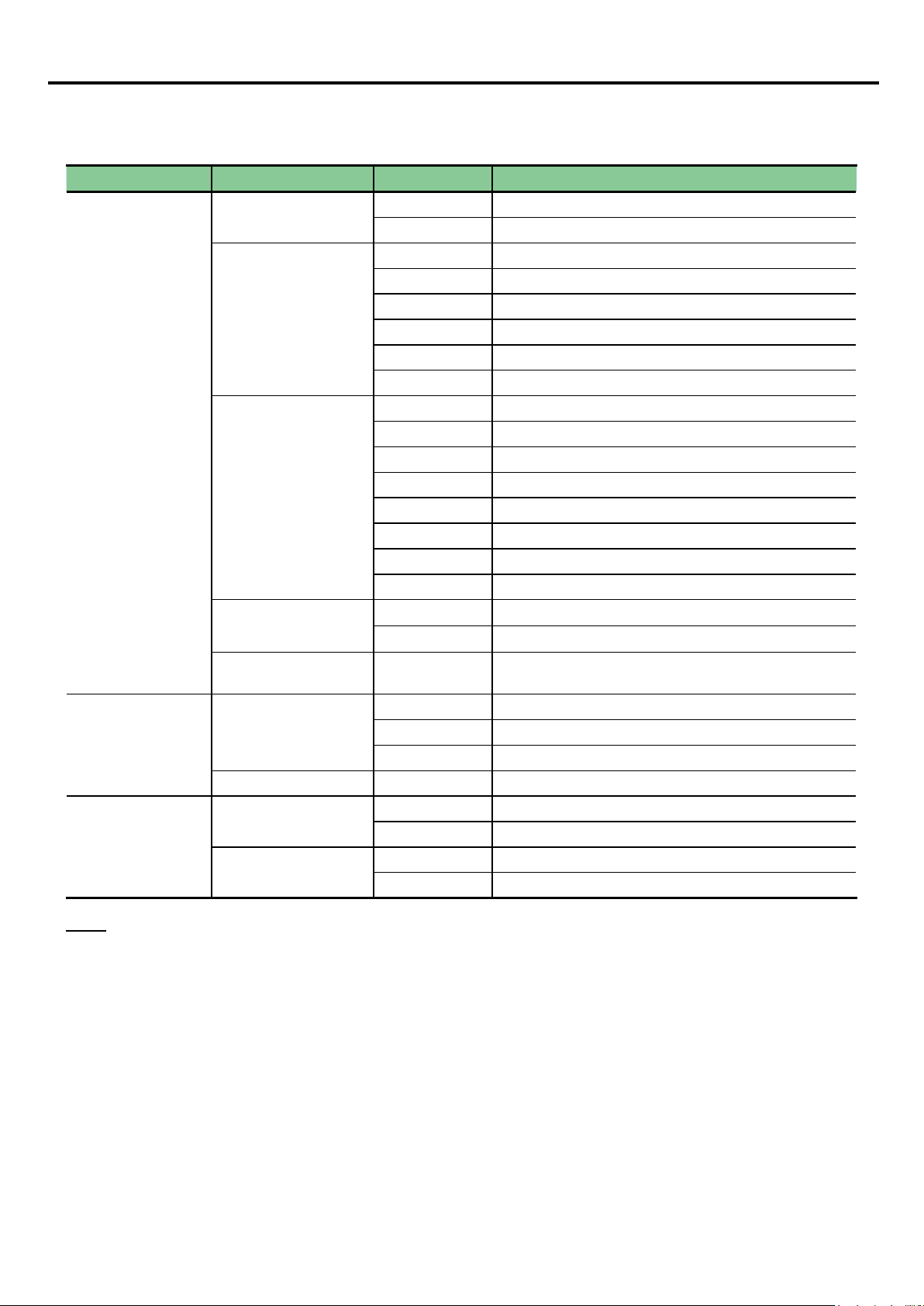

Product name Type Specication

NA0PB14R-34C

24V DC power supply, 24V DC digital input 8 points (High-speed: 100kHz, 2 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 4 points;), Ry output 6 points

Advance main unit

(NA0PB***)

Basic main unit

(NA0PA***)

NA0PB24R-34C

NA0PB32R-34C

NA0PB60R-34C

NA0PA14T-34C

NA0PA24T-34C

NA0PA32T-34C

NA0PA40T-34C

NA0PA60T-34C

NA0PA24T-31C

24V DC power supply, 24V DC digital input 14 points (High-speed: 100kHz, 2 points;

Medium-speed: 20kHz, 6 points; Medium-speed: 16.6kHz, 6 points;), Ry output 10 points

24V DC power supply, 24V DC digital input 20 points (High-speed: 100kHz, 2 points;

Medium-speed: 20kHz, 6 points; Medium-speed: 16.6kHz, 8 points;), Ry output 12 points

24V DC power supply, 24V DC digital input 36 points (High-speed: 100kHz, 2 points;

Medium-speed: 20kHz, 6 points; Medium-speed: 16.6kHz, 8 points;), Ry output 24 points

24V DC power supply, 24V DC digital input 8 points (High-speed: 200kHz, 2 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 4 points;), Tr sink output 6 points

(High-speed: 200kHz, 4 points; Medium-speed: 20kHz, 2 points), Detachable terminal block

24V DC power supply, 24V DC digital input 14 points (High-speed: 200kHz, 4 points;

Medium-speed: 20kHz, 4 points; Medium-speed: 16.6kHz, 6 points;), Tr sink output 10 points

(High-speed: 200kHz, 4 points; Medium-speed: 20kHz, 4 points), Detachable terminal block

24V DC power supply, 24V DC digital input 20 points (High-speed: 200kHz, 6 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 8 points;), Tr sink output 12 points

(High-speed: 200kHz, 6 points; Medium-speed: 20kHz, 2 points), Detachable terminal block

24V DC power supply, 24V DC digital input 24 points (High-speed: 200kHz, 6 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 8 points;), Tr sink output 16 points

(High-speed: 200kHz, 6 points; Medium-speed: 20kHz, 2 points), Detachable terminal block

24V DC power supply, 24V DC digital input 36 points (High-speed: 200kHz, 8 points;

Medium-speed: 16.6kHz, 8 points;), Tr sink output 24 points (High-speed: 200kHz, 8 points),

Detachable terminal block

100–240V AC power supply, 24V DC digital input 14 points (High-speed: 200kHz, 4 points;

Medium-speed: 20kHz, 4 points; Medium-speed: 16.6kHz, 6 points;), Tr sink output 10 points

(High-speed: 200kHz, 4 points; Medium-speed: 20kHz, 4 points),

Detachable terminal block

DIO expansion unit

(with power supply)

DIO expansion unit

(without power

supply)

NA0PA32T-31C

NA0PA40T-31C

NA0PA60T-31C

NA0E24R-34 24V DC power supply, 24V DC digital input 14 points, Ry output 10 points

NA0E24T-31 100–240V AC power supply, 24V DC digital input 14 points, Tr sink output 10 points

NA0E08R-3 24V DC digital input 4 points, Ry output 4 points

NA0E08T-3 24V DC digital input 4 points, Tr sink output 4 points

NA0E08X-3 24V DC digital input 8 points

NA0E08T-0 Tr sink output 8 points

NA0E16R-0 Ry output 16 points

NA0E16T-0 Tr sink output 16 points

100–240V AC power supply, 24V DC digital input 20 points (High-speed: 200kHz, 6 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 8 points;), Tr sink output 12 points

(High-speed: 200kHz, 6 points; Medium-speed: 20kHz, 2 points),

Detachable terminal block

100–240V AC power supply, 24V DC digital input 24 points (High-speed: 200kHz, 6 points;

Medium-speed: 20kHz, 2 points; Medium-speed: 16.6kHz, 8 points;), Tr sink output 16 points

(High-speed: 200kHz, 6 points; Medium-speed: 20kHz, 2 points),

Detachable terminal block

100–240V AC power supply, 24V DC digital input 36 points (High-speed: 200kHz, 8 points;

Medium-speed: 16.6kHz, 8 points;), Tr sink output 24 points (High-speed: 200kHz, 8 points),

Detachable terminal block

1-5

Page 14

Section 1 Overview

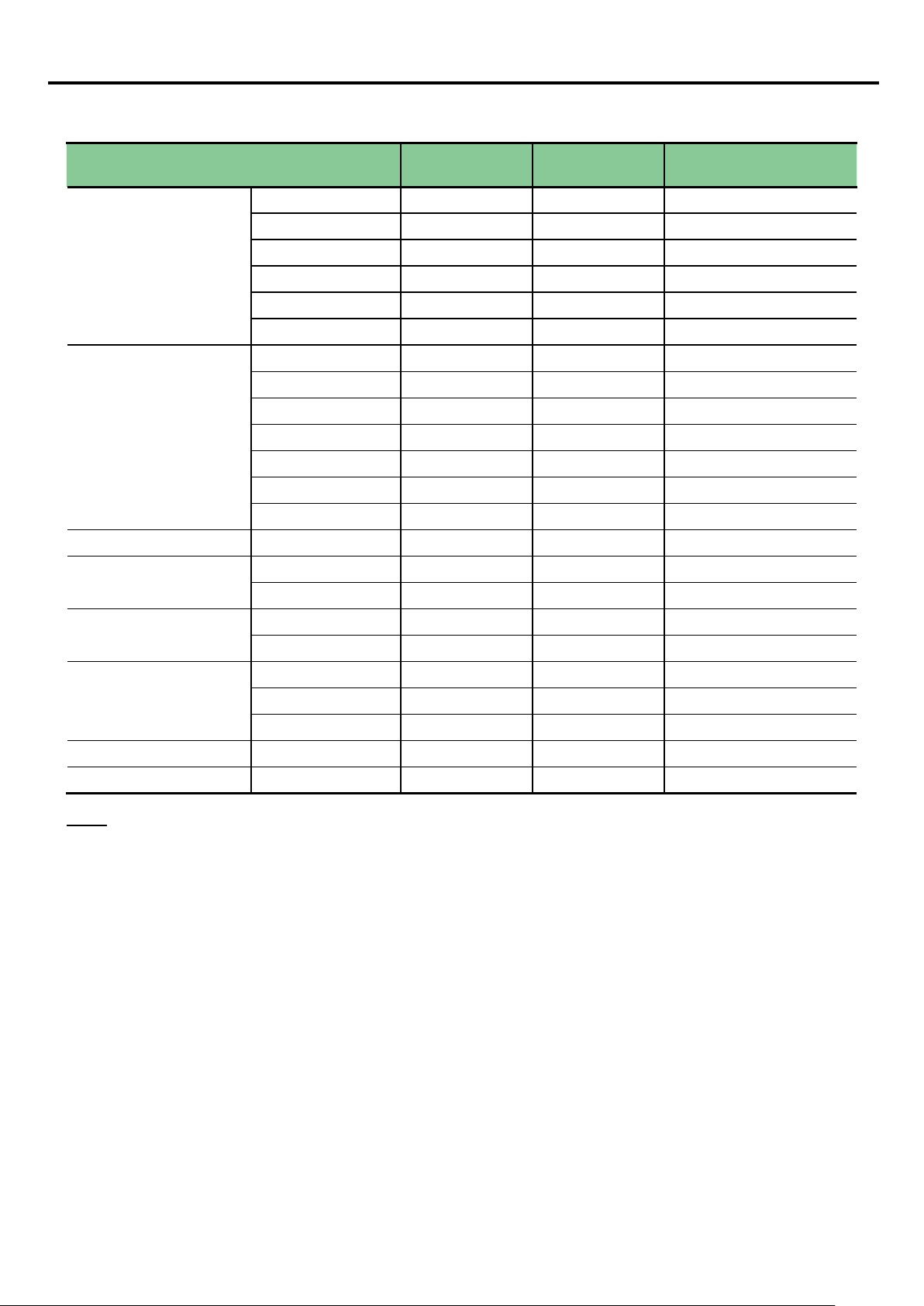

Product name Type Specication

NA0AX06-MR

Analog input unit,

6 channels: 14-bit analog input (-10 to 10V, 0 to 10V, -20 to 20mA, 0 to 20mA)

AIO expansion unit

(without power supply)

Temperature measurement

unit

(without power supply)

Load cell unit NA0F-LC1 Load cell unit, 1 channel

AIO board

(Front board type)

Communication board

(Front board type)

Communication unit

(Expansion left side unit)

NA0AY02-MR

NA0AW06-MR

NA0AX02-TC Thermocouple input unit: 2 channels, resolution 0.1°C

NA0AX06-TC Thermocouple input unit: 16 channels, resolution 0.1°C

NA0AX16-TC Thermocouple input unit: 6 channels, resolution 0.1°C

NA0AX06-PT Resistance thermometer element input unit: 6 channels, resolution 0.1°C

NA3AY02-MR

NA3AW03-MR

NA3LA-RS1 Communication board, RS232C (Port 1) + RS-485 (Port 2)

NA3LA-ET1 Ethernet communication board, 1 channel

NA0LA-RS3 Communication unit, 2 ports RS-232C (Port 3 + Port 4)

NA0LA-RS5 Communication unit, 2 ports RS-485 (Port 3 + Port 4)

NA0LA-ET1 Ethernet communication unit, 1 channel

Analog output unit,

2 channels: 14-bit analog output (-10 to 10V, 0 to 10V, -20 to 20mA, 0 to 20mA)

Analog input/output unit

4 channels: 14-bit analog input (-10 to 10V, 0 to 10V, -20 to 20mA, 0 to 20mA) +

2 channels: 14-bit analog output (-10 to 10V, 0 to 10V, -20 to 20mA, 0 to 20mA)

Analog output board,

2 channels: 12-bit analog output (0 to 10V, 0 to 20mA)

Analog input/output board,

2 channels: 12-bit analog input (0 to 10V, 0 to 20mA) +

1 channel: 12-bit analog output (0 to 10V, 0 to 20mA)

High-precision load cell unit

(Expansion left side unit)

Expansion power supply unit

Healthy unit

(Terminating connector)

Memory pack NA8PMF-20 Memory for storing a project and data

Loader connecting cable NA0H-CUV RS-232C/USB conversion cable for loader connection port (Port 0), 1.8m (Note 1)

Personal computer loader

NA0FA-LC1 High-precision load cell unit, 1 channel

NA0S-2

NA0S-4

NA8P-HE Unit for detecting a dropout/fault of expansion right side units

NP4H-SEDBV3 SX-Programmer Expert (D300win)

NP4H-SWN SX-Programmer Standard

Input voltage: 100–240V AC, Output: internal 5V DC; internal 24V DC

Service power supply output: 24V DC; 21W

Input voltage: 24V DC, Output: internal 5V DC; internal 24V DC

Service power supply output: 24V DC, 14W

Notes:

1) You need to install the USB driver into the personal computer.

See “Appendix 1 Installing USB Driver.”

1-6

Page 15

Section 1 Overview

1-4 Supported Versions

1-4-1 Program loader version

1) Program loader versions that support the SPF series

• SX-Programmer Expert (D300win) : V3.6.11.* or later

• SX-Programmer Standard : V3.0.16.* or later

2) Program loader versions that support Ethernet communication board (Type: NA3LA-ET1), Ethernet communication unit

(Type: NA0LA-ET1) and High-precision load cell unit (Type: NA0FA-LC1)

• SX-Programmer Expert (D300win) : V3.6.12.* or later

• SX-Programmer Standard : V3.0.17.* or later

1-4-2 Main unit version

1) V03 or later software version of main units support analog boards that are connected on the front of them (Type: NA3AY02-MR,

NA3AW03-MR). Analog boards cannot be used with a main unit the software version of which is earlier than V03.

2) V04 or later software version of main units support Ethernet communication board (Type: NA3LA-ET1) and Ethernet

communication unit (Type: NA0LA-ET1). Ethernet communication board/unit cannot be used with a main unit the software

version of which is earlier than V04.

1-7

Page 16

Section 2 System Conguration

2-1 System Conguration Specications .................................................... 2-1

2-1-1 Expansion specications ............................................................................ 2-2

2-1-2 Calculation of current consumption ............................................................ 2-3

(1) Suppliable current ....................................................................................... 2-3

(2) Current consumption of main unit............................................................... 2-3

(3) Current consumption of expansion unit ...................................................... 2-4

2-2 System denition ..................................................................................... 2-7

2-3 I/O address assignment .......................................................................... 2-8

2-3-1 Rules for assigning I/O addresses..............................................................2-8

2-3-2 Example of address assignment ................................................................2-9

Page 17

Section 2 System Conguration

Expansion

left side unit

Front board

Max. 6 (Note 1)

2-1 System Conguration Specications

You can connect up to six expansion units on the right side, one expansion uint on the left side, and one front board on the front

of the SPF series main unit, respectively.

Max. 1

Expansion

right side unit

Y1Y2C2 C4C0

Y0

Y3 Y4 Y6

Y10Y8 Y11 Y12 Y14

Y9C8 C10 C12 Y13 Y15

Y5 Y7

O0+O1+

24V IN

AG O0-

I0+I1+ I2+I3+

I0-I1- I2-I3-

O1-

PORT4 (RS485)

+

G

TNN

PORT3 (RS485)

+

G

T

Main unit

X12X10

24V OUT

S/S

AC100~240V

C0

X0

X1 X3

PORT0

Y2

Y0

C2

max.

TX

RX

TX

RX

400mA

IN

X8

X4X2

X6

X5 X7

RXTX

Y4

Y3

C4 C6

X11 X13

X9

Y5

Y6Y1

SINK

Y8

SRCE

Y7

Y9

NA0LA-RS5

Max. 1

Notes:

1) The maximum number of connectable AIO units is 3.

An expansion power supply unit and healthy unit are excluded from the number of connectable units (Max. 6).

O0+O1+

24V IN

AG O0-

I0+I1+ I2+I3+

I0-I1- I2-I3-

O1-

2-1

Page 18

Section 2 System Conguration

2-1-1 Expansion specications

The table below shows the connectable expansion units.

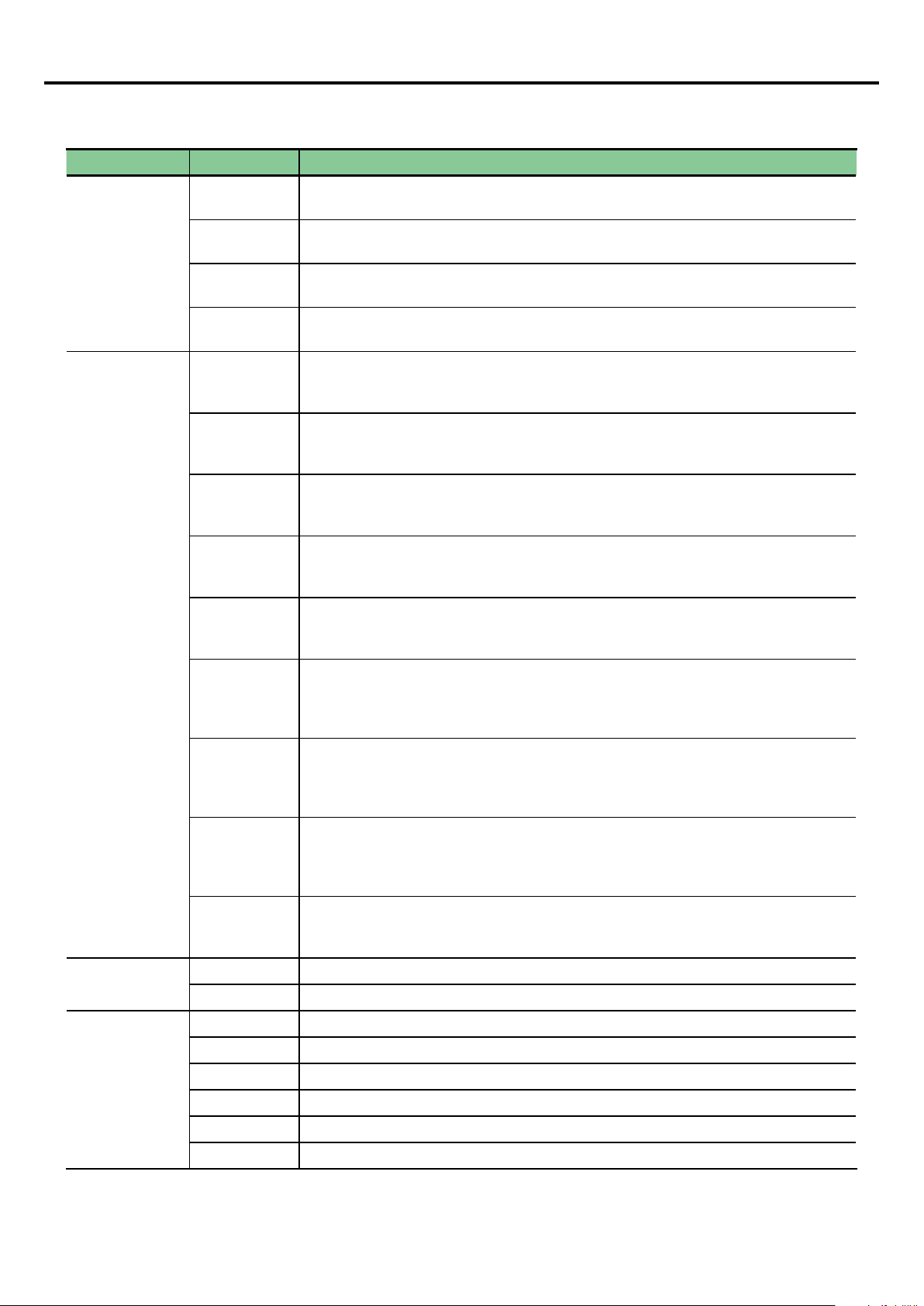

Classication Product name Type Specication

Expansion right side

unit

Expansion left side

unit

Front board

DIO expansion unit

(with power supply)

DIO expansion unit

(without power supply)

AIO expansion unit

(without power supply)

Expansion power supply

unit

Healthy unit

(Terminating connector)

Communication unit

Function unit NA0FA-LC1 High-precision load cell unit, 1 channel (Note 2)

AIO board

Communication board

NA0E24R-34

NA0E24T-31 Input 14 points, Tr sink output 10 points, AC power supply

NA0E08R-3 Input 4 points, Ry output 4 points

NA0E08T-3

NA0E08X-3 Input 8 points

NA0E08T-0

NA0E16R-0

NA0E16T-0 Tr sink output 16 points

NA0AX06-MR Analog input 6 channels

NA0AY02-MR Analog output 2 channels

NA0AW06-MR Analog input 4 channels, Analog output 2 channels

NA0AX02-TC Thermocouple input 2 channels

NA0AX06-TC Thermocouple input 6 channels

NA0AX16-TC Thermocouple input 16 channels

NA0AX06-PT Resistance thermometer element input 6 channels

NA0F-LC1 Load cell unit, 1 channel

NA0S-2 Input 100 to 240V AC

NA0S-4 Input 24V DC

NA8P-HE

NA0LA-RS2 RS-232c: 2 ports (Note 2)

NA0LA-RS5 RS-485: 2 ports (Note 2)

NA0LA-ET1 Ethernet 1 channel (Note 2)

NA3AY02-MR Analog output 2 channels

NA3AW03-MR Analog input 2 channels, Analog output 1 channel

NA3LA-RS1 RS-232C: 1 port, RS-485: 1 port (Note 2)

NA3LA-ET1 Ethernet 1 channel (Note 2)

Input 14 points, Ry output 10 points, DC power supply

Input 4 points, Tr sink output 4 points

Tr sink output 8 points

Ry output 16 points

Unit for detecting a dropout/fault of expansion right side

units (Note 1)

Notes:

1) A healthy unit is used to detect a dropout of expansion right side units.

Be sure to mount a healthy unit to stop the SPF system with a fatal fault when an expansion right side unit is dropped.

Unless a healthy unit is mounted, a dropout of the expansion right side unit is not detected and the SPF system continues

operation in the state where the expansion right side unit is dropped.

Connect a healthy unit to the expansion connector (OUT) of the rightmost expansion right side unit after removing the

cover.

When mounting a healthy unit, register it in the system denition.

A healthy unit is excluded from the number of connectable expansion right side units (Max. 6).

2) A dropout of the communication unit/board and high-precision load cell unit is not detected.

2-2

Page 19

Section 2 System Conguration

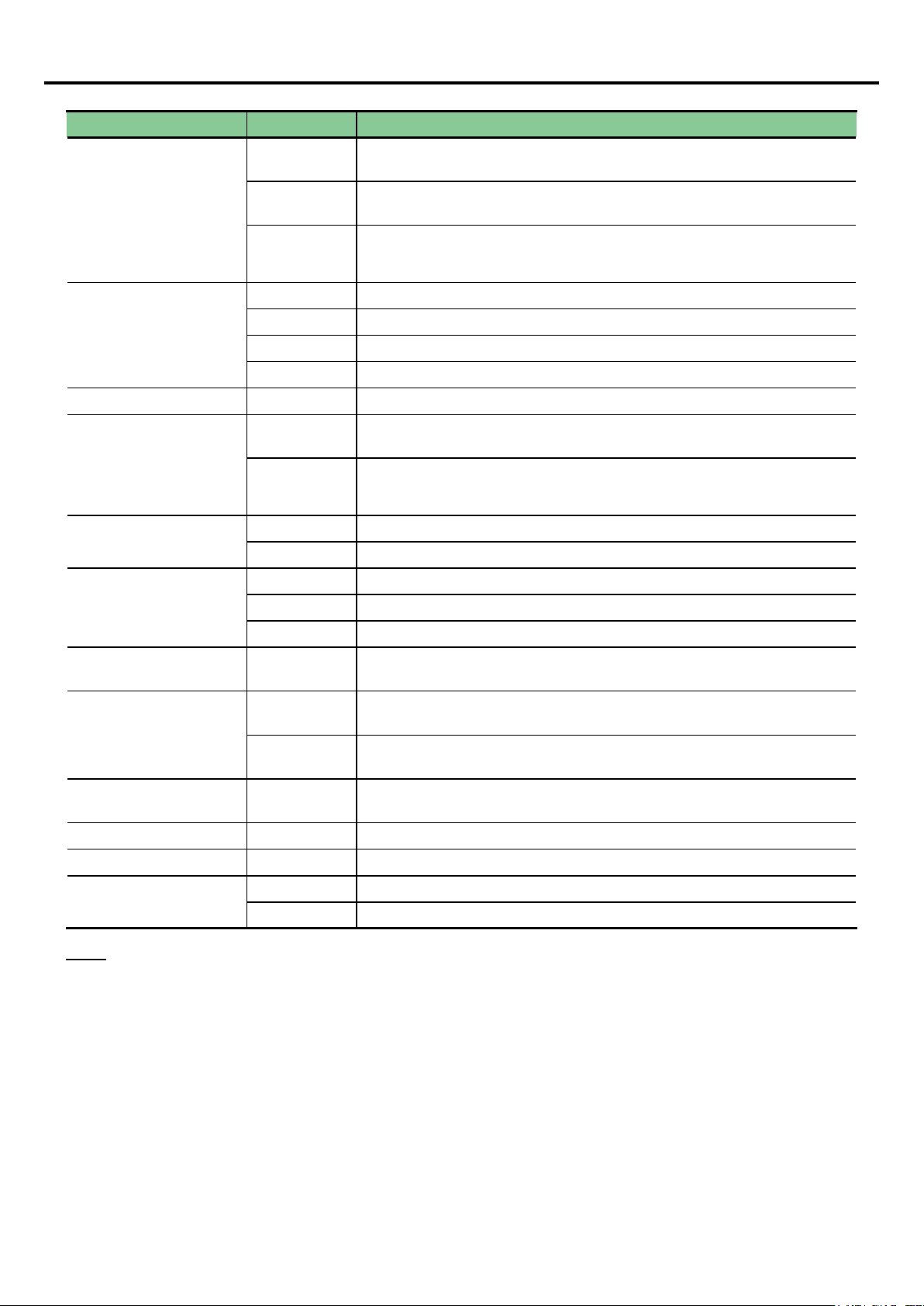

2-1-2 Calculation of current consumption

(1) Suppliable current

Type Internal 5V DC Internal 24V DC Externally supplied 24V DC

Main unit NA0P

Expansion unit with

power supply

Expansion power supply NA0S-2 / NA0S-4 400mA 250mA 250mA

Notes:

1) When using an AC power supply type unit at a power supply voltage of 120V AC or less, the total of the internal 24V DC

and externally supplied 24V DC becomes 575mA.

oooo-oo

NA0E24T-31 948mA 350mA 337mA

NA0E24R-34 948mA Total 337mA

C 1000mA 400mA (Note 1) 400mA (Note 1)

(2) Current consumption of main unit

Type Internal 5V DC Internal 24V DC

NA0PB14R-34C 360mA 65mA 60mA

Advance main unit

Basic main unit

NA0PB24R-34C 435mA 85mA 105mA

NA0PB32R-34C 520mA 110mA 138mA

NA0PB60R-34C 555mA 200mA 210mA

NA0PA14T-34C 360mA 65mA 60mA

NA0PA24T-ooC 435mA 85mA 105mA

NA0PA32T-ooC 520mA 110mA 138mA

Externally supplied 24V DC

(Note 2)

NA0PA40T-ooC 530mA 125mA 156mA

NA0PA60T-ooC 555mA 200mA 210mA

2-3

Page 20

Section 2 System Conguration

(3) Current consumption of expansion unit

Type Internal 5V DC Internal 24V DC

NA0E08R-3 30mA 34mA 18mA

NA0E08T-3 30mA 34mA 18mA

DIO expansion unit

AIO expansion unit

Load cell unit NA0F-LC1 32mA – 48mA

AIO board

NA0E08X-3 30mA – 36mA

NA0E08T-0 29mA 68mA –

NA0E16R-0 40mA 136mA –

NA0E16T-0 40mA 136mA –

NA0AX06-MR 25mA – 53mA

NA0AY02-MR 33mA – 90mA

NA0AW06-MR 35mA – 103mA

NA0AX02-TC 30mA – 21mA

NA0AX06-TC 30mA – 29mA

NA0AX16-TC 30mA – 58mA

NA0AX06-PT 32mA – 16mA

NA3AY02-MR 223 – –

NA3AW03-MR 158 – –

Externally supplied 24V DC

(Note 2)

Communication board

Communication unit

High-precision load cell unit NA0FA-LC1 120mA – 48mA

Healthy unit NA8P-HE 10mA – –

Notes:

2) These values show consumed current when externally supplied 24V DC power supply is used for input/output power

supply. When not using externally supplied 24V DC power supply for input/output power supply, the current consumption

of externally supplied 24V DC becomes 0mA.

NA3LA-RS1 55mA – –

NA3LA-ET1 110mA – –

NA0LA-RS3 18mA – –

NA0LA-RS5 95mA – –

NA0LA-ET1 160mA – –

2-4

Page 21

Section 2 System Conguration

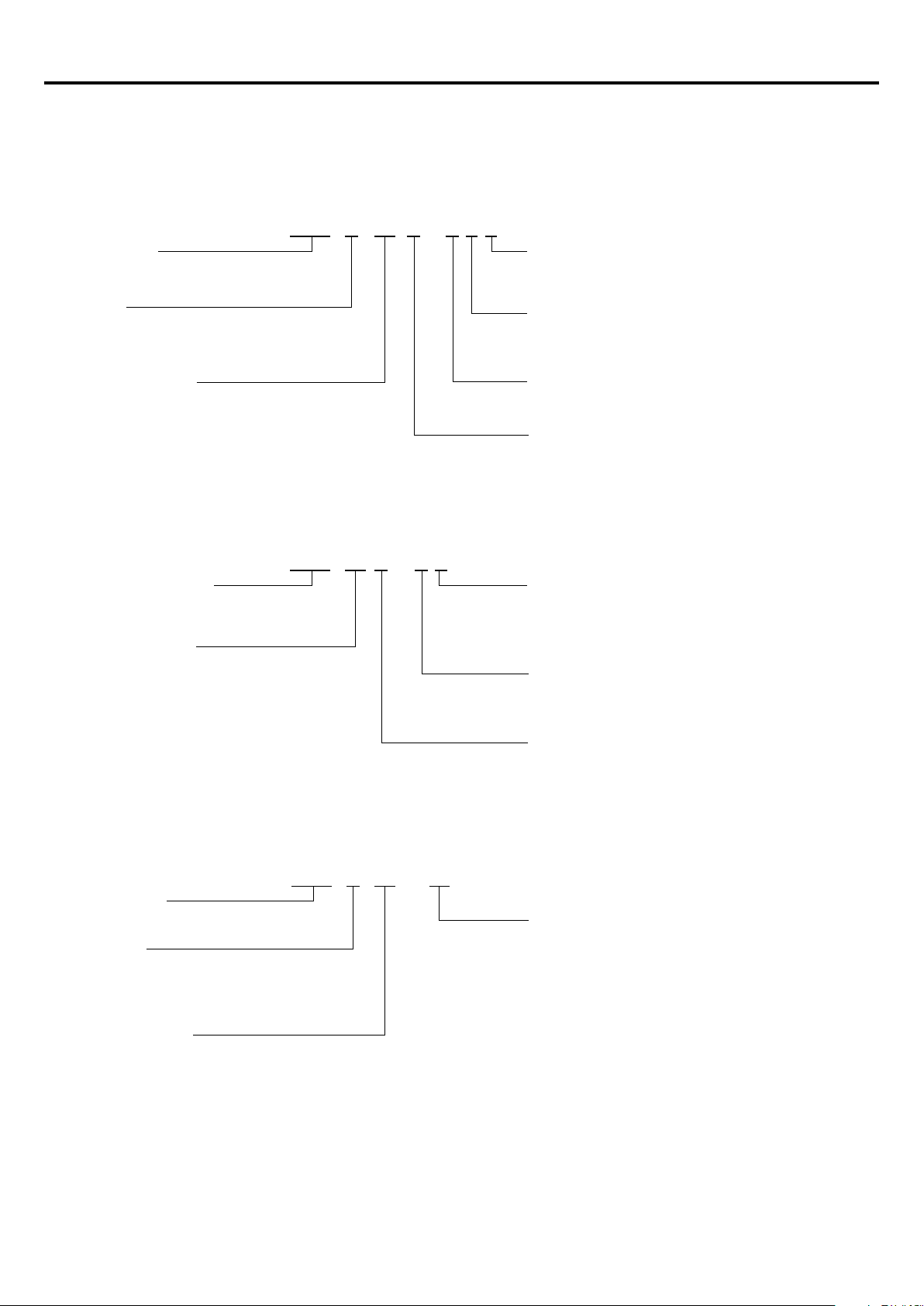

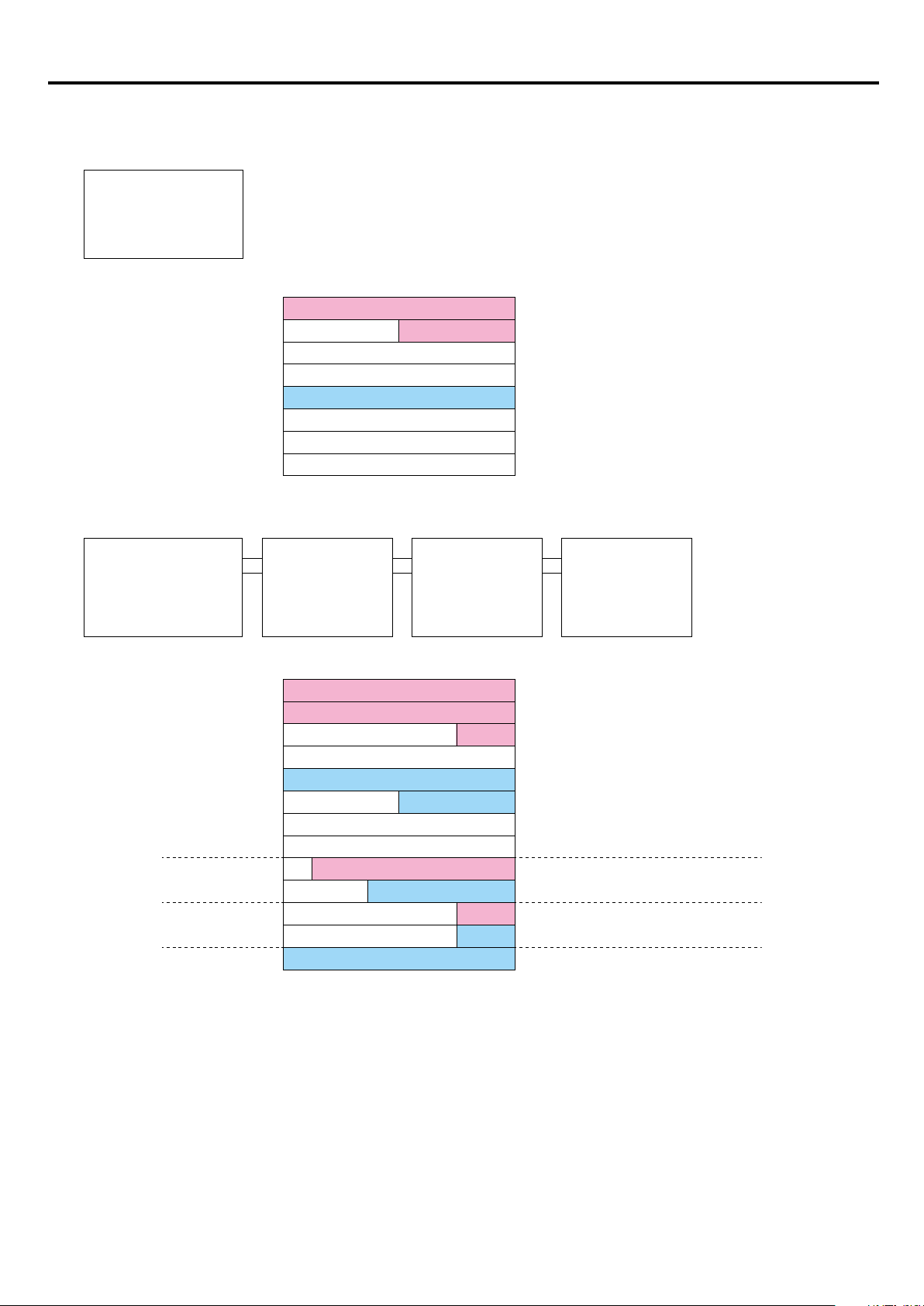

<Calculation example of current consumption>

Whether or not to use an expansion power supply is determined by the total current consumption of all the units. You need to

calculate the total current consumption and mount an expansion power supply unit if the current is insufcient.

Referring the tables on the previous page, calculate the current consumption.

Subtract the total current consumption of the main unit, additionally connected front board, expansion left side unit, and

expansion right side units from the current supplied from the main unit. When the result is minus, you need to mount an

expansion power supply. Thus mount an expansion power supply unit if the current is insufcient for the expansion units that are

connected on the right.

Expansion power supply units are excluded from the number of connectable expansion units.

● Main calculation formula

[Supplied current] - [Current consumption]

= [Current supplied from main unit] - [Current consumption of main unit]

- [Current consumption of front board]

- [Current consumption of expansion left side unit]

- [Total current consumption of expansion right side units]

>= 0

● Calculation formula for current consumption on the right of the expansion unit with power supply

(Expansion unit with power supply is referred to as “Exp_powunit” here.)

Exp_powunit receives the remaining current of the main unit on the left side and adds it to the current that Exp_powunit

supplies to supply expansion units connected on the right.

I_MainR + I_Exp_powunit - I_Exp >= 0

• I_MainR (Remaining current of main unit)

= [Current supplied from main unit] - [Current consumption of expansion left side unit]

- [Current consumption of expansion right side units]

- [Current consumption of front board]

• I_Exp_powunit (Current supplied from Exp_powunit)

• I_Exp (Total current consumption of expansion units that are connected on the right of Exp_powunit)

● Calculation formula when using an expansion power supply unit

Use the above calculation formula by replacing Exp_powunit with the expansion power supply unit.

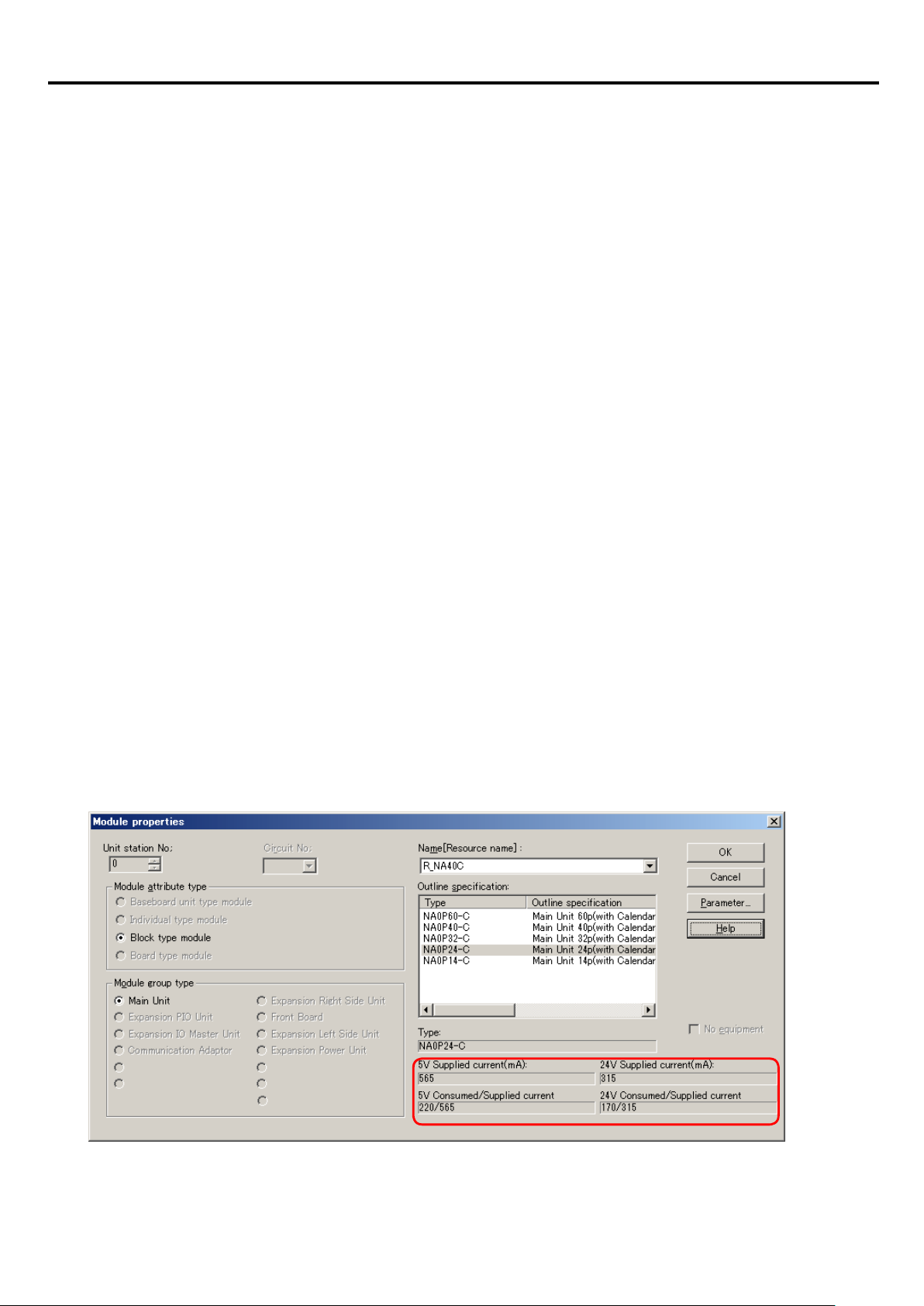

<Calculation of current consumption by using the loader function>

When registering units in the system denition by using the loader, you can check the total current consumption of the units and

the supplied current value.

(Since externally supplied 24V DC is not calculated by the loader, you need to calculate it.)

2-5

Page 22

Section 2 System Conguration

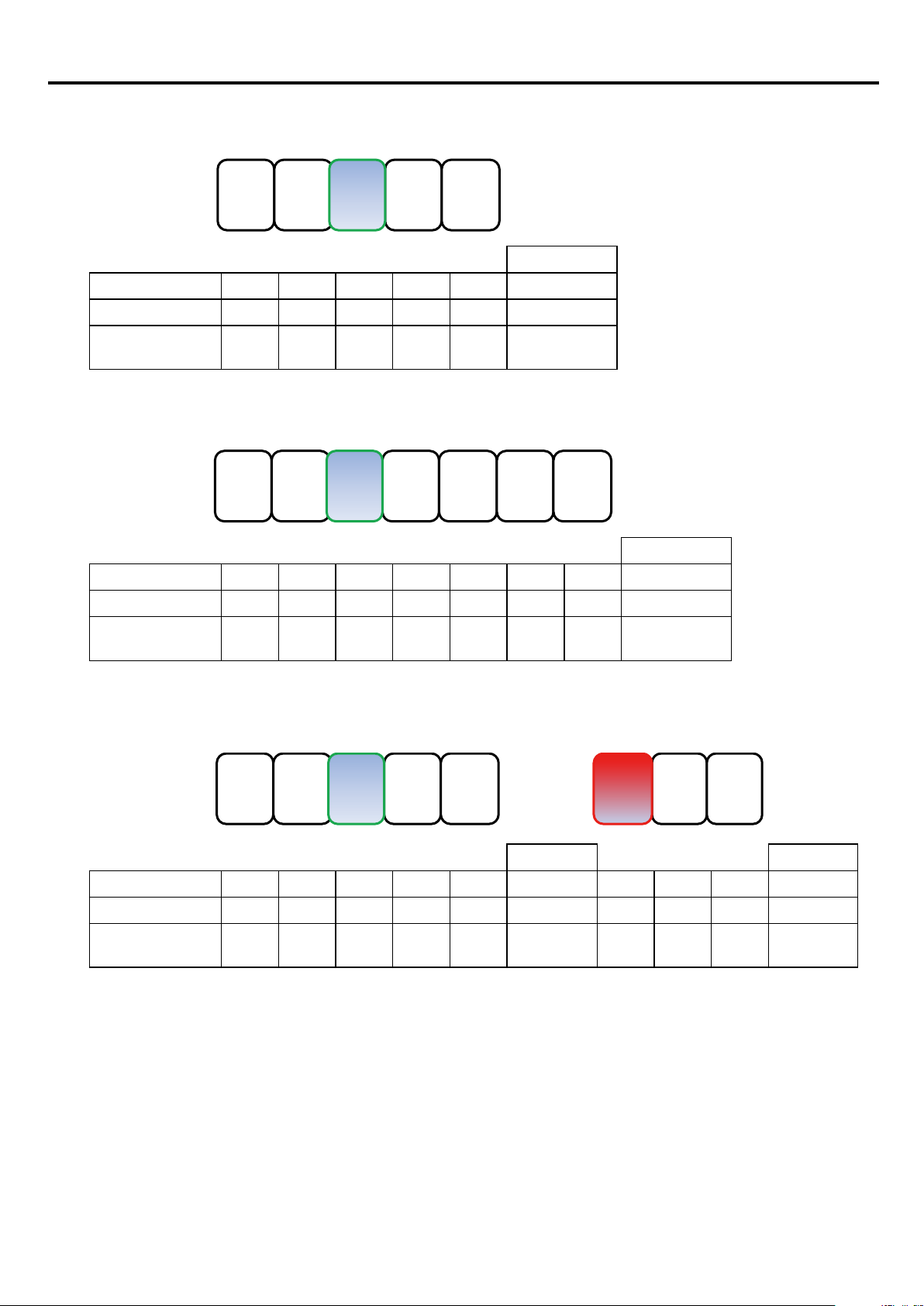

• Case 1

When the main unit can supply sufcient current

NA0L

A

-RS5

NA3L

A

-RS1

NA0P

A24T

-34C

NA0E

08R

-3

NA0E

16T

-0

Result

Internal 5V DC -95 -55 +565 -30 -40 +345 (OK)

Internal 24V DC +315 -34 -136 +145 (OK)

Externally supplied

24V DC

+295 -18 +277 (OK)

• Case 2

When the main unit cannot supply sufcient current

NA0L

A

-RS5

NA3L

A

-RS1

NA0P

A40T

-34C

NA0E

08R

-3

NA0E

16T

-0

NA0E

16T

-0

NA0A

X06

-MR

Result

Internal 5V DC -95 -55 +470 -30 -40 -40 -25 +185 (OK)

Internal 24V DC +275 -34 -136 -136 -31 (overload)

Externally supplied

24V DC

+244 -18 -53 +173 (OK)

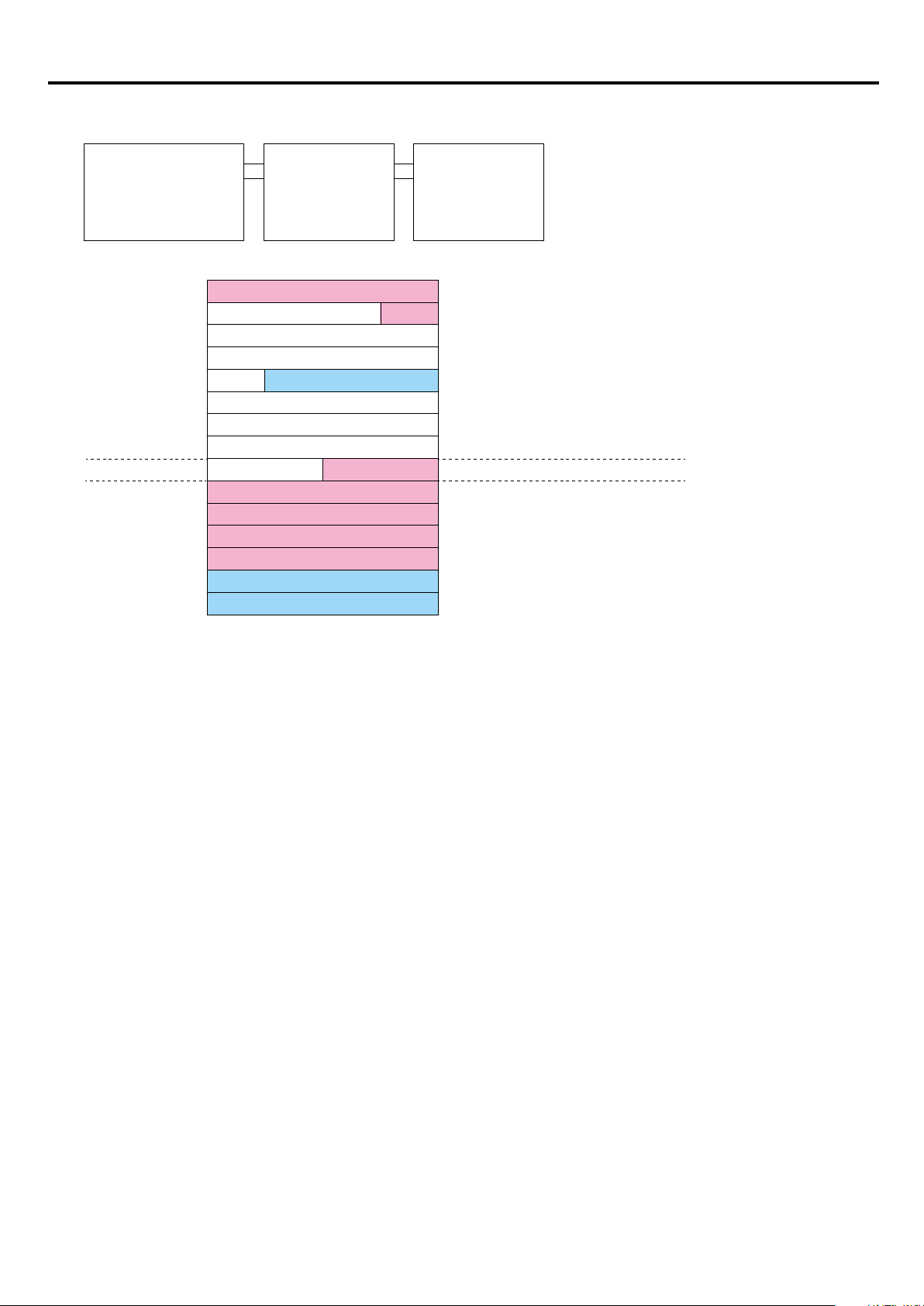

• Case 3

When an expansion power supply unit is mounted in the case 2

NA0L

A

-RS5

NA3L

A

-RS1

NA0P

A40T

-34C

NA0E

08R

-3

NA0E

16T

-0

NA0S

-4

NA0E

16T

-0

NA0A

X06

-MR

Result Result

Internal 5V DC -95 -55 +470 -30 -40 +250 (OK) 400 -40 -25 +585 (OK)

Internal 24V DC +275 -34 -136 +105 (OK) 250 -136 +219 (OK)

Externally supplied

24V DC

+244 -18 +226 (OK) 250 -53 +423 (OK)

2-6

Page 23

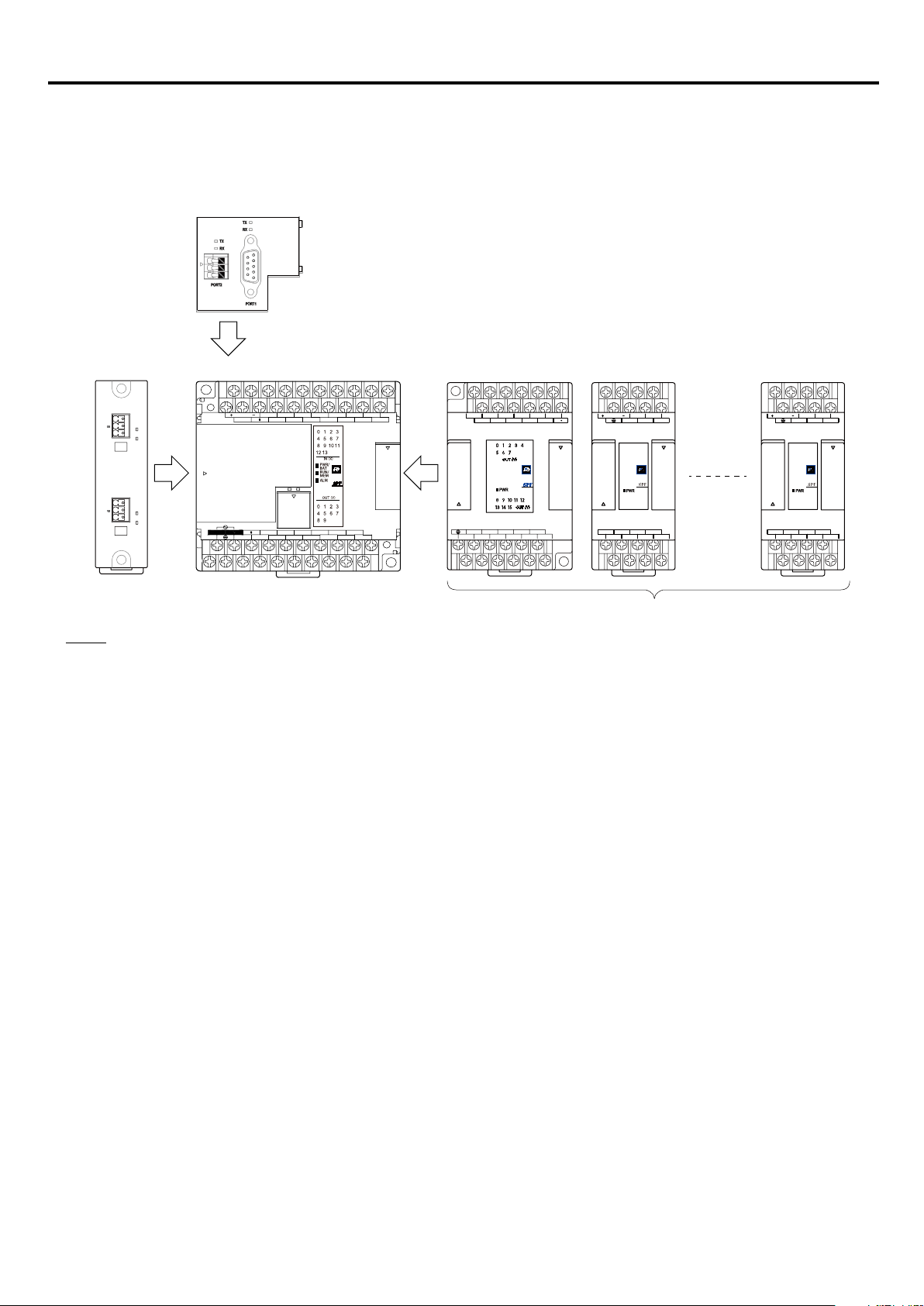

Section 2 System Conguration

Type: NA0PA40T-31C

Expansion left side unit

Type: NA0LA-RS5

Type: NA0E16T-0

Expansion right side unit

Type: NA0AX06-MR

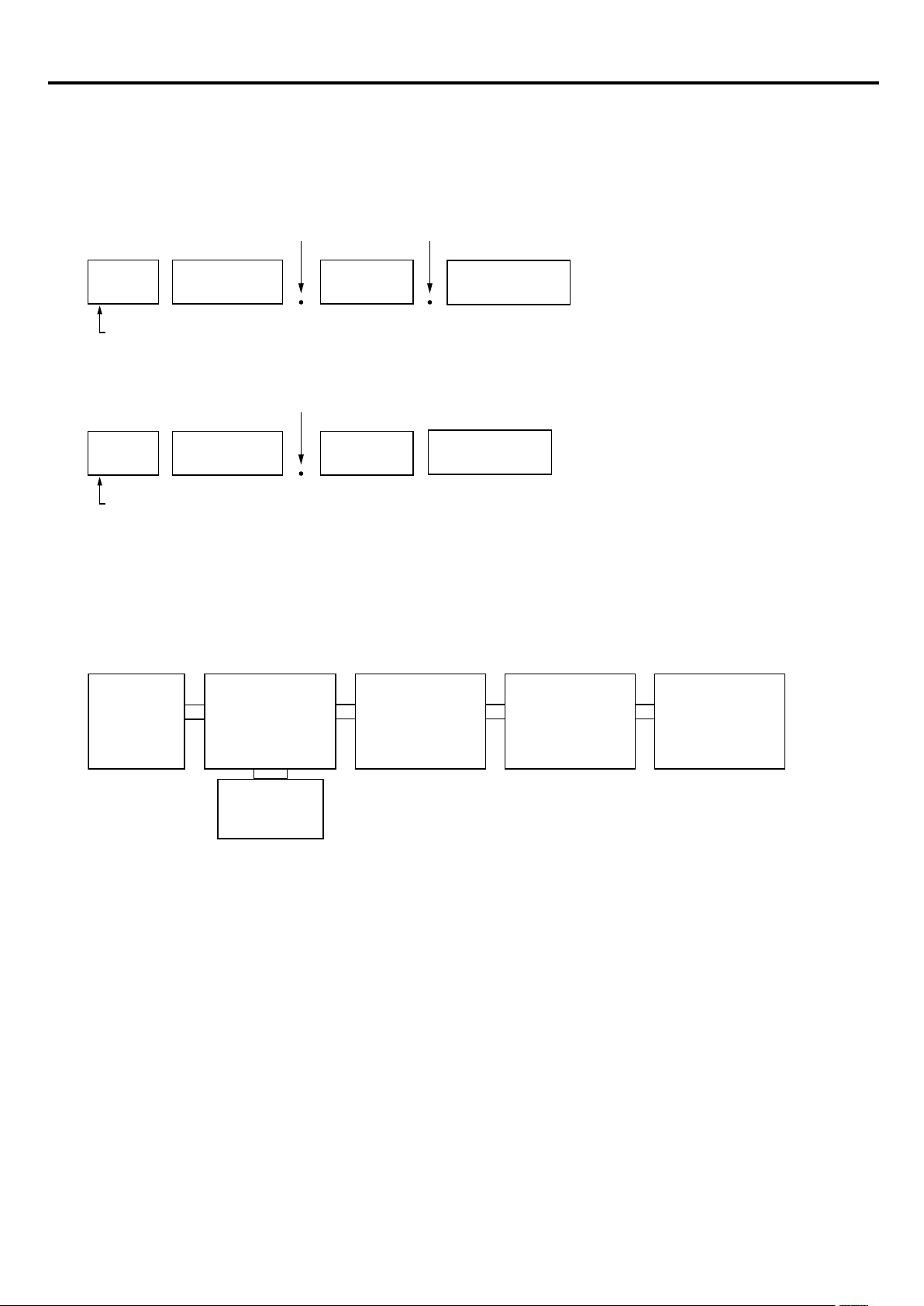

2-2 System denition

When using SPF series, you need to register the actual unit conguration in a project.

<Example of system conguration>

Front board

Type: NA3LA-RS1

PORT4 (RS485)

+

G

TNN

PORT3 (RS485)

+

G

T

NA0LA-RS5

X0 X2 X4 X6 X8 X10X12 X14X16 X18

24V OUT

.

x

a

m

S/S

400mA

TX

RX

TX

RX

IN AC100~240V

L N

X1 X3 X5 X7 X9 X11 X13X15 X17 X19

IN (X)

PWR/

BAT

RUN/

MEM

ALM

OUT (Y)

PORT0

Y1 Y2 Y4 Y5 Y6 Y8 Y10

C0 Y0 C2 Y3 C4 C6 Y7 C8 Y9 Y11

Main unit

X20X22

0

4

A

P

A

N

Y14Y12

C12Y13 Y15

X21X23

-

0

T

3

1

C

Y1Y2C2 C4C0

Y0

Y10Y8 Y11 Y12 Y14

Y9C8 C10 C12 Y13 Y15

Expansion right side unit

Y5 Y7

Y3 Y4 Y6

NA0E16T-0

O0+O1+

24V IN

AG O0-

NA0AW06-MR

I0+I1+ I2+I3+

I0-I1- I2-I3-

<System conguration denition tree window>

The system conguration denition tree for the above system conguration is shown below.

O1-

<Rules for dening system conguration>

• For system denition, the unit on the right of the main unit is registered just below the main unit.

As for the unit station Nos. of units, the main unit is always assigned “0” (zero), and numbers beginning with 1 (one) are

assigned to expansion right side units, in their connected order.

• The front board is connected on the front of the main unit and registered below the expansion right side unit in the conguration

denition tree. The unit station No. is xed to “100.”

• The expansion left side unit is connected to the left of the main unit and registered at the lowermost location in the conguration

denition tree. The unit station No. is xed to “200.”

2-7

Page 24

Section 2 System Conguration

{

Output:

<For Standard>

<For Expert (D300win)>

Y (bit), WY (word), DY (double-word)

2-3 I/O address assignment

2-3-1 Rules for assigning I/O addresses

In MICREX-SX series SPF, follow the rules below to assign I/O addresses.

Period

Prefix

Input:

{

Output:

Identifier

Input:

1) Unit No.

A number (1 to 6) is assigned to SPF expansion right side units, in their connected order. The number assigned to the main unit

is always “0” (zero). The front board is assigned “100” (xed) as an independent unit and the expansion left side unit with “200”

(xed).

<Example of unit No. assignment>

Unit No. Word No.

%IX (bit), %IW (word), %ID (double-word)

%QX (bit), %QW (word), %QD (double-word)

Period

Unit No. Word No.

X (bit), WX (word), DX (double-word)

Period

Bit address

(0 to 15)

Bit address

(0 to F)

Expansion

left side unit

Unit No. 200

2) Word No. and bit address

To each SPF unit, words starting from the word 0 (zero) are assigned for the number of words that the unit occupies. No same

word is assigned to both input and output. Therefore, for main unit and expansion units with both inputs and outputs, words are

assigned rst to inputs and then to outputs. All types of main units (regardless of the No. of I/O points provided) occupy eight

words of the I/O area (input: four words, output: four words).

Main unit

Unit No. 0

Front board

Unit No. 100

Expansion

right side unit

Unit No. 1

Expansion

right side unit

Unit No. 2

Expansion

right side unit

Unit No. 3

2-8

Page 25

Section 2 System Conguration

%QX0.4.0 to QX0.4.15 (Y0.40 to Y0.4F)

2-3-2 Example of address assignment

1) Example of a system consisting only of a main unit with 40 points

Main unit with 40 points

Unit No. 0

Input: 24 points

output: 16 points

(Word address)

%IW0.0 (WX0.0)

%IW0.1 (WX0.1)

%QW0.4 (WY0.4)

Input: 24 points

Output: 16 points

(Bit address)

0F

%IX0.0.0 to %IX0.0.15 (X0.00 to X0.0F)

%IX0.1.0 to %IX0.1.7 (X0.10 to X0.17)

2) Example of a system in which expansion units are connected to a main unit with 60 points

Main unit with 60 points

Unit No. 0

Input: 36 points

output: 24 points

(Word address)

%IW0.0 (WX0.0)

%IW0.1 (WX0.1)

%IW0.2 (WX0.2)

Expansion

right side unit

Unit No. 1

Input: 14 points

output: 10 points

Expansion

right side unit

Unit No. 2

Input: 4 points

output: 4 points

0F

Input: 36 points

Expansion

right side unit

Unit No. 3

Output: 16 points

(Bit address)

%IX0.0.0 to %IX0.0.15 (X0.00 to X0.0F)

%IX0.1.0 to %IX0.1.15 (X0.10 to X0.1F)

%IX0.2.0 to %IX0.2.3 (X0.20 to X0.23)

%QW0.4 (WY0.4)

%QW0.5 (WY0.5)

%IW1.0 (WX1.0)

%QW1.1 (WY1.1)

%IW2.0 (WX2.0)

%QW2.1 (WY2.1)

%QW3.0 (WY3.0)

Output: 24 points

Input: 14 points

Output: 10 points

Output: 16 points

%QX0.4.0 to %QX0.4.15 (Y0.40 to Y0.4F)

%QX0.5.0 to %QX0.5.7 (Y0.50 to Y0.57)

%IX1.0.0 to %IX1.0.13 (X1.00 to X1.0D)

%QX1.1.0 to %QX1.1.9 (Y1.10 to Y1.19)

Input:

4 points

Output:

4 points

%IX2.0.0 to %IX2.0.3 (X2.00 to X2.03)

%QX2.1.0 to %QX2.1.3 (Y2.10 to Y2.13)

%QX3.0.0 to %QX3.0.15 (Y3.00 to Y3.0F)

2-9

Page 26

Section 2 System Conguration

3) Example of a system in which expansion units are connected to a main unit with 32 points

Main unit with 32 points

Unit No. 0

Input: 20 points

output: 12 points

(Word address)

%IW0.0 (WX0.0)

%IW0.1 (WX0.1)

%QW0.4 (WY0.4)

%IW1.0 (WX1.0)

%IW2.0 (WX2.0)

%IW2.1 (WX2.1)

%IW2.2 (WX2.2)

%IW2.3 (WX2.3)

%QW2.4 (WY2.4)

%QW2.5 (WY2.5)

Expansion

right side unit

Unit No. 1

Input: 8 points

Input: 20 points

Output: 12 points

Input: 8 points

Input: 4 words

Output: 2 words

Expansion

right side unit

Unit No. 2

Input: 4 words

output: 2 words

(Bit address)

0F

%IX0.0.0 to %IX0.0.15 (X0.00 to X0.0F)

%IX0.1.0 to %IX0.1.3 (X0.10 to X0.13)

%QX0.4.0 to %QX0.4.11 (Y0.40 to Y0.4B)

%IX1.0.0 to %IX1.0.7 (X1.00 to X1.07)

2-10

Page 27

Section 3 Specications

3-1 General Specications ............................................................................ 3-1

3-2 Main Unit Specications ......................................................................... 3-2

3-2-1 Performance specications ........................................................................3-2

3-2-2 Memory backup and internal battery specications....................................3-3

3-2-3 Calendar specications ..............................................................................3-3

3-3 Power supply specications................................................................... 3-4

3-3-1 AC power supply type .................................................................................3-4

3-3-2 DC power supply type ................................................................................3-4

3-4 Input specications ................................................................................. 3-5

3-4-1 DC input specications ............................................................................... 3-5

(1) Specications ............................................................................................. 3-5

(2) Input circuit conguration and external connection .................................... 3-6

3-5 Output Specications .............................................................................. 3-7

3-5-1 Transistor output specications .................................................................. 3-7

(1) Specications ............................................................................................. 3-7

(2) Output circuit conguration and external connection.................................. 3-8

(3) Speeding up transistor output circuits ........................................................ 3-9

3-5-2 Relay output specications ....................................................................... 3-10

(1) Specications ........................................................................................... 3-10

(2) Output circuit conguration and external connections .............................. 3-11

3-5-3 Output device protection and noise suppression in DO circuit ................. 3-12

(1) Protection of relay contacts and noise suppression ................................. 3-12

(2) Contact transfer ........................................................................................ 3-13

(3) Protection of transistor output and noise suppression.............................. 3-14

3-6 Analog Unit/Board Specications ........................................................ 3-15

3-6-1 Analog input unit (NA0AX06-MR) ............................................................. 3-15

(1) Specications ........................................................................................... 3-15

(2) Names ...................................................................................................... 3-15

3-6-2 Analog output unit (NA0AY02-MR) ........................................................... 3-16

(1) Specications ........................................................................................... 3-16

(2) Names ...................................................................................................... 3-16

3-6-3 Analog input/output unit (NA0AW06-MR) ................................................. 3-17

(1) Specications ........................................................................................... 3-17

(2) Names ...................................................................................................... 3-18

3-6-4 Analog output board (NA3AY02-MR) ....................................................... 3-19

(1) Specications ........................................................................................... 3-19

(2) Names ...................................................................................................... 3-19

Page 28

3-6-5 Analog input/output board (NA3AW03-MR) ............................................. 3-20

(1) Specications ........................................................................................... 3-20

(2) Names ...................................................................................................... 3-20

3-6-6 Thermocouple input unit (NA0AX02-TC/NA0AX06-TC/NA0AX16-TC) .... 3-21

(1) Specications ........................................................................................... 3-21

(2) Names ...................................................................................................... 3-22

3-6-7 Resistance thermometer element input unit (NA0AX06-PT) .................... 3-24

(1) Specications ........................................................................................... 3-24

(2) Names ...................................................................................................... 3-24

3-7 Communication Unit/Board Specications ......................................... 3-25

3-7-1 RS-232C/RS-485 general purpose communication board

(NA3LA-RS1) ............................................................................................ 3-25

(1) Specications ........................................................................................... 3-25

(2) Names ...................................................................................................... 3-25

3-7-2 RS-232C general purpose communication unit (NA0LA-RS3) ................. 3-26

(1) Specications ........................................................................................... 3-26

(2) Names ...................................................................................................... 3-26

3-7-3 RS-485 general purpose communication unit (NA0LA-RS5) ...................3-27

(1) Specications ........................................................................................... 3-27

(2) Names ...................................................................................................... 3-27

3-7-4 Ethernet communication board (NA3LA-ET1) /

Ethernet communication unit (NA0LA-ET1) ............................................. 3-28

(1) Specications ........................................................................................... 3-28

(2) Names ...................................................................................................... 3-28

3-8 Function Unit Specications ................................................................ 3-29

3-8-1 Load cell unit (NA0F-LC1) ........................................................................ 3-29

(1) Specications ........................................................................................... 3-29

(2) Names ...................................................................................................... 3-29

(3) External connection .................................................................................. 3-30

3-8-2 High-precision load cell unit (NA0FA-LC1) ............................................... 3-31

(1) Specications ........................................................................................... 3-31

(2) Names ...................................................................................................... 3-31

3-9 Temperature derating of main unit ....................................................... 3-32

(1) Main unit with 14/24 points ....................................................................... 3-32

(2) Main unit with 32/40 points ....................................................................... 3-32

(3) Main unit with 60 points ............................................................................ 3-33

3-10 Terminal Arrangement ......................................................................... 3-34

3-10-1 Main unit ................................................................................................. 3-34

(1) Main unit with 14 points

(8 points input / common, 2 points output / common x 3 circuits)............. 3-34

(2) Main unit with 24 points

(14 points input / common, 2 points output / common x 3 circuits,

4 points output / common) ........................................................................ 3-34

(3) Main unit with 32 points

(20 points input / common, 2 points output / common x 4 circuits,

4 points output / common) ........................................................................ 3-35

Page 29

(4) Main unit with 40 points

(24 points input / common, 2 points output / common x 4 circuits,

4 points output / common x 2 circuits) ...................................................... 3-35

(5) Main unit with 60 points

(36 points input / common, 2 points output / common x 4 circuits,

4 points output / common x 4 circuits) ...................................................... 3-36

3-10-2 Expansion unit ........................................................................................ 3-37

(1) Expansion unit with 8 points

(4 points input / common, 2 points output / common x 2 circuits)............. 3-37

(2) Expansion unit with input 8 points (8 points input / common)................... 3-37

(3) Expansion unit with output 8 points

(2 points output / common x 4 circuits) ..................................................... 3-37

(4) Expansion unit with output 16 points

(2 points output / common x 4 circuits, 4 points output / common

x 2 circuits) ............................................................................................... 3-37

(5) Expansion unit with 24 points

(14 points input / common, 2 points output / common x 3 circuits,

4 points output / common) ........................................................................ 3-38

(6) Expansion power supply unit .................................................................... 3-38

3-11 Names and Functions ......................................................................... 3-39

3-11-1 Main unit ................................................................................................. 3-39

(1) Names ...................................................................................................... 3-39

(2) Functions .................................................................................................. 3-40

3-11-2 Expansion unit ........................................................................................ 3-42

(1) Names ...................................................................................................... 3-42

(2) Functions .................................................................................................. 3-43

3-12 Dimensions .......................................................................................... 3-44

3-12-1 Main unit ................................................................................................. 3-44

(1) Main unit with 14/24 points ....................................................................... 3-44

(2) Main unit with 32/40 points ....................................................................... 3-44

(2) Main unit with 60 points ............................................................................ 3-45

3-12-2 Expansion unit ........................................................................................ 3-46

(1) Expansion unit with 8 points, AIO expansion unit, Load cell unit,

Expansion power supply unit, High-precision load cell unit ...................... 3-46

(2) Expansion unit with 16 points ................................................................... 3-46

(3) Expansion unit with 24 points, Temperature measurement unit 16CH ..... 3-47

(4) Communication unit .................................................................................. 3-47

(5) Communication board, AIO board ............................................................3-48

(6) Healthy unit ............................................................................................... 3-48

3-13 Mass ...................................................................................................... 3-49

(1) Main unit ................................................................................................... 3-49

(2) Expansion unit .......................................................................................... 3-49

(3) Expansion power supply unit .................................................................... 3-49

(4) Analog board/unit ..................................................................................... 3-49

(5) Communication unit/board ........................................................................ 3-50

(6) Function unit ............................................................................................. 3-50

Page 30

Section 3 Specications

3-1 General Specications

Item Specication Remark

Physical

environmental

conditions

Mechanical

service

conditions

Electrical

service

conditions

Operating ambient

temperature

Storage (transportation)

temperature

Relative humidity

Pollution degree 2 (Note 1)

Corrosion immunity Free from corrosive gases. Not stained with organic solvents

Operating altitude 2000 m or less above sea level (Transport condition: 70 kPa or more)

Vibration

Shock

Electrostatic discharge Contact discharge: ±4kV, Aerial discharge: ±8kV IEC 61000-4-2

Radiated,

radio-frequency,

electromagnetic eld

EFT/B (Electrical fast

transient/burst)

0 to +55°C (Note 4) IEC 61131-2

-25 to +70°C

20 to 95%RH, no condensation

(Transport condition: 5 to 95%RH, no condensation)

Half amplitude: 0.15mm, Constant acceleration: 19.6 m/s

Two hours for each of three mutually perpendicular axes, Total six

hours (Note 2) (Note 3)

Acceleration peak: 98 m/s

Three times for each of three mutually perpendicular axes

80 to 1000MHz (10V/m)

1.4 to 2.0 GHz (3V/m)

2.0 to 2.7 GHz (1V/m)

Equipment power, I/0 power, AC I/O (unshielded): ±2kV

Data communication, digital and analog I/O s’ (except AC unshielded

I/O): ±1kV

2

2

IEC 61000-4-3

IEC 61000-4-4

Lightning impulse surge

Conducted radio

frequency

Power frequency

magnetic eld

Construction Panel-mounted type (open equipment)

Cooling Air cooling

Notes:

1) Pollution degree 2: This pollution does not conduct usually, but under certain circumstances temporary conductivity occurs

due to condensation.

2) The unit is xed by screws to the control panel. When the unit is mounted to the DIN rail, care must be taken that

vibrations or shocks will not occur.

3) In an environment where repetitive or continuous vibration occurs, be sure to take vibration-proong measures.

4) See “3-9 Temperature derating of main unit.”

AC equipment power: ±2kV common mode, ±1kV differential mode

DC equipment power: ±0.5kV common mode, ±0.5kV differential mode

150kHz to 80MHz, 10V IEC 61000-4-6

50Hz, 30A/m IEC 61000-4-8

IEC 61000-4-5

3-1

Page 31

Section 3 Specications

3-2 Main Unit Specications

3-2-1 Performance specications

Item

Control system

Input/output connection method Direct input/output (local bus)

I/O control system

CPU 16-bit processor

Memory types Program memory, data memory, temporary memory

Programming language

Length of instructions Variable length (depending on language)

Program memory capacity (Note 2) 8192 steps 20480 steps

Program steps in a POU 8192 steps 16384 steps

I/O memory 512 words

Standard memory 4096 words 8192 words

Retain memory 2048 words 4096 words

User FB memory 4096 words 8192 words

User FB memory

Initial value setting memory

Memory

(Note 1)

System FB

memory

System memory 512 words

Special relay/register (standard) 4096 words

Special relay/register (retain) 4096 words

No. of tasks

No. of programs

Timer 256 points 512 points

Integrating timer 0 point 0 point

Counter 256 points 512 points

Edge detection 1024 points 2048 points

Others 512 words 1024 words

Specication

Main unit with 14/24 points Main unit with 32/40/60 points

Stored program,

Cyclic scanning system (default task), periodic task, event task

Whole: Scan batch refresh system

Digital I/O: Task synchronized refresh system

<When using D300win>

Conforming to IEC61131-3

IL language (Instruction List)

ST language (Structured Text)

LD language (Ladder Diagram)

FBD language (Function Block Diagram)

SFC elements (Sequential Function Chart)

4608 words 9216 words

5632 words 11264 words

Default tasks (Cyclic scanning): 1

Fixed cycle tasks + Event tasks: 15 in total

64 / Default task

8 / Fixed cycle task, Event task

<When using Standard Loader>

Original LD language (Ladder

Diagram)

Notes:

1) You can freely increase or decrease the area sizes of the standard memory, retain memory, user FB memory, and system

FB memory. The above table shows the default values.

2) The initial value setting area of the standard memory and retain memory is included.

3-2

Page 32

Section 3 Specications

3-2-2 Memory backup and internal battery specications

The primary battery built in the main unit cannot be replaced. When a voltage drop of the battery is detected, you need to

replace the main unit.

The battery connection switch is set to OFF at the factory shipment to save battery consumption. When you start using the main

unit, set the battery connection switch to ON to enable memory backup by the built-in battery.

For the details of the battery connection switch, see “3-11-1 Main unit” in “3-11 Names and Functions.”

Item Specication Remark

Backup area

Battery Graphite uoride lithium primary battery Built-in battery, 1000mA/h, Unreplaceable

Backup time 10 years or more Ambient temperature: 55°C

Battery voltage drop

detection function

Battery voltage read

function

Battery life Life of primary battery: 10 years

<Notes on battery connection switch>

When the battery connection switch is OFF, the battery voltage drop detection LED also blinks. Check the switch status.

Retain memory, retain attributed memory of

user FB and System FB instance memory,

RAS history, Calendar

Provided

(Updated approximately every 10 minutes

while the main power is ON.)

Provided

(Updated approximately every 10 minutes

while the main power is ON.)

Backup target parts: SRAM, RTC

• When a voltage drop of the battery is detected (*1), the

PWR/BAT LED blinks alternately in red and orange.

The battery error in the system memory is set ON.

• When detected that the battery voltage is normal (*2),

the PWR/BAT LED lights up in red. The battery error in

the system memory is set OFF.

*1 2.4V or less

(battery voltage A/D conversion value 492)

*2 2.4V or more

(battery voltage A/D conversion value 493)

• Battery voltage A/D conversion value is stored in the

special register “%MW1.61450 (WM61450).”

• Battery voltage

= Battery voltage A/D conversion value * 4.883 [mV]

* Battery voltage drop can be detected by an application.